Abstract

The influence of structural properties and kinetic constraints on the behavior of Bacillus cereus was investigated on agar media. Dimensional criteria were used to study the growth in bacterial colonies. The architecture of the agar gel as modified by the agar content was found to influence the colony size, and smaller colonies were observed on media containing 50 to 70 g of agar liter−1. Except at low nutrient levels, colonies responded to nutrient gradients by decreasing in size the farther away they were from the nutrient source, and the decrease in colony size was influenced by the agar content. The diffusivities of glucose and a protein (insulin-like growth factor) were not affected by the gel architecture, suggesting that other factors, such as mechanical factors, could influence microbial growth in the agar systems used. Increasing the viscosity of the liquid phase of the agar media by adding polyvinylpyrrolidone resulted in a reduction in colony size. When the agar concentration was increased, the colony areas were not influenced by the viscosity of the system.

The chemical composition of food is a crucial determinant of microbial growth. Furthermore, the microstructure of the food matrix can affect the growth of a colony by imposing physical restraints on microorganisms, by limiting the diffusion of essential nutrients (or oxygen), or by preventing the diffusion of metabolic products (4, 11, 25).

In quasi-glassy-state food, in which the rates of diffusion of molecules are low, microbial growth should be prevented since the nutrients around a microcolony are utilized rapidly and not quickly replaced, while metabolites diffuse away slowly from the colony (3, 5).

The influence of structural and mechanical constraints on the behavior of microorganisms is poorly understood in general and has not been investigated in the case of Bacillus cereus.

Constraints of this nature can make structural properties and kinetic parameters, such as gel architecture (pore size and strand thickness), viscosity, and diffusivity, more relevant to microbial growth than water activity (aw).

The purpose of this study was to determine B. cereus responses on agar medium (aw, 0.985 to 0.990) surfaces with respect to (i) the architecture of the agar medium as modified by the agar concentration, (ii) the nutrient gradients established in agar gels at different agar concentrations, and (iii) the viscosity of the liquid phase of the media resulting from the addition of different quantities of polyvinylpyrrolidone (PVP).

(Part of this research was presented at Food Micro ’96, Budapest, Hungary.)

MATERIALS AND METHODS

Organism and growth conditions.

B. cereus ATCC 9139, a nonmotile strain obtained by The National Institute of Public Health and Environmental Protection (Bilthoven, The Netherlands), was used throughout this study. The Bacillus culture was grown in brain heart infusion (BHI) (Unipath, Milan, Italy) broth and maintained as a frozen stock preparation at −18°C. Working cultures were prepared as slants on BHI agar (12.0 g liter−1) and were maintained at 4°C. To prepare the inoculum, the organism was cultured for 24 h in BHI broth at 30°C.

B. cereus responses to increasing agar content.

BHI agar media were prepared with final concentrations of agar (bacteriological agar no. 1; Unipath) of 10, 50, and 70 g liter−1. If necessary, the pH was adjusted to 7.2 prior to autoclaving. After the BHI agar had been sterilized and tempered (70°C), 12-ml portions were pipetted into plastic petri dishes (diameter, 90 mm) and allowed to dry at room temperature for approximately 16 h. The water losses, expressed in terms of the agar concentration per plate (21), were 1.03% (10 g of agar liter−1), 5.15% (50 g of agar liter−1), and 7.22% (70 g of agar liter−1). Then 0.1 ml of a 24-h diluted peptone (1.0 g liter−1; pH 7.0) water culture of B. cereus was spread over the surface of each agar plate with a bent glass rod. The plates were incubated at 30°C for 24 h. The total water losses, expressed as described above, were 1.08% (10 g of agar liter−1), 5.32% (50 g of agar liter−1), and 7.68% (70 g of agar liter−1). When the number of colonies on a plate was less than 10 and the colonies were at least 1.5 cm from one another, the colony diameters were measured with a stereomicroscope (model M420; Wild Makroskop, Wild Heerbrugg, Switzerland) after the cover of the dish was removed. A grid placed under the plates was used to express diameters in graduations that were later transformed in millimeters. To establish the relationship between colony size and biomass, colonies on agar were removed and placed into 5 ml of sterile peptone water. Agar with surface growth was whirl mixed for 2 min, and the suspension was serially diluted and plated onto duplicate BHI agar plates. The plates were incubated at 30°C for 24 h, and the colonies were counted.

