Abstract

Burkina Faso's agricultural and industrial sectors are sources of biomass production which are not well tapped. However, the exact quantities available and mobilizable with connection to recovery technologies are not available in the literature. Also, there is very little data on the criteria for the optimal selection of the biomasses to be valorized. In this article, quantification of the main biomasses produced in Burkina Faso has been carried out. Additionally, sustainable biomass selection criteria have been established. A hybrid (AHP-TOPSIS) multi-criteria decision-making (MCDM) approach was used to prioritize suitable biomass resources based on defined criteria for bioenergy production. Based on expert opinions and an in-depth review of the literature, six main biomass selection criteria were established: i) biomass availability and accessibility, ii) competitive uses, iii) pollution potential related to residue accumulation, iv) economic impact, v) biomass energy content, and vi) availability of appropriate biomass conversion technologies. Moreover, five potential biomasses were investigated, including cotton stalks, rice husks, cashew nutshells, mango peels, and mango pits. The results of the evaluation showed that cotton stalks were the best option.

Keywords: Crop residues, AHP, TOPSIS, Multi-criteria decision making, Bioenergy

1. Introduction

Agriculture is the main activity in Burkina Faso. It employs over 80 % of the active population and accounts for 32 % of GDP [1]. The main food crops produced are sorghum, millet, corn, and rice, while the main cash crops are cotton, sesame, and peanuts. Burkina Faso generates large quantities of crop residues.

In addition, the country's industrial sector is dominated by small agro-industrial units [2]. These units generate large amounts of waste. The agro-industrial by-products are sometimes dumped on the ground causing environmental issues in the cities.

Very low quantities of organic waste from crops and agro-industries are converted into energy [3]. The crop residues are traditionally used as animal feed, fertilizer for soil improvement, and/or as fuel. The agro-industrial waste is not much valued and is usually disposed of without treatment in uncontrolled landfills [3]. Since the country faces many energy access challenges, these residues can be used as feedstock for sustainable energy production. Indeed, adequate treatment of these residues would allow their valorization into bioenergy and improve the energy access rate in rural areas. Various biomass resources available in Burkina are unevenly scattered throughout the country. Crop residues are mainly located in the major production areas, notably the Boucle du Mouhoun and Hauts-Bassins regions [4]. Agro-industrial residues are only available in major urban centers such as Ouagadougou and Bobo-Dioulasso. Burkina Faso has a significant biomass potential that can be valorized into energy [5]. However, the lack of data on potential biomass and the quantities that can be recovered hinders the establishment of viable supply chains. Also, the significant variability of the resource and the valorization technologies raises the problem of choosing the appropriate biomass to valorize. The lack of mastery of these elements often contributes to the failure of bioenergy projects. There is a need, therefore, to investigate in this direction to facilitate the understanding and sustainable exploitation of biomass.

Bioenergy projects are usually very complex and must meet a set of, sometimes conflicting, requirements [6]. The selection of the appropriate biomass for a bioenergy project is a multi-criteria decision-making (MCDM) problem [7,8]. The choice of biomass can have an impact not only on the project's economic feasibility but also on environmental and social issues [9]. Researchers propose several methods to solve decision-making problems. Among these methods, there is the Analytic Hierarchy Process (AHP), the ELimination and Choice Translating Reality (ELECTRE) method, the Technique of Order of Preference by Similarity to the Ideal Solution (TOPSIS), and the Preference Ranking Organization for Evaluation Enrichment (PROMETHEE) method [10]. They are also suitable for biomass selection problems. Solving this type of problem requires the development of clear criteria to evaluate the available alternatives. This study established a short list of six criteria after thoroughly analyzing the literature and expert opinions. Based on these criteria, a detailed questionnaire was developed and submitted to seven (7) experts selected by the snowball technique to determine their importance.

2. Literature review

This section aims to provide an overview of the importance of biomass selection criteria and the multi-criteria analysis methods used for appropriate biomass selection.

2.1. Selection criteria for bioenergy production

Biomass is recognized as one of the interesting options for the energy transition in developing countries [11]. However, bioenergy development still poses many challenges, mainly; the mobilization of large amounts of biomass, the price and affordability of the energy produced, and the sustainability of the production [12]. The development of sustainable bioenergy projects must consider several factors, encompassing economic, environmental, social, and technical issues. It is, therefore, necessary to have methodical approaches and tools that allow decision-makers to identify the best strategy. Wang et al., 2009 [13] indicated that it is important to develop evaluation criteria to select the most appropriate energy alternatives.

In the literature, researchers have proposed several criteria to select biomass for energy purposes [[14], [15], [16]]. Similarly, the importance of criteria in biomass selection was demonstrated by Pohekar and Ramachandran in 2004 [13]. They indicate that the formulation of criteria is a means that can enable decision-makers to identify and remove barriers to renewable energy development. Table 1 summarizes the criteria used by some authors in their work.

Table 1.

Summary of some criteria used for the selection of biomass for bioenergy.

| Applications | Criteria | Sub-criteria | References |

|---|---|---|---|

| Selection of the most appropriate crops | Irrigation demands, Fertilizer demands, Crop yield production, Labour, Energy plant calorific value | [14] | |

| Sustainable biomass crop selection |

|

|

[15] |

| Sustainable energy crop selection | Photosynthesis type, soil carbon sequestration, water adaptation, N input requirement, erosion control, the yield of dry materials, energy yield | [16] | |

| Selection of biomass materials for bio-oil yield | Lignin, cellulose, hemicellulose, volatile matter, fixed carbon, moisture content, and ash content | [17] | |

| Appropriate biomass resources for energy production selection | Creating technical side jobs, reserving non-renewable energy resources, the relative advantage of biofuel productivity, the complexity of the biofuel production process, cost of the biomass conversion process, biomass reusability, cost of biomass supply, environmental impacts of biomass accumulation, adaptability of the biofuel production process to the size of biomass production units and the attitude and knowledge of the producers, and energy self-sufficiency of the biomass producer | [7] | |

| Microalgal biomass selection for biofuel production |

|

|

[18] |

| Biomass production from crops residues |

|

|

[19] |

| Biomass type selection for boilers | Efficiency, fuel price, ease of operation, global warming potential, and acidification potential | [20] |

The Table 1 shows that several criteria are involved in selecting the appropriate resource for the sustainable bioenergy production. These criteria are often grouped into four sets: economic criteria, environmental criteria, social criteria, and technical criteria. Economic criteria refer to the criteria that may have an economic impact on the production or use of biomass. These criteria are essential when evaluating biomass potential. Its use enables the integration of economic aspects of the problem into its resolution. However, there are no fixed economic criteria. Each project's criteria are defined according to the context and the needs to be considered. Using renewable energy resources, mainly biomass, aims to contribute to protecting the environment. Environmental criteria are introduced to assess the environmental impact of using the biomass resource. As an essential parameter of sustainable development, environmental criteria are essential to assess projects' ecological impact. They are defined according to the context of the project, like the economic criteria, but pollution is generally considered. Failure to consider social factors can contribute to project failure. In the choice of biomass, taking these factors into account is essential. They can make it possible to assess whether biomass competes with food or is subject to other competitive uses. Therefore, considering social criteria is important to assess the social benefit of the choice of biomass. Finally, one of the important parameters that can impact resource use is the technical factor. Indeed, the choice of biomass for energy recovery strongly depends on the availability of the technology to recover it. The consideration of the technical criteria, therefore, allows to raise questions related to the technology (availability, maturity, yield, etc.).

2.2. Multi-criteria decision making (MCDM) for bioenergy

The criteria often have different units (money, time, dimensions, etc.). This makes it very expensive to acquire data and challenging to compare criteria during the decision-making process. Because of this diversity of factors, a multi-criteria decision analysis (MCDM) tool is needed to solve such a problem. Multi-criteria decision-making techniques (MCDM) are tools adapted to the energy sector and can also be used to select appropriate biomasses [14]. Several MCDM approaches are used to solve decision problems in the renewable energy sector [6,21,22]. Each of these methods has advantages and disadvantages. To improve the performance of these methods, some authors proposed hybridizing methods. This consists of combining two or more methods to exploit the advantages offered by each of them [23].

