Abstract

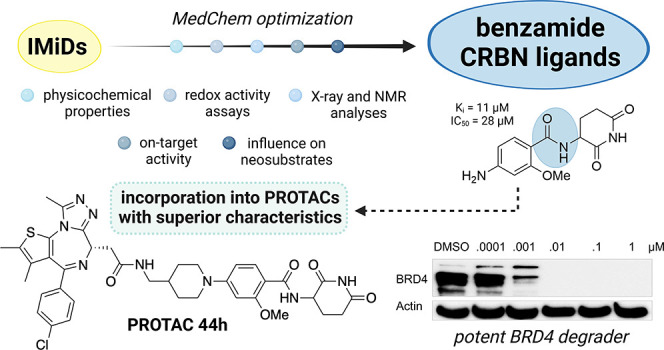

Immunomodulatory imide drugs (IMiDs) such as thalidomide, pomalidomide, and lenalidomide are the most common cereblon (CRBN) recruiters in proteolysis-targeting chimera (PROTAC) design. However, these CRBN ligands induce the degradation of IMiD neosubstrates and are inherently unstable, degrading hydrolytically under moderate conditions. In this work, we simultaneously optimized physiochemical properties, stability, on-target affinity, and off-target neosubstrate modulation features to develop novel nonphthalimide CRBN binders. These efforts led to the discovery of conformationally locked benzamide-type derivatives that replicate the interactions of the natural CRBN degron, exhibit enhanced chemical stability, and display a favorable selectivity profile in terms of neosubstrate recruitment. The utility of the most potent ligands was demonstrated by their transformation into potent degraders of BRD4 and HDAC6 that outperform previously described reference PROTACs. Together with their significantly decreased neomorphic ligase activity on IKZF1/3 and SALL4, these ligands provide opportunities for the design of highly selective and potent chemically inert proximity-inducing compounds.

Introduction

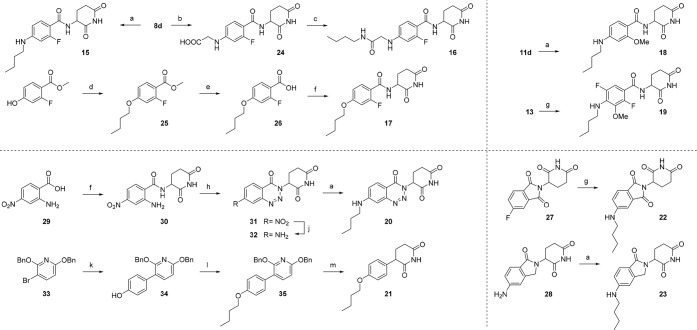

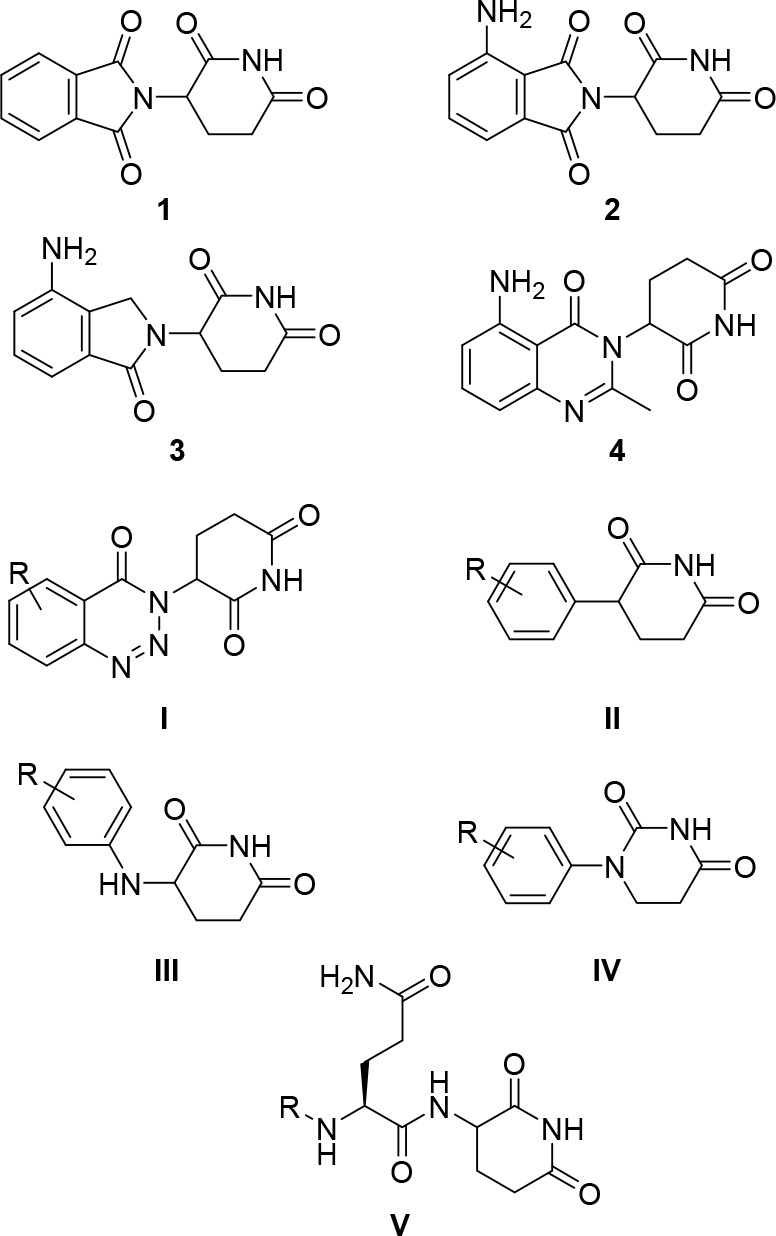

Deciphering thalidomide’s mechanism of action in 2010 by Ito et al. ignited a transformative process in drug discovery toward the development of proximity-induced pharmacology as a new therapeutic modality.1,2 The potential and benefits of targeted protein degradation (TPD) as a cutting-edge paradigm are thoroughly demonstrated by molecular glues (MGs) and proteolysis-targeting chimeras (PROTACs).3,4 Nowadays, the E3 ligase substrate receptor cereblon (CRBN), thalidomide’s primary target,1,5 is of particular importance in the fields of MGs and PROTACs.6,7 The immunomodulatory imide drugs (IMiDs) thalidomide (1, Figure 1), pomalidomide (2), lenalidomide (3), and avadomide (4) represent classical CRBN recruiters that are frequently exploited for PROTAC design.2,6,8 One feature, but also a potential caveat of this class of ligase binders, is their potential to promote the degradation of lymphoid transcription factors such as IKZF1, IKZF3, and SALL4, the last being responsible for severe teratogenicity caused by thalidomide analogs.9−13 Furthermore, the typical IMiD scaffolds are prone to hydrolytic and enzymatic degradation, rendering them less attractive for pharmacological application.14−16

Figure 1.

CRBN ligand landscape. Established CRBN modulators (1–4), novel scaffolds (I–IV) used in degrader design, and the terminal residues (QcQ) of a recently discovered natural degron (V).

These observations led to the development of a series of new CRBN binders that could potentially overcome the limitations above. For instance, benzotriazino glutarimides (scaffold I, Figure 1) have been successfully employed to generate BRD4-targeting PROTACs. Rankovic and colleagues recently reported on phenyl glutarimides (II), which retained CRBN affinity and significantly improved chemical stability over phthalimide-based recruiters.16 Phenyl glutarimides were incorporated in degraders targeting BRD4 and cancer-related kinases.16,17 Anilino glutarimides (III) and related aryl glutarimides were utilized to generate USP7-targeting PROTACs and PDE6D-directed MGs.18,19 We noted significant improvements in the solubility of anilinic ligands compared to classical scaffolds, which could pave the way for in vivo applications of such molecules. Recently, three groups reported on phenyl dihydrouracil derivatives (IV) as CRBN-engaging agents.20−22 These ligands combined several desirable features, including improved resistance to hydrolytic degradation. Furthermore, replacing the C-3 carbon of the glutarimide ring with nitrogen addressed commonly challenged racemization issues of IMiD-based degraders.

Our laboratories are interested in advancing E3 ligase ligands and have contributed in various ways to explore their structure–activity relationships within PROTAC design.14,18,23−25 CRBN ligands rely on only a small set of interactions that are classically limited to H-bonds of the glutarimide moiety within the conserved tri-tryptophan pocket and a further H-bond between one of the phthalimide carbonyls and a conserved asparagine (Asn351) in the sensor loop.26−28 We and others have suggested that simplifying classical phthalimide-based ligands can further improve the suitability of CRBN-hijacking probes. For instance, in 2016, we described a novel FRET reporter for the characterization of CRBN ligands based on a minimal uracil scaffold.29 Later, we utilized this recruiter to develop a BODIPY derivative suitable for microscale thermophoresis (MST) assays.30 Similar to the newly reported phenyl glutarimide- and phenyl dihydrouracil-based ligands, these reporters rely mainly on interactions within the tri-tryptophan pocket, but do not interact with Asn351 as phthalimide-based ligands do. However, the interplay with Asn351 can be restored by attaching an amide group to the core binding moieties of aminosuccinimide or aminoglutarimides, as exemplified by thalidomide hydrolysis products that maintained CRBN affinity.23,24 Intriguingly, we and others recently reported this particular minimal binding motif to be identical to a natural degron that interacts with CRBN (V, Figure 1).31−33 Based on these studies on minimal CRBN ligands and the medicinal chemistry-driven optimization of a benzamide-type screening hit, we have obtained attractive nonphthalimide CRBN binders for PROTAC design. Our design strategies build on the analysis of intramolecular bonds, cocrystal structures, physicochemical characteristics, stability data, and on-target activity.

Results and Discussion

Fluorinated Benzamide Derivatives Exhibit Increased CRBN Binding Affinity

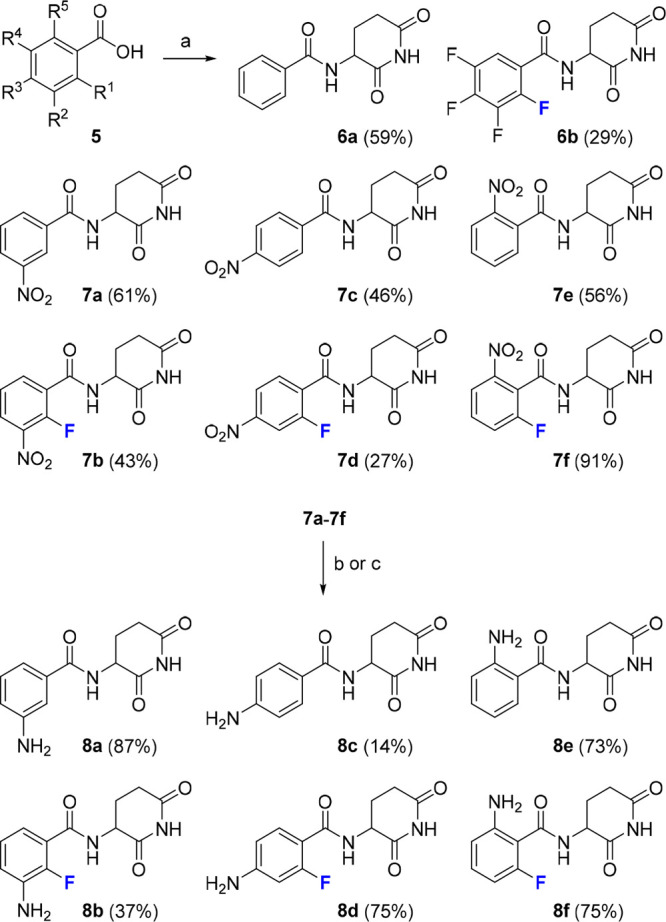

In previous studies, we discovered that the introduction of fluorine atoms improved the biological properties of thalidomide derivatives.34−36 Specifically, the perfluorination of benzamides increased the binding affinity compared to its nonfluorinated analog (6b vs 6a, Scheme 1).34 Fluoro-substituted compounds enjoy particular success in medicinal chemistry, and a high proportion of drugs in the pharmaceutical pipeline contain at least one fluorine atom.37 The incorporation of fluorine can affect several essential properties in drug design. For instance, lipophilicity, metabolic stability, membrane permeation, and binding affinity can be modulated by incorporating an electronegative fluorine atom.38 However, fluorine is also considered a conformation-controlling element through hyperconjugative electron donation of vicinal groups and, potentially, also through intramolecular hydrogen bonds (IMHBs) of the C–F···H–N type.39,40 Interestingly, fluorine-containing HBs were reported for ortho-fluorobenzamides.41 Accordingly, we proposed an amphiphilic character of the fluorine in 6b, i.e., as a hydrogen-bond acceptor and a hydrophobic moiety. To further clarify the effect of the substituent at the ortho position, we synthesized a series of six related compounds, having either a hydrogen or fluorine atom attached to the aromatic moiety (8a–8f, Scheme 1). In these molecules, an amino group was installed at the different unsubstituted positions to scan potential fragment growing and/or linker exit vectors.

Scheme 1. Synthesis of Substituted Benzamido Glutarimides.

Reagents and conditions: (a) (i) (COCl)2, DMF (cat.), CH2Cl2, 0 °C, 2 h; (ii) ArCOCl, Et3N, 3-aminopiperidine-2,6-dione hydrochloride, CH2Cl2, 0 °C, to rt, 18 h; (b) Pd/C, H2, DMF, rt, 18 h; (c) Fe, EtOH, AcOH, H2O, 110 °C, 30 min.

Next, we used our previously established MST assay to measure binding to the human CRBN thalidomide binding domain (hTBD).30 In three out of four cases, the fluorinated derivative displayed lower IC50 values than the nonhalogenated counterpart (Table 1). Additional IMHBs due to the second ortho substituent could explain the deviation from this trend in 8f. The fluorine-containing compound 8d exhibited the highest affinity in this series with an IC50 value of 63 ± 16 μM. In addition to the in vitro binding values, data on critical physiochemical properties were also collected. As expected, the introduction of fluorine increased the lipophilicity (log D) of the compounds. In contrast, plasma protein binding was less affected by these minor chemical modifications. Substituted derivatives had higher chromatographic hydrophobicity index (CHI) values, indicating less pronounced permeability obstacles.

