Graphical abstract

Keywords: Ultrasonic assisted extraction, Extract, Bioactive components, Equipment, Combined technologies

Highlights

-

•

The research progress of UAE for bioactive components was overviewed.

-

•

The application of ultrasonic in extracting bioactive components had great potential.

-

•

Ultrasonic enhances extraction speed and the extracts with better quality and yield.

-

•

Ultrasonic ruptures cell walls, aiding content release and improving mass transfer.

Abstract

The increasing focus on health and well-being has sparked a rising interest in bioactive components in the food, pharmaceutical, and nutraceutical industries. These components are gaining popularity due to their potential benefits for overall health. The growing interest has resulted in a continuous rise in demand for bioactive components, leading to the exploration of both edible and non-edible sources to obtain these valuable substances. Traditional extraction methods like solvent extraction, distillation, and pressing have certain drawbacks, including lower extraction efficiency, reduced yield, and the use of significant amounts of solvents or resources. Furthermore, certain extraction methods necessitate high temperatures, which can adversely affect certain bioactive components. Consequently, researchers are exploring non-thermal technologies to develop environmentally friendly and efficient extraction methods.

Ultrasonic-assisted extraction (UAE) is recognized as an environmentally friendly and highly efficient extraction technology. The UAE has the potential to minimize or eliminate the need for organic solvents, thereby reducing its impact on the environment. Additionally, UAE has been found to significantly enhance the production of target bioactive components, making it an attractive method in the industry. The emergence of ultrasonic assisted extraction equipment (UAEE) has presented novel opportunities for research in chemistry, biology, pharmaceuticals, food, and other related fields. However, there is still a need for further investigation into the main components and working modes of UAEE, as current understanding in this area remains limited. Therefore, additional research and exploration are necessary to enhance our knowledge and optimize the application of UAEE. The core aim of this review is to gain a comprehensive understanding of the principles, benefits and impact on bioactive components of UAE, explore the different types of equipment used in this technique, examine the various working modes and control parameters employed in UAE, and provide a detailed overview of the blending of UAE with other emerging extraction technologies. In conclusion, the future development of UAEE is envisioned to focus on achieving increased efficiency, reduced costs, enhanced safety, and improved reliability. These key areas of advancement aim to optimize the performance and practicality of UAEE, making it a more efficient, cost-effective, and reliable extraction technology.

1. Introduction

Plant active components refer to a wide range of substances that constitute the plant body, including essential components like water, sugars, proteins, fats, and other compounds. These components also include secondary metabolites such as terpenes, flavonoids, alkaloids, steroids, lignin, and minerals. The majority of plant active components are primarily located within the vacuole of cell protoplasm. When a solvent enters the cell tissue, it dissolves these active components, which then transform into a leaching solution [1]. Bioactive components found in plants possess significant physiological activity and economic value [2], [3]. As a result, the extraction of these bioactive components from plants holds immense importance, particularly in industries such as bioengineering, pharmaceutical engineering, and food processing. Extraction serves as a pivotal unit in the production and processing of these industries. The extraction technology employed has a direct impact on the consumption of materials and energy during production, as well as the quality and quantity of the final product. Hence, selecting and optimizing the extraction process is crucial to achieving efficient and high-quality extraction of bioactive components from plants [4].

Traditional thermal extraction processes such as Soxhlet extraction, water distillation extraction, steam distillation extraction has been used to extract bioactive compounds from plants. However, traditional thermal extraction methods have drawbacks such as high energy consumption, loss of volatile components, difficulty in controlling extraction efficiency, disadvantage for thermosensitive substances, dependence on the use of large amounts of solvents, and long processing cycles. Thermal processing also causes changes in various physical and chemical parameters, and also reduces the activity of such biologically active substances. In recent years, there has been a surge in the development of emerging extraction technologies, such as ultrasonic assisted extraction (UAE), microwave assisted extraction (MAE), and supercritical fluid extraction (SFE). These cutting-edge techniques aim to address the limitations of traditional methods by offering advantages like reduced extraction time, lower solvent consumption, improved extraction rates, and enhanced extract quality. By efficiently, economically, and environmentally friendly extracting bioactive components from the complex matrix of plants, these innovative extraction technologies have revolutionized the field of extraction [5]. In recent years, green extraction has emerged as a prominent research direction in the field of extraction technology. It focuses on developing environmentally friendly solvent extraction methods that can effectively reduce consumption, minimize energy waste, mitigate environmental pollution, and simultaneously enhance extraction yield [6]. Ultrasonic technology plays a pivotal role in achieving the principles of green chemistry and extraction objectives [7]. UAE enables the efficient extraction of targeted bioactive components by leveraging its distinct cavitation effect. This innovative technique not only reduces the extraction time but also enhances the quality and yield of the extract. The UAE exhibits exceptional advantages when extracting bioactive components from plants. Complete extraction with higher purity of the final product can be achieved by ultrasonication in a few minutes with high reproducibility, thus reducing the use of organic solvents. By employing the UAE, researchers can achieve the dual goals of efficient extraction and sustainable practices in a more environmentally friendly manner [8], [9], [10], [11], [12]. Furthermore, research findings have demonstrated that when employing optimized UAE conditions, it is possible to preserve the biological characteristics of the extract. This is a significant advantage, as it ensures that the extract retains its desired biological activity and functionality, thereby enhancing its potential applications in various fields [13]. Consequently, when compared to traditional extraction technologies, UAE emerges as an economical and highly efficient extraction technique. Ultrasonic technique is a proven green bio-refining technology, primarily due to its ability to lower the solvent consumption costs, reduce operation time, lower energy consumption and produce higher yields. These advantages directly address the rising market demand for plant bioactive components. Most current studies mainly introduce the principles of UAE and the factors that affect the extraction results. While most existing studies primarily focus on elucidating the principles of UAE and factors influencing extraction outcomes, they collectively highlight the immense potential of UAE as a transformative extraction technology for meeting the evolving needs of industries reliant on plant-derived bioactive components. Nevertheless, despite the extensive research on the principles and influencing factors of UAE, the available information regarding the commonly used types, working principles, and working modes of UAE is still limited. As a result, this study aims to provide a comprehensive overview of the UAE, not only offering a detailed summary of its principles and influential factors but also presenting an in-depth introduction to the various types, working principles, and working modes of the UAE. It also provides research on the application of hyphenated technology which combines UAE with other processing technologies in the food industry.

2. Ultrasonic assisted extraction technology

Sound waves occur when there is a variation in stress, particle displacement, and particle velocity within an elastic medium. When the frequency of these waves reaches the ultrasonic range, they are referred to as ultrasonic waves. Unlike electromagnetic waves, ultrasonic waves are mechanical in nature and can propagate through solid, liquid, and gaseous mediums [14]. Ultrasonic technology has found application across a wide range of fields. It has proven to be valuable in diverse areas such as medical testing, non-destructive testing, distance measurement, welding, cleaning, and food technology, among others [15]. The applications of ultrasonic technology are typically categorized into two distinct groups: low-intensity ultrasonics and high-intensity ultrasonics [16]. Low intensity ultrasonic is distinguished by its high frequency ranging from 5 to 10 MHz, along with a relatively low power level of less than 1 W/cm2. It is non-destructive and is well-suited for the testing and characterization of various stuffs, hence low intensity ultrasonic is also known as diagnostic ultrasonic [14]. High intensity ultrasonic technology, often referred to as power ultrasonics, operates at low frequencies ranging from 20 to 100 kHz and substantial power levels ranging from 10 to 1000 W/cm2. Unlike low intensity ultrasonics, high intensity ultrasonics are characterized by their destructive capabilities. It is an effective method to accelerate the chemical reaction by cavitation. The implosion of cavitation bubbles releases energy that can lead to various effects such as extraction, crushing, and emulsification [17].