To determine a pilot area for an optimal biomass cultivation plan in the region of Central Macedonia, C. Moulogianni and T. Bournaris, 2017 [19] performed a classification of seven regions according to their biomass production potentials. They used the ELECTRE III method, and the results showed that the agro-energy regions with cereals and arable crops were better than those with fruit trees and other crops. Firouzi et al., 2021 [7], on the other hand, developed a hybrid method based on the combination of three MCDM methods (TOPSIS, ARAS, WASPAS) and three ranking aggregation methods (Borda, Copeland, and Rank Mean) to prioritize suitable biomass resources for biofuel production in Iran. In 2012, M. Van Dael et al., 2012 [24] proposed an AHP model to select potentially attractive locations to establish a biomass project in the Limburg province of Belgium. In Thailand, S. Saelee et al., 2014 [20] used TOPSIS to select the preferred biomass among three alternatives for boilers. The proposed equations were then developed for more general use.

Several authors have also used these approaches to solve the problems of selecting appropriate technologies for biomass energy recovery. To identify the most relevant applications for the use of rice husk in Iran, H. Yaghoubi et al., 2019 [25] used AHP to evaluate the existing potential applications. The results showed that industrial use is the best economic, social, and environmental option. Qazi and Abushammala, 2020 [26] conducted a comprehensive review to select the most suitable waste-to-energy technologies for municipal solid waste valorization. Using the AHP method, they analyzed the main existing technologies. The results gave incineration as the best option. In this sense, O. T. Adenuga et al., 2020 [27] proposed a decision support model based on AHP analysis to select the appropriate technology for waste recovery in South Africa. From the four technologies examined, anaerobic digestion was selected as the best solution. Also, S. M. S. Rahman et al., 2016 [28] used the AHP method to set up a model for selecting an appropriate technology for waste-to-energy conversion in Dhaka. The approach allowed them to identify plasma gasification as the best alternative among the three alternatives studied. Similar studies were conducted by A. Kurbatova and H. A. Abu-Qdais, 2020 [29] in Moscow and A. Agbejule et al., 2021 [30] in Ghana. Using the AHP method, they developed models to determine the best alternative for waste-to-energy in their respective contexts. Using a hybrid Delphi-AHP method, P. Jusakulvijit et al., 2021 [31] developed a decision support model to evaluate Thailand's main criteria and indicators for second-generation bioethanol production. Their results showed that the economic criteria were the most significant. O. Demirtas, 2013 [32]; S. Ahmad and R. M. Tahar, 2013 [33] proposed models using AHP to evaluate the best technologies for renewable energy. A review of the scientific literature is proposed by I. Siksnelyte-Butkiene et al., 2020 [34] to highlight the most used MCDM methods as a tool for evaluating renewable energy technologies in households.

This state-of-the-art has made it possible to highlight a rapidly growing research activity on the use of MCDMs in solving the problems of renewable energies. The works already carried out show considerable progress, with two main families of models: simple models (AHP, TOPSIS, PROMETHEE, etc.) and hybrid models (a combination of several MDCMs). Simple models (AHP, TOPSIS, ELECTRE, etc.) are the most used for decision-making problems [35,36]. These methods are easy to use. However, they have many limitations. AHP, for example, is imprecise in the ranking when the number of elements (criteria, alternatives) becomes significant. Also, the method is dependent on qualitative data. Some also present inaccuracies in the correlation of criteria (TOPSIS). Others, however, need additional tools to finalize the calculations (ELECTRE, PROMETHEE). A comparative study between AHP, TOPSIS, and AHP-TOPSIS (hybrid method) conducted by D. Sharma et al., 2020 [37] showed that AHP combined with TOPSIS was the most accurate at the level of classification followed by AHP and finally TOPSIS. Also, based on execution time, it was TOPSIS, followed by AHP-TOPSIS, and finally, AHP. Individual simple methods are often less effective than hybrid methods [38]. Combining simple methods makes it possible to overcome their limitations and thus improve the accuracy of the results.

However, the complexity of the problems often forces researchers to seek more flexible and more straightforward methods.

3. Materials and methods

3.1. Biomass assessment in Burkina Faso

This section presents the methodology for assessing the potential of the country's main crop and agro-industrial residues. Nine residues will be evaluated, including four crop residues (cotton stalks, millet and sorghum stalks, corn stalks, and cob) and five agro-industrial residues (rice husks, groundnut hulls, cashew hulls, mango peels, and mango pits). The potential of the residues for energy recovery is assessed by considering several important parameters, namely the gross potential of the residues produced, the proportion to be left on the fields to ensure the sustainability of the farm (crop residues), and other competing uses. The calculation of biomass quantities can be done by determining the theoretical potential, the available potential, and the energy potential [4,39].

3.1.1. Theoretical potential

It is calculated from the residue-to-product ratio (RPR) and the raw product production before processing for crop residues and after processing for agro-industrial residues. The theoretical potential represents the total biomass produced by the crops or products evaluated. It is determined according to Equation (1) below:

| (1) |

where: is the quantity of residues produced by the product or the crop ,

the quantity of the production of the product or crop considered and,

residue to product ratio for the product or crop .

The values for the RPR used in this study are shown in Table 2.

Table 2.

| Crops | Residues | RPR |

|---|---|---|

| Millet | Stalks | 3.8 |

| Corn | Cobs | 0.65 |

| Stalks | 1.5 | |

| Rice | Straw | 2.8 |

| Sorghum | Stalks | 3 |

| Cotton | Stalks | 2 |

Data from the Ministry of Agriculture [42,43], and the National Institute of Statistics and Demography (INSD) [44] over the period 2016 to 2020 were used (Table 3).

Table 3.

Annual agricultural production of selected crops from 2016 to 2020 in Burkina Faso in ton.

| Years | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Millet | 905,071 | 828,234 | 1,189,079 | 970,176 | 957,253 |

| Sorghum | 1,663,844 | 1,365,898 | 1,929,834 | 1,871,791 | 1,839,570 |

| Corn | 1,602,525 | 1,533,431 | 1,700,157 | 1,710,898 | 1,920,101 |

| Cotton | 784,784 | 844,343 | 482,173 | 724,232 | 696,636 |

For agro-industrial residues, the RPR presented in Table 4 is used. The production data were obtained from the literature, and some were collected by interviewing local farmers’ associations.

Table 4.

| Products | Residues | Transformation ratio |

|---|---|---|

| Cashew nuts | Shells | 2,1 |

| Peanut | Shells | 0,5 |

| Rice | Husk | 0,21 |

Most of the mangoes processed in Burkina Faso are processed into dried mangoes and mango puree. Without precise data on the share of other products, these two products (Table 5) were used to determine mango residues. Pits represent about 39 % of mango residues, and peels 61 % [48].

Table 5.

Ratio of fresh mango processing to processed mango in Burkina Faso [46].

| Products | Fresh-to-process ratio |

|---|---|

| Dried mango | 20 kg: 1 kg |

| Puree | 2 kg: 1 kg |

It appears from these data that in Burkina Faso, the production of 1 kg kg of dried mango requires 20 kg of fresh mangoes. This generates a significant amount of waste that must be managed. Similarly, for the production of mango puree, 2 kg of fresh mangoes are needed to produce 1 kg of puree.

The data for the last five years (2016–2020) of processed raw materials are summarized in Table 6.

Table 6.

Quantities of rice, mango, and cashew nuts processed and groundnuts produced in Burkina Faso from 2016 to 2020 in ton.

| Years | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Paddy rice | 384,690 | 325,566 | 350,392 | 376,527 | 451,421 |

| Mango | 40,000 | 30,000 | 39,460.4 | 48,600 | 54,300.6 |

| Cashew nuts | 2000 | 5000 | 7000 | 9000 | 10,000 |

| Peanut | 519,345 | 334,328 | 329,783 | 396,129 | 630,526 |

The data illustrates the quantities of products processed locally in the country over the past five years (2016–2020). A jagged variation in production is observed for rice and groundnuts. The low yield, low rainfall can explain this. In addition, there has been an increase in the processing volumes of mangoes and cashew nuts over the years. It is linked, among other things, to the existence of modern processing units, to the good organization of the actors by link and in inter-profession, and also to the willingness of the actors to respond to the ever-increasing demand of the local and international market [1,47].

3.1.2. Available potential

The available or mobilizable potential represents the fraction of the theoretical potential that can be extracted without affecting the competing uses of the different biomass producers and respecting the rights of access and appropriation. The main potential uses of biomass are food (human than animal), bio-fertilizer (soil amendment), production of materials (consumer goods), and energy production (biofuels, heat, electricity). Fig. 1 shows the hierarchy of biomass uses. These uses are potentially in competition, which is why it is necessary to be able to articulate them about environmental and socio-economic issues. These competing uses could reduce the amount of biomass available for bioenergy [48]. The sustainability of the energy use of biomass is possible if the energy yield is optimized, as well as the articulation of uses [49]. Indeed, to ensure the appropriate use of biomass, it is essential to ensure that the share of biomass used does not threaten the local food supply. Then, the exploitation of biomass must not contribute to the degradation of soil quality.

