Abstract

The carbon footprint (CFP) is a measure of greenhouse gases (GHGs) emitted throughout the lifecycle of a product or activity, while the energy footprint (EFP) and water footprint (WFP) measure energy and water consumption, respectively. These footprints are essential for managing emissions and consumption and promoting low-carbon consumption. A carbon labeling scheme could help consumers make informed choices. Asia is a major textile producer and consumer, so studying textiles' carbon, energy, and water footprints is essential for managing domestic emissions, energy and water consumption, and international trade negotiations. This paper presents a method and framework for assessing CFP, EFP, and WFP at the product level and calculates the footprints for textile products. The results show that the total CFP of all textile products produced is 42,624.12 MT CO2e, with indirect emissions contributing significantly more than direct emissions. The total EFP is 248.38 PJ, with electricity consumption being the main contributor, while the total WFP is 80.71 billion liters. The spinning stage of production has the highest CFP and EFP, and energy consumption is the main contributor to all footprints. These results can help compare different products and reduce the footprints of the textile sector.

Keywords: Carbon footprint, Water footprint, Energy footprint, Textile industries, GHG emissions

1. Introduction

According to Malthusian Population Theory, resources increase arithmetically while population increases geometrically [1]. After the 1730s, the population increased significantly, accelerating the demand for industrial products. Along with population expansion, there is an increase in demand for water, electricity, agriculture, and textile goods. According to the Malthusian theory, any abrupt increase in population would significantly widen the existing gaps [2,3]. There is a need for resources and energy to operate the industry, which results in GHG emissions. Textile products are highly required to survive on this planet. However, the textile and garment industry contributes significant carbon emissions, with estimates ranging from 6 % to 8 % of global carbon emissions, second largest consumer [4] and polluter or roughly 1.7 billion tons of CO2 annually [5].

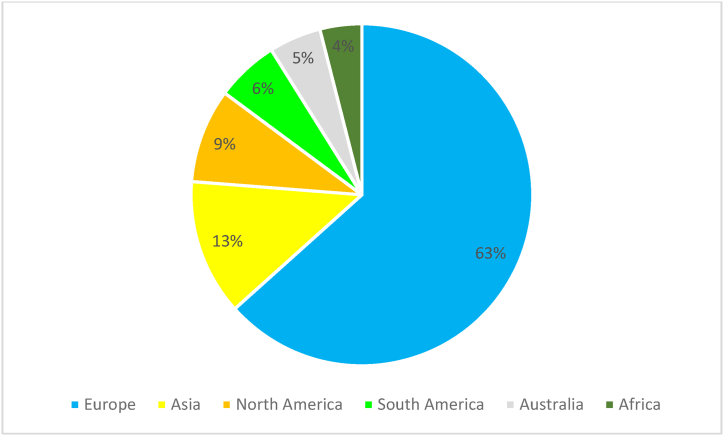

Many countries are trying to fulfill the requirement for textile products and trying to get more and more revenue from this sector. Top textile manufacturing and exporting countries include China (global textile exports leader) [6], Germany, the USA, Turkey, India, Vietnam, Italy, Pakistan, Bangladesh, and Indonesia. It is reported that 70 % of total global exports and 60 % of global imports belong to the top 18 cloth and apparel exporting countries [7]. Textile has around 4.6 % share in international merchandise export and generates $900 Bn in global exports, while it is expected to rise to $1.2 trillion by 2025-27 [8]. This rise will also increase energy consumption and GHG emissions worldwide, but GHG mitigation plans are nowhere in the world. China relies heavily on coal as an energy source [9], but Europe heavily relies on oil and gas [10]. Coal releases more GHGs than oil due to higher carbon content [11]. Because over 80 % of China's electricity is provided by coal-fired thermal power plants, textiles made there have a carbon footprint that is 40 % larger than those made in Europe. The carbon footprint ratios for various sites are shown in Fig. 1. The Paris Agreement aims to keep global warming to less than 2° Celsius over pre-industrial levels, with 1.5° Celsius being the preferred objective [12]. According to the agreement, significant carbon reductions are required to reach the target. The ultimate aim is to achieve net zero emissions by 2050, with a global decrease of roughly 45 % from 2010 to 2030 [13].

Fig. 1.

Ratio of the carbon footprint on different regions on the Earth [14].

From cradle to gate, a case study of South Indian industrial practices in the context of white T-shirt manufacture was carried out, producing interesting results. Out of 21,922.8 kg of CO2e emissions, manufacturing T-shirts was responsible for 19,080.4 kg. After further analysis of the emissions breakdown, the industrial activities that contributed the most to the overall carbon footprint were determined. The processing industry was shown to be the most significant emitter, with astounding emissions of 15,734.8 kg CO2e. The spinning sector came in second with 2787 kg of CO2e emissions. The environmental impact of the knitting and garment sectors was 253.8 kg and 304.8 kg, respectively. These numbers serve as a wake-up call because they demonstrate just how much the industrial sector is responsible for the state of the environment. Unexpectedly, despite the agricultural sector's contribution, the industrial sector accounted for an impressive 87 % of the overall emissions. This demonstrates how important it is to address the environmental issues that industrial activity has caused [15].

Furthermore, considering the worldwide consumption and pollution of water, it is evident that the textile industry is the second-largest polluter of clean water after agriculture [16]. Furthermore, in the textile industry, 3600 dyes are being manufactured [17] along with 3600 distinct colors, and 8000 different chemicals are used in bleaching, dyeing, printing, and finishing procedures. Many of these chemicals harm humans and marine life and pollute water and land. An average-sized textile mill uses 6056659 million gallons of water daily to process 8000 kg of cloth [18]. On average, 1893 L of water produce enough finished cloth to cover a sofa [19]. However, these industrial sectors are neither trying to reduce chemical consumption nor are they trying to adopt green chemicals to reduce the chemical impacts on the environment.

Asia is the region of the world where the production of textiles is the highest. Asia produces 40.58 % of the global volume of cotton [20] and is the highest textile exporter in the world [21]. China is the largest textile products manufacturer [22] and exporter globally, with a turnover of $266.41 Bn. The Chinese textile industry has an output volume of more than half of the global market [23,24]. As China is the most populated country in the world [25], the consumption of textile products is also very high there, which also causes a huge amount of energy consumption for this sector along with high GHG emissions from this sector.

In such a scenario, China is the most significant country where energy consumption has increased vigorously in the past three decades as it has increased from 41.1 Mt in 1991 to 99.6 Mt in 2015, while from 2001 to 2007, the average annual energy consumption rate was the highest as 7.7 and 8.5 % respectively [26]. The spinning process contributes 0.84 kg CO2e (0.98 %), weaving contributes 18.8 kg CO2e (22.00 %), processing contributes 27.8 kg CO2e (32.53 %), garmenting contributes 17.19 kg CO2e (20.11 %), and denim washing contributes 21.68 kg CO2e (25.37 %). Furthermore, an overall assessment of GHG emissions reveals that spinning accounts for 0.84 kg CO2e (1 %), weaving for 18.8 kg CO2e (22 %), processing for 27.8 kg CO2e (32 %), garmenting for 17.19 kg CO2e (20 %), and denim washing for 21.68 kg CO2e (25 %). Additionally, the study delves into the water footprint associated with these processes, showing that spinning requires 3.57 L (10 %), weaving requires 9.86 L (28 %), processing requires 8.31 L (24 %), garmenting requires 5.07 L (14 %), and denim washing requires 8.45 L (24 %) [27].

