Abstract

The EFSA Panel on Food Additives and Flavourings (FAF) was requested to evaluate the safety of the smoke flavouring Primary Product Scansmoke SEF7525 (SF‐004), for which a renewal application was submitted in accordance with Article 12(1) of Regulation (EC) No 2065/2003. This opinion refers to the assessment of data submitted on chemical characterisation, dietary exposure and genotoxicity of the Primary Product. Scansmoke SEF7525 is obtained from a tar produced from a mixture of red oak, white oak, maple, beech and hickory. Based on the compositional data, the Panel noted that the identified and quantified proportion of the solvent‐free fraction amounts to 32.6 weight (wt)%, thus the applied method does not meet the legal quality criterion that at least 50% of the solvent‐free fraction shall be identified and quantified. At the maximum proposed use levels, dietary exposure estimates calculated with Food Additive Intake Model (FAIM) ranged from 0.6 to 3.8 mg/kg body weight (bw) per day at the mean and from 1.1 to 10.1 mg/kg bw per day at the 95th percentile. Based on the available information on genotoxicity on 44 identified components, the Panel concluded that two substances in the Primary Product, styrene and benzofuran, raise a potential concern for genotoxicity. In addition, a potential concern for genotoxicity was identified for the unidentified part of the mixture. Considering that the exposure estimates for styrene and benzofuran are above the threshold of toxicological concern (TTC) value of 0.0025 kg/kg bw per day for DNA‐reactive mutagens and/or carcinogens and since further data are needed to clarify their potential genotoxicity, the Panel concluded that the potential safety concern for genotoxicity of the Primary Product cannot be ruled out.

Keywords: Scansmoke SEF7525, SF‐004, smoke flavouring Primary Product, genotoxicity, styrene, benzofuran

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

Regulation (EC) No 2065/2003 1 establishes a procedure for the safety assessment and the authorisation of smoke flavouring primary products with a view to ensuring a high level of protection of human health and the effective functioning of the internal market. No smoke flavouring or any food where such a smoke flavouring is present (in or on) can be placed in the market if the smoke flavouring is not an authorised Primary Product or is not derived therefrom and if the conditions of use laid down in the authorisation in accordance with this Regulation are not adhered to (Article 4(2) of Regulation (EC) No 2065/2003).

Commission Implementing Regulation (EU) No 1321/2013 2 authorised 10 smoke flavouring primary products for a 10‐year period, due to expire on 31 December 2023.

The European Commission has received an application for the renewal of the authorisation of the smoke flavouring primary product Scansmoke SEF7525 (SF‐004) for a 10‐year period, in accordance with Article 12 of Regulation (EC) No 2065/2003.

1.1.2. Terms of Reference

The European Commission requests the European Food Safety Authority (EFSA) to evaluate the safety of the smoke flavouring primary product Scansmoke SEF7525 (SF‐004), for which a renewal application has been submitted, in accordance with Article 12(1) of Regulation (EC) No 2065/2003.

The safety assessment shall be carried‐out in two steps. Firstly, EFSA shall give a scientific opinion on the data included in the renewal application dossier related to the chemical characterisation, the genotoxicity and the dietary exposure to Scansmoke SEF7525 (SF‐004). Secondly, provided that the genotoxic concern can be ruled out in the first part of the evaluation, EFSA shall complete the rest of the safety assessment without delay upon submission of the relevant pending data from the applicant.

1.2. Interpretation of the Terms of Reference

In line with the terms of reference (see Section 1.1.2), the safety of the Primary Product will be assessed in two steps.

The current (first) opinion will address the chemical characterisation, genotoxicity and dietary exposure to the smoke flavouring Primary Product.

If in the first opinion, no concern for genotoxicity is raised, EFSA will issue a second opinion assessing the toxicity other than genotoxicity data, as required by the EFSA guidance for the preparation of applications on smoke flavouring Primary Products (EFSA FAF Panel, 2021).

1.3. Additional information

EFSA issued a previous opinion on the safety of this smoke flavouring Primary Product Scansmoke SEF7525 in 2009 (EFSA CEF Panel, 2009).

Following the safety assessment from EFSA, Scansmoke SEF7525 was authorised in the European Union and assigned the unique code ‘SF‐004’, according to Commission Implementing Regulation (EU) No 1321/2013, establishing the Union list of authorised smoke flavouring Primary Products, for a 10‐year period with effect from 1 January 2014.

The present opinion refers to an assessment of the data submitted by the authorisation holder for the renewal of the authorisation of Scansmoke SEF7525 (SF‐004) as a smoke flavouring Primary Product, in line with Article 12(1) of Regulation (EC) No 2065/2003.

2. Data and methodologies

2.1. Data

The present evaluation is based on the data provided by the applicant in the form of a technical dossier, submitted according to Article 12(1) of Regulation (EC) No 2065/2003 for the renewal of the authorisation of the smoke flavouring Primary Product Scansmoke SEF7525 (SF‐004).

In accordance with Article 38 of the Regulation (EC) No 178/2002 3 and taking into account the protection of confidential information and of personal data in accordance with Articles 39 to 39e of the same Regulation and of the Decision of the EFSA's Executive Director laying down practical arrangements concerning transparency and confidentiality, 4 the non‐confidential version of the dossier is published on Open.EFSA. 5

According to Art. 32c(2) of Regulation (EC) No 178/2002 and to the Decision of EFSA's Executive Director laying down the practical arrangements on pre‐submission phase and public consultations, EFSA carried out a public consultation on the non‐confidential version of the application from 27 October to 17 November 2022, for which no comments were received.

Additional information was sought from the applicant during the assessment process by requests from EFSA sent on 25 November 2022 and was subsequently provided (see Documentation provided to EFSA No. 2).

The Panel acknowledged the submission of data on toxicity other than genotoxicity by the applicant in the technical dossier (see Documentation provided to EFSA No. 1). As indicated in Section 1.2, the assessment of these data is outside the scope of the present opinion.

2.2. Methodologies

The safety assessment of the Primary Product Scansmoke SEF7525 was conducted in line with the requirements laid down in Regulation (EC) No 2065/2003 and following the principles of the EFSA guidance for the preparation of applications on smoke flavouring Primary Products (EFSA FAF Panel, 2021).

The principles described in the EFSA Guidance on transparency with regard to scientific aspects of risk assessment (EFSA Scientific Committee, 2009) as well as the relevant cross‐cutting guidance documents from the EFSA Scientific Committee published after the adoption of the guidance on smoke flavourings (EFSA FAF Panel, 2021), in particular the ‘Guidance on technical requirements for regulated food and feed product applications to establish the presence of small particles including nanoparticles’ (EFSA Scientific Committee, 2021a), were also considered during the risk assessment.

The uncertainty analysis was performed by checking whether standard or non‐standard sources of uncertainties are present, as outlined in the standard procedure described in Section 4.2 of the EFSA guidance on smoke flavouring and listed in Table G.1 therein (EFSA FAF Panel, 2021). Standard uncertainties are not discussed in detail in the present assessment. In case of the presence of non‐standard uncertainties, these are reported in the relevant sections of the opinion and their combined impact on the assessment was evaluated by the Panel (see Section 4).

3. Assessment

3.1. Technical data

3.1.1. Manufacturing process

3.1.1.1. Source materials for the Primary Product

The source material of Scansmoke SEF7525 is a tar obtained by the applicant from an external supplier as by‐product of the production of liquid smoke. According to a statement of the supplier, the tar is produced from a mixture of 30–40% red oak (Quercus rubra), 30–40% white oak (Quercus alba), 5–15% maple (Acer saccharum), 5–15% beech (Fagus grandifolia) and 5–15% hickory (Carya ovata) (Documentation provided to EFSA No. 1 and 2). The hardwoods are blended as sawdust, which is then dried and heated to generate smoke.

The applicant submitted a statement of the supplier informing that the trees from which the tar is produced were not treated with chemical substances (including pesticides) during the 6 months preceding the felling (Documentation provided to EFSA No. 2). The tar is subjected to an internal quality control procedure (i.e. FSSC 22000 consisting of ISO 22000:2018 and ISO TS 22002‐1:2009).

The Panel noted that no information was provided on the pyrolysis conditions applied to produce the tar used as source material for the Primary Product by the applicant. This creates a non‐standard uncertainty with respect to the manufacturing process of the Primary Product (see Section 2.2 of this opinion and Table G.1 of the EFSA guidance document on smoke flavouring (EFSA FAF Panel, 2021)).

3.1.1.2. Method of manufacture of the Primary Product

As described by the applicant, the Primary Product is obtained by (i) extracting the tar raw material with diethyl ether, (ii) subjecting the extracts to purification steps and (iii) combining the obtained fractions (SEF1 and SEF2) at a defined ratio. In the first step, the extraction of an aqueous suspension of the tar is performed under alkaline conditions (pH‐adjustment by addition of sodium hydroxide). The organic phase is subjected to evaporation to remove solvent and water and subsequently to vacuum distillation. After re‐dilution with diethyl ether, the obtained distillate is treated with active carbon to remove polycyclic aromatic hydrocarbons (PAHs), and SEF1 is obtained after evaporation of the solvent and a final filtration (1 mm). In the second step, the pH of the heavy phase remaining after the first extraction is lowered to a less alkaline pH (addition of sulphuric acid). SEF2 results from the extraction with diethyl ether, followed by treatment of the extract with active carbon, evaporation of the solvent and filtration (1 mm). The final Primary Product is obtained by mixing SEF1 and SEF2 at a fixed ratio and is subjected to physico‐chemical testing to verify that it meets the product specifications (Documentation provided to EFSA No. 2).

The applicant submitted a description of the manufacturing process, with information on the drying step, the range of temperatures during the pyrolysis and the extraction and distillation conditions.

3.1.2. Identity of the Primary Product

3.1.2.1. Trade name of the Primary Product

The trade name of the product is Scansmoke SEF7525.