Fig. 1.

Hierarchy of biomass uses adapted from [50].

For this reason, part of the crop residues must be left in the fields to improve or maintain soil fertility or protect it against erosion. Then, the use of biomass for energy production must consider other local uses of biomass (energy supply, medicines, building materials).

The mobilizable potential is determined according to Equation (2).

| (2) |

with: , the available residue potential of the crop or product in tons and

, the recoverable fraction based on several residue use assumptions

According to the FAO recommendations [50], if the residues are produced or collected in the field, 25 % should be left there for soil amendment. Otherwise, if the residues are from industrial activities, 0 % is left. Based on the literature and surveys of the main stakeholders, the usage rates of the different residues studied have been established in Table 7 below.

Table 7.

Rate of use of crops and agro-industry residues in Burkina Faso.

| Residues | The proportion used (%) | Uses |

|---|---|---|

| Cotton stalks | 0 | – |

| Millet and sorghum stalks | 100 | Fuels, soil amendment, animal fodder |

| Corn stalks and cob | 100 | Fuels, compost, animal fodder |

| Peanut shell | 100 | Fuels, compost, animal fodder |

| Rice husk | 80 | Fuels, poultry litter |

| Cashew nutshell | 20 | Fuels |

| Mango pits and peelings | 0 | – |

3.1.3. Energy potential

The energy potential is determined by multiplying the lower heating value (LHV) by the available potential, as shown in Equation (3).

| (3) |

With the gross energy potential of the residues of the crop or product in tons of oil equivalent (toe) and the net calorific value of the residues of the crop or product in Megajoule per kilogram (MJ/kg). Table 8 shows the LHV of the residues studied.

Table 8.

Lower Heating Values (LHV) of crop agro-industrial residues.

3.2. Problem statement

In the literature, very few studies have focused on selecting crop and agro-industrial residues for bioenergy purposes. However, biomass from agriculture and agro-industries, once under-exploited, is of great interest for certain activities, mainly livestock breeding [40] and domestic energy. This strong interest in biomass can compromise or even limit the availability of biomass for energy recovery with modern technologies. Thus, for profitable and viable bioenergy projects, defining criteria that will allow the best possible choice of biomass to be used is very important. These criteria must consider the abovementioned factors; their relationships and relative importance must also be determined. In this work, we are interested in determining the most appropriate biomass for bioenergy production in Burkina. So, the hybrid AHP-TOPSIS approach was adopted. Based on the literature and expert opinions, six evaluation criteria were defined to analyze potential alternatives (biomasses).

3.3. Criteria and alternatives examined

3.3.1. Criteria

The criteria defined are the ones that consider environmental, technical, and socio-economic issues in the choice of biomass for responsible and sustainable use. These are global criteria, and other criteria or sub-criteria could be included. The criteria used are described in Table 9 below.

Table 9.

Evaluation criteria used.

| Criteria | Description |

|---|---|

| Biomass availability and accessibility (DA) | The selected biomass must be available in sufficient volume at accessible production sites with the possibility of increasing the production volume in a short period. |

| Competing use (CU) | The selection of biomass for energy production should not threaten the food supply or other local uses (traditional energy supply, medicine, building materials). |

| Pollution Potential (PP) | The use of the selected biomass must contribute to reducing the negative impacts of the accumulation of this biomass on water, soil, air, and biodiversity. |

| Economic impact (EI) | Using the selected biomass must contribute to reducing losses and shortfalls and promote the development of the local economy. |

| The energy content of the biomass (EC) | The amount of energy recovered from the selected biomass must be attractive. |

| Availability of appropriate technologies (DT) | Biomass for which mature recovery technologies exist is preferred. |

3.3.2. Alternatives

-

-

Crop residues

Agriculture in Burkina Faso generates a significant quantity of residues. In 2018, the theoretical potential of these residues was estimated at 4,342,127 tons of sorghum stalks, 2,016,664 tons of maize stalks, 1,092,356 tons of maize cobs, and 964,346 tons of cotton stalks “CT” [4]. The interest in these biomasses is because some are still very low exploited or valorized.

-

-

Agro-industrial residues

The agro-industrial residues studied are woody residues from the activities of the main agro-industrial units in the country.

Rice husk “RH” in 2018, the national rice production was estimated at 160,949 tons [44]. This production generated a theoretical potential of 32,486 tons of rice husk, of which the mobilizable part for energy purposes was estimated at 6497 tons [4]. In 2020, the rice production potential increased to 201,734 tons [43], with an increase of more than 40,000 tons. This also implies an increase in the residues produced. A significant portion of the rice husk produced remains untapped.

Groundnut hulls: production of groundnut hulls increased significantly between 2018 and 2020 with the increase in national groundnut production. Indeed, in 2018, 329,783 tons of peanuts were produced. This production could generate approximately 112,126 tons of hulls. In 2020, peanut production increased to 630,526 tons. This was almost double the national production of nuts. However, due to the lack of organization in the sector, this potential remains too diffuse and difficult to mobilize.

Cashew nuts “CNUT”: The cashew nut sector has great potential in Burkina Faso. In 2017, cashew products occupied the fourth place among exported products [1]. The national production of raw nuts in 2018 was estimated at more than 85,000 tons [57]. Most of these raw nuts produced are exported to India, Vietnam, and Ghana. Only about 10 % of the production is processed locally. After processing, the shells are often used as fuel in nut processing. However, cashew nut processing units in Burkina regularly face issues in managing the shells produced because they cannot fully valorize. This is why initiatives to valorize these shells have been developed in high-production areas [3]. The main technologies used are pyrolysis, briquetting, combustion in boilers or adapted stoves, and the production of cashew nut shell liquid (CNSL).

Mango peels “MPE” and pits “MPI”: Burkina Faso is part of the mango production basin in West Africa [58]. High-producing regions are the Cascades, the Hauts-Bassins, and the Centre-Ouest. National production in 2019 is estimated at 200,000 tons of fresh mangoes [46]. The mangoes produced are either exported as fresh or processed locally into dried mango, puree, jam, or juice. There are more than 100 mango processing units. These units generate significant waste, estimated at nearly 100,000 tons per year. These residues are essentially mango peelings and pits. This waste constitutes a source of feedstock that can be used for bioenergy production. The peels can be valorized by methanization or fermentation to produce biogas or bioethanol.

3.4. Data collection

Data collection for this study involved interviews with experts in various biomass-related fields in Burkina Faso. These interviews were conducted to gather valuable information. In addition, a thorough review of existing literature was carried out, leading to the identification of ten main criteria that could potentially have an impact on biomass source selection. The criteria have therefore been validated by experts considering the study context during a workshop.

As a result, some criteria were combined and others reformulated. Following this rigorous analysis, six key criteria emerged as the most relevant. Based on these criteria, a questionnaire was drawn up using Saaty's fundamental pairwise comparison scale [59] (Table 10). This questionnaire was then distributed to the experts to evaluate the various criteria. The Analytical Hierarchy Process (AHP) methodology was then used to determine the weight of each of the selected criteria.

Table 10.

Saaty's fundamental pairwise comparison scale [59].

| Definition | Abbreviation | Corresponding value |

|---|---|---|

| Equal importance | E | 1 |

| Moderate importance | W | 3 |

| Strong importance | FS | 5 |

| Very strong importance | VS | 7 |

| Extreme importance | AS | 9 |

| Intermediate values | - | 2, 4, 6, 8 |

For the evaluation of alternatives, biomass availability (AD) data are taken from the results of the residue evaluation conducted above. Competing uses (CU) are obtained from the literature and field surveys. Technology availability (DT) is derived from an inventory of technologies available in the country for each type of biomass. The technologies identified are combustion, gasification, pyrolysis, methanization, briquetting, rice husk kiln, and small carbonizers [3]. The residues' energy contents (EC) were taken from the literature. The economic impact (EI) was obtained from expert assessment. The pollution potential (PP) is determined by evaluating the Global Warming Potential (GWP) of the GHGs assessed and produced during the disposal of a kiloton of each residue in a year.

In Burkina Faso, cotton stalks are generally burned in the fields at the beginning of the rainy season. This activity is an important source of methane, carbon monoxide, nitrous oxide, and nitrogen oxide emissions [[60], [61], [62]]. For the assessment of GHG, only methane (CH4) and nitrous oxide (N2O) [63] are considered. Their different emissions are determined according to Equation (4) [[63], [64], [65], [66]].

| (4) |

Emission is the amount of GHG (CH4 or N2O) emitted, is the amount of biomass burned, is the emission factor, and is the type of biomass burned.

