Abstract

Aiming at the accuracy of modeling in existing integrated energy system planning methods, a comprehensive energy system p lanning method that takes into account the actual operating efficiency of the system is proposed. First, the output model of various equipment units based on the basic structure of the integrated energy system is established. Then, based on the traditional energy hub model, a correction model for the work efficiency of energy equipment to construct an improved dynamic efficiency model of energy equipment is established. With the goal of minimizing the comprehensive cost of the integrated energy system, an integrated energy system planning operation model that takes into account the operating characteristics of the equipment is proposed. Finally, the planning method proposed in this paper is verified through simulation. The results show that: compared with the traditional planning method based on energy hubs, the method proposed in this paper improves the actual part-load performance of the system by improving the accuracy of energy coupling equipment, making the proposed planning model more reasonable and economical.

Keywords: Integrated energy system, Capacity planning, Energy hub, Part-load performance

1. Introduction

In recent years, the rapid development of society increasingly emphasizes efficiency and economy. Research on integrated energy systems to enhance energy use efficiency becomes a research hotspot [[1], [2], [3], [4], [5]]. Integrated Energy System (IES) couples solar, wind and natural gas energy sources by using advanced energy conversion technologies. The system converts energy into various forms of energy, such as heat and thermoelectric, and greatly improves the efficiency of energy use [[6], [7], [8], [9]]. Therefore, it is important to research an integrated energy system planning approach that is suitable for practical engineering applications.

A large number of scholars have already researched integrated energy planning approaches. QIU J. et al. established a multi-stage planning model for campus IES and it considered the construction time sequence in the planning process of the integrated energy system [10]. Existing planning algorithms suffer from computational overload. LIU Di et al. made improvements in the algorithm to enhance the solving efficiency of the model [11]. WANG Y. et al. proposed a multi-objective optimization approach taking fully into account the diversity of system device types [12]. Ywa B. et al. considered the investment constraints of planning investors and got the best planning solution with limited funds [13]. Yanmei L. and Zeng C. proposed several evaluation indicators for the planning and design of integrated energy systems [14]. Sokolnikova P. et al. developed for planning the generation capacity and sizing the energy storage units based on economical, ecological, technical and social criteria [15]. In addition, controlling algorithms have been developed to deal with the volatility of renewable energy sources and integrate heat/electricity energy systems.

The above research sets the operating efficiency of the energy coupling equipment to a constant in describing the energy coupling relationship in an integrated energy system [[16], [17], [18]]. In fact, the operating efficiency of different equipment varies dynamically with load factor, environmental factors and start/stop status in practical engineering applications [[19], [20], [21]]. The traditional approach to integrated energy system planning treats the efficiency of energy conversion equipment as a constant. Actually, it ignores the actual operating status of the equipment, which in turn affects the validity of the operation planning results.

For this reason, LI Jianlin et al. considered multiple uncertainties in integrated energy systems and the author simulated the impact of multiple device operation scenarios on system planning results [22,23]. CHEN Wanqing et al. summarize and generalize the theory of energy hubs [24]. Meanwhile, the research studied the nonlinear characteristics of combined heat and power plants, boilers, air conditioners, and absorption chillers. However, the paper did not give its specific application in integrated energy system planning. The impact of the equipment load factor was considered in the scheduling scheme [[25], [26], [27]]. Although the proposed approach effectively improves the accuracy of equipment modeling, the application scenario is limited and will still have large errors. In the current work, the study of IES planning approaches for dynamic changes in system operating efficiency has not been reported. The overview of the reviewed energy planning models is shown in Table 1.

Table 1.

Overview of the reviewed energy planning models.

To solve the low accuracy of modeling in existing IES planning methods, this paper proposes an IES planning approach that takes into account the dynamic changes in the part-load performance of the system. The innovative work of this article mainly includes:

-

a)

Based on the basic structure of the integrated energy system, the output of various equipment units is established. Moreover, a modified model of energy equipment efficiency and an improved dynamic efficiency model of energy equipment are constructed and models are based on the traditional energy hub model. The proposed method improves the accuracy of energy-coupled device modeling.

-

b)

Considering the operating characteristics of the equipment, an integrated energy system planning model is established. The planning model aims at minimizing the comprehensive cost of the integrated energy system and improving the economy of operation.

The rest of the paper is organized as follows: Section 2 elaborates on the energy equipment modeling process. Section 3 presents an integrated energy system planning and operation model. In Section 4, the effectiveness of the proposed approach is verified through simulation.

2. Integrated energy system model

2.1. Integrated energy system structure

The regional comprehensive energy system contains multiple forms of energy, and through various coupling devices, heterogeneous energy flows can be coupled and mutually beneficial, meeting the diverse energy needs of users. The system is mainly composed of Photovoltaic (PV), Combined heat and power unit (CHP), Gas boiler (GB), Electric boiler (EB), Electric chiller (EC), Absorption chiller (AC) and Energy Storage (ES). In addition to supplying basic electrical loads, it can also provide various load forms such as steam heat load, high-temperature heat load, medium-temperature heat load, and cooling load. Through reasonable planning, the cascade utilization of energy can be achieved. Gas turbines consume natural gas to generate steam thermal energy and low-temperature thermal energy. Part of the steam thermal energy is converted into cold energy through an absorption refrigeration machine, part is used for producing high-temperature hot water from peak heaters, and the other part is used to supply high-temperature steam loads. The low-temperature thermal energy is heated by a waste heat boiler to supply medium-temperature hot water loads. The basic structure of the integrated energy system in this paper is established based on the energy coupling equipment in the actual project as shown in Fig. 1.

