Abstract

Despite the rapid growth of infrastructure development in Indonesia, work safety remains a major concern in construction projects. Design-for-safety (DfS) is a critical strategy to prevent work accidents. The implementation of design-for-safety is one of the most important strategies for preventing work accidents. This study aimed to analyze multiple factors that influence the implementation of work safety design using two statistical approaches: structural equation modeling and an artificial neural network. Structural equation modeling analyzes the relationship pattern between variables and their indicators, and artificial neural network maps various similar patterns to predict variables that influence implementation. Designers, owners, policies, tools/equipment, knowledge, and contract documents positively affect design-for-safety implementation, with design and contract documents being the most significant variables. Accordingly, industry and government agencies are advised to prioritize contract documents and design factors, along with other variables as supporting factors in their programs to accelerate design-for-safety implementation in Indonesia.

Keywords: Artificial neural network, Construction, Design-for-safety, Designers, Structural equation modeling

1. Introduction

Construction sites are known for being one of the most dangerous workplaces [1]. Hence, construction workers are at a higher risk of death or injury than workers in other industries [2]. In general, the probability of a fatal accident in the construction industry is 3–6 times higher than that in other industries [3]. In Indonesia, it is estimated that 30 % of work accidents occur in the construction sector, which affects 6.7 % of the workforce [4]. Furthermore, Indonesia's safety culture is severely deficient, with issues such as insufficient monitoring and infrequent safety training. This indicates the poor implementation of work safety in Indonesia. Hence, the improvement in work safety is urgently needed in Indonesia, specifically because the number of construction workers in the country continues to increase.

Numerous studies have shown that design decisions significantly affect worker safety [5]. Research conducted in America shows that 42 % of work accidents in construction projects can be attributed to design decisions made during the planning stage [6]. According to Szymberski's time–safety influence curve, it becomes exponentially more difficult to influence safety performance over the course of a project. Hossain et al. [7] mentioned that the design produced by designers during planning can significantly contribute to reducing the risk of work-related accidents. These studies have given rise to the concept of design-for-safety (DfS), which refers to the process of identifying, reducing, and mitigating safety and health risks through good design at the conceptual and planning stages of a project [8].

According to Tymvios et al. [9], DfS can become the basis for stakeholders to implement work safety during the construction phase. However, the application of DfS in the Indonesian construction industry is still lacking. The first regulation governing DfS implementation was enacted in 2021 under the Regulation of Ministry of Public Works Number 10 of 2021. However, designers are unfamiliar with the DfS concept and are not ready to apply DfS in construction projects.

Based on the literature, there are limited studies on DfS implementation in Indonesia's construction industry. Alvin et al. [10] studied the implementation of DfS and its obstacles were limited to the Surabaya area. Therefore, the level of knowledge and awareness of DfS and extent of its application among Indonesian designers remain unknown. This could hinder the industry and government agencies from developing effective measures to improve DfS implementation.

Therefore, this study aimed to examine the factors affecting the implementation of DfS. These factors were analyzed using partial-least-square–structural-equation modeling (PLS–SEM) and artificial neural network (ANN) methods. PLS–SEM accounts for multiple statistical relationships among the factors in DfS implementation. In contrast, ANN was used to rank the normalized importance of the significant factors based on a PLS–SEM analysis. A combination of PLS–SEM and ANN provides a comprehensive understanding of the topic, and the results from both methods complement each other [11]. The results of this study can be used as a foundation for developing strategies to improve the implementation of DfS in Indonesia.

2. Theoretical framework and hypotheses

2.1. Design-for-safety in construction

In 1997, Szymberki proposed a theory that the effectiveness of safety interventions diminishes exponentially over the lifecycle of a project. His theory is visualized as the time–safety influence curve, showing that the most influential time in the safety of construction work is during the initial phase of the project [9]. If the construction safety can be designed earlier in the conceptual and detailed engineering stages by designers, the safety impact will be much greater than that during the later stages. Subsequently, DfS was introduced as an innovative hazard prevention strategy to reduce and eliminate fatal and nonfatal work-related injuries to minimize the risk of work accidents [12]. Several studies have shown that designers can significantly influence construction work safety [13].

Several countries such as Australia and Singapore have applied the DfS concept to construction safety. Australia initiated a safety movement after several catastrophic construction fatalities [14]. Policymakers emphasized a form of safety movement for professionals in the 1980s and 1990s. The government defined the roles and responsibilities of safety professionals, created curricula for formal safety education, and created a professional-certification system [15]. According to the Work Health and Safety Act (WHS Act) of 2011 (Section 22), designers must ensure that their products pose no dangers to health and safety throughout their useful lives when utilized at a workplace. The WHS Act also emphasizes the need for designers to conduct adequate testing and examinations to guarantee that their products adhere to work health and safety regulations.

Besides Australia, Singapore passed a regulation regarding the affirmation of DfS in 2008 [16]. The Workplace Safety and Health Council introduced the Guidelines on DfS in Buildings and Structures in 2008 to aid clients, designers, and contractors in the implementation of design safety. This initiative facilitates the transfer of essential safety and health information along the building process chain. The rules outline the responsibilities of designers, including design reviews to examine the risks generated, removing hazards as is practicable, and offering mitigation measures for any remaining hazards.

In addition to the examples of DfS implementation in Australia and Singapore that we discussed in the previous paragraph, it is noteworthy to consider how the concept of DfS is being practiced in neighboring countries such as Malaysia and Thailand. In Malaysia, the construction industry has been making strides towards DfS adoption in recent years. The Malaysian government, recognizing the importance of construction safety, has introduced guidelines and regulations aimed at enhancing safety standards [17]. For instance, the Occupational Safety and Health (DfS) Regulations were enacted to ensure that safety considerations are integrated into the design phase of construction projects. Designers in Malaysia are encouraged to identify and address safety risks early in the project lifecycle, aligning with the principles of DfS [18].

Similarly, in Thailand, there has been a growing emphasis on DfS within the construction sector. The Thai government, in collaboration with industry stakeholders, has been promoting DfS practices to reduce construction accidents and improve overall safety performance [19]. Designers in Thailand are encouraged to proactively consider safety aspects during the design process, aligning with international best practices and standards [20]. These examples from Malaysia and Thailand demonstrate the expanding recognition of DfS as a crucial component of construction safety across Southeast Asia [17]. While our study primarily focuses on the Indonesian context, it is essential to acknowledge these regional developments as they contribute to the broader understanding of DfS practices in the region and offer opportunities for cross-border collaboration and knowledge sharing.

2.2. Implementation of construction safety in Indonesia

According to a survey [21], the construction sector's contribution to Indonesia's GDP increased from 4 % in 1973 to 9.82 % in 2019. This indicates that Indonesia's construction sector grew significantly. However, the construction industry is inseparable from the risks that affect 5 million construction workers in Indonesia [22]. The government of Indonesia (GoI) issued regulations to ensure occupational safety and health (OSH) implementation in the construction industry. Law Number 1 on occupational safety, enacted in 1970, has governed the implementation of the occupational health and safety management system (OHSMS) in Indonesia. This law regulates employers' and employees' obligations in terms of workplace safety. In accordance with Government Regulation No. 50 published in 2012, the GoI has established updated and more thorough regulations for OHSMS. To establish standards for construction-safety management systems, the Ministry of Public Works enacted Ministerial Regulation Number 10 in 2021. It outlines the management structure for implementing construction work to ensure safety. According to Ministerial Regulation Number 10, the output of the design phase is not only a detailed engineering design, but also a DfS document. Despite these laws and regulations, the implementation of DfS remains insufficient. According to Alvin et al. [10], most structural engineers have not used DfS. Nevertheless, they stated that designers must implement DfS in the planning stage; therefore, it can be said that the implementation of DfS received support from structural engineers. Thus, it has the potential to be implemented in the future.

2.3. Factors affecting DfS implementation

The identification of factors that significantly influence DfS implementation is informed by a comprehensive review of the literature. The specific factors will be explicated in the following section.

