Abstract

In order to help China achieve the double carbon target of total carbon peak and high-quality sustainable economic development, and to enrich the work and content of energy conservation and emission reduction in the building sector, the most complex and energy-consuming hospitals are taken as the key projects for energy conservation and emission reduction to carry out feasibility studies. The reasons for the high energy consumption of the existing hospital buildings were analysed, and it was proposed to upgrade the existing systems (including air conditioning, hot water system and intelligent control system) and to generate photovoltaic power for the existing buildings, taking into account the characteristics of the local climate. The results of the study showed that the energy saving and emission reduction effect of the hospital was obvious after the programme was adopted.

Keywords: Hospital, Energy saving, Carbon reduction, Emission reduction, Applications

1. Introduction

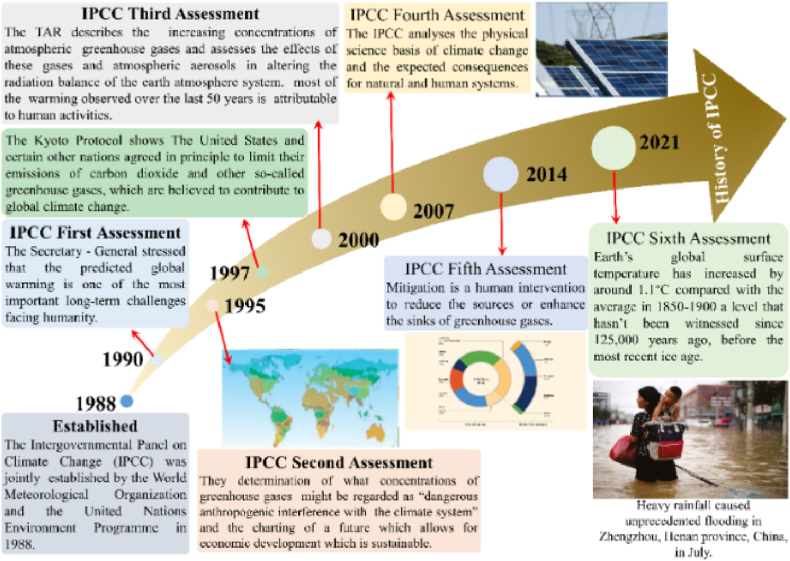

Since the beginning of the 21st century, the global economy and modern science and technology are developing rapidly, urbanisation is advancing rapidly, but environmental pollution, climate deterioration, resource depletion and waste have come along with the problems that have sounded the alarm to human beings [1]. The Intergovernmental Panel on Climate Change (IPCC) has published six Climate Change Assements [[2], [3], [4], [5], [6], [7], [8]], which pointed out that the use of fossil fuels has directly led to the warming of the climate as a global problem, while there are huge disasters caused by climate change [9]. The IPCC published six Climate Change Assement Reports [[2], [3], [4], [5], [6], [7], [8]], which pointed out that the use of fossil fuels has directly led to the global warming problem, while there are huge disasters caused by climate change [9], which have posed a major security risk to human development, as shown in Fig. 1. This has created unprecedented environmental challenges and problems, and the field of energy conservation and carbon reduction and low-carbon economy has become the focus of research and hot issues in related fields in recent years.

Fig. 1.

About the IPCC's climate change content progress chart.

Fig. 2 shows the Current global and regional energy consumption shares of major countries. According to incomplete statistics, China's rapid economic development has made it the largest energy consumer and the largest emitter of carbon dioxide, with about 10 billion tons of carbon dioxide emissions, accounting for 30 % of the world's total [10,11]. The emergence of greenhouse climate has also adversely affected the fields of agriculture, construction and economy, and in response, the Chinese government and related researchers have initiated a wave of energy conservation and emission reduction in many fields [12] as a way to ensure sustainable economic development. Fong et al. [13] studied the biofuel-powered trigeneration systems, which offered definite primary energy savings of up to 15 % and carbon emission reduction of at least 86 % in different types of non-residential buildings as compared to the conventional systems. Hospitals are an important building type [14] and complex building with unique energy requirements [15] that have a direct impact on people's daily lives and access to medical care. Some scholars have conducted an analysis around energy and carbon reduction in hospitals. Morgenstern investigated the staff-centred energy conservation initiatives may become an increasingly important part of carbon reduction strategies in hospitals in the future [15]. Based on the investigation of a typical health center in Linyi City, Guo et al. [16] proposed improvement measures using EnergyPlus simulation software and JePlus parameter chemical tools. Fraile et al. [17] applied to several actions being implemented in the hospital boiler room control system, the result show improve the efficiency of the heat production system and primary energy saving 3434.00 €/week savings in natural gas consumption, and CO2 reduction emissions of 20.3 tonnes/week. Hort et al. [18] presented findings relating to one representative type building, and then interviewed that relatively non-invasive measures would extend and increase its resilience whilst saving energy.

