Abstract

The effects of saltwater soaking (10–30 %, w/v) and thermal (60°C–90 °C) pre-treatment on the physicochemical and nutritional quality of sundried tilapia fish (Oreocromis niloticus) products were assessed. The wet reduction was 14.47 % in the sample treated with a 30 % salt solution at 90 °C, whereas the wet reduction of 21.23 % was observed in the sample without treatment (control). Protein, lipid, and ash content were increased significantly (P < 0.05) with higher pre-treatment salt concentration and temperature, while the moisture content showed the opposite trend. The content of essential and non-essential amino acids in the treated samples ranged from 7149.97 mg/100 g to 8063.42 mg/100 g and 10530.66 mg/100 g to 11365.59 mg/100 g, respectively, whereas the values were 7018.55 mg/100 g and 10400.84 mg/100 g, respectively in the control. The fatty acids composition, particularly ω-3 polyunsaturated fatty acids, was higher in pretreated samples (6.14–7.08 %) compared to the control. Mineral content was found to improve with saltwater and thermal pre-treatment, and the levels of heavy metals, including Ni and Cu, were significantly lower in the sundried tilapia fish. The sample pretreated with 10 % salt solution and 75 °C showed the highest rehydration capacity of 66.63 %. These findings suggest that saltwater and thermal pre-treatment can effectively enhance the physicochemical and nutritional properties of sundried tilapia fish products.

Keywords: Fish drying, Drying rate, amino acids, fatty acids, Minerals, Rehydration rate

Highlights

-

•

Saltwater and thermal pretreatment were applied to tilapia fish for sun drying.

-

•

Pretreatment significantly shortens drying time and enhances rehydration.

-

•

Pretreatment improved omega-3 fatty acids and enhanced amino acids.

-

•

Heavy metals were found significantly lower in the sundried tilapia fish.

-

•

It enhances the nutrition and processing efficiency of sundried fish products.

1. Introduction

Fish is one of the most important sources of animal proteins and other nutrients essential for maintaining a healthy body [1]. Fish is an essential source of livelihood, providing income and food for the rural poor people, who often suffer from nutritional deficiencies [2]. It is a good source of proteins, lipids, carbohydrates, vitamins, and minerals [3,4]. Tilapia (Oreochromis niloticus) fish are cultivated worldwide, and the FAO (Food and Agriculture Organization) estimates that global tilapia production will reach 7.3 million tons by 2030 [5]. Tilapia is recognized as a valuable source of high-quality protein and an essential provider of vitamin D, PUFAs, iodine, and selenium for human diet [6].

However, tilapia fish is a highly perishable commodity, prone to spoilage soon after death due to enzymatic and microbial actions. This can lead to disagreeable taste, smell, texture, and reduce consumer acceptability [7]. To address this issue, fish processing has been practised worldwide for a long time. Adopting efficient approaches to fish utilization through proper processing and preservation techniques is essential to prevent fish deterioration. It is possible to postpone or, in certain situations, avoid spoiling by employing various methods such as lowering the temperature (icing, chilling, freezing), removing water (sun drying, salting, curing, fermenting, etc.), or raising the temperature (incubating, heating, boiling, frying, retorting, etc.) [8]. Sun drying is a promising approach for minimizing fish spoilage and enhancing the shelf life by reducing moisture from fish flesh [9]. Consumers prefer dried fish products not only for their taste and flavor but also due to their considerable nutritional value [10]. However, sun drying is a time-consuming method, and prolonged exposure to sunlight can change the physical and chemical properties of fish [11]. Furthermore, this dependence also hinges on prevailing environmental conditions, specifically requiring sufficient solar radiation. Therefore, to mitigate these issues, a novel technique could involve applying a pre-treatment of saltwater soaking and thermal treatment before exposing the fish to sunlight, which can reduce the drying period. Saltwater and thermal treatment is an established method for reducing moisture content and water activity of fish flesh [12]. Thermal treatment also reduces the moisture content in fish flesh by increasing conductive heat transfer at high temperatures [13]. The existing fish processing practice utilizes convective hot air or sun-drying techniques to produce dried fish. However, these methods are associated with several concerns, such as being time-consuming, poor sanitary handling during processing, lack of sterilization, adding insecticides, resulting in low-quality products, and yielding finished products with unattractive appearances [11]. In this study, thermal treatment and a salt water bath were applied to raw tilapia fish before sun drying, which may slow down oxidation by inactivating enzymes and killing microbes. Furthermore, the salt treatment is expected to inhibit further microbial attacks from the atmosphere and prevent insect invasion. The proximate composition, including moisture, protein, lipid, and ash content, plays a significant role in the quality of dried fish and influences the shelf-life of the products [14]. Only a few attempts have been made to apply salt treatment to enhance fish drying efficiency [15,16], which investigated the effects of salt treatment on the properties of final dried products. There were no investigations on the drying patterns due to the salt treatment of the raw materials. Furthermore, as far as we know, there is no previous report available on the effects of thermal and saltwater soaking pre-treatment of raw tilapia fish on the final dried product quality and nutritional properties. Therefore, this study aimed to characterize the sundried tilapia fish, focusing on the physiochemical properties (wet reduction and rehydration capacity), proximate composition, and nutritional properties, including amino acid, fatty acid, mineral, and heavy metals contents in the sundried tilapia fish products.

2. Materials and methods

2.1. Chemicals and reagents

Potassium sulfate, copper sulfate, sulfuric acid, sodium hydroxide, boric acid, hexane, hydrogen chloride, green and methyl red were bought from Sigma Aldrich, USA. Edible sodium chloride salt was purchased from ACI salt Ltd., Dhaka, Bangladesh. All the additional reagents and chemicals used in this study were of the analytical or HPLC quality.

2.2. Sample preparation and experimental design

Fresh tilapia (O. niloticus) weighing approximately 50.28 ± 2.14 g were purchased from a local fish market in Jashore, Bangladesh. The fish were cleaned, gutted, scaled, and their fins were removed. After rinsing with tap water and draining excess water, the dressed fish underwent different thermal (60 °C, 75 °C, and 90 °C) and saltwater (10 %, 20 %, and 30 %, w/v; prepared by dissolving sodium chloride with distilled water) soaking treatments for 5 min. The treated samples were labeled as T1, T2, T3, T4, T5, and T6 (Table 1). Subsequently, the fish samples were placed on the bamboo mats and dried under sunlight and wind for ten (10) consecutive days (8:00 a.m. to 5:00 p.m.). Once properly dried, the samples were stored in airtight polyethene bags at 4 °C for further analysis.

Table 1.

Design of the experiment of the work.

| Sample | Experimental code | Saltwater (%) | Temperature (°C) | Duration (Min) |

|---|---|---|---|---|

| Without treatment | T1 (Control) | – | – | – |

| 10 % salt solution; 60°C | T2 | 10 | 60 | 5 |

| 20 % salt solution; 60°C | T3 | 20 | 60 | 5 |

| 10 % salt solution; 75°C | T4 | 10 | 75 | 5 |

| 20 % salt solution; 75°C | T5 | 20 | 75 | 5 |

| 30 % salt solution; 90°C | T6 | 30 | 90 | 5 |

2.3. Determination of the rate of wet reduction

The initial weights of the fish were measured using a tabletop weighing balance (Model: 80356, RFL, Dhaka-1212, Bangladesh). During the drying process, the weight of the fish was measured at every 2 h. The rate of wet reduction was calculated using the following formula:

2.4. The proximate composition of sundried tilapia fish products

The proximate composition, such as moisture, protein, lipid, and ash content of sundried tilapia fish was determined following the Analytical Methods Committee [17] with some modifications. For ash content determination, a muffle furnace (Model: L5/11, Nabertherm GmbH, Lilienthal, Germany) was used. The lipid content was determined by using a Soxhlet apparatus (64825 Supelco, Sigma Aldrich, St. Louis, MO, USA), with n-hexane was used as an extracting agent.

