Summary

Solar-driven thermochemical conversion of H2O and CO2 into sustainable fuels, based on redox cycle, provides a promising path for alternative energy, as it employs the solar energy as high-temperature heat supply and adopts H2O and CO2 as initial feedstock. This review describes the sustainable fuels production system, including a series of physical and chemical processes for converting solar energy into chemical energy in the form of sustainable fuels. Detailed working principles, redox materials, and key devices are reviewed and discussed to provide systematic and in-depth understanding of thermochemical fuels production with the aid of concentrated solar power technology. In addition, limiting factors affecting the solar-to-fuel efficiency are analyzed; meanwhile, the improvement technologies (heat recovery concepts and designs) are summarized. This study therefore sets a pathway for future research works based on the current status and demand for further development of such technologies on a commercial scale.

Subject areas: Engineering, Energy sustainability, Energy materials

Graphical abstract

Engineering; Energy sustainability; Energy materials

Introduction

Energy crisis and carbon neutrality are becoming trending topics across the globe, particularly in the power and energy sector in recent years. Relevant data show that over 80% of the global energy consumption is supplied by fossil fuels while only about 14% are derived from sustainable and renewable energy sources.1,2,3 This therefore indicates that the world is experiencing severe challenges in providing clean and sustainable energy for our present society which is confronted by severe energy and environmental issues. It is thus of significant importance to earnestly develop and utilize sustainable and renewable energy sources. The International Renewable Energy Agency (IRENA) recently reported the predicted share of renewable energy to be 28% by 2030 and 66% by 2050 in the global energy outlook.4 In other words, renewable energy is entering a new stage of development, and its explosive development will occur in the future.

Liquid hydrocarbon fuels (such as methanol, gasoline, diesel, kerosene, etc.) with high energy density have received wide applications in various industries due to their compatibility with existing and relevant infrastructures. In order to achieve the ambitious goal of reducing fossil fuels demand, non-fossil synthetic liquid fuels have become an intensively pursued alternative. At present, the synthetic liquid fuels are usually produced from low energy content carbonaceous sources. Typical representatives are gas-to-liquid5 and coal-to-liquid6 technologies which convert natural gas (or other gaseous hydrocarbons) and coal, respectively, into longer-chain liquid hydrocarbons such as gasoline or diesel fuel, on industrial and commercial scales. However, current synthetic liquid fuels technologies are not completely independent of fossil fuels. The upgrading of fuel quality is also accompanied with the consumption of additional energy according to energy conservation. This thus indicates that conventional synthetic liquid fuel technologies cannot meet the global requirement of non-fossil fuels and carbon neutralization.

Solar-driven thermochemical conversion of H2O and CO2, using concentrated solar power (CSP), into sustainable liquid fuels can meet this stringent requirement, as it employs only solar energy as high-temperature heat supply and adopts H2O and CO2 as initial feedstock.7 In other words, the conversion of solar energy into chemical energy stored in liquid fuels provides a promising pathway to significantly reduce dependence on fossil fuels. The technological challenge, however, is to produce renewable syngas from H2O and CO2 using solar energy. What needs to be explained here is that other existing pathways for H2O and CO2 splitting, such as photocatalysis, photo-electrolysis, and water electrolysis, cannot meet the requirements for energy generation. This is because both photocatalysis and photo-electrolysis cannot operate on an industrial scale due to constraints of relevant materials and their poor solar-to-fuel efficiency.8 Water electrolysis, on the other hand, requires a large amount of electricity source, although it can also adopt inexpensive electricity provided by renewable energy sources (solar or wind power), and multi-step energy conversion which in turn increases costs and reduces conversion efficiency. In contrast, thermochemical splitting of H2O and CO2 has a significantly higher energy efficiency potential9 due to the fact that such technology successfully bypasses intermediate energy conversion, such as the electricity required for electrolysis process, and directly converts solar energy into chemical energy.

Thermochemical fuel production based on redox cycles was initially proposed to produce hydrogen from water-splitting to tackle the first oil crisis in 1970s. Nuclear reactors were therefore employed to provide high-temperature heat source required for thermochemical water splitting. However, the rapid development of such research was not realized until 2000 due to the great potential of concentrated solar energy which can provide high-temperature heat for redox cycle process.10 Over the past two decades, a large number of research works have been reported and published on redox materials selection, reactors design, thermodynamic analysis, numerical validation and experimental testing.9,11,12,13,14,15,16,17 These studies indicate that solar-driven thermochemical splitting of H2O and CO2 based on redox cycles is a significant promising pathway to produce sustainable fuels, even though it is yet to be processed on industrial scale. At present, the major issue limiting the further development of such technology toward commercial production is its very low solar-to-fuel efficiency. However, thermodynamic analyses indicated that the potential solar-to-syngas efficiency can exceed an economically competitive 20% with a suitable heat recovery application.18,19 How to increase the thermochemical conversion efficiency from solar to fuels therefore becomes a major research focus. Other than the low conversion efficiency, the operating temperature of the entire thermochemical redox cycle is still high, especially in reduction step which usually requires a high temperature >1000°C.20,21 Such high temperature for the reduction reaction would limit its practicality on large scale, increase energy penalties due to heat losses, as well as place constraints on the redox materials and devices. Therefore, effective and stable redox cycle technology and design under a suitably low temperature for the thermochemical splitting of H2O and CO2 are attracting great interest of researchers in this field.22,23,24,25,26,27,28,29

Against the backdrop of energy crisis and the pursuit of carbon neutrality, more and more attention is currently given to exploration and utilization of renewable energy, which booms the development of sustainable fuels with concentrated solar energy serving as the high-temperature heat source. To date, several reviews of solar-driven thermochemical redox cycle for splitting of H2O and CO2 have been published.9,14,20,30,31,32,33,34,35 However, they all focused on one part of thermochemical redox cycles. For instance, Carrillo et al.,9 Bayon et al.,14 and Bhosale et al.33 mainly focused on the redox materials for thermochemical splitting of H2O and CO2. Zsembinszki et al.32 mainly introduced and summarized solar reactors used for thermochemical redox reactions. Pullar et al.34 only discussed solar thermochemical CO2 splitting which focused on exploring the advances in the synthesis of ceria materials with specific morphologies or porous macro- and microstructures. To the best of our knowledge, the thorough and comprehensive summary on sustainable fuels production from H2O and CO2 with the aid of concentrated solar energy are not covered in the existing published reviews. Hence, a contemporary and comprehensive review of the complete process of solar thermochemical fuel production is of significant importance within the energy and fuel research community for knowledge update. This article therefore presents the development of solar-driven thermochemical conversion of H2O and CO2 to sustainable fuels in recent decades. The complete fuel production system including detailed working principles, redox materials, and key devices are extensively discussed, especially for the heat recovery concepts integrating into the reactors. Meanwhile, particular issues for future work on the topic are also identified and discussed. This review therefore provides pathway for future research on solar-driven thermochemical fuel production technologies.

Solar-driven thermochemical conversion

System and key devices

A complete sustainable fuels production system, converting H2O and CO2 into sustainable fuels driven by the CSP technology consists of solar energy collection unit, thermochemical reaction unit, and sustainable fuel synthesis unit.36,37 Since H2O and CO2 production belong to another mature technology, it is not repeated here. The solar energy collection unit is employed to track and concentrate the sunlight into dense solar radiation power which serves as high-temperature heat supply to drive thermochemical reaction. Following the heating of the CSP, the thermochemical splitting of H2O and CO2 via redox cycle is then used to produce syngas in the thermochemical reaction unit.38 The syngas produced via the thermochemical reaction can be directly used as a source of pure hydrogen and carbon monoxide,30,39,40 or further served as basic raw materials to produce synthesis liquid hydrocarbon fuels (such as methanol or kerosene) in a sustainable fuel synthesis unit.41,42 Through this process, the solar energy therefore can be converted into chemical energy and stored in the form of sustainable liquid fuels as shown in Figure 1.

Figure 1.

Solar-driven thermochemical fuel production chain from H2O and CO2 to sustainable fuels

The key component of the solar energy collection unit is CSP which can provide high solar flux to heat reactor and drive the thermochemical reaction. The CSP can be achieved by a solar collector with a parabolic dish configuration which can provide a three-dimensional (3D) point focusing. Thermochemical splitting cycle of H2O and CO2 requires very high temperature (in excess of 1200 K),31 therefore, only dish solar collector with 3D point focusing can provide sufficient dense solar radiation to obtain such elevated temperature. If large-scale concentration of solar energy is required, a tower solar collector with the aid of a controllable heliostat field can be employed as it has been identified as a favorable path to attain commercial application.43 The thermochemical reaction unit is the most important part of the complete sustainable fuels production system as it simultaneously connects upstream of solar energy collection and downstream of liquid fuels synthesis. The key device of thermochemical reaction unit is the reactor which provides a place for the thermochemical splitting of H2O and CO2. In other words, the syngas (intermediate products for liquid fuels) is produced in the reactor. It should also be noted that the reactor also usually serves as a solar receiver, because the concentrated solar radiation can directly enter the reactor through the aperture. Thus, it is also known as a solar receiver-reactor. A suitable solar receiver-reactor design is required to simultaneously consider redox material, temperature, aperture size, energy loss, stable operation, among others. The detailed description of solar receiver-reactors is presented in Converting thermal energy to chemical energy. The liquid fuels are further synthesized in a catalyst packed-bed reactor via the synthesis technology, such as well-known Fischer-Tropsch (FT) synthesis technology.44 At present, liquid fuels (such as methanol, gasoline, kerosene, etc.) synthesis technologies41,45,46,47,48,49 are relatively mature and exist in many commercial applications.

In the entire production system from H2O and CO2 into sustainable fuels, some auxiliary devices are also necessary. For example, vacuum pumps are employed to control gas pressure in cavity of reactor; condenser is employed to recover liquid water; compressor and storage container are used to store syngas; and other control software and hardware. Therefore, a complete sustainable liquid fuels production chain involves a lot of devices, such that the practical operation is extremely complex, especially when considering the cooperative operation of the above mentioned three units, solar energy discontinuity problem, and heat recovery application. Most studies are still stuck in the conceptual design stage while there are only a few successful cases on an experimental scale. There are still a large number of scientific and technical issues (such as the concentration of solar energy, exploration of redox materials, design of reactor, liquid fuel synthesis, etc.) that need to be resolved for further commercial and industrial production.

