Abstract

The production of banana peel by the food-processing industry is substantial and the disposal of this waste material has become a matter of concern. However, recent studies have demonstrated that banana peel is a rich source of biologically active compounds that can be transformed into valuable products. This review aims to explore the potential of converting banana peel into valuable products and provides a comprehensive analysis of the physical and chemical composition of banana peel. Additionally, the utilization of banana peel as a substrate to produce animal feed, bio fertilizer, dietary fibers, renewable energy, industrial enzymes, and nanomaterials has been extensively studied. According to the researches that has been done so far, it is clear that banana peel has a broad range of applications and its effective utilization through biorefinery strategies can maximize its economic benefits. Based on previous studies, A plan for feasibility of a banana peel biorefinery has been put up which suggest its potential as a valuable source of renewable energy and high-value products. The utilization of banana peel through biorefinery strategies can provide a sustainable solution for waste management and contribute to the development of a circular economy.

Keywords: Banana peel, Physiochemical, Bioactive, Dietary fiber, Biorefinery, Waste utilization

Introduction

Bananas (Musaceae) are a tropical fruit that are produced throughout the year and play a crucial role in providing food security for many tropical communities [1]. According to the data from 2012, approximately 101,992,743 tonnes of bananas were harvested, accounting for 18.2% of the total fruit production worldwide [2]. The primary use of banana plant is for its fresh fruits, which are widely consumed and also utilized in various food processing applications, including the production of jam, chips, dried pulps, and alcoholic beverages such as beer or wine [3]. However, this widespread utilization of bananas in the food industries leads to a significant amount of waste in the form of banana peels, leaves, pseudostems, and stalks. Banana peels alone make up 30–40% (w/w) of a fresh banana fruit, which poses a major challenge for the safe disposal of solid waste [4]. In the past open burning or landfilling have been the most commonly used methods for disposing of banana peel waste, but these practices have negative environmental impacts [5].

Reusing banana peel is crucial from an environmental standpoint, as is investigating it as a possible raw material for creating a variety of products with additional value [6]. This would support the global economy and lessen the strain on the environment. Therefore, there is a growing need to develop a system or approach to repurpose banana peels and transform them into valuable and marketable products, or "wealth from waste." In recent years, various studies have been conducted to extract and produce beneficial byproducts from banana peels and these studies demonstrate the potential for creating different value-added products [7]. This not only supports the global economy but also helps to reduce the environmental burden associated with the disposal of banana peel waste.

Here, we take a look at a few of those studies that illustrate the creation of different value-added goods employing these wastes. Banana peel has been utilized for various industrial applications including bio-fuel production, bio-sorbents, pulp and paper, cosmetics, energy related activities, organic fertilizer, environmental cleanup and biotechnology related processes [8]. The banana peel is rich in phytochemical compounds than its pulp. The antifungal, antibiotic properties of banana peel can put to be good use [9]. The peel is used for home remedy for treating several skin problems including allergies and skin irritations. The banana peels waste is normally disposed in municipal landfills, which contributes to the existing environmental problems [10]. However, the problem can be recovered by utilizing its high-added value compounds, including the dietary fibre fraction that has a great potential in the preparation of functional foods [8].

Physicochemical Composition of Banana Peel

Banana peel constitutes a significant portion of fruit waste and its complete understanding in terms of physical characteristics and biochemistry is crucial for optimal utilization. An understanding of these characteristics could lead to the development of environmentally friendly utilization methods [11]. The composition of banana peel primarily consists of biopolymers such as cellulose, hemicellulose, lignin, pectin, chlorophyll, fiber, and other low molecular weight substances [12]. Chemical and elemental analysis of banana peel has revealed the presence of lipids, carbohydrates, protein, crude fibers, water-soluble sugar, phenolic compounds and minerals. Table 1 provides a quantitative breakdown of these components, while Table 2 outlines the mineral composition of banana peel. Results of proximate analysis (Table 3) reveal the high energy potential of banana peels, with a loss on ignition of 94% and carbon content of 40%. The nitrogen concentration, which ranges from 4 to 10%, is mainly composed of crude proteins [13]. The amino acid composition of banana peel is abundant in threonine, aspartic acid, serine, glutamic acid, glycine, proline, alanine, valine, cysteine, methionine, isoleucine, leucine, lysine, phenylalanine, and arginine, and is subject to variation based on the ripeness of the fruit. The composition of fruit peel waste varies based on factors such as the species and season, with fat, various extractives, and polyphenolics making up the remaining portion.

Table 1.

Chemical composition analysis of banana peel % dry matter basis

Table 2.

Mineral content of Banana peel

Table 3.

Proximate analysis of Banana peel % dry matter basis

Uses of Banana Peel

Banana peel has a diverse range of uses, both direct and indirect, primarily as a result of its versatile physical and chemical characteristics.

Direct Uses of Banana Peel

The direct use of banana peel primarily involves using it as a feedstock material for animals and as a biofertilizer. The whole Banana peels can be used as animal feed and biofertilizers in their natural state, without undergoing any alterations.

Animal Feed

Banana peel contains a range of micronutrients and amino acids, which are beneficial for animal health (as shown in Tables 1, 2). Although heavy metals and antinutrients are present in banana peel, their concentrations are within acceptable ranges. Banana peel is an economical source of feed for animals, but its nutritional value, digestibility, and antinutrient content can be improved through hydrothermal processes [14]. The ripe banana peels have higher nutritional value comapred to ripe and green peels. Lactating cows can have a diet with 15%to 30% of ripe banana peels without experiencing any negative impact on taste or performance. Dairy cows were observed to produce more milk when fed 14–21 kg of fresh, ripe banana peel daily. Growing pigs and rabbits gained weight significantly when 15–30% of banana peel was added to their diets without any adverse effects. Feeding zebu with grass and banana peel did not affect their palatability [15]. Adding banana peel to broilers diets as a growth promoter had no negative impact on the broilers' performance, according to research [16]. Goats fed with dried plantain peels, a form of banana peel, instead of maize showed no adverse effects. In Uganda, banana peel is used as an additional source of feed for cattle, pigs, goats, and poultry [17]. Hence, using banana peel as a feedstock material reduces the cost of the diets while serving as a supplementary food source that promotes weight gain and development [18, 19].

Biofertilizer

Composting, which is a cost-effective and environmentally friendly method for managing solid waste, has gained popularity as a means of reducing the growing volume of fruit peels. Banana peels are increasingly being utilized as a biofertilizer due to their high content of minerals, vitamins, and certain micronutrients. Composts, made from materials such as banana peels, can help improve soil fertility and quality by providing a source of potassium and nitrogen [20]. The agronomic utility of inoculated banana peels using a formulation including banana peels plus either cow manure, earthworms or poultry litter [21]. Studies have shown that the decomposition of banana peels is faster in aerobic conditions, resulting in a compost that has a higher content of potassium and nitrogen Additionally, the high alkaline pH of compost made from banana peels suggests that it may be able to reduce soil acidity. Vermicompost, which is produced through the decomposition of banana peels by earthworms (Eudrilus eugeniae), is also a valuable biofertilizer. It has been shown to enhance nutrient uptake and improve plant growth and production [22]. The biofertilizers derived from banana peels are effective organic fertilizers that may enhance plant growth and production.

