Abstract

Dairy quality affects the health and quality of life of consumers. Implementing supply chain management and collaborative quality control is an effective way to solve dairy quality problems. Based on the perspective of the combination of market failure and government intervention, this paper analyzes the conditions for the realization of collaborative quality control between dairy farmers and dairy processors. At the same time, this paper uses relevant data to verify the applicability of the model and the accuracy of the conclusions. The findings show that both low yields and high spillovers lead to market failures. When farmers adopt advanced prevention strategies and dairy processors adopt advanced inspection strategies with low yields, basic prevention and basic inspection will be the best combination of quality control strategies for both parties. In this case, the government should subsidize the advanced control strategy to provide adequate subsidies. This will provide incentives for both parties to work together to ensure the quality of dairy products. Secondly, when farmers adopt advanced prevention strategies or dairy processors adopt advanced inspection strategies yields increase but spillover rates are higher. Advanced prevention, basic inspection or basic prevention, advanced inspection would be the optimal combination of strategies for both parties. At this point, the government should increase the penalties. The simulation results further indicate that the government subsidy is more effective for dairy farmers. Government penalties have both the positive and negative reinforcing effects.

Keywords: Supply chain management, Quality prevention, Quality inspection, Collaborative control

1. Introduction

The dairy industry benefits the health of hundreds of millions of people. It is a Major industry that has a bearing on the country's economy and people's lives. In recent years, the Chinese government has begun to focus on the quality and efficiency of the dairy supply system. At the same time, the government has begun to strengthen the construction of high-quality milk supply bases and the upgrading of small and medium-sized dairy farms. China's milk production in 2022 was 40.265 million tons. The total number of dairy processing enterprises is 611, and the output of dairy products is 31.177 million tons. However, the per capita consumption of dairy products is 20.3 kg. This is only one third of the world's average. China's dairy industry still has great potential for development, but at the same time faces many problems. Problems include shrinking dairy farming, the impact of imported milk and weaker competitiveness. This is not conducive to the development of the dairy industry. At the same time, hidden problems in dairy product quality and safety are common, such as exceeding microbial standards and the use of additives is not standardized [1]. Ensuring dairy product safety and strengthening the prevention of dairy product safety risks that may result from each link in the supply chain has become a national priority [2].

Some scholars are now beginning to examine the economic effects [ [[3], [4], [5]]], sustainable technologies [ [[6], [7], [8]]] and consumer impacts of the dairy industry [9,10]. But the safety of dairy products is related to the ability of the entire industry to grow and prosper. Dairy products from the collection of raw milk to the consumption of the final product of milk involved in a number of subjects. The subjects involved are mainly dairy farmers, dairy processors and dairy distributors. They form a complex supply chain structure based on techno-economic linkages [11,12]. Dairy quality is the result of a synergy between dairy farmers, processors and distributors, in terms of both the production process and the quality of the product. In a typical dairy supply chain, there are three main segments. They are the raw milk supply chain, the dairy processing chain, and the dairy marketing chain. Raw milk supply may be subject to feed drug residues and substitution of low-quality milk [13,14]. Immature production equipment, poor production environments and low levels of enterprise technology can cause safety problems during processing [15]. Dairy processors may also use poor-quality raw milk for greater profit. Therefore, the implementation of supply chain management, the optimization of the behavior of dairy supply chain actors and the implementation of collaborative quality control are effective ways to solve the dairy quality problem [ [[16], [17], [18]]]. Asymmetric information and quality and safety externalities exist in dairy production and trading. This can lead to market failures. Based on the limited effectiveness of self-organized supply chain management, government intervention is necessary [19]. Many scholars are now focusing on how government intervention affects supply chain governance. These include automotive supply chains [20], oil industry supply chains [21], construction supply chains [22] and logistics supply chains [23]. But no scholars have focused on the role of government intervention in dairy supply chain. In dairy supply chain, government intervention refers to government subsidies or penalties to manage the whole supply chain.

In recent years, many scholars around the world have studied dairy quality and safety issues from the perspectives of economics, dairy supply chain operations, and the external environment. Information transfer and sharing in the supply chain is a major research area in supply chain quality management. Jiang (2013) [24] argue that the public goods attributes of dairy products, imperfectly competitive markets, external diseconomies and asymmetric information lead to the occurrence of market failures and regulatory failures. At the same time incomplete information between the government and dairy farmers and processors can exacerbate this phenomenon. This can lead to difficulties in guaranteeing the quality and safety of dairy products. Fan and Li (2012) [25] analyzed the quality and safety hazards in the dairy supply chain at the farming, processing and marketing stages. At the same time, they proposed corresponding solutions. Xu et al. (2012) [26] examined the quality assurance strategies of dairy farmers and dairy processing enterprises. He found that farming costs and compensation were the main factors affecting the coordination of quality control behaviors between the two parties. Tostivint et al. (2017) [27] estimated the food wasted in the dairy supply chain by interviewing dairy experts in Pakistan. Ding et al. (2019) [28] found that government regulation and corporate responsibility heavily influence the safety of dairy products. Meanwhile dairy farming model plays a positive regulatory role. Merrell et al. (2000) [29] argue that dairy quality and safety is positively exogenous and that there is information asymmetry in the trading process. Therefore, the production of dairy products requires government intervention. Liu and Jia (2010) [30] argue that incentivizing firms to implement private regulation through a favorable policy environment and government action is an ideal solution to dairy quality and safety. However, the existing regulatory mechanism does not operate efficiently, which may be due to a number of reasons for regulatory failure. Among them evolutionary games are also widely used in supply chain analysis. Zhang (2020) [31] used an evolutionary game to construct a model of suppliers and manufacturers to achieve logistics information collaboration in supply chains. Yu et al. (2022) [32] designed a financing system based on an evolutionary game model to help the agricultural supply chain get more financial help. However, there is no literature using evolutionary games to analyze dairy product supply chains. There are also many scholars who have taken various approaches to solve the problems that may arise in the dairy products supply chain. Kazancoglu et al. (2021) [33] improved the circularity of dairy supply chains by developing a fuzzy ANP-VIKOR mixed group decision model. Karwasra et al. (2021) [34] used explanatory structural modeling and graph-theoretic methods to attenuate the vulnerability of dairy product supply chains during the COVID-19 epidemic. Azizsafaei et al. (2022) [35] evaluated the possible risks in the dairy products supply chain by constructing a system dynamics model. They found that there are mainly macro risks and operational risks in the dairy products supply chain.

