Abstract

Demand for high-performance energy storage devices is growing tremendously. Supercapacitors possess an excellent candidature to fulfill the energy storage requisites such as high energy density when compared to conventional capacitors, high power density, and cycling stability as compared to batteries, though not only for large-scale devices for higher energy/power density applications but also for macro- to microdevices for miniaturized electrical components. With the aid of various routes, many materials have been explored with well-tuned properties with controlled surface architecture through various preparative parameters to find those best suited for supercapacitive electrodes. Growth of a thin film can be accomplished through chemical or physical (vacuum-assisted) routes. Vacuum-assisted (physical) growth yields high purity, precise dimensions with a line-of-sight deposition, along with high adhesion between the film and the substrates, and hence, these techniques are necessary to manufacture many macro- to microscale supercapacitor devices. Still, much effort has not been put forth to explore vacuum-assisted techniques to fabricate supercapacitive electrodes and energy storage applications. The present review explores the first comprehensive report on the growth of widespread materials through vacuum-assisted physical deposition techniques inclusive of thermal evaporation, e-beam evaporation, sputtering, and laser beam ablation toward supercapacitive energy storage applications on one platform. The theoretical background of nucleation and growth through physical deposition, optimization of process parameters, and characterization to supercapacitor applications from macro- to microscale devices has been well explored to a provide critical analysis with literature-reviewed materials. The review ends with future challenges to bring out upcoming prospects to further enhance supercapacitive performance, as much work and materials need to be explored through these routes.

1. Introduction

Mankind has benefited significantly from topical technological advancements. As technologies touch every element of human existence, appliances must be portable, flexible, lightweight, and multifunctional. These technologies necessitate the use of high-tech energy storage devices which are able to store a tremendous amount of energy, have strong structural integrity, charge quickly and discharge slowly, are eco-friendly, stable, small, lightweight, flexible, and have a long working durability. The scientific community is investigating a variety of electrochemical energy storage systems such as batteries, supercapacitors, and fuel cells, which mitigate issues related to environmental pollution through novel materials by improving the performance in terms of efficiency, life, and industry-scalable techniques of production to reduce the cost of energy storage devices from a small to large scale. Because of the remarkable energy density and charge storage capabilities, advanced rechargeable batteries have been used in most electronic devices and automobiles as they involve faradaic reversible redox reactions inside bulk electrode materials, but they are limited by power density and cyclic stability due to phase change and the generation of a range of toxic compounds. The main drawback of fuel cells is the release of heat at the time of their operation. On the other hand, capacitors can deliver high power due to rapid charge adsorption and recombination with a long life but suffer from low energy density. Contrarily, electrochemical capacitors or supercapacitors have attracted a lot of attention in recent years due to their unique properties like higher power density than batteries and higher energy density than the conventional capacitors, maintaining good cyclic stability as the charge storage occurs through surface adsorption, and intercalation or redox reaction at the electrode–electrolyte interface which may accompany the phase transformation. The institutive demonstration between energy and power densities and how the energy storage devices match up with the system can be well understood through a Ragone plot (Figure 1),1 for the performance of different energy storage devices.2,3

Figure 1.

Ragone plot.1

In 1957, the first supercapacitor prototype patent was reported by General Electric Engineers.4 Since then, as the need for electrical energy storage devices to power portable gadgets such as tablets, smartphones, smartwatches, laptops, state-of-the-art flexible medical implants, as well as wearable smart fabric has grown, the demand for supercapacitor research has been increased tremendously. Supercapacitors have gained a foothold in the electric vehicle industry because of their capability to deliver power efficiently. Supercapacitors are characterized by higher power density than batteries which can be applied in high load applications like powering automobiles with high load and fast exertion of energy when brakes are applied. They are expected to gain significance in other sectors seeking a superior energy bank. In the twenty-first century, supercapacitors present both challenges and potential for practical applications to meet the needs of the modern world, and innovative materials with high energy and power density should be explored. There have been numerous attempts to make supercapacitive electrodes5 and liquid-configured electrode devices.6

Owing to the portability and electrolyte leakage issues of conventional ultracapacitors, solid-state supercapacitors are gaining much attention in recent times,7 with the advantages being leakage-free, lightweight, portable, and capable of being miniaturized.8 Tiny energy storage devices have become critical requirements for a variety of pressing objectives such as for biomedical devices and portable electronics. For the fabrication of emerging solid-state flexible thin-film energy storage device electrodes, coating methods such as chemical vapor deposition (CVD),9 physical vapor deposition (PVD),10 electrochemical deposition (ED),11 chemical bath deposition (CBD),12 successive ionic layer adsorption and reaction (SILAR),13 the sol–gel coating method,14 spray coatings,15 dip coating,16 and electroless17 and advanced methods such as pulsed laser deposition (PLD)18 have been successfully employed. The formation of nanostructured layers in thin-film form is frequently more favorable for bendable energy device applications, with the most essential benefit being that the electrode is adhesive. The manufacturing of solid-state and microsupercapacitors is entering a new era due to the employment of physical vapor deposition techniques to grow the materials. Utilizing chemical methods to build microsupercapacitors is exceedingly challenging. Microsupercapacitors can be easily constructed using the physical vapor deposition approach because of their exact directional deposition using different masking techniques.

Even though physical deposition techniques are becoming more popular for developing supercapacitors due to their numerous advantages, it is disappointing to note that only a few research articles are available. According to our study, there is not a single review of the physical deposition for supercapacitors which can help researchers to find the most related information on a single platform. Therefore, the attempt is made in terms of this critical review to analyze various parameters and properties of diverse physical deposition techniques such as thermal evaporation, e-beam evaporation, sputtering, and laser beam ablation for the fabrication of supercapacitive materials. First, an introduction and general categorization of ultracapacitors is provided followed by a brief introduction regarding top-down and bottom-up methodologies, along with a brief discussion of the chemical and physical approach. Even though some research reports are being published, they are limited and include either a few methods or are only for microsupercapacitors. Hence, there is still a lot to learn and explore in this field, including vacuum-assisted deposition techniques for a variety of nanostructured materials for supercapacitor applications, not only in the form of liquid-configured devices but also in the formation of the solid-state device toward advanced flexibility as well as the formation of macro- to microsupercapacitors. In this regard, various materials have been explored such as metal, metal oxides, metal chalcogenides, metal nitrides, and their composites with carbon-based materials, etc., which have been well discussed in topics from synthesis and characterization to supercapacitive applications.

2. Classification of Supercapacitors

Supercapacitors can be mainly classified into three categories depending on the charge storage mechanisms: electric double-layer capacitor (EDLC), pseudocapacitor, and hybrid capacitor. Nonfaradaic and faradaic are the two main mechanisms through which charge storage takes place. In the nonfaradaic mechanism, charges are stored at the interface of the electrode–electrolyte through electrostatic adsorption, whereas a faradaic mechanism involves reversible redox reactions at the interface of the electrode–electrolyte to store the charges.

2.1. Electrochemical Double-Layer Capacitors

Electrochemical double-layer capacitors (EDLC) use a nonfaradaic process to store charges, which means there is no charge transfer between the electrolyte and the electrode through a chemical reaction.19 The charge storage mechanism of EDLC is dependent on the formation of an electrical double layer of electrolyte ions at the electrode surface, which was first reported by Helmholtz in 1879.20 The EDLC mechanism can be well explained by various theoretical models such as the Helmholtz model, Gouy–Chapman, or diffuse model and Stern modification of the diffuse double layer (Figure 2).21 The Helmholtz model provides the basic explanation where the opposite charges are adsorbed on the surface of the electrode when an electric field is applied by diffusing through the electrolytic medium by forming two parallel layers, called an electric double layer, but this theory did not consider the diffusion of ions through the electrolyte and neglected the dipole moment interaction between the electrode and electrolyte. The Gouy–Chapman model showed exponential decay of potential as it moved from the electrode surface to the electrolytic system. Even though it predicted larger specific capacitance, it failed to explain the system with highly charged layers. Both the Helmholtz model and the Gouy–Chapman model combined to give a Stern model, where adsorption is the main reason for the distribution of ions in the inner and outside regions, which are considered to be diffusion regions consisting of ionic charges; hence, the capacitance is given by21,22

| 1 |

Here, the total EDLC capacitance is represented by CDL, and capacitance due to the Stern layer and diffusion mechanism is represented by CST and CDif, respectively.

Figure 2.

Schematic representation of mechanisms involved in the (a) Helmholtz model, (b) Gouy–Chapman model, and (c) Stern model.21

The electric double-layer formation phenomenon is highly reversible; hence, it has quick charge and discharge; advantage being able to perform a large number of charging and discharging cycles without degradation of the electrode and hence, extremely stable and long-lasting.23,24 Carbon materials are used for the construction of EDLC-type supercapacitive electrodes inclusive of its allotropes such as graphene, reduced graphene oxide, activated carbon, carbon nanotubes, carbon aerogel, and carbon paste and are the most environmentally safe. Because of their excellent electrochemical properties, graphene and carbon nanotubes have acquired popularity in the scientific community.