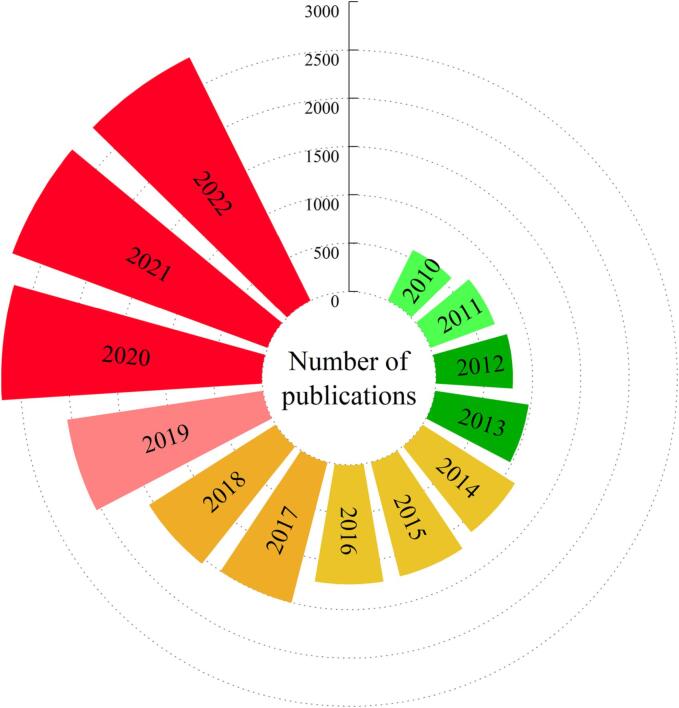

Fig. 1 shows the evolution of publications about UAE since 2010. On the whole, researchers' attention to UAE has increased dramatically over the past few decades.

Fig. 1.

Evolution of publications about UAE since 2010 (The search terms used for this chart were ultrasonic extraction or ultrasound extraction, and the database is WEB OF SCIENCE).

2.1. The principle of UAE

UAE belongs to power ultrasonic. Power ultrasonic is a branch of ultrasonology that focuses on the use of ultrasonic energy to process matter. UAE uses the thermal effect, the mechanical effect and the cavitation effect to extract bioactive components. During the action of ultrasonic, the cell wall is destroyed, while accelerating the release and diffusion of components in the cell [7]. In recent years, researchers have proposed several ultrasonic mechanisms of UAE. Several physical mechanisms, including fragmentation, erosion, the sonocapillary effect, sonoporation, local shear stress, and detexturation, have been identified and extensively discussed in numerous review articles [7], [18], [19].

The thermal effect of ultrasonic refers to the phenomenon where the vibration energy of ultrasonic is absorbed by the medium and converted into heat. Consequently, the heat of the medium increases accordingly. The calorific value is dependent on factors such as the properties of the medium, ultrasonic power, and exposure time [20]. The mechanical effect of ultrasonic refers to the phenomenon where the application of ultrasonic to a medium induces the vibration of particles within the medium in accordance with the mechanical wave. As a result, the motion of particles is enhanced, leading to an accelerated process of mass transfer [1]. Among the various ultrasonic effects, the cavitation effect is considered to be the most predominant [21]. Ultrasonic cavitation means that under the influence of the ultrasonic, the minuscule bubbles (cavitation nuclei) within the liquid undergo vibrations, expansion, and ongoing accumulation of energy from the acoustic field. And once the energy surpasses a specific threshold, the cavitation bubble collapses and closes sharply. There are generally two classifications of cavitation bubbles: transient cavitation bubble and stable cavitation bubble. The stable cavitation bubble has a relatively long life while the transient cavitation bubble exists for a very short time. When the cavitation bubble collapses sharply, it releases significant energy, creating a microjet that reaches speeds of about 200–700 m/s [166]. And this microjet possesses a substantial impact force. At the instant of sharp collapse, the cavitation bubble generates localized high temperature and high pressure (5000 K, 2000 atm), accompanied by an impressive cooling rate of up to 109 K/s [1]. During cavitation, intense hydrodynamic shear forces are present, which can result in the formation of free radicals and an increase in pressure and temperature [22]. Fig. 2 depicts the cavitation effect of ultrasonic.

Fig. 2.

The cavitation effect of ultrasonic.

The UAE applies the thermal effect, the mechanical effect and the cavitation effect produced by ultrasonic to the extraction process. As shown in Fig. 3, ultrasonic can enhance the penetration of solvents into cells, leading to improved mass transfer. Additionally, ultrasonic can disrupt cell walls, facilitating the release of cellular contents [23], [24], [25], [26]. Therefore, effective cell fragmentation and effective mass transfer are considered to be the two factors leading to the increase of production after employing UAE [27], [28]. In addition, of greater importance is the effect of ultrasound on changes in the intracellular matrix, as it has the potential to induce changes in the internal structure of the matrix [7]. While many laboratory scale studies attribute the increase in production to factors such as efficient cell fragmentation and enhanced mass transfer through UAE, another study presents a different perspective. This study suggests that the primary reason for the production increase after UAE is the enhanced solubility of substances, rather than the observed cell fragmentation [29]. The impact of UAE on different bioactive components varies when used in the extraction process. While most studies have reported an increase in the concentration of bioactive components due to ultrasonic treatment, there are also studies suggesting that ultrasonic cavitation can lead to the formation of free radicals and the subsequent reduction of bioactive components [30]. Thus, the effect of UAE on bioactive components can be both positive and potentially negative, depending on the specific conditions and parameters employed during the extraction process. As outlined in Chapter 3 of the article, achieving optimal extraction efficiency through UAE requires careful parameter optimization. The choice of extraction parameters significantly influences the extraction results. It is important to note that these different extraction parameters can also impact the physicochemical properties of bioactive components, further emphasizing the need for meticulous optimization to achieve desired outcomes.

Fig. 3.

The mechanism of ultrasonic assisted extraction. (a) indicates that ultrasonic will act on intact cell. (b) indicates cell rupture after ultrasonic treatment. (c) indicates that the bioactive components are released.

2.2. The effect of UAE on bioactive components

The UAE not only offers significant advantages in increasing the yield of bioactive components but also exerts certain favorable or unfavorable effects on the physicochemical properties of bioactivity. Using the three most common bioactive components (proteins, polyphenols, polysaccharides) as exemplars, the ensuing discussion will elucidate the influence of UAE on these bioactive components.

Protein is the most commonly encountered bioactive component. The structure of proteins can be categorized into four structural levels, which include primary, secondary, tertiary, and quaternary structures. The functionality of proteins is determined by its molecular structure. When subjected to high-intensity ultrasonic waves, proteins can undergo modifications that result in functional alterations. The disruptive effect of ultrasonic treatment on the interactions between protein molecules can lead to protein unfolding, thereby increasing the exposure of protein surfaces. This unfolding phenomenon induced by ultrasonic treatment has the potential to impact the functionality of proteins [31]. Different ultrasonic treatments conditions can change the secondary structure of protein to different extent. Specifically, low-frequency ultrasonic treatments (20, 28, and 35 kHz) have a more pronounced effect on the secondary structure of proteins compared to high-frequency ultrasonic treatments (40 and 50 kHz). This suggests that the choice of ultrasonic frequency significantly influences the extent of changes observed in the secondary structure of proteins [32]. Xue et al. [33] reported that ultrasonic pretreatment of rice protein can lead to spreading out of the α-helix region and the shaping of β-sheet. Similarly, Jin et al. [34] highlighted that subjecting corn prolamin to ultrasonic pretreatment resulted in noticeable changes in its secondary structure. Specifically, the ultrasonic treatment led to a reduction in the content of α-helix and an increase in the content of β-sheets within the prolamin. However, Huang et al. [35] observed the application of ultrasonic treatment for more than 10 min on soy protein isolate resulted in a significant increase in α-helix content, along with a noticeable decrease in the content of random coil structures. The disparity in these results could be attributed to variations in the inherent properties of different proteins and the specific methods employed for ultrasonic treatment. When using UAE for protein extraction, it is important to consider both the absolute sound pressure and the uniform distribution of the sound field. Similarly, ultrasonic power and time need to be taken into account. These considerations are crucial as they can potentially influence changes in protein structure, ultimately enhancing extraction efficiency.

Polyphenols are the collective term for all phenolic derivatives, mainly phenolic acids and flavonoids. UAE has demonstrated enhanced extraction efficiency for polyphenols compared to conventional methods, leading to higher yields of these valuable compounds. However, Zhang et al. [36] noted that gallic acid undergoes degradation when subjected to ultrasonic treatment. Similarly, catechin in tea can also be degraded under specific ultrasonic conditions. Furthermore, within a certain range, the degradation rate of catechin increases as the ultrasonic frequency and input power are elevated [37]. This might be due to under higher ultrasonic power, free hydroxyl radicals are generated, which form a reaction with phenolic compounds and disintegrate them. Thus, it is essential to evade the degradation of polyphenols triggered by higher power. Furthermore, in the case of polyphenol extraction using UAE, it is noteworthy that the optimal effectiveness is observed when utilizing a lower frequency, specifically below 40 kHz [13]. In parallel with the influence exerted by high ultrasound power, high-frequency ultrasound carries the potential to generate a significant quantity of free radicals, leading to the degradation of polyphenols and subsequent reduction in their biological activity. Moreover, due to the susceptibility of numerous phenolic compounds to hydrolysis and oxidation at elevated temperatures, it is imperative to carefully select an appropriate extraction temperature that ensures the maintenance of phenolic compound stability. Several studies have indicated that employing suitable ultrasonic conditions can not only enhance the content of phenolic compounds but also improve their antioxidant activity [38], [39]. On the other hand, the molecular weight of polyphenols may decrease under certain ultrasound conditions. This is because ultrasound can generate intense mechanical and shear forces, that can lead to molecular fracture and degradation. As a result, the average molecular weight of polyphenol molecules can be reduced, potentially improving their digestion, absorption, and utilization by organisms and increasing their bioavailability.

