Abstract

The purpose of this study was to investigate the effect of different solutions on the optical behavior of two types of 3D-printed resin (Detax and Asiga). The samples were randomly divided into 4 groups of cola, orange juice, tea and artificial saliva (control group) in the form of 14 x 10 mm blocks with a thickness of 1.5 ± 0.3 mm (10 samples in each group). By spectrophotometric device, the color of the examined samples was recorded in the CIE system and in three parameters *L (brightness), a* (red-green) and b* (blue-yellow) as the initial record. The color difference of the samples was recorded on 7 and 30 days after immersion as a secondary record. After that, using the formula, the color difference (ΔE) were calculated. T-test also was used to analyze the data. There was no significant difference between the amount of ΔE on 7th and 30th days after exposure to artificial saliva and cola and on 7th days after exposure to orange juice and tea. But on the 30th day, a significant difference was found in orange juice and tea drinks (p<0.05), so that the value of ΔE in Asiga printer was lower than Detax. ΔE changes in orange juice solution were more than other drinks. On the 30th day of immersion in tea drinks and orange juice, Asiga printer had significantly less color difference than Detax printer.

Key Words: resin, color difference, Asiga, Detax

Ethical Publication Statement

We confirm that we have read the Journal’s position on issues involved in ethical publication and affirm that this report is consistent with those guidelines.

