Abstract

Deep eutectic solvents (DESs), have been recognized as effective materials for the extraction of different compounds. In this study, the performance of a novel hydrophobic DES was evaluated for the extraction of phenol from aqueous solutions. Octanoic and dodecanoic fatty acid precursors with a definite molar ratio of 3:1, respectively, were used for the DES having a low melting point of 8.3 °C. The purity and stability of the product were confirmed via characterizing by FTIR, 1H and 13C NMR methods. The liquid–liquid equilibrium of the water + phenol + DES ternary system at different temperatures of 293.2, 298.2 and 308.2 K was accordingly studied through cloud point titration method and refractive index measurement. Interestingly, the important parameters of the solute distribution coefficient and the separation factor were, respectively, within the high levels of (6.8321–9.7787) and (895.76–2770.17), indicating the amazing capability of the DES. Reasonably, both of these parameters decreased with temperature. The NRTL and UNIQUAC thermodynamic models were employed to reproduce the obtained tie-lines and to determine the interaction parameters at each temperature. The low level root mean square deviations for the mentioned models were, respectively, within (0.0014–0.0027) and (0.0045–0.0063); confirming satisfactorily agreement with the experimental data.

Subject terms: Pollution remediation, Chemical engineering

Introduction

The extensive generation/utilization of phenol in various industries like refineries, petrochemical industries, coal gasification, pulp and paper, paint, pharmaceutical, plastics and resin has leaded to generating huge phenolic wastewaters. Non desired effects of phenol on the environment and human is mainly attributed to its toxicity and hazardous nature. Thus it seems quite beneficial to process wastewaters for separating phenol/phenolic compounds1.

Two main strategies for removing phenol from wastewater, reported by the investigators, are (i) degradation via wet oxidation, electrochemical and photocatalytic oxidation and (ii) separation via membrane, extraction and adsorption. Both of these strategies have the benefits and drawbacks. Indeed, recovery and reusability of phenol is not feasible in degradation strategy2.

Among various separation techniques such as liquid–liquid extraction, azeotropic distillation and extractive distillation; the latter, due to forming a binary azeotrope between water and phenol, is challenging and thus, liquid–liquid extraction is usually preferred3. In this regard, selecting an optimal solvent according to the main criteria of miscibility gap, separation capability, selectivity, environmental friendly and availability is important. In this regard, the undesired properties of most of the volatile conventional solvents such as flammability, toxicity, and regeneration problems have persuaded the researches to design and create novel solvents to overcome these problems4,5.

Accordingly, ionic liquids (ILs) and deep eutectic solvents (DESs) as new generations of green solvents have been introduced with desirable properties, e.g. low vapor pressure, non-flammability, biocompatibility and wide liquid phase range6,7. Worth mentioning that DESs, in comparison with ionic liquids, have the advantages of easier and cheaper preparation, more biodegradability and less toxicity8.

Generally, DESs consist of two or three substances, hydrogen bound donor (HBD) and hydrogen bound acceptor (HBA), bringing about a melting point of less than each substance9. In this regard, a typical DES, introduced by Abbot10 (2001), was made of choline chloride (HBA) and urea (HBD) with molar ratio of 1:2. Meanwhile, The limitation of utilizing hydrophilic DESs in polar systems encouraged Van Osch et al.11 (2015) to propose the first series of hydrophobic DESs for extraction process. Table 1 summarizes the recent investigations on using hydrophobic DESs in the extraction process. Since the involved components significantly influence the DES physico-chemical characteristics, the long hydrocarbon chains e.g. C8 and longer fatty acids with the unique properties of non-toxicity and biodegradability12,13 are preferred as precursors for preparing DESs14. It is while, those made of short hydrocarbon chain fatty acids are usually unstable in water15.

Table 1.

The list of studies on the using of hydrophobic DESs in liquid–liquid extraction.

| HBA | HBD | Molar ratio | Reference |

|---|---|---|---|

| Tetraoctylammonium bromide | Decanoic acid | 2:1 | 11 |

| Methyltrioctylammonium bromide | Decanoic acid | 2:1 | |

| Methyltrioctylammonium chloride | Decanoic acid | 2:1 | |

| Tetraoctylammonium chloride | Decanoic acid | 2:1 | |

| Tetraheptylammonium chloride | Decanoic acid | 2:1 | |

| Tetrabutylammonium chloride | Decanoic acid | 2:1 | |

| Menthol | Dodecanoic acid | 2:1 | 16,17 |

| Menthol | Palmitic acid | 12:1 | 18 |

| n-tetraoctylammonium bromide | Decanoic acid | 2:1 | 19 |

| Thymol | Decanoic acid | 1:1 | |

| Menthol | Decanoic acid | 1:1 | |

| Dodecanoic acid | Menthol | several | 20 |

| n-nonanoic acid | Menthol | 2:1 | |

| Decanoic acid | Menthol | 2:1 | |

| Undecanoic acid | Menthol | 2:1 | |

| Dodecanoic acid | Decanoic acid | 1:2 | 14 |

| Dodecanoic acid | Octanoic acid | 1:3 | 21 |

| Dodecanoic acid | Nonanoic acid | 1:3 | |

| Thymol | Octanoic acid | 1:2 | 22 |

| Menthol | Octanoic acid | 1:2 | |

| Thymol | Hexanoic acid | 1:1 | 23 |

| Thymol | Heptanoic acid | 1:1 | |

| Thymol | Octanoic acid | 1:1 | |

| Thymol | Nonanoic acid | 1:1 |

The desired properties of DESs such as low viscosity and density, flammability and vapor pressure, water immiscibility and stability are remarkable. On the other hand, in order to optimize and simulate the liquid–liquid extraction process, ternary diagrams of the liquid–liquid equilibrium (LLE) must be presented. Here, a novel DES, prepared from octanoic acid (C8) and dodecanoic acid (C12) precursors was prepared and characterized via FTIR spectroscopy as well as 1H and 13C NMR analyses. Afterward, the phenol extractability by the proposed DES was scrutinized at different temperatures. Othmer-Tobias, Hand, and Bachman well-known equations were employed to confirm the tie-lines consistency. Using the Aspen Plus simulator, the tie-line data were regressed using the well-known NRTL and UNIQUAC thermodynamic models. For this aim, regarding the composition complexity of the DES; a pioneering novel approach, based on group contribution, was employed for correlating the tie-lines and obtaining the binary interaction parameters.