To summarize, scholars around the world have examined the causes and solutions of dairy quality and safety problems from various angles. Most of them focus on internal coordination and external governance. However, there are fewer studies on dairy supply chain quality management. The innovations of this paper are as follows. First, we examine the collaborative control of dairy supply chain quality under the conditions of market failure and government intervention. Second, we use an evolutionary game model to analyze the evolution of dairy farmers' and dairy processors' quality control strategies, their stabilization strategies and their influencing factors. At the same time, we use simulation techniques to verify the accuracy of the conclusions. The purpose of this paper is to provide a reference for optimizing the quality control strategy choices of dairy farmers and dairy processors to improve the quality of dairy products.

2. Problem description and basic assumptions

We first consider a two-tier dairy supply chain consisting of dairy farmers and dairy processors. Dairy processors purchase raw milk from dairy farmers and then process the purchased raw milk into finished products for sale to customers. So the level of quality and safety of dairy products purchased by customers depends on the level of quality prevention by dairy farmers and the level of quality inspection by dairy processors. In the quality prevention process for dairy farmers, we believe that there are advanced quality prevention and basic quality prevention strategies. The advanced prevention strategy is that dairy farmers refer to fully recognize and understand the standards and requirements of raw milk quality control. Dairy farmers will rigorously implement behaviors such as monitoring, disease prevention and control, facility configuration, environmental maintenance, and animal welfare improvement. Basic prevention means that the dairy farmer only monitors water sources, protects against common diseases, and occasionally disinfects the farm. They only provide basic security facilities such as feeding and milking. And they do not provide welfare conditions such as exercise yards and health care equipment. There are advanced quality inspection and basic quality inspection strategies in the quality inspection process of a dairy processor. Advanced inspection strategy refers to the use of high technology and equipment and according to the relevant operational standards to carry out a comprehensive inspection of raw milk indicators such as physical and chemical indicators, microbiological limits, pollutant limits and pesticide and veterinary drug residue limits. Only the microbial limit, colony number and pesticide residue limit and other core indicators are tested is called the basic inspection strategy.

The collaborative quality control between dairy farmers and dairy processors refers to the adoption of advanced prevention strategies by dairy farmers, while dairy processors choose advanced inspection strategies. This creates a stable state of quality control that is conducive to the safety of dairy products. Both dairy farmers and dairy processors are individuals who need to make a profit. Both sides continuously adjust their strategies according to the changes in quality control costs and benefits. It is a process of evolutionary game. Therefore, we propose the following hypothesis.

First, the dairy farmer adopts the basic prevention strategy, and the dairy processor adopts the basic inspection strategy. The basic benefits for dairy farmers are , while the basic benefits for dairy processors are , and , 0.

Second, dairy farmers adopt advanced prevention strategies and dairy processors adopt basic inspection strategies in this case. The advanced preventive strategies of dairy farmers have improved the quality of raw milk. This will increase market demand, upsetting the existing supply-demand balance and further pushing up milk prices and earnings. At the same time, the spillover effect of raw milk quality and safety generates the “free-riding” behavior of dairy processing firms. Dairy processors will also gain more because of the dairy farmers' strategy. At this time, the dairy farmer's benefit is . () is the ratio of the increase in the benefit of the dairy farmer after adopting the advanced prevention strategy. In this paper, we refer to it as the yield rate. () is the incremental input cost to the dairy farmer for adopting the advanced prevention strategy. The benefit to the dairy processor from “free-riding” behavior is . Where () is the spillover rate.

Third, dairy farmers in the supply chain adopt a basic prevention strategy, while dairy processors adopt an advanced inspection strategy in this case. Retail and small-scale farmers are difficult to pass the advanced inspection or excessive inspection by dairy processing enterprises due to insufficient quality inputs. They are unable to sell the raw milk they produce in a timely manner, which can lead to them being forced out of the market. This will further lead to slow growth in milk supply capacity. At the same time the strict quality control by dairy processors will increase the market demand and increase the demand for milk. The average gain of both dairy farmers and dairy processors will increase. Thus, the benefit to the dairy processor is . ( is the ratio of the increase in the benefit to the dairy processor from adopting the advanced inspection strategy, and is the increase in the cost of inputs to the dairy processor from adopting the advanced inspection strategy. As in the second case, the gain from “free-riding” for dairy farmers still present in the market is . ( is the spillover rate.

Fourth, the dairy farmer adopts an advanced prevention strategy, and the dairy processing enterprise adopts an advanced inspection strategy in this case. As both sides work together to ensure the quality and safety of dairy products, dairy farmers will gain good reputation and relevant quality certification, and their profitability will increase. At the same time, dairy processors have won recognition from government departments and the public for their good quality. This will lead to a further increase in market demand and a steady increase in yields for both. The returns obtained by dairy farmers and dairy processors are and . and is the yield of the advanced prevention strategy adopted by dairy farmers and the advanced inspection strategy adopted by dairy processors which in turn generates synergistic effects. In this paper we refer to it as the synergy yield.

3. Analysis of evolutionary games

3.1. Evolutionary game revenue matrix

In the absence of government quality subsidies or quality penalties, we assume that the proportion of the dairy farmer group that adopts an advanced prevention strategy is (). The proportion of the dairy processor group that adopts the advanced inspection strategy is (). Then the proportions of dairy farmers adopting the basic prevention strategy and dairy processors adopting the basic inspection strategy are and . As shown in Table 1, we constructed a game payoff matrix for the evolution of quality control for dairy farmers and dairy processors.

Table 1.

Quality control game income matrix of dairy farmers and dairy processing enterprises.

| Dairy farmer | Dairy processing enterprise |

|

|---|---|---|

| Advanced inspection() | Basic inspection() | |

| Advanced prevention() | , | |

| Basic prevention() | ||

3.2. Replicating dynamic equations and equilibrium points

For dairy farmers, the expected benefits of adopting an advanced prevention strategy are shown in Equation (1).

| (1) |

The expected return to a dairy farmer adopting a basic prevention strategy is shown in Equation (2).

| (2) |

The average return for the dairy farmer group is shown in Equation (3).

| (3) |

According to the Malthusian equation, the growth rate of the number of advanced prevention strategies adopted by a group of dairy farmers is equal to the difference between their expected return and the average return . Where is time. We combine equation (1), equation (2) and equation (3) to obtain the equation for the replication dynamics of dairy farmers adopting advanced prevention strategies as shown in Equation (4).

| (4) |

Following the above reasoning process, the replication dynamic equation for dairy processors adopting advanced inspection strategies is shown in Equation (5).

| (5) |

Equations (4), (5)) form a two-dimensional dynamical system. The five local equilibrium points of this two-dimensional dynamical system can be obtained by making and . They are O (0, 0), A (0, 1), B (1, 0), C (1, 1) and saddle point D (). Where , .