Digital technology has created a huge change in all aspects of our life, including dentistry. Today, 3D printers are expanding rapidly in digital dentistry. This technology is developing as a new technology that has overcome the limitations of traditional systems in dentistry by developing materials and improving 3D printers.1 Discoloration of the materials used in temporary restorations during long-term treatment may lead to patient dissatisfaction and additional costs for replacement. Therefore, color stability is an important factor in material selection, especially in cosmetic areas. Color difference is caused by external and internal factors. External factors such as food, drinks or tobacco smoke. In particular, color stability must be maintained in clinical situations where temporary restorations are used for a long time.2 In the following, some studies conducted in this field are mentioned. For example, Ertaş et al. (2006) evaluated the discoloration of two nanohybrid, two microhybrid, and one posterior composite resin restoratives after exposure to tea, cola, coffee, red wine, and water.3 The results showed that for all the tested materials, their color difference in the coloring agents were ranked in ascending order: water < cola < tea < coffee < red wine. In terms of comparison between the five restorative materials, Filtek P60 and Z250 showed less discoloration than Nanohybrids and Quadrant LC. Guler et al. (2005) evaluated the color fastness of self-polymerized lightweight composite temporary restoratives, microfill-reinforced, and microhybrid resin composite restoratives after exposure to various staining agents.4 The color of all samples was measured before and after exposure with a colorimeter using CIE L*a*b*relative and then color difference (ΔE *) were estimated. For the 5 restorative substances tested, the lowest DeltaE* values were observed in water, cola and cherry juice groups. The biggest color difference for all restorative materials was observed in the red wine group. Spina et al. (2015) in a study evaluated the ΔE of polished resin composites for coloring in different drinking solutions.5 Experimental research was conducted on 40 discs in 4 groups and 10 samples per group. The data were analyzed using two-way ANOVA, repeated measures and Tukey's HSD test. For drinking solutions, ΔE values were 4.40, 2.59, 2.23, and 2.13 for wine, coffee, cola, and water, respectively. For time, the ΔE values for 30 days were 3.97 and then for 7 days 2.48 and after payment 2.04. The results showed that the color stability depends on the materials and the types of drinks consumed by the patients also affect the color stability of the restorative materials. Shin et al. (2020) evaluated the color stability of 3D printed crown and bridge materials against different sources.6 The color stability of ordinary blocks with the help of (CAD / CAM) and 3D printing resins was evaluated and in terms of the degree of their color difference based on the type of material, types of dyes (grape juice, coffee, curry, and distilled water control group) and storage time (2, 7 and 30 days) were investigated in dyes. Three-way ANOVA analysis showed that all three factors significantly change the color of the materials. Color difference (DE00) was significantly higher in all 3D printed resins (22.85–4.74 over 30 days) than CAD/CAM blocks (0.64–4.12 over 30 days) after immersion in all colors. After storage for 7 days or more, 3D printed resins showed a color difference higher than the clinical limit (2.25) in all experimental groups. Song et al. (2020) investigated the color stability of temporary restorative materials made by 3D printing, tooth milling and conventional dental materials.7 For the case groups, two 3D printed temporary resins, two dental milling blocks and two traditional dental materials were used. To test the color stability, coffee and black tea were used as dye solutions and the samples were kept for 12 weeks. Data were analyzed by one-way ANOVA and Tukey's HSD using SPSS version 22.0. In the color fastness test, the ΔE of the conventional material was different depending on the dyeing solution. PMMA milling blocks showed a relatively low ΔE up to 4 weeks and significantly increased after 8 weeks. 3D printed materials showed high ΔE or a significant increase over time (p<0.05). PMMA and 3D printed materials showed a faster change in ΔE after 8 weeks. This result may be due to the unremoved layer remaining after curing due to the characteristics of 3D printing fabrication. Haynie et al. (2021) evaluated the color stability of 3D printer resins that can be used in the manufacture of orthodontic brackets.8 Disc samples were fabricated through 3D printing using three resins: SG; LT and Clear. Five conditions were investigated for each resin (n = 10 per resin) to evaluate the corresponding effect on color: immersion in (1) red wine, (2) coffee, (3) tea, and (4) distilled water (control), and (5) exposure to accelerated aging. Color measurement before and after exposure was done using a spectrophotometer. The most obvious color difference (ΔE00) were as a result of wine staining effects on all three resins, from 14.5 ± 0.6 to 20.8 ± 1.2. Dental LT, Dental SG and Clear resins all showed color difference when exposed to specific staining agents. Lee et al. (2021) investigated the effect of post-curing time on color stability and related properties of tooth-colored 3D printing resin materials.9 According to the results, the longer the time after curing the tooth-colored 3D print resin, the better the color stability. The time after curing the 3D printing resin had an effect on DC, surface roughness after aging in the coloring environment, water contact angle, water absorption and water solubility. Aguiar et al. (2011) in a study investigated the effect of light cure units (LCU) on DC, surface staining (ΔE) and pigment concentration (PC) in a nanofilled composite resin (Z350, 3M ESPE) using different beverages.10 According to the results, LCUs interfered with DC and changed PC and ΔE of the composite resin submitted to different staining solutions. There was no correlation between DC, PC and ΔE. Also, the highest amount of pigment absorption was not associated with the highest surface coloring of the composite resin. Alcoholic beverages resulted in more surface stains and non-alcoholic solutions resulted in higher pigment concentrations. Khatri and Nandlal (2010) evaluated and compared the effect of coffee, chocolate drink and food coloring on the color stability of conventional composite resin and nanocomposite resin.11 The color difference values were analyzed at the beginning, 1 week and 4 weeks after immersion in the dye solution. The color difference of each sample was measured by spectrophotometer. L*a*b* values of each sample were measured 3 times. The results of the study showed that the nanocomposite has a greater resistance to stain and color difference. The conventional composite showed an unacceptable ΔE*, especially in the coffee-immersed samples. In recent years, the fabrication of temporary dental prostheses using 3D printing has become popular, but the available studies on the color stability of 3D printed resins exposed to different colors are scarce. Therefore, this study was carried out with the aim of evaluating the change and stability of the resin color of Asiga and Detax 3D printers due to exposure to colored substances.

Materials and Methods

The present research was carried out as an in vitro experiment in the Faculty of Dentistry of Hamadan University of Medical Sciences in the academic year of 2022-2023. For the current research, two 3D printers, Asiga and Detax, were used.

Asiga printer

Asiga 3D printer was used to print resins. This printer has an accuracy of 37 microns in X-Y and a layer accuracy of 1 micron in all layers. This printer has smart position system (sps) which ensures the printing of layers. It has a liquid heater, works with 12 V electricity and has an auto-calibration mechanism. Its wavelength is 385 nm and it prints all biocompatible materials by 100% and it has an encoder which is used to measure the speed, position, angle and direction of shaft movement. Specifications of SLA: UV LED 385nm (DLP) and IMETRIC4d scanner made in Switzerland with two micron accuracy on full arch.

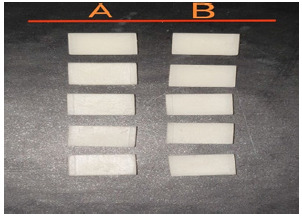

Fig 1.

