Abstract

The construction industry is one of the riskiest sectors worldwide, with crane operations being one of the most dangerous activities. The aim of this study was to gain insight into the key factors involved in crane-related occupational accidents in the construction industry in Spain. To this end, 1314 accidents involving cranes were analyzed from a total of 241,937 accidents that occurred in the construction of buildings. The data were collected from the Spanish government’s occupational accident statistics corresponding to the years 2012–2021. The results evidenced a statistically significant relationship between cranes as the material agent and the size of the company, with 95% of cases corresponding to small- or medium-sized companies (less than 250 employees). Additionally, it shows how the crane operator is identified as a material contributor to crane accidents in the construction industry, and may be considered a key component to these accidents. In conclusion, improving the knowledge gained about the key factors in crane-related accidents at work in the construction industry provides essential information that helps to design and implement appropriate preventive measures to avoid the recurrence of unwanted events with these machines.

Keywords: crane, occupational accident, construction of buildings, material agent, safety, accident statistics

1. Introduction

The construction industry is one of the sectors with the greatest impact on the economy of the European Union, and accounts for about 5.7% of its gross domestic product (GDP). Between 2010 and 2021, its contribution to the GDP dropped in 14 Member States, with the largest decreases in Bulgaria, Spain, Greece, and Slovakia, while it grew in other countries such as Hungary, Lithuania, Denmark, Germany, and Finland, which showed the largest rise in that period [1].

On the other hand, occupational accidents in the building industry are very frequent, which makes this sector one of the most dangerous and risky ones worldwide [2,3,4]. The International Labour Organization (ILO) reported more than 1.3 million victims of occupational accidents per year in the construction industry. Moreover, the rate of casualties due to accidents in the workplace in this sector is approximately six cases per 100,000 workers, i.e., three times higher than in any other industry [5]. Therefore, establishing safety measures in every phase of the activity of construction companies should be considered a social priority, with the aim of preventing or reducing occupational risk [6].

In this context, crane operations are among the most dangerous activities in construction because, although crane accidents are not particularly frequent, they are potentially very harmful [7,8]. Thus, 62 workers died in crane-related accidents in Spain between 2012 and 2021 [9], 47 died in Australia between 2003 and 2015 [7], 41 crane-related casualties were recorded in Japan in 2006 [10], and more than 100 tower-crane accidents—resulting in more than 180 deaths and a huge economic loss—were reported in China between 2016 and 2018 [11]. These data are evidence of the safety issues associated with crane operations and how they have become a global challenge [12].

1.1. Crane Classification and Types

Moving large or heavy loads in manufacturing or construction requires the use of cranes, which are an essential element for productivity, though subject to several safety concerns [13,14]. Throughout the entire construction phase of a project, cranes are used for most of the vertical or horizontal movements of building resources such as materials, equipment, or personnel [15].

Based on published studies such as that of Shapira et al. [16], cranes can be classified into two machine families: mobile cranes and tower cranes. According to these authors, mobile cranes can be quickly deployed to lift heavy loads, with telescopic booms enhancing versatility and movement capacity. In some regions of North America, the term “mobile cranes” is used for truck-mounted cranes, while track-mounted mobile cranes are considered a separate family, referred to as “crawler cranes”. Tower cranes, on the other hand, are suitable for tight urban construction and reduced spaces, and are available in a variety of sizes and configurations. In recent years, the large growth in real estate development promoted the use of tower cranes in tight construction sites to the point that these cranes have gained worldwide popularity [17].

In Spain, Rubio-Romero and Rubio-Gámez [18] proposed a classification of these machines into the following categories: tower cranes, mobile cranes, light cranes, and overhead cranes; while the Spanish Ministry of Labor and Social Affairs [19,20,21,22] classified them as follows:

- According to mobility

- Fixed cranes:

-

a)supported: attached to a concrete floor plate, rails, walls, etc.;

-

b)embedded: with a base embedded into a concrete foundation.

- Mobile cranes:

-

a)on rails: travelling on rails by its own means of motion;

-

b)climbers: supported on the structure, they grow as the construction progresses.

- According to the assemblage system

- Assembling tower crane

- Self-erecting tower crane

1.2. Factors Influencing Crane Operation Safety in the Construction Industry

Due to its particular characteristics, the construction industry is affected by inherent factors related to occupational health and safety [23]. The accident rate in the construction industry is among the highest ones worldwide, as compared to other industries or economic sectors [24]. To reduce such rates, it is essential to understand the involved key factors and their influence on health and safety in building projects. In this regard, Mohammadi et al. [2] identified 113 safety-related factors, which they classified into 13 main groups: (1) motivation, (2) rules and regulation, (3) competency, (4) safety investment and costs, (5) financial aspects and productivity, (6) resource and equipment, (7) work pressure, (8) work conditions, (9) culture and climate, (10) attitude and behavior, (11) lessons learned from accidents, (12) organization, and (13) safety programs and management systems. These authors explicitly stated that safety was not only determined by management activities within projects, but also by interactions between factors at different hierarchical levels.

Muñoz-La Rivera et al. [25] proposed a different classification of the factors influencing construction safety. In an interesting PRISMA-based literature review, these authors identified, described, and categorized 100 safety factors grouped in: (1) general aspects, (2) materials and equipment, (3) construction site, (4) human aspects-worker and work team, (5) worker actions/behaviour, and (6) communication. Those 100 identified factors were described and categorized according to the dimensions and aspects of the project that they affected, and were additionally sub-classified as originating factors, shaping factors, or immediate factors, behind the generation of accidents.

As mentioned, analyzing the factors that particularly affect crane-operation safety in the construction industry is essential. In this line, Shapira and Elbaz [26] identified 15 safety parameters related to the crane-operation mode. In their study, favorable and unfavorable work and safety conditions were observed for five working days, half-day from the operator’s cabin and half-day from the ground. From the 15 identified parameters, “Climbing to the cabin” was highlighted, since climbing to the cabin of a tower crane entails great physical effort and a time consumption. This lead some countries, such as France, the Netherlands, Denmark, and Sweden, to establish the regulation that a lift must be used to climb to a cabin higher than 25–30 m.

In a further study focused on crane-operation safety, Milazzo et al. [14] classified the main causes of crane accidents into four groups: (1) electrocutions, (2) blows with the suspended load, (3) collapse of the crane, and (4) blows with the boom. The authors concluded that most accidents were due to improper load handling and poor visibility during load movements.

Zhou et al. [27], in a study based on questionnaires administered to tower crane users, found nine main dimensions and 25 critical factors related to the safety system of tower cranes. This work was based on Rassmussen’s systemic or nonlinear complex conceptual model of accidents (hereinafter Accimap), since tower crane safety concerns are usually systemic or complex issues [28].

In a study by Zhang et al. [11] with an extension in Zhang et al. [29], the authors analyzed 141 crane accident reports from 2013 to 2014 and identified 34 causal factors, which they grouped into six sub-systems: (1) administrative–governmental, (2) tower crane safety management stakeholders, (3) safety management project, (4) staff management, (5) tower crane machinery, and (6) environment management.

In a further, interesting study based on interviews to experts in construction health and safety, Mohandes et al. [30] identified 21 crane-operation safety factors, which they grouped into four main categories: (1) site conditions, (2) crane operation, (3) site management, and (4) environment. According to these authors, the evidence indicates that crane operation activities are the largest source of accidents in the construction industry, affecting both crane operators and other involved workers.

Finally, Hu et al. [31] proposed an early risk-recognition approach through “Prevention through Design (PtD)”, to manage the exposure to hazards associated with the operation of one or more tower cranes in construction sites, by using a route-finding algorithm and building information modelling (BIM). They provided a taxonomy of crane-related construction risks based on the type of energy involved in the operation and grouped the 15 identified risks into four categories of energy: (1) electricity, (2) motion, (3) gravity, and (4) chemical.

