Status

It is well understood that the standard reporting condition (SRC, air mass (AM) 1.5 global/ 25°C/ 1000 W/m2) for measurement of photovoltaic (PV) solar cells is not relevant for ambient indoor PV (IPV) measurements [1]–[3]. Both the spectrum and the total irradiance of many artificial indoor light sources are significantly different from the AM 1.5 spectral irradiance. Unfortunately, no international standards or broadly adopted guidelines exist to clearly outline the measurement procedure to characterize and report the electrical performance of IPV devices. Hence, problems begin to arise when various laboratories report or compare the performance parameters of their IPV devices under common light sources such as fluorescent or white light emitting diode (LED) lighting. Currently, most laboratories report their IPV performance parameters under a light source that has been measured with a Lux meter, with the light intensity reported in the illuminance unit, lx (lm/m2). Typically, 1000 lx or fractions of it are considered appropriate for IPV measurements. However, it has been clearly demonstrated that illuminance is not an appropriate quantity for measuring and comparing IPV results so long as the precise reference spectrum remains undefined [4]. In some cases, an 18 % discrepancy in the short circuit current (Isc) may be reported under nominally similar lighting types at the same lux value, i.e., 1000 lx. It turns out the spectral distribution of the light source must also be considered. Adopting standards that clearly define the spectral irradiance profile of a given light source would help researchers conduct more accurate electrical measurements, even if lux continues to be used for measuring the light intensity. However, a more accurate method would involve extending the traditional reference-cell based method to IPV measurements under indoor lighting conditions. In short, reducing measurement uncertainties under well-defined reporting conditions (RC) would help advance the growing field of IPV and allow materials and device architects to better focus their efforts in developing high-efficiency devices, fine-tuned to specific ambient lighting profiles.

Current and Future Challenges

When it comes to accurate electrical characterization of PV devices, the biggest challenge is related to the accurate (low uncertainty) measurement of the irradiance of the light source used to perform the current vs. voltage (I-V) measurement. In an ideal world, all researchers would use the same exact light source with the same spectral and angular distribution. In this case, the intensity of the illumination incident on the cell could be measured and adjusted with a calibrated lux meter, spectroradiometer, reference solar cell or a similar equipment without any concerns or errors. However, indoor light sources or even solar simulators come in all sorts of spectral variations. Therefore, inter-comparison among different labs would be difficult unless everyone agreed on using one or a multitude of reference spectra for reporting results, much like we currently do with the AM 1.5 G or AM 0 spectra, as codified in ASTM or International Electrotechnical Commission (IEC) standards [5]. For indoor PV measurements, a reference spectrum has not yet been broadly adopted, although some steps towards that goal have been taken recently [6]. The challenge is that even if one agrees for their device to be traceable to a certain reference spectrum, achieving that exact illumination condition inside the laboratory is often unrealistic because spectral irradiance of artificial light sources vary significantly among manufacturers. Therefore, a universal protocol must be developed to allow each researcher to measure and adjust their light intensity such that everyone exposes their test specimen to the same exact effective irradiance when measuring I-V curves no matter the source of the illumination. For air mass 1.5 measurements, it is now universally accepted that the lowest uncertainty method to achieve traceability to this reference condition is accomplished through the use of a reference solar cell that has been calibrated by a primary national metrology institute or a secondary ISO-certified lab under a specific RC. There are currently efforts under way at some metrology institutes to extend this method to IPV measurements, but to do that, one or more appropriate reference spectra has to be adopted through international standard organizations.