3.3. Stability analysis of equilibrium point

The five system equilibrium points derived above are not necessarily stable points of the system. Therefore, we need to discuss its stability. According to the method proposed by Friedman (1991) [36], we first find the Jacobi matrix () of this two-dimensional dynamical system, and then substitute the equilibrium points into the and of the obtained matrix . If and , the equilibrium point is stable, which is called the evolutionary stabilization strategy (ESS). The Jacobi matrix of the two-dimensional dynamical system constructed by equations (4), (5)) is shown in Equation (6). Where , , and .

| (6) |

Combining the theoretical assumptions and the real situation, the stability of the equilibrium point will be analyzed in the following three scenarios.

First, the benefits to dairy farmers from adopting advanced prevention strategies or to dairy processors from adopting advanced inspection strategies are smaller than the basic benefits. In this case it is and , or and .

Second, dairy farmers adopting advanced prevention strategies or dairy processors adopting advanced inspection strategies gained more than the basic benefits, but the synergistic benefits were smaller than the spillover benefits. In this case it is and , or and . At the same time and , or and .

Third, the synergistic benefits of dairy farmers adopting advanced prevention strategies and dairy processors adopting advanced inspection strategies outweigh the spillover benefits. In this case it is and , or and .

We bring the above five equilibrium points into the and of the Jacobi matrix to determine the positivity and negativity of their values. Our aim is to determine the stabilization point, also called determining the evolutionary stabilization strategy. The results of the stability analysis of the equilibrium points in the three cases are shown in Table 2.

Table 2.

Stability analysis of equilibrium point in case 1,case 2and case 3.

| Case 1 |

Case 2 |

Case 3 |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Equilibrium point | Stability | Stability | Stability | ||||||

| (0,0) | – | + | ESS | + | + | Instability | + | + | Instability |

| (0,1) | – | Instability | – | + | ESS | – | Instability | ||

| (1,0) | – | Instability | – | + | ESS | – | Instability | ||

| (1,1) | + | + | Instability | + | + | Instability | – | + | ESS |

| (xD,yD) | 0 | Saddle point | 0 | Saddle point | 0 | Saddle point | |||

3.4. Analysis of the formation mechanism

The evolutionary stabilization strategies for quality control of dairy farmers and dairy processors in the three cases can be seen in Table 2. We will analyze and discuss the formation mechanism of evolutionary stabilization strategies in these 3 cases. For the following analysis, let .

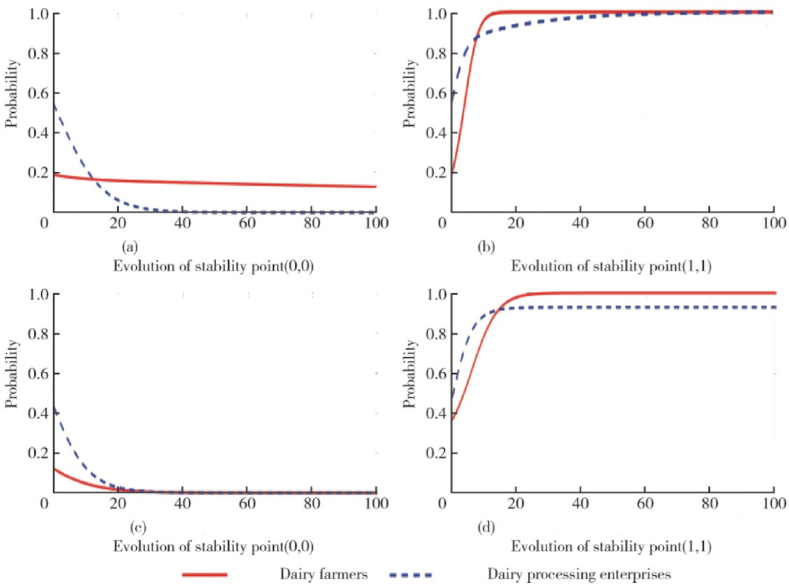

First, when the dairy farmer adopts the advanced prevention strategy or the dairy processor adopts the advanced inspection strategy, the gain is less than the basic gain. It can also be expressed as the return satisfies the conditions and . At this point dairy farmers will adopt a basic prevention strategy and dairy processors will adopt a basic inspection strategy. From Fig. 1(a), at this time (0, 0) is the stabilization point. This situation arises mainly from the following two reasons. First, the high cost of raw milk production and raw milk grading standards are not perfect. Dairy farming in China is dominated by hut-feeding. This is compared with foreign grazing and half-housed farming methods, which are much higher in infrastructure and labor costs. Feed prices in China are higher than international levels, and these problems are the underlying reasons for the low profitability of dairy farmers. In addition, raw milk grading standards are imperfect, and high-quality raw milk cannot be sold at a very high price. As a result, dairy farmers have not been able to get a considerable return on their quality investment, and it is difficult to improve the level of quality prevention. Second, the degree of dairy farming scale and dairy processing enterprises market concentration is low. For small and medium-sized farms, infrastructure and supporting services are relatively backward, including feed, epidemic prevention and milking transportation. In the process of enterprise transformation, the systematic cost of the industry chain is high, but it is difficult to significantly increase the revenue. On the other hand, the low market concentration of dairy processing enterprises has intensified competition in the industry. Enterprises must spend a lot of money to invest in advertising and acute publicity. As well as the enterprises will also reduce the price to get a larger market. All these cut down the profit. Compared with large-scale enterprises, small and medium-sized dairy processing enterprises have backward testing technology and high testing costs. If advanced inspection is carried out, it will directly increase the production cost. Moreover, their milk supply mainly relies on small and medium-sized farms. In order to control and stabilize the milk source and reduce production costs, the basic inspection strategy is the better choice.

Fig. 1.

Dynamic phase diagram of the quality control game between dairy farmers and dairy processors.