2.3.1. Designer

Designers play a key role in DfS implementation, consisting of architects and engineers who contribute to, or are responsible for any part of the design; contractors carrying out design work; temporary work engineers who design temporary works such as formwork and scaffolding; and others who carry out structural alteration, demolition, or dismantling work [23]. Designers' capabilities and competencies are strongly influenced by their skills, basic knowledge, experience, expertise, and attitudes [24]. Designer skills in safety design are important for identifying hazard recognition, analyzing risk, using safety technology/tools, and calculating financial risk costs/benefits. In addition, the basic knowledge that designers must possess is safety design features, OSH and DfS regulations, and contract management [25]. These skills and knowledge areas are honed upon by increasing expertise. Additionally, experience can assist designers in sharpening the justification, analysis, and dynamics of the design process [26]. However, the design results are ineffective if the designer's attitude is not collaborative. Therefore, designers must also collaborate with other stakeholders when implementing DfS [25]. In addition, the allocation of fees significantly affects designer participation in DfS implementation, and the fee should be reasonable, based on the designer's qualifications [27]. Using the above approach, six items attributed to designers are skill (X11), knowledge (X12), experience (X13), expertise (X14), attitude (X15), and designer's fee (X16).

2.3.2. Owner

Owners have a direct influence on determining the design direction of construction projects as one of the stakeholders with the highest positions in the project hierarchy. The owner's willingness to work together with designers and lead the DfS implementation is important [28]. Owners must also be committed to supporting work safety sustainability at construction sites. The owners' commitment can be demonstrated by providing technical assistance such as safety equipment [29]. In addition, owners may allocate DfS funds to designer fees and implement safety standards [30]. In accordance with the literature, the following three items were generated: commitment (X21), leadership (X22), and DfS funds (X23).

2.3.3. Policy

In Indonesia, regulations regarding safety have historically started with Law Number 1 of 1970 on occupational safety, which regulates OHSMS in general. Subsequently, a series of regulations were stipulated, such as the Government Regulation Number 50 of 2012 on OHSMS implementation and Ministerial Regulation Number 10 of 2021 on construction-safety management system guidelines. These regulations govern stakeholder roles regarding safety, from the planning and design phases to the completion of the project [31]. Aside from government regulations, there are regulations issued by associations or institutions, as well as guidelines issued by consultants for DfS designers. These regulations assist designers in complying with the ministry and government regulations. Using the above approach, the three items attributed to policy are government regulation (X31), company regulation (X32), and industry guidance (X33).

2.3.4. Tools/equipment

Construction activities occur in a complex and dynamic environment, which can lead to construction accidents, work-related injuries, and deaths. Accidents can occur despite workers wearing high-visibility clothing required by the existing safety codes and standards [32]. The availability of safety equipment that meets regulations is a critical issue in this regard. The application of modern technology to construction equipment in Indonesia has also become widespread. Most projects have started using renewable equipment methods to reduce risk levels. This poses a new challenge for safety designers in understanding the process of construction methods and the use of equipment to more comprehensive design for safety. Based on the literature, three items were generated: standard/codes (X41), technology (X42), and technology cost (X43).

2.3.5. Knowledge

Safety knowledge provided through formal education and positive training affects DfS implementation. Several studies have demonstrated the importance of literacy and education on the safety performance of construction workers. Formal educational background affects overall work performance, while training provides designers with practical knowledge and specific techniques, tools, and technologies [33]. Furthermore, prospective designers can learn through socialization, such as webinars and talk shows, to disseminate factual and recent information [34]. Designers with high levels of education and information are able to design critically and respond to problems appropriately [35]. Using the above approach, three items attributed to knowledge are socialization (X51), education (X52), and training (X53).

2.3.6. Contract

Work contracts are the fundamental foundation for designers to implement safety design. The contract must cover the designer's scope of work, responsibilities, fees, and obligations [25]. Safety-related contract clauses, which are a common point of reference, may consist of the scope of the work of designers, the design budget, designers' remuneration, and indemnity assurance as a guarantee of design outcomes. The contract's content is a form that administratively binds to all related technical and nontechnical matters. In accordance with the literature, five items were generated as follows: contract terms (X61), scope of work (X62), DfS budget (X63), liability (X64), and assurance (X65).

2.4. Development of hypotheses

Reasonable hypotheses are crucial for establishing PLS–SEM and ANN models. To build a theoretical research model to analyze DfS implementation and establish relationships among factors, the following hypotheses were developed based on the literature and theoretical analysis.

-

•

Hypothesis H1: Designer (X1) positively affects DfS implementation.

-

•

Hypothesis H2: Owner (X2) positively affects DfS implementation.

-

•

Hypothesis H3: Policy (X3) positively affects DfS implementation.

-

•

Hypothesis H4: Tools/equipment (X4) positively affects DfS implementation.

-

•

Hypothesis H5: Knowledge (X5) positively affects DfS implementation.

-

•

Hypothesis H6: Contract (X6) positively affects DfS implementation.

Furthermore, to measure and observe DfS implementation, three parameters/items were identified: designer capabilities (Y1), supportive environment (Y2), and design output (Y3). The first addresses the ability of designers to implement DfS and the second addresses the environment in the construction industry that supports DfS implementation. The third parameter addresses the design output. A total of twenty-six observed items were involved in the measurement of DfS implementation.

3. Methodology

3.1. Philosophical stances

Drawing inspiration from several notable accidents within Indonesia's construction industry, our research is underpinned by two pivotal philosophical perspectives. These perspectives encompass the realms of epistemology and ontology, with a keen focus on interpretivism and constructivism. This dual perspective is thoughtfully adopted due to its inherent capabilities. On one hand, the epistemological facet (interpretivism) guides our exploration of how knowledge pertaining to the implementation of design-for-safety (DfS) is garnered and comprehended [36]. Concurrently, the ontological aspect (constructivism) delves into the intricate essence of the very reality and existence of DfS implementation factors [37].

In aligning with an interpretivist epistemological standpoint, we embrace the notion that knowledge is intricately woven through human experiences and interactions. By immersing ourselves within this perspective, we gain a heightened awareness of the multifaceted nature of DfS implementation within Indonesia's construction landscape. This recognition illuminates the profound influence of contextual elements, subjective perceptions, and dynamic social dynamics in shaping the trajectory of DfS integration. This approach, in turn, paves the way for a meticulous dissection of the intricate tapestry that constitutes DfS implementation complexities. A notable manifestation of this approach is the incorporation of diverse expert insights. Three distinct experts, each possessing their unique contextual background, contribute their perspectives, thereby enriching our understanding of contextual factors, subjective viewpoints, and socio-environmental dynamics.

Complementing our epistemological vantage point is our ontological leaning towards constructivism. This perspective venerates the profound role of human interpretation in shaping our understanding of reality [38]. DfS implementation, we assert, is far from being a rigid, unyielding phenomenon; rather, it is an ever-evolving interplay of myriad elements within the expansive construction industry domain. With constructivism as our guiding beacon, our research embarks on an exploratory journey into the multifaceted essence of DfS. We illuminate the contributions of diverse stakeholders, unraveling the intricacies of their roles in the realization of DfS principles. This trajectory is inaugurated with an exhaustive literature review, meticulously identifying and examining factors that wield influence over DfS implementation. This preliminary step ensures a seamless alignment with our constructivist underpinning, as we unravel the interwoven tapestry of DfS realization.

In sum, our research, catalyzed by dual epistemological and ontological perspectives, embarks on an incisive journey into the core of DfS implementation in Indonesia's construction industry. By meticulously melding the interpretive epistemological lens and the constructivist ontological framework, we unlock profound insights, casting light on the intricate dance between human perception, contextual dynamics, and the actuality of DfS implementation.

3.2. Research approach

This study employs a mixed-methods approach, integrating quantitative and qualitative techniques to provide a comprehensive analysis of DfS implementation factors. By combining quantitative data from survey questionnaires with qualitative insights from industry experts, we ensure a holistic understanding of the subject matter. This approach allows us to triangulate findings, enhancing the validity and reliability of our results [39].

Our research design involves a two-staged analysis. The initial stage employs Partial Least Squares – Structural Equation Modeling (PLS-SEM) to unravel intricate relationships among latent constructs. PLS-SEM's ability to handle reflective and formative constructs, coupled with its suitability for complex data, aids in identifying key factors influencing DfS implementation. Subsequently, Artificial Neural Network (ANN) analysis is employed to capture non-linear patterns and interactions within the identified factors, contributing to a comprehensive understanding.