3.1.2.2. Information on existing evaluation from other regulatory bodies and authorisations in non‐EU countries

The applicant indicated that the smoke flavouring Scansmoke SEF7525 has not been evaluated by other regulatory bodies other than EFSA (Documentation provided to EFSA No. 1).

Regarding the existing authorisations in non‐EU countries, the applicant stated that Scansmoke SEF7525 is currently authorised in the United Kingdom and in China (see Documentation provided to EFSA No. 3).

3.1.2.3. Description of the physical state and sensory characteristics

The applicant described the smoke flavouring Primary Product as a ‘viscous liquid of dark brown colour with a characteristic strong odour of smoke’ (Documentation provided to EFSA No. 1). The Primary Product has an average density (at 20°C) of 1.1475 g/mL, refractive index (at 20°C) ranging from 1.50 to 1.70 and a viscosity (at 25°C) ranging from 2,214 to 2,349 mPa·s. In an additional data request, EFSA requested the applicant to specify the parameters of pH and staining index of the Primary Product. These parameters were not provided since they were considered by the applicant as ‘not meaningful for the characterisation of this Primary Product’ (Documentation provided to EFSA No. 2). Considering the low water content of the Primary Product, the Panel accepted that no pH value was provided. Furthermore, the Panel agreed that the staining index is not fundamental for the safety assessment.

3.1.2.4. Chemical composition of the Primary Product

The compositional data provided by the applicant for six batches of the Primary Product in the original dossier and in response to the EFSA requests for additional information are summarised in Table 1 (Documentation provided to EFSA No. 1 and 2).

Table 1.

Overview on the compositional data provided for six batches of the Primary Product (Documentation provided to EFSA No. 1 and 2)

| Batch no. | Density (g/L) | Total volatiles (wt%) | Identified volatiles (wt%) | Unidentified volatiles (wt%) | Total non‐volatiles (wt%) (1) | Identified non‐volatiles (wt%) | Unidentified non‐volatiles (wt%) | Water (wt%) | Solvent‐free fraction (wt%) | Ident./quant. proportion of solvent‐free fraction (wt%) (2) , (a) | Ident./quant. Proportion of volatile fraction (wt%) (3) , (b) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 13390 # | 1,149 | 33 | 27 | 5.9 | 66.4 | – | 66.4 | 0.6 | 99.4 | 27.2 | 81.8 |

| 14185 | 1,144 | 38.4 | 31.5 | 6.9 | 61.2 | – | 61.2 | 0.4 | 99.6 | 31.6 | 82.0 |

| 14300 | 1,151 | 43 | 34 | 8.3 | 57 | – | 57 | 0.3 | 99.7 | 34.1 | 79.1 |

| 14301 | 1,151 | 45 | 37 | 8.1 | 55 | – | 55 | 0.4 | 99.6 | 37.1 | 82.2 |

| 14302 | 1,148 | 42 | 34 | 7.4 | 57.9 | – | 57.9 | 0.4 | 99.6 | 34.1 | 81.0 |

| 14303 | 1,145 | 39 | 31 | 7.9 | 60.7 | – | 60.7 | 0.5 | 99.5 | 31.2 | 79.5 |

| Average | 1,148 | 40.1 | 32.4 | 7.4 | 59.7 | 59.7 | 0.4 | 99.6 | 32.6 | 80.9 | |

| SD | 3.0 | 4.3 | 3.4 | 0.9 | 4.0 | – | 4.0 | 0.1 | 0.1 | 3.4 | 1.4 |

| RSD (%) | 0.3 | 10.6 | 10.5 | 12.1 | 6.7 | – | 6.7 | 23.8 | 0.1 | 10.5 | 1.7 |

wt: weight; SD: standard deviation; RSD: relative standard deviation.

Calculated as 100 ‐ water (wt%) – total volatiles (wt%).

Calculated as: ((identified volatiles + identified non‐volatiles)/solvent‐free fraction) * 100.

Calculated as: (identified volatiles/total volatiles) * 100.

Batch tested in the newly submitted genotoxicity studies.

Regulatory quality criterion for the applied method according to Regulation (EC) No 627/2006 6 : ≥ 50 (wt%).

Regulatory quality criterion for the applied method according to Regulation (EC) No 627/2006: ≥ 80 (wt%).

3.1.2.4.1. Chemical characterisation

The water content of the Primary Product was determined by the Karl Fischer titration method (Documentation provided to EFSA No. 1). The applicant also provided data on the contents of the major chemical classes, i.e. acids, phenols and carbonyls, in six batches of the Primary Product (Table 2) (Documentation provided to EFSA No. 1 and 2).

Table 2.

Chemical compositions reported for six batches of the Primary Product

| Batch no. | Average | SD | ||||||

|---|---|---|---|---|---|---|---|---|

| 13390 # | 14185 | 14300 | 14301 | 14302 | 14303 | |||

| Acids (wt%) (as acetic acid) | 0.7 | 1.5 | 1.0 | 1.5 | 0.9 | 0.5 | 1.0 | 0.4 |

| Phenols (wt%) (as syringol) | 9.5 | 7.5 | 9.2 | 9.9 | 8.8 | 8.1 | 8.8 | 0.9 |

| Carbonyls (wt%) (as furfural) | 4.7 | 4.9 | 4.4 | 4.5 | 4.5 | 5.4 | 4.7 | 0.4 |

| Water (wt%) | 0.6 | 0.4 | 0.3 | 0.4 | 0.4 | 0.5 | 0.4 | 0.1 |

wt: weight; SD:standard deviation.

Batch tested in the newly submitted genotoxicity studies.

The Panel acknowledges the explanation provided by the applicant that the difference between the average concentration of carbonyls in the current application and the average concentration (1.9 weight (wt)%) reported in the previous opinion (EFSA CEF Panel, 2009) is not due to changes in the manufacturing process but related to differences in the performance of the analyses that are based on the reaction of carbonyls with hydroxylamine (Documentation provided to EFSA No. 1). The method applied for this renewal application differs from the method applied previously regarding pH‐adjustment of the reaction mixture and the heating conditions. The contract laboratory was not able to implement and apply the former method to the Primary Product. The Panel considers the values for carbonyl contents provided in this application as reliable, albeit method‐specific.

Concentrations of arsenic, cadmium, lead and mercury were determined by inductively coupled plasma–mass spectrometry (ICP–MS) and were submitted to EFSA (Table 3) (Documentation provided to EFSA No. 1 and 2).

Table 3.

Toxic elements reported for six batches of the Primary Product

| Batch no. (mg/kg) | Average (mg/kg) | SD | ||||||

|---|---|---|---|---|---|---|---|---|

| 13390 # | 14185 | 14300 | 14301 | 14302 | 14303 | |||

| Arsenic (As) | < 0.1 (a) | < 0.1 (a) | < 0.1 (a) | < 0.1 (a) | < 0.1 (a) | < 0.1 (a) | < 0.1 (a) | – |

| Cadmium (Cd) | < 0.01 (a) | < 0.01 (a) | < 0.01 (a) | < 0.01 (a) | < 0.01 (a) | < 0.01 (a) | < 0.01 (a) | – |

| Lead (Pb) | < 0.05 (a) | < 0.05 (a) | < 0.05 (a) | < 0.05 (a) | < 0.05 (a) | < 0.05 (a) | < 0.05 (a) | – |

| Mercury (Hg) | < 0.005 (a) | < 0.005 (a) | < 0.005 (a) | < 0.005 (a) | < 0.005 (a) | < 0.005 (a) | < 0.005 (a) | – |

SD: standard deviation.

Batch tested in the newly submitted genotoxicity studies.

Value below the corresponding limit of quantification (LOQ).

3.1.2.4.2. Identification and quantification of the volatile fraction

Gas chromatography–mass spectrometry (GC–MS) and gas chromatography–flame ionisation detection (GC‐FID) were applied for identification and quantification of the constituents of the volatile fraction of the Primary Product. Individual volatile constituents were considered as identified if their chromatographic (i.e. retention times) and mass spectral data were in agreement with those of reference standards. Quantifications of the volatile constituents were based on compound specific response factors and the use of anthracene d‐10 as internal standard. The analytical methods employed to identify and quantify the volatile constituents were submitted to EFSA together with the validation parameters (Documentation provided to EFSA No. 1).

Overall, using this approach, 41 constituents were identified and quantified in six batches of the Primary Product (for batch numbers see Table 1) (Appendix A, Table A.1). The lowest concentration reported by the applicant was 0.05 wt% for 1‐(4‐hydroxy‐3‐ methoxyphenyl)‐2‐propanone (CAS no.: 2503‐46‐0). For three additional identified constituents, quantitative data were not provided, i.e. 1‐hydroxy‐2‐butanone (CAS no.: 5077‐7‐8), syringyl acetone (CAS no.: 19037‐58‐2) and 2‐hydroxy‐γ‐butyrolactone (CAS no.: 19444‐84‐9) (Documentation provided to EFSA No. 1). The 20 principal volatile constituents of the Primary Product are presented in Table 4.

Table 4.

