Abstract

Wood waste and waste Polyethylene Terephthalate (PET) bottles are two of the solid wastes posing severe challenges to waste management facilities and constituting nuisance to humans and the environment in Nigeria due to poor management. These wastes could be utilized to produce solid biofuels for various energy applications to reduce CO2 emissions. This study, therefore, aims to investigate the potential of converting these wastes locally into solid waste-derived fuels (SWDF) briquettes in a bid to present an alternative approach to managing them. Four types of SWDF briquettes were produced from mixed wood waste and waste PET bottles in blend ratios of 100:0, 60:40, 50:50, and 40:60 using a screw press briquetting machine with single extrusion die. The effect of PET plastic amount on different properties, such as net calorific value, ash content, durability, and density, of the produced briquettes was investigated. In addition, obtained results were compared with the quality standards of densified fuels specified by the European Pellet Council. to ascertain the quality of the produced SWDF briquettes. The results revealed that the SWDF briquettes made only from mixed wood waste exhibited the lowest calorific value (17.15 MJ/kg) and highest ash content (2.74 %), while the SWDFs made from blends of mixed wood waste and PET bottles had higher calorific values (17.85–20.77 MJ/kg) and lower ash contents (1.05–1.37 %). Moreover, except for density and chlorine content (<750 kg/m3 and <0.03 wt% respectively), all the produced SWDFs complied with the quality standards of densified fuels specified by the European Pellet Council. These results suggest that these blends could yield SWDFs with improved quality and combustion properties, and could present a new way of managing these solid wastes.

Keywords: Calorific value, PET bottles, Plastic wastes, Solid wastes derived fuel, Waste-to-energy, Wood wastes

1. Introduction

Sustainable management of municipal solid waste (MSW) has been among the most significant challenges bedeviling urban communities around the world. In Nigeria, like in several developing countries, MSW is posing a major problem to the environment and human health. Population growth, increased socio-economic and industrial activities as well as changes in lifestyle and consumption pattern is being accompanied by an increase in per capita MSW generation rates [1,2]. The lack of coherent policy and vivid strategy for MSW management has exacerbated the challenge of managing MSW in the country [1,2]. Hence, indiscriminate dumping of wastes in dumpsites, street corners, roadsides, road medians, open spaces, around residential buildings, and drainage systems across the nation is common, resulting in flooding, an unsightly environment, and air pollution.

Since 2007, the yearly consumption of plastics in Nigeria has been increasing by 5 % per capita, rising from 4.0 kg in 2007 to 7.5 kg in 2020 [3]. About 80 % of these plastic wastes are poorly managed and indiscriminately discarded [4,5]. The use of Polyethylene Terephthalate (PET) bottles in packaging is quite popular and has dominated the consumer markets over the years, resulting in the generation of about 200 million waste PET bottles per day in Nigeria [6,7]. PET bottles account for a great fraction of plastic wastes generated and inundating in dumpsites and the environment across the country. This is because only a small fraction of them is harnessed for recycling by recycling companies and re-used in the local retail markets by small businesses to package their products like locally made beverages and dispense other products in smaller amounts The lack of a robust national policy on plastic waste management coupled with the nonchalant attitude of citizens to waste management [8,9], has seen waste PET bottles constituting a nuisance to animals, the environment, and humans in cities across the country.

Another threat to waste management facilities in Nigeria is wood waste. Nigeria is endowed with vast hectares of forest and other wooded lands, about 11 million and 5.5 million hectares respectively [10]. A significant volume of wood waste is produced yearly in Nigeria from wood processing at the forests and wood industries across cities in the country. These include about 295 thousand tonnes per year in Lagos [11], about 1430 tonnes per day in Abeokuta [12], and an estimated 5.2 million tonnes per year from Nigerian sawmills [13]. These wood wastes are usually burnt in the open air at industrial sites or disposed into water bodies by industries located close to rivers, with adverse consequences to humans, animals, and the environment [14,15]. According to a study by Ref. [16], the number of wood wastes will constantly be on the increase in Nigeria; due to poor timber recouping at both the forests and wood processing industries, the use of antiquated instruments and manufacturing procedures, and increasing requests for wood and woody products in the country.

To curtail the menace of MSW to public health and the environment in Nigeria, the country needs to upgrade its waste management policy to transcend “pick up the wastes and dump them in dumpsites” to include the adoption and implementation of engineering solutions that are designed to mitigate the number of wastes going to dumpsites as well as improve material recycling and energy recovery. Amongst the tenable engineering solutions is the concept of waste-to-energy in which MSW is transformed to solid biofuels such as solid waste-derived fuel (SWDF). This study therefore aims to contribute to sustainable solid waste management in Nigeria by investigating the potential of producing SWDFs from blends of wood waste and waste PET bottles.

SWDF (or refuse-derived fuel (RDF)) is a densified fuel obtained from MSW/biomass after the non-combustible fractions (like metal, glass, etc.) have been removed. SWDF technology (or briquetting technology) involves compacting low-density and loose organic materials into densified solid biofuels of various shapes, mainly cylindrical. Fig. 1 shows the production process of SWDF.

Fig. 1.

SWDF production process.