Table 1. Chemical Structures, Binding Data, Distribution Coefficients, Plasma Protein Binding Properties, and Phospholipid Interaction Capabilities of Benzamides 6 and 8.

| Ligand | R1 | R2 | R3 | R4 | R5 | IC50 (μM)a | Ki (μM)a | elog D7.4b | PPB (%)c | CHIIAMd |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 13 ± 2.7 | 3.3 ± 1.4 | 0.5 | 51 | –4.0 | |||||

| 3 | 19 ± 1.5 | 6.4 ± 0.8 | –0.4 | 12 | –2.6 | |||||

| 6a | H | H | H | H | H | 127 ± 40 | 63 ± 21 | –0.3 | 10 | 6.3 |

| 6b | F | F | F | F | H | 65 ± 26 | 30 ± 14 | 0.9 | 17 | 16.7 |

| 8a | H | NH2 | H | H | H | 107 ± 45 | 53 ± 24 | –1.2 | 4 | –1.1 |

| 8b | F | NH2 | H | H | H | 93 ± 19 | 45 ± 9.9 | –1.2 | 4 | 0.7 |

| 8c | H | H | NH2 | H | H | 86 ± 21 | 41 ± 11 | –2.0 | 3 | –1.1 |

| 8d | F | H | NH2 | H | H | 63 ± 16 | 29 ± 8.2 | –0.7 | 5 | 5.2 |

| 8e | H | H | H | H | NH2 | 74 ± 14 | 35 ± 7.0 | –0.5 | 9 | 6.2 |

| 8f | F | H | H | H | NH2 | 114 ± 60 | 56 ± 31 | –0.1 | 12 | 8.1 |

Affinity values determined in a competitive MST assay as described in the methods sections. For comparison, pomalidomide (2) and lenalidomide (3) were included, for which data is from ref (30).

Distribution coefficients at pH 7.4 were estimated by an HPLC-based method.

Plasma protein binding; experimentally determined percentage of compound bound to human serum albumin.

Chromatographic hydrophobicity index values referring to IAM chromatography (CHIIAM values), an estimate for drug–membrane interactions and permeability.

Intramolecular Hydrogen Bonds Predetermine Ligand Conformations

Inspired by the positive results of placing a fluorine atom at the ortho position of the benzamide scaffold, we sought to investigate the structure–activity relationships in more detail. Accordingly, analogous compounds were synthesized, allowing for IMHBs that pertain to motifs of the type C–O···H–N or C-X···H–N (with X = halogen). When appropriately substituting molecule 8c from R1 = H to R1 = X, the aromatic ring becomes more electron deficient, the amide NH group more acidic, and the entire molecule displays increased lipophilicity. Such features could favorably affect the biological activity of the CRBN ligands. To pinpoint whether the ortho substituents may improve binding affinity via IMHBs or electronic effects, we designed a series of 7 related compounds. Halo derivatives 8d (R = F) and 11a (R = Cl) could benefit from both mechanisms, haloalkyl compound 11b (R = CF3) displays strong deactivating properties, whereas compounds 11c (R = CH3), 11d (R = OMe), and 11e (R = OH) have ascending electron donating features. In addition, 11d and 11e could contribute to IMHBs. In 11f, the ortho-fluorine may constitute the major design element, but additional decorations at the benzamide scaffold could prove beneficial. Due to the rather tight spatial restraints of the thalidomide binding site,28 more spacious polar substituents (e.g., nitro, amide, ester) were not considered in our compound design.

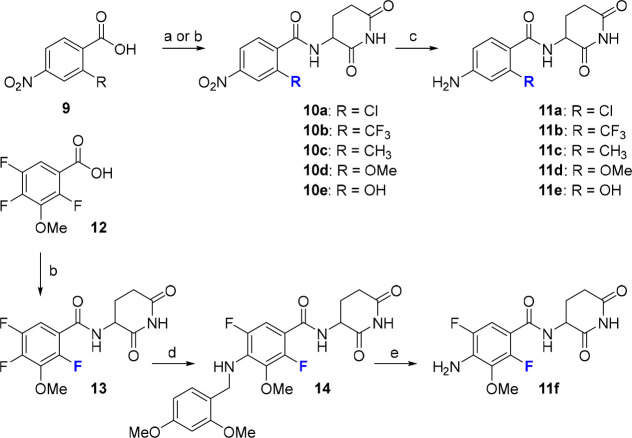

The syntheses of compounds 11 are outlined in Scheme 2 and proceeded in most cases via the established route of EDC/HOBt-mediated couplings between benzoic acid derivatives of type 9 and the aminoglutarimide building block.42 Subsequent reduction of the nitro group afforded the desired anilines 11a–11e. Derivative 11f was obtained from 12 after amide bond formation, SNAr at position 4 (Figure S1) with 2,4-dimethoxybenzylamine, and cleavage of the dimethoxybenzyl C–N bond with TFA in CH2Cl2.43

Scheme 2. Synthesis of Different Ortho-Substituted Para-Aminobenzoates.

Reagents and conditions: (a) (i) oxalyl dichloride, DMF (cat.), CH2Cl2, 0 °C to rt, 2 h; (ii) 3-aminopiperidine-2,6-dione hydrochloride, Et3N, CH2Cl2, rt, 16 h, 80–83%; (b) EDC × HCl, HOBt, 3-aminopiperidine-2,6-dione hydrochloride, DIPEA, DMF, rt, 16 h, 35–74%; (c) Pd/C, H2, DMF, rt, 18 h, 11–74%; (d) (2,4-dimethoxyphenyl)methanamine, DIPEA, DMSO, 90 °C, 16 h, 35%; (e) TFA, CH2Cl2, rt, 2 h, 77%.

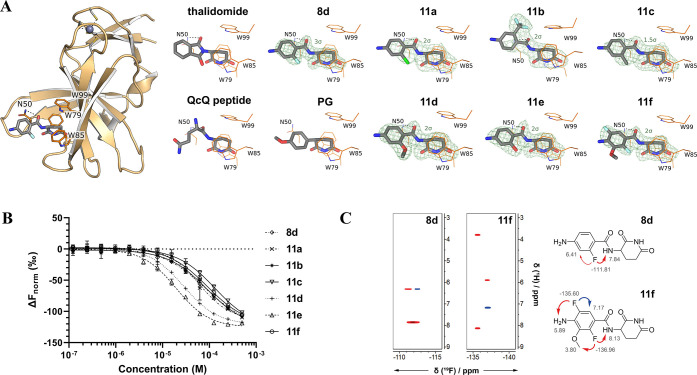

The inherent conformational flexibility of benzamides 11 along the amide bond was investigated using a force field-based method implemented in Schrödinger MacroModel. Global minimum conformations are depicted in Figure S2. As expected, IMHBs were observed in low-energy conformers, except for 11a–11c. Fortunately, we could study all compounds generated in this iterative step through cocrystal structures (Figure 2) in complex with the hTBD homolog MsCI4.44 These data confirmed that the preferred orientation of the ortho substituent toward the amide NH was preserved in the bound state of all ligands except for 11b. However, the intrinsic preference of these atoms for the formation of H-bonds through van der Waals forces may facilitate mimicking the bonded pose as in isoindoles of types 2 and 3. Sub van der Waals distances ranging from 1.3 to 2.0 Å were seen in 8d, 11a, 11c, 11d, 11e, and 11f (Table S1). Overall, compounds with C–O···H–N or C-X···H–N patterns achieved a higher affinity to the hTBD (Table 2). To investigate whether such intramolecular H-bonding may even persist in the polar environment of a solvated compound, we performed 2D NMR experiments in DMSO. We determined that F and the NH proton are closely spaced by observing correlation peaks between the NH proton and the F signals in the 19F,1H-HOESY NMR spectra of 8d and 11f (Figure 2C). The results, therefore, strongly suggest that IMHBs predetermine the ligand conformation in solution. Overall, the decreased conformational freedom may be attractive in terms of increased bioavailability and reduced entropic penalty upon binding with CRBN.45

Figure 2.

(A) Difference electron density (Fo – Fc) maps, contoured at the indicated sigma level, of ortho-substituted benzamide compounds bound to crystallized MSCI4. The full-size crystal structure is exemplary shown for 8d on the left. For comparison, thalidomide, a QcQ peptide (the two last amino acids of a natural degron peptide), and a phenyl glutarimide (PG) are shown (PDB identifiers: 4V2Y, 8BC7, and 7SHH, respectively). Nitrogen is shown in blue, carbon in gray, oxygen in red, fluorine in light blue, and chlorine in chartreuse. (B) Dose–response curves for compounds 8d and 11a–11f were obtained in competitive MST measurements with BODIPY-uracil and hTBD (n = 3). (C) Sections of 19F,1H-HOESY NMR spectra of 8d and 11f, respectively. Spatial proximity between F and the amide NH provides evidence for intramolecular interactions. NOE with residual water is not displayed.

Table 2. Chemical Structures, Binding Data, Physicochemical Properties, and Cellular Activities of Ortho-Substituted Benzamides.

| neosubstrate

deg (%)h,i |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ligand | R | IC50 (μM)a | Ki (μM)a | elog D7.4b | PPB (%)c | CHIIAMd | log(S)e | Redox activityf | UV/vis stabilityg | IKZF3 | SALL4 |

| 2 | C=O | 13 ± 2.7 | 3.3 ± 1.4 | 0.5 | 51 | –4.0 | –4.0 | n.a.j | <pH 9 | 86 | 95 |

| 3 | CH2 | 19 ± 1.5 | 6.4 ± 0.8 | –0.4 | 12 | –2.6 | –2.6 | not active | stable | 57 | 70 |

| 8d | F | 63 ± 16 | 29 ± 8.2 | –0.7 | 5 | 5.2 | –3.1 | not active | stable | 39 | 14 |

| 11a | Cl | 60 ± 13 | 28 ± 6.6 | –0.9 | 10 | 2.6 | –2.6 | not active | stable | 13 | <5 |

| 11b | CF3 | 87 ± 25 | 42 ± 13 | –0.3 | 6 | 6.7 | –3.5 | not active | stable | 69 | 45 |

| 11c | CH3 | 132 ± 55 | 65 ± 29 | –1.2 | 2 | –1.1 | –2.5 | not active | stable | 57 | <5 |

| 11d | OMe | 28 ± 2.6 | 11 ± 1.4 | 0.0 | 17 | 6.5 | –2.9 | not active | stable | 14 | 14 |

| 11e | OH | 20 ± 2.0 | 6.8 ± 1.0 | –0.3 | 18 | 8.8 | –3.0 | active | <pH 9 | 41 | <5 |

| 11f | F | 90 ± 17 | 44 ± 9.0 | –0.9 | 14 | 2.6 | –3.0 | not active | stable | 63 | 42 |

Affinity values determined in a competitive MST assay as described in the method sections (see Supporting Information).

Distribution coefficients at pH 7.4 were estimated by an HPLC-based method.

Plasma protein binding; experimentally determined percentage of compound bound to human serum albumin.

Chromatographic hydrophobicity index values referring to IAM chromatography (CHIIAM values), an estimate for drug–membrane interactions and permeability.

Logarithm of the solubility measured in mol/L at pH 6.8 by an HPLC-based method.

Redox activity assays for the detection of compounds that react with reducing agents in redox cycles by forming ROS (H2DCFDA assay) or free radicals (resazurin assay); see ref (49).

UV–vis-based assay for the evaluation of aqueous stability in phosphate buffer at pH 7.0, 8.0, and 9.0 after 4 h of incubation at 37 °C.

Percentage of degraded IKZF3 protein after 16 h treatment of MM.1S cells with 0.1 μM of each compound.

Percentage of degraded SALL4 protein after 16 h treatment of HuH6 cells with 0.1 μM of each compound. Western blots were analyzed by densitometric methods, and values were normalized to the respective loading controls and to DMSO-treated conditions. IKZF3/SALL4 degradation data represent the average of at least two independent biological experiments.

Not available due to spectral interference.

Next, ligands 11 were evaluated concerning their physicochemical properties, stability, intrinsic reactivity, and neosubstrate modulation features. For the former, relevant properties such as lipophilicity (determined by an HPLC method), plasma protein binding, permeability (using immobilized artificial membrane chromatography), and solubility (log S) were determined (Table 2). As expected, introducing hydrophobic substituents at the ortho position increased the lipophilicity compared to the unsubstituted derivative 8c (log D = −2.0), e.g., by up to two log units in compound 11d. As commonly accepted, increasing lipophilicity by adding halogen atoms is detrimental to aqueous solubility.46 Although a negative trend was observed (Figure S3A), this correlation was less pronounced in our series of compounds. In contrast, more lipophilic compounds increased the CHI value, which may indicate improved passive permeability (Figure S3B). When plotting the percentage of human serum albumin (HSA) binding or the IC50 versus log D7.4, the correlation of the linear regressions improved when only conformationally locked compounds were considered (Figure S3C,D). The latter observation is consistent with the enhanced CRBN binding affinities of hydrophobically decorated ligands.5,47,48

To detect a potential oxidative liability of the aniline moiety, we employed our previously optimized redox activity assays49 using the reagents resazurin and 2′,7′-dichloro-dihydrofluorescein diacetate (H2DCFDA), which are capable of detecting compounds that react with reducing agents in redox cycles (Table 2). Hit compound 11e had to be excluded from further development due to the formation of reactive oxygen species (ROS) in the presence of the reducing agent tris(2-carboxyethyl)phosphine (TCEP). Subsequently, the aqueous stability was determined spectrophotometrically by following the changes in the absorption spectra of the compounds at pH 7.0, 8.0, and 9.0. These data confirmed the known hydrolytic susceptibility of compound 2,14,24 and revealed poor stability of 11e at higher pH values.

