Abstract

The role of hydrogen in energy system decarbonization is being actively examined by the research and policy communities. We evaluate the potential “hydrogen economy” in global climate change mitigation scenarios using the Global Change Analysis Model (GCAM). We consider major hydrogen production methods in conjunction with delivery options to understand how hydrogen infrastructure affects its deployment. We also consider a rich set of hydrogen end-use technologies and vary their costs to understand how demand technologies affect deployment. We find that the availability of hydrogen transmission and distribution infrastructure primarily affects the hydrogen production mix, particularly the share produced centrally versus on-site, whereas assumptions about end-use technology primarily affect the scale of hydrogen deployment. In effect, hydrogen can be a source of distributed energy, enabled by on-site renewable electrolysis and, to a lesser extent, by on-site production at industrial facilities using natural gas with carbon capture and storage (CCS). While the share of hydrogen in final energy is small relative to the share of other major energy carriers in our scenarios, hydrogen enables decarbonization in difficult-to-electrify end uses, such as industrial high-temperature heat. Hydrogen deployment, and in turn its contribution to greenhouse gas mitigation, increases as the climate objective is tightened.

Keywords: low-carbon hydrogen, distributed hydrogen, hydrogen infrastructure, climate change mitigation, integrated assessment modeling

Short abstract

The role of hydrogen in the energy transition is investigated. Integrated assessment modeling of a low-emissions future shows that hydrogen delivery infrastructure primarily affects the hydrogen production mix, whereas end-use technology costs primarily affect the scale of hydrogen deployment.

1. Introduction

The possibility of using hydrogen (H2) as an energy carrier has been discussed for nearly half a century. While literature in the 1970s and 1980s noted its potential to enhance national energy security,1−4 a more recent focus has been its role in decarbonization, particularly in end-use sectors that are difficult to electrify. Like electricity, hydrogen can be produced from numerous primary energy sources using different production processes. But to contribute to decarbonization goals, it must be produced using low-carbon technologies. Examples include natural gas reforming with carbon capture and sequestration (CCS) to make “blue” hydrogen5 or renewable-based water electrolysis (“green” hydrogen6) and biomass gasification.7 The last of these methods could be coupled with CCS to produce hydrogen with negative emissions.8

Once produced, low-carbon hydrogen could be used to reduce emissions in several areas of the global energy system. In the industrial sector, hydrogen could provide a low-carbon fuel for high-temperature process heat,9 be used directly as a reducing agent for iron (hydrogen direct reduced iron [DRI]),10,11 or provide low-carbon feedstocks for chemical and fertilizer manufacturing.12 Hydrogen could similarly mitigate carbon dioxide (CO2) emissions in the transportation sector–particularly in heavy-duty transportation (e.g., trucks13 and marine vessels14). Furthermore, blending low-carbon hydrogen with natural gas15 could lower the carbon intensity of technologies that consume natural gas. Given such versatility, hydrogen has captured the attention of policymakers, as evidenced by the publication of hydrogen “roadmaps” by over a dozen nations.16−31

Evaluating the role of hydrogen in the energy transition involves understanding where and when it could be competitive with other decarbonization options. The role of hydrogen has been examined in some energy system models in the context of net-zero scenarios but typically at the country or regional level and often using exogenous assumptions about end-use demand.32−36 For this reason, technology-rich integrated assessment models (IAMs) are particularly well suited to advance our understanding, given that they have global coverage and endogenously represent competition within end-use demand sectors as well as within energy supply sectors.37,38 Several IAM-based studies have considered the role of hydrogen in climate mitigation. Barreto et al. (2003) employed MESSAGE-MACRO and found that hydrogen could potentially provide nearly half of all global final energy by the end of the century.39 Other early IAM studies found a more modest role for hydrogen, typically centered on the transportation sector. Using MiniCAM, Edmonds et al. (2004) found hydrogen could supply a significant share of global transportation final energy under emissions mitigation but only if advanced technological assumptions were realized (e.g., low-cost production and higher efficiency fuel cells).40 van Ruijven et al. (2007) similarly found, using TIMER 2.0, that hydrogen could play a key role in the transportation sector but primarily in the second half of the century.41 Using TIAM-UCL, Anandarajah et al. (2013) also found that hydrogen could contribute meaningfully to the decarbonization of road-based transportation.42

Recent studies have begun to consider the role of hydrogen in more detail. Using the Global Change Analysis Model (GCAM), Lazarou et al. (2018) found that hydrogen deployment was higher under increasingly stringent climate constraints.43 McPherson et al. (2018), using MESSAGE, demonstrated how hydrogen could support variable renewable electricity (VRE) deployment by providing electricity storage and firm electricity generation capacity under mitigation.44 More recently, an assessment by Oshiro and Fujimori (2022) using the AIM/Technology model found that by midcentury hydrogen and hydrogen-derived energy carriers could provide up to ∼9% of global industrial final energy demand and up to ∼50% of global transportation energy needs in scenarios that limited warming to 1.5–2 °C.45 While hydrogen was not the main focus of their analysis, Luderer et al. (2022) also showed pathways in REMIND-MAgPIE with significant amounts of hydrogen deployment under 1.5–2 °C policy scenarios.46

However, to our knowledge, no IAM studies have explicitly evaluated the impact of hydrogen delivery infrastructure, even though hydrogen transmission and distribution (T&D) costs are expected to be substantial and therefore an important factor in determining the hydrogen production mix and its competitiveness with other energy carriers. And while electrolysis-based hydrogen has received attention from the IAM literature, it remains less clear whether this production pathway will utilize grid electricity or dedicated renewable energy, as well as whether supply will be centralized or distributed in general. In addition, many possible hydrogen end-use technologies discussed by policymakers and the research community have not been fully incorporated into models. Oshiro and Fujimori (2022) included hydrogen-derived synthetic fuel utilization for rail and ammonia-powered marine applications, but they did not model hydrogen fuel cell technologies for these end uses. Similarly, Lazarou et al. (2018) only included hydrogen use in aggregate industry and light-duty vehicles. Anandarajah et al. (2013) evaluated hydrogen usage for road-based transportation, but they did not evaluate nonroad modes of transport or other end-use sectors.

In this study, we represent all major low-carbon hydrogen production methods, including both distributed (on-site) and central production, multiple hydrogen delivery options, and a rich set of hydrogen end-use technologies within GCAM. Compared to prior studies, this work considers a wider range of hydrogen uses across all major end-use sectors and calls attention to the role of hydrogen T&D in driving choices about hydrogen supply chains. Our results suggest that outcomes such as the production mix, the share of on-site production, and hydrogen’s contribution to mitigation in different end uses vary with key assumptions.

2. Methods

This research utilized the Global Change Analysis Model (GCAM),47 a publicly available global hierarchical equilibrium IAM. Specifically, GCAM version 5.448 was used as it was the most recent publicly available version of the model when this research began. Model enhancements were made to hydrogen-based technologies, as well as to other aspects of the energy system unrelated to hydrogen which are detailed in McJeon et al. (2021).49 GCAM links human and earth systems (the climate, water, land, and energy systems, as well as the economy), enabling examination of their interactions and responses to policy or technology changes. GCAM contains 32 energy and economic regions, 384 land areas, and 235 water basins, and the model projects various scenarios to the end of the century, running in five-year timesteps. Final energy demand in the model is driven by exogenous assumptions for income (GDP per capita) and population as well as endogenous changes in the cost of producing a given service (e.g., vehicle miles). The “middle-of-the-road” Shared Socioeconomic Pathway 2 (SSP2) assumptions50 are used in this study for population and GDP.