Polysaccharides are high molecular-weight compounds formed by a large number of monosaccharides through glycosidic bonds. Intense ultrasonic will excite loads of reactions within polysaccharides, for instance glycosylation, actualization, and oxidation [24]. Ultrasonic may reduce polysaccharide molecular weight. Kang et al. [40] discovered that the average molecular weight of Ganoderma lucidum polysaccharides extracted using hot water was higher when compared to those obtained through ultrasonic. In another investigation, a comparable outcome was observed, as the average molecular weight of starch exhibited a reduction from 3000KDa to 500KDa subsequent to undergoing ultrasonic treatment [41]. In addition, ultrasonic can enhance the bioactivities of polysaccharides. Xu et al. [42] conducted research to examine the impacts of ultrasonic on the characterization and bioactivities of the polysaccharide derived from blackcurrant fruits. It has been observed that ultrasonic treatment significantly enhances the antioxidant activity, including the hydroxyl and superoxide radicals scavenging, lipid peroxidation inhibition, and DNA damage protection activities. Additionally, it has also been found that ultrasonic treatment increases the α-amine and α-glossidase inhibition activities of polysaccharides. Specifically, higher power ultrasonic treatment at 600 W demonstrates superior effectiveness compared to lower power treatment at 400 W. However, another study showed that the antioxidant activity of Ganoderma lucidum polysaccharides, extracted using ultrasonic, exhibited a lower level compared to the traditional hot water extraction [40]. The researchers in this study proposed two explanations for these results. Firstly, they suggested that the antioxidant properties of polysaccharides may depend on the ratios of different monosaccharides present in their composition, as well as the specific linkages of their side chains. Secondly, they observed that the average molecular weight of Ganoderma lucidum polysaccharides treated with ultrasonic (465.65 KDa) was lower than the average molecular weight of Ganoderma lucidum polysaccharides extracted using hot water (703.45 KDa). This suggests that intense ultrasonic treatment can potentially cause damage to the primary structure of the polysaccharides, affecting factors such as the type of glycosyl units, substituents, and configuration of glycosidic bonds. On the other hand, the use of ultrasound can improve bioavailability. This is due to the ability of ultrasound can reduce the molecular weight of polysaccharides, which is beneficial for digestion, absorption, and utilization.

The aforementioned research findings collectively demonstrate that excessive ultrasound power, frequency, and duration can potentially lead to the loss or degradation of bioactive components. Therefore, it is imperative to make informed parameter selections based on specific circumstances to ensure maximal bioavailability during the UAE process.

2.3. The advantages of UAE

Fig. 4 illustrates the difference between the conventional extraction technique and the developed UAE. UAE offers distinct advantages, notably a significantly higher extraction rate and bioavailability rate [28]. The distinctive physical properties of ultrasonic waves enable them to effectively disrupt plant cell tissues, leading to the rupture or deformation of cell walls. This facilitates a more thorough extraction of the desired components, resulting in a significantly higher extraction rate compared to traditional methods. Moreover, the UAE offers the advantage of shorter extraction times while maintaining high extraction efficiency. Oprescu et al. [43] utilized UAE technology to extract rapeseed oil and compared its performance with the reflux method and impregnation method. The findings revealed that the UAE method achieved an extraction rate of 19.2 ± 0.04 within a remarkably short period of 5 min. The rate of increase then gradually slowed to reach an extraction rate of 21.36 ± 0.04 after 30 min. In comparison, the reflux extraction and impregnation methods yielded extraction rates of 21.32 ± 0.05 and 20.44 ± 0.05 respectively after 30 min. Although there is only a marginal disparity in the final extraction rates among the three methods, the advantage of the UAE method lies in its ability to approach oil saturation concentration in a significantly shorter timeframe. Furthermore, the UAE offers the advantage of low extraction temperatures. The optimal temperature range for UAE is typically set between 40 and 60° C, which proves beneficial for preserving the integrity of active components in materials. This is particularly important for compounds that are susceptible to degradation, hydrolysis, or oxidation at higher temperatures. Simultaneously, the utilization of lower extraction temperatures serves as an energy-saving approach, contributing to reduced energy consumption during the extraction process [44]. Fourthly, it is worth noting that water serves as the ideal medium for propagating ultrasonic waves [45], Therefore, when employing UAE, the process of water-based extraction is significantly enhanced without the need for additional solvents. In addition, when solvents are utilized, UAE offers the advantage of reducing the overall volume of solvents required for the extraction process. Bilgin et al. [46] obtained scarlet sage (Salvia Coccinea) extract using homogenizer assisted extraction and UAE respectively. The findings indicated that UAE shortened the extraction time and reduced the solvent consumption. Fifth, the extracted bioactive components has high purity [47], [48]. In the case of less impurity, separation and purification of effective components more easily achieved. Sixth, wide adaptability. The UAE method offers the advantage of being non-restricted by component polarity or molecular weight, making it suitable for extracting a wide range of plant types and various components [7]. Seventh, the UAE method is characterized by its simplicity and ease of operation [49]. Due to convenient equipment maintenance and low operating costs of the extraction process, the comprehensive economic benefits are significant. As a result, UAE technology is regarded as a green extraction technology. UAE is not limited to small scale extraction in laboratory settings but can also be successfully applied in pilot and industrial-scale operations.

Fig. 4.

Comparison between traditional extraction technique and developed UAE.

Indeed, the UAE process has some drawbacks. One prominent issue is the generation of approximately 65 dB of noise by the ultrasonic equipment during operation. To address this challenge, a feasible solution involves incorporating a sound shield, which increases the cost of the equipment. The second is the issue of UAE parameters need to be optimized. Several variables can impact the outcome of UAE. And the extraction parameters of different bioactive components on different substrates are not the same, so need to go through lots of experiments to optimize extraction parameters. Another challenge in the UAE process is the need to optimize the extraction parameters. Numerous factors can impact the effectiveness of UAE, and these parameters can vary for different bioactive components and substrates. Consequently, extensive experimentation is required to determine and fine-tune the optimal extraction parameters for each specific case. This iterative optimization process ensures that the UAE technique is tailored to achieve the best possible extraction outcomes based on the target bioactive components and substrate characteristics.

3. The factors affecting the extraction effect of UAE

Fig. 5 displays the factors that will affect the extraction effect when using UAE to extract bioactive components from plants, including physical parameters of ultrasonic equipment (such as power, frequency, etc.), characteristics of extraction solvent (such as viscosity, surface tension, etc.), and environmental parameters of extraction (such as temperature, pressure, etc.). To attain the optimum extraction efficiency, it is imperative to adjust these parameters. In the absence of optimized extraction conditions, UAE may result in low extraction efficiency, or even lower extraction efficiency than traditional extraction methods. Furthermore, inappropriate conditions may adversely affect the physicochemical properties and biological activities of bioactive components. For instance, high-frequency ultrasound can generate a large number of free radicals, disintegrate polyphenols, and diminish their biological activity [13]. Another study has proposed that ultrasonic conditions can affect the structure of proteins after UAE [50].

Fig. 5.

Factors affecting the extraction effect of UAE.

3.1. The physical parameters of UAE

3.1.1. Power of ultrasonic

Ultrasonic power in direct proportion to ultrasonic amplitude. Higher ultrasonic power generates a stronger shear force, which, in turn, enhances the yield and extraction efficiency of UAE [14]. Wang et al. [51] extracted curcumin species from turmeric with different ultrasonic power, it was observed that increasing the power from 100 W to 200 W led to an increase in yield. Also, Nipornram et al. [52] noticed a progressive rise in the yield of mandarin peel extract as the power level escalated from 30.34 to 59.36 W. However, pursuing a higher power may have negative effects. Ćurko et al. [53] observed a significant reduction of total polyphenols and total anthocyanidin in wine under high power. Because under high ultrasonic power, hydroxyl radicals are generated, which react with phenolic compounds and degrade them [13]. Similarly, Zhu et al. [54] revealed that there was a decrease in polysaccharide extraction from polygonum multiflorum when the ultrasonic power exceeded 140 W. Additionally, it was observed that the use of very high-intensity UAE or prolonged application of UAE can result in significant protein denaturation [22]. Hence, it is crucial to optimize the power parameters during the extraction experiment and carefully choose the suitable power level based on the specific characteristics of the sample.