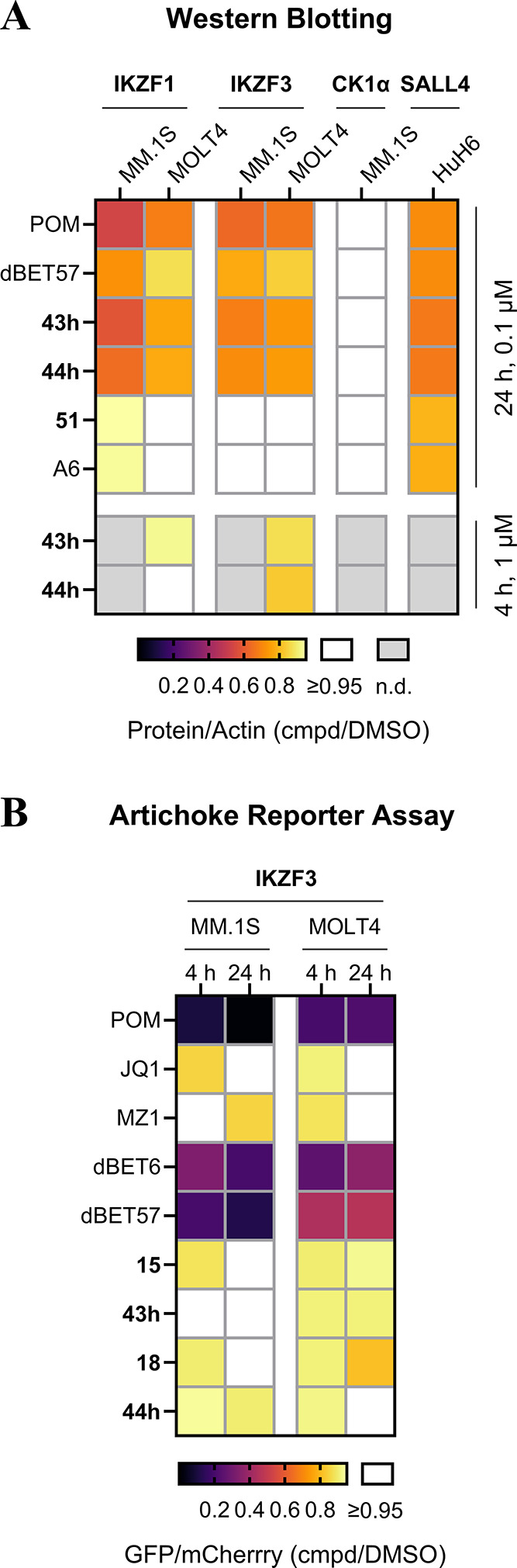

Benzamides 11 were assessed in MM.1S cells for their abilities to induce degradation of the CRBN neosubstrate IKZF3 (Figure S4A).10,50 Indeed, the substituted benzamides were less active recruiters of this transcription factor than pomalidomide (2) and lenalidomide (3). Nevertheless, neosubstrate degradation varied, although compounds of type 11 share the same anilinic degron motif and differ only in the ortho substituent. We hypothesized that the substituent is responsible for slight conformational changes (see Figure 2A), which could affect the recruitment efficiency. Among these compounds, 8d, 11a, and 11d represent exceptionally selective CRBN binders for PROTAC development. In contrast, compound 11b (R = CF3) led to the most pronounced degradation of IKZF3 (69%) at 0.1 μM (Table 2). As IMiDs such as 1 can induce the degradation of the spalt-like transcription factor 4 (SALL4), an oncofetal protein involved in limb development during embryogenesis, particular attention should be paid to potential teratogenic effects.12,13,51 We determined SALL4 degradation mediated by classical IMiDs and benzamides 11 in HuH6 hepatoblastoma cells (Figure S4B). Encouragingly, even compounds with CRBN binding affinity similar to lenalidomide, such as 11d and 11e, did not trigger substantial degradation of SALL4 (Table 2). In addition, our investigations did not reveal any discernible impact of benzamides on the activity of lenalidomide-selective neosubstrate CK1α or GSPT1, both of which are known to be targeted for degradation by IMiD-based PROTACs (Figure S4A). These proteins play crucial roles in several cell types and are implicated in toxicity-related processes. The entire set of available data (i.e., in vitro binding, physicochemical properties, and cellular neosubstrate attenuation) guided further development of bifunctional molecules based on the benzamide scaffold 11.

Evaluating the Effectiveness of Benzamides in the Design of MGs and PROTACs

In the next step, we sought to challenge linker-connected CRBN ligands for neosubstrate degradation. The attachment of a small linker could serve as a minimal degron to modulate substrate recognition of CRBN and could predict the scope of neosubstrate recruitment after the binding of benzamide-based PROTACs. In addition to the transcription factors IKZF1, IKZF3, and SALL4, we considered the degradation of GSPT1 as a problematic off-target, since their depletion causes profound effects in a variety of healthy tissues.52−54 Accordingly, evaluating CRBN ligands for their impact on attenuating these proteins is of great interest for MG and PROTAC development.

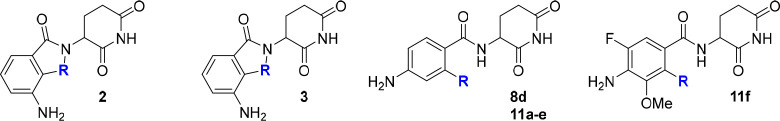

In compound 15 (Scheme 3), a short aliphatic linker was attached to the fluoro-substituted compound 8d by reductive amination with butyraldehyde. A two-carbon spacer was introduced in 8d with glycolic acid and coupled with n-butylamine to give 16. Such functional groups are frequently used in degrader design and are known to influence neosubstrate degradation capabilities significantly.6,14 A chemically different exit vector was realized in phenol ether 17. In addition to the prominent scaffold derived from 8d, we investigated two other hits, 11d and 11f. Corresponding linker conjugates were obtained via reductive amination or SNAr, respectively. The same linkers were realized in benzotriazino glutarimide 20, phenyl glutarimide 21, pomalidomide-type ligand 22, and isoindolinone 23.

Scheme 3. Synthesis of Linker-Functionalized CRBN Ligands.

Reagents and conditions: (a) (i) butyraldehyde, AcOH, DMF, rt, 1 h; (ii) STAB, 0 °C to rt, 16 h, 26–67%; (b) (i) glyoxylic acid monohydrate, AcOH, DMF, rt, 10 min; (ii) NaCNBH3, rt, 2 h, 20%; (c) n-butylamine, HATU, DIPEA, DMF, rt, 16 h, 25%; (d) n-butanol, PPh3, DIAD, THF, 0 °C to rt, 16 h; (e) NaOH, H2O, EtOH, rt, 1 h, 30% (2 steps); (f) EDC × HCl, HOBt, DIPEA, DMF, rt, 16 h, 35–43%; (g) n-butylamine, DMSO, DIPEA, 90 °C, 16 h, 40–43%; (h) NaNO2, AcOH, rt, 4 h, 80%; (j) Fe, THF, H2O, rt, 18 h, 44%; (k) (4-hydroxyphenyl)boronic acid, PdCl2(dppf) × CH2Cl2, K3PO4, dioxane, H2O, 110 °C, 18 h, 31%; (l) 1-bromobutane, K2CO3, DMF, 70 °C, 18 h, 79%; (m) Pd/C, H2, THF, rt, 18 h, 26%.

In vitro testing of the hTBD affinity of compounds 15–23 confirmed that linker attachment was well tolerated in all cases (Table 3). Notably, nonbenzamide scaffolds displayed slightly better binding values, with lenalidomide-derived compound 23 having the best CRBN binding. All compounds, except 16, were moderately hydrophobic with log D values between 1.8 and 2.6. In the case of 16, the additional amide group increases the polar surface area of the molecule, which is also detrimental to plasma protein binding and membrane interactions, as suggested by the significantly lower CHIIAM value. However, the reduced hydrophobicity of 16 is responsible for better lipophilic ligand efficiency (LLE).55 Equipping the benzamide scaffold with several hydrophobic substituents (as realized in 19) did not improve the binding affinity, which is also reflected by its lower LLE. None of the compounds were redox-active, and only 22 was unstable at pH above 8.0, as our high-throughput plate reader assay determined.49,56 However, refinement of the stability assessment by using an HPLC-based method and extending the treatment to 24 h at a pH of 7.4 revealed that most binders, with the exception of 21, were compromised through hydrolytic degradation. These results indicate that both the phthalimide and glutarimide rings are prone to hydrolysis.

Table 3. Physicochemical Properties, Binding Affinities, and Cellular Activities of Linker-Connected CRBN Ligands 15–23.

| Ligand | IC50 (μM)a | Ki (μM)a | elog D7.4b | LLEc | PPB (%)d | CHIIAMe | Redox activityf | UV/vis Stabilityg | Buffer stability (%)h | IKZF3 deg (%)i | SALL4 deg (%)j |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 62 ± 29 | 29 ± 15 | 2.0 | 2.2 | 85 | 29.8 | not active | stable | 67 | <5 | 14 |

| 16 | 55 ± 16 | 25 ± 8.5 | 0.7 | 3.6 | 30 | 15.1 | not active | stable | 56 | <5 | 21 |

| 17 | 65 ± 18 | 31 ± 9.2 | 2.2 | 2.0 | 89 | 31.2 | not active | stable | 47 | <5 | 37 |

| 18 | n.d.k | n.d. | 2.3 | n.d. | 90 | 30.3 | not active | stable | n.d. | <5 | 19 |

| 19 | 75 ± 30 | 35 ± 16 | 2.5 | 1.6 | 88 | 32.4 | not active | stable | 48 | 10 | 26 |

| 20 | 16 ± 3.6 | 4.9 ± 1.9 | 2.2 | 2.6 | 88 | 31.5 | not active | stable | 68 | 12 | 67 |

| 21 | 14 ± 1.5 | 3.9 ± 0.8 | 2.6 | 2.3 | 89 | 33.3 | not active | n.a.l | 98 | <5 | 55 |

| 22 | n.d. | n.d. | 2.4 | 2.4 | 89 | 32.8 | n.a.l | <pH 8 | 65 | <5 | 73 |

| 23 | 7.4 ± 1.3 | 0.43 ± 0.68 | 1.8 | 3.3 | 83 | 26.4 | not active | stable | 76 | <5 | 52 |

Affinity values determined in a competitive MST assay as described in the method sections (see Supporting Information).

Distribution coefficients at pH 7.4 were estimated by an HPLC-based method.

Lipophilic ligand efficiency, LLE = pIC50 – elog D.

Plasma protein binding; experimentally determined percentage of compound bound to human serum albumin.

Chromatographic hydrophobicity index values referring to IAM chromatography (CHIIAM values), an estimate for drug–membrane interactions and permeability.

Redox activity assays for the detection of compounds that react with reducing agents in redox cycles by forming ROS (H2DCFDA assay) or free radicals (resazurin assay); see ref (49).

UV–vis-based assay for the evaluation of aqueous stability in phosphate buffer at pH 7.0, 8.0, and 9.0 after 4 h of incubation at 37 °C.

Percentage stability refers to the remaining starting material as determined by HPLC after incubation for 24 h in 50 mM PBS buffer at pH 7.4. Values represent the mean of three independent repeats.

Percentage of degraded IKZF3 protein after 24 h treatment of MM.1S cells with 0.1 μM of each compound.

Percentage of degraded SALL4 protein after 24 h treatment of HuH6 cells with 0.1 μM of each compound. Values are normalized to respective loading controls and to DMSO-treated conditions. IKZF3/SALL4 degradation data represent the average of at least two independent biological experiments.

Not determined.

Not available due to spectral interference or low absorbance.

Next, effects on the crucial CRBN neosubstrates were evaluated in cellular models (Figure S5). Table 3 summarizes the percentage of IKZF3 degradation after treatment of MM.1S cells with MGs 15–23 and SALL4 attenuation in HuH6 cells. These experiments revealed an important caveat of classical degrader scaffolds (as in 22 and 23), i.e., the potential teratogenic risk through SALL4 degradation. Comparison between 15 and 17 suggests that neosubstrate recruitment is guided by chemical motifs rather than binding affinity or physicochemical properties. Linkages in compounds 15 and 18 were particularly promising in sparing SALL4 degradation.