Working principle and redox materials

Working principle

The essence of solar-driven thermochemical fuels production is to convert solar energy into chemical energy which is stored in a sustainable liquid fuels carrier. For the entire solar-driven thermochemical fuels production system, the technological challenge is to produce intermediate product syngas from thermochemical splitting of H2O or/and CO2, which is our most important concern. Because the solar energy collection (upstream) and final syngas processing to liquid fuels (downstream) can be considered as mature technologies due to the fact that they have realized commercial application, such as solar thermal power plant and FT catalytic synthesis in industrial scale. Therefore, the effective thermochemical splitting of H2O and CO2 becomes the first and important problem to be solved.

The thermochemical splitting of H2O and CO2 can obtain renewable syngas (H2 and CO), such as single-step direct thermolysis and two-step thermochemical splitting based on redox cycle. The single-step direct thermolysis of H2O or/and CO2 refers to the dissociation of chemical bonds with oxygen atoms at a high temperature. The detailed reaction can be expressed as:

| (Equation 1) |

| (Equation 2) |

Conceptually, direct thermolysis of H2O or CO2 seems to be the simplest reaction from Equations 1 and 2, however, it requires an extremely high temperature. Relevant study20 showed that the direct thermolysis of CO2 cannot proceed spontaneously below ∼3000°C, and even the thermolysis of H2O needs a higher temperature. Such elevated temperatures seriously hinder the further development toward commercial applications. In additions, the direct thermolysis of H2O or CO2 faces some inevitable challenges, for instance, (1) the solar reactors must withstand repeated thermal constraints at high temperatures; (2) H2 (or CO) and O2 separation needs to be proceeded at high temperature to avoid recombination of products (reverse reaction); (3) such high temperature required for the reaction is difficult to obtain under direct concentrated solar radiation because of selective absorption of H2O and CO2; and (4) even if the high temperature required for reaction is attained, radiation loss would be extremely serious according to the Planck’s law, and the solar energy conversion efficiency would be very low. At present, no existing technology can address these challenges, which means that alternative suitable routes to split H2O or/and CO2 need to be developed.

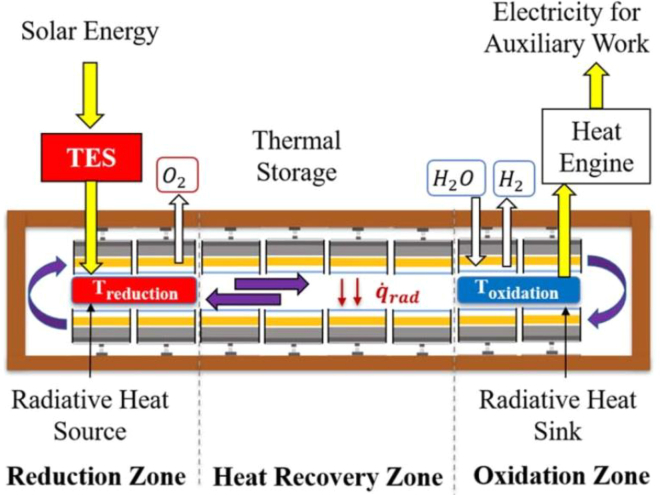

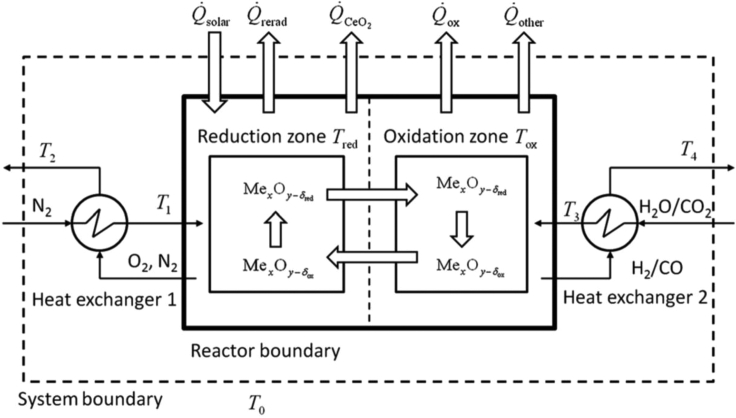

Thermochemical multistep cycles () is firstly proposed to decompose this direct thermolysis into different steps by Funk and Reinstrom50 in 1966. The thermochemical cycles are multiple consecutive chemical reactions, and their finial “net” sum is the splitting of H2O(CO2) into H2(CO) and O2. The initial aim of this study is to produce H2 from splitting of H2O using the high-temperature heat (∼950°C) supplied by nuclear reactors to face the first oil crisis in 1973. However, the interest in such research decreased drastically in the following two decades. Its real rapid development occurred at the beginning of this current century due to the great progress in alternative concentrated solar energy technologies. A typical thermochemical multistep cycle is two-step thermochemical cycles based on redox materials, which has been successfully applied in the dissociation of H2O or/and CO2 with the CSP directly served as the process heat source. Compared with direct thermolysis, the two-step thermochemical splitting cycles significantly reduces the temperature required for reaction, and thereby reduces radiative heat losses. This means a potentially higher solar-to-fuel conversion efficiency and more prospects to realize industrial-scale production. The state-of-the-art and attractive thermochemical cycles for dissociation of H2O or/and CO2 are those based on reduction and oxidation reactions of metal oxides.21,30 The two steps involves – Step 1: endothermic reduction reaction driven by concentrated solar energy, yielding an active oxygen-deficient metal oxides accompanied by pure oxygen release; and Step 2: exothermic oxidation reaction in the presence of H2O or/and CO2, regenerating the initial metal oxide and harvesting the products of H2 or/and CO. The detailed thermochemical cyclic operation is shown in Figure 2, and the reduction and oxidation reactions scheme can be described as:

| (Equation 3) |

| (Equation 4) |

where MOx represents redox materials, such as, metal oxide. It should be noted that the splitting of H2O and CO2 obey the same thermochemical principle. The swing of reduction step and oxidation step depends on temperature and oxygen partial pressure. Reduction reaction usually requires a relatively high temperature and low oxygen partial pressure while oxidation reaction need to proceed under a relatively low temperature and in the presence of H2O or/and CO2. Thus, O2 and H2 (CO or mixture of H2 and CO) are generated in separate stages (reduction and oxidation steps) in thermochemical cycle process, which eliminates necessary product separation and successfully avoid risk of explosive recombination of O2 and syngas products in the direct thermolysis.31 The comparison between direct thermolysis and two-step thermochemical splitting is given in Table 1. An additional advantage of the solar thermochemical two-step redox cycle51 is that it can co-split H2O and CO2 separately or simultaneously, to control the generation of H2 and CO species suitable for the synthesis of methanol48 or other liquid fuels (hydrocarbon fuels) by the FT synthesis,52 which eliminates the energy penalty associated with additional refinement steps for adjusting the syngas mixture (ratio of H2:CO). Moreover, compared with the electrolytic pathway (called “power-to-X”), the thermochemical approach bypasses the solar electricity generation, the electrolysis, and the reverse water-gas shift reaction steps, directly producing solar syngas.53

Figure 2.

Principle of solar-driven thermochemical redox cycle for production of H2/CO

Table 1.

Comparison between direct thermolysis and two-step thermochemical splitting

| Styles | Chemical reactions | Required temperature | Gas products separation |

|---|---|---|---|

| Direct thermolysis | Single step | Ultra-high (>2500K) | Required |

| Thermochemical splitting | Two steps | Depends on redox materials (<2500K) | Not required |

The solar-to-fuel efficiency is an important indicator that evaluates the performance of reactor.54 For a closed thermochemical fuel production system, the energy input is assumed to be provided by concentrated solar energy Qsolar. The energy loss Qloss includes re-radiation, conduction, and convection losses, and unrecovered sensible and latent heat in the reaction products and materials of construction. The auxiliary work Waux is the additional work that is required for the operation of the reactor, such as pumping work. The chemical energy Qchem is the energy stored in fuels, such as H2 and CO. It should be noted that the energy loss Qloss and auxiliary work Waux are both assumed to be offset by concentrated solar energy. Thus, a generic energy efficiency is defined as

| (Equation 5) |

| (Equation 6) |

where HHVfuel is the higher heating value of fuel.

Due to the temperature-swing of reduction and oxidation steps, the absence of heat recuperation from solids would lead to a significant energy loss to the ambient upon cooling from both. To address this issue, a novel concept of isothermal thermochemical operation has recently emerged as an important special case of two-step solar thermochemical cycle, because isothermal thermochemical cycling successfully doesn’t require heat recuperation from solids by eliminating the temperature difference.55,56,57,58 However, in fact, “isothermal” is just an idealized condition, because the absolute isothermal thermochemical cycling is hard to achieve. Thus, the near-isothermal thermochemical cycles with a relatively small temperature variation, such as ΔT < 150°C, is considered, which can take advantage of both high efficiency of two-temperature cycling and simple reactor design of isothermal cycling. At present, the pros and cons of isothermal versus two-temperature thermochemical cycling are still under debate. This is because the thermodynamic properties of redox materials play a significant role in the reactor design and energy conversion performance, which means selection of isothermal or two-temperature thermochemical cycling depends on redox materials. It is well known that materials with a lower reduction enthalpy and a higher reduction entropy are easier to be reduced while more difficult to be re-oxidized. For example, ceria-based materials with high reduction enthalpy and high reduction entropy, requires high temperature and low oxygen partial pressure to be reduced, but has favorable oxidation thermodynamics. Conversely, some perovskite oxides are easy to be reduced but require a large amount of H2O/CO2 gas or a lower oxidation temperature to be re-oxidized due to contradictory thermodynamic forces. Taking ceria as example, if the redox temperature is too high, the oxidation kinetics would be decreased, which is not conducive to oxidation step; if the redox temperature is too low, a lower oxygen partial pressure is required to drive reduction reaction, which means a higher energy consumption associated with vacuum pump or inert gas sweep. Whether final isothermal operation can improve the solar conversion efficiency needs further verification.

