Abstract

From scientific and technological points of view, poly(vinylidene fluoride), PVDF, is one of the most exciting polymers due to its overall physicochemical characteristics. This polymer can crystalize into five crystalline phases and can be processed in the form of films, fibers, membranes, and specific microstructures, being the physical properties controllable over a wide range through appropriate chemical modifications. Moreover, PVDF-based materials are characterized by excellent chemical, mechanical, thermal, and radiation resistance, and for their outstanding electroactive properties, including high dielectric, piezoelectric, pyroelectric, and ferroelectric response, being the best among polymer systems and thus noteworthy for an increasing number of technologies. This review summarizes and critically discusses the latest advances in PVDF and its copolymers, composites, and blends, including their main characteristics and processability, together with their tailorability and implementation in areas including sensors, actuators, energy harvesting and storage devices, environmental membranes, microfluidic, tissue engineering, and antimicrobial applications. The main conclusions, challenges and future trends concerning materials and application areas are also presented.

1. Introduction

In the scope of the circular economy concept, aiming to combine sustainability and social development, a collaborative and interrelated society based on smart technologies is needed to address the urgent and relevant issues raised in the scope of the energy transition, reduction of the environmental impact, novel healthcare paradigms, sustainable mobility, and artificial intelligence, among others.1,2 The ongoing technological transitions require advanced, smart, and multifunctional materials to support the Internet of Things (IoT) concept, based on an increasing number of interconnected physical objects, sensors, and actuators, also leading to the Industry 4.0 paradigm, aiming to optimize materials, processes, and products, from concept to manufacturing.3,4

Many of the materials required for these technologies are based on polymer, as they present chemical stability, easy processability, tailorable properties, and low cost, some of them also showing electroactive properties such as piezoelectricity, pyroelectricity, and ferroelectricity.5 In particular, piezoelectric polymers can convert mechanical to electrical signals or vice versa, a characteristic that is taken to advantage in different areas such as sensors and actuators, biomedicine, energy generation, and storage, among others.6,7

Within smart polymer-based materials, poly(vinylidene fluoride), PVDF, and its copolymers, poly(vinylidene fluoride-co-hexafluoropropylene) (poly(VDF-co-HFP)), poly(vinylidene fluoride-co-trifluoroethylene) (poly(VDF-co-TrFE)), and poly(vinylidene fluoride-co-chlorotrifluoroethylene) (poly(VDF-co-CTFE)), stand out based on their high dielectric constant (ε′ up to 18), high piezoelectric coefficients (|d31| up to 30 pC·.N–1, |d33| up to 140 pC·N–1), high purity, excellent mechanical properties, high resistance against chemicals, suitable thermal resistance, tailorable surface properties and morphology, among others, that depend on the specific crystalline phase of the polymer.8−13 Other polymers, such as odd-numbered Nylons,14 polylactic acid (PLLA),15 poly(lactic-co-glycolic acid) (PLGA),16 poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV),17 and cellulose acetate (CA),18 have also emerged and been applied in various technological applications based on their reasonable electroactive properties combined with some other suitable properties including biocompatibility, biodegradability, natural origin, or other relevante characteristics.

The piezoelectric properties of PVDF were discovered by Kawai in 1961 and were attributed to the cooperative alignment of dipoles and charge trapping caused by the high polarization of this polymer in specific phases.19 Further, it was demonstrated that the piezoelectricity in PVDF also depends on the electrostriction constant, Poisson ratio, and crystal structure.20 In 1961, the first commercially produced PVDF grades were named Kynar of Pennwalt (nowadays Arkema) and were synthesized by the polymerization of vinylidene fluoride (VDF), mainly by aqueous emulsion and suspension polymerization technique.21

PVDF and its copolymers are one of the most robust and multifunctional polymeric materials, demonstrating its applicability in a wide variety of applications, including sensors, electronic devices, piezoelectric generators, scaffolds for tissue engineering, and portable analytical devices, among others.22,23 The sustainability concerns of this fluorinated polymer are being addressed by its durability and multifunctionality in the applications. More environmentally friendly syntheses and efforts to recover and/or recycle and/or reuse them are also occurring.24−26

Considering its properties such as high mechanical strength and durability in harsh environmental conditions, PVDF is one of the most widely used fluoropolymers after poly(tetrafluoroethylene) (PTFE), with a market price around US $14/kg.27 Approximately 49% of the market share corresponds to HFP-modified PVDF, a monomer added to further increase polymer flexibility.27 Regarding other PVDF-based polymers and their applicability for advanced technological applications, the price will decrease with increasing production scale. Nevertheless, the price of these materials will not be as cheap as PVDF, taking into account the cost of other gas monomers and also the polymerization processes.25

In 2021, its market reached a value of ∼880 million dollars, and taking into account the market growth in the electronics sector and the demand for lithium (Li)-ion batteries applied in electric vehicles where PVDF is used as a polymer binder for electrodes, its annual growth rate is expected to increase ∼7% by 2027.28

This review focuses on the main properties and processing of PVDF, its copolymers, blends, and composites, together with their main application areas from sensors/actuators to biomedical applications, i.e, high value-added applications, with particular attention to the role of their electroactive properties.

2. Poly(vinylidene fluoride): Main Properties and Polymorphism

PVDF is a semicrystalline polymer that crystallizes radially into a spherulitic structure, with its chains being approximately plane-normal. It comprises of a repeating unit (CH2–CF2) with a spacing of 2.6 Å.10 Its dipole moment originates from the electronegative fluorine (δ−) to the electropositive hydrogen (δ+) and it is perpendicular to the polymer chains for the β-phase, while for the other phases, the dipole moment is not perpendicular to the polymer chain, as it will be described in the following.29,30

PVDF can crystallize in different crystalline phases, identified as α, β, γ, δ, and ε, depending on the processing conditions.31 The most relevant crystalline phases for applications are the α-phase, which is thermodynamically more stable when obtained by cooling from the melt, and the β-phase, which provides the highest electroactive properties: piezo-, pyro-, and ferroelectricity.32

The α-phase is characterized by an orthorhombic unit cell with a P2cm space group, the polymer chains being organized in a trans-gauche (TGTG–) conformational structure, as shown in Figure 1a). The dipole moment of the conformation repeat unit is 4.0 × 10–28 cm·C.33 The β-phase is also organized in orthorhombic unit cells, but with a Cm2m space group. In this phase, the chain conformation is planar zigzag (all-trans), as shown in Figure 1b), with the dipolar moments of the chains parallel to the crystallographic b-axis.34 The conformation repeat unit of the β-phase shows a dipolar moment of 7.0 × 10–28 cm·C and polarization of 131 mC·m–2. The δ-phase of PVDF is the polar version of the α-phase by the application of a high electric field, resulting in the inversion of the dipole moments along the applied field. The chain conformation is similar to the α-phase, Figure 1a. PVDF in the γ-phase reveals an intermediate conformation between β- and α-phases (TTTG+TTTG–)35 (Figure 1c). Furthermore, the ε-phase is quite difficult to obtain and its conformation is similar to the γ-phase. Due to those conformational characteristics, the α- and the ε-phases are nonpolar, whereas the, β-, γ-, and δ-phases are polar.29,36

Figure 1.

Polymer chain conformation of (a) α-phase, (b) β-phase, and (c) γ-phase of PVDF.

The identification of the different crystalline phases of PVDF is typically achieved by X-ray diffraction and Fourier-transform infrared spectroscopy (FTIR) techniques.11

PVDF is characterized by a glass transition temperature at Tg −34 °C, a degree of crystallinity between 35 and 60%, and a melting temperature between 160 and 190 °C, depending on the processing conditions and crystalline phases. Furthermore, the thermal degradation temperature is between 400 to 450 °C independent of the crystalline phase, the degree of crystallinity, and the processing method. In addition, the number of head-to-head defects is between 6% and 9%, as determined by nuclear magnetic resonance (NMR).37

PVDF is characterized by chemical, mechanical, radiation, and thermal resistance, due to the high electronegativity of the fluorine atoms in the chain and the high bond dissociation energy of the C–F bond.38

Regarding the electrical properties, the ε′ of PVDF is between 7 and 13, depending on the crystalline phase, the crystalline phase content and the crystalline domain size.39 The dielectric constant of the β-phase is highest when compared to the α- and γ-phases due to the higher polarity of this phase. Another critical parameter that contributes to the dielectric properties is the interfaces between the amorphous and crystalline regions.39 Also, a region defined as oriented amorphous fraction (OAF) that connects mobile amorphous fraction and the lamellar crystal, participates in ferroelectric switching of PVDF and enhances its β-phase, dielectric, and ferroelectric properties.40,41

The processing annealing temperature and time allow tuning the dielectric and piezoelectric characteristics of PVDF, the dielectric and piezoelectric responses decreasing strongly in the first 4 h at temperatures above 80 °C.42