Experimental

Materials

The fatty acid precursors of dodecanoic acid and octanoic acid were purchased from Sigma − Aldrich. Phenol was supplied from Merck and used without additional purification. A water deionizer apparatus (Hastaran, Iran) produced fresh deionized water with conductivity of less than 0.08 μS/cm, utilized for preparing solutions. The chemical names along with other related information are listed in Table 2.

Table 2.

Specification of the utilized chemicals.

| Chemical | CAS No | Supplier | Purity |

|---|---|---|---|

| Water | 7732 − 18 − 5 | Hastaran | Ultrapure |

| Phenol | 108 − 95 − 2 | Merck | > 99% |

| Octanoic acid | 124 − 07 − 2 | Sigma − Aldrich | ≥ 98% |

| Dodecanoic acid | 143 − 07 − 7 | Sigma − Aldrich | 98% |

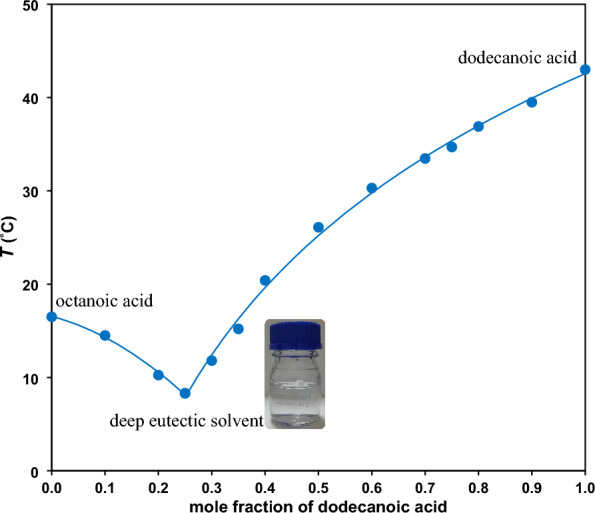

Preparation of DES and solid − liquid phase diagram

Different molar ratios of C8 and C12 carboxylic acids were gradually heated in a jacketed glass vessel up to 70 °C while magnetic stirring until reaching a homogeneous and clear solution of single phase21,24. The samples were prepared by mass using an Ohaus balance (Adventurer, Pro AV264, Switzerland, uncertainty 0.0001 g). Consequently, temperature was gradually reduced until the first evidences of solid phase was observed at a certain temperature. The corresponding solid − liquid phase diagram of the DES, illustrated in Fig. 1, shows obtaining a specific DES from octanoic and dodecanoic fatty acids with certain molar ratio of 3:1 (0.25 mol fraction of dodecanoic acid). It can be seen that the melting point of the DES (8.3 °C) is much lower than octanoic acid (16.5 °C) and dodecanoic acid (43.2 °C) bringing about a stable liquid state product for operations under conventional temperatures.

Figure 1.

Solid − liquid phase diagram for octanoic and dodecanoic fatty acid precursors.

The eutectic product was characterized by FTIR (Perkin Elmer FTIR spectrometer, USA) , 1H and 13C NMR analysis16,21 (Varian − Inova 500 MHz NMR, USA) using dimethyl sulfoxide (DMSO-d6) as solvent. The density and refractive index of the prepared DES and water were measured, respectively, with an oscillating densimeter (Anton Paar DMA4500, Austria) with a relative uncertainty of 0.001, and a refractometer (Abbe AR4 Kruss, Germany) with uncertainty of 0.0007. The obtained values and those reported in literatures are compared in Table 3, indicating a close agreement. Ensuring the stability of the DES in aqueous media, 50% volume ratio in water were stirred for 8 h and was left settling overnight. Therefore, both phases were thoroughly in contact and were separated.

Table 3.

Refractive index and density for water and the DES at temperature of 298.2 K and under atmospheric pressure of 81.5 kPaa.

| Component | nd | ρ (g/cm3) | ||

|---|---|---|---|---|

| Exp | Lit | Exp | Lit | |

| Water | 1.33250 | 1.3325025,26 | 0.99705 | 0.9970427 |

| 0.9969328 | ||||

| DES | 1.43050 | 1.4296721 | 0.90064 | 0.9010014 |

| 0.9011021 | ||||

aAverage uncertainties are u(T) = 0.1 K, u(nd) = 0.0007, and ur(ρ) = 0.001.

Solubility and LLE measurements

The basis of experiments in LLE experiments was the cloud-point titration and refractometry methods. Although various analytical methods have been developed to measure the concentration of components e.g., gas chromatography (GC) and high performance liquid chromatography (HPLC)29,30, the most applicable approach to determine the solubility of liquids is cloud point titration, also known as “turbid point titration”. The method has advantages of easily operation, high accuracy and cost effective. An extensive discussion about the conventional methods in LLE analysis has been recently reported by Arce et al.31. This approach has been used extensively in recent publications32,33. Noteworthy, the visual detection of turbidity and end-point of titration, and the requirement of a calibration curve are the limitation of this analytical method.

For analysis, a set up consisted of a miniature jacketed vial with approximated volume of 5 cm3, refractometer, thermostat (Julabo, Germany, uncertainty of 0.01 K) and magnetic stirrer were used. A water stream was circulated by a thermostat driving pump through the jacket and refractometer for maintaining temperature at a certain value. Temperature of the thermostat was calibrated via a reference thermometer (Amadigit, Germany, uncertainty 0.01 K).

Firstly, to determine the calibration curves (relationships between the concentration of each component and the refractive index), the binary mixtures of (water + phenol) or (DES + phenol) with specific amounts were prepared by means of the Ohaus balance. The next step was titrating of the binary mixtures, being stirred at a constant temperature, by precise addition of the remained component (DES or water) via a micro-siring until threshold of a stable cloudy solution. Then, the content was weighed to determine the amount of the third component and refractive index for the cloudy solution was measured immediately. In this way, the calibration curves were attained under atmospheric pressure of 81.5 kPa and different temperatures. In the Supporting materials (Table S1), the calibration curves and related data are presented. It can be seen in Figs. S1 and S2 that the refractive index of cloudy solutions increases with the phenol mass transfer which is attributed to its higher refractive index value.