Twenty principal volatile constituents of the Primary Product (Documentation provided to EFSA No. 1 and2)

| CAS no | FL‐no | Chemical name (a) | Average concentration (wt%) | |

|---|---|---|---|---|

| Current application (b) | Former application (c) | |||

| 91‐10‐1 | 04.036 | 2,6‐dimethoxyphenol | 4.9 | 1.8 |

| 6638‐05‐7 | 04.053 | 4‐methyl‐2,6‐dimethoxyphenol (2,6‐dimethoxy‐4‐methylphenol) | 3.4 | 6.9 |

| 90‐05‐1 | 04.005 | 2‐methoxyphenol | 2.3 | 1.4 |

| 93‐51‐6 | 04.007 | 2‐methoxy‐4‐methylphenol (creosol/methylguaiacol) | 2.3 | 0.4 |

| 14059‐92‐8 | 04.052 | 4‐ethyl‐2,6‐dimethoxyphenol | 2.2 | 2.8 |

| 20675‐95‐0 | 04.055 (d) | 2,6‐dimethoxy‐4‐prop‐1‐enylphenol (2,6‐dimethoxy‐4‐(2‐propenyl)‐phenol, E) | 1.4 | |

| 105‐67‐9 | 04.066 | 2,4‐dimethylphenol | 1.3 | 1.4 |

| 2785‐89‐9 | 04.008 | 4‐ethylguaiacol (4‐ethyl‐2‐methoxyphenol) | 1.2 | 1.9 |

| 95‐48‐7 | 04.027 | 2‐methylphenol | 1.1 | 1.1 |

| 108‐95‐2 | 04.041 | phenol | 0.9 | 0.9 |

| 5932‐68‐3 | 04.004 (e) | isoeugenol (trans‐isoeugenol) | 0.9 | 1.2 |

| 6627‐88‐9 | 04.051 | 4‐allyl‐2,6‐dimethoxyphenol (2,6‐dimethoxy‐4‐(2‐propenyl)‐phenol) | 0.9 | |

| 97‐53‐0 | 04.003 | eugenol | 0.6 | 1.2 |

| 576‐26‐1 | 04.042 | 2,6‐dimethylphenol | 0.6 | |

| 26624‐13‐5 | 04.055 (d) | 2,6‐dimethoxy‐4‐prop‐1‐enylphenol(4‐propenyl‐2,6‐dimethoxyphenol, Z) | 0.6 | 1.1 |

| 1121‐05‐7 | – | 2,3‐dimethyl‐2‐cyclopenten‐1‐one | 0.6 | |

| 108‐39‐4 | 04.026 | 3‐methylphenol | 0.6 | 0.6 |

| 527‐60‐6 | 04.095 | 2,4,6‐trimethyl phenol | 0.6 | |

| 2785‐87‐7 | 04.049 | 2‐methoxy‐4‐propylphenol | 0.5 | |

| 98‐00‐0 | 13.019 | furfuryl alcohol (2‐furanmethanol) | 0.4 | |

CAS: Chemical Abstract Service; FL‐no: FLAVIS number; wt: weight.

In case a constituent of the Primary Product is an authorised flavouring substance (FL‐no), the assigned chemical name corresponds to the respective entry in the EU Union List of flavourings. Deviating chemical names reported by the applicant in the dossier are given in brackets, if applicable.

From the analysis of the six batches presented in Table 1.

From the data presented in the previous safety evaluation of the Primary Product (EFSA CEF Panel, 2009).

[FL‐no: 04.055] refers to the mixture of E/Z stereoisomers of 2,6‐dimethoxy‐4‐prop‐1‐enylphenol.

[FL‐no: 04.004] refers to the mixture of E/Z stereoisomers of isoeugenol.

The applicant reported 280 tentatively identified volatile constituents (Documentation provided to EFSA No. 1). The identification was considered as tentative when it was (solely) based on structural similarities to identified constituents or when the mass spectral data were only compared to a fragmentation mass spectral library rather than to those of a reference standard. In accordance with the EFSA Scientific Guidance on Smoke Flavourings (EFSA FAF Panel, 2021), EFSA considered these tentatively identified constituents as part of the unidentified fraction.

According to the information provided by the applicant (Documentation submitted to EFSA No. 2), the total volatile fraction of Scansmoke SEF7525 accounted on average for 40.1 wt% of the Primary Product. The proportion of identified and quantified volatiles amounted to approximately 81% of the total volatile fraction; thus, the applied methods meet the legal quality criterion that at least 80% by mass of the volatile fraction shall be identified and quantified (Regulation (EC) No 627/2006).

Following an additional data request from EFSA, the applicant commented on the fact that the current list of identified volatile constituents does not fully match the list of identified volatile constituents provided at the time of the previous EFSA assessment of Scansmoke SEF7525 (EFSA CEF Panel, 2009). The applicant emphasised that there were no changes in the manufacturing process and explained that the observed differences are mainly due to the fact that in contrast to the previous application, volatiles were only considered as identified if their chromatographic and mass spectrometric data matched those of reference standards (Documentation provided to EFSA No. 2). The Panel acknowledges this explanation. The Panel further noted that the applicant reported differences in the conditions of the gas chromatography (GC)‐based quantification approaches, e.g. limitation of the upper GC column temperature to 250 °C in the analysis performed for the present application (Documentation provided to EFSA No. 1 and 2). It is very likely that the use of more recent analytical techniques allowed the applicant to perform a more accurate characterisation of the volatile fraction. Although, in the current application, the portion of identified and quantified volatile components is lower than in the former application, the newly developed GC–MS method allowed better peak separation and shape, and enhanced the retention of components with high boiling point and polarity. For this reason, the characterisation performed here is more reliable than the characterisation performed in the previous application (EFSA CEF Panel, 2009), and the product evaluated in the present assessment does not fundamentally deviate from the product evaluated formerly (EFSA CEF Panel, 2009).

3.1.2.4.3. Characterisation of the non‐volatile fraction

In order to characterise the non‐volatile fraction of the Primary Product, the applicant employed the following approaches (Documentation provided to EFSA No. 1):

Heating of the Primary Product at 350°C for determination of the residual non‐volatile fraction. The residue remaining amounted on average to approximately 24 wt%.

Size exclusion chromatography was performed for an untreated sample of the Primary Product and for a sample obtained after evaporation of the Primary Product at 80°C. Using a calibration curve for a polystyrene standard, the weight‐average molecular mass was estimated to be 1.4 kDa for both samples.

A sample of the Primary Product, obtained after evaporation at 80°C, was subjected to alkaline oxidation using H2O2/NaOH followed by GC–MS analysis to identify volatile products resulting from degradation of the non‐volatile material. After this oxidation step, 58 volatile constituents (Documentation provided to EFSA No. 1) were tentatively identified by GC–MS analysis, based on comparisons of their mass spectra to those from an MS‐library. Full identifications and quantifications of the constituents were not performed. The range of detected volatile degradation products encompassed compound classes as described for the oxidative cracking of precipitated hardwood lignin by hydrogen peroxide (Xiang and Lee, 2000). However, the Panel noted that this investigation of the non‐volatile fraction was performed following a treatment with H2O2 under alkaline conditions. Owing to the chemical changes expected under these oxidative conditions, the detected degradation products do not necessarily represent monomers of the non‐volatile material. Thus, the data provided contribute to a characterisation of the non‐volatile fraction, but this part of the Primary Product cannot be considered as identified.

The Panel considered that the applicant could have used a more direct method to identify and quantify constituents in the non‐volatile fraction, e.g. high performance liquid chromatography coupled to mass spectrometry (HPLC–MS), as suggested in the EFSA guidance on smoke flavourings (EFSA FAF Panel, 2021).

3.1.2.4.4. Unidentified fraction

The unidentified fraction of the Primary Product amounts to approximately 67 wt% and comprises the unidentified volatile constituents and the unidentified non‐volatile fraction (i.e. the total non‐volatile fraction); for the individual values see Table 1.

3.1.2.4.5. Overall composition of the Primary Product

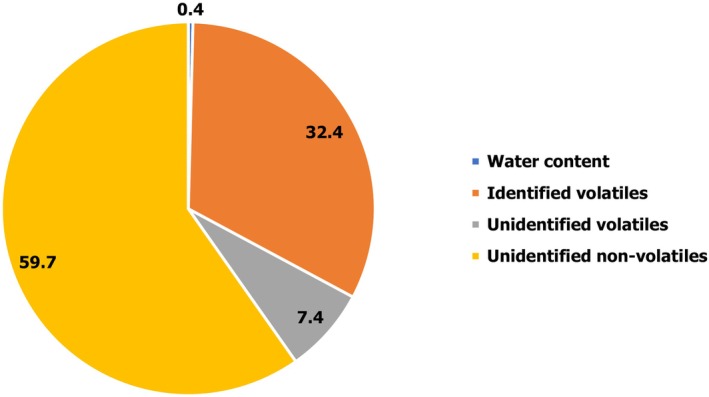

Based on the chemical analyses performed on the production batches of the Primary Product (Table 1), the overall composition of Scansmoke SEF7525 (wt% of Primary Product) is shown in Figure 1, whereas the composition (wt%) of the solvent‐free fraction is shown in Figure 2.

Figure 1.

Overall composition of Scansmoke SEF7525 (wt% of Primary Product)

Figure 2.

Composition (wt%) of the solvent‐free fraction of Scansmoke SEF7525

Regarding the identified and quantified proportion of the volatile fraction, the applied methods comply with the legal requirement that at least 80 wt% of the volatile fraction shall be identified and quantified (Regulation (EC) No 627/2006). The Panel noted that for the investigated batches of the Primary Product, the identified and quantified proportion of the solvent‐free fraction is on average 32.6 wt%; thus, the applied methods do not meet the legal quality criterion that at least 50% by mass (wt%) of the solvent‐free fraction shall be identified and quantified, as specified in Regulation (EC) No 627/2006. This creates a non‐standard uncertainty with respect to the chemical composition of the Primary Product (see Section 2.2 of this opinion and Table G.1 of the EFSA guidance document on smoke flavourings (EFSA FAF Panel, 2021)).

3.1.2.5. Polycyclic aromatic hydrocarbons (PAHs)

Analytical data on the contents of 16 PAHs were provided for six batches of the Primary Product. The analysis meets the performance criteria as set in Regulation (EC) No 627/2006. The levels reported for the individual PAHs (Table 5) are consistently below the minimum required limits of quantification according to Regulation (EC) No 627/2006.

Table 5.