Fig. 1.

The basic structure of the IES.

2.2. Equipment unit output model

-

(1)

Photovoltaic

The magnitude of the output of the photovoltaic panels can be described in (1):

| (1) |

Where is the photoelectric conversion efficiency [8]; S is the area of the photovoltaic cell array; I is the intensity of solar radiation (kw/m2); is the external temperature [28].

-

(2)

Combined heat and power unit

The mathematical model of the combined heat and power unit can be described as in (2)–(3).

| (2) |

| (3) |

Where and are the generation efficiency and heating efficiency of CHP, respectively.

-

(3)

Gas boiler

A gas boiler is a device that converts gas energy into heat energy [23], and its mathematical model is expressed as Equation (4):

| (4) |

Where, is the heating efficiency of the gas boiler.

-

(4)

Electric boiler

The electric boiler is a device that converts electrical energy into thermal energy. The mathematical model of the electric boiler can be described as follows:

| (5) |

Where, is the heating efficiency of the electric boiler.

-

(5)

Electric chiller

The mathematical model of the electric boiler can be described as follows:

| (6) |

Where, is the cooling efficiency of the electric chiller.

-

(6)

Absorption chiller

Similarly, the mathematical model of the absorption chiller can be described as Equation (7)

| (7) |

Where, is the cooling efficiency of the absorption chiller.

-

(7)

Energy Storage Equipment

The energy storage relationship for energy storage devices can be expressed as follows:

| (8) |

Where and are the energy before and after charging of the energy storage device, respectively, in kWh; is the discharge rate; is the actual operating power of the energy storage device at time t, in kw; and is the step length, in h.

| (9) |

| (10) |

In the above equations, , are the operating efficiency when charging and discharging energy respectively; , are the upper limit of operating power when charging and discharging energy respectively, in kw.

2.3. Improved energy hub model

The current study of the coupling relationship between equipment in integrated energy systems is mostly based on the energy hub model. The energy conversion efficiency of the device is set to a constant or the coupling relationship is simplified in the traditional model [29]. The simplified equation is shown as follows:

| (11) |

In equation (11), is the energy type; L is the energy output power vector; C is the energy coupling matrix vector; P is the input power vector; S is the attribution coefficient matrix of the energy storage equipment; E is the energy vector of the energy storage equipment and when the device is charged, the vector is positive; is the energy distribution coefficient of the energy form ; is the operating efficiency of the corresponding energy conversion equipment.

In this paper, based on the existing research, the traditional energy hub model is modified and the dynamic efficiency change model is constructed as shown in Fig. 2.

Fig. 2.

The EH model considering dynamic efficiency changes.

In Fig. 2, is the actual operating efficiency based on the dynamics of the load factor; is the load factor of the energy conversion equipment. The modified energy hub model is:

| (12) |

The mathematical relationship between the actual operating efficiency and the load factor of CHP units as well as GB units is expressed as follows:

-

(1)

CHP unit variable condition model

| (13) |

Where is the dynamic power generation efficiency of CHP unit; is the dynamic heat production efficiency of CHP unit; is the nth order fitting coefficient of CHP unit; is the electric load factor of CHP unit; is the heat load factor of CHP unit.

-

(2)

Gas boiler variable condition model

The heat loss of the gas boiler includes incomplete combustion heat loss, fuel exhaust heat loss and heat loss, etc. When the load factor is low, the operating efficiency of the gas boiler will be greatly reduced. The heat production efficiency of the gas boiler was fitted by a second-order polynomial as

| (14) |

Where, is the dynamic heat production efficiency of the gas boiler; is the gas GB loading factor; is the nth order fitting coefficient.

3. Integrated energy system capacity planning model

3.1. Objective function

In this paper, an integrated energy system planning and operation model is developed to minimize the investment cost , energy purchase cost and maintenance cost of IES [[30], [31], [32]]. The specific equation is as follows:

| (15) |

where

| (16) |

Where; is the rated capacity of equipment i; the investment cost per unit capacity of equipment i.

| (17) |

Where, is the number of typical days; and are the electricity and natural gas prices at time t, respectively; is the amount of electricity purchased from the grid at time t of day d; and are the amount of gas purchased in CHP and GB at time t of day d, respectively.

| (18) |

Where, , , , and are the maintenance costs of CHP, EB, GB, EC and AC, respectively; and are the thermal and electrical power of the CHP unit at time t, respectively; is the thermal power of the electric boiler at time t; I is the thermal power of the gas boiler at time t; is the cold power of the electric chiller at time t; is the cold power of the absorption chiller at time t.