The combination of PLS-SEM and ANN analyses enhances the rigor and validity of our study. By leveraging the strengths of both methods, we mitigate potential methodological biases and achieve a more robust interpretation of results. This approach ensures that our conclusions are not solely reliant on one analytical technique, bolstering the credibility of our findings and recommendations for expediting DfS implementation in the Indonesian construction industry.

3.3. Research design and data Collection's method

Before we distributed the questionnaire to the construction workers, we requested experts to check and validate the questionnaire. We also asked for expert feedback, which could be in the form of revising, adding, or reducing factors. The expert's knowledge was based on a safety qualification from an academia/consultant/contractor with a minimum of 10 years of experience. The feedback from the experts was then synthesized and used as input to construct the questionnaire, as shown in Table 1.

Table 1.

Expert's insights for questionnaire.

| Expert | Insights |

|---|---|

| Expert #1 (Academics) |

|

| Expert #2 (Professional Contractor) |

|

| Expert #3 (Professional Consultant) |

|

The questionnaire consisted of two main parts. The first part contained instructions, research objectives, and questions regarding the respondents’ demographics. The second part listed the factors that influenced DfS implementation. Each factor was elaborated upon a few items, and each item was quoted from literature and validated by experts. Table 2 presents a list of twenty-six items included in the questionnaire. All items in the research model were measured using a five-point Likert scale ranging from 1 (completely disagree) to 5 (completely agree). The target respondents for the questionnaire were construction workers from consultants or contractors who worked directly or indirectly with DfS.

Table 2.

Items considered significant to design-for-safety (DfS) implementation.

| Items | Descriptions |

|---|---|

| X1 | Designer |

| X11 | Skill (Designers can DfS in the conceptual and planning phase of a project) |

| X12 | Knowledge (Designers have basic or advanced knowledge of DfS) |

| X13 | Experience (Designers have experience working in safety design based on DfS) |

| X14 | Expertise (Designers have an expertise certificate in DfS) |

| X15 | Attitude (Designers have commitment in DfS implementation) |

| X16 | Designer’ fee (There is an allocation of salaries and remuneration for designers related to DfS) |

| X2 | Owner |

| X21 | Commitment (Owners have commitment by providing resource and material for DfS implementation) |

| X22 | Leadership (Owners have a leadership attitude toward the implementation of safety design) |

| X23 | DfS cost (Owners allocate funds for DfS implementation) |

| X3 | Policy |

| X31 | Government regulation (There are government regulations regarding DfS used as a basis/reference by designers, owners, and consultants) |

| X32 | Company regulation (There are guidelines from the company regarding DfS used as a basis/reference by designers) |

| X33 | Industry guidance (There are guidelines from associations regarding DfS used as a basis/reference by designers, owners, and consultants) |

| X4 | Tools/equipment |

| X41 | Standard/codes (There are DfS standards used as a basis/reference by designers, owners, and consultants) |

| X42 | Technology (There are technologies that assists designers in DfS and assists contractors in implementing safety designs in the field) |

| X43 | Technology cost (There is a cost allocation for the provision/improvement of technology related to safer and more modern work methods in the context of implementing DfS) |

| X5 | Knowledge |

| X51 | Socialization (Availability of socialization containing DfS information/knowledge for designers, owners, and consultants) |

| X52 | Training (Availability of training that provides opportunities for designers, owners, and consultants to practice DfS) |

| X6 | Contract |

| X61 | Contract terms (It is written that the designer is responsible for DfS in the contract document) |

| X62 | Scopes of work (It is written that one of the designer's responsibilities in the scope of work is design safety) |

| X63 | Designer's fee (It is written that there is a cost/salary allocation for designers for DfS) |

| X64 | Liability (It is written the liable party for DfS) |

| X65 | Assurance (It is written regarding a guarantee/insurance, indemnity assurance, and design product license for the safety design) |

| Y | DfS Implementation |

| Y1 | Designers' capabilities (The ability of the designer to implement DfS based on designers' background, experience, education, and knowledge) |

| Y2 | Supportive environment (Environment in construction industry that support DfS implementation DfS) |

| Y3 | Design output (The results of the design in the form of a work safety plan cost plan, work method plan, work implementation drawings are conveyed properly and comprehensively) |

3.4. Research Flow

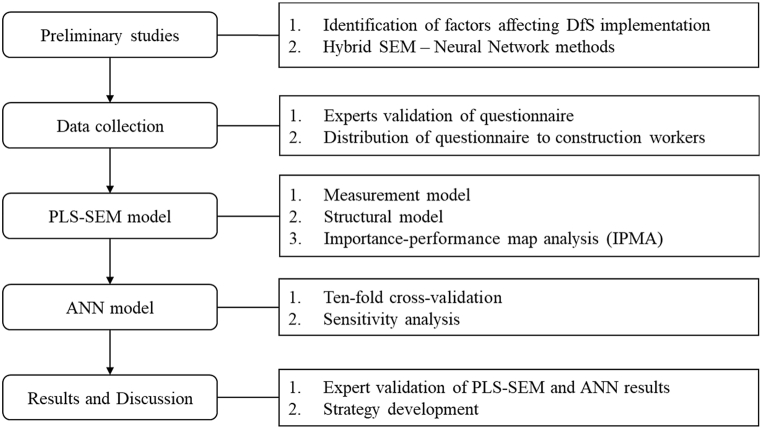

The methodology employed in this study is comprised of several stages that are briefly described based on Fig. 1.

Fig. 1.

Research flow.

This research methodology encompasses a sequential progression, commencing with a comprehensive literature review to discern the multifaceted factors influencing the successful implementation of design-for-safety (DfS) within the Indonesian construction industry. Following this foundational stage, a survey questionnaire was meticulously crafted and distributed among esteemed industry practitioners and subject matter experts, capturing their invaluable insights.

3.4.1. Partial Least Squares – structural equation modeling (PLS-SEM) analysis

The collected dataset was then subjected to rigorous analysis utilizing Partial Least Squares – Structural Equation Modeling (PLS-SEM) conducted through the adept SMARTPLS software. The rationale for employing PLS-SEM stemmed from its robustness in untangling intricate relationships between latent constructs. Remarkably versatile, PLS-SEM adeptly accommodates both reflective and formative constructs, while also demonstrating a reduced reliance on extensive sample sizes compared to conventional SEM methodologies.

The hyperparameters governing the PLS-SEM analysis were thoughtfully calibrated for precision. The number of iterations was meticulously set at 300 iterations, and the convergence criterion was established at an impressive threshold of 1.0E-7 [40]. These parameters were meticulously selected to ensure the convergence and stability of the model, underpinning the reliability and robustness of our analysis.

3.4.2. Artificial neural network (ANN) analysis

Subsequently, the seminal factors discerned through PLS-SEM were subjected to further scrutiny via an advanced Artificial Neural Network (ANN) analysis, facilitated by the sophisticated SPSS 27 software. The strategic choice of ANN was motivated by its inherent capability to discern intricate patterns and discern non-linear relationships amid variables, thus enabling predictions of complex systems. To engender optimal performance, the hyperparameters governing the ANN analysis were meticulously fine-tuned based on adjustment on previous research that used ANN model to analyze [41]. The architecture encompassed 7 nodes, while the learning rate was precisely set at 0.05 [42]. Additionally, a backpropagation algorithm was deftly employed to iteratively adjust the weights and biases of the neural network during training, enhancing the accuracy and reliability of our results.

3.4.3. Model validation: cross-validation and sensitivity analysis

Critical to the model's robustness, a comprehensive 10-fold cross-validation procedure was rigorously undertaken to gauge its predictive prowess and resilience [43]. This involved partitioning the dataset into ten subsets, iteratively employing nine for training and one for testing, ensuring the generalization of our findings. Furthermore, a sensitivity analysis was diligently conducted, scrutinizing the model's responsiveness to variations in input parameters. This procedure not only bolstered the model's stability but also underscored its reliability across diverse scenarios.

3.4.4. Synthesis and implications

Finally, the synthesized outcomes from both PLS-SEM and ANN analyses were seamlessly integrated to furnish strategic recommendations aimed at expediting the implementation of DfS within the Indonesian construction industry. The selection of software tools was underpinned by meticulous considerations of reliability, availability, and compatibility with the intricacies of our data and research objectives. Collectively, this comprehensive and meticulously orchestrated methodology aligns with our overarching goal to illuminate and inform stakeholders, practitioners, policymakers, and researchers within the realm of DfS implementation.

