Abstract

The photovoltaic module (PV) enhancer is a technology used for improving the PV performance. Recently, much research has been conducted to propose new concepts of PV enhancer such as coolers and reflectors. The PV enhancer performance is assessed by the common existing methods available in the literature, which solely depends on total exergy or energy, volume, area, weight and the manufacturing cost. These assessment methods are useful but cannot assess the PV enhancer's performance when considering the lifespan parameter. Hence, this study is intended to solve the current problem by linking the lifespan parameter into the existing methods by proposing three enhanced assessment methods: yield times lifespan per cost per area, yield times lifespan per cost per volume and yield times lifespan per cost per weight. The PV enhancer with the highest values of these factors will have the optimum performance. The influential parameters and limitations of the enhanced assessment methods are investigated. It is shown that the proposed methods can assess and classify the performance of the PV enhancer with different models when the lifespan is considered in the analysis. These assessment approaches can be applied by manufacturers and designers of PV enhancers.

Keywords: Solar energy, Photovoltaic solar thermal collector, Lifespan, Assessment

Nomenclature

- F

factor

- I

electrical current, (A)

- P

power, (W)

- PV

photovoltaic module

- RM

Ringgit Malaysia

- SS

stainless steel

- TEG

thermoelectric generator

- V

voltage, (V)

- YPA

yield per area, (J/m2)

- YPV

yield per volume, (J/m3)

- YPW

yield per weight, (J/kg)

Subscripts

- YLPAC

yield times lifespan per area per cost, (J.Year/m2. $)

- YLPVC

yield times lifespan per volume per cost, (J.Year/m3. $)

- YLPWC

yield times lifespan per weight per cost, (J.Year/kg. $)

- YPAC

yield per cost per area, (J/m2. $)

- YPVC

yield per cost per weight, (J/m3. $)

- YPWC

yield per cost per weight, (J/kg. $)

1. Introduction

Energy plays a vital role in economic activities. Consequently, a country's energy consumption per capital is considered an economic development indicator. Nowadays, energy is not only regarded as an input for production but is also considered a strategic principle that creates the basis of international relation and forms the economy and politics of the world. The energy demand is increasing daily, but the energy sources are limited. Furthermore, the energy resources distribution among countries is uneven. This is not only valid for the energy reserves but also at the consumption levels. This makes countries lacking abundant energy resources face difficulties in securing access to those resources in a manner that is both reasonable and sustainable, thereby hindering their ability to meet the growing demand for energy. Nowadays, research is being conducted to find solutions to overcome the energy shortage. Solar energy could be the future energy since the sun is not under anyone's monopoly [1,2]. It can be divided into solar thermal collector and photovoltaic system. Photovoltaic system is used to convert sun radiation into electrical current [3]. The photovoltaic efficiency can be improved by implementing an enhancer like a cooler or a reflector.

1.1. Literature review on some of the existing PV coolers

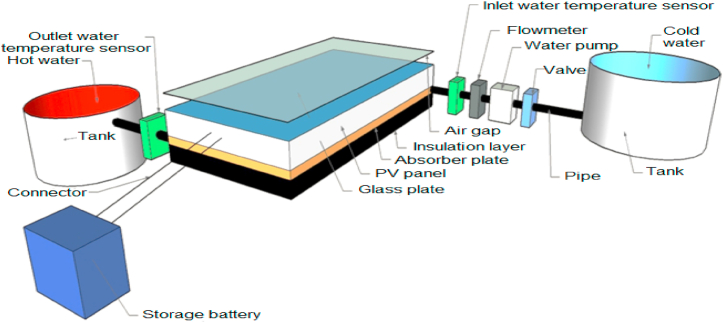

Depending on the weather conditions, the suitable enhancing technique is selected [4]. For example, in areas where solar radiation and ambient temperature values are high, a cooler is desirable to decrease the PV temperature. Consequently, the performance of PV can be enhanced. Several cooler types are available including passive, active, forced or natural cooling, using liquid, air or phase change materials (PCM). Fig. 1 indicates a diagram of a PV with a cooler. The fluid motion can enhance the transfer of heat to the PV surface. In recent years, extensive studies on PV coolers were conducted (see Table 1) [[5], [6], [7], [8], [9]]. Generally, the PV enhancers are made of stainless steel, aluminum, copper or other metals that have good thermal conductivity for heat transfer enhancement. Lifespans of these PV enhancers may vary and can be influenced by different weather conditions [36].

Fig. 1.

A diagram of a PV with a cooler.

Table 1.

Earlier studies on a PV with an enhancer.

| Authors and Reference | System Description |

|---|---|

| Sultan et al. [10] | A novel baffle-based collector for PV enhancer was presented to enhance power from the system. |

| Sultan et al. [11] | A glass rectangular cooler was imposed on the PV. |

| Mohamed et al. [12] | The analytical model was established based on energy balance equations. |

| Mohammad et al. [13] | The artificial neural networks (ANNs) were implemented for enhancing the PV cooler simulation model. |

| Nahar et al. [14] | A mathematical model for a PV cooler was developed. |

| Xiaojino et al. [15] | Experimental work was carried out to evaluate the efficiency of the PV with a cooler. |

| Ruobing et al. [16] | A PV cooler was examined to investigate the performance over a full day span. |

| Fuentesa et al. [17] | A forced circulation mode was adopted to cool the PV. |

| Hossein et al. [18] | A copper fin was developed. |

| Ali et al. [19] | The best combination of sheet and tube was determined. |

| Nahar et al. and Rahman et al. [20,21] | A novel cooler type was attached at the backside of the PV. |

| Fayaz et al. [22] | An aluminum cooler was introduced. |

| Sakellariou et al. [23] | A retrofitted PV cooler was installed together with a PV. |

| Al-Shamani et al. [24] | The rectangular tube was integrated with the PV's backside. |

| Al-Shamani et al. [25] | The cooler was attached at the bottom of the PV. |

| Tiwari et al. [26] | The electrical performance was carried out for a series connected water-based PV cooler. |

| Juwel et al. [27] | The energy balance equations were derived for the proposed PV cooler. |

| Bilbao et al. [28] | A transient model for water- based PV cooler was studied. |