Synthesis of Linker Conjugates for PROTAC Development

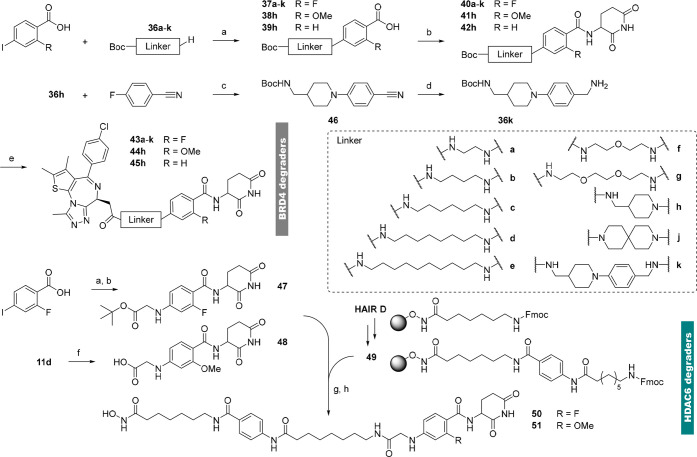

The final goal of this study was the incorporation of newly developed CRBN ligands into prototypic PROTAC molecules. In previous efforts (Scheme 3), linkers were attached via a reductive amination sequence. Although this technique was able to generate certain benzamide-linker conjugates (e.g., 40d), we found several limitations of this method: the in situ generation of aldehydes from PEG-type linkers was unsuccessful, and secondary amine-aryl conjugates could not be realized via this method. Due to the presence of the fluorine atom at the ortho position, SNAr reactions had to be omitted. Of note, SNAr reactions also failed in the case of 4-halo-2-methoxy analogs under various conditions.57,58 Despite several tested palladium-catalyzed transformations, only a recent variant of an Ullmann reaction was successfully employed to generate linker conjugates (Scheme 4).59 The copper-catalyzed amination was carried out starting from 2-fluoro-4-iodobenzoic acid and ω-Boc-protected primary or secondary amines (36a–36k) under mild conditions. The linker was first attached to the benzoic acid, as aryl iodides led to significant side products in the EDC/HOBt-mediated formation of amide bonds. Applying the Ullmann procedure and subsequent amide bond formation enabled synthesizing a diverse library of linker-functionalized benzamides. These derivatives comprised aliphatic linkers (40a–40e), PEGylated derivatives (40f and 40g), and rigidified analogs (40h–40k). Cleavage of the Boc protecting group under acidic conditions and subsequent HATU-mediated coupling with JQ1-acid culminated in 10 different BRD4-targeting PROTACs (43a–43k). Two more derivatives bearing a methoxy group (44h), or an H atom (45h) were realized to investigate the influence of the ortho substituent. A second target protein was addressed with 50 and 51, PROTACs based on a vorinostat-derived histone deacetylase 6 (HDAC6) ligand.60 A CRBN recruiter based on type 16 (Table 3) was selected due to its high LLE, similarity to the linker exit vector in A6, and the correct functional carboxylic acid handle required for the assembly of the final degrader via solid-phase synthesis. All HDAC6 degraders were synthesized according to our previously published approach using the preloaded resin 49 as key building block.60,61 After Fmoc-deprotection and coupling with the acids (liberated from 11d or 47), the final PROTAC 50 and 51 were released from the preloaded resin with trifluoroacetic acid and triisopropylsilane in CH2Cl2.

Scheme 4. Synthesis of Benzamide-Type PROTACs Targeting BRD4 or HDAC6.

Reagents and conditions: (a) (i) aryl iodide, CuI, l-proline, DMSO, 5 min; (ii) primary or secondary amines, DMSO, rt, 3 d, 19–79%; (b) EDC × HCl, HOBt, 3-aminopiperidine-2,6-dione hydrochloride, DIPEA, DMF, rt, 16 h, 27–82%; (c) DIPEA, DMSO, 90 °C, 16 h, 51%; (d) CoCl2, NaBH4, MeOH, 0 °C, 2 h, 22%; (e) (i) TFA, CH2Cl2, rt, 2 h; (ii) (+)-JQ1 carboxylic acid, HATU, DIPEA, DMF, rt, 16 h, 31–92%; (f) (i) glyoxylic acid monohydrate, NaOAc, AcOH, MeOH, 0 °C; (ii) NaCNBH3, 0 °C, 1 h, 29%; (g) (i) 47, TFA, CH2Cl2, rt, 2 h or 48; (ii) 49, 20% piperidine, DMF, rt, 2 × 5 min; (iii) 47-COOH or 48-COOH, 49-NH2, HATU/EDC × HCl, HOBt × H2O, DIPEA, DMF, rt, 18 h; (h) TFA, triisopropylsilane, CH2Cl2, rt, 1 h, 28–33% (7 steps).

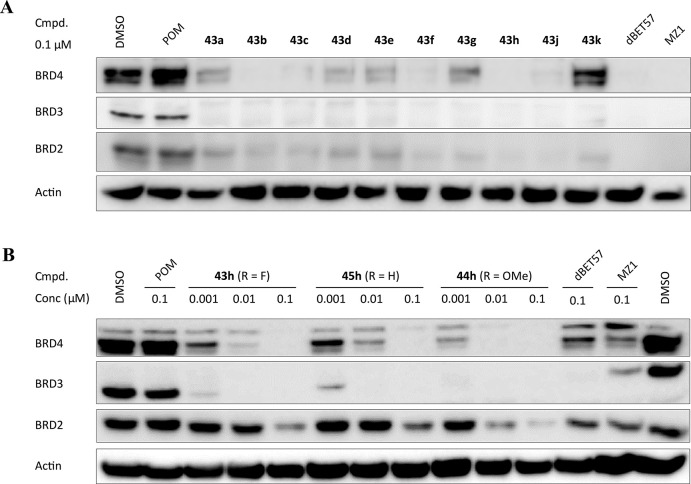

Cellular Evaluations of Novel Benzamide-Type PROTACs

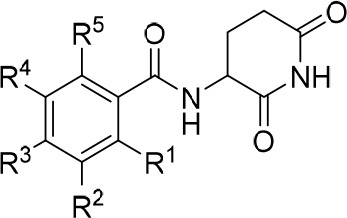

The 12 novel BRD4-targeting PROTACs were evaluated in the cell lines MOLT4 (Figure 3) and MV4;11 (Figure S6). For comparison, the established CRBN-recruiting PROTAC dBET57 and the VHL-addressing degrader MZ1 were included in the study.62,63 Degradation capabilities (% target degraded) and critical physicochemical properties are summarized in Table 4. All PROTACs, except for 43k, resulted in a pronounced reduction of BRD4 levels after a 24 h treatment with 0.1 μM of the PROTACs. Protein attenuation was comparable to dBET57 or MZ1 treatments. Surprisingly, even strongly rigidified compounds such as 43j triggered significant BRD4 degradation. The lipophilicity of PROTACs can be tuned by the choice of the linker, as exemplified by the increase in the log D value of homologs 43a–43e. Throughout the series, HSA binding values ranged from 90 to 96% but could be reduced by incorporating PEG-type linkers.18 Most PROTACs achieved CHIIAM values between 30 and 50, a previously defined optimal range to achieve good membrane permeability.64 Of note, potent BRD4 degraders with molecular weights below 700 g/mol (43a) or TPSA as low as 139 Å2 (43j) were obtained. If intramolecular HBs can lock the bonded isoindole conformation, a superior outcome for derived PROTACs can be expected. Furthermore, the shielding of one HBD could lead to improved cell permeability. Direct comparison between 43h (R = F), 44h (R = OMe), and 45h (R = H) revealed that a more pronounced target degradation was observed for 44h (Table 4 and Figure 3B). In a concentration-dependent experiment, DC50,24h (BRD4) values of 11, 4.7, and 0.59 nM were determined for dBET57, 43h, and 44h, respectively (Figure S7A,B). Next, we assessed the solubility of the BRD4 PROTACs (Table 4) and analyzed structure–property relationships. As expected, solubility of compounds possessing a PEG-type linker had improved solubilities (e.g., 43f and 43g), whereas highly hydrophobic compounds such as 43e bearing alkyl linkers displayed very poor solubility (<1 μg/mL). However, rigidified compounds including lead PROTAC 44h were poorly soluble in buffer. We expect that the incorporation of protonable nitrogen into the linker moiety could further optimize this feature.

Figure 3.

Evaluation of BRD4 PROTACs 43–45 in MOLT4 cells. (A) Western blot analyses of BRD4, BRD3, BRD2, and actin protein levels in MOLT4 cells treated with pomalidomide (POM), PROTACs 43 or the CRBN-recruiting reference dBET57 or the VHL-recruiting reference MZ1 for 24 h at 0.1 μM. (B) Western blot analyses of the homologous series 43h, 44h, and 45h at three different concentrations after treatment of MOLT4 cells for 24 h.

Table 4. Physicochemical Properties and Target Degradation Capabilities of BRD4-Targeting PROTACs 43–45 and the HDAC6 Degraders 50 and 51.

| PROTAC | elog D7.4a | PPB (%)b | CHIc | log(S)d | Target deg (%)e |

|---|---|---|---|---|---|

| dBET57 | 2.7 | 93 | 32.3 | –5.3 | 92 |

| MZ1 | 2.7 | 92 | 31.5 | –4.9 | 94 |

| 43a | 2.1 | 91 | 30.4 | –4.8 | 70 |

| 43b | 2.3 | 92 | 30.7 | –4.5 | 85 |

| 43c | 2.7 | 94 | 34.8 | n.a.g | 80 |

| 43d | 3.3 | 95 | 38.7 | n.a. | 69 |

| 43e | 3.8 | 96 | 43.9 | n.a. | 65 |

| 43f | 2.2 | 90 | 29.6 | –4.3 | 81 |

| 43g | 2.3 | 90 | 28.8 | –3.9 | 60 |

| 43h | 2.5 | 93 | 32.4 | –5.8 | 91 |

| 43j | 3.1 | 95 | 36.0 | n.a. | 83 |

| 43k | 2.9 | 95 | 36.7 | n.a. | 37 |

| 44h | 2.4 | 92 | 31.6 | –5.6 | 96 |

| 45h | 2.2 | 91 | 30.6 | –5.5 | 83 |

| 50 | 1.0 | 90 | 27.5 | n.d.f | 81 |

| 51 | 0.9 | 90 | 28.5 | n.d. | 87 |

| A6 | 1.3 | 91 | 29.2 | n.d. | 72 |

Distribution coefficients at pH 7.4 were estimated by an HPLC-based method.

Plasma protein binding; experimentally determined percentage of compound bound to human serum albumin.

Chromatographic hydrophobicity index values referring to IAM chromatography (CHIIAM values).

Logarithm of the solubility measured in mol/L at pH 6.8 by an HPLC-based method.

Percentage of degraded target protein (BRD4 after 24 h treatment of MOLT4 cells with 0.1 μM of PROTACs 43–45 or HDAC6 after 24 h treatment of MM.1S cells with 0.1 μM of PROTACs 50, 51, or A6). Values are normalized to respective loading controls and to DMSO-treated conditions. BRD4/HDAC6 degradation data represent the average of at least two independent biological experiments.

Not determined.

Not available (<1 μg/mL).

To evaluate the suitability of leading PROTACs for future in vivo applications, we conducted assessments of numerous parameters including chemical solubility and human plasma protein binding, as well as stability in human plasma, human liver microsomes, and aqueous buffer systems. Figure S8 and Figure 4 present physicochemical profiles of compounds 43h and 44h, respectively. Noteworthy, benzamide-type PROTACs exhibit exceptional stability in human plasma and demonstrate enhanced water stability compared to phthalimide-based drugs like dBET1 (Figure S8A). The observed moderate stability in human liver microsomes could possibly be attributed to JQ1’s vulnerability to metabolic processes.65 This notion is reinforced by the considerable stability shown by benzamide MGs, namely compounds 15 and 18, across all tested systems (Figure S8B).

Figure 4.

Physicochemical and biochemical profile of PROTAC 44h.

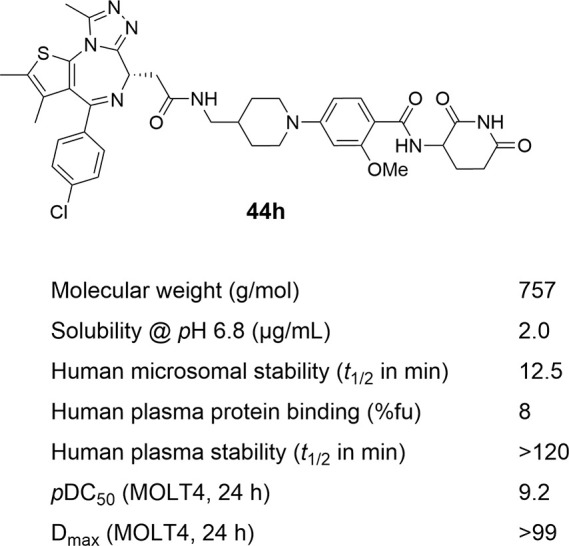

To demonstrate the general utility of novel CRBN ligands described in this study, we sought to degrade a second protein with benzamide-type PROTACs. The HDAC6-targeting degraders 50 and 51 were investigated in the multiple myeloma cell line MM.1S and compared to our previous hit compound A6 (Table 4 and Figure 5A).60 Compound 50 or 51 performed well and resulted in even more pronounced degradation of HDAC6 (85% and 91%, respectively) compared to treatment with A6 at 1 μM (80% degradation). Both compounds significantly outperformed this reference compound when tested at concentrations as low as 100 nM (Table 4 and Figure 5B). As expected, compound 51, bearing the methoxy substituent at the ortho position, performed slightly better than its fluorinated analog 50. Concentration-dependent experiments revealed DC50,24h (HDAC6) values of 6.5 and 5.8 nM for A6 and 51, respectively (Figure S7C,D). The control HDAC isoform HDAC1 (class I) was not affected by either compound (Figure 5A).

Figure 5.

HDAC6 degraders 50, 51, and A6 induce degradation of HDAC6. (A) Western blot analyses of HDAC6, HDAC1, and GAPDH protein levels in MM.1S cells treated with compounds 50, 51, and A6 for 24 h at the indicated dose. (B) Densitometric analysis of the Western blot assays. Data are normalized to loading control and are shown as mean ± s.d. (n = 3, independent experiments). * p < 0.05; ** p < 0.01; *** p < 0.001.

In the final analysis, we aimed to verify that the characteristic prevention of neosubstrate degradation of our benzamide-type ligands is also preserved in their corresponding PROTACs. We subjected MM.1S, MOLT4, or HuH6 cells to treatment with BRD4 PROTACs or pomalidomide for a period of 24 h and assessed protein levels by Western blot (Figure 6A). Remarkably, after treatment with 43h and 44h, as well as the reference CRBN-recruiting PROTAC dBET57, a significant reduction in the levels of the lymphoid transcription factors IKZF1 and IKZF3 was seen in the two examined cell lines. The degradation of IKZF1 and IKZF3 was less significant when MM.1S and MOLT4 cells were exposed to PROTACs 43h and 44h at a dose of 1 μM for a duration of 4 h. In contrast, the HDAC6-targeting PROTACs 51 and its related PROTAC A6 had negligible effects on the aforementioned transcription factors. Given the role of BRD4 in epigenetic regulation we hypothesized that downregulation of IKZF1 and IKZF3 may arise on the transcriptional level as a consequence of BRD4 inactivation.66 In order to distinguish direct effects on protein degradation from transcriptional RNA expression regulation, we applied the Artichoke lentiviral reporter vector that ectopically expresses an IKZF3-GFP fusion protein independent of cellular transcriptional control.67 In fact, the abundance of IKZF3-GFP was not significantly altered by either PROTACs 43h and 44h (Figure 6B) or their MG precursors 15 and 18, respectively. In contrast, significant decrease of IKZF3-GFP was observed with PROTACs generated from traditional IMiD-scaffolds (i.e., dBET6 and dBET57), while the BRD4 inhibitor JQ1 or the VHL-hijacking PROTAC MZ1 did not induce such changes. These results confirmed the absence of IMiD neosubstrate degradation and selectivity of benzamide-based PROTACs.