The dielectric behavior as a function of frequency and temperature shows two main relaxation processes dominated by the β-relaxation that corresponds to the Tg, attributed to cooperative segmental movements of the main chains within the amorphous and amorphous/crystalline interface regions of the polymer. The other main relaxation process is identified as α- or αc-relaxation, it occurs at temperatures above 60 °C, and it is associated with cooperative molecular motions within the crystalline fraction.43 These relaxations can also be observed by dynamical mechanical analysis. The poling process, the application of an electric field to provide orientation to the dipolar moments, affects the dynamics of these relaxation processes.43

The displacement (D)-electric field (E) hysteresis loops are also strongly dependent on crystal phase and crystallinity. They are affected by the processing conditions and thermal treatments, in particular in terms of maximum and remnant polarization.39 The irreversible polarization depends on the amorphous phase, as increasing amorphous phase content leads to more free space for the inversion of the crystalline domains.39

PVDF is characterized by excellent mechanical properties with a Young modulus >1.5 GPa, and the poling process increases the mechanical response along the preferred microstructure orientation. Also, as the temperature increases, the poling effect on mechanical behavior is reduced due to increased molecular mobility.44 The mechanical properties are also determined by the polymer’s morphology and degree of crystallinity and, therefore, by the processing conditions.8

The optical properties of PVDF are dependent on polymer microstructure. For a compact and dense morphology, the optical transmittance is between 80 and 90% in the visible spectrum with a refractive index between 1.39 and 1.47.45,46

Considering its excellent thermal, mechanical, electrical, and electroactive properties and also its tunability to be implemented in a wide range of application requirements, substantial efforts have been devoted to develop a variety of processing techniques and conditions with a focus on improving materials integration and device performance.

2.1. Processability

As referred previously, PVDF is a polymer with notable polymorphism, showing five main crystalline phases: α, β, γ, δ, and ε, depending on the processing conditions (mainly, processing temperature and time).47 From a technological point of view, the β-phase is the one with the highest piezoelectric, pyroelectric, and ferroelectric response, and it is the most implemented in applications where an electric response or a deformation (actuation) are required. In turn, the α-phase is the most stable thermodynamically when directly obtained from the melt.48

Figure 2 shows the main processing treatments to obtain the different phases of PVDF.

Figure 2.

Main processing treatments and conditions to obtain the different PVDF phases.

When processed above the temperature of 110 °C, the predominant phase is the α-phase. The β-phase is obtained from solution processing with polar solvent at crystallization temperatures below 70 °C. The γ-phase is typically obtained by annealing and mechanical stretching processed from other polymer phases.49

The β-phase can be induced from the α-phase through different processing strategies, such as mechanical stretching, annealing, cooling, pressing, the addition of different fillers and polymers, and electrical poling (Ep), among others.50−52

The merits of PVDF are not only based on their chemical, mechanical, and thermal stability, together with tunable electroactive properties but also on allowing it to be produced in a variety of designs and morphologies such as nonporous (dense) films, porous (membrane) films, fibers, microspheres, patterned/three-dimensional (3D) formats by processing techniques including extrusion,53 injection molding,54 electrospinning,55 phase separation processes, particulate leaching, freeze extraction, or printing technologies, among others.56 Thus, over the past decades, a large variety of processing methods have been developed to produce PVDF in specific shapes to meet specific application requirements, including sensors and actuators,57,58 energy storage,59 filtration membranes,60 microfluidics,61 tissue engineering,62 or drug delivery,63 among others.8

Together with the processing methods, the processing conditions, such as processing temperature, between 190 and 280 °C (230 to 290 °C for extrusion and 200 to 270 °C for injection molding) when processed from the melt and the solvent type and solvent evaporation temperature strongly affects polymer phase content, crystallinity, and morphology.64 With respect to solvent based processing, the selection of the solvent is essential because it affects the thermodynamic properties of the solution, the processing techniques that can be used, and the final physicochemical characteristics of the processed material. Figure 3 shows a schematic representation of characteristic processing techniques used to obtain PVDF in different morphologies, described below, from solvent-based solutions.

Figure 3.

Solvent-based processing techniques for PVDF: (a) doctor blade, (b) spin-coating, (c) screen-printing, (d) electrospinning, (e) direct-ink-writing (DIW), (f) inkjet printg, (g) roll-to-roll printing/coating processes, and (h) lithography.

In addition to conventional processing techniques, PVDF has also been processed by additive manufacturing techniques (Figure 3) such as direct-ink-writing (DIW),65 roll-to-roll printing/coating processes,66 among others, which are of low fabrication cost.

Common solvents of PVDF are N,N-dimethyl acetaminde (DMA), N,N-dimethylformamide (DMF), N-methyl-2-pyrrolidone (NMP), methyl ethyl ketone (MEK), tetrahydrofuran (THF), and dimethyl sulfoxide (DMSO), among others.67,68 However, from an environmental point of view, these solvents do not allow sustainable processing because of their toxicity. Thus, greener solvents are necessary to reduce the environmental impact of materials and processes. Thus, one of the main challenges in PVDF processing is to change the common solvents with environmentally friendlier ones.45 However, the challenge of green processing is not simple, still under strong development efforts. Nonetheless, 1, 3-dioxalane (DXL) and N,N′-dimethylpropyleneurea (DMPU) are promising alternatives for being environmentally friendly (toxicity index of 5 and 4, respectively, according to Hodge and Sterner scale).45,69

Various established solvent-based processing techniques have been applied to process PVDF in the electroactive β-phase and new ones have emerged in the past decades. In the scope of the present review, the most used ones to obtain a specific morphologies or structures will be briefly addressed in the following.47

PVDF dense films with a controllable thickness, ranging from a few to hundreds of micrometers, are typically fabricated by doctor blade.70 The phase obtained can be tailored according to the solvent evaporation temperature, the β-phase being obtained at solvent evaporation temperatures below 70 °C. In contrast, α-phase films are obtained at higher temperatures or above the polymer’s melting temperature where rapid evaporation of the solvent occurs. A transition from α- to β-phase can be induced by mechanical stretching of the α-film at a specific temperature and electrical poling is applied to optimize the electroactive response by favoring the orientation of the dipoles along the direction of the applied field.11 For smaller thicknesses, from hundreds tens of nanometers to dozens of micrometers, spin-coating is applied to produce highly uniform films deposited directly on the desired substrates.71,72 Films and specific structures can be also achieved by using additive manufacturing technologies, such as inkjet-printing, screen-printing, and spray-printing.73 In this case, dense or porous morphologies can be obtained by specific postprocessing thermal treatments. Nanoscale films can be prepared using a monomolecular film assembly method: the Langmuir–Blodgett (LB) method.74,75 Moreover, nonsolvent-induced phase separation (NIPS)76 and temperature-induced phase separation (TIPS)77 are used to obtained porous films.

Further, techniques such as solvent casting particulate leaching and solvent casting 3D nylon template [144] are also used to obtain porous membranes with controllable pore size and interconnectivity. In turn, patterned and 3D PVDF dense and porous structures can be obtained by replica molding using molds featuring the inverse desired structure78 or by 3D printing.79 To obtain random or aligned PVDF fibers, electrospinning is the technique usually employed, as it allows to produce fibers with diameters from hundreds to dozens of nanometers by using static or rotating collectors to obtain randomly oriented or oriented fibers, respectively.80 In the electrospinning process, parameters such as the solvent evaporation temperature, the electric applied field and the stretching forces exercise during the process induce the crystallization of the PVDF fibers predominantly in the β-phase.81 Further, by controlling processing parameters such as solution viscosity, microspheres can also be obtained by electrospray, with diameters ranging from hundreds of nanometers to a few micrometers, in addition to other conventional techniques such as phase separation or precipitation, emulsion/solvent evaporation, and microfluidics.82 In addition to the previously mentioned procedures to obtain PVDF in the electroactive β-phase, a common strategy is the integration of fillers, such as cellulose, carbon nanotubes (CNTs), zeolites, and piezoelectric ceramics nanoparticles, into the polymer solution.83 These type of fillers and others featuring active properties, e.g., magnetic iron oxide (Fe3O4) and cobalt ferrites (CoFe2O4) nanoparticles, have been introduced to obtain composites with tuned physicochemical and multifunctional properties.84 In order to implement β-phase PVDF for technological applications by maximizing the electroactive response, a poling process is applied through static electric fields allowing to realign the dipole moments along the field direction.85

2.2. Poly(vinylidene fluoride)-Based Copolymers

The development of PVDF copolymers such as poly(VDF-co-TrFE), poly(VDF-co-HFP), and poly(VDF-co-CTFE) has allowed not only to obtain the polymer directly in the electroactive phase when processed from the melt but also to improve/adapt the degree of crystallinity and the electroactive response for specific technological demands. The structure of the main PVDF copolymers is represented in Figure 4.11

Figure 4.