| Fadhel et al. and Sultan et al. [29,30] | A new cooler configuration was proposed. |

| Oussama et al. [31] | The considered PV air cooler was able to enhance the PV efficiency. |

| Chao et al. [32] | Exergy and energy analysis were evaluated. |

| Grubisic-Cabo et al. [33] |

Aluminum fin was installed at the backside of PV. |

| Karima et al. [34] | An analytical model was developed. |

| David et al. [35] | A PCM tank was integrated to PV's backside. |

| Anand et al. [38] | The influence of reflector's parameters on the PV efficiency was experimentally studied. |

| Palaskar et al. [39] | An aluminum sheet based PV was numerically and experimentally studied. |

| Bahaidarah et al. [42] | A predication model was presented for a V-trough concentrating system. |

| Naseer et al. [43] | A PV with a V-trough concentrating system was experimentally studied under outdoor operating conditions. |

| Elberki et al. [44] | A PV with reflector and cooler was experimentally studied. |

| Moon et al. [45] | An aluminum sheet based PV was analytically studied. |

| Jin et al. [46] | A new reflector with a curved shape for PV was proposed. |

| Amanlou et al. [47] | A PV with a cooler and flat plate reflector was theoretically and experimentally studied. |

| Monika et al. [48] | An efficient method to enhance the PV performance by attaching flat stainless-steel (SS) reflector was determined. |

| Eskandar et al. [49] | A novel model of PV-TEGs enhanced with flat plate mirror reflectors was presented. |

| Muslizainun et al. [50] | Mathematical modeling and experimental validation of bifacial PVT with mirror reflector were proposed. |

| Samira et al. [51] | Energy and exergy analysis of integrating PV with linear Fresnel reflector was studied. |

1.2. Literature review on existing PV reflectors

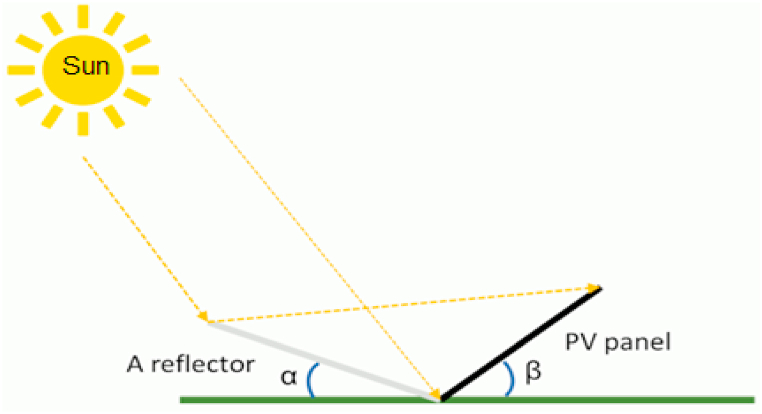

A reflector is preferable in areas that have low solar radiation and ambient temperature values. It was first introduced in 1958 for the purpose of increasing the collection area of the incident solar radiation. Consequently, there is a potential for enhancing the efficiency of the PV [[37], [38], [39], [40], [41]]. Fig. 2 shows a schematic diagram of a PV with a reflector. The power of a PV integrated V-trough concentrating system under outdoor operating conditions was numerically and experimentally obtained [42]. Results showed that the maximum power improvement was 31.2 %. In another study, an experiment was performed to explore the effect of reflector's parameters on the output power [38]. It was shown that the reflectors boosted the output power by up to 60 %. An aluminum sheet based PV was constructed to increase the output power by 15 % [39]. An outdoor experiment on a PV with a V-trough concentrating system was carried out. It was found that there is 48 % increment of the output power. An experiment and economic feasibility study on a PV with a cooler and a reflector was performed [44]. Results showed that the PV efficiency increased to 10.68 %, and there are 4.2 years of payback time. A numerical study on an aluminum sheet based PV was conducted to examine the impact of tilt angles on the PV efficiency [45]. Results demonstrated that the PV performance can be increased when the tilt angle increases. A new PV with a curved shape reflector was proposed. Results indicated that the spatial solar power of the system was increased to 61 % [46]. An analytical and experimental work was performed on a PV with a flat plate reflector and cooler [47]. Results revealed that the PV efficiency increased to 36 %. A three dimensional model was proposed for a PV with a stainless steel (SS) to increase the PV efficiency to 34.16 % [48].

Fig. 2.

A schematic diagram for a PV with a reflector [45].

1.3. The existing PV enhancer assessment methods

Existing assessment methods were suggested in a previous study, to evaluate the performance of different PV enhancer types, which are based on yield per area (YPA), volume (YPV) or weight (YPW), as shown in Table 2 [52]. Later, in another study, YPA, YPV and YPW were developed by including the PV enhancer's manufacturing cost into the analysis (see Table 2) [53].

Table 2.

Existing equations for assessing and comparing the PV enhancer performance.

To demonstrate the significance of the developed factors, let us consider a PV enhancer with three distinct models: Model A, Model B, and Model C. Table 3 presents their respective total energy values as 200 J, 150 J, and 130 J. Assuming a uniform area of 1 m2 for all models, Model A has a volume and weight of 0.5 m3 and 1 kg, respectively, Model B has volume of 0.4 m3 and weight of 2 kg, and Model C comes with volume of 0.3 m3 and weight of 3 kg. The manufacturing cost values are $20 for Model A, $18 for Model B, and $12 for Model C. Applying the existing method (), the values are 10 J/m2, 8.33 J/m2, and 10.83 J/m2 for Model A, Model B, and Model C, respectively. Model C exhibits a higher value compared with Model A and Model B, indicating better performance. Furthermore, considering values, the values are 20 J/m3, 20.83 J/m3, and 36.11 J/m3 for Model A, Model B, and Model C, respectively. Model C outperforms Model A and Model B in terms of . Lastly, examining values, it is found that 10 J/kg, 4.17 J/kg, and 3.61 J/kg are for Model A, Model B, and Model C, respectively. Model A shows higher performance as compared with Model B and Model C, based on . In conclusion, it is evident that , and can effectively evaluate the performance of PV enhancer with different models when the lifespan parameter is not included in the analysis.