2.2. Pseudocapacitors

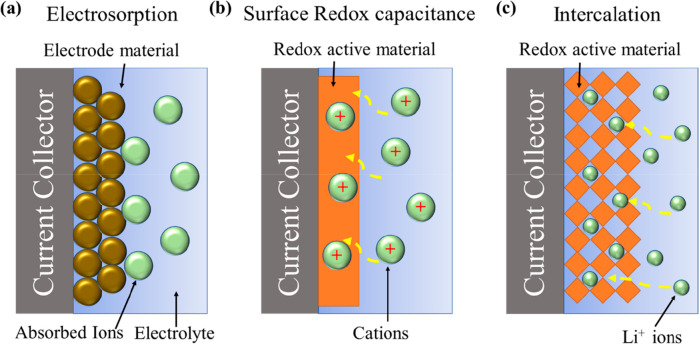

Pseudocapacitors were well explored by Conway around 1975–1981.25 Their charge storage mechanism is much more complex than EDLC. A deposited active layer on the electrode of a pseudocapacitor enhances its capacitance by fast and reversible faradaic reactions, associated with electron transfer. This effect is called pseudocapacitance.26 Here, part of the electric charge is stored by physical adsorption, while a larger amount of charge was stored either by electrolyte ion electrosorption, surface redox reactions, or intercalation processes. These result in higher specific capacitance and energy density of pseudocapacitors compared to EDLCs, and it was reported that they have many times higher capacitance value than EDLCs for an equal area.27

Figure 3 depicts the mechanisms involved in different pseudocapacitive materials,28 but the main problems associated with them are material degradation as they might undergo phase change during electrochemical activities, irreversible redox reactions and electrodes possessing limited power density, and cyclic stability.28 Metal oxides, conductive polymers, metal chalcogenides, etc., are used in pseudocapacitor electrodes. Many parameters affect the performance of pseudocapacitors such as the active surface area of the electrode, particle size, porosity, conductivity of active materials, and the electrolyte nature.26

Figure 3.

Schematic representation of charge storage mechanisms in pseudocapacitor (a) electrosorption, (b) surface redox, and (c) intercalation.28

2.3. Hybrid Capacitors

Hybrid capacitors utilize the advantages of both EDLC and pseudocapacitors by coupling different types of electrode materials through the material “mutualism concept”.13 They store electric charges by both nonfaradaic and faradaic mechanisms resulting in long-lasting, high specific capacitance and energy density and power density supercapacitors.29 Hybrid supercapacitors can further be classified into composite and battery-type supercapacitors.

The EDLC electrode materials have a high specific surface area, mechanical stability, low ESR, and no Joule heating, but they suffer from low specific capacitance,31 which can be increased by forming a composite with pseudocapacitive materials.32 By doing this, one can overcome the limitations of pseudocapacitors such as lower mechanical stability, low conductivity, and cyclic stability. The material mutualism of both the EDLC and pseudocapacitive mechanisms contributes to better performance in composite electrodes.33 The batteries provide much larger energy density when compared to the supercapacitors. By intercalating battery-type materials such as Li ions in the porous structure of electrode material, it is possible to increase the specific capacitance and, hence, the energy density of the supercapacitors.34 Another way to increase the specific capacitance is by a combination of two different electrodes forming an asymmetric configuration. The asymmetric supercapacitors by their name differ from hybrid supercapacitors, and it is generally accepted that hybrid supercapacitors contain electrodes which store charges from different mechanisms. However, asymmetric supercapacitors include a wide variety of supercapacitors where electrodes may store charges through the same mechanism, but different electrode materials were used as the anode and cathode.28

3. Electrochemical Aspects of Supercapacitors

Cyclic voltammetry (CV), galvanostatic charge–discharge (GCD), and electrochemical impedance spectroscopy (EIS) are the main tools to study the electrochemical behavior of energy storage devices. Through CV and GCD, one can study electrochemical behavior and calculate the capacitance (specific/areal/volumetric) of the supercapacitor, whereas through EIS, one can study electrical conductivity, ion diffusion, the origin of capacitive property, and the charge transfer process in supercapacitors. CV is a potentiodynamic method, where the potential of the electrode is varied linearly with the time between the fixed potential window and the corresponding current is measured. GCD is also called chronopotentiometry, where the potential between the electrodes is recorded at a constant current in response to the time.35 In EDLC supercapacitors, capacitance arises purely from the physical adsorption of ions onto the electrode, and it shows a rectangular box-like profile in CV and a symmetric triangular curve in GCD as current is potential independent (Figure 4a and b).36

Figure 4.

Schematic illustration of the electrochemical performance of (a,b) EDLC, (c,d) a surface redox pseudocapacitor, (e,f) an intercalation pseudocapacitor, and (g,h) faradaic battery type36 through cyclic voltammetry and charge–discharge curves.

Charge storage in surface redox pseudocapacitors is mainly attributed to redox reactions and charge transfer occurring at the electrode–electrolyte interface. The capacitance in such supercapacitors arises not only from faradaic or redox reactions but also from the surface electric double-layer mechanism at the electrode–electrolyte interface. Hence, the CV and GCD profiles show quasi-rectangular shapes with some redox peaks (Figure 4c and d). Pseudocapacitors can also store energy through the intercalation of electrolyte ions into the layered structure of the electrode materials without changing the phase. This type of mechanism is common in nonaqueous electrolyte systems, and its CV and GCD behavior are depicted in Figure 4e and f. In battery-type electrodes, the redox process at the electrode–electrolyte interface results in the phase change of active electrode materials, and they exhibit reduction and oxidation peaks in CV and a plateau type curve in GCD, quite similar to conventional batteries (Figure 4g and h).36−38

The important parameters of supercapacitors include specific capacitance, energy density, and power density. The specific capacitance (CS) of supercapacitors can be determined through CV using the formula39

| 2 |

where C is specific capacitance

(F/g); m is mass loading; ΔV is potential window;  is the scan rate; and the integration term

gives the area under the CV voltammogram. The specific capacitance

can also be determined from the GCD plot with the help of the formula

given by39

is the scan rate; and the integration term

gives the area under the CV voltammogram. The specific capacitance

can also be determined from the GCD plot with the help of the formula

given by39

| 3 |

where I is current density, and the integration term gives the area under the discharge curve. Energy and power density are the important parameters of supercapacitors. Energy density represents the quantity of charge or energy stored, whereas power density represents the rate at which it can deliver energy. The E specific energy density (Wh/kg) and P specific power density (W/kg) can be calculated using the formula39 given below.

| 4 |

| 5 |

where C is specific capacitance (F/g); V is voltage window; and Δt (s) is discharging time.

The deeper aspects related to the electrochemical behavior of supercapacitors can be studied effectively through electrochemical impedance spectroscopy (EIS). The EIS measurements involve the evaluation of system parameters without significantly altering the system where it is performed in open-circuit voltage conditions at a very low amplitude of alternating potential in a particular frequency range. With this, we can compute the equivalent series resistance (ESR) of the supercapacitor and analyze different charge storage mechanisms involved at the electrode–electrolyte interface and charge transfer mechanism.40 In AC impedance, the real part represents resistive behavior, while the imaginary part explains the capacitive behavior of supercapacitors. The most used EIS technique is the Nyquist plot which is a plot between real (Zreal) and imaginary (Zimg) impedance. It can be partitioned into three regions as high-, medium-, and low-frequency regions, and each region signifies the behavior of the supercapacitor (Figure 5). The semicircle at high frequencies corresponds to the bulk electrolyte resistance, and the starting point of the semicircle represents electrode resistance, a sum of which corresponds to the internal resistance (RS) of the system. We can observe a line inclined at an angle of almost 45° at a medium frequency region corresponding to the diffusion mechanism, whereas a line which is almost normal represents the ideal capacitive ion diffusion. The resistance due to the charge transfer mechanism and diffusion of electrolyte ions into electrode material is described as interfacial charge transfer resistance (RCT).41

Figure 5.

Electrochemical impedance spectroscopy.41

4. Influencing Parameters for Supercapacitor Performance

Supercapacitors are a novel class of energy storage devices as they show superior behaviors which include long life, ultrahigh power-delivering capability, fast charging–discharging characteristics, safe operation, and a wide thermal operating domain. Supercapacitors are promising candidates for energy storage applications in the future, which can have widespread applications from flexible and portable electronic devices to hybrid electric automobiles.42 Even with all these benefits, they have not found themselves in commercial large-scale production and widespread applications due to their limited energy density. Further, their low potential window and high self-discharge inhibit their performance. There are various parameters such as voltage window, surface area, pore size, electrolytes, and electrical conductivity, etc., which affect the energy density.21

A proper study of these parameters is

very essential in order to

overcome the limitations of supercapacitors. The energy density of

an electrode or device can be calculated by the equation  , which shows that energy density is directly

proportional to the capacitance and square of the potential window.43 By increasing the capacitance and voltage window,

it is very much possible to increase the energy density of the system.44Figure 6 shows the possible way to enhance energy density through

increasing the capacitance and voltage window.45

, which shows that energy density is directly

proportional to the capacitance and square of the potential window.43 By increasing the capacitance and voltage window,

it is very much possible to increase the energy density of the system.44Figure 6 shows the possible way to enhance energy density through

increasing the capacitance and voltage window.45

Figure 6.

Parameters influencing the energy density of a supercapacitor.

4.1. Surface Area

The dependence of capacitance

on an area of the substrate can be given by the equation  . Hence, by increasing the surface area

of the electrode, it is possible to enhance the energy density. The

increased active specific area results in better interaction between

the electrode and electrolyte by providing active sites for redox

reactions, adsorption, and intercalation.46 However, the accessibility of electrolyte ions to the active electrode

material is very important, but practically, the relation is not linear.