Moreover, other Asian countries are more populated than any other region of the world. They are highly ranked in textile manufacturing and exports, like India, which comes in second place regarding population [28], while in textile manufacturing countries, it is ranked fifth. Similarly, Bangladesh comes in 8th place in the population ranking and has secured third place in textile manufacturing and exporting countries. Indonesia is the 4th most populated country, while Pakistan comes in 5th in terms of population. Pakistan's textile sector has secured the 8th position in textile products exporting countries [25,29].

Pakistan is the eighth largest textile exporter in the world as the exports comprised 8.5 % of the total GDP of Pakistan in 2018 while generating $7.72 Bn in revenue from this sector [30]. It is the 4th largest producer and 3rd largest consumer of cotton. The textile sector employs 40 % of the workforce, and 46 % is used in manufacturing. Moreover, the volume of textile exports was 61.2 % (US$ 15.4 Billion) of Pakistan's national export volume (US$ 25.3 Billion) in 2021. The current data suggests that the percentage contribution of textile-related products to Pakistan's overall exports has hovered around 60 % during the time horizon considered. For 2017 and 2021, this sector contributed 61.2 %, although it dropped below 60 % (58–59 %) between these years [31].

Pakistan's textile sector is the second-largest contributor to GHG emissions, the cement industry being the first. The textile sector emits 8.1 million tons of CO2 equivalent (MT CO2e) per annum [32]. It uses 27 % of the electricity and 40 % of the natural gas consumed in industry [33].

The novel aspect of this research is that it evaluates the usefulness of several assessment methodologies, including the CFP, the EFP, and the WFP, as well as their supporting frameworks and databases. This paper examines the gate-to-gate processing of different textile products produced in the manufacturing sector of Pakistan. The investigation requires collecting data from the textile manufacturers and analyzing it thoroughly. This research calculates the CFP, EFP, and WFP at each production stage while factoring in the fluctuating availability of national energy supplies. The study's results serve as a realistic example and point of reference for future researchers, managers, and stakeholders interested in the CFP situation for Pakistani clothing, T-shirts, and denim trousers. The study also explains the sources of GHG emissions from Pakistan's textile industry and highlights potential areas of intervention by critical stakeholders, including the government. Essential guidance for environmentally friendly operations, the paper specifies which fuel types should be utilized in the textile industry to lower GHG emissions.

2. Methodology

The bottom-up research technique was employed to give CFP, EFP, and WFP data for each step of the product life cycle. It allows the comparisons and identification of process and impact factor variations. This study investigated multiple textile companies in Pakistan between 2021 and 2022 that produced various textile products, including T-shirts, denim jeans, and other apparel items.

In this study, the functional units used to observe industrial production are a T-shirt with an average weight of 0.25 kg, a pair of denim jeans with an average weight of 0.5 kg, and other clothing items with a width of 3.2 m and a gram square meter (GSM) of 0.2, regardless of their color, thickness, and patterns. The actual calculation of GHG emissions needs to account for quality loss during production and other processes, such as average material loss and quality loss. This research employs gate-to-gate energy, carbon, and water footprint data in the Pakistani textile manufacturing sector as boundary conditions. This study includes the analysis of the energy, carbon, and water footprint from raw material entering the spinning sector to its finishing as a textile product in the form of garments.

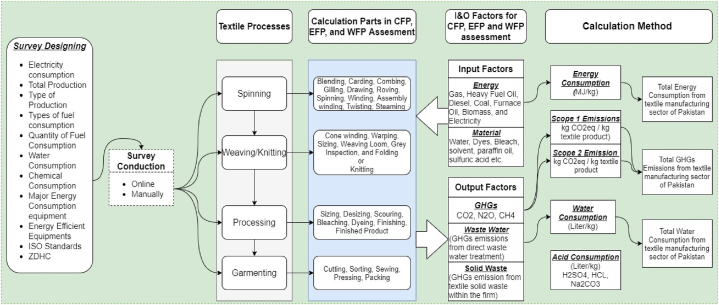

The IPCC report and ISO 14067 provide evaluation concepts and a framework. This research used IPCC methodology to define the system boundary for measuring the CFP, EFP, and WFP of textile items such as T-shirts, denim jeans, and apparel (Fig. 2). This study's CFP assessment estimates indirect emissions (Scope 2 emissions) from product manufacture in addition to NAMA-recommended direct and detectable GHG emissions (Scope 1 emissions). Companies must use energy efficiency, renewable energy, and emission reduction technologies to decrease Scope 1 emissions. However, scope 3 emissions were not studied in this research. According to the NAMA program, the investigation assessed various types of emissions and divided them into two main categories. The analysis began with direct emissions (Scope 1), including GHG emissions from sources regulated by sub-sectors, such as burning industrial fuels in furnaces and boilers. Second, indirect emissions (Scope 2), which come from outside sources like power companies, were also examined in this research. This comprehensive investigation addresses direct and indirect emissions from Pakistan's textile industry's production processes, which is essential for sustainability analysis.

Fig. 2.

Methodology of the study.

Cotton production, transit, industrial manufacturing, product transportation, consumption, and disposal comprise a textile product's life cycle. The gate-to-gate analysis comprises all system-bound textile operations. The system boundaries of CFP, EFP, and WFP assessments should encompass cradle-to-cradle processes, but the focus of this research is on gate-to-gate assessment, as indicated in Fig. 2.