4. Results

4.1. Demographic profile of respondents

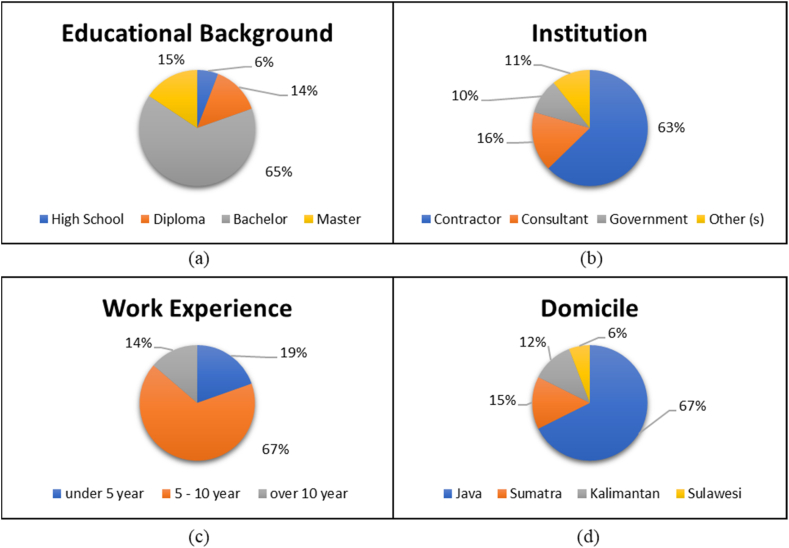

A total of 102 respondents were selected for data collection. A summary of the sample demographics is presented in Fig. 2. Fig. 2(a) reveals that most of the respondents were bachelor's degree graduates. Additionally, based on Fig. 2(b), the majority of the respondents were contractors, and Fig. 2(c) indicates that they possessed five to ten years of work experience. While the majority of the respondents were from Java Island, Fig. 2(d) shows that there were also respondents from other islands. Therefore, the respondents can be considered representative of Indonesia.

Fig. 2.

Summary of respondents' demographic: (a) education background; (b) institution; (c) work experience; (d) domicile.

4.2. Multivariate analysis

Several preliminary statistical tests were performed before modeling to ensure that the data were appropriate for multivariate analysis. To evaluate the normality assumption, it was essential to perform a normal distribution test. Pearson's Skewness and Kurtosis parameters were used to assess normality; the results are summarized in Table 3. The data show that the value of the “knowledge” variable (3.843) is outside the normal distribution range (−2.58 to +2.58) [44].

Table 3.

Skewness and kurtosis for the research constructs.

| Statistics | Designer | Owner | Policy | Tools | Knowledge | Contract Doc |

|---|---|---|---|---|---|---|

| Skewness | −0.778 | −1.077 | −1.005 | −1.471 | −1.792 | −1.176 |

| Kurtosis | +0.037 | +0.306 | +0.112 | +2.265 | +3.843 | +1.135 |

The Kolmogorov–Smirnov and Shapiro–Wilk tests were conducted to verify the non-normal distribution of all data, as shown in Table 4. The results show that data distribution is non-normal because all of the significance values are less than 0.05. Due to the non-normality of the distribution, PLS–SEM was selected instead of covariance-based SEM because it is more robust to non-normal distributions [45]. SmartPLS3 was used to verify the assumptions of the proposed model.

Table 4.

Normal distribution test.

| Parameter | Kolmogorov–Smirnov | Shapiro–Wilk |

|---|---|---|

| Designer | 0.146 | 0.906 |

| Owner | 0.271 | 0.789 |

| Policy | 0.293 | 0.787 |

| Tools/Equipment | 0.246 | 0.779 |

| Knowledge | 0.239 | 0.761 |

| Contract Document | 0.212 | 0.833 |

To verify the linear and nonlinear relationships, we assessed the Variance Inflation Factors (VIF) with a threshold value of 10, as shown in Table 5. Because there were nonlinear interactions between the independent and outcome variables, as shown by the VIF value, we performed an additional analysis using ANN to rank the normalized importance of the relevant variables based on the PLS–SEM analysis. Implementing a two-stage PLS–ANN technique is complementary because PLS–SEM is suitable for hypothesis testing of linear relationships but cannot capture the nonlinearity of interactions. The ANN can detect nonlinear correlations; however, because of its “black box” operation, it cannot be used to evaluate hypotheses [45].

Table 5.

Collinearity statistics: Variance inflation factors (VIF).

| Variable | Designer | Owner | Policy | Tools | Knowledge | Contract Doc |

|---|---|---|---|---|---|---|

| VIF | 1.891 | 2.383 | 2.461 | 3.434 | 2.196 | 2.978 |

4.3. PLS–SEM approach

4.3.1. Measurement model

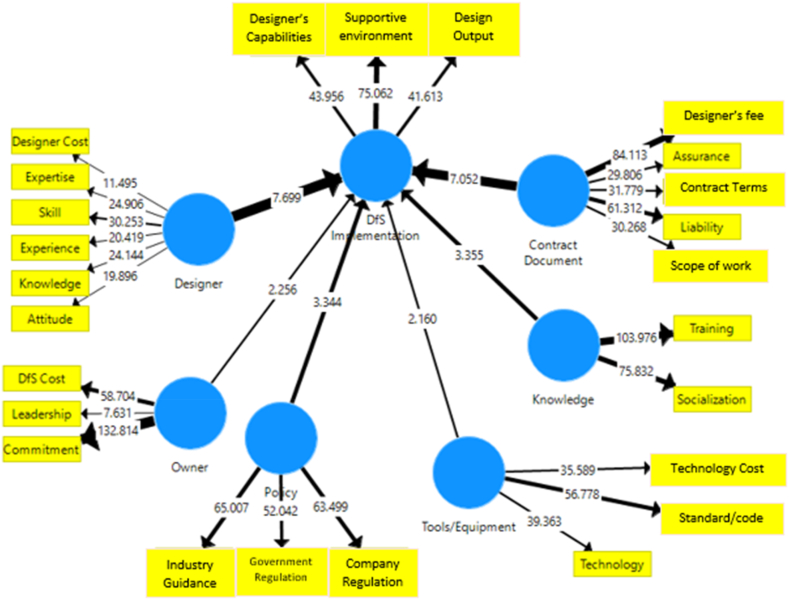

The hypothetical model was described according to the framework shown in Fig. 3. The framework has six latent variables as influencing factors (Variable X) and one latent variable as a phenomenon, defined as the implementation of DfS (Variable Y). The model was used to determine the relationship patterns between the variables. The thickness of the arrow defined the effect proportional to the value of the T-statistics, which functioned as a reference for the inner model.

Fig. 3.

Framework model.

To evaluate the measurement model, we used internal reliability, convergent validity, and discriminant validity criteria [46]. Cronbach's Alpha and Dijkstra–Henseler's rho are two commonly used measures for assessing construct reliability. Convergent validity was determined by examining the values of the item loadings, composite reliability, and Average Variance Extracted (AVE). Similarly, we investigated the discriminant validity by examining the correlations between the measures of potentially confounding variables. The composite reliability and Cronbach's Alpha values for each factor were greater than 0.70, as shown in Table 6. Therefore, we can attest the high build reliability of the measurement model. In addition, the AVE value of all factors was greater than 0.50, confirming that the items converged to the relevant factors. Consequently, factor validity was confirmed from the perspective of convergent validity.

Table 6.

Construct of reliability and validity.

| Cronbach's Alpha | Composite Reliability | AVE | |

|---|---|---|---|

| Designer | 0.768 | 0.838 | 0.464 |

| Owner | 0.702 | 0.827 | 0.632 |

| Policy | 0.837 | 0.902 | 0.755 |

| Tools/Equipment | 0.785 | 0.874 | 0.699 |

| Knowledge | 0.818 | 0.917 | 0.846 |

| Contract Document | 0.882 | 0.914 | 0.681 |

| DfS Implementation | 0.800 | 0.882 | 0.714 |

4.3.2. Structural model

A structural model was created to explain the structure of the formed relationship or causality between factors of the hypothetical model. After confirming the acceptable psychometric properties of the measurement model, we assessed the structural model with bootstrapping using 102 samples. For endogenous and latent variables, the predictive power of the structural model was measured using the R2 value [47]. The value of R2 was 0.753, indicating that 75.3 % of the variation in behavioral intention was explained by the model. Given that the percentage of variance explained was significantly greater than 30 %, the model was successful and substantial. The results showed that designers, owners, regulations, tools, knowledge, and contract documents have a significant impact on the implementation of DfS.