Table 3.

Cases to demonstrate , and analysis.

| Model | Total energy output (J) | Area (m2) | Volume (m3) | Weight (kg) | Cost of manufacturing ($) | (J/m2.$) | (J/m3.$) | (J/kg.$) |

|---|---|---|---|---|---|---|---|---|

| A | 200 | 1 | 0.5 | 1 | 20 | 10 | 20 | 10 |

| B | 150 | 1 | 0.4 | 2 | 18 | 8.33 | 20.83 | 4.17 |

| C | 130 | 1 | 0.3 | 3 | 12 | 10.83 | 36.11 | 3.61 |

1.4. Motivation of the current work

Although the PV enhancer lifespan plays an important role in evaluating and comparing the performance of different models of PV enhancers, it was not considered in previous studies. Consequently, the PV enhancer performance evaluation and comparison become difficult. To illustrate the problem, we consider the examples given in Table 3. By assuming that the lifespan values for Model A, Model B and Model C are now 3, 6 and 2 years, respectively. Now, which PV enhancer design is more effective? Because the existing assessment methods are facing the difficulty of given an appropriate answer, enhanced assessment methods are proposed to solve the current issue by creating a correlation between the PV enhancer lifespan and its exergy or energy, volume, area, weight and cost of manufacturing. These enhanced assessment methods can evaluate and compare the performance of PV enhancer with different models, as compared with the existing methods when the lifespan parameter is considered in the analysis. The influential parameters on the enhanced assessment method will be studied in details. Also, testing the proposed methods on real case will be conducted to validate their applicability. The modified methods can be valuable tools for PV enhancer designers and manufacturers, as they are the intended users of these approaches. It's worth mentioning that extensive research should be carried out to develop more assessment methods for PV enhancers.

2. The modified assessment methods for PV enhancer

2.1. The yield times lifespan per cost per area factor,

The represents the ratio of the total exergy or energy of the PV enhancer multiplied by its lifespan to the product of the area and manufacturing cost of the PV enhancer, which can be denoted as

| (7) |

2.2. The yield times lifespan per cost per volume factor,

The yield times lifespan per cost per volume factor ( is the ratio of the total exergy or energy of PV enhancer multiplied by its lifespan to the product of volume and cost of manufacturing of the PV enhancer, which can be expressed as

| (8) |

2.3. The yield times lifespan per cost per weight factor,

The yield times lifespan per cost per weight factor ( is the ratio of total exergy or energy of PV enhancer multiplied by its lifespan to the product of weight and cost of manufacturing of the PV enhancer, which can be written as

| (9) |

From Eqs. (7), (8), (9), the PV enhancer with higher , and values has optimum performance.

3. Results and discussions

The conditions of applicability, significance and limitations of , and are similar to , and and are all given in Ref. [53]. However, there is an additional limitation related to the proposed methods, as the following. The lifespan of materials could vary from one place to another depends on weather conditions such as ambient temperature, humidity, solar radiation, wind velocity, and etc., which may affect the , and values. In the following section, an analysis is given to investigate the influence of changing the parameters such as manufacturing cost, lifespan, energy, area, volume and weight on the values of , and .

3.1. Analysis on , and

3.1.1. The impact of on PV enhancer with different models

It should be stressed that the numbers are arbitrarily selected to illustrate the applicability of proposed methods. There is no need to justify the rationale of the selected values, as they do not affect the validity of the proposed methods. Consider the provided examples in Table 3, where we have a PV enhancers available in Model A, Model B, and Model C. These models are associated with total energy values of 200, 150, and 130 J, correspondingly, as indicated in Table 4. Assuming a uniform area of 1 m2 for all models, we can further specify the lifespan values, which are 3 years for Model A, 6 years for Model B, and 2 years for Model C. Additionally, the cost of manufacturing for each model is 20$, 18$, and 12$, respectively.

Table 4.

Cases to demonstrate analysis.

| Model | Total energy (J) | Lifespan (Year) | Area (m2) | Manufacturing cost ($) |

(J. Year/m2. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 1 | 20 | 30 |

| B | 150 | 6 | 1 | 18 | 50 |

| C | 130 | 2 | 1 | 12 | 21.67 |

By using formula (Eq. (7)), the values are 30, 50 and 21.67 J.Year/m2. $ for Model A, Model B and Model C, correspondingly. It can be seen that Model B has higher value as compared to the values of for Model A and Model C, showing a better performance as compared to Model A and Model C. From above results, the decision on the performance of PV enhancer with Model A, B and C has been changed accordingly, when applying the enhanced assessment method that includes the lifespan parameter. On the other hand, when the existing assessment method is used that does not consider the lifespan parameter, Model C was better in terms of performance as compared with Model A and Model B, as shown in Table 3. It is seen that the lifespan of PV enhancer is a very significant entity that can be used to evaluate and compare the PV enhancer performance accurately. It is revealed that is able to classify PV enhancer with different models.

3.1.2. The impact of changing the PV enhancer lifespan on

Let us consider a scenario where the lifespan of PV enhancer models, as outlined in Tables 4 and is decreased. The total energy, area, and cost of manufacturing values for all PV enhancer models are unchanged, as presented in Table 5. The updated lifespan values are 1 year for Model A, 2 years for Model B, and 3 years for Model C. Consequently, Model A exhibits an value of 11.11 J.Year/m2.$, while Model B and Model C have values of 27.27 J.Year/m2.$ and 39 J.Year/m2.$, respectively. Notably, Model C now has the highest value, indicating superior performance as compared to Model A and Model B. These results demonstrate the influence of the PV enhancer lifespan on the value.

Table 5.