Fig. 2.

Current global and regional energy consumption shares of major countries.

Some researchers have studied and modified the complex energy consumption structure of hospitals from a resource perspective. Renewable resources are used as the primary energy source due to their economic and environmental advantages [19], such as photovoltaic (PV) systems, Combined heat and power (CHP) [20], and distributed generation (DG) [21], which can effectively reduce CO2 emissions. The use of energy-saving devices strongly influences their improvement, especially when the energy comes from forced production photovoltaic (PV) sources [22]. From the above analysis, it was found that few studies on energy saving and carbon reduction have been carried out specifically for hospital projects, especially for the design of PV systems on existing hospital buildings. There is an urgent need to conduct relevant studies to complement and enrich the field of feasibility studies for carbon reduction initiatives in hospitals.

As a hospital with the highest energy saving potential, it is particularly important to clearly and accurately demonstrate the effects of implementing various energy saving measures to reduce the building energy consumption of existing hospital buildings. The paper relies on the existing building structure of the hospital, first of all, its main energy-consuming structure to carry out research and analysis, through the development of energy-saving and emission reduction programmer design, including upgrading and renovation of the original high-energy-consuming hot water and air-conditioning structure, with photovoltaic power generation programmer, the hospital's energy efficiency, energy-saving effect and economic benefits of the analysis of the hospital compared with the effectiveness of the above energy-saving measures and feasibility, to optimize the energy-consuming structure of the hospital structure to achieve energy saving and emission reduction. Optimisation of the energy consuming structure of the hospital structure achieves the purpose of energy saving and emission reduction. It is expected to provide meaningful conclusions for similar hospital projects to achieve energy saving and emission reduction targets, and can be used as a demonstration case to enrich the action plan of China's dual carbon target.

2. Project overview

Shenzhen Hospital of Guangzhou University of Traditional Chinese Medicine is located in Futian District of Shenzhen City, which is a national pilot area for comprehensive reform of traditional Chinese medicine, Guangdong-Hong Kong-Macao Greater Bay Area and early demonstration area of socialism with Chinese characteristics, and its geographical advantage is obvious, the specific location is No. 6001 Beihuan Avenue, Futian District, Shenzhen City, as shown in Fig. 3 (a) and (b). The project is located at 114.04° N latitude and 22.56° E longitude. Futian District, with a total area of 78.8 km2, mainly consists of the central city and the strip of economic development areas on both sides of Shennan Avenue, and some hills, mountains and beaches, with a high topography in the north and a low topography in the south, located south of the Tropic of Cancer, and a subtropical maritime climate zone. The Hospital and the Sixth Clinical Medical School (in Fig. 3 (c)), which is directly affiliated to Guangzhou University of Chinese Medicine is a Grade III A Chinese medicine hospital and a five-star Chinese medicine hospital. The hospital land area is 17,505 m2, as shown in Fig. 3 (d) and (e). The hospital building floor area is 111,586 m2. The main building has 13 floors, the science and education building has 4 floors, the inpatient building has 16 floors and the outpatient building has 14 floors.

Fig. 3.

Schematic diagram of hospital location. (a) Map of China. (b) Map of Guangdong Province. (c) Topographical map of the hospital. (d) Top view of the hospital. (e) Panoramic view of the hospital.

3. Analysis of energy consumption causes

3.1. Energy consumption data

The main type of energy consumed by the hospital is electricity, of which the energy consumption in 2021 and 2022 is as follows: the total electricity consumption of the hospital in 2021 is 18,867 MWh (energy consumption statistics: October 2020–September 2021), with an annual consumption of 168.5 kWh/(m2/year) per unit area. The main energy consuming systems are air conditioning, hot water, lighting, electricity (lift, water supply, oxygen production), medical equipment and other facilities. The proportion of energy consumption from largest to smallest is air conditioning, medical equipment, lighting, oxygen machine, hot water, lift and domestic water.

In term of energy consumption, the main energy-consuming uses are air-conditioning refrigeration, heating system (including domestic hot water, air-conditioning heating) and air-conditioning air circulation system, of which the annual energy consumption of air-conditioning refrigeration is about 7550 MWh, heating system (including domestic hot water) is about 1900 MWh, the actual annual energy consumption of air-conditioning air circulation system is about 2500 MWh, and the actual annual energy consumption of lighting system is about 1500 MWh. The total energy consumption of refrigeration + heating + air-conditioning + lighting accounts for 70 % of the total energy consumption of the hospital, and the total annual energy consumption of the hospital in 2022 is 18,950 MWh, with an annual energy consumption of 169 kWh/m2 per unit area. Table 1 shows the air conditioning, hot water and lighting energy consumption table. e energy saving project is mainly carried out from different aspects of cooling, heating, air conditioning and lighting, and the energy consumption statistics of each sub-section are shown in Fig. 4, Fig. 5 below.