B. cereus responses to nutrient gradients on agar gels modified by modifying the agar content.

Agar at final concentrations of 10, 50, and 70 g liter−1 was used to prepare gels. After each gel had been autoclaved and tempered (70°C), 50-ml portions were pipetted into plastic petri dishes (diameter, 120 mm) and allowed to dry overnight at room temperature. A central hole (diameter, 42 mm), made by using a mold, was filled with 6 ml of sterile BHI agar (10 g of agar liter−1). To prevent mixing of the two gels, the BHI agar was cooled to just above the gelling point before it was poured. Diffusion from the BHI agar resulted in the development of a nutrient concentration gradient in the gel. The agar gel was inoculated before the BHI agar was poured. The inoculation procedure was as follows. A platinum needle was dipped into 3 ml of a 24-h culture of B. cereus poured into a petri dish (diameter, 90 mm) to form a thin layer, and then we touched the agar surface with the needle in nine locations arranged in a spiral (a grid was placed under the petri dish). Locations were split into two plates to avoid interactions between colonies. Twenty to forty cells were inoculated in this way at each inoculation point. The plates were incubated at 30°C for 24 h. The diameters of the colonies were measured as reported above.

Calculation of diffusion coefficients.

The gel systems described above were used to evaluate the concentration profiles of d-[6-3H]glucose (catalog no. TRK 85B001; specific activity, 165 mCi mg−1; radioactive concentration, 1.0 mCi ml−1; Amersham International, Little Chalfont, Buckinghamshire, United Kingdom) and iodinated recombinant human insulin-like growth factor (125I-rhIGF-I) (specific activity, 82.73 mCi mg−1; radioactive concentration, 0.17 mCi ml−1). The rhIGF-I, obtained from Escherichia coli (Boehringer Mannheim, Milan, Italy), was labelled as described by Salacinski et al. (26). The labelled compounds (10 μl) were separately added to melted BHI (10 ml), and the mixtures were poured as described above for BHI agar. After 24 h of incubation at 30°C, the labelled compound concentrations in the gels were determined by removing 13 plugs (3 in the BHI agar and 10 in the agar gel) along the radius of the plate gel at regular intervals (starting 9.1 mm from the centrum of the plate). The weight of each plug was recorded, and the d-[6-3H]glucose activity was measured with a beta counter (model 1600 TR; Packard, Milan, Italy) by using 2.0 ml of deionized water and 3.0 ml of scintillation medium (Ultima Gold; Packard). After the water was added and before the scintillation medium was added, the vial was heated in a water bath to melt the gel. The 125I-rhIGF-I activity was measured with a gamma counter (model Riastar Tm; Packard). The activities of both of the labelled compounds were expressed as counts per minute per gram. The activities of control samples (at least two samples for each trial) were defined as Co, and the relative concentration of each labelled compound in the diffusion system was calculated by determining C·Co−1.

The diffusion coefficients of the labelled compounds were determined from a best-fit approximation between the measured concentrations and the model obtained by applying the governing equation for the one-dimensional axisymmetric form of the diffusion equation for homogeneous medium, based on Fick’s second law (2):

|

where De is the diffusion coefficient (in square centimeters per second), C is the concentration, t is the time (in seconds), and r is the radial coordinate.

The numerical solution of this equation was based on the finite element method (31). The finite element mesh consisted of 15 bidimensional parabolic elements and 78 nodes. Time, space, and concentration were adimensionalized. The initial dimensionless concentration of the diffusant in the inner part of the system was assumed to be equal to unity, while the outer dimensionless concentration was equal to zero. The dimensionless inner radius was assumed to be equal to 0.021/0.06 (0.35). The dimensionless time step used was 10−5. The boundary conditions were of the second kind, with no mass transfer at the surface.

B. cereus responses to increasing viscosity.

Different quantities (100, 150, 200, 250, and 300 g liter−1) of PVP-30 (Fluka, Chemika-Biochemika, Buchs, Switzerland), which had a molecular weight of 40,000, were used to prepare supplemented BHI agar plates. The agar concentrations used were 10, 50, and 70 g liter−1. Plates were inoculated and incubated as described above for the experiments in which the responses to increasing agar contents were determined, and colony diameters were measured. The controls, BHI solutions containing PVP-30, were inoculated with a diluted 24-h peptone water culture of B. cereus to give an initial concentration of viable bacteria of approximately 10 CFU ml−1. After incubation at 30°C for 24 h, suspensions were serially diluted and plated onto duplicate BHI agar plates. The plates were incubated at 30°C for 24 h, and the colonies were counted. Growth of B. cereus was also evaluated by a microtiter plate kinetics assay. The BHI solutions containing PVP-30 (160 μl) and exponentially growing B. cereus (40 μl containing approximately 106 CFU ml−1) were added to each well of a polystyrene 96-well microtiter plate. The optical density at 630 nm was recorded every 15 min for 7 h at 30°C by using a model EL340 microplate reader (Bio-Tek Instruments, Inc., Winooski, Vt.). The microplate reader was controlled and data were recorded with an Epson computer. The mean slope and r2 value were computed for each well of the microplate.