Second, dairy farmers adopting advanced prevention strategy or dairy processors adopting advanced inspection strategy gain more than the basic return, but the synergistic return is less than the spillover return. This can also be expressed as the rate of return and . At this point dairy processors choose the basic inspection strategy or dairy farmers choose the basic prevention strategy. From Fig. 1(b) and (c), it can be seen that (1, 0) and (0, 1) are stable points. The reason for the formation of the stability point (1, 0) can be explained by the increase in the number of standardized and large-scale farms and the overall quality of the farming industry. This will significantly improve the quality control level of raw milk. The trust of dairy processors in dairy farmers is increasing, and dairy supply chain partnerships are more stable. In this context, the spillover effect of improved raw milk quality and safety is obvious. If the benefits of collaborative quality control by dairy processors are less than the benefits of “free-riding”, then when farmers adopt advanced prevention strategies, dairy processors will adopt basic inspection strategies to secure milk supply and stabilize revenues.

Another situation is that (0, 1) is the stable point. This happens when the dairy market is highly concentrated and large dairy processors dominate the industry by virtue of their high market share. Their strict quality control brings long-term benefits. For example, a brand name builds a branding effect among consumers, who are happy to buy it. It also gains a large number of loyal consumers who are willing to go and pay a higher price for the brand. At the same time, the advanced inspection strategy can distinguish between the superior and inferior grades of milk sources, which facilitates the implementation of product differentiation strategy by enterprises. Therefore, the adoption of advanced inspection strategy can bring high yield for them. However, high-quality milk mainly comes from large-scale farms and enterprise-owned milk source base. In the face of increasing market demand, the supply of milk from large farms and own farms is still far from enough. Most of the milk sources still need to be purchased from various local small and medium-sized farms, and then entrusted to local dairy processing enterprises for processing. Small and medium-sized farms do not have an advantageous price for raw milk compared to large farms and have more difficulty in liquidity. In the face of high-quality inputs, dairy farmers have little incentive or ability to adopt advanced prevention strategies. Dairy processors, faced with such a quality and safety situation and demand gap, will also purchase raw milk at the basic prevention level to realize economies of scale. Dairy farmers enjoy quality sales channels and stabilized income by virtue of the good reputation of dairy processors and stable demand. If the benefits of increasing the level of quality precaution are less than the benefits of “free-riding”, then farmers will choose the basic prevention strategy. Dairy processors will adopt an advanced inspection strategy to maintain their reputation and market share.

Thirdly, the gain from quality synergistic control by dairy farmers and dairy processors is greater than the spillover gain, which is also expressed as the rate of return and . At this point, the dairy farmers will adopt the advanced prevention strategy and the dairy processors will adopt the advanced inspection strategy. From Fig. 1(d), (1, 1) is the stable point. This happens mainly in the mature period of dairy industry development. The overall quality of the industry has improved significantly. At this time, the level of dairy farming scale is higher, the number of high-quality brands has increased, and there is greater innovation in the way dairy products are distributed. Diversification of sales channels, consumer awareness of the quality of domestically produced dairy products and the improvement of the raw milk grading standard system have also contributed to the development of the dairy industry. The operational efficiency of the dairy supply chain has improved significantly. Dairy farmers' returns on quality inputs are guaranteed, and the international competitiveness of dairy processing enterprises will be enhanced. Therefore, there will be a synergistic effect when dairy farmers adopt advanced prevention strategies and dairy processors adopt advanced inspection strategies, and both sides will see a significant increase in revenue.

From the above analysis, if the yield of the dairy farmer adopting the advanced prevention strategy or the dairy processing company adopting the advanced inspection strategy is low, then neither party will choose the advanced control strategy. If the return of dairy farmers adopting advanced prevention strategy or dairy processors adopting advanced inspection strategy is greater than the basic return, but less than the spillover return. When the dairy farmer adopts an advanced prevention strategy or the dairy processor adopts an advanced inspection strategy, the other party will adopt " free-riding” behavior. In other words, both low returns and high spillovers lead to market failure. Therefore, government intervention is needed to compensate for the shortcomings of the market mechanism. This will lead to synergistic quality control by dairy farmers and processors.

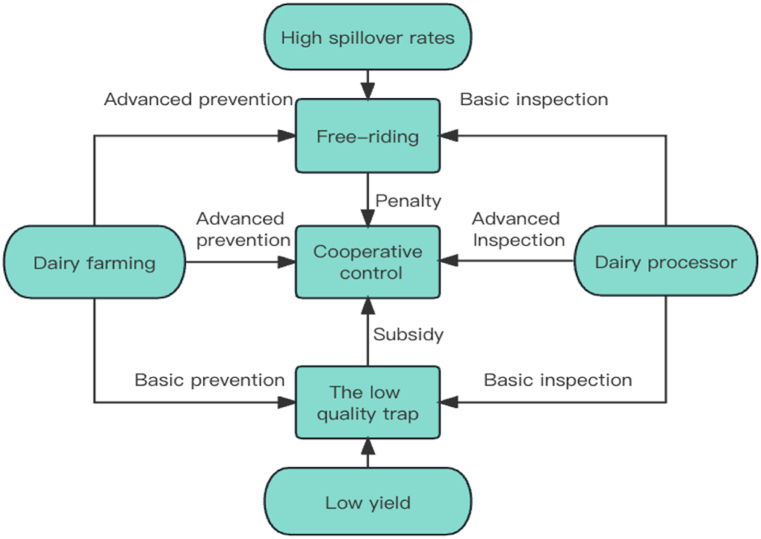

4. Analysis of evolutionary games under government intervention

The analysis in part three shows that low yields and high spillover rates are very likely to lead to market failure, so government intervention is needed. In this paper, government interventions are divided into subsidies and penalties. The following section discusses the conditions for the realization of synergistic quality control between dairy farmers and dairy processors under the subsidies and penalties mechanisms. The specific realization path is shown in Fig. 2.

Fig. 2.

Paths to achieve collaborative quality control between dairy farmers and dairy processors.

4.1. Game analysis of quality control under the subsidy mechanism

In the first case, the yield of dairy farmers adopting advanced prevention strategy or dairy processors adopting advanced inspection strategy is low, which can also be expressed as and . The government can guide the two parties to implement collaborative quality control through subsidies. Assuming that the amount of government subsidy is and when dairy farmers adopt advanced prevention strategy and dairy processors adopt advanced inspection strategy, the benefit matrix of both parties is shown in Table 3.