Table 1.

Air conditioning, hot water and lighting energy consumption table (2022).

| Category | Application | Total installed power/kW | Installed power/kW | Parameters | Annual energy consumption/104kW | Ratio |

|---|---|---|---|---|---|---|

| Cold Water | Air Conditioning | 12180 | Outpatient Building: 2 × 250RT +2 × 250 + 3 × 160RT; |

Summer: 7/12 °C | 835 | 44.25 % |

| Inpatient building: 3 × 400RT | ||||||

| Winter: 11/16 °C | ||||||

| Synthetic building: 2 × 860 kW + 1000 kW + 120 kW | ||||||

| Hot Water | Washing and rinsing, Air Conditioning | 3400 | Outpatient Rooftop: 3 × 200RT Heat Pumps | 45/40 °C | 190 | 10.07 % |

| Highland air source heat pumps: 2 × 300 kW | ||||||

| Low zone air source heat pump: 2 × 350 kW | ||||||

| Solar hot water on the sky of outpatient + complex building: about 500m2 | ||||||

| Air circulation | Air Conditioning | / | Comfort area: fan coils + fresh air | Cleanliness/Comfort | 250 | 13.25 % |

| Outpatient building 6F, complex building 4F for clean area: all air system | ||||||

| Lighting facilities | Lighting | / | / | / | 150 | 7.95 % |

| Other | / | / | / | / | 462 | 24.48 % |

Fig. 4.

Monthly electricity consumption of each functional hospital building in 2021.

Fig. 5.

Monthly electricity consumption in 2022.

3.2. Energy consumption causes

3.2.1. Structural energy consumption

-

(1)

Air Conditioning System

According to the site survey and design data analysis, the air conditioning system is mainly as follows: four water-cooled chiller mainframes in the cold room of the out-patient building and three water-cooled chiller mainframes in the cold room of the in-patient building use semi-manual operation, which consumes more energy. Three air-cooled screw chillers and hot water chillers on the roof of the outpatient building, all of which have lost their heat recovery function, cannot provide a heating function for the clean area and use semi-manual operation. The air conditioning system in the clean area requires both cooling and heating, and the cooling and heating cannot be matched.

-

(2)

Water Pump

The flow rate of the cooling water pump was too high, and the cooling water temperature was only 2 °C. The cooling water pump in the cooling room of the hospital building adopts fixed frequency operation, the pump selection is too large, and the temperature difference of the supplied water is only 1.4 °C. The flow rate of the cooling water pump, the head selection is too large, the control strategy of the chilled water system is not good, did not consider the outside temperature and humidity on the cooling water temperature.

-

(3)

Cooling Tower

Outpatient and inpatient building cooling tower inlet electric valve damage can not be closed, electric valve and fan chain is not normal, there is cooling water bypass, cooling tower fans are fixed frequency operation. Cooling water are no automatic drainage function.

-

(4)

End of installations

The problems are as follows: The underground distribution rooms and other rooms rely mainly on split air conditioning for cooling, which consumes a lot of energy. The number of fan coils in the comfort zone is large and difficult to monitor, and they cannot be automatically shut down in time. The sensors and actuators of the recirculating air cabinet in the clean zone are damaged and the automatic control system cannot operate automatically.

3.2.2. Energy-saving diagnosis

For the domestic hot water system in the low zone, three heat recovery units on the roof of the outpatients' building were not operating normally; for the domestic hot water system in the high zone, the solar hot water system has sufficient heat during the day, but the hot water load is low, resulting in a waste of resources; at night, all rely on air source heat pumps to provide hot water, and the machine load is high. Problems of high energy consumption caused by the control system: The hospital already has an automatic control system, but it does not include a domestic hot water system. Due to problems with the on-site actuators, it is necessary to operate in a combination of manual and automatic control system, and due to cumbersome operation, the automatic control system is currently only used for equipment; due to cumbersome operation, the current automatic control system is only used for equipment start/stop and parameter setting, and the degree of automation is not high, mainly to monitor the operating status of equipment. The system lacks daily maintenance, resulting in a large number of parameter abnormalities in the system, and the equipment managers cannot understand the accurate energy consumption information of the air conditioning system in real time, and cannot adjust the equipment operation in time according to the real-time changing demand, resulting in wasted energy consumption or end discomfort.