The equilibrium cells containing different samples with specific and accurate amounts of involved components (water, phenol and DES) were tightly closed. These were agitated in a shaking water bath (N − BIOTEK − 304, South Korea, uncertainty of 0.1 K) at constant temperature and 175 rpm under ambient pressure for 4 h, then the phases were completely separated by resting more than 12 h time.

Collecting the organic phase (top) and aqueous phase (bottom) samples with a syringe, the related refractive indices were determined. It is worth noting that ensuring the accurate experimental data, the analysis of each sample was repeated three times. Using aqueous and organic phase calibration curves and the corresponding refractive indices, the mass fraction of each component with the uncertainty of 0.0002 except u(w31) and u(w11) as 0.0003 was determined. Table 4 presents the tie-line data at different temperatures.

Table 4.

Experimental tie-line mass fractions (w) for water (1) + phenol (2) + DES (3) along with distribution coefficient of water (D1), of phenol (D2) and separation factor of phenol (S) at different temperatures and under atmospheric pressure 81.5 kPaa.

| Aqueous phase | Organic phase | D1 | D2 | S | ||||

|---|---|---|---|---|---|---|---|---|

| w11 | w21 | w31 | w13 | w23 | w33 | |||

| T = 293.2 K | ||||||||

| 0.9932 | 0.0042 | 0.0026 | 0.0035 | 0.0406 | 0.9559 | 0.0035 | 9.7787 | 2770.17 |

| 0.9885 | 0.0090 | 0.0025 | 0.0038 | 0.0765 | 0.9197 | 0.0039 | 8.4983 | 2205.24 |

| 0.9858 | 0.0118 | 0.0024 | 0.0040 | 0.0961 | 0.8999 | 0.0041 | 8.1368 | 1989.05 |

| 0.9814 | 0.0164 | 0.0022 | 0.0043 | 0.1262 | 0.8695 | 0.0044 | 7.6931 | 1745.39 |

| 0.9785 | 0.0194 | 0.0021 | 0.0046 | 0.1462 | 0.8492 | 0.0047 | 7.5361 | 1618.77 |

| 0.9755 | 0.0225 | 0.0020 | 0.0048 | 0.1684 | 0.8268 | 0.0049 | 7.4844 | 1528.61 |

| 0.9726 | 0.0255 | 0.0019 | 0.0050 | 0.1897 | 0.8053 | 0.0052 | 7.4392 | 1437.83 |

| 0.9701 | 0.0281 | 0.0018 | 0.0052 | 0.2084 | 0.7864 | 0.0053 | 7.4164 | 1392.21 |

| T = 298.2 K | ||||||||

| 0.9928 | 0.0043 | 0.0029 | 0.0042 | 0.0395 | 0.9563 | 0.0042 | 9.2045 | 2198.14 |

| 0.9880 | 0.0093 | 0.0027 | 0.0045 | 0.0741 | 0.9214 | 0.0046 | 8.0045 | 1744.67 |

| 0.9850 | 0.0124 | 0.0026 | 0.0048 | 0.0943 | 0.9009 | 0.0049 | 7.6091 | 1547.12 |

| 0.9807 | 0.0168 | 0.0024 | 0.0052 | 0.1248 | 0.8700 | 0.0053 | 7.4154 | 1407.73 |

| 0.9770 | 0.0208 | 0.0023 | 0.0054 | 0.1527 | 0.8419 | 0.0056 | 7.3573 | 1321.84 |

| 0.9742 | 0.0236 | 0.0022 | 0.0057 | 0.1729 | 0.8214 | 0.0059 | 7.3181 | 1246.45 |

| 0.9714 | 0.0265 | 0.0021 | 0.0060 | 0.1931 | 0.8009 | 0.0061 | 7.2863 | 1188.31 |

| 0.9681 | 0.0299 | 0.0020 | 0.0062 | 0.2162 | 0.7776 | 0.0064 | 7.2304 | 1125.02 |

| T = 308.2 K | ||||||||

| 0.9928 | 0.0043 | 0.0029 | 0.0053 | 0.0365 | 0.9583 | 0.0053 | 8.8729 | 1676.23 |

| 0.9880 | 0.0093 | 0.0027 | 0.0056 | 0.0670 | 0.9274 | 0.0057 | 7.8353 | 1379.55 |

| 0.9850 | 0.0124 | 0.0026 | 0.0060 | 0.0964 | 0.8977 | 0.0061 | 7.2643 | 1197.67 |

| 0.9807 | 0.0168 | 0.0024 | 0.0063 | 0.1217 | 0.8699 | 0.0064 | 7.0973 | 1104.71 |

| 0.9770 | 0.0208 | 0.0023 | 0.0066 | 0.1486 | 0.8480 | 0.0067 | 6.9739 | 1037.36 |

| 0.9742 | 0.0236 | 0.0022 | 0.0068 | 0.1674 | 0.8241 | 0.0070 | 6.9513 | 988.25 |

| 0.9714 | 0.0265 | 0.0021 | 0.0071 | 0.1931 | 0.7997 | 0.0074 | 6.9065 | 938.47 |

| 0.9681 | 0.0299 | 0.0020 | 0.0074 | 0.2157 | 0.7797 | 0.0076 | 6.8321 | 895.76 |

aStandard uncertainties are: u(p) = 0.3 kPa, u(T) = 0.1 K, u(nd) = 0.0007, and u(w) = 0.0002 except u(w33) = u(w11) = 0.0003.

The DES capability for selective separation of phenol was evaluated from separation factor (S) criterion:

| 1 |

where D1 is the water distribution coefficient and D2 the phenol distribution coefficients obtained from:

| 2 |

| 3 |

The greater than unity values of the separation factor and distribution coefficient confirms the capability of the DES for extraction of phenol. A higher D2 is desired because of a higher extracted solute. In other words, less solvent is required to achieve a specific extraction. Also, S indicates the separation possibility and the solvent selectivity for the solute extraction5,34.

Results and discussion

DES characterization

The FTIR spectra of the DES just after preparation and after mixing with water, are presented in Fig. S3. As can be seen, there is no change in DES structure after mixing with water. 1H and 13C NMR spectra are also given in Supporting materials (Figs. S4 and S5), respectively. Considering no additional peak after mixing with water, it can be concluded that there was no chemical reaction or dissociation of fatty acids, i.e. stable in contact with water. Also, the lack of the precursor peaks in the FTIR and 1H NMR of water phase (Fig. S6) confirms again the stability. The summary of the DES analysis data is given in Table 5.