Concentrations of PAHs in the Primary Product, average from six batches (for batch numbers see Table 1) (Documentation provided to EFSA No. 1)

| PAH | Conc. range (μg/kg) | Average (μg/kg) | SD |

|---|---|---|---|

| benzo[a]anthracene (a) | 6.9–15.2 | 9.4 | 3.0 |

| chrysene (a) | 5.0–11.2 | 6.7 | 2.7 |

| benzo[b]fluoranthene (a) | 1.8–3.5 | 2.4 | 0.6 |

| benzo[k]fluoranthene | 0.9–1.04 | 1.0 | 0.2 |

| benzo[j]fluoranthene | 1.4–2.9 | 1.9 | 0.6 |

| benzo[a]pyrene (a) | 2.2–4.7 | 3.0 | 0.9 |

| indeno[123‐cd]pyrene | < 0.5 (b) –1.1 | 0.8 | 0.2 |

| dibenzo[a,h]pyrene | < 1 (b) | < 1 (b) | – |

| benzo[g,h,i]perylene | 1.0–2.8 | 1.6 | 0.7 |

| dibenzo[a,l]pyrene | < 1 (b) | < 1 (b) | – |

| dibenzo[a,i]pyrene | < 1 (b) | < 1 (b) | – |

| dibenzo[a,h]anthracene | < 0.5 (b) | < 0.5 (b) | – |

| dibenzo[a,e]pyrene | < 1 (b) | < 1 (b) | – |

| cyclopenta[cd]pyrene | 7.3–26.3 | 17.5 | 7.8 |

| 5‐methylchrysene | < 1 (b) | < 1 (b) | – |

| benzo[c]fluorene | 44.7–75.7 | 57.6 | 11.5 |

| PAH4 | 16.8–34.6 (c) | 21.4 | 4.2 (d) |

PAH: polycyclic aromatic hydrocarbon; SD: standard deviation.

PAHs printed in bold are included in the calculation of ‘PAH4’, which is used for the evaluation of the exposure to these contaminants (see Section 3.3.3.2).

Value below the corresponding Limit of Quantification (LOQ).

Values for range of PAH4 represent the PAH4 values for the individual batches.

Value calculated as the square root of the summed variances.

The levels of benzo[a]pyrene and benzo[a]anthracene are below their respective limits of 10 and 20 μg/kg as laid down in the Regulation (EC) No 2065/2003.

3.1.2.6. Batch‐to‐batch variability

The batch‐to‐batch variability of the 20 principal volatile constituents of the batches presented in Table 1 was investigated by GC–MS and GC‐FID. The Panel considered that the batch‐to‐batch variability of the six investigated production batches (Table 6), with production dates spanning 15 months, was acceptable, also taking into account information on the other measured parameters evaluated in this opinion. Information on the criteria underlying the selection of these batches was not provided.

Table 6.

Batch‐to‐batch variability of the Primary Product

| CAS no. | Chemical name | Batch no. (production date) | Average (wt%) | SD | RSD (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 13390 # (12‐07‐2021) | 14185 (16‐11‐2021) | 14300 (30‐09‐2020) | 14301 (14‐12‐2020) | 14302 (17‐08‐2020) | 14303 (30‐06‐2021) | |||||

| 91‐10‐1 | 2,6‐dimethoxyphenol | 4.1 | 4.1 | 5.5 | 6.7 | 5.3 | 4.1 | 4.9 | 1.1 | 21.4 |

| 6638‐05‐7 | 4‐methyl‐2,6‐dimethoxyphenol (2,6‐dimethoxy‐4‐ methylphenol) | 2.6 | 3.3 | 3.9 | 4.0 | 3.7 | 3.2 | 3.4 | 0.5 | 15.2 |

| 90‐05‐1 | 2‐methoxyphenol | 2.0 | 2.0 | 2.5 | 3.1 | 2.3 | 2.0 | 2.3 | 0.4 | 18.8 |

| 93‐51‐6 | 2‐methoxy‐4‐methylphenol (creosol/methylguaiacol) | 1.9 | 2.2 | 2.4 | 2.5 | 2.3 | 2.2 | 2.3 | 0.2 | 9.2 |

| 14059‐92‐8 | 4‐ethyl‐2,6‐dimethoxyphenol | 1.6 | 2.1 | 2.6 | 2.6 | 2.4 | 2.1 | 2.2 | 0.4 | 17.1 |

| 20675‐95‐0 | 2,6‐dimethoxy‐4‐(2‐propenyl)‐phenol, E | 1.0 | 1.3 | 1.7 | 1.2 | 2.1 | 1.4 | 1.4 | 0.4 | 27.2 |

| 105‐67‐9 | 2,4‐dimethylphenol | 1.1 | 1.4 | 1.3 | 1.2 | 1.3 | 1.4 | 1.3 | 0.1 | 9.1 |

| 2785‐89‐9 | 4‐ethylguaiacol (4‐ethyl‐2‐methoxyphenol) | 1.0 | 1.2 | 1.3 | 1.2 | 1.3 | 1.2 | 1.2 | 0.1 | 9.1 |

| 95‐48‐7 | 2‐methylphenol | 1.1 | 1.2 | 0.8 | 1.2 | 0.9 | 1.1 | 1.1 | 0.1 | 15.6 |

| 108‐95‐2 | phenol | 1.0 | 1.0 | 0.8 | 1.0 | 0.9 | 1.0 | 0.9 | 0.1 | 8.8 |

| 5932‐68‐3 | trans‐isoeugenol | 0.6 | 0.9 | 1.0 | 0.9 | 1.2 | 0.9 | 0.9 | 0.2 | 21.2 |

| 6627‐88‐9 | 4‐allyl‐2,6‐dimethoxyphenol (2,6‐dimethoxy‐4‐(2‐propenyl)‐phenol) | 0.6 | 0.8 | 1.1 | 1.0 | 1.1 | 0.8 | 0.9 | 0.2 | 22.2 |

| 97‐53‐0 | eugenol | 0.5 | 0.6 | 0.7 | 0.6 | 0.7 | 0.6 | 0.6 | 0.1 | 12.2 |

| 576‐26‐1 | 2,6‐dimethylphenol | 0.63 | 0.64 | 0.60 | 0.61 | 0.60 | 0.61 | 0.61 | 0.02 | 2.6 |

| 26624‐13‐5 | 4‐propenyl‐2,6‐dimethoxyphenol, Z | 0.51 | 0.63 | 0.68 | 0.43 | 0.68 | 0.62 | 0.59 | 0.1 | 16.9 |

| 1121‐05‐7 | 2,3‐dimethyl‐2‐cyclopenten‐1‐one | 0.51 | 0.60 | 0.59 | 0.61 | 0.60 | 0.58 | 0.58 | 0.04 | 6.6 |

| 108‐39‐4 | 3‐methylphenol | 0.61 | 0.63 | 0.43 | 0.60 | 0.55 | 0.63 | 0.58 | 0.08 | 13.2 |

| 527‐60‐6 | 2,4,6‐trimethyl phenol | 0.55 | 0.57 | 0.57 | 0.55 | 0.56 | 0.52 | 0.55 | 0.02 | 3.6 |

| 2785‐87‐7 | 2‐methoxy‐4‐propylphenol | 0.48 | 0.46 | 0.50 | 0.44 | 0.46 | 0.43 | 0.46 | 0.02 | 5.0 |

| 98‐00‐0 | furfuryl alcohol (2‐furanmethanol) | 0.46 | 0.40 | 0.33 | 0.38 | 0.41 | 0.38 | 0.39 | 0.04 | 10.3 |

wt: weight; SD: standard deviation; RSD: relative standard deviation.

Batch tested in the newly submitted genotoxicity studies.

3.1.2.7. Solubility and particle size

According to the applicant Scansmoke SEF7525 is a viscous liquid (Section 3.1.2.3) obtained from the combination of two individual fractions. One of the fractions (SEF1) is obtained by subjecting the ether extract of the alkalised tar material to vacuum distillation followed by treatment with active carbon and filtration (1 mm). However, in order to obtain the second fraction (SEF2) the ether extract of the acidified tar material is not subjected to distillation but only to treatment with active carbon and filtration, which is not sufficient to exclude the presence of particles. Therefore, EFSA requested the applicant to clarify the potential presence of small particles including nanoparticles, in line with the EFSA ‘Guidance on technical requirements for regulated food and feed product applications to establish the presence of small particles including nanoparticles’ (EFSA Scientific Committee, 2021a).

The applicant submitted a study report based on dynamic light scattering (DLS) analysis (Documentation provided to EFSA No. 2). The DLS profiles of the Primary Product and of the Primary Product in seven selected solvents (i.e. water, propylene glycol, ethanol, acetic acid, cyclohexane, diethyl ether and medium chain triglycerides (MCT)) were submitted. The justification for selecting these solvents was not provided, although it can be noted that they span a polarity range and could be used as carriers of the Primary Product in foods. DLS profiles of four pure solvents (i.e. water, ethanol, propylene glycol and MCT) were also provided. As a positive control, the applicant added platinum nanoparticle clusters (Pt‐NP) to the pure solvents at a concentration of 15 μg/mL (Documentation provided to EFSA No. 2). The applicant stated that the solubility of the Primary Product in water and cyclohexane was poor, whereas its solubility in propylene glycol, ethanol, acetic acid and MCT was high. The applicant further stated that in one part of diethyl ether (1:1), Scansmoke SEF7525 was fully soluble, but an increase of diethyl ether led to precipitation. However, quantitative data on the solubility of the Primary Product in the selected solvents was not provided. Based on the analyses performed, the applicant concluded that the Primary Product is a true liquid, and consequently, does not contain small particles, including nanoparticles.

The Panel noted that the DLS profiles of the Primary Product and of the Primary Product in propylene glycol (1:5) exhibit one peak in the range of around 1 nm, which is likely to be an artefact due to the limitation of the DLS method. However, when the Primary Product is mixed with the other solvents, the DLS profiles show various peaks up to 10,000 nm, which do not correspond to the peaks observed in the DLS profiles of the four pure solvents for which data were submitted.