Indirect Uses of Banana Peel

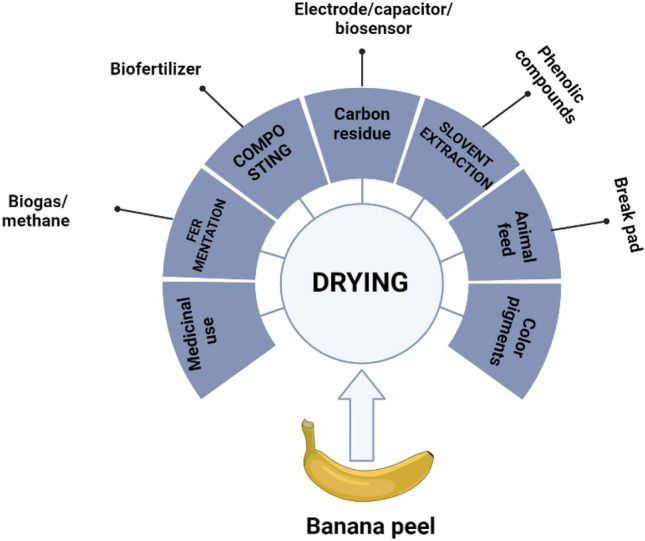

Biorefining refers to the transformation of biomass, derived from living or recently deceased organisms, into a wide range of products, including fuels, chemicals, energy, and materials. This concept is inspired by the petroleum refining industry, where crude oil is processed into valuable products [23]. One of the simplest and most cost-effective ways to dispose of banana peels, a common form of biomass, is to use them as animal feed or compost. However, banana peels contain several useful chemicals with antioxidant, medicinal, and nutritional properties that can be extracted through biorefining. The resulting products can range from high-value nanomaterials to antioxidants, phenolic compounds, and pigments. Moreover, it is feasible to increase the value of banana peels by employing a biorefinery to produce a variety of goods. Figure 1 illustrates how banana peel has been valued. After drying, banana peel may be used as an immediate source of animal fodder and for the combustion or gasification of fuel (pyrolysis). The biorefining of banana peels involves a series of unit processes, including decoction, separation techniques such as supercritical CO2 extraction, solvent extraction, and antisolvent extraction. The resulting products from these processes include enzymes, protein, ethanol, biogas, and other valuable substances. Additionally, activated carbon produced by pyrolyzing banana peel can be used to create carbon nanotubes and metal composites, and even for electrochemical applications. After composting with organic materials, the remaining residue can be used as organic fertilizer.

Fig. 1.

Utilization of banana peel

Extraction of Most Valuable Compounds

Dietary Fiber

Dietary fiber, which is a combination of both soluble (such as pectins, gums) and insoluble (such as cellulose, lignin, and certain hemicelluloses) fractions, has been shown to have a positive impact on human health, including prevention of diverticulosis, colon cancer, irritable bowel syndrome, constipation, and cardiovascular disease. The high concentration of dietary fiber in banana peel makes it a valuable ingredient for various nutraceutical and pharmaceutical applications. Pectin, a complex heteropolysaccharide primarily composed of galacturonic acid, plays a significant role in the food, cosmetic, and pharmaceutical industries due to its properties as a gel-forming agent, stabilizers or emulsifier [24]. The extraction of dietary fiber from banana peel using several techniques such as wet milling with hot water, wet milling with tap water, wet milling, and dry milling yielded values of 83.00 ± 0.28, 87.77 ± 0.35, 89.21 ± 0.85, and 89.35 ± 0.62 g/100 g of dry matter, respectively [25]. The yield of pectin was observed 3.2%, 17.05%, and 15% by ultrasonification, liquid–solid extraction with citric acid (0.5 N, pH 1.7), and hydrochloric acid (0.5 N, pH 1.5), respectively [11]. Pectin extracted from banana peel has a molecular weight range of 132–573 kDa [26]. previous research has indicated that low pH extraction methods result in significant yields of pectin from banana peels [27].

Polyphenols

Polyphenols are the most abundant bioactive compounds found in banana peel extracts [28]. These extracts contain between 0.9 and 3.0 g of total phenolic compounds per 100 g of dry matter [29]. Different extraction methods can be used, including vacuum microwaves (30.6–3.55 mg/g) and ultrasonification (35.1–1.15 mg/g) [30]. Other extrcation methods include methanol, ethanol, ethyl acetate, acetone, water, methanol: water, ethanol: water, and acetone: water extrcation [31]. Additionally, flavonoids (196.1–6.70 mg/g) can be isolated from banana peel. The inhibin of DPPH radical (84.5–6.48%) technique is commonly used to evaluate the antioxidant capacity of banana peel [32].

Organically produced banana peels have a higher soluble polyphenol content (1.960.43 mg GAE ml/vegetable extract (VE) and 3.170.26 mg GAE ml/VE) compared to conventionally cultivated banana peels (3.170.26 mg GAE ml/VE) [33]. Gallocatechin concentration can also be used to assess a banana's antioxidant capability as it is abundant in banana peel (158 mg/100 g dry weight) [34]. Dopamine, a potent water-soluble antioxidant, is present in banana peel in an abundance of 80–560 mg/100 g. Unripe banana peels have the highest antioxidant activity and antioxidant enzyme levels compared to ripe and leaky ripe banana peels, but these levels decrease as the banana fruit matures [29].

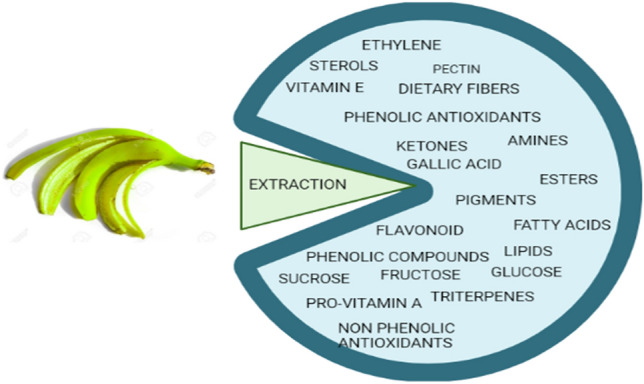

Banana peel contains both phenolic (flavanones, catecholamines, flavonols, tocopherols, etc.) and nonphenolic (carotenes, ascorbic acid, cyanidin) antioxidants [35]. Glutathione is also present in banana peel [36]. Triterpenic ketones (cycloeucalenone and 31-norcyclolaudenone) are present in the lipophilic extract of banana peel, along with substantial amounts of steryl esters (469–24,405 mg/kg) and diacylglycerols (119–878 mg/kg). The banana peel extract contains a considerable amount of steryl glucosides, ranging from 273 to 888 mg/kg [37]. However, it is important to note that some of the lipids in the extract lack phenolic rings and thus exhibit limited antioxidant activity. The bioactive compounds that can be extracted from banana peel include pro-vitamin A components (flavonol gallocatechin, trans-carotene, and -cryptoxanthin), sterols (campesterol and stigmasterol), triterpenes (cycloeucalenol, cycloartenol, and 2,4-methylenecycloartenol), and cyclo. The extraction of these biological substances can be achieved through various techniques, including vacuum, ultrasonic extraction, and microwave extraction [38], supercritical CO2 extraction [39], and liquid extraction [40]. The comprehensive list of chemicals that can be obtained from banana peel is depicted in Fig. 2. Thus, banana peel can serve as a valuable raw material for the production of various bioactive chemicals.

Fig. 2.

Chemicals extracted from banana peel

Banana Peels for Generating Energy

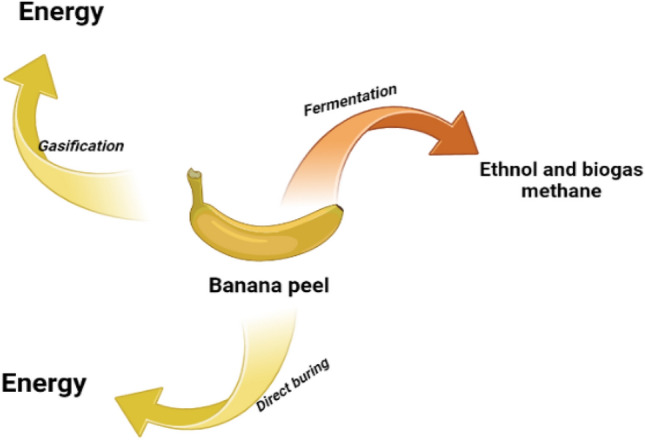

Bananas were also evaluated as a bio resource for the renewable energy production [41]. Studies suggest that there are two processes for converting banana peel into energy: thermal and biological (Fig. 3). Direct combustion and supercritical water gasification are methods used to produce heat and electrical energy through the thermal process. The energy content of dry banana peel is estimated to be 18.89 MJ/kg. Banana peel-based briquettes can also be used to generate energy source [42]. The biological process, anaerobic digestion, produces biogas which can be transformed into electricity. The use of banana peel as a feedstock for energy production accomplishes two objectives: it produces clean energy and a sustainable means of solid waste disposal [43]. Using a laboratory batch approach, banana peel combined with cow manure produced 875–1210 ml of biogas per day, with a rate of 0.55–0.76 vol/vol/day, comprising approximately 53%-57% methane [44]. Under mesophilic fermentation conditions, methane is also generated by co-digesting (1) banana peel (composition of total solids ranges from 2.5 to 10% w/v) and (2) banana peel mixed with pure or waste glycerol [45].

Fig. 3.

