Highlights

-

•

The underlying change of rice starch quality was investigated under straw return (SR).

-

•

Long-term SR increased cooked texture indica rice in South China.

-

•

SR improved the thermal and pasting properties of indica rice starch.

-

•

Straw burning return worsened cooked indica rice texture, especially late rice.

-

•

Cooked rice texture improved was attributed to the starch fine structure under SR.

Keywords: Straw returning, Double-season indica rice, Starch fine structure, Starch physicochemical properties, Textural properties, Long-term field experiment

Abstract

Straw return can improve rice eating quality by modifying starch formation from long-term field trials, whereas the relevant mechanisms are still unknown. A long-term field experiment, including straw removal (CK), straw burning return (SBR), and straw return (SR) was conducted to investigate the starch structure, physicochemical properties, and cooked rice textures of indica early- and late-rice. Compared with CK, SBR and SR enhanced relative crystallinity, amylopectin long chains in both rice seasons, and gelatinization temperatures in late rice. Compared to SBR, SR decreased protein content and amylopectin short chains but increased starch branching degree, breakdown, and stickiness, ultimately contributing to improved starch thermal and pasting properties. Meanwhile, SR decreased hardness, cohesiveness, and chewiness, resulting in cooked texture meliorated, which was mainly attributed to amylopectin chain length and starch granule size. The results suggest that SR increased cooked texture of indica rice by altering starch structural and physicochemical properties.

Introduction

With the increase in people's standard of living, the improvement in rice grain quality, especially cooking and eating quality (CEQ), has become an important objective for rice production. Starch and protein as the main components of rice are often used to evaluate rice CEQ. However, rice varieties with similar amylose and protein content also differ greatly in their CEQ, indicating that the traditional measurement traits cannot match the demand for rice taste assessment. In recent years, numerous studies presented that starch quality such as multiscale structure and physicochemical properties could affect rice CEQ (Li and Gilbert, 2018, Shi et al., 2021, Zhou et al., 2020). Zhu et al. (2021) found that higher proportion of amylopectin short chains was a key factor in determining rice CEQ. Yu et al. (2012) reported that changes in rice starch multiscale structure altered pasting properties of rice flour. Higher protein content competes with starch for more water during cooking, resulting in the creation of a network of disulfide bonds that inhibits starch granule swelling and, as a result, lowers CEQ (Xiong et al. 2023). In addition, the pasting and textural properties of starch strongly also determined cooked rice palatability (Zhao et al. 2019), and rice textures including hardness, stickiness, springiness, cohesiveness, and chewiness are important traits for evaluating the taste of cooked rice. Therefore, rice starch quality, especially the multiscale structure and physicochemical properties should be investigated to acquire a better knowledge of rice CEQ.

China produces about 700 million tons of straw annually, of which about 200 million tons is rice straw (Chen et al. 2016). Straw return that is strongly implemented by government departments has a long history as an important straw-field management method in China, due to the important role in increasing soil fertility and rice grain yield. The decomposition process of straw can promote the aggregation of soil particles, which enhances the soil aeration in the capacity of water infiltration and retention (Guo et al. 2021); then as crop straw is rich in carbon, nitrogen, potassium and other nutrients, the addition of straw return can improve soil organic matter and its composition, and enhance the capacity of soil nutrient supply through actuating soil microbial activity (Li et al. 2019). Later, these effects feed back to the above-ground rice plants, to increase the effective tillers and biomass accumulation, optimize plant type structure for prolonging the function period of photosynthetic, and promote grain filling and grain quality formation (Che et al., 2023, Iqbal et al., 2021). In rice–wheat rotation systems, straw return increased rice amylose content and protein content, which altered rice CEQ (Hou et al. 2015). Our earlier study demonstrated that long-term straw return instead of some chemical fertilizers increased rice grain yield and simultaneously improved soil organic matter (Wu et al. 2013), while necessarily increased rice grain carbon content and relatively decreased protein content. If the improvement of grain carbon content via straw return increases starch content and decreases amylose content, thereby improves the physicochemical properties of rice starch and cooked rice texture, yet those are lack of study.