Table 5.

FTIR, 1H NMR and 13C NMR spectrums specification for DES and water phases.

| Component | Condition | Spectrums | Details |

|---|---|---|---|

| DES | After preparation | FTIR |

The peaks at 2856 cm−1 and 2926 cm−1 represents the stretching of ─CH2 and ─CH3 vibrations The peak at 1466 cm−1 represents the deformation vibration of ─CH2 or ─CH3 groups The peak at of 1712 cm−1 represents the stretching vibration of C = O The peak at of 1285 cm−1 represents stretching vibration of C─O The peak at of 938 cm−1 represents the stretching vibration of ─OH |

| 1H NMR | δ (ppm) = 0.83 (6H, 2CH3), 1.22 (24H, 12CH2), 1.47 (4H, 2CH2), 2.14 (4H, 2CH2), 2.49 (DMSO-d6), 11.87 (2H, 2OH) | ||

| 13C NMR | δ (ppm) = 14.16, 22.52, 24.95, 29.04, 31.66, 34.06, 39.57, 174.72 | ||

| After mixing with water | FTIR |

The peaks at 2856 cm−1 and 2927 cm−1 represents the stretching of ─CH2 and ─CH3 vibrations The peak at 1466 cm−1 represents the deformation vibration of ─CH2 or ─CH3 groups The peak at of 1712 cm−1 represents the stretching vibration of C = O The peak at of 1285 cm−1 represents stretching vibration of C─O The peak at of 937 cm−1 represents the stretching vibration of ─OH |

|

| 1H NMR | δ (ppm) = 0.83 (6H, 2CH3), 1.22 (24H, 12CH2), 1.47 (4H, 2CH2), 2.14 (4H, 2CH2), 2.49 (DMSO-d6), 11.87 (2H, 2OH) | ||

| 13C NMR | δ (ppm) = 14.15, 22.52, 24.95, 28.94, 31.66, 34.06, 39.89, 174.72 | ||

| Water | After mixing with DES | FTIR |

The peaks at 3435 cm−1 represents the stretching vibration of O─H The peaks at 1637 cm−1 represents the bending vibration of O─H |

| 1H NMR | δ (ppm) = 2.49 (DMSO-d6), 3.53 (2H, 2H2O) |

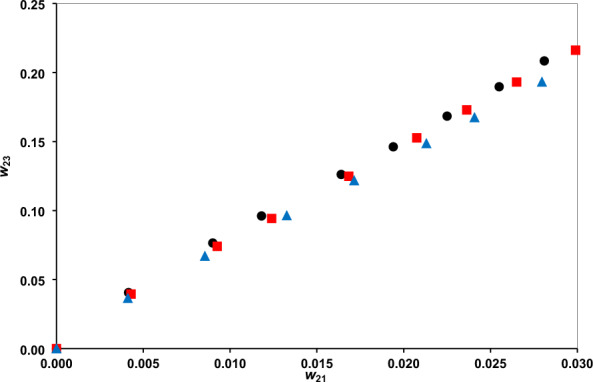

Tie-line results

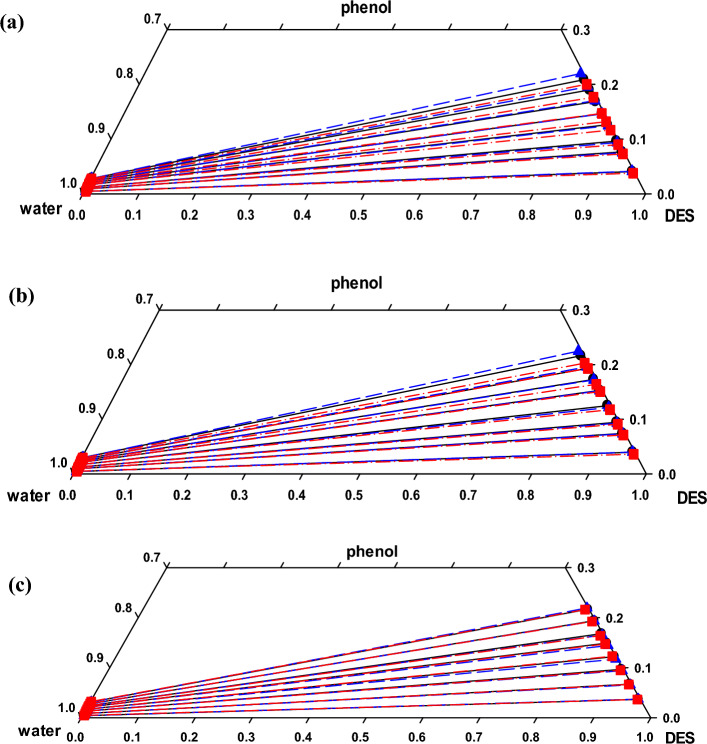

The tie-line data for the ternary system of water + phenol + DES at different temperatures of 293.2, 298.2 and 308.2 K are listed in Table 4. Corresponding phase diagrams are presented in Fig. 2. In general, mass fractions of the ith component of water = 1, phenol = 2 and DES = 3 are presented as wi1 and wi in the aqueous and organic (DES) phases, respectively. Regarding immiscibility of water and DES, partial miscibility of water and phenol as well as DES and phenol, the investigated system is assigned as a type − 2 LLE system35.

Figure 2.

Ternary diagrams of (water + phenol + DES) system at T = 293.2 (a), 298.2 (b) and 308.2 (c) K; ● and solid lines experimental,  and dashed lines NRTL predicted tie-lines,

and dashed lines NRTL predicted tie-lines,  and dash-dotted lines UNIQUAC predicted tie-lines.

and dash-dotted lines UNIQUAC predicted tie-lines.

As illustrated in Fig. 2, the higher solubility of the solute in the DES phase is consistent with the slope of the obtained tie-lines and can be attributed to the potential hydrogen bonding between phenol and the DES36,37. With respect to temperature effect, a gradual diminishing of the binary area is observed with increasing temperature. This can be attributed to the little miscibility tend of water and DES and to some extent, decreasing the phenol hydrogen bound with the DES38. It is necessary to mention that the effect of temperature is more evident at higher concentrations of the solute. The same results were previously reported for several chemical systems, for instance, water + phenol + imidazolium ionic liquid36, water + phenol + cumene27 and water + acetone + HMIMPF6 IL39.