Besides contributing to keeping the environment clean, SWDF technology provides solid biofuels, with higher energy content than the municipal solid waste fractions [17], which can be used as substitute fuel in electrical power generation plants [18], cement kilns in cement industries, and for cooking [[19], [20], [21], [22]] to reduce CO2 emission. Several studies have demonstrated the feasibility of obtaining SWDF from MSW and biomass. The studies investigated the influences of certain parameters like feedstock properties, moisture content, size, and blend ratios, on the properties of SWDFs. Effects of other factors such as use of binders, production temperatures and die pressures were also investigated. Some of the studies considered different solid wastes such as palm kernel shells [23,24]), rice husk [25,26], Norway spruce [27], rice straw [28], corn stover [29], barley straw [30], Maize cob [31], wheat straw [32,33], sorghum stover [17], sawdust [21,34]. While Other studies considered blends of various MSW fractions and agro-wastes such as palm kernel shell and palm fibre [35], sawdust and wheat straw [36], sawdust and rice-powder wastes [37], charcoal and pinewood dust [38], bamboo and rice straw [39], rice husk and wheat straw [40], corn stover and switch-grass [41,42], hospital solid waste, plastic waste, and biomass [43], garden waste and Polyethylene Terephthalate plastic wastes [44], rice husk and bran [45], corncob and oil palm trunk bark [46], banana peels and sawdust [47], groundnut shells, rice husk, sawdust, and wastepaper [48], oil palm fibre and kernel meal residues [49], and corncob and rice husk [20].

Ajimotokan et al. [38] studied the combustion properties of SWDFs made from charcoal particles, pinewood sawdust and their blends using gelatinized cassava peels. They reported that different blend ratios of the raw materials had a considerable impact on every characteristic studied. The proximate and ultimate analyses, and calorific values of the obtained fuel briquettes revealed that they possess great combustion characteristics in contrast to the raw materials used. Therefore, they concluded that the obtained SWDFs could serve as a high-quality fuel for use domestically and in the industries. Liu et al. [39] reported the successful production of SWDF using bamboo and rice straw. The produced biofuels that had an ash content less than 8% and a calorific value greater than 17.5 MJ/kg. Hence, they recommended the utilization of mixed solid wastes for the production of solid waste-derived fuels. Auprakul et al. [50] investigated the properties of SWDF produced from densification of mixed plastic wastes and corn stover at a pressure of 150 MPa. They concluded that mixing plastic wastes with corn stover improved the quality of the produced SWDFs in terms of physicochemical properties, higher calorific value and lower ash content than SWDFs produced from corn stover alone. The study observed that the optimum blend ratio of raw materials was 55:45. Manatural et al. [51] studied the combustion properties of SWDFs made from a mixture of waste polyethylene terephthalate and teak sawdust using a polyethylene terephthalate to sawdust ratio of 9:1. They discovered that briquetting at this ratio yielded SWDFs with uniform dimension that could be handled, stored, and transported as easily as woody briquettes. Furthermore, they concluded that the properties of the SWDFs made from blend of PET and teak sawdust, including a high calorific value of 19.20 MJ/kg, indicated that they were suitable for combustion.

From the reviewed literature, it has been observed that specific species of wood waste has been shown to be viable raw materials for the production of quality SWDFs [21,34]. However, SWDFs produced from blends of wood waste with other types of waste have been shown to have higher calorific value, lower moisture content, lower ash content and more durability than SWDFs produced from wood waste alone [36,37]. Other studies have blended Polyethylene Terephthalate/other plastic wastes with wood waste/other solid wastes in a bid to enhance the properties of SWDFs [43–44, 51]. They reported that more of plastic waste percentage in SWDFs constantly increased their calorific value and durability while lowering their ash content. In these studies, the PET bottles were simply shredded into tiny pieces of at least 1 mm in size.

From previous literature, it could be seen that the deployment of blends of mixed wood wastes (a mixture of wood wastes from various species of wood) and Polyethylene Terephthalate (PET) plastic wastes as raw feedstock for the production of SWDFs is yet to be investigated. Therefore, this paper presents the production of SWDFs from mixed wood waste and its blends with Polyethylene Terephthalate (PET) plastic wastes. For this, the effect of the PET plastic wastes amount on the energy content and other properties of the obtained solid waste-derived fuel was studied, in comparison with the quality standards of densified fuels specified by the European Pellet Council. The method of waste PET bottles treatment to powder form is an additional novelty of this work.

The remaining part of this article is structured thus; section 2 illustrates the materials and methods deployed in the work, in section 3 the obtained results were discussed, and lastly, in section the concluding remarks from the work were presented.

2. Materials and method

2.1. Raw materials

The materials used included wood wastes, waste PET bottles, cassava starch, water, a wooden spatula, a digital weighing scale, bowls, a bucket, a pot, a sieve of 2 mm mesh size, PET bottles pulverizing machine and a briquetting machine.

2.1.1. Preparation of raw materials

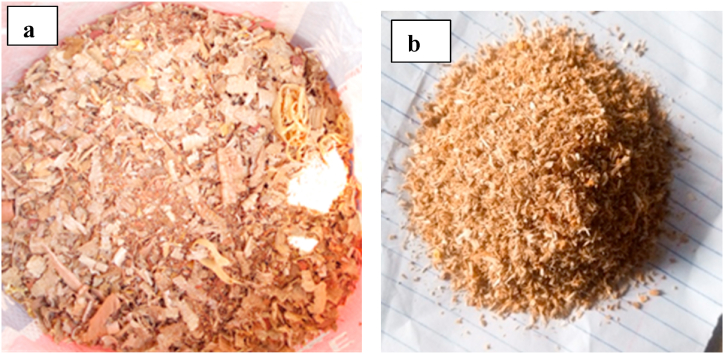

Wood wastes were obtained from the wood workshop at the Faculty of Engineering, University of Benin, Benin City, Nigeria. The wood waste collected is a mix of the wastes from the various species of wood utilized at the workshop. The collected wood wastes (Fig. 2a) were dried in the sun for a week to lower the moisture in the wood wastes. It was thereafter sieved to achieve uniform grain distribution using a 2 mm mesh sieve (Fig. 2b).

Fig. 2.

(a) collected wood wastes from the workshop, (b) sieved wood wastes.