2.5. Determination of amino acid composition of sundried tilapia fish products

The amino acid content of the sundried tilapia fish products was determined following the method of Salman et al. [18] with some modifications. A high-speed amino acid analyzer (LA 8080, Hitachi, Tokyo, Japan) equipped with a Hitachi high-performance cation-exchange column at a column temperature of 57 °C was used. The pretreated sample was mixed with 25 mL of 6 M HCl in a glass tube. The tube was then heated at 110 °C for 24 h using a heated sand bath. Afterward, the solid was obtained by evaporating HCl and diluted with 6 mL of distilled water, then filtered using a 0.45 μm syringe filter.

2.6. Determination of the fatty acid composition of sundried tilapia fish products

The fatty acid composition of sundried tilapia fish oil was analyzed by using a gas chromatograph (Model: 6890, Agilent Technologies, Wilmington, USA) equipped with a flame ionization detector (FID) and fused silica capillary column (100 m length, 0.25 mm internal diameter, and 0.2 μm film) (Supelco, Bellefonte, USA). Fatty acid methyl esters were prepared following the method of the American Oil Chemists Society [19]. The oven temperature of the gas chromatograph was programmed to reach 130 °C in 3 min, then increased at a rate of 4 °C/min up to 240 °C, and then soaked for 10 min. The injector and detector temperature were maintained at 250 °C. Standards of fatty acid methyl esters (SupelcoR 37 Component FAME Mix, Bellefonte, PA., USA) were used to identify the fatty acid methyl esters, and quantification was done by obtaining peak area (%).

2.7. Determination of mineral and heavy metal content of sundried tilapia fish products

The mineral and heavy metal content of the sundried tilapia fish product was determined using an ICP-OES optimum 2000 DV (PerkinElmer) equipped with winLab32 software, following the method of Kumaravel and Alagusundaram [20] with some modifications. Briefly, 1 g of sundried sample was taken and transferred into a muffle furnace at 600 °C for 6 h to obtain the ash. After ashing, 4 mL of concentrated HNO3 and 1 mL H2O2 (70 %) were added to the ashed powder. Distilled water was then added to make the total solution 60 mL. The solution was heated on a hot plate and reduced to a half (30 mL), then adding 4 mL of distilled water and 1 mL of H2O2 (70 %). The solution (35 mL) was heated again to reduce to a half (17.5 mL). Subsequently, distilled water was added to make a 20 mL solution, which was filtered using a 125 mm filter paper. The filtering was performed twice, and the resulting sample solution was used for minerals and heavy metal analysis.

2.8. Determination of rehydration ratio of sundried tilapia fish products

The rehydration ratio was determined following the method of Aniesrani et al. [21] with some modifications. Briefly, 5 g of the dried sample was placed into 200 mL of distilled water at 40 °C and left to rehydrate for 40 min. After rehydration, the sample was removed from the water and weighed.

Where m = The weight of the sample after rehydration, mt = The weight of the sample before rehydration.

2.9. Statistical analyses

Values are presented as means ± standard deviations of triple determinations. The data were analyzed using one-way analysis of variance (ANOVA) along with Duncan's Multiple Range Tests in SPSS 20.0 (SPSS Inc., Chicago, IL). A significance level of P < 0.05 was considered statistically significant.

3. Results and discussion

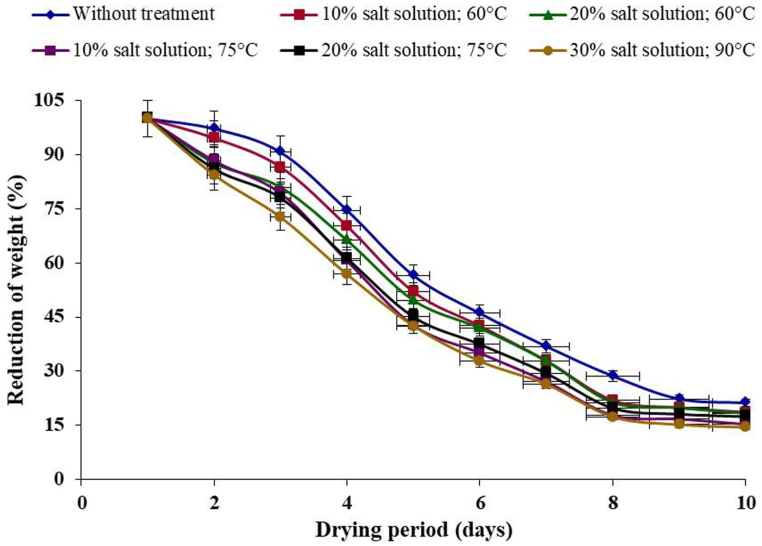

3.1. Effects of salt concentration and thermal treatment on wet reduction

The drying rate, specifically the wet reduction of various foods during the drying process, is a crucial parameter for determining the quality of dried products. The faster drying rate ensures premium quality dried products by allowing less time for the quality deterioration of fish through autolysis, oxidation, or microbial decomposition. Fig. 1 illustrates the weight reduction pattern of different saltwater and thermal-treated dried tilapia fish products. The results show that the fish weight reduction was increased with the drying period. Furthermore, there was a significant relationship between saltwater and thermal pre-treatment and the reduction of fish weight during the drying process.

Fig. 1.

Weigh reduction pattern of different salt and thermal treated tilapia fish products.

Interestingly, the reduction in fish weight was higher in the sample treated with high salt concentration and temperature (Fig. 1). The removal of fish weight gradually increased with the increase in thermal treatment and salt concentration. Among the samples, the maximum moisture reduction was observed in the sample treated with a 30 % salt solution at 90 °C, with a final moisture content of 14.47 ± 0.43 %. The minimum moisture reduction was found in the sample without pre-treatment, which contained a moisture content of 21.23 ± 1.03 % after 10 days of drying. These results can be attributed to osmotic dehydration caused by different salt concentrations, which reduced the water activity in the fish and resulted in faster moisture removal compared to the sample without pre-treatment. The thermal treatment expedited quick fish drying rates by facilitating water migration inside the fish and increasing the evaporation rate at high temperatures [22]. The salt concentration contributed to reduce the drying rate curves by forming a curst on the surface of the fish. These findings are consistent with the previous study by Kituu et al. [23]. However, the moisture reduction rate was faster during the initial drying stages, but it slowed down after the 8th day of the drying process. As time progresses, the drying rate decreases as the moisture content of the sample diminishes [24]. The reduction in heat penetration within the dried product could potentially slow down the drying rates. Furthermore, during the late drying stages, the decrease in drying rate might be attributed to the reduction of the porosity of sample caused by shrinkage, which leads to increased resistance to moisture movement [25]. In general, the drying process of food materials is influenced by various factors, such as drying temperature, relative humidity of the air, air velocity, material thickness, and other related parameters [26]. The present study indicates that fish pre-treated with saltwater and thermal treatment can significantly reduce the drying period.