The Panel noted that the evidence provided is not sufficient to prove the absence of a fraction of small particles in the Primary Product since:

the presence of peaks in the DLS profiles of the Primary Product when mixed with the selected solvents is not explained by the applicant, and may indicate the presence of particulate matter, e.g. the DLS profile of the Primary Product in diethyl ether (1:1) shows various peaks from 10 to 10,000 nm;

the DLS profile of the pure diethyl ether was not provided for comparison with the DLS profile of the Primary Product in diethyl ether (1:1). In addition, the applicant claimed that the increase of diethyl ether in the mixture with the Primary Product would lead to precipitation. This contradicts the assumption that the Primary Product is fully soluble in diethyl ether;

the Pt‐NP do not represent an appropriate positive control, as they have different light scattering properties compared to the organic particles potentially present (if any) in the Primary Product. Moreover, since large nanoparticles produce very high DLS signal, this could have covered the signals belonging to smaller particles, thereby reducing the sensitivity of the testing. Since the size of the Pt‐NP was not specified, it is not possible to judge if the Pt‐NP positive control would have introduced DLS signalling bias.

Based on the above, the Panel concluded that more evidence is needed to exclude the presence of nanoparticles in the Primary Product. This creates a non‐standard uncertainty with respect to the solubility and particle size of the Primary Product (see Section 2.2 of this opinion and Table G.1 of the EFSA guidance document on smoke flavouring (EFSA FAF Panel, 2021)).

3.1.3. Specifications

The applicant provided the required product specification data and reported that the Primary Product Scansmoke SEF7525 is manufactured within its proposed specifications (Documentation provided to EFSA No. 1 and 2). Information on parameters relevant for the specifications has been compiled by the Panel in Table 7.

Table 7.

Relevant information for specifications of the Primary Product

| Specifications for Scansmoke SEF7525 as proposed by the applicant | Specifications as reported in in EFSA CEF Panel (2009) | Specifications as laid down in Regulation (EU) No 1321/2013 | |

|---|---|---|---|

| Description | Smoke flavouring Primary Product obtained from a combination of different wood species. | ||

| Source material | |||

|

Red oak (Quercus rubra; 35%), white oak (Quercus alba; 35%), maple (Acer saccharum; 10%), beech (Fagus grandifolia; 10%) and hickory (Carya ovata; 10%) | Red oak (Quercus rubra; 35%), white oak (Quercus alba; 35%), maple (Acer saccharum; 10%), beech (Fagus grandifolia; 10%) and hickory (Carya ovata; 10%) | |

| Identity parameters: | |||

|

|||

|

n.d. | ||

|

n.d. | ||

|

1.14–1.16 g/mL | ||

|

1.50–1.70 | ||

| Chemical composition: | |||

|

|||

|

0.43–1.64 wt% (0.07–0.27 mEq/g) (as acetic acid) |

0.09–0.25 mEq/g | 0.09–0.25 mEq/g (as acetic acid) |

|

4.0–6.0 wt% (as furfural) |

1.2–3.0 wt% | 1.2–3.0 wt% |

|

7.0–12.0 wt% (as syringol) |

8–12 wt% | 8–12 wt% |

|

0.3–0.9 wt% | 0.3–0.9 wt% | 0.3–0.9 wt% |

| 20 principal constituents of the volatile fraction | See Table 4 | ||

| Purity: | |||

|

< 10 μg/kg | < 10 μg/kg | |

|

< 20 μg/kg | < 20 μg/kg | |

|

|||

|

< 3 mg/kg | < 1 mg/kg | < 3 mg/kg |

|

< 1 mg/kg | < 0.025 mg/kg | < 1 mg/kg |

|

< 5 mg/kg | < 0.1 mg/kg | < 5 mg/kg |

|

< 1 mg/kg | < 0.01 mg/kg | < 1 mg/kg |

wt: weight; n.d.: not determined. The applicant did not determine staining index and pH of the Primary Product.

The Panel noted that in the specifications proposed by the applicant, the woods used as raw material are presented in a fixed percentage. However, the Primary Product is manufactured using the wood materials in the range of proportion described in Section 3.1.1.1 This is confirmed by the applicant following an additional data request from EFSA (Documentation provided to EFSA No. 2).

The Panel noted that the analytical data for the batches analysed indicated that actual concentrations of toxic elements and PAHs, reported in Tables 3 and 5, respectively, are lower than the currently proposed limits (Table 7), being the same as the limits laid down in the respective Regulations (i.e. Regulation (EU) No 1321/2013 for toxic elements and Regulation (EC) No 2065/2003 for benzo[a]pyrene and benzo[a]anthracene).

With regard to carbonyl compounds, the applicant informed that the difference between the concentration range of carbonyls in the current application and in the technical dossier evaluated by EFSA formerly (EFSA CEF Panel, 2009) is not due to changes in the manufacturing process but related to the measurement technique (Documentation provided to EFSA No. 1). In addition, based on the newly provided compositional data, the Panel considered that the proposed extension of the range of phenols and acids (see Table 7) is justified.

3.1.4. Stability and fate in food

Stability tests were performed for one of the batches of the Primary Product (batch no. 14185) listed in Table 1.

A stability test was performed with the batch stored for 6 months at temperature between 7 and 25°C, and approximately 60% of relative humidity. In addition, the batch was subjected to an accelerated stability test (forced ageing) at 40°C for 5.5 months. The storage stability of the Primary Product Scansmoke SEF7525 was assessed by monitoring the volatile constituents of the Primary Product; based on the observed relative standard deviations (on average approximately 10%), their concentrations were sufficiently stable under both storage conditions. On the basis of these data, the Panel considered the stability of the Primary Product upon storage under the intended conditions not to be of concern. No data on the stability of the Primary Product in commercial formulations or in the proposed food categories were provided.

3.2. Proposed uses and use levels

The applicant applied for a renewal of authorisation of the Primary Product Scansmoke SEF7525 for use in the food at the proposed maximum and expected typical use levels as presented in Table 8.

Table 8.

Proposed maximum and expected typical use levels of Primary Product (mg/kg) in food categories according to Annex II of Regulation (EC) No 1333/2008 7

| Food category number | Food category name | Restrictions/Exceptions | Proposed maximum use levels (mg/kg) (a) | Expected typical use levels (mg/kg) (a) |

|---|---|---|---|---|

| 1.4 | Flavoured fermented milk products including heat‐treated products | 2 | 2 | |

| 1.7 | Cheese and cheese products | 160 | 100 | |

| 1.8 | Dairy analogues, including beverage whiteners | 160 | 140 | |

| 2.2.2 | Other fat and oil emulsions including spreads as defined by Regulation (EC) No 1234/2007 and liquid emulsions | 50 | 20 | |

| 3 | Edible ices | 2 | 2 | |

| 4.1.3 | Frozen fruits and vegetables | Vegetables only | 50 | 45 |

| 4.2.2 | Fruits and vegetables in vinegar, oil, brine | 50 | 45 | |

| 4.2.3 | Canned or bottled fruits and vegetables | Vegetables only | 50 | 45 |

| 4.2.5.4 | Nut butters and nut spreads | 50 | 45 | |

| 5.1 | Cocoa and Chocolate products as covered by Directive 2000/36/EC | 2 | 2 | |

| 5.4 | Decorations, coatings and fillings, except fruit‐based fillings covered by category 4.2.4 | 80 | 75 | |

| 6.4.5 | Fillings of stuffed pasta (ravioli and similar) | 50 | 45 | |

| 6.5 | Noodles | 50 | 45 | |

| 6.6 | Batters | 50 | 45 | |

| 6.7 | Pre‐cooked or processed cereals | 50 | 45 | |

| 7.2 | Fine bakery wares | 80 | 25 | |

| 8.2 | Meat preparations as defined by Regulation (EC) No 853/2004 of the European Parliament and of the Council | 160 | 150 | |

| 8.3 | Meat products | 160 | 150 | |

| 9.2 | Processed fish and fishery products including crustaceans and molluscs | 160 | 150 | |

| 9.3 | Fish roe | 160 | 150 | |

| 10.2 | Processed eggs and egg products | 10 | 10 | |

| 12.2.2 | Seasonings and condiments | 180 | 120 | |

| 12.5 | Soups and broths | 50 | 45 | |

| 12.6 | Sauces | 50 | 45 | |

| 12.7 | Salads and savoury based sandwich spreads | 50 | 50 | |

| 12.9 | Protein products, excluding products covered in category 1.8 | 160 | 100 | |

| 14.1.4 | Flavoured drinks | 50 | 30 | |

| 14.1.5 | Coffee, coffee and chicory extracts, tea, herbal‐ and fruit‐infusions; coffee substitutes, coffee mixes and mixes for ‘hot beverages’ | 50 | 45 | |

| 14.2 | Alcoholic beverages, including alcohol‐free and low‐alcohol counterparts | 50 | 10 | |

| 15.1 | Potato‐, cereal‐, flour‐ or starch‐based snacks | 80 | 70 | |

| 15.2 | Processed nuts | 80 | 50 | |

| 16 | Desserts excluding products covered in category 1, 3 and 4 | 10 | 10 |

Use levels are provided for the foods as consumed.

The proposed maximum and expected typical use levels were used to assess the dietary exposure to this Primary Product (see Section 3.3.2). 7

3.3. Exposure

3.3.1. Food consumption data used for the exposure assessment

The food consumption data used for the exposure assessment are from the EFSA Comprehensive European Food Consumption Database. 8 This database contains food consumption data at the level of the individual consumer from the most recent national dietary surveys carried out in EU countries and includes the currently best available food consumption data across the EU. These data cover infants (from 0 weeks of age), toddlers (1–2 years), children (3–9 years), adolescents (10–17 years), adults (18–64 years) and the elderly (65 years and older). As these data were collected by different methodologies, direct country‐to‐country comparisons of exposure estimates based on these data may not be appropriate.

The dietary exposure to the Primary Product was calculated by the applicant and EFSA using Food Additive Intake Model (FAIM, version 2.1). The food consumption data in FAIM (version 2.1) used in the exposure assessment were based on the version of the Comprehensive Database that was published in July 2021. These data cover 42 dietary surveys carried out in 22 EU countries (Table 9).

