Abstract

After the Industrial Revolution, the ever-increasing atmospheric CO2 concentration has resulted in significant problems for human beings. Nearly all countries in the world are actively taking measures to fight for carbon neutrality. In recent years, negative carbon emission technologies have attracted much attention due to their ability to reduce or recycle excess CO2 in the atmosphere. This review summarizes the state-of-the-art negative carbon emission technologies, from the artificial enhancement of natural carbon sink technology to the physical, chemical, or biological methods for carbon capture, as well as CO2 utilization and conversion. Finally, we expound on the challenges and outlook for improving negative carbon emission technology to accelerate the pace of achieving carbon neutrality.

Keywords: Carbon neutrality, Renewable energy, Negative carbon emission, Carbon utilization, Carbon footprint reduction, Climate change mitigation

Graphical abstract

Highlights

-

•

State-of-the-art negative carbon emission technologies are reviewed and summarized.

-

•

The challenges and prospects of each technology are given.

-

•

Since both capture and conversion are relatively energy-consuming, the intelligent design of combined systems can significantly reduce costs and operational steps, which may be the focus of future negative carbon technology development.

1. Introduction

The ever-increasing worldwide fossil fuel consumption has caused a rapid increase in atmospheric concentrations of CO2 from a pre-industrial value of 280 ppm to 415 ppm by 2021, resulting in a severe greenhouse effect [[1], [2], [3]]. Global temperatures have risen by an average of 1.07 °C and, over the past four decades, have been the warmest for any period since 1850 [3]. However, in 2021, 330 billion tonnes of CO2 emissions from anthropogenic activities remained at high levels, of which more than three-quarters came from burning fossil fuels [4]. If left unchecked, the global warming caused by the greenhouse effect would lead to more severe environmental crises, including catastrophic melting glaciers, rising sea levels, frequent extreme weather, and biodiversity loss [3,5,6].

Global warming could be attributed to the increased absorbance of solar radiation by greenhouse gases (CO2, methane, etc.) [7]. Reducing excessive greenhouse effects could decrease solar energy absorbance, thus mitigating climate change. Several promising approaches have been promoted recently to reduce greenhouse gas emissions. Developing low-carbon and zero-carbon technologies, including renewable energy technologies such as solar, hydropower, bioenergy, wind, geothermal, and tidal power, along with energy storage and energy-efficient technologies, could solve global warming from the source [[8], [9], [10]]. However, fossil fuels still cover about 80% of current worldwide energy needs, which might play an essential role over a decade or so [9]. There is still a long way to go toward developing highly efficient energy systems with zero-carbon emissions. On the other hand, other perspectives proposed that global warming may also result from the imbalance between the radiation imported into the Earth and that reflected into outer space. Thus a solar radiation management strategy was developed to combat the Earth’s warming by reducing the percent of sunlight received by the Earth, such as space mirrors, sulfate aerosols, and cloud whitening [[11], [12], [13], [14]]. This approach may succeed in coping with climate emergencies. For example, the melting of the Greenland ice sheet constantly releases large amounts of methane. Adopting this strategy could obtain a good result in a short time as compared with other methods [13]. Although the solar radiation management pathway could temporarily stabilize global temperatures by reducing the contribution of other factors to increased temperatures to offset the contribution of increased CO2 concentrations, the issues of the increasing greenhouse gas concentrations accumulated in the atmosphere still exist [14]. In addition, the impact of solar radiation reduction on other non-climatic factors (such as plant photosynthesis, ecosystem stability, and even human health) is unknown [11,14].

To date, countries worldwide have made many efforts to deal with global warming. At the recent 26th United Nations Climate Change Conference of the Parties (COP26), nearly 200 parties finally reached the Glasgow Climate Pact, which further clarified the reduced greenhouse gas emissions to keep the average temperature rise within 1.5 °C and avoid the catastrophic consequences of exacerbated climate change [5,15]. Holding the global temperature rise within 1.5 °C above the pre-industrial levels (currently 1.2 °C) is the most ambitious goal of the Paris Agreement [15,16]. With that aim, a 55% cut is required in global CO2 emissions by 2030 from 2010 levels, and net emissions of greenhouse gases become net-zero by 2050, which means the balance between anthropogenic emissions and removal of greenhouse gas in the second half of the 21st century [3,15]. For this reason, countries worldwide need to formulate policy planning and objectives on climate and energy based on the state of respective national energy systems and take positive measures to fulfill their commitments to reduce emissions and mitigate global climate change. In addition to vigorously developing renewable energy and energy-efficient technologies, the intergovernmental panel on climate change (IPCC) assessment reports highlight the crucial role of negative carbon emission technologies in achieving the aims of the Paris Agreement [5,[17], [18], [19]]. Negative carbon emission technologies could remove CO2 from the atmosphere and store or use it to offset carbon emissions that are difficult to reduce.

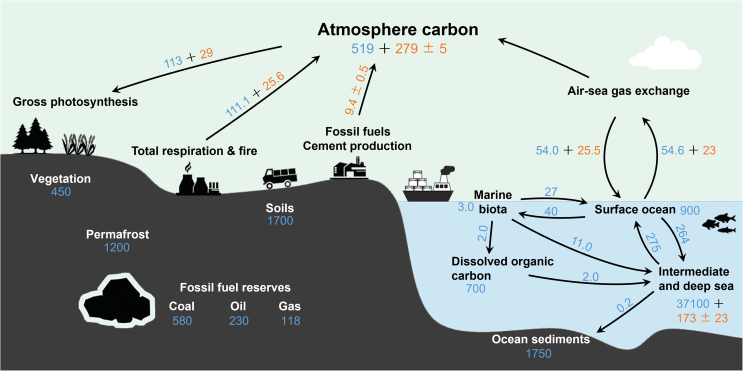

In addition to the combustion of fossil fuels, CO2 comes from the respiration of animals and plants and the decomposition of animal carcasses by microorganisms as well. The vast majority of carbon in nature is stored in crustal rocks, and the rest is in the atmosphere, soil, ocean, plants, and fossil fuels. The carbon exchange and circulation processes in the biosphere, lithosphere, hydrosphere, and atmosphere are called the carbon cycle, as shown in Fig. 1. In the natural carbon cycle, green plants and marine photosynthetic organisms consume CO2 to synthesize organic matter for removing CO2 from the atmosphere. The essence of negative carbon emission technologies is to enhance the sink of atmospheric CO2 and weaken its source.

Fig. 1.

A schematic diagram of the main Earth’s carbon cycle shows the movement of carbon between the atmosphere, lithosphere, hydrosphere, and biosphere. The blue numbers represent natural fluxes or stocks, and the orange numbers represent anthropogenic fluxes or stocks (Flux: Billion tonnes of Carbon per year, PgC/yr; Stocks: Billion tonnes of Carbon, PgC). Data source: IPCC Sixth Assessment Report, Work Group 1, Chapter 5 (2021).

In this review, we begin with a summary of recent advances in land- or ocean-based technologies and methods, whose principle is largely based on photosynthesis. Unfortunately, these natural process-based carbon sinks still have limited CO2 capture capacity due to limited land and ocean resources, even with artificially enhanced interventions, taking a long time to have a significant effect. Given the current urgency of climate change, the above technologies need to be combined with other negative carbon technologies based on physicochemical or biological mechanisms, mainly including carbon capture and storage technologies and utilization and transformation technologies. The most recent results of each technique are now reviewed and summarized. Then the challenges encountered and perspectives for future development are outlooked at last.

2. Land- or ocean-based technologies

Atmospheric CO2 can be maintained at a certain level based on natural processes such as photosynthesis, soil and ocean uptake, etc. With the increase in human activities, the natural carbon sink is not enough to maintain the balance of CO2 in the atmosphere, so several measures have been taken to enhance some natural carbon sink processes to enhance the carbon sink to maintain the carbon balance (Table 1).

Table 1.