Hypothesis testing was performed to validate the hypotheses described in the framework model. Hypothesis testing showed satisfactory results, as there were no large deviations between the original sample value (O) and the sample mean (M), as shown in Table 7. The standard deviation was below 5 %. The T-statistics value, with a minimum value of 1.96, indicates that all variables have a high significance value. In addition, the P-values of all variables were less than 0.05, indicating that all variables had a significantly strong influence.

Table 7.

Hypotheses testing.

| Original Sample (O) | Sample Mean (M) | Standard Deviation | T-Statistics | P-Values | |

|---|---|---|---|---|---|

| Designer | 0.274 | 0.277 | 0.036 | 7.577 | 0.000 |

| Contract Document | 0.315 | 0.313 | 0.043 | 7.282 | 0.000 |

| Owner | 0.121 | 0.121 | 0.049 | 2.461 | 0.014 |

| Knowledge | 0.100 | 0.100 | 0.031 | 3.243 | 0.001 |

| Regulation | 0.123 | 0.125 | 0.038 | 3.206 | 0.001 |

| Tools | 0.097 | 0.098 | 0.046 | 2.129 | 0.034 |

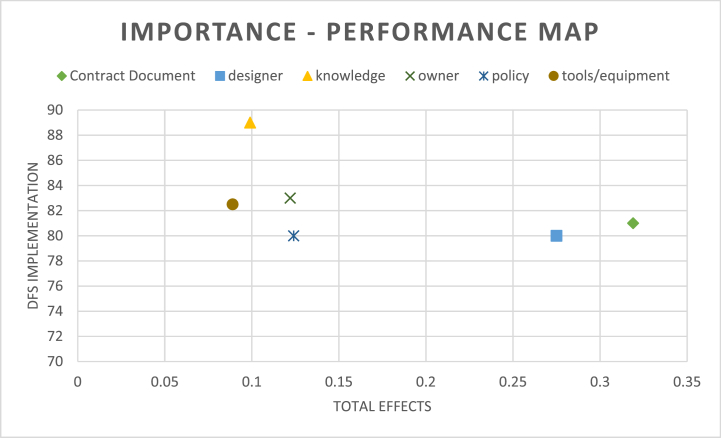

4.3.3. Importance-performance map analysis (IPMA)

An IPMA was performed to observe the importance of the predecessor variable and its performance in describing the target variable. This analysis identified the factors that need to be prioritized. The performance scores ranged from 1 (lowest performance) to 100 (highest performance). As shown in Fig. 4, the map shows that all factors have high performance values above seventy-five, while knowledge has the highest performance (89.378), followed by the “owner” and “tools” variables. Considering importance, “contract document” and “designer” variables have a much larger total effect value than the other variables, with values of 0.305 and 0.274, respectively. In summary, since the difference in performance values between factors is not large for industry and government agencies, the “contract document” and “designer” variables should be prioritized in the program. This is because both factors have significantly different importance values compared with the other factors.

Fig. 4.

Importance-performance map.

4.4. ANN approach

4.4.1. Diagram path model

We used the significant factors obtained from SEM–PLS as the input neurons for the ANN model. Non-normal data distribution and the presence of nonlinear correlations between exogenous and endogenous variables are two grounds for implementing the ANN. An ANN is resistant to noise, outliers, and has short sample sizes. Additionally, it may manage non-compensatory models in which a drop in one factor does not always require an increase in another. IBM's SPSS neural network module was used to implement the ANN analysis. The ANN algorithm does not require a normal distribution, and can detect both linear and nonlinear correlations [48].

To optimize the data, data preprocessing techniques such as removing outliers and missing values, normalization, and feature selection were used. The number of neurons in the artificial neural network was determined through trial and error, by gradually increasing the number of neurons until the desired level of accuracy was achieved. A combination of gradient descent and backpropagation algorithms was used for training the model to optimize it and minimize the error between the predicted and actual values. The sigmoid transfer function was used in the hidden layers of the network and a linear transfer function in the output layer to ensure that the model was able to effectively capture the non-linear relationships between the input and output variables.

To validate the model, the hold-out method was used, where a portion of the data was set aside for testing the model's performance. Cross-validation techniques were also employed to ensure that the model was able to generalize well to new data and avoid overfitting. The performance metrics such as mean squared error, correlation coefficient, and deviation rates were calculated to assess the model's accuracy and performance. The convergence of the loss function was monitored to check that the training phase was completed in an ideal way, and the performance metrics were monitored during training to ensure that they were improving and not plateauing or worsening.

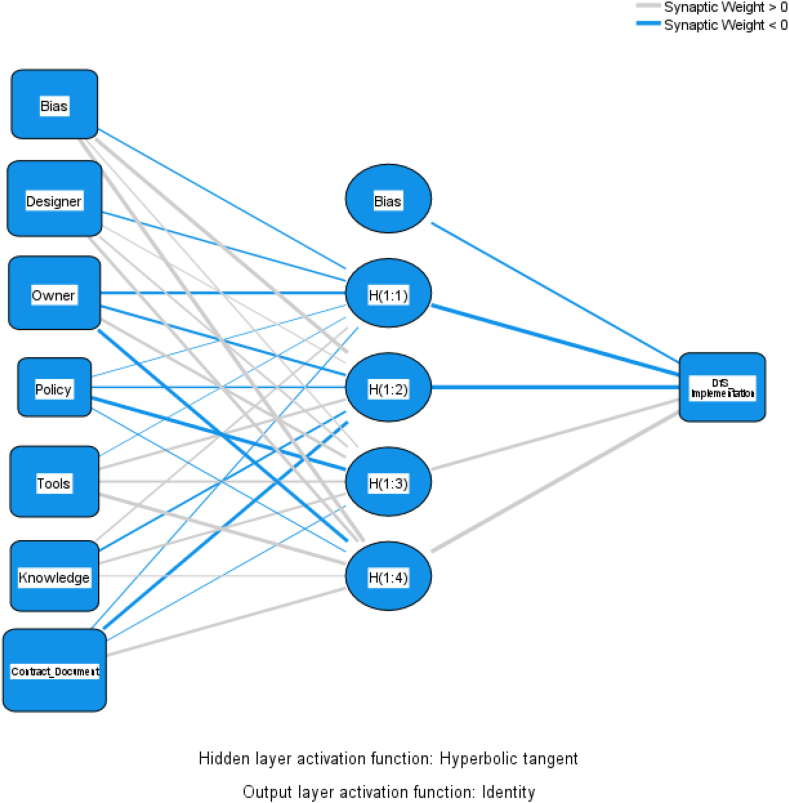

Using a feed-forward–backward-propagation algorithm, where inputs are fed in a forward path, and the estimated errors travel in a backward direction, the system can be trained to predict the results of the analysis [49]. Sigmoid activation functions and multilayer perceptrons were employed [50]. These errors can be reduced, and the prediction accuracy can be further increased by iteration [51]. We employed 70%–80 % of the samples for the training, and the remaining samples were used for the testing phase. The analysis produced a path-analysis diagram consisting of four types of hidden layers, as shown in Fig. 5. These layers aim to remap the relationship-analysis pattern based on ANN synapses.

Fig. 5.

Neural network path analysis.

4.4.2. Error measurement

Error measurements were performed and adjusted according to the amount of trained and tested data. By using the training iteration ranging from 70 % to 80 %, the optimum values of data testing were seen in the compositions of 74 % and 28 % for the training and testing data with the smallest RMSE value (0.261), as shown in Table 8. This reference can be used as a basis for further research.

Table 8.