4. Methods

4.1. Photovoltaic power generation design solutions

Considering that the hospital is located in a good geographical location and has sufficient sunshine, in order to better enhance the energy-saving and carbon-reducing ability of the project, we propose to install photovoltaic power generation systems in suitable locations of the buildings in the project area to reduce the dependence on electricity generation and fully utilise the geographical advantages. The design of the photovoltaic power generation is as follows:

According to the technical requirements of the Assessment Method for Solar Energy [23] of the Chinese Meteorological Industry, the empirical relationship between the total solar irradiance and the percentage of insolation is determined based on Equation (1) as follows:

| (1) |

where QM is total monthly solar irradiance; Q0 is total monthly astronomical solar irradiance; S is the percentage of insolation, %; a and b are empirical coefficients that can be determined by least squares fitting [24].

The total monthly astronomical insolation is obtained by adding the total daily astronomical insolation, the formula for calculating the total daily astronomical insolation determined based on Equation (2) as follows:

| (2) |

where Qn is the total daily astronomical solar radiation; T is the time period (24 × 60 min/d); I0 is the solar constant of 0.0820 MJ/(m2·min); ρ is the solar-terrestrial distance coefficient, dimensionless; φ is the geographic latitude, rad; δ is the solar declination, rad; ω0 is the angle at sunrise and sunset, rad.

The percentage of monthly sunshine is determined based on Equation (3) as follows:

| (3) |

where S1 is the actual monthly sunshine hours, h; TM is the monthly sunshine hours, i.e. the accumulation of sunshine hours day by day throughout the month; INT() is the rounding function.

Two evaluation metrics, Mean Relative Error (MMAPE) and Root Mean Square Error (RRMSE) were determined using Equations (4), (5), and were chosen to test the results of the model calculations, as follows:

| (4) |

| (5) |

where Sim is the i-th radiometric observation; Sic is the i-th radiometric observation.

Based on the total annual solar irradiance and sunshine hours of the reference station - Shenzhen Observatory from 2007 to 2021, the above formula is used to derive the average monthly solar irradiance in the site area, as shown in Table 2.

Table 2.

Monthly average of total solar radiation in the assessment area (Unit: MJ/m2).

| Month | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Radiant quantity | 218.3 | 259.9 | 393.3 | 450.0 | 509.6 | 454.5 | 434.5 | 408.0 | 347.5 | 290.9 | 218.8 | 190.7 |

In summary, using the solar radiation and sunshine hours observation value of Shenzhen meteorological station in the past 15 years, according to the technical requirements and methods of Assessment Method for Solar Energy [23] of Chinese meteorological industry, it is deduced that the solar radiation in Shenzhen area in the past 15 years is 4027.74 MJ/m2 and the sunshine hours is 1218.5 h. Based on the current construction status and spatial location, and with reference to existing specifications, the project uses 555Wp monocrystalline PV modules with cell parameters as shown in Table 3. The specific installation locations include the Inpatient Building and the Science and Education Building, as shown in Fig. 6.

Table 3.

555Wp monocrystalline silicon cell parameter table.

| Category | Unit | Model/Size |

|---|---|---|

| 555Wp monocrystalline PV modules | / | Monocrystalline silicon modules |

| Length | mm | 2278 × 1134 × 30 |

| Weight | kg | 26.2 |

| Efficiency | % | 20.7 |

| Peak power | Wp | 555 |

| Open circuit voltage | v | 49.8 |

| Peak power voltage | v | 41.95 |

| Short-circuit current | a | 13.98 |

| Peak power current | a | 13.12 |

| Peak power temperature coefficient | %/°C | −0.350 |

| Temperature coefficients of voc | %/°C | −0.270 |

| Temperature coefficients of isc | %/°C | +0.048 |

Fig. 6.

Diagram of PV module installation location.

4.2. System upgrade program

-

(1)

Air conditioning energy saving programme

According to the current operation of the air conditioning system, problems and energy-saving needs, and combined with the current more mature air conditioning energy-saving technology, the air conditioning system of the hospital from the air conditioning system transformation and intelligent management and other levels of energy-saving transformation. The air conditioning system mainly includes cooling and heating units, cooling water system, chilled water system and end equipment.

-

(2)

Energy-saving solution for hot water system

For the hot water system, the energy-saving solutions are Low-zone hot water system. Repair the heat recovery unit; Reduce the hot water supply temperature setting; ②High zone domestic hot water system. Reduce the hot water supply temperature setting; install connecting pipes for high and low zone hot water storage tanks, and the solar hot water system can supply high and low zone hot water at the same time.