In each end-use sector, hydrogen competes with other energy carriers based on the levelized cost of supplying a given service (e.g., process heat for industrial needs) using a logit choice formulation.51,52 Hydrogen production technologies compete based on cost in a similar manner. When emissions are priced, as they are in climate mitigation scenarios, differences in emissions between technologies also affect competition. Emissions associated with resource production (e.g., natural gas) and energy conversion (e.g., electricity generation), along with emissions associated with energy requirements for T&D, are included within GCAM. In this way, GCAM accounts for the major sources of emissions across the life cycles of different fuels.

2.1. Hydrogen Production

Figure 1 shows the hydrogen structure in the updated version of GCAM used for this paper. This configuration allows hydrogen to be produced from biomass with or without CCS, fossil fuels with CCS, and multiple electrolysis pathways, including grid electrolysis, dedicated wind and solar electrolysis, and nuclear high temperature electrolysis (HTE). Hydrogen produced from fossil sources without CCS is not included given the focus on climate change mitigation scenarios in this study. Hydrogen can be produced centrally (i.e., at large-scale facilities that produce hydrogen that is subsequently delivered to end users) for all production methods. Alternatively, it can be produced on-site at the physical location of the end user, but on-site production is restricted to grid electrolysis, renewable electrolysis (green hydrogen), and natural gas with CCS (blue hydrogen). On-site blue hydrogen is assumed to be available only within industry given the scale required for CO2 capture. The representation of on-site green hydrogen assumes that renewable electricity is transmitted by the electricity grid from the VRE source to the end user that is producing hydrogen on-site. In contrast, central green hydrogen production is assumed to generate hydrogen at the VRE source, with hydrogen moved to the end user. While we assume both types of green hydrogen are produced synchronously with renewable electricity generation, the difference in their configurations allows one to investigate whether it may be advantageous to distribute green hydrogen rather than green electricity. On-site and central grid electrolysis is represented in a similar manner; however, these configurations are agnostic to the source of the electricity and therefore are assumed to operate at high capacity factors.

Figure 1.

Representation of GCAMv5.4 hydrogen supply and demand, as modified for this study.

Hydrogen production assumptions are harmonized with the National Renewable Energy Laboratory’s (NREL’s) Hydrogen Analysis Production Models (H2A) version 3.2018,53 except for assumptions about electricity generation needed for green hydrogen, nuclear HTE, and bioenergy with CCS (BECCS), which are described below. Blue hydrogen is based on assumptions for gas steam methane reforming (SMR) with CCS. All forms of electrolysis utilize H2A’s data for proton exchange membrane (PEM) electrolyzers, which are considered compatible with intermittent electricity.54,55 Levelized costs are calculated using the regional capacity factors of their paired renewables. Solar panel and wind turbine nonenergy costs were aligned with GCAM’s default power sector assumptions, which are based on NREL’s Annual Technology Baseline (ATB) version 2019.56 Additional details regarding GCAM’s power sector methodology can be found in Muratori et al. (2017).57 Nuclear HTE assumptions are also informed by NREL’s H2A models, but because there is no 2018 H2A version for this technology, we utilized the 2008 H2A version,58 the most recent publicly available, and updated the reactor costs using ATB version 2019. The H2A models provide assumptions for biomass hydrogen without CCS, so the additional costs and energy requirements for CCS were added to define the BECCS hydrogen technology. For all hydrogen production technologies coupled with CCS, capture fractions increase from 91% in 2020 to 93% in 2050.

Table S1 contains the levelized nonenergy costs for hydrogen production as well as feedstock and/or energy requirements for each production technology. Given the global scope and projection horizon, specific policy measures related to hydrogen that have been adopted by some countries, such as the Inflation Reduction Act in the US, are not included in this analysis. Regional policy measures, combined with differences in market conditions across regions, may lead to differences in the realized costs of hydrogen production technologies. Additional hydrogen production assumptions are discussed in the Supporting Information (S.1.A).

2.2. Hydrogen Transmission and Distribution

As a means of delivering centrally produced hydrogen, we represent liquid hydrogen truck and gaseous hydrogen pipeline T&D (both are referred to as dedicated hydrogen T&D in this study). The cost and efficiency assumptions for hydrogen delivery, found in Table S2, are based on Argonne National Laboratory’s Hydrogen Delivery Scenario Analysis Model (HDSAM) version 3.1.59 Hydrogen delivery from central production facilities is assumed to require 100 km of transmission to the end user, except for central green hydrogen production, which is assumed to require 500 km of transmission. The additional distance reflects an assumption that electrolyzers would be colocated with large wind or solar farms, which are generally sited where the renewable resource quality is highest, not near hydrogen demand centers. The first year of hydrogen pipeline operation in cases that allow pipeline delivery is 2030, reflecting the fact that it would take time to build out the hydrogen pipeline network. Trade of hydrogen between GCAM’s 32 native regions via continental pipelines or oceanic-based tankers is not included within this analysis.

The modified version of GCAM also allows blending of hydrogen into natural gas T&D networks as a third method of transporting hydrogen to consumers. The share of hydrogen blended into natural gas pipelines could be limited by multiple factors, including the potential for hydrogen to degrade the structural integrity of pipelines and compatibility with end-use technologies. This blend tolerance varies not only by pipeline type (materials) but also by end-use technology. A wide range of blend limits ranging from 2 to 30% has been reported in the literature.9,60−62 In the High Demand cases (discussed below), we assume a 20% blend by volume, or roughly a 7% blend by energy content,63 phased into natural gas distribution networks such that all new gas technologies in the relevant end-use sectors are consuming the blend by midcentury. In the Reference Demand cases (discussed below), we do not allow for any hydrogen blending with natural gas. See section S.1.B. for additional details on hydrogen T&D and blend assumptions. Figure 2 provides representative 2050 levelized costs of hydrogen for several key technologies in GCAM.

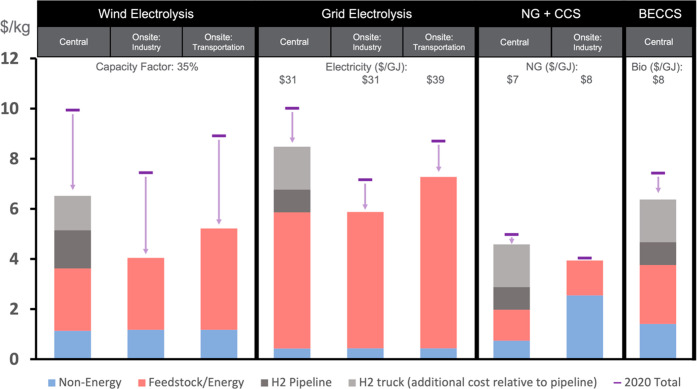

Figure 2.

Levelized Cost of Hydrogen (LCOH) in 2020 dollars per kg of H2 in 2050. The LCOH for a given production method varies regionally and across scenarios due to differences in the projected prices of delivered energy as well as renewable capacity factors. LCOH values presented here use illustrative delivered energy prices and renewable capacity factors, which are within the model’s ranges for these assumptions and projections across regions. “Non-Energy” costs refer to levelized capital and operating expenses. “Feedstock/Energy” costs refer to the costs associated with the feedstock and other energy inputs. The “Feedstock/Energy” cost for electrolysis is primarily the cost of electricity, which is either purchased (e.g., grid electrolysis) or produced on-site (e.g., central wind electrolysis). The total cost of delivering hydrogen via trucks is equal to the sum of costs for the “H2 pipeline” and “H2 truck (additional cost relative to H2 pipeline)”. The “2020 Total” is the total levelized cost for a given production technology in 2020.