Error values.

| Training |

Testing |

Total sample | ||||

|---|---|---|---|---|---|---|

| N | SSE | RMSE | N | SSE | RMSE | |

| 71 | 11.592 | 0.401 | 31 | 6.344 | 0.452 | 102 |

| 72 | 10.617 | 0.379 | 30 | 4.284 | 0.378 | 102 |

| 74 | 10.017 | 0.363 | 28 | 1.907 | 0.261 | 102 |

| 76 | 10.642 | 0.367 | 26 | 4.694 | 0.425 | 102 |

| 79 | 10.861 | 0.368 | 23 | 3.369 | 0.383 | 102 |

| Mean | 10.746 | 4.120 | Mean | 0.376 | 0.380 |

4.4.3. Sensitivity analysis

To assess the predictive power of each input neuron, we used a sensitivity analysis to calculate the normalized importance of these neurons by dividing their relative importance by their maximum importance and presenting it as a percentage. The results show that contract document (100 %) is the most important variable, followed by designer (74.2 %) and owner (66.3 %) in the second and the third place, as shown in Table 9.

Table 9.

Sensitivity analysis.

| Neural Network | Designer | Owner | Policy | Tools | Knowledge | Contract Doc |

|---|---|---|---|---|---|---|

| NN (i) | −0.151 | 0.438 | 0.143 | 0.466 | −0.151 | 0.438 |

| NN (ii) | −0.179 | 0.116 | 0.216 | 0.378 | −0.179 | 0.116 |

| NN (iii) | −0.318 | −0.294 | 0.345 | −0.402 | −0.318 | −0.294 |

| NN (iv) | −0.044 | −0.175 | −0.414 | −0.057 | −0.044 | −0.175 |

| Average Importance | 0.202 | 0.181 | 0.035 | 0.157 | 0.153 | 0.272 |

| Normalized Importance (%) | 74.2 | 66.3 | 12.8 | 57.6 | 56.3 | 100 |

5. Discussions

This study successfully analyzed the factors that influence the implementation of DfS in Indonesia. A two-stage–multi-analytic approach using SEM–PLS and an ANN was used to determine and validate the factors influencing DfS implementation. This research complements previous research by Maya et al. [42], who used the cascading effect and machine learning to analyze construction safety. This study also addressed the shortcomings of previous studies that require large datasets. With SEM–PLS analysis, the required dataset does not need to be as large as machine learning to analyze small datasets more comprehensively. This research used a questionnaire methodology to obtain data, and the questionnaire was distributed to construction workers. Most of the respondents were concentrated on Java Island with a bachelor's degree and between five and ten years of experience.

This study showed that contract documents and designers are the most significant factors in the implementation of DfS, using either SEM–PLS or an ANN. The other four factors, including owner, policy, tools/equipment, and knowledge, strongly influenced the implementation of DfS, as evidenced by the measurement results of the SEM–PLS and ANN models, which were above the parameter limit. Therefore, all hypotheses developed in this study were proven.

Referring to the T-statistics and P-values of the SEM–PLS results, the “designer” variable had the highest level of influence significance. The results of the cross-loading of the outer model indicators also had a positive impact on the “designer” variable. This indicates that designer indicators, such as skills, knowledge, experience, expertise, and designer fees, are directly proportional to DfS implementation. Meanwhile, according to IPMA as one of SEM–PLS results, the importance effects of “contract document” and “designer” variables were significantly larger than other variables. Therefore, this study recommends industry and government agencies to place “contract document” and “designer” variables as prioritized factors, with other variables as supporting factors, as all variables are interconnected.

Continuing with the results of ANN processing, the relationship between variables that was previously known through SEM–PLS were re-assessed to observe the positive or negative neural relationships for each variable with the implementation of DfS. Unlike the SEM results, the contract document and designer variables were ranked first and second in terms of the “important performance” value of DfS implementation.

The results of SEM–PLS and ANN show a slight difference in the order of the factors affecting the implementation of DfS. The contract document has a positive synaptic ANN, indicating that a greater certainty of content in the contract document, such as liability, design budget, scope of work, assurance, and contract terms, will have a positive impact on the implementation of DfS. Nevertheless, when viewed intrinsically from the results of the outer-loading factor SEM, only the design budget, scope of work, assurance, and contract terms are indicators that have a positive impact on the contract document variables. However, liabilities have a negative impact. This indicates that clear contract terms, a higher design budget, more specific scope of work, and clear assurance have positive implications for the certainty of contract documents. Note that design liability is transferred to the company rather than to the designers.

According to the experts interviewed during this study, the contract documents and designer variables require support from other factors. Support includes owner commitment through budgeting DfS funds, formulating a comprehensive policy that regulates stakeholders to implement DfS, using and applying BIM as an advanced technology for safety design purposes, and increasing the frequency of training and socialization, accompanied by appropriate certifications.

The results of the expert validation are synergistically supported by previous research on the importance of tightening regulations related to safe construction, especially in Indonesia. Machfudiyanto et al. [52] explained that tightening regulations would have implications for increasing designer capabilities. Subsequently, a designer's capabilities can be increased through training programs and workshops. Training formulations must be adapted to the work environment of Indonesian construction workers to be more fit for purpose. The training formulation can be found in a previous study by Xu et al. [53]. Finally, the expert recommendation to use BIM-related technologies for DfS training was supported by previous research by Semaan et al. [54], who stated that BIM, virtual reality, augmented reality, and other technologies are effective tools for construction worker training.

6. Conclusions

In conclusion, this study identified the main factors that influence the implementation of Design-for-Safety (DfS) in the Indonesian construction industry. Specifically, contract documents related to safety construction and designers' intrinsic capabilities were found to be crucial factors in implementing DfS. Therefore, stakeholders should focus on these factors when implementing the strategic plan validated by the experts in this study. The recommended strategies include tightening regulations related to DfS implementation in contract documents, improving designer capabilities through various training programs and workshops, and developing Building Information Modelling (BIM)-related technologies for implementing DfS plans.

However, this study had some limitations that should be considered. Firstly, it focused only on the implementation of DfS in Indonesia. Nonetheless, the findings may serve as a benchmark for other developing countries in Southeast Asia with a similar expansion of the construction industry. Secondly, the study's predictive power was limited by the R2 value (75.3 %), indicating that only 75.3 % of the identified factors can be explained. Future research should aim to identify additional factors that can increase the predictive power and refine the recommendations for implementing DfS in the Indonesian construction industry.

7. Study implications and contributions

The implications of this study ripple through both theoretical and practical dimensions. Theoretically, our findings bolster the existing knowledge base, deepening our understanding of the intricate tapestry that underlies DfS implementation. On a practical plane, the identified factors beckon stakeholders to recalibrate their focus, intensifying efforts towards fortifying regulations enshrined within contract documents and nurturing the intrinsic capacities of designers. These implications collectively serve as a clarion call for heightened awareness and strategic action to foster a culture of safety within the Indonesian construction arena.

The practical implications of our study hold significant promise for the enhancement of existing local guidelines within the Indonesian construction industry. Our findings serve as a valuable resource for local stakeholders, offering insights to improve and adapt safety regulations and guidelines in a manner that aligns with the unique challenges faced by developing countries like Indonesia. By highlighting specific factors critical to Design-for-Safety (DfS) implementation, our research provides a practical roadmap for industry practitioners, regulatory bodies, and policymakers, enabling them to make informed decisions that foster a culture of safety and compliance in the Indonesian construction sector. In this way, our study not only bolsters the local safety framework but also addresses the broader theoretical context within developing countries.

This study's contributions reverberate across multifarious spheres. By pinpointing critical factors, we proffer a navigational compass for stakeholders, directing their endeavors towards efficacious DfS implementation. The ramifications extend to policymakers who can harness these insights to craft regulations and policies that galvanize safety measures. Moreover, the methodological amalgamation of PLS-SEM and ANN stands as a novel contribution, ushering in a paradigm shift in how DfS factors are comprehensively unearthed.

8. Future directions

While this study serves as a cornerstone, its scope beckons for future explorations. To broaden the horizons, researchers are encouraged to delve into the realm of DfS implementation beyond the Indonesian context. These findings could serve as a touchstone for developing nations across Southeast Asia undergoing similar construction industry expansion. Additionally, the predictive prowess of the model, albeit commendable at 75.3 %, opens avenues for enhancing its robustness. Future research endeavors could delve deeper to unravel additional factors, thereby augmenting the predictive power and precision of recommendations, leading to more efficacious DfS integration.