1.3. Scope and Contribution of This Research

In the context of the above-mentioned findings, the objective of this study was to gain insight into the key factors involved in cane-related occupational accidents in the construction industry in Spain. To that end, a total of 242,937 cases of construction accidents were analyzed, which included 1314 accidents with the participation of the crane material agent. The data were extracted from the occupational accident statistics of the Spanish Ministry of Labor, Migration, and Social Security, corresponding to the 2012–2021 period. Besides the use of an extensive, updated database, the main novelty in this study was to consider the “crane” as the material agent causing the accidents.

The first step in the proposal of this study is to determine to what extent the degree of injury suffered is related to the associated material agent, in this case the “crane”. Secondly, the aim is to find out to what extent there is a relationship between the material agent “crane” and the age and length of service of the injured person. The third aim is to find out to what extent there is a relationship between the material agent “crane” and whether the company where the injured person worked acted as a contractor or subcontractor. The fourth aim is to find out to what extent the size of the company of the employee involved in the accident is related to the material agent “crane”. This approach makes our study an original contribution, relevant for improving construction health and safety standards and designing strategies aimed at focusing efforts and limiting the serious consequences of this type of accident.

After this introduction to the context and objectives of the study, the Data and Methods section describes the used sample of occupational accident reports and methodology, including the analyzed variables and statistical analysis, followed by a section of Results and a Discussion of the main findings. Finally, the Conclusions of the study are presented and limitations of the present study.

2. Data and Methods

2.1. Data Source

In the Member States of the European Union, companies must notify occupational accidents suffered by any of their employees to the corresponding labor authorities in compliance with the regulations of the European Statistics on Accident at Work (ESAW) [32]. Such notification entails codification and registration of the information related to the circumstances of the accident. Since 2003, the Spanish Ministry of Labor and Social Economy registers all accidents that result in one or more days’ sick leave. Such information is harmonized following the guidelines of Directive 89/391/EEC [33] to homogenize the processing of occupational accidents’ data throughout the EU member states. In Spain, the information is recorded on a computer system called Delt@, an acronym for Declaración Electrónica de Trabajadores Accidentados (Electronic Declaration of Injured Workers), which in turn collects the information from occupational accident reports, organized in accordance with Order TAS/2926, of 21 November 2002 [34]. The aforementioned accident reports do not equate to accident investigation reports made by the directly responsible OHS technical advisors in an online investigation.

In Spain, the severity of an occupational accident is evaluated by the physician who manages the victim and reflected in the sick leave certificate [35]. Table 1 shows the total number of occupational accidents in Spain during the 2012–2021 period, according to their degree of severity. A total of 5,506,182 accidents caused sick leave of at least one day.

Table 1.

Total occupational accidents with sick leave in Spain during the period 2012–2021 classified per severity.

| Year | Total | Minor | Serious | Fatal |

|---|---|---|---|---|

| 2012 | 471,223 | 466,953 | 3798 | 472 |

| 2013 | 468,030 | 464,153 | 3420 | 457 |

| 2014 | 491,099 | 486,306 | 4213 | 580 |

| 2015 | 529,248 | 524,210 | 4409 | 629 |

| 2016 | 575,235 | 560,957 | 4649 | 629 |

| 2017 | 596,606 | 591,009 | 4968 | 629 |

| 2018 | 617,488 | 611,727 | 5032 | 729 |

| 2019 | 650,602 | 644,709 | 5394 | 721 |

| 2020 | 505,528 | 500,299 | 4474 | 755 |

| 2021 | 601,123 | 595,616 | 4796 | 742 |

| TOTAL | 5,506,182 | 5,445,939 | 45,153 | 6343 |

By using the identification code corresponding to the activity of the involved company, as defined by the CNAE (the national classification of economic activities), which is the Spanish equivalent to the international NACE, CIIU, or ISIC, all accidents occurring in the construction of residential and non-residential buildings (NACE code 41.2) were identified, with a total of 242,937 accidents occurring in Spain in 2012–2021 (Table 2). Crane-related accidents in other economic activities related to the F section “construction” of the NACE Rev.2 classification, such as civil engineering (NACE code 42) or specialized construction (NACE code 43), were out of the scope of this study. The data were collected from the Spanish Government’s Occupational Accident Statistics corresponding to the years 2012–2021.

Table 2.

Occupational accidents in building construction with sick leave in Spain during the period 2012–2021 according to severity.

| Year | Total | Minor | Serious | Fatal |

|---|---|---|---|---|

| 2012 | 20,357 | 20,015 | 316 | 26 |

| 2013 | 16,181 | 15,939 | 22 | 4 |

| 2014 | 16,351 | 16,101 | 225 | 25 |

| 2015 | 18,771 | 18,473 | 272 | 26 |

| 2016 | 21,144 | 20,819 | 293 | 32 |

| 2017 | 24,970 | 24,611 | 329 | 30 |

| 2018 | 29,240 | 28,828 | 372 | 40 |

| 2019 | 35,151 | 34,626 | 466 | 59 |

| 2020 | 28,464 | 27,995 | 426 | 44 |

| 2021 | 32,308 | 31,899 | 369 | 40 |

| TOTAL | 242,937 | 239,306 | 3090 | 326 |

To analyze occupational accidents related to material agent “crane” in particular, the information in the mentioned database was filtered, classified, and organized, by using the code corresponding to this material agent in the Spanish system for notification of occupational accidents Delt@ [36] and the European Statistics of Accidents at Work (ESAW) of the European Commission [37]. The 1314 crane-related accidents recorded in 2012–2021 were classified according to the severity of injuries and the period required for recovery (Table 3).

Table 3.

Total occupational accidents related to cranes with sick leave in Spain during the period 2012–2021 according to severity.

| Year | Total | Minor | Serious | Fatal | No Information |

|---|---|---|---|---|---|

| 2012 | 109 | 94 | 3 | 1 | 11 |

| 2013 | 70 | 59 | 2 | 1 | 7 |

| 2014 | 83 | 72 | 4 | 0 | 8 |

| 2015 | 93 | 84 | 3 | 0 | 6 |

| 2016 | 116 | 104 | 3 | 0 | 9 |

| 2017 | 155 | 143 | 4 | 2 | 6 |

| 2018 | 167 | 152 | 2 | 0 | 13 |

| 2019 | 205 | 188 | 4 | 2 | 11 |

| 2020 | 139 | 135 | 0 | 1 | 3 |

| 2021 | 177 | 169 | 2 | 1 | 5 |

| TOTAL | 1314 | 1200 | 27 | 8 | 79 |

2.2. Variables

After collecting the information on the total number of accidents in the construction of residential and non-residential buildings in Spain and organizing it according to their degree of severity, we sought to identify factors particularly related to the characterization of those accidents involving cranes.

To analyze crane-related accidents in the workplace regardless of the occupation of the involved worker, this research was designed on certain criteria for screening the data in accident reports. The criteria consisted of selecting all accidents in which a crane was coded as the material agent associated to the specific physical activity, the deviation, or the contact mode of injury. The material agent was further classified using the 8-digit system of CIRCA (Communication and Information Resource Centre for Administrations), where the first four digits of the variable material agent are equivalent to those of the ESAW, and the last four digits provide more detailed information.

Subsequently, variables useful for describing the recorded accidents were selected; thus, our analysis was finally based on the following six variables: (a) codification of the material agent as “crane”, (b) degree of severity of the injury, (c) worker’s length of service, (d) company acting through a contract/subcontract, (e) worker’s age, and (f) company staff (Table 4).

Table 4.