Control group samples: A) Asiga B) Detax

Detax printer

Detax 3D printer was also used to print resins. This printer has light cure resin, environmentally friendly and suitable for 3D printing of temporary crowns and bridges. Resistance to breakage and protrusion, high wear resistance, natural tooth beauty, bright and transparent colors. Easy surface processing and polishing, low viscosity for less material consumption and faster cleaning. Resistant to oral conditions, without irritation of smell or taste, class IIa medical device, has colors: A1, A2, A3. Any corrections that require the use of additional materials after delivery are performed using light-curing FreeForm® Clear Plast/Fix Gel Resin (also by Detax). 405 nm / 378-388 nm UV, accurate detail reproduction, maximum surface hardness, fast manufacturing speed, high resolution, no MMA are other features of Detax.

Sampling method

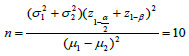

The samples were designed as blocks of 10 x 14 mm with a thickness of 1.5 ± 0.3 mm, using a 3D modeling software and exported as a file in standard Tessellation Language (STL) format. A variety of colored drinks were used to analyze the time-dependent color difference of samples prepared from 3D printer resins. The prepared samples were randomly divided into 4 groups: cola, orange juice, tea and artificial saliva as control group (Figure 1). Black tea would be prepared by placing a tea bag in 500 cc of boiling water for 15 minutes. The required sample size was calculated according to equation 1.7

|

(1) |

While the confidence level of this test was 95% and the power of the test was 80%, the expected difference in the average color parameters was 5 units and the standard deviation was 4. After replacing the values of the minimum sample volume required in this study, 10 samples were determined for each group (a total of 80 samples in 8 groups). Then, all the samples were kept in an incubator at 37 degrees Celsius for 30 days. Tea solutions are refreshed after every 24 hours of immersion. According to the study of Guler et al. (2005),4 24 hours of exposure to tea simulates approximately 30 days of regular consumption. All samples were kept in a dark place at 37°C for simulation. The characteristics of the used samples are shown in Table 1.

Table 1.

Characteristics of samples used in the research

| IMMERSION SOLUTION | MANUFACTURE | CHEMICAL COMPOSITIO N | PH | TEMPERATURE |

|---|---|---|---|---|

| Artificial saliva | Professional Dietetics, Italy | KCl (0.4 g L-1), NaCl (0.4gL-1), CaCl2_2H2O (0.906 g L-1), NaH2PO4_2H2O (0.690gL-1), Na2S_9H2O (0.005 g L-1), and urea (1 g L-1) | 6.5 | 37 |

| Orange juice | Coca-Cola | Orange juice, water, sugar, orange pulp, naturalflavors, antioxidant ascorbic acid, and citric acid | 3.5 | 5 |

| Cola | Coca-Cola | Carbonated water, sugar, cola nut extract, yellow dye IV, acidulant INS 338, and natural flavors | 2.4 | 5 |

| Tea | Tetley | Tea Leaves | 4.9 | 55 |

Method of data collection

Color parameters were measured using a spectrophotometer Vita easy shade compact Zahnfabrik, Germany on two standard black and white backgrounds. The spectrophotometer features used are given below. The conditions of measurement with spectrophotometer for all the samples were standard inside a positioning jig. The initial color values and the time-dependent color difference of the samples were measured on days 1, 7 and 30 under D65 lighting conditions, using a spectrophotometer. Measurements were repeated three times for each sample and mean scores were recorded. Three repeated measurements were performed in a central area and the mean value of parameters L*, a* and b* was applied in the CIEDE2000 formula (ΔE) to determine the color discrimination caused by experimental variables. KL, KC, and KH parameter values were set to 1. ΔE values are assumed to be understandable if higher than 1.30 and clinically acceptable if below 2.25 (Köroğlu et al., 2016).12 ΔE was calculated by the CIELAB system according to the ΔE76 formula given below. The CIELAB system was used to quantify ΔE by means of a three-dimensional coordinate. The parameter L* evaluates the amount of brightness (scale from 0 to 100 where 0 indicates black and 100 indicates white), coordinates a* indicates the amount of red color (positive values) and the amount of green color (negative values), b* indicates the amount of yellow color and the amount of blue color. This system was chosen due to the recognition of small amounts of ΔE and its extensive use for previous researches. Also, L* values were measured on black and white backgrounds.13

| (2) |

Perceptible ΔE may compromise the clinical acceptability of the temporary restoration. The ΔE* value represents the numerical distance between the L*a*b* coordinates and the relative color difference that the observer may report for the material. When the ΔE value of two colors is 0, the color difference is described as "excellent". A value of 0.5 to 1 unit is “very good,” 1 to 2 is “good,” 2 to 3.5 is “clinically acceptable,” and >3.5 is unacceptable.14 In the present study, ΔE lower than 3.5 was called “acceptable”, and higher than 3.5 was called unacceptable. The data of the study were analyzed according to the objectives of the study using SPSS 21 and descriptive statistics methods and statistical tests such as analysis of variance with repeated measurements and t-test. The significance level was considered equal to 0.05 in all the examined tests.