2.3. Hydrogen End Uses

End-use consumption of hydrogen is limited to final energy applications in GCAM: cement production process heat, other industrial energy uses (e.g., process heat and cogeneration of power plus heat), passenger cars (multiple size classes), buses, freight trucks (multiple size classes), marine vessels (domestic and international), and freight rail transport. We use the term ‘other industrial energy use’ to refer to GCAM’s “industrial energy use” sector, which considers all energy use for industrial applications that are not already explicitly represented as separate sectors within this version of the model (note that energy used for mining, construction, and agriculture is included in ‘other industrial energy use’). While hydrogen-powered aviation has also been considered as a potential future hydrogen application, it was not included in this analysis, as there is a high level of uncertainty around this technology, making it difficult to identify plausible techno-economic assumptions. Given this study’s focus on hydrogen’s use for final energy, we do not consider hydrogen utilization for feedstocks (e.g., chemicals or hydrogen-derived fuels) or within the electricity sector. Hydrogen storage costs and energy requirements are included for refueling stations in the transportation sector (based on HDSAM) but not for the industrial sector given that comparable costs (e.g., on-site fuel storage) for other industrial technologies are not included within GCAM. When available, the hydrogen/natural gas blend can be consumed by specific end uses: cement manufacturing (process heat), other industrial energy uses (process heat and cogeneration), and building and industrial heat (district heat, direct residential and commercial heat, as well as other building energy needs such as water heating and cooking). Given that the blend limit and decision to phase in the blend are based on delivery tolerance and end-use technology thresholds, we do not include additional costs for end users to consume the blend above the cost differential of the fuel. However, we include the additional cost of compressing hydrogen for delivery through natural gas pipelines.

2.4. Energy Transition Scenarios

Table 1 describes the core scenarios examined using GCAM, which are defined by supply and demand assumptions. In this study, GCAM is coupled with the MAGICCv5.3 climate model.64 All core scenarios limit warming below 2 °C through the century, with a terminal temperature of 1.75 °C, by imposing a uniform global carbon price beginning in 2025 which rises 3% annually. Non-CO2 emissions (converted to CO2e emissions using the GWP-100) are abated using a marginal abatement cost curve to estimate the amount of abatement that would occur at the realized carbon price each year.65 The starting values of the carbon price are adjusted to attain the climate objective. We also consider a reduced set of scenarios that limit warming to 1.5 °C (with a terminal temperature of 1.35 °C; see section S.3). Temperature outcomes were also calculated using MAGICC v7.5.3 under the “IPCC AR6 WGI (Probabilistic)” setting, returning a median 1.84 °C temperature in 2100 for the below 2 °C scenarios and a 1.5 °C median for the more stringent climate objective.66 For the below 2 °C climate objective, we consider three options for hydrogen delivery:

-

(1)

No dedicated hydrogen T&D infrastructure available (only on-site production allowed)

-

(2)

Hydrogen delivery by hydrogen trucks is allowed (in addition to on-site production)

-

(3)

Hydrogen delivery by dedicated pipelines is allowed beginning in 2030 (in addition to truck delivery and on-site production).

Table 1. Core Scenarios Examined in This Studya.

T&D refers to transmission and distribution. All core scenarios limit warming below 2 °C through the century. Additional sensitivities, including scenarios that limit warming to 1.5 °C, can be found in the Supporting Information (see sections S3–S4).

We also consider two sets of assumptions for hydrogen demand technologies:

-

(1)

Reference Demand: capital costs for hydrogen technologies in the transportation and industrial sectors remain constant after their first year of availability (see Table S3 for availability years).

-

(2)

High Demand: capital costs for hydrogen technologies in the transportation sector decline after their first year of availability; nonenergy costs for hydrogen technologies in the industrial sector also decline, attaining a 25% cost reduction between 2020 and 2050; and hydrogen blending into natural gas networks is allowed.

In addition to 1.5 °C sensitivity cases, we consider several other sensitivities in the Supporting Information. Two scenarios limit bioenergy consumption globally, with one further constraining the amount of globally available carbon sequestration (“Bio Low” and “Bio Low/CCS Low”, S.4.A). We also include sensitivity scenarios (S.4.B–S.4.C) that restrict hydrogen production to central facilities and include direct air capture (DAC).

3. Results

3.1. Global Hydrogen Production through Midcentury

In all core scenarios, global hydrogen production remains below 2.5 EJ through 2030, but it reaches 10–22 EJ across scenarios by 2050 (Figure 3). For a sense of scale, in 2050, this equates to roughly 9–20% of total final energy consumed within just the transportation sector in 2015 (113 EJ). In each case, green hydrogen provides the largest share of production by midcentury–ranging from 36% to 69% of all hydrogen produced. The vast majority (>90%) of green hydrogen is produced on-site due to its lower cost (Figure 2). On-site production has slightly higher nonenergy costs (since electrolyzer costs are lower for central production due to economies of scale) as well as higher feedstock/energy costs (primarily from the cost of delivering solar- or wind-based electricity produced offsite), but these additional costs are more than offset by the cost savings from avoiding hydrogen T&D. On-site green hydrogen production (and its share of total production) further increases when warming is limited to 1.5 °C (section S.3).

Figure 3.

Annual global hydrogen production (EJ) by technology through midcentury for the core scenarios. Centrally produced hydrogen is shown using solid colors, whereas on-site production is shown using diagonal hashed colors. For the hydrogen production mix by end-use sector, see Figure S4. The production mix also varies by region, primarily due to differences in regional energy/feedstock costs and renewable capacity factors.

A key insight from this analysis is that on-site production of hydrogen, which is dominated by on-site green hydrogen in all GCAM scenarios, is a substantial proportion of total hydrogen production. In 2050, on-site production of hydrogen accounts for more than half of total hydrogen production in all but one of the six scenarios (in which it accounts for 43%). Still, the role for on-site production is not limited to green hydrogen, as industrial on-site blue hydrogen is also competitive with other technologies (Figure 2). Blue hydrogen accounts for 24–29% of total hydrogen production in 2050. But even when central blue hydrogen is available (with dedicated hydrogen T&D), 33–66% of all blue hydrogen is produced on-site.

Interestingly, the scale of hydrogen deployment is largely unaffected by the availability of dedicated hydrogen T&D infrastructure. Under Reference Demand assumptions, allowing both pipelines and truck delivery increases total hydrogen production by <2 EJ in 2050. While not materially impacting the scale of hydrogen production, dedicated hydrogen T&D enables delivered hydrogen to play a larger role. For instance, central production accounts for 0–19% without dedicated T&D (blending with natural gas allows for some central production), 30–48% when truck delivery is available, and 47–57% when pipelines are also available. High Demand scenarios exhibit higher overall hydrogen deployment than their corresponding Reference Demand scenarios but a similar production mix. As shown in Figure S11, the scale of hydrogen deployment is also found to be strongly sensitive to the climate objective, more than doubling by midcentury under scenarios limiting warming to 1.5 °C (30–48 EJ).

The introduction of dedicated hydrogen T&D opens the door for hydrogen produced centrally using natural gas with CCS, coal with CCS, biomass (including BECCS), and nuclear to contribute to emissions mitigation. Among these options, natural gas with CCS and BECCS are the most competitive (Figure 2). Although BECCS has a higher total levelized cost than industrial on-site green and blue hydrogen when there is no carbon price, BECCS provides a source of negative emissions and receives a subsidy under carbon policies. By 2050, BECCS hydrogen ranges from 1.2 to 4.6 EJ or 11 to 21% of total hydrogen production (with dedicated hydrogen T&D). However, BECCS hydrogen is only a small share of total biomass consumption (4% of modern biomass consumption in 2050 when pipelines are available under the Reference Demand assumptions), because other BECCS options in GCAM (e.g., in power, liquids production) are more attractive, either due to cost or their potential deployment scale. We consider two sensitivity scenarios–one in which biomass is limited and a second in which carbon sequestration is also limited–in the Supporting Information (section S.4.A). Lastly, the production mix (shares of each production type) as well as hydrogen production volumes in our core scenarios are well within the ranges found in scenarios limiting warming to 2 °C in the IPCC AR6 database67 (Figures S5 and S6).