. Hence, by increasing the surface area

of the electrode, it is possible to enhance the energy density. The

increased active specific area results in better interaction between

the electrode and electrolyte by providing active sites for redox

reactions, adsorption, and intercalation.46 However, the accessibility of electrolyte ions to the active electrode

material is very important, but practically, the relation is not linear.

4.2. Pore Size

Pore size plays an important role in enhancing specific areas and the interaction between electrolyte and electrode material. The macropores (>50 nm) help in the transportation of ions into the interior part of the electrode; mesopores (2–50 nm) facilitate the diffusion of ions; and micropores (<2 nm) accommodate the electrolyte ions. The performance of supercapacitors is greatly influenced by the distribution of pores, their connectivity, and surface wettability.47

4.3. Faradaic Reactions

The faradaic redox reactions increase the specific capacitance by giving higher current output. The use of compounds with multiple oxidation state elements, bimetal compounds, and the addition of faradaic material to the electrolyte system might facilitate higher redox mechanisms.48,49

4.4. Conductivity

Besides these, the electrical conductivity of electrode materials also increases specific capacitance by better transportation of electrons and high current output. Metal oxides, metal chalcogenides, and metal phosphate suffer from internal resistances, which can be overcome by the fabrication of composite electrodes or anchoring metal nanoparticles and increase the electrode conductivity.17,50

4.5. Potential Window

The energy density of the energy storage devices can also be increased by increasing the potential window. The electrolyte decides cell voltage along with providing ions for electrochemical activities, and when the system is operated beyond that voltage, the electrolyte decomposes. Aqueous electrolytes, liquid electrolytes, and organic electrolytes are the main classes of electrolytes. All aqueous electrolytes provide good ionic conduction; however, they are limited by lower potential windows, whereas organic electrolytes and ionic liquids can work in higher potential windows up to 3 and 6 V, respectively.51

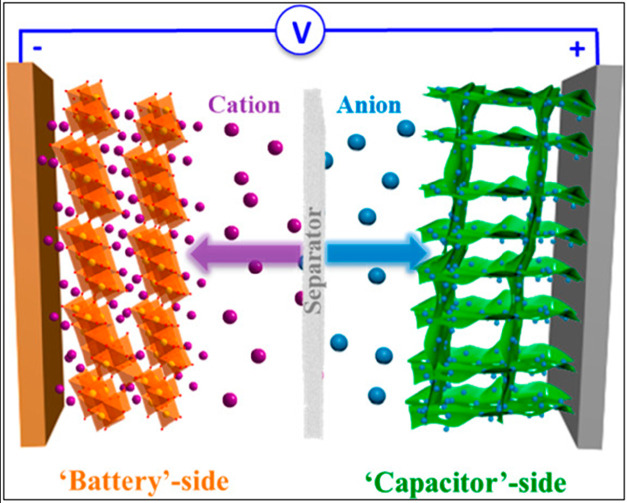

Supercapacitors can be assembled in symmetric and asymmetric configurations: in the symmetric, both electrode materials are of the same type, whereas in asymmetric, both are different. An asymmetric supercapacitor with a higher potential window can be designed by coupling electrodes which store charges through different mechanisms and work at different potential windows. Figure 7 represents the mechanism involved in asymmetric supercapacitors.30

Figure 7.

Schematic representation of an asymmetric supercapacitor. Reprinted with permission from Ding et al.30 Copyright 2018 American Chemical Society Chemical Reviews.

5. Material Requirements for Supercapacitors

The charge storage, capacitance, energy density, and power density of supercapacitors mainly depend on electrode materials, and hence, it is very important to select superior electrode materials which can enhance the energy storage performance. The capacitance of the supercapacitor majorly depends on the active surface area, but it is important to note that not all the active surface is accessible for ion interaction at the electrode–electrolyte interface. Hence, the active surface area must be electrochemically available for electrolyte ions.52 Better charge transfer requires the material to be conductive. To enhance the electrochemically activities, the electrode material should be redox active, and materials with multiple oxidation states are beneficial.48 Carbon materials such as graphene,53 carbon nanotubes,54 and activated carbon55 possess large surface area, better conductivity, mechanical stability, and cost-effectiveness, which make them a good candidate for supercapacitor application. They have been extensively used in EDLC supercapacitors.

Metal oxide, conducting polymers, metal chalcogenides, and metal phosphides are the prominent pseudocapacitive materials. Some metal oxides provide very high conductivity and low ESR. These materials have high specific capacitance, hence the high energy density. Ruthenium oxide (RuO2),56 nickel oxides (NiO),57 manganese dioxide (MnO2),58 cobalt oxide (Co3O4),59 and vanadium oxide (V2O5)60 are extensively studied materials for supercapacitor applications due to their porous structure and redox activities which result in a better interaction between electrode and electrolyte ions and fast charge transfer. In recent decades, conducting polymers have been studied for supercapacitor applications because of their high energy density, nontoxicity, reversible redox reactions, and low cost. They conduct electrons through a matrix of conjugated bonds.61 Metal chalcogenides make good electrode materials for supercapacitor applications due to their high specific area, improved life cycles, flexibility, catalytic activities, improved conductivity, reduced internal resistance, and ohmic loss.62 Further, they transfer ions quickly through 2D channels, which can easily expand and contract.63 Metal phosphides are highly abundant and environmentally friendly and possess high theoretical capacity due to their improved conductivity and better redox activities, which make them good candidates for supercapacitor applications.39

6. Growth Kinetics

The atom or ion striking the surface of the substrate interacts with the surface atoms electronically and physically at a distance of a few angstroms. When atoms or ions collide with the substrate, they lose most of their momentum, and hence, the kinetic energy lowers the surface energy by adsorbing onto it.64 The barrier energy at the impurities, defects, other adatoms, grain boundaries, dislocations, steps, and kinks present on the surface is minimum, facilitating diffusion of atoms onto the substrate, and nucleation and growth processes take place.65 The dipole and quadrupole moments of the surface atoms attract the impinging atoms, and if the incident kinetic energy of an impinging atom is not too high, then it loses its velocity component perpendicular to the surface in a short period. Further, the atom gets adsorbed physically onto the surface. The adatoms may or may not act as nucleation centers depending on the thermal equilibrium, whether it is established or not. The thermal activation of the surface and kinetic energy component of adatoms parallel to the surface results in the moment of adatoms from one potential well to another. The adatoms with finite stay over the surface interact with other atoms and form a nucleation center. The adatoms may desorb or re-evaporate into the vapor phase, and thus, the condensation is the net equilibrium between the adsorption and desorption process.

6.1. Nucleation

Nucleation is a process of the formation of seeds or nuclei, which further acts as a template for further growth. The thin-film formation is highly dependent on interface potential, molecular diffusion, and phase transition, etc., which regulate the kinetics and transport properties. The nucleation process requires the formation of a critical radius, which involves the creation of high surface area to volume ratio sites on the surface.66 The nucleation process can proceed through one of the two models, viz., homogeneous and heterogeneous nucleation, depending on the system in the absence of any foreign entity. When the nuclei are formed uniformly throughout the system, homogeneous nucleation takes place, while a system with structural inhomogeneities like defects, impurities, dislocations, substrate surface, and grain boundaries, etc., prefers heterogeneous nucleation. The homogeneous nucleation can be understood thermodynamically by considering the total Gibbs’s free energy as the sum of the surface energy and volume energy. If the particle is of spherical nature with radius r and surface energy γ, bulk free energy ΔGν, then Gibbs’s free energy is given by67,68

| 6 |

The maximum free energy through which a nucleus

must pass to form a stable nucleus can be determined by differentiation

of the above equation with respect to the radius and equating it to

0, i.e.,  , which gives the critical free energy and

critical radius.

, which gives the critical free energy and

critical radius.

The critical radius (r*) is defined as the smallest radius a nucleus must form so that it can survive in the system without being redissolved or converted into the vapor phase. Similarly, the critical free energy (ΔG*) is the smallest free energy a nucleus must possess to form a stable nucleus which is given by68

| 7 |

| 8 |

Figure 8(a) shows the plot between ΔG and r. Here the size of the nuclei must overcome the critical radius so that the growth process can take place.69 If the size of the nuclei is less than the r*, then the nuclei will desorb or redissolve into the system. The Arrhenius type equation can be used to determine the rate of nucleation of N particles in t time68

| 9 |

Here, kB is Boltzmann constant, and K is the pre-exponential constant.

Figure 8.