In the present study, the evaluation is done on one biomass unit to maintain the criteria's independence. The EF considered is 3.3 g/kg for methane [67] and 0.07 g/kg for N2O [63].

The agro-industrial residues are generally disposed of in landfills in Burkina Faso [3]. This results in the high production of methane. The emission of methane under these conditions is determined according to Equation (5) [63].

| (5) |

With , the amount of biomass in landfills, taken as one unit, is the methane correction factor that corrects for a fraction of waste that decomposes under anaerobic conditions and is taken as 0.4 [65]. is the fraction of degradable organic carbon and was set as 0.15 for mango peels, the default value for food waste, 0.5 for rice husk and cashew hulls, and 0.43 for mango pits. is the fraction of that is converted to landfill gas and was taken as the default value of 0.77 [65]. is the fraction of methane in the landfill gas, and the default value of 0.5 was used [63,68]. Then, the different gases were converted to kiloton CO2 equivalent. The GWPs for methane and nitrous oxide used are 25 and 298, respectively [66].

Regarding the attributes of the criteria, UC is better when its value is smaller but for the other criteria, the larger their values, the better.

3.5. Hybrid AHP-TOPSIS method

This study uses the hybrid AHP-TOPSIS method to determine the best alternative. AHP is used to provide the order and magnitude of the criteria preferences as well as the consistency of the data. In this work, the comparison matrix was filled using the geometric mean technique described by Buckley [69] to pool the different scores provided by the experts. The equation below is used (Equation (6)).

| (6) |

where is the number of respondents.

The consistency of the matrix used is determined by calculating the consistency ratio () according to Equation (7) below, defined by Saaty [59].

| (7) |

CI is the consistency index determined according to Equation (8):

| (8) |

where is determined by averaging the value of the coherence vector, and represents the order of the matrix.

is a function of the order of the matrix () and is given in Table 11 below.

Table 11.

RI indices to calculate the coherence ratio [10].

| n | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 .58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.51 | 1.54 | 1.56 |

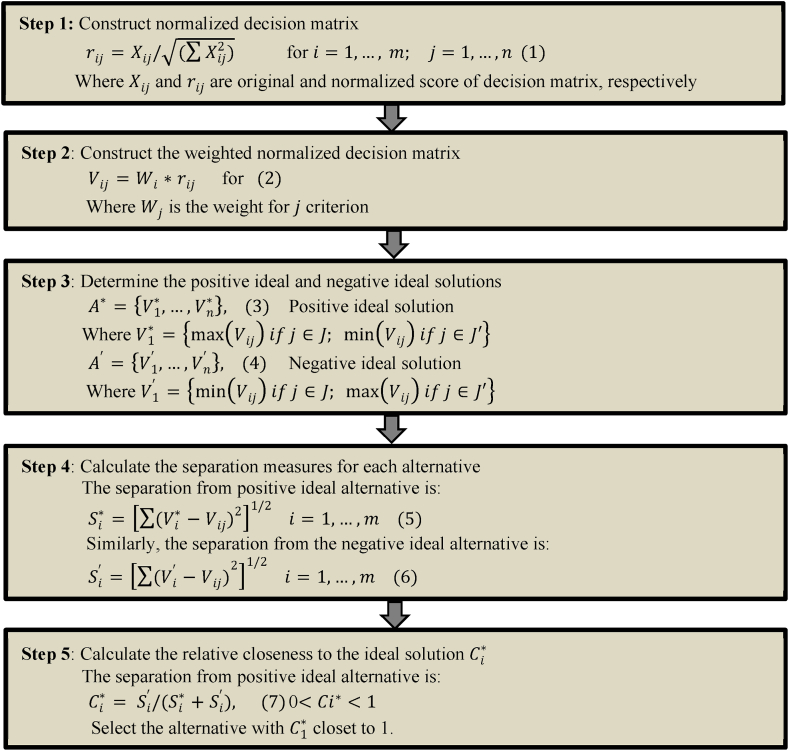

TOPSIS allows the determination of the final ranking of the alternatives by exploiting the weighting derived from AHP. Fig. 2 summarizes the five main steps of the TOPSIS methodology.

Fig. 2.

TOPSIS methodology adapted from [71].

The procedure of the AHP-TOPSIS approach is presented in Fig. 3.

Fig. 3.

AHP-TOPSIS methodology.

3.6. Sensitivity analysis

Sensitivity analysis is a fundamental and mandatory step in the MCDM, given the uncertainties in the data often used [70]. In most cases, it is used to measure variations in the weighting of criteria when ranking alternatives. A solution is then considered stable if it remains valid for different variations. Sensitivity analysis thus enables precise decisions to be made [71].

In this study, the selection of suitable biomass is based on criteria whose weights are determined by AHP analysis. Due to the uncertainty of the data on some criteria, a weight change is likely to affect the ranking obtained. A sensitivity analysis is undertaken to assess the robustness of the ranking when the weights of important criteria in the model are subject to variations.

4. Results and discussion

This section presents the evaluation results of the studied biomass's available, mobilizable, and energy potential. The biomasses studied are crop residues (stalks of millet, sorghum, corn, cotton, and corn cobs) and agro-industrial residues (rice husks, cashew nut shells, peanut shells, and mango residue). This section also presents and discusses the results of the multi-criteria and sensitivity analyses for selecting the appropriate biomass.

4.1. Potential of crop and agro-industrial residues

4.1.1. Theoretical potential

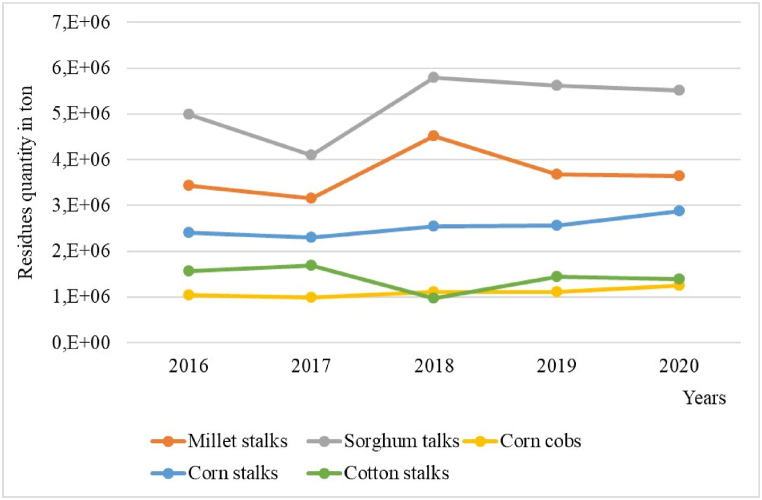

The theoretical potential of the evaluated crop residues is illustrated in Fig. 4.

Fig. 4.

Theoretical crop residue potential.

There is significant production of crop residues in the country. These results show that sorghum residues rank first, followed by millet, corn stalks, cotton, and corn cobs. It should also be noted that sorghum and millet are the main food crops and the most consumed in Burkina.

The analysis of Fig. 4 shows a relative increase in corn and sorghum residues since 2016. However, a decrease in millet residues starting from 2018 is observed. This can be explained by poor rainfall and yield and the country's security situation, which forces farmers to leave production areas. There is also a sawtooth variation in cotton stalks, with a significant drop in 2018 before resuming growth in 2019. The same factors mentioned above could also justify this decrease.

Agro-industrial activities are also sources of biomass in the country. Fig. 5 shows the results of evaluating the theoretical potential of the main residues generated.

Fig. 5.

Theoretical potential of agro-industrial residues.

These results show a strong evolution of the different residues over the years. This is explained by the increasing demand for products and the willingness of stakeholders to increase the capacity of processing units to meet this demand. For example, from a processing capacity of 13,500 t/year in 2015, the cashew processing capacity has increased to 40,000 t/year in 2021. The Burkinabe Cashew Council (CBA) plans to increase this capacity to 90,000 t/year within the next few years to meet the high market demand for almonds. This means that the potential of cashew nut shells will increase significantly next years. Following this example, Fig. 5 shows that the production of mango residues has also increased significantly since 2016, from 15,211 tons to 31,874 tons of kernels in 2020 and from 2393 tons to 49,854 tons of peels in 2020. Mango processing in Burkina Faso is a developing activity, and processing capacities are increasing because of the potential of the local and international markets. Like other products, rice processing in Burkina Faso also produces significant waste. The rice husk produced rose from 35,733 tons in 2016 to 42,364 tons in 2020 and is projected to keep increasing in the coming years.