Figure 6.

Investigation of neomorphic activities of BRD4 and HDAC6 PROTACs as compared to reference compounds. (A) Quantification of Western blot band intensities after treating the respective cell line with compound at the indicated conditions. Heatmap colors refer to the remaining protein levels after cell treatment. Values are normalized to respective loading controls and to DMSO-treated conditions and represent an average of at least two independent experiments. POM: pomalidomide. dBET57: BRD4 PROTAC. A6: HDAC6 PROTAC. (B) Influence on the pomalidomide-sensitive zinc-finger protein IKZF3 in cells by IMiDs, benzamide-type CRBN ligands, and BRD4 degraders. Cells stably expressing IKZF3-GFP were treated with PROTACs followed by flow cytometry to assess IKZF3 degradation. The graph shows the average of normalized GFP/mCherry ratios for drug-treated versus untreated cells (n = 3).

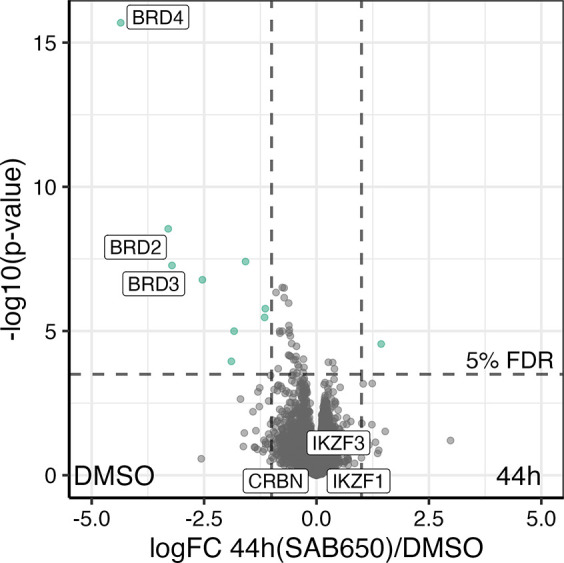

Quantitative proteomics (Figure 7) in MOLT4 cells endorsed the slight preference of PROTAC 44h for BRD4 down-regulation over BRD2 and BRD3, which are all targeted by the POI ligand JQ1. The IMiD neosubstrates IKZF1 and IKZF3, CK1a and GSPT1 remained unaffected by 44h at a concentration of 1 μM, which is in line with the results from Western blot analyses (Figure 6A) and ectopically expressed IKZF3 (Figure 6B). Consistent with previous findings on other BRD4 degraders such as dBET1 and MZ1, the administration of 44h resulted in the transcriptional repression of the oncogene MYC (Figure S9).68

Figure 7.

Quantitative proteomics for BRD4 PROTAC 44h. Total proteome of the MOLT4 cells treated with compound 44h at 1 μM for 4 h was compared to the proteome of the control cells (DMSO) using the moderated 2-sided 2-sample t test (n = 5). For each protein the log 10 p-value (y-axis) is plotted against the log 2 log FC 44h(SAB650)/DMSO. p-values were adjusted using the Benjamini–Hochberg procedure. The regulated proteins (5% FDR and absolute log FC > 1) are indicated by color.

Conclusions

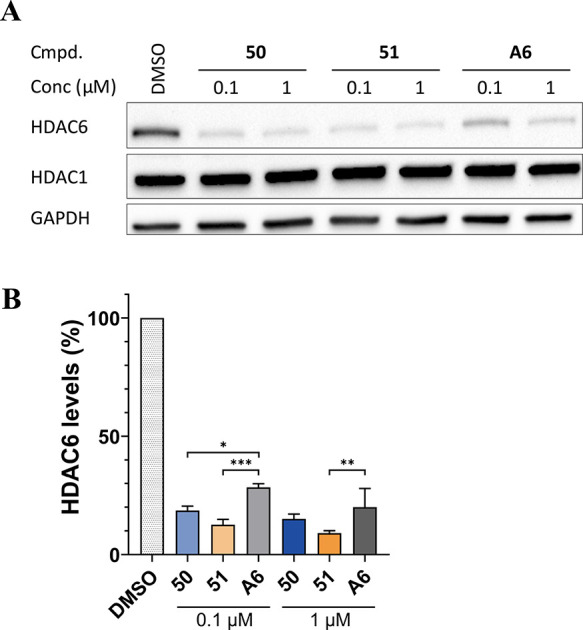

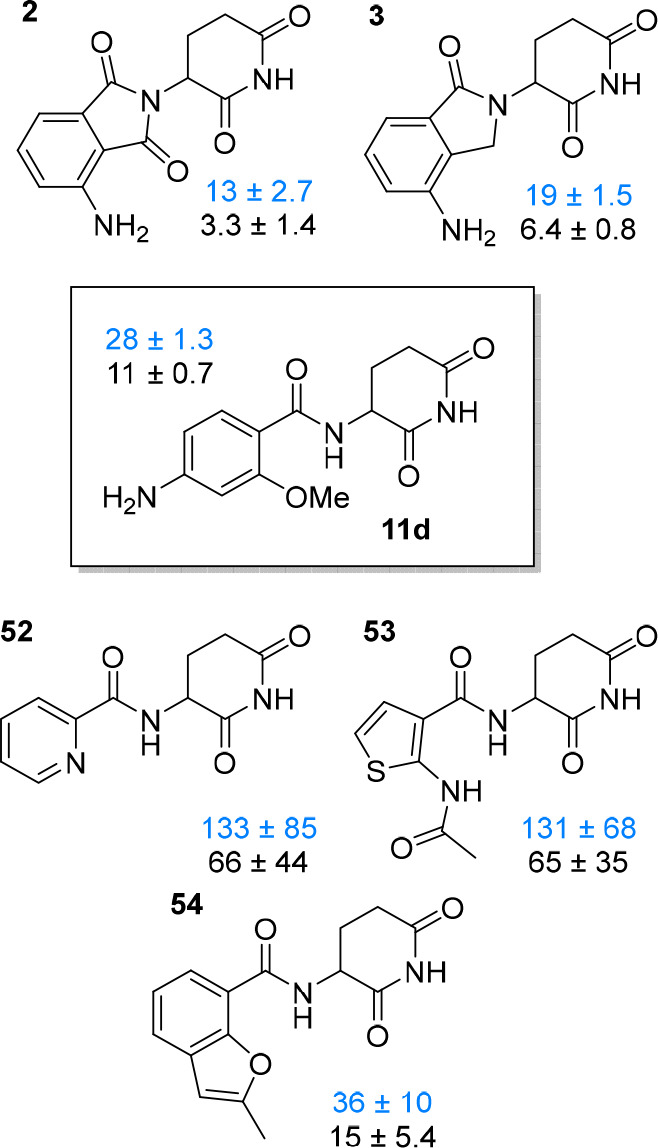

In this study, we systematically investigated an alternative CRBN recruiting scaffold that could find use in various TPD applications. Our results show that ortho-substituted benzamide derivatives represent very attractive derivatives for PROTAC development. Starting from an initial weak CRBN ligand, we rationalized nonbonded interactions between the chemical entities and their receptors.69 Part of the medicinal chemistry-driven optimization strategy was the analysis of van der Waals interactions, hydrogen bonds, and hydrophobicity. The compound refinement was accompanied by a critical assessment of important physicochemical and biologically relevant properties. The affinity of the lead compound 11d to the hTBD was close to those of classical scaffolds such as 2 or 3 (Figure 8) or the natural CRBN degron,32 but higher than those of other aryl amides 52–54 taken from the recent patent literature (Figure S10).70−73 We were able to translate conformationally locked benzamide-type ligands into potent degraders of BRD4 and HDAC6 that possessed advantages compared to IMiD-based prototypes such as dBET57, particularly in terms of stability and neosubstrate selectivity. Our efforts highlight the importance of medicinal chemistry optimization of E3 ligase ligands and PROTAC development to be balanced and multidimensional.

Figure 8.

Affinity ranking of ligand 11d among the established CRBN ligands pomalidomide (2) and lenalidomide (3), as well as novel chemotypes (52–54) extracted from patent literature. IC50 and derived Ki values (both in μM) are shown in blue and black, respectively, together with their confidence intervals.

Experimental Section

Chemistry

General Synthetic Methods and Materials

Preparative column chromatography (CC) was performed using Merck silica gel 60 (0.063–0.200 mm) or using an automated flash chromatography (FC) system puriFlash XS 520Plus. Solid phase synthesis was processed in PP-reactors equipped with a PE frit (5 mL, 25 μm pore size, MultiSyn Tech GmbH). The synthesis was carried out at room temperature on an orbital shaker (RS-OS 5, Phoenix Instruments GmbH). Melting points were determined on a Büchi 510 oil bath apparatus or on a Reichelt hot-stage apparatus and were uncorrected. 1H NMR and 13C NMR spectra were recorded on a Bruker Avance 400 MHz NMR spectrometer, Bruker Avance 500 MHz NMR spectrometer or on a Bruker Avance III 600 MHz NMR spectrometer, respectively. NMR spectra were processed and analyzed in MestReNova. Chemical shifts are given in parts per million (ppm), coupling constants J are given in Hertz, and spin multiplicities are given as s (singlet), d (doublet), t (triplet), q (quartet), or m (multiplet). In the case of overlapping extraneous solvent peaks, multiplet analyses in 1H NMR spectra were performed using qGSD (quantitative Global Spectral Deconvolution). Resonance assignments were made based on one- and two-dimensional NMR techniques which include 1H, 13C, DEPT, HSQC, and HMBC experiments. The purity and identity of the compounds were determined by HPLC-UV obtained on an LC–MS instrument (Agilent Infinity Lab LC/MSD-system with ESI-source coupled with an Agilent HPLC 1260 Infinity II) or separately on an LC instrument (Dionex UltiMate 3000 UHPLC modular system) and High-Resolution Mass Spectrometer (Thermo Scientific Q Exactive Plus). For the former, an EC50/2 Nucleodur C18 Gravity 3 μm column (Macherey-Nagel) was used. The column temperature was 40 °C. HPLC conditions started with 90% H2O containing 2 mM NH4Ac. The gradient ramped up to 100% MeCN in 10 min, followed by further flushing with 100% MeCN for 5 min. The flow rate was 0.5 mL/min. The samples were dissolved in H2O, MeOH, or MeCN (approximately 1 mg/mL), and 2 μL sample solution was injected. Positive total ion scans were observed from 100 to 1000 m/z (or more if necessary), and UV absorption was detected from 190–600 nm using a diode array detector (DAD). The purity was determined at 220–600 nm, unless indicated otherwise. For the latter, a Waters Acquity UPLC HSS C18 SB column (1.8 μm, 2.1 mm × 50 mm) was used, thermostated at 40 °C. The mobile phase consisted of 0.1% TFA in H2O and MeCN, employing the following gradient: 5% to 95% MeCN in 10 min, then 95% MeCN for 4 min, with flow rate of 0.3 mL/min and injection volume of 5 μL. For PROTACs 50 and 51, the following HPLC systems were used: A Thermo Fisher Scientific Ulti-MateTM 3000 UHPLC system with a Nucleodur 100-5 C18 (250 × 4.6 mm, Macherey Nagel) with a flow rate of 1 mL/min and a temperature of 25 °C with an appropriate gradient was used. For preparative purposes, an AZURA Prep. 500/1000 gradient system with a Nucleodur 110-5 C18 HTec (150 × 32 mm, Macherey Nagel) column and a flow rate of 20 mL/min was used. Detection was implemented with UV absorption measurement at wavelengths of λ = 220 nm and λ = 250 nm. If not stated otherwise, the indicated purity was determined at a wavelength of 250 nm. H2Odd with an addition of 0.1% TFA (A) and MeCN (B) were used. The following gradient was used for purification via preparative HPLC: A 95% for 5 min equilibration, in 35 min to B 95% and 8 min isocratic. All compounds that were evaluated in biological assays are >95% pure by LC/MS or UPLC analysis, respectively.

General Procedure A. Preparation of Benzamido Glutarimides by Acylation

3-Aminopiperidine-2,6-dione hydrochloride (0.33 g, 2.0 mmol) was suspended in dry CH2Cl2, and it was cooled to 0 °C. Subsequently, Et3N (0.56 mL, 4.0 mmol) and the corresponding in situ-generated benzoyl chloride (2.0 mmol) were added. After stirring the mixture for 18 h at rt, it was quenched by the addition of half-saturated NH4Cl solution (100 mL), and then extracted with 10% MeOH in EtOAc (2 × 100 mL). The combined organic layers were washed with H2O (100 mL) and brine (100 mL), dried over Na2SO4, filtered, and concentrated in vacuo.

General Procedure B. Preparation of Benzamido Glutarimides with EDC/HOBt42

The corresponding benzoic acid derivative (5.0 mmol), 3-aminopiperidine-2,6-dione hydrochloride (3.29 g, 20 mmol), and DIPEA (3.48 mL, 20 mmol) were suspended in dry DMF (20 mL). Subsequently, EDC × HCl (1.05 g, 5.5 mmol) and HOBt × H2O (0.84 g, 5.5 mmol) were added. After stirring the mixture for 18 h at rt, it was quenched by the addition of half-saturated NH4Cl solution (100 mL) and then extracted with 10% MeOH in EtOAc (2 × 100 mL). The combined organic layers were washed with H2O and brine (each 100 mL), dried over Na2SO4, filtered, and concentrated in vacuo.