Schematic representation of the chemical structure of (a) poly(VDF-co-TrFE), (b) poly(VDF-co-HFP), and (c) poly(VDF-co-CTFE).

Table 1 shows the main application fields of PVDF and its copolymers. For each application, the most used PVDF and copolymers are indicated.

Table 1. Main Application Areas of PVDF and Copolymers.

| application

area |

|||||||

|---|---|---|---|---|---|---|---|

| polymer | sensors | actuators | energy generation | energy storage | environmental monitoring and remediation | microfluids | biomedical applications |

| PVDF | yes | yes | yes | yes | yes | yes | |

| poly(VDF-co-TrFE) | yes | yes | yes | yes | yes | yes | yes |

| poly(VDF-co-HFP) | yes | yes | |||||

| poly(VDF-co-CTFE) | yes | ||||||

The PVDF copolymer less used is poly(VDF-co-CTFE), being evaluated for applications such as Li-ion batteries, but still being little explored because it has similar properties to poly(VDF-co-HFP). The most used fluorinated polymers for Li-ion batteries are PVDF as polymer binder for electrodes and poly(VDF-co-HFP) for separator membranes and solid polymer electrolytes (SPEs).86,87

For applications that require the piezoelectric effect, the most used polymers are PVDF and poly(VDF-co-TrFE).88 In fact, poly(VDF-co-TrFE) is one of the most studied copolymers of PVDF. When the VDF content (ContentVDF) is <49 mol%, poly(VDF-co-TrFE) crystallizes into 3/1-helical phase and when 49 mol% ≤ ContentVDF ≤ 55 mol%, poly(VDF-co-TrFE) crystallizes into 3/1-helical phase and trans-planar phase. Moreover, when 55 mol% < ContentVDF < 80 mol%, poly(VDF-co-TrFE) crystallizes into trans-planar phase,13 independently of the processing conditions, once the addition of the third fluoride atom in the TrFE monomer unit leads to a significant steric hindrance that favors the all-trans polymer chain conformation and induces the ferroelectric β-phase independently of the processing method and conditions: melt or solution casting. Due to the intrinsic presence of chemical defects (TrFE units), randomly distributed among PVDF sequences, this copolymer typically has a reduced degree of crystallinity compared to the PVDF homopolymer.89 However, the crystallinity can be tuned between 35 and nearly 100% depending on the polymerization method and processing conductions.72 Those properties ensure high electric output, sensitivity, comprehensive frequency response, and flexibility, characteristics required for applications such as haptics, sensors, and artificial muscles.90 Moreover, poly(VDF-co-TrFE) has two phase transitions, depending on the crystallization conditions, thermal treatment and molar ratio.91 The copolymer poly(VDF-co-TrFE) in the molar ratio (VDF/TrFE) (75/25) shows a first-order ferroelectric–paraelectric (FE-PE) transition at 140 °C under heating and a PE-FE transition by cooling at 75 °C, showing therefore a large thermal hysteresis.91,92 For this copolymer, an emerging toroidal polar topology has been observed in poly(VDF-co-TrFE) with VDF content of 70 mol%.72 This consists of the effective alignment of the lamellar crystal with its interchain dipoles perpendicular to the polymer chains self-organizing into a concentric pattern.72

In turn, poly(VDF-co-HFP), consisting of incorporating the amorphous phase of hexafluoropropylene (HFP) in the PVDF homopolymer, is a chemically inert copolymer, presenting a lower crystallinity when compared with PVDF due to the presence of the bulky CF3 groups. For such reasons, this polymer has been mainly used for applications in polymer electrolytes for rechargeable Li-ion batteries and for producing membranes for organophilic pervaporation. Poly(VDF-co-HFP) has the highest d31 piezoelectric constant (21 pC·N–1) among all PVDF’s copolymers.

In the case of poly(VDF-co-CTFE), the crystalline properties depend on the CTFE content, the semicrystalline state being only obtained for CTFE contents lower than 16 mol%, while an amorphous state is present for higher CTFE concentrations. The introduction of bulky CTFE makes the structure lose, resulting in an easier orientation of dipoles under an external electric field. Poly(VDF-co-CTFE) exhibits optimized piezoelectric properties (|d33| can reach values of 140 pC·N–1 when poled at a DC bias of 70 MV·m–1), higher electrostrictive strain response (5.5%), and higher ε′ of 13 when compared with PVDF. As a result, broader ferroelectric hysteresis loops are commonly observed in poly(VDF-co-CTFE) that are advantageous for energy storage applications, ensuring a high overall electric-energy density that can be charged/discharged in specific electronics applications.48,93

An interesting polymer in the PVDF family is poly(vinylidene fluoride-ter-trifluoroethylene-ter-chlorofluoroethylene) (poly(VDF-ter-TrFE-ter-CFE)) which is a ter-polymer with relaxor ferroelectric properties and high dielectric constant.94 This polymer has been used in electrocaloric devices with entropy changes of 37.5 J ·kg–1·K–1,95 actuators,96 bioMEMs, and microfluidic devices,97 among others. The addition of the third monomer affects the crystalline properties and consequently the dielectric properties.25 This terpolymer under 40 MV·m–1 shows an electromechanical coupling factor (k33) of 88% and a d33 > 1000 pC·V–1.98 Considering its properties, this ter-polymer has been also used as a polymer binder for electrodes in Li-ion batteries devices.99 In the future, it is expected to find application in other high-tech areas.

2.3. Poly(vinylidene fluoride)-Based Composites

The exciting properties of PVDF have led to a high and growing interest, resulting in the combination with specific fillers for the development of high-performance and multifunctional PVDF-based composites with distinct morphologies and physicochemical properties. Thus, PVDF-based composites result from the combination of one or two different fillers with complementary characteristics to improve some specific properties or to induce new ones, such as electrical conductivity or magnetic properties. It has been reported that there are PVDF composites with more than 30 different fillers. Recently, the trend has been the development of PVDF composites with the addition of more than one filler with complementary properties to reduce the filler amount and enhance the functionality.100 The most representative and commonly used fillers in PVDF and its copolymers-based composites are magnetic nanoparticles (CoFe2O4 or Fe3O4),101−103 CNTs,104−106 ceramic particles, e.g., barium titanate (BaTiO3),107,108 zinc oxide (ZnO),109−111 titanium dioxide (TiO2),112−114 zeolites, or clays,115,116 among others, promoting the development of a wide range of multifunctional composites materials.

PVDF composites are interesting because their final properties can be fine-tuned by the proper selection of filler size, shape and content, dispersion, interface, and interaction between filler and polymer, together with the processing conditions.117,118 Moreover, the easy processability of PVDF composites allows its integration in various application areas, including sensors and actuators, energy generation and storage systems, environmental sensing and remediation, and biomedical applications, among others, as it will be shown in the following chapters in this review.

2.4. Poly(vinylidene fluoride)-Based Blends

PVDF and copolymers are also widely used in blends with different types of polymers, including poly(methyl methacrylate) (PMMA),119 poly(o-methoxyaniline) (POMA),120 poly(aniline) (PANI),121 PLLA,122 poly(ethylene terephthalate) (PET),123 poly(vinyl chloride) (PVC),124 poly(ethylene oxide) (PEO),125 poly(vinyl alcohol) (PVA),126 poly(amide 11) (PA11),127 and poly(carbonate) (PC),128 among others, as well as with different ionic liquids (ILs).129 Those polymer blends allow to improve processability, nucleate specific crystalline phases, or tune optical and electrical properties, among others.

PVDF/PMMA is the most used blend in which the dynamic heterogeneity130 promotes the formation of the β-phase.131 Further, the piezoelectric effect increases with the addition of PMMA to PVDF.132 This blend has been applied in optical applications,92 separator membranes for Li-ion batteries,133 controllable wettability switching triggered by external electric field,134 pyroelectric application,135 as well as a coating for the conservation of historic structures exposed to atmospheric agents,136 among several other applications.

Another interesting blend is PLLA/PVDF, composed of two piezoelectric polymers and suitable for energy harvesting devices.122

To enhance electrical properties, various blends of PVDF with conductive polymers (PANI),137 polypyrrole (PPy),138 and poly(3,4polyethylenedioxythiophene-polystyrenesulfonate) (PEDOT:PSS)139 have been produced for electrodes in sensors/actuators and biomedical applications.

Also, to improve dielectric strength and flexibility, blends of PVDF with poly(VDF-ter-TrFE-ter-CFE) have been developed, being suitable for dielectrics and energy storage applications, as the dielectric breakdown strength of this blend is improved due to increased modulus of elasticity and reduced mobility of the polymer chains.94

More recently, PVDF blends with different ILs are being developed taking into account the tunability of ILs, leading to diverse applications from biomedicine to energy storage.129,140

2.5. Sustainability and Circular Economy Considerations

Considering the excellent properties and applicability of PVDF-based materials, leading to an increasing demand, sustainability, and end-of-life considerations are essential.