The production of all of these residues is increasing significantly with the increase in the capacity of processing units and the new incentive policies for the local processing of products.

4.1.2. Mobilizable potential

Biomass mobilization for energy must respect the hierarchy of uses [72,73]. These uses are factors that can significantly reduce the availability of biomass [48,74]. Considering Burkina Faso's other uses of crop residues, only cotton stalks are available for energy production. In determining this availability, the FAO recommendation on using residues harvested in the fields was applied [50]. A recovery factor of 75 % was therefore applied. Fig. 6 shows the results of mobilizable potentials of residues.

Fig. 6.

Available potential of cotton stalks (a); Available potential of agro-industrial residues (b).

These results show that in 2018 Burkina Faso had a mobilizable cotton stalk potential of around 723,259.5 tons (Fig. 6 (a)). These results corroborate those obtained by F. Barry et al., 2021 [4], who had estimated this potential at 723,260 tons. The available potential of cotton stalks rose from 2018 to 2020 to 1,044,954 tons, an increase of around 44.42 % due to solid incentive policies and good rainfall. For agro-industrial residues, between 2018 and 2020, the mobilizable potential of rice husks rose from 6759.85 tons to 8472.82 tons, an increase of 25.34 %, that of cashew nut shells from 4480 tons to 6400 tons, an increase of 42.85 %, and that of mango residues from 58,049.883 tons (pits and peelings) to 81,728.44 tons, an increase of around 40.8 % (Fig. 6 (b)). These production increases can be explained by the dynamism of the country's agro-industrial sector, with regular growth in production capacity, and by the political will to increase local processing of these products. However, these residues, which are still under-utilized, could lead to environmental and health problems for the population.

Energy recovery from these residues could help solve these problems and improve the country's energy access conditions. Several locally feasible technologies could help achieve this objective, including gasification, pyrolysis, combustion, briquetting, and methanization [3]. Table 12 shows the energy potential of the various residues from 2016 to 2020.

Table 12.

Energy potential of residues in toe.

| Residues | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Cotton stalks | 19,187,968.8 | 20,644,186.35 | 11,789,129.85 | 17,707,472.4 | 17,032,750.2 |

| Rice husk | 106,484.87 | 103,310.81 | 100,721.88 | 110,926.8 | 126,245.13 |

| Cashew nutshells | 27,264 | 68,160 | 95,424 | 122,688 | 136,320 |

| Mango pits | 279,899.88 | 225,871.77 | 416,565.96 | 438,995.24 | 586,483.28 |

| Mango peels | 466,343.78 | 376,327.05 | 694,044.4 | 731,414.03 | 977,145.22 |

4.2. Selection of appropriate biomass by implementing AHP-TOPSIS

4.2.1. Criteria weighting

The comparison matrix from the experts' scores is presented in Table 13. It is used to determine the weights of the different criteria. To evaluate the consistency index, λmax was calculated. The parameters used to evaluate the consistency of the matrix are recorded in Table 14. As a reminder, six criteria were considered for biomass selection, including the availability and accessibility of biomass (DA), competing uses (UC), pollution potential (PP), economic impact (EI), the energy content of biomass (EC), and availability of appropriate technologies (DT). Using the AHP approach, the criteria were evaluated to determine their order of importance. The calculated consistency ratio is 0.082, below 0.1, reflecting the consistency of the matrix.

Table 13.

Criteria pairwise comparison matrix.

| Criteria | DA | UC | PP | IE | CE | DT |

|---|---|---|---|---|---|---|

| DA | 1 | 4.21 | 7.45 | 1.5 | 1.73 | 5.54 |

| UC | 0.24 | 1 | 2.82 | 3.41 | 0.81 | 1.34 |

| PP | 0.13 | 0.35 | 1 | 0.27 | 0.48 | 0.8 |

| IE | 0.67 | 0 | 3.70 | 1 | 0.91 | 1.5 |

| CE | 0.58 | 1.23 | 2.08 | 1.10 | 1 | 1 |

| DT | 0.18 | 0.75 | 1.25 | 0.67 | 1.00 | 1 |

Table 14.

Parameters for determining the consistency of the matrix.

| λmax | Consistency index |

Consistency ratio |

Random index |

|---|---|---|---|

| CI = (λmax-n)/(n-1) | CR = CI/RI | RI(n) | |

| 6.509 | 0.102 | 0.082 | 1.24 |

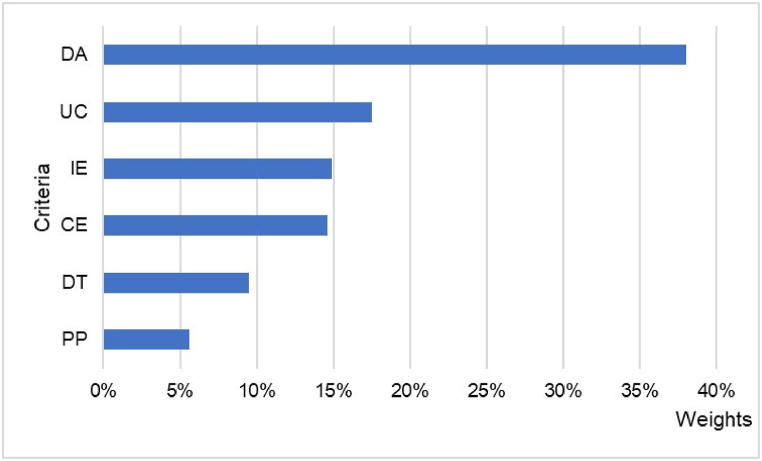

From the above, Fig. 7 illustrates the order of priority of the different criteria.

Fig. 7.

Prioritization of criteria.

According to expert opinion, the DA criterion is the most important factor, weighing 38 %. The importance given to these criteria can be justified by the need to be able to meet the demands of valorization units. The highly dispersed nature of biomass resources in the country, spatially and temporally, and the inadequacy of road infrastructure can considerably hamper supply chains. Therefore, in Ref. [31] academic and research institutes, non-governmental organizations, and NGOs also prioritized this criterion. Its paramount importance has also been emphasized by Refs. [[75], [76], [77], [78]]. The second important criterion, according to the experts, is competing uses (17.5 %). As demonstrated by D. Alfonso et al., 2009 [79], competitive uses of biomass are key factors to consider in biomass exploitation. Since biomass is a resource still widely used in production areas for livestock feed and energy supply, strong competitive uses can lead to disruptions in biomass availability or price rises. The expert analysis results showed that the economic impact criterion is the third key factor in biomass selection, weighing 14.9 %. P. Jusakulvijit et al., 2021 [31] also defined this criterion as very important in their work. Concerns about investment costs, profitability, and possible financial incentives for investors can explain the importance given to this factor by experts. The results also spotlight the energy balance factor, particularly energy content (CE). According to the experts, this is the fourth key factor. This interest could be explained by the fact that this factor significantly impacts conversion costs and yields. Moreover, in Thailand, this criterion was considered the highest priority by industrial and commercial players [31]. Similar to the results obtained in Refs. [7,8], the weight of criteria related to the environment (PP) and conversion technologies (DT) are the least important. This low ranking could be explained by some experts' impoverished current understanding of environmental issues and the relative availability of biomass conversion technologies.

4.2.2. Selection of alternatives

The data used in the analysis of the alternatives are presented in Table 15.

Table 15.

Data of the different alternatives.

| Weight |

0,38 |

0,175 |

0056 |

0,149 |

0,146 |

0,095 |

|---|---|---|---|---|---|---|

| Criteria |

DA |

UC |

PP |

IE |

CE |

DT |

| Unit | t | % | KtCO2eq/y | - | MJ/kg | - |

| CT | 1044951 | 0 | 0.12 | 15.1 | 16.30 | 5 |

| RH | 8472.830 | 80 | 2.566 | 36 | 14.900 | 4 |

| CNUT | 6400 | 20 | 2.566 | 28.1 | 21.300 | 5 |

| MPE | 49854.350 | 0 | 0.77 | 11.7 | 13.16 | 1 |

| MPI | 31874.092 | 0 | 2.202 | 9 | 18.010 | 5 |

This AHP-TOPSIS analysis yielded the results in Table 16.

Table 16.

Ranking of alternatives.

| Residues | Relative closeness (C*) | Rank |

|---|---|---|

| Cotton stalks (CT) | 73.6 | 1 |

| Mango pits (MPI) | 70.4 | 2 |

| Mango peels (MPE) | 30.7 | 3 |

| Cashew nutshells (CNUT) | 28 | 4 |

| Rice husk (RH) | 15.3 | 5 |

The results show that cotton stalks (CT) (C* = 0.736), mango pits (C* = 0.704), and mango peels (C* = 0.307) are the three best biomass resources for sustainable bioenergy production in Burkina, considering the six criteria defined here.