(a) Vitiation of change in Gibbs free energy (ΔG) with respect to radius (r). (b) Nucleation barriers (ΔG*) for both homogeneous nucleation (blue plot) and heterogeneous nucleation (red plot).69

Heterogeneous nucleation occurs more frequently than the homogeneous nucleation due to the minimum activation energy of homogeneous nucleation. The heterogeneous nucleation occurs on the surface of substrates of different materials, or near defects, impurities, dislocations, and grain boundaries, etc. Here, the critical nucleus is cap shaped with contact angle θ, and then the system is solved by using Young’s equation for minimization of free energies of surfaces. The contact angle varies according to Young’s equation given by68

| 10 |

where γ is the surface free energy at the interface of condensate (c), vapor (ν), and substrate (s). Thus, the Gibbs’s free energy is given by68

| 11 |

In homogeneous nucleation, a correction term must be included, i.e., the function of contact angle (θ), and the critical free energy of heterogeneous nucleation is the product of critical homogeneous nucleation and ϕ (function of θ). The critical free energy of the heterogeneous nucleation is less than the homogeneous nucleation as defects, impurities, dislocations, substrate surface, and grain boundaries, etc., facilitate the easy nucleation by reducing the free energy (Figure 8 b).69

| 12 |

Here

| 13 |

6.2. Growth

This section deals with the subsequent growth of the nuclei or island. The growth process regulated the size distribution of nanoparticles through multiple steps starting from the generation of growth species, diffusion of growth species from the system to growth substrate, physical adsorption of growth species followed by chemical attachment onto the substrate surface, and irreversible growth from the addition of growth species onto the substrate. The growth process is classified into two processes, viz., diffusion and surface growth. The diffusion process involves supplying growth species onto the growth surface through generation, diffusion, and adsorption mechanisms, and the surface growth process involves incorporation of growth atoms which are adsorbed on the substrate. The comparison between different growth processes is illustrated in the plot of δr/r vs r and t (Figure 9). In the diffusion regime, the growth rate is due to concertation variation of growth species in the system and interface (ΔC), which is given by67

| 14 |

When the concentration of the growth species in the system and surface is the same, the diffusion process is sufficiently fast; the growth is controlled by the surface mechanism; and mononuclear growth takes place layer by layer. The growth rate is given by the equation67

Figure 9.

Growth mechanism controlled by a diffusion process and surface process: (a) δr/r vs r and (b) δr/r vs t.70

| 15 |

where km is the proportionality constant, and C′ = Ci – Cr (difference in equilibrium concentration and concentration of growth species at the surface).

If the surface concentration reaches a certain maximum, the mechanism becomes rapid, and polynuclear growth results. Here, the second layer growth starts even before the completion of the first layer, and it does not depend on the size of the growth species or time; hence, it is constant and given by70

| 16 |

The growth mechanisms can be illustrated mainly by three different models: (i) Frank–van der Merwe growth (2D growth), in which a complete single layer of the film grows before the growth of subsequent layers (it is also called “layer by layer” growth), (ii) Volmer–Weber growth (3D growth), in which epitaxial growth takes place where the subsequent layer starts to grow before the completion of the first layer (it is also called island growth), and (iii) Stranski–Krastanov growth, which is a combination of both layer-by-layer and island growth.

7. Synthesis Approaches

The material’s synthesis process is crucial in determining the material’s qualities. The synthesis process should be carefully selected to determine the material’s nanocharacteristics requisite. Top-down and bottom-up are two approaches for the growth of nanomaterials.

7.1. Top-Down Approaches

The top-down approach is commonly achieved via ball milling, etching, and grinding routes to produce the required small structural patterns. Fine details can be produced by using a top-down approach, starting from large particles by removing extraneous material to form the required product.71 To produce artificial stuff, the top-down method is applied in several industries, the most prominent of which is the semiconductor industry. MOSFETs on silica wafers are manufactured using photolithography processes. However, this form of technology has its limitations. Quantum effects and defects emerge throughout the patterning process, playing an increasingly critical role as smaller and smaller features are fabricated.72 The top-down technique has a significant impact on nanoparticle uniformity and resolution.71

7.2. Bottom-Up Approaches

Contrarily, the bottom-up approach entails using growth assisted through ion-by-ion, atom-by-atom, or molecule-by-molecule assemblies for widespread compounds.71−73 The bottom-up approach was primarily inspired by the way that molecules self-assemble in nature through supramolecular interactions. By carefully choosing the beginning conditions of physical and chemical processes, a similar process may be accomplished in the lab. The result appears uniform, thanks to the bottom-up method. Different nanoparticle morphologies and shapes can be produced by altering the reaction’s beginning conditions. A repeatable, economical, and easy process for the creation of a functionalized thin film can be produced by the assembly of nanoparticles on two-dimensional substrates such as a conductor, semiconductor, or insulator.74−78 Due to its potential to be crucial in the development of electronic devices and sensors, the two-dimensional thin film is a subject of investigation.74−76 Due to their benefit in microelectronic fabrication, thin films are employed frequently in supercapacitor technology.

8. Deposition Techniques

The method of preparation of electrode material plays a vital role in deciding the morphology and properties of the prepared materials and, hence, the device. The route of preparation greatly affects the synthesized materials. Thin-film deposition techniques can be classified in to two methods, chemical deposition and physical deposition (vacuum assisted) (Figure 10). Each preparation method has its own advantages and disadvantages.

Figure 10.

Thin-film deposition techniques.

Specific capacitance and electrochemical properties are largely influenced by morphologies of nanomaterials in thin-film form. The same material with different morphology shows distinct electrochemical properties.63,79 Optimal morphology and nanostructure can be tailored by controlling the preparative parameters of a procedure.80 The common steps involved in the deposition of thin films involve generation of atoms, ions, or molecules from a source which may be in the solid, liquid, or vapor phase, transportation of these constituents to the substrate, and deposition through nucleation and growth.81

8.1. Chemical Techniques

The deposition of the thin film through chemical reactions with the vapor species or precursors which contain the film constituents is called chemical deposition.81 Chemical routes are a cost-effective way to produce nanomaterials. The chemical solution-based methods enable the use of various types of substrates (organic or inorganic) due to low temperature processing.82−84 The chemical reaction mechanism has a huge influence on the process and the parameters. The outcome can be controlled by changing the thermodynamic parameters like pressure, temperature, concentration, catalyst, impurities, and pH, etc. Although chemical methods are successful in depositing a range of supercapacitive materials, the main disadvantage is that many impurities get added to the product. In chemical methods, normally reactive unstable materials, solvents, and reagents are used, generating toxic bioproducts during the process. Adhesion of chemical-based films is poor; hence, binders and additives are required for the deposition of films which adversely affect the electrochemical properties of the materials.85

8.2. Physical (Vacuum Assisted) Techniques

The deposition of thin films where atoms or molecules of the reactant material are vaporized by physical routes like sputtering or thermal evaporation is termed as a physical deposition technique.86Figure 11 shows different techniques of physical deposition. Here atoms, ions, or molecules are transported to the substrate which mainly depends on the physical process. Through physical deposition techniques, it is possible to get uniform layers on nanoscale, and it is possible to deposit almost all inorganic compounds. The formed thin films are strongly adhered to the substrate with improved mechanical properties such as hardness, wear resistance, etc.87

Figure 11.

Physical deposition techniques.

8.2.1. Influencing Factors for Vacuum-Assisted Routes

Preparative parameters such as electric biasing voltage, pressure, nature, temperature of the substrate, and doping etc., can be used to tailor the film properties which can be used for supercapacitive electrode application (Figure 12). The films with porous morphology and high active surface area increase the charge storage capacity of the supercapacitor electrode material. In the following section, a discussion has been made about the various factors in physical deposition techniques affecting thin-film growth which can be effectively used to tailor the film properties required to achieve high electrochemical performance of the supercapacitor.

Figure 12.

Influencing of physically deposited films.

8.2.1.1. Electric Biasing Voltage

The charge carried by the nanoparticles plays an important role in the thin-film deposition. In many deposition techniques such as DC sputtering, RF sputtering, and PVD, etc., charged nanoparticles are produced spontaneously, and these nanoparticles act as the building blocks for the growth mechanism. The neutral nanoparticles most probably undergo Brownian motion and result in porous films, whereas charged nanoparticles self-assemble by epitaxial crystallization and result in compact and dense films.64,88

Kim et al.89 studied the effect of pressure and biasing voltage on the deposition of Ti films on the Si substrate by RF sputtering. The FE-SEM images (Figure 13) depicted the variation in the film thickness deposited under various biasing voltages at a pressure of 80 mTorr for 15 min. They obtained film with a thickness of 132, 133, 97, and 29 nm at a bias voltage of −30, −10, 0, and 50 V, respectively. The drastic decrease in film thickness with an increase in the biasing from −30 to 50 V indicates that Ti nanoparticles were positively charged; hence, at lower biasing voltage nanoparticles were attracted to the substrate, resulting in film with larger thickness due to the increased growth rate. Hence, biasing can be used to achieve higher mass loading of the material for supercapacitive application.

Figure 13.

SEM images of the Ti thin films deposited on Si substrates at bias voltages of (a) −30 V, (b) −10 V, (c) 0 V, and (d) +50 V under 80 mTorr. Reprinted with permission from Kim et al.89 Copyright 2021 MDPI coatings.

8.2.1.2. Pressure

The quality of the environment is measured by the pressure inside the system. With less impurity and better adhesion, films can be obtained by application of low pressure.90 Sometimes reactive gases (Ar, N2, O2, etc.) were used where deposition pressure is maintained. Increasing pressure leads to the large number of collisions between atoms and the substrate. Hema Chandra et al.91 deposited InP thin films on the glass substrate at different pressure through RF magnetron sputtering in an argon atmosphere. Figure 14 shows the SEM images of InP grown at a constant RF power of 150 W and substrate temperature of 448 K with varied pressure.

Figure 14.

SEM images of InP films formed at various argon pressures: (a) 0.4 Pa, (b) 0.6 Pa, and (c) 1.0 Pa. Reprinted with permission from Chandra et al.91 Copyright 2011 IOP Semiconductor Science and Technology.