3.2. Proximate composition of different sundried tilapia fish products

3.2.1. Moisture content of different sundried tilapia fish products

The moisture content (%) of sun dried tilapia fish varied depending on the salt concentration and thermal treatment of the fish, as shown in Fig. 2. There was a significant difference (P < 0.05) in moisture content values between the pre-treated samples and the control. The moisture content notably decreased with an increase in the salt concentration and temperature of pre-treatment of the fish (Fig. 2). The lowest moisture content of 7.86 ± 0.38 % was found in the sample treated with a 30 % salt water solution at 90 °C among various treatments involving different salt concentrations and temperatures. This phenomenon may be attributed to the salt penetrating the fish body through osmotic migration, thereby removing water from the body of fish. Additionally, the evaporation of water likely increased on both the surfaces and inner muscles of the fish during thermal treatment, resulting in faster moisture reduction [27]. Furthermore, the salting procedure was believed to reduce the amount of unbound moisture in the fish before drying. It can be inferred that there is a reverse relationship between salt concentration and thermal treatment with moisture content [28]. Thus, saltwater and thermal pre-treatments are considered beneficial in improving the drying rate of tilapia fish.

Fig. 2.

Proximate composition of different sundried tilapia fish products (wet weight basis).

3.2.2. Protein content of different sundried tilapia fish products

Dried fish products serve as a valuable protein source that offers several health benefits. However, it is essential to consider the processing methods and possible additives in commercially available dried fish products, as these factors can influence its overall nutritional profile. Fig. 2 displays the outcomes of the protein content. Among the sundried tilapia fish products, the protein content was found to increase with increased salt concentration and pre-treatment temperature of the fish. The highest amount of protein was found in the sample treated with a 30 % salt solution at 90 °C, and the lowest content of protein was observed in the sample without treatment. Protein nitrogen remained consistent during drying, but the protein of processed fish was found to increase as moisture decreased [29]. Another reason for the increase in protein content might be that, at high temperatures (75 °C and 90 °C), water was rapidly reduced from the fish flesh, leading to enhanced protein content [30]. A previous report revealed that the protein content of Indian mackerel with salt was significantly higher than the raw one [31]. The findings of this investigation demonstrated that the salt concentration and thermal treatment significantly influenced the protein content in the sundried tilapia fish products.

3.2.3. Lipid content of different sundried tilapia fish products

Lipids play a crucial role in the drying process of fish and can significantly influence the quality of the dried product. Therefore, it is essential to consider the lipid content of the fish being dried and implement appropriate drying techniques. As evident from Fig. 2, the lipid content of samples treated at T2, T3, T4, T5, and T6 of salt water soaking and thermal pre-treatment for 5 min were (16.87 ± 1.03 %, 17.40 ± 1.32 %, 17.54 ± 1.41 %, 17.66 ± 1.15 %, and 18.21 ± 1.62 %, respectively), whereas sample without treatment contained 16.02 ± 1.20 % lipid. The lipid content was found to vary significantly (P < 0.05) depending on the thermal and salt water treatments (Fig. 2). The lowest lipid content was found to be 16.02 ± 1.02 % in the sample without treatment (T1), and the highest lipid content was found to be 18.21 ± 1.62 % in the sample treated with a 30 % salt solution at 90 °C. As the thermal and saltwater content in pre-treatment were increased, the higher amount of water was reduced from the samples increasing lipid content [32]. The higher lipid content at T6 might also be due to the fastest evaporation rate in the sample pre-treated at high temperature and salt solution which decreased lipid oxidation. Lipid oxidation is a concern during the processing of fish products, and factors like drying methods, pre-treatment and storage influence the lipid stability of dried fish products. These results are consistent with the previous report on capelin fish drying [33].

3.2.4. Ash content of different sundried tilapia fish products

The ash content of the control sample (T1) of dried fish was 13.20 %, whereas the highest ash content was 15.44 % at T6. As seen in Fig. 2, the ash content gradually increased with increased the pre-treatment temperature and salt concentration. This could result from the high concentration of salts in the flesh due to dehydration caused by high temperature [32,34]. These results indicated that a higher amount of ash was present in all pre-treated samples with salt and thermal treatment except the control. Jo et al. [35] reported a significant increase in ash content during salt treatment on salted semi-dried mullets.

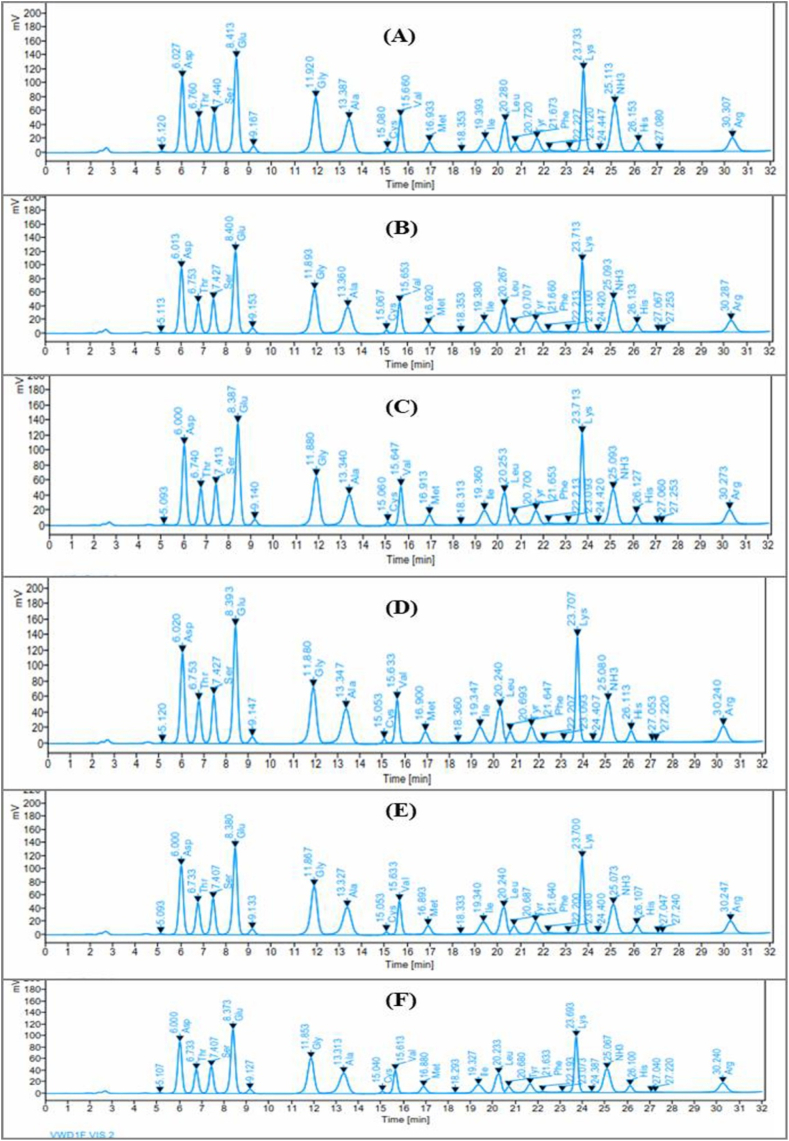

3.3. Amino acid composition of sundried tilapia fish products

Table 2, Table 3 present the effects of different salt concentrations and temperature pre-treatments on the amino acid profile of sundried tilapia fish products. This study detected seventeen amino acids in the sundried tilapia fish products (Fig. 3). Among these, nine essential amino acids were found such as valine, leucine, isoleucine, threonine, methionine, phenylalanine, arginine, histidine, and lysine (Table 2). Lysine was the most dominant essential amino acid among the treatments and the content was 2299.50 mg/100 g in the sample pre-treated with a 10 % saltwater solution at 75 °C. It plays a crucial role in calcium absorption in the human body, contributing to the development of bones and connective tissues [36]. The maximum content of essential amino acids was 8063.42 mg/100 g in the sample treated with a 20 % salt solution at 75 °C. In contrast, the lowest essential amino acid content was 7018.55 mg/100 g in the control (T1) sample. Interestingly, the amount of essential amino acids was increased with increasing the pre-treatment salt concentration and temperature (Table 2). However, the amount of essential amino acids was found to drop suddenly in sample pre-treated with a 30 % salt solution at 90 °C (T6). The possible reason for this could be the Maillard reaction at a temperature of 90 °C, which reduced the essential amino acid contents in the dried fish [37]. The salt concentrations might also be responsible for the breakdown of essential amino acids.