Redox materials

The oxygen exchange capacity in one cycle (i.e., reduction extent of redox materials from highest-metal-valence oxide to lower-metal-valence/zero-metal-valence oxide) is not only related to the temperature and/or oxygen partial pressure conditions, but also depends on the redox material itself. Redox materials developed for thermochemical conversion process can be divided into three categories: (1) volatile redox materials, (2) non-volatile stoichiometric redox materials, and (3) non-stoichiometric redox materials. The volatile redox materials include: ZnO/Zn redox pair,59,60,61,62,63 CdO/Cd redox pair,64,65,66 SnO2/SnO redox pair,67,68,69,70 and GeO2/GeO redox pair.71 This category of materials are accompanied by a phase change during redox cycles, since the temperature required for reduction step exceeds the boiling temperatures of the reduced species. Although the phase change is thermodynamically beneficial for redox cycles, oxygen products mixed with gaseous metal or lower valence oxide would face significant challenges of recombination issues back to the initial reactants in the product gas stream, particularly if they are not separated in time. The non-volatile stoichiometric redox materials include: Fe3O4/FeO redox pair,72,73,74 CeO2/Ce2O3 redox pair,75 and hercynite redox material.76,77,78 They would not change into gaseous state during the entire redox cycles process, thereby successfully bypass the recombination issues. In addition, the stoichiometric reactions involve a change in crystal structure during redox cycle and have a great oxygen exchange capacity. However, a complete reduction reaction usually requires a very high temperature (such as 2100k for Fe3O4 reduction20) under which the redox materials would change into liquid, meanwhile the oxidation reaction process requires a relatively low temperature (such as the minimum temperature 450K for FeO oxidation79). Solid-to-liquid phase change during reduction step and large temperature difference between reduction and oxidation steps would not only cause poor stability and slower reaction kinetics, but also seriously decrease the solar-to-fuel efficiency. Compared with these two categories, the non-stoichiometric redox materials are more advanced in term of operation, efficiency, and stability. The materials comparatively presented in recent publications are ferrites,80,81,82,83 ceria,33,75,84,85,86 and perovskites.14,87,88,89,90,91 The maximum difference from non-volatile stoichiometric redox materials is that the non-stoichiometric redox materials only involve partial reduction during cycle, while maintaining the crystallographic structure. Although oxygen generated in reduction step and syngas generated in subsequent oxidation step are both decreased, this can avoid phase transformations which can induce structure disruption, and make redox cycle operate more stably and efficiently. A detailed introduction of prominent non-stoichiometric redox materials is presented in subsequent sections.

Ferrite materials

The initial research works on non-stoichiometric redox materials referred to ferrite system, which were experimentally tested for hydrogen production from the splitting of H2O.80 Nowadays, it has become one of the most advanced systems and been tested to the stage of a 100 kW (using a solar tower) pilot-scale demonstrator.92 The initial ferrite redox materials usually require a high temperature for thermal reduction (TR) in thermochemical cycle, however, such high temperature would cause significant sintering of the oxides. For example, the Fe3O4/FeO redox pair requires a temperature of 2100K during reduction step, while the melting temperatures of Fe3O4 and FeO are 1811K and 1650K, respectively. Thus, the Fe3O4/FeO redox pair need a milling to obtain a fine powder to warrant a sufficient specific surface area to process repeated redox cycle, which would make redox cycle seriously complicated to be implemented. In addition, a quenching below 570°C is required to avoid the formation of Fe3O4 and metallic Fe from the produced FeO species by disproportionation reaction. Ferrite materials usually do not have a sufficient cycling stability because of unavoidable sintering and induced losses of redox activity and fuel production capacity.

To decrease the redox cycle temperature of ferrites, the metallic dopant idea (i.e., replacing some iron atoms in the lattice with other metals) has been proposed and investigated. Some other more readily reducible metals (like Mg, Mn, Co, Ni, Zn, etc.) are inserted into Fe3O4 to form (Fe1−xMx)3O4 formula. Although the reactivity of the doped metals to the oxidant (H2O or CO2) becomes relatively low, the reduction step is further facilitated because such a doping creates a structural deformation of the spinel, thereby favoring oxygen mobility. Thus, the doped ferrites can participate in non-stoichiometric redox cycle under a lower temperature than pure Fe3O4. A series of ferrites has been developed including only one bivalent metal cations in the A site such as MnFe2O4,80 ZnFe2O4,93 NiFe2O4,94 CoFe2O4,95 and two bivalent metal cations in the A site such as Ni0.5Mn0.5Fe2O4,96 and Mn0.5Zn0.5Fe2O4.97 Numerous experimental testing and thermodynamic studies of ferrites for splitting of H2O or/and CO2 via two-step redox cycle indicated that the nickel-based ferrites that are operated under a reduction step temperature below ∼1400°C–1500°C have an optimal performance in terms of fuel production yield and thermochemical stability.81,98,99 However, the improved reduction temperature is still high for the operating process which would be accompanied by sintering, and induced losses of redox activity and fuel production capacity. To further enhance cycling stability of ferrites, an idea supporting the redox reagent on high-temperature-stable ceramic support was widely considered.82,83 It was reported that the yttrium-stabilized zirconia (YSZ)100 and monoclinic zirconia (m-ZrO2)22 have been adopted to serve as substrates of ferrites. In addition, Coker et al.101,102 found that Fe ions dissolved within the YSZ lattice are more “redox-active”, which would lead to higher oxygen yields accompanied with more H2 or CO produced per cycle.

Reaction kinetic of ferrites for thermochemical redox cycle (such as establishment of kinetic models, extraction of the kinetic parameters of ferrites during redox reactions, etc.) have been studied by many experts. For example, Go et al.103 adopted thermogravimetric analyzer to determine reaction kinetics of Mn and Zn doped ferrites during redox cycle for splitting of H2O. They found that the reduction conversion of the ferrites increased with temperature (above 1073K) and the oxidation reaction was controlled by the product-layer diffusion mechanism. Neises et al.104 built a laboratory scale test rig to examine and monitor the hydrogen production in oxidation step by analyzing the product gas. They also investigated the effects of temperature and water concentration on the hydrogen production, and thereafter calculated the activation energy from the experimental data. Kostoglou et al.99 proposed an improved kinetic model of nickel-based ferrite for thermochemical splitting of H2O via redox cycles. They considered two oxygen storage regions existing in ferrite material and thought that the oxygen storage regions communicate to each other by a solid-state diffusion mechanism, which can well explain why thermochemical cycles converge to a periodic steady state. In addition, an interesting phenomenon that the oxidation reaction of ferrites is much faster than corresponding reduction reaction during splitting of H2O or/and CO2 cycle, which means a shorter time for one cycle (i.e., more H2 or/and CO yield at the same time), was also discovered from these investigations.

Ceria materials

Ceria is an excellent catalytic material used for oxidizing exhaust gases to reduce gaseous pollutants due to its facilitated solid-state diffusion and exchange of oxygen ion in crystalline lattice. It is just suitable for thermochemical redox cycle for splitting of H2O or/and CO2, which attracts a great deal of research interests of experts from all over the world. Furthermore, ceria can maintain its cubic fluorite structure without sintering due to its high melting temperature. Compared with ferrites, ceria has better stability, cyclability during the long-term operation. Thus, since ceria was firstly proposed to serve as redox materials for splitting of H2O via two-step thermochemical cycle in 2006,75 its attractive research interest has continued until now. It is regarded as the current state-of-the-art redox material due to several desirable thermodynamic and physicochemical properties (i.e., favorable oxidation thermodynamics, rapid reaction kinetics, and morphological stability). For the pure ceria, only a partial Ce4+ in CeO2 is reduced during reduction step (non-stoichiometric reduction). Thus, the redox of ceria can be described as

| (Equation 7) |

| (Equation 8) |

where is the non-stoichiometry which represents reaction extent of CeO2 in one redox cycle. The reaction extent of CeO2 depends on the reduction temperature and oxygen partial pressure which are usually adopted as swing between reduction and oxidation reactions. Usually the non-stoichiometry parameter is very small in the thermochemical redox cycle. It is reported that a maximum non-stoichiometry without changing the fluorite structure of CeO2 for redox recycling of ceria was 0.286 at 1000°C. The oxygen evolution kinetics of CeO2 during reduction step are also limited by the heating rate,7 while reaction rate during oxidation step is primarily dictated by the chemical kinetics which mainly depends on chemical composition, as well as microstructure and available surface area of the material. For the redox pair, if the reduction temperature is decreased, the reaction extent would be low, which limits the H2 or/and CO yields per cycle. However, it should also be noted that oxidation reaction rate is high due to rapid oxidation kinetics of CeO2-δ, which means a great deal of cycles can be completed in limited sunny time.

To further improve the reaction extent of CeO2 for H2 or/and CO production, the cationic-dopant scheme is proposed and applied, namely, by substituting transition metal and rare earth metal oxides (such as Li2+, Sr2+, Ca2+, Mg2+, Sc3+, Dy3+, La3+, Sm3+, Gd3+, Y3+, Pr3+, Hf4+, and Zr4+) into the crystal structure, the thermodynamic properties and redox performance of CeO2 may be tuned. For instance, if the tetravalent cationic Zr4+ was employed to dope the CeO2, the reduction extent would be improved, but the oxidation kinetics of doped CeO2 would decrease compared with pure CeO2.25,105,106 The trivalent cations La3+, Gd3+, and Y3+ are further doped into the Zr4+ doped CeO2, which can continue to improve reduction extents and fuel yields. Meanwhile, it was also found that trivalent cation La3+ dopant can improve the thermal stability and resistance to material deactivation during cyclic operation.107 Meng et al.26,108 investigated a series of doping schemes including Mg2+, Sc3+, Hf4+ and Pr3+, and they found these dopants all improve the reduction extent compared with pure CeO2. Among them, Mg2+, Sc3+, and Hf4+ dopants schemes can yield a smaller effective cation radius to obtain greater reducibility, and Pr3+ dopant of 5 mol % and 10 mol % can improve O2 and H2 yields due to a reduced enthalpic energy penalty, though Pr did not participate in oxidation reaction. In contrast, Hf4+ dopant exhibited the largest improvement in O2 evolution at the expense of a lower H2 production rate than undoped CeO2. Scheffe et al.18 performed a thermodynamic analysis of Gd3+, Y3+, Sm3+, Ca2+, and Sr2+ doped CeO2 during redox cycle for solar thermochemical fuel production, and observed an interesting phenomenon that the dopants are not always of better performance. For example, at high reduction temperature larger than 1700K, the reduction extents of pure CeO2 are larger than those of the dopants, while at lower reduction temperature, just the opposite is achieved. If the dopant concentrations were too large, the entropy change during oxidation with H2O or CO2 would be decreased, which means that the oxidation of pure CeO2 is more favorable than that of doped CeO2 at temperatures below 1200K. At present, the development of new formulations for doped CeO2 become a research trend, various novel research results (including their chemical synthesis, performance testing, and reaction kinetics) are reported continuously.109,110,111,112,113,114,115,116