Variables used in the analysis of crane accidents.

| Variable | Categories | Reference |

|---|---|---|

| Material Agent | (11.03.00.00) Fixed, mobile, vehicle-mounted, overhead, overhead cranes, levelling equipment | ESAW Variable [37] |

| (11.03.01.00) Cranes, bridge cranes | ESAW Variable [37] | |

| (11.03.01.019 Cranes | ESAW Variable [37] | |

| (11.03.01.02) Loading/unloading manipulator | ESAW Variable [37] | |

| (11.03.01.03) Overhead and gantry cranes | ESAW Variable [37] | |

| (11.03.01.04) Vehicle loading arm | ESAW Variable [37] | |

| (11.03.02.00) Winches, hoists, balancers | ESAW Variable [37] | |

| (11.03.02.01) Winches, hoists, lifting pulleys, mufflers, balancers | ESAW Variable [37] | |

| (11.03.99.00) Other overhead lifting equipment | ESAW Variable [37] | |

| (14.11.00.00) Loads—suspended from leveling device, a crane | ESAW Variable [37] | |

| Severity of injury |

|

Fuentes-Bargues et al. [38] |

|

Fuentes-Bargues et al. [38] | |

|

Fuentes-Bargues et al. [38] | |

| Length of service |

|

Camino-López et al. [39] |

|

Camino-López et al. [39] | |

|

Camino-López et al. [39] | |

|

Camino-López et al. [39] | |

|

Camino-López et al. [39] | |

|

Camino-López et al. [39] | |

|

Camino-López et al. [39] | |

|

Camino-López et al. [39] | |

| Contracts or subcontracts |

|

Salguero-Caparrós et al. [40] |

|

Salguero-Caparrós et al. [40] | |

| Age of the injured worker |

|

Fontaneda et al. [41] |

|

Fontaneda et al. [41] | |

|

Fontaneda et al. [41] | |

|

Fontaneda et al. [41] | |

|

Fontaneda et al. [41] | |

| Company staff |

|

Fuentes-Bargues et al. [38] |

|

Fuentes-Bargues et al. [38] | |

|

Fuentes-Bargues et al. [38] | |

|

Fuentes-Bargues et al. [38] | |

|

Fuentes-Bargues et al. [38] | |

|

Fuentes-Bargues et al. [38] | |

|

Fuentes-Bargues et al. [38] |

2.3. Statistical Analysis

Data were organized and analyzed by using Microsoft EXCEL and the SPSS Statistics V25 software (Statistical Package for the Social Sciences). Besides a descriptive statistical analysis, an inferential statistical analysis was carried out to improve our knowledge on the studied occupational accidents, using the Pearson’s chi-squared test. Variables included in the analysis were pretreated to reduce the originally high number of classes. Thus, classes with higher absolute frequencies were maintained as such, while those with the lower frequencies were grouped under “other”. Subsequently, the significance of possible relationships between different variables was analyzed. In order to select the most suitable test to be used for the inferential analysis, variables were first tested for normality using the Kolmogorov–Smirnov test or the Shapiro–Wilk test, depending on the sample size; results indicated that the distributions were non-parametric. Given that the variables were quantitative, non-parametric, and with multiple categories, the chi-squared test was used to analyze possible associations between different pairs of them. To this end, tests were performed using different pairs of variables that had previously been tested for normality and had shown non-normal distributions. Cases in which a significant association was found between two of these variables were included in the results of the statistical analysis. For this analysis, contingency tables were prepared and the statistical chi-square value (χ2) was calculated in order to accept or reject the null hypothesis of independence. This statistic associated with a significance level p < 0.05 allows us to verify with a confidence level of 95% the relationship of dependence between the variables analysed.

3. Results

3.1. Severity of the Injury

An analysis of the severity of occupational accidents in Spain in the studied period (2012–2021) showed that the number of accidents grew throughout the years in all sectors, in the construction of buildings and in crane-related events, with the highest figures in the year before the COVID-19 pandemic, which was 2019.

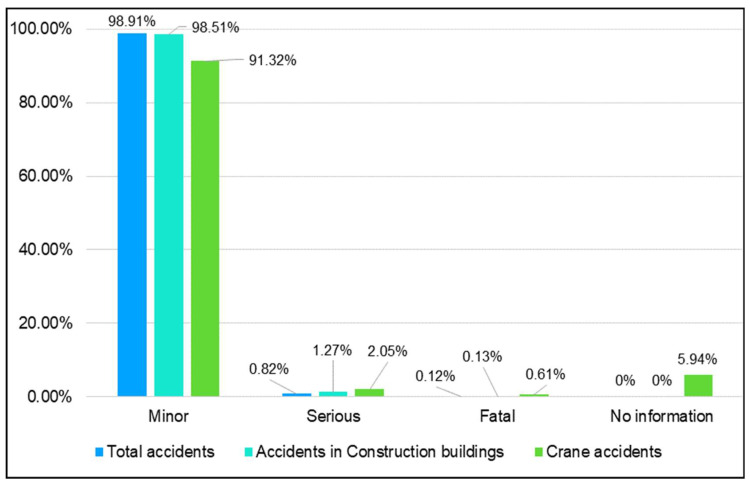

Figure 1 shows the relative frequencies of the different degrees of severity of accidents in Spain in the studied period. From the total occupational accidents, 98.91% were minor, 0.82% were serious, and 0.12% were fatal. The frequencies were similar in the construction of buildings with 98.51% minor accidents, 1.27% serious accidents, and 0.13% casualties. However, the relative frequencies of notified accidents involving cranes were slightly different, with 91.32% minor accidents, 2.05% serious accidents, and 0.61% casualties. This latter finding could be influenced by the fact that 5.94% of the corresponding accident reports did not provide information on the severity.

Figure 1.

Distribution of occupational accidents with sick leave according to severity in Spain in 2012–2021. Classification according to total accidents, accidents in building construction, and accidents with cranes.

3.2. Material Agent

The harmonized variable material agent of the ESAW coding system for the analysis of accidents includes the following sub-categories: material agent of the specific physical activity, material agent associated with the deviation, and material agent associated with the contact mode of injury [37]. The first one is defined as the tool, object or instrument used by the victim immediately before the accident, the second one is the tool, object, or instrument involved in the abnormal event (the deviation), and the third one is the object, instrument, or tool with which the victim came into contact.

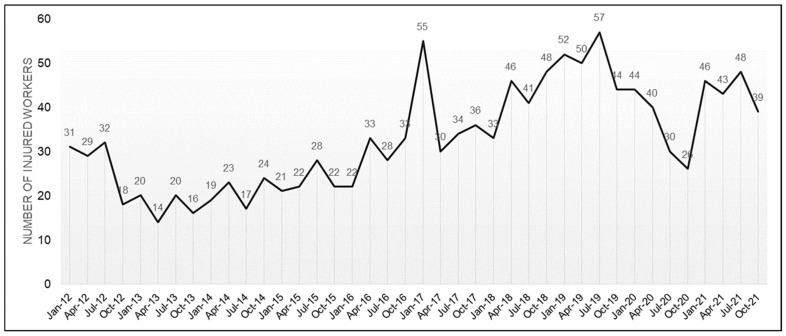

Accidents involving cranes as the material agent associated to the specific physical activity, the deviation or the contact mode of injury amounted to 1314 cases. Figure 2 shows that the evolution of the number of accidents was uneven throughout the studied period, January 2012 to December 2021 (Figure 2).

Figure 2.

Distribution of accidents involving cranes in Spain between January 2012 and December 2021.

The eight-digit codification of crane-related material agents yielded 10 different subtypes (Table 5). Remarkably, code 11.03.01.01 “cranes” accounted for one-third of notified accidents in all the three material agent associations. It was also noticeable that almost a quarter of all accidents included code 14.11.00.00 “load suspended from a hoisting device, a crane”. Most remarkable was code 11.03.01.02 “load/unload handler” with an average of 13.27 of notified cases, which indicated that the crane operator was identified as a material agent contributing to this type of accident.