Comparison of different land- or ocean-based technologies.

| Type | Earth system | Mechanism | Measure | Advantage | Disadvantage |

|---|---|---|---|---|---|

| Afforestation and reforestation | Land | Photosynthesis | Mixed plantation; Plantation management | Ecological and economic benefits | Long growth cycle; Large land occupation |

| Soil carbon sequestration | Land | Photosynthesis; Microbial CO2 fixation | Fertilization and organic amendments; No-tillage systems; Crop rotation, Cover cropping | Large carbon sink capacity; Improvement of land quality | Availability of suitable land |

| Biochar | Land | Photosynthesis; Physicochemical process | High-temperature pyrolysis and hydrothermal carbonization of biomass or other organic matter | Improving soil fertility; Reducing the use of chemical fertilizer; High stability | High-temperature preparation process |

| Bioenergy with carbon capture and storage | Land | Photosynthesis; Physicochemical process | Pyrolysis, gasification, fermentation, or combustion of biomass or other organic matter to produce bioenergy; Carbon capture technologies | Renewable, low pollution; A wide range of raw material sources | High cost; Land occupation; Part of the bioenergy is made from food crops |

| Enhanced weathering | Land | Physicochemical process | Addition of carbonate or silicate | Increasing the essential nutrients; Mitigation of ocean acidification | High cost; Increasing soil pH |

| Ocean alkalinization | Ocean | Physicochemical process | Addition of alkaline minerals | Mitigation of ocean acidification | Increasing ocean pH; Affecting marine communities |

| Ocean fertilization | Ocean | Photosynthesis | Addition of iron, nitrogen, or phosphorus | Increasing productivity of marine life | Red tides; Production of other toxic acids; Lower oxygen levels in the ocean |

2.1. Afforestation and reforestation

Forests play an essential role in global sustainability because of their ability to combat global warming, protect biodiversity, provide food, and improve environmental quality [20,21]. However, with economic development and population growth, the increasing demand for agricultural products results in the demand for agricultural land, and forests have faced the problem of over-exploitation. About 420 Mha of worldwide forests have been degraded and deforested since 1990, and approximately 130 Mha of tropical and subtropical forest cover loss was estimated between 1900 and 2016 [[21], [22], [23]]. Deforestation and forest degradation are among the largest sources of anthropogenic emissions of greenhouse gases to the atmosphere, contributing to almost 20% of total anthropogenic carbon emission annually through the combustion and decomposition of forest residuals, second only to the fossil fuels that burn out [24,25]. Therefore, afforestation and reforestation are considered as one of the most common approaches to combat greenhouse gas emissions. Afforestation refers to the establishment of trees in places where there has been no forest cover recently (at least 50 years), while reforestation refers to the re-establishment of forested lands that were recently deforested [24,[26], [27], [28]]. Since forests usually grow slowly and inconspicuously, carbon density changes in forest biomass and soil are often not intuitively perceptible by humans, leading to the underestimation of the forests’ contribution to terrestrial carbon sinks [29]. But tropical forests, as important carbon sources and sinks, play a huge role in stabilizing the climate. Tropical forests cover 96% of the world’s tree species and account for about 33% of the net terrestrial primary productivity, storing 25% of the global carbon [30]. The “Reducing Emissions from Deforestation and Degradation (REDD)” program, proposed at the United Nations Framework Convention on Climate Change (UNFCCC) in 2007, was seen as a cost-effective approach to mitigating global climate change for developing countries [24,31,32].

Good forest management can significantly increase the forest carbon sink and achieve twice the result with half the effort. Many factors affect the ability of forests to sequester CO2 from the atmosphere, such as vegetation species, climate conditions, soil conditions, and mixed plantation types [[33], [34], [35]]. In tropical rainforests, the rate of biological nitrogen fixation is high, and nitrogen does not become a limiting element for plant growth. However, this is different in tropical plantations with nutrient-poor sandy soils, where regular nitrogen supplementation is required. In order to save manpower and material resources, the introduction of nitrogen-fixation tree species may be an optimal choice to maintain tree growth, such as Eucalyptus spp [36]. In addition, mixed plantations can acquire and retain more carbon than monocultures [34,37]. With a meta-analysis of the relevant data, Xiang et al. found that mixed plantations could have a 12% higher carbon capture capacity than monocultures when the mixing ratio is less than 55% [34]. A reasonable portfolio of vegetation species should be adopted in the process of afforestation and reforestation to maximize the potential of forests to sequester greenhouse gases.

2.2. Soil carbon sequestration

Soils are a critical component of the global cycle and the largest reservoirs of the global terrestrial carbon stocks [27,38]. Soil carbon sequestration refers to the storage of captured atmospheric CO2 with the pedosphere in a manner that could increase its mean residence time and minimize the possibility of re-emissions [39,40]. The emission of CO2 can be offset by increasing soil organic carbon and reallocating atmospheric CO2 to soil carbon pools [41]. Significant efforts have been devoted to increasing soil carbon sequestration, including fertilization and organic amendments, no-tillage systems, crop rotation, and cover cropping [40,42,43]. The effectiveness of these practices is closely related to the activities among the microbes [44]. For example, fertilization is an essential part of agriculture, and long-term variations in pH values, soil nutrients, and soil microbial community structures caused by different fertilization modes may ultimately affect the production and decomposition of soil organic carbon [40,45]. A long-term experiment in an alpine meadow on the Tibetan Plateau was conducted by Yuan et al. [46], which revealed that the addition of phosphorus promotes the generation of particulate organic carbon due to the suppressive decomposition by lower fungal biomass. In contrast, the particulate organic carbon was barely changed by nitrogen addition, likely improving the ability of soil microbes to decompose biomass inputs. Although it reduced the limit of soil nitrogen to plant growth, the carbon added to the soil via plant biomass was rapidly broken down [46]. Therefore, understanding the soil microbial communities, their key role in carbon cycling, and their interactions with the soils are necessary to develop and adopt effective agricultural measures.

2.3. Biochar

Biochar is a solid substance with a high carbon content, which can be formed by pyrolysis under a high temperature (generally below 700 °C) with an oxygen-limited condition. Biochar has a long history and is rooted in the practice of the indigenous soil in the Amazon region called Terra Preta de Índio (also known as Amazon Dark Earths), which has nothing to do with modern environmental governance and was created by the indigenous inhabitants of the Amazon [47,48].

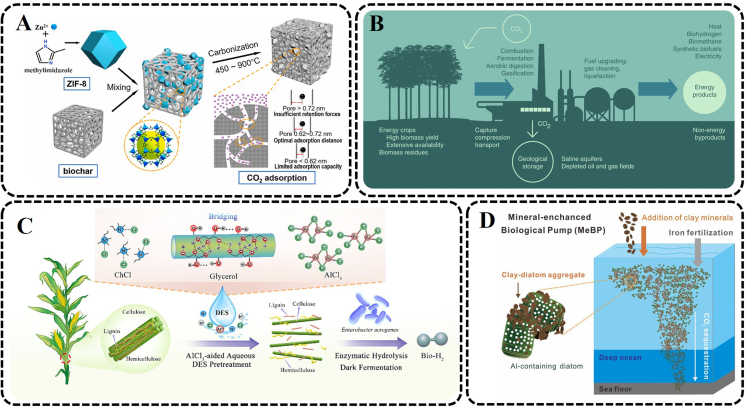

The organic feedstock for soil amendment could form carbon-rich charcoal substances to mitigate climate change [49,50]. Unlike other agricultural organic materials, biochar with a high proportion of recalcitrant organic carbon and a highly condensed aromatic structure has great carbon sequestration potential, which can lock most of the biomass carbon without releasing it into the atmosphere, reducing carbon emissions in the soil [[48], [49], [50], [51]]. Biochar can be prepared by many easily available biomass and waste materials as feedstock, for example, rich straw, wheat straw, sawdust, sugar cane bagasse, bamboo, hardwood, and sewage sludge [[52], [53], [54], [55]]. The influence of different biochar on the potential to store carbon in soil was evaluated by Tarin and coworkers [52]. Three different types of biochar at varying concentrations produced by bamboo, hardwood, and rice strew, respectively, were mixed with the soil in outdoor pots. The experimental result indicated that the cumulative CO2 emissions were greatly affected by the biochar level, and there was a significant interaction between biochar type and the level of cumulative CO2 emissions. Among them, the biochars prepared from hardwood and rice strew had a solid ability to isolate the carbon. Feedstock type and production conditions have a significant impact on the biochar adsorption of CO2. At the same time, there are many studies to effectively improve the adsorption characteristics of biochar through modification [56,57]. A clean modification method for activation-free synthetic nitrogen-doped biochar, which is obtained by pyrolysis after mechanical mixing of biochar particles and ZIF-8 particles, was developed by Zhang et al. [57], as shown in Fig. 2A. For the modified biochar, its surface area increased substantially from 3.0 m2/g to 989.3 m2/g, and its CO2 adsorption capacity increased from 0.52 mmol/g to 2.43 mmol/g. The improvement is mainly due to the fact that oxygen groups promote the CO2 affinity of nitrogen groups, and they have a significant synergistic effect on the adsorption of CO2. Moreover, the pore size of 0.62–0.72 nm plays a major role in the CO2 adsorption on the modified biochar. In practical application, appropriate biomass raw materials and preparation conditions should be selected, and nitrogen-containing and oxygen-containing groups should be modified to maximize the potential of biochar to mitigate climate change.

Fig. 2.

Examples of land- or ocean-based technologies for carbon neutrality. (A) Schematic diagram of nitrogen-doped biocarbon preparation and CO2 adsorption mechanism (Reprinted from ref. [57], Copyright (2022), with permission from Elsevier). (B) Schematic illustration of bioenergy with carbon capture and storage (Reprinted from ref. [61], Copyright (2014), with permission from Springer Nature). (C) Schematic diagram of enhanced enzymatic hydrolysis and biohydrogen production of corn straw with an AlCl3-aided aqueous deep eutectic solvent (Reprinted from ref. [65], Copyright (2022), with permission from Elsevier). (D) Schematic representation of the idealized mechanisms of the mineral-enhanced biological pump (Reprinted from ref. [81], Copyright (2021), with permission from Elsevier). ZIF-8, zeolitic imidazolate framework-8; ChCl, choline chloride; DES, deep eutectic solvent; Bio-H2, biohydrogen.