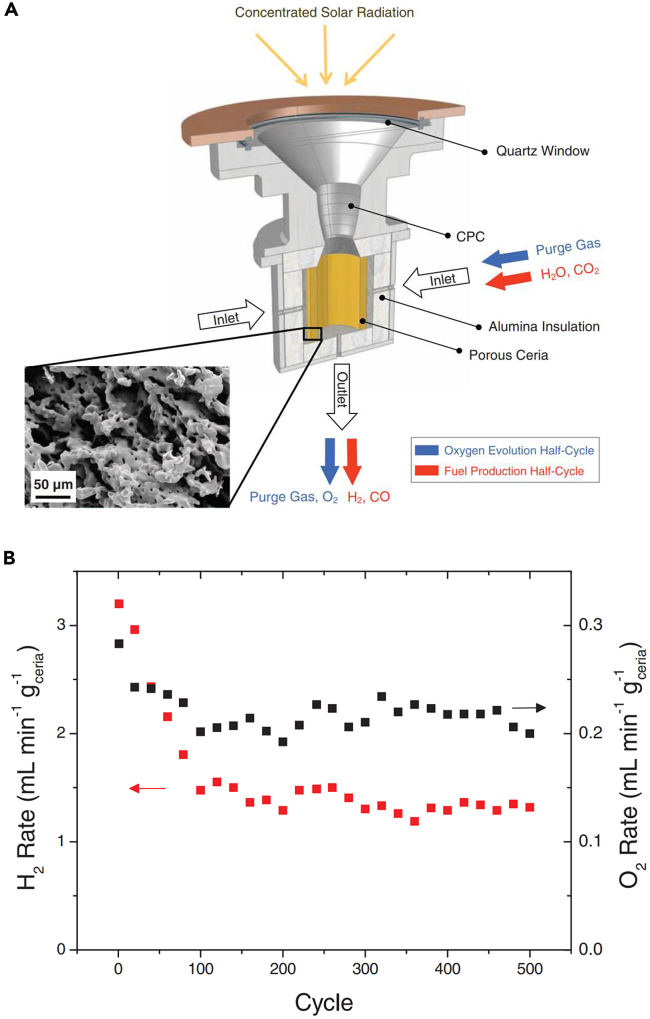

In addition to the ceria material’s own performance, heat transfer behavior related to structure and morphology of the material is also a limiting factor. When the concentrated solar radiation enters reactors through the aperture, ceria exposed directly to the high-flux radiant energy will first raise the temperature to the reduction temperature, while other ceria remains in low temperature due to its low thermal conductivity. Inhomogeneous temperature distribution limits the majority of reduction reaction to the near-surface layer closed to the aperture.117 To address this limitation, the structure and morphology of the ceria need to be designed to improve the heat transfer performance. Porous structure concepts (like reticulated porous ceramic foam) become an attractive choice because of their excellent volumetric absorption of incident radiation.118,119 A macro-porous structure can make radiation pass through internal medium (i.e., enhancing heat transfer capability) and make the entire porous structure ceria be heated more homogeneously (i.e., a lower temperature gradient throughout the ceria material). Furler et al.120 observed that the average efficiency increased by over a factor of 10 by adopting reticulated porous ceria redox system. Another study121 found that the oxidation kinetics of the porous ceria would be limited by its relatively low specific surface area. Consequently, they proposed the concept of CeO2-based porous structures with dual-scale porosities, in which the millimeter-sized pores can enhance heat transfer behavior and the micrometer-sized pores can improve specific surface area. The dual-scale porosities structure perfectly solve the low reduction kinetics issue.122,123 Marxer et al.41,124 investigated thermochemical splitting of H2O and CO2 based on CeO2-based porous structures with dual-scale porosities, and they obtained a solar-to-fuel energy conversion efficiency of 5.25%. Recently, Oliveira et al.125,126,127 proposed a novel concept of three-dimensionally ordered macroporous structures (such as cork-templated or wood-templated ceria) based on biomimetic approaches to improve the redox cycle performance of ceria for splitting of H2O and CO2.

At present, the ceria-based redox materials are experiencing explosive development, and various recent advances in the field are continuously reported.128,129,130,131,132 However, there are still several aspects that need to be further developed before commercial application. To plainly take profit of the advantages of ceria-based redox cycles, Abanades20 reviewed the development of ceria-based redox materials and gave some suggestions: (1) the dopant schemes of ceria need to be further optimized including development of new dopants and utilization of composite materials; (2) synthesis method is also an important aspect, especially when the powdered ceria-based material is adopted, synthesis material must be warranted high-temperature resistance; and (3) for porous structure ceria-based material, thermally resistant supports and efficient coating methods are needed, and elaboration of architecture porous structures (such as biomimetics, 3D printing, etc.) are good choices.

Perovskites materials

Perovskites are regarded as a type of crystal structure with a general formula ABO3 where A and B are both cations with the oxygen in the edge centers. Research indicate that the A cation is 12-fold coordinated with oxygen while the B atom is 6-fold coordinated. Thus, perovskites are commonly cubic, but sometimes may exhibit orthorhombic and rhombohedral crystal structures. Such structures allow some A and B sites to be substituted with other cations, which means that the structural stability may be altered by creating defects. Perovskite materials have been discovered for a long time and become well known for their applications in fuel cells based on reversibility in delivering and picking up oxygen at high temperatures.133 However, perovskites as non-stoichiometric redox materials for thermochemical splitting of H2O and CO2 first appeared in the publication in 2013.134 In other words, the development of perovskites for thermochemical redox cycle is less than a decade.

Reasonable selection of cations in A and B sites and dopant schemes can make perovskites become excellent redox materials with high non-stoichiometric oxygen exchange capacities and diffusion rates. The two-step thermochemical redox non-stoichiometric reactions based on perovskites can be described as:

| (Equation 9) |

| (Equation 10) |

where is the non-stoichiometry which represents reaction extent of ABO3 in one redox cycle. Similar to the ceria-based materials, the non-stoichiometry is also small and determined by temperature and oxygen partial pressure. It is reported that a general range of non-stoichiometry between 0.03 and 0.23. At present, perovskites used for thermochemical fuel production have attracts great interests of experts. In design aspect, Ezbiri et al.135 gave the design principles of perovskites with balanced redox energetics, in which the electronic structure computations were adopted to predict the activity of lattice oxygen vacancies and stability against crystal phase changes and detrimental carbonate formation, and they also experimentally validated the predicted perovskite materials. Antoine et al.136 presented a high-throughput computational screening strategy to select the potential candidates of perovskite ABO3 for splitting of H2O in term of thermodynamic stability and oxygen vacancy formation energy, and they finally identified 139 perovskites favorable for application. In kinetics study aspect, to better characterize a material for thermochemical splitting of H2O and CO2, various kinetics methods have been proposed and implemented, such as, mechanistic model-fitting method and non-mechanistic isoconversional method.137 Reduction kinetics focus on oxygen evolution of perovskites, while oxidation kinetics focus on splitting reaction. Kinetics study aims to determine the maximum fuel amount which can be produced in a reasonable duration. Existing research works indicate that the oxidation kinetics of perovskites are lower than that of pure ceria while their oxygen exchange capacity (namely, fuel productivity per mass of material) is higher. In thermodynamic study aspect, a series of thermodynamic analysis on ceria for redox cycle have been reported.138,139,140,141 In contrast, corresponding related works on perovskites are very few. Muhich et al.142 pioneered a thermodynamic analysis of perovskites for thermochemical splitting of H2O and CO2, and comparison indicated that the solar-to-fuel efficiency of perovskites is lower than that of ceria due to their relative reducibility and re-oxidizability. However, opposite results are observed in the work of Vieten et al.,87 in which they found that many perovskite materials have higher H2/CO production. This therefore suggests that the performance and types of perovskite materials need to be further developed.

Doping scheme of perovskites is another research content, and a series of doped perovskites as redox materials have been reported.143,144,145,146,147,148,149,150,151 Typical perovskites materials include lanthanum-manganite perovskites, lanthanum-cobalt perovskites, and yttrium-manganese perovskites. For lanthanum-manganite perovskites, the most studied is La1−xSrxMnO3. The presence of Sr in the A-site significantly increases reduction extent,134,152 thereby can obtain a higher fuel production. In addition, the use of Sr as dopant can also affect grain morphology153 and increase the characteristic time during the oxidation step.154 For lanthanum-cobalt perovskites, Ca, Sr, and Fe dopants are proposed to substitute in the A or/and B-site. Studies concluded that Ca dopant in the A-site can promote oxygen production, but if Ca content is too high (such as >40%), hydrogen production would decrease. The La0.6Ca0.4CoO3 is regarded as the most promising material in Ca dopant scheme in term of O2 and CO production.155 Sr dopant instead of partial La in material can improve reduction extent, and even La0.6Sr0.4CoO3 can achieve a higher H2 yield (514 μmol/g) than that of La0.6Sr0.4MnO3 (234 μmol/g).156 However, Orfila et al.157 found that the fuel production of the Sr doped perovskites would decrease after 4 consecutive cycles, which means its stability need to be further improved. Fe as dopant in LaCoO3 neither improve the stability of material nor re-oxidation yield.158 Even the presence of Fe would decrease the O2 production. For yttrium-manganese perovskites, Sr as dopant (Y0.5Sr0.5MnO3) exhibited a higher reduction extent than La0.5Sr0.5MnO3 in similar conditions,159 which can be attributed to a smaller ionic radius of Y3+. This smaller ionic radius increases the MnO6 octahedron inclination and the lattice distortion, thereby promoting oxygen departure. At the same time, a lack of CO (a lower re-oxidation) was observed in both Chan160 and Nair et al.,159 which means the re-oxidation ability of such perovskites needs to be improved. Ca dopant was also investigated in yttrium-manganese perovskites. Both yttrium and calcium can increase the reduction extent compared with lanthanum and strontium.161

Perovskites as a relatively “new” redox material have exhibited a great potential for solar fuel production via thermochemical redox cycle. For example, Barcellos et al.162 discussed the BaCe0.25Mn0.75O3 (BCM) within the context of thermochemical water splitting materials, and this novel material exhibited a polymorph phase transition during thermal reduction and yielded nearly three times H2 more than ceria when adopting a reduction temperature of 1350°C. Moreover, BCM exhibited faster oxidation kinetics and higher water-splitting favorability than popular Mn-based perovskite SrxLa1−xMnyAl1−yO3 (x, y = 0.4, 0.6). Although perovskite materials may exhibit superior redox performance but have not yet proven to be as stable as ceria.36 Bayon et al.14 therefore suggested that perovskites should be further developed toward adequate thermochemical properties, large redox extents, fast redox kinetics, high mechanical stability and sintering resistance, adequate vapor pressure at working temperatures, high thermal conductivity, and ultimately, abundance, low toxicity and low cost.