Viscosity measurements.

The viscosities of BHI solutions containing different quantities of PVP-30 were determined at 30°C by using a Hoppler type falling ball viscosimeter (Haake Mess. GmbH, Berlin, Germany).

aw measurements.

The aw values of BHI agar plates containing different quantities of agar and PVP-30 were determined with a dew point hygrometer (model AquaLab CX2; Decagon Devices, Inc., Pullman, Wash.). The aw values were 0.985 to 0.990 irrespective of the quantities of the ingredients used in the experiments.

RESULTS AND DISCUSSION

Although microbial colonization of surfaces is ubiquitous and growth of colonies of bacteria on the surfaces of solid nutrient media is a general experimental method used to study microbial behavior, the laws which govern colonial growth have not been completely elucidated (7). In several experimental studies (8, 15, 22, 23, 28) the growth of bacteria and yeasts on solid media has been monitored by measuring increases in colony diameter and, occasionally, thickness. The radial growth rates of the majority of bacteria appear to be linear, with most of the growth occurring near the colony periphery (18, 24, 28). A linear relationship between viable cell number per colony and colony radius has been also observed for Salmonella typhimurium growth (20). Thus, dimensional criteria have generally been used to study growth in bacterial colonies.

Agar, a complex mixture of polysaccharides (14) widely used in microbiology, was used to form the physical structure in this study. The molecular structure of agar gels has been described as arising both from double helix formation and from subsequent aggregation of the helices into bundles (10). A polydispersity of bundle thickness (3 to 20 nm) and pore size (30 to 600 nm) has been reported (6). With increasing polymer concentration, the helical chain segments are forced to aggregate to form more dense networks (27). It has been reported that commercially available agars contain low levels of oligomers, proteins, and electronegative groups which can influence the diffusion of charged molecules (29).

In this work we examined the responses of B. cereus to increasing quantities of agar, and the results are shown in Fig. 1. The measured biomass and size values are the mean values obtained with at least 12 colonies from three separate experiments. Decreases in both colony areas and numbers of cells per colony with the increase in agar concentration from 10 to 50 g liter−1 were observed. For example, in the presence of 10 g of agar liter−1 we found a colony area of 162 mm2 and a cell number of log10 8.85 CFU per colony, whereas in the presence of 50 g of agar liter−1 we found an area of 32 mm2 and a cell number of log10 8.15 CFU per colony. The colony counts seemed to decrease linearly up to 70 g of agar liter−1 while the areas seemed to level off at an agar concentration of 50 g liter−1.

FIG. 1.

Responses (colony surface area and log CFU per colony) of B. cereus to increasing agar concentrations. Symbols: ○, colony area; □, colony biomass. The vertical bars indicate standard deviations.

We examined the response of B. cereus to nutrient concentration gradients in gels at different agar concentrations, and the results are shown in Fig. 2. The measured surface areas are the mean values obtained with two colonies from each of three separate experiments. The colonies decreased in size as the distance from the nutrient reservoir increased, confirming the dependence of the organism on nutrient availability (16). Furthermore, the colony surface areas were affected by the agar concentration, decreasing with increases in the agar content. The surface areas converged 16 mm from the nutrient source. These results are consistent with the results of Mendelson and Salhi (21) and Matsushita (19), who found that nutrient levels govern the differences in Bacillus subtilis colony diameters as a function of agar concentration.

FIG. 2.

Plot of response (colony surface area) of B. cereus to nutrient gradients established in gels at different agar concentrations versus squared distance from the nutrient source. Symbols: ▪, 10 g of agar liter−1; ▴, 50 g of agar liter−1; •, 70 g of agar liter−1. The vertical bars indicate standard deviations.