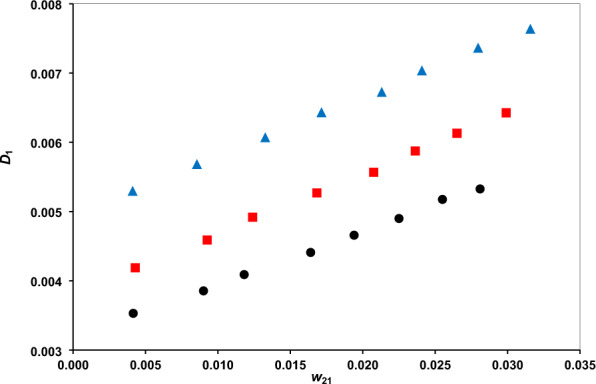

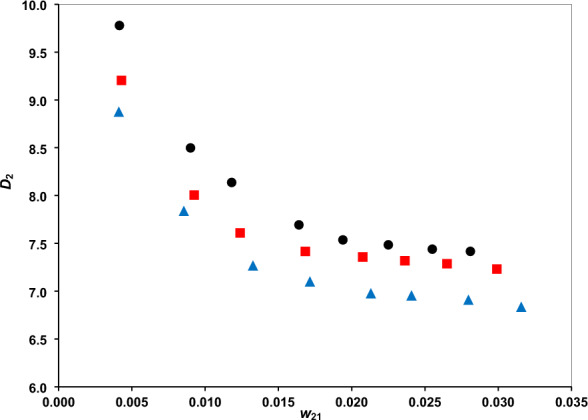

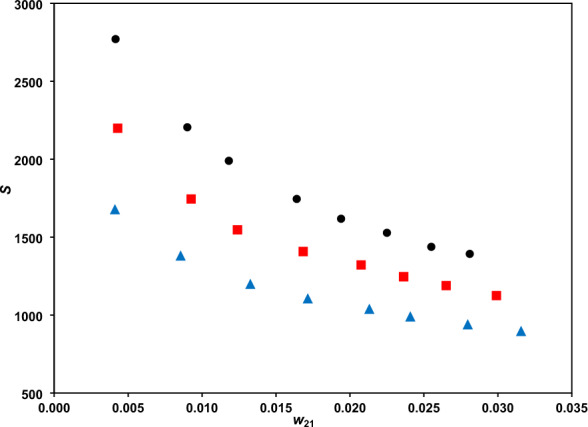

Distribution coefficients and selectivity criteria

The distribution coefficients are presented in Figs. 3 and 4, and the separation factor in Fig. 5. The phenol distribution coefficient lies within the range (6.8321–9.7787) and the separation factor within (895.76–2770.17). These confirm the amazing capability of the DES for phenol extraction. The comparison of separation factor ranges of DES with several other solvents, examined for separation phenol from water, at a typical temperature of 298.2 K, is provided in Table 6. There is significantly higher separation factor for the DES than ILs and some other conventional solvents. Indeed, the higher separation factor of methyl tert-butyl ketone should be regarded with the environmental issues which limits the applications.

Figure 3.

The water distribution coefficients vs. phenol mass fraction at temperatures of 293.2 K (●), 298.2 K ( ) and 308.2 K (

) and 308.2 K ( ).

).

Figure 4.

The phenol distribution coefficients of vs. its mass fraction at temperatures of 293.2 K (●), 298.2 K ( ) and 308.2 K (

) and 308.2 K ( ).

).

Figure 5.

The DES separation factor vs. phenol mass fraction at different temperatures of 293.2 K (●), 298.2 K ( ) and 308.2 K (

) and 308.2 K ( ).

).

Table 6.

Separation factor for several solvents in phenol extraction from aqueous phase at 298.2 K.

| System | Solvent | Separation factor (Ref.) |

|---|---|---|

| Water + phenol + cumene | Cumene | 93.41–240.5827 |

| Water + phenol + imidazolium IL | [Hmim][NTf2] | 134.68–948.7536 |

| Methyl tert − butyl Ketone + phenol + water | Methyl tert − butyl ketone | 1334–395340 |

| Water + phenol + dibutyl ether | Dibutyl ether | 50.53–1182.3941 |

| Water + phenol + 1-octanol | 1-octanol | 99.5–495.542 |

| Water + phenol + cyclohexanone | Cyclohexanone | 126.3–168.042 |

| Water + phenol + 2-ethyl-1-hexanol | 2-ethyl-1-hexanol | 131.9–398.142 |

| Mesityl oxide + phenol + water | Mesityl oxide | 1007–259943 |

| Choline IL + phenol + water | [choline][NTF2] | 27.8–41.3y44 |

| Water + phenol + DES | DES | 1125.02–2198.14 (present work) |

The separation factor decreases with increasing phenol mass fraction in aqueous phase (Fig. 5). The reason is relevant to the fact that the water content in the organic DES phase increases with solute concentration. On the other hand, increasing temperature leads to a lower separation factors because of weakening the hydrogen bond between phenol and the DES38. Figure 6 presents the phenol equilibrium distribution between the organic (DES) and aqueous (water) phases at different temperatures, showing rather linear variations.

Figure 6.

Equilibrium distribution of phenol between the DES and water phases at different temperatures of 293.2 K (●), 298.2 K ( ) and 308.2 K (

) and 308.2 K ( ).

).

Consistency tests

The reliability of the experimental data was evaluated based on the Othmer − Tobias, Hand and Bachman well-known correlations as

| 4 |

| 5 |

| 6 |

where A1 and B1, A2 and B2, and A3 and B3 are, respectively, intercepts and slopes of the Othmer − Tobias, the Hand and the Bachman correlations31. The value of intercepts, slopes and related determination coefficients (R2) are tabulated in Table 7. The close to unity determination coefficient verifies the tie-line data consistency.

Table 7.