-

(3)

Establishment of intelligent control system

In order to maximise the energy savings and carbon reduction of the project, an intelligent control system was established (as shown in Fig. 7), focusing on the Refrigeration System Module, Air Handling Unit Module, Alarm Module, Terminal Equipment Monitoring Module, Real-Time Energy Consumption Monitoring Module, and a new system for energy consumption monitoring. Real-time Energy Consumption Monitoring Module, Algorithm Deployment. Table 4 shows the configuration of the technology module. The system is used to dynamically and accurately adjust and manage the high energy consuming and energy wasting systems in the project. During project operation, the cooling and heating source control strategy is iteratively updated based on the hundreds of IOT sensors ultimately installed, basedat the end on the basis of the original expert rules, predicting that the system will always be in the optimal operating state.

Fig. 7.

Intelligent control system.

Table 4.

Technology module configuration.

| Number | Module name | Module Content and Functions |

|---|---|---|

| 1 | Data acquisition | Monitoring of the airconditioning system, including line temperature, pressure, mainframe operating parameters, thermostat setting parameters, power consumption, temperature of the least favourable end line, and temperature and humidity of part of the room; |

| 2 | Heating and cooling source control | Communicate with the host to enable remote monitoring and control by the host. |

| 3 | Frequency conversion optimisation | Configure variable frequency optimisation for circulating pumps, according to temperature, pressure, temperature difference, differential pressure and other parameters, to achieve self-regulation of the pump frequency, to achieve the flow rate to matches the end demand. |

| 4 | Intelligent Algorithm Statistics | Implant intelligent control logic rules to achieve schedule control, optimisation control and energy-saving control functions; the control strategy is based on expert rules collected from big data, including: load prediction, equipment optimisation, water temperature control, pressure control, adding and subtracting machine control, multi-pump operation and so on. |

| 5 | System Alarms | Access to alarm messages from the host computer; preset alarm information for the main operating parameters of the system. Provide alarm rule setting function; Provide alarm information SMS, voice push. |

| 6 | AIOT platform | Configure visualisation WEB side platform and APP application; Provide data professional data analysis tools; Historical records, energy consumption data export. |

5. Results

According to the 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventory [25], Carbon emission calculation standards for buildings [26] yields the carbon emission factors for electricity energy as shown in Table 5.

Table 5.

Electricity energy carbon emission factor.

| Materials/Energy | Emission factors | Unit |

|---|---|---|

| Electricity | 0.61000 | t/(MW·h) |

5.1. Carbon emission calculation of photovoltaic power generation

The useable area of the two buildings is 1834 m2 and the area available for the installation of PV modules is 523 m2, of which the total area available for the installation of PV modules in positions 1 and 2 is 148 m2, while the area available for the installation of PV modules in position 3 is 375 m2. Through detailed planning of the photovoltaic system and combining influencing factors such as the shape of the ground structure in the project area, it was finally decided to install 48 pieces of 555Wp monocrystalline silicon photovoltaic modules on the roof of the inpatient building, with an installed capacity of approximately 26.64 kWp; and to install 200 pieces of 555Wp monocrystalline silicon photovoltaic modules on the roof of the science and education building, with an installed capacity of approximately 111 kW, making the total installed capacity of 137.64 kW. The total annual electricity production is approximately 141.9 MWh, which can effectively reduce the project's dependence on thermal power generation, while reducing the annual emission of 86,559 tonnes of carbon dioxide, with good economic and social benefits.

5.2. Carbon emission calculation of system upgrade

5.2.1. Energy-saving effect of air-conditioning retrofit technology

-

(1)

Fan coil

The air conditioning opening guidelines were adjusted by temperature changes as follows: the original approach was no air conditioning in winter (outside temperature less than 22 °C), an average of 0.6 air conditioning in the transition period (outside temperature 22–25 °C) and air conditioning in summer (outside temperature greater than 25 °C). See Fig. 8 (a) for specific air conditioning in the hours before the retrofit. After the retrofit, no air conditioning is allowed in winter (outside temperature less than 24 °C), 0.5 air conditioning is allowed in the transition period (outside temperature 24–25 °C) and air conditioning is allowed in summer (outside temperature greater than 26 °C). See Fig. 8 (b) for the specific air conditioning on hours after conversion. A comparative analysis of Fig. 8 (c) shows that by changing the start-up temperature, the number of hours the air conditioner runs each month is significantly reduced and the air conditioner consumes more electricity from April to September when the outdoor temperature is high. The number of hours a single fan coil unit runs before and after the renovation is 3647.4 and 2549.5 respectively, saving 1097.9 h per year for a single unit, an energy saving of 30.1 % compared to before the renovation. At present, there are 1629 fan coils in the hospital, of which 800 units in the renovated public area, with an average operating power of 150 W. According to the above statistics of operating hours, the estimated power saving of the fan coils in the public area of the project is as follows 800 × 1097.9 × 150 = 131748000 Wh = 131.748 MWh. 80.366 tonnes of carbon dioxide emissions reduced per year.