Energy consumption—coal, boiler oil, gas, heavy fuel oil, diesel, biomass, and electricity—is the main input for CFP, EFP, and WFP estimates in this research. The indirect GHG emissions analysis solely considers electricity. Emissions from spinning, weaving, knitting, processing, and garmenting are included in calculating textiles' CFP, EFP, and WFP. Each step's GHG emissions are computed from energy, material, and direct GHG emissions like CO2, CH4, and NOX. This study excludes HFCs, PFCs, and SF6 since they contribute little to GHG emissions. These three GHGs have little influence due to their negligible emissions. For WFP assessment, the specific assessment model is estimated using Eq. (1):

| (1) |

for EFP assessment, the specific assessment model is estimated using Eq. (2):

| (2) |

for CFP assessment, the specific assessment model is estimated using Eq. (3):

| (3) |

Here,

n = the number of WFP, EFP or CFP assessment processes in a textile,

WFn = the WFP of assessment process n,

EFn = the EFP of assessment process n,

CFn = the CFP of assessment process n,

Win = the consumption of water in the assessment process n,

Ein = the consumption of energy or fuel i in assessment process n,

Pin = total production of textile product i in assessment process n,

ωidr = the direct CFP conversion factors for energy or fuel i,

ωiin = the indirect CFP conversion factors for energy or fuel i,

idr = the direct CFP conversion factors for material i,

iin = the indirect CFP conversion factors for material i

This research includes a comprehensive study of clothing manufacturers of varying sizes to collect data on the various processes involved in industrial textile production, including spinning, weaving, knitting, processing, and garmenting. The model developed in this research provides a detailed simulation of the crucial manufacturing procedures commonly utilized in Pakistan's small to large-scale production facilities. This research carefully includes micro (≤250), SME (250 ≤ x ≤ 600), and large-scale (≥600) textile firms in Lahore, Chiniot, Nankana Sahib, Jhang, Toba Tek Singh, Gujranwala, Multan, Kasur, Sheikhupura, and Faisalabad. The spread of the companies is shown in Table 1. The data was collected from the representative sample of different size companies and was used to plot the sectoral profile.

Table 1.

Spread of the textile sector in the selected regions of Punjab

| Type of Industry | District |

||||||||

|---|---|---|---|---|---|---|---|---|---|

| Chiniot | Faisalabad | Jhang | Kasur | Lahore | Nankana Sahib | Sheikhupura | Toba Tek Singh | Grand Total | |

| Large | 37 | 3 | 35 | 19 | 2 | 10 | 1 | 107 | |

| SME | 4 | 1034 | 18 | 120 | 445 | 18 | 83 | 3 | 1725 |

| Micro | 1 | 108 | 11 | 63 | 24 | 9 | 48 | 5 | 269 |

| Grand Total | 5 | 1179 | 32 | 218 | 488 | 29 | 141 | 9 | 2101 |

The statistical analysis of the data collected from the industries was conducted using IBM SPSS Statistics 27. The reliability analysis of the results revealed that Cronbach's alpha value for all sectors was above 0.7, indicating high internal consistency. Table 2 details the standard deviation and mean of each sector's micro, SME, and large industries.

Table 2.

Statistical analysis of the industrial data using IBM SPSS.

| Sector | Size | Electricity consumption |

Heat consumption |

Cronbach's Alpha | ||

|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | |||

| Spinning | Micro | 31.320 | 4.871 | 1.360 | 0.080 | 0.754 |

| SME | 28.650 | 4.605 | 1.820 | 0.129 | ||

| Large | 24.150 | 4.347 | 1.009 | 0.109 | ||

| Total | 28.040 | 4.608 | 1.396 | 0.106 | ||

| Weaving | Micro | 7.330 | 0.350 | 1.281 | 0.146 | 0.751 |

| SME | 7.250 | 0.690 | 1.117 | 0.111 | ||

| Large | 7.029 | 0.818 | 1.124 | 0.081 | ||

| Total | 7.203 | 0.619 | 1.174 | 0.113 | ||

| Processing | Micro | 1.530 | 0.170 | 6.143 | 0.601 | 0.764 |

| SME | 1.247 | 0.062 | 5.537 | 0.676 | ||

| Large | 1.127 | 0.165 | 5.161 | 0.530 | ||

| Total | 1.301 | 0.132 | 5.614 | 0.602 | ||

| Knitting | Micro | 8.231 | 0.355 | 2.911 | 0.313 | 0.761 |

| SME | 8.054 | 0.682 | 2.791 | 0.417 | ||

| Large | 7.759 | 0.516 | 2.621 | 0.382 | ||

| Total | 8.015 | 0.518 | 2.774 | 0.371 | ||

| Garmenting | Micro | 1.311 | 0.115 | 6.198 | 0.421 | 0.759 |

| SME | 1.161 | 0.072 | 6.192 | 0.449 | ||

| Large | 1.044 | 0.093 | 6.114 | 0.471 | ||

| Total | 1.172 | 0.093 | 6.168 | 0.447 | ||

2.1. Data collection

This research used a manual, online, and statistical yearbooks as data sources. The investigation and survey data were collected between 2021 and 2022 as data from the previous three years. Data on electricity consumption, total production, fuel consumption, water consumption, chemical consumption, energy equipment, energy-efficient equipment, ISO standards, and ZDHC were gathered from typical textile companies in Pakistan to track industrial production processes. The CFP assessment included energy sources such as gas, oil, biomass, and electricity. Direct and indirect GHG emissions associated with textile factory operations were considered, with direct CFP conversion factors determined using IPCC AR6. Previous studies and the Statistical Yearbook were used to estimate the indirect conversion factor. The assessment processes for calculating these conversion factors are detailed in Table 3.

Table 3.

Conversion factors to measure carbon footprint.

| Type of fuel | Amount (MJ) | Emissions per unit fuel consumption |

GWP Conversion Factor |

GWP |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CO2 (kg/MJ) | CH4 (kg/MJ) | N2O (kg/MJ) | CO2 | CH4 | N2O | CO2 (kg CO2e) | CH4 (kg CO2e) | N2O (kg CO2e) | ||

| Gas | 1 | 0.0561 | 0.000001 | 0.0000001 | 1 | 82.5 | 273 | 0.0561 | 0.0000825 | 0.0000273 |

| Heavy Fuel Oil | 1 | 0.0774 | 0.000003 | 0.0000006 | 1 | 82.5 | 273 | 0.0774 | 0.0002475 | 0.0001638 |

| Diesel | 1 | 0.0741 | 0.000003 | 0.0000006 | 1 | 82.5 | 273 | 0.0741 | 0.0002475 | 0.0001638 |

| Coal | 1 | 0.0946 | 0.000001 | 0.0000015 | 1 | 82.5 | 273 | 0.0946 | 0.0000825 | 0.0004095 |

| Furnace Oil | 1 | 0.0774 | 0.000003 | 0.0000006 | 1 | 82.5 | 273 | 0.0774 | 0.0002475 | 0.0001638 |

| Wood | 1 | 0.112 | 0.00003 | 0.000004 | 1 | 82.5 | 273 | 0.112 | 0.002475 | 0.001092 |

| Biomass | 1 | 0.1 | 0.000003 | 0.000004 | 1 | 82.5 | 273 | 0.1 | 0.0002475 | 0.001092 |

2.2. Uncertainty and sources of error

The validity of the CFP evaluation approach and the potential for data mistakes are the main areas of doubt in this study. The accuracy of the evaluation framework and the system limits are the main determinants of the method's reliability. The framework used in this study is developed from well-known approaches, including those of ISO, Carbon Trust, and IPCC, as well as, to the greatest extent feasible, from all significant processes involved in manufacturing textiles. The existing evaluation process is, therefore, quite secure. However, all data sources, including statistics yearbooks, research and survey studies, and experimental simulations, can potentially introduce inaccuracies. Although the statistics yearbooks provide official information regularly used in numerous studies, it is hard to assess their correctness. These yearbooks are commonly used for research, even if the information on water, energy, and greenhouse gas usage may be scant, particularly for small garment factories and independent home-based clothing makers. In order to calculate from specification data sheets or take readings from manufacturing equipment, the information from the investigation and survey was acquired. The sum of each subprocess was checked with statistical data on overall material and energy usage within businesses to guarantee the data's correctness. This was done to ensure that any data inaccuracies would not impact the outcomes. By identifying the variables that affect these values, the CFP, EFP, and WFP approach enables consumers to make more environmentally friendly lifestyle and shopping decisions that lower greenhouse gas emissions and energy and water use. Due to manufacturers' wide variations in individual consumption patterns, securing correct data during the research process was impossible when exact calculations were not pursued during the production or manufacturing phase. As a result, rather than thoroughly investigating any particular habits, the research acts as a broad overview of regional consumption trends. This method acknowledged the study's limitations while allowing for a wider grasp of the subject.