2.4. Bioenergy with carbon capture and storage

Bioenergy with carbon capture and storage (BECCS), owing to the advantage of generating energy and sequestrating atmosphere carbon, has been considered an attractive and pivotal carbon and storage method [58,59]. Biomass can be converted into a variety of bioenergies through pyrolysis, gasification, fermentation, or combustion, which is accompanied by the production of CO2 streams with different flows and concentrations. The resulting CO2 is captured and stored in geological formations, as indicated in Fig. 2B [60,61]. Biomass used for BECCS comes from a wide range of sources, such as crops, forestry residues, municipal organic waste, solid waste, landfill gas, marine microorganisms, and algae [59,62,63]. Most integrated assessment models suggest that BECCS is a key approach to reducing CO2 concentrations and avoiding catastrophic climate change [59]. In contrast, the carbon capture and storage of fossil fuels is pseudo net zero emission, because the carbon captured from fossil fuels is originally from the geosphere. BECCS temporarily transfers the carbon in the atmosphere to the biosphere through plant photosynthesis, which will then be permanently stored in the geosphere. Without capture and storage, the utilization of bioenergy is, at best, carbon neutral. BECCS could be applied to various industrial sectors such as combined heat and power plants, combustion biomass power plants, pulp industry, ethanol fermentation, and biomass gasification [61]. BECCS is essentially the combination of fuel conversion technologies and carbon capture technologies, and here is only for the current bioenergy production technologies, with a section on the carbon capture technologies later.

BECCS may be one of the important ways to achieve sustainable development. The techno-economic and environmental feasibility of sustainable aviation fuels produced through forestry residues-derived syngas via Fischer-Tropsch (FT) technology was studied by Michaga et al. [64]. This method can produce 1.91 tonnes of jet fuel from 20 tonnes of dry forest residues per hour, while 11.26 tonnes of CO2 are stored permanently. More importantly, the minimum selling price of sustainable aviation fuel prepared is only a little higher compared with traditional fuel, which has great potential for large-scale promotion. In addition, improving the efficiency of biomass use is also critical because biomass production is limited by land. Chen et al. developed an AlCl3-aided aqueous deep eutectic solvent (ChCl-glycerol) to improve enzymatic hydrolysis rate and biohydrogen production from corn straw (Fig. 2C) [65]. Lignocellulosic biomass, which is widespread in agricultural wastes, is composed of lignin, cellulose, and hemicellulose. The addition of AlCl3 promoted the dissociation and removal of hemicellulose and lignin, making enzymes and microorganisms approach the fermentable substrate and improve substrate utilization and hydrogen production efficiency. This may be mainly due to the build of the chlorine ions-glycerol-metal cation system, which increases the reactivity of the deep eutectic solvent. In addition, the production of biomass should be maximized through reasonable planting.

2.5. Enhanced weathering

Weathering releases alkaline components from carbonate or silicate, mainly as HCO3−, the main form of dissolved inorganic carbon in freshwaters, by consuming CO2 that comes from the atmosphere, thus sequestering CO2 in terrestrial waters or the ocean [66]. Nature weathering is a significant but very slow carbon cycle process, which can consume about 0.25 Pg C/yr of atmospheric CO2, accounting for approximately 3% of fossil fuel emissions [67]. Enhanced weathering is facilitating this process through human intervention, e.g., the distribution of pulverized rocks rich in alkaline minerals in farmland and woodland to further offset anthropogenic carbon emissions, including crushed calcium- and magnesium-rich carbonate and silicate rocks [[66], [67], [68], [69]]. It is a chemical storage pathway based on the reaction of CO2 with alkaline earth metal oxide-rich minerals [70]. Although silicates containing calcium and magnesium may not be as reactive as hydroxide minerals, their abundance makes them ideal candidates for enhanced weathering studies [71]. Agricultural land can provide a large area for the application of silicates to enhanced weathering. Hence, it is not only necessary to study the effect of certain alkaline minerals on carbon sequestration, but also to consider the effect of adding minerals on soil quality and plant yield, especially in highly weathered acidic and nutrient-deficient soil [72]. Silicon, a non-essential plant micronutrient, helps plants to increase yield and improve the tensile strength and thermal stability of natural fibers [73].

Haque et al. investigated the influence of wollastonite (CaSiO3) enhanced weathering on plants in soil [71]. It was found that soil amendment with wollastonite can promote the growth of plants (beans and corn). Meanwhile, the amount of CO2 sequestered by the wollastonite-amended soil was nine times higher than that without wollastonite amendment. Jariwala et al. found that improving different types of wollastonite skarn in the soil could make agricultural and horticultural plants grow better and sequestrate inorganic carbon [72]. In addition, a strategy of coating the mineral onto the fertilizer was developed to avoid the application of minerals alone and improve the plant uptake of the nutrient. Enhanced weathering is not limited to the addition of individual minerals to increase carbon capture, but requires an understanding of the effects of enhanced weathered minerals on soil nutrients and plant growth to achieve enhanced weathering and ecological effects synergy.

2.6. Ocean alkalinization

The ocean is the second largest reservoir of carbon, after the solid Earth, far beyond the atmospheric and biological reservoirs, and plays a central role in regulating Earth’s climate [74]. Due to its large volume and wide range, the ocean constantly exchanges CO2 with the atmosphere rapidly through the sea and air interface, thus controlling CO2 concentration in the atmosphere. Ocean alkalinization, also known as ocean liming, is a method of improving the CO2 capacity of the ocean by adding alkaline substances such as calcium hydroxide to increase the pH of the ocean ecosystem and simultaneously slow down the speed of the ocean acidification [3,19,75]. At present, ocean alkalization still needs laboratory and field experiments to determine the consequences of application and its optimal deployment. One key issue to consider is the stability of alkalinity added to seawater [76,77]. Calcium carbonate minerals in seawater are already oversaturated, and the increase in total alkalinity and the corresponding shift in carbonate chemistry to higher carbonate ion concentrations may lead to a further increase in supersaturation and possible solid carbonate precipitation. Precipitation of carbonate minerals consumes alkalinity and increases dissolved CO2 in seawater, thus reducing the efficiency of CO2 removal by ocean alkalinization.

2.7. Ocean fertilization

Ocean fertilization allows ocean phytoplankton to proliferate rapidly by adding limiting nutrients like iron, nitrogen, or phosphate, which can absorb CO2 from the atmosphere through the enhancement of photosynthesis, with the expectation that carbon would sink with dead biological matter and be stored for a long time [26,63,78]. Despite the abundance of macronutrients in many open ocean regions, the phytoplankton biomass is limited, mainly due to the limited micronutrient (iron). Additionally, the chemical composition (by atom) of typical algal cells is 106 carbon : 16 nitrogen : 1 phosphorus : 0.0001 iron [79]. Therefore, ocean iron fertilization is a cost-effective option.

Emerson has developed a new method of ocean iron fertilization based on biogenic iron dust [80]. A poorly crystalline Fe-oxides, which could be dropped from high altitude by aircraft and dispersed into the ocean by wind, were produced by chemosynthetic iron-oxidizing bacteria. This method, based on biogenic iron oxides, overcomes the disadvantage of low bioavailability of phytoplankton to refractory crystalline iron oxide minerals. Furthermore, the iron powder has a long enough residence time in the photic area to increase the possibility of contact time with phytoplankton. Moreover, Yuan et al. found that transporting carbon to the deep ocean after ocean fertilization was not strengthened, which could lead to another carbon release (Fig. 2D) [81]. A biological carbon pump enhancement strategy is adopted to agglomerate with diatomaceous biogenic silica through clay minerals, while the aluminum of clay minerals can inhibit diatomaceous biogenic silica dissolution, benefiting the increase in diatomaceous biogenic silica settlement and reducing organic carbon loss. In the ocean fertilization process, the specific conditions of the ocean need to be considered so that the added nutrients can achieve maximum carbon sequestration efficiency. Meanwhile, attention should also be paid to whether the organic carbon captured by ocean phytoplankton can be permanently enclosed in the deep ocean.

3. Carbon capture technologies

Negative carbon emission technologies based on land and ocean are mainly intervened through human activities to improve the natural carbon sink capacity. However, these technologies are limited by land and ocean, and the natural carbon sink capacities are not unlimited as well. If human intervention exceeds the self-regulation capacity of the ecosystem, it may have an irreversible impact on the ecosystem and human health. To achieve ambitious climate goals, carbon capture technologies with greater potential and cost-effectiveness may flourish shortly.

In carbon capture and storage technology, CO2, generated during the combustion of fossil fuels and other processes, is collected and captured through carbon capture facilities before emission. The captured CO2 is compressed to form liquid CO2, which facilitates CO2 transport and storage, before being piped into underground storage facilities [82,83]. More than 90% of CO2 generated from power plants can be removed by such technology [83]. In this review, four carbon capture technologies are mainly summarized and compared in Table 2.