Results

The results of ΔE parameter measurements on each artificial saliva solution, orange juice, tea and cola on days 7 and 30 are given in the Table 2. According to Table 2 and using the t-test for which the p-values were more than 0.05, we concluded that there was no significant difference between the ΔE level in 7 and 30 days after exposure to artificial saliva. In other words, there was no significant difference between the two types of printers on the investigated days. According to Table 2 and using the t-test, where the p-values were greater than 0.05, we concluded that there was no significant difference between the ΔE level in 7 and 30 days after exposure to cola. In other words, there was no significant difference between the two types of printers on the days under review. According to Table 2 and p values, we found that there was no significant difference between the amounts of ΔE in 7 days of exposure to tea, but on the 30th day, a significant difference was obtained, which showed that there was a difference between the two types of printers. The mean values showed that the value of ΔE in the Asiga printer was lower than that of the Detax printer. According to Table 2 and using the t-test and the obtained p values, we concluded that there was no significant difference between the amount of ΔE in 7 days after exposure to orange juice, but on the 30th day, a significant difference was obtained, which showed that there was a difference between the two types of printers. The mean values showed that the value of ΔE in the Asiga printer was lower than that of the Detax printer.

Table 2.

Comparison of ΔE score on days 7 and 30 after exposure to artificial saliva, cola, tea and orange juice

| Sample | Day | Printer | Mean | SD | P- value |

|---|---|---|---|---|---|

| Artificial saliva | 7 | Detax | 1 | 0/22 | 0/088 |

| Asiga | 1/15 | 0/23 | |||

| 30 | Detax | 1/24 | 0/27 | 0/38 | |

| Asiga | 1/35 | 0/25 | |||

| Cola | 7 | Detax | 1/55 | 0/55 | 0/06 |

| Asiga | 1/15 | 0/24 | |||

| 30 | Detax | 2/42 | 0/83 | 0/22 | |

| Asiga | 2/07 | 0/32 | |||

| Tea | 7 | Detax | 1/66 | 0/6 | 0/52 |

| Asiga | 1/5 | 0/51 | |||

| 30 | Detax | 2/98 | 0/91 | 0/035 | |

| Asiga | 2/14 | 0/71 | |||

| Orange juice | 7 | Detax | 2 | 0/53 | 0/08 |

| Asiga | 1/56 | 0/54 | |||

| 30 | Detax | 3/41 | 0/51 | 0/033 | |

| Asiga | 2/62 | 0/96 |

Discussion

In this comparative study, the effect of different solutions on the optical behavior of two types of resins used for 3D printers (Detax and Asiga) was investigated. For this purpose, the samples were placed in four solutions of artificial saliva, orange juice, tea and cola for 7th and 30th days. Then the color parameters including *L*, b*, a* were measured to calculate ΔE. Changes in ΔE parameter were observed after immersion in different solutions. The highest color difference was obtained in orange juice solution and 30 days after immersion. The results of the present study showed that after immersion in artificial saliva on the 7th day, the ΔE of Detax printer was very good and ΔE of Asiga printer was good and on the 30th day, the ΔE for both printers was good. The results of immersion in cola solution showed that ΔE on 7th day was good in both Asiga and Detax printer and acceptable on 30th day in both printers. The results of immersion in tea solution on 7th day showed that the ΔE level was good in both printers, and on 30th day, it was acceptable in the both Asiga and Detax. The results of immersion in orange juice solution showed that the ΔE value on 7th day was good in Asiga printer and acceptable in Detax printer, on 30th day this value was calculated as acceptable in both printers. Among the solutions examined and compared, ΔE was obtained on days 7 and 30 in both Asiga and Detax printers in the form of orange juice > tea > cola > artificial saliva. On the 7th day after immersion in different drinks, there was no significant difference between the two printers. Also, on the 30th day after immersion in artificial saliva and cola, no significant difference was observed (p>0.05). There was a significant difference between the two printers in the tea on day 30, and the ΔE level in Asiga printer was lower than that of Detax (p<0.05). There was a significant difference between the two printers in the orange juice on the 30th day, and the ΔE level in Asiga printer was lower than that of Detax (p<0.05). This finding is in agreement with the study by Catelan et al. (2011).15 In that study the highest amount of color difference was related to orange juice solution. In Ertaş et al.'s study,3 the color difference rate of tea was higher than that of cola, and in Hasani-Tabatabaei et al. study,16 the color difference of coffee and tea drinks was higher than that of cola, which is in line with this research. Hipólito et al. showed that the pH of the solution in which the ceramics are immersed has an effect on the color difference rate.18 Although the pH level of cola solution is the lowest compared to other solutions; however, the color difference of ceramics immersed in it has been clinically acceptable, which is probably due to the low amount of yellow pigment in the cola solution (as reported by Catelan et al., 2011,15 and Bagheri et al., 2005.18 In addition, there are carbonic and phosphoric acids in the cola solution, and the acid in the orange juice solution is citric acid, which can explain the difference in the color of these two solutions (Catelan et al., 2011).15