Table 2.

Essential amino acids contents (mg/100g wet weight basis) of different sundried tilapia fish products.

| Essential amino acids | Without treatment | 10 % salt solution; 60 °C | 20 % salt solution; 60 °C | 10 % salt solution; 75 °C | 20 % salt solution; 75 °C | 30 % salt solution; 90 °C |

|---|---|---|---|---|---|---|

| Threonine | 856.80 ± 5.64d | 978.26 ± 6.45a | 957.99 ± 6.29b | 958.55 ± 8.43b | 941.93 ± 4.43c | 825.31 ± 5.53e |

| Valine | 841.82 ± 2.55b | 842.95 ± 3.64b | 844.06 ± 6.45b | 885.69 ± 3.64a | 887.30 ± 4.65a | 739.99 ± 3.27c |

| Methionine | 359.67 ± 2.43d | 380.70 ± 3.17c | 383.06 ± 4.76c | 408.38 ± 5.65b | 455.17 ± 2.46a | 396.00 ± 5.36b |

| Isoleucine | 512.99 ± 4.54d | 518.98 ± 4.43cd | 526.40 ± 3.53c | 576.18 ± 5.56b | 605.44 ± 2.43a | 609.55 ± 3.45a |

| Phenylalanine | 679.63 ± 3.32e | 683.10 ± 2.54e | 753.23 ± 4.35c | 820.05 ± 2.81b | 842.50 ± 3.31a | 726.18 ± 5.48d |

| Lysine | 1716.99 ± 8.54d | 1797.26 ± 6.75c | 1861.52 ± 9.54b | 1899.50 ± 9.56a | 1880.49 ± 4.56a | 1676.08 ± 7.65e |

| Histidine | 357.58 ± 4.43d | 367.35 ± 3.64c | 404.55 ± 5.35b | 436.33 ± 3.26a | 400.68 ± 6.54b | 358.05 ± 4.35d |

| Leucine | 900.40 ± 5.53d | 975.95 ± 3.26c | 1007.61 ± 5.46b | 1018.96 ± 5.28b | 1075.51 ± 3.53a | 986.22 ± 4.38c |

| Arginine | 792.67 ± 5.37d | 831.31 ± 5.28c | 855.26 ± 3.85b | 855.31 ± 4.48b | 974.40 ± 6.36a | 832.59 ± 2.82c |

| Total | 7018.55 | 7375.86 | 7593.68 | 7858.95 | 8063.42 | 7149.97 |

Values are presented as means ± standard deviation of triplicates. Different superscript small letters on each row indicate significant differences (p ≤ 0.05).

Table 3.

Non-essential amino acids contents (mg/100g wet weight basis) of different sun dried tilapia fish products.

| Non-essential amino acids | Without treatment | 10 % salt solution; 60 °C | 20 % salt solution; 60 °C | 10 % salt solution; 75 °C | 20 % salt solution; 75 °C | 30 % salt solution; 90 °C |

|---|---|---|---|---|---|---|

| Asp | 1837.08 ± 8.43b | 1908.13 ± 5.67a | 1921.11 ± 9.37a | 1959.37 ± 3.65a | 1989.83 ± 7.67a | 1796.32 ± 8.45c |

| Ser | 718.48 ± 4.36e | 734.48 ± 2.53d | 796.95 ± 4.39c | 814.03 ± 5.46a | 801.68 ± 4.42b | 787.75 ± 2.54c |

| Glu | 2769.66 ± 9.54d | 2801.01 ± 10.42c | 2853.60 ± 12.53b | 2874.07 ± 10.53b | 2962.35 ± 9.46a | 2784.93 ± 7.85 |

| Gly | 1120.13 ± 6.43c | 1156.88 ± 6.47b | 1162.13 ± 3.64b | 1192.25 ± 5.36a | 1109.88 ± 7.53c | 1090.50 ± 6.57d |

| Ala | 1038.56 ± 8.56d | 1089.36 ± 7.54c | 1148.99 ± 7.43b | 1253.57 ± 6.54a | 1279.70 ± 10.58a | 1034.58 ± 8.54d |

| Cys | 93.78 ± 2.24a | 75.63 ± 3.32b | 75.02 ± 1.65b | 80.47 ± 3.54b | 76.55 ± 2.56b | 68.08 ± 2.58c |

| Tyr | 446.17 ± 6.43c | 465.40 ± 4.35b | 471.64 ± 5.65b | 505.90 ± 3.65a | 449.79 ± 2.76c | 374.67 ± 2.86d |

| Pro | 2376.98 ± 9.86d | 2404.85 ± 10.54c | 2515.20 ± 12.76b | 2685.93 ± 9.98a | 2568.20 ± 12.54b | 2593.83 ± 10.48b |

| Total | 10400.84 | 10635.74 | 10944.64 | 11365.59 | 11237.98 | 10530.66 |

Values are presented as means ± standard deviation of triplicates. Different superscript small letters on each row indicate significant differences (p ≤ 0.05).

Fig. 3.

Amino acids chromatogram of different sundried tilapia fish products. A: Without treatment; B: 10 % salt solution, 60 °C; C: 20 % salt solution, 60 °C; D: 10 % salt solution, 75 °C; E: 20 % salt solution, 75 °C; F: 30 % salt solution, 90 °C.

On the other hand, eight non-essential amino acids, including aspartic acid, serine, glutamic acid, glycine, alanine, cysteine, tyrosine, and proline were found in sundried tilapia fish products (Table 3). Among all the treatments, glutamic acid was found to predominate among the non-essential amino acids. Noticeably, the amount of non-essential amino acids was higher in all treatments involving saltwater and thermal pre-treatments, except sample pre-treated with a 30 % salt solution at 90 °C (T6), compared to the control sample (Table 3). The non-essential amino acids content were lower at T6 due to heat-sensitive proteins, and protein molecules are degraded at high temperatures [38] and high salt treatments. These results indicate that the optimum temperature (75 °C) and salt concentration significantly affect the amino acid composition in sun dried tilapia fish. These findings align with other studies on the essential amino acid composition of tilapia fish [39,40].

3.4. Fatty acid composition of different sundried tilapia fish products

Fatty acids undergo significant changes during the fish drying process, impacting the quality and characteristics of the dried fish. To ensure optimal quality, it is crucial to consider the fatty acid profile of fish and employ appropriate drying techniques that minimize oxidative damage. Fatty acids composition (area %) of different sundried tilapia fish products is shown in Table 4. Seventeen fatty acids were identified in the sundried tilapia fish products. The fatty acid composition varied depending on the saltwater and thermal pre-treatments applied. Palmitic acid (C16:0) was the most abundant fatty acid, followed by palmitoleic acid (C16:1), myristic acid (C14:0), and stearic acid in this study. The saturated fatty acid contents in different sundried tilapia fish products ranged between 70.86 % and 78.02 %, depending on the saltwater and thermal treatment.

Table 4.