Table 2.

Comparison of different CO2 capture technologies.

| Type | Introduction | Advantage | Disadvantage | Application |

|---|---|---|---|---|

| CO2 captured by sorbents | The physical or chemical properties of sorbents are used to adsorb CO2 | Convenient application; Rapid response; Controllable adsorption capacity | High use cost; Difficult to reuse the sorbent; Possible environmental impacts; Limited operation time | Industrial application |

| CO2 captured by membranes | Using the difference in permeability of different components, the purpose of separation can be achieved through a membrane | High separation accuracy; Fast separation speed; Excellent durability | High demand for equipment; Periodic replacement of membrane | Industrial application |

| CO2 captured by electrochemical separation | The adsorption and desorption of CO2 were realized by electrochemical means using electrolytes as a mediator | Availability of liquid products; High separation accuracy | High demand for equipment; Energy consumption is higher than other methods | Industrial; Research experiment |

| CO2 captured by algae cultivation | Algae capture CO2 through photosynthesis | Cost-effective; Sustainable; Applicable to a wide range of CO2 concentration; Produce value-added biomass | High footprint; Light-dependent; Operation and maintenance are complicated | Industrial; Research experiment |

3.1. CO2 captured by sorbents

The technology of carbon dioxide capture by sorbents is one of the most commonly used technologies, which can be divided into liquid sorbents and solid sorbents according to the state of the adsorbents.

3.1.1. Liquid sorbents

The CO2 in the flue gas can be separated by a liquid sorbent, and then the used absorbent can be regenerated by heating, decompression, or stripping, while the CO2 released by the absorbent is stored. Due to the characteristics of cheap and easy access, liquid absorbers have gained wide popularity and are widely used in the industrial field, which is also one of the advanced technologies available today for negative carbon emission [84]. Amine scrubbing is identified as one of the earliest and most widely used technology to capture CO2 from flue gas, which also has a commercial application history of more than 90 years [85]. Unfortunately, one prominent drawback of the traditional CO2 absorption technologies is highly energy intensive and requires high-temperature heat sources and a large number of energy costs, which are mainly reflected in the re-release of carbon dioxide and the regeneration of absorbers. It is, therefore, necessary to improve the liquid absorption process to reduce the fossil fuel energy demand for CO2 regeneration [[86], [87], [88]]. Novek et al. have adopted a carbon capture technology that completely uses ample low-temperature waste heat from the thermal power industry as an energy source, which has not been fully utilized in some low-grade power plants due to thermodynamic limitations on the conversion of low-temperature heat into electricity (Fig. 3A) [86]. An aqueous ammonia solution containing a small amount of CO2 was used to absorb CO2 in the flue gas to form a CO2-rich solution in the technology. Adding water-soluble organic solvent (acetone, acetaldehyde, or dimethoxymethane) to the absorption solution produced high-purity CO2, and then the organic solvent was distilled by low-temperature waste heat. The regenerated aqueous ammonia solution and the organic solvent were further recycled. The low cost, widely available reagents, and running under room temperature and atmospheric pressure conditions make this strategy more competitive than other methods.

Fig. 3.

Example of CO2 capture by liquid sorbents. (A) Schematic of the solvent addition ammonia/carbon dioxide carbon capture process (Reprinted with permission from ref. [86]. Copyright (2016) American Chemical Society). (B) Schematic diagram of carbon black nanoparticle CO2 regeneration (Used with permission of Royal Society of Chemistry, from ref. [87], permission conveyed through Copyright Clearance Center, Inc.). (C) Schematic illustration of the developed flow chemistry platform utilizing a tube-in-tube packed-bed microreactor for continuous solar-enabled CO2 desorption from aqueous amines (Reprinted with permission from ref. [88]. Copyright (2021) American Chemical Society). (D) Concept illustration of the CO2 capture material based on the Pickering emulsion (Used with permission of Royal Society of Chemistry, from ref. [89], permission conveyed through Copyright Clearance Center, Inc.). hv, light energy; MFC, mass flow controller; W, Power of light source; L, distance; CNT, carbon nanotube.

In addition, renewable energy is also a good alternative method, such as solar energy. Nguyen et al. reported the regeneration of CO2 from a carbon capture fluid (aqueous monoethanolamine solution or a CO2-binding organic liquid) containing nanoparticles, which could absorb actinic light to produce a photothermal effect (Fig. 3B) [87]. Carbon black nanoparticles were adopted as strong absorbers of light. And in the presence of sunlight, the photo-thermal effect generated the gas film with a lower thermal conductivity around carbon black nanoparticles, which could insulate the nanoparticle surface to raise its surface temperature. As the film gets larger and larger, carbon black nanoparticles rise closer to the surface of the solution, releasing CO2 before the nanoparticles return to the solution, and the process repeats. High CO2 regeneration efficiencies were obtained by increasing the nanoparticle concentrations and the initial solution temperatures. These photothermal nanoparticles used sunlight, instead of fossil energy, to quickly reach the temperature to regenerate the capture fluid, and could incorporate CO2 capture fluids at low loading levels without compromising the chemical absorption performance of the absorbent. Although the strategy of adding photothermal nanoparticles has achieved the desired effect, there are some technological problems, including the weakening of light penetration, the settlement of the particles, and the damage to the relevant equipment. Recently, Campbell et al. employed a microscale fluidic strategy that can use solar energy to drive continuous desorption while recovering CO2 captured from aqueous amine solutions (Fig. 3C) [88]. Light-absorbing graphite-titania composite microparticles were prepared as fillers of the optically transparent flow reactor for efficient solar desorption of CO2 from saturated aqueous amine absorbents. The flow reactor using graphite-titania composite microparticles has the highest desorption efficiency, the lowest pressure drop, and, therefore, the lowest cost compared with other light-absorbing materials, including titania and carbon black. Moreover, the developed flow chemistry platform has excellent stability with dynamic solar irradiance.

At present, many liquid absorbents have been developed for industrial high-concentration CO2 emission sources, such as coal or oil-fired boiler, natural gas turbine exhaust, and blast furnace gas cement kiln off-gas, among others. Unfortunately, these absorbents may not be suitable for an indoor environment with low concentrations at the ppm level. For example, some common liquid absorbents (such as monoethanolamine, methanol, and methyldiethanolamine) may face several challenges, including toxicity, volatileness, and corrosiveness, as well as performance degradation of absorbents. Strong alkaline NaOH is an inexpensive and nonvolatile absorbent that can react with CO2. In order to ensure the safety of indoor CO2 capture, NaOH solution should be in a stationary fluid state. However, NaHCO3 crystallization would be generated by the reaction of NaOH and CO2 at the gas-liquid interface, which could hinder the carbon capture process. A recyclable carbon nanotube/silicone oil emulsion with NaOH aqueous solution was adopted to overcome the difficulty by Lee et al. (Fig. 3D) [89]. Lipophilic-modified carbon nanoparticles have high dispersion stability in high-viscosity silicone oil, thus controlling the size of NaOH solution droplets and increasing the specific surface area and the rate of reaction with CO2. One gram of NaOH-based emulsion-type solvent can absorb 1.31 mmol of CO2. After CO2 capture, the absorbent can be easily separated from the aqueous and oil phases, and the oil phase can be reused.

3.1.2. Solid sorbents

Solid adsorbents, compared with liquid absorbents, have the advantages of non-volatility, high concentration of CO2 output, and low energy consumption [90]. CO2 adsorption depends on the porous structures (pore sizes and pore geometries) and the electron density of the solid adsorbents. Generally, large surface areas and basic groups are more likely to adsorb more gas. According to the pore size, the solid adsorbents can be divided into microporous materials (<2 nm), mesoporous materials (2–50 nm), and macroporous materials (>50 nm) [91]. The adsorption of CO2 by porous materials mainly occurs in micropores, and the adsorption process can be analogous to a pore-filling process. The Lennard-Jones potentials from around the pore wall will stack, leading to higher adsorption enthalpy and thus an enhanced filling process. The factor affecting the enthalpy of adsorption is usually the size of the adsorbent micropore. When the pore size is similar to the kinetic diameter of the guest molecule CO2 (0.33 nm), it takes a very long time to fill all pores and reach the adsorption equilibrium [92]. On the contrary, if the size of the micropore is relatively large (more than 2–3 times the kinetic diameter), the increase in the adsorption enthalpy can be ignored, and correspondingly little CO2 enters automatically into the adsorption sites, especially at low concentrations [93]. Therefore, the bulk of efforts has been made to prepare outstanding adsorbents with suitable pore structures and chemical properties for selective adsorption of CO2, including carbon-based porous materials, zeolites and metal-organic structures, silica, activated carbon, and the constituents that demonstrate high affinity towards CO2 adsorption even at low concentrations.