Advances in Science and Technology to Meet Challenges

Efforts are currently under way to meet the challenges discussed above. Recently, the standard SEMI PV80–0218 [6], Specification of Indoor Lighting Simulator Requirements for Emerging Photovoltaic was published, which clearly defined the normalized spectral distribution of five light sources adopted for IPV measurements from the International Commission of Illumination (CIE). These sources include illuminant A, which is a standard incandescent light bulb, and illuminant TL 84, which is a tri-band fluorescent lamp. Although the actual test method as described in this standard is still based on lux meter measurements, the methodology outlined will help reduce discrepancies between measurements. A more accurate method, however, is based on the use of a reference solar cell that has been specifically calibrated under a RC defined by one of the light sources in PV80–0218 or newly designated light sources. Such a calibrated reference solar cell can now be obtained from the National Institute of Standards and Technology in the USA. NIST uses the absolute irradiance spectral responsivity method to calibrate an appropriate reference solar cell under any adopted reference spectrum, including three unique NIST-proposed reference spectra based on white LEDs of different correlated color temperatures [4]. The chosen reference spectra are in absolute spectral irradiance (units: W/m2·nm) and they are designed such that they correspond to a total illuminance of 1000 lx. Because the integrated irradiance value incident on the cell is known for a given RC, power conversion efficiency can be easily computed, a task that is hard to achieve with low uncertainty if one only used lux to quantify the incident light intensity.