In particular, large amounts of straw are produced annually in double-cropping indica rice system in southern China. However, straw burning is also a common practice in this region that is not absolutely banned, and there is a need to compare the specific impacts and differences between straw return and straw burning on rice starch quality. Our previous study presented that straw return improved the eating quality and decreased the nutritional quality of early and late rice (Zeng et al. 2013). However, the internal mechanisms underlying the change in rice starch quality are still not clear. To the best of our knowledge, the effects of straw return on the starch structure, functional, and textural properties of indica rice have not been reported. Therefore, we hypothesized that straw return could affect rice starch quality by changing starch structural, physicochemical, and textural properties. A long-term straw-returning paddy experiment from 2010 was conducted to investigate the structural and physicochemical properties of rice starch and textural properties of cooked rice. These results provide a foundation for the improvement on rice starch quality and its application in food industry and rational utilization of straw resources through straw return management.

Materials and methods

Materials

In this study, two indica rice cultivars, Wufengyou 286 (WFY286) and Taiyou 871 (TY871), provided by Jiangxi Modern Seed Industry Co., Ltd. of China were used. WFY286 was sowed in March and transplanted in April of the early rice season, and TY871 was sowed in June and transplanted in July of the late rice season in 2020.

Experimental design and agronomic management

The experimental site was located at the national cultivated land quality monitoring point base (116°5′29.73″E, 28°20′7.14″N) in Wenzhen town, Jinxian county, Jiangxi province, China. The terrain of the experimental site is flat, with an annual average temperature of 17.5 °C, rainfall of 1600–1800 mm, relative humidity of 77 %, and sunlight duration of 1900.5 h. The test soil was paddy soil developed from quaternary red clay. The soil properties at the beginning of the trial were as follows: organic carbon 19.8 g kg−1, total nitrogen 2.27 g kg−1, alkaline hydrolyzed nitrogen 126.0 mg kg−1, available potassium 97.9 mg kg−1, and available phosphorus 31.3 mg kg−1.

A long-term positioning experiment for rice straw return to the field began in 2010. The field trials were designed as random blocks with a plot area of 120 m2 and the trials were repeated three times. Cement ridges were used to isolate and prevent seepage between the plots, and separate irrigation and drainage facilities were established. Three treatments were set in this experiment: straw burning return (SBR), straw return in situ (SR), and straw removal with only chemical fertilizer application (CK). Specific details of these treatments, including chemical fertilizer application and the nutrient content of straw/straw ash, were described in the previous study (Chen et al. 2022).

Other field management procedures were the same as in traditional double-season rice cultivation. Early rice and late rice were harvested in 2020 after eleven years, and 200 plants from each plot were threshed, shelled, and processed into fine rice flour to determine the structure and physicochemical properties of starch.

Rice starch extraction

The sample (20 g) was immersed in an aqueous sodium metabisulfite solution containing 10 mg per gram of alkaline protease and kept at 42 °C for 24 h. The sample was then filtered through a 200-mesh sieve. The filtrate was completely washed with aqueous sodium sulfite solution and left overnight. After the supernatant was removed, a new sodium sulfite solution was added and left to stand, and the operation was repeated 5–8 times. When the starch was white and the supernatant was clear, it was poured out completely and the remaining starch was dried naturally. It was then transferred to an incubator for water balance for one week. The exact steps were referenced by the method of Xiong et al. (2023).

Rice grain amylose and protein contents

The amylose content in rice flour was determined according to the national standards of the rice quality evaluation GB/T 17871–2017, the People’s Republic of China. The total nitrogen content in rice flour was determined using a FOSS Kjeldahl instrument (KJeldahlTM 8400) and then multiplied by a conversion factor of 5.95 to obtain the protein content.

Starch structural properties

Starch granule size distribution

Prepared starch samples were soaked in sodium sulfite solution for one week and then sent to a Mastersizer 3000 instrument (Malvern Instruments Ltd, Worcestershire, UK) for the determination of starch granule size distribution. The volume, surface area, and number of starch granules were divided into two categories: small & medium granules (diameter < 10 μm) and large granules (diameter > 10 μm). The average diameter of starch granules was calculated directly from the software of the instrument used.

Amylopectin chain length distribution

The distribution of branched chain starch was analyzed by ion chromatography (HP AEC-ICS-5000, Thermo Fisher Scientific, Sunnyvale, USA) equipped with a pulsed aperture detector. Briefly, immersion in sodium sulfite (CAS 7757–83-7, Sinopharm, Beijing, China) solution for one week at 200 mA and 40 kV was used to examine starch samples. 2 diffraction angles were ranged from 3 to 40 degrees, with a velocity of 0.02 degrees and a counting time of 0.6 s. The specific procedure was referenced by the method of Xiong et al. (2022).