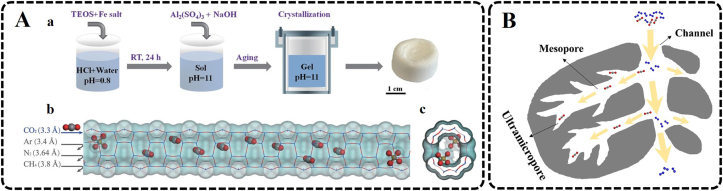

Zhou et al. prepared a self-assembled iron-containing mordenite zeolite monolith, which can serve as a molecular sieve for selective rapid adsorption of CO2 from mixed gas, by a simple and template-free hydrothermal method (Fig. 4A) [94]. The incorporation of iron ions in the mordenite framework was achieved through an acid co-hydrolysis route that enables slow co-condensation of iron and silica/aluminum precursors in the initial gelation stage, achieving precisely narrowed microchannels to obtain molecular sieving abilities. The pore characteristics of the material confer high capacity and high selectivity for CO2 adsorption, as well as excellent moisture resistance capability and stable recyclability. In addition to the uniform pore structure, the solid adsorbent materials can also be designed as a hierarchical pore architecture combining a certain number of mesopores and abundant ultramicropores. On the one hand, ultramicropores provide adsorption sites for CO2. On the other hand, the mesopores serve as transmission channels for gas molecules, which reduce the resistance to diffusion and allow CO2 to quickly reach the ultramicropores. Liu et al. reported that a well-defined hierarchical porous carbon with ultramicropore-mesopore interconnected pore architectures prepared by dual metal in-situ activation could significantly enhance CO2 adsorption capacity at low partial pressure (Fig. 4B) [93]. The porous carbon materials synthesized by this dual metal in-situ activation method can form a considerable number of mesopores without sacrificing the distribution of ultramicropores. The unique structures significantly improve the transmission efficiency of CO2 and the accessibility of ultramicropores, which can reach equilibrium in a short time. Moreover, the introduced heteroatoms could also help to improve the selectivity of CO2.

Fig. 4.

Examples of CO2 capture by solid sorbents. (A) Self-assembly of Fe-MOR monoliths. Shown are schematic illustrations of the synthetic procedure (a) and a side view (b) and top view (c) of precisely narrowed microchannels (kinetic diameter: 3.3 to 3.4 Å) by occupying isolated tetrahedral Fe species inside the 12-MR MOR microchannel. Blue indicates Si or Al, red is O, light brown is Fe, and gray is C (From ref. [94]. Reprinted with permission from AAAS). (B) Schematic diagram of enhanced CO2 adsorption capacity with well-defined hierarchical porous carbon with ultramicropore-mesopore interconnected pore architectures (Reprinted from ref. [93], Copyright (2022), with permission from Elsevier).

3.2. CO2 capture by membranes

Membrane separation for CO2 belongs to an emerging technology, mostly based on the differences in solubility, diffusivity, adsorption, and absorption abilities of different gases on different materials. When not necessary to obtain high-purity products, membrane separation is a more economical and flexible technology compared to other separation technology [84]. Membrane separation of CO2 is currently becoming increasingly attractive in recent years [85]. For example, significant research efforts have been made in CO2-philic membranes prepared from poly(ethylene oxide) (PEO) and its derivatives, driven by their strong dipole-quadrupole interaction with CO2 molecules [95]. However, the performance of membrane-based gas separation technology is still restricted by the trade-off between selectivity and permeability expressed typically by Robeson’s “upper bound” [96].

Mixed matrix membranes, first reported in 1970, are usually composed of a processable polymer matrix and dispersed inorganic particles, including zeolite, carbon molecular sieve, carbon nanotubes, silica, graphene, or metal/nonmetal nano-sized particles. The disadvantage regarding the selectivity and permeability trade-off is overcome by the mixed matrix membrane materials, combining the excellent gas separation properties of inorganic materials and the outstanding mechanical properties and cost advantages of polymers [97]. While inorganic fillers provide a standout permeation pathway for smaller gas molecules, mixed matrix membranes face uncertain compatibility between fillers and polymers as the proportion of inorganic fillers increases, resulting in undesirable defects between the inorganic material and the organic matrix and uneven dispersion of fillers. A facile in situ bottom-up growth approach has been proposed for the preparation of mixed matrix membranes with considerable organic loadings and enhanced permeability and compatibility [98]. The precursors of metal-organic framework (MOF) are uniformly dispersed in a polymerization mixture for the polymer membranes. The mixture was placed at the melting temperature of the polymer for the purpose of rearranging the MOF precursor and enabling its uniform distribution in rubbery cross-linked poly(ethylene oxide)-based polymer membrane. The MOF nanocrystal content in the obtained hybrid membranes was up to 67.7 wt%, and the MOFs were densely and orderly distributed on the polymer support. Notably, compared with other studies related to the “bottom-up” strategy, the methodology employs a solvent-free approach to dissolve the MOF precursors in poly(ethylene oxide) containing monomers, which is beneficial to generating a well-ordered array of MOF precursors. The CO2/N2 selectivity and CO2 permeabilities were 38.5 and 1083.7 barrier, respectively, which were significantly higher than the performance of conventional polymer membranes. Alternatively, a method of polymer blending was used to avoid the uncertain compatibility between polymers and fillers. A one-step approach to reducing crystallinity and improving mechanical strength by the in situ polymerization of highly flexible polyethylene glycol was proposed by Zhu et al. [99]. Sufficient entanglement between short poly(ethylene oxide) chains and the polymer matrix made the loading of linear polyethylene glycol very high. The robust structure gives polymer membranes enhanced gas separation properties and toughness, demonstrating the great potential of industrial carbon capture and gas purification.

3.3. CO2 capture by electrochemical separation

Electrochemical capture of CO2 dates back to the late 1960s when molten carbonate electrolytes were used in manned spacecraft to control the concentration of CO2 in the cabin [100,101]. Electrochemical CO2 capture has widely received increasing attention for its outstanding advantages of non-degradable operation, high energy efficiency, and flexible operation for easier retrofits [102]. Electrochemical processes directly target molecules rather than the surrounding medium and thus have considerable energy-saving potential [103]. In addition, The electrochemical capture device can be retrofitted as a plug-and-play process with a flexible shape and small footprint, which does not require a source of heat or high pressures/vacuum to operate [104]. Current methods related to the electrochemical capture of CO2 could be to any scenario containing CO2, such as air, flue gas, and ocean, regardless of the concentration [100].

In addition, electrochemical reduction of organic redox compounds (e.g., quinones, thiols, and bipyridines) is used to generate nucleophiles that could bind to the electrophiles with sufficient Lewis acidity CO2 to selectively capture CO2 from the gas mixture [105]. Nevertheless, most methods are limited by the presence of oxygen, because the reduced carriers can react with O2, causing unproductive carrier oxidation and the production of superoxide (O2·−). O2·− could react with the carrier, electrolyte, and solvent [106]. To overcome this shortcoming, Barlow et al. adopt a quinone redox carrier modified with common alcohol additives to obtain an anodic change of the reduction potential to improve the selectivity of electrochemical carbon capture [107]. The intermolecular hydrogen-bonding interactions produced by the addition of alcohol tune the properties of redox carriers into ideal ranges that cannot be achieved through traditional molecular functionalization, showing O2 stability. There are also electrochemically controlled pH swings to drive CO2 capture [108]. This approach takes advantage of the responsiveness of the thermodynamic equilibrium of CO2 to pH changes [100,109].

3.4. CO2 capture by algae cultivation

Biological CO2 sequestration is receiving increasing interest worldwide for its advantages in cost and scalability. Plants consume 100 Gt CO2 annually through photosynthesis [110]. Thereinto, the efficiency of CO2 captured by algae is 10–50 times higher than that by the embryophyte (i.e., green plants) due to their high growth rate [111]. Each kilogram of algal biomass consumed 1.48–1.98 kg CO2, with an average value of 1.81 kg CO2 [112]. Zhao et al. [113] have estimated that a cultivation area of 100,000 km2 can capture up to 2.35 Gt CO2, accounting for 5%–8% of global carbon emission. The outstanding ability to utilize CO2 makes algae the ideal organisms for carbon capture. Besides, most of the algae have evolved CO2-concentrating mechanisms (CCMs) to concentrate CO2 in the vicinity of Rubisco (the CO2-fixing enzyme), facilitating algae to capture low-concentration CO2 in the atmosphere [114]. Although the growth of many algae may be inhibited by 10% CO2, some strains (e.g., Dunaliella tertiolecta) can tolerate a high concentration, even 100% CO2 [115]. The wide applicable CO2 concentration range enabled algae to have enormous potential as carbon sinks of natural CO2 and absorbents of flue CO2. Furthermore, algal biomass is a sustainable source of the third generation of biofuels [116,117]. The CO2 emitted after biofuel usage can be re-captured into algal biomass, and thus recycled. Collectively, optimizing the cultivation strategy to accelerate algae growth is a promising way to achieve a carbon-neutral future.