Fatty acids composition (area % of total fatty acids) of different sundried tilapia fish products.

| Fatty acids | Without treatment | 10 % salt solution; 60 °C | 20 % salt solution; 60 °C | 10 % salt solution; 75 °C | 20 % salt solution; 75 °C | 30 % salt solution; 90 °C |

|---|---|---|---|---|---|---|

| Lauric Acid (C12:0) | 2.72 ± 0.32a | 1.98 ± 0.08b | 1.42 ± 0.11c | 1.38 ± 0.45c | 1.32 ± 0.15c | 1.21 ± 0.12c |

| Tridecanoic Acid (C13:0) | 0.47 ± 0.02a | 0.33b ± 0.05b | 0.05 ± 0.01c | 0.06 ± 0.11c | 0.05 ± 0.41c | 0.08 ± 0.01c |

| Mystric Acid (C14:0) | 10.32 ± 1.04a | 10.17 ± 0.80a | 10.19 ± 1.32a | 10.07 ± 1.78a | 10.42 ± 1.58a | 10.32 ± 1.14a |

| Myristoleic Acid (C14:1) | 0.15 ± 0.01a | 0.13 ± 0.04a | 0.14 ± 0.01a | 0.13 ± 0.03a | 0.16 ± 0.07a | 0.17 ± 0.01a |

| Pentadaecanoic Acid (C15:0) | 0.85 ± 0.13a | 0.92 ± 0.81a | 0.95 ± 0.11a | 0.94 ± 1.02a | 0.98 ± 0.14a | 1.01 ± 0.09a |

| Palmitic Acid (C16:0) | 50.53 ± 1.45a | 48.12 ± 1.42a | 47.70 ± 2.45ab | 47.92 ± 1.04ab | 45.98 ± 1.41b | 45.00 ± 3.53b |

| Palmitoleic Acid (C16:1) | 11.41 ± 1.34b | 15.78 ± 1.46a | 16.47 ± 1.53a | 16.78 ± 1.25a | 17.15 ± 1.45a | 17.35 ± 1.58a |

| Heptadecanoic Acid (C17:0) | 0.13 ± 0.01a | nd | nd | nd | nd | nd |

| cis −10-Heptadecanoic Acid (C17:1) | 0.53 ± 0.10a | 0.63 ± 0.08a | 0.64 ± 0.09a | 0.63 ± 0.08a | 0.65 ± 0.28a | 0.65 ± 0.11a |

| Stearic Acid (C18:0) | 10.02 ± 1.34a | 8.96 ± 1.04ab | 9.18 ± 1.25a | 8.97 ± 1.08ab | 9.68 ± 1.13a | 10.61 ± 1.42a |

| Linolelaidic Acid (C18:2n6t) | 0.19 ± 0.05a | 0.18 ± 0.01a | 0.19 ± 0.02a | 0.19 ± 0.01a | 0.21 ± 0.08a | 0.22 ± 0.01a |

| r-Linoleic Acid (C18:3n6) | 1.77 ± 0.11c | 1.86 ± 0.11bc | 1.85 ± 0.14bc | 1.89 ± 0.45bc | 1.96 ± 0.14b | 2.28 ± 0.10a |

| Eicosadienoic Acid (C20:2) | 0.07 ± 0.01a | nd | nd | nd | nd | nd |

| Eicosatrienoic Acid (C20:3n3) | 2.27 ± 0.13b | 2.55 ± 0.28a | 2.61 ± 0.24a | 2.61 ± 0.29a | 2.56 ± 0.56a | 2.70 ± 0.41a |

| Arachidonic Acid (C20:4n6) | 2.21 ± 0.12a | 1.99 ± 0.27a | 2.09 ± 0.10a | 1.98 ± 0.16a | 1.67 ± 0.06a | 1.39 ± 0.07b |

| Tricosanoic Acid (C23:0) | 2.98 ± 0.23a | 2.81 ± 0.28a | 2.84 ± 0.21a | 2.84 ± 0.28a | 2.98 ± 1.21a | 2.63 ± 0.16a |

| Docosahexanoic Acid (C22:6n3) | 3.38 ± 0.10ab | 3.59 ± 0.08ab | 3.68 ± 0.08ab | 3.71 ± 0.14ab | 4.23 ± 0.34a | 4.38 ± 0.09a |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| ∑SFAs | 78.02 | 73.29 | 72.33 | 72.18 | 71.41 | 70.86 |

| ∑USFAs | 21.98 | 26.71 | 27.67 | 27.82 | 28.59 | 29.14 |

| ∑ω-3 FAs | 5.65 | 6.14 | 6.20 | 6.32 | 6.79 | 7.08 |

Values are presented as means ± standard deviation of triplicates. Different superscript small letters on each row indicate significant differences (p ≤ 0.05).

nd: Not detected.

∑SFAs: Total saturated fatty acids.

∑USFAs: Total unsaturated fatty acids.

∑ω-3 FAs: Total omega-3 fatty acids.

Notably, the control sample exhibited the highest content of saturated fatty acids (78.02 %) in this study. The saturated fatty acids content in the sample treated at T3 and T6 was 71.16 % and 70.86 %, respectively. The saturated fatty acids content of different sundried tilapia fish products was found to decrease with increasing salt concentration and thermal pre-treatment. In the present study, the saturated fatty acid contents was dominated compared to polyunsaturated fatty acids. The amounts of polyunsaturated fatty acids in the control sample, T3, and T6 were found to be 21.98 %, 28.84 %, and 29.14 %, respectively. Interestingly, the content of unsaturated fatty acids increased with increasing salt concentration and temperature at pre-treatment. The present studies found that the composition of polyunsaturated fatty acids was higher with increased salt concebtration and thermal treatment. The sundried tilapia fish products contained ω-3 polyunsaturated fatty acids ranging from 5.56 to 7.08 %, depending on saltwater and thermal treatment (Table 4). The highest amount of ω-3 polyunsaturated fatty acids, 7.08 %, was obtained at T6. These findings are consistent with previous reports fatty acid composition in Nile and red tilapia [41]. However, no previous reports were found regarding the fatty acid composition related to saltwater and thermal treatment of sundried tilapia fish products.

3.5. Mineral composition of different sundried tilapia fish products

Minerals are essential for the growth and development of organisms, as they perform crucial physiological and metabolic activities in living bodies. In sundried tilapia fish products, three significant minerals, namely sodium (Na), calcium (Ca), and potassium (K), and two microelements such as iron (Fe) and zinc (Zn) were found at different saltwater and thermal treatments (Table 5). Among all the minerals, Ca was the predominant mineral in the sundried tilapia fish products. The highest concentration of Ca was found to be 961.60 ± 3.49 mg/100 g of dried fish pre-treated with a 20 % salt solution at 75 °C (T5), while the lowest concentration of Ca was obtained 956.10 ± 6.32 mg/100 g of sundried tilapia fish pre-treated with a 20 % salt solution at 75 °C (T2). In contrast, the Ca concentration was 959.65 ± 10.23 mg/100 g in the sample without treatment (T1). Following Ca, the second most dominant mineral was K, and the highest concentration was 82.90 ± 2.17 mg/100 g in sample pre-treated with a 30 % salt solution at 90 °C (T6), while the lowest K concentration was found to be 80.20 ± 2.30 mg/100 g of dried fish at control (T1).

Table 5.

Minerals contents (mg/100g wet weight basis) of different sundried tilapia fish products.

| Minerals | Na | Ca | K | Fe | Zn |

|---|---|---|---|---|---|

| Without treatment | 51.85 ± 1.56b | 959.65 ± 10.23a | 80.20 ± 2.30a | 13.30 ± 1.32a | 12.5 ± 1.32a |

| 10 % salt solution; 60 °C | 52.60 ± 1.39ab | 959.75 ± 9.34a | 81.25 ± 2.55a | 13.35 ± 0.56a | 12.30 ± 1.38a |

| 20 % salt solution; 60 °C | 53.90 ± 2.43ab | 957.60 ± 8.91a | 82.25 ± 1.38a | 12.95 ± 0.81a | 12.30 ± 1.11a |

| 10 % salt solution; 75 °C | 55.00 ± 1.83a | 959.05 ± 10.32a | 82.30 ± 2.12a | 12.55 ± 0.89a | 12.8 ± 1.21a |

| 20 % salt solution; 75 °C | 56.65 ± 2.31a | 956.10 ± 6.32a | 82.65 ± 1.94a | 13.50 ± 1.17a | 12.65 ± 1.60a |

| 30 % salt solution; 90 °C | 58.10 ± 1.72a | 961.60 ± 3.49a | 82.90 ± 2.17a | 13.00 ± 1.09a | 12.65 ± 1.20a |

Values are presented as means ± standard deviation of triplicates. Different superscript small letters on each column indicate significant differences (p ≤ 0.05).