3.1.2. Power density of ultrasonic

Power density, also known as ultrasonic intensity. Without losing the mass transfer efficiency, it can be represented by the following formula (1). Power density can better describe the intensity of ultrasonic compared to ultrasonic power.

| (1) |

where UI represents ultrasonic intensity (W/cm3), P denotes for ultrasonic power (W) and V stands for sample volume (cm3).

Generally, an increase in ultrasonic intensity (UI) results in a proportional increase in the acoustic chemical effect. This is due to the fact that higher UI leads to an increased number of cavitation bubbles. However, beyond a certain limit, excessive UI can lead to bubble collisions, which in turn reduce the cavitation effect. Furthermore, during the utilization of an ultrasonic probe, a significant accumulation of cavitation bubbles occurs on the surface of probe. This accumulation can impede the transfer of energy and subsequently diminish the efficiency of extraction [55]. Moreover, considering the properties of certain target molecules, the use of high-intensity ultrasonic power can cause the degradation of bioactive substances, ultimately leading to a decrease in extraction efficiency.

3.1.3. Frequency of ultrasonic

Ultrasonic with frequencies exceeding 20 kHz have demonstrated the ability to efficiently extract bioactive components from natural products [56]. Frequencies ranging from 20 kHz to 100 kHz are frequently employed. Frequency has a profound impact on the cavitation effect during extraction. It influences the physical and chemical consequences associated with the bursting of cavitation bubbles during the process. Specifically, frequencies ranging from 20 kHz to 100 kHz primarily govern the physical effects generated by the bursting of cavitation bubbles. On the other hand, frequencies within the range of 200 kHz to 500 kHz predominantly regulate the chemical effects resulting from cavitation bubbles during the extraction process [21]. Zhang et al. [30] used an oscilloscope and spectrum analyzer to observe the oscillation cycle of cavitation bubbles, as well as to analyze the intensity and distribution of the sound field. The research results show that various frequencies exhibit distinct oscillation cycles. As the ultrasonic frequency decreases, the oscillation cycle of cavitation bubbles increases, resulting in a larger bubble radius. Consequently, this leads to the generation of more powerful mechanical waves and a pronounced cavitation effect. There is also a connection between frequency and ultrasonic intensity. In order to attain the intended cavitation effect, the ultrasonic intensity should be amplified with rising frequency to conquer the cohesiveness in the mixture [57]. The choice of frequency range for UAE varies depending on the type of material being extracted. Based on numerous studies, it is generally recommended to use low frequencies (20–40 kHz) for extracting flexible materials such as vegetable matter and algae. On the other hand, rigid structures necessitate the use of higher frequencies (≤500 kHz) [13], [58]. Furthermore, there is a category of sound waves known as megasonic waves which operate within the frequency range of 400 kHz to 2 MHz. High frequency ultrasonic waves in this range as an innovative approach to enhance oil recovery and accelerate milk fat creaming [59]. Consequently, determining the ideal frequency for specific extractions necessitates conducting a significant number of optimization experiments and tests. This process is essential to identifying the most effective frequency tailored to each extract's unique characteristics.

3.1.4. Duty cycle of ultrasonic

The duty cycle is believed to have an indirect impact on the extraction effect by influencing the duration of ultrasonic exposure and the temperature. Kobus et al. [55] examined the effect of duty cycle on phenolic compounds. The study observed that the antioxidant activity of the extracts and the yield of chlorogenic acid, rutin, and total flavonoids were noticeably influenced by the duty cycle. Moreover, the study determined that the impact of the duty cycle on the yield was contingent upon the strength and time of the ultrasonic treatment.

3.1.5. Time of extraction

Extending the extraction time can enhance the extraction yield. However, it also carries the risk of degrading plant components due to prolonged exposure [60]. To accommodate longer ultrasonic processing times, it is advisable to utilize the pulse mode. This mode involves the generator periodically activating and deactivating the power of the ultrasonic probe. By intermittently switching the power, the pulse mode effectively prevents excessive buildup of reaction temperature during extended processing durations. Moreover, Kobus et al. [55] showed that the utilization of pulsed ultrasonic leads to energy savings ranging from 20 % to 51 % while achieving an increase in extraction efficiency. Yogesh et al. [61] used ultrasonic to enhance the extraction of catechins from the bark of Syzygium cumini. And they studied how varying ultrasonic times affected the extraction outcome. Experimental trials were conducted at temperatures of 30° C, 40° C, 50° C, and 60° C. The results showed that the extraction yield initially increased as the extraction time was prolonged to 15–20 min. However, beyond this point, longer extraction times led to a decrease in yield. Based on these findings, Yogesh et al. recommended keeping the processing time relatively short, typically between 5 and 15 min, depending on the specific component being extracted and the ultrasonic method employed [61].

3.1.6. The efficiency of the transducer

The efficiency of an ultrasonic transducer refers to the percentage of the output power to input power. In ultrasonic transducers, a portion of the input alternating current power is converted into electromagnetic losses, while the remaining energy is transformed into mechanical power through vibrations. A portion of the mechanical power is lost due to factors such as friction and sound absorption, while the remaining portion is emitted as radiation power to the sound transmission medium. Therefore, the efficiency of the transducer encompasses three distinct aspects and meanings: electromechanical efficiency, mechanical-acoustic efficiency, and electroacoustic efficiency. It is essential to enhance the efficiency of energy conversion in the transducer and reduce unnecessary energy losses. This entails selecting suitable manufacturing materials and considering the geometric shape of the transducer, both of which can impact the extraction effectiveness. Zea et al. [62] conducted a study to evaluate the acoustic properties of four transducers with varying geometries and assess their effectiveness in the extraction. These four transducers are the base model (T1), a larger cylindrical headmass (T2), a stepped circular section sonotrode (T3) and a multiplate configuration (T4). The result showed that the T4 exhibited the highest nominal power density. The T2 generated an evenly distributed ultrasonic field and a greater acoustic pressure. Therefore, the shape of the transducer affects the quantity and apportionment of energy transferred to the sample, consequently affecting the extraction effect.

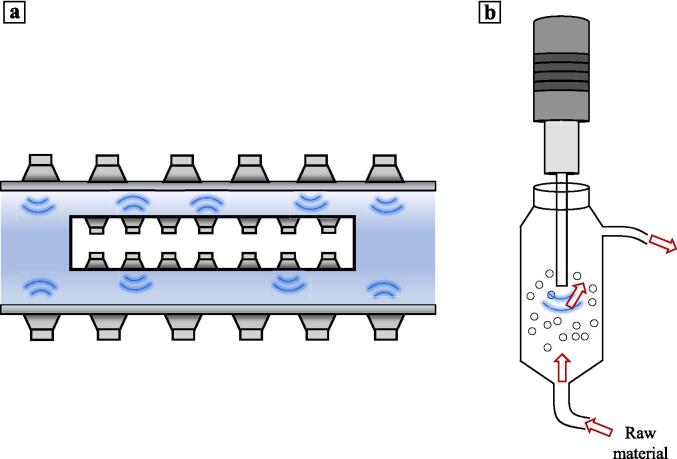

3.1.7. The geometry of the reactor

It is crucial to carefully consider the reactor's shape and size in order to reduce energy loss due to sound wave reflection at solid surfaces. Opting for a flat-bottomed reactor, such as a conical flask, can help minimize wave reflection. Additionally, the thickness of the reactor also influences wave reflection attenuation. Therefore, conducting calculations to determine the optimal shape and size of the reactor becomes necessary in order to reduce energy loss. Moreover, when designing larger ultrasonic reactors, it is important to incorporate multiple transducer arrays to ensure efficient coverage of the sound field. By strategically configuring the transducers, a more effective and comprehensive sound field can be achieved. Fig. 6a illustrates a tubular ultrasonic reactor, which achieves effective coverage of the sound field through multiple transducer arrays. Fig. 6b is a countercurrent ultrasonic device, that realizes the efficient utilization of sound field by changing the flow form of treated samples.