Table 3.

Matrix of payoffs from the quality control game under the subsidy mechanism.

| Dairy farmer | Dairy processing enterprise |

|

|---|---|---|

| Advanced inspection() | Basic inspection() | |

| Advanced prevention() | , | |

| Basic prevention() | ||

The Malthusian equation for the system at this point in time is shown in equation (7) and Equation 8

| (7) |

| (8) |

As shown in the previous analysis, whether dairy farmers adopt advanced prevention strategies and whether dairy processors adopt advanced inspection strategies depends on the yield. As long as the amount of government subsidy is greater than a certain critical value, both parties will implement collaborative quality control. (1, 1) is the ESS of the two-dimensional dynamical system. According to the method proposed by Friedman, (1, 1) is a sufficient condition for the stabilization point of two-dimensional dynamical system (7), (8) as and . That is, + and , so there are, and , so there are and . Through the above proof, we can see that when the yield of dairy farmers adopting advanced prevention strategies or dairy processors adopting advanced inspection strategies is low, the government can guide the quality control strategy choices of both parties through the subsidy mechanism. And the amount of government subsidy must be greater than the difference between the spillover benefits and the synergistic benefits. Only in this way can the contradiction between positive externalities and profit maximization be resolved, and only in this way can the subsidy mechanism be effective.

4.2. Game analysis under the penalty mechanism

In the second case, the benefits to the farmer from adopting an advanced prevention strategy or to the dairy processor from adopting an advanced inspection strategy are greater than the basic benefits, but the synergistic benefits to the other party are less than the spillover benefits. In this case the dairy processor or the farmer has an incentive to “free-riding”. So the market failure phenomenon will occur. At this point, if the subsidy is still in place, and the party with the superior control strategy is subsidized, then the gain to the subsidized party increases, but is still less than the spillover. At this point the subsidy mechanism will be inefficient. If the amount of subsidy is large and the post-subsidy benefits are greater than the spillover benefits, then both parties will likely achieve collaborative quality control. But such regulatory measures increase the fiscal burden. The subsidy mechanism is inefficient at this point. Therefore, the government can only punish the “free-riding” party. This will force it to adopt advanced control strategies. Assuming that the government's penalties are and , the payoff matrices for both sides of the quality control game are shown in Table 4.

Table 4.

Matrix of quality control game payoffs under penalty mechanism.

| Dairy farmer | Dairy processing enterprise |

|

|---|---|---|

| Advanced inspection() | Basic inspection() | |

| Advanced prevention() | , | , |

| Basic prevention() | ||

The Malthusian equations for the system at this point are shown in equation (9) and Equation (10).

| (9) |

| (10) |

Consistent with the above account, (1, 1) is the sufficient condition for and for the stabilization points of the two-dimensional dynamical systems (9) and (10) (see Table 5). When dairy farmers or dairy processing enterprises adopt “free-riding” behavior, it is difficult to guarantee the quality of dairy products and the market operates inefficiently. In this case, the government needs to penalize the " free-riding " party. If the penalty is greater than the difference between the spillover benefits and the synergistic benefits, the free rider will not be able to profit. Then, the result of the evolutionary game of quality control between the two sides will be that both sides will adopt advanced control strategies.

Table 5.

Parameter settings of the evolutionary game simulation model.

| Year | x | y | Pd | Cd | Pe | Ce | Figure | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2002 | 0.12 | 0.43 | 1.8 | 0.29 | 0.10 | 0.03 | 0.15 | 4.20 | 0.4 | 0.06 | 0.05 | 0.08 | 3(c) | ||||

| 2007 | 0.19 | 0.55 | 2.1 | 0.36 | 0.17 | 0.04 | 0.2 | 5.19 | 0.5 | 0.08 | 0.07 | 0.09 | 3(a) | ||||

| 2012 | 0.37 | 0.48 | 3.28 | 0.56 | 0.18 | 0.06 | 0.19 | 12 | 0.5 | 0.08 | 0.08 | 0.09 | 4(c) | ||||

| 2014 | 0.48 | 0.50 | 3.73 | 0.59 | 0.19 | 0.07 | 0.2 | 12 | 0.6 | 0.09 | 0.10 | 0.1 | 4(a) | ||||

| 2017 | 0.53 | 0.65 | 3.52 | 0.65 | 0.22 | 0.02 | 0.18 | 14 | 0.6 | 0.1 | 0.10 | 0.12 | 5(a) | ||||

| 2002 | 0.12 | 0.43 | 1.8 | 0.29 | 0.10 | 0.03 | 0.15 | 4.20 | 0.4 | 0.06 | 0.05 | 0.08 | 0.35 | 3(d) | |||

| 2007 | 0.19 | 0.55 | 2.1 | 0.36 | 0.17 | 0.04 | 0.2 | 5.19 | 0.5 | 0.08 | 0.07 | 0.09 | 0.45 | 3(b) | |||

| 2012 | 0.37 | 0.48 | 3.28 | 0.56 | 0.18 | 0.06 | 0.19 | 12 | 0.5 | 0.08 | 0.08 | 0.09 | 4(d) | ||||

| 2014 | 0.48 | 0.50 | 3.73 | 0.59 | 0.19 | 0.07 | 0.2 | 12 | 0.6 | 0.09 | 0.10 | 0.1 | 0.65 | 4(b) | |||

| 2017 | 0.53 | 0.65 | 3.52 | 0.65 | 0.22 | 0.02 | 0.23 | 14 | 0.6 | 0.1 | 0.10 | 0.17 | 5(b) | ||||

5. Numerical simulation

In order to verify the reasonableness and accuracy of this research argument, we will simulate the model with actual data. The dairy industry is characterized by large fluctuations in production and sales. In order not to lose the generality of this study, we have selected the relevant data for 2002, 2007, 2012, 2014 and 2017. The data are mainly from the China Dairy Yearbook and the National Compendium of Agricultural Product Costs and Benefits. The initial level of quality control of the dairy farmer group is expressed by its degree of scale. The initial state of the dairy processor group is represented by its market concentration (CR10).

