Abstract

Polydimethylsiloxane (PDMS)—the simplest and most common silicone compound—exemplifies the central characteristics of its class and has attracted tremendous research attention. The development of PDMS‐based materials is a vivid reflection of the modern industry. In recent years, PDMS has stood out as the material of choice for various emerging technologies. The rapid improvement in bulk modification strategies and multifunctional surfaces has enabled a whole new generation of PDMS‐based materials and devices, facilitating, and even transforming enormous applications, including flexible electronics, superwetting surfaces, soft actuators, wearable and implantable sensors, biomedicals, and autonomous robotics. This paper reviews the latest advances in the field of PDMS‐based functional materials, with a focus on the added functionality and their use as programmable materials for smart devices. Recent breakthroughs regarding instant crosslinking and additive manufacturing are featured, and exciting opportunities for future research are highlighted. This review provides a quick entrance to this rapidly evolving field and will help guide the rational design of next‐generation soft materials and devices.

Keywords: additive manufacturing, flexible electronics, polydimethylsiloxane (PDMS), programmable materials, sensors, silicone, soft actuators

Polydimethylsiloxane (PDMS), transforms from the central component in children's toy—silly putty, to the material of choice for many emerging technologies such as flexible electronics, soft actuators, and more, thanks to the advancement in composite science, multifunctional surfaces, and additive manufacturing. This article reviews latest progress in PDMS‐based elastomers and the integrated functionalities, highlighting the opportunities as well as challenges.

1. Introduction

Silicone, also known as polysiloxane, is a synthetic polymer with backbone chains of alternating Si and O atoms. Silicone is a chemically inert, thermally stable substance with excellent water and oxidation resistance. It is used in a wide range of products, such as everyday chemicals, sealants, and biomedical implants. The simplest and most common silicone compound, polydimethylsiloxane (PDMS), represents the central characteristics of this class of materials and has been extensively researched. Based on the degree of interlinking, PDMS exists as a colorless, viscous fluid (i.e., lubricants) or as an elastomer film. The advancement of PDMS‐based materials has experienced several stages, as shown in Figure 1a, and the advancements vividly reflect modern industries' development. The term “silicone” was initially coined by British chemist Frederic S. Kipping in 1901[ 1 ] because he thought the Si and O atoms were connected with a double bond similar to a ketone. (In fact, the 3p electrons of Si do not overlap effectively with the 2p electrons of C or O, so the Si═O or Si═C multiple bonds are not commonly found in stable molecules.) In the 1940s, PDMS was successfully synthesized for the first time owing to the pioneering efforts of the General Electric Company and the Dow Corning Corporation. However, until the 1960s, PDMS was not widely available in industrial products and people's daily lives (such as in silly putty). In the 1990s, PDMS applications expanded to newer technologies such as soft lithography[ 2 , 3 , 4 ] and microfluidics.[ 5 ] In the 21st century, especially in the past decade, PDMS has been considered the material of choice for many emerging technologies, including flexible electronics, biomedical devices, actuators, and structured surfaces.[ 6 , 7 , 8 , 9 , 10 , 11 , 12 ]

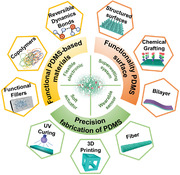

Figure 1.

Evolution of PDMS‐based elastomer. a) Frederic S. Kipping, the founder of organosilicon chemistry, introduced the term “silicone” in 1901. He successfully synthesized hydrolyzable silanes with various functionalities using the Grignard reaction. Image 1901: Reproduced with permission.[ 365 ] Copyright 2010, Springer. PDMS was first successfully synthesized in the 1940s owing to the seminal efforts of General Electric and Dow Corning, and by the 1960s, it was widely available in industrial products and consumer goods. In the 1990s, PDMS became the material of choice for new technologies such as soft lithography and microfluidics. Images 1940, 1960 and 1990: Reproduced with permission.[ 262 ] Copyright 2017, American Chemical Society. By the 21st century, especially during the past decade, interest in PDMS has soared and this compound has been further modified for use in emerging technologies, including flexible electronics, bioengineering, actuators, and structured surfaces. Image 2010: Reproduced with permission. Photo courtesy of 51yuansu.com. b) Research trends in the field of PDMS are illustrated by the number of publications per year (Data from the Web of Science).

PDMS is well‐known for its extraordinary optical transparency, biocompatibility, processability, and thermal and chemical stability. However, along with the rapid development of science and technology in modern society, conventional silicones' mechanical and physicochemical properties cannot fully meet the needs for diverse implementation scenarios of advanced technological applications. A new generation of silicone elastomers with various functionalities and actuating/sensing capabilities is required. Therefore, significant advancements in functional silicones have been made in the past several years. The modification of PDMS generally includes the innovative design of novel side chains or crosslinkers, the incorporation of functional fillers (with electrical, optical, thermal, magnetic, or mechanical properties), and the fabrication of advanced micro‐ and nanostructures. Through these improvements, the elastomer composites' mechanical, optical, electrical, thermal, chemical, and surface properties can be systematically manipulated and tailored across a wide range and precisely controlled for specific needs or novel applications.

As shown in Figure 1b, the research interest in PDMS‐related materials and systems has exploded in the past few years, coinciding with the rapid development of soft functional materials and flexible electronics. Therefore, a critical review of this rapidly evolving field is urgently needed, especially on the added functionalities, use as smart materials in multidisciplinary fields, and cutting‐edge additive manufacturing paradigms. We notice that there exist a handful of reviews on PDMS‐related materials, either focused on a specific application (e.g., dielectric transducer,[ 13 ] protective coating,[ 14 ] microfluidic devices,[ 15 ] substrates for stretchable electronics[ 16 ]), or regarding the earlier‐stage development in this field.[ 17 , 18 ] In this review, we aim to condense many concepts from various communities that use PDMS into one place, and provide critical insights on the latest (e.g., in the past three years) advances in this field. Additive manufacturing represents a revolutionary strategy for the three‐dimensional (3D) production of materials with digital design and high energy efficiency and is gaining increasing momentum[ 19 ] and 3D printing of PDMS, despite a number of inherent challenges associated with the material, already has been demonstrated to be feasible. In this comprehensive review, we aim to elucidate the versatile aspects of the PDMS‐based elastomer as a material uniquely positioned for a plethora of fields. In Section 2, we present an introduction to the fundamental properties that underpin PDMS's growing prominence in the realm of multifaceted applications. In Section 3, we delve into the development of PDMS‐based functional materials. On one hand, the composites and the modification and compounding protocols will be discussed, categorized by the integrated functionalities (such as electrical, optical, thermal, magnetic, mechanical, and chemical properties). On the other hand, we will explore the functionality of the PDMS surface, with an emphasis on the superwetting features and bimorph actuators that have garnered significant attention in recent years. In Section 4, we highlight the state‐of‐the‐art breakthroughs in expediting crosslinking and additive manufacturing processes of PDMS‐based materials, which hold immense potential in a variety of applications. Lastly, we provide a concise summary of our findings, pinpointing the most promising research directions and uncharted territories ripe for future investigation. We hope that this timely, in‐depth review serves both as a fundamental starting point and a handbook for researchers interested in understanding this rapidly evolving field.

2. Fundamental Properties of PDMS

2.1. Cross‐Linking Chemistry

PDMS can be prepared based on various chemistries, such as hydrosilylation addition, condensation reaction, and ultraviolet (UV) curing.[ 20 , 21 ] Among these methods, thermal crosslinking through hydrosilylation addition between vinyl terminals (CH2═CH–) and silicon hydride (Si–H) is most widely employed (such as in Dow Corning Sylgard 184 series) and remains an optimal option for many applications owing to its simple, non‐toxic, and byproduct‐free curing process, which allows for facile preparation with high molding accuracy.[ 22 ] The vinyl functional (Sylgard 184‐like) PDMS usually consists of two parts (Figure 2 ), and the polymerization is based on a platinum‐catalyzed process between a dimethylsiloxane oligomer with vinyl terminal groups and a curing agent (dimethyl methylhydrogen siloxane) containing Si–H bond. Crosslinking can be accelerated at elevated temperatures. It should be noted that multiple categories of species can inhibit hydrosilylation crosslinking.[ 22 ] Lone pairs of specific nitrogen or sulfur compounds tend to complex with and defunctionalize the Pt catalyst,[ 23 , 24 ] and the Si–H bond can be added onto multiple unsaturated bonds if organic molecules containing alkenes, alkynes, imines, or carbonyls are present.[ 25 , 26 ]

Figure 2.

Scheme showing the most widely employed crosslinking mechanism of PDMS. The polymerization is based on a platinum‐catalyzed process between a dimethylsiloxane oligomer with vinyl terminal groups and a curing agent (dimethyl methylhydrogen siloxane) containing a Si–H bond. The crosslinking can be accelerated by heat.

2.2. Physical and Chemical Properties

The general physical properties of PDMS are listed in Table 1 . PDMS is naturally hydrophobic with a water contact angle (WCA) of ≈110° due to its intrinsically low surface energy (21.3 mJ m−2).[ 27 ] PDMS prefers to form conformal contact, making it extraordinarily biocompatible and highly favorable for biomedical applications. The mechanical properties of PDMS are affected by the degree of cross‐linking, and the commercial Sylgard 184 PDMS usually possesses Young's modulus of 1–3 MPa, the tensile strength of 3.5–7.7 MPa,[ 28 ] and an elongation at break up to 210%. PDMS is also equipped with unique thermal properties, including one of the lowest glass transition temperatures (Tg ≈ −123 °C), one of the highest thermal expansion coefficients (CTE) among polymers, good heat resistance (thermally stable at temperatures below 400 °C) and low thermal conductivity (∼0.2 W m−1 K−1) owing to the flexibility of the siloxane backbone and high Si‐O bond dissociation energy of 460 kJ mol−1.[ 29 , 30 , 31 ] In addition, PDMS is an electrical insulator with a low electrical conductivity of ≈10−14 S m−1 and a high breakdown voltage of 2 × 107 V m−1.[ 17 ] Furthermore, PDMS is optically transparent between 240 and 1100 nm and is permeable to certain gases.