3.2. Constraint condition

-

(1)

Equipment operating constraints

| (19) |

| (20) |

| (21) |

| (22) |

| (23) |

| (24) |

| (25) |

| (26) |

| (27) |

where is the maximum capacity of equipment i.

-

(2)

Electrical power balance constraint

| (28) |

Where, is the electrical load demand at time t.

-

(3)

Thermal power balance constraint

| (29) |

Where, is the heat load demand at time t.

-

(4)

Cold power balance constraint

| (30) |

Where, is the cooling load demand at time t.

-

(5)

Natural gas power balance constraint

| (31) |

Where, is the natural gas load demand at time t.

4. Example analysis

4.1. Parameters setting

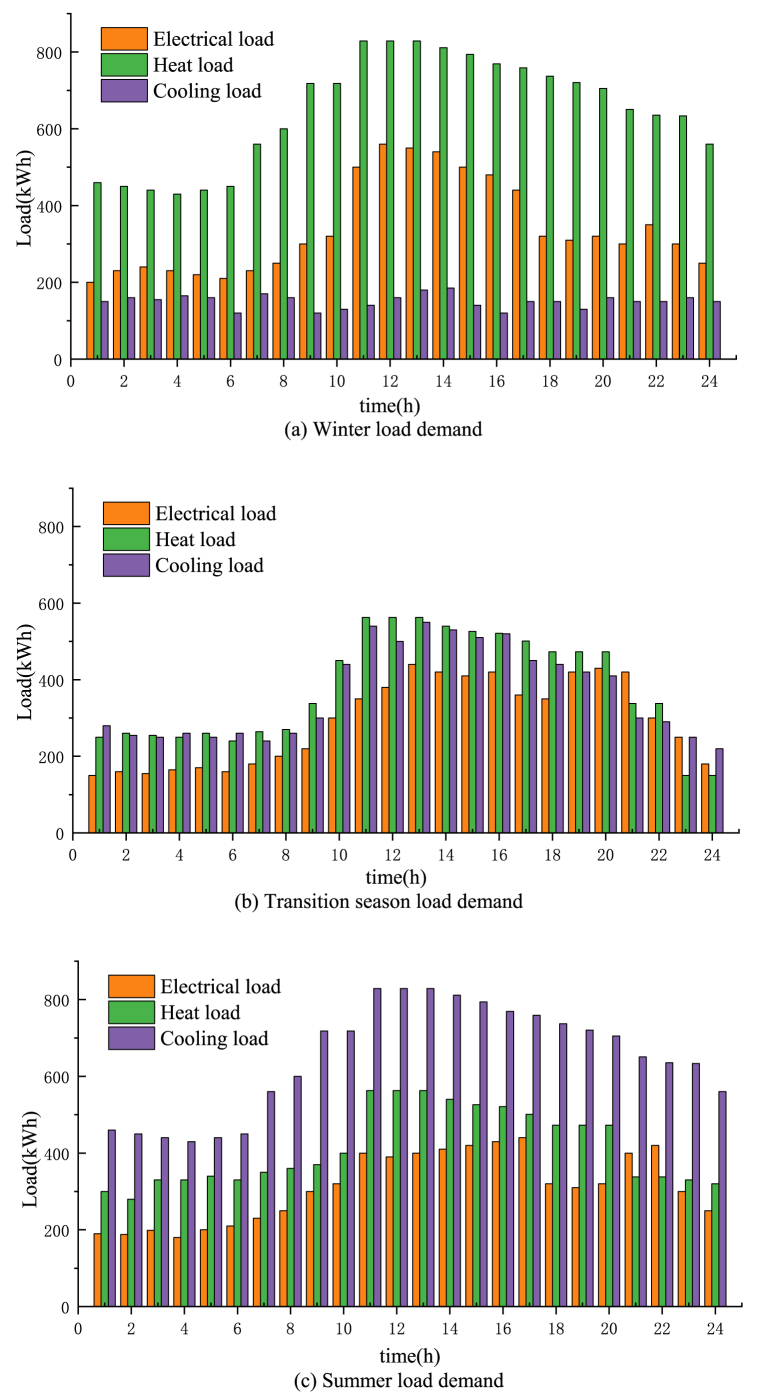

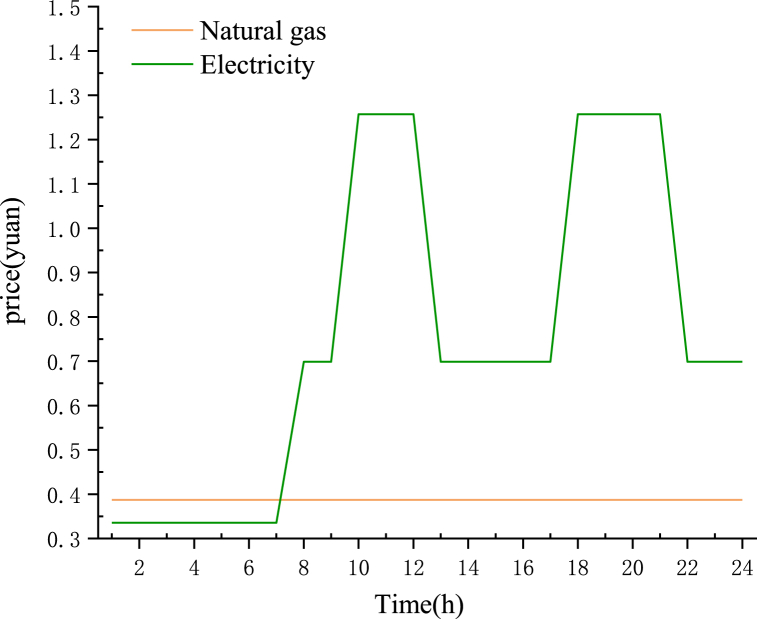

This paper selects an IES park as the object and the proposed integrated energy planning method for the park is validated through simulation. The IES park includes a 180,000 m2 hotel, a 70,000 m2 residential area, a 13,200 m2 shopping mall, and a 153,000 m2 hospital. According to the characteristics of climate change in the region, the whole year is divided into winter typical days, transitional season typical days, and summer typical days in sequence. Based on the energy consumption survey and statistics of typical commercial buildings in the region, load demand data for four types of buildings were obtained. Hospitals and hotels have annual demand for cooling, heating, and electricity loads, while residential areas and shopping malls only have demand for cooling and electricity loads. During typical days of each season, hospitals, hotels, and shopping malls have higher daytime loads and lower nighttime loads. On the contrary, residential areas have a higher nighttime load than daytime load. Comparing the load scales of four types of buildings, the load scales of hospitals and hotels are much larger than those of the other two buildings, which will affect the installation location of system power generation equipment in the area. The typical daily winter load demand, transition season load demand, and summer load demand are shown in Fig. 3. The energy prices are shown in Fig. 4. The relevant parameters of the