In terms of durability, PVDF polymer is highly durable as it can be reused and processed for up to five times, which is very important in advanced applications and in the scope of sustainability.141

A life cycle assessment (LCA) has been carried out to assess the environmental impact of PVDF, in which an acceptable value for the global warming potential (GWP) has been obtained (55.8 kg CO2 equiv·kg–1 PVDF) due to the large demand for chlorine during its production.142

With regard to processing and to increase sustainability, it has been demonstrated the suitability of replacing the conventional solvents with green solvents, including cyclic carbonate solvents143 and acetyl tributyl citrate (ATBC),144 among others.

To further reduce environmental impact, it is necessary to define more efficient processing and recycling routes, as this polymer starts to degrade at relatively low temperatures (>400 °C). Thermal degradation process such as thermolysis is used to reuse and recycle PVDF.141 Also, the decomposition of PVDF and its copolymers can be obtained by mineralization processes in subcritical water with the addition of KMnO4 as oxidizing agent.145

One of the possible ways is mechanical recycling through remelting through extrusion. In the United States of America (USA) and Europe, several companies are specialized in recycling PVDF.146 Furthermore, considering that PVDF is a partially fluorinated polymer, more assessments of the toxicity and low carbon economy are important in the future.

In summary, considering its demand, two major producers (Solvay and Arkema) will expand its production capacity in the next year,147 being therefore urgent to reduce environmental impact all along the value chain of PVDF by implementing green chemistry, safe and recyclable by design concepts.148

3. Applications

Initially, PVDF was used in wires, cables, and tubes, among others, based on its excellent mechanical properties, high thermal stability, and processability, but considering also its electroactive properties, it has been applied in high added-value applications such as sensors, actuators, energy harvesting, and storage systems, environmental, microfluidics, and biomedical applications, which is the focus of this review. Thus, in this review, the state-of-art and corresponding discussion are divided by application type.

Considering its wide range of applications, including sensors, actuators, energy harvesting, and storage, environmental monitoring and remediation and biomedicine (including microfluidics, portable analytical devices (point-of-care, POC)), Figure 5 shows the growing number of scientific articles published in recent years by focusing on PVDF and copolymers. The publications by application area are also stated.

Figure 5.

Scientific articles published over the years until 2022, considering PVDF and its copolymers, also indicated by application area. Search performed in Scopus database: accessed on July 7, 2023, with the keywords “PVDF”, “PVDF co-polymers,” and their corresponding applications.

Figure 5 shows the strong growth of works related to PVDF for various applications in recent years, focusing on the development and understanding of multifunctional composites, the development of advanced processing conditions and procedures, and the demonstration of their applicability in different areas.

In the following, the state of the art on the different application areas is presented, composed by a brief introduction, principal challenges, respective trends, and final remarks. A particular focus relies on the main functional, electroactive, and physicochemical properties of the developed materials, which as summarized in Figure 6, are also emphasized according to the application requirements.

Figure 6.

Summary of the main application areas of PVDF-based materials, together with the main properties that may play a relevant role in those applications.

The main property common to most applications is the piezoelectric effect, which is one of the main differential characteristics of PVDF-based polymers with respect to other polymers.

Furthermore, for many applications, the morphology of the samples plays a critical role, Figure 7 showing the main morphologies of PVDF-based materials required for the different applications.

Figure 7.

Main morphology types of PVDF-based materials for different application areas.

Morphologies can be obtain through the different techniques previously discussed (section 2.1). Considering the different materials functional characteristics and morphologies, the state-of-art for each application area will be presented in the following.

3.1. Sensors

A sensor is a device that detects different stimuli and provides a specific response. Different types of sensors have been developed based on PVDF considering the specific stimulus, transduction mechanism, and materials morphology.

Over the past decades, PVDF-based sensors have experience a growing interest, as shown by the high number of published articles related to this subject (∼400) and the number of areas in which these materials had substantial impact ranging from engineering to medicine (Figure 8a).

Figure 8.

(a) Number of papers (reported on SCOPUS database: accessed on February 1, 2023) regarding the PVDF+sensor topic until 2022. Inset: Distribution of papers (reported on SCOPUS database: accessed on February 1, 2023) by area regarding the PVDF+sensor topic until 2023. (b) Very recent (2022) example of using a PVDF-based sensor on a smart traffic monitoring and management system with IoT connectivity. Reproduced with permission from ref (149). Copyright 2022 Elsevier.

Forty years separate the theoretical work of Lang et al.150 that introduced the idea of using PVDF stress sensors for biomedical piezoelectric palpation devices, and the very recent triboelectric sensor array for the IoT-based smart traffic monitoring and management system reported by Yan et al.149 that allows speed, overlapping, and overload detection as well as dynamic tidal flow regulation, under the framework of smart traffic control (Figure 8b). In this historical leap, the focus has shifted from the most fundamental studies (although there is still need for them) to the exploration of technological niches, to develop new technologies that respond to the requirements of modern cities and smart societies. The dramatic growth and densification in modern cities require smart solutions to address critical demands such as mobility, healthcare, energy, and civil infrastructure. In this context, the digitalization of the society and the economy, enabled by the IoT concept, is one of the most promising enabling technologies for tackling these challenges by creating interconnected physical objects, sensors, and networks.151 To ensure effective communication between all those objects/materials, smart materials, particularly piezoelectric, and pyroelectric ones, are needed; once these smart materials allow the development of sensors that can measure properties such as vibration, strain, temperature, and heat.152

Even knowing that PVDF’s both piezoelectric and pyroelectric coefficients (including those found in its copolymers) are lower than those reported for ferroelectric ceramics, PVDF, its copolymers, and PVDF-based composites display relevant advantages for sensing applications such as softness and flexibility, lightweight, low electrical permittivity, small thermal conductivity, printability, and excellent impedance matching to both air and water.11

For the above-mentioned characteristics, PVDF’s piezoelectric effect has been extensively used in technological applications that involve the detection of mechanical stimuli such as force, pressure, and strain (both compressive and tensile), tactile awareness, vibrational, acceleration, and acoustic.11 This widespread applicability is also intimately related to the PVDF’s broad frequency bandwidth, high sensitivity, robustness, easy processing, high environmental and chemical stability, and reliability. Also relevant is that PVDF-based sensing devices can be self-powered, only requiring a simple ground connection to one of their electrodes.153,154 This particular attribute is a pivotal milestone for sustainability, processability, and integrability in mobile, wearable and hard-to-access devices and objects, over competing sensing technologies.153,155 Additionally, the addition of fillers into the PVDF matrix, besides being able to increase the dielectric, pyroelectric, and piezoelectric responses of the polymeric matrix, also allows introduction of new functionalities/capabilities such as magnetic, ionic, or conductive, opening new application highways for other technological devices, such as magnetic sensors, moisture sensors or piezoresistive sensors.11,156

Important figures of merit (FOM) for PVDF-based sensors are the sensitivity (s) and electromechanical coupling coefficient (K), the sensitivity being highly dependent on the piezoelectric voltage coefficient (g). In practice, if the generated voltage signal is small, it has to be enhanced by an electronic amplifier.157 The electromechanical coupling coefficient k is usually used to describe such conversion efficiency between electrical and mechanical energy, according to eqs 1 and 2,157 where d refers to piezoelectric coefficient, ε′ refers to dielectric constant, ε0 refers to the permittivity of free space, and s refers to the compliance.

| 1 |

| 2 |

From the experimentally pioneer PVDF insole multisensor for pedobarography (study of the pressure distribution under the foot in standing and walking animals) developed by Pedotti et al.,158 key innovations in the PVDF-sensing area are now related to the optimization of new structures or processing technologies for better performances (increasing electrical performance while maintaining flexibility), or new application scenarios that have rarely employed PVDF-based materials,157 such as piezotronics, spintronics, sensors based on luminescence (photo or mechano), steady-state sensors, and supersensitive cellular sensing devices.159

This section highlights the use of PVDF in sensing technologies since the 1980s. It will focus on examples showcasing the use of PVDF-based materials on temperature, pH, gas, stress, biosensors/human health monitoring, and environmental sensing. In each of the examples, an emphasis will be given on detailing the polymer’s key feature to achieve the desired application and the reported FOM (sensitivity, selectivity, limit of detection, reproducibility, and stability) for the described sensing platforms.