3. Results and discussions

This information was acquired via an extensive survey of 293 Pakistani textile firms, ranging in size from small-to large-scale enterprises. An ANOVA test was carried out in this research to examine the total amount of water and energy consumed in the textile sub-sectors. IBM SPSS was used to conduct this test. The ANOVA was performed with respect to the organization's size in all textile industry sub-sectors, and the results revealed statistically significant differences (p < 0.05) between the energy and water consumption in organizations of different sizes.

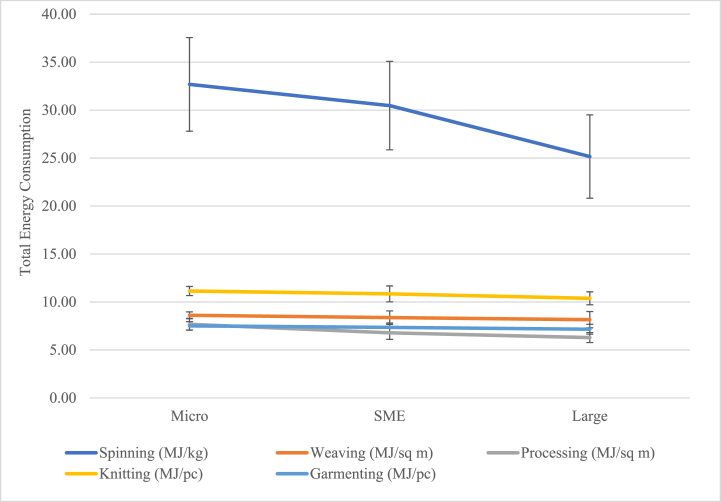

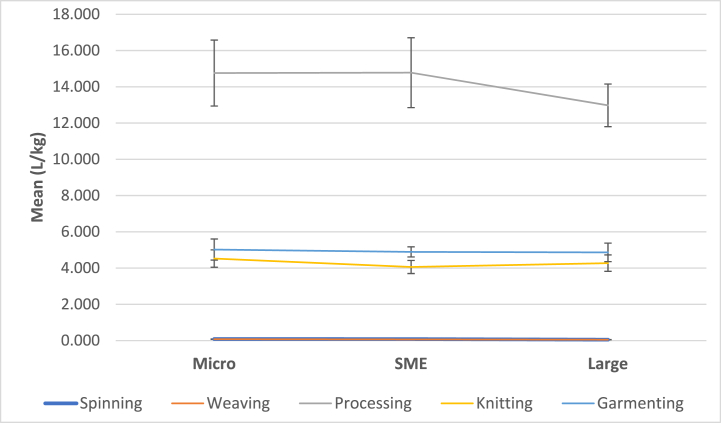

Table 4 and Table 5 show further details on the test's outcomes of total energy and water consumed in Pakistan's textile sub-sectors, respectively. Fig. 3, Fig. 4 display the mean of total energy and water consumed for each sub-sector, including spinning (MJ/kg and L/kg), weaving (MJ/sq m and L/sq m), processing (MJ/sq m and L/sq m), knitting (MJ/piece and L/piece), and garmenting (MJ/piece and L/piece). Error bars that display the standard deviations associated with these measurements are also included in the graph. It is evident from the analysis that organizations of smaller size are less energy and water-efficient, and their specific consumption of both in all sub-sectors of textile is higher than the larger organizations. It has also been noted that the difference in specific consumption of energy and water in micro and SMEs is relatively smaller as compared to the difference in the same between SMEs and large organizations.

Table 4.

ANOVA test of the total energy consumption from different textile sub-sectors.

| ANOVA | |||||

|---|---|---|---|---|---|

| Total Energy Consumption (MJ/kg) | Sum of Squares | df | Mean Square | F | Sig. |

| Spinning | |||||

| Between Groups | 2657.378 | 2 | 1328.689 | 59.839 | 0.000 |

| Within Groups | 9547.881 | 430 | 22.204 | ||

| Total | 12205.259 | 432 | |||

| Weaving | |||||

| Between Groups | 5.050 | 2 | 2.525 | 11.198 | 0.000 |

| Within Groups | 52.995 | 235 | 0.226 | ||

| Total | 58.046 | 237 | |||

| Processing | |||||

| Between Groups | 40.631 | 2 | 20.316 | 53.142 | 0.000 |

| Within Groups | 230.904 | 604 | 0.382 | ||

| Total | 271.535 | 606 | |||

| Knitting | |||||

| Between Groups | 4.595 | 2 | 2.297 | 9.440 | 0.000 |

| Within Groups | 95.404 | 392 | 0.243 | ||

| Total | 99.999 | 394 | |||

| Garmenting | |||||

| Between Groups | 2.249 | 2 | 1.124 | 5.739 | 0.003 |

| Within Groups | 83.264 | 425 | 0.196 | ||

| Total | 85.513 | 427 | |||

Table 5.

ANOVA test of the total water consumption from different textile sub-sectors.

| ANOVA | |||||

|---|---|---|---|---|---|

| Water Consumption (L/kg) | Sum of Squares | df | Mean Square | F | Sig. |

| Spinning | |||||

| Between Groups | 0.012 | 2 | 0.006 | 777.934 | <0.001 |

| Within Groups | 0.000 | 52 | 0.000 | – | – |

| Total | 0.013 | 54 | – | – | – |

| Weaving | |||||

| Between Groups | 2.257 | 2 | 1.129 | 27634.778 | <0.001 |

| Within Groups | 0.002 | 57 | 0.000 | – | – |

| Total | 2.260 | 59 | – | – | – |

| Processing | |||||

| Between Groups | 35.900 | 2 | 17.950 | 14.219 | <0.001 |

| Within Groups | 70.695 | 56 | 1.262 | – | – |

| Total | 106.595 | 58 | – | – | – |

| Knitting | |||||

| Between Groups | 2.203 | 2 | 1.101 | 3.450 | 0.039 |

| Within Groups | 16.921 | 53 | 0.319 | – | – |

| Total | 19.124 | 55 | – | – | – |

| Garmenting | |||||

| Between Groups | 0.284 | 2 | 0.142 | 0.390 | 0.679 |

| Within Groups | 21.822 | 60 | 0.364 | – | – |

| Total | 22.106 | 62 | – | – | – |

Fig. 3.