In summation, this study reverberates as a vanguard of insights, paving the way for informed action within the Indonesian construction milieu. As our findings resonate across theoretical, practical, and methodological dimensions, they beckon stakeholders, policymakers, and researchers alike to embark on a collective journey towards an enhanced culture of safety and a brighter future for all those intertwined with the construction industry.

Funding

This research was funded by the Directorate of Research and Development, Universitas Indonesia, under Hibah PUTI Q1 2022 (Grant No: NKB-1155/UN2.RST/HKP.05.00/2022).

Institutional review board statement

Not Applicable.

Informed consent statement

Informed consent was obtained from all subjects involved in this study.

Data availability statement

The data that has been used is confidential.

CRediT authorship contribution statement

Rossy A. Machfudiyanto: Conceptualization, Funding acquisition, Methodology, Project administration, Resources. Sunkuk Kim: Formal analysis, Investigation, Supervision. Yusuf Latief: Conceptualization, Investigation, Project administration, Supervision, Validation. Titi Sari Nurul Rachmawati: Investigation, Methodology, Supervision, Validation, Writing – review & editing. Naufal Budi Laksono: Data curation, Formal analysis, Investigation, Methodology, Resources, Software, Visualization, Writing – original draft, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

- ANN

Artificial Neural Network

- AVE

Average Variance Extracted

- BIM

Building Information Modeling

- DfS

Design-for-Safety

- GoI

Government of Indonesia

- IPMA

Importance-performance map analysis

- ML

Machine Learning

- OSH

Occupational safety and health

- PLS

Partial-Least Square

- RMSE

Root Mean Square Error

- SEM

Structural Equation Modeling

- VIF

Variance Inflation Factor

References

- 1.Zhou W., Whyte J., Sacks R. Construction safety and digital design: a review. Autom. ConStruct. 2012;22:102. [Google Scholar]

- 2.Nnaji C., Gambatese J., Karakhan A., Osei-Kyei R. Development and application of safety technology adoption decision-making tool. J. Construct. Eng. Manag. Apr. 2020;146(4) doi: 10.1061/(ASCE)CO.1943-7862.0001808. [DOI] [Google Scholar]

- 3.Choi J., Gu B., Chin S., Lee J.-S. Machine learning predictive model based on national data for fatal accidents of construction workers. Autom. ConStruct. Feb. 2020;110 doi: 10.1016/j.autcon.2019.102974. [DOI] [Google Scholar]

- 4.Lestari F., Sunindijo R.Y., Loosemore M., Kusminanti Y., Widanarko B. A safety climate framework for improving health and safety in the Indonesian construction industry. Int. J. Environ. Res. Publ. Health. Oct. 2020;17(20):7462. doi: 10.3390/ijerph17207462. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Bust P.D., Gibb A.G.F., Pink S. Managing construction health and safety: migrant workers and communicating safety messages. Saf. Sci. Apr. 2008;46(4):585–602. doi: 10.1016/j.ssci.2007.06.026. [DOI] [Google Scholar]

- 6.Tymvios N., Gambatese J.A. Direction for generating interest for design for construction worker safety—a delphi study. J. Construct. Eng. Manag. Aug. 2016;142(8) doi: 10.1061/(ASCE)CO.1943-7862.0001134. [DOI] [Google Scholar]

- 7.Hossain Md A., Abbott E.L.S., Chua D.K.H., Nguyen T.Q., Goh Y.M. Design-for-Safety knowledge library for BIM-integrated safety risk reviews. Autom. ConStruct. Oct. 2018;94:290–302. doi: 10.1016/j.autcon.2018.07.010. [DOI] [Google Scholar]

- 8.Schulte P.A., Rinehart R., Okun A., Geraci C.L., Heidel D.S. National prevention through design (PtD) initiative. J. Saf. Res. Jan. 2008;39(2):115–121. doi: 10.1016/j.jsr.2008.02.021. [DOI] [PubMed] [Google Scholar]

- 9.Tymvios N., Hardison D., Behm M., Hallowell M., Gambatese J. Revisiting Lorent and Szymberski: evaluating how research in prevention through design is interpreted and cited. Saf. Sci. Nov. 2020;131 doi: 10.1016/j.ssci.2020.104927. [DOI] [Google Scholar]

- 10.Alvin V., Nugroho S., Alifen R.S. IMPLEMENTASI DAN FAKTOR HAMBATAN DESIGN FOR CONSTRUCTION SAFETY (DfCS) J. Dimensi Pratama Tek. Sipil. Nov. 2019;8(2) Art. no. 2. [Google Scholar]

- 11.Scott J.E., Walczak S. Cognitive engagement with a multimedia ERP training tool: assessing computer self-efficacy and technology acceptance. Inf. Manag. May 2009;46(4):221–232. doi: 10.1016/j.im.2008.10.003. [DOI] [Google Scholar]

- 12.Gao R., Chan A., Utama W., Zahoor H. Multilevel safety climate and safety performance in the construction industry: development and validation of a top-down mechanism. Int. J. Environ. Res. Publ. Health. Nov. 2016;13(11):1100. doi: 10.3390/ijerph13111100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Tymvios N., Gambatese J.A. Perceptions about design for construction worker safety: viewpoints from contractors, designers, and university facility owners. J. Construct. Eng. Manag. Feb. 2016;142(2) doi: 10.1061/(ASCE)CO.1943-7862.0001067. [DOI] [Google Scholar]

- 14.Ray M.S. Safety Management: A Human Approach. 2. D. Petersen, Aloray Inc; New York: 1988. p. 380. 0-913690-12-0.,” Dev. Chem. Eng. Miner. Process. 2–3, pp. 186–187, 1994. [DOI] [Google Scholar]

- 15.Lingard H., Rowlinson S. Routledge; London: 2017. Occupational Health and Safety in Construction Project Management. [DOI] [Google Scholar]

- 16.Goh Y.M., Chua S. Knowledge, attitude and practices for design for safety: a study on civil & structural engineers. Accid. Anal. Prev. Aug. 2016;93:260–266. doi: 10.1016/j.aap.2015.09.023. [DOI] [PubMed] [Google Scholar]

- 17.Christermaller F., Ibrahim C., Manu P., Belayutham S., Mahamadu A.-M., Yunusa-Kaltungo A. Implementation of design for safety (DfS) in construction in developing countries: a study of designers in Malaysia. Constr. Econ. Build. 2022;22(Jun) doi: 10.5130/AJCEB.v22i2.8105. [DOI] [Google Scholar]

- 18.Analysis of designers' Prevention through Design (PtD) competence in the construction industry: a study of Malaysia, Nigeria, and South Africa. Saf. Sci. Jun. 2022;150 doi: 10.1016/j.ssci.2022.105710. [DOI] [Google Scholar]

- 19.Aksorn T., Hadikusumo B. Measuring effectiveness of safety programmes in the Thai construction industry. Constr. Manag. Econ. Apr. 2008;26:409–421. doi: 10.1080/01446190801918722. [DOI] [Google Scholar]

- 20.Benjaoran V., Bhokha S. An integrated safety management with construction management using 4D CAD model. Saf. Sci. Mar. 2010;48(3):395–403. doi: 10.1016/j.ssci.2009.09.009. [DOI] [Google Scholar]

- 21.Nursjanti F. An analysis of the construction sector and GDP of Indonesia. Int. J. Innov. 2019;6(12):10. [Google Scholar]

- 22.Soemardi B.W., Soenaryo I., Wahyudi E. The role and function of mandor in construction project organization in Indonesia. Procedia Eng. 2011;14:859–864. doi: 10.1016/j.proeng.2011.07.109. [DOI] [Google Scholar]

- 23.S.Bong, R.Rameezdeen, J.Zuo, R.Y.M.Li, G.Ye The designer's role in workplace health and safety in the construction industry: post-harmonized regulations in South Australia. Int. J. Constr. Manag. Oct. 2015;15(4):276–287. doi: 10.1080/15623599.2015.1094850. [DOI] [Google Scholar]

- 24.Che Ibrahim C.K.I., Manu P., Belayutham S., Mahamadu A.-M., Antwi-Afari M.F. Design for safety (DfS) practice in construction engineering and management research: a review of current trends and future directions. J. Build. Eng. Jul. 2022;52 doi: 10.1016/j.jobe.2022.104352. [DOI] [Google Scholar]