3.1.1. Capacitive Sensors

In the 1960s, capacitive sensors started to be used to measure strains at high temperatures with good long-term stability.160,161 Capacitive sensors have some advantages such as low-power consumption (capacitive sensors do not consume DC currents), and the sensor output can be directly designed to digital output using energy-efficient capacitance-to-digital converter circuitry, avoiding nonidealities of voltage buffers and signal conditioning integrated circuits.162

More recently, flexible pressure sensors have attracted much attention due to their ability to measure the local contact pressure and its spatial distribution with exceptional stability and repeatability. Such features are beneficial for a wide range of applications including prosthetics, health monitoring, or human–machine interaction.163 In this context, Luo et al. proposed a micropillar–PVDF device with high sensitivity (0.43 kPa–1) in the low-pressure regime (<1 kPa) and with a ΔC/C = 0.6 under a bending angle of 90°, suitable for capacitive pressure sensors on wearable devices and human-machine interactive tools.

PVDF has also been used in wearable applications for capacitive sensing in the form of fibers.164 The reported change in capacity in the PVDF sample reaches maximum values of ΔC/C = 0.38 for a pressure of 69.35 kPa. The introduction of TiO2 nanoparticles into the PVDF fiber composition increased the ΔC/C to the value of 0.47, which is appropriate for insole sensors in sports shoes.165 Still in composites, a (poly(VDF-co-HFP))/1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ([EMIM][TFSI]) IL composite film (with a 6.5/3.5 weight ratio) has been proposed for textile-based capacitive pressure sensing.164 The proposed device exhibited a large value of ΔC/C (∼200) and a sensitivity of 9.51 kPa–1 for a pressure of 100 kPa. Additionally, a 3 × 3 pressure sensor array able to detect not only position but also weight and object types was discussed. In a different strategy and aiming the successful detection of harmful gases under the umbrella of wearable electronics, a bendable capacitive sensing device composed of UiO-66-NH2 and electrospun PVDF was also proposed. The ΔC/C = 0.01 allowed to detect small concentrations of sulfur dioxide (SO2) (150 ppm),166 opening a new exciting application area in this type of polymer-based composites.

3.1.2. Pyroelectric Sensors

Once PVDF has piezoelectric properties and a robust pyroelectric response (dipolar variations induced by heat variations167), it can be used for pyroelectric sensing as demonstrated by S. Pullano et al.,168 which presented a ferroelectric polymer-based temperature sensor designed and optimized for microfluidic devices (area that will be discussed in more detail in section 3.5) (Figure 9).

Figure 9.

(a) Cross-section representation and (b) photograph of the PVDF-based microfluidic device on which the gold (Au) contacts were deposited to act as both active and electrical components to the read-out circuit. (c) Experimental results (charge amplifier voltage output vs time) were obtained at five different target temperatures (from 43 to 65 °C). The black line exhibits the data obtained for infrared radiation-light-emitting diode (IR-LED) stimulation. (d) Calibration of the proposed pyroelectric sensing device inside the microfluidic channel. Reproduced with permission from ref (168). Copyright 2017 Multidisciplinary Digital Publishing Institute.

The reported performance of the PVDF pyroelectric sensor (∼0.3 V voltage variation for a temperature range between 25 and 65 °C) took advantage of the high compatibility between PVDF and PMMA in the fabrication of disposable devices. Such performance can be even further improved with the inclusion of electronic microsystems such as low-noise complementary metal-oxide semiconductor (CMOS) charge amplifiers and filtering tools on silicon boards. In a similar approach, the successful integration of a ∼28 μm thick film of PVDF into a system-on-a-chip board was achieved, facilitating the fast monitoring of temperature in specific sites of the biological fluid and avoiding errors in the assessment of thermal evolution of the fluid during the study.168 Such PVDF-based pyroelectric sensor can detect the absolute temperature instead of the temperature gradient, with a ∼0.005 s response time in a temperature range of −40 to 65 °C and with a sensitivity of 5 mV·°C–1.

From a theoretical point of view, Jia et al.169 conceived a PVDF-based pyroelectric sensor at the circuit level, being the theoretical model optimized with the introduction of experimental details in the environment of Multisim so that the simulated data could be accurately compared with real data. The theoretical sensitivity of the device was found to be 0.1063 V·°C–1, very similar to the experimentally measured one (0.1068 V·°C–1). Additionally, it was stated that the key features to achieve consistent simulated results were the: (i) intensity of pulse current and (ii) width of the current pulse.

Aiming to mimic some of the functionalities of human skin, Lee et al.170 demonstrated that an ∼80 μm thick polymer-based film (composed of PVDF, ZnO nanostructures, and graphene (Gr) electrodes) was capable of simultaneously measuring pressure (∼10 Pa resolution by sensing the electrical resistance variation through the piezoresistance of the material) and temperature (in the 20–120 °C range with a sensitivity of ∼13 mΩ·°C–1). Such a technological platform exhibited a pressure detection limit 3 orders of magnitude higher than the required for artificial skin with a sensitivity of ∼11 mΩ.Pa–1, opening promising application potential in the area of biorobotics.

Still with respect to the e-skin concept, a similar PVDF film with a thickness of ∼110 μm, a piezoelectric response of 106 pC·(Vm)−1, an area of 10 cm2, a pyroelectric coefficient of 300 C·(m2 °C)−1, and an output voltage of about 3 mV has been reported by Yuji et al.171 to monitor temperature variations of the human skin. The sensitivity was found to be 2 mV·°C–1 in the 10–50 °C temperature range.

A novel, lightweight, low-cost, and high flexible triboelectric nanogenerator composed of PVDF (6 cm × 3 cm × 1 mm), polytetrafluoroethylene (PTFE), and copper foil as the electrode was used by Zhu et al.172 as a self-powered temperature sensor, exhibiting a detection range of 10–90 °C, 0.01 s response time, and a 3.5 s reset time. Humidity was found to be an essential factor in the output voltage of the sensor: at 20 °C, the output voltages were 42, 37, and 32 V for a relative humidity of 70, 80, and 90%, respectively, being the sensitivity maximized for the measurement at 70% relative humidity conditions (2.1 mV.°C–1), showing a promising application potential in the environmental, safety, and biomedical fields.

By adding BaTiO3 into a poly(VDF-co-TrFE) matrix, Gupta et al.173 was able to monitor temperatures in the 26–70 °C range with an almost linear response and a sensitivity of 15.34 mV·°C–1, opening new and exciting directions for temperature tactile sensing in robotic applications.

In the same “composite strategy,” Hernández-Rivera et al.174 produced a piezoelectric PVDF/Gr membrane through electrospinning, for respiratory rate and temperature sensing with a maximum sensitivity of ∼0.34 pC·°C–1. Such sensors can be applied to other areas such as moisture, light, and pressure sensing due to their optimized electroactive properties.

Knowing that temperature sensing ability is essential for successful robot perception (allowing biomimetic information acquisition), Sun et al.175 developed a soft robotic manipulator capable of temperature sensing. The structure of the PVDF-based sensor composed of a poled PVDF film, silver (Ag) electrodes on both surfaces of PVDF, and a PET thin film packing allowed a sensitivity of 0.478 V·°C–1. When coupled to the triboelectric nanogenerator tactile sensory data, such temperature data obtained from the PVDF-based sensor can allow shape recognition of objects and devices, offering great potential for IoT-related human-machine interfaces.

Changing the focus to near-infrared (NIR) sensing/manipulation, Liu et al.176 proposed a flexible battery-less implantable device composed of Gr and PVDF. Such a device was found to exhibit a good relationship between its response (temperature, temperature-change rate, output open-circuit, voltage, and short-circuit current) and the NIR irradiation stimulus. The maximum voltage and current were 2 V and 200 nA, respectively. Additionally, the harvested energy was able to light up 4 commercial LEDs, stimulate a live rat’s heart and actuate a frog’s nerve, opening possible applications in the bioelectronics field.

Because PVDF cannot be directly used to detect light because of its weak absorption in the visible and NIR zone, the incorporation of nanostructures such as gold (Au) nanocages has been proposed to develop PVDF-based composites able to convert light into heat and electricity.177 A voltage output of 7.2 V, a current of 28.1 nA, and a temperature variation of 50 °C were detected when the PVDF/Au composite was subjected to NIR cycles (808 nm diode laser with a power density of 0.2 W·cm–2). More recently, electrospun PVDF/cesium tungsten oxide composites were evaluated for NIR-triggered pyroelectric sensing and harvesting.178 For the sample with 7 wt % (weight percentage) of cesium tungsten oxide it was determined that an output of 4.36 V and 214 nA (for a NIR radiation with 2.26 kW·m–2) was high enough to power liquid crystal display (LCD) timers and 4 LEDs.