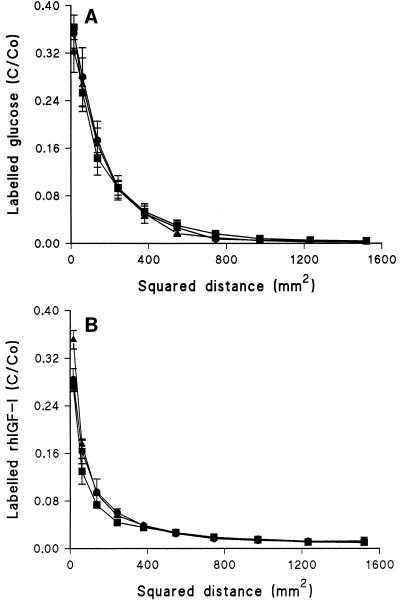

To test the possibility that microbial growth could be restricted by limited diffusion of nutrients, which was related to the agar content, we examined the diffusion of glucose and a small protein in agar media containing different agar concentrations. The protein used was chosen as a standard diffusant on the basis of its molecular weight (7,500), which is within the molecular weight range of the peptides in commercially available peptones. The measured concentration profiles for d-[6-3H]glucose and 125I-rhIGF-I (each datum point is the mean of duplicate values from three separate experiments) showed that the concentrations decreased as the distance from the source increased, irrespective of the agar content (Fig. 3). The best linear correlation (regression) coefficient (r2 = 0.98) for the glucose profile with the microbial responses (areas) was observed in the presence of 10 g of agar liter−1; the regression coefficients observed in the presence of 50 and 70 g of agar liter−1 were 0.89 and 0.67, respectively.

FIG. 3.

Concentration profiles of d-[6-3H] glucose (A) and 125I-rhIGF-I (B). Symbols: ▪, 10 g of agar liter−1; ▴, 50 g of agar liter−1; •, 70 g of agar liter−1. The vertical bars indicate standard deviations.

In general, the diffusion coefficient decreases as the molecular size of the diffusant increases. For high-molecular-weight macromolecules, a marked effect of agar concentration in the gel on effective diffusivities has been found (17). The diffusivity of most low-molecular-weight solutes is essentially the same in water and in gels, irrespective of the agar concentration (9).

In our study, although we used nonhomogeneous matrices in which there were possible interactions between the diffusing compound and the BHI medium components, we found good agreement between predicted and experimental values for glucose and protein gradients. The diffusion coefficient of glucose, obtained by matching the model profiles with the experimental data (each experimental datum point is the mean of the values obtained with the three agar systems) (Fig. 4A), was 6.5 × 10−6 cm2 s−1, which was in agreement with previously published data (17). The change in diffusion for 125I-rhIGF-I was small (Fig. 4B), and the diffusion coefficient was 6.2 × 10−6 cm2 s−1, suggesting that the protein molecule was not large enough to be affected by the gel structure.

FIG. 4.

(A) Measured diffusion profiles (mean values from the three gel systems) of d-[6-3H]glucose (A) and 125I-rhIGF-I (B) compared with calculated values. The solid lines are curves generated from the mathematical model; the datum points are experimental values.

Thus, in the agar concentration range tested, colony growth was affected by the reduction in the pore size and the increase in the strand thickness of the gel, but not by the reduced diffusion of nutrients. The possible hindrance of diffusion of nutrients to the cell surface by a microbial exopolymer and the diffusion of toxic compounds produced by the cells remain to be determined, even if these problems may be insignificant with the young colonies examined (24, 30). Thus, it is likely that other factors, such as mechanical hindrances, could influence the colony growth in these systems. We hypothesize that reduction in pore size might result in cell trapping, hindering the colony peripheral growth at the base of the colony in contact with the growth medium.

We also examined the responses of B. cereus to increases in the viscosity of the liquid phase of the agar media, and the results are reported in Fig. 5. The measured areas are the mean values obtained with at least 12 colonies from three separate experiments. In the presence of 10 g of agar liter−1 a significant reduction in colony areas, apparently related to the increase in the viscosity of the system, was observed. When the agar concentration was increased, the colony areas were not influenced by the viscosity of the system. The presence of PVP-30 in the BHI broth media did not affect the cell yield, and the final counts were similar to those obtained in unsupplemented BHI broth (approximately log10 8.18 CFU ml−1); however, PVP-30 decreased the growth rate (linear correlation) (data not shown).

FIG. 5.

Response of B. cereus to increasing viscosity of the liquid phase of the BHI agar media resulting from the addition of PVP. Symbols: ▪, 10 g of agar liter−1; ▴, 50 g of agar liter−1; •, 70 g of agar liter−1. The vertical bars indicate standard deviations.