Another major mineral, Na exhibited the highest concentration of 58.10 ± 1.72 mg/100 g in T6, followed by 56.65 ± 2.31 mg/100 g, 55.00 ± 1.83 mg/100 g, 53.90 ± 2.43 mg/100 g, 52.60 ± 1.39 mg/100 g and 51.85 ± 1.56 mg/100 g in T5, T4, T3, T2 and T1, respectively. A possible reason for this phenomenon is that tilapia fish may accumulate Na in their tissues when soaked in salt water [42]. A clear significant difference was noticed between the treatments and the control. Regarding Fe content, the highest value of 13.50 mg/100 g was found in T5, followed by 13.35 mg/100 g, 13.30 mg/100 g, 13.00 mg/100 g, 12.95 mg/100 g, 12.55 mg/100 g in T2, T1, T6, T3 and T4, respectively. The highest value of Zn in sundried tilapia fish was found 12.80 ± 1.21 mg/100 g in T4, while the control had a content of 12.50 ± 1.32 mg/100 g. There was no significant difference observed for Fe and Zn among the different sundried tilapia fish products, although some fluctuations were noticed among the treatments for Ca, Fe, and Zn. Overall, mineral contents were higher in samples pre-treated with different salt concentrations and thermal treatments compared to the control, except Fe and Zn. The higher mineral contents in sundried tilapia fish might be attributed to the higher concentration in pre-treated saltwater. These results indicate that salt and thermal treatments influence the minerals composition in sundried tilapia fish products, possibly due to deposition of minerals from salt water. The present study agrees with previous reports that stated that saltwater and thermal treatments have little or no impact on the nutritional composition of dried fish [42].

3.6. Heavy metals content of different sundried tilapia fish products

Heavy metals are usually present in the fish body, which directly affects human health when these fish are consumed. There are standard acceptable ranges for each heavy metal contained in fish. In the present study, three heavy metals, including lead (Pb), copper (Cu), and nickel (Ni), were found with acceptable ranges of ≤0.5, ≤0.15–1.0, and ≤2 ppm, according to FAO and USEPA [43]. In the present study, the Pb concentration in different sundried tilapia fish products with varying salt concentrations and thermal pre-treatments ranged from 0.19 to 0.36 mg/100 g of dried tilapia fish, as shown in Fig. 4. The study revealed that the highest Pb concentration was 0.36 mg/100 g in sample pre-treated with a 30 % salt solution at 90 °C (T6) of sun dried tilapia fish, whereas the lowest Pb concentration was 0.17 at 60 °C in sample pre-treated with a with a 20 % salt solution at concentration (T3). However, the Pb concentration was 0.19 mg/100 g of dried tilapia fish in the control group. The Pb concentration increased with increasing thermal temperature and salt concentration. These results might indicate that higher applied salt concentration can cause a migration of some inorganic impurities presented in applied salt solution to fish meat. Another heavy metal, Cu, was significantly higher in the control group, whereas the lower concentration of Cu was found in a sample pre-treated with a 20 % salt solution at 60 °C (T3). The average Cu concentration varied from 0.36 to 0.62 mg/100 g among the sundried tilapia fish products. The Cu concentration was found to decrease with increasing the salt concentration and temperature increment up to T3; however, after that, it was found to increase with the increasing salt concentration and pre-treatment temperature (Fig. 4). Cu is considered as an essential element required for adequate growth, lung elasticity, cardiovascular integrity, neuroendocrine function, and iron metabolism. The Ni concentration among all the treatments was found to vary from 0.09 to 0.12 mg/100 g of sundried tilapia fish products. The lowest concentration of Ni was found to be 0.06 in a sample pre-treated with a 20 % salt soluttion at 60 °C (T3), whereas the highest amount of Nickel (Ni) was obtained in the T1 and T2. The overall study revealed that salt concentration and thermal treatment significantly affect the concentrations of heavy metals in sundried tilapia fish products treated with different salt solutions and thermal pre-treatment. The results of the present study are consistent with a previous report that indicated the combined effect of salt and sun-drying on tilapia fish resulted in higher concentrations of heavy metals concentration compared to the control group [44]. Another study also supported the findings of the present study, stating that different salted and dried fish species contained high amounts of heavy metals [45].

Fig. 4.

Heavy metals contents (mg/100 g) of different sundried tilapia fish products (wet weight basis). Different small letters on each group of heavy metal indicates significant (P ≤ 0.05) differences.

3.7. Rehydration ability of sundried tilapia fish products

Rehydration curve is often drawn for a dried sample that has been submerged in water for various periods of time. The rehydration capacity of the dried product is a crucial characteristic to consider. It provides valuable information about the ability of product in regaining its original form upon water absorption [46]. By evaluating the rehydration rate, one can determine the suitability of the drying method and conditions. The influences of different temperatures (60 °C, 75 °C, and 90 °C) and different salt concentrations (10 %, 20 %, and 30 %) treatments of sundried tilapia fish products on their rehydration ability are shown in Fig. 5. The maximum rehydration rate of the sundried tilapia fish products was found in the sample pre-treated with a 10 % salt solution at 75 °C (T4), whereas the minimum rehydration rate was observed in the sample treated with 10 % saltwater at 60 °C (T2). In the case of T5 and T6, the rehydration rate was also higher compared to the control group. The possible reason for this might be that sample treated at higher temperatures, required shorter drying time, and the inner structure of the fish body has been reached more effectively, leading to an enhanced rehydration rate. This result indicates that pre-treatment of the tilapia in a salt solution and temperature can minimize cell rupture and tissue damage in sun drying. Moreover, the rehydration rate significantly increased gradually with an increase in the soaking period. For most dried products, quick rehydration is a desirable attribute for their use. The degree of physical changes experienced by a product due to pre-treatment and processing conditions significantly influence the rehydration value [47]. The rehydration rate can also indicate the extent of fish tissue damage during drying [48].

Fig. 5.

Rehydration pattern of different sundried tilapia fish products.

4. Conclusions

The saltwater and thermal pre-treatment significantly influenced the physicochemical and nutritional properties of the sundried tilapia fish products. The pre-treatment led to a considerable reduction in moisture content by harnessing the moisture reduction rate. There was high moisture reduction rate found due to pre-treatment of the samples and the rate was increased with increasing salt concentration and temperature. Theere was 14.47 % moisture content found in sample treated with a 30 % salt water solution at 90 °C whereas the content was 21.23 % in case of in control sample. Additionally, the nutritional parameters, including proximate composition, omega-3 fatty acids contents, and amino acids contents, were found to be significantly higher (P < 0.05) in the pre-treated sample compared to control sample. One crucial factor for dried products is the quick rehydration rate, and the pre-treated samples exhibited higher rehydration rate than the control one. Sample pre-teated with 10 % salt water solution at 75 °C exhibited 66.63 % rehydration at 40 min soaking period whereas the value was 32.72 % in control sample. Furthermore, the proximate composition revealed a significant reduction in moisture content while maintaining a notably high protein content (58.33 % in sample pre-treated with 30 % salt water solution at 90 °C), making the dried fish suitable for consumption after sun drying. The study identified essential amino acids vital for our health and found that lysine, a crucial essential amino acid, was the most abundant among the amino acids, with a content of 2299.50 mg/100 g in the sample pre-treated with a 10 % saltwater solution at 75 °C. These findings suggest that saltwater and thermal pre-treatment enhance nutritional quality, shorten drying time, and improve the processing efficiency of sundried fish products.