-

(2)

Air conditioner cabinet

Fig. 8.

Air conditioning on working time statistics. a) Pre-retrofit start-up time; b) Start-up time after retrofitting; c) Hours on per month.

In order to design safety, the air conditioner cabinet fan selection and air duct design are reserved for more than 15 % margin, the current site air conditioner cabinet fans are kept running at 50 Hz, with space for variable frequency adjustment, the energy saving rate is predicted to be 10 %. According to the drawings, the total power of the air cabinet fans in the hospital is 132.9 kW, which is expected to run up to 300 days a year, 14 h a day (07:00–21:00) to provide basic ventilation. Using variable frequency control, the energy savings are as follows 132.9 × 1000 × 300 × 14 × 10 % = 55818000 Wh = 55.818 MWh. This corresponds to a reduction of 34.049 tonnes of CO2 emissions per year.

-

(3)

Distribution room air conditioning retrofit

The original configuration of split air conditioner distribution 24 kW year-round energy efficiency 2.0, its energy saving rate predicted value 33 %. Original electricity consumption: 24 × 1000 × 365 × 24 × 80 % = 168.192 MWh. After the renovation, electricity consumption is 4 × 1000 × 365 × 24 × 80 % + 48 × 365 × 24 × 0.8/4 = 112.128 MWh. In total, 56.064 MWh of electricity will be saved each year, and 34.199 tonnes of CO2 emissions will be reduced each year.

-

(4)

Retrofitting the cooling system

In the Outpatients’ Building, fully automatic control is used mainly to save energy. According to statistical data, the total electricity consumption of the original air conditioning system was 5306.2 MWh, of which 34 % was for the end use and 66 % for the refrigeration system. The operating strategy of the control system after the retrofit is to prioritise the use of air-cooled modules for cooling, and to increase the size of the screw chiller mainframe unit by unit as the load continues to increase, so that the overall operating efficiency is maintained at the highest level. The use of air-cooled modules will also support the heat recovery units and supplement the hot water supply. Based on the estimated 15 % energy savings for the cooling system in the Outpatients Building, the energy savings for the Outpatients Building are: 5306.2 × 66 % × 15 % = 525.314 MWh. 320.441 tonnes of CO2 emissions will be reduced annually.

For the inpatient building, the air conditioning system was replaced with fully automatic controls to save energy. Based on the load rates collected at different operating ratios and the number of days operating at each operating ratio, the total electricity consumption of the original air conditioning system was estimated to be 2240.1 MWh, with an average system EER of 3.5. The new main unit was replaced by a new one with a COP between 6.4 and 6.7; the programme also modified and replaced the auxiliary units to reduce their energy consumption to less than 25 %. The total electricity consumption of the air conditioning system in the in-patient wing after the renovation was approximately 1301.2 MWh, based on the number of operating days in each operating condition percentage, which represents an energy saving of 40.91 % compared to the original system. The estimated energy savings for the new air conditioning system in the inpatient wing is 2240.1 × 35 % = 784, based on an estimated energy savings of 35 % for the inpatient wing. 478.561 tonnes of CO2 emissions will be reduced annually.

-

(5)

Air conditioning hot water conversion

The power of electric auxiliary heat in the clean zone is 100.5 kW, through on-site research and investigation, we know that the clean zone is in operation most of the time throughout the year, under the clean condition, due to the large reheat load, all the electric auxiliary heat is used, the annual power consumption is about 100. 5 × 1000 × 24 × 365 × 80 % = 704.304 MWh, after the transformation, 80 % of the reheat demand in the clean zone is provided by the heat recovery unit, the original clean zone can save power of 704.304 × 80 % = 563.443 MWh. The rated power of the heat recovery pump is 18.5 kW, and the estimated energy consumption is 18.5 × 24 × 365 × 0.7 = 113.442 MWh, then the annual power saving of the system is 450.001 MWh. 274.501 tonnes of CO2 emissions will be reduced annually.

5.2.2. Energy saving effect of the renovation of the hot water system

The annual electricity consumption of the air source heat pump is approximately 17.5 × 3 × 24 × 365 = 459.900 MWh. After the renovation, the heat source is mainly provided by the solar hot water on the roof of the whole building and the heat recovery unit with a heat recovery capacity of 1250 kW. The heat supply of this unit is much greater than the heat production of the air source heat pump unit, so it can replace 100 % of the heat source, which can save 459.900 × 80 % = 367.920 MWh per year according to the calculation of 80 %. 224.431 tonnes of carbon dioxide emissions are reduced per year.