In conclusion, the obtained results indicate that the changes of ΔE in orange juice solution were more than other solutions. On the 30th day of immersion in tea and orange juice, Asiga printer showed significantly less color difference than Detax printer.

Acknowledgments

None

List of acronyms

- *L

brightness

- ΔE

color difference

- 3D

three dimensional

- a*

red-green

- b*

blue-yellow

- CIE

Commission Internationale de l´Eclairage

- DC

Degree of Conversion

- LCUs

Light Cure Unit

- MMA

Methyl Methacrylate

- PC

Pigment Concentration

- PMMA

Poly Methyl Methacrylate

- SLA

Stereolithography

- STL

standard Tessellation Language

- ΔE00

Basic Color Difference

Funding Statement

Funding: None

Contributor Information

Arash Shishehian, Email: Pashrs2@yahoo.com.

Farnaz Firouz, Email: farnazfirouz@yahoo.com.

Sara Khazaee, Email: Sarakhazaei_83@yahoo.com.

Hossein Rajabi, Email: rajabi1369.hr@gmail.com.

Maryam Farhadian, Email: Maryam_farhadian80@yahoo.com.

References

- 1.Shayegh S. S., Hakimaneh S. M. R., Derakhshi H.. Three-Dimensional Printers and Their Application in Dental Prostheses. J.Mashhad Dental School. 2022; 46(2), 112-134. doi: 10.22038/jmds.2022.58089.2055 [Google Scholar]

- 2.Heydari B, Vafaee F, Torkan A. Effect of Repeated Firings on the Color of Dental Ceramics and Their Color Stability Submitted to Colored Solution. Avicenna J Clin Med 2012; 19(2):58-65.URL: http://sjh.umsha.ac.ir/article-1-191-fa.html [Google Scholar]

- 3.Ertaş E, Güler AU, Yücel AC, Köprülü H, Güler E. Color stability of resin composites after immersion in different drinks. Dent Mater J. 2006. Jun;25(2):371-6. PMID: 16916243. [PubMed] [Google Scholar]

- 4.Guler AU, Yilmaz F, Kulunk T, Guler E, Kurt S. Effects of different drinks on stainability of resin composite provisional restorative materials. J Prosthet Dent. 2005. Aug;94(2):118-24. doi: 10.1016/j.prosdent.2005.05.004. PMID: 16046965. [DOI] [PubMed] [Google Scholar]

- 5.Spina DR, Grossi JR, Cunali RS, Baratto Filho F, da Cunha LF, Gonzaga CC, Correr GM. Evaluation of Discoloration Removal by Polishing Resin Composites Submitted to Staining in Different Drink Solutions. Int Sch Res Notices. 2015. Aug 20;2015:853975. doi: 10.1155/2015/853975. PMID: 27347551; PMCID: PMC4897394. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Spina DR, Grossi JR, Cunali RS, Baratto Filho F, da Cunha LF, Gonzaga CC, Correr GM. Evaluation of Discoloration Removal by Polishing Resin Composites Submitted to Staining in Different Drink Solutions. Int Sch Res Notices. 2015. Aug 20;2015:853975. doi: 10.1155/2015/853975. PMID: 27347551; PMCID: PMC4897394. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Song SY, Shin YH, Lee JY, Shin SW. Color stability of provisional restorative materials with different fabrication methods. J Adv Prosthodont. 2020. Oct;12(5):259-264. doi: 10.4047/jap.2020.12.5.259. Epub 2020 Oct 26. PMID: 33149846; PMCID: PMC7604238. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Haynie AS, English JD, Paravina RD, Moon A, Hanigan J, Abu Al Tamn MA, Kasper FK. Colour stability of 3D-printed resin orthodontic brackets. J Orthod. 2021. Sep;48(3):241-249. doi: 10.1177/14653125211001079. Epub 2021 Mar 15. PMID: 33719707. [DOI] [PubMed] [Google Scholar]