Concentrating solar energy to thermal energy

Research on thermochemical redox cycle for splitting H2O or/and CO2 instigated an explosive development in the current century, which also benefit from the aid of CSP technologies. For such evaluated temperature required for thermochemical redox reaction, the high-flux solar energy with high concentration ratio (generally >2000 suns) is required. The open market currently provides four types of CSP technologies, including parabolic troughs, fresnel mirrors, power towers, and solar dish concentrators.163 However, only solar dish and tower concentrators can provide such high-temperature heat source for thermochemical cycle process,164 because they both provide 3D point-focus concentration. The applications of these two types of solar concentrators for the thermochemical splitting cycles of H2O or/and CO2 are described and discussed in subsequent sections.

Parabolic dish concentrator

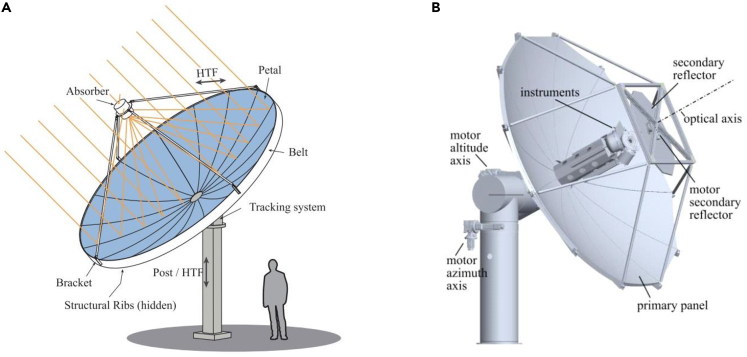

Parabolic dish solar concentrator can be used to reflect, concentrate, and deliver sunlight onto a receiver at the focal point.165 Its high concentration ratio and optical efficiency position it as one of the most perfect solar concentrators for high-temperature heat source. A typical parabolic dish concentrator consists of a parabolic dish reflector which is usually made up of a set of mirrors, solar receiver which collects concentrated solar energy and solar tracing devices.166,167,168 If needed, a secondary reflector can also be integrated into the solar concentrating dish system to change sunlight pathway, to make the whole system more compact at the expense of increasing optical loss. In addition, a secondary reflector (flat or hyperboloid) can flexibly change focal point while keeping the whole system stationary, which is very suitable for the simultaneous operation of two or more adjacent solar receiver-reactors.169 The generic configuration of parabolic dish concentrator is shown in Figure 3.

Figure 3.

Configuration of parabolic dish concentrators

(A) Parabolic dish concentrator with only primary reflector; Reproduced with permission.168 Copyright 2020, Elsevier.

(B) Parabolic dish concentrator with another secondary reflector. Reproduced with permission.169 Copyright 2018, Elsevier.

At present, most studies on solar-driven thermochemical redox cycle were conducted for performance testing and validation of numerical models.4,31,170,171 Thus, parabolic dish concentrator was employed to supply high-temperature heat by establishing ray tracing model in theoretical or modeling research works on solar-driven thermochemical redox cycle. For example, Monte Carlo ray tracing method was employed to design the parabolic dish system.172 The model-generated concentrated radiant fluxes served as CSP to provide high-temperature energy for two-step solar thermochemical splitting of CO2 in the established CFD model whose numerical results were employed to analyze the influences of geometric factors on the performance. The ceria-based thermodynamic cycle combined with parabolic dish for solar hydrogen production is developed and achieved as high as a solar-to-fuel efficiency of 21.2% after optimizing the concentration ratio, reactor pressures and temperatures.173 If the parabolic dish concentrator (optimal diameter is 5.168m) is optimized, the amount of hydrogen produced can reach 34 mol m−3 in a 10 kWth solar reactor.174 In addition, some researchers even used the simulated concentrated solar light to power the reaction and directly equated the concentrated solar energy to a specific value or assumed the temperatures provided by concentrated solar energy to be known to simplify the model in their numerical studies.175,176,177 This is majorly because their focus is on thermochemical redox cycle process and its performance, rather than concentrated solar technology.

Most experimental studies on thermochemical redox cycle adopted indoor solar simulators to provide high-temperature heat sources in laboratory scale.70,120,123,125,178 In order to be closer to the real conditions, some researchers designed parabolic dish concentrators to investigate solar-driven thermochemical redox cycle for splitting H2O or/and CO2 outdoors. For example, Dähler et al.169 designed several parabolic dish concentrators for successive thermochemical splitting of H2O and CO2 based on redox cycles. They obtained a peak solar concentration ratio of 5,010 suns and an average of 2,710 suns over the 30 mm-radius apertures of the solar reactor. Schäppi et al.179 applied a parabolic dish concentrator to provide concentrated solar energy for the thermochemical splitting of CO2, and a secondary rotating reflector was designed to alternate the concentrated solar input between two reactors, which ensure simultaneous operation of both reactors. The team36 later presented a complete solar fuels production chain based on the above study, which can directly produce methanol from sunlight and air with the aid of parabolic dish concentrator. Abanades et al.131 adopted parabolic dish concentrator to directly and indirectly provide high-temperature heat for H2O and CO2 dissociation in solar reactors, and they observed highest fuel production rate of ∼9.5 mL g−1 min−1 and peak solar-to-fuel energy efficiency of ∼9.4% from directly irradiation style.

It can be known from the above research examples (including simulations and experiments) that the parabolic dish concentrator with high concentration ratio and optical efficiency has been successfully applied in solar-driven thermochemical splitting of H2O or/and CO2 based on redox cycle. A series of experimental data indicated that the combination of concentrated solar energy and thermochemical conversion is a perfect pathway to produce syngas with only H2O and CO2 as feedstock. It should be noted that intercept losses are unavoidable due to inaccurate tracking in practice. To achieve enough high concentration ratio, sunlight needs to be reflected multiple times and finally concentrated to the designated focus position, which causes some solar energy loss but can reduce re-radiation from aperture of reactor. At present, the parabolic dish concentrator is just suitable for experimental research in laboratory scale, due to the limitation of size. Scale-up of solar-driven thermochemical splitting of H2O or/and CO2 based on redox cycle can consider solar tower system with a heliostat field concentrator, which is introduced in the following section.

Heliostat field concentrator

Large scale application of concentrated solar energy focuses on solar tower technology with a heliostat field concentrator,180,181,182,183,184,185 because the parabolic dish concentrator configuration is limited in size considering mechanical constraints caused by wind and weight loads.53 There is no commercial parabolic dish whose diameter is over 10 m in the current market. Although employing a group of solar parabolic dishes can increase the scale of solar energy collection, its investment and cost will be lost to those of solar tower configuration with significant economy-of-scale advantages.186 At present, solar towers are considered as the most suitable CSP technology to carry out solar-driven thermochemical cycle processes on industrial scale due to it can provide high-power CSP with relatively low cost.43 A typical concentrated solar tower system usually consists of (1) solar receiver mounted on top of the tower, (2) heliostat field concentrating and delivering solar irradiation onto the aperture of receiver; (3) control room adapting the angle of heliostat to optimize solar collection. These three parts collaboratively operate to finish the tracking, concentrating, and delivering of sunlight. A complete solar tower configuration is depicted in Figure 4.

Figure 4.

Configuration of solar tower with a heliostat field

Reproduced with permission.53 Copyright 2022, Elsevier.

The heliostat field concentrator is made up of a family of heliostats. A single heliostat is composed of a set of reflect mirrors, a tracking system, a frame, a structure foundation, and control system187 as shown in Figure 5. The optical efficiency of heliostat field mainly depends on cosine effect, shadowing effect, blocking effect, mirror reflectivity, atmospheric attenuation, and receiver spillage. For the entire solar tower system with a heliostat field concentrator, the almost 50% of investment and 40% of energy loss are attributed to the heliostat field. Thus, optimal design of heliostat and optimal layout of heliostat field are significantly important to improve solar efficiency and reduce the capital cost. In heliostat field layout design aspects, Wei et al.184,188,189,190,191 have done a lot of works involving mechanism, method, and optimization of heliostat field layout design toward the performance improvement of solar tower system. Till date, the heliostat field concentrator technology is one of the most effective methods providing high concentrated solar energy whose scale is far larger than other solar concentrators.

Figure 5.

Configuration of single heliostat

Reproduced with permission.187 Copyright 2013, Elsevier.

Laboratory-scale research usually adopted indoor solar simulators or outdoor solar parabolic dish concentrator configuration. In contrast, published literatures on the use of concentrated solar tower to drive thermochemical redox cycle for dissociation of H2O or/and CO2 are relatively few. This is due to the fact that a relatively large-scale study of thermochemical redox cycle based on concentrated solar tower configuration needs a lot of manpower and financial support. The concept of combination of a high-temperature (∼1000°C) power tower and a sulfuric acid/hybrid thermochemical cycle is proposed by Kolb et al.192 using a combination of thermal input and an electrolyzer to produce hydrogen, and they predicted the solar thermochemical plant will have a much lower cost of hydrogen product than a solar-electrolyzer plant of similar size. After that, solar thermochemical processes based on solar tower is thoroughly studied, including design,193 control strategy, and validation.194 And even a successful test operation of a 100 kW pilot plant for thermochemical water splitting is implemented on a solar tower platform under real conditions.92 More recently, Zoller et al.53 experimentally demonstrated a fully integrated thermochemical production chain from H2O and CO2 to kerosene for the first time, and adopted solar tower with a controllable heliostat field to provide high solar flux (2500 suns) to achieve a solar-to-syngas energy conversion efficiency of 4.1% in the absence of any heat recovery system.