The PET bottles were gathered by picking discarded PET bottles from waste bins in the faculty. The covers and labels of the collected PET bottles were removed to get a homogenous sample. The PET bottles were first heated at 260 °C to melt them, then the melted plastic was left to cool for about 3 min. Thereafter, the melted PET bottles were pulverized using a locally constructed plastic pulverizing machine. The machine crushed the melted plastic into powder (Fig. 3) to achieve uniform grain distribution.

Fig. 3.

Sample of pulverized plastic PET bottles.

The binder used in this study was cassava starch gel. The gel was prepared by dissolving 50g of cassava starch in a bowl containing 80 ml of cold water and mixing thoroughly to form cassava starch paste. 150 ml of boiled water was added to the paste and stirred thoroughly with a spatula to produce starch gel (Fig. 4). The starch gel was left to cool before application.

Fig. 4.

Cassava starch solution.

2.1.2. Characterization of raw materials

The physicochemical properties of the sieved wood wastes and pulverized PET bottles were analysed in accordance with the recommendations of the American Society of Testing Materials (ASTM). The ultimate analysis was conducted with a LECO CHNS 932 analyser following the.

ASTM D3176-15 [52] method. The proximate analysis was determined in line with the ASTM E870-82 [53] specification. The calorific value was determined using a LECO AC-350 bomb calorimeter following the ASTM D5865-13 [54] method.

2.2. Production of solid waste-derived fuel (SWDF)

The detailed procedure deployed for the production of the SWDFs is presented in Fig. 5.

Fig. 5.

detail procedure for the SWDFs production process.

The pulverized waste PET bottles (PET) and sieved wood wastes (WW) were blended in four different proportions as shown in Table 1 to produce four SWDF types: A, B, C, and D.

Table 1.

Blends of different SDWF.

| SWDF Type | Mixing ratios (wt%) |

|---|---|

| SWDF-A | 100 wt% WW and 0 wt% PET |

| SWDF-B | 60 wt% WW and 40 wt% PET |

| SWDF-C | 50 wt% WW and 50 wt% PET |

| SWDF-D | 40 wt% WW and 60 wt% PET |

100g of each blend was carefully added to 10g of starch gel [23] in plastic buckets and stirred with a wooden spatula to obtain a homogeneous mixture. The mixture was then loaded into a pilot screw press briquetting machine to produce densified solid waste-derived fuel (SWDF). The briquetting machine has a single extrusion die. The compacted SWDF blends (Fig. 6) were sun-dried for 5 days.

Fig. 6.

Dried SWDF samples.

2.2.1. SWDF characterization and testing

The quality of the dried SWDF types was assessed by evaluating their physicochemical properties, calorific values, bulk density, and durability. Obtained results were compared with the specified European standard for densified fuels [55]. Table 2 presents the specified European standard for essential properties of densified fuels.

Table 2.

Specified European standard for essential properties of densified fuels [55].

| Property | Unit | ENplus A1 | ENplus A2 | ENplus B |

|---|---|---|---|---|

| Moisture content | %wt (1) | ≤10.00 | ||

| Ash content | %wt (2) | ≤0.70 | ≤1.20 | ≤2.00 |

| Mechanical durability | %wt (1) | ≥98.00 | ≥97.50 | |

| Net calorific value | MJ/kg (1) | ≥16.50 | ||

| Bulk Density | kg/m(3) | 600.00 ≤ Bd ≤ 750.00 | ||

| Nitrogen | %wt (2) | ≤0.30 | ≤0.50 | ≤1.00 |

| Sulphur | %wt (2) | ≤0.04 | ≤0.05 | |

| Chlorine | %wt (2) | ≤0.02 | ≤0.03 | |

(1) As received.

(2) dry basis.

(3) a maximum of 1 wt% of the pellets may be longer than 40 mm, no pellets >45 mm are allowed.

i. SWDF Durability: Durability (Sd) of the produced SWDF was determined based on mass loss of samples in accordance with ASAE Standard S269.4 [56]. Equal mass was weighed out from each SWDF type using a digital weighing scale and recorded. The weighted mass was placed in a vibrating sieve of screen size 3 mm and left for 15 min, after which, the SWDF was removed from the sieve, weighed again, and recorded. The test was conducted in triplicate for each SWDF type. The SWDFs’ durability was computed using Equation (1).

| (1) |

where Sd is the SWDF durability (wt%), z is samples' mass loss (g), and mi is samples' initial mass (g).

-

ii.

SWDF Density: Mass to volume ratio was used to evaluate the density of the SWDFs according to the ASABE standard S269.4 [56]. The SWDFs were weighed to determine their masses, their volumes were determined from their diameter and length, measured using a Vernier calliper. The analysis was conducted in triplicate for each SWDF type.

-

iii.

Calorific Value: The energy content of SWDF samples was determined with a LECO AC-350 bomb calorimeter following the ASTM D5865-13 [54] method. A sample weight of 1 g was placed inside the calorimeter sample cup with the aid of tweezers. A nickel fuse wire (10 cm) was connected to the electrodes. Thereafter, the sample cup was carefully positioned inside a cup holder, while the nickel wire was placed close to the sample but not touching it. The bomb was thereafter carefully filled with oxygen up to 30 atm before ignition. The lid of the calorimeter was closed and thereafter turned on by depressing the start button. After sometimes the calorimeter will ignite the SWDF samples and display the calorific value on the screen. Each experiment was conducted twice.

-

iv.

Physicochemical Properties: To determine the basic properties of the produced SWDF types, proximate and ultimate analyses were carried out. The proximate analysis of the fuels was determined in line with the ASTM E870-82 [53] specification. The ultimate analysis was conducted using a LECO CHNS 932 analyser following the ASTM D3176-15 [52] method. The proximate analyses were conducted to ascertain the percentages of volatile matter, ash, and fixed carbon respectively in the produced SWDFs. Ultimate analysis reveals the elemental composition of the materials. Generally, the major elements in these SWDFs include carbon, hydrogen, nitrogen, sulphur, oxygen, and chlorine.