- 9.Lee EH, Ahn JS, Lim YJ, Kwon HB, Kim MJ. Effect of post-curing time on the color stability and related properties of a tooth-colored 3D-printed resin material. J Mech Behav Biomed Mater. 2022. Feb; 126:104993. doi: 10.1016/j.jmbbm.2021. 104993. Epub 2021 Nov 24. PMID: 34871954. [DOI] [PubMed] [Google Scholar]

- 10.Aguiar FH, Georgetto MH, Soares GP, Catelan A, Dos Santos PH, Ambrosano GM, Figueroba SR, Lovadino JR. Effect of different light-curing modes on degree of conversion, staining susceptibility and stain's retention using different beverages in a nanofilled composite resin. J Esthet Restor Dent. 2011. Apr;23(2):106-14. doi: 10.1111/j.1708-8240.2011.00406.x. PMID: 21477037 [DOI] [PubMed] [Google Scholar]

- 11.Khatri A, Nandlal B. Staining of a Conventional and a Nanofilled Composite Resin Exposed in vitro to Liquid Ingested by Children. Int J Clin Pediatr Dent. 2010. Sep-Dec;3(3):183-8. doi: 10.5005/jp-journals-10005-1074i. Epub 2010 Sep 15. PMID: 27616840; PMCID: PMC4993824. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Köroğlu A, Sahin O, Dede DÖ, Yilmaz B. Effect of different surface treatment methods on the surface roughness and color stability of interim prosthodontic materials. J Prosthet Dent. 2016. Apr;115(4):447-55. doi: 10.1016/j.prosdent.2015. 10.005. Epub 2015 Dec 23. PMID: 26723092. [DOI] [PubMed] [Google Scholar]

- 13.Ardu S, Braut V, Gutemberg D, Krejci I, Dietschi D, Feilzer AJ. A long-term laboratory test on staining susceptibility of esthetic composite resin materials. Quintessence Int. 2010. Sep;41(8):695-702. PMID: 20657860. [PubMed] [Google Scholar]

- 14.Lin WS, Harris BT, Pellerito J, Morton D. Fabrication of an interim complete removable dental prosthesis with an in-office digital light processing three-dimensional printer: A proof-of-concept technique. J Prosthet Dent. 2018. Sep;120(3):331-334. doi: 10.1016/j.prosdent.2017.12.027. Epub 2018 Apr 30. PMID: 29724559.. [DOI] [PubMed] [Google Scholar]

- 15.Catelan A, Briso AL, Sundfeld RH, Goiato MC, dos Santos PH. Color stability of sealed composite resin restorative materials after ultraviolet artificial aging and immersion in staining solutions. J Prosthet Dent. 2011. Apr;105(4):236-41. doi: 10.1016/S0022-3913(11)60038-3. PMID: 21458648. [DOI] [PubMed] [Google Scholar]

- 16.Hasani-Tabatabaei M, Yassini E, Moradian S, Elmamooz N. Color stability of dental composite materials after exposure to staining solutions: a spectrophotometer analysis. J Iran Dent Assoc. 2009, 21(1): 69-78. URL: http://jida.ir/article-1-557-en.html. [Google Scholar]

- 17.Hipólito AC, Barão VA, Faverani LP, Ferreira MB, Assunção WG. Color degradation of acrylic resin denture teeth as a function of liquid diet: ultraviolet-visible reflection analysis. J Biomed Opt. 2013. Oct;18(10):105005. doi: 10.1117/1.JBO.18.10. 105005. PMID: 24126696. [DOI] [PubMed] [Google Scholar]

- 18.Bagheri R, Burrow MF, Tyas M. Influence of food-simulating solutions and surface finish on susceptibility to staining of aesthetic restorative materials. J Dent. 2005. May;33(5):389-98. doi: 10.1016/j.jdent.2004.10.018. Epub 2004 Dec 9. PMID: 15833394 [DOI] [PubMed] [Google Scholar]