At lower pressure of 0.4 Pa, they obtained InP film with better crystallinity and improved surface morphology, which is attributed to the higher kinetic energy and surface mobility of adatoms at lower pressure. Uniform conical-shaped, vertically projected grains were obtained with a P/In ratio of 0.93. Increasing the pressure to 0.6 Pa resulted in a coral shape with spherical tip tentacles. Further increasing the pressure to 1 Pa, the surface showed irregular morphology. With changing pressure, several factors affect the surface morphology of the thin film, such as angular distribution of the incident atom flux, surface diffusion of atoms, nucleation, overlap of neighboring grains, and the growth rate of different crystal planes91 which will be interesting to use as one parameter while synthesizing the material for supercapacitor application.

8.2.1.3. Temperature

The bias voltage, process pressure, and temperature effect the kinetics of growth species on the substrate which governs the morphology and microstructure of the film. The crystallinity and crystal size increase with the increase in the process temperature.92 The MoS2 thin films deposited by Chen et al.93 by magnetron sputtering at different temperatures showed a change in the surface morphology (Figure 15). At 50 °C it showed clear granular structure, and with an increase in temperature to 100, 200, and 300 °C, the film became loose and smooth with a stripe-like crystalline structure. There were many feet-like structures on the stripe when viewed under high magnification. These feet play an important role in increasing the chemical activities and electron conductivity.

Figure 15.

Scanning electron microscope (SEM) images of the MoS2 films prepared at different deposition temperatures: (a) 50 °C, (b) 100 °C, (c) 200 °C, (d) 300 °C, (e) high magnification (300 °C), and (f) cross section. Reprinted with permission from Chen et al.93 Copyright 2020 MDPI materials.

Ghorannevis et al.94 analyzed the effect of substrate temperature on morphology, structure, and optical properties of Al/ZnO thin films deposited by DC magnetron sputtering. The energy of the adatoms or ions plays an important role in the surface morphology. The SEM images (Figure 16) showed an increase in the crystalline growth structures or grain size and heterogeneous distribution of grains with increasing substrate temperature.

Figure 16.

Top and cross-sectional views of Al/ZnO thin films prepared at (a) 150 °C, (b) 250 °C, and (c) 350 °C substrate temperature. Reprinted with permission from Ghorannevis et al.94 Copyright 2014 SPRINGER Journal of Theoretical and Applied Physics.

As the substrate temperature increases, the mobility of nanoparticles increases, which activates conglomeration of small grains resulting in larger grain size. Further, the average thickness of the film also increases with an increase in the temperature. The AFM images (Figure 17) show topographies of deposited Al/ZnO thin films. The surface roughness plays an important role in the properties of thin films. The average and RMS surface roughness is reduced with decreasing substrate temperature. As the grain increases on the surface of the substrate, the surface roughness also increases.94

Figure 17.

2D and 3D AFM images of Al/ZnO films deposited at (a) 150 °C, (b) 250 °C, and (c) 350 °C substrate temperatures. Reprinted with permission from Ghorannevis et al.94 Copyright 2014 SPRINGER Journal of Theoretical and Applied Physics.

8.2.1.4. Doping

The dopant concentration largely affects properties of the thin film. Mahdhi et al.95 studied the effect of variation of dopant concentration and temperature on structural, electrical, and optical properties of Ga-ZnO thin films deposited through RF magnetron sputtering. The grain size increases with increasing concentration of Ga 3%, and a further increase in concentration of the dopant reduces the grain size. The crystallinity improves with the increase in grain size. Table 1 shows the Hall measurements of the Ga-ZnO with different dopant concentrations and temperature. The 3% Ga-doped ZnO showed a maximum band gap and minimum resistivity. Variation of doping leads to the tuning of properties of deposited materials, and hence it will contribute to achieving maximum supercapacitive parameters.

Table 1. Electrical and Optical Properties of GZO Thin Films with Different Doping Concentrations of Ga and at Different Deposition Temperaturesa.

| Ga-doping

level (content %) |

||||||

|---|---|---|---|---|---|---|

| Temperature | Parameters | 1% | 2% | 3% | 4% | 5% |

| RT | Resistivity (10–3 Ω cm) | 11.2 | 7.82 | 3.50 | 5.00 | 7.40 |

| Mobility (cm2/(V s)) | 5.87 | 7.01 | 9.30 | 7.02 | 4.23 | |

| Carrier concentration (1020 cm–3) | 0.95 | 1.14 | 1.92 | 1.78 | 1.71 | |

| Eg (eV) | 3.37 | 3.43 | 3.63 | 3.57 | 3.50 | |

| 100 °C | Resistivity (10–3 Ω cm) | 9.00 | 6.74 | 3.40 | 4.60 | 6.00 |

| Mobility (cm2/(V s)) | 6.67 | 8.27 | 8.75 | 8.60 | 6.94 | |

| Carrier concentration (1020 cm–3) | 1.04 | 1.12 | 2.10 | 1.58 | 1.51 | |

| Eg (eV) | 3.36 | 3.41 | 3.57 | 3.44 | 3.36 | |

| 150 °C | Resistivity (10–3 Ω cm) | 8.70 | 6.00 | 2.85 | 4.00 | 5.00 |

| Mobility (cm2/(V s)) | 6.53 | 8.60 | 9.99 | 8.97 | 5.92 | |

| Carrier concentration (1020 cm–3) | 1.10 | 1.21 | 2.27 | 1.74 | 2.11 | |

| Eg (eV) | 3.34 | 3.46 | 3.60 | 3.58 | 3.50 | |

| 200 °C | Resistivity (10–3 Ω cm) | 8.00 | 6.00 | 2.20 | 3.00 | 4.20 |

| Mobility (cm2/(V s)) | 7.30 | 7.71 | 16.42 | 12.18 | 10.19 | |

| Carrier concentration (1020 cm–3) | 1.07 | 1.35 | 1.73 | 1.71 | 1.46 | |

| Eg (eV) | 3.41 | 3.48 | 3.65 | 3.55 | 3.50 | |

Reproduced with permission from Mahdhi et al.95 Copyright 2014 ELSEVIER Superlattices and Microstructures.

8.2.1.5. Substrate

The substrate affects several growth mechanisms like physical adsorption, surface adsorption, and crystal arrangement of the atoms, which decides the crystallinity, morphology, atomic and molecular arrangement, etc. Mirabito et al.96 studied the morphology of ZnPc films grown over different substrates such as Cu, Si, SiO2/Si, and carbon plane sapphire by physical vapor deposition. The SEM images (Figure 18) of ZnPc showed almost similar morphology when deposited over the bare substrate, but a clear distinction was observed when grown over a substrate using single-layer graphene as a growth template. ZnPc exhibited nanowire morphology when deposited on a bare substrate, while nanowires were very different and formed continuous thin films when deposited on graphene-supported substrates. The crystallite arrangement, microstructures, and surface roughness varied depending on the underlying substrate.

Figure 18.

Plane-view (top) and side-view (bottom) SEM images (in-lens detector) of ZnPc deposited by PVD using a source temperature of 450 °C, a substrate temperature of 250 °C, and a deposition duration of 30 s. ZnPc is deposited on both graphene (left side) and on bare substrate (right side): (a) Cu, (b) SiO2, (c) C-plane sapphire, and (d) Si. Reprinted with permission from Mirabito et al.96 Copyright 2021 American Chemical Society ACS Omega.

9. Vacuum-Assisted Thin Films toward Supercapacitive Applications

As seen above, by optimizing various preparative parameters, different morphologies can be obtained through vacuum-assisted deposition techniques. This surface architecture can be well explored toward supercapacitor applications. These technologies provide very precise control over material deposition, guaranteed the final electrodes with excellent quality, and have the attributes required to operate effectively in supercapacitor applications. There are few reports available where vacuum-assisted deposition techniques are used to deposit different materials for supercapacitor application which are well summarized in this section.

The domain of microsupercapacitors has been gaining prominence in recent times, which leads to numerous interests in vacuum-assisted techniques to grow the essential microsupercapacitor electrodes and devices. The highly focused deposition of materials necessary for microsupercapacitor electrodes makes these approaches an appealing alternative since several masking techniques may be utilized to easily manufacture them.97 Physical approaches also stand out to produce solid-state supercapacitor devices, which successfully handle the issue of liquid electrolyte leakage and enable completely formed microsupercapacitor devices.98,99 The solid-state microsupercapacitor can be assembled through physical vapor deposition,99 sputtering,7,100 and even pulsed laser deposition.101 Furthermore, the primary advantage of employing vacuum-assisted thin-film techniques to make microsupercapacitor electrodes is their adaptability to produce devices with varied materials and designs. This implies that researchers may test a wide range of materials deposited onto various substrates and designs to maximize the performance of the microsupercapacitor devices for several applications.

9.1. Evaporation

Evaporation is where the source material is heated to transform into a vapor phase. The transformation through various routes categorized the type of evaporation. Table 2 represents the critical overview of evaporation techniques for supercapacitor applications.