Cases to illustrate the impact of varying the lifespan on .

| Model | Energy (J) | Lifespan (Year) | Area (m2) | Manufacturing cost ($) |

(J.Year/m2. $) |

|---|---|---|---|---|---|

| A | 200 | 1 | 1 | 18 | 11.11 |

| B | 150 | 2 | 1 | 11 | 27.27 |

| C | 130 | 3 | 1 | 10 | 39 |

3.1.3. The impact of varying the total energy of PV enhancer on

Assuming that the total energy of PV enhancer is changed for Model A, Model B and Model C, while the other parameters are kept unchanged, as depicted in Table 4. Model A, Model B and Model C have total energy values of 100, 90 and 80 J, respectively, as demonstrated in Table 6. Now, values are 15, 30 and 13.33 J.Year/m2. $ for Model A, Model B and Model C, respectively. Now, Model B has higher value and has better performance as compared with Model A and Model C. It is concluded that the PV enhancer total energy has an effect on the value of . Suppose we modify the total energy of the PV enhancer for Model A, Model B, and Model C, while keeping the other parameters constant, as displayed in Table 4. In this case, Model A, Model B, and Model C exhibit total energy values of 100 J, 90 J, and 80 J, respectively, as presented in Table 6. Consequently, the values are 15 J.Year/m2.$ for Model A, 30 J.Year/m2.$ for Model B, and 13.33 J.Year/m2.$ for Model C. Notably, Model B now has the maximum value, indicating its superior performance compared to Model A and Model C. These results emphasize the impact of the PV enhancer's total energy on the value.

Table 6.

Cases to illustrate the impact of varying the PV enhancer total energy on .

| Model | Total energy (J) | Lifespan (Year) | Area (m2) | Manufacturing cost ($) |

(J.Year/m2. $) |

|---|---|---|---|---|---|

| A | 100 | 3 | 1 | 20 | 15 |

| B | 90 | 6 | 1 | 18 | 30 |

| C | 80 | 2 | 1 | 12 | 13.33 |

3.1.4. The impact of varying the PV enhancer area on

Assuming that the area of PV enhancer models is changed. The other parameters remain constant, as depicted in Table 4. Now, the new area value of all PV enhancer models is 3 m2, as demonstrated in Table 7. By applying Eq. (7), values are 10, 16.67 and 7.22 J.Year/m2. $ for Model A, Model B and Model C, respectively. Now, Model B exhibits the highest value. Hence, it performs better as compared to Model A and C. It is shown that the PV enhancer area has an impact on the values.

Table 7.

Cases to demonstrate the impact of varying the area of PV enhancer on .

| Model | Total energy (J) | Lifespan (Year) | Area (m2) | Manufacturing cost ($) |

(J.Year/m2. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 3 | 20 | 10 |

| B | 150 | 6 | 3 | 18 | 16.67 |

| C | 130 | 2 | 3 | 12 | 7.22 |

3.1.5. The impact of varying the cost of manufacturing of PV enhancer on

Assuming that the PV enhancer cost of manufacturing is reduced. The total energy, lifespan and area values remain constant, as shown in Table 8. Now, the manufacturing cost values are $7, $8 and $9 for Model A, Model B and Model C, respectively. By applying Eq. (7), values are 85.71, 112.5 and 28.89 J.Year/m2. $ for Model A, Model B and model C, respectively. Now, Model B has the maximum value. Consequently, it exhibits superior performance when compared with Model A and C. This demonstrates the impact of the cost of manufacturing of the PV enhancer on the value of .

Table 8.

Cases to demonstrate the impact of varying the cost of manufacturing of PV enhancer on .

| Model | Total energy (J) | Lifespan (Year) | Area (m2) | Manufacturing cost ($) |

(J.Year/m2. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 1 | 7 | 85.71 |

| B | 150 | 6 | 1 | 8 | 112.5 |

| C | 130 | 2 | 1 | 9 | 28.89 |

3.1.6. The impact of on PV enhancer

Table 9 is compiled using Table 3. Applying Eq. (8), values are 60, 125 and 72.22 J.Year/m3.$ for Model A, Model B and Model C, respectively. Now, Model B has the maximum value and has superior performance compared with Model A and C. From Table 3, by using the existing evaluation method, , when the lifespan is not included in the analysis, Model C is better in terms of performance as compared with other models. It can be revealed that the lifespan is an important entity for assessing the PV enhancer performance. Hence, it is seen that is a very significant factor that can be utilized to accurately evaluate and compare the PV enhancer's performance with different models.

Table 9.

Cases to demonstrate the analysis of .

| Model | Total energy (J) | Lifespan (Year) | Volume (m3) | Manufacturing cost ($) |

(J.Year/m3. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 0.5 | 20 | 60 |

| B | 150 | 6 | 0.4 | 18 | 125 |

| C | 130 | 2 | 0.3 | 12 | 72.22 |

3.1.7. The impact of varying the lifespan of PV enhancer on

Assume that the values of the lifespan of PV enhancer models, shown in Table 9, are changed. On the other hand, the total energy, volume and cost of manufacturing values of the PV enhancer models are kept unchanged, as depicted in Table 10. The updated values of lifespan are 1, 2 and 3 years for Model A, Model B and Model C, respectively. Now, Model A has value of 22.22 J.Year/m3. $. The values are 68.18 and 130 J.Year/m3. $ for Model B and Model C, correspondingly. Now, Model C has the maximum value of . Thus, it has better performance as compared with Model A and Model B. It is shown that the PV enhancer lifespan affects the value of .

Table 10.

Cases to demonstrate the impact of varying the PV enhancer's lifespan on .

| Model | Total energy (J) | Lifespan (Year) | Volume (m3) | Manufacturing cost ($) |

(J.Year/m3. $) |

|---|---|---|---|---|---|

| A | 200 | 1 | 0.5 | 18 | 22.22 |

| B | 150 | 2 | 0.4 | 11 | 68.18 |

| C | 130 | 3 | 0.3 | 10 | 130 |

3.1.8. The impact of varying the PV enhancer total energy on

Assuming that the PV enhancer total energy is altered for all models, while the other entities are kept unchanged, as depicted in Table 9. Model A, Model B and Model C have total energy values of 100, 90 and 80 J correspondingly, as demonstrated in Table 11. Now, values are 30, 75 and 44.44 J.Year/m3. $ for Model A, Model B and Model C, correspondingly. Now, Model B exhibits the highest value and has better performance as compared with Model A and Model C. It is concluded that the PV enhancer's total energy influences the value of .

Table 11.