Above studies successfully push solar tower technology toward application in large-scale solar-driven thermochemical fuel production. However, up to now, no solar tower plants for thermochemical fuel production are employed on a commercial scale, because there are still many scientific and technical issues, including efficiency, cost, intermittent solar energy, weather, seasons, operation maintenance that all need to be resolved in the future. Nevertheless, existing publications have proven that the solar tower with heliostat field concentrator is the most promising pathway to provide high-temperature heat supply for realizing large scale commercial application of thermochemical conversion process of H2O and CO2 to sustainable liquid fuels.

Converting thermal energy to chemical energy

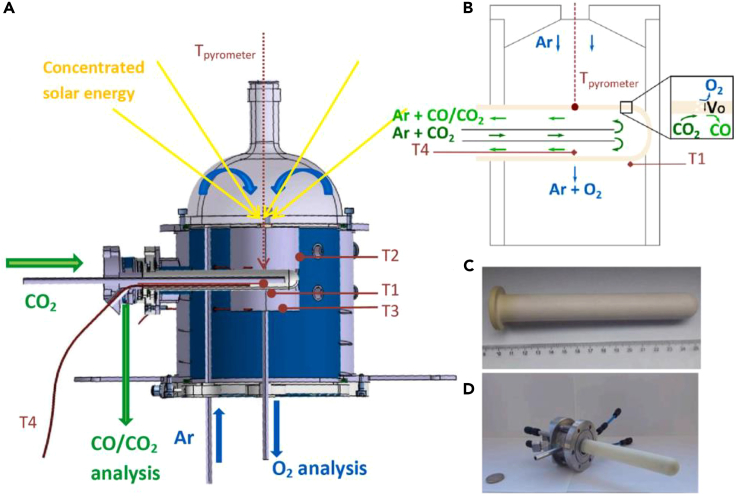

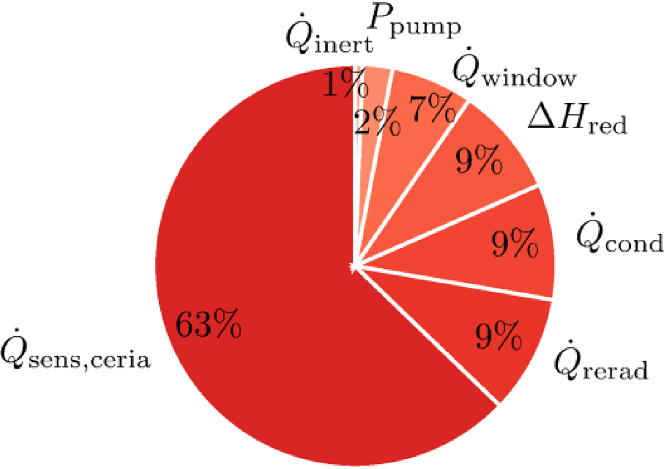

Once the solar energy has been concentrated to the intensive thermal energy, the next step is transferring the thermal energy to the thermochemical reactor to trigger the thermochemical conversion of H2O or/and CO2 to H2 or/and CO. The energy transfer can be generally divided into two categories according to the mechanism of transfer: one is the indirect irradiation, during which absorbing surfaces are exposed to the concentrated solar radiation with heat conducted across their walls to the thermal fluid, and the other is direct irradiation, during which fluid streams or solid particles/structures are directly exposed to the concentrated solar radiation.195 A typical example of the indirect irradiation is conventional tubular reactors consisting of absorbing surfaces exposed to concentrated solar irradiation while the heat transfer fluid is moving in a direction vertical to that of the incident solar radiation.196 The later type is also known as “volumetric” reactor that enables the concentrated solar radiation to penetrate and be absorbed by the absorber without the transfer through the wall.38 The majority of reactors are in the category of direct irradiation that use solid particles or structures directly exposed to concentrated solar radiation. Hence, the reactors must be equipped with a transparent window, which allows concentrated light to enter the receiver while isolating the working gas from ambient air.197

Continuous utilization of thermal energy

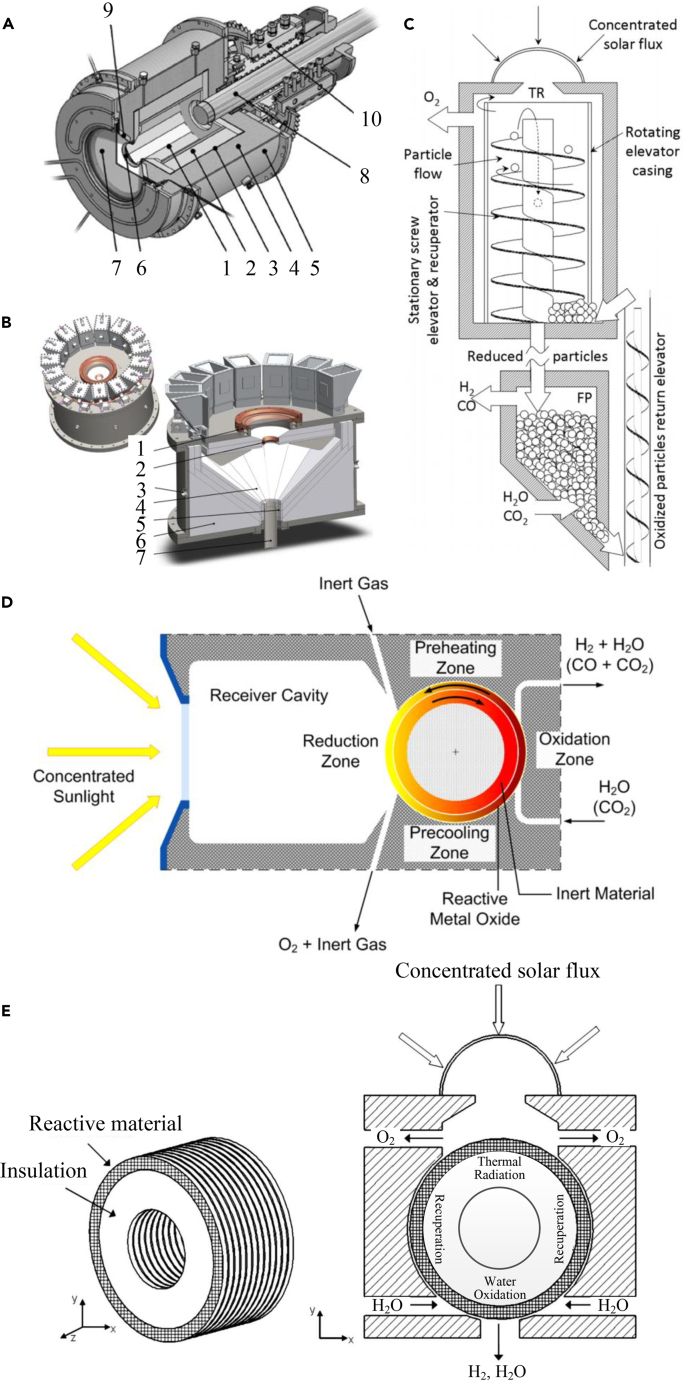

There are two types of solar reactors based on the redox chemistry of volatile and non-volatile redox cycles. A gaseous mixture of the reduced phase and oxygen occurs during the TR phase, and special treatment is required to prevent its recombination back to its original oxidized form, which is a common feature of all proposed volatile cycles. As a result, each of these systems has two distinct reactors: one that plays out the TR step from which a dense decreased stage is gotten along with vaporous oxygen and a second one where this consolidated stage is oxidized and plays out the necessary splitting of H2O or CO2 step.198 The cyclic operation can thus be separated into two stages: one during the day for thermal reduction and one at night for the production of syngas. Therefore, the thermal energy is difficult to be continuously used by one reactor in this manner. As a result, we include and discuss the reactors that intend to carry out the TR step and innovative reactors that could continuously use thermal energy in this section. Partial reactor designs are presented in Figure 6 while their main characteristics are summarized in Table 2.

Figure 6.

Schematic of thermochemical reactors

(A) Solar thermochemical reactor with a rotating cavity-receiver: 1-rotating cavity, 2-insulation, 3-ceramic matrix composite, 4-alumina fibers, 5-Al reactor shell, 6-aperture, 7-quartz window, 8-dynamic feeder, 9-conical frustum, and 10-rotary joint; Reproduced with permission.199 Copyright 2009, Elsevier.

(B) Beam-down solar thermochemical reactor: 1-water-cooled window mount and vortex-flow generation, 2-water-cooled cavity aperture, 3-BOP and data-acquisition cavity access ports, 4-alumina-tile reaction surface, 5-annular solid ZnO exit, 6-bulk insulation and cavity-shape support, 7-central product-vapor and gas exit; Reproduced with permission.200 Copyright 2012, Elsevier.

(C) Moving packed particle bed reactor; Reproduced with permission.201 Copyright 2013, The American Society Mechanical Engineers.

(D) Solar thermochemical reactor realizing a nonstoichiometric partial redox cycle with solid-solid heat recuperation; Reproduced with permission.202 Copyright 2013, The American Society Mechanical Engineers.

(E) Counter-rotating-ring receiver/reactor/recuperation (CR5). Reproduced with permission.203 Copyright 2008, The American Society Mechanical Engineers.

Table 2.