Fig. 6.

Tubular ultrasonic reactor (a) and Countercurrent ultrasonic (b).

The ultrasonic intensity decreases rapidly in both the radial and axial directions when using an ultrasonic probe. To ensure effective extraction, it is essential to maintain an effective spacing between the probe and the bottom of the container. It is also important to avoid any contact between the probe and the container to prevent damage. Consequently, factors such as the vertical position of the probe (that is, the depth at which the probe is submerged) and the horizontal arrangement of the probe all impact the efficiency of UAE. Consideration of these factors is crucial for optimizing the ultrasonic extraction technology. Son et al. [63] studied the effects of the depth at which the probe is submerged, power input and liquid height on the extraction results using an ultrasonic probe in a 500 mL container. The optimal extraction conditions they obtained was an immersion depth of 60 mm, setting input power at 75 %, and liquid height maintained at 70 mm.

3.2. The characteristics of medium

3.2.1. The type of solvent

The selection of solvent relies on the solubility and polarity of the extract. At the same time, the potential impact on UAE should also be considered. For instance, water is commonly used to extract acids, bases, sugars, amino acids and other polar substances. Ethanol is used to extract phenols, aldehydes, ketones, esters and other polar compounds. Chloroform is used to extract vegetable oil, spices, fatty acids and other fat-soluble substances. Ether is commonly used for extracting fat-soluble compounds as well. Benzene is used to extract phenol, phenylacetic acid, benzaldehyde and other aromatic compounds. When selecting an extraction solvent for bioactive compounds, various factors should be considered, including molecular affinity, mass transfer, environmental safety, human toxicity, and economic feasibility. Different solvents have varying properties, leading to different effects of ultrasonic cavitation under identical conditions. Firstly, the polarity and solubility of the target compound in the solvent can significantly impact the extraction efficiency. Secondly, the viscosity of the solvent plays a role, as more viscous solvents reduce the cavitation effect. Finally, the volatility of the solvent should be considered. If the extraction is conducted at higher temperatures for prolonged periods, volatile solvents may evaporate, leading to a potential reduction in extraction efficiency. Taking these factors into account is important when selecting an appropriate solvent for extraction to obtain optimal results. Bellumori et al. [64] had conducted such an experiment that extracting romanic and carnotic acids from rosemary leaves using UAE. The experimental results indicate that using ethanol as the solvent yields a high content of rosmarinic acid (6.8 % of the dried extract), while employing n-hexane as the solvent results in a high content of carnosic acids (13 % of the dried extract). Furthermore, it was found that the concentration of the solvent also affects the extraction results. Xu et al. [65] conducted a research investigation on the relationship between ethanol concentration and the total antioxidant activity of the extract. Specifically, the total antioxidant activity of the extract significantly increased as ethanol concentration raised from 10 % to 50 % (v/v). However, as ethanol concentration raised from 50 % to 90 %, a significant decrease was observed. These results highlight the critical role of ethanol concentration in influencing the antioxidant properties of the extract.

3.2.2. The property of substrate

Several parameters, such as substrate viscosity, surface tension, particle size, and pretreatment techniques, have an impact on the efficiency of UAE. Viscosity and surface tension, for instance, influence the threshold at which cavitation occurs. The motion impedance of the sample to the ultrasonic probe will increase with the stickiness of the sample on the rise. Consequently, it is recommended to use high intensities (or high amplitudes) to generate the required mechanical vibrations for inducing cavitation when dealing with high stickiness samples. Particle size reduction has been found to enhance extraction efficiency, leading to the grinding of samples in some studies. Grinding is just one type of pretreatment method, with others including chemical crushing, enzyme treatment, and degreasing. Numerous studies have demonstrated that extraction rates can be improved through appropriate preconditioning techniques [66]. Liu et al. [67] improved the sulforaphane extracted from broccoli seeds by using UAE through microwave pretreatment. Tzima et al. [68] examined the application of pulsed electric field (PEF) as a pretreatment for UAE to improve the extraction efficiency of phenolics from rosemary and thyme by-products. According to the findings, the utilization of PEF augmented (p < 0.05) the retrieval of phenolic compounds and antioxidant capacity in comparison to the standalone use of UAE. The content of phenolic compounds pretreated with PEF (297 mg GAE 100 g-1 FW) was 1.5 times higher than that treated with UAE alone (196 mg GAE 100 g-1 FW). In addition, the antioxidant capacity of phenolic compounds pretreated with PEF (593 mg TE 100 g-1 FW) was 1.3 times higher than that treated with UAE alone (445 mg TE 100 g-1 FW).

3.2.3. The solvent to material ratio

UAE can better blend solvents and materials, thereby reducing the amount of solvent added. Determining the optimal amount of solvent used in the extraction process holds economic importance. Typically, a larger volume of solvent yields higher extraction yields by enhancing the dissolution efficiency of the target compound. This can be attributed to the fact that an increased solvent-to-material ratio reduces the density of the mixture. As a result, the propagation speed of ultrasonic waves is enhanced while the attenuation of ultrasonic power is decreased. The reduction in mixture density enables more effective energy transfer, thereby improving extraction efficiency. Additionally, the decreased density of the mixture enhances the cavitation effect, further contributing to improved extraction. Understanding and optimizing the solvent-to-material ratio is therefore crucial for maximizing extraction efficiency and achieving higher yields. Maran et al. [69] found in their research that the production of anthocyanidin and polyphenols exhibited a progressive increase when the solid–liquid ratio gradually increased from 1:10 to 1:20 (g/ml). Setyaningsih et al. [70] also obtained the same result. The result showed that a solvent-to-material ratio of 5:1 (ml/mg) could yield more polyphenols than a solvent-to-material ratio of 2.5:1 (ml/mg) under UAE.

3.3. Parameters of environment

3.3.1. The temperature of extraction

The temperature of the sample solution is significant and should maintain at its optimum value. When the temperature is increased, the kinetic energy of the extracting fluid molecules is also increased. This heightened kinetic energy accelerates the diffusion rate of compounds, allowing for a more efficient extraction process. Moreover, the elevated temperature helps to break down the external chemical bonds present in the matrix, further enhancing the effectiveness of the ultrasonic field. However, excessively high temperatures can have detrimental effects on the integrity of the extracted material. While elevated temperatures can enhance extraction efficiency, there is a threshold beyond which the extracted material may be compromised. Wang et al. [164] conducted a study on the effect of temperature on the extraction of pea starch using UAE. According to their research results, as the temperature gradually increases from 30° C to 40° C, the starch production shows a gradual increase. However, beyond 40 °C, the yield decreases significantly. This phenomenon can be attributed to the potential damage to the starch structure caused by excessively high extraction temperatures. Liao et al. [165] conducted a study on the effect of temperature on the extraction of total phenolics and total anthocyanins using UAE. Their research findings indicate that increasing the extraction temperature increases the mass transfer rate of solutes. Therefore, as the temperature increases from 30° C to 45° C, there is an increase in the production of total phenolic and total anthocyanins. However, once the temperature exceeds 45° C, the extraction yield shows a decreasing trend. This can be attributed to the degradation of thermosensitive substances caused by excessively high temperatures. Similarly, prolonged exposure to ultrasonic waves may lead to damage to the ultrasonic transducer. Thus, finding the right balance between temperature and extraction time is crucial to ensuring optimal results without compromising the integrity of the extracted material or the functionality of the ultrasonic equipment. Tekin et al. [71] performed an extraction of essential oils from cloves, employing variables such as temperature, extraction time, and plant concentration. The findings indicated that extraction temperature was an important factor affecting extraction yield. The elevation in temperature leads to a rise in the vapor pressure of the solvent, which subsequently decreases the surface tension and viscosity of the liquid phase. This reduction in surface tension and viscosity enhances the occurrence of ultrasonic cavitation and mechanical decomposition of plant cells. Consequently, mass transfer between the plant material and the solvent is promoted. However, it is important to note that higher extraction temperatures can also result in a reduction of cavitation due to the presence of solvent vapors filling the cavitation voids. This causes the cavitation bubbles to collapse with less intensity. These insights highlight the complex relationship between temperature, ultrasonic cavitation, and the mass transfer processes during extraction, providing a clearer understanding of the underlying mechanisms involved. In conclusion, extraction must be carried out at a suitable temperature to improve the performance of UAE while protecting the structure and function of extract from being destroyed.