Gould and Christian (13) indicated that high viscosity can greatly interfere with the growth of microorganisms in foods because transport processes between cells and the aqueous environment eventually slow down. However, Ballesteros et al. (1) did not find a correlation between the Staphylococcus aureus response to solute dissolution and viscosity, as well as other physical properties.

In our attempt to separate the individual effects of aw and kinetic constraints on microbial growth, we used PVP-30, a high-molecular-weight polymer, at a maximum concentration of 300 g liter−1, which strongly increased the viscosity and had negligible effects on the aw. The addition of PVP-30 to BHI broth did not result in any specific antibacterial effect. Thus, it is likely that the viscosity of the liquid phase can effectively retard microbial growth in BHI solutions and reduce colony size in the presence of agar. It has been reported that small-molecule migration is controlled by microscopic or local viscosity of the solution in the gel network (12). Therefore, the solution bulk viscosity alone may underestimate the whole hindering effect of the solution-network system.

Thus, our data confirm that there is an interaction between the growth of B. cereus and the structure of the media and emphasize the real need to further elucidate the underlying mechanisms and mode of action. Increased understanding could lead to improved methods of food preservation.

ACKNOWLEDGMENTS

We are grateful to A. Cesaro and T. Brocklehurst for useful discussions.

REFERENCES

- 1.Ballesteros S A, Chirife J, Bozzini J P. Specific solute effects on Staphylococcus aureus cells subjected to reduced water activity. Int J Food Microbiol. 1993;20:51–66. doi: 10.1016/0168-1605(93)90094-w. [DOI] [PubMed] [Google Scholar]

- 2.Bird R B, Steward W E, Lightfoot E N. Fenomeni di trasporto. Milan, Italy: Casa Editrice Ambrosiana; 1970. [Google Scholar]

- 3.Blissett S J, Bolton K J, Dodd C E R, Gould G W, Waites W M. Survival of Salmonella senftenberg and Salmonella typhimurium in glassy and rubbery states of gelatin. J Appl Bacteriol. 1994;76:345–349. doi: 10.1111/j.1365-2672.1994.tb01638.x. [DOI] [PubMed] [Google Scholar]

- 4.Boddy L, Wimpenny J W T. Ecological concepts in food microbiology. J Appl Bacteriol Symp Suppl. 1992;73:23S–38S. doi: 10.1111/j.1365-2672.1992.tb03622.x. [DOI] [PubMed] [Google Scholar]

- 5.Bolton K J, Dodd C E R, Gould G W, Waites W M. Survival of Staphylococcus aureus and enterotoxin A in glassy and rubbery states of gelatin. J Appl Bacteriol. 1996;81:191–194. doi: 10.1111/j.1365-2672.1996.tb04499.x. [DOI] [PubMed] [Google Scholar]

- 6.Brigham J E, Gidley M J, Hoffmann R A, Smith C G. Microscopic imaging of network strands in agar, carrageenan, locust bean gum and kappa carrageenan/locust bean gum gels. Food Hydrocolloids. 1994;8:331–344. [Google Scholar]

- 7.Chapuis C, Rosso L, Flandrois J P. Relationship between colonial surface and density on agar plate. J Appl Bacteriol. 1995;79:542–550. [Google Scholar]

- 8.Cooper A L, Dean A C R, Hinshelwood C. Factors affecting the growth of bacterial colonies on agar plates. Proc R Soc Lond B Biol Sci. 1968;171:175–199. doi: 10.1098/rspb.1968.0063. [DOI] [PubMed] [Google Scholar]

- 9.Diaz G, Wolf W, Kostaropoulos A E, Spiess W E L. Diffusion of low-molecular-weight compounds in food model systems. J Food Process Preserv. 1993;17:437–454. [Google Scholar]

- 10.Djabourov M, Clark A H, Rowlands D W, Ross-Murphy S B. Small-angle X-ray scattering characterization of agarose sols and gels. Macromolecules. 1989;22:180–188. [Google Scholar]

- 11.Dodd C. Detection of sites of microbial growth in food by cryosectioning and light microscopy. Food Sci Technol Today. 1990;4:180–182. [Google Scholar]

- 12.Giannakopoulos A, Guilbert S. Determination of sorbic acid diffusivity in model food gels. J Food Technol. 1986;21:339–353. [Google Scholar]

- 13.Gould G W, Christian J H B. Characterization of the state of water in foods—biological aspects. In: Seow C C, Teng T T, Quah C H, editors. Food preservation by moisture control. London, United Kingdom: Elsevier Applied Science; 1988. pp. 43–56. [Google Scholar]