3.2. Global Hydrogen Consumption through Midcentury

Under both Reference and High Demand scenarios, industrial hydrogen demand by 2050 is comparable to or larger than transportation hydrogen demand, accounting for 40% to 76% of hydrogen consumption or ∼7 to 11 EJ (or up to 12.5 EJ when including hydrogen blended with gas, Figure 4 and Table 2). Total hydrogen consumption in the High Demand scenarios is higher than in the corresponding Reference Demand scenarios by 8–9 EJ (or 70–84%) in 2050. Assumed cost reductions in hydrogen-based transportation lead to a noticeable increase in the level of hydrogen consumption for road transportation. However, even with High Demand assumptions and the ability to deliver hydrogen in pipelines, only 7% of freight road and 5% of international shipping service demand (tonne-km) are fulfilled by hydrogen technologies in 2050. Most of the remaining demand (66% of freight road and 94% of international shipping) is met by technologies that consume liquid fuels.

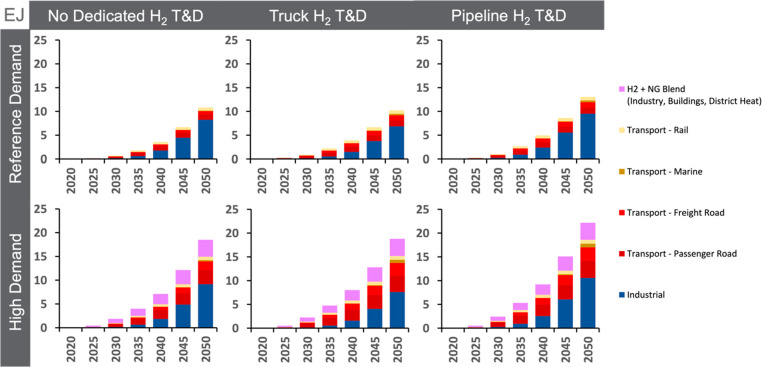

Figure 4.

Annual global hydrogen consumption (EJ) by end-use sector through midcentury for the core scenarios. Only the amount of hydrogen within the hydrogen/natural gas blend is included in the pink part of each bar.

Table 2. Annual Global Hydrogen Consumption (EJ) by Each End-Use Sector in 2050 for Two of the Core Scenariosa.

| Scenario | ||||||||

|---|---|---|---|---|---|---|---|---|

| No Dedicated H2 T&D, Reference Demand | Pipeline H2 T&D, High Demand | |||||||

| Sector | Final energy (EJ) | H2 demand (EJ) | % final energy | % service output | Final energy (EJ) | H2 demand (EJ) | % final energy | % service output |

| Industry | 278.9 | 8.2 | 3.0% | — | 281.4 | 12.5 | 4.4% | — |

| Cement | 15.3 | 1.2 | 7.6% | — | 15.3 | 1.4 | 9.1% | — |

| Other industrial energy use | 196.3 | 7.1 | 3.6% | — | 198.5 | 11.1 | 5.6% | — |

| Transportation | 135.0 | 2.6 | 1.9% | — | 134.2 | 8.0 | 6% | — |

| Passenger Vehicle | 39.0 | 0.6 | 1.4% | 1.5% | 38.6 | 3.0 | 7.7% | 8.3% |

| Bus | 6.0 | 0.6 | 9.8% | 22.1% | 6.0 | 0.7 | 11.1% | 24.6% |

| Freight Road | 47.8 | 0.7 | 1.5% | 1.7% | 47.1 | 2.8 | 6.0% | 6.9% |

| Freight Rail | 3.8 | 0.7 | 17.3% | 16.5% | 4.0 | 0.8 | 20.7% | 19.7% |

| Domestic Shipping | 2.3 | 0.03 | 1.4% | 1.5% | 2.3 | 0.2 | 8.2% | 8.7% |

| International Shipping | 13.2 | 0.1 | 0.6% | 0.7% | 13.2 | 0.6 | 4.4% | 5.5% |

| Buildings | 171.0 | 0 | 0% | — | 171.9 | 1.5 | 0.9% | — |

| Heat | 33.2 | 0 | 0% | — | 33.5 | 0.9 | 2.7% | — |

| Other | 121.3 | 0 | 0% | — | 121.7 | 0.6 | 0.5% | — |

| Total | 584.9 | 10.8 | 1.9% | — | 587.4 | 22.0 | 3.7% | — |

Values (EJ and %) are rounded to the nearest tenth if larger than or equal to 0.05 (otherwise values are presented to the nearest hundredth). ‘Other industrial energy use’ refers to the GCAM sector “industrial energy use”. The subsector “Other” within the buildings sector refers to the sum of GCAM’s “residential other” and “commercial other” subsectors. Hydrogen contained within the hydrogen/natural gas blend is included within these values. Subsectors will not sum to the sector total given that there are subsectors that do not consume hydrogen and are thus not reported here (e.g., building cooling, aviation, industrial feedstocks, N fertilizer production, and energy for water).

Compared to other energy carriers, hydrogen provides a smaller share of total final energy at midcentury (2–4%), with a similar share in transportation (2–6%) and industry (2–4%). The shares of hydrogen in final energy in the transportation and industrial sectors in our scenarios are well within the ranges for these outcomes assessed by the IPCC AR655 with comparable climate objectives (Figure S7). Despite being a small portion of total final energy in 2050, hydrogen deployment could further increase after midcentury or before midcentury under more stringent climate objectives. For example, while the role of hydrogen in international shipping is modest through 2050 in the core scenarios, we find hydrogen-fueled international ships provide 65–89% of this subsector’s final energy by 2100 (SI section S.2.A). In addition, hydrogen provides 58–90% of the final energy in international shipping by 2050 in scenarios that limit warming to 1.5 °C (Table S7).

Within industry, most hydrogen is expected to be used in processes that require high-temperature heat (>400 °C). IEA (2017) noted that high-temperature heat accounted for 48% of global industrial heat requirements or nearly 36% of industrial energy demand (not including feedstocks).68 These applications are contained within GCAM’s cement and “industrial energy use” sectors, in which hydrogen deployment is relatively modest through midcentury across scenarios (e.g., <10% of final energy for cement). However, these subsectors decarbonize more substantially after midcentury in the core scenarios or before midcentury when the climate objective is tightened.

In the High Demand scenarios, hydrogen blended into the natural gas pipeline network accounts for 36–47% of hydrogen consumption (∼0.9 EJ) in 2030. But by midcentury, the proportion of hydrogen consumption from the blend shrinks to 16–19%. This is because the approximate 7% emissions reduction from a 20% hydrogen blend by volume51 is not sufficient to avoid the increasing penalty on carbon emissions from natural gas. And although the blend (hydrogen + natural gas) represents ∼38% of final energy for heating buildings across the High Demand scenarios in 2050, the hydrogen contained within the blend represents < 3% of final energy for building heating and a smaller share of total buildings final energy. See Table 2 for additional details about hydrogen consumption and end use.

3.3. Connecting Hydrogen Supply and Demand: Delivery Pathways to End Uses

Figure 5 shows hydrogen consumption by each major end-use sector and delivery pathway. Truck and pipeline transport can be significant, with pipeline transport generally favored over truck transport when both are available due to differences in assumed costs. However, in all cases, on-site hydrogen production is larger than hydrogen delivered by truck or pipeline (as well as the amount blended into the natural gas networks). Furthermore, consumption by industry is comparable to and often larger than consumption by the transportation sector.

Figure 5.

Annual global hydrogen consumption by delivery method to end-use sectors through midcentury for the core scenarios. The figure does not include hydrogen blended with natural gas and delivered by the natural gas pipeline network.