Table 2. Literature Review Table for Evaporation Techniques.

| Physical

Parameters |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Temperature | Pressure | Crystal Structure | Morphology | Configuration | Electrolyte | Type | PW | SC | ED | PD | Capacitive retention @ cycles | Ref |

| Thermal | |||||||||||||

| Cu | 1 × 10–6 Torr | Solid state | LiF | Symmetric | –0.4 to 1.0 | 10 μF/cm2 | (99) | ||||||

| Mo-V2O5 | 5 × 10–5 mbar | Orthorhombic | Liquid state (3 electrodes) | 1 M KCl | - | 0.1 to 0.7 | 175 mF/cm2 @ 1 mA/cm2 | (103) | |||||

| V2O5 | 300 °C | 1 × 10–6 mbar | Orthorhombic | Nanograins | Liquid state (3 electrodes) | 1 M LiSO4 | - | –0.6 to 0 | 730 mF/cm2 @ 1 mA/cm2 | (104) | |||

| V2O5 | 10–5 mbar | Orthorhombic | Nonuniform particles | Solid state | PVA-KOH | Symmetric | 0 to 1.0 | 9.7 mF/cm2 | 0.68 μWh/cm2 | 180 μW/cm2 | 97% @ 30000 | (105) | |

| Al-CuI | 2 × 10–5 mbar | Cubic | Nanocubes | Liquid state (3 electrodes) | 0.1 M Na2SO4 | –1 to 1 | 142.8 F/g @ 2 mV/s | 89.1% @ 2000 | (106) | ||||

| E beam | |||||||||||||

| MnOx | 5 × 10–6 mbar | Amorphous | Nanoclusters | Liquid state (3 electrodes) | 0.5 M Na2SO4 | –0.4 to 1.0 | 320 F/g @ 10 mV/s | (107) | |||||

| NiO | 5 × 10–6 mbar | Crystalline | Round rock | Liquid state (3 electrodes) | 1 M Et4NBF4 | –0.4 to 1.0 | 187.2 F/g @ 25 mV/s | 100% @ 5000 | (108) | ||||

| WO3 | 5 × 10–6 mbar | Amorphous | Round rock | Liquid state (3 electrode) | 1 M Et4NBF4 | –0.4 to 1.0 | 194.8 F/g @ 25 mV/s | 100% @ 5000 | (108) | ||||

| Mn3O4 | 473 K | 6 × 10–4 mbar | Tetragonal | Nanoflower | Liquid state (3 electrodes) | 1 M Na2SO4 | –0.1 to 0.9 | 568 F/g @ 1 A/g | 93% @ 5000 | (109) | |||

| N-G-Carbon | 3.5 × 10–6 mbar | Crystalline | Nano onions | Solid state | PVA-H2SO4 | Symmetric | 0 to 1 | 1.16 mF/cm2 @ 10 mV/s | 0.16 μWh/cm2 | 24.87 μW/cm2 | 80% @ 10000 | (110) | |

| Mn3O4 | 473 K | 6 × 10–4 mbar | Tetragonal | Flakes | Liquid state (3 electrodes) | 1 M Na2SO4 | –0.1 to 0.9 | 754 F/g @ 1 A/g | 89% @ 4000 | (111) | |||

9.1.1. Thermal Evaporation

The technique of generating a thin film via evaporation is reasonably simple since it is based mostly on the notion of thermal evaporation. The procedure essentially entails heating the source material, which can be any solid material, until it reaches its boiling point. As a result, the substance evaporates and forms vapor, which rises upward toward a cold substrate, and it condenses to form a thin film as depicted in Figure 19.102

Figure 19.

Schematic diagram of a thermal evaporation setup.102

Thermal evaporation involves placing the substance to be deposited in a high vacuum chamber, which is then elevated to a high enough temperature to evaporate the material using a current through coils or boats. By altering the temperature of the precursor and the substrate, as well as the deposition rate and pressure, the thickness and characteristics of the film may be controlled. Thermal evaporation has the virtue of being simple and versatile. Achieving uniform deposition across vast regions is difficult due to uneven evaporation of material from the center to the edges of the film. Heated boat material may evaporate; hence, the process might be susceptible to impurities in the produced film. Moreover, the high temperatures employed in thermal evaporation might harm or change the characteristics of some materials.

Depending on the desired application of the film, the substrate may be metal, semiconductor, or insulator. It is critical to remember that the substrate must be kept at a lower temperature for the vapor to condensate on its surface. An important parameter that decides the rate of evaporation of the material source is determined by the material’s vapor pressure at the evaporation temperature. A high vacuum (10–2 Pa) is maintained to prevent the source from oxidizing. Further, the low-pressure environment reduces the possibility of gaseous contamination in the deposited films.

Many ways can be used to heat the source material. Inductive heating, which employs an alternating magnetic field to create heat in a metallic crucible containing the source material, is one frequent approach. Joule heating is another approach that includes delivering an electric current via a wire coil that surrounds the crucible. The crucible should withstand the high working temperature of the evaporation; hence, molybdenum or tungsten crucibles hold out against a temperature of about 2800 K, which is adequate to evaporate most metals. Both technologies quickly and effectively create heat, making them excellent for evaporation operations, but they cannot be reached beyond the boiling point of certain metals and high-temperature boiling point solid-state materials. For heating, the materials at higher temperature e-beam evaporation prove very effective. Overall, evaporation is a flexible and commonly used approach for producing thin films. Its ease of use and ability to produce uniform thin films make it a popular choice in industries such as semiconductor production, optics, and material science. One of the first reports of a supercapacitor device created by an evaporation process was used to build early solid-state supercapacitors.99

The physical characteristics are greatly influenced by the microstructure of the material, which includes grain boundaries, grain orientation distribution, and grain size. Dhananjaya et al.104 studied the effect of the temperature of the substrate on vanadium pentaoxide film growth for supercapacitor applications. Vanadium pentoxide thin films formed at different substrate temperatures and electrochemical performances. The grain size of the produced films grew with the rise in temperature of the substrate. At substrate temperatures of 200, 250, and 300 °C, the mean crystallite size of the produced samples was 100, 106, and 148 nm, respectively. The specific capacitance of the film formed on Ni substrates was found to be 95.3, 205.9, and 241 mF/cm2 at a 10 mV/s scan rate with substrate temperatures of 200, 250, and 300 °C, respectively, in 1 M LiSO4.104 With the increase in temperature, the intercalation and deintercalation mechanism of Li+ ions into vanadium pentaoxide is enhanced. In GCD one can observe nonlinear curves signifying pseudocapacitive behavior of V2O5 thin films.104

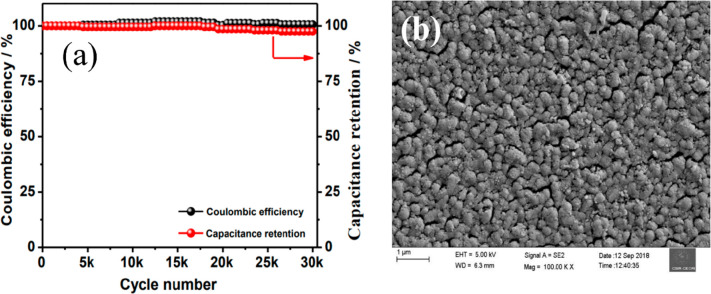

Further, Velmurugan et al.105 successfully fabricated a symmetric supercapacitor device using V2O5 films by a thermal evaporation technique and showed a very high aerial capacitance of 9.7 mF/cm2 at a scan rate of 10 mV/s in PVA-KOH gel electrolyte. A solid-state supercapacitor device exhibited outstanding stability (capacitance retained) of 95% after 30000 cycles (Figure 20a).105Figure 20b shows the SEM image of the annealed V2O5 sample, which exhibited nonuniform large grains. The annealing enhances the crystallinity and electrochemical performance of the electrode material.105

Figure 20.

(a) Capacitance retention of an ultracapacitor and (b) SEM image of the film. Reprinted with permission from Velmurugan et al.105 Copyright 2019 American Chemical Society ACS Sustainable Chemistry & Engineering.

Doping is the addition of extra elements to the host material in order to improve its various qualities. The doping of different materials is very straightforward in PVD deposition. Ghazal et al.106 produced copper iodide (CuI) thin films effectively, which were doped with aluminum in 5, 3, 7, and 9 mol %. The value of specific capacitance was increased with an increase in doping concentration of Al doping. Pure copper iodide thin films had a specific capacitance of 91.5 F/g at a scan rate of 2 mV/s. After, aluminum doping in CuI films with 3, 5, 7, and 9 mol % improved the specific capacitance to 108.3, 126.2, 148.8, and 131.1 F/g, respectively, at a scan rate of 2 mV/s. Figure 21 shows the GCD curves for bare and doped CuI films with the Al at various concentrations and the correlation of specific capacitance of the produced film with variation in current density. These films had irregular nanocube-like structures.106

Figure 21.

(a) Galvanostatic charge–discharge curves of various doping concentrations of Al in CuI. (b) Correlation of specific capacitance with variation in current density for various concentrations of the Al doping in CuI. Reprinted with permission from Ghazal et al.106 Copyright 2021 Royal Society of Chemistry RSC Advances.