-

a.

Percentage moisture content (%MC) determination:

Percentage moisture content was determined by weighing out a 10g of the SWDF sample and drying the sample in an open crucible inside an oven at 105 °C till no further change in mass was recorded. The percentage moisture content was thereafter determined using the change in mass of the sample and Equation 2

| (2) |

Where, MC = moisture content, md = change in mass of sample and ms = initial mass of sample(g).

-

b.

Percentage Volatile Matter:

Volatile matter indicates the type of gases (both combustible and non-combustible) present in any solid fuel. The volatile matter (VM) percentage was ascertained by placing 10g of dried SWDF sample in a covered crucible and heated inside a muffle furnace at 950 °C for 10 min. The sample was thereafter cooled in a desiccator and weighed. VM was then computed using Equation (3).

| (3) |

Where, md = change in mass of sample after oven drying and mc = mass of sample after heating in the furnace.

-

c.

Percentage ash content:

Percentage ash content (%Ash) was determined by heating 10g of the SWDF samples in a muffle furnace at 600 °C for 45 min. The residue after heating the sample was cooled in a desiccator and weighed. %Ash was thereafter computed using Equation (4).

| (4) |

-

d.

Percentage fixed carbon:

Fixed carbon is the residual solid portion of solid fuels after their volatile matter has been distilled off. Percentage fixed carbon (%FC) was obtained from the algebraic subtraction of the sum of %VM and %Ash from 100 as highlighted in Equation (5).

| (5) |

-

e.

Ultimate Analysis:

Ultimate analysis reveals the various elements (Carbon, Hydrogen, Nitrogen, Sulphur, and Oxygen) in solid fuels. Ultimate analysis was carried out in a a LECO CHNS 932 analyser CHNS analyser following the ASTM D3176-15 [52] method. Oven-dried SWDF samples was grinded into fine powder and kept in a desiccator before analysing in the a LECO CHNS 932 analyser.

3. Results and discussions

3.1. Physicochemical properties of raw materials

Table 3 highlights the proximate and ultimate analyses as well as the calorific value (CV) of the raw materials (waste PET bottles and wood wastes) utilized in this study. It can be observed from the tabulated results that the PET wastes had lower moisture and ash contents compared to the wood wastes, but had higher percentages of volatile matter, chlorine, and calorific value than wood wastes. According to results reported by Refs. [57,58] the nature of the plastic material could be the reason for this.

Table 3.

Physicochemical properties of the raw materials utilized in the study.

| Raw materials | Proximate analyses (%wt) |

Ultimate analyses (%wt) |

NCV (MJ/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MC | VM | FC | Ash | C | H | O | N | S | Cl | ||

| PET | 4.8 | 83.76 | 9.35 | 2.09 | 76.3 | 11.5 | 11.77 | 0.08 | 0.02 | 0.33 | 21.57 |

| WW | 10.78 | 78.33 | 8.26 | 2.63 | 56.41 | 6.32 | 37.1 | 0.11 | 0.04 | 0.02 | 15.57 |

3.2. SWDF characteristics

3.2.1. physicochemical properties

Table 4 shows the physicochemical properties of the SWDF types (A–D) produced in this study. Results of the proximate analysis indicate that the SWDFs containing plastics had higher volatile matter than SWDF-A with no plastics They contained volatile matter within the range reported by Refs. [43,44]. Obtained fixed carbon ranged between approximately 7 and 10 wt%. SWDF-B was observed to have the lowest percentage of fixed carbon, while SWDF-D had the highest percentage of fixed carbon. Usually, after heat processes, a portion of the carbon in PET plastics is converted to fixed carbon [44,59], this could be the reason for the observed fixed carbon content of the produced SWDFs B-D.

Table 4.

SWDF physicochemical characteristics and net calorific value.

| SWDF Types | Proximate analyses (%wt) |

Ultimate analyses (%wt) |

NCV MJ/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MC | VM | FC | Ash | C | H | O | N | S | Cl | ||

| SWDF-A | 9.32 | 80.69 | 7.25 | 2.74 | 55.34 | 6.11 | 38.43 | 0.1 | 0.02 | 0 | 17.15 |

| SWDF-B | 8.32 | 81.98 | 8.33 | 1.37 | 57.26 | 6.01 | 36.59 | 0.1 | 0.02 | 0.02 | 17.85 |

| SWDF-C | 5.64 | 83.78 | 9.4 | 1.18 | 59.82 | 5.15 | 34.74 | 0.07 | 0.01 | 0.21 | 19.88 |

| SWDF-D | 3.85 | 85.15 | 9.95 | 1.05 | 60.95 | 4.77 | 33.93 | 0.06 | 0.01 | 0.28 | 20.77 |

*MC is moisture content, VM is volatile matter, and FC is fixed carbon.

Mixing ratios of PET plastics and wood wastes have a huge influence on the moisture content of the produced SWDF (Table 4). Wood wastes contain moisture in their pores, so it is difficult to evaporate, unlike plastics that have it on their surfaces [59]. The more the amount of PET plastics in the blend, the lower the water content as indicated in Table 4. A similar trend was reported by Refs. [43,44]. This is due to the low moisture content in PET plastics, so when mixed with wood wastes, it affects the moisture content of the finished product. The produced SWDF types satisfied the European standard requirement of less than 10 % moisture content value.

Table 4 also presents the outcomes of the ultimate analyses. The levels of carbon, hydrogen, and oxygen in the SWDFs were approximately between 55 and 61 wt%, 5 – 6 wt%, and 34 - 38 wt% respectively. Similarly, the percentage of nitrogen and sulphur varied among the SWDFs from 0.06 to 0.1 wt% and 0.02–0.08 wt% respectively. Nevertheless, all the SWDFs met the required European standard for nitrogen and sulphur limits. The nitrogen and Sulphur contents were substantially low. This implies low emissions of oxides of nitrogen (NOx) and sulphur (SOx) could be expected when these SWDFs are used as fuel in combustion or co-combustion processes. Higher chlorine amount was observed in SWDF-C and SWDF-D, probably due to the higher amount of PET plastics in them, as equally observed in the study by Ref. [50]. Hence, SWDF-C and SWDF-D didn't meet the required European standard for chlorine levels.