Mean of total energy consumption from the different sub-sectors of the textile industry of Pakistan.

Fig. 4.

Mean of total water consumption from the different sub-sectors of textile industry of Pakistan.

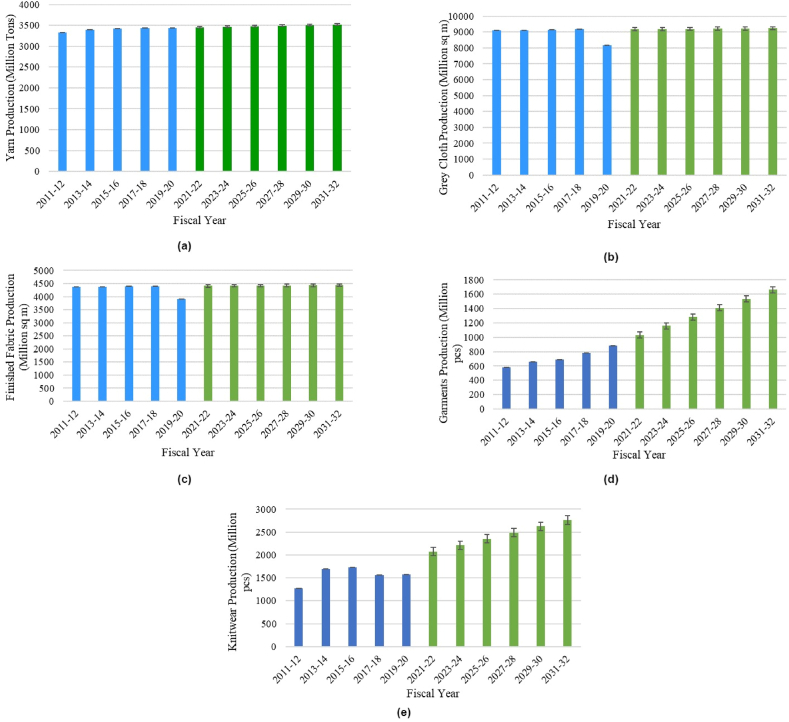

Moreover, the forecasted data is extracted using the ARIMA Model of forecasting in IBM SPSS by assuming that if suitable interventions are not done, then the consumption will be just like the trend shown in the graphs below. Fig. 5 shows that yarn output has been rising significantly over the previous two decades, reaching a record of 3520.8 million tons in FY2032-33. This is a considerable increase compared to the 3333.4 million tons produced in FY2012–2013. There are many causes for the increase in yarn output, including the textile and apparel sectors' rising need for yarn. The government emphasizes positioning the textile sector as a significant export business because of accessibility to low-cost labor and supplies. Moreover, there has also been an increase in the production of grey fabric, which peaked in FY2032-33 at 9244.9 million square meters. This represents a considerable rise compared to the 9115 million square meters generated in FY2012–2013. The same causes that contributed to the increase in yarn output also increased the production of grey fabric. Production of finished fabrics increased more slowly than that of yarn and grey cloth in FY2032-33, reaching 4437.5 million square meters. This is still a significant rise compared to the 9115 million square meters produced in FY2012–2013. There are many causes for the finished fabric industry's sluggish development, including the growing rivalry between nations that produce textiles and the high cost of inputs, including energy.

Fig. 5.

Yarn (a), Grey cloth (b), Finished Fabric (c), Garments (d), and Knitwear (e) Production for the previous and next decade.

Out of all the textile sub-sectors, garment output has grown at the quickest rate, reaching 1723.8 million pieces in FY2032-33. This is a considerable increase compared to the 580.9 million pieces generated in FY2012–2013. Several causes, including the following, may be credited with the clothing industry's explosive growth: the expanding local and global market demand for clothing, Pakistan's accessibility to a trained workforce, and the government's emphasis on positioning the apparel sector as a significant export business. Knitwear production has also increased quickly, reaching 2832.7 million pieces in FY2032-33. There is a considerable increase compared to the 1275.7 million pieces generated in FY2012–2013. Pakistan's textile industry has grown quickly over the last 20 years. The rising demand for textile goods from local and foreign markets will likely fuel this expansion in the next years. Growth in the sector will also be aided by the government's emphasis on marketing the textile industry as a significant export sector.

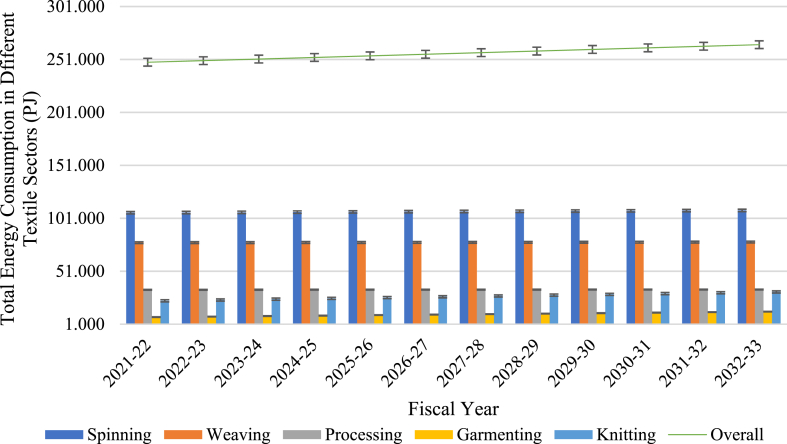

Fig. 6 shows the total energy consumption from the different textile sectors. This shows that the spinning sector is the most energy-intensive component of Pakistan's textile industry, using 106.187 PJ in FY2021-22 and is predicted to use 108.423 PJ in FY2032-33. This is because spinning requires massive, powerful equipment, humidification, and compressors to provide an optimal atmosphere for spinning. Spinning in Pakistan uses 30.795 MJ/kg of specific energy per kilogram, which is much greater than other textile subsectors. Electricity provides the bulk of the energy needed in spinning, with heat energy accounting for the remaining 5 %.

Fig. 6.

Total Energy Consumption (PJ) in Different Textile Sectors for forecasted years.

Weaving is the second-most energy-intensive sub-sector of Pakistan's textile industry, using 77.974 PJ in FY2021-22 and is expected to use 78.533 PJ in FY2032-33. The specific energy required for weaving in Pakistan is 8.49475 MJ/sq meter, less than the specific energy requirement for spinning but more than that for other textile sub-sectors. The bulk of the energy needed in weaving is electricity (85 %), with thermal energy accounting for the remaining 15 %. Processing is Pakistan's third-most energy-intensive sub-sector, using 33.478 PJ in FY2021-22, and is predicted to use 33.718 PJ in FY2032-33. Pakistan consumes 7.59825 MJ/sq m of specific energy for processing, which is less than the country's requirements for spinning and weaving but still more than those for other textile subsectors. Electricity accounts for 20 % of processing energy, while heat energy accounts for 80 %.