3.1.3. Piezoelectric Sensors

Due to the wide frequency response range, wide pressure range (up to 20 GPa), high sensitivity, good mechanical properties, and easy processing, PVDF is the most used material for polymer-based stress, strain, impact, and vibration sensors. This reputation came in the 80s of the last century when Domenici et al.179 produced a shear stress detection sensor composed of an elastic layer of PVDF sandwiched between two rubber layers and fixed to a rigid substrate. The experimentally obtained sensitivity (6 nC·N–1·m–1) was double than the one predicted analytically (3 nC·N–1·m–1), a substantial difference in the sensor output attributed to factors such as the presence of friction between PVDF and rubber layers. Two decades later, Kärki et al.180 developed a stress sensing device prototype composed of commercial PVDF with four separated sensor components. The reported sensitivities were found to be 12.6 mV·N–1 for the normal force, 223.9 mV·N–1 for the anterior–posterior shear force, and 55.2 mV·N–1 for the medial–lateral shear force. Despite such promising results, the proposed sensor is only an early prototype; further developments such as the development of a matrix sensor, electronic components, array-type solutions, and long-term evaluation are still needed.

Following a different strategy, a PVDF (22 mm × 18 mm × 0.3 mm) piezoelectric smart sensor (PVDF as a sensing element that is insulated and protected by PET layers to ensure good toughness, tensile strength, and impact resistance) was used to monitor impact (Figure 10). For that, the PVDF-based sensor was placed into a multilayer structure and successfully applied to study the internal stress of the concrete core of a concrete-filled steel tubular column under impact loads with a sensitivity of ∼1.32 MPa·V–1.181

Figure 10.

(a) Schematic representation of (a) the PVDF smart sensor, and (b) the location of the PVDF smart sensors (S-1, S-2, and S-3). Reproduced with permission from ref (181). Copyright 2018 Multidisciplinary Digital Publishing Institute.

The authors stated that similar PVDF-based impact sensors could be embedded in the concrete-filled steel tubular structures in a distributed way to evaluate the internal stress distribution when the material structure is exposed to impact loads.

With the aim to measure the interfacial stress of a composite aluminum (Al) beam with a deposited ice layer, Akitegetse et al.182 embedded ∼25 μm thick PVDF strips, reporting good repeatability in the measurements (standard deviation of 4–8%), providing a new and creative tool for the accurate measure of ice’s adhesion strength on different substrates. The proposed PVDF-based sensing device directly measured (through the piezoelectric effect) the mechanical stresses (0.5 MPa for an ice thickness of 2.5 mm, 0.2 MPa for an ice thickness of 4 mm, and 0.05 MPa for an ice thickness of 10 mm) induced by mechanical stimulus at the substrate/ice interface.

Four years later, Cai et al.183 designed a PVDF (∼30 μm × 30 mm2× 30 mm2) stress sensor with fast response (ns), high sensibility (49.2 GN·C–1), and wide working range (0–5 cm) suitable for antiexplosion elements.

Still, in an explosive/ballistic perspective, Ma et al.184 designed a temperature compensation of a PVDF stress sensor to be used to evaluate gun propellant charge compression stress with a sensitivity of ∼53 pC·N–1. Additionally, the maximum relative error after temperature compensation in the −40 to 30 °C range was found to be less than 0.0134%, revealing that PVDF stress sensors can be accurately used on the compression stress test of a gun’s propellant charge.

More recently, and linking biomedicine with robotics, Li et al.185 developed a built-in sensor system for internal shear strain and stress distribution measurement by embedding PVDF within the artificial skin of soft robotics. The determined 50 pC·mm–1 sensitivity is suitable for application in soft material strain/stress measurements and in soft robotics development. Electrospun PVDF was also used for vibration measurement in a string.152 The proposed sensor (composed of 218 ± 53 nm fibers) exhibited a linear relationship (0.2 mV·με–1) between output voltage (0–600 mV) and strain (0–2300 με).

3.1.4. pH and Gas Sensors

The sensing of pH value is relevant in many areas, such as chemical engineering, environmental industry, and the biomedical field.186 Due to the combined effect of the variation in surface chemistry and the roughness of the PVDF structure, linked to its high mechanical strength, chemical resistance, and thermal stability, this ferroelectric polymer is often used in pH sensing applications.187

In this context, a self-powered pH sensor based on a PVDF/ZnO hybrid composite nanogenerator was produced through a solution-casting technique by Saravanakumar et al.188 The proposed PVDF/ZnO hybrid composite revealed a maximum open-circuit voltage of 6.9 V and a short-circuit current of 0.96 μA, with an output power of 6.624 μW under uniaxial compression that powered the sensor with a sensitivity of 0.06 V per pH unit (pH–1).

A pH-sensitive porous membrane composed of PVDF and acrylic acid was successfully synthesized through molecular graft copolymerization of acrylic acid with ozone-preactivated PVDF backbone.189 The flux of the aqueous solution through the PVDF-based sensor induced a strong and reversible dependence on pH solution (the solution flux through the membrane decreased from ∼5 mL·cm–2·min–1 to ∼2 mL·cm2–·min–1 with increasing pH from 1 to 6), a fact that proved the pH-sensing capability of the device. Flow measurements and caffeine release experiments performed with a similar membrane composition (PVDF/acrylic acid) showed that the porous structures exhibited a pH-dependent behavior.190 The solution flux through the membrane decreased from ∼4 mL·cm–2·min–1 to ∼1 mL·cm–2·min–1 with increasing pH from 1 to 6.5. Other preliminary results reported in the same work, related to release experiments with caffeine as a model drug, suggested that it is possible to use similar pH-sensitive-PVDF membranes to induce pH-sensitive dissolution of drugs. Ju el al.191 presented the development of antifouling PVDF/poly(methyl methacrylate-2-hydroxyethyl methacrylate-acrylic acid) microfiltration composite membranes for pH-sensing applications. Such membranes were found to have excellent pH sensitivity (the solution flux through the membrane decreased from ∼1 mL·cm–2·min–1 to ∼0.7 mL·cm2–·min–1 with increasing pH from 2 to 11), pH reversibility response, and good protein antifouling properties.

More recently, Pastore et al.192 improved the pH determination of a PVDF-based colorimetric sensor by combining two acid–base indicators (tetrabromophenol blue and phenol Red), the resulting hue being detected with a charge-coupled device (CCD) camera. The reported inflection prediction error of the sensor was in the range of 0.01–0.16 pH unit, and the sensitivity (ΔH/ΔpH) of 1.01 is appropriate for pH colorimetric sensors.

Changing the focus to the biomedical area and knowing that detecting the pH value at the wound sites could monitor and support the wound healing process, Zhao et al. fabricated a PANI-modified PVDF yarn for pH sensing,186 being reported an 8.53 mV·pH–1 sensitivity in the pH range from 4.0 to 8.0. Such performance proved that the electrospun PANI-PVDF yarn has high potential application in smart surgery dressings.

PVDF has also been used in gas sensing devices due to its flexibility, mechanical strength, thermal stability, tailorable porosity, and superior adsorption and desorption characteristics.193 In this line, a PVDF/palladium (Pd) all-optical laser-intensity-amplitude-modulated hydrogen (H2) sensor has been produced by Mandelis et al.194 The detection range of this durable and robust sensor (0.2 −100% of hydrogen volume concentration) is suitable for sensitive monitoring of the explosive range (4% by volume of H2 in the air), the sensor’s output reflectivity varying from ∼0.273 to ∼0.250 when the H2 volume concentration increases from 0.2 to 100%. A solid-state sensor for detecting H2 gas concentrations as small as 0.075% in volume has been developed based on commercial PVDF pyroelectric films sputter-coated with Pd (or an aluminum-nickel (Al-Ni) double layer).195 The high resolution is related to the variation of the pyroelectric coefficient of the film due to electrostatic interactions of adsorbed H2 ions with the PVDF matrix upon hydrogenation and selective absorption by the metallic coating.

PVDF/iron vanadate (FeVO4) porous layers produced by a doctor blade have been successfully tested for oxygen (O2) sensing devices, being the best sensitivity (resistance of O2/resistance of nitrogen (N2)) of 0.29 ± 0.01 obtained at an optimal working temperature of 250 °C.196 The trapping of electrons can explain such high sensitivity to adsorbed O2 species and the resulting band bending that caused the measured resistance change.

The AC/DC electrical properties of Li and PVDF/titanium (Ti) codoped nickel oxide (NiO) composites were studied and optimized for their use as ammonia (NH3) sensors.197 It was discovered that the response time (decreasing from ∼250 s to ∼30 s with increasing temperature from 300 to 420 °C) and sensitivity (decreasing from ∼0.12 to ∼0 ppm–1 with increasing temperature from 300 to 420 °C) of the sensor was strongly dependent on temperature.

After proposing a new type of organic H2 gas sensor in which a β-PVDF film was coated with thin films of Pd on both sides with a sensitivity of ∼50 mV·L–1·min–1,198 Imai et al.199 (Figure 11a,b) tested the response characteristics of the sensors (response at H2 exposure ∼100%, detection sensitivity of ∼250 mV·L–1·min–1 and recovery time of ∼500 s), demonstrating that the characteristics of the sensor response depends on the PVDF’s microstructure.199

Figure 11.