6. Discussion

Fig. 9 shows the electricity savings and carbon dioxide emission reduction for the renovate existing hospital building before and after the retrofit. By designing the energy saving and carbon reduction plan for the project, the hospital can save or replace 1987.486 MWh of electricity per year and reduce a total of 1212.666 tonnes of carbon dioxide emissions. The analysis shows that the annual power generation capacity of the photovoltaic power generation system can reach 141.9 MWh, which indirectly saves 283.800 MWh in the thermal power generation shop and can replace thermal power generation to a certain extent. By upgrading the existing structure of the hospital, 1845.586 MWh of electricity can be effectively saved, of which the top three savings are in the air conditioning and refrigeration system, the air conditioning and hot water system, and the hot water system. The air conditioning and refrigeration system saves 784,035 MWh of electricity, accounting for 39.45 % of the total electricity saved, and is the main power-consuming area of the hospital. Similarly, the design of the air-conditioning and hot water renovation programme is reasonable and can save 450.001 MWh of electricity.

Fig. 9.

Hospital energy and carbon reduction data chart.

7. Conclusion

By analysing the causes of energy consumption in existing hospital buildings, identifying the main energy consuming structures, upgrading and modifying the existing systems (including air conditioning, hot water system, intelligent control system) of existing hospital buildings, and designing the photovoltaic power generation system in combination with the local climatic characteristics, the current situation of high energy consumption in hospitals can be optimised and the purpose of energy saving and emission reduction can be achieved at the same time. The main conclusions of the paper are summarised below.

-

(1)

The analysis showed that carrying out energy-saving renovation of the existing structure of the hospital has obvious effects, which can achieve the optimisation of the high energy-consuming structural system of the hospital and reduce the degree of dependence on the traditional mode of power generation, so as to realise energy saving and emission reduction. The total annual energy saving of the hospital is 1987.486 MWh, and the total energy saving rate of the hospital is 14 %. Assuming that the calculation is based on 0.8/kWh, the total annual energy saving is $0.29 million. According to the energy saving ratio of 2:8, the hospital can gain $57,848 per year. This provides information for promoting and implementing energy saving and carbon reduction programmers in other hospitals at a later stage.

-

(2)

Clean new energy, represented by the photovoltaic power generation system. The project installed a total of 248 blocks of 555Wp monocrystalline silicon photovoltaic modules and their supporting structures, covering an area of 523 m2 in the useable area of the existing building, with an estimated annual power generation of up to 141.9 MWh and a reduction of carbon dioxide emissions of 86,559 tonnes, thus contributing to the achievement of the carbon reduction target.

-

(3)

As a very crowded place, the hospital has a high demand for air conditioning and hot water, and a high demand for resources. Therefore, upgrading the air-conditioning and hot water systems and the intelligent control system of the hospital project will save up to 1,845,586 MWh of electricity per year. Taking into account the local climate characteristics, the maximum electricity saving is 784,035 MWh if the focus is on upgrading the air conditioning and refrigeration system.

Data availability

No data was used for the research described in the article.

Additional information

No additional information is available for this paper.

CRediT authorship contribution statement

Dongchao Yu: Writing – review & editing, Writing – original draft, Data curation, Conceptualization. Xu Tan: Data curation, Conceptualization. Zehui Liu: Validation, Resources, Methodology. Dongliang Li: Software, Resources. Zhenxing Wang: Investigation, Formal analysis. Pingping Yan: Software, Resources, Investigation. Jinhong Ni: Visualization, Software, Resources.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

None.

References

- 1.Tao L., Wang Z., Shi C., Zhang H. Investigation of the longitudinal mechanical response of pipeline or tunnel under reverse fault dislocation. Rock Mech. Rock Eng. 2023;56(9):6237–6259. doi: 10.1007/s00603-023-03371-7. [DOI] [Google Scholar]

- 2.WMO . 1988. UNEP Report of the First Session of the WMO/UNEP Intergovernmental Panel on Climate Change. [Google Scholar]

- 3.IPCC IPCC second assessment climate change 1995. Intergov. Panel Clim. Chang. 1995;48:4596–4603. [Google Scholar]

- 4.RCED Climate Change Observations on EPA's March 2000 Climate Change Report 5. 2000. [Google Scholar]

- 5.Griggs D.J., Noguer M. vol. 57. 2002. Climate change 2001: the scientific basis. (Contribution of Working Group I to the Third Assessment Report of the Intergovernmental Panel on Climate Change). [Google Scholar]

- 6.Wener R.E. Climate change 2007: mitigation of climate change. J. Environ. Psychol. 2009;29:533–535. doi: 10.1016/j.jenvp.2009.10.008. [DOI] [Google Scholar]