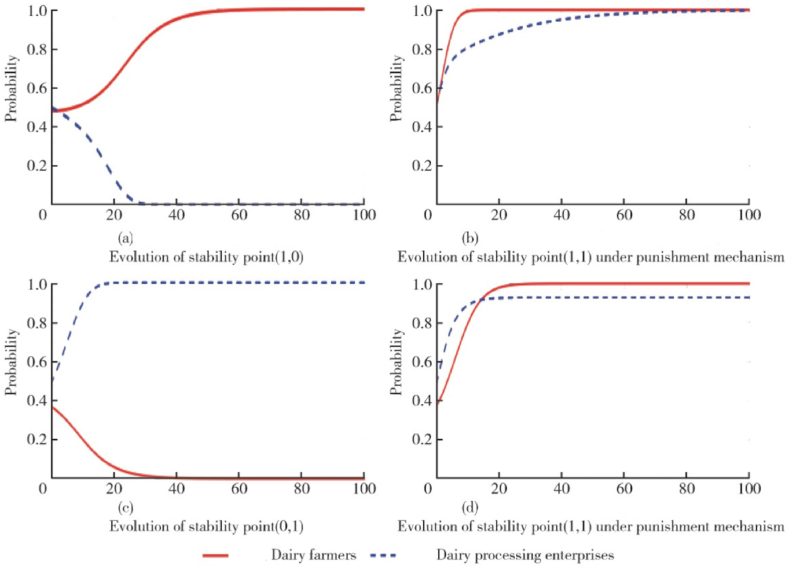

First, the formation of the “low-quality trap” and the way to break it when the yield rate is low. In 2007, dairy farming in China was mainly backyard farming, with less than 20 % of dairy cattle being raised on a large scale. Dairy farming infrastructure was backward, the proportion of total mixed ration (TMR) technology used was only 30 %, and the proportion of mechanized milking was only 50 %. The transition costs of dairy farming are high, resulting in low yields. Fig. 3(a) shows that dairy processors are unwilling to increase investment to improve quality and prevention. In addition, the dairy processing industry is highly competitive (CR8 = 43.8 %) and has many loss-making enterprises, with 166 out of 735 large-scale dairy processing enterprises losing money. The large number of small and medium-sized enterprises has led to a backwardness of the industry's overall inspection standards and technology [[37], [38], [39]]. Faced with a competitive environment, dairy processors are also unwilling to invest in upgrading their quality inspection standards. As a result, dairy safety was trapped in a “low-quality trap”. We assume that the dairy farmers and dairy processing enterprises are given a subsidy of 0.45 RMB/kg to optimize their quality control strategies. From Fig. 3(b), both parties will choose the advanced control strategy after the subsidy. At this point (1, 1) is the system stabilization point. It can also be seen from the figure that under the same subsidy strength, the convergence speed of dairy farmers is faster. This indicates that the marginal utility of the subsidy for dairy farmers is higher. This also reflects that dairy farmer are in a weaker position in the dairy supply chain. The simulated results for 2002 (Fig. 3(c) and (d)) and 2007 are similar, but the level of government subsidy is higher in 2007 than in 2002. This could be attributed to the increase in production costs.

Fig. 3.

Comparison of the simulation results before and after the subsidy mechanism.

Second, we analyze corrective measures for market failures when spillovers are high. It is clear from the above analysis that spillover effects will arise from the adoption of advanced prevention strategies by dairy farmers or advanced inspection strategies by dairy processors. Therefore, the other party can " free-riding “. After 2008, dairy farming began to transform. Farming plots and large-scale farms have gradually emerged, with the level of dairy farming reaching 48 % in 2014. Raw milk quality and safety levels have improved, and the profitability of dairy farmers has increased significantly. At this time, dairy processing companies were seeking economies of scale while riding on the back of quality milk sources. Thus, the situation of advanced prevention and basic inspection (Fig. 4(a)) is gradually formed, and at this time there are hidden problems in milk quality. We assume that the dairy processing company is given a penalty of 0.65 RMB/kg. From Fig. 4(b), both parties will adopt high-level control strategies. At this point (1, 1) is the stabilization point of the system. It can also be seen from the figure that the punishment mechanism not only changes the strategic choices of dairy processing enterprises, but also accelerates the evolution of the dairy farmers' group to the ideal state. This suggests that government punishment has both negative and positive reinforcing effects. The simulation results for the 2012 data are shown in Fig. 4(c) and (d). 2012 was a year in which the industry was in a phase of reshaping, and dairy farming was still in a transitional phase, with progressively more testing.

Fig. 4.

Comparison of simulation results before and after the penalty mechanism.

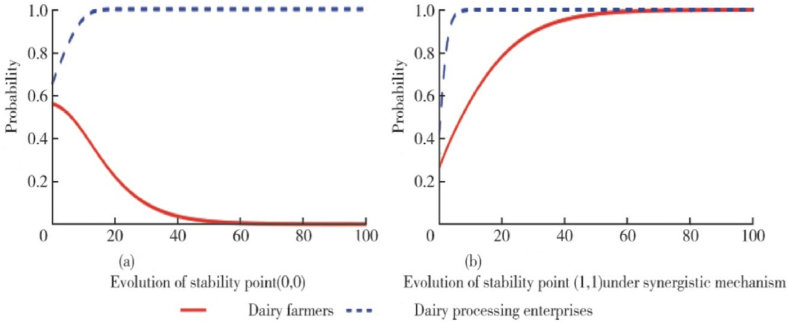

Third, we analyze the role of synergies in avoiding market failures. The results of the simulation of the relevant data for the year 2017 are shown in Fig. 5(a). The highly competitive market environment in 2017 forced a number of small and medium-sized dairy processing enterprises to withdraw. This has led to a further shift in market share towards large players (CR10 = 65 %). The monopoly power of large dairy processors is gradually increasing. In order to maintain their reputation in the market and capture the high-end milk market, large dairy processors have adopted advanced inspection strategies. The domestic dairy industry is still in transition. Faced with a structural shortage of milk supply and a huge demand gap, dairy companies can only accept raw milk at the basic precautionary level. Dairy farmers enjoy a quality sales channel in the process of trading. In addition, the industry is expected to be in the doldrums, so dairy farmers choose not to make changes. Thus, China has developed a stable situation of basic prevention and advanced inspection. If the market environment of high quality and good price tends to be mature, let's assume that dairy farmers have increased their income by 5 %. Dairy processing enterprises also gain higher market reputation and customer loyalty due to more high-quality milk sources, and also increase their income by 5 %. At this point, the quality control game between the two parties is shown in Fig. 5(b). Both parties will finally realize the collaborative quality control.