alternative energy coupling devices are shown in Table 2. The relevant parameters of the energy storage devices are shown in Table 3 and the fitting coefficients of the energy coupling devices are shown in Table 4. The computer platform used for simulation is a 64-bit Windows 10 operating system with 8 GB RAM and Intel (R) Core (TM) i5-7300HQ CPU @ 2.50 GHz, using a CPLEX solver for model solving.

Fig. 3.

Typical daily load demand.

Fig. 4.

Energy prices.

Table 2.

Optional equipment parameters.

| Equipment | Investment cost (yuan/kW) | Operation and maintenance cost (yuan/kW) | Life cycle (year) | Efficiency (−) |

|---|---|---|---|---|

| CHP | 7900 | 0.06 | 20 | = 0.3 |

| = 0.173 | ||||

| GB | 400 | 0.04 | 30 | 0.94 |

| EB | 1000 | 0.32 | 25 | 0.95 |

| AC | 1100 | 0.08 | 20 | 1.3 |

| EC | 970 | 0.097 | 10 | 3.5 |

| PV | 8000 | 0.01 | 20 | – |

| ES | 3000 | 0.0125 | 20 | 0.98 |

| HS | 320 | 2.43 | 20 | 0.92 |

| CS | 320 | 2.43 | 25 | 0.92 |

Table 3.

Energy storage equipment parameters.

| Equipment | Investment cost (yuan/kW) | Operation and maintenance cost (yuan/kW) | Life cycle (year) | Efficiency (−) | Storage consumption rate (−) | Maximum charging and discharging power (kW) |

|---|---|---|---|---|---|---|

| ES | 3000 | 0.0125 | 20 | 0.98 | 0.01 | 60 |

| HS | 320 | 2.43 | 20 | 0.92 | 0.02 | 12.5 |

| CS | 320 | 2.43 | 25 | 0.92 | 0.02 | 12.5 |

Table 4.

Fitting coefficients of the energy conversion devices.

| Equipment | Fitting coefficients |

|||||

|---|---|---|---|---|---|---|

| K4 | K3 | K2 | K1 | K0 | ||

| CHP | 0.05 | −0.22 | −0.05 | 0.32 | 0.23 | |

| – | – | 3.31 | −5.73 | 4.62 | ||

| GB | – | – | 2.11 | 0.12 | 0.72 | |

4.2. Planning results

To compare and analyze the effectiveness of the proposed approach in this paper, 2 scenarios are constructed for comparison as follows.

Scenario 1: A method for planning and operating an integrated energy system in a park considering dynamic changes in equipment coupling efficiency.

Scenario 2: The traditional energy hub-based planning operation method for the integrated energy system of the park. The planning results are shown in Table 5.

Table 5.