Table 1.

Comprehensive collection of the physical properties of Sylgard 184‐like PDMS.

| Physical property | Value | Reported year |

|---|---|---|

| Electrical conductivity | 10−14 S m−1 | 2016[ 50 ] |

| Breakdown voltage | 2 × 107 V m−1 | 2018[ 17 ] |

| Thermal conductivity | 0.2 W m−1 K−1 | 2021[ 30 ] |

| Coefficient of thermal expansion | ≈9 × 10−14 K−1 (Volumetric) | 2021[ 293 ] |

| Glass transition temperature | −123 °C | 2020[ 29 ] |

| Refractive index | ≈1.4 at 589–1554 nm | 2018[ 17 ] |

| Young's modulus | 1–3 MPa | 2014[ 28 , 343 ] |

| Compressive modulus | 118–187 MPa | 2014[ 28 , 343 ] |

| Elongation at break | 210% | 2017[ 344 ] |

| Stiffness | ≈0.4 kJ m−12 | 2021[ 103 ] |

| Tensile strength | 3.5–7.7 MPa | 2014[ 28 , 343 ] |

| Compressive strength | 28.4–51.7 GPa | 2014[ 28 , 343 ] |

| Surface energy | 21.3 mJ m−12 | 2020[ 27 ] |

| Density | 0.971 g cm−13 | 2007[ 29 ] |

| Diffusion coefficient (Oxygen) | ∼2000–4000 µm2 s−1 | 2012[ 345 ] |

| Diffusion coefficient (CO2) | ∼1000 µm2 s−11 | 2015[ 346 ] |

| Diffusion coefficient (Water) | ∼1000–6000 µm2 s−11 | 2007[ 347 ] |

| WCA | ≈110° | 2016[ 348 ] |

The molding ability and tendency to seal other flat surfaces without adhesives make PDMS indispensable for molding applications, soft lithography, soft robotics, microfluidics, and flexible substrates. Another appealing feature of PDMS is its high chemical stability and non‐toxicity. It is inert to acidic solutions (e.g., hydrofluoric acid, hydrogen peroxide, and Piranha) and certain organic solvents (e.g., hexane and methanol). When other moieties replace part of the methyl groups in PDMS, the performance of the polymer will alter to a certain extent. The difference is related to the type, nature, and substitution degree of the substituents. This establishes the foundation for polysiloxane products' variety and versatility, which is uncommon in other polymeric systems. The exceptional features discussed in this section render PDMS a key component for various applications, which will be systematically introduced in the following sections.

3. Latest Advances in Functional PDMS‐Based Materials

3.1. Bulk PDMS Composites with Specifically Designed Functionality

Although pure PDMS possesses distinct attributes, its utility as an elastomer in various fields remains limited. For instance, its subpar mechanical properties impede applications in electronic or robotic stretchable devices. Additionally, unmodified PDMS exhibits insensitivity to electrical, optical, and magnetic stimuli. The incorporation of fillers serves as an efficacious method to ontologically modify PDMS, given its straightforward preparation (merely via physical mixing) and considerable enhancement efficiency. Indeed, this strategy has been implemented for numerous elastomer systems, including natural rubber where carbon black is the preferred filler.

Zero‐dimensional (0D) fillers similar to carbon black encompass micro/nanoscale particles such as SiO2,[ 32 ] CaCO3,[ 32 ] and ZnO,[ 33 ] which have a high specific surface area, ensuring ample interfacial contact for robust interactions and augmented reinforcement efficiency. Moreover, one‐dimensional (1D) fillers like carbon nanotubes (CNTs) and metal wires, two‐dimensional (2D) platelets such as BN nanosheets[ 34 ] and 3D structures (e.g., graphene foam[ 35 ]) can be utilized to bolster the properties of PDMS or imbue it with novel functionalities. In the following subsections, the development of the filler material, compositing method, and the added functionality will be extensively reviewed, and the explored application will be introduced as well.

3.1.1. Magnetism

PDMS itself is nonmagnetic. However, by adding magnetic components, the composites can be equipped with magneto‐active properties for new‐generation magnetic actuators.[ 36 ] A recently explored architecture is a cilia‐inspired pillar array,[ 37 , 38 , 39 ] which can swing back and forth in response to an external magnetic field. The hair‐like micro‐actuator array was fabricated by filling pre‐designed templates or molds with a composite paste made of PDMS prepolymer and magnetic particles, as illustrated in Figure 3a. The tilting angle and speed of the pillars can be manipulated by the direction and amplitude of the applied external magnetic field. Ben et al. prepared cilia‐like elastomer arrays with cobalt magnetic particles as the key ingredient (Figure 3b),[ 37 ] and they demonstrated that under alternating magnetic field modulation, nonmagnetic polystyrene (PS) microspheres could be guided to transport directionally and continuously following the motion of the flexible arrays. Compared to the columnar shape, the conically shaped array led to a higher transport efficiency. In addition, the spatial distribution of the magnetic particles within the cilia (e.g., linearly aligned or locally concentrated at the tips) can be controlled by applying a magnetic field or changing the thermal crosslinking temperature in the curing process.[ 37 , 38 ] Furthermore, various motions of the pillar array can be generated by manipulating the magnetic actuation mode. For example, Zhang et al. used the magnetic pillar array to induce a variety of flow types in a microfluidic channel, such as circulatory, direction‐reversible, oscillating, and pulsatile flows.[ 38 ]

Figure 3.

Equipping PDMS with magnetic properties. a) Fabricating flexible magnetic cilia array. Reproduced with permission.[ 37 ] Copyright 2018, Wiley‐VCH. b) Oscillation mechanism of the magnetic micro cilia array under an external magnetic field.[ 37 ] c) Capability of spatial resolved manipulation has been demonstrated. Locally irradiated micropillars can be partially demagnetized and are able to recover their initial vertical position.[ 40 ] d) Heat‐assisted magnetic programming for deformable soft machines. Magnetic particles embedded in PDMS are locally demagnetized upon laser irradiation and then reorient under an external magnetic field. Reproduced with permission.[ 41 ] Copyright 2020, American Association for the Advancement of Science.

It is even possible to achieve site‐selective modulation in the micro‐actuator array matrix. Figure 3c shows micropillars of magnetic CrO2 particles mixed with PDMS were prepared with a height–diameter aspect ratio of 8.2 and the susceptibility to force‐induced deformation.[ 40 ] The light was used as a local stimulus (by a photothermal effect), which added another degree of freedom due to the low Curie temperature of CrO2 (395 K) and the high optical absorption of the black composite in the visible range (> 97%). Localized light‐induced demagnetization was successfully realized, demonstrating an excellent case of remote and precise local actuation in a PDMS‐based microstructural matrix.

Heat‐assisted magnetic programming can be utilized to build advanced and complex shape‐morphing magnetic soft machines. Alapan et al. reported a high‐throughput magnetic programming strategy (Figure 3d) based on heating magnetic soft materials above the Curie temperature and reorienting their magnetic domains via applied magnetic fields during cooling.[ 41 ] Through laser‐assisted thermal magnetization, shape‐changing instructions in 3D can be encoded discretely and reprogrammed on‐demand with high resolution (≈38 µm). Taking advantage of magnetic re‐programmability, reconfigurable mechanical behavior of an auxetic metamaterial structure, tunable locomotion patterns of a quadrupedal soft robot, and adaptive grasping behavior of a soft gripper was achieved, respectively.

Besides mechanical actuators, magnetic elastomers can play a vital role in other types of smart devices. The addition of conductive components (such as CNTs and liquid metals (LMs)) facilitates the broad application of magnetic elastomers in flexible and wearable electronics like magneto‐resistive strain sensors[ 42 , 43 ] and flexible electromagnetic‐triboelectric nanogenerators (TENGs).[ 44 , 45 ] With the help of sugar templates, magnetic PDMS sponges can be prepared for on‐demand drug delivery and localized medical treatment.[ 46 ]

3.1.2. Electrical Conductivity

PDMS is intrinsically electrical insulating with an electrical conductivity of ≈10−14 S m−1. Adding conductive fillers such as metals, LMs, and carbon‐based materials can endow PDMS composites with widely tunable conductivities, as summarized in Table 2 and featured in Figure 4a. Elastic conductors are particularly intriguing and promising for high‐performance flexible electronics with remarkable stretchability, adhesiveness, and tunable sensitivity.

Table 2.