Comparison among different types of reactors for continuous utilization of thermal energy

| Reactors | Solar irradiation types | Thermochemical process | Redox material and its shape | Power | Maximum temperature | Solar conversion efficiency | Reference |

|---|---|---|---|---|---|---|---|

| Stacked bed-rotary reactor | Directly | Dissociation of ZnO | ZnO particles | ∼10 kW | ∼2136 K | ∼3.1% | Schunk et al.199 |

| Stacked bed-mobile bed | Directly | Dissociation of H2O | ZnO powders | ∼10 kW | ∼1900 K | / | Koepf et al.200 |

| Moving packed bed | Directly | Dissociation of H2O or CO2 | CeO2 particles | / | ∼1500°C | ∼30% | Ermanoski et al.201 |

| Directly-irradiated reactor | Directly | Dissociation of H2O or CO2 | Ceria porous medium | / | ∼2203 K | / | Lapp et al.202 |

| CR5 reactor | Directly | Dissociation of H2O | Ferrite fins | ∼36 kW | ∼2300 K | ∼29.9% | Diver et al.203 |

| Solar chemical reactor | Directly | Dissociation of ZnO | ZnO particles | ∼10 kW | >2000 K | / | Haueter et al.204 |

| Solar reactor | Directly | Dissociation of ZnO | ZnO particles | ∼100 kW | ∼1936 K | / | Villasmil et al.205 |

| Rotary cavity-type reactor | Directly | Dissociation of H2O | ZnO powders | ∼1.4 kW | ∼1600°C | / | Chambon et al.206 |

| Moving-front reactor | Directly | Dissociation of H2O | ZnO and SnO2 powders | ∼1 kW | ∼1993 K | ∼2.9% | Chambon et al.207 |

| Rapid reaction aerosol flow reactor | Indirectly | Dissociation of H2O | ZnO particles | / | ∼2123 K | / | Perkins et al.208 |

| Circulating fluidized bed | Directly | Dissociation of H2O | NiFe2O4/m-ZrO2 particles | 2.6 kW | ∼1200°C | <1% | Gokon et al.209 |

| Rotary-type reactor | Directly | Dissociation of H2O | CeO2 or Ni, Mn-ferrite ceramics | / | ∼1623 K | / | Kaneko et al.210 |

Reactors performing only the reduction step

The reduced materials and evolved O2 are inherently separated in this reactor concept, which operates isothermally throughout the day and decouples the reduction and oxidation processes in space and time for potential 24-h syngas generation. Haueter et al.204 described the solar thermochemical reactor’s design, fabrication and initial testing, which uses a windowed rotating cavity-receiver lined with ZnO particles held by centrifugal force to conduct the thermal dissociation of ZnO into zinc and oxygen at temperatures above 2000 K. ZnO functions as a radiant absorber, a thermal insulator, and a chemical reactant in this arrangement while also being directly exposed to high-flux solar radiation. The limitations imposed by the chemistry of the decomposition reaction and the transitory nature of solar energy are considered when designing the reactor. The high-temperature thermal dissociation of ZnO in a solar-powered thermochemical pilot plant was also planned, built, and tested by Villasmil et al.205 They tested the solar reactor by exposing it to concentrated radiation fluxes of up to 4477 suns and a peak solar radiation power input of 140 kWth at the PROMES-CNRS large-scale solar concentrating facility. The solar reactor operated at temperatures as high as 1936 K, producing a Zn molar fraction of 12–49% of the condensed products. This Zn molar fraction was largely determined by the flow rate of Ar that was injected into the reactor to cool the gaseous products that were forming. Chambon et al.206 designed, constructed and operated a prototype high-temperature lab-scale solar reactor based on a rotating cavity-type solar radiation absorber made of standard refractory materials that allow continuous ZnO thermal dissociation in a controlled atmosphere at lower pressure. By increasing the rate of dissociation and operating at lower temperatures, lower pressures increase the overall dissociation yield by thermodynamic displacement toward the gaseous products. The reactant oxide powder is infused persistently inside the hole and the created Zn particles are recuperated in a downstream fired channel. With a neutral gas flow rate of 5 NL/min and a typical dilution ratio of 300, the filter produced a maximum yield of 21% for particle recovery and a dissociation yield of up to 87% (Zn weight content in the final powder). The gravity-fed, entrained-bed reactor proposed by Koepf et al.,200 which is abbreviated as GRAFSTRR (Gravity-Fed Solar-Thermochemical Receiver/Reactor), is closed off from the outside and has a reaction surface in the shape of an inverted conical. Along this surface, reactant powder continuously descends as a moving bed, undergoing a thermochemical reaction at high temperatures when exposed to highly concentrated sunlight within the reaction cavity. Chambon et al.207 investigated the high-temperature thermal dissociation reaction of ZnO and SnO2 simultaneously. To ensure continuous reactant feeding, the reactor’s design permits the movement of the reaction front. Thermal dissociation of ZnO and SnO2 was carried out successfully at around 1900 K, resulting in the recovery of up to 50% of the products as nano powders with high specific surface areas (between 20 and 60 m2/g) and mass fractions of reduced species of up to 48 wt. % for Zn and 72 wt. % for SnO. Perkins et al.208 conducted an experimental investigation into how ZnO particles break apart at room temperature in aerosol flow, and used a cooling lance and quench tube to reduce product recombination and sharpen residence time determination. Chemical analysis revealed that the material in the gravity vessel lack significant reaction. Particles collected in the quench tube and filter were found to have undergone some recombination and conversion to Zn through physical and chemical analysis. After recombination, the net conversions had a maximum value of 18% and a mean value of 8%. The surface area of the product particles, which ranged from 5 to 70 nm, was anticipated to accelerate the Zn hydrolysis step of the cycle.

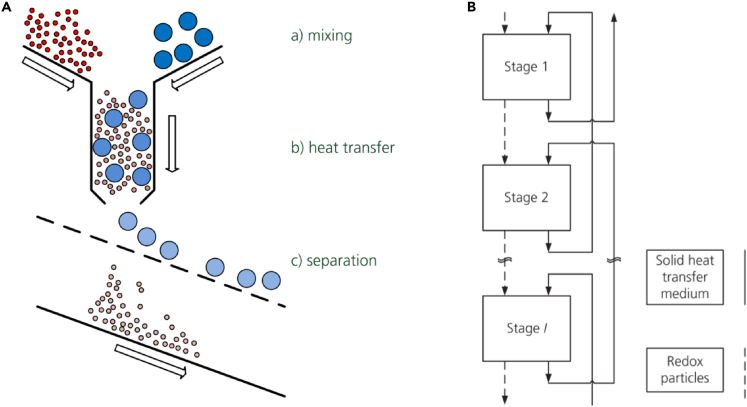

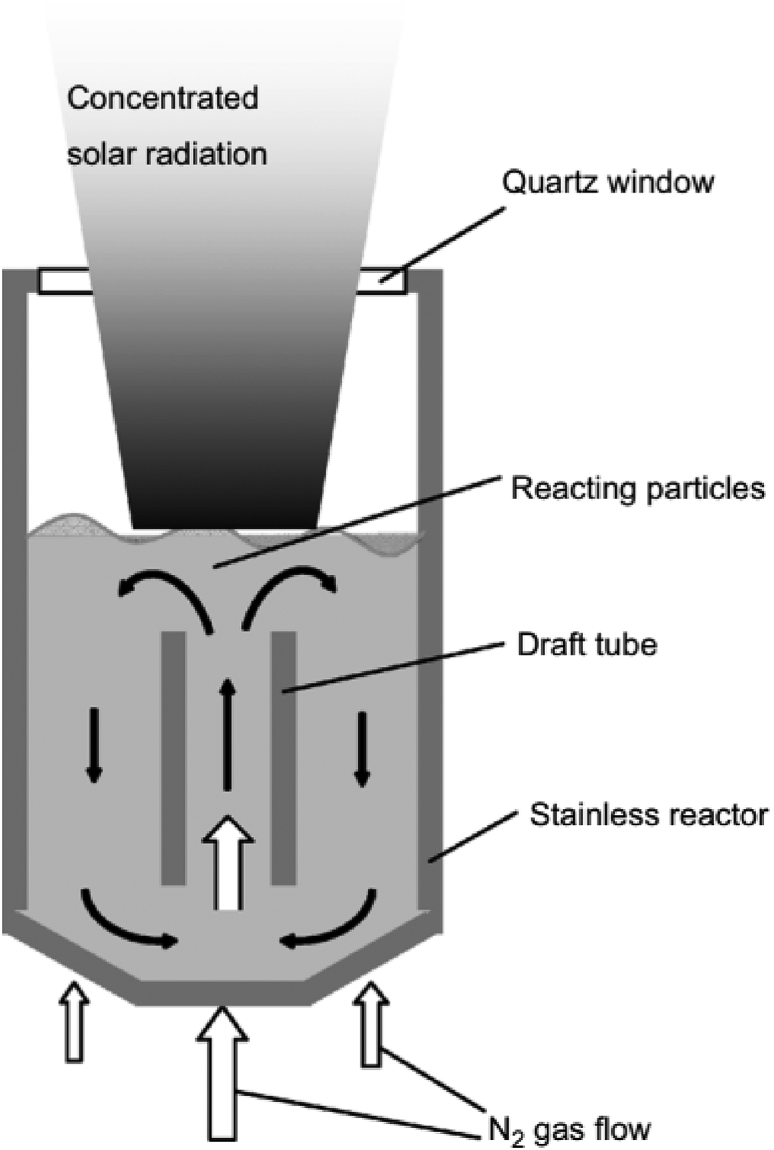

Moving packed bed reactors

Gokon et al.209 demonstrated a single reactor of an internally circulating fluidized bed, with which thermochemical hydrogen production by a two-step reaction on a laboratory scale can be achieved. In the TR step, the internally circulating fluidized bed was subjected to simulated solar light from Xe lamps with input powers of 2.4-2.6 kWth and 1.6-1.7 kWth, respectively. The fed gas was changed from an inert gas (N2) to a mixture of N2 and steam in the splitting of H2O step. As a fluidized bed of reacting particles, NiFe2O4/m-ZrO2 and unsupported NiFe2O4 particles were evaluated, and the reactivity of reacting particles as well as the rate and productivity of hydrogen production were examined. The ferrite conversion was 35% and the hydrogen productivity was 951 Ncm3 for the NiFe2O4/m-ZrO2 particles. The hydrogen productivity of the unsupported NiFe2O4 particles was 1072 Ncm3 while the ferrite conversion rate was 5%. Ermanski et al.211 evaluated the effectiveness of a reactor that makes use of a moving packed bed of reactive particles and concluded that the packed bed reactor must possess the following characteristics to achieve high efficiency: the reactor’s pressure and temperature, reaction products being separated spatially, sensible heat recovery throughout the process of reaction, continuous use of the irradiation, and the working material being directly illuminated. In addition, it was demonstrated that vacuum pumping outperformed inert gas sweeping in terms of efficiency owing to the pressure separation technique and the conversion efficiency of solar energy into H2 and CO that could exceed 30% in a fully developed system employing CeO2 as a reactive material. Effective heat recuperation is the central idea, with the packed bed of reduced particles supposed to move downward through a connecting tube in a counter-flow arrangement with the oxidized particles moving upward, essentially pre-heating them.