The garments subsector in Pakistan's textile industry had the lowest energy consumption in FY2021-22 and was predicted to rise to 12.831 PJ in FY2032-33 because of the low energy consumption process involved. The increase in energy consumption in the garments sub-sector may be attributed to the government's financial programs and policies, such as the Textiles and Apparel Policy 2020-25, which encourages businesses to create more garment factories in the country. Garments in Pakistan consume less energy (7.44375 MJ/sq meter) than all other textile sub-sectors combined. Electricity accounts for 17 % of the energy consumed in clothing, with heat accounting for the remaining 83 %.

Knitting is the fourth most energy-intensive sub-sector in Pakistan's textile industry, using 23.054 PJ in FY2021-22 and predicted to use 31.438 PJ in FY2032-33. The specific energy consumption for knitting in Pakistan is 11.098 MJ/sq meter, which is higher than the country's specific energy needs for garments but lower than those for spinning, weaving, and processing. Electricity provides 74 % of the energy needed in knitting, while heat energy provides 26 %.

Pakistan's textile industry is expected to utilize more energy, growing from 248.375 PJ in FY2021-22 to 264.943 PJ in FY2032-33. The development of the textile industry, the use of more energy-intensive equipment and processes, and government funding programs and policies that stimulate the building of new textile factories around the country all contribute to this increase in energy consumption. The textile sector's energy use in Pakistan is a substantial source of greenhouse gas emissions. In fiscal years 2021-22, the textile industry generated around 10 % of the nation's total greenhouse gas emissions.

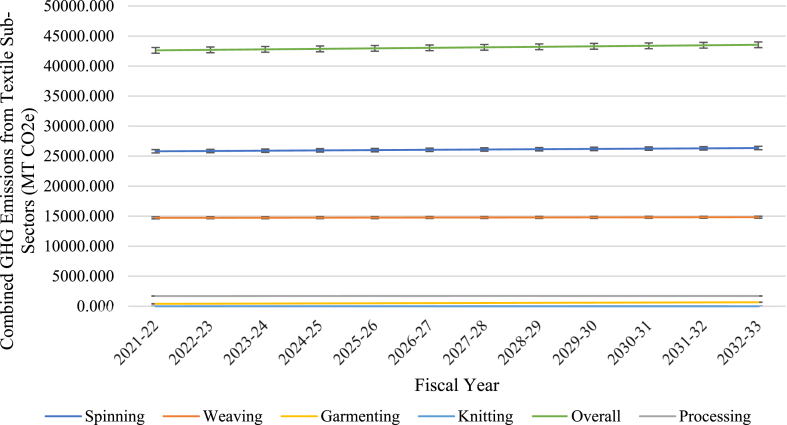

According to Fig. 7, Pakistan's total textile sector is predicted to emit 43,550.726 Mt CO2e in FY2032-33, a little increase over the 42,624.115 Mt CO2e emitted in FY2022-23. Scope 2 emissions are predicted to total 34,330.923 Mt CO2e in FY2032-33, making them the most significant source of emissions. This is much greater than the predicted scope 1 emissions of 9219.803 Mt CO2e in FY2032-33. The high level of Scope 2 emissions is due to textile industry's dependence on purchased electricity generated by fossil fuels. Renewable energy sources accounts for just 5.4 % of the national energy mix in 2021, according to the National Electric Power Regulatory Authority (NEPRA).

Fig. 7.

Combined GHG emissions (MT CO2e) from different textile sectors.

The spinning sector was likewise shown to be the top GHG emitter in the textile industry, followed by weaving, processing, garment, and knitwear. The spinning sector is responsible for 60 % of total GHG emissions from the textile industry, while the weaving sector is responsible for 23 %, the processing sector is responsible for 8 %, the garment sector is responsible for 6 %, and the knitwear sector is responsible for 3 %. The study's findings highlight the need for Pakistan's textile industry to reduce its reliance on fossil fuels and adopt more sustainable practices. This might be done via the use of renewable energy sources, increased energy efficiency, and greener industrial techniques.

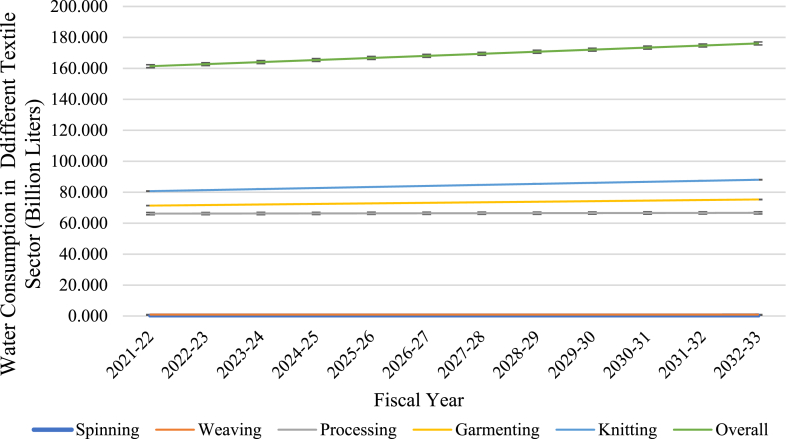

Fig. 8 depicts the estimated water usage in Pakistan's various textile sectors from FY2021-22 to FY2032-33. According to official statistics, water usage would not increase significantly over the next ten years, growing from 0.281 billion liters in FY2022-23 to 0.287 billion liters in FY2032-33. According to data, the spinning industry consumes the least quantity of water. According to weaving industries data, water use would increase slightly over the next ten years, rising from 0.666 billion liters in FY2022-23 to 0.671 billion liters in FY2032-33. According to projected processing statistics, water usage would increase over the next ten years, going from 65.223 billion liters in FY2022-23 to 65.690 billion liters in FY2032-33. According to garment data, water use would rise in the next ten years, from 5.179 billion liters in FY2022-23 to 8.652 billion liters in FY2032-33. Knitting data reveals that water use will increase in the next ten years, from 9.358 billion liters in FY2022-23 to 12.761 billion liters in FY2032-33, according to forecasts. Overall forecast data reveals that water use would increase over the next ten years, going from 5.397 billion liters in FY2022-23 to 9.016 billion liters in FY2032-33. The rise in the production of textile products is due to the higher population and government schemes to increase the volume of exports due to the growing global demands [34].

Fig. 8.

Water consumption in different textile sectors (billion liters).