- 14.Guiseley K B. Chemical and physical properties of algal polysaccharides used for cell immobilization. Enzyme Microb Technol. 1989;11:706–716. [Google Scholar]

- 15.Kamath R S, Bungay H R. Growth of yeast colonies on solid media. J Gen Microbiol. 1988;134:3061–3069. doi: 10.1099/00221287-134-11-3061. [DOI] [PubMed] [Google Scholar]

- 16.Koch A L. Diffusion, the crucial process in many aspects of the biology of bacteria. Adv Microb Ecol. 1991;11:37–70. [Google Scholar]

- 17.Lebrun L, Junter G A. Diffusion of sucrose and dextran through agar gel membranes. Enzyme Microb Technol. 1993;15:1057–1062. doi: 10.1016/0141-0229(93)90054-6. [DOI] [PubMed] [Google Scholar]

- 18.Lewis M W A, Wimpenny J W T. The influence of nutrition and temperature on the growth of colonies of Escherichia coli K12. Can J Microbiol. 1981;27:679–684. doi: 10.1139/m81-105. [DOI] [PubMed] [Google Scholar]

- 19.Matsushita M. Formation of colony patterns by a bacterial cell population. In: Shapiro J A, Dworkin M, editors. Bacteria as multicellular organisms. Oxford, United Kingdom: Oxford University Press; 1997. pp. 366–393. [Google Scholar]

- 20.McKay A L, Peters A C. The effect of sodium chloride concentration and pH on the growth of Salmonella typhimurium colonies on solid medium. J Appl Bacteriol. 1995;79:353–359. doi: 10.1111/j.1365-2672.1995.tb03148.x. [DOI] [PubMed] [Google Scholar]

- 21.Mendelson N H, Salhi B. Patterns of reported gene expression in the phase diagram of Bacillus subtilis colony forms. J Bacteriol. 1996;178:1980–1989. doi: 10.1128/jb.178.7.1980-1989.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Palumbo S A, Johnson M C, Rieck V T, Witter L D. Growth measurements on surface colonies of bacteria. J Gen Microbiol. 1971;66:137–143. doi: 10.1099/00221287-66-2-137. [DOI] [PubMed] [Google Scholar]

- 23.Pirt S J. A kinetic study of the mode of growth of surface colonies of bacteria and fungi. J Gen Microbiol. 1967;47:181–197. doi: 10.1099/00221287-47-2-181. [DOI] [PubMed] [Google Scholar]

- 24.Reyrolle J, Letellier F. Autoradiographic study of the localization and evolution of growth zones in bacterial colonies. J Gen Microbiol. 1979;111:399–406. doi: 10.1099/00221287-111-2-399. [DOI] [PubMed] [Google Scholar]

- 25.Robins M M, Wilson P D G. Food structure and microbial growth. Trends Food Sci Technol. 1994;5:289–293. [Google Scholar]

- 26.Salacinski P R, McLean C, Sykes J E, Clement-Jones V V, Lowry P J. Iodination of protein, glycoproteins and peptides, using a solid-phase oxidizing agent, 1,3,4,6-tetracloro-8α,6α diphenyl glycolaril (iodogen) Anal Biochem. 1981;117:136–146. doi: 10.1016/0003-2697(81)90703-x. [DOI] [PubMed] [Google Scholar]

- 27.Watase M, Nishinari K, Clark A H, Ross-Murphy S B. Differential scanning calorimetry, rheology, X-ray, and NMR of very concentrated agarose gels. Macromolecules. 1989;22:1196–1201. [Google Scholar]

- 28.Wimpenny J W T. The growth and form of bacterial colonies. J Gen Microbiol. 1979;114:483–486. doi: 10.1099/00221287-114-2-483. [DOI] [PubMed] [Google Scholar]

- 29.Wimpenny J W T, Leistner L, Thomas L V, Mitchell A J, Katsaras K, Peetz P. Submerged bacterial colonies within food and model systems: their growth, distribution and interactions. Int J Food Microbiol. 1995;28:299–315. doi: 10.1016/0168-1605(95)00065-8. [DOI] [PubMed] [Google Scholar]

- 30.Wimpenny J W T, Lewis M W A. The growth and respiration of bacterial colonies. J Gen Microbiol. 1977;103:9–18. doi: 10.1099/00221287-103-1-9. [DOI] [PubMed] [Google Scholar]

- 31.Zienkiewicz O C, Taylor R L, editors. The finite element method. 4th ed. Vol. 1. London, United Kingdom: McGraw-Hill; 1989. [Google Scholar]