Table 5.

Frequency distribution of accidents per material agent associated with the specific physical activity, the deviation, or the contact mode of injury.

| Associated to the Specific Physical Activity | Associated to the Deviation | Associated to the Contact Mode of Injury | |||||

|---|---|---|---|---|---|---|---|

| Code | Material Agent | Absolute Frequency |

Relative Frequency (%) | Absolute Frequency |

Relative Frequency (%) | Absolute Frequency |

Relative Frequency (%) |

| 11.03.00.00 | Fixed, mobile, vehicle-mounted, overhead, overhead cranes, levelling equipment | 180 | 17.27% | 151 | 16.01% | 141 | 16.02% |

| 11.03.01.00 | Cranes, bridge cranes | 36 | 3.45% | 31 | 3.29% | 29 | 3.30% |

| 11.03.01.01 | Cranes | 327 | 31.38% | 273 | 28.95% | 245 | 27.84% |

| 11.03.01.02 | Loading/unloading manipulator | 141 | 13.53% | 130 | 13.79% | 110 | 12.50% |

| 11.03.01.03 | Overhead and gantry cranes | 3 | 0.29% | 4 | 0.42% | 5 | 0.57% |

| 11.03.01.04 | Vehicle loading arm | 22 | 2.11% | 29 | 3.08% | 18 | 2.05% |

| 11.03.02.00 | Winches, hoists, balancers | 4 | 0.38% | 1 | 0.11% | 1 | 0.11% |

| 11.03.02.01 | Winches, hoists, lifting pulleys, mufflers, balancers | 27 | 2.59% | 25 | 2.65% | 22 | 2.50% |

| 11.03.99.00 | Other overhead lifting equipment | 33 | 3.17% | 25 | 2.65% | 30 | 3.41% |

| 14.11.00.00 | Loads—suspended from levelling device, a crane | 269 | 25.82% | 274 | 29.06% | 279 | 31.70% |

| Total | 1.042 | 100% | 943 | 100% | 880 | 100% | |

3.3. Length of Service

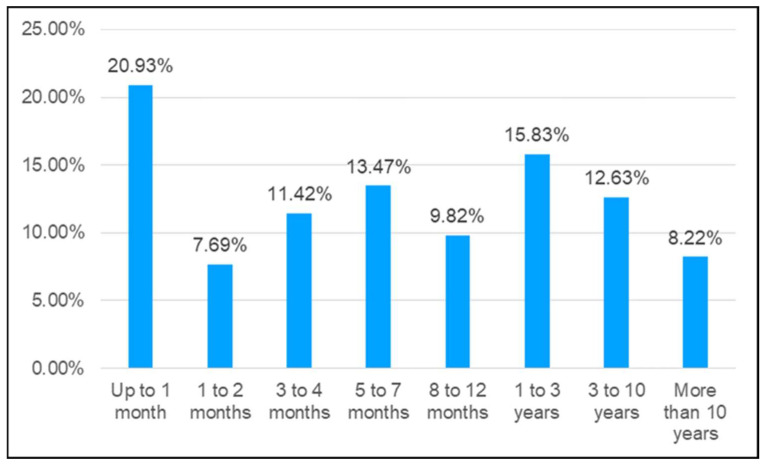

Workers’ length of service was analyzed using the following categories: up to 1 month, 1 to 2 months, 3 to 4 months, 5 to 7 months, 8 to 12 months, 1 to 3 years, 3 to 10 years, and more than 10 years. As shown in Figure 3, most injured workers had up to 1 month experience, with a relative frequency of 20.93%. Moreover, 63.33% of notified crane accidents involved workers with less than 1 year experience, as compared with 8.22% of accidents corresponding to workers with more than 10 years.

Figure 3.

Frequency of accidents involving cranes in Spain 2012–2021 according to length of service in the workplace.

3.4. Company Acting through a Contract/Subcontract

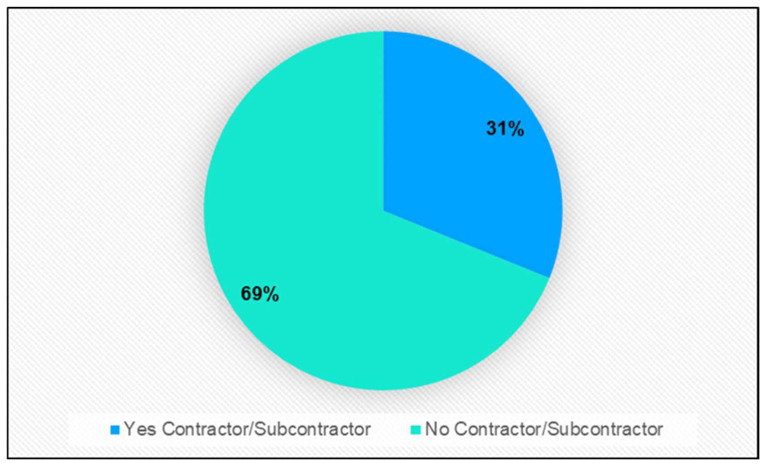

The contractor/subcontractor role of involved companies was analyzed from accident reports. In these reports, “Yes” had to be marked if, at the moment of the accident, the worker was paying service as part of a contractor/subcontractor company, namely their company was in charge of tasks related to the own-activity of a third company. The general concept “own-activity” does not include hiring companies dedicated to the cleaning, maintenance, security, or repair/extension of premises. The results showed than only one-third of reports stated that the victim was working in a company that acted as a contractor/subcontractor in the construction of buildings (Figure 4).

Figure 4.

Frequency of accidents involving cranes in Spain 2012–2021 according on where they provided their services.

3.5. Age of the Injured Worker

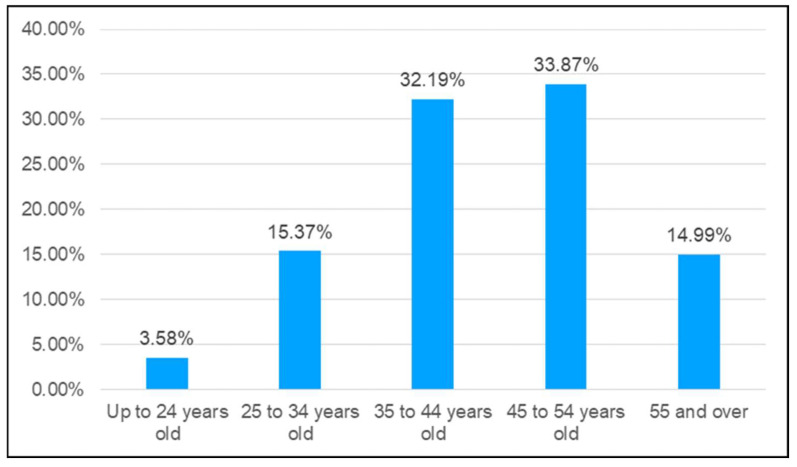

Accidents were then analyzed according to the age of injured workers, classified into the following ranges: up to 24 years of age, from 25 to 34 years, from 35 to 44 years, from 45 to 54 years, and 55 or more years. Figure 5 shows that most of the injured workers were between 45 and 54 years old, followed by workers from 35 to 44 years old, with frequencies of 33.87% and 32.19%, respectively.

Figure 5.

Frequency of accidents involving cranes in Spain 2012–2021 according to the injured worker’s age.