Conductivity of PDMS composites with various fillers.

| Electrically conductive filler | Concentration (wt% or vol%) | Mixing method | Conductivity (S m−11) | Reported year | Note |

|---|---|---|---|---|---|

| Ni microwires | 1.2 vol% | physical blending | 8 × 10−11 | 2021[ 51 ] | Solidification under a magnetic field to promote alignment |

| Silver NWs | 25 wt% | xylene assisted mixing | 5.8 × 105 | 2021[ 50 , 349 ] | NW length: 50 nm |

| Dendrite‐structured Ag powders | 70 wt% | physical blending | 2.7 × 104 | 2018[ 52 ] | |

| Silver flakes | 21 vol% | physical blending | 1.2 × 105 | 2019[ 49 ] | Flake size: 2–5 µm |

| Silver flakes/Ag‐coated PDMS beads | 10 vol% | physical blending | 1.2 × 105 | 2019[ 49 ] | |

| Eutectic gallium‐indium alloy | 50 wt% | stepwise printing | 1.98 × 106 | 2021[ 54 ] | |

| Graphene nanosheets | 15 vol% | chloroform assisted mixing | 1.0 × 10−11 | 2016[ 55 ] | Low molecular‐weight PDMS crosslinked by boric acid |

| Polypyrrole NWs on graphene | dip coating | 5.2 × 102 | 2021[ 71 ] | ||

| PU‐Cu/Ag network | dip coating | 1.5 × 103 | 2013[ 63 ] | ||

| Graphene honeycomb | dip coating | 7.2 × 10 | 2018[ 65 ] | ||

| Graphene aerogel | dip coating | 1.9 × 10 | 2020[ 66 ] | Concentration of graphene:12.5 mg/ml | |

| Graphene foam | 0.7 wt% | dip coating | 9.1 × 10−11 | 2020[ 35 ] | |

| Graphene foam | 0.5 wt% | dip coating | 10 | 2011[ 64 ] | |

| Multi‐walled CNTs & Silicon dioxide micro‐particles | chloroform assisted mixing | 6.1 × 10−14 | 2019[ 60 ] | Diameter of silicon dioxide micro‐particles: 85 µm | |

| CNT (diameter 15 nm) | 5 wt% | toluene assisted mixing | 1.0 × 10−11 | 2012[ 350 ] | |

| Cellulose aerogels | 2.24 wt% | dip coating | 47 | 2021[ 30 ] | |

| Graphene oxide‐coated cellulose aerogels | 3.05 wt% | dip coating | 75 | 2021[ 30 ] |

Figure 4.

PDMS composites with various electrical conductivity. a) PDMS composites can be endowed with a wide range of conductivities by varying filler materials. b) Squeezing the PDMS beads encapsulated by silver establishes conductive paths between silver flakes. Reproduced with permission.[ 49 ] Copyright 2019, American Chemical Society. c) Force‐induced bending of the microcilia array electrodes prepared from a mixture of PDMS and silver particles increases the contact area with the skin, which fills the void between the electrodes and the skin, leading to an exponential decay of resistivity. Reproduced with permission.[ 52 ] Copyright 2018, Wiley‐VCH. d) EGaIn forms a continuous conductive network in the PDMS frame, and the conductivity remains stable at 0–100% strain owing to the protection of the frame. Reproduced with permission.[ 54 ] Copyright 2021, Wiley‐VCH. e) Photograph of hand‐rolled spheres of putty and G‐putty. With the increase of graphene content, the conductivity of G‐putty can be increased to 0.1 S m−1. Reproduced with permission.[ 55 ] Copyright 2016, American Association for the Advancement of Science. f) The graphene aerogel conductive backbone substantially improves the conductivity of PDMS composites, while the high porosity and the enhancement of free electrons confer electromagnetic shielding properties to the composites. Reproduced with permission.[ 63 ] Copyright 2020, Royal Society of Chemistry.

Silver is a highly conductive metal with an intrinsic conductivity of 6.3 × 107 S m−1.[ 47 ] Including 25 vol% Ag powder with an average size of 3 µm in PDMS results in a conductivity of 6.0 × 104 S m−1.[ 48 ] Both the distribution condition of the filler units and the interfacial connection are critical to electrical performance. For PDMS composites containing silver flakes ranging from 2 to 5 µm, the additional incorporation of silver‐coated PDMS beads (PDMS@Ag, ≈20 µm in diameter) was found to lock the position of the silver flakes in the gaps between microspheres and the dense conductive networks (Figure 4b) and improve the conductivity (surpassing 103 S m−1) by 139 times.[ 49 ]

Metal nanowires (NMs) or nanorods with high aspect ratios can entangle to form conductive networks. Karimi et al.[ 50 ] simply mixed ≈50 nm long silver NW with PDMS prepolymer in xylene, and after solvent removal and thermal crosslinking, they successfully fabricated a conductive film (5.8 × 105 S m−1 with 25 wt% silver). Promoting the directional arrangement of linear fillers can further improve anisotropic electrical conductivity. Magnetic field‐assisted al/.=o][l..ignment of nickel microwires with a length‐to‐diameter ratio of 150:1 was realized in a PDMS film during the crosslinking process, increasing the conductivity to 0.8 S m−1 with only 1.2 vol% of Ni[ 51 ]; this material can be applied toward the development of highly sensitive flexible piezoresistive pressure sensors.

Conductive electrodes with 3D microstructures were also explored for advanced electromechanical applications. Jin et al.[ 52 ] cured PDMS prepolymers doped with dendritic silver particles in a polymethyl methacrylate (PMMA) mold to prepare microcilia array electrodes with a conductivity of 2.7 × 104 S m−1. As illustrated in Figure 4c, under external pressure, the cilia bent to increase the contact surface area between the electrode and the skin, resulting in an exponential decay of the resistivity. This structure allows the accurate measurement of the bioelectrical signals on rough skin without compromising the electrode's performance.

LMs, such as gallium‐based eutectic alloys, possess not only high conductivity but also excellent processability and good fluidity, and are perfect fillers for stretchable conductors. However, LMs also experience high surface tension with a thin oxide skin (≈1–3 nm in thickness) spontaneously formed upon exposure to air,[ 53 ] resulting in the parasite separate blocks in the elastomer matrix, which hinders a continuous conductive path. Wang et al. invented a stepwise 3D printing approach to fill the open cells of the PDMS framework with a gallium‐indium alloy (EGaIn) to impart a 3D continuous conductive network with conductivity as high as 1.98 × 106 S m−1 (with 50 wt% of EGaIn).[ 54 ] One invaluable finding is that this composite was electrically invariant, showing only 2% resistance change across a wide strain range from 0 to 100% (Figure 4d). Surprisingly, the EGaIn content had a negligible impact on the mechanical properties of the composites, avoiding the conventionally observed impairment caused by severe filler agglomeration.

Carbon nanomaterials, such as CNTs and graphene, have been intensively investigated as nanofillers in PDMS for different purposes. With the latest advances in these carbon nanomaterials, this field has enormous possibilities. Advanced methods for fabricating PDMS composites have been developed to produce various functional elastic conductors. Boland et al. mixed graphene nanosheets with viscoelastic polymer putty (low molecular‐weight PDMS lightly crosslinked by boric acid) in chloroform to obtain a high‐performance electromechanical material, G‐putty (Figure 4e),[ 55 ] which exhibited unusual and exceptional electromechanical behaviors, such as post‐deformation temporal relaxation of electrical resistance and non‐monotonic changes in resistivity with strain. These extraordinary features are related to the mobility and connectivity of the nanosheets in the low‐viscosity polymer matrix. The electrical conductivity of the G‐putty increased with graphene content, reaching ≈0.1 S m−1 at ≈15 vol%. G‐putty is also a highly sensitive electromechanical sensor with gauge factors > 500 in a sample fabricated with a 6.8 vol% of graphene nanosheet content and can measure pulse, blood pressure, and even the footsteps of tiny spiders.

CNTs have long been considered essential fillers for flexible conductive composites due to their extraordinary electrical conductivity and high aspect ratio.[ 56 ] Still, the uncontrollable distribution of CNTs in the matrix often severely jeopardizes the performance of PDMS composites. It is also important to note that CNTs represent an extraordinarily rich and diverse class of materials featuring vastly different structures and thus physical properties.[ 57 , 58 , 59 ] Judicious choices of specific CNT types are critical to understand the literature and harnessing their remarkable properties in intended applications.

To overcome the CNT dispersion challenge in PDMS, Chen et al. introduced SiO2 particles into the PDMS‐CNT matrix for a highly sensitive piezoresistive sensor and observed a fivefold increase in conductivity because the SiO2 particles exhibited a volume exclusion effect on the dense CNTs filler material.[ 60 ] SiO2 particles with high modulus values transfer stress to the PDMS/CNT phase, resulting in higher sensitivity. A recently explored architecture is a highly porous PDMS‐CNT foam synthesized via a sacrificial sugar template.[ 61 , 62 ] The resultant material was highly sensitive to the applied external force, with a response time of milliseconds and a detection limit as low as 0.077% in strain or 0.18 Pa in vertical pressure.

Composites prepared by a conventional physical blending method often show unsatisfactory performance, primarily owing to unwanted filler aggregation, unstable conductive networks, and the significantly reduced stretchability of composites at high filler loading. Zheng et al. developed a strategy using a 3D conductive network as the filler in the elastomer to produce conductive composites. They deposited metal flakes (Cu, Ag, and Au) on a chemically functionalized porous polyurethane (PU) sponge to form a continuous 3D conductive network and mixed it with PDMS to obtain PU‐metal‐PDMS conductive composites (Figure 4f). The sponge structure acts as a strain buffer, that prevents crack formation. Interestingly, the PU‐metal‐PDMS composites were patternable by printing methods, which is crucial for their application as interconnects.[ 63 ] The 3D conductive network approach has been further explored recently. Graphene foam has been frequently used to construct elastic conductors due to its 3D interconnected structure. The composite exhibited a conductivity of 0.9 S m−1 at a relatively low graphene loading of 0.7 wt%,[ 35 ] and 10 S m−1 with a higher loading of 5 wt%.[ 64 ] Additionally, composites with such architectures can attain high stretchability while maintaining stable conductivity through the design of macroscopic and microscopic continuous carbon networks. The superior mechanical flexibility of the honeycomb‐like graphene induced an unchanged conductivity of 72 S m−1 under the strain range of 0%–60%.[ 65 ] Ni et al. successfully prepared a conductive film with an electrical conductivity of 19 S m−1 by sealing a multi‐interfaced graphene aerogel in PDMS[ 66 ] and tested the as‐synthesized composite for its performance in electromagnetic interference shielding applications. The overall shielding effectiveness is as high as 60 dB, which is attributable to the graphene aerogel's high porosity and the improved reflection of electromagnetic waves resulting from enhanced free electron density.