These results are relevant to the evaluation of hydrogen leakage potential, which is of increasing interest, in part, due to the indirect impact of hydrogen emissions on the climate.69,70 Other work has begun to evaluate which areas of the supply chain would have greater or lesser leakage risk, with production, transportation by pipeline, and industrial uses appearing to have lower risk than truck transport or use in transportation.71

A wide range of hydrogen leakage rates across hydrogen supply and demand has been published in the literature.71−74 The hydrogen leakage rate could be reduced if hydrogen were produced on-site, with estimates suggesting less than half a percent lost from electrolysis and SMR71 (not withstanding losses from storage). Leakage potential is also thought to be lower for dedicated gaseous pipeline delivery than for liquid hydrogen truck T&D.71,72 Our results show that when pipelines are available, truck delivery plays a smaller role. When both hydrogen T&D options are available, 13–15% of total hydrogen is distributed by trucks and 34% by pipelines in 2050 (not including blended hydrogen). Thus, leakage potential is likely reduced with pipeline availability relative to a scenario in which T&D is limited to trucks. Greater leakage risk is likely to occur when hydrogen is delivered by truck to the transportation sector, because, after hydrogen is loaded onto trucks, additional hydrogen can be lost at refueling stations.71 Yet, we find truck delivery to the transportation sector to be a small portion of total hydrogen consumption across scenarios (less than 9% in 2050, not including blended hydrogen). Further study of leakage rates across different production, delivery, and consumption pathways would help to inform an assessment of overall H2 leakage potential and options to mitigate leakage.

4. Discussion

This study investigated hydrogen’s potential contribution to decarbonization focusing on the role of hydrogen T&D infrastructure availability, end-use technology costs, and climate policy stringency in GCAM scenarios. Results from these scenarios provide several insights about the potential role for hydrogen in an energy transition. On the supply side, when distributed production options are represented, the availability of hydrogen T&D primarily affects the production mix rather than the scale of hydrogen deployment. In effect, on-site production places a floor on production in our scenarios and is found to be cost-effective (accounting for over half of production in five of the six core scenarios) even when T&D infrastructure is available to deliver centrally produced hydrogen. Consistent with other recent IAM analyses that have noted the potential role for electrolysis-based hydrogen,45 we find that the largest share of on-site production is from green hydrogen due to its modularity. However, the role of on-site blue hydrogen in industry is also significant.

The large portion of on-site generation coming from green hydrogen is notable as modular electrolyzers are “granular” technologies (smaller in physical and/or economic scale per unit), and it has been demonstrated that increased granularity can be associated with quicker learning and diffusion timeframes as well as lower investor risk.75 On-site production of low-carbon hydrogen (whether blue or green) could also avoid aspects of the ‘three-sided chicken-and-egg’ problem,76 that is the need to simultaneously foster demand, supply, and delivery infrastructure. This is because the supply and demand for hydrogen would be balanced within a facility (i.e., a consumer need not wait for a centralized supply of hydrogen, which may not materialize until demand is apparent). While hydrogen exports may expand the role of centrally produced hydrogen, the inclusion of hydrogen trade across GCAM regions is not likely to significantly change our results since the high cost of moving hydrogen regionally already limits the deployment of the centralized supply.

On the demand side, industrial use of hydrogen is found to be greater than the sum of all transportation uses in most of our core scenarios, reflecting in part the overall size of final energy demand in these sectors (industrial final energy demand is about twice transportation final energy demand in 2050). However, in scenarios with lower end-use costs, the hydrogen share of transportation final energy is greater than the hydrogen share of industrial final energy, suggesting that hydrogen demand is sensitive to end-use technology costs. Indeed, we find that the overall amount of deployment is driven more by end-use technology costs than by assumptions about T&D infrastructure. In addition, we find that overall hydrogen deployment is sensitive to increased climate policy stringency (increasing both in absolute terms and as a share of final energy), suggesting that hydrogen will remain a key focus in policy and planning related to the energy transition.

We also note that the small share of hydrogen transported by truck and delivered to the transportation sector across our scenarios may diminish the risk of leakage relative to scenarios in which those pathways are more dominant. Leakage risk would also presumably be lower when a larger share of hydrogen is produced and consumed on-site. Given the pathways by which hydrogen is produced and consumed in GCAM scenarios and the increasing discussion of hydrogen leakage, it would be helpful for future research to consider leakage at each stage of the supply chain explicitly, such that leakage assumptions are consistent with the pathways. Finally, while our focus has been on hydrogen demand by energy end uses, questions remain about the role of hydrogen in the power sector and in the production of hydrogen-derived fuels, which will be a focus of future GCAM development.

Acknowledgments

The PNNL authors acknowledge support from the ExxonMobil Technology and Engineering Company.

Data Availability Statement

The GCAM model and the data system are available as an open-source package (see https://github.com/JGCRI/gcam-core). The customized version of the model used in this study, as well as the scenario data, can be accessed at 10.5281/zenodo.8329505.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acs.est.3c03751.

Additional details on methodology for hydrogen production, delivery, and end-use technologies, as well as supplementary results for core scenarios and supporting sensitivities (PDF)

The views and opinions expressed in this paper are those of the authors alone.

The authors declare no competing financial interest.

Supplementary Material

References

- Winsche W. E.; Hoffman K. C.; Salzano F. J. Hydrogen: Its Future Role in the Nation’s Energy Economy.. Science 1973, 180, 1325–32. 10.1126/science.180.4093.1325. [DOI] [PubMed] [Google Scholar]

- Dawson J. K. Prospects for Hydrogen as an Energy Resource.. Nature 1974, 249 (5459), 724–26. (June) 10.1038/249724a0. [DOI] [Google Scholar]

- Silverstein Harvey B. Energy Security and the Hydrogen Economy. Naval War College Review 1980, 33 (5), 48–62. [Google Scholar]

- Gomberg H.; Gordus A. A. Hydrogen for Synthetic Fuels via Nuclear Energy.. Journal of Fusion Energy 1982, 2 (4), 319–39. (October 1) 10.1007/BF01063684. [DOI] [Google Scholar]

- van Renssen Sonja. The Hydrogen Solution?. Nature Climate Change 2020, 10 (9), 799–801. (September) 10.1038/s41558-020-0891-0. [DOI] [Google Scholar]

- Oliveira Alexandra M.; Rebecca R Beswick; Yushan Yan. A Green Hydrogen Economy for a Renewable Energy Society. Current Opinion in Chemical Engineering 2021, 33 (September 1), 100701. 10.1016/j.coche.2021.100701. [DOI] [Google Scholar]

- Spath P.; Aden A.; Eggeman T.; Ringer M.; Wallace B.; Jechura J.. Biomass to Hydrogen Production Detailed Design and Economics Utilizing the Battelle Columbus Laboratory Indirectly-Heated Gasifier; May 1, 2005; https://doi.org/10.2172/15016221 (accessed 2023-10-22).

- Rosa Lorenzo; Marco Mazzotti. Potential for Hydrogen Production from Sustainable Biomass with Carbon Capture and Storage. Renewable and Sustainable Energy Reviews 2022, 157 (April 1), 112123. 10.1016/j.rser.2022.112123. [DOI] [Google Scholar]

- The Future of Hydrogen; International Energy Agency (IEA): 2019. https://iea.blob.core.windows.net/assets/9e3a3493-b9a6-4b7d-b499-7ca48e357561/The_Future_of_Hydrogen.pdf (accessed 2023-10-22).