3.2.2. Ash content

Results in Table 4 show that the more the amount of PET plastics in the SWDF, the lower the ash content. The required European standard for densified fuels specified that the amount of ash in solid fuels must not exceed 2 wt%. Except for SWDF-A, other SWDF types met the European standard specification. Liu et al. [39] reported that the combustion process and composition of feedstocks influence the percentage of ash in SWDF. PET plastics had very low ash content, while wood waste exhibited a higher ash content than PET plastics as revealed by the proximate analysis (Table 4). From Table 4, SWDF-A with the highest wood wastes proportion had the highest ash content (2.74 %), while SWDF-D with the highest PET plastics proportion had the lowest ash percent (1.05 %). This is an indication that the low ash content of the PET plastics influenced the final ash content of the SWDF types. A similar trend was also reported by Refs. [43,44].

3.2.3. Net calorific value

Moisture levels of fuels directly influence their energy content. Hence, higher moisture levels lead to a decrease in calorific value [60], and this distinguishes the combustibility of fuels. Furthermore, Nath et al. [32] reported that the raw material composition of SWDF profoundly affects its calorific value. Table 4 highlights the SWDFs net calorific values (NCV) obtained in this study. From Tables 4 and it could be seen that the higher the amount of wood waste in the mixture, the lower the calorific value. This is due to the moisture content of wood waste, thereby resulting in a decrease in the calorific value, which concurs with the findings of [61]. Conversely, the higher the percentage of PET plastics in the SWDF, the higher the calorific values. This agrees with the findings of [43,44,50,51,62], that the addition of plastic waste can increase the calorific value of solid waste-derived fuel. Furthermore, it can be seen that the calorific value of the wood waste briquette was increased when PET plastic was added. Similar findings were reported by Refs. [63,64]. They found that SWDF made from mixed paper had low calorific value due to high ash content. However, when plastics were blended with the mixed paper, the properties of the resulting SWDFs were improved. In this work, all SWDFs had calorific values (≥16.5 MJ/kg) and satisfied the required European standard for densified fuels.

3.2.4. SWDF durability

Durability is essential to ascertain the quality of SWDF. High durability has been linked to high-quality SWDFs [47,65]. In this study, durability was used as a factor to ascertain the strength of the produced SWDFs. The durability values obtained for the different types of SWDF are highlighted in Table 5.

Table 5.

Average values of durability and density of SWDF types ± SD.

| SWDF Type | Durability (Sd) wt% | Bulk Density, Bd (kg/m3) |

|---|---|---|

| SWDF-A | 97.90 ± 0.02 | 565.81 ± 0.36 |

| SWDF-B | 97.50 ± 0.02 | 579.96 ± 0.41 |

| SWDF-C | 96.60 ± 0.01 | 636.54 ± 1.41 |

| SWDF-D | 96.50 ± 0.03 | 664.83 ± 1.41 |

*SD signifies standard deviation.

The produced SWDFs exhibited high durability (≥96.5 wt%), when compared with the specified European standard for densified fuels. All the SWDFs contained a high amount of wood waste, which accounted for the high durability obtained in this study. SWDF-D with wood waste and PET plastic ratio of 40:60 had the lowest durability, while SWDF-A with 100:0 of mixed wood waste and PET plastics exhibited the highest durability. It can be deduced that more PET plastic decreases durability under similar conditions. Additionally, wood waste has fiber, protein and lignin that can enhance pellet durability. This implies that SWDF with high content of biomass (wood waste) should be more durable. This agreed with the findings by Refs. [43,50,51].

3.2.5. SWDF density

In evaluating the properties of densified biofuels, density plays a crucial role in ascertaining their quality, storage space requirements, handling efficiency, and transportation costs, according to several national standards [[53], [66], [67]]. The mean values of density obtained for the various SWDF types are listed in Table 5. SWDF-C and SWDF-D were found to comply with the specified European standard for densified fuels, while SWDF-A and SWDF-B did not. SWDF-A was found to have the lowest density (565.81 kg/m3) while SWDF-D had the highest density (664.83 kg/m3). This indicates that the increasing amount of PET plastics in the blend increases the SWDF density. These findings were in contrast to those obtained by Refs. [43,50], who reported a decrease in SWDF density with increase in plastic content.

4. Conclusions

Solid waste-derived fuel (SWDF) was successfully produced from the combination of mixed wood waste and waste PET bottles. Four types of SWDFs were made by blending different percentages by weight of mixed wood waste and waste PET bottles. The quality of produced SWDFs was ascertained and compared with the specified standards for densified fuels set by the European Pellet Council. Obtained results revealed that, except for chlorine content, the produced SWDF types (A, B, C and D) all satisfied the specified standards for densified fuels set by the European Pellet Council with regard to the analysed properties (calorific value, ash content, durability and density). SWDF-A and SWDF-B exhibited chlorine contents lower than the specified European standard, making them more suitable than SWDF-C and SWDF-D as fuel, especially for indoor cooking purposes. The low chlorine content and high net calorific value showed by SWDF-B make the blend (60:40) more attractive for use as fuel for energy, and hence is recommended for further consideration. The results from this work indicate that SWDF can be successfully obtained from blends of mixed wood waste and waste PET plastics. This study presents a new method to manage and utilise municipal solid wastes, especially mixed wood waste and waste PET bottles, in a sustainable manner.

Data availability statement

No additional information is available for this paper.