Different energy routs from banana peel

The maximum yield and production rate of biomethane was found 439 ml/g TVS and 5.31 ml/h at a total solids concentration of 7.5% [46]. However, to achieve 90% of the methane output from banana peel, fermentation must occur for 40–50 days. The anaerobic digestion of banana peel also results in the production of hydrogen and methane, as well as volatile fatty acids such as acetic acid4 [47]. The quality of the methane output is influenced by the size of the banana peel particles, with research suggesting that the methane output is relatively constant for different banana cultivars with the same particle sizes [48]. Ethanol, which can partially replace gasoline and has other uses, can also be produced from banana peel through the simultaneous co-culturing Aspergillus niger and Saccharomyces cerevisiae [49]. Other yeast strains, including S. kluyveri K-6, S. cerevisiae R-2, S. cerevisiae R-8, S. cerevisiae T-7, and Debaryomyces hansenii B-2, have also been used to produce ethanol from banana peel [50]. Table 4 provides information on the ethanol yield for various cultures. Banana peel can thus be utilized as a source for alternative energy sources such as ethanol, methane, biogas.

Table 4.

Yield of ethanol with different cultures

Medicinal Properties of Banana Peels

Banana peel has been extensively researched for its potential health benefits. The high concentration of gallocatechin in banana peel makes it a valuable dietary source for cancer and heart disease prevention. The presence of phenolic compounds, including flavonoids and dietary fiber, in jelly made from banana peel contributes to its antioxidant potential and makes it a preferred alternative to tablets and pills [51]. Research has indicated that the dietary supplement arabinoxylans from banana peel has potential health promoting properties. A new cell-adhesion inhibitor called 7, 8-Dihydroxy-3-methyl-isochromosome-4 that was isolated from banana peel may be utilized to treat atherosclerotic endothelium damage [52]. The antimicrobial properties of banana peel oil, lipids, phenols, and tannins against Proteus Vulgaris and Klebsiella pneumonia have also been explored, making it a potential treatment for certain illnesses [53]. Fresh yellow banana peel extract has been found to be more effective against both Gram-positive and Gram-negative bacteria, as well as possessing strong antibacterial and antiallergic properties [54].

Studies with castrated rats have indicated that banana peel extracts may have potential in the treatment of benign prostate hyperplasia [55]. The efficacy of a gel made from unripe banana peel and the alcoholic bark extracts for wound healing has also been demonstrated in rats [56]. The effects of banana peel extracts on tissue lipid peroxidation, thyroid hormones, insulin, and glucose levels have been studied in male rats [12]. In addition, banana peel has been used to create a green biopolymer/HAP nanocomposite for potential use in natural bone replacement [57]. Despite its potential medical uses, it is important to note the issue of pesticide residue in in commercially grown banana peel, which requires further attention [58].

Banana Peel for the Production of High-Value Goods

Protein

Proteins play a critical role in the growth and development of all living organisms. As a result, the search for alternative protein sources has become increasingly important, particularly in regions where access to traditional protein sources is limited. Single-cell protein (SCP) has been identified as a promising alternative due to its high protein content [59]. SCP can be produced through the cultivation of various microorganisms, including Aspergillus oryzae, Rhizopus oligosporus, and S. cerevisiae, using banana peel as a carbon source [60]. Additionally, mycelia protein can be produced through the use of the fungus A. niger and banana peel as a substrate [61]. The extraction of protein from banana peel can be accomplished through various techniques, including phenol extraction, TCA-acetone precipitation, and TCA precipitation [62].

Industrial Enzymes

Because banana peel contains significant levels of carbs, proteins, and fiber, it is a perfect substrate for the manufacture of goods with added value [63]. Banana peel has been identified as a promising substrate for the production of high-value industrial enzymes. Alpha-amylase, which is widely used in various industries such as baking, culinary, textile, brewing, detergent, paper, and pharmaceuticals [64], can be produced through solid-state fermentation (SSF) using bacteria such as Bacillus subtilis and A. niger produces [65]. Various fungal species have been isolated from banana peel, including Aspergillus flavus, Aspergillus niger, Aspergillus fumigatus, Helminthosporium oxysporum, and P. frequents [66], and their viability for producing alpha-amylase and amyloglucosidase through SSF has been evaluated [67]. Additionally, SSF using Trichoderma long, A. niger, S. cerevisiae, and Trichoderma viride GIM 3.0010 can produce cellulase, which has multiple application in the textile, paper and pulp, and food industries[68]. SSF can also produce poly galacturonase and xylanase using Trichoderma harzianum and Trichoderma virens, which are commonly used enzymes in the textile, paper, and pulp industries [69]. The production of polyphenol oxidase from banana peel can be used to degrade a variety of phenolic textile colors [70].

The production of enzymes such as cellulase, xylanase, laccase, and manganese peroxidase by white rot fungus species is influenced by the presence of various species, including Current maxima IBB 681, Coriolopsis polyzoan 38443, Funalia tragic IBB 146, Pycnoporus coccineus 38527, Pleurotus ostreatus, Trametes pubescens IBB 663, and Trametes Versicolor IBB 897[39]. Triacylglycerols may be hydrolyzed by the water-soluble enzyme lipase to produce free acids and glycerol. Lipase, which is useful in the dairy and food sectors, can be extracted from banana peel using groundnut oil as the extraction medium [71]. Additionally, banana peel has been demonstrated as an effective source of carbon for the production of laccase (copper-containing oxidases) from P. ostreatus DSM 1833 and Phoma sp. UHH 5-1-03 under both SSF and submerged culture conditions [72]. Manganese peroxidase can also be produced through SSF conditions using A. fumigatus (VkJ2.4.5) during the fermentation of laccase [73].

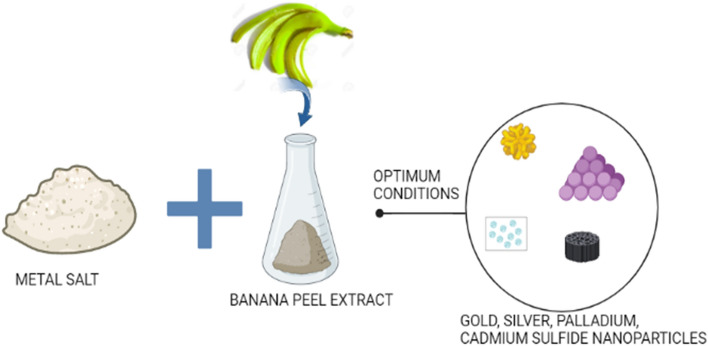

Nanoparticles

The utilization of banana peel as a source material in the production of nanoparticles has been widely studied in recent years. Research has shown that the peel, which is rich in polymers such as hemicellulose, lignin, and pectins, can be utilized to produce nanoparticles of palladium, gold, silver, Mn3O4, cadmium sulfide, and hydroxyapatite [12] (Fig. 4). The latter, being the main inorganic component of natural bone, has several biomedical applications [74]. Additionally, the use of banana peel extracts has been successful in combating the pathogenic strain of Pseudomonas aeruginosa through the creation of Au–Ag nanocomposites [75]. Furthermore, various treatments such as chemical bleaching, alkaline treatment, and acid hydrolysis, as well as enzymatic hydrolysis with xylanase and alkaline treatment, have enabled the recovery of cellulose nanofibers from banana peel. These nanofibers, due to their mechanical robustness and high clarity, have found applications in various industries such as the pharmaceutical, biomedical, and paper sectors [76]. Additionally, carbon nanotubes can be created from a combination of activated banana peel carbon and mineral oil through the process of pyrolysis [77]. Thus, banana peel has been shown to be an efficient and environmentally friendly source material for the rapid and reliable formation of nanomaterials, as it is non-toxic, affordable, and widely available.

Fig. 4.

Preparation of nanoparticles using banana peel

Banana Peel for Treating Wastewater

Banana peel has been reported to have potential in removing impurities from wastewater, including organic pollutants, dyes, and heavy metals. Banana peel has been employed as a component in bio adsorbents and is known to have high adsorption capacity for various contaminants due to the presence of hydroxyl, carboxyl, and amino groups [78]. Studies have shown its effectiveness in removing heavy metals and organic chemicals from aqueous solutions. An effective adsorbent for removing these pollutants from aqueous solutions is banana peel, both natural and physically and chemically engineered [79]. The removal of copper ions using the banana peels previously isolated from their antioxidant compounds supports their continued usage as an adsorbent [80]. Banana peel has also been utilized in refining carcinogenic components in used frying oil, increasing the oil's brightness by adsorbing peroxides [81]. Beyond its adsorptive properties, banana peel fibers have been incorporated in the creation of commercial spiral-wound reverse osmosis membranes [82], and chemically altered banana peel has been utilized in creating microporous/mesoporous carbon with intestine-like properties for size-selective separation of proteins and potential use in drug separation and biological macromolecule immobilization [83].