Fig. 5.

Comparison of simulation results before and after the synergy mechanism.

6. Conclusions and policy recommendations

The quality prevention level of dairy farmers and the quality inspection level of dairy processing enterprises are crucial to ensure the quality and safety of dairy products. In this paper, we used an evolutionary game model to analyze the collaborative quality control mechanism between dairy farmers and dairy processors in the dairy supply chain. We find the conditions for the realization of synergistic quality control in case of market failure. We also validate the applicability of the model and the accuracy of the conclusions using relevant data. The results of this paper show that the choice of quality control strategies by dairy farmers and processors is influenced by the yield and profitability of unilateral high-level control strategies and the co-yield of simultaneous high-level control strategies. The stabilizing strategies for quality control of dairy farmers and processors are (0, 0), (0, 1), (1, 0) and (1, 1) in the order of variation of yield and profitability and co-efficient of return. Further research has found that effective government intervention can remedy the shortcomings of the market mechanism. Dairy farmers and milk processors should actively cooperate with the government. They should consciously regulate their production processes when the government is facing difficulties such as shortage of funds. When yields are low, dairy farmers and processors have lower than basic returns from advanced control strategies. At this point (0, 0) is the quality control stabilization strategy. The government should provide sufficient subsidies to the adopter of the advanced control strategy to optimize the choice of quality control strategy for both parties. Under the assumptions made in this paper, the subsidies in 2002 and 2007 should be 0.35 RMB/kg and 0.45 RMB/kg. When the rate of return increases but the profitability also increases, then (0, 1) and (1, 0) are stable strategies for quality control. The government should increase penalties to force both parties to engage in collaborative quality control. Under the assumptions in this paper, the 2012 and 2014 penalties should be 0.38 RMB/kg and 0.65 RMB/kg. The simulation results confirm the effectiveness of government intervention in promoting collaborative quality control between dairy farmers and dairy processors. It was also found that government subsidies were more effective for dairy farmers. Government penalties have both positive and negative reinforcing effects. However, the paper still has the following limitations. This paper only focuses on the synergistic control between dairy farmers and milk processing firms and fails to comprehensively consider all the factors in the supply chain. Secondly, the paper uses a relatively short time period of data in the simulation due to data availability. This may not lead to comprehensive conclusions.

In view of the above conclusions, this paper puts forward the following policy recommendations. First, the government should strengthen its support for dairy farmers in terms of capital, credit and land use policies. The government should increase subsidies for the purchase of good dairy cows, milking facilities and cold storage and transportation equipment. At the same time, the government should also innovate credit products and develop mortgage loans for breeding equipment and land, to increase the confidence and ability of dairy farmers to adopt advanced prevention strategies. Second, the government should accelerate the improvement of the raw milk quality grading system and work to promote the pilot third-party testing of raw milk quality. The government should also monitor the behavior of dairy processing companies, establish a fair order for the purchase and sale of fresh milk, and enhance the transparency and credibility of quality testing procedures. Dairy-related organizations should also vigorously promote knowledge of dairy product safety. These actions will provide an external guarantee of the profitability of advanced prevention strategies for dairy farmers. Third, the government should regulate the competitive order of the market to increase the rate of return on synergies. Specifically, the government should increase sampling and inspection of dairy product quality and safety to prevent low-priced and inferior products from taking over most of the market. The government should also create a favorable market competition atmosphere to promote dairy farmers and dairy processing enterprises to compete properly by improving the quality of dairy products.

Ethics approval

The submitted manuscript is original and have not been published elsewhere in any form or language.

Consent to participate

Done.

Consent to publish

All authors agreed with the content and that all gave explicit consent to submit.

Data availability

Data will be made available on request.

Funding

Not available.

CRediT authorship contribution statement

Mingde Yang: Writing - original draft, Supervision, Software, Data curation, Conceptualization. Cem Işık: Writing - review & editing, Methodology. Jiale Yan: Resources, Project administration, Methodology.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Andersen H.J. The issue ‘Raw milk quality’from the point of view of a major dairy industry. J. Anim. Feed Sci. 2007;16(1):240–254. [Google Scholar]

- 2.Montgomery H., Haughey S.A., Elliott C.T. Recent food safety and fraud issues within the dairy supply chain (2015–2019) Global Food Secur. 2020;26 doi: 10.1016/j.gfs.2020.100447. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Yan J., Sheng Y., Yang M., et al. Local government competition, new energy industry agglomeration and urban ecological total factor energy efficiency: a new perspective from the role of knowledge. J. Clean. Prod. 2023 [Google Scholar]

- 4.Franco D., Nagrale B.G. Dairy industry: hurdles ahead in an economic perspective. Dairy Processing: Advanced Research to Applications. 2020:263–281. [Google Scholar]

- 5.Mikuš T., Mikuš O. Early weaning: new insights on an ever-persistent problem in the dairy industry. J. Dairy Res. 2020;87(S1):88–92. doi: 10.1017/S0022029920000503. [DOI] [PubMed] [Google Scholar]

- 6.Chokshi K., Pancha I., Ghosh A., et al. Microalgal biomass generation by phycoremediation of dairy industry wastewater: an integrated approach towards sustainable biofuel production. Bioresour. Technol. 2016;221:455–460. doi: 10.1016/j.biortech.2016.09.070. [DOI] [PubMed] [Google Scholar]

- 7.Feil A.A., Schreiber D., Haetinger C., et al. Sustainability in the dairy industry: a systematic literature review. Environ. Sci. Pollut. Res. 2020;27:33527–33542. doi: 10.1007/s11356-020-09316-9. [DOI] [PubMed] [Google Scholar]

- 8.Gholizadeh H., Fazlollahtabar H. Analysis of new product development between product innovation and product financial performance assessment: a case of Doosheh Dairy Company. Environ. Dev. Sustain. 2021;23(12):18556–18581. [Google Scholar]

- 9.Mikkola M., Colantuono F. Consumer insight and approaches in new dairy products development. Advances in Dairy Products. 2017:404–419. [Google Scholar]

- 10.Yang R., Ramsaran R., Wibowo S. An investigation into the perceptions of Chinese consumers towards the country‐of‐origin of dairy products. Int. J. Consum. Stud. 2018;42(2):205–216. [Google Scholar]