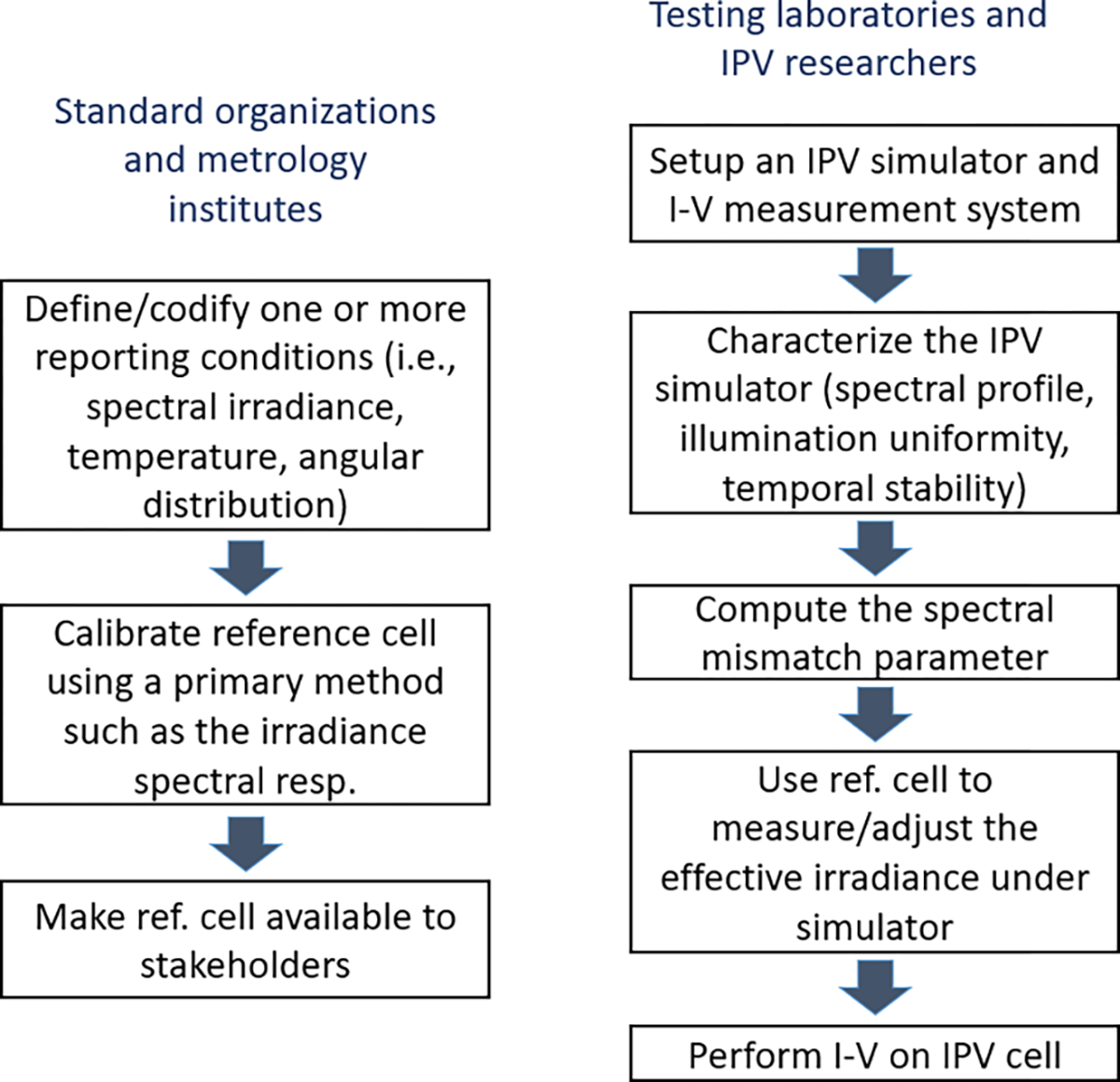

The complete procedure on how to use a calibrated reference cell to perform accurate I-V measurements traceable to a given RC has been published and is conceptually very similar to how we do I-V measurements under the SRC [4], [7]. The flowcharts in Fig. 2 outline the steps needed for accomplishing a traceable IPV measurement metrology. We believe relative expanded uncertainties (K = 2) of 2 % or lower is easily achievable with this technique for electrical performance measurements of IPV cells.

Figure 2.

Under this proposed approach, standard organizations such as the ASTM would draft the necessary new standards for defining IPV reporting conditions and the metrology institutes would calibrate reference cells under the published RCs. The testing labs or individual researchers will then use their in-house IPV simulators and the reference cells to carry out traceable I-V measurements.

Concluding Remarks

In conclusion, significant effort is under way to establish and formulate a well-defined metrology for electrical performance characterization of IPV cells. Given the significant market penetration and growth of IPV in recent years for energy harvesting under a variety of lighting conditions [8], it is imperative that accurate and traceable measurement procedures are followed when evaluating and reporting the performance parameters of these devices. Recent interlab-comparisons [9] have helped to better define and formulate the outline of this task but more inter-lab measurements among metrology institutes are needed to accelerate the progress towards standardization of IPV measurements.