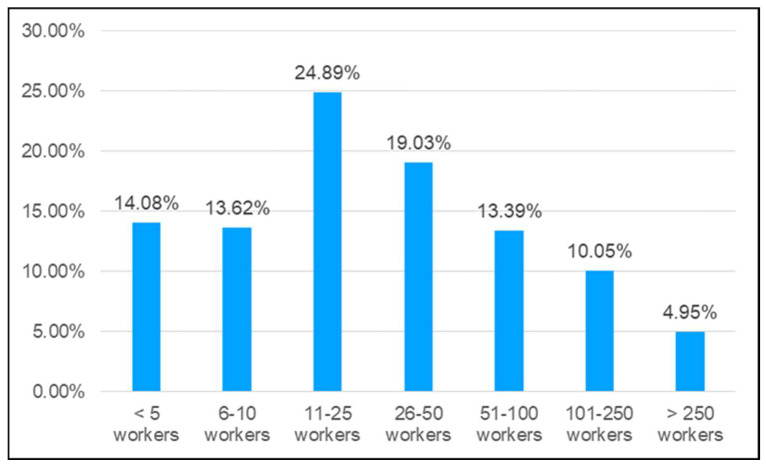

3.6. Company Staff

This analysis was focused on the size of the company injured workers were working for, expressed as the number of workers, and classified into the following ranges: less than 5 workers, 6 to 10 workers, 11 to 25 workers, 26 to 50 workers, 51 to 100 workers, 101 to 250 workers, and more than 250 workers. Figure 6 shows that 95% of crane accidents occurred in companies with less than 250 workers. Remarkably, 52.59% of them occurred in companies of less than 25 workers.

Figure 6.

Frequency of accidents involving cranes in Spain 2012–2021 according to the company staff.

3.7. Inferential Statistical Analysis

In the inferential statistical analysis, possible associations between different variables were assessed. Table 6 summarizes the main results.

Table 6.

Main results of the inferential statistical analysis.

| Independent Variable | Dependent Variable | Pearson’s Chi-Square. Significance Level (p-Value) |

Pearson’s Chi-Square (χ2) |

|---|---|---|---|

| Severity of injury | Material agent associated with specific physical activity | 0.118 | 25.264 |

| Material agent associated with the deviation | 0.365 | 19.451 | |

| Material agent associated with the contact mode of injury | 0.220 | 22.272 | |

| Length of service | Material agent associated with specific physical activity | 0.227 | 71.052 |

| Material agent associated with the deviation | 0.794 | 53.612 | |

| Material agent associated with the contact mode of injury | 0.171 | 73.533 | |

| Contracts or subcontracts | Material agent associated with specific physical activity | <0.001 | 16.674 |

| Material agent associated with the deviation | 0.289 | 10.806 | |

| Material agent associated with the contact mode of injury | 0.170 | 12.839 | |

| Age of the injured worker | Material agent associated with specific physical activity | 0.739 | 30.237 |

| Material agent associated with the deviation | 0.353 | 38.585 | |

| Material agent associated with the contact mode of injury | 0.268 | 40.783 | |

| Company staff | Material agent associated with specific physical activity | <0.001 | 127.638 |

| Material agent associated with the deviation | <0.001 | 108.629 | |

| Material agent associated with the contact mode of injury | <0.001 | 108.642 |

The Pearson’s chi-squared test indicated no significant association between the severity of the injury and the material agent, associated either to the specific physical activity, the deviation or the contact mode of injury; although the relationship between the severity and the material agent associated to the specific physical activity showed the most stable value (p = 0.118).

Similarly, the analysis of the relationship between the material agent and the worker’s length of service failed to show any significant association, with the material agent associated to the contact mode of injury being the closest one to significance (p = 0.171).

The analysis of the variable company-acting-through-a-contract/subcontract showed a significant association with the material agent associated to the specific physical activity (p < 0.001), while no significance was found for the relationship with the material agent associated to the deviation (p = 0.289) or the contact mode of injury (p = 0.170), for which the null hypothesis was accepted.

Regarding the injured worker’s age, the Pearson’s chi-squared test failed to reveal any significant association with the material agent; thus, the null hypothesis was accepted. Finally, the size of the company was significantly associated to all the material agent associations, i.e., with the specific physical activity, the deviation and the contact mode of injury (p < 0.001); thus, the null hypothesis was rejected.

4. Discussion

Identifying and coding the variable material agent in any of its associations is critical to establishing the circumstances under which an accident occurred [42,43,44,45,46,47,48]. However, few published studies have used this variable in the analysis of occupational accidents in the construction industry. Among them, Camino-López et al. [39] analyzed a total of 1,630,452 accidents suffered by construction workers in Spain between 1990 and 2000; Betsis et al. [49] analyzed a sample of 413 notified construction accidents that occurred in the north of Greece between 2003 and 2007; and finally, Fontaneda et al. (2022) [50] analyzed 455,491 construction accidents in Spain notified between 2011 and 2018. Only the mentioned study by Camino-López et al. [39] included “cranes and lifting equipment” among the analyzed material agents.

From our results and analysis of the 10 subtypes of a material agent crane, it is remarkable that “loading/unloading manipulator”, which might be assimilated to the crane operator, is a factor contributing to this type of accident in 13.27% of notified cases. The relevance of the crane operator as a key factor in safety operations with these machines was evidenced in studies such as Zhou et al. [27], who considered that it was the third most important factor out of 25 that directly affect the safety of tower crane operations. Mohandes et al. [30] also identified the “crane operator skills” as a safety factor in crane operations in construction projects. Such skills are directly linked to the training that a crane operator has received; hence, authors such as Manzoor et al. [51] identified “non-qualification of the crane operator” as a contributing factor in accidents occurred in the construction of high-rise buildings.

Also noteworthy is the relationship between crane accidents and the company acting through a contract/subcontract. In recent years, outsourcing in the construction industry has experienced a dramatic unprecedented growth. This phenomenon had negative effects resulting in violations of the occupational health and safety regulations, which contributed to higher rates of accidents in the workplace and promoted poor working conditions, often due to a cascade of subcontractors [52,53]. Some authors, e.g., Choudhry et al. [54], proposed that outsourcing in the construction industry should be regulated with the aim of reducing the number of subcontractor levels to effectively manage the communication gap between the main contractor and the subcontractor. Furthermore, subcontracting has adverse influences on the health and safety of construction workers [55]. Therefore, in addition to reducing the number of subcontractor levels, working with a regular chain of subcontractors, accredited and controlled by the corresponding occupational safety authority, should be encouraged [56]. In this line, Zhang et al. [11] reported that one of the factors particularly affecting crane operation safety in the construction industry was misuse of safety regulations, such as subcontracting out of regulations, as described by Tam and Fung (2011) [57]. The latter authors investigated tower crane safety in relation to the understanding and degree of observation of legal requirements, as well as non-legal practices in the Hong Kong construction industry. They found that indolent performance of tower crane operation professionals was one of the main causes behind unsafe practices related to these tasks.

In Spain, Law 32/2006 of 18 October, which regulates subcontracting in the construction industry [58], addressed this situation by, among other things, restricting the number of subcontractor levels in this area. This Law regulates the subcontracting regime and seeks to eliminate subcontracts that are economically unproductive or harmful for workers’ health and safety. As a complement to the Subcontracting Law 32/2006, Royal Decree 1109/2007 of 24 August, aimed to establish the rules for the application and development of the aforementioned regulatory law in the construction sector [59]. Thus, it was particularly perplexing that up to 69% of the crane accident reports analyzed in this study indicated that the workers were not paying services with a contractor/subcontractor, given that all construction work must be integrated into one of the legally established contractor/subcontractor levels. This situation could be accounted for by errors in completing the accident notification for the labor authorities, something that may happen if the person who completes the notification, whether administrative or technical staff, does not work for the same company as the injured worker or has poor training or knowledge of the correct way to complete these reports. Authors such as Salguero-Caparrós et al. [46], Molinero-Ruiz et al. [47], and Jacinto et al. [60] also found that errors completing and coding accident reports were common.