Added Applications

Banana peel has been found to have various unique and original applications, particularly in the fields of food science and technology, materials science, and environmental sustainability. One of the key components of banana peel is color pigments such as anthocyanin and lipofuscin (fluorescent pigments), which can be used as natural food colorants. The graded shape of banana peel has been demonstrated to have effective energy-absorption properties and can be utilized as a protective layer. At low impact velocities, this shape is in charge of safeguarding the inner, soft core of the banana peel [84]. Total starch, digestible starch, resistant starch, dietary fiber, and soluble and insoluble dietary fibers composed banana peel flour. The high phenolic content and strong antioxidant activity of banana peel flour extracts have been reported, and banana peel flour has been partially substituted for wheat flour in the preparation of low glycemic index noodles while maintaining the same tensile strength and having greater elasticity values [85]. In addition, banana peel has been used as a source of materials for high-density Na–Li ion battery anodes [86] and as an electrode for Li-ion capacitors [87]. The hierarchical porous carbon foam derived from banana peel has also been utilized as a supercapacitor and a template for aminophenol furfural resin-zinc complexes. Zn ions may likely align with the hydroxyl and carboxylic groups found in the pores of banana peel to create Zn complexes, which are comparable to metal–organic frameworks [88]. To create a disk-shaped nonpolar electric double-layer capacitor employed banana peel [89]. A biosensor was developed by immobilizing tissue homogenates of banana peel onto a glassy carbon electrode surface. This biosensor is capable of detecting a range of phenolic chemicals, including pyrogallol, caffeic acid, cinnamic acid, ascorbic acid, catechol, resorcin, and phenol, withanalysis taking 10–12 min [90]. In the field of materials engineering, banana peel has been utilized to produce eco-friendly and cost-effective alternatives to traditional materials. For example, grounded banana peel has been utilized to make ply boards as a substitute for expensive prefabricated wall components [91]. Banana peel has also been used in the production of brake pads, which serve as crucial parts of disc brakes, to replace asbestos fiber and phenolic resin [92]. Additionally, banana peel has been incorporated into the production of an antibacterial edible film, which was utilized to package food alongside glycerol as a clove oil and plasticizer as an antimicrobial [93].

The chemical composition of banana peel has been explored for its potential uses, including as a source of alkali-based products in the form of potash and trace elements [94]. Banana peel has also been shown to have potential as a natural dye, due to its UV protection and antibacterial qualities when applied to cotton [95]. In the field of aquaculture, the use of banana peel as a growth stimulant for Macrobrachium rosenbergii beyond the larval stage has been demonstrated, with the authors recommending its inclusion in the composition of aqua feed [96].

In terms of materials engineering, the mechanical characteristics of HDPE and epoxy composites reinforced with banana peel fibers have been found to be enhanced [97]. Additionally, a combination of banana peel charcoal and various metal salts such as copper nitrate [Cu (NO3)2], aluminum oxide (Al2O3), magnesium sulfate or zinc chloride (ZnCl2) has been utilized to create the metal–carbon composite materials (MgSO4 0.7H2O), with the materials being utilized for hydrogen storage. This research found that Cu-carbon composites acquired the maximum hydrogen storage capacity (6.06–6.22 wt%) [98]. As a result, banana peel demonstrates that it is a low-cost and promising bio resource with a broad variety of uses in many fields.

Suggested Biorefinery for Banana Peel

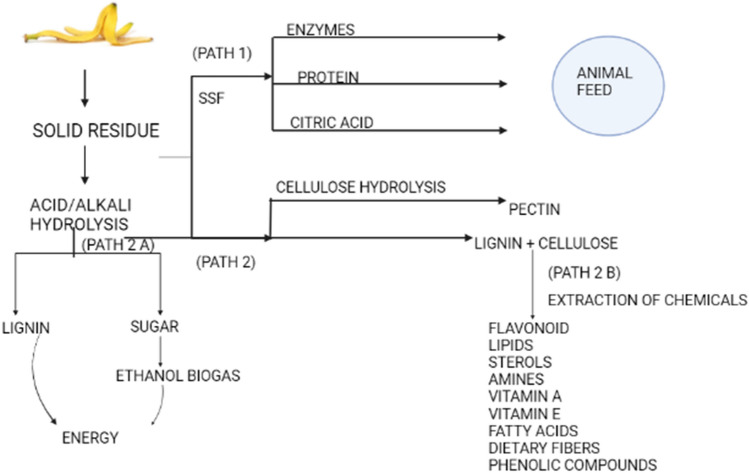

In this section, a biorefinery strategy is proposed based on extensive into the physicochemical composition and potential utilization of banana peel. Dried banana peel has been found to contain high concentration of valuable compounds. including pectin (17.05%) [59], protein (approximately > 4.32%) [28], and phenolic compounds (about > 3.0%) [99]. Additionally, the peel contains significant levels of cellulose and hemicellulose, which can be converted into sugar [48], and thus into various value-added products such as ethanol (7.45 v/v) and biogas, which comprises 53–57% methane [18]. The proposed banana peel biorefinery plan is depicted in Fig. 5, and it presents a potential alternative for the integrated utilization of banana peel for the production of valuable goods [100]. However, it should be noted that the application of this strategy is currently only being tested in laboratory settings and it has not yet been implemented on a big scale. Future developments could involve optimizing the product portfolio and incorporating methods such as multicriteria analysis and multicriteria decision analysis to present a more comprehensive and economically feasible biorefinery plan. Additionally, a material balance has been calculated for the proposed banana peel biorefinery, with 1 tonne of bone-dry, ground-up banana peel being used as the unit of measurement. This provides a framework for analyzing the potential viability of the biorefinery and serves as a basis for future work in this area. Two distinct pathways have been proposed for the conversion of banana peel into useful products.

Fig. 5.

Suggested biorefinery scheme of banana peel

In the first pathway, SSF route is utilized to produce 170 kg of citric acid and 432 kg of protein from 1 ton of banana peel [98]. After the recovery of valuable compounds, the residual solid can be utilized as animal feed. The second pathway involves the hydrolysis of cellulose to produce 170 kg of pectin [101]. The solid residue is then subjected to acid–alkali hydrolysis to produce lignin, cellulose, and hemicellulose, which can be further converted into energy or valuable compounds [48]. Under pathway 2A, the lignocellulose material can be fermented to produce ethanol with a yield of 7.45% v/v [40]. This process results in the production of 325 m3 of ethanol or 220 m3 of methane [101]. Under pathway 2B, lignocellulose can be processed into various chemicals, including phenolic compounds, dietary fibers, antioxidants, flavonoids, lipids, ketones, esters, amines, fatty acids, triterpenes, and pigments, through various unit operations and processes, such as leaching, liquid extraction, and fermentation [102].

The cost of establishing a banana peel biorefinery is challenging to estimate due to the lack of comprehensive costing literature and studies, which are only available at the pilot stage. However, the raw material, banana peel, can be obtained at a low costs, as only administrative costs, such as collection, drying, and size reduction, are incurred. Assuming no changes are made to other expenses, banana peel can serve as a low-cost building block for a biorefinery.

Potential Challenges and Future Perspectives

Banana peel holds significant potential for the production of various value-added goods, existing data on its utilization is based exclusively on in vitro studies. While in vitro extraction technologies are widely available, practical applications remain challenging to implement. The physical, chemical, and mechanical properties of banana peel are influenced by various factors such as the starting point, seasonality, variety, ripening stage, and geographical location. This presents a significant barrier in standardizing the quality of raw materials for the banana peel biorefinery. Banana peel has a high moisture content, which poses challenges in terms of collection, storage, handling, and transportation. The high organic matter and moisture content also increase the material's susceptibility to biodegradation, which may lead to instability [103]. As a result, drying of banana peel prior to use is necessary, and there is need to develop a simple, affordable dry that can utilize solar energy, waste heat, or any other accessible heating source. A continuous, cost-effective, and practical supply of banana peels is required for industrial-scale production or the use as animal feed. However, inadequate handling, processing, and transportation expertise, may result in instability during long-term storage [104]. Using banana peel as a feedstock for energy production is contingent upon its heating value or energy content. However, the high moisture content leads to low energy efficiency. Hence, there is a need for improved technologies to enhance conversion and tackle the technological and economical challenges associated with generating clean energy from banana biomass [105].