- Bhaskar Abhinav; Mohsen Assadi; Homam Nikpey Somehsaraei. Decarbonization of the Iron and Steel Industry with Direct Reduction of Iron Ore with Green Hydrogen. Energies 2020, 13 (3), 758.(January) 10.3390/en13030758. [DOI] [Google Scholar]

- Sasiain A.; Rechberger K.; Spanlang A.; Kofler I.; Wolfmeir H.; Harris C.; Bürgler T. Green Hydrogen as Decarbonization Element for the Steel Industry.. BHM Berg- Und Hüttenmännische Monatshefte 2020, 165 (5), 232–36. (May 1) 10.1007/s00501-020-00968-1. [DOI] [Google Scholar]

- Ostadi Mohammad; Kristofer Gunnar Paso; Sandra Rodriguez-Fabia; Lars Erik Øi; Flavio Manenti; Magne Hillestad. Process Integration of Green Hydrogen: Decarbonization of Chemical Industries. Energies 2020, 13 (18), 4859.(January) 10.3390/en13184859. [DOI] [Google Scholar]

- Anselma Pier Giuseppe; Giovanni Belingardi. Fuel Cell Electrified Propulsion Systems for Long-Haul Heavy-Duty Trucks: Present and Future Cost-Oriented Sizing. Applied Energy 2022, 321 (September 1), 119354. 10.1016/j.apenergy.2022.119354. [DOI] [Google Scholar]

- Alkhaledi Abdullah NFNR.; Sampath uresh; Pilidis Pericles Economic Analysis of a Zero-Carbon Liquefied Hydrogen Tanker Ship.. Int. J. Hydrogen Energy 2022, 47 (66), 28213–23. (August 1) 10.1016/j.ijhydene.2022.06.168. [DOI] [Google Scholar]

- Topolski Kevin; Evan Reznicek; Burcin Erdener; Chris San Marchi; Joseph Ronevich; Lisa Fring; Kevin Simmons; Omar Jose Guerra Fernandez; Bri-Mathias Hodge; Mark Chung.. Hydrogen Blending into Natural Gas Pipeline Infrastructure: Review of the State of Technology; 2022; https://doi.org/10.2172/1893355 (accessed 2023-10-22).

- COAG Energy Council. Australia’s National Hydrogen Strategy; Commonwealth of Australia: 2019. https://www.dcceew.gov.au/sites/default/files/documents/australias-national-hydrogen-strategy.pdf (accessed 2023-10-22).

- Hydrogen Strategy for Canada: Seizing the Opportunities for Hydrogen - A Call to Action; Government of Canada: 2020. https://natural-resources.canada.ca/sites/nrcan/files/environment/hydrogen/NRCan_Hydrogen-Strategy-Canada-na-en-v3.pdf (accessed 2023-10-22).

- Ministry of Energy . National Green Hydrogen Strategy: Chile, a Clean Energy Provider for a Carbon Neutral Planet; Government of Chile: 2020. https://energia.gob.cl/sites/default/files/national_green_hydrogen_strategy_-_chile.pdf (accessed 2023-10-22).

- Ministerio de Minas y Energía . Hoja de Ruta Del Hidrógeno En Colombia; Government of Colombia: 2021. https://www.minenergia.gov.co/static/ruta-hidrogeno/src/document/Hoja%20Ruta%20Hidrogeno%20Colombia_2810.pdf (accessed 2023-10-22).

- Ministry of Industry and Trade . The Czech Republic’s Hydrogen Strategy; Government of Czech Republic: 2021. https://www.mpo.cz/assets/cz/prumysl/strategicke-projekty/2021/9/Hydrogen-Strategy_CZ_2021-09-09.pdf (accessed 2023-10-22).

- Stratégie Nationale Pour Le Développement de l’hydrogène Décarboné En France; Government of France: 2020. https://www.ecologie.gouv.fr/sites/default/files/DP%20-%20Stratégie%20nationale%20pour%20le%20développement%20de%20l%27hydrogène%20décarboné%20en%20France.pdf (accessed 2023-10-22).

- Federal Ministry for Economic Affairs and Energy . The National Hydrogen Strategy; Government of Germany: 2020. https://www.bmwk.de/Redaktion/EN/Publikationen/Energie/the-national-hydrogen-strategy.pdf?__blob=publicationFile&v=6 (accessed 2023-10-22).

- Hungary’s National Hydrogen Strategy; Government of Hungary: 2021. https://cdn.kormany.hu/uploads/document/a/a2/a2b/a2b2b7ed5179b17694659b8f050ba9648e75a0bf.pdf (accessed 2023-10-22).

- Ministerial Council on Renewable Energy, Hydrogen and Related Issues . Basic Hydrogen Strategy; Government of Japan: 2017. https://policy.asiapacificenergy.org/sites/default/files/Basic%20Hydrogen%20Strategy%20%28EN%29.pdf (accessed 2023-10-22).

- Government Strategy on Hydrogen; Government of the Netherlands: 2020. https://www.government.nl/documents/publications/2020/04/06/government-strategy-on-hydrogen (accessed 2023-10-22).

- Norwegian Ministry of Petroleum and Energy, and Norwegian Ministry of Climate and Environment . The Norwegian Government’s Hydrogen Strategy: Towards a Low Emission Society; Government of Norway: 2020. https://www.regjeringen.no/en/dokumenter/the-norwegian-governments-hydrogen-strategy/id2704860/ (accessed 2023-10-22).

- Ministry of Business, Innovation & Employment . A Vision for Hydrogen in New Zealand; Government of New Zealand: 2019. https://www.mbie.govt.nz/dmsdocument/6798-a-vision-for-hydrogen-in-new-zealand-green-paper (accessed 2023-10-22).

- Ambiente e Ação Climática . Estratégia Nacional para o Hidrogénio (EN-H2); Government of Portugal: 2020. https://planapp.gov.pt/instrumento/estrategia-nacional-para-o-hidrogenio-en-h2/ (accessed 2023-10-22).

- Ministerio para la Transición Ecológica y el Reto Demográfico . Hydrogen Roadmap: A Commitment to Renewable Hydrogen (executive summary); Government of Spain: 2020. https://www.miteco.gob.es/es/ministerio/planes-estrategias/hidrogeno/h2executivesummary_tcm30-513831.pdf (accessed 2023-10-22).

- Secretary of State for Business, Energy & Industrial Strategy . UK Hydrogen Strategy; Government of the United Kingdom: 2021. https://www.gov.uk/government/publications/uk-hydrogen-strategy (accessed 2023-10-22).

- United Nations Economic Commission for Europe (UNECE) . Draft Roadmap for Production and Use of Hydrogen in Ukraine; 2021. https://unece.org/sites/default/files/2021-03/Draft%20Roadmap%20for%20production%20and%20use%20of%20hydrogen%20in%20Ukraine_Final%20.pdf (accessed 2023-10-22).

- Browning Morgan; James McFarland; John Bistline; Gale Boyd; Matteo Muratori; Matthew Binsted; Chioke Harris; Trieu Mai; Geoff Blanford; Jae Edmonds; Allen A.; cett; Ozge Kaplan; John Weyant. Net-Zero CO2 by 2050 Scenarios for the United States in the Energy Modeling Forum 37 Study. Energy and Climate Change 2023, 4 (December 1), 100104. 10.1016/j.egycc.2023.100104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Glynn James; Maurizio Gargiulo; Alessandro Chiodi; Paul Deane; Fionn Rogan; Brian Ó Gallachóir. Zero Carbon Energy System Pathways for Ireland Consistent with the Paris Agreement. Climate Policy 2019, 19 (1), 30–42. (January 2) 10.1080/14693062.2018.1464893. [DOI] [Google Scholar]

- Oshiro Ken; Toshihiko Masui; Mikiko Kainuma. Transformation of Japan’s Energy System to Attain Net-Zero Emission by 2050. Carbon Management 2018, 9 (5), 493–501. (October) 10.1080/17583004.2017.1396842. [DOI] [Google Scholar]

- Williams James H.; an A. Jones; Ben Haley; Gabe Kwok; Jeremy Hargreaves; Jamil Farbes; Margaret S. Torn. Carbon-Neutral Pathways for the United States.. AGU Advances 2021, 2 (1), e2020AV000284 10.1029/2020AV000284. [DOI] [Google Scholar]