General Procedure C. Reduction of Nitro Group

The corresponding nitro-containing compound (1.0 mmol) was dissolved in dry DMF (10 mL), and 10% Pd/C (20% by mass) was added under an argon atmosphere. The reaction mixture was stirred under H2 (1 atm, balloon) for 18 h at rt. The mixture was filtered through Celite and washed with MeOH (2 × 20 mL), and the filtrate was concentrated.

General Procedure D. Copper-Catalyzed Ullmann-Type Coupling

The corresponding 4-iodobenzoic acid derivative (3.0 mmol), anhydrous CuI (114 mg, 0.6 mmol), and l-(−)-proline (138 mg, 1.2 mmol) were placed in a Schlenk tube, and it was evacuated and refilled with argon gas. The solids were suspended in dry DMSO (5 mL) and then stirred under an argon atmosphere for 5 min. Subsequently, a solution of the corresponding amine (9.0 mmol) in dry DMSO (5 mL) was added, and it was mixed for 3 d at rt and protected from light. The mixture was portioned between EtOAc (50 mL) and 10% KHSO4 solution (50 mL). The aqueous layer was extracted again with EtOAc (50 mL), and the combined organic layers were washed with 5% LiCl solution and brine (each 50 mL), dried over Na2SO4, filtered, and concentrated in vacuo.

General Procedure E. Assembly of BRD4-Targeting PROTACs

The corresponding Boc-protected linker-ligand derivative 40, 41, or 42 (0.1 mmol) was dissolved in dry CH2Cl2 (8 mL) and treated with TFA (2 mL). The mixture was stirred at rt for 2 h, after which it was concentrated in vacuo, coevaporated with dry CH2Cl2 (2 × 5 mL), and dried under high vacuum. Subsequently, (+)-JQ1 carboxylic acid (40 mg, 0.1 mmol), DIPEA (35 μL, 0.2 mmol), and HATU (42 mg, 0.11 mmol) were dissolved in dry DMF (4 mL) and stirred for 5 min at rt. The deprotected amine, dissolved in dry DMF (4 mL) and DIPEA (70 μL, 0.4 mmol), was added, and the combined mixture was stirred at rt for 16 h. It was quenched by the addition of half-saturated NH4Cl solution (50 mL) and then extracted with EtOAc (2 × 50 mL). The combined organic layers were washed with 5% LiCl solution and brine (each 50 mL), dried over Na2SO4, filtered, and concentrated in vacuo.

Synthetic Details for the Synthesis of Compounds 6 to 53. N-(2,6-Dioxo-3-piperidyl)benzamide (6a)

This compound was synthesized as described previously.34

N-(2,6-Dioxo-3-piperidyl)-2,3,4,5-tetrafluorobenzamide (6b)

This compound was synthesized as described previously.34

N-(2,6-Dioxo-3-piperidyl)-3-nitrobenzamide (7a)

This compound was prepared using the General Procedure A and 3-nitrobenzoyl chloride (0.37 g). The crude product was purified by CC (gradient of petroleum ether/EtOAc 1:2 to EtOAc) to give a colorless solid. Yield 0.34 g (61%); mp 206–210 °C; Rf = 0.54 (EtOAc); 1H NMR (600 MHz, DMSO-d6) δ 1.98–2.05 (m, 1H), 2.08–2.19 (m, 1H), 2.52–2.60 (m, 1H), 2.77–2.86 (m, 1H), 4.80–4.87 (m, 1H), 7.81 (t, J = 8.0 Hz, 1H), 8.29–8.33 (m, 1H), 8.38–8.43 (m, 1H), 8.71 (t, J = 2.0 Hz, 1H), 9.17 (d, J = 8.3 Hz, 1H), 10.89 (s, 1H); 13C NMR (151 MHz, DMSO-d6) δ 24.22 (C-4′), 31.12 (C-5′), 49.92 (C-3′), 122.13, 126.34, 130.45 (C-2, C-4, C-5), 133.98, 135.42 (C-1, C-6), 148.00 (C-3), 164.25 (CO), 172.11, 173.15 (C-2′, C-6′); LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 6.84 min, 99% purity. m/z [M + H]+ calcd for C12H11N3O5, 278.08; found, 278.0.

N-(2,6-Dioxo-3-piperidyl)-2-fluoro-3-nitrobenzamide (7b)

This compound was prepared using the General Procedure A and 2-fluoro-3-nitrobenzoyl chloride (0.41 g). The crude product was recrystallized from 90% EtOAc/n-hexanes give a colorless solid. Yield 0.25 g (43%); mp 184–186 °C; Rf = 0.57 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.99–2.07 (m, 1H), 2.04–2.14 (m, 1H), 2.50–2.59 (m, 1H), 2.74–2.84 (m, 1H), 4.74–4.83 (m, 1H), 7.53 (t, J = 8.0 Hz, 1H), 7.93–7.99 (m, 1H), 8.22–8.29 (m, 1H), 8.93 (d, J = 8.2 Hz, 1H), 10.87 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.08, 30.98, 49.92, 125.26 (d, J = 4.7 Hz), 126.64 (d, J = 14.5 Hz), 128.12 (d, J = 2.2 Hz), 135.66 (d, J = 3.7 Hz), 137.70 (d, J = 8.5 Hz), 151.93 (d, J = 266.2 Hz), 162.31, 171.63, 172.98; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 220–400 nm), tR = 2.69 min, 99% purity. m/z [M + H]+ calcd for C12H11FN3O5, 296.07; found, 296.1. HRMS (ESI) m/z [M + H]+ calcd for C12H11FN3O5, 296.0677; found, 296.0665.

N-(2,6-Dioxo-3-piperidyl)-4-nitrobenzamide (7c)

This compound was prepared using the General Procedure A and 4-nitrobenzoyl chloride (0.37 g). The crude product was purified by FC (40 g, 30 μm, gradient from 60 to 100% EtOAc in n-hexanes) to give a colorless solid. Yield 0.26 g (46%); mp 238–240 °C; Rf = 0.51 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.96–2.05 (m, 1H), 2.07–2.19 (m, 1H), 2.51–2.60 (m, 1H), 2.75–2.86 (m, 1H), 4.81 (ddd, J = 5.1, 8.1, 12.9 Hz, 1H), 8.07–8.13 (m, 2H), 8.31–8.37 (m, 2H), 9.09 (d, J = 8.2 Hz, 1H), 10.87 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.16, 31.08, 49.90, 123.77, 128.96, 139.65, 149.34, 164.73, 172.00, 173.07; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 2.93 min, 99% purity. m/z [M + H]+ calcd for C12H11N3O5, 278.08; found, 278.1. HRMS (ESI) m/z [M + H]+ calcd for C12H11N3O5, 278.0772; found, 278.0766.

N-(2,6-Dioxo-3-piperidyl)-2-fluoro-4-nitrobenzamide (7d)

This compound was prepared using the General Procedure A and 2-fluoro-4-nitrobenzoyl chloride (0.41 g). The crude product was recrystallized from 80% EtOAc/n-hexanes give a colorless solid. Yield 0.16 g (27%); mp 196–200 °C; Rf = 0.60 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.99–2.18 (m, 2H), 2.50–2.59 (m, 1H), 2.74–2.85 (m, 1H), 4.79 (ddd, J = 5.7, 8.2, 12.1 Hz, 1H), 7.87 (t, J = 7.7 Hz, 1H), 8.16 (dd, J = 2.2, 8.5 Hz, 1H), 8.22 (dd, J = 2.2, 9.8 Hz, 1H), 8.94 (d, J = 8.2 Hz, 1H), 10.87 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.05, 30.98, 49.89, 112.32 (d, J = 27.8 Hz), 119.81 (d, J = 3.6 Hz), 129.81 (d, J = 15.5 Hz), 131.41 (d, J = 3.4 Hz), 149.48 (d, J = 8.9 Hz), 158.70 (d, J = 253.8 Hz), 162.48, 171.62, 172.98; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 2.98 min, 99% purity. m/z [M + H]+ calcd for C12H11FN3O5, 296.07; found, 296.1. HRMS (ESI) m/z [M + H]+ calcd for C12H11FN3O5, 296.0677; found, 296.0667.

N-(2,6-Dioxo-3-piperidyl)-2-nitrobenzamide (7e)

This compound was prepared using the General Procedure A and 2-nitrobenzoyl chloride (0.37 g). The crude product was purified by FC (40 g, 30 μm, gradient from 60 to 100% EtOAc in n-hexanes) to give a beige solid. Yield 0.31 g (56%); mp 174–176 °C; Rf = 0.53 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 2.00–2.10 (m, 2H), 2.50–2.59 (m, 1H), 2.73–2.84 (m, 1H), 4.69–4.77 (m, 1H), 7.64 (dd, J = 1.5, 7.6 Hz, 1H), 7.67–7.74 (m, 1H), 7.78–7.85 (m, 1H), 8.05 (dd, J = 1.2, 8.2 Hz, 1H), 9.01 (d, J = 8.2 Hz, 1H), 10.85 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.01, 30.85, 49.63, 124.25, 129.23, 131.10, 132.06, 133.79, 147.14, 165.53, 171.76, 173.01; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 220–400 nm), tR = 1.29 min, 99% purity. m/z [M + H]+ calcd for C12H11N3O5, 278.08; found, 278.1. HRMS (ESI) m/z [M + H]+ calcd for C12H11N3O5, 278.0772; found, 278.0765.

N-(2,6-Dioxo-3-piperidyl)-2-fluoro-6-nitrobenzamide (7f)

This compound was prepared using the General Procedure A and 2-fluoro-6-nitrobenzoyl chloride (0.41 g). The crude product was purified by FC (40 g, 30 μm, gradient from 60 to 100% EtOAc in n-hexanes) to give a gray solid. Yield 0.54 g (91%); mp >240 °C; Rf = 0.64 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.88–2.00 (m, 1H), 2.07–2.16 (m, 1H), 2.48–2.59 (m, 1H), 2.71–2.82 (m, 1H), 4.73–4.82 (m, 1H), 7.70–7.81 (m, 2H), 8.01 (dd, J = 1.8, 7.5 Hz, 1H), 9.15 (d, J = 7.9 Hz, 1H), 10.85 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.04, 30.67, 49.83, 120.53 (d, J = 3.1 Hz), 121.38 (d, J = 24.2 Hz), 122.18 (d, J = 22.3 Hz), 131.78 (d, J = 8.8 Hz), 146.79 (d, J = 5.2 Hz), 158.57 (d, J = 249.8 Hz); LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 1.33 min, 98% purity. m/z [M + H]+ calcd for C12H11FN3O5, 296.07; found, 296.1. HRMS (ESI) m/z [M + H]+ calcd for C12H11FN3O5, 296.0677; found, 296.0669.

3-Amino-N-(2,6-dioxo-3-piperidyl)benzamide (8a)

This compound was prepared using the General Procedure C and nitro compound 7a (0.28 g). The crude product was purified by CC (gradient of EtOAc 10% EtOH/EtOAc) to give a colorless solid. Yield 0.54 g (87%); mp 196–198 °C; Rf = 0.49 (10% EtOH/EtOAc); 1H NMR (600 MHz, DMSO-d6) δ 1.90–2.01 (m, 1H), 2.01–2.14 (m, 1H), 2.49–2.59 (m, 1H), 2.65–2.87 (m, 1H), 4.73 (ddd, J = 5.3, 8.3, 12.4 Hz, 1H), 5.23 (s, 2H), 6.63–6.76 (m, 1H), 6.90–7.00 (m, 1H), 7.04 (t, J = 2.0 Hz, 1H), 7.08 (t, J = 7.8 Hz, 1H), 8.47 (d, J = 8.4 Hz, 1H), 10.80 (s, 1H); 13C NMR (151 MHz, DMSO-d6) δ 24.39, 31.16, 49.56, 113.02, 114.54, 116.82, 128.83, 135.05, 148.88, 167.01, 172.48, 173.21; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–400 nm), tR = 3.02 min, 99% purity. m/z [M + H]+ calcd for C12H14N3O3, 248.10; found, 247.9. HRMS (ESI) m/z [M + H]+ calcd for C12H14N3O3, 248.1030; found, 248.1022.

3-Amino-N-(2,6-dioxo-3-piperidyl)-2-fluorobenzamide (8b)

This compound was prepared using the General Procedure C and nitro compound 7b (0.30 g). The crude product was recrystallized from 80% EtOAc/n-hexanes give a beige solid. Yield 98 mg (37%); mp 186–188 °C; Rf = 0.47 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.96–2.13 (m, 2H), 2.51–2.56 (m, 1H), 2.70–2.82 (m, 1H), 4.68–4.77 (m, 1H), 5.30 (s, 2H), 6.74 (t, J = 6.8 Hz, 1H), 6.86 (t, J = 8.2 Hz, 1H), 6.92 (t, J = 7.6 Hz, 1H), 8.38 (dd, J = 2.8, 8.5 Hz, 1H), 10.80 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.22, 31.02, 49.67, 115.91, 118.16 (d, J = 5.2 Hz), 123.44 (d, J = 11.4 Hz), 124.16 (d, J = 3.7 Hz), 137.14 (d, J = 13.4 Hz), 147.79 (d, J = 243.0 Hz), 164.34, 172.04, 173.06; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 0.82 min, 99% purity. m/z [M + H]+ calcd for C12H13FN3O3, 266.09; found, 266.1. HRMS (ESI) m/z [M + H]+ calcd for C12H13FN3O3, 266.0936; found, 266.0926.