Table 9.

Population groups and countries considered for the exposure estimates of the Primary Product obtained with FAIM

| Population | Age range | Countries with food consumption surveys covering more than 1 day |

|---|---|---|

| Infants | From 12 weeks up to and including 11 months of age | Bulgaria, Cyprus, Denmark, Estonia, Finland, France, Germany, Italy, Latvia, Portugal, Slovenia |

| Toddlers (a) | From 12 months up to and including 35 months of age | Belgium, Bulgaria, Cyprus, Denmark, Estonia, Finland, France, Germany, Hungary, Italy, Latvia, the Netherlands, Portugal, Slovenia, Spain |

| Children (b) | From 36 months up to and including 9 years of age | Austria, Belgium, Bulgaria, Cyprus, Czechia, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Italy, Latvia, the Netherlands, Portugal, Spain, Sweden |

| Adolescents | From 10 years up to and including 17 years of age | Austria, Belgium, Cyprus, Czechia, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Italy, Latvia, the Netherlands, Portugal, Romania, Slovenia, Spain, Sweden |

| Adults | From 18 years up to and including 64 years of age | Austria, Belgium, Croatia, Cyprus, Czechia, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, the Netherlands, Portugal, Romania, Slovenia, Spain, Sweden |

| The elderly (b) | From 65 years of age and older | Austria, Belgium, Cyprus, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, the Netherlands, Portugal, Romania, Slovenia, Spain, Sweden |

The term ‘toddlers’ in the Comprehensive Database (EFSA, 2011) corresponds to ‘young children’ (from 12 months up to and including 35 months of age) in Regulations (EC) No 1333/2008 and (EU) No 609/2013 9 .

In FAIM, the terms ‘children’ and ‘the elderly’ correspond, respectively, to ‘other children’ and the merge of ‘elderly’ and ‘very elderly’ in Comprehensive Database (EFSA, 2011).

The food consumption data from the Comprehensive Database in FAIM are codified according to the food categories as presented in Annex II, Part D, of Regulation (EC) No 1333/2008, which is the relevant regulation for the food categories of the smoke flavourings. 9

3.3.2. Exposure assessment to the Primary Product using FAIM

Using FAIM, dietary exposure to the Primary Product was calculated by multiplying the relevant use level for each food category with its respective consumption amount for each individual. This was done for all individuals in the surveys (i.e. the estimates are not based on consumers only). The exposures per food category were subsequently added and divided by the individual body weight (bw) (as registered in the consumption survey) to derive an individual total exposure per day expressed per kilogram bw. These exposure estimates were averaged over the number of survey days in the survey, resulting in an individual average exposure per day. Dietary surveys with only 1 day per subject were excluded as they are not considered adequate to assess repeated exposure. The calculations resulted in distributions of individual exposure per survey and population group. Based on these distributions, the mean and the 95th percentile of exposure were calculated per survey and population group. The 95th percentile of exposure was only calculated for those population groups with a sufficiently large sample size to obtain a reliable estimate (EFSA, 2011).

3.3.2.1. Exposure assessment using FAIM

The applicant provided estimates of dietary exposure to the Primary Product using FAIM, based on the proposed maximum (proposed maximum use level exposure assessment scenario) and expected typical use levels (expected typical use level exposure assessment scenario) (Documentation provided to EFSA No. 1). These estimates were re‐calculated by EFSA following a submission of updated uses and use levels from the applicant (Documentation provided to EFSA No. 2).

In FAIM, use levels were linked to the corresponding food categories according to the instructions provided for its use. 10 Furthermore, all foods belonging to the food categories (FC) were included in the assessment without applying the restrictions/exceptions as indicated in Table 8. This tool does not allow to include or exclude specific foods from the exposure assessment. See Annex A1 for the food categories and use levels considered in FAIM.

Exposure estimates using FAIM

In Table 10, the dietary exposure estimates of the Primary Product with FAIM are presented.

Table 10.

Summary of dietary exposure to the Primary Product from its proposed maximum and expected typical use levels as a smoke flavouring in six population groups and estimated with FAIM (minimum‐maximum across the dietary surveys in mg/kg body weight (bw) per day)

| Infants (12 weeks–11 months) (n = 11/9) | Toddlers (12–35 months) (n = 15/13) | Children (3–9 years) (n = 19/19) | Adolescents (10–17 years) (n = 21/20) | Adults (18–64 years) (n = 22/22) | The elderly (≥ 65 years) (n = 22/21) | |

|---|---|---|---|---|---|---|

| Proposed maximum use level exposure assessment scenario | ||||||

| Mean | 0.6–3.0 | 1.4–3.8 | 1.4–3.7 | 0.7–2.0 | 0.7–1.5 | 0.6–1.4 |

| 95th percentile | 1.7–10.1 | 2.5–9.4 | 2.3–8.6 | 1.4–4.5 | 1.3–3.3 | 1.1–2.2 |

| Expected typical use level exposure assessment scenario | ||||||

| Mean | 0.5–2.6 | 1.2–3.3 | 1.0–3.2 | 0.5–1.7 | 0.6–1.3 | 0.4–1.1 |

| 95th percentile | 1.5–9.1 | 2.2–8.2 | 1.8–7.6 | 1.0–3.9 | 1.0–2.9 | 0.8–2.0 |

n: number of surveys from which a mean/P95 could be calculated.

At the proposed maximum use levels, the mean exposure to the Primary Product from its use as a smoke flavouring ranged from 0.6 mg/kg bw per day in infants and the elderly to 3.8 mg/kg bw per day in toddlers. The 95th percentile of exposure to the Primary Product ranged from 1.1 mg/kg bw per day in the elderly to 10.1 mg/kg bw per day in infants.

At the expected typical use levels, the mean exposure to the Primary Product from its use as a smoke flavouring ranged from 0.4 mg/kg bw per day in the elderly to 3.3 mg/kg bw per day in toddlers. The 95th percentile of exposure to the Primary Product ranged from 0.8 mg/kg bw per day in the elderly to 9.1 mg/kg bw per day in infants.

Because the maximum and typical use levels were similar (Table 10), the exposure results of the two exposure scenarios were almost the same.

The Primary Product is requested for renewal of authorisation in 32 food categories (Table 8). For all these 32 food categories considered, it was assumed that 100% of the foods belonging to these food categories will contain the Primary Product at the proposed maximum or expected typical use levels. As it is unlikely that the Primary Product will be added to all foods and given the restrictions/exceptions for two food categories (Table 8), the Panel considered that the calculated exposure to the Primary Product using FAIM is an overestimation of the expected exposure in EU countries if this Primary Product is used at the proposed maximum or expected typical use levels.

Additionally, overall sources of standard uncertainties (Annex A6) also contributed to an overestimation of the exposure.

Detailed results per population group and survey are presented in Annexes A2 (Proposed maximum use level exposure assessment scenario) and A3 (Expected typical use level exposure assessment scenario).

Main food category contributing to exposure to the Primary Product using FAIM

Under the conservative assumptions mentioned above, the main food categories contributing to the total mean exposure to the primary product for both exposure scenarios contributing to at least 30% to the total mean exposure in at least one population group in one survey, listed in order of the number of the FCs, are:

FC 01.7.1 Unripened cheese excluding products falling in category 16.

FC 04.1 Unprocessed fruit and vegetables.

FC 12.5 Soups and broths.

FC 14.1.4.1 Flavoured drinks with sugar.

FC 14.1.5.1 Coffee, coffee extracts.

FC 14.1.5.2 Other.

Considering the conservative nature of the underlying assumption that 100% of the foods within the food categories (Table 8) contain the Primary Product, the Panel emphasises that the main food categories listed here may not reflect the food categories that contribute most to the exposure in real life.

Detailed results of the contributing food categories are presented in Annexes A4 (proposed maximum use level exposure assessment scenario) and A5 (expected typical use level exposure assessment scenario).

3.3.3. Anticipated exposure to impurities in the Primary Product

The potential exposure to the impurities arsenic, lead, cadmium, mercury and PAHs (as PAH4) from the use of the Primary Product can be calculated by assuming that they are present in the Primary Product up to a limit value and then by calculating pro‐rata to the estimates of exposure to the Primary Product itself.

With regard to the dietary exposure to the Primary Product, the Panel considered the highest mean and the highest 95th percentile exposure estimates resulting from the exposure assessment using FAIM among the different population groups, i.e. 3.8 mg/kg bw per day for toddlers and 10.1 mg/kg bw per day for infants, respectively (Table 10).

The level of the impurities in the Primary Product combined with the estimated exposure to the Primary Product (Table 10) can be used to estimate the exposure to these impurities. This exposure can then be compared with reference points (RP, i.e. lower limit of the benchmark dose (BMDL) for arsenic, lead and PAH4) or health‐based guidance values (HBGV, i.e. tolerable weekly intake (TWI) for cadmium and mercury) for the undesirable impurities present in the Primary Product (Table 11).

Table 11.