Fish drying by depending on the weather associated with lowered quality due to extended drying time, autolysis, oxidation, and attack of microbes. To counter this, our study suggests pre-treatment with salt water and exposed to temperature enhance drying speed and final product quality. Salt water hinders microbes, ensuring safe consumption, while heat deactivates enzymes and microbes, aiding water release from the fish tissues. This accelerates drying, preserving product traits. Unlike harmful insecticides, this method used saltwater and heat pre-treatment to prevent infestations which played role as a natural insect deterrent. This safe approach improves dried fish quality and safety. Implementing these steps in production assures nutritious, safe, and appealing dried fish products, fostering the trust of consumers. Actually, drying rates are predominantly influenced by factors such as sunlight intensity, temperature, humidity, and day length. This research was conducted during a specific season; therefore, it is imperative to verify these findings across all seasons of the year. Additionally, it is vital to evaluate the sensory attributes of the dried products both prior to and after cooking. Consumer preferences for food commodities frequently hinge on organoleptic acceptance and microbiological loads, making it crucial for further investigation.

CRediT authorship contribution statement

Puja Basak: Conceptualization, Formal analysis, Methodology, Writing – original draft. Md Sadek Ali: Data curation, Formal analysis, Methodology, Writing – original draft. Lilatul Isra: Formal analysis, Validation, Visualization, Writing – review & editing. Md Habibur Rahman: Funding acquisition, Investigation, Project administration, Visualization. Monjurul Haq: Conceptualization, Funding acquisition, Investigation, Project administration, Resources, Supervision, Writing – review & editing.

Declaration of Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The authors are grateful to Research Cell, Jashore University of Science and Technology, Jashore, Bangladesh for funding the project in 2021-22.

References

- 1.Suraiy S., Ahmmed M., Haq M. Heliyon; 2022. Immunity Boosting Roles of Biofunctional Compounds Available in Aquafoods: A Review. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Charlton K.E., Russell J., Gorman E., Hanich Q., Delisle A., Campbell B., Bell J. Fish, food security and health in Pacific Island countries and territories: a systematic literature review. BMC Publ. Health. 2016;16(1):285. doi: 10.1186/s12889-016-2953-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Rifat M.A., Wahab M.A., Rahman M.A., Nahiduzzaman M., Mamun A.A. Heliyon; 2023. Nutritional Value of the Marine Fish in Bangladesh and Their Potential to Address Malnutrition: A Review. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Rajesh G.K., Thirupathi V., Nambi V.E., Pandiselvam R. Optimization of extrusion cooking process for rice-fish extrudates with an underutilized fish mince based on physical, functional and textural properties. Agric. Eng. 2015;2:9–21. [Google Scholar]

- 5.Debbarma A., Kumar S.S., Kumar J.S., Tripura A. Impact of stocking density as the growth and biomass production of hybrid tilapia (red strain) in cages. J. Sci. Res. & Rep. 2021;27(4) 114-113. [Google Scholar]

- 6.Adeyemi O.T., Osilesi O., Adebawo O.O., Onajobi F.D., Oyedemi S.O., Afolayan A.J. Variations in proximate composition of Clupea harengus (Fillet & Skin, Head and Bones (SHB)) after different heat treatment. Variations. 2015;5(1):117–122. [Google Scholar]

- 7.Gyan W.R., Alhassan E.H., Asase A., Akongyuure D.N., Qi-Hui Y. Assessment of postharvest fish losses: the case study of Albert Bosomtwi-Sam fishing harbour, Western Region, Ghana. Mar. Policy. 2020;120 [Google Scholar]

- 8.Rasul M.G., Faruk M.O., Sarkar M.S.I., Yuan C., Akter T., Shah A.K.M. Post-mortem biochemical, microbiological and sensory quality changes in the grass carp (Ctenopharyngodon idella) during ice storage. Egypt. J. Aquat. Biol. Fish. 2022;26(5):175–187. [Google Scholar]

- 9.Al Banna M.H., Hoque M.S., Tamanna F., Hasan M.M., Mondal P., Hossain M.B., Khan M.S.I. Nutritional, microbial and various quality aspects of common dried fish from commercial fish drying centers in Bangladesh. Heliyon. 2022;8(10) doi: 10.1016/j.heliyon.2022.e10830. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Rasul M.G., Yuan C., Azad Shah A.K.M. Chemical composition and nutritional value of dried fish in Bangladesh. Egypt. J. Aquat. Biol. Fish. 2021;25(4):389–399. [Google Scholar]

- 11.Richa R., Shahi N.C., Lohani U.C., Kothakota A., Pandiselvam R., Sagarika N.…Kumar A. Design and development of resistance heating apparatus‐cum‐solar drying system for enhancing fish drying rate. J. Food Process. Eng. 2022;45(6) [Google Scholar]

- 12.Arason S., Nguyen M.V., Thorarinsdottir K.A., Thorkelsson G. Preservation of fish by curing. Seafood Processing: Technology, Quality and Safety. 2014:129–160. [Google Scholar]

- 13.Nagwekar N., Tidke V., Thorat B. Microbial and biochemical analysis of dried fish and comparative study using different drying methods. Dry. Technol. 2017;35(12):1481–1491. [Google Scholar]

- 14.Haider M.N., Bhattacharjee S., Shikha F.H., Hossain I. Bacterial count and proximate composition of an indian sub-continental freshwater barb, Punti (Puntius sophore) and a gangetic catfish, gulsha (Mystus cavasius) during drying-up process. J. Aquat. Food. Prod. T. 2021;30(4):474–483. [Google Scholar]

- 15.Jahan M.P., Chakraborty S.C., Kamal M., Haider M.N., Hasan M.M. Effect of salt concentration on the quality aspects of sun-dried ribbon fish (Trichiurus lepturus) Bangladesh J. Fish. 2019;31(1):147–156. [Google Scholar]

- 16.Uddin K.B., Reza M.S., Islam M.N., Kamal M. Influence of salt drying performance of silver jewfish (Otolithes argentatus) in a Hohenheim type solar tunnel dryer. J. Bangladesh Agril. Univ. 2014;12:227–233. [Google Scholar]

- 17.AOAC . AOAC International; 2005. Official Methods of Analysis of AOAC International. 2005. [Google Scholar]

- 18.Salman M., Suraiya S., Das P., Islam M., Haq M. Variation in the proximate composition, amino acids content and fatty acids of Thai pangus (Pangasianodon hypophthalmus) fish depending on size. Asian Food Sci. J. 2021;20(6):35–49. [Google Scholar]

- 19.AOCS Official Method Ce 1-62 . American Oil Chemists’ Society; Champaign, Illinois, USA: 2006. Fatty Acid Composition by Gas Chromatography. [Google Scholar]

- 20.Kumaravel S., Alagusundaram K. Determination of mineral content in Indian spices by ICP-OES. Orient. J. Chem. 2014;30(2):631–636. [Google Scholar]

- 21.Aniesrani Delfiya D.S., Sneha R., Prashob K., Murali S., Alfiya P., Samuel M.P. Hot air‐assisted continuous infrared dryer for anchovy fish drying. J. Food Process. Eng. 2022;45(6):1–11. [Google Scholar]