4-Amino-N-(2,6-dioxo-3-piperidyl)benzamide (8c)

Nitro precursor 7c (0.28 g, 1.0 mmol) was dissolved in EtOH (10 mL) and AcOH (2.5 mL). A mixture of Fe (0.28 g, 5.0 mmol) in H2O (10 mL) and AcOH (10 mL) was added, and the combined mixture was stirred at 110 °C for 30 min. After cooling, it was diluted with EtOAc (100 mL) and carefully quenched with saturated NaHCO3 solution (100 mL). The organic layer was separated, washed with brine (100 mL), dried over Na2SO4, filtered, and concentrated in vacuo. The crude product was purified by FC (40 g, 30 μm, gradient from 60 to 100% EtOAc in n-hexanes) to give a beige solid. Yield 30 mg (14%); mp 234–236 °C; Rf = 0.32 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.88–1.97 (m, 1H), 2.02–2.14 (m, 1H), 2.53 (t, J = 3.8 Hz, 1H), 2.70–2.81 (m, 1H), 4.70 (ddd, J = 5.3, 8.4, 13.1 Hz, 1H), 5.61 (s, 2H), 6.52–6.57 (m, 2H), 7.55–7.60 (m, 2H), 8.23 (d, J = 8.3 Hz, 1H), 10.75 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.59, 31.17, 49.43, 112.66, 120.69, 129.02, 151.98, 166.17, 172.75, 173.20; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 0.56 min, 98% purity. m/z [M + H]+ calcd for C12H14N3O3, 248.10; found, 248.1. HRMS (ESI) m/z [M + H]+ calcd for C12H14N3O3, 248.1030; found, 248.1037.

4-Amino-N-(2,6-dioxo-3-piperidyl)-2-fluorobenzamide (8d)

This compound was prepared using the General Procedure C and nitro compound 7d (0.30 g). The crude product was purified by FC (40 g, 30 μm, gradient from 60 to 100% EtOAc in n-hexanes) to give a beige solid. Yield 0.20 g (75%); mp 216–218 °C; Rf = 0.41 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.95–2.15 (m, 2H), 2.50–2.56 (m, 1H), 2.69–2.81 (m, 1H), 4.65–4.75 (m, 1H), 5.97 (s, 2H), 6.30 (dd, J = 2.1, 14.5 Hz, 1H), 6.41 (dd, J = 2.1, 8.6 Hz, 1H), 7.49 (t, J = 8.8 Hz, 1H), 7.81 (t, J = 7.6 Hz, 1H), 10.78 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.35, 31.13, 49.87, 99.29 (d, J = 26.5 Hz), 108.04 (d, J = 12.4 Hz), 109.72, 132.09 (d, J = 4.7 Hz), 153.98 (d, J = 12.7 Hz), 161.78 (d, J = 245.8 Hz), 163.36 (d, J = 2.8 Hz), 172.50, 173.08; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 1.01 min, 95% purity. m/z [M + H]+ calcd for C12H13FN3O3, 266.09; found, 266.1. HRMS (ESI) m/z [M + H]+ calcd for C12H13FN3O3, 266.0936; found, 266.0925.

2-Amino-N-(2,6-dioxo-3-piperidyl)benzamide (8e)

This compound was synthesized by analogy with 8c, but using precursor 7e (0.28 g, 1.0 mmol). The crude product was recrystallized from 20% EtOH/EtOAc give a colorless solid. Yield 0.18 g (73%); mp 244–248 °C; Rf = 0.52 (EtOAc); 1H NMR (600 MHz, DMSO-d6) δ 1.90–1.99 (m, 1H), 2.06–2.16 (m, 1H), 2.50–2.57 (m, 1H), 2.73–2.82 (m, 1H), 4.68–4.75 (m, 1H), 6.39 (s, 2H), 6.49–6.55 (m, 1H), 6.70 (dd, J = 1.2, 8.3 Hz, 1H), 7.12–7.18 (m, 1H), 7.50 (dd, J = 1.6, 8.0 Hz, 1H), 8.44 (d, J = 8.3 Hz, 1H), 10.80 (s, 1H); 13C NMR (151 MHz, DMSO-d6) δ 24.33, 31.15, 49.22, 114.17, 114.67, 116.55, 128.25, 132.09, 149.89, 168.80, 172.57, 173.17; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 1.46 min, 99% purity. m/z [M + H]+ calcd for C12H14N3O3, 248.10; found, 248.1. HRMS (ESI) m/z [M + H]+ calcd for C12H14N3O3, 248.1030; found, 248.1020.

2-Amino-N-(2,6-dioxo-3-piperidyl)-6-fluorobenzamide (8f)

This compound was prepared using the General Procedure C and nitro compound 7f (0.30 g). The crude product was triturated with EtOAc and dried to give a beige solid. Yield 0.20 g (75%); mp 234–236 °C; Rf = 0.60 (EtOAc); 1H NMR (600 MHz, DMSO-d6) δ 1.94–2.02 (m, 1H), 2.04–2.14 (m, 1H), 2.50–2.56 (m, 1H), 2.71–2.82 (m, 1H), 4.69–4.77 (m, 1H), 5.98 (s, 2H), 6.28–6.34 (m, 1H), 6.50 (d, J = 8.2 Hz, 1H), 7.04–7.11 (m, 1H), 8.50 (dd, J = 2.8, 8.3 Hz, 1H), 10.87 (s, 1H); 13C NMR (151 MHz, DMSO-d6) δ 23.99, 31.11, 49.61, 101.69 (d, J = 23.0 Hz), 107.44 (d, J = 18.8 Hz), 111.42, 131.36 (d, J = 11.3 Hz), 149.53 (d, J = 6.4 Hz), 160.43 (d, J = 243.2 Hz), 164.59, 172.83 (d, J = 84.6 Hz); LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 2.02 min, 99% purity. m/z [M + H]+ calcd for C12H13FN3O3, 266.09; found, 266.0. HRMS (ESI) m/z [M + H]+ calcd for C12H13FN3O3, 266.0936; found, 266.0927.

2-Chloro-N-(2,6-dioxo-3-piperidyl)-4-nitrobenzamide (10a)

This compound was prepared using the General Procedure B and 2-chloro-4-nitrobenzoic acid (1.00 g). The crude product was purified by CC (CH2Cl2/MeOH 20:1) to give a gray solid. Yield 1.12 g (74%); mp 204–207 °C; Rf = 0.20 (CH2Cl2/MeOH 20:1); 1H NMR (400 MHz, DMSO-d6) δ 2.01–2.10 (m, 2H), 2.55–2.61 (m, 1H), 2.74–2.87 (m, 1H), 4.75–4.84 (m, 1H), 7.73 (d, J = 8.4 Hz, 1H), 8.28 (dd, J = 8.4, 2.2 Hz, 1H), 8.36 (d, J = 2.2 Hz, 1H), 9.08 (d, J = 8.3 Hz, 1H), 10.92 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 23.99, 30.78, 49.47, 122.46, 124.68, 130.07, 131.12, 141.93, 148.33, 164.92, 171.50, 172.91; UPLC-retention time, 3.51 min; purity 90%. HRMS (ESI) m/z [M + H]+ calcd for C12H9N3O5Cl, 310.0236; found, 310.0237.

N-(2,6-Dioxo-3-piperidyl)-4-nitro-2-(trifluoromethyl)benzamide (10b)

This compound was prepared using the General Procedure A (5 mmol scale) and 4-nitro-2-(trifluoromethyl)benzoyl chloride (1.27 g). The crude product was purified by FC (80 g, 30 μm, gradient from 10 to 100% EtOAc in cyclohexane) to give a beige solid. Yield 1.03 g (60%); mp 210–212 °C; Rf = 0.64 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.96–2.04 (m, 1H), 2.01–2.10 (m, 1H), 2.50–2.59 (m, 1H), 2.70–2.85 (m, 1H), 4.73–4.81 (m, 1H), 7.85 (d, J = 8.4 Hz, 1H), 8.50 (d, J = 2.3 Hz, 1H), 8.60 (dd, J = 2.3, 8.4 Hz, 1H), 9.13 (d, J = 8.2 Hz, 1H), 10.88 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 23.96, 30.91, 49.67, 121.82 (d, J = 5.1 Hz), 122.64 (q, J = 274.4 Hz), 127.49 (q, J = 33.1 Hz), 127.78, 130.85, 141.29, 148.02, 165.58, 171.58, 172.98; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 220–600 nm), tR = 4.08 min, 99% purity. m/z [M – H]− calcd for C13H9F3N3O5, 344.05; found, 344.1. HRMS (ESI) m/z [M – H]− calcd for C13H9F3N3O5, 344.0500; found, 344.0499.

N-(2,6-Dioxo-3-piperidyl)-2-methyl-4-nitrobenzamide (10c)

This compound was prepared using the General Procedure A (5 mmol scale) and 2-methyl-4-nitrobenzoyl chloride (1.00 g). The crude product was suspended in 1 M HCl (aq), and the solid product was collected by filtration, washed with H2O (2 × 10 mL), Et2O (2 × 10 mL), and dried in vacuo to give a gray solid. Yield 1.17 g (80%); mp 233–236 °C; Rf = 0.25 (CH2Cl2/MeOH 20:1); 1H NMR (400 MHz, DMSO-d6) δ 1.98–2.14 (m, 2H), 2.49 (s, 3H), 2.53–2.60 (m, 1H), 2.75–2.86 (m, 1H), 4.73–4.83 (m, 1H), 7.59 (d, J = 8.3 Hz, 1H), 8.12 (dd, J = 8.4, 2.4 Hz, 1H), 8.16 (d, J = 2.3 Hz, 1H), 8.87 (d, J = 8.4 Hz, 1H), 10.90 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 19.00, 23.99, 30.96, 49.37, 120.86, 124.98, 128.38, 137.69, 142.76, 147.70, 167.59, 171.84, 173.00; UPLC-retention time, 3.44 min; purity 89%. HRMS (ESI) m/z [M + H]+ calcd for C13H14N3O5, 292.0928; found, 292.0927.

N-(2,6-Dioxo-3-piperidyl)-2-methoxy-4-nitrobenzamide (10d)

This compound was prepared using the General Procedure A (5 mmol scale) and 2-methoxy-4-nitrobenzoyl chloride (1.08 g). The crude product was suspended in 1 M HCl (aq), and the solid product was collected by filtration, washed with H2O (2 × 10 mL), Et2O (2 × 10 mL), and dried in vacuo to give a gray solid. Yield 1.27 g (83%); mp 179–181 °C; Rf = 0.22 (CH2Cl2/MeOH 9:1); 1H NMR (400 MHz, DMSO-d6) δ 2.03–2.19 (m, 2H), 2.53–2.58 (m, 1H), 2.74–2.85 (m, 1H), 4.01 (s, 3H), 4.74–4.84 (m, 1H), 7.89 (s, 1H), 7.91–7.96 (m, 2H), 8.76 (d, J = 7.8 Hz, 1H), 10.92 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 23.99, 30.90, 49.92, 56.76, 107.13, 115.42, 128.88, 131.43, 149.69, 157.31, 163.58, 171.92, 172.95; UPLC-retention time, 3.80 min; purity 90%. HRMS (ESI) m/z [M + H]+ calcd for C13H14N3O, 308.0877; found, 308.0876.

N-(2,6-Dioxo-3-piperidyl)-2-hydroxy-4-nitrobenzamide (10e)

This compound was prepared using the General Procedure B and 2-hydroxy-4-nitrobenzoic acid (0.92 g). The crude product was purified by CC (CH2Cl2/MeOH 20:1) to give an off-white solid. Yield 0.77 g (53%); mp 195–198 °C; Rf = 0.18 (CH2Cl2/MeOH 20:1); 1H NMR (400 MHz, DMSO-d6) δ 2.07–2.18 (m, 2H), 2.54–2.59 (m, 1H), 2.74–2.86 (m, 1H), 4.79–4.87 (m, 1H), 7.74 (d, J = 2.2 Hz, 1H), 7.77 (dd, J = 8.6, 2.3 Hz, 1H), 8.09 (d, J = 8.6 Hz, 1H), 9.18 (d, J = 7.5 Hz, 1H), 10.96 (s, 1H), 12.43 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 23.87, 30.95, 50.03, 111.71, 113.57, 123.05, 131.00, 150.01, 158.20, 165.27, 171.89, 172.92; UPLC-retention time, 3.91 min; purity 95%. HRMS (ESI) m/z [M – H]− calcd for C12H10N3O6, 292.0575; found, 292.0573.

4-Amino-2-chloro-N-(2,6-dioxo-3-piperidyl)benzamide (11a)

Compound 10a (0.52 g, 1.69 mmol) and 1,2-dichlorobenzene (3.80 mL, 4.97 g, 33.8 mmol) were dissolved in dry DMF (15 mL) under an argon atmosphere. Pd/C (0.10 g, 20% by mass) was added and the mixture was stirred under a hydrogen atmosphere for 18 h at rt. The suspension was filtered through Celite and washed with MeOH (50 mL), and the volatiles were evaporated. The crude product was purified by CC (CH2Cl2/MeOH/NH4OH 9:1:0.1) to obtain a colorless solid. Yield 50 mg (11%); mp 182–186 °C; Rf = 0.22 (CH2Cl2/MeOH/NH4OH 9:1:0.1); 1H NMR (400 MHz, DMSO-d6) δ 1.93–2.10 (m, 2H), 2.55 (s, 1H), 2.69–2.83 (m, 1H), 4.62–4.73 (m, 1H), 5.76 (s, 2H), 6.50 (dd, J = 8.4, 2.2 Hz, 1H), 6.59 (d, J = 2.2 Hz, 1H), 7.24 (d, J = 8.4 Hz, 1H), 8.28 (d, J = 8.3 Hz, 1H), 10.82 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 24.26, 30.82, 49.45, 111.59, 113.84, 121.71, 130.76, 131.50, 151.47, 166.25, 172.19, 173.09; UPLC-retention time, 1.81 min; purity 97%. HRMS (ESI) m/z [M + H]+ calcd for C12H13N3O3Cl, 282.0640; found, 282.0636.