Reference points/health‐based guidance values for the impurities potentially present in the Primary Product

| Impurity/constituent/HBGV/RP | Basis/Reference |

|---|---|

| Arsenic (As)/0.3–8 μg/kg bw per day (BMDL01) | The reference point is based on a range of benchmark dose lower confidence limit (BMDL01) values between 0.3 and 8 μg/kg body weight (bw) per day identified for cancers of the lung, skin and bladder, as well as skin lesions. MOE should be at least 10,000 if the reference point is based on carcinogenicity in animal studies. However, as the BMDL for As is derived from human studies, an interspecies extrapolation factor (i.e. 10) is not needed, i.e. a MOE of 1,000 would be sufficient (EFSA CONTAM Panel, 2009a; EFSA Scientific Committee, 2012). |

| Cadmium (Cd)/2.5 μg/kg bw per week (TWI) | The derivation of the reference point is based on a meta‐analysis to evaluate the dose–response relationship between selected urinary cadmium and urinary beta‐2‐microglobulin as the biomarker of tubular damage recognised as the most useful biomarker in relation to tubular effects. A group‐based BMDL5 of 4 μg Cd/g creatinine for humans was derived. A chemical specific adjustment factor of 3.9 was applied to account for human variability in urinary cadmium within each dose‐subgroup in the analysis resulting in a reference point of 1.0 μg Cd per g creatinine. In order to remain below 1 μg Cd/g creatinine in urine in 95% of the population by age 50. The average daily dietary cadmium intake should not exceed 0.36 μg Cd/kg bw. Corresponding to a weekly dietary intake of 2.5 μg Cd/kg bw (EFSA CONTAM Panel, 2009b). |

| Lead (Pb)/0.5 μg/kg bw per day (BMDL01) | The reference point is based on a study demonstrating perturbation of intellectual development in children with the critical response size of 1 point reduction in IQ. The EFSA CONTAM Panel mentioned that a 1‐point reduction in IQ is related to a 4.5% increase in the risk of failure to graduate from high school and that a 1‐point reduction in IQ in children can be associated with a decrease of later productivity of about 2%. A risk cannot be excluded if the exposure exceeds the BMDL01 (MOE lower than 1) (EFSA CONTAM Panel, 2010). |

| Mercury (Hg)/4 μg/kg bw per week (TWI) | The HBGV was set using kidney weight changes in male rats as the pivotal effect. Based on the BMDL10 of 0.06 mg/kg bw per day, expressed as mercury, and an uncertainty factor of 100 to account for inter and intra species differences, with conversion to a weekly basis and rounding to one significant figure, a TWI for inorganic mercury of 4 μg/kg bw per week, expressed as mercury was established (EFSA CONTAM Panel, 2012). |

| PAH4/340 μg/kg bw per day (BMDL10) | Polycyclic aromatic hydrocarbons (PAHs) are considered genotoxic and carcinogenic. The reference point is based on a carcinogenicity study by Culp et al. (1998), as reported by the EFSA CONTAM Panel (2008), who concluded that PAH4 (i.e. the sum of benzo[a]anthracene, benzo[a]pyrene, benzo[b]fluoranthene and chrysene) is a suitable indicator for the occurrence and toxicity of PAHs in food. The MOE should be at least 10,000 (EFSA CONTAM Panel, 2008). |

HBGV: health‐based guidance value; RP: reference point; BMDL01: lower confidence limit of the benchmark dose associated with a 1% extra risk for tumours (EFSA Scientific Committee, 2017a); BMDL10: lower confidence limit of the benchmark dose associated with a 10% extra risk for tumours (EFSA Scientific Committee, 2017a); TWI: tolerable weekly intake; MOE: margin of exposure.

The risk assessment of the undesirable impurities helps to determine whether there could be a possible health concern if these impurities were present at their limit values in the Primary Product. The assessment is performed by calculating the MOE by dividing the reference point (i.e. BMDL, Table 11) by the exposure estimate for an impurity (Table 10), or by estimating the contribution of the exposure to an impurity due to the use of Primary Product to the HBGV (expressed as percentage of the HBGV).

3.3.3.1. Toxic elements

The results of the analysis of arsenic, cadmium, lead and mercury in six batches of the Primary Product were reported (Table 3).

The applicant proposed maximum limits for these toxic elements, which are the same as the limits in the current EU specifications (Table 7). The Panel noted that the actual measured levels of the toxic elements in commercial samples of the Primary Product were substantially lower than these limits.

The Panel assessed the risk that would result if these toxic elements were present in the Primary Product according to two concentration scenarios: (i) at the current limits in the EU specifications and (ii) at the reported LOQ multiplied by a factor of 10, since the analytical data were below the LOQs (see Table 3); this to account for standard variability with respect to representativeness, homogeneity and analytical measurement.

The outcome of the risk assessment for the two concentration scenarios and based on the highest mean and the highest 95th percentile exposure estimates among the different population groups (see Section 3.3.2) is presented in Table 12.

Table 12.

Risk assessment for four toxic elements present in the Primary Product according to two concentration scenarios, using the reference points/health‐based guidance values as provided in Table 11

| Exposure to Scansmoke SEF7525 (mg/kg bw/day) | (i) Considering the presence of toxic elements at the current EU specifications limits for Scansmoke SEF7525 | |||

|---|---|---|---|---|

| MOE for As at 3 mg/kg | % of the TWI for Cd at 1 mg/kg | MOE for Pb at 5 mg/kg | % of the TWI for Hg at 1 mg/kg | |

| 3.8 (a) | 26.3–701.8 | 1.1 | 26.3 | 0.7 |

| 10.1 (b) | 9.9–264 | 2.8 | 9.9 | 1.8 |

| (ii) Considering the presence of toxic elements at the reported LOQs multiplied by a factor of 10 | ||||

| MOE for As at 1 mg/kg | % of the TWI for Cd at 0.1 mg/kg | MOE for Pb at 0.5 mg/kg | % of the TWI for Hg at 0.05 mg/kg | |

| 3.8 (a) | 78.9–2105 | 0.1 | 263.2 | 0.03 |

| 10.1 (b) | 29.7–792.1 | 0.3 | 99.0 | 0.1 |

bw: body weight; MOE: margin of exposure; TWI: tolerable weekly intake; LOQ: limit of quantification.

Highest mean exposure level among the different population groups (proposed maximum use level exposure assessment scenario – toddlers (Table 10)).

Highest 95th percentile exposure level among the different population groups (proposed maximum use level exposure assessment scenario – infants (Table 10)).

When considering the current limits of the EU specifications (scenario (i) in Table 12), the Panel concluded that for arsenic the ranges of the calculated MOE values were insufficient, i.e. below the target value of 1,000 (Table 11). For the other three toxic elements (cadmium, lead and mercury), the EU current specifications limit values do not give rise to safety concerns.

When considering the LOQs multiplied by a factor of 10 (scenario (ii) in Table 12), the Panel concluded that for arsenic (a) the lower end of the range for the highest mean and (b) the range for the highest 95th percentile of the calculated MOE values were insufficient, i.e. below the target value of 1,000 (Table 11). The presence of the other toxic elements in the Primary Product does not give rise to concern.

Overall, the Panel considered that the limits in the EU specifications for arsenic, cadmium, lead and mercury should be established based on actual levels in the commercial Primary Product. If the European Commission decides to revise the current limits in the EU specifications, the estimated exposure to the toxic elements as described above could be considered.

3.3.3.2. Polycyclic aromatic hydrocarbons (PAHs)

The results of the analysis of 16 PAHs were reported by the applicant for six batches of the Primary Product (Table 5).

The proposed limits for two of these PAHs (i.e. benzo[a]pyrene and benzo[a]anthracene) are below their respective limits of 10 and 20 μg/kg as laid down in Regulation (EC) No 2065/2003. However, the Panel noted that the actual measured levels for benzo[a]pyrene and benzo[a]anthracene in the Primary Product (Table 5) were lower than the current limits in Regulation (EC) No 2065/2003.

According to the data submitted by the applicant, the Panel considered the maximum reported level of PAH4 in the Primary Product, i.e. 34.6 μg/kg (Table 5). Based on this level, the Panel assessed the risk that would result if PAH4 were present in the Primary Product: (i) at the specifications limits for the sum of benzo[a]pyrene and benzo[a]anthracene in the Primary Product, i.e. 30 μg/kg, as proposed by the applicant (Table 7) and setting the concentration of the other two members of PAH4 (chrysene and benzo[b]fluoranthene) at zero for the purpose of this concentration scenario, and also (ii) at the maximum reported level of PAH4 in six batches of the Primary Product (Table 5). The outcome of the risk assessment for the two concentration scenarios and based on the highest mean and the highest 95th percentile FAIM exposure estimates among the different population groups (see Section 3.3.2) is presented in Table 13.

Table 13.

Risk assessment for PAH4, i.e. benzo[a]anthracene, benzo[a]pyrene, benzo[b]fluoranthene and chrysene in the Primary Product according to two concentration scenarios, using the reference points/health‐based guidance values as provided in Table 11

| Exposure to Scansmoke SEF7525 (mg/kg bw/day) | MOE for PAH4 |

|---|---|

| (i) Considering the presence of PAH4 at the sum of the specifications limits for benzo[a]pyrene and benzo[a]anthracene in Scansmoke SEF7525 (30 μg/kg) | |

| 3.8 (a) | 2.98 × 106 |

| 10.1 (b) | 1.12 × 106 |

| (ii) Considering the presence of PAH4 at their maximum reported level in Scansmoke SEF7525 (34.6 μg/kg) | |

| 3.8 (a) | 2.59 × 106 |

| 10.1 (b) | 9.73 × 105 |

bw: body weight: MOE: margin of exposure.

Highest mean exposure level among the different population groups (proposed maximum use level exposure assessment scenario – toddlers (Table 10)).

Highest 95th percentile exposure level among the different population groups (proposed maximum use level exposure assessment scenario – infants (Table 10)).

The Panel noted that the resulting MOEs for PAH4 were far above the target value of 10,000 for both concentration scenarios and both exposure estimates of the Primary Product (EFSA Scientific Committee, 2012) (Table 11).

Furthermore, the Panel noted that at the highest proposed maximum use level of the Primary Product in any of the food categories, i.e. 160 mg/kg food (Table 8), and the maximum reported level of PAH4 in the Primary product, i.e. 34.6 μg/kg, the concentration of PAH4 in food would be 6.2 × 10−3 μg/kg food, which is far below the lowest maximum level (ML) of these contaminants in any of the foodstuffs as listed in Regulation (EU) 2023/915 11 (i.e. 1 μg PAH4/kg food).