CRediT authorship contribution statement

Peter E. Akhator: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Resources, Supervision, Writing – original draft, Writing – review & editing. Lewis Bazuaye: Data curation, Formal analysis, Investigation, Methodology, Resources, Writing – original draft. Aliemeke Ewere: Data curation, Formal analysis, Investigation, Resources. Odior Oshiokhai: Data curation, Formal analysis, Investigation, Resources, Writing – original draft, Methodology.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

We would like to appreciate the contributions of all participants in this study.

References

- 1.Bakare W. 2018. Solid Waste Management in Nigeria.https://www.bioenergyconsult.com/solid-waste-nigeria/ Retrieved from. [Google Scholar]

- 2.Ayuba K.A., Manaf L.A., Sabrina A.H., Azmin S.W.N. Current status of municipal solid waste management practise in FCT Abuja. Res. J. Environ. Earth Sci. 2013;5(6):295–304. [Google Scholar]

- 3.Brandspur, Nigeria Plastic Production Q4 (2017). https://brandspurng.com/2017/11/07/nigeria-plastic-production-4-2017/. (Accessed 25 September 2020).

- 4.Babayemi J.O., Ogundiran M.B., Weber R., et al. Initial inventory of plastics imports in Nigeria as a basis for more sustainable management policies. J. Health. Pol. 2018;8(18) doi: 10.5696/22156-9614-8.18.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Jambeck J.R., Geyer R., Wilcox C., et al. Plastic waste inputs from land into the Ocean. Science. 2015;347(6223):768–771. doi: 10.1126/science.1260352. [DOI] [PubMed] [Google Scholar]

- 6.National Association for PET Container Resources [NAPCOR] 2011. Report on Postconsumer Pet Container Recycling Activity Final Report. [Google Scholar]

- 7.Egun N.K., Evbayiro O.J. Beat the plastic: an approach to polyethylene terephthalate (PET) bottle waste management in Nigeria. Waste Disposal & Sustainable Energy. 2020;2:313–320. doi: 10.1007/s42768-020-00052-x. [DOI] [Google Scholar]

- 8.Duru R.U., Ikpeama E.E., Ibekwe J.A. Challenges and prospects of plastic waste management in Nigeria. Waste Disposal & Sustainable Energy. 2019;1:117–126. [Google Scholar]

- 9.Egun N.K. Environmental responsibility: Nigerians how far? J. Appl.Technol. Environ.Sanitation. 2011;1(2):143–147. [Google Scholar]

- 10.Food and Agriculture Organization of the United Nations (Fao) Retrieved; 2017. Global Forest Sheet Facts and Figures.http://www.fao.org/faostat/en/#data/QD 02. Dec. 20 [Google Scholar]

- 11.Dosunmu O.O., Ajayi A.B. Problems and management of sawmill waste in Lagos. Procee. Int. Sym. Environ. Pol. Control.Waste Manag. 2002;7–10:271–278. January, 2002, Tunis. [Google Scholar]

- 12.Aina O.M. 2006. Wood Waste Utilization for Energy Generation. Proceedings of the International Conference on Renewable Energy for Developing Countries. Retrieved from chrome-extension. [Google Scholar]

- 13.Francescato V., Antonini E., Bergomi L.Z., Metschina C., et al. AIEL: Italian Agriforestry Energy Association; Legnaro: 2008. Wood Fuels Handbook. [Google Scholar]

- 14.Arimoro F.O., Ikomi R.B., Osalor E.C. The impact of sawmills wood wastes on the water quality and fish communities of Benin River, Niger delta area, Nigeria. Int. J. Sci. Technol. 2007;2(1):1–12. [Google Scholar]

- 15.Wihersaari M. Evaluation of greenhouse gas emissions risk from storage of wood residues. Biomass and Energy. 2005;28:444–453. [Google Scholar]

- 16.Ogunwusi A.A. Wood waste generation in the forest industry in Nigeria and prospects for its industrial utilization. Civ. Environ. Res. 2014;6(9):224–233. [Google Scholar]

- 17.Olaoye J.O., Kudabo E.A. Evaluation of constitutive conditions for production of sorghum stovers briquette. Arid Zone Journal of Engineering, Technology and Environment. 2017;13(3):400–412. [Google Scholar]

- 18.Sarquah K., Narra S., Beck G., Awafo E.A. Bibliometric analysis; characteristics and trends of refuse derived fuel research. Sustainability. 2022;14:1994. [Google Scholar]

- 19.Kosajan V., Wen Z., Fei F., et al. The feasibility analysis of cement kilns as an MSW treatment infrastructure: from a life cycle environmental impact perspective. J. Clean. Prod. 2020 doi: 10.1016/j.jclepro.2020.122113. Epub ahead of print 10 September 2020. [DOI] [Google Scholar]

- 20.Oladeji J.T. Fuel characterization of briquettes produced from corncob and rice husk resides. Pac. J Sci. Technol. 2010;11(1):101. [Google Scholar]

- 21.Sotannde O.A., Oluyege A.O., Abah G.B. Physical and combustion properties of briquettes from sawdust of azadirachta indica. J. For. Res. 2010;21(1):63–67. [Google Scholar]

- 22.The European Cement Association . CEMBUREAU; Brussels, Belgium: 2015. Markets for Solid RECOVERED FUEL Data and Assessments on Markets for SRF. [Google Scholar]

- 23.Bonsu B.O., Takase M., Mantey J. Preparation of charcoal briquette from palm kernel shells: case study in Ghana. Heliyon. 2020;6 doi: 10.1016/j.heliyon.2020.e05266. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Ugwu K.E., Agbo K.E. Briquetting of palm kernel shell. J. Appl. Sci. Environ. Manag. 2011;15:447–450. www.bioline.org.br/ja Retrieved from. 10 Feb. 20. [Google Scholar]