Rice husk is ranked last in this analysis. These results are consistent with the realities observed in the field. Indeed, rice husk is a much-used resource for livestock feed and litter production. Therefore, the availability of this resource for energy purposes is very low. Similarly, in recent years there has been a great deal of interest in cashew nut shells by agro-industrial units. Previously unexploited, these shells are now used as fuel in cashew processing and mango-drying units. Other local initiatives are working on the valorization of this residue into biochar. These competing uses contribute to the reduction of the availability of this biomass. However, a significant portion of this biomass, approximately 80 %, is still untapped. With increasing production and transformation capacities, an urgent need to manage these residues arises. Bioenergy seems to be an interesting alternative to explore in managing these residues. These results also show that residues with low competitive and available uses are preferred.

4.3. Sensitivity analysis results

The sensitivity analysis results were obtained based on scenarios to assess the robustness of the ranking obtained. For the construction of the scenarios, biomass availability and accessibility (DA) and competing use (UC) were the varied criteria. Data on biomass energy content (EC) and pollution potential (PP) are not subject to uncertainty. Also, the criteria of economic impact (IE) and availability of appropriate technologies (DT) have low weights and therefore have little influence on the ranking. Sensitivity was assessed based on two sets of five scenarios, described as follows:

Serie 1: the weight of Competing Use (UC) was kept constant at 17.5 %, and Biomass availability and accessibility (DA) was varied with a step of 10 from 8 % to 48 %.

Serie 2: Biomass availability and accessibility (DA) was kept constant at 38 %, and Competing Use (UC) was varied by 7.8 % with a step of 10–47.5 %. Fig. 8 shows the results of set 1.

Fig. 8.

Sensitivity analysis following scenario set 1.

The results of this series show that cotton stalks (CT) are ranked first under all series scenarios, followed by mango pits with relative closeness (C*) close to each other.

Mango Peels drop to fourth place at the expense of Cashew Shells in the first scenario before regaining third place in the second scenario. This implies that the classification of peels has been very sensitive to competing uses (UC). Indeed, in the original assessment, these residues had no other uses. Applying a high usage of 17.5 % to these residues lowered their availability. Thus, exploiting biomasses with no competing uses at the start could face major difficulties if competing uses appear, which is not followed by a good increase in availability (Fig. 8). The scenario results show the importance of the other biomass selection criteria, economic impact (IE), energy content (CE), and technologies availability (DT) in addition to competing use (UC) and biomass availability (DA).

Rice husk remains the least appropriate in all scenarios in both series. Fig. 9 shows the ranking for the different scenarios in series 2.

Fig. 9.

Sensitivity analysis of series 2 scenarios.

When competing use (UC) varies, and biomass availability (DA) remains constant (Series 2), mango pits (MPI) and mango peels (MPE) lose their second and third place in the first scenario in favor of cashew nutshells. This is also explained by the fact that these biomasses were not used in other competing uses in addition to their relatively low availability. The introduction of new uses, therefore, impacts the availability of these biomasses and, thus, the ranking. It also appears that the competing use (UC) and biomass availability (DA) criteria are not the only ones involved in the ranking but that it is a combination of different criteria.

In selecting biomasses, the criteria of availability and competing uses alone are insufficient to make an optimal choice. A thorough review must be conducted to determine what other criteria should be considered.

In all scenarios, cotton stalks (CT) remain at the top of the ranking as shown in the Table 17.

Table 17.

Weights of criteria and ranking of alternatives for both series.

| Series | Criteria Weights |

Alternatives rank |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DA (%) | UC (%) | PP (%) | IE (%) | CE (%) | DT (%) | CT | RH | CNUT | MPE | MPI | |

| Serie 1 |

8 |

17.5 |

5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 2nd | 4th | 3rd |

| 18 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 3rd | 2nd | ||

| 28 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 3rd | 2nd | ||

| 38 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 3rd | 2nd | ||

|

48 |

5.6 |

14.9 |

14.6 |

9.5 |

1st |

5th |

4th |

3rd |

2nd |

||

| Serie 2 | 38 | 7.5 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 3rd | 2nd | 5th | 4th |

| 17.5 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 3rd | 2nd | ||

| 27.5 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 2nd | 3rd | ||

| 37.5 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 2nd | 3rd | ||

| 47.5 | 5.6 | 14.9 | 14.6 | 9.5 | 1st | 5th | 4th | 2nd | 3rd | ||

The ranking of the other biomasses remains almost constant in more than half of the ten scenarios studied, illustrating the robustness of the ranking obtained through the AHP-TOPSIS analysis.

5. Conclusion

Bioenergy production from local resources can contribute to developing sustainable energy systems in Burkina Faso. For this, a good choice of biomass to be exploited must be made by considering the main sustainability factors and some technical factors. Multi-criteria decision-making methods could help solve these complex problems. The hybridization of MCDMs allows the exploitation of the strengths of the pooled methods. It is a practical approach to improve the performance of the decision-making process and thus improve the quality of the results. This study proposed a hybrid AHP-TOPSIS model to determine the appropriate biomass for bioenergy production in Burkina Faso. Six criteria were used to evaluate five resources (cotton stalks, rice husks, cashew nuts, mango pits, and mango peels). The results showed that based on the defined criteria, with biomass availability (DA) and competing use (UC) being the predominant criteria, cotton stalks are the best biomass suitable for bioenergy production in Burkina Faso. They are most available and less used in competitive uses. In addition, they have a good energy content (16.3 MJ/kg) and can be used in several technologies. Mango pits and peels come second and third respectively, due to their lack of competitive use and availability. These results could serve as a basis for decision-makers in choosing biomass to establish viable bioenergy systems.

Furthermore, this study must be supplemented by a technical and economic study of the different elements of each link in the sector. This is to facilitate an understanding the adequacy of biomass and technologies and the establishment of viable sectors in Burkina Faso.

Funding statement

This work was supported by the International Institute of Water and Environmental Engineering (2iE) through the Africa Centers of Excellence (ACE) project of the World Bank, particularly the College of Engineering (CoE-2iE) (IDA6388-BF/D443-BF).

Data availability statement

Data will be made available on request.

CRediT authorship contribution statement

Fernand Zoma: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Resources, Software, Validation, Writing – original draft, Writing – review & editing. Marie Sawadogo: Conceptualization, Formal analysis, Funding acquisition, Methodology, Project administration, Resources, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2023.e20999.

Contributor Information

Fernand Zoma, Email: fernand.zoma@2ie-edu.org.

Marie Sawadogo, Email: marie.sawadogo@2ie-edu.org.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

References

- 1.APEX . 2018. Fiche sectorielle : Anacarde du Burkina Faso; pp. 1–10. [Google Scholar]

- 2.INSD . 2018. Rapport d’analyse du VIIème - Recensement industriel et commercial. [Google Scholar]

- 3.Villard S., Sancho J.A., Baguignan Y., Aïde M.S. Capitalisation des technologies innovantes de valorisation des biodéchets. 2018;33(0):71. [Google Scholar]

- 4.Barry F., Sawadogo M., Ouédraogo I.W.K., Traoré/Bologo M., Dogot T. Geographical and economic assessment of feedstock availability for biomass gasification in Burkina Faso. Energy Convers. Manag. X. 2021;13(December):2022. doi: 10.1016/j.ecmx.2021.100163. [DOI] [Google Scholar]

- 5.PANER . Paner; Burkina Faso: 2015. Plan d ’ Action National des Energies Renouvelables. [Google Scholar]

- 6.Scott J.A., Ho W., Dey P.K. A review of multi-criteria decision-making methods for bioenergy systems. Energy. 2012;42(1):146–156. doi: 10.1016/j.energy.2012.03.074. [DOI] [Google Scholar]

- 7.Firouzi S., Allahyari M.S., Isazadeh M., Nikkhah A., Van Haute S. Hybrid multi-criteria decision-making approach to select appropriate biomass resources for biofuel production. Sci. Total Environ. 2021;770 doi: 10.1016/j.scitotenv.2020.144449. [DOI] [PubMed] [Google Scholar]

- 8.Ossei-Bremang R.N., Kemausuor F. A decision support system for the selection of sustainable biomass resources for bioenergy production. Environ. Syst. Decis. 2021;41(3):437–454. doi: 10.1007/s10669-021-09810-6. [DOI] [Google Scholar]