Conclusion

Banana peel, a byproduct of the food industry, has the potential to be transformed into a range of commercially viable compounds with therapeutic, nutritional, and antioxidant properties through a series of processing techniques, including drying, fermentation, solvent extraction, size reduction, and pyrolysis. Despite the promising results obtained in laboratory experiments, the scalability of these extraction methods remains a challenge. The consistent availability of raw materials and the need to isolate specific components are significant obstacles that must be overcome. The high concentration of phenolic compounds in the dietary fiber of banana peel has led to its increasing popularity as a functional food ingredient. These phenolic molecules are responsible for the antioxidant properties of banana peel, highlighting its potential for a variety of applications, including its usage as a feedstock and substrate for the production of nanomaterials, as well as for generating clean energy and for wastewater treatment.

Funding

NA.

Data Availability

Data will be made available on request.

Declarations

Conflict of interest

The authors declare no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Padam BS, Tin HS, Chye FY, Abdullah MI. Banana by-products: an under-utilized renewable food biomass with great potential. J Food Sci Technol. 2014;51:3527–3545. doi: 10.1007/s13197-012-0861-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Hailu M, Seyoum Workneh T, Belew D. Effect of packaging materials on shelf life and quality of banana cultivars (Musa spp.) J Food Sci Technol. 2014;51:2947–2963. doi: 10.1007/s13197-012-0826-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Aurore G, Parfait B, Fahrasmane L. Bananas, raw materials for making processed food products. Trends Food Sci Technol. 2009;20:78–91. doi: 10.1016/j.tifs.2008.10.003. [DOI] [Google Scholar]

- 4.Sial TA, Khan MN, Lan Z, Kumbhar F, Ying Z, Zhang J, Sun D, Li X. Contrasting effects of banana peels waste and its biochar on greenhouse gas emissions and soil biochemical properties. Process Saf Environ Prot. 2019;122:366–377. doi: 10.1016/j.psep.2018.10.030. [DOI] [Google Scholar]

- 5.Mohapatra D, Mishra S, Sutar N (2010) Banana and its by-product utilisation: an overview

- 6.Zaini HM, Roslan J, Saallah S, Munsu E, Sulaiman NS, Pindi W. Banana peels as a bioactive ingredient and its potential application in the food industry. J Funct Foods. 2022;92:105054. doi: 10.1016/j.jff.2022.105054. [DOI] [Google Scholar]

- 7.Singh K, Kumar T, Prince VK, Sharma S, Rani J. A review on conversion of food wastes and by-products into value added products. Int J Chem Stud. 2019;7:2068–2073. [Google Scholar]

- 8.Prashanthi D, Chaitanya M. A review on multiple uses of banana peel. Int J Sci Dev Res. 2020;5:120–122. [Google Scholar]

- 9.Hikal WM, Ahl SA, Hussein AH, Bratovcic A, Tkachenko KG, Sharifi-Rad J, Kačániová M, Elhourri M, Atanassova M. Banana peels: a waste treasure for human being. Evid-Based Complement Altern Med. 2022 doi: 10.1155/2022/7616452. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Ranjha MM, Irfan S, Nadeem M, Mahmood S. A comprehensive review on nutritional value, medicinal uses, and processing of banana. Food Rev Intl. 2022;38:199–225. doi: 10.1080/87559129.2020.1725890. [DOI] [Google Scholar]

- 11.Emaga TH, Robert C, Ronkart SN, Wathelet B, Paquot M. Dietary fibre components and pectin chemical features of peels during ripening in banana and plantain varieties. Bioresour Technol. 2008;99:4346–4354. doi: 10.1016/j.biortech.2007.08.030. [DOI] [PubMed] [Google Scholar]

- 12.Gopi D, Kanimozhi K, Bhuvaneshwari N, Indira J, Kavitha L. Novel banana peel pectin mediated green route for the synthesis of hydroxyapatite nanoparticles and their spectral characterization. Spectrochim Acta Part A Mol Biomol Spectrosc. 2014;118:589–597. doi: 10.1016/j.saa.2013.09.034. [DOI] [PubMed] [Google Scholar]

- 13.Pathak PD, Mandavgane SA, Kulkarni BD. Fruit peel waste as a novel low-cost bio adsorbent. Rev Chem Eng. 2015;31:361–381. doi: 10.1515/revce-2014-0041. [DOI] [Google Scholar]

- 14.Adeniji AO, Mabayoje VO, Raji AA, Muhibi MA, Tijani AA, Adeyemi AS. Feto–maternal haemorrhage in parturients: incidence and its determinants. J Obstet Gynaecol. 2008;28:60–63. doi: 10.1080/01443610701812181. [DOI] [PubMed] [Google Scholar]

- 15.Wadhwa M, Bakshi MP. Utilization of fruit and vegetable wastes as livestock feed and as substrates for generation of other value-added products. Rap Publ. 2013;4:67. [Google Scholar]

- 16.Salem M, Abdel-Ghany HM. Effects of dietary orange peel on growth performance of Nile tilapia (Oreochromis niloticus) fingerlings. Aquac Stud. 2018;18:127–134. doi: 10.4194/2618-6381-v18_2_06. [DOI] [Google Scholar]

- 17.Katongole CB, Sabiiti E, Bareeba F, Ledin I. Utilization of market crop wastes as animal feed in urban and peri-urban livestock production in Uganda. J Sustain Agric. 2011;35:329–342. doi: 10.1080/10440046.2011.554318. [DOI] [Google Scholar]

- 18.Gupta G, Baranwal M, Saxena S, Reddy MS. Utilization of banana waste as a resource material for biofuels and other value-added products. Biomass Convers Biorefinery. 2022 doi: 10.1007/s13399-022-02306-6. [DOI] [Google Scholar]

- 19.Mercy S, Mubsira BS, Jenifer I. Application of different fruit peels formulations as a natural fertilizer for plant growth. Int J Sci Technol Res. 2014;3:300–307. [Google Scholar]

- 20.Kalemelawa F, Nishihara E, Endo T, Ahmad Z, Yeasmin R, Tenywa MM, Yamamoto S. An evaluation of aerobic and anaerobic composting of banana peels treated with different inoculums for soil nutrient replenishment. Bioresour Technol. 2012;126:375–382. doi: 10.1016/j.biortech.2012.04.030. [DOI] [PubMed] [Google Scholar]

- 21.Achsah RS, Prabha ML. Potential of vermicompost produced from banana waste (Musa paradisiaca) on the growth parameters of Solanum lycopersicum. Int J ChemTech Res. 2013;5:2141–2153. [Google Scholar]

- 22.Cherubini F. The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Convers Manag. 2010;51:1412–1421. doi: 10.1016/j.enconman.2010.01.015. [DOI] [Google Scholar]

- 23.Castillo-Israel KA, Baguio SF, Diasanta MD, Lizardo RC, Dizon EI, Mejico MI. Extraction and characterization of pectin from Saba banana [Musa'saba'(Musa acuminata × Musa balbisiana)] peel wastes: a preliminary study. Int Food Res J. 2015;22(1):190–195. [Google Scholar]

- 24.Wachirasiri P, Julakarangka S, Wanlapa S. The effects of banana peel preparations on the properties of banana peel dietary fibre concentrate. Songklanakarin J Sci Technol. 2009;31:605–611. [Google Scholar]

- 25.Pathak PD, Mandavgane SA, Kulkarni BD. Valorization of banana peel: a biorefinery approach. Rev Chem Eng. 2016;32:651–666. doi: 10.1515/revce-2015-0063. [DOI] [PubMed] [Google Scholar]

- 26.Rivadeneira JP, Wu T, Ybanez Q, Dorado AA, Migo VP, Nayve FR, Castillo-Israel KA. Microwave-assisted extraction of pectin from “Saba” banana peel waste: optimization, characterization, and rheology study. Int J Food Sci. 2020 doi: 10.1155/2020/8879425. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Faller AL, Fialho EF. Polyphenol content and antioxidant capacity in organic and conventional plant foods. J Food Compos Anal. 2010;23:561–568. doi: 10.1016/j.jfca.2010.01.003. [DOI] [Google Scholar]