Cases to demonstrate the impact of varying the PV enhancer's total energy on .

| Model | Total energy (J) | Lifespan (year) | Volume (m3) | Manufacturing cost ($) |

(J.Year/m3. $) |

|---|---|---|---|---|---|

| A | 100 | 3 | 0.5 | 20 | 30 |

| B | 90 | 6 | 0.4 | 18 | 75 |

| C | 80 | 2 | 0.3 | 12 | 44.44 |

3.1.9. The impact of varying the PV enhancer's volume on

Assuming that the volume of PV enhancer is changed while keeping the other parameters unchanged, as demonstrated in Table 9. Model A, Model B and Model C have new volume values of 0.3, 0.2 and 0.1 m3, correspondingly, as depicted in Table 12. Applying Eq. (8), values are 100, 250.02 and 216.67 J.Year/m3. $ for Model A, Model B and Model C, respectively. Notably, Model B exhibits the highest value, indicating superior performance compared with Model A and C. This highlights the influence of volume on the value of .

Table 12.

Cases to demonstrate the impact of varying the volume of PV enhancer on .

| Model | Total energy (J) | Lifespan (Year) | Volume (m3) | Manufacturing cost ($) |

(J.Year/m3. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 0.3 | 20 | 100 |

| B | 150 | 6 | 0.2 | 18 | 250.02 |

| C | 130 | 2 | 0.1 | 12 | 216.67 |

3.1.10. The impact of varying the PV enhancer's manufacturing cost on

Assuming that the manufacturing cost values have been decreased. The PV enhancer's total energy, lifespan and area values remain constant, as depicted in Table 13. The updated cost of manufacturing values for Model A, Model B, and Model C are 18, 11, and 10$, respectively. By applying Eq. (8), the corresponding values are 66.67, 204.55, and 86.67 J.Year/m3. $ for Model A, Model B, and Model C, respectively. Model B now exhibits the maximum value, indicating superior performance compared to Model A and Model C. These findings illustrate the influence of manufacturing cost on the value of .

Table 13.

Cases to demonstrate the impact of varying the PV enhancer's cost of manufacturing on .

| Model | Total energy (J) | Lifespan (Year) | Volume (m3) | Manufacturing cost ($) |

(J.Year/m3. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 0.5 | 18 | 66.67 |

| B | 150 | 6 | 0.4 | 11 | 204.55 |

| C | 130 | 2 | 0.3 | 10 | 86.67 |

3.1.11. The impact of on PV enhancer with different models

Table 14 is constructed based on the data provided in Table 3, considering lifespan values of 3, 6, and 2 years for Model A, Model B, and Model C, respectively. By applying Eq. (9), the resulting values are 30, 25, and 7.22 J.Year/kg.$ for Model A, Model B, and Model C, respectively. Notably, Model A exhibits the highest value, indicating superior performance compared with Model B and Model C. It is seen that the lifespan is an important entity that can evaluate the performance of PV enhancer. It is seen that is a very vital factor that can assess and compare the PV enhancer's performance with different models.

Table 14.

Cases to demonstrate analysis.

| Model | Total energy (J) | Lifespan (Year) | Weight (kg) | Manufacturing cost ($) |

(J.Year/kg. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 1 | 20 | 30 |

| B | 150 | 6 | 2 | 18 | 25 |

| C | 130 | 2 | 3 | 12 | 7.22 |

3.1.12. The impact of varying the lifespan of PV enhancer on

Assuming that the PV enhancer's lifespan, shown in Tables 14 and is changed. The total energy, volume and cost of manufacturing values of PV enhancer's models are kept unchanged, as illustrated in Table 15. The updated values of lifespan are 1, 2 and 3 years for Model A, Model B and Model C, respectively. Now, Model A has value of 10 J.Year/kg. $. The values are 8.33 and 10.83 J.Year/kg. $ for Model B and Model C, correspondingly. Now, Model C exhibits the highest value of . Thus, it has better performance compared to Model A and Model B. It is demonstrated that the lifespan has an effect on the value of .

Table 15.

Cases to demonstrate the impact of varying the lifespan of PV enhancer on .

| Model | Total energy (J) | Lifespan (Year) | Weight (kg) | Manufacturing cost ($) |

(J.Year/kg. $) |

|---|---|---|---|---|---|

| A | 200 | 1 | 1 | 20 | 10 |

| B | 150 | 2 | 2 | 18 | 8.33 |

| C | 130 | 3 | 3 | 12 | 10.83 |

3.1.13. The impact of varying PV enhancer total energy on

Suppose we changed the total energy of PV enhancer models, while keeping the other parameters constant (refer to Table 14). In this case, Model A, Model B, and Model C have total energy values of 50, 40, and 30 J, respectively, as indicated in Table 16. Consequently, the values are calculated as 7.5, 6.66, and 1.66 J.Year/kg.$ for Model A, Model B, and Model C, respectively. Notably, Model A exhibits the maximum value, indicating superior performance compared to Model B and Model C. It is evident that the total energy of the PV enhancer has an impact on the value of .

Table 16.

Cases to demonstrate the impact of varying the total energy of PV enhancer on .

| Model | Total energy (J) | Lifespan (Year) | Weight (kg) | Manufacturing cost ($) |

(J. Year/kg. $) |

|---|---|---|---|---|---|

| A | 50 | 3 | 1 | 20 | 7.5 |

| B | 40 | 6 | 2 | 18 | 6.66 |

| C | 30 | 2 | 3 | 12 | 1.66 |

3.1.14. The impact of varying the weight of PV enhancer on

Assuming that the weight of PV enhancer is changed while the other entities remain unchanged, as depicted in Table 14. Model A, Model B and Model C have new weight values of 2, 3 and 4 kg, respectively, as demonstrated in Table 17. Applying Eq. (9), values are 15, 16.67 and 5.42 J.Year/kg. $ for Model A, Model B and Model C, respectively. Now, Model B exhibits the highest value, indicating superior performance compared to Model A and C. It is shown that the weight influences the value of .

Table 17.