The algal biofilm has recently emerged as an attractive alternative to traditional suspension cultivation techniques such as raceway ponds [118]. Due to the light-dependent nature of algae cultivation, the algae pond for suspension cultivation has to be shallow, which may occupy huge land resources. Comparatively, algal biofilm exploits the vertical space and minimizes the footprint by the delicate design of attaching surfaces [119]. Besides, algal biofilm consumed much less energy for biomass harvesting than suspension cultivation, saving 20%–30% of the overall capital cost [120]. A life cycle assessment between the raceway pond and the attached culture system finds that the algal biofilm produces 50% more biomass while consuming 55% less energy and 30% water. The enhanced biomass production and reduced energy consumption benefit the net increment of CO2 sequestration. Miyauchi et al. used an infrared analyzer to measure the CO2 amount captured by Chlorella biofilm [121]. They reported that the biofilm captured 11,000 t CO2/km2 and suggested optimizing the attaching surfaces (e.g., configuration and material) and supplying higher concentration CO2 to further increase the capture efficiency. With numerous novel biofilm reactors to be developed [118] and increasing efforts to optimize operating parameters (e.g., hydraulic retention time and light intensity) [122], adopting the algal biofilm for the full-scale practice of CO2 capture is on the horizon.

Bacteria co-exist in algal biofilm because the attaching surface is continuously exposed to the ambient environment, and an axenic environment is practically unaffordable. Bacteria can benefit algal growth and carbon recycling in symbiosis [111]. Typically, algae assimilate CO2 to produce organic substrates and oxygen for heterotrophic bacteria, and in turn, bacteria mineralize organic matters to supply inorganic nutrients and CO2 for algae [123]. The cross-feeding between algae and bacteria could significantly change the physicochemical conditions of the phycosphere [124]. This changes the way algae interact with inorganic nutrients, including CO2 [125]. Thus, CO2 released from bacteria is supposed to provide a high-concentration CO2 phycosphere that facilitates algae to uptake CO2. Besides, bacteria can also provide infochemicals (e.g., vitamin B12 and indole-3-acetic acid) to promote algal cell growth and division [124], which can indirectly increase CO2 capture. Nevertheless, bacteria are not always beneficial to the algae. For example, Pseudomonas protegens can substantially inhibit the growth and carbon fixation of Chlamydomonas reinhardtii [126]. Therefore, promoting the synergistic effect and reducing the antagonistic relationship between algae and bacteria are pivotal to constructing a symbiosis with high CO2 capture capacity.

4. CO2 utilization and conversion

After the CO2 is separated, it is usually compressed and transported to a suitable storage place through pipelines or ships [127,128]. Although the soil and ocean have a large storage capacity of CO2, such carbon storage technologies still face the potential risks of leakage and the accompanying second disasters. Meanwhile, as the cost of carbon capture and storage technologies increases, the strategy of CO2 utilization and conversion is considered an efficient, economical, and environmentally benign option that can not only solve the storage problem of captured CO2 but also realize its economic value [3,6,63].

4.1. CO2 utilization

CO2 has always been used in many industrial-scale applications, such as carbonated beverages, refrigerants, and fire extinguishers. In addition, liquid CO2 can replace organic solvents in biological medicine, polymer production, furniture manufacturing, and other fields, because the density of CO2 in the liquid state is comparable to that of other organic solvents with low viscosity and good wetting properties. And supercritical CO2 is also an excellent solvent that can be used in the cleaning, food, and electronics industries [6,129].

Besides the aforementioned applications, CO2-enhanced oil recovery is another promising carbon utilization technology that can not only increase oil production but also permanently store CO2 underground [130]. CO2 injection has been adopted to increase the recovery of oil reservoirs since the middle of the last century. The excellent dissolution properties enable CO2 to be mixed with the in-situ oil at a relatively small pressure (the minimum-miscibility pressure) and drag the oil out of the pores through the production of reduced interfacial tension, reduced viscosity, and oil swelling. The Department of Energy has always invested in the next generation CO2 enhanced oil recovery projects in the United States, and CO2 has been successfully stored in geological formations in many parts of the United States [131]. Regarding the CO2-enhanced oil recovery technology in conventional reservoirs matures, hundreds of CO2 projects have been implemented worldwide, producing more than barrels a day in the United States alone. In addition, the depleted oil and gas reservoirs have the necessary infrastructure and facilities, including injection wells, ground implementation, transporting pipelines, and the structural integrity containing fluids over a very long time, broadly recognized as ideal geological bodies for CO2 storage. Additional oil and gas are obtained when injecting CO2 into depleted oil as a replacement agent [4,132]. However, there are still some challenges in the co-optimizations of CO2 storage and oil recovery, such as CO2 override, viscosity fingering, and gravity segregation [133]. Liu et al. adopted a storage-driven CO2-enhanced oil recovery method that used dimethyl ether (DME) as an efficient agent to maximize oil recovery and achieve net-zero or even negative carbon emission [4]. The introduction of DME not only enhanced the solubility of CO2 in situ oil recovery but also suppressed the “escape” of lighter hydrocarbons from the crude oil, which is beneficial for the solubility capture of CO2 storage and sustainable oil recovery. It is noteworthy that the amount of emission from the combusting of the oil is less than the amount of sequestrated CO2 in storage-driven CO2-enhanced oil recovery. That means sequestrated CO2 includes both current emissions and past emissions.

4.2. CO2 conversion

CO2 conversion to value-added fuels and chemicals is deemed an effective method of much interest because it can help reduce excess CO2 emissions as well as the consumption of nonrenewable energy resources to alleviate the energy crisis. CO2, as an unavoidable product of the oxidation of organic molecules during biological respiration and the combustion of carbon-containing molecules, such as fossil fuels, is kinetically and thermodynamically stable and difficult to be chemically activated to react. Therefore, an excellent catalyst featured with the ability to promote CO2 reduction has long been sought after [134,135]. The CO2 catalytic reduction process is a complex multi-step reaction, which, according to the energy source, can be divided into photocatalytic reduction, electrocatalytic reduction, and thermocatalytic reduction (Table 3). In addition, some combined technologies have been proposed, for example, photoelectrocatalytic reduction and photothermal catalytic reduction. Each method has its advantages and limitations, but should not be considered competitors or substitutes [136]. CO2 reduction could produce various chemicals, including carbon monoxide (CO), methane (CH4), methanol (CH3OH), formate (HCOOH), and other longer-chain hydrocarbons [137]. In short, CO2 reduction conversion is to achieve negative carbon emissions under the action of catalysts through solar, electricity, or thermal energy, leading to the permanent removal of CO2 from the atmosphere. Unlike sustainable fuel production, the energy density carried by the transformed products is not particularly important and is often more focused on carbon density [138]. In addition, captured CO2 can usually be used as raw material for CO2 conversion through release, compression, transportation, storage, and other steps, which require high energy consumption and cost. Therefore, researchers are trying to integrate the processes of CO2 capture and conversion, that is, directly converting the captured CO2 into value-added products [139]. Moreover, many infrastructure departments have made efforts to reduce emissions and achieve sustainability, such as wastewater treatment plants, which are considered to be one of the largest sources of greenhouse gas emissions [140]. Reasonable wastewater treatment design can offset the greenhouse gas footprint of the industry and promote it to become an important contributor to global negative carbon emissions [141]. In addition, some studies reported co-conversion of CO2 with other air pollution gas, which improves the conversion efficiency [142,143].

Table 3.

Comparison of different CO2 reduction technologies.

| Type | Energy | Temperature | Advantage | Challenge |

|---|---|---|---|---|

| Photochemical CO2 reduction | Photon | Ambient temperature | Environment-friendly; Energy conservation; Simple operability. | Low photon efficiency; Low product selectivity and reaction rate; Expensive catalysts; Low stability of the catalyst. |

| Electrochemical CO2 reduction | Electricity | Ambient temperature | Environment-friendly; Mild operating conditions; Good product adjustability; Rich product types. | High overpotential; Low solubility of CO2 in aqueous solutions; Liquid product mixed with electrolyte; Low Faradaic efficiencies, current densities, and high energy consumption; Low stability of the catalyst. |

| Thermochemical CO2 reduction | Heat | 500–1000 °C | High-value product; Efficient selectivity; Large scale. | High energy consumption, high-temperature, and high-pressure conditions. |

4.2.1. Photochemical CO2 reduction

In nature, green plants use solar energy for photosynthesis to balance the carbon/oxygen cycle, which provides the energy needed for life on earth and the basis of human survival. Over the past three decades, researchers have tried to imitate the exquisite process in nature. The purpose is to use solar energy as the sole energy source to convert atmospheric CO2 into value-added chemicals [144,145]. Because it does not require additional energy intake, artificial photosynthesis is considered to have great potential to make a significant contribution to our future energy supply [146].

Sunlight is mainly composed of ultraviolet (UV) light (λ < 400 nm), visible light (400 nm < λ < 800 nm), and infrared light (λ > 800 nm), which account for 4%, 53%, and 43% of the whole solar energy, respectively [147]. To achieve maximum solar energy utilization efficiency, photocatalysts that respond to visible light are developed. The catalysts can form the photogenerated electron and hole pairs under sunlight irradiation conditions, which migrate to the surface of catalysts to participate in reduction and oxidation processes, respectively [148]. Having more accessible active sites and absorbed CO2 concentration on the photocatalysts could be beneficial to accelerate the CO2 reduction process [149].