Water quality in the textile industry can vary due to different production procedures and chemicals used. Typically, it contains a variety of contaminants, such as suspended solids, chemicals, heavy metals, acids, alkalis, organic compounds, and biological agents, which can affect pH and temperature. Depending on the makeup of the pollutants, numerous approaches can be used to purify the water. These techniques can be Reverse Osmosis, Activated Carbon Filtration, Ultrafiltration, Chemical Coagulation and Flocculation, and Electrocoagulation. These technologies can be used individually or in combination to effectively purify water in the textile industry. The chosen technology will depend on the impurities present and the desired level of purification.

According to the data received from the industries, it came to knowledge that gas, heavy fuel oil, furnace oil, diesel, and coal were being used to produce energy. Among the given fossil fuels, gas typically has the lowest GHG emissions per kilogram. Natural gas primarily comprises methane, which has a lower carbon-to-hydrogen ratio than other fossil fuels like coal, diesel, heavy fuel oil, and furnace oil. Gas is a more reliable fossil fuel than heavy fuel oil, diesel, furnace oil, and coal due to its lower emissions. Coal, with its carbon-rich composition, has the highest emissions, while other fuels emit more than gas. The composition of GHGs from different fuels per megajoule can be seen in Table 6. However, the GHG emissions associated with a particular fuel are influenced by various factors such as the fuel's energy density, combustion efficiency, and source.

Table 6.

Fuel and their associated emissions per megajoule.

| Type of Fuel | Unit | Emissions per unit fuel consumption |

||

|---|---|---|---|---|

| CO2 (kg/MJ) | CH4 (kg/MJ) | N2O (kg/MJ) | ||

| Gas | MJ | 0.0561 | 0.000001 | 0.0000001 |

| Heavy Fuel Oil | MJ | 0.0774 | 0.000003 | 0.0000006 |

| Diesel | MJ | 0.0741 | 0.000003 | 0.0000006 |

| Coal | MJ | 0.0946 | 0.000001 | 0.0000015 |

| Furnace Oil | MJ | 0.0774 | 0.000003 | 0.0000006 |

| Wood | MJ | 0.112 | 0.00003 | 0.000004 |

| Biomass | MJ | 0.1 | 0.000003 | 0.000004 |

Moreover, fossil fuel extraction, transportation, and processing also contribute to GHG emissions. Therefore, it is crucial to prioritize using gas in this era of the climate crisis to mitigate GHG emissions. The government should explore new gas resources, and stakeholders must collaborate to make the country less polluted and more sustainable.

4. Conclusions

This study examines Pakistan's textile industry's carbon, energy, and water footprints throughout manufacturing processes. It emphasizes the textile industry's need for sustainable environmental and resource management. The investigation found a gate-to-gate textile product carbon footprint of 42624.115 MTCO2e, with an indirect CFP of 42619.207 MTCO2e. Spinning produces 25809.37 MTCO2e, whereas knitting adds 1.9 MT to the CFP. Electricity and heat usage are high, at 192.916 and 55.557 PJ, respectively. Spinning uses energy-intensive air conditioning and hefty machinery. Beyond academics, the research helps firms, regulators, and consumers make educated textile product decisions. Energy-efficient and renewable technology must be promoted to reduce the spinning industry's excessive energy usage. Projections also emphasize the need for sustainable energy. This study also informs strategic decision-making and policy execution to reduce textile production's environmental effects. As the textile industry evolves, these insights provide a sustainable and ecologically conscientious future. Climate change and energy use must be addressed to protect the environment and economy. Green and energy-efficient textile solutions that reduce greenhouse gas emissions should be researched first. Creating an atmosphere that encourages firms to embrace these eco-friendly and energy-efficient technologies is crucial. Pakistan's textile manufacturing industry has the potential to contribute significantly to a more sustainable future by reducing its carbon footprint. By embracing and implementing eco-friendly practices, the sector can play a pivotal role in addressing the pressing challenges of climate change and resource conservation. This holistic approach, merging research and action, will pave the way towards a more environmentally responsible textile industry in Pakistan.

Additional information

No additional information is available for this paper.

CRediT authorship contribution statement

Shahid Imran: Writing – review & editing, Supervision, Data curation, Conceptualization. M.A. Mujtaba: Writing – review & editing, Formal analysis, Data curation. Muhammad Manan Zafar: Writing – original draft, Methodology, Data curation. Amjad Hussain: Writing – review & editing, Validation, Formal analysis. Amjad Mehmood: Writing – review & editing, Validation, Software, Formal analysis. Umm E. Farwa: Writing – review & editing, Formal analysis. T. Korakianitis: Writing – review & editing, Project administration. M.A. Kalam: Writing – review & editing. H. Fayaz: Writing – review & editing, Funding acquisition. C Ahamed Saleel: Writing – review & editing, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through a large group Research Project under grant number RGP2/106/44.

References

- 1.Dr Obinna Victor Obiagwu, Obasi Ugochukwu. Ulysses International Journal of Humanities and Contemporary Studies; 2022. A Philosophical Review of the Malthusian Theory of Population and Wealth.https://ulyssesjournals.com/pub/index.php/ulyssesjournalspub/article/view/22 [Online]. Available: [Google Scholar]

- 2.Rehman A., Ma H., Ozturk I., Ulucak R. Sustainable development and pollution: the effects of CO2 emission on population growth, food production, economic development, and energy consumption in Pakistan. Environ. Sci. Pollut. Control Ser. 2022;29(12):17319–17330. doi: 10.1007/s11356-021-16998-2. [DOI] [PubMed] [Google Scholar]

- 3.Nabi A.A., Shahid Z.A., Mubashir K.A., Ali A., Iqbal A., Zaman K. Relationship between population growth, price level, poverty incidence, and carbon emissions in a panel of 98 countries. Environ. Sci. Pollut. Control Ser. 2020;27:31778–31792. doi: 10.1007/s11356-020-08465-1. https://link.springer.com/article/10.1007/s11356-020-08465-1 Online]. Available: [DOI] [PubMed] [Google Scholar]

- 4.McFall-Johnsen M. The fashion industry emits more carbon than international flights and maritime shipping combined. Here are the biggest ways it impacts the planet. Business Insider. 2019;21 https://www.businessinsider.com/fast-fashionenvironmental-impact-pollution-emissions-waste-water [Online]. Available: [Google Scholar]

- 5.Sharpe S., Dominish E., Martinez Fernandez M.C. ILO Working Paper; 2022. Taking Climate Action: Measuring Carbon Emissions in the Garment Sector in Asia. [DOI] [Google Scholar]

- 6.O. Analytica, “China is key to sustainability of textile sector,” Emerald Expert Briefings, doi: 10.1108/OXAN-DB266838.. [DOI]

- 7.Mehar M.A. Magnitude of investment and global value chain: a case study of textile and clothing industry of Pakistan. J. Text. Inst. 2022;113(2):191–198. doi: 10.1080/00405000.2020.1868138. [DOI] [Google Scholar]

- 8.Connor J.O., Ostrander C.R. 2020. THE FIBERS ROADMAP,” Sustainable Agriculture and Food Systems Funders.https://forainitiative.org/wp-content/uploads/SAFSF-Fibers-Roadmap.pdf [Online]. Available: [Google Scholar]

- 9.Liang L., Jin L., Selopal G.S., Rosei F. Peace engineering in practice: China's energy diplomacy strategy and its global implications. Sustainability. 2023;15(2):1442. doi: 10.3390/su15021442. [Online]. Available: [DOI] [Google Scholar]

- 10.Eurostat, “Energy statistics - an overview ISSN 2443-8219,” Eurostat Statistics Explained (2022) no. March, pp. 9–10 https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_statistics_-_an_overview.