3.1.3. Thermal Properties

PDMS‐based composites are promising candidates for thermal interface materials due to the high mechanical flexibility, electrical insulation, and chemical inertness of PDMS.[ 67 ] However, the intrinsically low thermal conductivity of PDMS (≈0.15 W m−1 K−1)[ 68 ] may prevent its use in high‐performance applications. To overcome this limitation, thermally conductive fillers are required. As summarized in Table 3 , a variety of thermally conductive fillers (such as metal, metal oxide, CNT, graphene, and boron nitride (BN)) have been incorporated in the PDMS matrix to tune its thermal conductivity.

Table 3.

Thermal properties of PDMS composites with various fillers.

| Thermally conductive filler | Concentration (wt% or vol%) | Thermal conductivity (W m−11 K−11) | Increased thermal stable temperature ΔTd (°C) | Reported year |

|---|---|---|---|---|

| Al | 14 vol% | 9 × 10−11 | 2021[ 69 ] | |

| 3D Al | 14 vol% | 1.6 | 2021[ 69 ] | |

| Al2O3‐ZnO NWs | 40 vol% | 1.8 | 270 | 2020[ 33 ] |

| Polypyrrole NWs anchor graphene | 4.8 × 10−11 | 2021[ 71 ] | ||

| Nickel‐coated carbon fibers | 51.54 wt% | 1.1 × 10 | 2021[ 68 ] | |

| Highly oriented graphite | 17.6 vol% | 3.5 × 10 | 2022[ 73 ] | |

| Cellulose carbon aerogel@rGO | 3.05 wt% | 6.5 × 10−11 | 30 | 2021[ 30 ] |

| Silica‐coated graphene nanoplatelet | 2 wt% | 4.9 × 10−11 | 2019[ 72 ] | |

| Cellulose nanocrystals | 4 wt% | 140 | 2016[ 351 ] | |

| Polyethylene microfibers | 55 wt% | 3.8 × 10 | 2021[ 352 ] | |

| BN nanosheets | 35 wt% | 1.2 | 2020[ 34 ] | |

| Sphere BN | 35 wt% | 7.7 × 10−11 | 2020[ 34 ] | |

| BN nanosheet‐cellulose nanocrystal | 7.3 | 2021[ 75 ] | ||

| BN aerogel | 25.4 wt% | 1.6 | 2020[ 74 ] | |

| Silica aerogel | 12 wt% | 1.8 × 10−12 | 2019[ 77 ] | |

| Carbon Fibers | 0.5 wt% | 25 | 2021[ 353 ] | |

| CNT (multi‐walled) | 5 wt% | 8.2 × 10−11 | 9 | 2016[ 354 ] |

Traditional metal fillers can impart high thermal conductivity but they may also result in undesired electrical conductivity that hampers the electronic systems. For such applications fillers that are thermally conductive while electrically insulating are highly desirable. Wei et al. sealed a 10 nm‐thick SiO2 layer‐coated 3D continuous Al framework in PDMS,[ 69 ] forming a composite that was electrically insulative while attaining a high thermal conductivity of 1.6 W m−1 K−1. Ceramic materials such as Al2O3 have been widely employed to fabricate thermally conductive and electrically insulative composites, but high filler loading is required to construct a continuous phonon transport path. Liu et al. designed a “hairy sphere” structure (Al2O3 spheres with ZnO NWs grown perpendicularly to the surface) as a novel hybrid filler.[ 33 ] The ZnO NWs reduced the interfacial thermal resistance between the Al2O3 spheres and PDMS matrix, eliciting a high thermal conductivity of ≈1.2 W m−1 K−1 with a filler content of 40 vol%.

Graphene has attracted much attention as a promising thermal conductive filler owing to its high thermal conductivity (≈5300 W m−1 K−1) and lightweight.[ 70 ] Surface modification of the graphene filler has been explored to tune the composites' conductivity and interfacial thermal resistance. Zhang et al. deposited polypyrrole NWs on a graphene surface with an electrochemical polymerization method and found that the nanowires deeply penetrated the PDMS matrix after compounding, reducing the interfacial thermal resistance.[ 71 ] SiO2 shows excellent compatibility and wettability with PDMS; therefore, a SiO2 coating layer can facilitate the interaction between graphene and PDMS and effectively prevent agglomeration.[ 72 ] A 3D carbon network can be built to provide a continuous thermal conductive path. Zhang et al.[ 73 ] reported a facile, one‐step liquid expansion method to construct a directional graphene network, achieving a high cross‐surface thermal conductivity of 35.4 W m−1 K−1 with a graphene content of 17.6 vol%.

Novel filler materials have also been explored recently. BN nanosheets, which are electrically insulative and highly thermal conductive (1700–2000 W m,−1 K−1) were incorporated via direct mixing for efficient heat dissipation.[ 34 ] In addition, BN aerogels were integrated with PDMS to generate a composite with high thermal conductivity and low electrical conductivity of 10−13 S m−1.[ 74 ] Recent experiments demonstrated that the device based on a sandwich structure with the BN‐cellulose nanocrystal mixture in the middle of two PDMS layers managed to cool down the surface of a ceramic heating plate from 105 to 76 °C within 60 s.[ 75 ]

The PDMS composite can be used for thermal insulation as well. Pores in the composite significantly reduce the thermal conductivity ascribed to the ultralow thermal conductivity of the entrapped air (≈0.026 W m−1 K−1).[ 76 ] Lee et al. fabricated a flame‐retardant, porous PDMS‐silica aerogel composite with a thermal conductivity as low as 0.018 W m−1 K−1 after removing the ethanol that was pre‐packed in the gap of the silica aerogel.[ 77 ] Zhou et al. reported a porous PDMS sponge prepared with a recyclable micro‐sugar template for passive radiative cooling.[ 78 ] The synthesized white sponge exhibits strong visible light scattering and thermal emission, demonstrating a cooling power of 43 W m−2 and temperature drop of 4.6 °C under 1 sun irradiation. Furthermore, the air‐filled voids within the PDMS sponge suppressed the overall thermal conductivity to 0.06 W m−1 K−1. The combination of the PDMS sponge's radiative cooling and thermal insulation properties enables smart heat‐regulation and promising energy‐saving applications.

3.1.4. Optical Features

PDMS is optically transparent at 240–1100 nm and can serve as a flexible substrate or carrier for various light‐absorbing and luminescent materials, allowing the fillers to define the optical properties of the composite. These composites have demonstrated practical applications within the areas of smart displays,[ 79 ] camouflage,[ 80 ] anti‐counterfeiting,[ 81 ] wearable light‐emitting devices,[ 82 ] and various sensors.[ 83 ] For example, the surface plasmonic resonance of metal nanoparticles with controllable size can generate precisely tunable absorption characteristics. Au@SiO2 nanoparticles were dispersed in PDMS for fabricating eyeglass lenses with tunable and narrow absorption bands, which can be customized for patients with color vision deficiency at specific wave bands.[ 84 ]

Quantum dots (QDs) have attracted significant attention owing to their optical tunability and solution processability,[ 85 ] and can contribute to flexible luminescent devices when coupled with PDMS. To prevent particle aggregation and performance degradation,[ 86 , 87 ] new approaches have been executed to improve the dispersion of the QDs. An amphiphilic polymer, poly(styrene‐co‐maleic anhydride), was used to encapsulate CdSe@ZnS/ZnS core/shell QDs and further crosslink them with amine‐terminated PDMS at a low curing temperature owing to the ring‐opening reaction between maleic anhydride and the diamines (Figure 5a). The resulting composite demonstrated the uniform distribution of QDs and high transparency even at a high QD concentration (30 wt%) and was used to fabricate a light‐emitting diode device with impressive efficiency.[ 88 ]

Figure 5.

PDMS with diverse optical properties. a) Surface‐modified QDs act as a crosslinker for PDMS owing to the ring‐opening reaction between maleic anhydride and diamines. Reproduced with permission.[ 88 ] Copyright 2020, Elsevier. b) Schematic of the synthesis of the organometallic halide perovskite quantum dots (OHP‐QDs) well dispersed in PDMS. Scale bar = 1 cm. Reproduced with permission.[ 92 ] Copyright 2020, Royal Society of Chemistry. c) Photoactuated polymer pens made of PDMS and surface functionalized short CNTs. Due to the superior photothermal properties of CNTs and the high CTE of PDMS, the localized photoactuation enables the dynamic control of polymer pens for molecular printing. Image on the left‐hand side: Reproduced with permission.[ 96 ] Copyright 2018, Wiley‐VCH. Image on the right‐hand side: Reproduced with permission.[ 22 ] Copyright 2023, Multidisciplinary Digital Publishing Institute. d) Schematic of PDMS grafted by MeO‐gDCC for mechanochromism and chemical signaling. The film turns pink due to the bimolecular chromogenic reaction between the released HCl and the rhodamine dye. Reproduced with permission.[ 98 ] Copyright 2020, American Chemical Society. e) Mechanically triggered color switchable photonic crystal PDMS kirigami. States 1–5 are the tensioning process in which the gate is raised and the color changes from red to blue. Conversely, states 5–8 are the unloading process, in which the color returns to the same value as in the loading process. Reproduced with permission.[ 80 ] Copyright 2021, Wiley‐VCH.