Planning results.

| Equipment | Scenario 1 | Scenario 2 | |

|---|---|---|---|

| Equipment power configuration (kW) | CHP | 450 | 256 |

| GB | 843 | 1250 | |

| EB | 0 | 0 | |

| AC | 860 | 456 | |

| EC | 520 | 600 | |

| PV | 3000 | 3000 | |

| ES | 800 | 1000 | |

| HS | 2500 | 1800 | |

| CS | 2500 | 1800 | |

| Cost (million yuan) | Annual investment cost | 30.468 | 28.361 |

| Annual operation and maintenance cost | 18.634 | 26.328 |

As can be seen from Tables 5 and in scenario 2, due to the relatively low investment cost of gas boilers, the gas boiler capacity is quite high. The combined heat and power unit meets the base load and uses gas boilers for peaking. In scenario 1, because of the consideration of dynamic changes in efficiency, the capacity configuration of the gas boiler is lower than in scenario 2. The capacity of CHP units is closely related to the capacity of gas boilers, so a reduction in gas boiler capacity will increase the capacity of CHP unit installations. Compared to Scenario 2, Scenario 1 has a 7.5 % increase in investment costs and a 41.3 % decrease in operating costs. The overall cost of Scenario 1 is much lower than that of Scenario 2, and the payback period is shorter as the number of years of operation increases.