Cases to demonstrate the impact of varying the PV enhancer's weight on .

| Model | Total energy (J) | Lifespan (Year) | Weight (kg) | Manufacturing cost ($) |

(J.Year/kg. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 2 | 20 | 15 |

| B | 150 | 6 | 3 | 18 | 16.67 |

| C | 130 | 2 | 4 | 12 | 5.42 |

3.1.15. The impact of varying the PV enhancer's cost of manufacturing on

Let's consider that the PV enhancer manufacturing cost, as depicted in Table 4, has been altered. While keeping the total energy, lifespan, and weight values constant (as presented in Table 18), the new values of manufacturing cost for Model A, Model B, and Model C are $18, $11, and $10, respectively. By applying Eq. (9), we calculate the values as 33.33, 40.91, and 8.67 J.Year/kg.$ for Model A, Model B, and Model C, respectively. Notably, Model B exhibits the highest value, indicating better performance compared to Model A and C. These results highlight the influence of manufacturing cost on the value of .

Table 18.

Cases to demonstrate the impact of varying the manufacturing cost of PV enhancer on .

| Model | Total energy (J) | Lifespan (Year) | Weight (kg) | Manufacturing cost ($) |

(J.Year/kg. $) |

|---|---|---|---|---|---|

| A | 200 | 3 | 1 | 18 | 33.33 |

| B | 150 | 6 | 2 | 11 | 40.91 |

| C | 130 | 2 | 3 | 10 | 8.67 |

3.2. Experimental validation for the proposed methods

The experimental validation is conducted to support the applicability of the proposed methods on a real case, as follows. A previous study was conducted for PVT with PCM [54]. Results revealed that 30 kWh is the highest energy obtained which is equivalent to 108 MJ. According to Ref. [54], the lifespan and cost of the PVT are 25 years and 1804 Yuan (1142.34 RM). If we assume that the PVT's area, volume and weight are 2 m2, 0.6 m3 and 5 kg, respectively. Now, applying the proposed methods, the , and and are 1.18 MJ.Year/m2.RM, 3.94 MJ.Year/m3.RM and 0.47 MJ.Year/kg.RM, respectively, as shown in Table 19, Table 20, Table 21. From the above results, it can be concluded that the proposed methods are applicable on a real case.

Table 19.

The applicability of on a real case.

| Model | Total energy (MJ) | Lifespan (Year) | Area (m2) | Manufacturing cost (RM) |

(MJ.Year/m2. RM) |

|---|---|---|---|---|---|

| Previous study [54] | 108 | 25 | 2 | 1142.34 | 1.18 |

Table 20.

The applicability of on a real case.

| Model | Total energy (MJ) | Lifespan (Year) | Volume (m3) | Manufacturing cost (RM) |

(MJ.Year/m3. RM) |

|---|---|---|---|---|---|

| Previous study [54] | 108 | 25 | 0.6 | 1142.34 | 3.94 |

Table 21.

The applicability of on a real case.

| Model | Total energy (MJ) | Lifespan (Year) | Weight (kg) | Manufacturing cost (RM) |

(MJ.Year/kg. RM) |

|---|---|---|---|---|---|

| Previous study [54] | 108 | 25 | 5 | 1142.34 | 0.47 |

3.3. Summary for the existing and enhanced PV enhancer assessment methods

Table 22 illustrates the comparison summary between the existing and enhanced assessment methods for PV enhancer. From Tables 22 and it is shown that the existing methods do not include the PV enhancer's lifespan parameter, making the decision-making process on the different models of PV enhancer difficult, as shown in the earlier parts of the results and discussions section. On the other hand, the modified assessment methods include the lifespan in the analysis to accurately evaluate and compare the different types of PV enhancers.

Table 22.

Summary for the existing and modified PV enhancer assessment methods.

4. Conclusion

Currently, PV enhancer research focuses on improving the PV performance. Assessment approaches are available in the literature to evaluate the performance of PV enhancer. But the lifespan of PV enhancer was not considered in the existing assessment methods; making the PV enhancer's performance evaluation and comparison difficult when the lifespan is to be considered in the analysis. To solve the current issue, a relationship between the PV enhancer's lifespan and the existing evaluation methods is created. The outcomes are three modified assessment methods, which are yield times lifespan per cost per area factor , yield times lifespan per cost per volume factor and yield times lifespan per cost per weight factor (). The proposed factors play a crucial role in distinguishing the performance of a PV enhancer, with higher values indicating better performance. The limitations and influential parameters of the proposed method were also highlighted, and examples were presented to illustrate the significance of these methods. It is seen that the enhanced approaches can accurately evaluate the performance of PV enhancer with different designs, compared to the existing methods, when the lifespan parameter is included in the analysis. The potential users of the proposed methods are PV enhancer designers and manufacturers. Future research should be carried out to develop more assessment methods for PV enhancers.

Data availability statement

No data was used for the research described in the article.

CRediT authorship contribution statement

Sakhr M. Sultan: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. C.P. Tso: Funding acquisition, Writing – review & editing. K. Sopian: Software, Writing – review & editing. Raheem K Ajeel: Software, Writing – review & editing. K. Sobayel: Software, Writing – review & editing. A. Ibrahim: Software, Writing – review & editing. M. Z. Abdullah: Software, Supervision, Writing – review & editing.

Declaration of competing interest

I am pleased to submit a research paper entitled “Development of assessment methods for the photovoltaic module enhancing techniques using the lifespan parameter” for consideration for publication in Heliyon.

This manuscript has not published and is not under consideration for publication elsewhere. We have no conflicts of interest to disclose.