At present, extensive efforts have been made to develop various metal photocatalyst materials, such as metal oxides, metal sulfides, and MOFs [[150], [151], [152], [153], [154], [155], [156]], for efficient sunlight-driven CO2 reduction. 2D imide-based covalent organic polymer nanosheets (CoPcPDA-CMP NSs) were prepared using tetraaminophthalocyanatocobalt(II) (CoTAPc) and 3,4,9,10-perylenetetracarboxylic dianhydride (PTCDA) for photocatalytic CO2 conversion by Zhi et al. (Fig. 5A) [157]. The integrated cobalt phthalocyanine and 3,4,9,10-perylenetetracarboxylic diimide moieties realize the reduction of CO2 and the oxidation of H2O, respectively, leading to a Z-scheme charge transfer. Compared to other catalysts, the catalyst has excellent light absorption capacity, charge separation efficiency, and electronic conductivity on the photocatalytic of CO2. In addition, many studies are dedicated to developing metal-free photocatalysts (e.g., conjugated microporous polymers and covalent organic frameworks) [[158], [159], [160]]. Barman et al. used an electron donor (tris(4-ethynylphenyl)amine, TPA) and an acceptor (phenanthraquinone, PQ) to prepare a redox-active conjugated microporous polymer (CMP), TPA-PQ, as a metal-free catalyst, which was used to efficiently and selectively transform CO2 into CH4 by visible light as shown in Fig. 5B [158]. Due to the poor light utilization and rapid recombination of photogenerated carriers, the efficiency of photochemical CO2 reduction is still low [155,161]. Therefore, we need to construct more reasonable catalyst materials for photocatalytic CO2 conversion into high-value-added products to meet the requirements of actual industrial applications.

Fig. 5.

Examples of different CO2 reduction technologies. (A) Schematic illustration of CoPcPDA-CMP NSs synthesis (Reproduced with permission from ref. [157], Copyright (2022) John Wiley and Sons). (B) Schematic illustration of visible-light-driven CO2 reduction involving a donor–acceptor CMP with fast, selective, and efficient CH4 production (Reprinted with permission from ref. [158]. Copyright (2021) American Chemical Society). (C) DFT calculations. (a) Key reaction pathways for C2+ products formation via C–C coupling. Blue, copper; brown, carbon; red, oxygen; white, hydrogen. (b) Reaction energies (ΔEreaction) of the C–C coupling step at different ∗CO coverage on a 3 × 3 Cu(111) surface. (c) Scheme illustration for the tandem catalysis of CO2RR over Au-Cu Janus NSs (Reproduced with permission from ref. [178], Copyright (2022) John Wiley and Sons). (D) Schematic diagram of the MES system (Reprinted from ref. [191], Copyright (2022), with permission from Elsevier). (E) Solar thermochemical looping reforming process (Reprinted from ref. [198], Copyright (2020), with permission from Elsevier). (F) Tubular reactor for CO2 and H2O splitting from FeO particles (Reprinted from ref. [206], Copyright (2011), with permission from Elsevier). CoTAPc, tetraaminophthalocyanatocobalt(II); PTCDA, 3,4,9,10-perylenetetracarboxylic dianhydride; CoPcPDA-CMP NSs, 2D imide-based covalent organic polymer nanosheets; PCET, proton-coupled electron transfer; NSs, nanostructures; ROS, reactive oxygen species; PEP, phosphoenolpyruvate; pBBR-Plac-CrtEBI2, lycopene strain; H2ases, hydrogenases.

4.2.2. Electrochemical CO2 reduction

From the perspective of technical and economic analysis, the electrochemical reduction of CO2 is considered a viable route for the production of carbon feedstocks for fuels and chemicals to achieve net-zero CO2 emission energy systems [162,163]. In electrocatalytic CO2 reduction reaction (eCO2RR), using water instead of molecular hydrogen can avoid high energy consumption from heating [164]. Combined with electricity from renewable sources, this method is expected to replace conventional petroleum-based processes for industrial implementation [165,166]. The technological viability of the process is contingent on the design and synthesis of highly efficient and selective catalysts for this reaction and their reaction mechanism.

In the complete electrolysis system, oxygen evolution generally occurs at the anode, while CO2 conversion occurs at the cathode [164,167]. The product distribution of CO2 electroreduction mainly depends on the cathode catalyst. And the highly efficient catalyst can greatly inhibit the process of hydrogen evolution reaction. Moreover, in order to meet the requirements of practical implementation, techno-economic analyses show that the Faradaic efficiency (FE) should be more than 90%, the partial current should be more than 200 mA/cm2, the energy conversion efficiency (EE) should be more than 60%, and the stable operation should exceed 1000 h, in the process of CO2 electroreduction generation of a single product [162,168].

CO2 reduction products have been mainly restricted to the C1 products and their derivatives in the last few decades [[169], [170], [171]]. For example, Our research group adopted a partial-carbonization strategy to prepare Cu single-atom catalysts for converting CO2 to CH4 [171]. And the overall endothermic energy of key intermediates was reduced by modifying the electronic structures of single-atom catalysts (SACs). The Faradaic efficiency of the electrochemical reduction to CH4 was as high as 78%, and the hydrogen evolution reaction was greatly inhibited with more than 99% of the reduction product being CH4. In most cases, reducing CO2 to C2+ hydrocarbons and oxygenates was more popular because of their better economic value, higher energy density, wider applications, and bigger contribution to decreasing net CO2 emission [172]. However, the current method of CO2 electroreduction to produce C2 products still fails to meet the thresholds necessary for industrial application, especially with regard to FE, EE, and stability [173]. The obstacles are associated with the fact that the fully oxidized CO2 requires large overpotentials to be thermodynamically activated. In addition, the multicarbon products generally involve the formation of the C–C bond via dimerization (in the form of CO–CO) or coupling (in the form of CO–COH) pathways, accompanied by multiple electron/proton transfers and multi-step oxidation/hydrogenation processes, which have significant energy barriers [174,175]. The HER at the cathode has close equilibrium potential to CO2 electroreduction, leading to reduced efficiency.

Metal catalysts are among the commonly used electrocatalysts for CO2RR, which can be divided into four categories depending on the binding ability of intermediates and products [146]. The first type is the CO-producing metal catalysts, including Au, Ag, and Zn. These catalysts have a strong affinity for ∗COOH intermediates to generate ∗CO, and the bond between ∗CO and the catalyst is relatively weak, resulting in desorption to release CO. The second type is HCOOH-producing metal catalysts, including Pb, Sn, Hg, and Bi, which have a low affinity for CO2·−. The third type is H2-producing metal catalysts, including Ni, Fe, and Pt, which have strong binding ability with ∗CO intermediates. The last type is hydrocarbons- and alcohol-producing Cu-based catalysts, which have negative adsorption energy for ∗CO intermediates and positive adsorption energy for ∗H. Cu is the most widely studied metal that exhibits a suitable binding capacity with the ∗CO intermediate, facilitating the hydrogenation reaction of the ∗CO and the C–C coupling reaction [[176], [177], [178]]. For example, Zheng et al. used a typical seeded growth strategy to prepare Au-Cu Janus nanostructures, which increased CO coverage on the Cu sites due to CO spillover from the adjacent Au sites (Fig. 5C) [178]. This tandem catalyst significantly reduces the C–C coupling reaction energy in favor of C2+ product formation. Alternatively, metal-free carbon-based materials for electrochemical CO2 reduction have received much attention due to their low cost and environmental friendliness [179,180].

Moreover, some studies are focusing on the combination of electrocatalysis and photocatalysis, namely photoelectrocatalysis, which combines the advantages of both [181]. On the one hand, the utilization of solar energy can significantly reduce the applied voltage, thus decreasing electricity consumption. On the other hand, the imposition of an external bias voltage can enhance the separation of electrons and holes to improve the efficiency of photocatalysis [182]. The external bias voltage may be provided by renewable electricity supplied by solar or wind energy, thus offering a sustainable solution for CO2 conversion. Photoelectrocatalysis, similar to photocatalysis, has three key steps, namely sunlight harvesting, charge separation/transport, and surface redox reaction [183]. To date, various semiconductor photocathodes, including p-Si, CdTe, p-InP, ZnTe, Cu2O, and p-NiO [[184], [185], [186], [187], [188]], have been studied for Photoelectrochemical CO2 reduction to CO, usually used in combination with molecular complexes or metal cocatalysts (including Ag, Au, and derivatives) to achieve selective CO production [189]. Photochemical reduction of CO2 is a high potential, but the expansion of the negative carbon emission technology portfolio in the current technology maturity situation still has a high risk [138].