Metal halide perovskites (APbX3, X = Cl, Br, and I) have attracted great interest owing to their extraordinary optical properties;[ 89 , 90 ] however, critical problems remain regarding size uniformity and long‐term stability. The marriage between PDMS and perovskite QDs has opened the door to new solutions. PDMS can be used to fabricate soft templates to confine the size and position of the perovskite nanocrystals during the growth process.[ 91 ] Cha et al. created a porous template by etching Au nanoparticles with a specific size that had been previously embedded in the PDMS film.[ 92 ] The template was then immersed in a methylammonium lead trihalide (MAPbX3) precursor solution for multiple times for the full growth of MAPbX3 QDs in pores (Figure 5b). The pores defined the size of QDs, prevented aggregation, and kept the QDs away from the ambient environment. Consequently, the photoluminescence (PL) peak of the QDs shifted as the size of the original Au nanoparticles varied, and the PL quantum yield remained stable even after seven months. Encapsulated liquid PDMS prepolymers affect the growth of the perovskite nanocrystals as well. Halide perovskite inks were inkjet‐printed into liquid PDMS prepolymer,[ 86 ] which significantly retarded the crystallization process by prohibiting contact with air and reducing the solvent evaporation rate. The obtained fluorescent single crystals demonstrated that the simple inkjet printing method can produce wafer‐scale, air‐stable, and flexible perovskite fluorescent patterns. In addition, PDMS can be utilized as a gas‐permeable and diffusive flexible host to control a room‐temperature anion exchange reaction for embedded CsPbBr3 nanocrystals, providing a tunable halide component in the matrix.[ 93 ]

Chemical composition and surface moiety modification effectively enhance the optical property of the perovskite QDs and their dispersion in PDMS. Gong et al. adopted an organosilicon (3‐aminopropyltriethoxy‐silane‐glutaric anhydride) ligand to cap CsPbBr3 QDs, which enhanced the thermal stability of QDs and improved the compatibility and cohesion between brittle QDs and the flexible polymer matrix owing to the similar structure of PDMS and the ligands.[ 94 ] After heat treatment at an elevated temperature (125 °C), the composites still achieved 95.5% PL quantum yields. Strikingly, PL enhancement occurred during material elongation, which was interpreted as the elimination of emission reabsorption among QDs. Wang et al. dissolved Mn2+ doped perovskite QDs (CsPbX3: Mn) in cyclohexane and PDMS prepolymer to form fluorescent inks that could be used to print fluorescent patterns on different flexible substrates. The printed patterns showed bright red, green, and cyan colors that remained bright after 60 days due to the optical and thermal stability induced by Mn2+ doping and the encapsulating effect by PDMS.[ 95 ]

Optically tailored PDMS composites can enable diverse applications, including actuators and sensors. Photoactuation is especially preferable for inducing local mechanical work with high spatiotemporal precision and resolution due to its intrinsic advantages, which include remote control, wireless access, and spatial selectivity. Huang, Wang, and co‐workers developed photoactuated polymer pens (Figure 5c) made of PDMS and surface‐functionalized short CNTs for molecular printing.[ 22 , 96 ] The surface grafting of long alkyl chains on CNT walls facilitated the dispersion of these carbon nanomaterials in the PDMS matrix, producing a highly light‐absorbing yet transparent composite nearly free of light scattering. Localized photoactuation of selected polymer pens, which was directed by a digital micromirror device, created an out‐of‐plane motion by more than 7 µm adequate for active molecular printing. This strong photoactuation effect could not be achieved without the superior photothermal properties of CNTs and the high CTE of PDMS.

A chemical sensor, the PDMS‐ZnO QDs‐based fluorescent mouthguard, was invented to accurately locate dental lesion sites.[ 97 ] The chemical reaction between ZnO and volatile sulfur compounds (such as H2S) released by normal dental caries quenched the fluorescence locally in the composite, showing a 40–50% decline in intensity between 550 and 570 nm within 7 min.

Mechanochromic devices are designed and fabricated based on a stain‐triggered color change. Lin et al. designed a novel mechanophore for mechanochromic response.[ 98 ] The mechanoacid 2‐methoxy‐substituted gem‐dichlorocyclopropane (MeO‐gDCC) generates HCl in a mechanochemical ring‐opening reaction (Figure 5d) with a transition force as low as 880 pN. Based on this chemistry, Lin et al. incorporated multiple segments of MeO‐gDCC into the PDMS polymer backbone to produce a clear, pale pink elastomer. The film turned pink when it was exposed to tensile strain, compression, or localized compression due to the bimolecular chromogenic reaction between the released HCl and the rhodamine dye. Since the response is slow and time‐dependent, it is possible to trace back to the initial starting time by extrapolating an apparent activation point from the late‐time behavior.[ 98 ]

Advanced approaches have also been developed to build flexible mechanoluminescence (ML) devices. Since a soft and flexible elastomer matrix might act as a stress buffer and decrease the sensitivity, SiO2 nanoparticles were included in the hybrid ink to concentrate stress in ZnS:M2+(Mn/Cu)@Al2O3 micro‐sized particles.[ 82 ] The intense ML, ascribed to the piezoelectrically induced electron detrapping electrofluorescence in doped ZnS, was realized under weak stimulation (strain = 5–30%). The printed SiO2 nanoparticle‐doped composite matrix film is compatible with the elasticity modulus of human skin and can achieve skin‐driven ML, enabling the presentation of fetching augmented animated expressions.

Structural color, based on the dynamic scattering of light by micro‐ or nano‐structures, has been found in birds, butterflies, and plants, and continues to fascinate scientists with its high tunability and enduring photonic properties.[ 83 ] Inspired by the color‐switching modulation ability found in nature, Lai et al. created a mechanically triggered color‐switchable elastomer kirigami with unprecedented repeatability (recyclability >104), by fabricating an array of rectangular cuts on a thin PDMS film and then firmly bonding the mono‐dispersed PS spheres onto the PDMS surface. The 2D photonic crystal array presented a color variation across the entire visible spectrum from violet to red by varying the view angle (see Figure 5e), and the out‐of‐plane pop‐up angle of the kirigami could be controlled by in‐plane stretching in a programmable manner.[ 80 ] This research is critical for advancing practical applications such as cryptography, sensor technology, dynamic displays, and camouflage.

Phase transition materials can be coupled with PDMS for a temperature‐induced smart display. The elastic PDMS serves as a compatible host for vapor, liquids, or solids. Paraffin is a mixture of hydrocarbons with ≈18–30 carbons and melts at ≈45–55 °C.[ 99 , 100 ] The PDMS‐paraffin composite film enabled reversible switching between a transparent and opaque surface under a thermal stimulus.[ 101 ] The solid‐to‐liquid phase transition of paraffin enhanced the average transmittance of the composite film to > 80% between 400 and 800 nm,[ 102 ] and the composite holds promise for use in smart windows.

3.1.5. Mechanical Properties

As an elastomer, PDMS is known for its excellent flexibility and stability. However, its crack resistance, or toughness, is relatively poor. The mechanical properties of pure PDMS are usually controlled by the degree of crosslinking present in the polymer. Adjusting the degree of crosslinking can effectively tune the polymer's Young's modulus (i.e., 0.3 to 3 MPa). However, strong crosslinking may also lead to the impairment of PDMS's stretchability. Conventional wisdom believes that there usually exists a tradeoff between stiffness and extensibility/toughness for covalently crosslinked polymers. Nevertheless, the latest advances in materials science, compounding methods, and modification chemistry provide exciting opportunities to tune the mechanical properties of elastomer composites at a much wider range (Figure 6a) and successfully move past these aforementioned trade‐offs (Figure 6b).

Figure 6.

Strategies to mechanically strengthen PDMS. a) Young's modulus of PDMS can be manipulated across a wide range. b) Summary of PDMS composites that have achieved a significant increase in both Young's modulus and toughness values simultaneously. c) Preparation process of the nacre‐inspired PDMS‐montmorillonite layered nanocomposites. The continuous scaffold in PDMS can bear high loads and prevent crack extension. Reproduced with permission.[ 103 ] Copyright 2021, Nature Publishing Group. d) Mastering hydrogen‐bonding clusters (red parts in polymer networks) to simultaneously improve cg‐ECN's stiffness and extensibility. Reproduced with permission.[ 104 ] Copyright 2022, Cell Press. e) Homogeneous, strong, reversible network consisting of PDMS chains (blue) and octuple hydrogen bonds. Reproduced with permission.[ 105 ] Copyright 2022, Wiley‐VCH. f) PDMS‐based high‐strength elastomer designed with a high‐density network structure combining permanent chemical bonding and dynamic physical bonding, B represents benzi‐diNCO, U represents UPy‐NCO, and E represents e‐NCO. Reproduced with permission.[ 106 ] Copyright 2023, Cell Press.

Inspired by nacre, Cheng and Tang et al. prepared PDMS‐montmorillonite layered nanocomposites via ice‐templating, which led to a 23‐ and 12‐fold enhancement in Young's modulus and toughness, respectively.[ 103 ] Montmorillonite, a natural clay, was exfoliated into nanosheets and blended with aggregation‐induced emission (AIE) luminogens‐decorated polyvinyl alcohol to form a homogeneous solution, followed by bidirectional freezing, during which ice crystals formed parallel platelets and generated a lamellar structure (Figure 6c). After the sublimation of the ice, PDMS was eventually introduced into the lamellar scaffold to fill the voids. The authors used AIE‐assisted confocal fluorescence microscopy to observe the crack propagation and probe the stiffening and toughening mechanisms. The researchers determined that the substantial increase in the value of Young's modulus arose from the continuous scaffolding, which can bear a higher load at the beginning of the stretching, and that the enhanced toughness stemmed from the crack deflection and crack bridging in the layered structure, preventing the rapid transverse propagation of the crack.