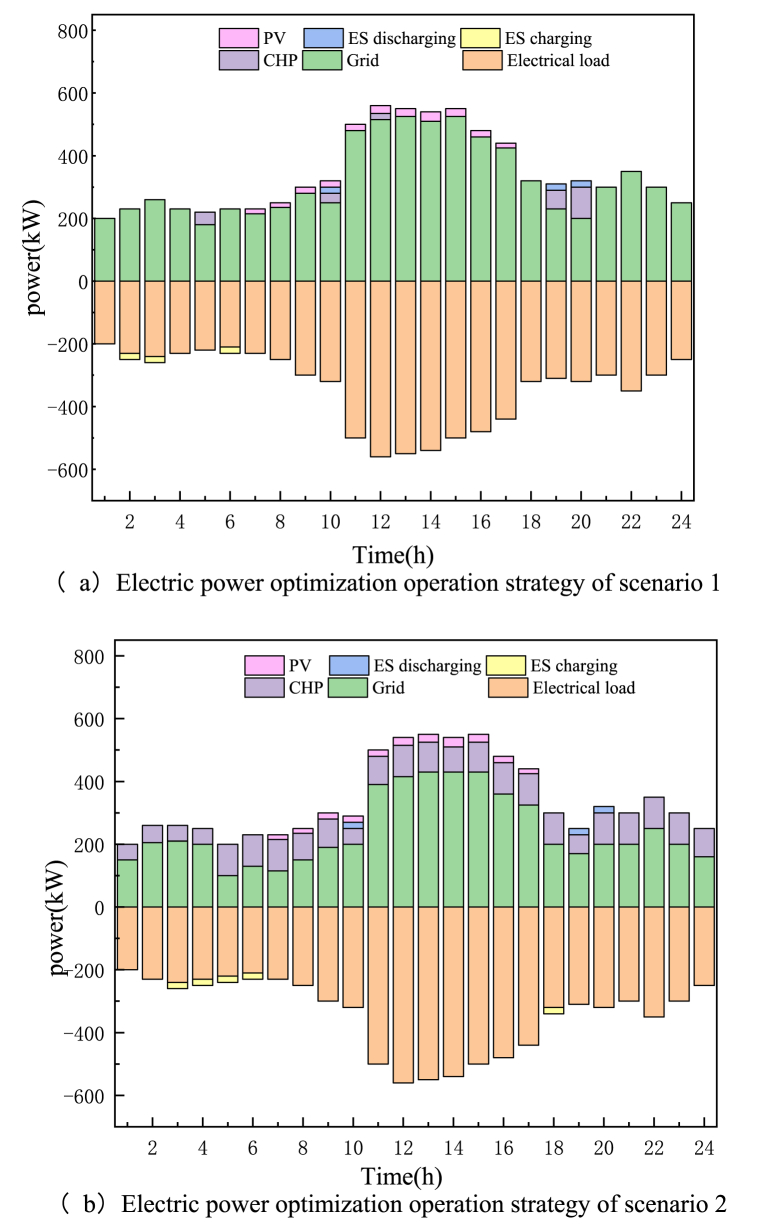

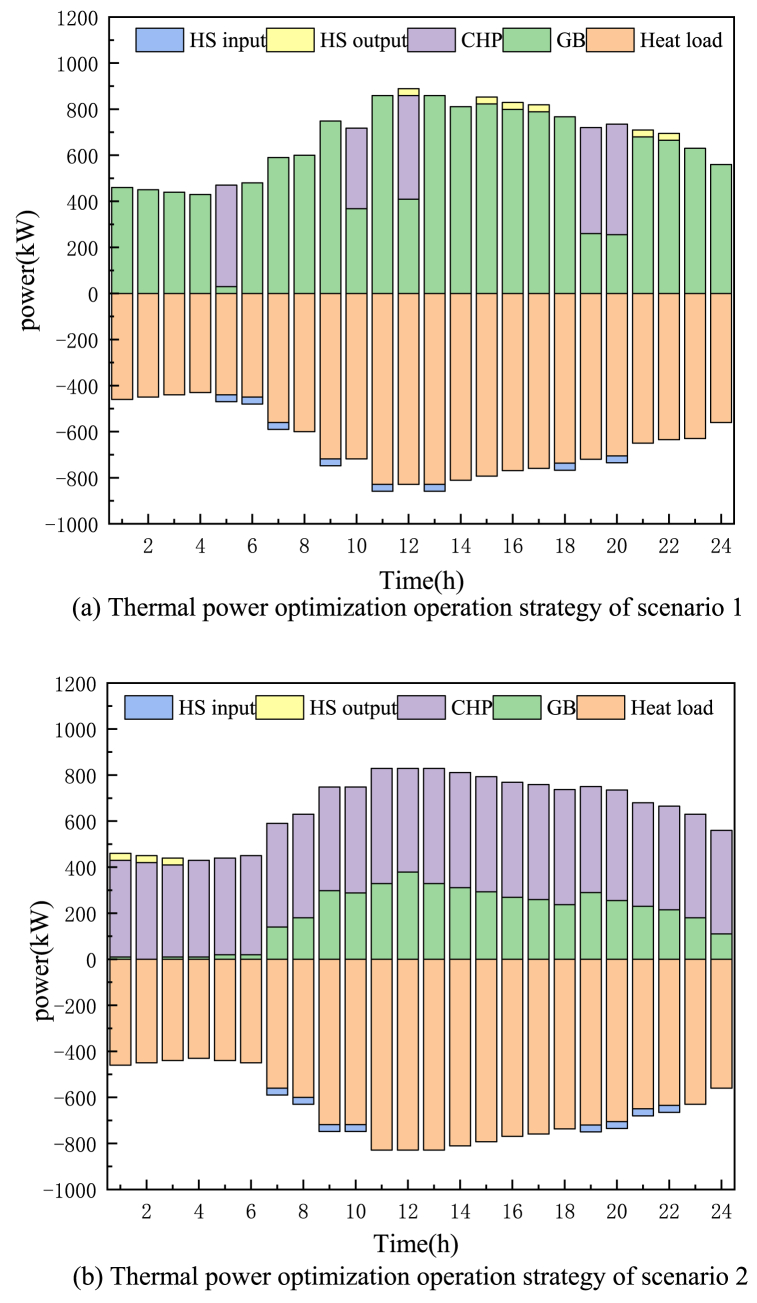

4.3. Analysis of the necessity to consider dynamic changes in equipment power

In order to verify the necessity of considering the dynamic change of equipment power in the method of this paper, the load demand of a typical winter day is used as an example for comparative analysis. The optimal operation strategy for thermoelectric power is shown in Fig. 5, Fig. 6.

Fig. 5.

Electric power optimization operation strategy comparison.

Fig. 6.

Thermal power optimization operation strategy comparison.

From Fig. 5(a) and (b), in scenario 1, it can be seen that the improved integrated energy system planning and operation approach takes the method of purchasing power from the grid to meet the power load most of the time. Meanwhile scenario 2 runs the CHP unit most of the time. The reason is that the energy hub model for scenario 2 is linear and based on the optimal operation of the equipment, so the more efficient equipment is run whenever possible. The comparison of operating strategies shows that the way the system operates changes significantly when the actual operating efficiency changes.

As shown in Fig. 6(a), scenario 1 is mainly selected for heating with GB. Meantime, Scenario 2 chooses a CHP unit for heating and GB is used for peak-load regulation. The main reason is that scenario 1 considers the variable conditions of the equipment, while scenario 2 considers the equipment efficiency as rated efficiency under the constant efficiency model. As shown in Fig. 6(b), The model for scenario 2 is similar to the electric power operation strategy, which leads to an increase in operating costs because changes in load characteristics are not considered. In actual operation, CHP units do not always operate at a high level of efficiency. When the operating efficiency is lower than the rated efficiency it will increase the actual operating cost of the system.

5. Conclusion

Aiming at the accuracy of modeling in existing integrated energy system planning methods, a comprehensive energy system planning method that takes into account the actual operating efficiency of the system is proposed. First, with reference to the basic structure of an integrated energy system, the output of various equipment units is modeled. Then, based on the traditional energy hub model, a correction model for the work efficiency of energy equipment to construct an improved dynamic efficiency model of energy equipment is established. With the goal of minimizing the comprehensive cost of the integrated energy system, an integrated energy system planning operation model that takes into account the operating characteristics of the equipment is proposed. The simulation results verify the validity of the model and draw the following conclusions:

-

a)

The improved dynamic efficiency model of energy equipment can accurately reflect the input-output relationship of system energy and improve the accuracy of energy-coupled equipment modeling. The cascade utilization of energy allows the system to flexibly coordinate the output of various equipment to supply different grades of energy demand by enriching the regulation methods of energy forms and coupled equipment. Compared with traditional planning models, the planning model with energy cascade utilization reduces the system operating cost by 41.3 %.

-

b)

Compared with the traditional energy hub-based planning method, the proposed method in this paper can improve the actual part-load performance of the system. Further, it improves the rationality of integrated energy system planning and the economy of actual operation.

Data availability statement

No data was used for the research described in the article.