4-Amino-N-(2,6-dioxo-3-piperidyl)-2-(trifluoromethyl)benzamide (11b)

This compound was prepared using the General Procedure C and compound 10b (0.35 g). The crude product was purified by FC (25 g, 30 μm, gradient from 50 to 100% EtOAc in cyclohexane) to give a colorless solid. Yield 0.23 g (74%); mp 216–218 °C; Rf = 0.39 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.89–2.07 (m, 2H), 2.49–2.56 (m, 1H), 2.70–2.81 (m, 1H), 4.64 (ddd, J = 5.5, 8.4, 12.0 Hz, 1H), 5.82 (s, 2H), 6.76 (dd, J = 2.2, 8.3 Hz, 1H), 6.90 (d, J = 2.2 Hz, 1H), 7.27 (d, J = 8.2 Hz, 1H), 8.40 (d, J = 8.4 Hz, 1H), 10.77 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.23, 30.97, 49.44, 110.84 (d, J = 5.3 Hz), 115.46, 122.33, 124.02 (q, J = 274.6 Hz), 127.71 (q, J = 31.0 Hz), 130.28, 150.38, 167.51, 172.15, 173.11; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 220–600 nm), tR = 1.81 min, 98% purity. m/z [M + H]+ calcd for C13H13F3N3O3, 316.09; found, 316.1. HRMS (ESI) m/z [M + H]+ calcd for C13H13F3N3O3, 316.0904; found, 316.0895.

4-Amino-N-(2,6-dioxo-3-piperidyl)-2-methylbenzamide (11c)

This compound was prepared using the General Procedure C and compound 10c (1.15 g, 3.94 mmol). The crude product was purified by CC (CH2Cl2/MeOH/NH4OH 9:1:0.1) to obtain a colorless solid. Yield 0.21 g (21%); mp 146–150 °C; Rf = 0.30 (CH2Cl2/MeOH/NH4OH 9:1:0.1); 1H NMR (400 MHz, DMSO-d6) δ 1.89–2.12 (m, 2H), 2.28 (s, 3H), 2.52–2.56 (m, 1H), 2.71–2.82 (m, 1H), 4.62–4.70 (m, 1H), 5.38 (s, 2H), 6.34–6.39 (m, 2H), 7.16–7.21 (m, 1H), 8.08 (d, J = 8.4 Hz, 1H), 10.79 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 20.43, 24.36, 31.02, 49.23, 110.21, 115.53, 122.72, 129.15, 137.82, 150.23, 168.85, 172.54, 173.12; UPLC-retention time, 0.92 min; purity 95%. HRMS (ESI) m/z [M + H]+ calcd for C13H16N3O3, 262.1186; found, 262.1182.

4-Amino-N-(2,6-dioxo-3-piperidyl)-2-methoxybenzamide (11d)

This compound was prepared using the General Procedure C and compound 10d (0.61 g, 3.94 mmol). The crude product was purified by CC (CH2Cl2/MeOH/NH4OH 9:1:0.1) to obtain a colorless solid. Yield 80 mg (14%); mp 174–179 °C; Rf = 0.35 (CH2Cl2/MeOH/NH4OH 9:1:0.1); 1H NMR (400 MHz, DMSO-d6) δ 1.97–2.17 (m, 2H), 2.52–2.53 (m, 1H), 2.69–2.81 (m, 1H), 3.83 (s, 3H), 4.64–4.73 (m, 1H), 5.80 (s, 2H), 6.20 (dd, J = 8.5, 2.0 Hz, 1H), 6.24 (d, J = 2.0 Hz, 1H), 7.65 (d, J = 8.5 Hz, 1H), 8.34 (d, J = 6.9 Hz, 1H), 10.86 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 24.53, 31.10, 50.06, 55.43, 95.90, 106.18, 108.08, 132.76, 153.68, 159.24, 164.62, 172.86, 173.02; UPLC-retention time, 2.28 min; purity 96%. HRMS (ESI) m/z [M + H]+ calcd for C13H16N3O4, 278.1135; found, 278.1129.

4-Amino-N-(2,6-dioxo-3-piperidyl)-2-hydroxybenzamide (11e)

This compound was prepared using the General Procedure C and compound 10e (0.42 g, 3.94 mmol). The crude product was purified by CC (CH2Cl2/MeOH/NH4OH 9:1:0.1) to obtain a colorless solid. Yield 0.23 g (44%); mp 199–202 °C; Rf = 0.26 (CH2Cl2/MeOH/NH4OH 9:1:0.1); 1H NMR (400 MHz, DMSO-d6) δ 1.92–2.01 (m, 1H), 2.02–2.17 (m, 1H), 2.53–2.57 (m, 1H), 2.72–2.84 (m, 1H), 4.69–4.79 (m, 1H), 5.80 (s, 2H), 5.96 (d, J = 2.2 Hz, 1H), 6.07 (dd, J = 8.7, 2.2 Hz, 1H), 7.50 (d, J = 8.7 Hz, 1H), 8.55 (d, J = 8.1 Hz, 1H), 10.87 (s, 1H), 12.52 (s, 1H); 13C NMR (101 MHz, DMSO-d6) δ 24.19, 31.03, 49.11, 100.19, 106.15, 128.93, 162.25, 169.32, 172.32, 173.02; UPLC-retention time, 1.97 min; purity 97%. HRMS (ESI) m/z [M + H]+ calcd for C12H14N3O4, 264.0979; found, 264.0973.

4-Amino-N-(2,6-dioxo-3-piperidyl)-2,5-difluoro-3-methoxybenzamide (11f)

Compound 14 (0.46 g, 1.0 mmol) was dissolved in dry CH2Cl2, treated with TFA (0.23 mL, 3.0 mmol), and stirred at rt for 4 h. The brown suspension was filtrated, and the filtrate was subjected to FC (50 g, 30 μm, gradient from 30 to 100% EtOAc in cyclohexane) to give a slightly yellow solid. Yield 0.24 g (77%); mp 182–184 °C; Rf = 0.60 (80% EtOAc in cyclohexane); 1H NMR (500 MHz, DMSO-d6) δ 1.95–2.04 (m, 1H), 2.04–2.15 (m, 1H), 2.50–2.55 (m, 1H), 2.70–2.81 (m, 1H), 3.79 (s, 3H), 4.70 (ddd, J = 5.4, 7.9, 12.8 Hz, 1H), 5.83 (s, 2H), 7.16 (dd, J = 6.2, 11.6 Hz, 1H), 8.09 (dd, J = 5.5, 7.9 Hz, 1H), 10.75 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.21, 31.08, 49.93, 60.96 (d, J = 3.7 Hz), 107.50 (dd, J = 7.2, 13.2 Hz), 110.46 (dd, J = 4.0, 21.8 Hz), 134.26 (dd, J = 7.4, 16.5 Hz), 135.02 (dd, J = 5.2, 15.4 Hz), 145.95 (d, J = 234.9 Hz), 151.27 (d, J = 244.6 Hz), 162.54, 172.23, 173.05; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 2.62 min, 99% purity. m/z [M + H]+ calcd for C13H14F2N3O4, 314.09; found, 314.1. HRMS (ESI) m/z [M + H]+ calcd for C13H14F2N3O4, 314.0947; found, 314.0948.

N-(2,6-Dioxo-3-piperidyl)-2,4,5-trifluoro-3-methoxybenzamide (13)

This compound was prepared using the General Procedure A (4 mmol scale) and 2,4,5-trifluoro-3-methoxybenzoyl chloride (0.90 g). The crude product was purified by FC (40 g, 30 μm, gradient from 50 to 80% EtOAc in cyclohexane) to give a beige solid. Yield 0.53 g (42%); mp 174–176 °C; Rf = 0.69 (EtOAc); 1H NMR (500 MHz, DMSO-d6) δ 1.96–2.14 (m, 2H), 2.48–2.57 (m, 1H), 2.72–2.83 (m, 1H), 4.01 (s, 3H), 4.74 (ddd, J = 5.5, 8.2, 13.0 Hz, 1H), 7.35–7.44 (m, 1H), 8.67–8.72 (m, 1H), 10.85 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 24.06, 30.97, 49.94, 62.41 (t, J = 3.3 Hz), 110.43 (dd, J = 3.4, 20.5 Hz), 119.79 (d, J = 14.4 Hz), 137.64 (d, J = 14.5 Hz), 144.81 (dd, J = 10.5, 175.9 Hz), 147.45 (d, J = 9.1 Hz), 149.28 (d, J = 249.6 Hz), 161.77, 171.69, 172.98; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 200–600 nm), tR = 4.17 min, 99% purity. m/z [M + H]+ calcd for C13H12F3N2O4, 317.07; found, 317.1. HRMS (ESI) m/z [M + H]+ calcd for C13H12F3N2O4, 317.0744; found, 317.0732.

4-[(2,4-Dimethoxyphenyl)methylamino]-N-(2,6-dioxo-3-piperidyl)-2,5-difluoro-3-methoxybenzamide (14)

Compound 13 (0.88 g, 2.8 mmol) was dissolved in dry DMSO (28 mL). 2,4-Dimethoxybenzylamine (0.46 g, 2.8 mmol) and DIPEA (0.97 mL, 5.6 mmol) were added, and the mixture was stirred at 90 °C for 18 h. After cooling, it was diluted with EtOAc (100 mL) and washed with half-saturated NH4Cl solution (100 mL). The aqueous layer was extracted EtOAc (100 mL) again, and the combined organic layers were washed with 5% LiCl solution and brine (each 100 mL), dried over Na2SO4, filtered, and concentrated in vacuo. The crude product was purified by FC (80 g, 30 μm, gradient from 50 to 80% EtOAc in cyclohexane) to give a colorless solid. Yield 0.45 g (35%); mp 102–104 °C; Rf = 0.55 (80% EtOAc in cyclohexane); 1H NMR (600 MHz, DMSO-d6) δ 1.93–2.01 (m, 1H), 2.02–2.12 (m, 1H), 2.70–2.79 (m, 1H), 3.72 (d, J = 17.3 Hz, 6H), 3.78 (s, 3H), 4.41 (dd, J = 1.7, 7.0 Hz, 2H), 4.69 (ddd, J = 5.4, 8.0, 12.8 Hz, 1H), 5.74–5.79 (m, 1H), 6.42 (dd, J = 2.4, 8.3 Hz, 1H), 6.53 (d, J = 2.3 Hz, 1H), 7.03 (d, J = 8.3 Hz, 1H), 7.11 (dd, J = 6.3, 13.3 Hz, 1H), 8.18 (dd, J = 4.5, 8.1 Hz, 1H), 10.81 (s, 1H); 13C NMR (151 MHz, DMSO-d6) δ 24.18, 31.07, 49.89, 55.27, 55.54, 61.43, 98.53, 104.33, 109.91 (dd, J = 7.8, 13.7 Hz), 111.49 (dd, J = 4.1, 24.2 Hz), 120.21, 128.48, 134.48 (dd, J = 4.2, 11.2 Hz), 136.29 (dd, J = 8.1, 16.1 Hz), 146.90 (d, J = 236.6 Hz), 150.82 (d, J = 245.8 Hz), 157.84, 159.85, 162.33, 172.15, 173.08; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 220–600 nm), tR = 6.15 min, 99% purity. m/z [M + H]+ calcd for C22H24F2N3O6, 464.16; found, 464.3. HRMS (ESI) m/z [M + H]+ calcd for C22H24F2N3O6, 464.1628; found, 464.1628.

4-(Butylamino)-N-(2,6-dioxo-3-piperidyl)-2-fluorobenzamide (15)

A solution of 8d (0.27 g, 1.0 mmol) in dry DMF (20 mL) was added to a mixture of butyraldehyde (0.14 g, 2.0 mmol) in dry DMF (2 mL) and AcOH (1 mL) under an argon atmosphere. After stirring the solution for 1 h at rt, the mixture was cooled to 0 °C, and STAB (1.27 g, 6.0 mmol) was added portionwise. The mixture was stirred at rt for 18 h, after which MeOH (10 mL) was added, and the volatiles were then evaporated. The crude product was purified by FC (40 g, 30 μm, gradient from 30 to 100% EtOAc in cyclohexane) to give a blueish solid. Yield 0.22 g (68%); mp 150–152 °C; Rf = 0.53 (80% EtOAc in cyclohexane); 1H NMR (500 MHz, DMSO-d6) δ 0.90 (t, J = 7.4 Hz, 3H), 1.31–1.42 (m, 2H), 1.47–1.56 (m, 2H), 1.95–2.15 (m, 2H), 2.46–2.54 (m, 1H), 2.69–2.80 (m, 1H), 3.04 (td, J = 5.4, 7.0 Hz, 2H), 4.65–4.74 (m, 1H), 6.31 (dd, J = 2.2, 15.1 Hz, 1H), 6.44 (dd, J = 2.2, 8.6 Hz, 1H), 6.46–6.52 (m, 1H), 7.54 (t, J = 8.9 Hz, 1H), 7.81 (t, J = 7.6 Hz, 1H), 10.79 (s, 1H); 13C NMR (126 MHz, DMSO-d6) δ 13.86, 19.84, 24.36, 30.67, 31.14, 42.26, 49.89, 97.17 (d, J = 27.5 Hz), 107.54 (d, J = 12.7 Hz), 108.22, 131.92 (d, J = 4.8 Hz), 153.64 (d, J = 12.4 Hz), 162.01 (d, J = 245.8 Hz), 163.36 (d, J = 2.9 Hz), 172.52, 173.08; LC–MS (ESI) (90% H2O to 100% MeCN in 10 min, then 100% MeCN to 20 min, DAD 220–600 nm), tR = 5.37 min, 99% purity. m/z [M + H]+ calcd for C16H21FN3O3, 322.16; found, 322.3. HRMS (ESI) m/z [M + H]+ calcd for C16H21FN3O3, 322.1562; found, 322.1563.

4-[[2-(Butylamino)-2-oxo-ethyl]amino]-N-(2,6-dioxo-3-piperidyl)-2-fluorobenzamide