Regarding workers’ length of service, more than two-thirds of the notified accidents occurred to workers with less than one year experience. This finding is in line with the results of Camino-López et al. [39] and Betsis et al. [49], who reported that 68.1% and 68% of notified accidents, respectively, involved workers with less than one year experience. This aspect may be linked to the high temporality, workplace turnover, and successive job changes that are rather frequent in this sector and is one of the best-known risk factors for crane accidents [11].

Regarding the worker’s age, up to two-thirds of accidents involved 35–54-year-old subjects. This result cannot be compared with other studies, since no studies analyzing the age of the injured worker are available. We would like to highlight the positive finding that only 3.58% of accidents involved workers younger than 24 years. Length of service and age are important factors to be considered in the interpretation of crane-related accidents [7], and full comprehension of the roles of both personal variables in this type of analysis requires further research. In this way, it may be possible to reduce the gaps in our knowledge of this subject and their serious consequences when it comes to improving health and safety.

An analysis of the size of the companies involved in crane-related accidents revealed that smaller companies accumulated more accidents. Based on the definition provided by the European Commission [61], companies with less than 250 employees were considered small- and medium-sized companies, including micro-companies (4–9 employees), small companies (10–49), and medium-sized companies (50–249). The results of this study (2012–2021) showed that crane operators working for micro-companies suffered 27.7% of all crane-related accidents, those working for small companies suffered 43.92% and those belonging to medium-sized companies accounted for 23.44% of the total reported cases. These data were in agreement with those of Camino-López et al. [39] and Fontaneda et al. [50], both related to the Spanish construction industry. The analysis of the relationship between the size of the company and the rate of crane-related occupational accidents evidences an important, largely neglected risk factor of psychological nature; namely, operating a crane is more sophisticated and mentally demanding than operating other equipment; therefore, crane operators may be more vulnerable to human error [62].

5. Conclusions

Our results suggest that both occupational accidents in the construction of buildings and occupational accidents related to the material agent crane have progressively increased in the last decade in Spain. In particular, a statistically significant relationship was observed between the material agent crane and the small or medium size of the construction company.

Small- and medium-sized companies are one of the strengths of the European economy, with up to 60% of the total workforce and key resources for innovation, growth, and productivity. In addition, the construction industry directly impacts the national economy and plays an important role in its growth. On the other hand, the construction industry is associated to high accident rates, as evidenced by the alarming statistics. Furthermore, since cranes are one of the most frequently used equipment in construction sites, and are also associated to high accident rates, preventing crane accidents is an urgent mission. This situation was the main reason behind the present research, focused on the key factors related to crane accidents in the construction industry.

This study also evidenced that 63.33% of workers suffering accidents with cranes in Spain in the studied period had no more than one year experience, which suggests that longer time working in the company entails more training and experience and may reduce the probability of suffering an accident. However, it should be kept in mind that experienced workers, who have become highly familiar with the involved tasks, may tend to disregard the danger and underestimate the risks.

This study also showed how the crane operator is identified as a material contributor to crane accidents in the construction industry, and may be considered a key component to these accidents. Aspects such as long working hours, insufficient rest breaks, working under pressure due to tight deadlines, communication failures between the crane operator and the signalman of the operations or inadequate training of the crane operator support the proposal that human factors are relevant to crane-operation safety. Naturally, technical issues are one of the most dangerous risk factors with cranes and should not be disregarded, although the human factor is a priority that requires the implementation of corrective actions.

In conclusion, the different approaches to safety-based decision-making associated with crane operations show several shortcomings, including the lack of an inclusive approach to identifying critical causal factors. Besides using a holistic inclusive approach, such factors should also be addressed in a specific way, since cranes are complex installations that constitute a critical aspect of safety in construction sites. In summary, improving our knowledge of the key factors in crane-related occupational accidents in the construction industry provides essential information to design and implement suitable measures to prevent unwanted events with these machines. Finally, we propose that efforts should be devoted not only to negative aspects such as accidents, human error, or technical issues, but also to positive aspects of the widely variable daily performance of a system as complex as that of the construction industry.

Limitations

The abovementioned conclusions should be seen in the light of the limitations of the present study. First, possible errors in coding and fulfilling the accident reports; second, the lack of specific data concerning the description of the occupational accidents, although the results of our study are of interest for the whole of the Spanish construction industry; third, the data source might be incomplete because, although all accidents in the construction of residential and non-residential buildings notified in 2012–2021 were analyzed, there might be more accidents that were not notified; finally, accidents that did not result in the loss of working days are not notified as occupational accidents.

Acknowledgments

We acknowledge the support of the Ministry of Economic Affairs and Digital Transformation of the Government of Spain through the project “Complexity and resilience: a systemic approach for the monitoring and improvement of safety management in construction” with the code number PID2020-114502GB-I00. Funding for open access charge: Universidad de Malaga/CBUA.

Author Contributions

Conceptualization, J.C.R.-R.; methodology, M.d.C.P.-F. and F.S.-C.; software, F.S.-C.; validation, J.C.R.-R., M.d.C.P.-F. and F.S.-C.; formal analysis, F.S.-C. and M.d.C.P.-F.; investigation, V.H.-P., M.d.C.P.-F. and F.S.-C.; resources, F.S.-C. and M.d.C.P.-F.; data curation, F.S.-C..; writing—original draft preparation, V.H.-P. and F.S.-C.; writing—review and editing, F.S.-C.; visualization, F.S.-C.; supervision, J.C.R.-R.; project administration, J.C.R.-R.; funding acquisition, J.C.R.-R. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data available on request at the Spanish Government’s Occupational Accident Statistics.

Conflicts of Interest

The authors declare no conflict of interest.

Funding Statement

The APC was partially funded by University of Málaga.

Footnotes

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

- 1.Eurostat Construction Sector—European Commission. 2023. [(accessed on 24 June 2023)]. Available online: https://ec.europa.eu/eurostat/cache/digpub/housing/bloc-3a.html?lang=en.

- 2.Mohammadi A., Tavakolan M., Khosravi Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018;109:382–397. doi: 10.1016/j.ssci.2018.06.017. [DOI] [Google Scholar]

- 3.Oswald D., Sherratt F., Smith S. Problems with safety observation reporting: A construction industry case study. Saf. Sci. 2018;107:35–45. doi: 10.1016/j.ssci.2018.04.004. [DOI] [Google Scholar]

- 4.Pardo-Ferreira M.C., Rubio-Romero J.C., Gibb A., Calero-Castro S. Using functional resonance analysis method to understand construction activities for concrete structures. Saf. Sci. 2020;128:104771. doi: 10.1016/j.ssci.2020.104771. [DOI] [Google Scholar]

- 5.ILO—International Labor Organization. World Statistic. [(accessed on 24 June 2023)]. Available online: https://www.ilo.org/moscow/areas-of-work/occupational-safety-and-health/WCMS_249278/lang--en/index.htm.

- 6.Forteza F.J., Carretero-Gomez J.M., Sese A. Occupational risks, accidents on sites and economic performance of construction firms. Saf. Sci. 2017;94:61–76. doi: 10.1016/j.ssci.2017.01.003. [DOI] [Google Scholar]

- 7.Lingard H., Cooke T., Zelic G., Harley J. A qualitative analysis of crane safety incident causation in the Australian construction industry. Saf. Sci. 2021;133:105028. doi: 10.1016/j.ssci.2020.105028. [DOI] [Google Scholar]

- 8.Chen Y., Zeng Q., Zheng X., Shao B., Jin L. Safety supervision of tower crane operation on construction sites: An evolutionary game analysis. Saf. Sci. 2022;152:105578. doi: 10.1016/j.ssci.2021.105578. [DOI] [Google Scholar]

- 9.Ministerio de Trabajo y Seguridad Social Estadisticas de Accidentes de Trabajo. 2022. [(accessed on 1 June 2022)]. Available online: http://www.mitramiss.gob.es/estadisticas/eat.