- 7.Intergovernmental Panel on Climate Change - IPCC Climate Change 2014: Mitigation of Climate Change. Summary Chapter for Policymakers.; 2014. [Google Scholar]

- 8.IPCC Climate Change - the Physucal Science Basis. 2021. [Google Scholar]

- 9.Tollefson J. IPCC climate report: earth is warmer than it's been in 125,000 years. Nature. 2021;596:171–172. doi: 10.1038/d41586-021-02179-1. [DOI] [PubMed] [Google Scholar]

- 10.Shan Y. China CO2 emission accounts 1997–2015. Sci. Data. 2018:5. doi: 10.1038/sdata.2017.201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Shan Y., Huang Q., Guan D., Hubacek K. China CO2 emission accounts 2016–2017. Sci. Data. 2020;7:54. doi: 10.1038/s41597-020-0393-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Dong Y., Qin T., Zhou S., Huang L., Bo R., Guo H., Yin X. Comparative whole building life cycle assessment of energy saving and carbon reduction performance of reinforced concrete and timber stadiums-a case study in China. Sustain. Times. 2020;12 doi: 10.3390/su12041566. [DOI] [Google Scholar]

- 13.Fong K.F., Lee C.K. Biofuel-driven trigeneration systems for non-residential building applications: a holistic assessment from the energy, environmental and economic perspectives. Build. Simulat. 2023 doi: 10.1007/s12273-022-0958-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Yue J., Li W., Cheng J., Xiong H., Xue Y., Deng X., Zheng T. A dynamic calculation model of the carbon footprint in the life cycle of hospital building: a case study in China. Eng. Construct. Architect. Manag. 2022 doi: 10.1108/ECAM-05-2022-0395. [DOI] [Google Scholar]

- 15.Morgenstern P., Raslan R., Huebner G. Applicability, potential and limitations of staff-centred energy conservation initiatives in English hospitals. Energy Effic. 2016;9:27–48. doi: 10.1007/s12053-015-9346-2. [DOI] [Google Scholar]

- 16.Guo S., Wang W., Zhou Y. Research on energy saving and economy of old buildings based on parametric design: a case study of a hospital in Linyi city, shandong Province. Sustain. Times. 2022;14 doi: 10.3390/su142416681. [DOI] [Google Scholar]

- 17.Fraile J.C., San-José J., González-Alonso A. A boiler room in a 600-bed hospital complex: study, analysis, and implementation of energy efficiency improvements. Energies. 2014;7:3282–3303. doi: 10.3390/en7053282. [DOI] [Google Scholar]

- 18.Short C.A., Lomas K.J., Giridharan R., Fair A.J. Building resilience to overheating into 1960's UK hospital buildings within the constraint of the national carbon reduction target: adaptive strategies. Build. Environ. 2012;55:73–95. doi: 10.1016/j.buildenv.2012.02.031. [DOI] [Google Scholar]

- 19.Zhu Z., Wang Y., Yuan M., Zhang R., Chen Y., Lou G., Sun Y. Energy saving and carbon reduction schemes for families with the household PV-BES-EV system. Energy Build. 2023:288. doi: 10.1016/j.enbuild.2023.113007. [DOI] [Google Scholar]

- 20.Bartolucci L., Cordiner S., De Maina E., Mulone V. Data-driven optimal design of a CHP plant for a hospital building: highlights on the role of biogas and energy storages on the performance. Energies. 2022;15 doi: 10.3390/en15030858. [DOI] [Google Scholar]

- 21.Yingjun R., Qingrong L., Weiguo Z., Ryan F., Weijun G., Toshiyuki W. Optimal option of distributed generation technologies for various commercial buildings. Appl. Energy. 2009;86:1641–1653. [Google Scholar]

- 22.Kampik M., Fice M., Pilśniak A., Bodzek K., Piaskowy A. An analysis of energy consumption in small- and medium-sized buildings. Energies. 2023;16 doi: 10.3390/en16031536. [DOI] [Google Scholar]

- 23.ACM Assessment Method for Solar Energy. 2008. p. 14. [Google Scholar]

- 24.Fengying Wei. China Meteorological Press: Beijing; China: 2007. Modern Climate Statistical Diagnosis and Prediction Technology. ISBN. [Google Scholar]

- 25.IPCC, Calvo Buendia E., Tanabe K., Kranjc A., Baasansuren J., Fukuda M., S N., Osako A., Pyrozhenko Y., Shermanau P., et al. Published: IPCC; Switzerland: 2019. Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2019. [Google Scholar]

- 26.GB/T51366-2019 Carbon Emission Calculation Standards for Buildings. 2019. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.