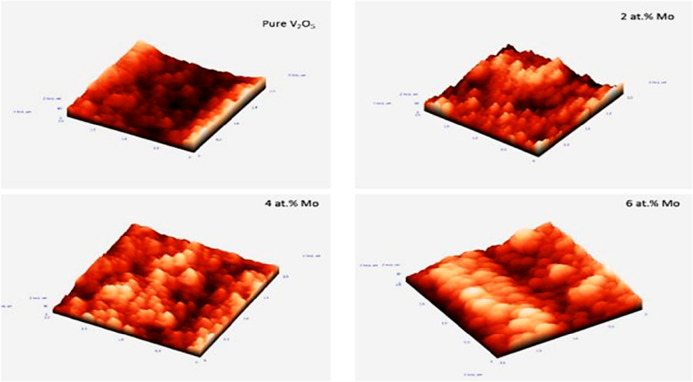

V2O5 film is easily mixed with other elements such as Li, Mn, Ag, Al, Cr, Na, Ni, Cu, Sn, Ti, Pt, and F. Prakash et al.103 doped V2O5 film with Mo since Mo is a promising metal for doping as vanadium has the (5+) stable oxidation state (ionic radii 0.68 Å) and Mo has the (6+) state (ionic radii 0.73 Å). When Mo is doped into V2O5, its electrochemical, structural, electrical, and optical characteristics can be altered by high valence cations, which produce donor-like defects.103Figure 22 depicts the surface roughness of thermally evaporated pure film and Mo-doped V2O5 films formed at various concentrations of Mo doping at a fixed temperature (250 °C). The AFM observations indicate that the films had grain sizes ranging from 28 to 63 nm.

Figure 22.

Effect of Mo doping on the roughness of V2O5 films. Reprinted with permission from Prakash et al.103 Copyright 2016 ELSEVIER Materials Today: Proceedings.

Table 3 shows the grain size and roughness of the V2O5 films with a variation in Mo doping concentration. The data show that as the concentration grew the related roughness increased up to 4%; however, when the Mo doping concentration climbed to 6%, the roughness marginally decreased. Thus, areal capacitance estimated from CV curves (Figure 23) is increased with the maximum value of specific capacitance for 4% Mo doping and starts to decrease after 6% as mentioned in Table 3.103

Table 3. Effect of Mo Doping on Grain Size and Roughness of V2O5 Thin Filmsa.

| Sample | Grain size (nm) | Roughness (nm) | Areal Capacitance (mF/cm2) |

|---|---|---|---|

| Pure V2O5 | 28 | 6 | 56 |

| 2% of Mo | 30 | 9 | 66 |

| 4% of Mo | 56 | 12 | 83 |

| 6% of Mo | 63 | 10 | 52 |

Reproduced with permission from Prakash et al.103 Copyright 2016 ELSEVIER Materials Today: Proceedings.

Figure 23.

Variation in cyclic voltammetry due to Mo doping in the V2O5 films.103 Reprinted with permission from Prakash et al.103 Copyright 2016 ELSEVIER Materials Today: Proceedings.

9.1.2. E-Beam Evaporation

In e-beam evaporation, an electron beam can be used to heat the material at higher temperatures, which is an effective approach for heating a variety of materials. In e-beam evaporation, the beam of electrons is controlled precisely with the help of electromagnets to heat the target material illustrated in Figure 24(112) and due to this contamination by crucible material is also quite low. Moreover, to avoid the interaction between the crucible and the source material at the time of working, the flash evaporation (rapid temperature increase) approach is used. The film properties for simple thermally evaporated films and flash-evaporated films differ.113

Figure 24.

E-beam thermal evaporation equipment.112

This method includes heating a material to its evaporation point with an electron beam controlled by electromagnetic fields, resulting in the rapid generation of a material vapor that condenses on a substrate. The e-beam evaporation deposits a wide variety of substances, including metals, semiconductors, and oxides. Moreover, the electron beam’s high energy allows for quick and accurate heating of the source material, allowing for excellent control over the film deposition. The thermal evaporation process may be used to deposit a wide range of materials. According to the literature review, researchers have succeeded in the deposition of Cu, Mo-doped V2O5, V2O5, and Al-doped CuI using thermal evaporation and MnOx, NiO, WO3, Mn3O4, and nanoporous gold–nitrogen-doped carbon nano-onions using an e-beam evaporation deposition.

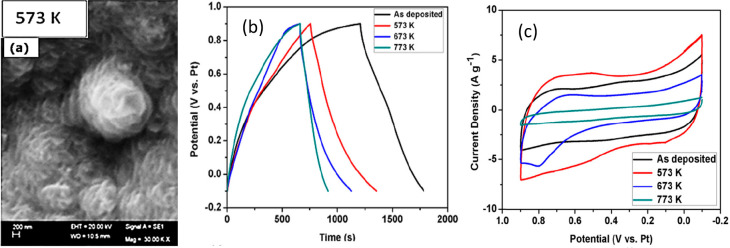

Shaik et al.109 analyzed the supercapacitive performance of the Mn3O4 films grown by e-beam evaporation followed by annealing at various temperatures (Figure 25). The SEM scan revealed that the whole surface of the film was covered with vertical flower-like growth for the film with an annealing temperature of 573 K exhibiting a peak value of 568 F/g specific capacitance with a potential window between 0.1 and 0.9 V as depicted in Figure 25. Films annealed at 673 and 773 K exhibited lower discharge time resulting in lower capacitance of 443 F/g and 240 F/g, respectively.109

Figure 25.

(a) Flower-like morphology of Mn3O4 films, (b) galvanostatic charge–discharge plot, and (c) cyclic voltammogram of films at various temperatures. Reprinted with permission from Shaik et al.109 Copyright 2018 ELSEVIER Materials Science in Semiconducting Processing.

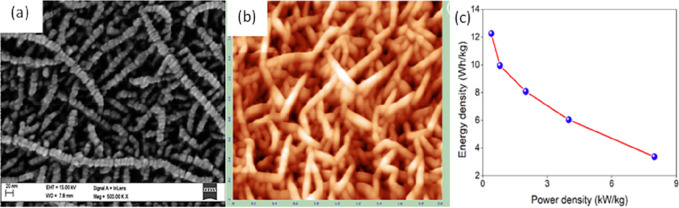

In another study, Shaik et al.111 deposited Mn3O4 films on pyrex glass (PG), stainless steel (SS), and Au/Ti/SiO/(textured) silicon (ATS). According to the results of the SEM and AFM analysis, the films that were deposited on PG, SS, and ATS substrates had irregularly shaped spherical grains, flake-like grains, and well-distributed pyramidal grains, respectively. The film deposited on the ATS substrate showed a very high specific capacitance of 754 F/g at a specific current density of 1 A/g.111 The films formed on PG substrates are made up of evenly dispersed spherical grains with a mean diameter and root-mean-square roughness of 20 and 9 nm, respectively (Figure 26a). The surface of Mn3O4 films formed on SS is made up of vertically growing flake-like shaped grains with root-mean-square roughness of 6 nm (Figure 26b). On the surface of ATS substrates (Figure 26c), well-structured pyramidal form grains with an average diameter of 200 nm and RMS roughness of 68 nm were detected. With the increase in grain size, the charge density of the film rose; as a result, the film conductivity increased, which is an essential characteristic of the electrodes of ultracapacitors.111 This study proposed the effect of substrate on the formation of the film. Figure 26e depicts the surface morphology of Mn3O4 thin films formed on PG substrates. The film topography on PG substrates is rough, with round grains dispersed evenly with an average diameter of grains of 400 nm. In contrast, the surface of Mn3O4 films on SS substrates is covered with flakes resembling grains with flake sizes ranging from 300 to 400 nm (Figure 26f). As illustrated in Figure 26g, the films are vertically formed on the surface of ATS substrates with an average size of grains of 500 nm. Figure 26d depicts the CV curves for the SS and ATS substrates at 10 mV/s, which demonstrated capacitive-like properties. The area of the CV curve of the films formed on ATS substrates appears to be greater than that of the films deposited on SS substrates, resulting in higher specific capacitance. The galvanostatic charge/discharge curves of SS and ATS samples are shown in Figure 26h. The ATS sample has a high discharge current with a low internal resistance [a quick potential drop at the starting point of the discharge curve contributes to a high specific capacitance].111

Figure 26.

AFM micrographs of Mn3O4 thin films on (a) PG, (b) SS, and (c) ATS substrates. SEM images of Mn3O4 thin films on (e) PG, (f) SS, and (g) ATS substrates as well as (d) and (h) images showing the electrochemical study of the film on SS and ATS substrates. Reprinted with permission from Shaik et al.111 Copyright 2019 ELSEVIER Journal of Electroanalytic Chemistry.

One of the most important qualities of PVD grown films is their strong adhesion with a range of substrates. Chen et al.108 deposited NiO and WO3 films by employing the e-beam evaporation method on carbon electrodes to take advantage of the porous structure of a carbon electrode. Figure 27a and b shows the SEM images of NiO and WO3 which exhibited round rock-like morphology. The porous structure of carbon helps to increase the effective surface area to increase the capacitance of the electrodes. NiO and WO3 exhibited specific capacitance of 187.2 and 194.8 F/g, respectively, at 25 mV/s. NiO films showed excellent stability, and after 5000 cycles the charge\discharge efficiency remained close to 100% (Figure 27c).108

Figure 27.

SEM micrographs of (a) NiO and (b) WO3 deposited on mesocarbon microbeads (MCMBs) and (c) charge–discharge efficiency of NiO/MCMB electrodes. Reprinted with permission from Chen et al.108 Copyright 2016 MDPI Applied Sciences.