The parameters for Othmer − tobias, Hand and Bachman correlations and the corresponding regression coefficients for (water + phenol + DES) system at different temperatures.

| T (K) | Othmer − Tobias | Hand | Bachman | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 293.2 | 2.7150 | 1.1596 | 0.9995 | –2.1192 | 1.0238 | 0.9958 | –0.1206 | 1.1181 | 0.9999 |

| 298.2 | 2.8509 | 1.2053 | 0.9997 | –2.0861 | 1.0592 | 0.9970 | –0.1196 | 1.1162 | 0.9999 |

| 308.2 | 2.8305 | 1.2218 | 0.9992 | –2.0416 | 1.0377 | 0.9968 | –0.1294 | 1.1259 | 0.9999 |

Correlation models

The consistency of the attained ternary data against the NRTL and UNIQUAC thermodynamic models was checked by utilizing Aspen Plus (V. 8.4) simulator through introducing DES as a pseudo component. Hence, the physico-chemical properties of the DES including normal boiling point, molecular weight and density were introduced to the software. For this aim the method proposed by Mirza et al.45 was employed. Relevantly, simultaneous utilization of the modified Lydersen − Joback − Reid (LJR) method along with the mixing rules has been proposed for critical properties estimation as well as normal boiling points. The accuracy of the method has been tested for 39 different DESs46. In this regard, group contribution method and the type and frequency of the groups of atoms were considered. The contributions are summated to obtain the final estimate of the boiling point as

| 7 |

where (K), and (K) are, respectively, the normal boiling point of a DES, the frequency of appearance of the ith group of atoms in the molecule, and group contribution in boiling point for the modified LJR method45. Based on Eq. (7) the DES normal boiling point was obtained as 551.0 K.

In the NRTL thermodynamic model, the non-randomness parameter (αij) was considered to be 0.2 and 0.347. In the UNIQUAC model, the ri parameter of the number of segments in each molecule and the qi parameter of the relative surface area per molecule are listed in Table 848.

Table 8.

UNIQUAC structral parameters.

| Component | r | q |

|---|---|---|

| Water | 0.0092 | 1.4000 |

| Phenol | 3.5517 | 2.6800 |

| DES | 27.6928 | 23.4080 |

The corresponding interaction parameters of the both models at different temperatures are listed in Table 9. In a previous study, the proper description of the binary interaction parameters are provided49. The LLE phase diagram of ternary system based on the obtained data and those of the predicted values by the models are depicted in Fig. 2. Obviously, the models reasonably fit the experimental data.

Table 9.

Interaction parameters obtained from NRTL and UNIQUAC models for water (1) + phenol (2) + DES (3) system at different temperatures.

| T (K) | i − j | NRTL | UNIQUAC | |||||

|---|---|---|---|---|---|---|---|---|

| (K) | (K) | RMSD | (K) | (K) | RMSD | |||

| 293.2 | 1 − 2 | 1022.69 | 465.63 | 0.2 | 0.0027 | 199.22 | –2655.13 | 0.0063 |

| 1 − 3 | 2299.76 | 735.93 | 0.3 | 175.98 | –1146.29 | |||

| 2 − 3 | –780.80 | 1129.03 | 0.3 | 306.63 | –411.06 | |||

| 298.2 | 1 − 2 | 1008.16 | 416.85 | 0.3 | 0.0020 | 480.09 | –1098.45 | 0.0058 |

| 1 − 3 | 2339.33 | 677.67 | 0.2 | 178.22 | –1106.37 | |||

| 2 − 3 | –757.61 | 1057.36 | 0.2 | 227.34 | –214.64 | |||

| 308.2 | 1 − 2 | 1027.34 | 393.92 | 0.3 | 0.0014 | 527.04 | –712.97 | 0.0045 |

| 1 − 3 | 2322.88 | 642.03 | 0.3 | 181.39 | –1101.86 | |||

| 2 − 3 | –821.307 | 1077.02 | 0.3 | 180.86 | –170.61 | |||

The comprehensive root mean square deviation (RMSD) values were determined from the following equation for each of the investigated models and listed Table 9.

| 8 |

where and represent the experimental and the model predicted mass fractions, respectively. Here, the subscripts of i = 1, 2, 3 are for the components and m = I, II are for the aqueous and organic phases. Further, the n = 1, 2, …, N subscript stand for the number of tie-lines. As shown in Table 9, the RMSD values are very low for the NRTL model within (0.0014–0.0027) and for the UNIQUAC within (0.0045–0.0063). Therefore, the more appropriate model for predicting the tie-line data is the NRTL model

Conclusions

Utilizing a novel hydrophobic DES, consisted of octanoic and dodecanoic acid precursors, the extraction of phenol from aqueous phase was feasible at different temperatures. The liquid state DES was stable for satisfactory extraction operations. Liquid–liquid equilibrium experiments were performed based on the cloud point titration method and refractive index measurements. The results revealed that low amounts of the DES was required for a specific task and that the tie-lines were with positive slopes since phenol tends to be more in the organic phase. Relevantly, the distribution coefficient and separation factor confirmed the high capacity and selectivity of the DES compared to the conventional organic solvents. Higher separation factors were corresponding to the lower temperature which can be attributed to forming hydrogen bond between phenol and the DES. Meanwhile, the consistency of tie line data was appropriately assessed by the Othmer − Tobias and Bachman equations. Finally, the data were correlated by employing a pioneering approach in group contribution calculations relevant to the thermodynamic models of NRTL and UNIQUAC. The appropriate low RMSD values, particularly for the NRTL model, confirmed good agreement with the experimental data.

To extend investigations, capability of the DES in mass transfer of phenol extraction could be scrutinized. For this aim, the viscosity of the solvent and the molecular diffusivity of phenol in the solvent have to be considered.

Supplementary Information

Acknowledgements

The financial support for this research by Bu-Ali Sina University authorities is highly acknowledged.

Author contributions

J.S.: Methodology, supervision, review and editing. M.B.: Experiments, conceptualization, methodology, investigation. F.J.: Experiments, editing, software, evaluating.

Data availability

Correspondence and requests for data and materials should be addressed to J.S.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-023-44600-x.