- 25.Japhet J.A., Tokan A., Muhammad M.H. Production and characterization of rice husk pellet. American Journal of Energy Resources. 2015;4(12):112–119. [Google Scholar]

- 26.Missagia B., Guerrero C., Narra S., Sun Y., Ay P., Krautz H.J. Physicomechanical properties of rice husk pellets for energy generation. Energy Fuels. 2011;25(12) 5786e5790. [Google Scholar]

- 27.Cesprini Emanuele, Greco Rosa, Causin Valerio, Urso Tiziana, Cavalli Raffaele, Zanetti Michela. (2021). Quality assessment of pellets and briquettes made from glued wood Waste. Eur. J. Wood. Wood Prod. 2021:1153–1162. doi: 10.1007/s00107-021-01695-1. 79. [DOI] [Google Scholar]

- 28.Ishii K., Furuichi T. Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets. Waste Manag. 2014;34 doi: 10.1016/j.wasman.2014.08.008. [DOI] [PubMed] [Google Scholar]

- 29.Mani S., Tabil L.G., Sokhansanj S. Specific energy requirement for compacting corn stover. Bioresour. Technol. 2006;97(12) doi: 10.1016/j.biortech.2005.06.019. [DOI] [PubMed] [Google Scholar]

- 30.Serrano C., Monedero E., Lapuerta M., Portero H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011;92:699e706. doi: 10.1016/j.fuproc.2010.11.031. [DOI] [Google Scholar]

- 31.Wilaipon P. Physical charactistics of maize cob briquettes under moderate die pressure. Am. J. Appl. Sci. 2007;4:995–998. [Google Scholar]

- 32.Nath Bidhan, Chen Guangnan, Bowtell Les, Mahmood Raid Ahmed. (2023). Assessment of densified fuel quality parameters: a case study for wheat straw pellet. J. Biores.Biopro, 2023;8:45–58. doi: 10.1016/j.jobab.2022.10.001. [DOI] [Google Scholar]

- 33.Stelte W., Clemons C., Holm J.K., Ahrenfeldt J., Henriksen U.B., Sanadi A.R. Fuel pellets from wheat straw: the effect of lignin glass transition and surface waxes on pelletizing properties. Bioenergy Res. 2012;5:450e458. doi: 10.1007/s12155-011-9169-8. [DOI] [Google Scholar]

- 34.da Silva C.E.S., Gomes F.J.B., Batalha L.A.R., Lelis R.C.C., Carvalho A.M.M.L., de Cassia Oliveira Carneiro A., de Carvalho A.M. Recovering wood waste to produce briquettes enriched with commercial kraft lignin. Nat. Resour. 2021;12:181–195. doi: 10.4236/nr.2021.125013. [DOI] [Google Scholar]

- 35.Yee Sing Chin, Shiraz Aris M. A study of biomass fuel briquettes from oil palm mill residues. Asian J. Sci. Res. 2013;6:537–545. doi: 10.3923/ajsr.2013.537.545. [DOI] [Google Scholar]

- 36.Wamukonya L., Jenkins B. Durability and relaxation of sawdust and wheat straw briquettes as possible fuels for Kenya. Biomass Bioenergy. 1995;8(3):175–179. [Google Scholar]

- 37.Munsin Ronnachart, Udtasri Jakkarin, Topaiboul Subongkoj, Kowtakul Pichet, Yeunyongkul Pracha, Nuntapap Nawee, Jarupoom Parkpoom, Rakyat Manop, Laoonual Yossapong, Srichai Prathan, Ruttanadech Nuttapong, Chungcharoen Thatchapol. (2022). A study on binderless co-pelletization of industrial rice-powder wastes and teak sawdust at low and elevated temperatures. Case Studies in Chemical and Environmental Engineering. 2022;6 doi: 10.1016/j.cscee.2022.100250. [DOI] [Google Scholar]

- 38.Ajimotokan H.A., Ehindero A.O., Ajao K.S., Adeleke A.A., Ikubanni P.P., Shuaib- Babata Y.L. Combustion characteristics of fuel briquettes made from charcoal particles and sawdust agglomerates. Scientific African. 2019 doi: 10.1016/j.sciaf.2019.e00202. [DOI] [Google Scholar]

- 39.Liu Z., Fei B., Jiang Z., Cai Z., Yu Y. The properties of pellets from mixing bamboo and rice straw. Renew. Energy. 2013;55:1–5. doi: 10.1016/j.renene.2012.12.014. [DOI] [Google Scholar]

- 40.Ríos-Badran I.M., Luzardo-Ocampo I., Garcia-Trejo J.F., Santos-Cruz J., Gutierrez-Antonio C. Production and characterization of fuel pellets from rice husk and wheat straw. Renew. Energy. 2020;145:500–507. doi: 10.1016/j.renene.2019.06.048. [DOI] [Google Scholar]

- 41.Kaliyan N., Morey R. Densification characteristics of corn stover and switchgrass. Trans. ASABE (Am. Soc. Agric. Biol. Eng.) 2009;52(3) [Google Scholar]

- 42.Kaliyan N., Morey R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010;101(3):1082e1090. doi: 10.1016/j.biortech.2009.08.064. [DOI] [PubMed] [Google Scholar]

- 43.Tanvir Alam Md, Lee Jang-Soo, Lee Sang-Yeop, Bhatta Dhruba, Yoshikawa Kunio, Seo Yong-Chil. Low chlorine fuel pellets production from the mixture of hydrothermally treated hospital solid waste. Pyrolytic PlasticWaste Residue and Biomass energies. 2019;12:4390. doi: 10.3390/en12224390. [DOI] [Google Scholar]