- Pickering Bryn; Francesco Lombardi; Stefan Pfenninger. Diversity of Options to Eliminate Fossil Fuels and Reach Carbon Neutrality across the Entire European Energy System.. Joule 2022, 6 (6), 1253–76. (June 15) 10.1016/j.joule.2022.05.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Weyant John. Some Contributions of Integrated Assessment Models of Global Climate Change.. Review of Environmental Economics and Policy 2017, 11 (1), 115–137. (January) 10.1093/reep/rew018. [DOI] [Google Scholar]

- Fisher-Vanden Karen; John Weyant. The Evolution of Integrated Assessment: Developing the Next Generation of Use-Inspired Integrated Assessment Tools.. Annual Review of Resource Economics 2020, 12, 471–487. 10.1146/annurev-resource-110119-030314. [DOI] [Google Scholar]

- Barreto L.; Makihira A.; Riahi K. The Hydrogen Economy in the 21st Century: A Sustainable Development Scenario. Int. J. Hydrogen Energy 2003, 28 (3), 267–84. (March 1) 10.1016/S0360-3199(02)00074-5. [DOI] [Google Scholar]

- Edmonds Jae; John Clarke; James Dooley; Son H.; Steven J. Smith. Stabilization of CO2 in a B2 World: Insights on the Roles of Carbon Capture and Disposal, Hydrogen, and Transportation Technologies.. Energy Economics, EMF 19 Alternative technology strategies for climate change policy, 2004, 26 (4), 517–537. (July 1) 10.1016/j.eneco.2004.04.025. [DOI] [Google Scholar]

- van Ruijven Bas; Detlef P.; Vuuren; Bert de Vries. The Potential Role of Hydrogen in Energy Systems with and without Climate Policy.. Int. J. Hydrogen Energy 2007, 32 (12), 1655–1672. (August 1) 10.1016/j.ijhydene.2006.08.036. [DOI] [Google Scholar]

- Anandarajah Gabrial; Will McDowall; Paul Ekins. Decarbonising Road Transport with Hydrogen and Electricity: Long Term Global Technology Learning Scenarios. Int. J. Hydrogen Energy 2013, 38 (8), 3419–3432. (March 19) 10.1016/j.ijhydene.2012.12.110. [DOI] [Google Scholar]

- Lazarou Stavros; Vasiliki Vita; Maria Diamantaki; Diotima Karanikolou-Karra; George Fragoyiannis; Sofoklis Makridis; Lambros Ekonomou. ;A Simulated Roadmap of Hydrogen Technology Contribution to Climate Change Mitigation Based on Representative Concentration Pathways Considerations. Energy Science & Engineering 2018, 6 (3), 116–125. 10.1002/ese3.194. [DOI] [Google Scholar]

- McPherson Madeleine; Nils Johnson; Manfred Strubegger. The Role of Electricity Storage and Hydrogen Technologies in Enabling Global Low-Carbon Energy Transitions. Applied Energy 2018, 216, 649–661. (April 15,) 10.1016/j.apenergy.2018.02.110. [DOI] [Google Scholar]

- Oshiro Ken; Shinichiro Fujimori. Role of Hydrogen-Based Energy Carriers as an Alternative Option to Reduce Residual Emissions Associated with Mid-Century Decarbonization Goals. Applied Energy 2022, 313 (May 1), 118803. 10.1016/j.apenergy.2022.118803. [DOI] [Google Scholar]

- Luderer Gunnar; Silvia Madeddu; Leon Merfort; Falko Ueckerdt; Michaja Pehl; Robert Pietzcker; Marianna Rottoli; Felix Schreyer; Nico Bauer; Lavinia Baumstark; Christoph Bertram; Alois Dirnaichner; Florian Humpenöder; Antoine Levesque; Alexander Popp; Renato Rodrigues; Jessica Strefler; Elmar Kriegler. Impact of Declining Renewable Energy Costs on Electrification in Low-Emission Scenarios. Nature Energy 2022, 7 (1), 32–42. (January) 10.1038/s41560-021-00937-z. [DOI] [Google Scholar]

- Global Change Analysis Model (GCAM). R; Joint Global Change Research Institute: 2016. https://github.com/JGCRI/gcam-core (accessed 2023-10-22).

- Bond-Lamberty Ben; Pralit Patel; Joshua Lurz; Steve Smith; snyder abigail; pkyle kvcalvin; Kalyn R. heim; Robert Link; mbins skiḿ; Aaron S.; Leyang Feng; Sean W D Turner; cwroney Cary Lynch; jhoring Zarrar Khan; Haewon mwisepnnl; mollycharles Gokul Iyer; Alexey Shiklomanov; swaldhoff Richard Plevin; matteomuratori amundra; Corinne Hartin; Kanishka Narayan.. JGCRI/Gcam-Core: GCAM 5.4; Zenodo; July 12, 2021; https://doi.org/10.5281/zenodo.5093192 (accessed 2023-10-22).

- McJeon Haewon; Bryan K.; none; Patrick O’Rourke; Russell Horowitz; Haroon S. Kheshgi; Leon Clarke; Page Kyle; Pralit Patel; Jae Edmonds Fossil Energy Deployment through Midcentury Consistent with 2°C Climate Stabilization. Energy and Climate Change 2021, 2 (December 1), 100034. 10.1016/j.egycc.2021.100034. [DOI] [Google Scholar]

- Fricko Oliver; Petr Havlik; Joeri Rogelj; Zbigniew Klimont; Mykola Gusti; Nils Johnson; Peter Kolp; Manfred Strubegger; Hugo Valin; Markus Amann; Tatiana Ermolieva; Nicklas Forsell; Mario Herrero; Chris Heyes; Georg Kindermann; Volker Krey; David L.ollum; Michael Obersteiner; Shonali Pachauri; Shilpa Rao; Erwin Schmid; Wolfgang Schoepp; Keywan Riahi. The Marker Quantification of the Shared Socioeconomic Pathway 2: A Middle-of-the-Road Scenario for the 21st Century. Global Environmental Change 2017, 42, 251–67. (January 1,) 10.1016/j.gloenvcha.2016.06.004. [DOI] [Google Scholar]

- Clarke J. F.; Edmonds J. A. Modelling Energy Technologies in a Competitive Market. Energy Economics 1993, 15 (2), 123–129. 10.1016/0140-9883(93)90031-L. [DOI] [Google Scholar]

- McFadden D.Conditional Logit Analysis of Qualitative Choice Behavior. In Frontiers in Econometrics; Academic Press: 1973; pp 105–142. https://eml.berkeley.edu/reprints/mcfadden/zarembka.pdf (accessed 2023-10-22).

- H2A: Hydrogen Analysis Production Models, version 3.2018; National Renewable Energy Laboratory (NREL): 2018. https://www.nrel.gov/hydrogen/h2a-production-models.html (accessed 2023-10-22).

- Schmidt O.; Gambhir A.; Staffell I.; Hawkes A.; Nelson J.; Few S. Future Cost and Performance of Water Electrolysis: An Expert Elicitation Study.. Int. J. Hydrogen Energy 2017, 42 (52), 30470–92. (December 28) 10.1016/j.ijhydene.2017.10.045. [DOI] [Google Scholar]

- Saba Sayed M.rtin Müller; Martin Robinius; Detlef Stolten. The Investment Costs of Electrolysis – A Comparison of Cost Studies from the Past 30 Years.. Int. J. Hydrogen Energy 2018, 43 (3), 1209–1223. (January 18) 10.1016/j.ijhydene.2017.11.115. [DOI] [Google Scholar]

- Vimmerstedt Laura; Sertac Akar; Chad Augustine; Philipp Beiter; Wesley Cole; David Feldman; Parthiv Kurup; Eric Lantz; Robert Margolis; Debo Oladosu; Tyler Stehly; Craig Turchi.. 2019 Annual Technology Baseline ATB Cost and Performance Data for Electricity Generation Technologies; National Renewable Energy Lab (NREL), Oak Ridge National Lab. (ORNL): Golden, CO (United States), Oak Ridge, TN (United States), July 24, 2019; https://doi.org/10.11578/1544562 (accessed 2023-10-22).