References

- 1.Jiao T, et al. Separation of phenol and pyridine from coal tar via liquid–liquid extraction using deep eutectic solvents. Chem. Eng. Res. Des. 2019;145:112–121. [Google Scholar]

- 2.Beradinelli S, Resini C, Arrighi L. Technologies for the removal of phenol from fluid streams. J. Haz. Mater. 2008;160:265–288. doi: 10.1016/j.jhazmat.2008.03.045. [DOI] [PubMed] [Google Scholar]

- 3.Xie Y, et al. Exploring bubble oscillation and mass transfer enhancement in acoustic-assisted liquid-liquid extraction with a microfluidic device. Sci. Rep. 2015;5:1–9. doi: 10.1038/srep12572. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Fan Y, et al. Extraction of phenols from water with functionalized ionic liquids. Ind. Eng. Chem. Res. 2014;53:20024–20031. [Google Scholar]

- 5.Warrag SE, Alli RD, Kroon MC. Liquid–liquid equilibrium measurements for the extraction of pyridine and benzothiazole from n-alkanes using deep eutectic solvents. J. Chem. Eng. Data. 2019;64:4882–4890. [Google Scholar]

- 6.Rogošić M, Kučan KZ. Deep eutectic solvent based on choline chloride and propylene glycol as a potential medium for extraction denitrification of hydrocarbon fuels. Chem. Eng. Res. Des. 2020;161:45–57. [Google Scholar]

- 7.Nemati M, Tuzen M, Farazajdeh MA, Kaya S, Mogaddam MRA. Development of dispersive solid-liquid extraction method based on organic polymers followed by deep eutectic solvents elution; application in extraction of some pesticides from milk samples prior to their determination by HPLC-MS/MS. Anal. Chim. Acta. 2022;1199:339570. doi: 10.1016/j.aca.2022.339570. [DOI] [PubMed] [Google Scholar]

- 8.Ahmadi R, Azooz EA, Yamini Y, Ramezani AM. Liquid−liquid microextraction techniques based on in-situ formation/decomposition of deep eutectic solvents. TrAC-Trends Anal. Chem. 2023;161:117019. [Google Scholar]

- 9.Farajzadeh MA, et al. Experimental and density functional theory studies during a new solid phase extraction of phenolic compounds from wastewater samples prior to GC–MS determination. Microchem. J. 2022;177:107291. [Google Scholar]

- 10.Abbott AP, et al. Preparation of novel, moisture-stable, Lewis-acidic ionic liquids containing quaternary ammonium salts with functional side chainsElectronic supplementary information (ESI) available: plot of conductivity vs. temperature for the ionic liquid formed from zinc chloride and choline chloride (2∶ 1) Chem. Commun. 2001;19:2010–2011. doi: 10.1039/b106357j. [DOI] [PubMed] [Google Scholar]

- 11.van Osch DJ, Zubeir LF, van den Bruinhorst A, Rocha MA, Kroon MC. Hydrophobic deep eutectic solvents as water-immiscible extractants. Green Chem. 2015;17:4518–4521. [Google Scholar]

- 12.Kudłak B, Owczarek K, Namieśnik J. Selected issues related to the toxicity of ionic liquids and deep eutectic solvents—A review. Environ. Sci. Pollut. Res. 2015;22:11975–11992. doi: 10.1007/s11356-015-4794-y. [DOI] [PubMed] [Google Scholar]

- 13.Ghaffari F, Khorsandi M, Shekaari H, Zafarani-Moattar MT. Liquid–liquid equilibrium measurements and computational study of salt–polymer aqueous two phase system for extraction of analgesic drugs. Sci. Rep. 2022;12:1–11. doi: 10.1038/s41598-022-18122-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Florindo C, Romero L, Rintoul I, Branco LC, Marrucho IM. From phase change materials to green solvents: Hydrophobic low viscous fatty acid–based deep eutectic solvents. ACS Sustain. Chem. Eng. 2018;6:3888–3895. [Google Scholar]

- 15.Santos LB, et al. Deep eutectic solvents in liquid−phase microextraction: Contribution to green chemistry. TrAC-Trends Anal. Chem. 2022;146:116478. [Google Scholar]

- 16.Florindo C, Branco L, Marrucho I. Development of hydrophobic deep eutectic solvents for extraction of pesticides from aqueous environments. Fluid Phase Equilib. 2017;448:135–142. [Google Scholar]

- 17.Verma R, Banerjee T. Liquid–liquid extraction of lower alcohols using menthol-based hydrophobic deep eutectic solvent: experiments and COSMO-SAC predictions. Ind. Eng. Chem. Res. 2018;57:3371–3381. [Google Scholar]

- 18.Verma R, Banerjee T. Palmitic-acid-based hydrophobic deep eutectic solvents for the extraction of lower alcohols from aqueous media: liquid-liquid equilibria measurements. Validat. Process Econom. Glob. Chall. 2019;3:1900024. doi: 10.1002/gch2.201900024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Dietz CH, Kroon MC, Di Stefano M, van Sint Annaland M, Gallucci F. Selective separation of furfural and hydroxymethylfurfural from an aqueous solution using a supported hydrophobic deep eutectic solvent liquid membrane. Faraday Discuss. 2018;206:77–92. doi: 10.1039/c7fd00152e. [DOI] [PubMed] [Google Scholar]

- 20.Wang X, Lu Y, Shi L, Yang D, Yang Y. Novel low viscous hydrophobic deep eutectic solvents liquid-liquid microextraction combined with acid base induction for the determination of phthalate esters in the packed milk samples. Microchem. J. 2020;159:105332. [Google Scholar]

- 21.Sas OG, Castro M, Domínguez Á, González B. Removing phenolic pollutants using deep eutectic solvents. Sep. Purif. Technol. 2019;227:115703. [Google Scholar]

- 22.Cea-Klapp E, et al. Separation of furfuryl alcohol from water using hydrophobic deep eutectic solvents. J. Mol. Liq. 2023;384:122232. [Google Scholar]

- 23.Pochivalov A, et al. Liquid−liquid microextraction with hydrophobic deep eutectic solvent followed by magnetic phase separation for preconcentration of antibiotics. Talanta. 2023;252:123868. doi: 10.1016/j.talanta.2022.123868. [DOI] [PubMed] [Google Scholar]

- 24.Arcon DP, Franco FC., Jr All-fatty acid hydrophobic deep eutectic solvents towards a simple and efficient microextraction method of toxic industrial dyes. J. Mol. Liq. 2020;318:114220. [Google Scholar]

- 25.Shekaari H, Mousavi SS. Volumetric properties of ionic liquid 1, 3-dimethylimidazolium methyl sulfate+ molecular solvents at T=(298.15–328.15) K. Fluid Phase Equilib. 2010;291:201–207. [Google Scholar]