Singh et al.110 created a microsupercapacitor by depositing Au, Ag, and Cr by the e-beam method on a Si/SiO2 substrate and annealed it. Following that, it was dealloyed by treating it with HNO3 acid, which led to the formation of nanoporous gold (NPG). The nitrogen-doped carbon nano-onions (NCNOs) were then electrophoretically deposited on an NPG. Figure 28a and b depicts the morphologies of NPG-NCNO electrodes having very high porous structures. Figure 28c and d shows the precisely created microsupercapacitor electrode architecture. The NPG-NCNO solid-state microsupercapacitor was fabricated using PVA H2SO4 gel electrolyte (Figure 29a). The NPG-NCNO microsupercapacitor device has a high areal capacitance of 1.16 mF/cm2, an energy density of 0.16 μWh/cm2, and a power density of 24.87 μW/cm2. It showed a capacitive retention of over 80% up to 10000 cycles (Figure 29b).110

Figure 28.

FEG-SEM images of (a) NPG, (b) NPG after deposition of NCNO, (c) NPG–NCNO electrode architecture, and (d) the solid-state NPG–NCNO microsupercapacitor device. Reprinted with permission from Singh et al.110 Copyright 2019 ELSEVIER Nano-Structures & Nano-objects.

Figure 29.

(a) Microsupercapacitor device fabrication process and (b) stability of the NPG–NCNO microsupercapacitor device. Reprinted with permission from Singh et al.110 Copyright 2019 ELSEVIER Nano-Structures & Nano-objects.

MnOx thin film was synthesized by Abdur et al.107 through electron beam evaporation for supercapacitor applications. They carried out electrochemical analysis in three different potential windows of 0.0 to 1.0 V, −0.1 to 1.0 V, and −0.4 to 1.0 V. At 1 V potential window it exhibited rectangular CV, whereas in later potential windows, it showed pseudocapacitive behavior. It showed a maximum specific capacitance of 320 F/g at a 10 mV/s scan rate with a potential window of 1.4 V.107

9.2. Sputtering

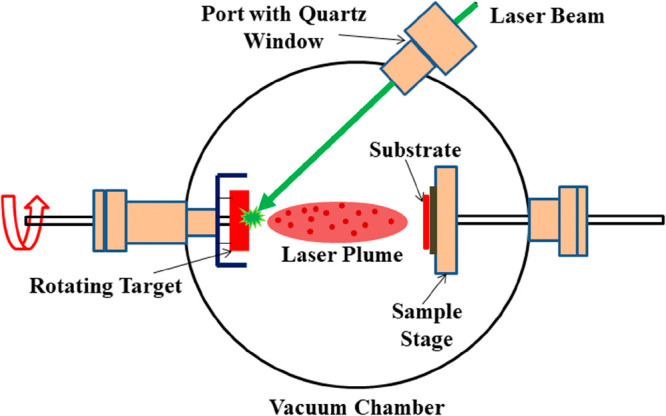

Sputtering is a type of deposition process that is widely employed in industrial and research applications. It is a plasma-assisted technique in which inert gases like argon are ionized to generate positive ions. The target material serves as the cathode and produces electrons which collide with the argon atoms to ionize it. These ions are subsequently drawn to target material, which is negatively charged, due to electrostatic interactions. Sputtering involves hitting the target material with these ions, which supply the target particles with enough energy and momentum to get removed from the target and get deposited on a substrate; therefore, sputtering provides good adhesion of the film to the substrate compared to the thermal evaporation technique. In this situation, the substrate serves as an anode. Atoms blasted into the substrate produce a thin film or coating that may be employed for a range of applications. The schematic diagram of the sputtering unit is shown in Figure 30.114

Figure 30.

Schematic diagram of a sputtering setup. Reprinted with permission from Hishimone et al.114 Copyright 2020 INTECKOPEN.

Sputtering has the benefit of a low substrate temperature, making it appropriate for a wide range of materials such as polymers, alloys, pure metals, compounds, and low-heating material substrates. Also, lower substrate temperature lowers the residual stress.115−117 Parameters such as power and pressure influence the deposition rate. The use of larger-surface targets improves the uniformity and enables thickness control by regulating process parameters and deposition time. By altering the polarity of the substrate and target, excellent in situ substrate cleaning can be performed. The etching technique facilitates the removal of oxides and other impurities from the surface layer of the substrate. Good adherence is assured by effective plasma etching and substrate surface cleanliness.118 Nonetheless, it possesses high deposition rates with no thickness restriction.119 One of the disadvantages of sputtering is film densification, which adversely affects the surface area of the film. Sputtering techniques prove to be a good alternative where stoichiometry, surface roughness, and grain size are important. These properties influence the electrochemical performance of the ultracapacitors.

Plasma is created when a strong electric field is applied, resulting in free electrons, free radicals, ions, excited atoms, and molecules.138 Subsequently, the plasmonic environment provides a platform for free radical chemistry, resulting in a favorable setting for the majority of the reactions. Ionized hydrogen plasma, for example, has far higher reducibility than hydrogen gas because it contains high-energy radicals and species.139 Surface modification, etching, polymerization, deposition, doping, reduction, and oxidation may all take place in such a reactive environment.139−142 Sputtering is employed in most publications to produce supercapacitor electrodes and fully functioning supercapacitor devices as presented in Table 4 because of its adaptability in the deposition of a wide range of materials.

Table 4. Literature Review for Sputtering Techniques.

| Physical parameters |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Type | Temperature | Pressure | Crystal Structure | Morphology | Configuration | Electrolyte | Type | PW | SC | ED | PD | Capacitive retention @ cycles | Ref |

| RuO2 | DC reactive | 5 × 10–3 Torr | Amorphous | Smooth surface | Solid state | LixPOyNz | Symmetric | 0 to 2 | 656.57 F/g @ | 53% @ 500 | (120) | |||

| MoO3 | Magnetron | 2 × 10–5 mbar | Crystalline | Nanocluster | Liquid state (3 electrodes) | 1 M Na2SO4 | –1.0 to 1.0 | 70 F/g @ 10 mV/s | 82% @ 1000 | (121) | ||||

| Graphene | Magnetron | 620 °C | Hexagonal | Crumpled and folded | PVA-H3PO4 | Symmetric | 0 to 1.0 | 325 F/g @ 1 mV/s | 13.9 Wh/kg | 50 kW/kg | 100% @ 5000 | (122) | ||

| ZnO/CNT | Reactive magnetron | 2 × 10–5 mbar | Crystalline | Macroporous | Liquid state (2 electrodes) | 0.1 M TBAPC/DMF | Symmetric | –2.0 to 1.0 | 59 F/g @ 5 mV/s | 13.1 Wh/kg | 3.0 W/kg | (123) | ||

| CrN | Reactive DC magnetron | 3.5 Pa | FCC | Wormlike | Liquid state (2 electrodes) | 0.5 M H2SO4 | Symmetric | 0 to 0.8 | 6.5 mF/cm2 @ 1 mA/cm2 | 8.2 mWh/cm3 | 0.7 W/cm3 | 90% @ 20000 | (124) | |

| TiO2/FMWCNT | Reactive magnetron | 2 × 10–5 mbar | Nanoparticles | Liquid state (2 electrodes) | 0.5 M Na2SO4 | Symmetric | –1 to 1 | 110 F/g @ 5 mV/s | 70% @ 500 | (125) | ||||

| Graphene | Magnetron | 3.0 Pa | Fluffy and corrugated | Liquid state (3 electrodes) | 6 M KOH | 0.1 to 0.6 | 122 F/g @ 1 A/g | 99% @ 1000 | (126) | |||||

| CuO | Reactive RF magnetron | 10–2 Torr | Monoclinic | Granular, porous morphology | Liquid state (3 electrodes) | 6 M KOH | 0 to 0.5 | 272 F/g @ 5 mV/s | 85% @ 3000 | (127) | ||||

| CuO2 | Reactive RF magnetron | 10–2 Torr | Cubic | Granular, porous morphology | Liquid state (3 electrodes) | 6 M KOH | 0 to 0.5 | 215 F/g @ 5 mV/s | 80% @ 3000 | (127) | ||||

| MnO2 | DC magnetron | 3 × 10–2 Torr | Tetragonal | Nanorods | Liquid state (2 electrodes) | 1 M Na2SO4 | Symmetric | 0 to 0.8 | 203 F/g @ 2 mV/s | 4.2 Wh/kg | 151 W/kg | 89.83% @ 5000 | (128) | |

| Mo2N | Reactive DC magnetron | FCC | Spinous shape | Liquid state (3 electrodes) | 0.5 M Li2SO4 | 0.005 to 0.85 | 722 F/cm3 @ 5 mV/s | 100% @ 2000 | (129) | |||||

| TiC | 750 °C | 10–2 mbar | FCC | Liquid state (3 electrodes) | 1 M H2SO4 | –0.6 to 0.3 | 103 mF/cm2 | (130) | ||||||

| TiN | Reactive magnetron | 2 Pa | FCC | Liquid state (2 electrodes) | 0.5 M H2SO4 | Symmetric | 0 to 0.8 | 27.3 mF/cm2 @ 1 mA/cm2 | 17.6 mWh/cm3 | 10.8 W/cm3 | 98.2% @ 20000 | (131) | ||

| MoS2 | DC magnetron | 300 °C | 5 × 10–3 Torr | Hexagonal | Nanoworms | Liquid state (3 electrodes) | 1 M Na2SO4 | –0.2 to 0.6 | 138 F/g @ 1 A/g | 12.26 Wh/kg | 7.98 kW/kg | 86% @ 5000 | (132) | |