- 22.Kouhila M., Moussaoui H., Lamsyehe H., Tagnamas Z., Bahammou Y., Idlimam A., Lamharrar A. Drying characteristics and kinetics solar drying of Mediterranean mussel (Mytilus galloprovincilis) type under forced convection. Renew Energ. 2020;147:833–844. [Google Scholar]

- 23.Kituu G.M., Shitanda D., Kanali C., Mailutha J., Njoroge C., Wainaina J., Ondote P. 2009. Influence of Brining on the Drying Parameters of tilapia (Oreochromis niloticus) in a Glass-Covered Solar Tunnel Dryer. [Google Scholar]

- 24.Jeevarathinam G., Pandiselvam R., Pandiarajan T., Preetha P., Balakrishnan M., Thirupathi V., Kothakota A. Infrared assisted hot air dryer for turmeric slices: effect on drying rate and quality parameters. LWT. 2021;144 [Google Scholar]

- 25.Delfiya D.A., Prashob K., Murali S., Alfiya P.V., Samuel M.P., Pandiselvam R. Drying kinetics of food materials in infrared radiation drying: a review. J. Food Process. Eng. 2022;45(6) [Google Scholar]

- 26.Jeevarathinam G., Pandiselvam R., Pandiarajan T., Preetha P., Krishnakumar T., Balakrishnan M.…Amirtham D. Design, development, and drying kinetics of infrared‐assisted hot air dryer for turmeric slices. J. Food Process. Eng. 2022;45(6) [Google Scholar]

- 27.Odoli C.O., Oduor‐Odote P., Arason S. The influence of lipid content and pre-treatment methods on protein conformation in fish (capelin, Mallotus villosus) during smoking and drying. Food Sci. Nutr. 2019;7(4):1446–1454. doi: 10.1002/fsn3.980. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Sannaveerappa T., Ammu K., Joseph J. Protein‐related changes during salting of milkfish (Chanos chanos) J. Sci. Food Agric. 2004;84(8):863–869. [Google Scholar]

- 29.Kumolu-Johnson C., Aladetohun N., Ndimele P. The effects of smoking on the nutritional qualities and shelf-life of Clarias gariepinus (Burchell 1822) Afr. J. Biotechnol. 2010;9(1) [Google Scholar]

- 30.Wu T., Mao L. Influences of hot air drying and microwave drying on nutritional and odorous properties of grass carp (Ctenopharyngodon idellus) fillets. Food Chem. 2008;110(3):647–653. [Google Scholar]

- 31.Murali S., Sathish Kumar K., Alfiya P., Delfiya D.A., Samuel M.P. Drying kinetics and quality characteristics of Indian mackerel (Rastrelliger kanagurta) in solar–electrical hybrid dryer. J. Aquat. Food Prod. T. 2019;28(5):541–554. [Google Scholar]

- 32.Aberoumand A. Nutrient composition analysis of gish fish fillets affected by different cooking methods. Int. Food Res. J. 2014;21(5):1989–1991. [Google Scholar]

- 33.Odoli C.O., Oduor‐Odote P., Arason S. The influence of lipid content and pre-treatment methods on protein conformation in fish (capelin, Mallotus villosus) during smoking and drying. J. Food Sci. 2019;7(4):1446–1454. doi: 10.1002/fsn3.980. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Islam M., Hossain M., Mian S. Nutritive value of dried and heat processed mola fish (Amblypharyngodon mola) products. Int. J. Nat. Sci. 2012;2(2):43–48. [Google Scholar]

- 35.Jo H.-G., Chilakala R., Kim M.-J., Sin Y.-S., Lee K.-S., Cheong S.-H. Assessment of the effects of salt and Salicornia herbacea L. on physiochemical, nutritional, and quality parameters for extending the shelf-life of semi-dried mullets (Chelon haematocheilus) Foods. 2022;11(4):597. doi: 10.3390/foods11040597. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Liu X., Zheng C., Luo X., Wang X., Jiang H. Recent advances of collagen-based biomaterials: Multi-hierarchical structure, modification and biomedical applications. J. Mater. Sci. 2019:1509–1522. doi: 10.1016/j.msec.2019.02.070. [DOI] [PubMed] [Google Scholar]

- 37.Cao J., Feng A., He Y., Wang J., Liu Z., Xia G., Lin X., Shen X., Zhou D., Li C. The effect and mechanism of four drying methods on the quality of tilapia fillet products. Food Frontiers. 2022;3(2):316–327. [Google Scholar]

- 38.Brishti F.H., Chay S.Y., Muhammad K., Ismail-Fitry M.R., Zarei M., Karthikeyan S., Saari N. Effects of drying techniques on the physicochemical, functional, thermal, structural and rheological properties of mung bean (Vigna radiata) protein isolate powder. Food Res. Int. 2020;138 doi: 10.1016/j.foodres.2020.109783. [DOI] [PubMed] [Google Scholar]

- 39.do Nascimento T.M., Mansano C.F., Peres H., Rodrigues F.H., Khan K.U., Romaneli R.S., Sakomura N.K., Fernandes J.B. Determination of the optimum dietary essential amino acid profile for growing phase of Nile tilapia by deletion method. Aquaculture. 2020;523 [Google Scholar]

- 40.Rodrigues A.T., Mansano C.F., Khan K.U., Nascimento T.M., Boaratti A.Z., Sakomura N.K., Fernandes J.B. Ideal profile of essential amino acids for Nile tilapia (Oreochromis niloticus) in the finishing growth phase. Aquac. Res. 2020;51(11):4724–4735. [Google Scholar]

- 41.Teoh C.-Y., Turchini G.M., Ng W.-K. Genetically improved farmed Nile tilapia and red hybrid tilapia showed differences in fatty acid metabolism when fed diets with added fish oil or a vegetable oil blend. Aquaculture. 2011;312(1–4):126–136. [Google Scholar]

- 42.Kiczorowska B., Samolińska W., Grela E.R., Bik-Małodzińska M. Nutrient and mineral profile of chosen fresh and smoked fish. Nutrients. 2019;11(7):1448. doi: 10.3390/nu11071448. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Cabuga C.C., Jr., Velasco J.P.B., Leones J.A.M., Orog B.Y., Jumawan J.C. Levels of cadmium, copper, lead, nickel and mercury in the muscles of Pigok (Mesopristes cancellatus) and sediments collected at lower Agusan river basin, Brgy. Pagatpatan, Butuan City, Agusan Del Norte, Philippines. Int. J. Fish Aquat. Stud. 2016;4(4):206–215. [Google Scholar]

- 44.Essuman K.M. FAO; 2005. Evaluation of Heavy Metal Content in Fresh and Processed Fish from Yeji. [Google Scholar]

- 45.Igwegbe A., Negbenebor C., Chibuzo E., Badau M., Agbara G. Effects of season, salting and drying on heavy metal contents of four fish species from three locations in Borno state of Nigeria. Glob J. Food Sci. Technol. 2014;2:127–136. [Google Scholar]

- 46.Pandiselvam R., Aydar A.Y., Kutlu N., Aslam R., Sahni P., Mitharwal S.…Kothakota A. Ultrasonics Sonochemistry; 2022. Individual and Interactive Effect of Ultrasound Pre-treatment on Drying Kinetics and Biochemical Qualities of Food: A Critical Review. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Pravitha M., Manikantan M.R., Kumar V.A., Beegum S., Pandiselvam R. Optimization of process parameters for the production of jaggery infused osmo-dehydrated coconut chips. LWT. 2021;146 [Google Scholar]

- 48.Wang Y., Zhang M., Mujumdar A.S., Mothibe K.J. Quality changes of dehydrated restructured fish product from silver carp (Hypophthalmichthys molitrix) as affected by drying methods. Food Bioprocess Technol. 2013;6:1664–1680. [Google Scholar]