- 26.Domingues L, Cussolin PA, da Silva JL, de Oliveira LH, Aznar M. Liquid–liquid equilibrium data for ternary systems of water+ lactic acid+ C4–C7 alcohols at 298.2 K and atmospheric pressure. Fluid Phase Equilib. 2013;354:12–18. [Google Scholar]

- 27.Saien J, Razi Asrami M. Liquid–liquid equilibrium of the ternary system of water+ phenol+(propan-2-yl) benzene at several temperatures. J. Chem. Eng. Data. 2017;62:3663–3670. [Google Scholar]

- 28.Lide DR. CRC Handbook of Chemistry and Physics. Boca Raton, Florida: CRC Press; 2004. [Google Scholar]

- 29.Saien J, Daliri S, Norouzi M. Liquid–liquid equilibria for the system water + 4-methylpentan-2-one + acetic acid at several temperatures. J. Chem. Eng. Data. 2012;57:2553–2559. [Google Scholar]

- 30.Chen Y, et al. Liquid− liquid equilibria of aqueous biphasic systems composed of 1-butyl-3-methyl imidazolium tetrafluoroborate + sucrose/maltose + water. J. Chem. Eng. Data. 2010;55:3612–3616. [Google Scholar]

- 31.Arce A, Arce A, Jr, Rodriguez O. Revising concepts on liquid–liquid extraction: data treatment and data reliability. J. Chem. Eng. Data. 2021;67:286–296. [Google Scholar]

- 32.Pir M, Ghanadzadeh Gilani A, Mohammadi-Khanghah B. Liquid–liquid equilibria in aqueous mixtures of phosphoric acid with two primary aryl alcohols at T=(298.2, 308.2, and 318.2) K: measurements and correlation. J. Solut. Chem. 2021;50:73–89. [Google Scholar]

- 33.Mascietti VA, Farias LS, Tavares FW, Ndiaye PM. Liquid–liquid equilibria of ternary mixtures of methanol + MEG + n-C5, ethanol + MEG + n-C5, and n-butanol + MEG + n-C5. Can. J. Chem. Eng. 2023;101:3512–3521. [Google Scholar]

- 34.Hadj-Kali MK, Salleh Z, Ali E, Khan R, Hashim MA. Separation of aromatic and aliphatic hydrocarbons using deep eutectic solvents: A critical review. Fluid Phase Equilib. 2017;448:152–167. [Google Scholar]

- 35.Magnussen T, Sørensen JM, Rasmussen P, Fredenslund A. Liquid-liquid equilibrium data: Their retrieval, correlation and prediction Part III: Prediction. Fluid Phase Equilib. 1980;4:151–163. [Google Scholar]

- 36.Saien J, Asrami MR, Salehzadeh S. Phase equilibrium measurements and thermodynamic modelling of water+ phenol+[Hmim][NTf2] ionic liquid system at several temperatures. J. Chem. Thermodyn. 2018;119:76–83. [Google Scholar]

- 37.Huang F, et al. Surfactant-based ionic liquids for extraction of phenolic compounds combined with rapid quantification using capillary electrophoresis. Electrophor. 2014;35:2463–2469. doi: 10.1002/elps.201300589. [DOI] [PubMed] [Google Scholar]

- 38.Pan L, et al. Extraction of bisphenol F three isomers from water with 1-octyl-3-methylimidazolium tetrafluoroborate ionic liquid. Can. J. Chem. Eng. 2017;95:516–523. [Google Scholar]

- 39.Saien J, Badieh MMS, Norouzi M, Salehzadeh S. Ionic liquid 1-hexyl-3-methylimidazolium hexafluorophosphate, an efficient solvent for extraction of acetone from aqueous solutions. J. Chem. Thermodyn. 2015;91:404–413. [Google Scholar]

- 40.Liu D, Luo L, Li L, Chen Y. Liquid–liquid equilibria for the methyl tert-butyl ketone+ phenol+ water ternary system at 298.15, 313.15 and 323.15 K. J. Solut. Chem. 2015;44:1891–1899. [Google Scholar]

- 41.Yuan X, Chen Y. Experimental study of liquid–liquid equilibria for systems of (dibutyl ether+ phenol+ water) at different temperatures. J. Chem. Thermodyn. 2021;152:106261. [Google Scholar]

- 42.Gilani HG, Gilani AG, Sangashekan M. Tie-line data for the aqueous solutions of phenol with organic solvents at T= 298.2 K. J. Chem. Thermodyn. 2013;58:142–148. [Google Scholar]

- 43.Liu D, Li L, Lv R, Chen Y. Liquid–liquid equilibria for the ternary system mesityl oxide+ phenol+ water at 298.15, 313.15, and 323.15 K. J. Chem. Eng. Data. 2016;61:2493–2498. [Google Scholar]

- 44.Cesari L, Canabady Rochelle L, Mutelet F. Extraction of phenolic compounds from aqueous solution using choline bis (trifluoromethylsulfonyl) imide. Fluid Phase Equilibr. 2017;446:28–35. [Google Scholar]

- 45.Mirza NR, Nicholas NJ, Wu Y, Kentish S, Stevens GW. Estimation of normal boiling temperatures, critical properties, and acentric factors of deep eutectic solvents. J. Chem. Eng. Data. 2015;60:1844–1854. [Google Scholar]

- 46.Alvarez V, Valderrama J. A modified Lydersen-Joback-Reid method to estimate the critical properties of biomolecules. Alimentaria. 2004;254:55–66. [Google Scholar]

- 47.Simoni LD, Lin Y, Brennecke JF, Stadtherr MA. Modeling liquid−liquid equilibrium of ionic liquid systems with NRTL, electrolyte-NRTL, and UNIQUAC. Ind. Eng. Chem. Res. 2008;47:256–272. [Google Scholar]

- 48.Chen B, Wu Y, Suo M, Yang S. Liquid–liquid equilibrium and data correlation for quaternary (methyl isobutyl ketone + n-pentanol + phenol + water) system at 101 kPa and 298.2 K: phenol coextraction with synergistic solvents. J. Chem. Eng. Data. 2020;65:4567–4574. [Google Scholar]

- 49.Banerjee T, Singh MK, Sahoo RK, Khanna A. Volume, surface and UNIQUAC interaction parameters for imidazolium based ionic liquids via Polarizable Continuum Model. Fluid Phase Equilib. 2005;234:64–76. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Correspondence and requests for data and materials should be addressed to J.S.