- 25.Keun Oh T., Jun Kwon Y., Oh B.-H., Gwon Y.-I., Yoon H.-K. Suggestions for safety coordinator's roles at each construction stage (client, designer, supervisor, and contractor) to improve safety and health activities in South Korea. Saf. Sci. Jan. 2021;133 doi: 10.1016/j.ssci.2020.104994. [DOI] [Google Scholar]

- 26.Adaku E., Ankrah N.A., Ndekugri I.E. Prevention through design: conceptual models for the assessment of a principal designer's skills, knowledge and experience. J. Eng. Des. Technol. Apr. 2022;20(3):595–623. doi: 10.1108/JEDT-07-2020-0278. [DOI] [Google Scholar]

- 27.Gao R., Chan P.C., Lyu S., Zahoor H., Utama W.P. Investigating the difficulties of implementing safety practices in international construction projects. J. Occup. Accid. Oct. 2018;108:39–47. doi: 10.1016/j.ssci.2018.04.018. [DOI] [Google Scholar]

- 28.Wu C., Wang F., Zou P.X.W., Fang D. How safety leadership works among owners, contractors and subcontractors in construction projects. Int. J. Proj. Manag. Jul. 2016;34(5):789–805. doi: 10.1016/j.ijproman.2016.02.013. [DOI] [Google Scholar]

- 29.Chunxiang W. Safety responsibilities for owner and example in public works. Procedia Eng. Jan. 2012;43:523–527. doi: 10.1016/j.proeng.2012.08.091. [DOI] [Google Scholar]

- 30.Gambatese J., Toole T., Abowitz D. Owner perceptions of barriers to prevention through design diffusion. J. Construct. Eng. Manag. Feb. 2017;143 doi: 10.1061/(ASCE)CO.1943-7862.0001296. [DOI] [Google Scholar]

- 31.Baxendale T., Jones O. Construction design and management safety regulations in practiceÐprogress on implementation. Int. J. Proj. Manag. 2000;8 [Google Scholar]

- 32.Zhu Z., Park M.-W., Koch C., Soltani M., Hammad A., Davari K. Predicting movements of onsite workers and mobile equipment for enhancing construction site safety. Autom. ConStruct. Aug. 2016;68:95–101. doi: 10.1016/j.autcon.2016.04.009. [DOI] [Google Scholar]

- 33.Ferine K.F., Aditia R., Rahmadana M.F., Indri An empirical study of leadership, organizational culture, conflict, and work ethic in determining work performance in Indonesia's education authority. Heliyon. Jul. 2021;7(7) doi: 10.1016/j.heliyon.2021.e07698. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Karimi H., Taghaddos H. The influence of craft workers' educational attainment and experience level in fatal injuries prevention in construction projects. Saf. Sci. 2019;117:417–427. doi: 10.1016/j.ssci.2019.04.022. [DOI] [Google Scholar]

- 35.Kheni N.A., Gibb A.G.F., Dainty A.R.J. Health and safety management within small- and medium-sized enterprises (SMEs) in developing countries: study of contextual influences. J. Construct. Eng. Manag. Oct. 2010;136(10):1104–1115. doi: 10.1061/(ASCE)CO.1943-7862.0000218. [DOI] [Google Scholar]

- 36.Zarman W. Information and knowledge in epistemology perspective. IOP Conf. Ser. Mater. Sci. Eng. Aug. 2018;407(1) doi: 10.1088/1757-899X/407/1/012121. [DOI] [Google Scholar]

- 37.Sherratt F., Leicht R. Unpacking ontological perspectives in CEM research: everything is biased. J. Construct. Eng. Manag. Feb. 2020;146 doi: 10.1061/(ASCE)CO.1943-7862.0001734. [DOI] [Google Scholar]

- 38.Ejnavarzala H. Epistemology–ontology relations in social research: a review. Sociol. Bull. Apr. 2019;68(1):94–104. doi: 10.1177/0038022918819369. [DOI] [Google Scholar]

- 39.Zou P., Sunindijo R., Dainty A. A mixed methods research design for bridging the gap between research and practice in construction safety. Saf. Sci. Dec. 2014;70:316–326. doi: 10.1016/j.ssci.2014.07.005. [DOI] [Google Scholar]

- 40.Zeng N., Liu Y., Gong P., Hertogh M., König M. Do right PLS and do PLS right: a critical review of the application of PLS-SEM in construction management research. Front. Eng. Manag. Sep. 2021;8(3):356–369. doi: 10.1007/s42524-021-0153-5. [DOI] [Google Scholar]

- 41.Jin M., Liao Q., Patil S., Abdulraheem A., Al-Shehri D., Glatz G. Hyperparameter tuning of artificial neural networks for well production estimation considering the uncertainty in initialized parameters. ACS Omega. Jul. 2022;7(28):24145–24156. doi: 10.1021/acsomega.2c00498. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Maya R., Hassan B., Hassan A. Develop an artificial neural network (ANN) model to predict construction projects performance in Syria. J. King Saud Univ. - Eng. Sci. May 2021 doi: 10.1016/j.jksues.2021.05.002. [DOI] [Google Scholar]

- 43.Ayhan B.U., Tokdemir O. Accident analysis for construction safety using latent class clustering and artificial neural networks. J. Construct. Eng. Manag. Dec. 2019;146 doi: 10.1061/(ASCE)CO.1943-7862.0001762. [DOI] [Google Scholar]

- 44.Azzalini A., Capitanio A. Cambridge University Press; 2013. The Skew-Normal and Related Families. [DOI] [Google Scholar]

- 45.Leong L.-Y., Hew T.-S., Ooi K.-B., Lee V.-H., Hew J.-J. A hybrid SEM-neural network analysis of social media addiction. Expert Syst. Appl. May 2019;133 doi: 10.1016/j.eswa.2019.05.024. [DOI] [Google Scholar]

- 46.Hair J., Ringle C., Sarstedt M. vol. 46. Long Range Plann; Jan. 2013. pp. 1–12. (Partial Least Squares Structural Equation Modeling: Rigorous Applications, Better Results and Higher Acceptance). [DOI] [Google Scholar]

- 47.Cepeda-Carrion G., Cegarra J., Cillo V. 2018. Tips to Use Partial Least Squares Structural Equation Modelling (PLS-SEM) in Knowledge Management. [Google Scholar]

- 48.Teo A., Tan G., Ooi K., Lin B. Why consumers adopt mobile payment? A partial least squares structural equation modelling (PLS-SEM) approach. Int. J. Mob. Commun. Jan. 2015;13:478. doi: 10.1504/IJMC.2015.070961. [DOI] [Google Scholar]

- 49.Taneja A., Arora A. Recommendation research trends: review, approaches and open issues. Int. J. Web Eng. Technol. Jan. 2018;13:123. doi: 10.1504/IJWET.2018.092831. [DOI] [Google Scholar]

- 50.Sharma S., Sharma M. Examining the role of trust and quality dimensions in the actual usage of mobile banking services: an empirical investigation. Int. J. Inf. Manag. Feb. 2019;44:65–75. doi: 10.1016/j.ijinfomgt.2018.09.013. [DOI] [Google Scholar]

- 51.El Idrissi T., Idri A., Abnane I., Bakkoury Z. Sep. 2019. Predicting Blood Glucose Using an LSTM Neural Network; pp. 35–41. [DOI] [Google Scholar]

- 52.Machfudiyanto R.A., Latief Y., Suraji A. Integration of structure, conduct, performance interrelation of institutional policy and safety culture in construction industry. J. Eng. Sci. Technol. Oct. 2022;17(5):3433–3446. [Google Scholar]

- 53.Xue J., Shen G.Q., Li Y., Wang J., Zafar I. Dynamic stakeholder-associated topic modeling on public concerns in megainfrastructure projects: case of Hong Kong–zhuhai–Macao bridge. J. Manag. Eng. Nov. 2020;36(6) doi: 10.1061/(ASCE)ME.1943-5479.0000845. [DOI] [Google Scholar]

- 54.Semaan J., Underwood J., Hyde J. An investigation of work-based education and training needs for effective BIM adoption and implementation: an organisational upskilling model. Appl. Sci. Jan. 2021;11(18) doi: 10.3390/app11188646. Art. no. 18. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data that has been used is confidential.