- 28.González-Montelongo R, Lobo MG, González M. Antioxidant activity in banana peel extracts: testing extraction conditions and related bioactive compounds. Food Chem. 2010;119:1030–1039. doi: 10.1016/j.foodchem.2009.08.012. [DOI] [Google Scholar]

- 29.Anal AK, Jaisanti S, Noomhorm A. Enhanced yield of phenolic extracts from banana peels (Musa acuminat a Colla AAA) and cinnamon barks (Cinnamomum varum) and their antioxidative potentials in fish oil. J Food Sci Technol. 2014;51:2632–2639. doi: 10.1007/s13197-012-0793-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.González-Montelongo R, Lobo MG, González M. The effect of extraction temperature, time and number of steps on the antioxidant capacity of methanolic banana peel extracts. Sep Purif Technol. 2010;71:347–355. doi: 10.1016/j.seppur.2009.12.022. [DOI] [Google Scholar]

- 31.Akbar A, Anal AK. Zinc oxide nanoparticles loaded active packaging, a challenge study against Salmonella typhimurium and Staphylococcus aureus in ready-to-eat poultry meat. Food Control. 2014;38:88–95. doi: 10.1016/j.foodcont.2013.09.065. [DOI] [Google Scholar]

- 32.Polinati RM, Faller AL, Fialho E. The effect of freezing at − 18 °C and − 70 °C with and without ascorbic acid on the stability of antioxidant in extracts of apple and orange fruits. Int J Food Sci Technol. 2010;45:1814–1820. doi: 10.1111/j.1365-2621.2010.02333.x. [DOI] [Google Scholar]

- 33.Someya S, Yoshiki Y, Okubo K. Antioxidant compounds from bananas (Musa Cavendish) Food Chem. 2002;79:351–354. doi: 10.1016/S0308-8146(02)00186-3. [DOI] [Google Scholar]

- 34.Sundaram S, Anjum S, Dwivedi P, Rai GK. Antioxidant activity and protective effect of banana peel against oxidative hemolysis of human erythrocyte at different stages of ripening. Appl Biochem Biotechnol. 2011;164:1192–1206. doi: 10.1007/s12010-011-9205-3. [DOI] [PubMed] [Google Scholar]

- 35.Chen XD, Wei GY, Zhang JL, Dong YY. Efficient production of glutathione using hydrolyzate of banana peel as novel substrate. Korean J Chem Eng. 2011;28:1566–1572. doi: 10.1007/s11814-010-0535-6. [DOI] [Google Scholar]

- 36.Oliveira L, Freire CS, Silvestre AJ, Cordeiro N. Lipophilic extracts from banana fruit residues: a source of valuable phytosterols. J Agric Food Chem. 2008;56:9520–9524. doi: 10.1021/jf801709t. [DOI] [PubMed] [Google Scholar]

- 37.Khadhraoui B, Ummat V, Tiwari BK, Fabiano-Tixier AS, Chemat F. Review of ultrasound combinations with hybrid and innovative techniques for extraction and processing of food and natural products. Ultrason Sonochem. 2021;76:105625. doi: 10.1016/j.ultsonch.2021.105625. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Rombaut N, Tixier AS, Bily A, Chemat F. Green extraction processes of natural products as tools for biorefinery. Biofuels Bioprod Biorefin. 2014;8:530–544. doi: 10.1002/bbb.1486. [DOI] [Google Scholar]

- 39.Jadhav M, Pignatari M, Herwig F, Zinner E, Gallino R, Huss GR. Relics of ancient post-AGB stars in a primitive meteorite. Astrophys J Lett. 2013;777:L27. doi: 10.1088/2041-8205/777/2/L27. [DOI] [Google Scholar]

- 40.Tock JY, Lai CL, Lee KT, Tan KT, Bhatia S. Banana biomass as potential renewable energy resource: a Malaysian case study. Renew Sustain Energy Rev. 2010;14:798–805. doi: 10.1016/j.rser.2009.10.010. [DOI] [Google Scholar]

- 41.Wilaipon P. The effects of briquetting pressure on banana-peel briquette and the banana waste in Northern Thailand. Am J Appl Sci. 2009;6:167. doi: 10.3844/ajassp.2009.167.171. [DOI] [Google Scholar]

- 42.Selvarajoo A, Muhammad D, Arumugasamy SK. An experimental and modelling approach to produce biochar from banana peels through pyrolysis as potential renewable energy resources. Model Earth Syst Environ. 2020;6:115–128. doi: 10.1007/s40808-019-00663-2. [DOI] [Google Scholar]

- 43.Krishnan R, Arshinder K, Agarwal R. Robust optimization of sustainable food supply chain network considering food waste valorization and supply uncertainty. Comput Ind Eng. 2022;171:108499. doi: 10.1016/j.cie.2022.108499. [DOI] [Google Scholar]

- 44.Housagul S, Sirisukpoka U, Boonyawanich S, Pisutpaisal N. Biomethane production from co-digestion of banana peel and waste glycerol. Energy Procedia. 2014;61:2219–2223. doi: 10.1016/j.egypro.2014.12.113. [DOI] [Google Scholar]

- 45.Pisutpaisal N, Nathao C, Sirisukpoka U. Biological hydrogen and methane production in from food waste in two-stage CSTR. Energy Procedia. 2014;50:719–722. doi: 10.1016/j.egypro.2014.06.088. [DOI] [Google Scholar]

- 46.Nathoa C, Sirisukpoca U, Pisutpaisal N. Production of hydrogen and methane from banana peel by two phase anaerobic fermentation. Energy Procedia. 2014;50:702–710. doi: 10.1016/j.egypro.2014.06.086. [DOI] [Google Scholar]

- 47.Tumutegyereize P, Muranga FI, Kawongolo J, Nabugoomu F. Optimization of biogas production from banana peels: effect of particle size on methane yield. Afr J Biotechnol. 2011;10:18243–18251. doi: 10.5897/AJB11.2442. [DOI] [Google Scholar]

- 48.Itelima J, Onwuliri F, Onwuliri E, Onyimba I, Oforji S. Bio-ethanol production from banana, plantain and pineapple peels by simultaneous saccharification and fermentation process. Usak Univ J Eng Sci. 2020;3:34–47. [Google Scholar]

- 49.Brooks AA. Ethanol production potential of local yeast strains isolated from ripe banana peels. Afr J Biotechnol. 2008;7:3749–3752. [Google Scholar]

- 50.Lee EH, Yeom HJ, Ha MS, Bae DH. Development of banana peel jelly and its antioxidant and textural properties. Food Sci Biotechnol. 2010;19:449–455. doi: 10.1007/s10068-010-0063-5. [DOI] [Google Scholar]

- 51.Fu Y, Freymueller JT, Jensen T. Seasonal hydrological loading in southern Alaska observed by GPS and GRACE. Geophys Res Lett. 2012 doi: 10.1029/2012GL052453. [DOI] [Google Scholar]

- 52.Mathew NS, Negi PS. Traditional uses, phytochemistry and pharmacology of wild banana (Musa acuminata Colla): a review. J Ethnopharmacol. 2017;196:124–140. doi: 10.1016/j.jep.2016.12.009. [DOI] [PubMed] [Google Scholar]

- 53.Chabuck ZA, Al-Charrakh AH, Hindi NK, Hindi SK. Antimicrobial effect of aqueous banana peel extract. Iraq Res Gate Pharm Sci. 2013;1:73–75. [Google Scholar]

- 54.Murata K, Hayashi H, Matsumura S, Matsuda H. Suppression of benign prostate hyperplasia by Kaempferia parviflora rhizome. Pharmacogn Res. 2013;5:309. doi: 10.4103/0974-8490.118827. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Rosida SS, Khotib JU. The increasing of VEGF expression and re-epithelialization on dermal wound healing process after treatment of banana peel extract (Musa acuminata Colla) Int J Pharm Pharm Sci. 2014;6:427–430. [Google Scholar]

- 56.Parmar HS, Kar A. Medicinal values of fruit peels from Citrus sinensis, Punica granatum, and Musa paradisiaca with respect to alterations in tissue lipid peroxidation and serum concentration of glucose, insulin, and thyroid hormones. J Med Food. 2008;11:376–381. doi: 10.1089/jmf.2006.010. [DOI] [PubMed] [Google Scholar]

- 57.Rodríguez-Ambriz SL, Islas-Hernández JJ, Agama-Acevedo E, Tovar J, Bello-Pérez LA. Characterization of a fibre-rich powder prepared by liquefaction of unripe banana flour. Food Chem. 2008;107:1515–1521. doi: 10.1016/j.foodchem.2007.10.007. [DOI] [Google Scholar]