CRediT authorship contribution statement

Ma Hengrui: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. Bo Wang: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. Hongxia Wang: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. Shu Wang: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. Ma Fuqi: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. Xin Wang: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. Min Li: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work is supported by National Natural Science Foundation of China (52167022), Natural Science Foundation of Qinghai (2022-ZJ-935Q).

Nomenclature

Indices and Sets

Index for step length

Index for energy type

Index for energy form

Index for the number of typical days

Parameters

Photoelectric conversion efficiency

- S

The area of the photovoltaic cell array

External temperature

Generation efficiency

The heating efficiency of CHP

The heating efficiency of the gas boiler

The heating efficiency of the electric boiler

The cooling efficiency of the electric chiller

The cooling efficiency of the absorption chiller

The energy before charging of the energy storage device

The energy after charging the energy storage device

The discharge rate

The operating efficiency when charging

The operating efficiency when discharging

The upper limit of operating power when charging

The upper limit of operating power when discharging

The operating efficiency of the corresponding energy conversion equipment

The load factor of the energy conversion equipment

The nth order fitting coefficient of CHP unit

The electric load factor of CHP unit

The heat load factor of CHP unit

Gas GB loading factor

The nth order fitting coefficient

The rated capacity of equipment i

The investment cost per unit capacity of equipment i

The electricity prices at time t

The natural gas prices at time t

The maximum capacity of equipment i

Variables

- I

The intensity of solar radiation

The actual operating power of the energy storage device

The actual operating efficiency based on the dynamics of the load factor

The dynamic power generation efficiency of CHP unit

The dynamic heat production efficiency of CHP unit

The dynamic heat production efficiency of the gas boiler

Investment cost

Energy purchase cost

Maintenance cost

The amount of electricity purchased from the grid at time t of day d

The amount of gas purchased in CHP at time t of day d

The amount of gas purchased in GB at time t of day d

The maintenance costs of CHP

The maintenance costs of EB

The maintenance costs of GB

The maintenance costs of EC

The maintenance costs of AC

The thermal of the CHP unit at time t

The electrical power of the CHP unit at time t

The thermal power of the electric boiler at time t

The cold power of the electric chiller at time t

The cold power of the absorption chiller at time t

The electrical load demand at time t

The heat load demand at time t

The cooling load demand at time t

The natural gas load demand at time t

References

- 1.Tan Hong, Li Zhenxing, Wang Qiujie, Mohamed Mohamed A. A novel forecast scenario-based robust energy management method for integrated rural energy systems with greenhouses. Appl. Energy. 2023;330 [Google Scholar]

- 2.Huang Wujing, Zhang Ning, Dong Ruibiao, et al. Coordinated planning of multiple energy networks and energy hubs[J] Proceed. CSEE. 2018;38(18):5425–5437. [Google Scholar]

- 3.Romanova T. Russia's political discourse on the EU's energy transition (2014–2019) and its effect on EU-Russia energy relations[J] Energy Pol. 2021;154(2) [Google Scholar]

- 4.Wang Jun, Gu Wei, Lu Shuai, et al. Coordinated planning of multi-district integrated energy system combining heating network mod-el[J] Autom. Electr. Power Syst. 2016;40(15):17–24. [Google Scholar]

- 5.Ren Dejiang, Wu Jiekang, Xiao M.A.O., et al. Optimal method for source-load coordinated operation of integrated energy system considering wind power absorption[J] Smart Power. 2019;47(9):37–44. [Google Scholar]

- 6.Lei Jinyong, Guo Zuogang, Chen Cong, et al. Two-stage planning-operation co-optimization of IES considering uncertainty and electrical/thermal energy storage[J] Electric Power Auto-mation Equipment. 2019;39(8):169–175. [Google Scholar]

- 7.Seyed Amir Mansouri, Maroufi Siavash, Ahmarinejad Amir. A tri-layer stochastic framework to manage electricity market within a smart community in the presence of energy storage systems[J] J. Energy Storage. 2023:71. [Google Scholar]

- 8.Song Jie, Li Shupeng, Zhang Weiguo, et al. Day-ahead optimized dispatching strategy of integrated energy system with regenerative electric heating[J] Smart Power. 2021;49(4):14–20. [Google Scholar]

- 9.Lu Bingwen, Wei Zhenbo, Wei Ping'an, et al. Optimal configuration of PIG and energy stor-age equipment in regional integrated energy system considering wind power consumption[J] Smart Power. 2021;49(5):7–14+68. [Google Scholar]

- 10.Qiu J., Dong Z.Y., Zhao J.H., et al. Multi-stage flexible expansion Co-planning under uncertainties in a combined electricity and gas market[J] IEEE Trans. Power Syst.: Publicat. Power Eng. Societ. 2015;(4):30. [Google Scholar]

- 11.Liu Di, Wu Junyong, Lin Kaijun, et al. A planning method of integrated energy system based on kriging model[J] Power Syst. Technol. 2019;43(1):185–194. [Google Scholar]