- 44.Zahra N.L., Septiariva I.Y., Sarwono A., Qonitan F.D., Sari M.M., Gaina P.C., Ummatin K.K., Arifiyanti Q.A.M.O., Faria N., Lim J.W., Suhardono S., Suryawan I.W.K. Substitution of garden and polyethylene terephthalate (PET) plastic waste as refused derived fuel (RDF) Int. J. Renew. Energy Dev. 2022;11(2):523–532. doi: 10.14710/ijred.2022.44328. [DOI] [Google Scholar]

- 45.Yank A., Ngadi M., Kok R. Physical properties of rice husk and bran briquettes under low pressure densification for rural applications. Biomass Bioenergy. 2016;84:22e30. [Google Scholar]

- 46.Kpalo S.Y., Zainuddin M.F., Manaf L.A., Roslam A.M. Production and characterization of hybrid briquettes from corncobs and oil palm trunk bark under low pressure densification technique. Sustainability. 2020;12:1–16. [Google Scholar]

- 47.Thulu F.G.D., Kachaje O., Mlowa T. A study of combustion characteristics of fuel briquettes from a blend of banana peelings and saw dust in Malawi. Int. J.The.Proj. Disser. 2016;4(3):135–158. [Google Scholar]

- 48.Akpepuun T.D., Salau J., Durotoye M. Physical and combustion properties of briquettes produced from a combination of groundnut shell, rice husk, sawdust and waste paper using starch as binder. J. Appl. Sci. Environ. Manag. 2020;24(1):171–177. [Google Scholar]

- 49.Siva S., Prawit T., Sittipong L., et al. The design of experimental production of briquette solid fuel from oil palm fibre and kernel meal residue. Eng. J. 2020;24(6):31–42. [Google Scholar]

- 50.Auprakul U., Promwungkwa A., Tippayawong N., Chaiklangmuang N. Factors affecting properties of fuel pellets from compaction of mixed biomass and waste plastics. Agri.Eng. Int.: CIGR J. 2019;21(3):123–129. [Google Scholar]

- 51.Manatura K., Samaksaman U. Characteristics and combustion kinetics of fuel pellets composed of waste of polyethylene terephthalate and biomass. Global J. Environ. Sci. Manage. 2021;7(4):625–642. doi: 10.22034/gjesm.2021.04.09. [DOI] [Google Scholar]

- 52.ASTM D3176-15 . ASTM International; West Conshohocken, PA, USA: 2015. Standard Practice for Ultimate Analysis of Coal and Coke. [Google Scholar]

- 53.ASTM E870-82 . ASTM International; West Conshohocken, PA: 2013. Standard Test Method for Analysis of Wood Fuels. [Google Scholar]

- 54.ASTM D5865-13 . ASTM International; West Conshohocken, PA, USA: 2013. Standard Test Method for Gross Calorific Value of Coal and Coke. [Google Scholar]

- 55.Enplus Handbook for Quality Certification Scheme for Wood Pellets . version 3; Brussels, Belgium: 2015. Part 3: Pellet Quality Requirements, European Pellet Council; pp. 1–10. [Google Scholar]

- 56.ASABE . St-Joseph, MI; 2007. Standard s269.4: Cubes, Pellets, and Crumbles - Definitions and Methods for Determining Density, Durability, and Moisture Content. [Google Scholar]

- 57.Luo J., Li Q., Meng A., Long Y., Zhang Y. Combustion characteristics of typical model components in solid waste on a macro-TGA. J. Therm. Anal. Calorim. 2018;132:553–562. [Google Scholar]

- 58.Zhao L., Giannis A., Lam W., Lin S., Yin K., Yuan G., Wang J. Characterization of Singapore RDF resources and analysis of their heating value. Sustain. Environ. Res. 2016;26:51–54. [Google Scholar]

- 59.Montejo C., Costa C., Ramos P., Márquez M., del C. Analysis and comparison of municipal solid waste and reject fraction as fuels for incineration plants. Appl. Therm. Eng. 2011;31(13):2135–2140. doi: 10.1016/j.applthermaleng.2011.03.041. [DOI] [Google Scholar]

- 60.Wang L., Chang Y., Zhang X., Yang F., Li Y., Yang X., Dong S. Hydrothermal co-carbonization of sewage sludge and high concentration phenolic wastewater for production of solid biofuel with increased calorific value. J. Clean. Prod. 2020;255 doi: 10.1016/j.jclepro.2020.120317. [DOI] [Google Scholar]

- 61.Yildiz S., Yaman C., Demir G., Ozcan H.K., Coban A., Okten H.E., Sezer K., Goren S. Characterization of municipal solid waste in Istanbul, Turkey. Environ. Prog. Sustain. Energy. 2013;32(3):734–739. doi: 10.1002/ep.11640. [DOI] [Google Scholar]

- 62.Syguła E., Świechowski K., Stępień P., Koziel J.A., Białowiec A. The prediction of calorific value of carbonized solid fuel produced from refuse-derived fuel in the low-temperature pyrolysis in CO2. Materials. 2021;14(Issue 1) doi: 10.3390/ma14010049. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Li Y., Liu H. High-pressure binderless compaction of waste paper to form useful fuel. Fuel Process. Technol. 2000;67(1):11–21. [Google Scholar]

- 64.Yaman S., Şahan M., Haykiri-açma H., Şeşen K., Küçükbayrak S. Production of fuel briquettes from olive refuse and paper mill waste. Fuel Process. Technol. 2000;68(1):23–31. [Google Scholar]

- 65.Temmerman M., Rabiera F., Jensenb P.D., Hartmannc H., Bohm T. Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy. 2006;30(11) [Google Scholar]

- 66.Filbakk T., Skjevrak G., Høibø O., Dibdiakova J., Jirjis R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011;92:871–878. [CrossRef] [Google Scholar]

- 67.Fasina O. Physical properties of peanut hull pellets. Bioresour. Technol. 2008;99:1259–1266. doi: 10.1016/j.biortech.2007.02.041. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No additional information is available for this paper.