Dynamic hydrogen bonding is key in manipulating the elastomer's mechanical properties. Cao et al. reported that both Young's modulus and elongation at break can be improved simultaneously via controlling the distribution, size, and topology of the incorporated hydrogen‐bonding clusters.[ 104 ] Aza‐Michael addition between (aminopropylmethylsiloxane)‐dimethylsiloxane copolymer (four amines per polymer chain) and the acryloxy‐terminated ethyleneoxide dimethylsiloxane‐ethylenoxide block copolymer created an elastic chemical network (recorded as ECN), while hydrogen‐bonding units, such as 2‐ureido‐4[1H]‐pyrimidinone (UPy), were introduced through physical blending or chemical grafting on the side chains of PDMS (recorded as cg‐ECN, see Figure 6d). Both stiffness and extensibility were enhanced by 158 and 3 times, respectively, for the chemically grafted elastic chemical network, whose dynamic stretching process was discovered to contain two stages: an elastic recovery region (0–10% strain) and the breakage of chemical bonds and rearrangement of UPy clusters (10–150% strain). This study highlights the importance of the interaction between the hydrogen‐bonding pairs, along with the topology of hydrogen‐bond clusters, on the mechanical properties of PDMS composites. Similarly, by adding strong, reversible, and sacrificial octuple hydrogen bonding into linear PDMS via the chain extension reaction, Zhuo et al. built highly homogeneous and energy dissipative networks (Figure 6e) which were capable of evenly distributing the stress to each polymer chain thus, decreasing the stress concentration and delaying fracture.[ 105 ] Furthermore, the synthesized elastomer exhibited distinct microphase separation, containing the soft hydrophobic PDMS segments and hard hydrophilic hydrogen bonding nanodomains. These strong hydrogen bonding nanodomains restricted the mobility of polymer chains and transformed between different configurations to dissipate energy under stress, further enhancing both stiffness and toughness.

An innovative recyclable elastic network (REN) elastomer, based on PDMS, was developed by Cao et al., featuring a high‐density network that seamlessly integrates permanent chemical bonds with dynamic physical ones. The precursor PDMS, rich in side chains (with 48 amine units), facilitated the formation of an extremely high crosslinking density network through sequential reactions with benzidine‐isophorone diisocyanate (benzi‐diNCO), ethyl isocyanate (e‐NCO), and ureido‐4[1H]‐pyrimidinone isocyanate (UPy‐NCO) (refer to Figure 6f). The incorporation of benzi‐diNCO transformed it into a robust chemical cross‐linker, enhancing the mechanical properties, while the quadruple hydrogen bonding sites of UPy create a potent physical dynamic network. Lastly, the addition of e‐NCO transformed the remaining amine into urea units, engendering another dynamic network based on hydrogen bonding. The resulting REN elastomers far exceed most of their PDMS counterparts in mechanical strength (10 MPa) and toughness (66 MJ/m3) as per report.[ 106 ]

Interfacial interaction between the filler and the matrix is critical to the overall performance of the composite. Gardea et al. created a CNT‐PDMS composite with the nanofiller‐polymer interfacial chemistry rendered responsive to UV light through photoreactive benzophenone. This light‐responsive interface allows programming the composite's elastic modulus and yield stress by exposure to the light stimulus.[ 107 , 108 ]

By controlling the crosslinking process, PDMS‐based composites can also be made extremely soft and super‐stretchable (Figure 7 ). One facile but clever method is to involve the solvent in the curing process. Yu and co‐workers reported a solvothermal polymerization process with the addition of n‐hexane to change the structure of crosslinking networks; the researchers synthesized a PDMS‐based material with a maximum elongation of over 3000% (>10 times above normal values) and a tensile modulus lower than 0.15 MPa (< 1/10 of typically observed values), which can be utilized for oil collection and organic solvent sensing.[ 109 ] Another approach is to manage the crosslinking speed and density by controlling the catalyst amount or the type of crosslinking chemistry. As mentioned in Section 2.1, a variety of chemical groups can be used to inhibit the crosslinking chemistry of PDMS based on the reaction between Si‐H and vinyl terminals. The polar functional groups in a widely used non‐ionic surfactant, Triton‐X, interact with the Pt catalyst, and were utilized to intentionally hinder the crosslinking and modulate the mechanical properties of the PDMS polymer.[ 110 ] As a result, the soft PDMS composite film was highly adhesive, compliant, and comfortable, enabling its application in epidermal biosensors. Skov et al. discovered that the unwanted side‐reaction (oxidative crosslinking of Si‐H groups in the presence of oxygen) in the conventional formulations proceeded very slowly and allowed for the preparation of highly diverse networks using a simple one‐pot reaction.[ 111 ] Furthermore, by leveraging the intrinsic “supersoft” characteristics of bottlebrush polymers, Reynolds et al. synthesized a photocurable bottlebrush PDMS, with a modulus of 104–105 Pa that is 10–100 times smaller than conventional linear analogs and can be used for highly sensitive capacitive pressure sensor applications affording an enhanced sensitivity (up to 53 times greater) compared to Sylgard 184.[ 112 ]

Figure 7.

Strategies for developing supersoft PDMS. a) Solvothermal polymerization of PDMS in hexane ensures that the network of crosslinked elastomer molecules is untangled and unbroken during subsequent stretching. Reproduced with permission.[ 109 ] Copyright 2021, Springer. b) Adding crosslinking inhibitor (herein, Triton‐X) to reduce the degree of crosslinking. Reproduced with permission.[ 110 ] Copyright 2018, American Chemical Society. c) Synthesizing highly branched bottlebrush PDMS with minimum chain entanglement. Reproduced with permission.[ 112 ] Copyright 2020, Royal Society of Chemistry Mater.

3.1.6. Self‐Healing Capability

Self‐healing is the capability of a material to recover from physical damage,[ 113 ] and, depending upon the mechanism by which it operates, can be classified as either microencapsulated self‐healing or intrinsically self‐healing (Figure 8 ), with the latter triggered by reversible dynamic covalent bonds (e.g., disulfide bonds, imine bonds, etc.) or non‐covalent bonds (hydrogen bonds, ionic bonds, etc.). Due to its irreversibly crosslinked structure, PDMS cannot usually recover its original form and function after sustaining damage. However, the newly developed self‐healing silicone composites (as summarized in Table 4 ) have extended the service life of the materials and increased the types of applications into which they can be incorporated (e.g., coatings, sensors, nanogenerators, controlled‐release drugs, and sealing materials).

Figure 8.

Display of a handful of reversible dynamic bonds with inherent self‐healing mechanisms, which have been successfully introduced to PDMS‐based elastomer.

Table 4.

Summary of self‐healing PDMS designed by diverse strategies.

| Operation principle | Healing efficiency (condition) | Reported year | The parameter used to calculate the healing efficiency |

|---|---|---|---|

| Capsule based | 2006[ 115 ] | tear strength | |

| Capsule based | 70–100% | 2007[ 117 ] | tear strength |

| Nanofibers based | 2017[ 118 ] | – | |

| Ionic interactions (amino groups and the acid groups) | 77% | 2016[ 132 ] | strain |

| Ionic bonds | 84% (4 h at 80 °C) | 2020[ 134 ] | strain |

| Hydrogen bonds | 100% (20 min at 40 °C) | 2018[ 355 ] | strain |

| Hydrogen bonds | 78% (48 h at RT) | 2018[ 129 ] | strain |

| Hydrogen bonds | 78% (48 h at RT) | 2018[ 130 ] | strain |

| Hydrogen bonds | ≈100% (12 h at 60 °C) | 2019[ 123 ] | – |

| Hydrogen bonds | 100% (5 h at 80 °C) | 2020[ 124 ] | strain |

| Hydrogen bonds | 97% (30 min at RT) | 2021[ 125 ] | mechanical toughness |

| Hydrogen bonds | 100% (1 h at 120 °C) | 2021[ 120 ] | stress |

| Hydrogen bonds | 98%–100% | 2017[ 119 ] | mechanical toughness |

| Ce‐coordination bonds | 80% (48 h at 60 °C) | 2018[ 356 ] | strain |

| Zn‐coordination bonds | ≈98% (24 h at RT) | 2019[ 357 ] | strain |

| Zn‐coordination bonds | ≈76% | 2016[ 135 ] | strain |

| Zn‐coordination bonds | ≈90% (24 h at RT) | 2020[ 136 ] | strain |

| Fe‐coordination bonds | ≈90% | 2017[ 137 ] | strain |

| Imine bonds | 94% (12 h at RT) | 2018[ 142 ] | strain |

| Imine bonds | 96% (6 h at 60 °C) | 2021[ 143 ] | strain |

| Disulfide bonds | 95% (10 h at RT) | 2020[ 139 ] | strain |

| (B‐H) Covalent boroxine bonds | 100% (12 h at 70 °C) | 2016[ 146 ] | strain |

| B‐O bonds | 2021[ 147 ] | – | |

| Hydrogen bonds(healing) and Al‐coordination bonds (robustness and elasticity) | 91% (36 h at RT) | 2019[ 358 ] | integral area in tensile curve after healing divided by that of the uncut samples |

| Hydrogen bonds, imine bonds and Si‐O chains | 95% (24 h at RT) | 2020[ 150 ] | strain |

| Hydrogen bonds and disulfide bonds | 93% (2 h at RT) | 2020[ 151 ] | strain |

In 2001, White et al. reported a buried microencapsulated self‐healing material.[ 114 ] The capsule containing the repair agent ruptures when the material is damaged, and the released repair agent moves to the damaged site and completes the repairing reaction. White's group then applied this design to PDMS.[ 115 , 116 ] To further improve the stability of the restorative agent, Keller et al. separated the vinyl‐functionalized PDMS and Pt catalysts from the PDMS with active sites by placing them into different microcapsules. When the designed microcapsules were embedded into a PDMS matrix with a low modulus and prone to strain‐failure, the self‐healing efficiency increased to 76%.[ 117 ] Furthermore, nanofibers (polyacrylonitrile fiber) can be used to store the PDMS matrix (repair agents) to impart the self‐healing capability.[ 118 ]