- 12.Wang Y., Zhang N., Zhuo Z., et al. Mixed-integer linear programming-based optimal configuration planning for energy hub: starting from scratch[J] Appl. Energy. 2018;210(jan.15):1141–1150. [Google Scholar]

- 13.Ywa B., Rla B., Hda B., et al. Capacity planning and optimization of business park-level integrated energy system based on investment constraints[J] Energy. 2019;189 [Google Scholar]

- 14.Yanmei L., Zeng C. Evaluation index system and evaluation method of China's regional potential for electrical energy substitution[J] Math. Probl. Eng. 2018;2018(PT.8) 3834921.1-3834921.16. [Google Scholar]

- 15.Sokolnikova P., Lombardi P., Arendarski B., et al. Net-zero multi-energy systems for Siberian rural communities: a methodology to size thermal and electric storage units[J] Renew. Energy. 2020:155. [Google Scholar]

- 16.Js A., Nr A., Jz A., et al. Capacity planning and optimization for integrated energy system in industrial park considering environmental exter-nalities[J] Renew. Energy. 2021;167:56–65. [Google Scholar]

- 17.Yu H., Liu Z., Li C., et al. Study on pricing mech-anism of cooling, heating, and electricity considering demand response in the stage of park integrated energy system planning[J] Appl. Sci. 2020;10(5):1565. [Google Scholar]

- 18.Sokolnikova P., Lombardi P., Arendarski B., et al. Net-zero multi-energy systems for Siberian rural communities: a methodology to size thermal and electric storage units[J] Renew. Energy. 2020:155. [Google Scholar]

- 19.Cheng Y.A.N.G., Huang Zhifeng, Ma Xiaoqian. Study on off-design characteristics of combined heat and power based on combined cycle gas turbine units[J] Proceed. CSEE. 2017;37(12):3514–3524+3680. [Google Scholar]

- 20.Yang Jingwei, Zhang Ning, Wang Yi, et al. Multi-energy system towards renewable energy accommodation: review and prospect[J] Autom. Electr. Power Syst. 2018;42(4):11–24. [Google Scholar]

- 21.Zhang N., Cai R. Analytical solutions and typical characteristics of part-load performances of sin-gle shaft gas turbine and its cogeneration[J] Energy Convers. Manag. 2002;43(9):1323–1337. [Google Scholar]

- 22.Jianlin L.I., Tian Liting, Cheng Lin, et al. Optimal planning of micro-energy system considering off-design performance Part One general model and analysis[J] Autom. Electr. Power Syst. 2018;42(19):18–26+49. [Google Scholar]

- 23.Liting T.I.A.N., Cheng Lin, Jianlin L.I., et al. Optimal planning of a micro-energy system considering off-design performance Part Two optimization model and method[J] Autom. Electr. Power Syst. 2018;42(20):17–23. [Google Scholar]

- 24.Cheng Haozhong, Xiao H.U., Wang Li, et al. Review on research of regional integrated energy system planning[J] Autom. Electr. Power Syst. 2019;43(7):2–13. [Google Scholar]

- 25.Chen Wanqing, Mu Yunfeil, Jia Hongjie, et al. Operation optimization method for regional integrated energy system considering part-load performances of devices[J] Power Syst. Technol. 2021;45(3):951–958. [Google Scholar]

- 26.Mansouri S.A., Ahmarinejad Javadi, et al. Improved double-surface sliding mode observer for flux and speed estimation of induction motors[J] IET Electr. Power Appl. 2020;14(6):1002–1010. [Google Scholar]

- 27.Deng S., Wu Q., Jing Z., et al. Optimal capacity configuration for energy hubs considering part-load characteristics of generation units[J] Energies. 2017;10(12):19–31. [Google Scholar]

- 28.Al-Ghussain, Loiy, Adnan Darwish Ahmad, Abubaker Ahmad M., Mohamed Mohamed A. An integrated photovoltaic/wind/biomass and hybrid energy storage systems towards 100% renewable energy microgrids in university campuses. Sustain. Energy Technol. Assessments. 2021;46 [Google Scholar]

- 29.Alnowibet Khalid, Andres Annuk, Dampage Udaya, Mohamed Mohamed A. Effective energy management via false data detection scheme for the interconnected smart energy hub–microgrid system under stochastic framework. Sustainability. 2021;13(21) [Google Scholar]

- 30.Mansouri S.A., Nematbakhsh E., Jordehi A.R., et al. An interval-based nested optimization framework for deriving flexibility from smart buildings and electric vehicle fleets in the tso-dso coordination[j] Appl. Energy. 2023:341. [Google Scholar]

- 31.Adetokun Bukola Babatunde, Muriithi Christopher Maina. Application and control of flexible alternating current transmission system devices for voltage stability enhancement of renewable-integrated power grid: a comprehensive review. Heliyon. 2021;7(3) doi: 10.1016/j.heliyon.2021.e06461. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Eltamaly A.M., Addoweesh K.E., Bawa U., Mohamed M.A. Economic modeling of hybrid renewable energy system: a case study in Saudi Arabia. Arabian J. Sci. Eng. 2014;39:3827–3839. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.