Recently, microbial electrosynthesis (MES) systems, which combine the advantages of inorganic and microbial-catalyzed electrocatalysis, could synthesize multi-carbon organic chemicals using CO2 as a substrate and are considered a promising platform for CO2 reduction [[190], [191], [192]]. The MES systems consist of electrode materials, biocatalysts, reactors, and membranes, among which biocatalysts or microbial communities are considered to be important parts [190]. During the conversion process, electrochemical reactions provide the necessary redox equivalents (such as H2, electrons, and formate) to trigger certain biochemical reactions of microorganisms, making it possible to convert CO2 into complex molecules in one step [191,[193], [194], [195]]. Wu et al. developed an MES system for the one-step synthesis of lycopene utilizing CO2 as the sole carbon source (Fig. 5D) [191]. Lycopene can reduce the cytotoxic reactive oxygen species (ROS) produced by the electrochemical system and improve the compatibility between microbial and electrochemical catalysis. Moreover, the feasibility of lycopene production by the MES system was demonstrated by using the actual waste gas from the coal-fired power plant as feedstock without affecting the growth of bacteria. However, the yield of lycopene was not as high as that of other simple chemical products. It is necessary to further optimize the reactors and adopt biological methods to further modify the metabolic pathways for improving energy efficiency.

4.2.3. Thermochemical CO2 reduction

In 1902, Sabatier proposed the feasibility of converting CO2 and H2 into CH4 [196,197]. At atmospheric pressure, the thermal catalytic reduction of CO2 is based on the reverse water-gas shift (RWGS) reaction and methanation reaction to produce CO and CH4. Although the thermal catalytic CO2 reduction has a high conversion efficiency compared with photocatalysis and electrocatalysis, the heat source is mainly from fossil fuels, which is not conducive to carbon neutralization. Therefore, most of the current research is combined with solar energy to reduce carbon emissions [[198], [199], [200]]. The photothermal effect is another way to use solar energy efficiently. Compared to conventional photocatalysis, which only harvests UV and part of visible light and wastes a lot of energy, photothermal catalysis utilizes the full wavelength range of the solar spectrum, especially the low-energy IR light, which not only performs electron/hole-engage redox reactions but also produces the photothermal effect caused by the photoexcitation of semiconducting materials to promote endothermic reactions [201,202]. There are currently three scenarios for photothermal catalysis: (1) The catalysts produce electron/hole pairs and heat, where photocatalysis and thermocatalysis are achieved, respectively; (2) Solar energy is only used as the heating source to provide photons, which can achieve photo-to-thermal conversion under irradiation on the catalyst. When reaching a certain temperature, photo-driven thermal catalysis occurs; (3) Solar energy is coupled to thermal energy resulting in a synergistic effect of photocatalysis and thermocatalysis [[203], [204], [205]]. A high-flux solar simulator filled with NiFe2O4@alumina for the thermochemical CO2 reduction to produce syngas was adopted by Lougou et al. (Fig. 5E) [198]. The NiFe2O4@Alumina porous medium in a solar reactor has good chemical energy-flux density, thermal conversion efficiency, and thermal-to-chemical energy conversion efficiency. Abanades et al. used an iron oxide redox pair to reduce CO2 through two-step solar thermal chemical looping to generate syngas (Fig. 5F) [206]. The first step was to oxidize iron(II, III) oxide to O2 and FeO in a high-temperature solar chemical reactor heated by concentrated solar energy. The second step was to convert CO2 and H2O into H2 and CO, while FeO decomposed into Fe3O4, which can be recycled to the first step indefinitely.

4.2.4. Other CO2 conversion technologies

In addition to the three basic pathways of CO2 conversion, there are also numerous studies focusing on combining CO2 conversion with other applications. The significant advantage of this combination technique is that it can greatly reduce cost, improve efficiency, and promote synergy between different technologies.

4.2.4.1. Integrate CO2 conversion with capture

Carbon capture technologies still have a high total cost, including capital costs and energy demand [207]. For specific carbon capture, the cost of CO2 from different sources also varies greatly. The cost of carbon capture in high-concentration CO2 streams generated in natural processing or ethanol production is USD 15–25/t CO2, while that in the low-concentration gas streams produced by cement production or power generation is USD 40–120/t CO2 [208]. Capturing CO2 from the air is the most expensive. For large-scale plants built today, the capture cost of CO2 per ton is between USD 125 and USD 335, which may decrease in the future as the technology matures [209].

While many CO2 conversion technologies have been reported in the previous literature, CO2 is not free. In fact, CO2 needs to be recovered from many sources of different dilutions, and the capture, desorption, compression, transportation, and storage of each CO2 molecule have operational costs. Therefore, the development of capture and conversion integration technology is an effective strategy to save costs and improve energy utilization, which can avoid the intermediate cumbersome steps from capture to conversion after energy-intensive capture and conversion coupling. The integration of capture and conversion can be divided into three categories according to the degree of direct coupling between the capture and conversion technologies, i.e., independent (Type-I), subsequent stage (Type-II), and fully integrated (Type-III) capture and conversion processes [210].

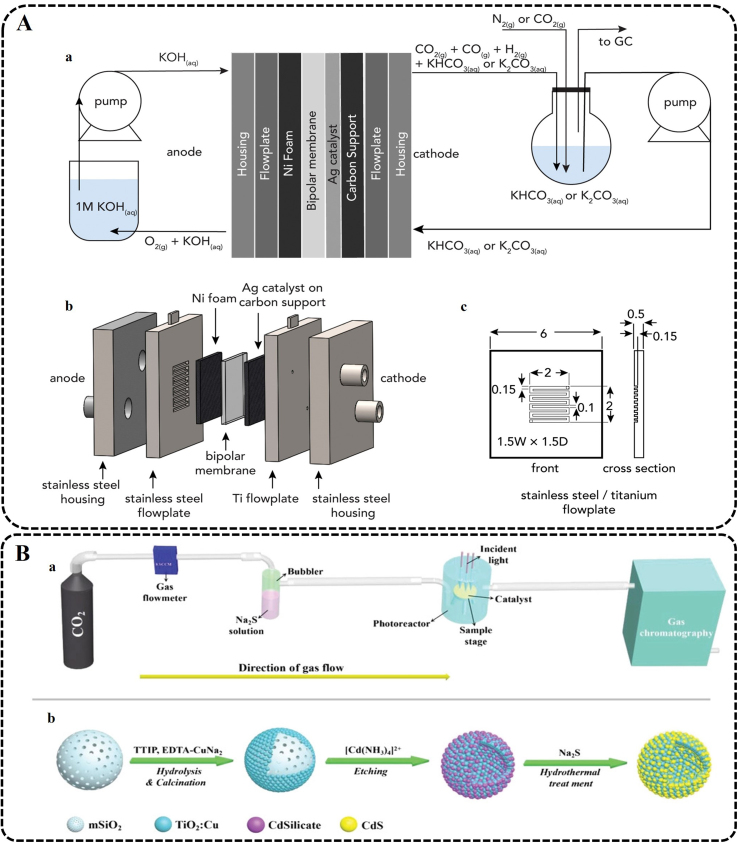

The capture and conversion processes in Type-I occur independently with minimal correlation and strong flexibility. For example, the operating temperatures of the thermochemical release of CO2 and the solvent regeneration are not the same as that of the electrochemical reduction of CO2, which requires them to be completely separated [211,212]. However, because of this independence, the high-energy requirements and operating costs can not be significantly reduced in the operation process. Type-II involves the coupling of partial capture and conversion processes. Here, the reactants of the conversion process remain molecular CO2, but a flux match between the capture and the conversion process is required to achieve optimal system performance. For example, the electrochemical reduction of CO2 is combined with electrochemically mediated amine regeneration [103]. Type III, which bypasses conventional capture agents for releasing CO2 and directly electroreduction of CO2-loaded capture agents, is considered to be one of the most effective and promising approaches [210,213]. Li et al. built an electrochemical flow reactor to reduce the KHCO3 solution without providing a gaseous CO2 for the electrolyte, breaking the widespread perception that CO2 feed is necessary for the generation of CO (Fig. 6A) [214]. The bipolar membrane of the electrolyzer can transfer the generated H+ flux to the cathode chamber, where it converts HCO3− and CO32− into catalytically active CO2. The Faraday efficiency of the KHCO3 system without CO2 feed to produce CO is comparable to that of similar systems with a CO2 feed solution. Regeneration of the capture medium and conversion of CO2 in the form of CO2 adducts occur simultaneously during this fully integrated CO2 capture and conversion process, significantly reducing the overall capture and conversion energy.

Fig. 6.

Examples of other CO2 conversion technologies. (A) Experimental setup of (a) electrochemical flow-cell experiment, (b) an expanded view of the flow cell, and (c) dimensions of the cathode and anode flow plates (Reprinted from ref. [214], Copyright (2019), with permission from Elsevier). (B) Schematic of (a) the online photocatalytic test system, and (b) the synthesis of CdS/TiO2:Cu hollow spheres (Reproduced with permission from ref.[142], Copyright (2022) John Wiley and Sons).TTIP, titanium isopropoxide; EDTA-CuNa2, ethylenediaminetetraacetic acid copper disodium salt hydrate.