3.4. Genotoxicity data

The present evaluation is conducted in line with the applicable EFSA guidance on smoke flavourings (EFSA FAF Panel, 2021) which encompasses all the EFSA guidance documents on genotoxicity (EFSA Scientific Committee, 2011, 2017b, 2019, 2021b). These documents were not available at the time when the smoke flavourings were evaluated previously by the CEF Panel. In addition, for the assessment of the renewal applications, the reliability and relevance of all submitted genotoxicity studies were evaluated by the FAF Panel (see Sections 3.4.1 and 3.4.2) based on the criteria described in Appendix C.

3.4.1. Genotoxicity assessment of the individual components

The 44 identified components of Scansmoke SEF7525 (SF‐004) (i.e. 41 identified and quantified components as listed in the Appendix A, Table A.1 plus 3 identified, but not quantified, components as described in Section 3.1.2.4.2) were evaluated individually for genotoxicity considering first the data available from the literature as provided by the applicant and then, in the absence of relevant information from the literature, considering the in silico information/data submitted by the applicant, when available, supplemented by in silico data generated by EFSA (see Annex B).

Out of the 41 identified and quantified components, the applicant reported that 31 were already evaluated by EFSA and/or JECFA/CoE as flavouring substances and relied on these assessments to conclude on their genotoxic potential. For the remaining 10 components, the applicant's conclusions were based on literature search, in silico analysis, applying (Q)SAR models, i.e. Derek Nexus (version 6.1.0) 12 and Organisation for Economic Co‐operation and Development (OECD) quantitative structure–activity relationship (QSAR) Toolbox v. 4.5 13 and read‐across.

The following models, as implemented in Derek Nexus, were considered by the applicant (Documentation provided to EFSA No. 1):

Chromosome damage in vitro;

Chromosome damage in vivo;

Photo‐induced chromosome damage in vitro;

Mutagenicity in vitro;

Mutagenicity in vivo;

Photomutagenicity in vitro;

Non‐specific genotoxicity in vitro;

Non‐specific genotoxicity in vivo;

Photo‐induced non‐specific genotoxicity in vitro;

Photo‐induced non‐specific genotoxicity in vivo.

Alerts were reported for Mutagenicity in vitro and in vivo and for Chromosome damage in vitro and in vivo, but not for any of the other models.

The following profilers as implemented in OECD QSAR Toolbox v. 4.5 13 were also considered by the applicant to complement the in silico analysis:

DNA alerts for AMES, Chromosomal Aberrations (CA) and Micronucleus (MN) by OASIS;

DNA binding by OASIS;

DNA binding by OECD;

Protein binding alerts for chromosomal aberration by OASIS;

In vitro mutagenicity (Ames test) alerts by ISS;

In vivo mutagenicity (Micronucleus) alerts by ISS.

A short summary of the data available from the literature as submitted by the applicant and of the overall conclusions from the applicant on the genotoxicity of the individual components, including the in silico analysis, when available, is reported in Annex B of this opinion (see columns ‘G’ and ‘I’). The complete set of information from the applicant is available under the section ‘Genotoxicity’ of the technical dossier (see Documentation provided to EFSA No. 1).

In line with the EFSA guidance on smoke flavourings (EFSA FAF Panel, 2021), the Panel conducted a (Q)SAR analysis for all the 44 identified components of the Primary Product using the same six profilers available in the OECD QSAR Toolbox v. 4.5, as listed above.

As described in column ‘K’ of Annex B, reporting the EFSA's conclusions on the genotoxicity of the components of the Primary Product based on the available data, the individual structural alerts identified by the six profilers may have different positive predictivity (i.e. rate of positives to the total number of substances with the alert) for the genotoxicity of the target substance. The concepts of the alerts are described by the European Chemicals Agency (ECHA, 2008) and the predictivities of the individual alerts are documented by Benigni et al. (2008 and 2009). When necessary, the application of profilers was followed by an expert review (e.g. check of close analogues/structurally related substances).

Overall, regarding the genotoxicity assessment of the individual components of the Primary Product the Panel noted that:

genotoxicity data were available from the literature for all the 44 identified components of the Primary Product, either on the substance or on structurally related substances. Based on these (often‐limited) data, the Panel concluded for 42 substances that these data did not indicate a concern for genotoxicity.

for two components, i.e. styrene (CAS No. 100‐42‐5; former [FL‐no: 01.015]) and benzofuran (CAS No. 271‐89‐6), the Panel identified a potential concern for genotoxicity for which additional data would be needed to reach a final conclusion on the genotoxic potential of these substances (see Annex B and Appendix B).

The Panel investigated if the potential concern for genotoxicity for styrene and benzofuran could be ruled out by application of the threshold of toxicological concern (TTC) approach for DNA‐reactive mutagens and/or carcinogens (EFSA Scientific Committee, 2019). For this purpose, the Panel calculated the exposure to each of these components by multiplying the estimated exposure to the Primary Product (proposed maximum use level exposure assessment scenario, estimated with FAIM – Table 10) by the average content of these components in the Primary Product (see Appendix A).

The obtained exposure estimates were compared with the TTC value of 0.0025 μg/kg bw per day for DNA‐reactive mutagens and/or carcinogens. All exposure estimates were at least a factor of 4,440 above this TTC value (see Table 14) and therefore the application of the TTC approach could not rule out the (potential) concern for genotoxicity for these components.

Table 14.

Dietary exposure in μg/kg body weight (bw) per day to the two individual components for which a potential concern for genotoxicity has been identified (see Appendix B), based on the proposed maximum use level exposure assessment scenario using FAIM (Table 10)

| CAS No. | Chemical name | Average content in the Primary Product (wt%) | Exposure | Infants (12 weeks‐11 months) | Toddlers (12–35 months) | Children (3–9 years) | Adolescents (10–17 years) | Adults (18–64 years) | The elderly (≥ 65 years) | Ratio between the highest exposure estimate and TTC |

|---|---|---|---|---|---|---|---|---|---|---|

| Components for which a potential concern for genotoxicity is identified | ||||||||||

| 100‐42‐5 | Styrene | 0.15 | Mean 95th percentile | 0.9–4.5 | 2.1–5.7 | 2.1–5.6 | 1.1–3.0 | 1.1–2.3 | 0.9–2.1 | 6.08 × 103 |

| 2.6–15.2 | 3.8–14.1 | 3.5–12.9 | 2.1–6.8 | 2.0–5.0 | 1.7–3.3 | |||||

| 271‐89‐6 | Benzofuran | 0.11 | Mean 95th percentile | 0.7–3.3 | 1.5–4.2 | 1.5–4.1 | 0.8–2.2 | 0.8–1.7 | 0.7–1.5 | 4.44 × 103 |

| 1.9–11.1 | 2.8–10.3 | 2.5–9.5 | 1.5–5.0 | 1.4–3.6 | 1.2–2.4 | |||||

wt: weight; TTC: threshold of toxicological concern.

The lack of robust experimental data on genotoxicity for the two components listed in (ii) for which a potential concern for genotoxicity was identified is a non‐standard uncertainty with respect to the genotoxicity assessment of the individual components (see Section 2.2 of this opinion and Table G.1 of the EFSA guidance document on smoke flavouring (EFSA FAF Panel, 2021)). This uncertainty can only be addressed with additional genotoxicity data.

3.4.2. Genotoxicity assessment of the Primary Product (whole mixture)

The applicant resubmitted the genotoxicity studies on the Primary Product (whole mixture) that were already evaluated by the CEF Panel in 2009 (except the in vivo rat liver unscheduled DNA synthesis (UDS) assay), to investigate the genotoxicity of the unidentified fraction of the Primary Product, in line with the EFSA Scientific Committee statement on genotoxicity assessment of chemical mixtures (EFSA Scientific Committee, 2019): a bacterial reverse mutation test (Lab International Research Centre, 2005a), an in vitro mammalian cell gene mutation assay in mouse lymphoma cells (Lab International Research Centre, 2005b), an in vitro mammalian chromosomal aberration test (Lab International Research Centre, 2005c) and an in vivo MN assay in mouse bone marrow (Lab International Research Centre, 2005d).

The evaluation of these studies as described in the scientific opinion ‘Safety of smoke flavour Primary Product – Scansmoke SEF7525’ (EFSA CEF Panel, 2009) is reported in Section 3.4.2.1. For each study, comments and evaluation by the FAF Panel are reported. These studies are summarised in Tables D.1 and D.2 (Appendix D), where the evaluation of reliability and relevance are reported (according to the approach described in Appendix C).

Table D.1.

Summary of in vitro genotoxicity studies on Scansmoke SEF 7525 (SF‐004) including re‐evaluation of reliability and relevance by the FAF Panel (approach described in Appendix C)

| Name | Test system in vitro | Test object | Concentrations and test conditions | Result | Reliability/comments | Relevance of test system/relevance of the result | Reference |

|---|---|---|---|---|---|---|---|

| Scansmoke SEF 7525 | Bacterial Reverse Mutation test |

S. Typhimurium TA98, TA100, TA1535, TA1537 E. coli WP2 uvrA |

Experiment 1: 78.13–2500 μg/plate (+/−S9, plate incorporation) Experiment 2: 78.13, − 2500 μg/plate (+/−S9, pre‐incubation) |

Negative | Reliable without restrictions. Study performed according to OECD TG 471 and in compliance with GLP | High/High | LAB International Research Centre, 2005a |

| In vitro mammalian cell gene mutation test in mouse lymphoma cells | L5178Y TK+/− mouse lymphoma cells |

Experiment 1: 5–150 μg/mL (3 + 21 h, +S9) 5–40 μg/mL (3 + 21 h, −S9) Experiment 2: 5–150 μg/mL (3 + 21 h, +S9) 5–25 μg/mL (24 h −S9) |

Positive |

Reliable with restrictions (historical controls not provided). Study performed according to OECD TG 476 (applicable at that time, now OECD TG 490) and in compliance with GLP | High/Limited | LAB International Research Centre, 2005b | |

| In vitro mammalian chromosomal aberration test | Chinese hamster ovary cells (CHO‐KI cell line) |