3.3.2. Air pressure

Air pressure has an impact on the cavitation bubbles' strength of collapse. Specifically, higher air pressure raises the cavitation threshold, making it necessary to employ a more intense level of ultrasonic energy to induce cavitation. The majority of UAE experiments are conducted under atmospheric pressure conditions, and these experiments have yielded satisfactory results [72]. This suggests that the prevailing atmospheric pressure is generally sufficient to generate the desired effects of ultrasonic cavitation. The use of atmospheric pressure allows for practical and effective implementation of UAE without requiring additional adjustments or equipment modifications.

In summary, a variety of factors can impact the effectiveness of the UAE. The effects of different factors on different substrates and different bioactive components vary greatly. Therefore, it is essential to understand how UAE parameters such as power, frequency, time, and temperature affect the extraction results and efficiency. By optimizing these extraction conditions, we can not only minimize material and solvent waste but also maximize extraction yield and preserve the biological properties of the extract. However, it's important to note that achieving high extraction yields should not be the sole objective of the extraction process. Sustainable practices, including the conservation of non-renewable resources and energy consumption, also need to be considered.

4. Ultrasonic assisted extraction equipment (UAEE)

UAEE is an equipment based on the principles of UAE that researchers continuously improve to effectively extract bioactive compounds from plants. Over the past few years, numerous research institutions and companies have been working on developing new UAEE to meet different application requirements. For example, a continuous flow ultrasonic crusher was developed based on the experimental ultrasonic crusher. The control circuit of this new equipment uses a microcomputer, which can control various functions at will. In addition, continuous flow processing can be performed on the sample, overcoming the disadvantage of ordinary models that cannot be processed continuously. In order to overcome the shortcomings of a single UAEE, a microwave light wave ultrasonic extraction instrument was also developed, which fully utilizes the cavitation effect of ultrasonic and the high-energy effect of light waves (microwaves) to carry out collaborative extraction under low temperature and atmospheric pressure conditions. These devices can effectively extract bioactive components, improve the concentration of bioactive components, improve efficiency on the premise of ensuring the quality, and bring good economic benefits for research and development in field of plant extraction and separation.

4.1. The main components of UAEE

An ultrasonic equipment setup typically consists of two main components: an ultrasonic generator and an ultrasonic oscillator. The term “ultrasonic oscillator” serves as a general term encompassing both ultrasonic transducer and ultrasonic horn.

The ultrasonic generator is an essential component of the equipment responsible for supplying alternating current power to the ultrasonic transducer. It plays a crucial role in generating the electrical power required to drive the transducer effectively [167]. Because of its role in providing power, it is often referred to as ultrasonic power.

The ultrasonic transducer is the core component of ultrasonic equipment [73]. The ultrasonic transducer is responsible for the conversion of energy, transforming the signals or energy from another source into the necessary ultrasonic signals or energy. There are numerous types of ultrasonic transducers available, each designed to fulfill specific requirements and perform particular functions [168], [169]. In terms of electroacoustic ultrasonic transducers, there are piezoelectric transducer, magnetostrictive transducer, electric transducer and electromagnetic transducer, etc. Piezoelectric ceramic ultrasonic transducer has become the most widely used ultrasonic transducer in modern ultrasonic instruments because of its own acoustic characteristics, such as high sound pressure amplitude and low power output [74]. The piezoelectric ceramic ultrasonic transducer is generally of the sandwich type, made up of a group of piezoelectric wafers forming the driving parts. These wafers are sandwiched between matching blocks of the same or different materials (commonly referred to as front and back cover plates), and a certain amount of prestress is applied.

The function of the ultrasonic horn is to magnify the amplitude produced by the ultrasonic transducer. The geometric shapes of the ultrasonic horn include uniform cylinder [75], flat [76], hemispherical [77], conical [78], etc. The magnification of the amplitude is determined by the configuration of the ultrasonic horn. The higher the amplitude provided by the ultrasonic horn, the more intense the ultrasonic treatment will be. The ultrasonic horn is usually made of titanium alloy, because titanium has heat and corrosion resistance properties in addition to low mass and high rigidity.

4.2. Two classifications of UAEE

At present, there are two main types of ultrasonic equipment used in the UAE: bath type ultrasonic equipment and probe type ultrasonic equipment [79]. And the ultrasonic bath (Fig. 7a) and ultrasonic probe (Fig. 7c) are the widely adopted ultrasonic equipment in numerous laboratories worldwide [14]. Among them, the bath type ultrasonic equipment mainly uses horn transducers, which are attached to the bottom of the bath (Fig. 7b) or attached to the four walls. The probe type ultrasonic equipment uses a long strip transducer that is inserted from the top of the target solution (Fig. 7d).

Fig. 7.

Ultrasonic bath (a,b) and Ultrasonic probe (c,d).

In addition, UAEE can be classified into direct extraction equipment and indirect extraction equipment. Direct ultrasonic and indirect ultrasonic are the two forms of UAE [170], [171]. In general, directly ultrasonic extraction can get a lot of extract, but processing the sample amount is not much. On the contrary, the sample size of indirect ultrasonic treatment is larger, but the extraction amount of target compounds is relatively small [1]. The corresponding UAEE of these two ultrasonic forms is represented by the ultrasonic probe and ultrasonic bath, respectively. The probe type ultrasonic equipment is direct ultrasonic extraction equipment, which is widely used in the ultrasonic processing of small volume samples. The ultrasonic bath is an indirect extraction, used to extract a large number of samples. Under the same conditions, the probe ultrasonic has stronger ultrasonic effect than ultrasonic bath [73]. Due to the ultrasound intensity is propagated solely at the tip of the horn [80], the horn is directly immersed in the solution for ultrasonic processing, which increases the contact area with the material and reduces the mass transfer resistance. However, During the procedure of utilizing probe ultrasonic treatment, the temperature of the sample will rise sharply. Also, due to the potential corrosion caused by chemical reactions between the ultrasonic probe material and the sample, the ultrasonic probe is likely to be damaged over time. Although the probe ultrasonic has a stronger ultrasonic effect than the ultrasonic bath, it cannot be understood that the probe ultrasonic is superior to the bath ultrasonic when choosing the ultrasonic mode. However, in terms of energy loss, probe ultrasonic is superior to ultrasonic bath [21]. Because when using an ultrasonic bath, the intensity will decrease as it traverses two media (water bath and sample container) prior to the sound waves reaching the sample. However, compared to probe ultrasonic, the advantage of an ultrasonic bath is that two consecutive experiments do not produce cross contamination. Table 1 shows the extraction experiments performed in recent years using ultrasonic probes and ultrasonic baths.

Table 1.

Extraction experiments using Ultrasonic probes and Ultrasonic baths.

| Equipment type |

Equipment diagram |

Extractive | Extraction conditions |

Extraction effect |

Ref. |

|---|---|---|---|---|---|

| Ultrasonic probe |

|

Polyphenolic from Thymus serpyllum |

P = 750 W f = 20 kHz t = 15 min T = 25 °C A = 20,50,80 % S: ethanol |

Compared with maceration and heat-assisted technique, significantly higher yields of total flavonoids in the UAE | [81] |

| Phenolic from Achyrocline satureioides |

T = 25 °C Solute: Solvent ratio = 1: 40 |

UAE increased total phenolic compound content by 6.1 times and antioxidant activity by 3.4 times compared to conventional extraction. | [82] | ||

| Phenolic from Lime peel waste |

P = 750 W f = 20 kHz t = 4 min A = 38 % S: Ethanol |

UAE proved more effective in extracting total phenolics (54.4 mg GAE/g) with high antioxidant activity, saving 33 % of time compared to MAE. | [83] | ||

| Anthocyanins from Purple yam |

P = 750 W f = 20 kHz t = 10 min T = 60 °C A = 60 % S: Ethanol |

UAE was better than conventional extraction of soxhlet extraction and low-pressure solvent extraction | [84] | ||

| Phenolic from Mango peels |

t = 10 min T = 45 °C A = 30 % S: Ethanol |

The maximum extraction rate by UAE was 35.5 mg GAE/g. UAE is more advanced technique than conventional technique | [85] | ||

| Cannabinoids and Terpenes from Cannabis |

P = 450 W f = 20 kHz t = 60 min T = 30 °C A = 20–100 % S: Ethanol |

Compared to MAE, UAE increased crude oil yield by 14.39 %, cannabinoid concentration by 13.21–39.24 %, and total terpene extraction by 14.67 % | [86] | ||