- 9.Cobuloglu H.I., Büyüktahtakin I.E. A multi-criteria approach for biomass crop selection under fuzzy environment. IIE Annu. Conf. Expo. 2014;(Mcdm):4003–4012. 2014. [Google Scholar]

- 10.Tzeng G.-H., Hang J.-J. CRC Press; Boca Raton: 2011. Making, Multiple Attribute Dacision. [Google Scholar]

- 11.Vanegas Cantarero M.M. Of renewable energy, energy democracy, and sustainable development: a roadmap to accelerate the energy transition in developing countries. Energy Res. Social Sci. 2020;70(November 2019) doi: 10.1016/j.erss.2020.101716. [DOI] [Google Scholar]

- 12.Gazull L., Lagrée S. Maison D’édition La Connaiss.; 2015. Les enjeux de la transition énergétique.http://www.planete-energies.com/fr/medias/decryptages/les-enjeux-de-la-transition-energetique?&xtmc=transition energetique&xtnp=1&xtcr=1 [Online]. Available: [Google Scholar]

- 13.Wang J.J., Jing Y.Y., Zhang C.F., Zhao J.H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009;13(9):2263–2278. doi: 10.1016/j.rser.2009.06.021. [DOI] [Google Scholar]

- 14.Kylili A., Christoforou E., Fokaides P.A., Polycarpou P. Multicriteria analysis for the selection of the most appropriate energy crops: the case of Cyprus. Int. J. Sustain. Energy. 2016;35(1):47–58. doi: 10.1080/14786451.2014.898640. [DOI] [Google Scholar]

- 15.Cobuloglu H.I., Büyüktahtakin I.E. A stochastic multi-criteria decision analysis for sustainable biomass crop selection. Expert Syst. Appl. 2015;42(15–16):6065–6074. doi: 10.1016/j.eswa.2015.04.006. [DOI] [Google Scholar]

- 16.Balezentiene L., Streimikiene D., Balezentis T. Fuzzy decision support methodology for sustainable energy crop selection. Renew. Sustain. Energy Rev. 2013;17(2013):83–93. doi: 10.1016/j.rser.2012.09.016. [DOI] [Google Scholar]

- 17.Madhu P., Sowmya Dhanalakshmi C., Mathew M. Multi-criteria decision-making in the selection of a suitable biomass material for maximum bio-oil yield during pyrolysis. Fuel. 2020;277(May) doi: 10.1016/j.fuel.2020.118109. [DOI] [Google Scholar]

- 18.Kokkinos K., Karayannis V., Moustakas K. Optimizing microalgal biomass feedstock selection for nanocatalytic conversion into biofuel clean energy, using fuzzy multi-criteria decision making processes. Front. Energy Res. 2021;8(February):1–20. doi: 10.3389/fenrg.2020.622210. [DOI] [Google Scholar]

- 19.Moulogianni C., Bournaris T. Biomass production from crops residues: ranking of agro-energy regions. Energies. 2017;10(7) doi: 10.3390/en10071061. [DOI] [Google Scholar]

- 20.Saelee S., Paweewan B., Tongpool R., Witoon T., Takada J., Manusboonpurmpool K. “Biomass Type Selection for Boilers Using TOPSIS Multi-Criteria Model,”. 2014;(November) doi: 10.7763/IJESD.2014.V5.474. [DOI] [Google Scholar]

- 21.Sitorus F., Brito-Parada P.R. A multiple criteria decision making method to weight the sustainability criteria of renewable energy technologies under uncertainty. Renew. Sustain. Energy Rev. 2020;127(May) doi: 10.1016/j.rser.2020.109891. [DOI] [Google Scholar]

- 22.Kamari M.L., Isvand H., Nazari M.A. “Applications of multi-criteria decision-making (MCDM) methods in renewable energy development. A Review,”. 2020;1(1):47–54. doi: 10.22044/RERA.2020.8541.1006. [DOI] [Google Scholar]

- 23.Sakthivel G., Ilangkumaran M., Gaikwad A. MECHANICAL ENGINEERING A hybrid multi-criteria decision modeling approach for the best biodiesel blend selection based on ANP-TOPSIS analysis. Ain Shams Eng. J. 2014 doi: 10.1016/j.asej.2014.08.003. [DOI] [Google Scholar]

- 24.Van Dael M., Van Passel S., Pelkmans L., Guisson R., Swinnen G. Determining potential locations for biomass valorization using a macro screening approach. Biomass Bioenergy. 2012;45(0):175–186. doi: 10.1016/j.biombioe.2012.06.001. [DOI] [Google Scholar]

- 25.Yaghoubi H., Allahyari M.S., Firouzi S., Damalas C.A., Marzban S. Identifying sustainable options for rice husk valorization using the analytic hierarchy process. Outlook Agric. 2019;48(2):117–125. doi: 10.1177/0030727018821384. [DOI] [Google Scholar]

- 26.Qazi W.A., Abushammala M.F.M. INC; 2020. Multi-criteria Decision Analysis of Waste-To-Energy Technologies. [DOI] [PubMed] [Google Scholar]

- 27.Adenuga O.T., Mpofu K., Modise K.R. An approach for enhancing optimal resource recovery from different classes of waste in South Africa: selection of appropriate waste to energy technology. Sustain. Futur. 2020;2(January) doi: 10.1016/j.sftr.2020.100033. [DOI] [Google Scholar]

- 28.Rahman S.M.S., Azeem A., Ahammed F. Selection of an appropriate waste-to-energy conversion technology for Dhaka City, Bangladesh. Int. J. Sustain. Eng. 2017;10(2):99–104. doi: 10.1080/19397038.2016.1270368. [DOI] [Google Scholar]

- 29.Kurbatova A., Abu-Qdais H.A. Using multi-criteria decision analysis to select waste to energy technology for a Mega city: the case of Moscow. Sustain. Times. 2020;12(23):1–18. doi: 10.3390/su12239828. [DOI] [Google Scholar]

- 30.Agbejule A., Shamsuzzoha A., Lotchi K., Rutledge K. Application of multi-criteria decision-making process to select waste-to-energy technology in developing countries: the case of Ghana. Sustain. Times. 2021;13(22) doi: 10.3390/su132212863. [DOI] [Google Scholar]

- 31.Jusakulvijit P., Bezama A., Thrän D. Criteria prioritization for the sustainable development of second-generation bioethanol in Thailand using the Delphi-AHP technique. Energy. Sustain. Soc. 2021;11(1):1–25. doi: 10.1186/s13705-021-00313-5. [DOI] [Google Scholar]

- 32.Demirtas O. Evaluating the best renewable energy technology for sustainable energy planning. Int. J. Energy Econ. Pol. 2013;3(SPECIAL ISSUE):23–33. [Google Scholar]

- 33.Ahmad S., Tahar R.M. Selection of renewable energy sources for sustainable development of electricity generation system using analytic hierarchy process: a case of Malaysia. Renew. Energy. 2014;63:458–466. doi: 10.1016/j.renene.2013.10.001. [DOI] [Google Scholar]

- 34.Siksnelyte-Butkiene I., Zavadskas E.K., Dalia S., Streimikiene D. The assessment of renewable energy technologies in a household : a review. Energies. 2020;13(Mcdm):1164. https://www.mdpi.com/1996-1073/13/5/1164 [Online]. Available: [Google Scholar]

- 35.Kaya İ., Çolak M., Terzi F. Use of MCDM techniques for energy policy and decision-making problems: a review. Int. J. Energy Res. 2018;42(7):2344–2372. doi: 10.1002/er.4016. [DOI] [Google Scholar]

- 36.Emovon I., Oghenenyerovwho O.S. Application of MCDM method in material selection for optimal design: a review. Results Mater. 2020;7(June) doi: 10.1016/j.rinma.2020.100115. [DOI] [Google Scholar]

- 37.Sharma D., Claudio D., Sridhar S. “Comparison of AHP-TOPSIS and AHP-AHP methods in multi-criteria decision-making problems Deepak Sharma *. Srinivasan Sridhar and. 2020;34(2):203–223. [Google Scholar]

- 38.Asadabadi M.R., Chang E., Saberi M. Are MCDM methods useful? A critical review of analytic hierarchy process (AHP) and analytic network process (anp) Cogent Eng. 2019;6(1):1–11. doi: 10.1080/23311916.2019.1623153. [DOI] [Google Scholar]