References

- 1.Sakhr M.S., Abdullah M.Z. A new method for assessing photovoltaic module cooler based on lifespan effectiveness factor. Case Stud. Therm. Eng. 2022;35 [Google Scholar]

- 2.Mehrdad A., Ali S., Arian G. The effects of a novel baffle-based collector on the performance of a photovoltaic/thermal system using SWCNT/Water nanofluid. Therm. Sci. Eng. Prog. 2022;34 [Google Scholar]

- 3.Hamza R., Cherif O. Study on the overall energy and exergy performances of a novel water-based hybrid photovoltaic-thermal solar collector. Energy Convers. Manag. 2020;222 [Google Scholar]

- 4.Paul R. The photovoltaic effect and its utilization. Sol. Energy. 1959;3:8–18. [Google Scholar]

- 5.Green M.A. Photovoltaics: technology overview. Energy Pol. 2000;28:989–998. [Google Scholar]

- 6.Sultan S.M., Tso C.P., Ervina E.M.N. A new production cost effectiveness factor for assessing photovoltaic module cooling techniques. Int. J. Energy Res. 2020;44:574–583. [Google Scholar]

- 7.Shah N.A., Animasaun I.L., Ibraheem R.O., Babatunde H.A., Sandeep N., Pop I. Scrutinization of the effects of Grashof number on the flow of different fluids driven by convection over various surfaces. J. Mol. Liq. 2018;249:980–990. [Google Scholar]

- 8.Animasaun I.L. Effects of thermophoresis, variable viscosity and thermal conductivity on free convective heat and mass transfer of non-darcian MHD dissipative Casson fluid flow with suction and nth order of chemical reaction. Journal of the Nigerian Mathematical Society. 2016;34(1):11–31. [Google Scholar]

- 9.Kolade K., Oreyeni O., Johnm O.T., Lare A.A.I. Homotopy analysis of MHD free convective micropolar fluid flow along a vertical surface embedded in non-darcian thermally-stratified medium. Open J. Fluid Dynam. 2016;6(3):198–221. [Google Scholar]

- 10.Sultan M.S., Tso C.P., Ervina E.M.N. Comments on “Performance evaluation of photovoltaic thermal solar air collector for composite climate of India”. Sol. Energy Mater. Sol. Cell. 2019;198:63–64. [Google Scholar]

- 11.Sultan S.M., Ervina E.M.N. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Sol. Energy. 2018;173:939–954. [Google Scholar]

- 12.Mohamed H., M’barek F., Monssif N., Adil C. Numerical study of a covered Photovoltaic-Thermal Collector (PVT) enhancement using nanofluids. Sol. Energy. 2020;199:115–127. [Google Scholar]

- 13.Mohammad H.A., Alireza B., Milad S., Mohammad Z., Amir M., Shahaboddin S., Ravinder K., Mohammad M. Engineering Applications of Computational Fluid Mechanics; 2020. Evaluation of Electrical Efficiency of Photovoltaic Thermal Solar Collector. [DOI] [Google Scholar]

- 14.Nahar A., Hasanuzzaman M., Rahim N.A., Parvin S. Numerical investigation on the effect of different parameters in enhancing heat transfer performance of photovoltaic thermal systems. Renew. Energy. 2019;132:284–295. [Google Scholar]

- 15.Xiaojiao Y., Liang lS., Yanping Y., Xudong Z., Xiaoling C. Experimental investigation on performance comparison of PV/T-PCM system and PV/T system. Renew. Energy. 2018;119:152–159. [Google Scholar]

- 16.Ruobing L., Qiangguang P., Peng W., Jili Z. Experiment research of solar PV/T cogeneration system on the building façade driven by a refrigerant pump. Energy. 2018;161:744–752. [Google Scholar]

- 17.Fuentesa M., Vivar M., Casa J., Aguilera J. An experimental comparison between commercial hybrid PV-T and simple PV systems intended for BIPV. Renew. Sustain. Energy Rev. 2018;93:110–120. [Google Scholar]

- 18.Hossein A., Roghayeh G., Mohammad B.S., Mohammad H.A., Wei-Mon Y., Mohammad A.N. Numerical simulation of PV cooling by using single turn pulsating heat pipe. Int. J. Heat Mass Tran. 2018;127:203–208. [Google Scholar]

- 19.Ali N.A., Alghoul M.A., Elbreki A.M., Ammar A.A., Azher M.A., Sopian K. Mathematical and experimental evaluation of thermal and electrical efficiency of PV/T collector using different water based nano-fluids. Energy. 2018;145:770–792. [Google Scholar]

- 20.Nahar A., Hasanuzzaman M., Rahim N.A. Numerical and experimental investigation on the performance of a photovoltaic thermal collector with parallel plate flow channel under different operating conditions in Malaysia. Sol. Energy. 2017;144:517–528. [Google Scholar]

- 21.Rahman M.M., Hasanuzzaman M., Rahim N.A. Effects of operational conditions on the energy efficiency of photovoltaic modules operating in Malaysia. J. Clean. Prod. 2017;143:912–924. [Google Scholar]

- 22.Fayaz H., Nasrin R., Rahim N.A., Hasanuzzaman M. Energy and exergy analysis of the PVT system: effect of nanofluid flow rate. Sol. Energy. 2018;169:217–230. [Google Scholar]

- 23.Sakellariou E., Axaopoulos P. Simulation and experimental performance analysis of a modified PV panel to a collector. Sol. Energy. 2017;155:715–726. [Google Scholar]

- 24.Al-Shamani A.N., Mat S., Ruslan M.H., Abed A.M., Sopian k. vol. 11. WSEAS Transactions on Environment and Development; 2016. pp. 23–28. (Numerical Study on the Characteristics of a Specially Designed Rectangular Tube Absorber Photovoltaic Thermal Collector (PVT)). [Google Scholar]

- 25.Al-Shamani A.N., Mat S., Ruslan M.H., Abed A.M., Sopian K. Effect of new ellipse Type on the performance enhancement of PV/T collector: CDF Approach. International Journal of Environment and Sustainability. 2016;5:54–60. [Google Scholar]

- 26.Tiwari G.N., Fischer O., Mishra R.K., Al-Helal I.M. Performance evaluation of N-photovoltaic thermal (PVT) water collectors partially covered by photovoltaic module connected in series: an experimental study. Sol. Energy. 2016;134:302–313. [Google Scholar]

- 27.Juwel C.M., Wen T.C., Hwai C.O., Leong K.Y., Abdullah A. An experimental investigation on performance analysis of air type photovoltaic thermal collector system integrated with cooling fins design. Energy Build. 2016;130:272–285. [Google Scholar]

- 28.Bilbao J.I., Sproul A.B. Detailed PVT-water model for transient analysis using RC networks. Sol. Energy. 2015;115:680–693. [Google Scholar]