- Muratori Matteo; Catherine Ledna; Haewon McJeon; Page Kyle; Pralit Patel; Son H.; Marshall Wise; Haroon S. Kheshgi; Leon E. Clarke; Jae Edmonds. Cost of Power or Power of Cost: A U.S. Modeling Perspective.. Renewable and Sustainable Energy Reviews 2017, 77 (September 1), 861–874. 10.1016/j.rser.2017.04.055. [DOI] [Google Scholar]

- H2A: Hydrogen Analysis Production Models, version v2.1.1; National Renewable Energy Laboratory (NREL): 2008. https://www.nrel.gov/hydrogen/h2a-production-archive.html (accessed 2023-10-22).

- Hydrogen Delivery Scenario Analysis Model (HDSAM); version 3.1; Argonne National Laboratory: https://hdsam.es.anl.gov/index.php?content=hdsam (accessed 2023-10-22).

- Timmerberg Sebastian; Martin Kaltschmitt. Hydrogen from Renewables: Supply from North Africa to Central Europe as Blend in Existing Pipelines – Potentials and Costs. Applied Energy 2019, 237 (March 1), 795–809. 10.1016/j.apenergy.2019.01.030. [DOI] [Google Scholar]

- Quarton Christopher J.d; Sheila Samsatli. Should We Inject Hydrogen into Gas Grids? Practicalities and Whole-System Value Chain Optimisation.. Applied Energy 2020, 275 (October 1), 115172. 10.1016/j.apenergy.2020.115172. [DOI] [Google Scholar]

- Net Zero by 2050; International Energy Agency (IEA): 2021. https://www.iea.org/reports/net-zero-by-2050 (accessed 2023-10-22).

- Global Hydrogen Trade to Meet the 1.5°C Climate Goal: Part II – Technology Review of Hydrogen Carriers; International Renewable Energy Agency (IRENA): 2022. https://www.irena.org/publications/2022/Apr/Global-hydrogen-trade-Part-II (accessed 2023-10-22).

- Wigley T.MAGICC/SCENGEN 5.3 User Manual, version 2; NCAR: Boulder, CO, 2009. https://www2.cgd.ucar.edu/cas/wigley/magicc/UserMan5.3.v2.pdf (accessed 2023-10-22).

- Ou Yang; Christopher Roney; Jameel Alsalam; Katherine Calvin; Jared Creason; Jae Edmonds; Allen A.cett; Page Kyle; Kanishka Narayan; Patrick O’Rourke; Pralit Patel; Shaun Ragnauth; Steven J. Smith; Haewon McJeon. Deep Mitigation of CO2 and Non-CO2 Greenhouse Gases toward 1.5 °C and 2 °C Futures.. Nat. Commun. 2021, 12 (1), 6245.October 29 10.1038/s41467-021-26509-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- MAGICC, Version 7.5.3; https://live.magicc.org/ (accessed 2023-03-29).

- Byers Edward; Volker Krey; Elmar Kriegler; Keywan Riahi; Roberto Schaeffer; Jarmo Kikstra; Robin Lamboll; Zebedee Nicholls; Marit Sandstad; Chris Smith; Kaj van der Wijst; Alaa Al -Khourdajie; Franck Lecocq; Joana Portugal-Pereira; Yamina Saheb; Anders Stromman; Harald Winkler; Cornelia Auer; Elina Brutschin; Matthew Gidden; Philip Hackstock; Mathijs Harmsen; Daniel Huppmann; Peter Kolp; Claire Lepault; Jared Lewis; Giacomo Marangoni; Eduardo Müller-Casseres; Ragnhild Skeie; Michaela Werning; Katherine Calvin; Piers Forster; Celine Guivarch; Tomoko Hasegawa; Malte Meinshausen; Glen Peters; Joeri Rogelj; Bjorn Samset; Julia Steinberger; Massimo Tavoni; Detlef van Vuuren.. AR6 Scenarios Database, v1.1; Intergovernmental Panel on Climate Change: November 9, 2022. https://zenodo.org/records/7197970 (accessed 2023-10-22).

- Philibert Cédric.Renewable Energy for Industry: From Green Energy to Green Materials and Fuels; International Energy Agency (IEA): 2017. https://iea.blob.core.windows.net/assets/48356f8e-77a7-49b8-87de-87326a862a9a/Insights_series_2017_Renewable_Energy_for_Industry.pdf (accessed 2023-10-22).

- Bertagni Matteo B.; ephen W. Pacala; Fabien Paulot; Amilcare Porporato. Risk of the Hydrogen Economy for Atmospheric Methane. Nat. Commun. 2022, 13 (1), 7706.December 13 10.1038/s41467-022-35419-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hauglustaine Didier; Fabien Paulot; William Collins; Richard Derwent; Maria Sand; Olivier Boucher. Climate Benefit of a Future Hydrogen Economy. Communications Earth & Environment 2022, 3 (1), 295.(November 26) 10.1038/s43247-022-00626-z. [DOI] [Google Scholar]

- Arrigoni A.; Bravo Diaz L.. Hydrogen Emissions from a Hydrogen Economy and Their Potential Global Warming Impact : Summary Report of the Clean Hydrogen Joint Undertaking Expert Workshop on the Environmental Impacts of Hydrogen; European Commission, Joint Research Centre: 2022; https://data.europa.eu/doi/10.2760/065589 (accessed 2023-10-22).

- van Ruijven Bas; Bas Jean-Francois Lamarque; Detlef P. Vuuren; Tom Kram; Hans Eerens. Emission Scenarios for a Global Hydrogen Economy and the Consequences for Global Air Pollution.. Global Environmental Change, Symposium on Social Theory and the Environment in the New World (dis)Order, 2011, 21 (3), 983–94. (August 1) 10.1016/j.gloenvcha.2011.03.013. [DOI] [Google Scholar]

- Bond S. W.; Gül T.; Reimann S.; Buchmann B.; Wokaun A. Emissions of Anthropogenic Hydrogen to the Atmosphere during the Potential Transition to an Increasingly H2-Intensive Economy. International Journal of Hydrogen Energy 2011, 36 (1), 1122–35. 10.1016/j.ijhydene.2010.10.016. [DOI] [Google Scholar]

- Schultz Martin G.; omas Diehl; Guy P. Brasseur; Werner Zittel. Air Pollution and Climate-Forcing Impacts of a Global Hydrogen Economy.. Science 2003, 302 (5645), 624–627. 10.1126/science.1089527. [DOI] [PubMed] [Google Scholar]

- Wilson C.; Grubler A.; Bento N.; Healey S.; De Stercke S.; Zimm C. Granular Technologies to Accelerate Decarbonization.. Science 2020, 368 (6486), 36–39. (April 3) 10.1126/science.aaz8060. [DOI] [PubMed] [Google Scholar]

- Schlund David; Simon Schulte; Tobias Sprenger. ;The Who’s Who of a Hydrogen Market Ramp-up: A Stakeholder Analysis for Germany. Renewable and Sustainable Energy Reviews 2022, 154 (February 1), 111810. 10.1016/j.rser.2021.111810. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The GCAM model and the data system are available as an open-source package (see https://github.com/JGCRI/gcam-core). The customized version of the model used in this study, as well as the scenario data, can be accessed at 10.5281/zenodo.8329505.