- 10.Kawata M. Safety Use of Cranes in the Construction Industry. Occupational Safety and Health Council; Hong Kong, China: 2007. [Google Scholar]

- 11.Zhang X., Zhang W., Jiang L., Zhao T. Identification of critical causes of tower-crane accidents through system thinking and case analysis. J. Constr. Eng. M. 2020;146:04020071. doi: 10.1061/(ASCE)CO.1943-7862.0001860. [DOI] [Google Scholar]

- 12.Sadeghi S., Soltanmohammadlou N., Rahnamayiezekavat P. A systematic review of scholarly works addressing crane safety requirements. Saf. Sci. 2021;133:105002. doi: 10.1016/j.ssci.2020.105002. [DOI] [Google Scholar]

- 13.Li H., Chan G., Skitmore M. Integrating real time positioning systems to improve blind lifting and loading crane operations. Const. M. Econ. 2013;31:596–605. doi: 10.1080/01446193.2012.756144. [DOI] [Google Scholar]

- 14.Milazzo M.F., Ancione G., Spasojevic Brkic V. Safety in crane operations: An overview on crane-related accidents; Proceedings of the 6th International Symposium on Industrial Engineering, SIE; Tokyo, Japan. 23–25 August 2015; pp. 36–39. [Google Scholar]

- 15.Fang Y., Cho Y.K., Chen J. A framework for real-time pro-active safety assistance for mobile crane lifting operations. Autom. Constr. 2016;72:367–379. doi: 10.1016/j.autcon.2016.08.025. [DOI] [Google Scholar]

- 16.Shapira A., Lucko G., Schexnayder C.J. Cranes for building construction projects. J. Constr. Eng. M. 2007;133:690–700. doi: 10.1061/(ASCE)0733-9364(2007)133:9(690). [DOI] [Google Scholar]

- 17.Swuste P. A ‘normal accident’with a tower crane? An accident analysis conducted by the Dutch Safety Board. Saf. Sci. 2013;57:276–282. doi: 10.1016/j.ssci.2013.03.002. [DOI] [Google Scholar]

- 18.Rubio-Romero J.C., Rubio-Gámez M.D.C. Manual de Coordinación de Seguridad y Salud en Las Obras de Construcción. Ediciones Díaz de Santos; Madrid, Spain: 2005. En su capitulo 17 Aparatos y elementos de elevación. [Google Scholar]

- 19.Tamboreno del Pino J.M. Grúas-Torre. Recomendaciones de Seguridad en su Manipulación. (Technical Note NTP 701-2015) Instituto Nacional de Seguridad e Higiene en el Trabajo; Madrid, Spain: 2015. [(accessed on 1 August 2023)]. Available online: https://www.insst.es/documents/94886/326775/ntp_701.pdf/30b60e0e-ef6b-4088-8046-bb5abbffe262?version=2.1&t=1680080875219. [Google Scholar]

- 20.Tamboreno del Pino J.M. Grúas Hidráulicas Articuladas Sobre Camión (I). (Technical Note NTP 868-2010) Instituto Nacional de Seguridad e Higiene en el Trabajo; Madrid, Spain: 2010. [Google Scholar]

- 21.Tamboreno del Pino J.M. Grúas Hidráulicas Articuladas Sobre Camión (II). (Technical Note NTP 869-2010) Instituto Nacional de Seguridad e Higiene en el Trabajo; Madrid, Spain: 2010. [(accessed on 1 August 2023)]. Available online: https://www.insst.es/documents/94886/328681/869w.pdf/89d845af-66ed-4ed1-913d-65a0e9336809. [Google Scholar]

- 22.Tamboreno del Pino J.M. Grúas Móviles Autopropulsadas: Seguridad. (Technical Note NTP 1.077-2016) Instituto Nacional de Seguridad e Higiene en el Trabajo; Madrid, Spain: 2016. [(accessed on 1 August 2023)]. Available online: https://www.insst.es/documents/94886/329011/ntp-1077.pdf/33f5d5d4-33e0-4a8f-9e67-ea06a81641b0. [Google Scholar]

- 23.Forteza F.J., Carretero-Gómez J.M., Sese A. Organizational factors and specific risks on construction sites. J. Saf. Res. 2022;81:270–282. doi: 10.1016/j.jsr.2022.03.004. [DOI] [PubMed] [Google Scholar]

- 24.Martinez-Rojas M., Antolín R.M., Salguero-Caparrós F., Rubio-Romero J.C. Management of construction Safety and Health Plans based on automated content analysis. Autom. Constr. 2020;120:103362. doi: 10.1016/j.autcon.2020.103362. [DOI] [Google Scholar]

- 25.Muñoz-La Rivera F., Mora-Serrano J., Oñate E. Factors influencing safety on construction projects (FSCPs): Types and categories. Int. Environ. Res. Public. Health. 2021;18:10884. doi: 10.3390/ijerph182010884. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Shapira A., Elbaz A. Tower crane cycle times: Case study of remote-control versus cab-control operation. J. Constr. Eng. M. 2014;140:05014010. doi: 10.1061/(ASCE)CO.1943-7862.0000904. [DOI] [Google Scholar]

- 27.Zhou W., Zhao T., Liu W., Tang J. Tower crane safety on construction sites: A complex sociotechnical system perspective. Saf. Sci. 2018;109:95–108. doi: 10.1016/j.ssci.2018.05.001. [DOI] [Google Scholar]

- 28.Rasmussen J. Risk management in a dynamic society: A modelling problem. Saf. Sci. 1997;27:183–213. doi: 10.1016/S0925-7535(97)00052-0. [DOI] [Google Scholar]

- 29.Zhang W., Xue N., Zhang J., Zhang X. Identification of critical causal factors and paths of tower-crane accidents in China through system thinking and complex networks. J. Constr. Eng. Manag. 2021;147:04021174. doi: 10.1061/(ASCE)CO.1943-7862.0002186. [DOI] [Google Scholar]

- 30.Mohandes S.R., Abdelmageed S., Hem S., Yoo J.S., Abhayajeewa T., Zayed T. Occupational Health and Safety in Modular Integrated Construction projects: The case of crane operations. J. Cleaner Prod. 2022;342:130950. doi: 10.1016/j.jclepro.2022.130950. [DOI] [Google Scholar]

- 31.Hu S., Fang Y., Moehler R. Estimating and visualizing the exposure to tower crane operation hazards on construction sites. Saf. Sci. 2023;160:106044. doi: 10.1016/j.ssci.2022.106044. [DOI] [Google Scholar]

- 32.European Statistics on Accidents al Work (ESAW)—Methodology, 2001 ed.; DG Employment and Social Affairs, European Commission, Luxembourg. 2002. [(accessed on 1 August 2023)]. Available online: http://europea.eu.int/comm/employment_social/h&s/index_en.