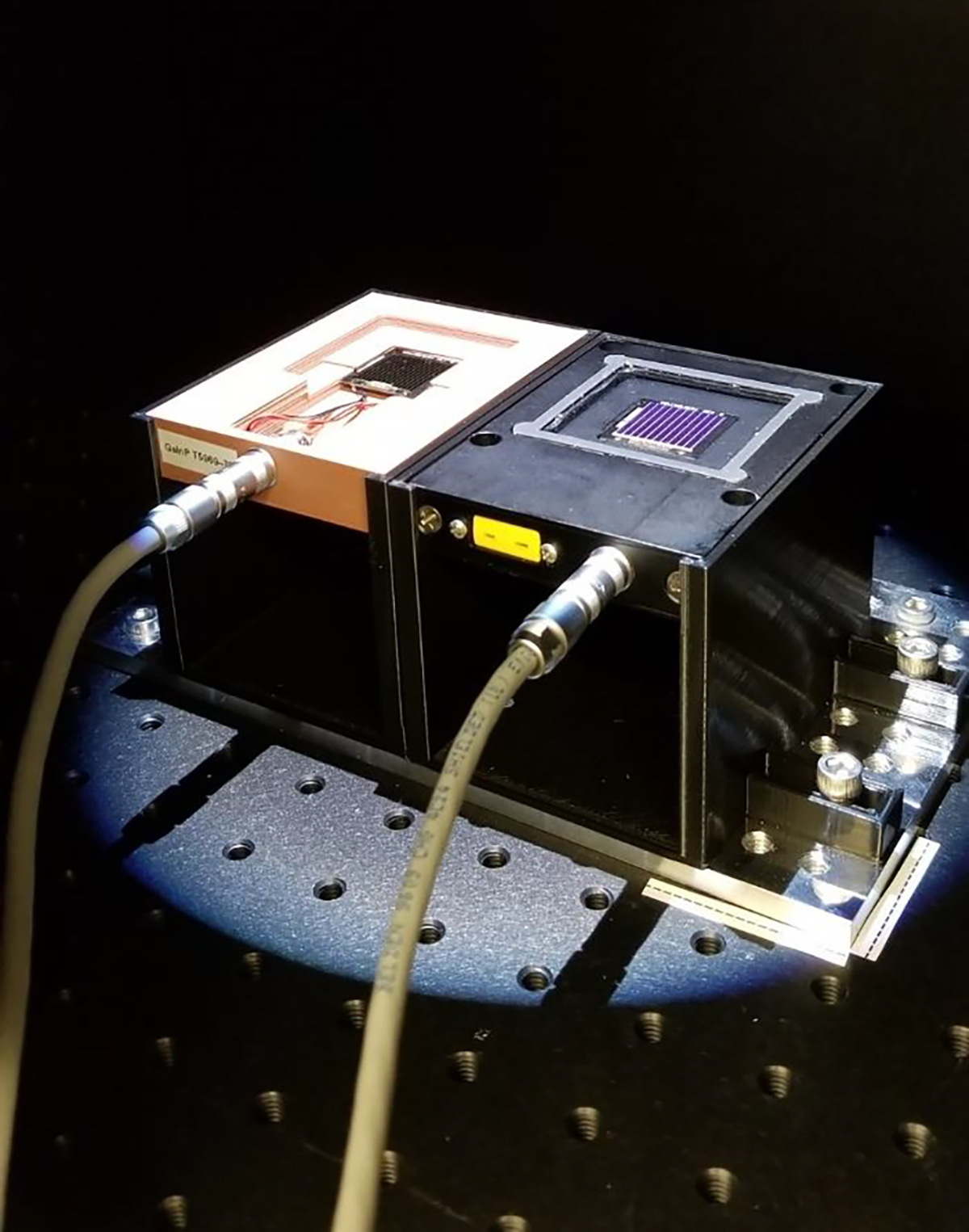

Figure 1.

For IPV current vs. voltage measurements, a calibrated reference cell (right) is placed next to the IPV cell (left) and used to measure and adjust the effective irradiance of the incident LED light. The objective is to measure and report the IPV electrical performance parameters under a pre-defined reporting condition.

Acknowledgements

B. H. Hamadani would like to thank Dr Mark Campanelli of Intelligent Measurement Systems LLC and Dr Howard Yoon of NIST for continued interest and stimulating discussions regarding this work spanning the course of the last several years.

References

- [1].Randall JF and Jacot J, “Is AM1.5 applicable in practice? Modelling eight photovoltaic materials with respect to light intensity and two spectra,” Renew. Energy, vol. 28, no. 12, pp. 1851–1864, Oct. 2003. [Google Scholar]

- [2].Freunek M, Freunek M, and Reindl LM, “Maximum efficiencies of indoor photovoltaic devices,” IEEE J. Photovoltaics, vol. 3, no. 1, pp. 59–64, Jan. 2013. [Google Scholar]

- [3].Minnaert B and Veelaert P, “A Proposal for Typical Artificial Light Sources for the Characterization of Indoor Photovoltaic Applications,” Energies, vol. 7, no. 3, pp. 1500–1516, Mar. 2014. [Google Scholar]

- [4].Hamadani BH and Campanelli MB, “Photovoltaic Characterization Under Artificial Low Irradiance Conditions Using Reference Solar Cells,” IEEE J. Photovoltaics, vol. 10, no. 4, pp. 1119–1125, Jul. 2020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [5].IEC 60904–3, “Photovoltaic Devices – Part 3: Measurement Principles for Terrestrial Photovoltaic (PV) Solar Devices with Reference Spectral Irradiance Data. 2008. [Google Scholar]

- [6].SEMI PV80–0218 Specification of Indoor Lighting Simulator Requirements for Emerging Photovoltaic. 2018. [Google Scholar]

- [7].Hamadani BH and Dougherty B, “Solar Cell Characterization,” in Semiconductor Materials for Solar Photovoltaic Cells, 2016, pp. 229–245. [Google Scholar]

- [8].Mathews I, Kantareddy SN, Buonassisi T, and Peters IM, “Technology and Market Perspective for Indoor Photovoltaic Cells,” Joule, vol. 3, no. 6, pp. 1415–1426, Jun. 2019. [Google Scholar]

- [9].Hamadani B, Long Y-S, Tsai M-A, and Wu T-C, “Interlaboratory Comparison of Solar Cell Measurements Under Low Indoor Lighting Conditions,” IEEE J. Photovoltaics, vol. 11, no. 6, pp. 1430–1435, Nov. 2021. [Google Scholar]