- 11.Zhou H., Yang Q., Zhu S., Song Y., Zhang D. Life cycle comparison of greenhouse gas emissions and water consumption for coal and oil shale to liquid fuels. Resour. Conserv. Recycl. 2019;144:74–81. doi: 10.1016/j.resconrec.2019.01.031. [DOI] [Google Scholar]

- 12.Meinshausen M., et al. Realization of Paris Agreement pledges may limit warming just below 2 C. Nature. 2022;604(7905):304–309. doi: 10.1038/s41586-022-04553-z. https://www.nature.com/articles/s41586-022-04553-z [Online]. Available: [DOI] [PubMed] [Google Scholar]

- 13.International Labour Organization . 2021. Reducing the Footprint? How to Assess Carbon Emissions in the Garment Sector in Asia ILO Asia-Pacific Report Decent Work in Garment Supply Chains Asia. March. [Online]. Available. [Google Scholar]

- 14.Rana S., Pichandi S., Moorthy S., Bhattacharyya A., Parveen S., Fangueiro R. Handbook of Sustainable Apparel Production. CRC Press; 2015. Sustainable UV-protective apparel textile; pp. 128–155. [DOI] [Google Scholar]

- 15.Muthu S. second ed. Environmental Impact Assessment Review; 2014. Assessing the Environmental Impact of Textiles and the Clothing Supply Chain.https://www.sciencedirect.com/book/9781782421047/assessing-the-environmental-impact-of-textiles-and-the-clothing-supply-chain [Online]. Available: [Google Scholar]

- 16.Reddy S., Osborne J. An insight on the advancements of biological technologies in the bioremediation of textile effluents. Urban Water J. 2022;0(0):1–13. doi: 10.1080/1573062X.2022.2030369. [DOI] [Google Scholar]

- 17.Koval M., Victoria Y., Angela G. vol. 547. EDITORIAL BOARD; 2022. (Experimental Research of Using Wastewater in Dyeing of Cotton Fabric by Dye Direct Red Light-Resistant). [Online]. Available: [Google Scholar]

- 18.Khandaker S., Bashar M.M., Islam A., Hossain M.T., Teo S.H., Awual M.R. Sustainable energy generation from textile biowaste and its challenges: a comprehensive review. Renew. Sustain. Energy Rev. Apr. 2022;157 doi: 10.1016/J.RSER.2021.112051. [DOI] [Google Scholar]

- 19.Hussain T., Wahab A. A critical review of the current water conservation practices in textile wet processing. J. Clean. Prod. 2018;198:806–819. doi: 10.1016/j.jclepro.2018.07.051. Online]. Available: [DOI] [Google Scholar]

- 20.Textile Exchange “Preferred fiber & materials market report 2021,”. Textile Exchange. 2021:1–118. https://textileexchange.org/app/uploads/2021/08/Textile-Exchange_Preferred-Fiber-and-Materials-Market-Report_2021.pdf [Online]. Available: [Google Scholar]

- 21.The World Trade Organization . 2019. Technological Innovation, Supply Chain Trade, and Workers in a Globalized World.https://www.wto.org/english/res_e/booksp_e/gvc_dev_report_2019_e.pdf [Online]. Available: [Google Scholar]

- 22.Pepermans A. China as a textile giant preserving its leading position in the world, and what it means for the EU. Taiwanese Journal of Political Science. 2019:63–108. doi: 10.6166/TJPS.201906_(80).0004. [DOI] [Google Scholar]

- 23.Ren Y., Yuan Z. Marketing strategy and consumer psychology A quantitative study of Chinese luxury consumption in the context of new media. Proceedings of the 2021 International Conference on Social Development and Media Communication (SDMC 2021) 2022;631:100–106. doi: 10.2991/assehr.k.220105.021. [DOI] [Google Scholar]

- 24.Fibre2Fashion, “Top 10 Exporting Countries of Textile and Apparel Industry - Fibre2Fashion.” https://www.fibre2fashion.com/industry-article/8471/top-10-exporting-countries-of-textile-and-apparel-industry (accessed July. 3, 2023)..

- 25.World Population Data Sheet, “World Population,”. 2020. p. 22.https://www.prb.org/wp-content/uploads/2020/07/letter-booklet-2020-world-population.pdf [Online]. Available: [Google Scholar]

- 26.Wang L., Li Y., He W. The energy footprint of China's textile industry: perspectives from decoupling and decomposition analysis. Energies. 2017;10(10) doi: 10.3390/en10101461. [DOI] [Google Scholar]

- 27.Luo Y., Wu X., Ding X. Carbon and water footprints assessment of cotton jeans using the method based on modularity: a full life cycle perspective. J. Clean. Prod. 2022;332 doi: 10.1016/j.jclepro.2021.130042. [Online]. Available: [DOI] [Google Scholar]

- 28.Kim M. Export competitiveness of India's textiles and clothing sector in the United States. Economies. 2019;7(2) doi: 10.3390/economies7020047. [DOI] [Google Scholar]

- 29.Invest Pakistan, “Textile | Board of Investment,” Board Of Investment. https://invest.gov.pk/textile (accessed July. 3, 2023).

- 30.Memon J.A., Aziz A., Qayyum M. The rise and fall of Pakistan's textile industry: an analytical view. European Journal of Business. 2020 doi: 10.7176/EJBM/12-12-12. [DOI] [Google Scholar]

- 31.Textile Commissioner’s Organization . 2023. Ministry of Textile Industry.http://pbit.gop.pk/system/files/Textile%20Industry.pdf [Online]. Available: [Google Scholar]

- 32.Ministry of Energy, “NEECA Strategic Plan 2020-25 -Draft”, Accessed: July. 3, 2023. [Online]. Available: https://neeca.gov.pk/SiteImage/Misc/files/NEECA%20Strategic%20Plan%202020-25%20-Draft.pdf.

- 33.Imran I.R. Evaluation of catastrophic global warming due to coal combustion, paradigm of South asia. International Journal of Innovations in Science and Technology. 2022 doi: 10.33411/IJIST/2021030406. [DOI] [Google Scholar]

- 34.Textile Wing Ministry of Commerce, “Textiles and Apparel Policy 2020-25.” Accessed: July. 3, 2023. [Online]. Available: https://aptma.org.pk/textiles-and-apparel-policy-2020-25/.