(a) Schematics of the piezoelectric H2 sensor composed of PVDF and Pd. (b) Output voltages (mV) of the proposed gas sensor as a function of time (h). The inset reveals the magnified response curve collected for 0.001% H2 concentration. Reproduced with permission from ref (199). Copyright 2017 Elsevier.

In the field of resonators, a mechanical resonator made of a thin glass plate driven by ferroelectric PVDF polymer foils was optimized for N2-sulfur hexafluoride (SF6) gas flow and humidity measurements.200 The particular 2/0 mode vibrational deflection of the plate was selected, as it ensures high sensitivity (the resolution was in the order of 2% relative humidity and 0.2 m·s–1 gas flow), appropriate for the determination of both the density of gases and humidity in the air.

Chen et al.201 also applied a resonator composed of ZnO piezoelectric stack, a tungsten/silicon dioxide (W/SiO2) Bragg reflector, and a PVDF sensing material for the detection of nerve gas. The testing results revealed that the proposed resonator has high sensitivity (718 kHz·ppm–1), reversibility (15 min recovery), and reproducibility (over 30 days) in the sensing of nerve gas.

More recently, Xu et al.202 incorporated porous PVDF/Gr membranes on surface acoustic wave sensors to increase the sensor’s response time. The sensitivity of the dimethyl methyl phosphonate (DMMP) sensor reached the remarkable value of −1.407 kHz·ppm–1, the response time and recovery time of the sensor being improved 4.5 and 5.8 s, respectively, with the incorporation of the PVDF/Gr membranes. The much improved performance was explained through increased adsorption as a result of the electrostatic interaction between DMMP and PVDF chains.

3.1.5. Biomedical Sensors

The capability of transforming electrical stimuli into mechanical response, and mechanical stimuli to electrical response, in combination with the excellent physical, chemical, and mechanical characteristics of PVDF and its copolymers, have been increasingly applied in the biomedical field to develop biosensors and tools for health monitoring.8

One of the most cited work on the use of PVDF-based biosensors is the one from Manesh et al.,203 regarding the evaluation of electrospun PVDF/poly(aminophenylboronic acid) (PAPBA) composite nanofibrous membranes as a glucose sensor. The sensor worked on the 1–15 mM glucose concentration range with a sensitivity of 2.3 μA·mM–1, linearity of 0.997, and a response time of less than 6 s, all those features being stable over 50 days. Such work opened the way for the electrospinning technology to be extended to the fabrication of other sensors through judicious loading of sensing materials into the polymer-based fibrous matrix.

A similar strategy was followed by Zhang et al.204 by adding multiwalled carbon nanotubes (MWCNTs) and platinum (Pt) nanoparticles to PVDF. After electrospinning, polymer-based nanofibrous membranes were obtained with highly stable biosensing properties (with selective detection of both hydrogen peroxide (H2O2) and glucose with a sensitivity of −0.2 μA·mM–1). Such composite structures can be easily used in other technological applications such as energy storage, cytology, and tissue engineering.

Tanaka et al. designed a haptic finger using PVDF piezopolymer films as a sensory receptor.205 The suitability of the proposed sensor to monitor human skin conditions was investigated after sliding the sensor over skin surfaces from 30 people, being found that the two parameters (index of roughness and hardness) generated using such haptic finger displayed good agreement with subjective/clinical assessments of the tested skin conditions. PVDF sensor output from 0 to ∼30 mV allowed conclusion that from all 30 persons who participated in the study, 5 exhibited xerosis, 7 atopic dermatitis, and 2 psoriases. Such results were encouraging for looking at the suitability of similar devices in other fields, such as the cosmetic area, where the variations of skin properties are more subtle and more challenging to be detected.

Knowing that problematic and recurrent sleep apnea upsets the sleep of humans and that it can lead to sleep disorders such as severe snoring, fatigue, daytime sleepiness, and systemic hypertension, Hwang et al.206 presented a sleep apnea monitoring method based on PVDF sensors (4 × 1 array with ∼1.1 mm thick) for continuous and accurate monitoring of apneic events that occurred during sleep. The correlation coefficient of the sensors for the apnea–hypopnea index (AHI) values was determined to be 0.94. The areas under the receiver operating curves at three AHI threshold levels (>5, >15, and >20) for sleep apnea diagnosis were 0.98, 0.99, and 0.98, respectively, and most importantly, for minute-by-minute apnea detection, the method classified sleep apnea with an average sensitivity of 72.9%, specificity of 90.6%, accuracy of 85.5% and kappa statistic of 0.60. All of these experimental results validate the PVDF sensor system for the monitoring/detection of sleep apnea in both home and ambulatory environments.

Being the continuous glucose sensing with reliable in vivo performance expected to improve glucose concentration regulation and thus reduce the number of complications related to diabetes mellitus, PVDF-Nafion nanomembranes coated microneedles were produced for in vivo transcutaneous implantable glucose sensing (Figure 12).207

Figure 12.

Schematic representation of the glucose sensing needle. (a) Layered nanostructures and (b) operation principle. (c) Relation between current (μA) and time (s) with successive additions of 0.5 mM glucose (twice), 0.1 mM uric acid (UA), 0.1 mM ascorbic acid (AA), and 0.1 mM l-cysteine (Cys) under 0.65 V electrode potential. Reproduced with permission from ref (207). Copyright 2015 Elsevier.

The obtained porous structure with a nanosphere top layer fabricated using one-time deposition avoided multiple dipping and subsequent loss of enzyme activity, leading to high selectivity, low response time (30 s), high sensitivity (∼0.23 μA.mM–1), and high linearity (R2 = 0.998) in the 0–20 mmol·L–1 range. Additionally, reliable in vivo test results in mice were reported.

Aiming also to detect glucose, Xing et al.208 introduced nickel(II) hydroxide (Ni(OH)2) and CNTs into a PVDF matrix, obtaining a highly stable sensing material whose stability was confirmed by cyclic voltammetry measurements in sodium hydroxide solution (NaOH) (0.50 M, scan rate 100 mV·s–1). The PVDF-based composite films maintained the electrocatalytic activity of the nano-Ni(OH)2 and, for such reason, was used to fabricate a nonenzymatic biosensors for electrochemical detection of glucose. Amperometric measurements revealed that the proposed sensor exhibited good anti-interference properties toward some substances (maltose, fructose, urea, and AA), with a reported detection limit of 0.023 mM and a wide linear range from 0.25 to 39.26 mM (R2 = 0.998), which are comparable with commercially available blood glucose sensors. The calculated sensitivity was 0.65 μA·mM–1 with a deviation of less than 5%.

Another glucose sensing device was developed using a capacitive biosensor based on PVDF thin film, consisting of a PVDF film sandwiched between two Ag electrodes.209 The sensor was evaluated for glucose concentrations in the 0.013–5.85 M range and various glucose oxidase (GOx) enzyme concentrations between 4882.8 and 2.5 million units·L–1, reported that the device output increased from 0 to ∼5.5 μV with increasing glucose concentration up to 5.85 M, showing a detection limit of 1.3 × 10–2 M.

Regarding antigen sensing, Sanguino et al.210 reported the use of PVDF Immobilon-P as a sensitive layer coupled with a transducer to function as affinity immunosensors, able to distinguish phosphate-buffered saline (PBS) buffer and antigen horseradish peroxidase (HRP) solutions, based on the capacitance variations (PBS, 0 to −0.6 pF; and HRP, 0 to 0.1 pF). Such measurements could be taken at a fixed frequency, making the sensor instrumentation particularly simple and easily scalable for practical applications such as clinical diagnosis, food monitoring, industrial controls, and environmental measurements.

Once nucleic acid testing (NAT) represents stable, safe, selective, and specific detection of infectious and inherited diseases, a new diaphragm mass biosensor based on PVDF piezoelectric film was developed for detecting nucleic acids.211 Experimental results showed that the mass sensitivity was 0.185 kHz·μg–1, obtained for a diaphragm with a diameter of 5 mm. Additionally, the value of frequency shift was found to be directly proportional to the content of the target solution. Such performance validated the PVDF-based sensor for low-cost real-time fabrication of NAT tools.

With respect to electrochromic sensing, Santiago-Malagón et al.212 used a PVDF-based ion-gel electrolyte (poly(VDF-co-HFP), IL 1-ethyl-3-methylimidazolium trifluoromethanesulfonate, EMIM-Tf, and potassium triflate) to protect the cathode display and to provide an adequate chemical environment for the operation of a skin-patch electrochromic lactate biosensor. Such a protection layer avoided the bleaching of the cathode by acids (ascorbic and uric). The sensor was found to work with lactate concentrations in the range of 0–10 mM with a contrast ratio of 1.43, up to 24 min response time, and 85% of the color change displayed within 10 min. The skin-patch electrochromic lactate biosensor represents a promising route for controlling target molecules that are exerted through perspiration.