- 33.European Council . Official Journal of the European Communities 32 (LI 83), 29 June 1989. European Council; Luxembourg: Jun 29, 1989. European Directive 89/391/EEC of 12 June: Introduction of measures to encourage improvements in the safety and health of workers at work. [Google Scholar]

- 34.de 19 de Noviembre, Por la Que se Establecen Nuevos Modelos Para la Notificación de los Accidentes de Trabajo y se Posibilita su Transmisión por Procedimiento Electrónico; (BOE nº 279, de 21 de noviembre de 2002) Ministerio de Trabajo y Asuntos Sociales; Castellana, Madrid: 2002. [Google Scholar]

- 35.Carrillo-Castrillo J.A., Rubio-Romero J.C., Onieva L. Causation of severe and fatal accidents in the manufacturing sector. Int. J. Occup. Saf. Ergo. 2013;19:423–434. doi: 10.1080/10803548.2013.11076999. [DOI] [PubMed] [Google Scholar]

- 36.Ministerio de Empleo y Seguridad Social, editor. Sistema Delt@. Guía de Cumplimentaci’on del Parte de Accidente de Trabajo (PAT) Subdirección General de Estadística, Secretaría General Técnica; Madrid, Spain: 2015. [Google Scholar]

- 37.European Commission . In: Methodologies & Working Papers. European Statistics on Accidents at Work (ESAW), editor. Eurostat; Brussels, Belgium: 2013. [Google Scholar]

- 38.Fuentes-Bargues J.L., Sánchez-Lite A., González-Gaya C., Rosales-Prieto V.F., Reniers G.L.L.M.E. A study of situational circumstances related to Spain’s occupational accident rates in the metal sector from 2009 to 2019. Saf Sci. 2022;150:105700. doi: 10.1016/j.ssci.2022.105700. [DOI] [Google Scholar]

- 39.López M.A.C., Ritzel D.O., Fontaneda I., Alcantara O.J.G. Construction industry accidents in Spain. J. Saf. Res. 2008;39:497–507. doi: 10.1016/j.jsr.2008.07.006. [DOI] [PubMed] [Google Scholar]

- 40.Salguero-Caparrós F., Martínez-Rojas M., Pardo-Ferreira M.D.C., Rubio-Romero J.C. Performance of barrier systems and functions in the construction industry. Int. J. Occup. Saf. Ergo. 2023;29:376–385. doi: 10.1080/10803548.2022.2055867. [DOI] [PubMed] [Google Scholar]

- 41.Fontaneda I., López M.A.C., Alcántara O.J.G., Ritzel D.O. Gender differences in lost work days due to occupational accidents. Saf. Sci. 2019;114:23–29. doi: 10.1016/j.ssci.2018.12.027. [DOI] [Google Scholar]

- 42.Jacinto C., Aspinwall E. A survey on occupational accidents’ reporting and registration systems in the European Union. Saf. Sci. 2004;42:933–960. doi: 10.1016/j.ssci.2004.07.002. [DOI] [Google Scholar]

- 43.Rajala H.K., Väyrynen S. Constructing “core stories” for contributing practical safety actions in industrial units. Saf. Sci. 2010;48:1393–1401. doi: 10.1016/j.ssci.2010.05.014. [DOI] [Google Scholar]

- 44.Jacinto C., Soares C.G., Fialho T., Silva S.A. An overview of occupational accidents notification systems within the enlarged EU. Work. 2011;39:369–378. doi: 10.3233/WOR-2011-1187. [DOI] [PubMed] [Google Scholar]

- 45.Palamara F., Piglione F., Piccinini N. Self-Organizing Map and clustering algorithms for the analysis of occupational accident databases. Saf. Sci. 2011;49:1215–1230. doi: 10.1016/j.ssci.2011.04.003. [DOI] [Google Scholar]

- 46.Salguero-Caparrós F., Suarez-Cebador M., Rubio-Romero J.C. Analysis of investigation reports on occupational accidents. Saf. Sci. 2015;72:329–336. doi: 10.1016/j.ssci.2014.10.005. [DOI] [Google Scholar]

- 47.Molinero-Ruiz E., Pitarque S., Fondevila-McDonald Y., Martin-Bustamante M. How reliable and valid is the coding of the variables of the European Statistics on Accidents at Work (ESAW)? A need to improve preventive public policies. Saf. Sci. 2015;79:72–79. doi: 10.1016/j.ssci.2015.05.005. [DOI] [Google Scholar]

- 48.Salguero-Caparrós F., Suarez-Cebador M., Carrillo-Castrillo J.A., Rubio-Romero J.C. Quality evaluation of official accident reports conducted by labour authorities in Andalusia (Spain) Work. 2018;59:23–38. doi: 10.3233/WOR-172666. [DOI] [PubMed] [Google Scholar]

- 49.Betsis S., Kalogirou M., Aretoulis G., Pertzinidou M. Work accidents correlation analysis for construction projects in Northern Greece 2003–2007: A retrospective study. Safety. 2019;5:33. doi: 10.3390/safety5020033. [DOI] [Google Scholar]

- 50.Fontaneda I., Camino López M.A., González Alcantara O.J., Greiner B.A. Construction accidents in Spain: Implications for an aging workforce. BioMed. Res. Int. 2022;2022:9952118. doi: 10.1155/2022/9952118. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Manzoor B., Othman I., Waheed A. Accidental safety factors and prevention techniques for high-rise building projects–A review. Ain Shams Eng. J. 2022;13:101723. doi: 10.1016/j.asej.2022.101723. [DOI] [Google Scholar]

- 52.Forteza F.J., Carretero-Gómez J.M., Sesé A. Safety in the construction industry: Accidents and precursors. Rev. Const. 2020;19:271–281. doi: 10.7764/rdlc.19.2.271-281. [DOI] [Google Scholar]

- 53.Kshaf D.A., Mohamed M.A., El-Dash K.M. The major problems between main contractors and subcontractors in construction projects in Egypt. Ain Shams Eng. J. 2022;13:101813. doi: 10.1016/j.asej.2022.101813. [DOI] [Google Scholar]

- 54.Choudhry R.M., Hinze J.W., Arshad M., Gabriel H.F. Subcontracting practices in the construction industry of Pakistan. J. Constr. Eng. Manag. 2012;138:1353–1359. doi: 10.1061/(ASCE)CO.1943-7862.0000562. [DOI] [Google Scholar]

- 55.Manu P., Ankrah N., Proverbs D., Suresh S. Mitigating the health and safety influence of subcontracting in construction: The approach of main contractors. Inter. J. Project Manag. 2013;31:1017–1026. doi: 10.1016/j.ijproman.2012.11.011. [DOI] [Google Scholar]

- 56.Lingard H.C., Cooke T., Blismas N. Safety climate in conditions of construction subcontracting: A multi-level analysis. Const. Manage Econ. 2010;28:813–825. doi: 10.1080/01446190903480035. [DOI] [Google Scholar]

- 57.Tam V.W., Fung I.W. Tower crane safety in the construction industry: A Hong Kong study. Saf. Sci. 2011;49:208–215. doi: 10.1016/j.ssci.2010.08.001. [DOI] [Google Scholar]

- 58.de 18 de Octubre, Reguladora de la Subcontratación en el Sector de la Construcción. Agencia Estatal Boletín Oficial del Estado; de Manoteras, Madrid: 2006. [Google Scholar]

- 59.de 24 de Agosto, por el que se Desarrolla la Ley 32/2006, de 18 de Octubre, Reguladora de la Subcontratación en el Sector de la Construcción. Agencia Estatal Boletín Oficial del Estado; de Manoteras, Madrid: 2007. [Google Scholar]

- 60.Jacinto C., Santos F.P., Soares C.G., Silva S.A. Assessing the coding reliability of work accidents statistical data: How coders make a difference. J. Saf. Res. 2016;59:9–21. doi: 10.1016/j.jsr.2016.09.005. [DOI] [PubMed] [Google Scholar]

- 61.European Commission Commission Recommendation of 6 May 2003 Concerning the Definition of Micro, Small and Medium-sized Enterprises. Off. J. Eur. Union. 2003;46:36–41. [Google Scholar]

- 62.Fang Y., Cho Y.K., Durso F., Seo J. Assessment of operator’s situation awareness for smart operation of mobile cranes. Autom. Constr. 2018;85:65–75. doi: 10.1016/j.autcon.2017.10.007. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data available on request at the Spanish Government’s Occupational Accident Statistics.