- 58.Khan A, Ahmad A, Akhtar F, Yousuf S, Xess I, Khan LA, Manzoor N. Ocimum sanctum essential oil and its active principles exert their antifungal activity by disrupting ergosterol biosynthesis and membrane integrity. Res Microbiol. 2010;161:816–823. doi: 10.1016/j.resmic.2010.09.008. [DOI] [PubMed] [Google Scholar]

- 59.Yousufi MK. To determine protein content of single cell protein produced by using various combinations of fruit wastes and two standard food fungi. Int J Adv Biotechnol Res. 2012;3:533–536. [Google Scholar]

- 60.Yabaya A, Ado SA. Mycelial protein production by Aspergillus niger using banana peels. Sci World J. 2008 doi: 10.4314/swj.v3i4.51819. [DOI] [Google Scholar]

- 61.Zhang LL, Feng RJ, Zhang YD. Evaluation of different methods of protein extraction and identification of differentially expressed proteins upon ethylene-induced early-ripening in banana peels. J Sci Food Agric. 2012;92:2106–2115. doi: 10.1002/jsfa.5591. [DOI] [PubMed] [Google Scholar]

- 62.Oberoi HS, Vadlani PV, Saida L, Bansal S, Hughes JD. Ethanol production from banana peels using statistically optimized simultaneous saccharification and fermentation process. Waste Manag. 2011;31:1576–1584. doi: 10.1016/j.wasman.2011.02.007. [DOI] [PubMed] [Google Scholar]

- 63.Krishna A. An integrative review of sensory marketing: engaging the senses to affect perception, judgment and behavior. J Consum Psychol. 2012;22:332–351. doi: 10.1016/j.jcps.2011.08.003. [DOI] [Google Scholar]

- 64.Unakal C, Kallur RI, Kaliwal BB. Production of α-amylase using banana waste by Bacillus subtilis under solid state fermentation. Eur J Exp Biol. 2012;2:1044–1052. [Google Scholar]

- 65.Sobukola OP, Adeniran OM, Odedairo AA, Kajihausa OE. Heavy metal levels of some fruits and leafy vegetables from selected markets in Lagos, Nigeria. Afr J Food Sci. 2010;4:389–393. [Google Scholar]

- 66.Denton RM, An J, Adeniran B. Phosphine oxide-catalysed chlorination reactions of alcohols under Appel conditions. Chem Commun. 2010;46:3025–3027. doi: 10.1039/c002825h. [DOI] [PubMed] [Google Scholar]

- 67.Omojasola PF, Jilani OP. Cellulase production by Trichoderma longi, Aspergillus niger and Saccharomyces cerevisae cultured on plantain peel. Res J Microbiol. 2009;4:67–74. doi: 10.3923/jm.2009.67.74. [DOI] [PubMed] [Google Scholar]

- 68.Mohamed SA, Al-Malki AL, Khan JA, Kabli SA, Al-Garni SM. Solid state production of polygalacturonase and xylanase by Trichoderma species using cantaloupe and watermelon rinds. J Microbiol. 2013;51:605–611. doi: 10.1007/s12275-013-3016-x. [DOI] [PubMed] [Google Scholar]

- 69.Jadhav U, Salve S, Dhawale R, Padul M, Dawkar V, Chougale A, Waghmode T, Salve A, Patil M. Use of partially purified banana peel polyphenol oxidase in the degradation of various phenolic compounds and textile dye blue 2RNL. Text Light Ind Sci Technol. 2013;2:27–35. [Google Scholar]

- 70.Elisashvili V, Penninckx M, Kachlishvili E, Tsiklauri N, Metreveli E, Kharziani T, Kvesitadze G. Lentinus edodes and Pleurotus species lignocellulolytic enzymes activity in submerged and solid-state fermentation of lignocellulosic wastes of different composition. Biores Technol. 2008;99:457–462. doi: 10.1016/j.biortech.2007.01.011. [DOI] [PubMed] [Google Scholar]

- 71.Yaradoddi J, Patil V, Ganachari S, Banapurmath N, Hunashyal A, Shettar A, Yaradoddi JS. Biodegradable plastic production from fruit waste material and its sustainable use for green applications. Int J Pharm Res Allied Sci. 2016;5:72–81. [Google Scholar]

- 72.Vivekanand V, Dwivedi P, Pareek N, Singh RP. Banana peel: a potential substrate for laccase production by Aspergillus fumigatus VkJ2. 4.5 in solid-state fermentation. Appl Biochem Biotechnol. 2011;165:204–220. doi: 10.1007/s12010-011-9244-9. [DOI] [PubMed] [Google Scholar]

- 73.Bankar A, Joshi B, Kumar AR, Zinjarde S. Banana peel extract mediated novel route for the synthesis of silver nanoparticles. Colloids Surf A. 2010;368:58–63. doi: 10.1016/j.colsurfa.2010.07.024. [DOI] [PubMed] [Google Scholar]

- 74.Newase S, Bankar AV. Synthesis of bio-inspired Ag–Au nanocomposite and its anti-biofilm efficacy. Bull Mater Sci. 2017;40:157–162. doi: 10.1007/s12034-017-1363-7. [DOI] [Google Scholar]

- 75.Tibolla H, Pelissari FM, Menegalli FC. Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT Food Sci Technol. 2014;59:1311–1318. doi: 10.1016/j.lwt.2014.04.011. [DOI] [Google Scholar]

- 76.Mopoung S. Occurrence of carbon nanotube from banana peel activated carbon mixed with mineral oil. Int J Phys Sci. 2011;6:1789. [Google Scholar]

- 77.Akter M, Rahman FB, Abedin MZ, Kabir SF. Adsorption characteristics of banana peel in the removal of dyes from textile effluent. Textiles. 2021;1:361–375. doi: 10.3390/textiles1020018. [DOI] [Google Scholar]

- 78.Munagapati VS, Wen JC, Pan CL, Gutha Y, Wen JH, Reddy GM. Adsorptive removal of anionic dye (Reactive Black 5) from aqueous solution using chemically modified banana peel powder: kinetic, isotherm, thermodynamic, and reusability studies. Int J Phytoremediat. 2020;22:267–278. doi: 10.1080/15226514.2019.1658709. [DOI] [PubMed] [Google Scholar]

- 79.Albarelli JQ, Rabelo RB, Santos DT, Beppu MM, Meireles MA. Effects of supercritical carbon dioxide on waste banana peels for heavy metal removal. J Supercrit Fluids. 2011;58:343–351. doi: 10.1016/j.supflu.2011.07.014. [DOI] [Google Scholar]

- 80.Ahmed E, Zeitoun A, Hamad G, Zeitoun MA, Taha A, Korma SA, Esatbeyoglu T. Lignocellulosic biomasses from agricultural wastes improved the quality and physicochemical properties of frying oils. Foods. 2022;11:3149. doi: 10.3390/foods11193149. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 81.Datta A, Truong D, Minhas P, Parra LC, Bikson M. Inter-individual variation during transcranial direct current stimulation and normalization of dose using MRI-derived computational models. Front Psychiatry. 2012;3:91. doi: 10.3389/fpsyt.2012.00091. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 82.Moerz ST, Huber P. pH-dependent selective protein adsorption into mesoporous silica. J Phys Chem C. 2015;119:27072–27079. doi: 10.1021/acs.jpcc.5b09606. [DOI] [Google Scholar]

- 83.Ali M, Qamhiyah A, Flugrad D, Shakoor M. Theoretical and finite element study of a compact energy absorber. Adv Eng Softw. 2008;39:95–106. doi: 10.1016/j.advengsoft.2006.12.006. [DOI] [Google Scholar]

- 84.Rebello LP, Ramos AM, Pertuzatti PB, Barcia MT, Castillo-Muñoz N, Hermosin-Gutierrez I. Flour of banana (Musa AAA) peel as a source of antioxidant phenolic compounds. Food Res Int. 2014;55:397–403. doi: 10.1016/j.foodres.2013.11.039. [DOI] [Google Scholar]

- 85.Lotfabad EM, Ding J, Cui K, Kohandehghan A, Kalisvaart WP, Hazelton M, Mitlin D. High-density sodium and lithium ion battery anodes from banana peels. ACS Nano. 2014;8:7115–7129. doi: 10.1021/nn502045y. [DOI] [PubMed] [Google Scholar]