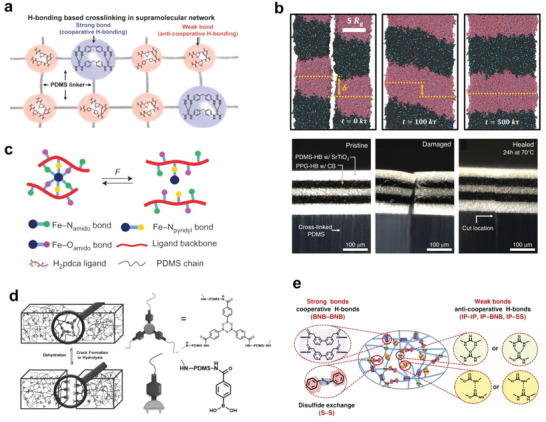

Intrinsic self‐healing can be realized through reversible, dynamic, non‐covalent bonds. Dynamic hydrogen bonding, based on the interaction between a couple of functional moieties (e.g., isofuranone diisocyanate (IPDI),[ 119 , 120 ] 4,4′‐methylenebis(phenylisocyanate), Upy,[ 121 ] and 2‐acrylamido‐2‐methyl‐1‐propanesulfonic acid[ 122 ]) and the PDMS matrix possessing different terminal groups (mainly NH2‐PDMS‐NH2), has become a widely employed strategy.[ 123 , 124 , 125 ] Wang et al. designed a new hydrogen‐bonded supramolecular elastomer through the condensation reaction of PDMS macromolecules with the diisocyanate coupling agents, and the content of H‐bonds can be precisely adjusted by a rational molecular design, which tunes the flexibility of the polymer chains.[ 126 ] Besides excellent self‐healing capabilities, other mechanical properties, such as toughness and elongation at break, can also be improved simultaneously. For example, Du et al. introduced a sliding crosslinker (polyrotaxanes) into PDMS and IPDI. As a result, under massive stretching (when the hydrogen bonds had already been broken), the cyclodextrins in the polyrotaxanes slid to dissipate energy, rendering the composite an elongation at break up to 2800% and a breaking strength of 1.05 MPa.[ 127 ] Liquids such as silicone oil, water, and sweat can further promote the healing effect. The addition of silicone oil to the gelatinized NH2‐PDMS‐NH2 and IPDI condensates swelled and diluted the polymer chains, which improved the mobility of the urea groups formed on the polymer chains and thus facilitated rapid self‐healing.[ 128 ] Yao et al. prepared a self‐healing PDMS based on hydrogen bonding between Upy and NH2‐PDMS‐NH2, and the reversible dissociation/association of the hydrogen bonds was promoted in water. The low permeability of the PDMS phase allowed the water molecules to pass through the polymer network to exchange with UPy motifs, while the hydrophobicity of PDMS localized the UPy‐rich microphases to ensure reversible dissociation and reformation of the hydrogen bonds between UPy motifs. Eventually, 98% of the mechanical properties were recovered in water at 70 °C in as little as 5 min.[ 121 ] Kang's team prepared a self‐healing material by a condensation reaction between NH2‐PDMS‐NH2, 4.4′‐methylenebis (isocyanatophenyl ester), and IPDI. The 4,4′‐methylenebis (phenyl urea) unit formed strong hydrogen bonds to transfer elasticity, while the isophorone bisurea unit formed weak hydrogen bonds to dissipate energy (Figure 9a). Due to the synergistic effect, the material exhibited an elongation at break of up to 1200%, and fracture energy of 12 000 J m−2, respectively. The mechanical properties of the material can be almost completely restored after 24 h of repair in water or bionic sweat.[ 129 , 130 ]

Figure 9.

Arrangements of diverse dynamic bonds in PDMS. a–c) Dynamic non‐covalent bonds: a) combinations of strong and weak hydrogen bonds, with the strong transferring elasticity and the weak dissipating energy; reproduced with permission.[ 129 ] Copyright 2018, Wiley‐VCH. b) multilayered polymeric films undergo autonomous realignment upon damage to minimize interfacial free energy during the healing process, with simulation (top) and microscopic observation (bottom); reproduced with permission.[ 131 ] Copyright 2023, American Association for the Advancement of Science. c) Fe(III)‐N bonds for modulus enhancement and Fe(III)‐O bonds for energy dissipation, both stabilized by chelation. Reproduced with permission.[ 137 ] Copyright 2016, Nature Publishing Group. d) Dynamic covalent bonds: reversible equilibrium transition of boroxane bonds in response to humidity stimulation. Reproduced with permission.[ 146 ] Copyright 2016, Wiley‐VCH. e) Multiple reversible dynamic bonds: the supramolecular polymer network consisting of strong and weak hydrogen bonds and disulfide metathesis. Reproduced with permission.[ 151 ] Copyright 2020, Nature Publishing Group.

Addressing the growing demand for multifunctional, self‐healing devices that can handle increasing complexity, Bao et al. ingeniously integrated bisurea bonds generated by MPU and IU into PDMS and polypropylene glycol (PPG), respectively. Altering the MPU:IU ratio and backbone's average molecular weight facilitated healing kinetics across a broad temperature range (30 – 100 °C). PDMS and PPG have immiscible backbones but share the same dynamic bonds to maintain interlayer adhesion. Interestingly, these multilayered polymeric films underwent autonomous realignment post‐damage to minimize interfacial free energy during the healing process (see Figure 9b). This design concept extends to numerous molecular systems, enabling the production of thin film devices incorporating conductive, dielectric, and magnetic particles, demonstrating 96% self‐healing capability.[ 131 ]

Reversible ionic interactions also play a part in self‐healing PDMS, such as the ionic bonding between amines and acids,[ 132 , 133 ] and carboxyl groups and ZnO. The mechanical properties and self‐healing ability of dynamic ionic polymers can be modulated by changing the crosslinking density of the PDMS prepolymer and the molar ratio of –COOH/ZnO.[ 134 ] Metal ions complex with certain ligands on PDMS terminals or side groups to form coordination bonds, which undergo dissociation and complexation to confer self‐healing properties to PDMS. Bipyridines grafted onto PDMS can form coordination bonds with Zn2+ and Fe2+ due to their well‐defined coordination geometries.[ 135 , 136 ] Bao and co‐workers crosslinked PDMS oligomers containing 2,6‐pyridinedicarboxamide groups with FeCl3 to form highly stretchable PDMS elastomers that were able to undergo self‐healing at a remarkably low temperature of −20 °C (Figure 9c).[ 137 ] To further improve the strength of the elastomer, their team introduced Zn(II)‐carboxylate interactions in PDMS to achieve a combination of stiffness (Young's modulus value of up to 480 MPa) and self‐healing capability.[ 138 ]

Reversible dynamic covalent bonds, such as disulfide bonds,[ 139 , 140 , 141 ] imine bonds,[ 142 , 143 , 144 ] and borate ester/boroxyl bonds,[ 145 , 146 , 147 ] have been explored to construct self‐healing PDMS. Reversible imine bonds are formed through amine‐terminated PDMS or by grafting functional groups containing primary amines to PDMS through Schiff base reactions[ 142 ] between primary amines and aldehydes or ketones.[ 143 ] Boronic ester bonds are often obtained through condensation reactions between boronic acids and 1,2‐ or 1,3‐diol compounds.[ 145 ] Lai et al. prepared a water‐enabled healing material based on a boron‐oxygen covalent bonding system through the amidation of arylboroxanes with NH2‐PDMS‐NH2. As shown in Figure 9d, in a humid environment, the surface‐exposed boric acid generated a large amount of free boric acid, resulting in the decrosslinking of PDMS chains. This process was reversed after water removal, causing complete healing.[ 146 ] Ma et al. reported the synthesis of an ultrathin (less than 10 nm‐thick) film with a PDMS network and dynamic boronic acid ester crosslinking that exhibited long‐term hydrophobic properties.[ 147 ]

It is difficult to achieve both satisfactory self‐healing capability and mechanical properties relying on a sole dynamic bond. Including multiple reversible dynamic covalent/non‐covalent bonds in one material holds the promise to break this bottleneck.[ 148 , 149 ] Yang et al. synthesized transparent (92% in the visible spectrum) self‐healing PDMS elastomers with dynamic intermolecular hydrogen bonds, reversible imine bonds, and highly flexible Si‐O chains by reacting NH2‐PDMS‐NH2 and IPDI and a Schiff base reaction with benzaldehyde. The resulting elastomers exhibited a high stretchability value of 1670% and a healing efficiency value of 89% and 78% in water and artificial sweat, respectively.[ 150 ] In another study, the combination (Figure 9e) of disulfide bonds (S–S), strong hydrogen bonds, and weak hydrogen bonds gave rise to an elongation at break value of 14000% and the encouraging self‐healing speeds in a variety of extreme environments (e.g., ultralow temperature (−40 °C), high concentration brine, and strong acids/bases).[ 151 ]

3.1.7. Dielectric Properties

PDMS is a promising candidate polymer,[ 152 ] despite its low dielectric constant (ε = 2.5–3.0 at 1 kHz), for the dielectric elastomeric actuator (DEA), which consists of a soft elastomeric film with compliant electrode patterns on both sides, enabling the conversion of electrical energy to mechanical work. As shown in Figure 10a, the application of an external electric field across these electrodes induces an electrostatic attractive force between opposite charges, generating electrostatic stress or pressure on the film. Consequently, the film undergoes a decrease in thickness with an increase in horizontal area.[ 153 ] PDMS's relatively low modulus as well as physicochemical inertness[ 154 , 155 ] result in fast response and low dielectric loss.[ 156 ] Especially, softer PDMS, either by decreasing crosslinking density or adopting bottlebrush PDMS[ 111 ] are more suitable for driving DEA at lower voltages.[ 157 ]

Figure 10.