3.1.6. Environmental Sensors

Among several materials used for the fabrication of polymer-based environmental sensors, PVDF is one of the most commonly used due not only to its excellent mechanical strength and high thermal and chemical resistance but also because this polymer withstands chlorine disinfection.213

Aiming to evaluate random environmental vibrations (such as wind flow, waterfall, or transportation of vehicles), a large area, highly sensitive, and flexible pressure sensor has been produced based on electrospun Ce3+/PVDF/Gr composite nanofibers.214 The developed Ce3+/PVDF/Gr composite sensing device could detect pressure as low as ∼2 Pa with high sensitivity (30 mV·Pa–1). Furthermore, the Ce3+/PVDF/Gr composite sensor could also be used as an effective nanogenerator as it can generate an output voltage of 11 V with a current density of ∼6 nA·cm–2 upon repetitive application of mechanical stress, making this device self-powered.

Also, from a “self-powered device” perspective, Guo et al.215 developed a stretchable sensor fabricated by serpentine PVDF film for multiple dynamic monitoring, which can efficiently detect various mechanical stimuli relevant to specific environmental or biological species. The serpentine device, composed of three layers, with two aluminum layers coated on a piezoelectric PVDF film, exhibited a sensitivity of 6mV·stretch–1 and a maximum voltage of 350 mV at a frequency of 10 Hz.

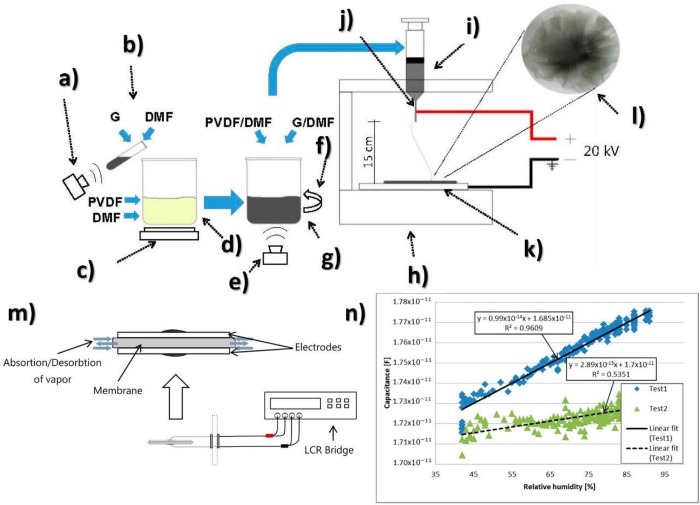

Once humidity sensors are widely required in agriculture, environmental conservation, and climatology, PVDF/Gr membranes were evaluated as capacitive humidity sensors (Figure 13).216

Figure 13.

(a) Schematics of the production procedure: (a) sonication, (b) Gr/DMF solution, (c) electric heater, (d) PVDF/DMF solution, (e) sonication, (f) stirring, (g) PVDF/Gr/DMF solution, (h) electrospinning equipment, (i) needle, (j) syringe tip, (k) collector plate, and (l) electrospun membrane. (m) Scheme of the humidity sensing principle. (n) Capacitive response as a function of the relative humidity of the PVDF-based sensor. Reproduced with permission from ref (216). Copyright 2017 Multidisciplinary Digital Publishing Institute.

PVDF blended with Gr was developed to improve the PVDF electrical properties, allowing the use of PVDF/Gr membranes as capacitive humidity sensors. The observed good response time (18 s), high sensitivity (0.0463 pF/% of relative humidity), repeatability, linearity (R2 = 0.993), and low noise of the PVDF/Gr composite membrane sensors open other possible applications such as filtration, growth of living tissues, and prosthetics applications.

To explore underwater environments and operate in underwater missions, sensing the surrounding environment is an essential topic for developing innovative underwater robots. Once this issue is particularly sensitive on robotic fish, a PVDF pressure sensor was developed217 and integrated with a small water-proofed charge amplifier. The pressure PVDF-based sensor was optimized in a water tank, reporting a sensitivity of 0.071 Pa·mV–1. This sensor can be used to study other fishes and their actions/reactions in real-time.

Other environmental stimuli, such as light or pressure, can also be monitored by using both piezoelectricity and pyroelectricity of PVDF.218 Multipiezo/pyroelectric sensors with transparent electrodes (Ag nanowires and PEDOT:PSS) exhibit a pressure and light sensitivity of 80 mV·Pa–1 and 42 V·cm2·W–1, respectively. These values are favorably compared to the ones of Al-based electrodes, with the advantage of defining the electrodes directly on the sensitive foil. The reported optimized sensors reach root-mean-square powers for the piezoelectric effect and pyroelectric effect of ∼1 μW and ∼0.42 μW, respectively, for an active PVDF area of 8 cm2. This strategy makes it easy to detect and quantify all kinds of environmental properties such as humidity, pressure, heat, light, or vibration.

More recently, Jang et al.219 developed PVDF/ZnO-based hydrazine sensors. As a working principle, ZnO was previously functionalized with poly(VDF-co-HFP) to expose the polymeric chains to hydrazine, allowing physical H2 bonding/interactions that induced a change in the charge transfer properties of the ZnO films and improved the sensing behavior of the device. Hydrazine is regarded as a toxic and carcinogenic chemical that damages the liver, lungs, kidneys, and central nervous system (CNS), and for such reason, the Environmental Protection Agency (EPA) has limited the threshold in drinking water to less than 10 ppb (∼0.3 μmol·L–1). Thus, the study reported by Jang et al. is in line with the need to define suitable sensing strategies of the toxic hydrazine. The PVDF/ZnO-based sensor exhibited hydrazine detection limits up to 0.01 nM (sub-ppt level) and reproducibility over 96%.

3.1.7. Magnetic Sensors

Besides the nucleation of the electroactive phases of PVDF (such as β or γ), the addition of fillers induces additional effects that bring added value to the use of PVDF-based nanocomposites for technological applications.11 As an essential family of PVDF-based nanocomposites, magnetic nanocomposites with magnetically responsive features have attracted increasing attention because of their magnetic functionality and wireless activation.220,221

Despite PVDF-based magnetic composites find many major applications as actuators,222 vibration control,223 ultrasonic transducers,224 batteries,225 filters,226 chemical warfare protection,227 and in the biological field,228 their impact with respect to magnetoelectric sensing applications are particularly interesting.156 For example, the addition of magnetostrictive fillers into the PVDF matrix allows the production of all-printed multilayer magnetic-responsive materials with improved magnetoelectric response suitable for sensing devices,229 transparent magnetoelectric materials for advanced invisible sensing applications,230 and anisotropic magnetoelectric sensors with good linearity (R2 = 0.995) with application potential on digital compasses, global positioning system (GPS) devices, and biomedical sensing.231

It has been reported that the introduction of different nanoparticles into a poly(VDF-co-TrFE) matrix, such as Zn0.2Mn0.8Fe2O4 (ZMFO), CoFe2O4, and Fe3O4, do not change the piezoelectric response of the polymer matrix (∼−28 pC·N–1) but leads to distinct magnetoelectric responses,232 such as 6.5 mV·cm–1·Oe–1, at an optimum magnetic field of 0.26 T, and 0.8 mV·cm–1·Oe–1, at an optimum magnetic field of 0.15T, for poly(VDF-co-TrFE)/CoFe2O4 and poly(VDF-co-TrFE)/Fe3O4 composites, respectively. In contrast, the magnetoelectric response of poly(VDF-co-TrFE)/ZMFO showed no hysteresis and high dependence on the ZMFO filler content. Such findings allow further tailoring of the magnetoelectric sensing properties for specific magnetic environments.

Regarding laminated composites, the combination of PVDF and Vitrovac 4040 materials on trilayered and bilayered magnetoelectric flexible composite structures of varying geometries and sizes allowed to optimize the magnetic sensitivity of polymer-based magnetic sensors233 (Figure 14).

Figure 14.

(a) Schematic representation of Vitrovac/PVDF magnetoelectric composites produced in the study (A–F). Representation of the lateral view of the three-layer composites (G,H). (b) magnetoelectric response obtained from laminates with bilayer composite (sample A), three-layer magnetostrictive–piezoelectric–magnetostrictive (MPM) (sample G) composite, and three-layer PMP (sample H) configurations. (c) Magnetoelectric response obtained as a function of the different aspect ratios. Reproduced with permission from ref (233). Copyright 2015 Elsevier.

From the magnetoelectric measurements, it was confirmed that trilayered composite structures, i.e., MPM type, revealed a higher magnetoelectric response (75 V·cm–1·Oe–1) than the bilayer structure (66 V·cm–1·.Oe–1). Additionally, the magnetoelectric voltage coefficient decreased with an increasing longitudinal aspect ratio between PVDF and Vitrovac layers (from 1.1 to 4.3), with a maximum magnetoelectric voltage coefficient of 66 V·cm–1·Oe–1.