- 86.Arie AA, Lee JK. Fullerene C60 coated silicon nanowires as anode materials for lithium secondary batteries. J Nanosci Nanotechnol. 2012;12:3547–3551. doi: 10.1166/jnn.2012.5557. [DOI] [PubMed] [Google Scholar]

- 87.Lv H, Geletii YV, Zhao C, Vickers JW, Zhu G, Luo Z, Song J, Lian T, Musaev DG, Hill CL. Polyoxometalate water oxidation catalysts and the production of green fuel. Chem Soc Rev. 2012;41:7572–7589. doi: 10.1039/c2cs35292c. [DOI] [PubMed] [Google Scholar]

- 88.Semenchuk PR, Gillespie MA, Rumpf SB, Baggesen N, Elberling B, Cooper EJ. High Arctic plant phenology is determined by snowmelt patterns but duration of phenological periods is fixed: an example of periodicity. Environ Res Lett. 2016;11:125006. doi: 10.1088/1748-9326/11/12/125006. [DOI] [Google Scholar]

- 89.Ozcan HM, Sagiroglu A. A novel amperometric biosensor based on banana peel (Musa cavendish) tissue homogenate for determination of phenolic compounds. Artif Cells Blood Substit Biotechnol. 2010;38:208–214. doi: 10.3109/10731191003776744. [DOI] [PubMed] [Google Scholar]

- 90.Ganiron TU., Jr Sustainable management of waste coconut shells as aggregates in concrete mixture. J Eng Sci Technol Rev. 2013;6:7–14. doi: 10.25103/jestr.065.02. [DOI] [Google Scholar]

- 91.Idris J, Shirai Y, Anduo Y, Ali AA, Othman MR, Ibrahim I, Husen R, Hassan MA. Improved yield and higher heating value of biochar from oil palm biomass at low retention time under self-sustained carbonization. J Clean Prod. 2015;104:475–479. doi: 10.1016/j.jclepro.2015.05.023. [DOI] [Google Scholar]

- 92.Astuti P, Erprihana AA. Antimicrobial edible film from banana peels as food packaging. Am J Oil Chem Technol. 2014;2:65–70. [Google Scholar]

- 93.Babayemi JO, Dauda KT, Kayode AA, Nwude DO, Ajiboye JA, Essien ER, Abiona OO. Determination of potash alkali and metal contents of ashes obtained from peels of some varieties of Nigeria grown Musa species. BioResources. 2010;5:1384–1392. doi: 10.15376/biores.5.3.1384-1392. [DOI] [Google Scholar]

- 94.Salah SM. Antibacterial activity and ultraviolet (UV) protection property of some Egyptian cotton fabrics treated with aqueous extract from banana peel. Afr J Agric Res. 2013;8:3994–4000. [Google Scholar]

- 95.Aarumugam P, Bhavan PS, Muralisankar T, Manickam N, Srinevasan V, Radhakrishnan S (2013) Research article Growth of Macrobrachium rosenbergii fed with mango seed kernel, banana peel and papaya peel incorporated feeds

- 96.Pereira PH, Carvalho Benini KC, Watashi CY, Voorwald HJ, Cioffi MO. Characterization of high-density polyethylene (HDPE) reinforced with banana peel fibers. BioResources. 2013;8:2351–2365. doi: 10.15376/biores.8.2.2351-2365. [DOI] [Google Scholar]

- 97.Mopoung S, Singse W, Sirikulkajorn A. Preparation of metal-carbon composites from banana peel charcoal and metal salts for hydrogen storage by pyrolysis method. J Indian Chem Soc. 2014;91:1071–1078. [Google Scholar]

- 98.Hai-Lian Y, Zhen H. Study of extraction technology of pectin from banana peel by ultrasonic wave. Sci Technol Food Ind. 2009;7:218–223. [Google Scholar]

- 99.Siqueira G, Milagres AM, Carvalho W, Koch G, Ferraz A. Topochemical distribution of lignin and hydroxycinnamic acids in sugar-cane cell walls and its correlation with the enzymatic hydrolysis of polysaccharides. Biotechnol Biofuels. 2011;4:1–9. doi: 10.1186/1754-6834-4-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 100.Karthikeyan A, Sivakumar N. Citric acid production by Koji fermentation using banana peel as a novel substrate. Biores Technol. 2010;101:5552–5556. doi: 10.1016/j.biortech.2010.02.063. [DOI] [PubMed] [Google Scholar]

- 101.Oberoi S, Knueppel S. Three-dimensional assessment of impacted canines and root resorption using cone beam computed tomography. Oral Surg Oral Med Oral Pathol Oral Radiol. 2012;113:260–267. doi: 10.1016/j.tripleo.2011.03.035. [DOI] [PubMed] [Google Scholar]

- 102.Amer BM, Hossain MA, Gottschalk K. Design and performance evaluation of a new hybrid solar dryer for banana. Energy Convers Manag. 2010;51:813–820. doi: 10.1016/j.enconman.2009.11.016. [DOI] [Google Scholar]

- 103.Sarkar D, Prajapati S, Poddar K, Sarkar A. Ethanol production by Klebsiella sp. SWET4 using banana peel as feasible substrate. Biomass Convers Biorefinery. 2020 doi: 10.1007/s13399-020-00880-1. [DOI] [Google Scholar]

- 104.Ayala-Ruíz N, Malagón-Romero DH, Milquez-Sanabria HA. Exergoeconomic evaluation of a banana waste pyrolysis plant for biofuel production. J Clean Prod. 2022;359:132108. doi: 10.1016/j.jclepro.2022.132108. [DOI] [Google Scholar]

- 105.Guerrero AB, Aguado PL, Sánchez J, Curt MD. GIS-based assessment of banana residual biomass potential for ethanol production and power generation: a case study. Waste Biomass Valoriz. 2016;7:405–415. doi: 10.1007/s12649-015-9455-3. [DOI] [Google Scholar]

- 106.Cheng NG, Hasan M, Kumoro AC, Ling CF, Tham M. Production of ethanol by fed-batch fermentation. Pertan J Sci Technol. 2009;17:399–408. [Google Scholar]

- 107.Ntaikou I, Nikolaos M, Alexandropoulou M, Antonopoulou G. Valorization of kitchen biowaste for ethanol production via simultaneous saccharification and fermentation using co-cultures of the yeasts Saccharomyces cerevisiae and Pichia stipites. Bioresour Technol. 2018;263:75–83. doi: 10.1016/j.biortech.2018.04.109. [DOI] [PubMed] [Google Scholar]

- 108.Jahangir MA, Shamoli A, Shohana A, Tarikul MI, Sayeem EM. Development of fiber and mineral enriched cookies by utilization of banana and banana peel flour. J Microbiol Biotechnol Food Sci. 2021;10:329–334. [Google Scholar]

- 109.Hamid HA, Masripan NAB, Abdallah MFB, Hasan R. Characterization of raw and ripen of banana peel was less and its oils extraction using soxhlet method. Int J Appl Chem. 2016;12:1–5. [Google Scholar]

- 110.Kabenge I, Omulo G, Banada N, Seay J, Ahamada Z, Kiggundu N. Characterization of banana peels wastes as potential slow pyrolysis feedstock. J Sustain Dev. 2018;11:14–24. doi: 10.5539/jsd.v11n2p14. [DOI] [Google Scholar]

- 111.Mitan NMM, Saadon MFR. Temperature effect on densification of banana peels briquette. Mater Today Proc. 2019;19:1403–1407. doi: 10.1016/j.matpr.2019.11.159. [DOI] [Google Scholar]

- 112.Pyar H, Peh KK. Chemical compositions of banana peels (Musa sapientum) fruits cultivated in Malaysia using proximate analysis. Res J Chem Environ. 2018;22:108–111. [Google Scholar]

- 113.Anhwange BA, Ugye TJ, Nyiaatagher TD. Chemical composition of Musa sapientum (banana) peels. Electron J Environ Agri Food Chem. 2009;6:437–442. [Google Scholar]

- 114.Debabandya M, Mishra S, Sutar N. Banana and its by-product utilisation: an overview. J Sci Ind Res. 2010;69:323–329. [Google Scholar]

- 115.Phirom-on K, Apiraksakorn J. Eco-friendly extraction of banana peel cellulose using a wood charcoal ash solution and application of process wastewater as a naturally-derived product. Bioresour Technol Rep. 2022;19:101–174. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.