- 11.Mor R.S., Bhardwaj A., Singh S. A structured-literature-review of the supply chain practices in dairy industry. Journal of Operations and Supply Chain Management. 2018;11(1):14–25. [Google Scholar]

- 12.Glover J. The dark side of sustainable dairy supply chains. Int. J. Oper. Prod. Manag. 2020;40(12):1801–1827. [Google Scholar]

- 13.O'Callaghan S O., Connor D., Goulding D. Raw milk collection in Ireland: insights into the challenges facing the industry. Br. Food J. 2022;124(11):4024–4037. [Google Scholar]

- 14.Zavala Nacul H., Revoredo-Giha C. Food safety and the informal milk supply chain in Kenya. Agric. Food Secur. 2022;11(1):8. [Google Scholar]

- 15.Huang J., Xu C.C., Ridoutt B.G., et al. Water availability footprint of milk and milk products from large-scale dairy production systems in Northeast China. J. Clean. Prod. 2014;79:91–97. [Google Scholar]

- 16.Beulens A.J.M., Broens D.F., Folstar P., et al. Food safety and transparency in food chains and networks Relationships and challenges. Food Control. 2005;16(6):481–486. [Google Scholar]

- 17.Konuspayeva G., Faye B., Loiseau G., et al. Lactoferrin and immunoglobulin contents in camel's milk (Camelus bactrianus, Camelus dromedarius, and Hybrids) from Kazakhstan. J. Dairy Sci. 2007;90(1):38–46. doi: 10.3168/jds.S0022-0302(07)72606-1. [DOI] [PubMed] [Google Scholar]

- 18.Yan J., Zhang Y. Quantitative assessment, spatial and temporal characteristics, and dynamic evolution of carbon emissions from animal husbandry in China: 2001–2020. Environ. Sci. Pollut. Control Ser. 2023:1–16. doi: 10.1007/s11356-023-30548-y. [DOI] [PubMed] [Google Scholar]

- 19.Sinayi M., Rasti-Barzoki M. A game theoretic approach for pricing, greening, and social welfare policies in a supply chain with government intervention. J. Clean. Prod. 2018;196:1443–1458. [Google Scholar]

- 20.Fander A., Yaghoubi S. Dynamic and stochastic modeling for a closed-loop automotive supply chain under fuel issue and government intervention: a case study. Comput. Ind. Eng. 2022;174 [Google Scholar]

- 21.Zhang X., Yousaf H.M.A.U. Green supply chain coordination considering government intervention, green investment, and customer green preferences in the petroleum industry. J. Clean. Prod. 2020;246 [Google Scholar]

- 22.Xie Y., Zhao Y.Q., Chen Y.H., et al. Green construction supply chain management: integrating governmental intervention and public–private partnerships through ecological modernisation. J. Clean. Prod. 2022;331 [Google Scholar]

- 23.Mahmoudi A., Govindan K., Shishebori D., et al. Product pricing problem in green and non-green multi-channel supply chains under government intervention and in the presence of third-party logistics companies. Comput. Ind. Eng. 2021;159 [Google Scholar]

- 24.Jiang B, Li C.X. Research on supply chain security control mechanism under background of dairy products quality crisis. Research of Agricultural Modernization. 2013;34(6):698–702. (in Chinese) [Google Scholar]

- 25.Fan B., Li C.X. Evolutionary game analysis of hidden violations in dairy products procesing enterprises based on quality and safety. Journal of Agrotechnical Economics. 2012;(1):56–64. (in Chinese) [Google Scholar]

- 26.Xu M.L., Wang Q., Ouyang L.H. Investment of food supply chain quality based on evolutionary game. Chinese Journal of Management Science. 2012;20(5):131–141. (in Chinese) [Google Scholar]

- 27.Tostivint C., de Veron S., Jan O., et al. Measuring food waste in a dairy supply chain in Pakistan. J. Clean. Prod. 2017;145:221–231. [Google Scholar]

- 28.Ding H., Fu Y., Zheng L., et al. Determinants of the competitive advantage of dairy supply chains: evidence from the Chinese dairy industry. Int. J. Prod. Econ. 2019;209:360–373. [Google Scholar]

- 29.Merrill R.A., Francer J.K. Organizing federal food safety regulation. Seton Hall L. Rev. 2000;31:61. [Google Scholar]

- 30.Liu D, Jia Y. Study on food quality safety regulation in food supply chain: taking dairy products as a case. Commercial Research. 2010;(2):100–106. (in Chinese) [Google Scholar]

- 31.Zhang X., Yousaf H.M.A.U. Green supply chain coordination considering government intervention, green investment, and customer green preferences in the petroleum industry. J. Clean. Prod. 2020;246 [Google Scholar]

- 32.Yu Z., Rehman Khan S.A. Evolutionary game analysis of green agricultural product supply chain financing system: COVID-19 pandemic. Int. J. Logist. Res. Appl. 2022;25(7):1115–1135. [Google Scholar]

- 33.Kazancoglu Y., Sagnak M., Mangla S.K., et al. A fuzzy based hybrid decision framework to circularity in dairy supply chains through big data solutions. Technol. Forecast. Soc. Change. 2021;170 [Google Scholar]

- 34.Karwasra K., Soni G., Mangla S.K., et al. Assessing dairy supply chain vulnerability during the Covid-19 pandemic. Int. J. Logist. Res. Appl. 2021:1–19. [Google Scholar]

- 35.Azizsafaei M., Hosseinian-Far A., Khandan R., et al. Assessing risks in dairy supply chain systems: a system dynamics approach. Systems. 2022;10(4):114. [Google Scholar]

- 36.Friedman D. Evolutionary games in economics. Econometrica: J. Econom. Soc. 1991:637–666. [Google Scholar]

- 37.Işık C., et al. Renewable energy, climate policy uncertainty, industrial production, domestic exports/re-exports, and CO2 emissions in the USA: a SVAR approach. Gondwana Res. 2023 doi: 10.1016/j.gr.2023.08.019. [DOI] [Google Scholar]

- 38.Işık C. The importance of creating a competitive advantage and investing in information technology for modern economies: an ARDL test approach from Turkey. J. Knowl. Econ. 2013;4:387–405. doi: 10.1007/s13132-011-0075-2. [DOI] [Google Scholar]

- 39.Xia L., Wan L., Wang W., et al. Energy accessibility via natural resources: do natural resources ensure energy accessibility in low income countries? Resour. Pol. 2023;86 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.