- 29.Fadhel M.I., Sultan S.M., Alkaff S.A. Theoretical study of new configuration of PVT system design. J. Adv. Microsc. Res. 2013;772:681–687. [Google Scholar]

- 30.Sultan S.M., Fadhel M.I., Alkaff S.A. Performance analysis of the photovoltaic/thermal solar collector for different Malaysian climatic condition. Journal of Applied Mechanics and Materials. 2014;467:522–527. [Google Scholar]

- 31.Oussama H., Mahmoud B., Abdellah M. Performance analysis of photovoltaic-thermal air collectors combined with a water to air heat exchanger for renewed air conditioning in building. Environ. Sci. Pollut. Control Ser. 2020 doi: 10.1007/s11356-020-08052-4. [DOI] [PubMed] [Google Scholar]

- 32.Chao Z., Ruobing L., Jili Z., Ahmad R. Experimental study on the cogeneration performance of roll-bond-PVT heat pump system with single stage compression during summer. Appl. Therm. Eng. 2019;149:249–261. [Google Scholar]

- 33.Grubišić‐Čabo F., Nižetić S., Duje C., Ivo M.K., Agis P. Experimental investigation of the passive cooled free-standing photovoltaic panel with fixed aluminum fins on the backside surface. J. Clean. Prod. 2018;176:119–129. [Google Scholar]

- 34.Karima E., Amori M.A.A. Field study of various air based photovoltaic/thermal hybrid solar Collectors. Renew. Energy. 2014;63:402–414. [Google Scholar]

- 35.David G., Iván A., Montserrat D., Cristina A. Experimental analysis of a novel PV/T panel with PCM and heat pipes. Sustainability. 2020;12:1710. [Google Scholar]

- 36.Michael L. Durability and climate change: changing climatic loads as may affect the durability of building materials, components and assemblies. proceedings of CIB/NRC symposium. 2018 [Google Scholar]

- 37.Tabor H. Stationary mirror systems for solar collectors. Sol. Energy. 1958;2(3–4):27–33. [Google Scholar]

- 38.Anand V.P., Khan A.E., Amuthan V., Pesala B. Performance improvement of solar module system using flat plate reflectors. International Conference on Advanced Electrical Engineering (ICAEE) 2014:1–4. [Google Scholar]

- 39.Palaskar V.N., Deshmukh S.P. Design and performance analysis of reflectors attached to commercial PV module. Int. J. Renew. Energy Resour. 2014;4(1):240–245. [Google Scholar]

- 40.Tanaka H. Theoretical analysis of solar thermal collector with a flat plate bottom booster reflector. Energy Rep. 2011;2(2):26–34. [Google Scholar]

- 41.Gopinath M.S., Balaji R., Kirubakaran V. Cost effective methods to improve the power output of a solar panel: an experimental investigation. Power and Energy Systems: towards Sustainable Energy IEEE. 2014:1–4. [Google Scholar]

- 42.Bahaidarah H.M., Tanweer B., Gandhidasan P., Rehman S. A combined optical, thermal and electrical performance study of a V-trough PV system experimental and analytical investigations. Energies. 2015;8(4):2803–2827. [Google Scholar]

- 43.Naseer K.K., Ahmed F.A., Fadhil M.E. Improve the performance of solar modules by reflectors. The Sixth Scientific Conference “Renewable Energy and its Applications”. 2018;1032 [Google Scholar]

- 44.Elbreki A.M., Muftah A.F., Sopian K., Jarimi H., Fazlizan A., Ibrahim A. Experimental and economic analysis of passive cooling PV module using fins and planar reflector. Case Stud. Therm. Eng. 2021;23 [Google Scholar]

- 45.Moon K.K., Khalid O.A., Jiying L., Joon-Ho C., Huiqing W. Optimal design strategy of a solar reflector combining photovoltaic panels to improve electricity output: a case study in Calgary, Canada. Sustainability. 2021;13:6115. [Google Scholar]

- 46.Jin S., Choi B.G., Choi J.H., Kim S.R., Chun R.T., Yun-Su K. New curved reflectors for significantly enhanced solar power generation in four seasons. Energies. 2019;12:4602. [Google Scholar]

- 47.Amanlou Y., Hashjin T.T., Ghobadian B., Najafi G. Air cooling low concentrated photovoltaic/thermal (LCPV/T) solar collector to approach uniform temperature distribution on the PV plate. Appl. Therm. Eng. 2018;141:413–421. [Google Scholar]

- 48.Monika A., Priyank C., Amartya C. Performance analysis of photovoltaic module with reflector: optimizing orientation with different tilt scenarios. Renew. Energy. 2022;186:10–25. [Google Scholar]

- 49.Eskandar J., Mohammad H.N., Behrooz M.Z., Morteza K. Performance analysis of a novel model of photovoltaic PV-TEGs system enhanced with flat plate mirror reflectors. Renew. Energy. 2023;297 [Google Scholar]

- 50.Muslizainun M., Ahmad F., Nurul S.N., Muhammad I.A.Z., Nurul N.R., Wan M.W.S., Ks Mathematical modeling and experimental validation of bifacial photovoltaic–thermal system with mirror reflector. Case Stud. Therm. Eng. 2023;43 [Google Scholar]

- 51.Samira J., Mehran A. Integrating photovoltaic/linear Fresnel reflector with supercritical carbon dioxide energy storage system: energy and exergy analysis. J. Energy Storage. 2022;53 [Google Scholar]

- 52.Ali H., Sopian K., Kazem H., Chaichan M. Novel criteria for assessing PV/T solar energy production. Case Stud. Therm. Eng. 2019;16 [Google Scholar]

- 53.Sultan S.M., Abdullah M., Hussein H., Tso C., Sopian K. Modified methods for assessing photovoltaic solar thermal collectors. Case Stud. Therm. Eng. 2021;28 [Google Scholar]

- 54.Jianhui L., Wei Z., Lingzhi X., Zihao L., Xin W., Oufan Z., Jianmei Z., Xiding Z. A hybrid photovoltaic and water/air based thermal (PVT) solar energy collector with integrated PCM for building application. Renew. Energy. 2022;199:662–671. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.