| Phenolic from Raspberries Strawberries and Blackberries |

P = 700 W f = 20 kHz t = 45 min T ≤ 40 °C A = 50 % S: Ethanol |

Using methanol or ethanol as solvent is better than using water as solvent | [87] | ||

| Anthocyanin from Jaboticaba skin |

Pd = 150 W/L f = 20 kHz t = 10 min |

UAE was a time-saving extraction technology in comparison to agitated-bed and high hydrostatic pressure-assisted extraction. And UAE was mainly influenced by the extraction time | [88] | ||

| Oil from Rice bran |

P = 750 W f = 20 kHz t = 1 min T = 25 °C A = 40 % |

The yields obtained by solvent extraction and UAE were similar, but UAE significantly reduced the extraction time | [89] | ||

| Starch from Mango |

P = 480 W f = 20 kHz t = 20 min |

UAE significantly enhances starch properties, such as amylose content, water- and oil-holding capacity, solubility, and swelling power | [90] | ||

| Ultrasonic bath |

|

Oil from Peanut seeds |

P = 300 W f = 40 kHz t = 60 min T = 30 °C S: Hexane |

Oxidation of oils extracted with UAE was slightly higher than that without UAE | [91] |

| Oil from Olea europaea L. | P = 165 W f = 40 kHz and 585 kHz t = 10 min |

A combination of low-frequency sonication and megasonic has more advantages than a double megasonic treatment | [92] | ||

| Oil from Crambe seed |

P = 165 W f = 25 kHz t = 90 min T = 60 °C S: Hexane |

UAE boosts the yield by 20 % compared to without UAE | [93] | ||

| Phenolic, Flavonoid, and Anthocyanin from Blueberry |

P = 64 W f = 35 kHz t = 30, 40, 60, 90 min T = 20,40,60 °C S: Water or Ethanol |

UAE is a preferred method for extracting bioactive phenolics from blueberry pomace | [94] | ||

| Polyphenolic from Blueberry pomace |

f = 35 kHz t = 5,10,15 min T = 20,40,80 °C S: Acidulated ethanol, Acidulated methanol |

UAE is inferior to pulsed electric field in improving polyphenol extraction from blueberries | [95] | ||

| Anthocyanins Phenolics from Jabuticaba peel |

Pd = 50 W/L f = 25 kHz t = 25 min |

UAE improves the yield of phenolic compounds obtained | [96] | ||

| Phenolics, Flavonoids, and Anthocyanins from Raspberry fruits |

f = 50 kHz t = 120 min T = 50 °C S: Acidulated methanol |

UAE maximizes the yield of total phenolics and flavonoids | [97] | ||

| Anthocyanin and Phenolic compound from Black jamun fruit | P = 100 W f = 40 kHz t = 150 min T = 70 °C |

Compared with microwave, UAE can obtain more phenolic compound and Anthocyanidin | [98] | ||

| Protein from Cherimoya seed |

P = 300 W f = 35 kHz t = 26.1 min T = 41.8 °C |

The combined UAE and alkaline extraction yielded 6 % more extraction and 12 % higher protein content than alkaline extraction alone | [99] | ||

| Pectin from Grape pomace |

P = 200 W f = 25 kHz t = 60 min |

Pulsed ultrasonic caused pectin breakdown, therefore lesser emulsifying properties | [100] |

Note: P: Power; Pd: Power density; f: Frequency; t: Time; T: Temperature; A: Amplitudes; S: Solvents.

4.3. Working modes of UAEE

To maximize the extraction effect of different plant active components, a variety of different ultrasonic modes have been developed, including single frequency ultrasonic and multi-frequency ultrasonic, continuous ultrasonic and pulse ultrasonic, fixed frequency ultrasonic and sweeping frequency ultrasonic. Among the multi-frequency ultrasonic modes, there are also dual-frequency multi-angle ultrasonic (Fig. 8a), multi-frequency variable power ultrasonic, dual-frequency (or multi-frequency) sequential ultrasonic (Fig. 9abc) and dual-frequency (or multi-frequency) simultaneous ultrasonic (Fig. 9def) and other modes. In addition, the liquid phase can not only be stationary, but can be forced to flow. According to the direction of forced liquid flow and the direction of ultrasonic action, it can be divided into countercurrent ultrasonic (Fig. 6b) and tangential flow ultrasonic (Fig. 8b).

Fig. 8.

Dual-frequency multi-angle ultrasonic (a) and Tangential flow ultrasonic (b).

Fig. 9.

Dual-frequency sequential ultrasonic (a,b,c) and Dual-frequency simultaneous ultrasonic (d,e,f).

Compared to single frequency ultrasonic, double frequency ultrasonic significantly enhance the rate of cavitation [101], [102], [103]. Due to its ability to generate a greater quantity of cavitation bubbles and induce “combined resonance”, double frequency ultrasonic produce significantly higher levels of sonochemical energy [104]. Xu et al. [105] studied the extraction of rose polyphenols under the influence of multi-frequency power ultrasonics. The results showed that the yield of rose polyphenols under single-frequency ultrasonic is 167.92 mg/g, and the yield of rose polyphenols under triple-frequency ultrasonic is 187.13 mg/g. Compared to single-frequency ultrasonic, multi-frequency ultrasonic exhibited a higher extraction rate, and concurrently, the hydrophone recorded a more robust sound signal. In addition, Xu et al. [106] also examined the impact of dual-frequency ultrasonic pretreatment on the vacuum freeze-drying of strawberry slices. The study showed that the drying time using dual-frequency ultrasonic was 6 h, while the drying time using single-frequency ultrasonic was 10 h. The dual-frequency ultrasonic significantly outperformed the single-frequency ultrasonic in terms of drying efficiency. The reason for the analysis is that the working frequency of dual frequency ultrasonic is higher, which overcomes the limitations of single frequency ultrasonic.

Dual-frequency multi-angle ultrasonic refers to the utilization of ultrasonic probes operating at two different frequencies, positioned at a specific angle for material treatment, as shown in Fig. 8a. Zhang et al. [30] examined the influence of different angles of dual-frequency ultrasonic (40 + 20 kHz 0°, 40 + 20 kHz 30°, 40 + 20 kHz 45°) on the physicochemical properties of raw soymilk and the structure of soybean protein, and compared them with conventional single-frequency ultrasonic (40 kHz, 20 kHz). The findings indicated that dual-frequency ultrasonic treatment, particularly at 40 + 20 kHz and 45-degree angle, significantly enhanced the soybean protein content (SPC) in raw soymilk compared to single-frequency treatment. The SPC of the 40 + 20 kHz 45° treatment was 20.01 % higher than that of the 40 kHz treatment and 12.05 % higher than that of the 20 kHz treatment. This difference can be attributed to the use of cavitation bubbles generated by high-frequency ultrasonic as the core for low-frequency ultrasonic, resulting in more intense cavitation in dual-frequency ultrasonic. The increased cavitation, in turn, induced significant shear forces, resulting in higher extraction of proteins. Moreover, the application of dual-frequency multi-angle ultrasonic treatment not only increased the SPC of raw soymilk, but also improved its physical and chemical properties, such as color, rheological properties, surface tension, emulsifying properties, and foaming properties. These improvements ultimately helped to improve the flavor of the raw soymilk.

Countercurrent ultrasound refers to force the direction of liquid phase flow to be opposite to the direction of ultrasound action. Specifically, it involves circulating the sample in a countercurrent manner through the ultrasonic field, enabling enhanced treatment efficacy, as shown in Fig. 6b. The operation of sweeping frequency (a ± b kHz) refers to a cyclic frequency sweep ranging from a - b to a + b kHz and then back from a + b to a − b kHz, following an isosceles triangle waveform with a consistent linear speed. Ma et al. [107] conducted a study to investigate the impact of single frequency countercurrent ultrasonic (SFCU) and sweeping frequency ultrasonic (SFU) on the ACE inhibitory activities of garlic powder. According to the findings, the ACE inhibitory activity of garlic powder after pretreatment with SFU and SFCU was 65.88 % and 67.78 %, respectively, while the untreated sample showed only 47.88 % ACE inhibitory activity. The application of SFU and SFCU pretreatments both led to significantly increased ACE inhibitory activity in garlic powder compared to untreated garlic. Furthermore, from an acoustic perspective, SFU has the ability to create a sound field that is more favorable for enhancing the cavitation effect [108].