- 39.Kemausuor F., Kamp A., Thomsen S.T., Bensah E.C., Stergård H. Assessment of biomass residue availability and bioenergy yields in Ghana. Resour. Conserv. Recycl. 2014;86:28–37. doi: 10.1016/j.resconrec.2014.01.007. [DOI] [Google Scholar]

- 40.FAO . 2014. Résidus agricoles et sous-produits agro-industriels en Afrique de l'Ouest. [Google Scholar]

- 41.Lal R. World crop residues production and implications of its use as a biofuel. Environ. Int. 2005;31(4):575–584. doi: 10.1016/j.envint.2004.09.005. [DOI] [PubMed] [Google Scholar]

- 42.DGESS Annuaire des statistiques agricoles. 2019:2020. [Google Scholar]

- 43.DGESS . 2021. Annuaire des statistiques agricoles 2020.https://pacte.agriculture.bf/wp-content/uploads/2020/02/Annuaire-des-Statistiques-Agricoles-2018-MAAH-2020.pdf [Online]. Available: [Google Scholar]

- 44.INSD “Annuaire statistique 2020,”. 2020. https://www.sante.gov.bf/fileadmin/user_upload/storages/annuaire_statistique_ms_2020_signe.pdf [Online]. Available:

- 45.Terrapon-Pfaff J.C. Linking energy- and land-use systems: energy potentials and environmental risks of using agricultural residues in Tanzania. Sustainability. 2012;4(3):278–293. doi: 10.3390/su4030278. [DOI] [Google Scholar]

- 46.Logic Agri. Rvo; 2019. Analyse de la chaîne de valeur des fruits transformés au Burkina Faso, au Mali et en Côte d'Ivoire. [Google Scholar]

- 47.COLEACP, “Profil de marché: La mangue du Burkina Faso.”.

- 48.Morato T., Vaezi M., Kumar A. Assessment of energy production potential from agricultural residues in Bolivia. Renew. Sustain. Energy Rev. 2019;102(November 2018):14–23. doi: 10.1016/j.rser.2018.11.032. [DOI] [Google Scholar]

- 49.Stratégie Nationale de Mobilisation de la Biomasse.”.

- 50.FAO . 2014. “Bioénergie et sécurité alimentataire évaluation rapide (BEFS RA) Manuel d'Utilisation. [Google Scholar]

- 51.Diedhiou A., Ndiaye L.G., Bensakhria A., Sock O. Thermochemical conversion of cashew nut shells, palm nut shells and peanut shells char with CO2 and/or steam to aliment a clay brick firing unit. Renew. Energy. 2019;142:581–590. doi: 10.1016/j.renene.2019.04.129. [DOI] [Google Scholar]

- 52.INGESAHEL “Etude De Faisabilite D’Une Valorisation Des Residus Agricoles Et Agro-Industriels Comme Combustibles Domestiques Au Senegal,”. 1998;221:1–28. [Google Scholar]

- 53.Godjo T., Tagutchou J.-P., Naquin P., Gourdon R. Valorisation des coques d’anacarde par pyrolyse au Bénin. Déchets, Sci. Tech. 2015;N°70:11–18. doi: 10.4267/dechets-sciences-techniques.3282. [DOI] [Google Scholar]

- 54.Tagutchou J.-P., Naquin P. Caractérisation et traitement thermochimique des coques d’anacarde en vue de leur valorisation énergétique dans les procédés de transformation artisanale de noix de cajou. Déchets, Sci. Tech. 2012;62:21–24. doi: 10.4267/dechets-sciences-techniques.2722. [DOI] [Google Scholar]

- 55.Jekayinfa S.O., Omisakin O.S. The energy potentials of some agricultural wastes as local fuel materials in Nigeria. Agric. Eng. Int. CIGR J. 2005;7:1–10. [Google Scholar]

- 56.“Mango sector/Characterization of waste - Biostar - Bionergy For Smes In West Africa.” https://www.biostar-afrique.org/en/the-sectors/characterization-of-waste/mango-sector (accessed July. 20, 2022)..

- 57.n’kalô . Afrique De L’ouest; 2018. “Bilan De Campagne De Commercialisation Anacarde | 2018. [Google Scholar]

- 58.Parrot L., Biard Y., Kabré E., Klaver D., Vannière H. 2017. Analyse de la chaîne de valeur mangue au Burkina Faso. [Google Scholar]

- 59.Saaty T.L. 1989. How to Make a Decision: the Analytic Hierarchy Process. [Google Scholar]

- 60.Wikström H., Adolfsson R. Field Burning of Crop Residues. 2004;62 [Google Scholar]

- 61.E. Cassou, “Agricultural Pollution Field Burning.”.

- 62.FAO . 2015. Estimating Greenhouse Gas Emissions in Agriculture. [Google Scholar]

- 63.IPCC . 2006. Guidelines for National Greenhouse Gas Invebtories. [Google Scholar]

- 64.Yuxiang L.U.O., Wei W., Xiao W.A.N., Zhou D., Cuiping Z.H.U. Estimation of methane and nitrous oxide emissions from biomass waste in China : a case study in Hebei Province. January. 2010 doi: 10.1007/s11431-009-0411-y. [DOI] [Google Scholar]

- 65.D. Cardoen, P. Joshi, L. Diels, P. Sarma, and D. Pant,“Agriculture Biomass in India : Part 2. Post-harvest Losses , Cost and Environmental Impacts .”.

- 66.Ministère de l'Environnement et de la Lutte contre les Changements Climatiques (MELCC), Guide de quantification des émissions de gaz à effet de serre. 2019. [Google Scholar]

- 67.Laris P., et al. Methane gas emissions from savanna fires: what analysis of local burning regimes in a working West African landscape tell us. Biogeosciences. 2021;18(23):6229–6244. doi: 10.5194/bg-18-6229-2021. [DOI] [Google Scholar]

- 68.Xin C., Zhang T., Tsai S., Zhai Y., Wang J. 2020. Applied Sciences an Empirical Study on Greenhouse Gas Emission Calculations under Di Ff Erent Municipal Solid Waste Management Strategies. [Google Scholar]

- 69.Buckley J.J. Fuzzy hierarchical analysis. Fuzzy Set Syst. 1985;17(3):233–247. doi: 10.1016/0165-0114(85)90090-9. [DOI] [Google Scholar]

- 70.Munier N., Hontoria E., Jiménez-Sáez F. 2019. Strategic Approach in Multi-Criteria Decision Making A Practical Guide for Complex Scenarios. [Google Scholar]

- 71.Amini A., Alinezhad A. Sensitivity analysis of TOPSIS technique: the results of change in the weight of one attribute on the final ranking of alternatives. J. Optim. Ind. Eng. 2011;7(2011):23–28. [Google Scholar]

- 72.Gérault L., Bonneville A. 2019. Schéma régional biomasse des pays de la loire. [Google Scholar]

- 73.Ladanai S., Vinterbäck J. “Certification Criteria for Sustainable,”. 2010 [Google Scholar]

- 74.Milhau A., Fallot A. Assessing the potentials of agricultural residues for energy: what the CDM experience of India tells us about their availability. Energy Pol. 2013;58:391–402. doi: 10.1016/j.enpol.2013.03.041. [DOI] [Google Scholar]

- 75.Cutz L., Haro P., Santana D., Johnsson F. Assessment of biomass energy sources and technologies: the case of Central America. Renew. Sustain. Energy Rev. 2016;58:1411–1431. doi: 10.1016/j.rser.2015.12.322. [DOI] [Google Scholar]

- 76.Amer M., Daim T.U. Selection of renewable energy technologies for a developing county: a case of Pakistan. Energy Sustain. Dev. 2011;15(4):420–435. doi: 10.1016/j.esd.2011.09.001. [DOI] [Google Scholar]

- 77.Kheybari S., Rezaie F.M., Naji S.A., Najafi F. Evaluation of energy production technologies from biomass using analytical hierarchy process: the case of Iran. J. Clean. Prod. 2019;232:257–265. doi: 10.1016/j.jclepro.2019.05.357. [DOI] [Google Scholar]

- 78.Van Holsbeeck S., Srivastava S.K. Feasibility of locating biomass-to-bioenergy conversion facilities using spatial information technologies: a case study on forest biomass in Queensland, Australia. Biomass Bioenergy. 2020;139(May) doi: 10.1016/j.biombioe.2020.105620. [DOI] [Google Scholar]

- 79.Alfonso D., Perpiñá C., Pérez-Navarro A., Peñalvo E., Vargas C., Cárdenas R. Methodology for optimization of distributed biomass resources evaluation, management and final energy use. Biomass Bioenergy. 2009;33(8):1070–1079. doi: 10.1016/j.biombioe.2009.04.002. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.