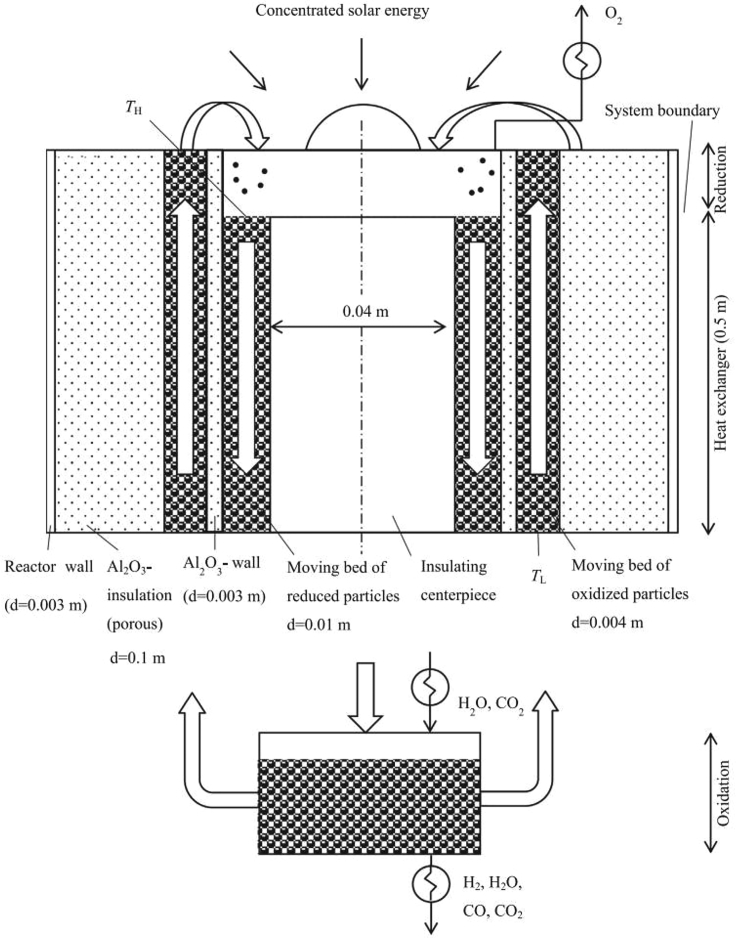

Rotary-type reactors

To decouple the reduction and oxidation processes in space and time for potential 24-h syngas generation, Kaneko et al.212 used a special reactive ceramic to develop and fabricate the rotary-type reactor for the production of solar hydrogen through a two-step WS reaction. The dual-cell rotary-type reactor has two distinct types of reaction rooms: one for oxygen discharge and the other for splitting of H2O. Its efficiency and detailed specifications were examined. In oxygen discharging and H2O-splitting reaction cells, oxygen and hydrogen underwent successive evolutions, respectively. With Ni and Mn-ferrite, the optimal reaction temperatures for the reactions were 1173 K and 1473 K, respectively. The same research group further210 used the rotary solar reactor with CeO2 and found that the optimal reaction temperatures of the O2-releasing and H2O-splitting were 1623 K and 1273 K, respectively. It was demonstrated that the approximately 10-fold scaled-up rotary-type reactor was able to achieve a higher O2-releasing reaction temperature of over 1800 K. Lapp et al.202 predicted heat transfer for a rotary-type reactor that uses direct radiation to create a metal oxide-based nonstoichiometric redox cycle for making synthesis gas from CO2 and H2O. In this reactor, the reactive porous medium forms the outer cylinder, which alternates between the high-temperature reduction zone and the low-temperature oxidation zone. Chemically inert and heat-recovering solid makes up the inner cylinder. This system therefore can transfer heat from a porous reactive material’s rotating hollow cylinder to an inert solid cylinder in form of radiation. A parametric study of the geometric and material parameters resulted in a heat recovery efficiency of more than 50%.

The CR5 reactor

The CR5 reactor has the most distinctive feature of a stack of counter-rotating rings or disks that are surrounded by fins made of a redox metal oxide. The reactive material moves back and forth between a relatively low-temperature hydrolysis reactor where the reactant material undergoes a H2O-splitting reaction and a solar-irradiated high-temperature TR as the rings rotate. After rotating, each ring rotates in the opposite direction of its neighbor. The oxidized redox material in the fins meets hotter fins leaving the TR reactor on both sides as it enters the recuperator from the H2O-splitting reactor. As the adjacent fins moving in the opposite direction cool, it heats up in the recuperator. Diver et al.213 first invented the CR5 two-step solar-driven thermochemical heat engines based on working materials made of iron oxide and iron oxide mixed with other metal oxides (ferrites). A major obstacle to achieving highly efficient thermal recuperation between solids in effective counter-current arrangements was overcome by employing two sets of moving beds that are adjacent to one another but moving in opposite directions. They also naturally separated the product of hydrogen and oxygen. The core of the CR5 system is a set of annular rings made of reactive solid ferrite. These rings are cycled chemically and thermally to produce O2 and H2 from H2O in separate steps. From a material standpoint, this design is extremely demanding. After months of thermal cycling and exposure to temperatures greater than 1100°C, the ferrite rings must maintain their high reactivity and structural integrity. In addition, the rings must have a large geometric surface area to adsorb incident solar radiation and make contact with the solids.

As successful application of ceria-based materials in thermochemical redox cycle, Diver et al.178 further designed and built a CR5 thermochemical heat engine prototype made of ceria, and tested its redox cycle performance in the 16 kWt National Solar Thermal Test Facility (NSTTF) solar furnace in Albuquerque, NM. The initial tests indicated the CR5 was promising thermochemical heat engine concept for fuel production and would achieve ultimate goal of 20% efficiency in the future. Miller et al.214,215,216 carried out a series of initial screenings, selected Co0.67Fe2.33O4 as the starting point for demonstration of the CR5 and further characterized and developed this material. Robocasting was used to produce monolithic structures with intricate three-dimensional geometries for chemical, physical, and mechanical evaluation concurrently with the powder studies. Ferrite/zirconia mixtures can be made into small, 3D and monolithic lattice structures that gave consistent hydrogen yields over multiple cycles. Kim et al.217 presented a comparison of the environmental effects of gasoline derived from petroleum and sunshine to petrol (S2P) using a life cycle assessment (LCA) method. According to the findings, S2P gasoline scored lower than conventional gasoline in all of the impact categories. The environmental benefits, such as the reduction of greenhouse gases and the reduction of external costs, were then examined in light of the findings of the LCA. Based on the current fleet of vehicles, it was determined that 3.6 Mt CO2-eq of greenhouse gas emissions (77% of the total regional emissions) would be mitigated if S2P gasoline could be successfully introduced to satisfy the gasoline demand. In addition, the reduced impact results in annual cost savings of 4.2 million dollars due to avoided environmental damage.

Intermittent utilization of thermal energy

In contrast to the continuous utilization of thermal energy, another strategy where the thermal energy is being used intermittently has also been studied worldwide. The intermittent utilization of thermal energy enables the reduction and oxidation steps to happen separately or within the same system. The major types of such reactor structures include packed bed reactors, spouted bed reactors, honeycomb reactors and foam reactors. Their partial representatives are summarized in Table 3. The details are discussed in the following sections.

Table 3.

Comparison among different types of reactors for intermittent utilization of thermal energy

| Reactors | Solar irradiation types | Thermochemical process | Redox material and its shape | Power | Maximum temperature | Solar conversion efficiency | Reference |

|---|---|---|---|---|---|---|---|

| Packed bed reactor | Directly | Dissociation of H2O | Ni0.5Mn0.5Fe2O4 powder | ∼15 kW | ∼1373 K | / | Tamaura et al.218 |

| Internally circulating fluidized bed | Directly | Dissociation of H2O | NiFe2O4/m-ZrO2 particles | ∼1.2 kW | / | <1% | Gokon et al.219 |

| Internally circulating fluidized bed | Directly | Dissociation of H2O | NiFe2O4/m-ZrO2 particles | ∼1 kW | ∼1500°C | / | Gokon et al.220 |

| Windowed solar chemical reactor | Directly | / | Coal coke particles | ∼0.94 kW | ∼850°C | 12% | Kodama et al.221 |

| Stacked bed-Fixed bed | Directly | Dissociation of H2O | Ferrite-coated monoliths | ∼100 kW | ∼1473 K | / | Roeb et al.222 |

| Solar receiver-reactors | Directly | Dissociation of H2O | Iron-oxides coated on ceramic substrate | ∼100 kW | 1200°C | / | Neises et al.223 |

| Monolithic reactor | Directly | Dissociation of H2O | Ferrites ceramic honeycombs | / | 1300°C | / | Agrafiotis et al.224 |

| Monolithic reactor | Directly | Dissociation of H2O | Monolith coated with ZnxFe1-xO | / | / | / | Roeb et al.225 |

| Honeycomb reactor | Directly | Dissociation of CO2 | Zirconia and iron oxide ceramic honeycombs | / | 1200°C | / | Walker et al.226 |

| Solar cavity reactor | Directly | Dissociation of H2O | / | ∼1 MW | 1020°C | / | Houaijia et al.227 |

| Foam reactor | Directly | Dissociation of H2O | Fe3O4 or NiFe2O4 reticulated ceramic foam | ∼0.7 kW | 1773 K | / | Gokon et al.228 |

| Quartz reactor | Directly | Dissociation of H2O | Fe3O4/c-YSZ particles | 7 kW | 1450°C | / | Gokon et al.100 |

| Foam reactor | Directly | Dissociation of H2O | NiFe2O4/m-ZrO2 or Fe3O4/m-ZrO2 powders | 7 kW | 1450°C | / | Gokon et al.22 |

Packed bed reactors

In 1995, Steinfeld et al. reported their work on utilizing a packed bed solar reactor for the two-step water splitting cycle.218 The design of the reactor is as shown in Figure 7, which is composed of a 2 cm-diameter quartz tube containing a packed-bed of powder reactants. The reactants were made of Ni0.5Mn0.5Fe2O4 powder mixed with Al2O3 grains for avoiding sintering. During its operation, the reactor was first heated to about 1373 K by directly exposing it to the solar flux for releasing the oxygen from the ferrite lattice with the carrying gas of a flow of 0.3 L min−1 Ar passing through the sample. Thereafter, the reactor would be cooled down to 573 K while 0.04 L min−1 steam carried by 0.8 L min−1 Ar passing through the sample for 5 min. By further raising the reactor temperature to 773 K, 823 K, and 873 K, the oxidation process would take place and H2 would be produced. Such a novel design thus eliminated the need for high-temperature gas separation while proving the capability of this designed system for reduction and oxidation reactions in the same structure.

Figure 7.

Design of packed bed reactor

Reproduced with permission.218 Copyright 1995, Elsevier.

Spouted bed reactors