Dielectric property of PDMS composites. a) Structure and operation mode of DEA, where the electrostatic gravitational force between the two electrodes under external voltage causes the elastomer film to be compressed. b) 3D microstructure of LM inside PDMS, showing the homogeneous dispersion of LM droplets of the composite in the PDMS. Image of the DEA of LM‐PDMS elastomeric nanocomposite under voltage for one driving cycle. Reproduced with permission.[ 164 ] Copyright 2019, Wiley‐VCH. c) PDMS elastomer prepared by cross‐linking reaction between multifunctional imidazole grafted PDMS and bis‐IL. Reproduced with permission.[ 172 ] Copyright 2022, American Chemical Society.

DEA's performance can be enhanced by raising the dielectric constant of the DEA film, leading to increased capacitance and less required electric field strength.[ 157 ] Elastomer composites have traditionally been employed to augment dielectric constant, but this necessitates a balance between high dielectric constant, reduced dielectric loss, and low Young's modulus.[ 158 ] Nanofiller behavior hinges on their type, quantity, and interaction with the polymer.[ 159 ] Numerous studies have employed nanofillers like multi‐walled carbon nanotubes (MWCNT)[ 160 ] and graphene layers[ 161 ] to modulate polymers' dielectric behavior.[ 162 ] The nanofiller and PDMS interface affects the dielectric properties of the composites significantly. Noteworthy is Huang et al.’s work, where carbon black particles encapsulated in PDMS embedded in silicone resin significantly enhanced the composite's dielectric constant (by 244%) while preventing carbon black conductivity, yielding high breakdown voltage and reduced dielectric loss. This technique also saw increased bending amplitude and strain in composite DEA.[ 163 ]

To prevent nano‐fillers from decreasing elastic mechanical properties of composite films, Majidi et al. used liquid metal EGaIn as the filler. As shown in Figure 10b, their study showed that high‐concentration nanoscale EGaIn improved the dielectric constant without significant losses in elasticity, tensile properties, or dielectric breakdown strength. Despite minor hardening through incorporating smaller liquid metal, the composites remained soft and highly deformable.[ 164 ] In addition, high‐dielectric inorganic fillers, such as ZnO,[ 165 ] TiO2,[ 166 , 167 ] BaTiO3,[ 168 ] BN,[ 169 ] and conductive carbon,[ 170 ] can enhance an elastomer's dielectric constant without altering its dielectric attributes. For example, PDMS‐coated TiO2 boosts the breakdown strength of Styrene‐ethylene‐butadiene‐styrene rubber film from 44 to 54.8 V µm−1, an increase ideally suited for facilitating high‐strain EDA operation at elevated voltages.[ 171 ]

Another strategy to improve polymer's dielectric property involves chemical modification of the backbone. Skov et al. presented a novel method using a cross‐linking reaction between imidazole‐grafted PDMS and bis(1‐ethylene‐imidazole‐3) brominated ionic liquid (bis‐IL) (see Figure 10c). The resultant IL‐elastomers amplified the dielectric constant by 200% and significantly decreased the modulus (to ≈0.04 MPa), enabling greater strain and lower voltage. Consequently, the developed dielectric actuator demonstrated 20% area strain at 15 V/µm.[ 172 ] In addition, vinyl‐functionalized Dipole (N‐allyl‐N‐methyl‐p‐nitroaniline) can also be used as a high dielectric grafting molecule in PDMS matrix, increasing the dielectric constant of PDMS from 2.84 to a maximum of 6.15.[ 173 ]

3.2. Functionality Emerging at PDMS Surface

3.2.1. Physical and Chemical Modification of PDMS Surface

Surface properties, such as surface energy, morphology, wettability, and adhesion, play a decisive role in various applications. The PDMS surface can be modified by both physical and chemical approaches. The former mainly refers to the construction of micro‐ or nano‐scale periodic structural patterns on the surface, some inspired by nature. The latter includes the precise control of the chemical composition and molecular identity of the surface layer of PDMS through surface treatment and chemical grafting. The surface modification of PDMS is very extensive and is based on the powerful silane chemistry,[ 174 ] which has been used to make stretchable chemical patterns, gradients, and molecular layers. With the synergistic effect of physical and chemical modifications, novel surface functions can be created and empower numerous practical, real‐life applications.

Vinyl‐terminated PDMS is inherently hydrophobic with a low surface energy (21.3 mJ m−2).[ 27 ] Water droplets form a spherical shape on the PDMS surface, with a WCA of ≈110 °C. Hydrophilic PDMS surfaces (Figure 11 ) are essential for microfluidic chips and cell culture. For instance, a straightforward surface modification employing amino acid‐functionalized self‐assembled monolayers renders the PDMS surface hydrophilic, thereby furnishing an optimal environment to facilitate cellular maturation.[ 175 ] Besides UV irradiation, oxygen plasma treatment (see Table 5 ) can introduce hydrophilic moieties (Si‐OH, SiO2) to replace the methyl groups (Si‐CH3) on the PDMS surface.[ 176 , 177 , 178 , 179 , 180 , 181 ] A further polyvinyl alcohol layer generated by dip coating extended the hydrophobicity for two months.[ 182 ] He et al. grafted poly(acryloyloxyethyl phosphorylcholine) (PMPC) onto an Au‐coated PDMS film, which reduced the WCA to 0° and formed a self‐cleaning electrode.[ 183 ] It was also reported that surface modification of PDMS foam with polyacrylic acid could maintain superhydrophilicity (≈1° of WCA) for up to 18 months.[ 184 ]

Figure 11.

Modifications of the PDMS surface generating diverse properties: a) hydrophilic, b) superhydrophobic, and c) icephobic. a) Multiple methods are used to produce hydrophilic PDMS surfaces. Inset shows the superhydrophilic zwitterionic polymer brush grafted onto the PDMS surface. Reproduced with permission.[ 183 ] Copyright 2020, Wiley‐VCH. PDMS microstructured arrays depicted in (b) and (c) can be prepared by duplicating the microstructure of the lotus leaf surface or laser etching. c) Illustration of the ray trace and photothermal anti‐icing mechanism in the modified microstructure. Reproduced with permission.[ 220 ] Copyright 2022, Elsevier.

Table 5.

Functional PDMS surfaces with hydrophilic or superhydrophobic properties.

| Modification approach | WCA (°) | Slide angle (°) | Featured application | Reported year |

|---|---|---|---|---|

| Low‐energy electron beam irradiation | 60 in 1 min | Cell‐adherent | 2018[ 178 ] | |

| Loading of polyvinyl alcohol and plasma treatment | 7 immediately after plasma oxidation | Drug delivery | 2017[ 179 ] | |

| PMPC brush on Au‐coated PDMS surface | 10 | Self‐cleaning skin electrode | 2020[ 183 ] | |

| Polyacrylic acid coating | 9 | Portable pressure pump | 2019[ 184 ] | |

| Zn coating | 2 | Water collector | 2021[ 180 ] | |

| Pt deposition on silica PDMS aerogel surface | 0 | Water harvesting | 2017[ 181 ] | |

| Hierarchical micro/nano structures | 146 (159 after flame treatment) | Sweat‐resistant wearable TENG | 2022[ 190 ] | |

| Hexagonal convex microlense array | 156 | 4 | Water collector | 2021[ 180 ] |

| Microstructure from solvent‐induced polycarbonate mold | 172 | < 1 | Self‐cleaning surface | 2020[ 27 ] |

| CO2 laser engraver irradiation | 155 | 5 | Superhydrophobic and wearable strain sensors | 2022[ 187 ] |

| CO2 laser engraver irradiation | 153 | Light‐driven floating device | 2017[ 191 ] | |

| Labyrinth‐like wrinkles of Zn film | 169 | 0 | Self‐cleaning surface | 2022[ 195 ] |

| ZnSn(OH)6 layer coating | 158 | 1 | Self‐cleaning coating | 2017[ 196 ] |

| Coating of fluorinated nanoparticle/binder | 157 | <1 | Transparent self‐cleaning surface | 2017[ 359 ] |

| With microstructure of lotus leaf surface | >170 | 2 | Anti‐icing | 2016[ 218 ] |

| With cauliflower‐like micro‐nano structure | 161 | 1 | Anti‐icing | 2022[ 221 ] |

| With micro‐nano‐NW triple structure | 159 | 2 | Anti‐icing | 2022[ 360 ] |

| Candle soot coating | 162 | Bimorph actuators | 2021[ 296 ] | |

| Microstructure and carnauba wax | 169 | Detection of adulterant rhodamine B | 2022[ 361 ] |