Dual-frequency sequential ultrasonic (Fig. 9abc) refers to the alternating operation of two different ultrasound frequencies in a continuous and non-overlapping manner [109]. Dual-frequency simultaneous ultrasonic (Fig. 9def) refers to the simultaneous operation of two different ultrasonic frequencies. Xue et al. [110] had noted the significance of the ultrasonic working mode in protein extraction. They investigated the impact of ultrasonic treatment with multiple modes on the extraction of rice protein. The findings demonstrated that the sequential frequency ultrasonic treatment exhibited a higher protein extraction rate compared to simultaneous or single frequency ultrasonic treatment. Also, Xue et al. [31] examined the influence of ultrasonic frequency mode, power density, pretreatment time, and other parameters at low power density on the degree of hydrolysis (DH) of defatted wheat germ protein (DWGP) and the angiotensin-I-converting enzyme (ACE) inhibitory activity of DWGP hydrolysate. Under the dual-fixed frequency ultrasonic mode of 28/40 kHz, an ultrasonic power density of 60 W/L, a pretreatment time of 70 min, a temperature of 60 °C and a substrate concentration of 60 g/L, the DWGP hydrolysate exhibited the highest ACE inhibitory activity. Ding et al. [111] investigated the impact of ultrasonic pretreatment with various working modes, such as mono frequency ultrasonic (MFU), simultaneous dual frequency ultrasonic (SDFU), and alternate dual frequency ultrasonic (ADFU), utilizing energy-gather counter flow ultrasonic equipment. The results show that ADFU at 20/35 kHz exhibited the highest angiotensin-converting enzyme inhibitory activity.

The ultrasonic probe emits ultrasonic waves intermittently in the form of pulses, known as pulsed ultrasonic. For example, the meaning of a 5 s − 2 s pulse is that the ultrasonic is turned on for 5 s, turned off for 2 s, turned on for 5 s, and turned off for 2 s, in a cyclic manner. Pan et al. [112] used UAE to extract antioxidants from pomegranate peel in continuous and pulsed modes. This research unequivocally showcased the superior performance and effectiveness of pulse ultrasonic assisted extraction (PUAE) for producing antioxidants from the peel of pomegranate marc. From the point of view of industrial use, it is recommended to run the ultrasonic transducer in pulse mode. In this way, the service life of the transducer can be extended while the thermal effect of the extract is minimal. Pan et al. [113] extracted antioxidants from pomegranate peel by conventional extraction, continuous ultrasonic extraction and pulsed ultrasonic extraction, and studied the extraction yield and antioxidant activity. The findings from the experiment indicated that compared to conventional extraction, the amount of antioxidant extracted by pulsed ultrasonic extraction was increased by 22 % and the extraction time was shortened by 87 %. Similarly, a 24 % increase in antioxidant yield and a remarkable 90 % reduction in extraction time when utilizing continuous ultrasonic extraction at the same intensity level. However, pulsed ultrasonic extraction saves 50 % more energy compared to continuous ultrasonic extraction.

5. Application of UAEE

5.1. UAEE using generally recognized as safe (GRAS) solvents

The majority of studies have indicated that the utilization of organic solvents can enhance the efficiency of extraction. However, the cost of removing organic solvents after extraction is a significant limitation of employing organic solvents for extraction [114]. The application of ultrasonic technology in extraction has widened the range of available extraction solvents, enabling the substitution of toxic organic solvents with GRAS solvents in certain cases. Opting for GRAS solvents offers significant health and safety benefits, while also reducing extraction costs. A typical example is that Li et al. [115] extracted carotenoids from carrots using sunflower seed oil as solvent, combined with UAEE, and then compared it with the traditional extraction method using hexane as solvent. According to the findings, the highest yield of β-carotene (334.75 mg/L) using sunflower as a solvent was achieved by the UAEE within a short duration of 20 min. In contrast, the extraction using hexane as the solvent obtained a similar yield (321.35 mg/L) but required a longer extraction time of 60 min. Johanna et al. [114] used UAEE to extract caffeine from pills. The research investigated the efficacy of environmentally friendly solvents, namely ethyl acetate and water, in comparison to four conventional solvents (ethanol, methanol, acetone, and acetonitrile) for extracting caffeine from coffee pills. And they developed a solvent assessment method related to environmental capacity and sustainability, which is known as the GD. The study found that water achieved the highest GD rating for caffeine extraction. Moreover, its easy availability and low cost make it a viable alternative solvent for caffeine extraction. And they think that water could be an excellent alternative solvent in the extraction process. Table 2 shows the recent studies on UAEE using GRAS solvent as an extraction agent.

Table 2.

UAEE using GRAS solvent as extraction agent.

| Matrix | Extractive | Solvent | Benefit | Extraction conditions | Ref. |

|---|---|---|---|---|---|

| Camellia sinensis (green tea) leaves | Polyphenols Flavonoids |

Water | 1.Cheaper and easier to obtain; 2. More environmentally friendly; 3.Non-flammable, safer extraction; 4. More pollution-free to the environment; 5.Cost savings compared to organic solvents |

P = 500 W f = 20 kHz T = 77 °C A = 77 % |

[116] |

| Olive leaves | Oil | P = 2.8 kW f = 20 kHz A = 80 % |

[117] | ||

| Cinnamomum cassia bark | Essential oil | P = 300 W f = 25 kHz t = 35 min |

[118] | ||

| Leaf (Sinara Sko Rems L.) |

Phenolic Flavonoid |

P = 500 W f = 20 kHz t = 20.05 min T = 25 °C A = 65.02 % |

[119] | ||

| Coffee pills | Caffeine | P = 144–480 W f = 37 kHz t = 5–13 min |

[114] | ||

| Date palm | Phenolic Flavonoid |

f = 28, 40 kHz t = 20,40,60 min T = 30,45,60 °C |

[120] | ||

| Olive | Antioxidants (manly phenolic compounds and flavonoid) | Ethanol | 1. Volatile and easy to remove; 2.Easy to obtain; 3.General solubility; 4.By changing the concentration, the solvent polarity can be adjusted to meet the extraction needs of different solutes; 5.Can be recovered and reused by methods such as distillation, helping to reduce costs |

P = 400 W f = 24 kHz t = 15 min A = 70 % |

[121] |

| Hibiscus sabdariffa calyces | Anthocyanins | P = 296.6 W f = 20 kHz t = 26.1 min T = 30–35 °C |

[122] | ||

| Olive pomace | Hydroxytyrosol Maslinic acid Oleanolic acid |

f = 60 kHz t = 5 min T = 50 °C |

[123] | ||

| Pyrus communis ‘Starkrimson’ fruit peel | Cyanidin-3-O-galactoside | P = 162 W t = 11 min T = 71 °C |

[124] | ||

| Raphanus sativus L | Oil | P = 165 W f = 25 kHz t = 20,40,60 min T = 30,45,60 °C |

[125] | ||

| Cannabis | Cannabinoids Terpenes |

P = 450 W f = 20 kHz t = 30 min T = 50 °C |

[86] | ||

| Chinese propolis | Polyphenols | P = 135 W f = 22 kHz t = 20 min T = 40 °C |

[126] |

Note: P: Power; f: Frequency; t: Time; T: Temperature.

5.2. The use of UAEE in combination with other technologies

The extraction effect of using UAEE alone can be further improved. In order to enhance the extraction efficiency and improve the biological activity of the desired extract, UAEE can be combined with various emerging extraction techniques. Fig. 10 illustrates the microwave-assisted extraction (MAE) technologies, enzymatic assisted extraction (EAE) technologies, pulsed electric field-assisted extraction (PEFAE) technologies, and supercritical fluid extraction (SFE) technologies used in combination with UAEE.

Fig. 10.

The combination of UAEE and other extraction technologies.

SFE is an environmentally friendly process that utilizes supercritical fluids as solvents to extract compounds from solid substrates [127]. In the majority of SFE experiments, carbon dioxide is commonly employed as the preferred solvent. CO2 is non-toxic, non-flammable, cost-effective, and possesses a low critical temperature. It can be efficiently recycled during the extraction process and easily removed afterward. Additionally, CO2 exhibits high solubility for non-polar molecules, making it an ideal solvent in SFE [128]. The high diffusivity and low surface tension of SFE enable the solvent to better penetrate the sample. UAE can break the aggregation and agglomeration of particles. This facilitates the penetration of the supercritical fluid into the sample. So, the combination of UAE and SFE with excellent solubility can significantly improve extraction efficiency. SFE can selectively extract the required compounds by adjusting the pressure, temperature and ratio of supercritical fluid. So that, the combination of UAE and SFE can extract target components more quickly and accurately. By combining the high efficiency of UAE and the high selectivity of SFE towards target components, USFE can achieve more significant extraction results.