Starch branching degree

The starch branching degree was determined using 1H NMR (Bruker BioSpin GmbH, Germany) with a scan frequency of 32 and a resonance frequency of 500.23 MHz, 1H NMR spectrum. The specific procedure was conducted according to the method of Xiong et al. (2022). The following formula was calculated: degree of branching (DB) (%) = (I-1,6) / (I-1,6 + I-1,4) *100. I-1,6 means α-1,6 linkage and I-1,4 means α-1,4 linkage.

X-ray diffraction analysis

The X-ray diffraction of rice starch was determined using an X-ray powder diffractometer (X' Pert Pro, P A Nalytical, Netherlands). Relative crystallinity (%) was calculated by MDI (Materials Data, Inc) Jade 6 software.

Starch physicochemical properties

Starch thermal properties

The differential scanning calorimeter (DSC-Q2000, TA Instruments, USA) was used for the determination of thermal properties. The thermal properties included onset temperature (To), peak temperature (Tp), conclusion temperature (Tc), and enthalpy of gelatinization (△Hgel). In addition, the gelatinization temperature range (R) was computed as (Tc-To), and the peak height index (PHI) was calculated by the equation: PHI=△Hgel / (Tp-To) (Xiong et al. 2022).

Starch pasting properties

Starch pasting viscosities were measured by using a rapid viscosity analyzer (RVA) (Starch Master TM 17133, Newport Scientific Pvt. Ltd, Warier Wood, Australia). In brief, in a dedicated aluminum container, 3 g of starch was weighed and 25 g of ultrapure water was added. The program was configured to heat at 50 °C for one minute, then to 95 °C at a rate of 12 °C per minute, and to 50 °C at a rate of 12 °C per minute, with a test time of 12 min for a single sample. The pasting properties included peak viscosity (PV), trough viscosity (TV), final viscosity (FV), breakdown viscosity (BD = PV-TV), setback viscosity (SB = FV-PV), and pasting temperature (PaT). The viscosity value was recorded as centipoise (cP).

Textural properties of cooked rice

The cooked rice preparation method was specified in the GB/T 15682-2008 National Standard of the People's Republic of China. The textural properties of cooked rice were evaluated with a texture analyzer (TVT 6700, Perten, Stockholm, Sweden), and the specific methods were referred to the method of Xiong et al (2022). Briefly, three intact cooked rice grains were chosen for testing, and each sample was tested eight times. The instrument's parameters were as follows: 80 % compression, 1.0 mm s−1 probe descent rate, 2.0 mm s−1 retraction rate, and 5 g trigger force. The textural properties of cooked rice included hardness, stickiness, springiness, cohesiveness, and chewiness.

Statistical analysis

The data in this study represent the mean of three replicates for each treatment. The figures were created by using the Origin 2021 software. Data analysis was performed by using SPSS (version 22.0, SPSS Inc., Chicago, USA) to determine the least significant difference (LSD) at the significance level of p < 0.05. Pearson correlation analysis was used to examine the correlations between starch composition, multilevel structure, and physicochemical properties of different rice cultivars under all treatments, as well as the correlations between starch composition, multilevel structure, and physicochemical properties of rice and textural properties at significance levels of 0.05 and 0.01.

Results and discussion

Amylose content, protein content and amylopectin chain length distribution

SR had a significantly higher amylose concentration than SBR in early rice, however, for late rice, no significant variation on amylose content was observed across all treatments (Table 1). This could be attributed to lower amount of −1,4 linkage in early rice, whereas it remained no difference in late rice (Table 1). As a result, the starch branching degree of SBR was decreased in early rice but was unchanged in late rice (Man et al. 2014). According to Shi et al. (2021), the reduced protein level in grains is beneficial for improving rice palatability. This showed that, when compared to SBR, SR treatment may be a more effective strategy for improving the taste of cooked rice in both early and late rice.

Table 1.

Composition and structural properties of rice starch under different straw returning.

| Seasons | Early rice | Late rice | |||||

|---|---|---|---|---|---|---|---|

| Treatments | CK | SBR | SR | CK | SBR | SR | |

| Amylose content (%) | 14.39ab | 13.69b | 15.10a | 16.24a | 15.95a | 15.66a | |

| Protein content (%) | 7.99a | 8.69a | 6.58b | 7.14c | 8.94a | 8.17b | |

| Amylopectin chain length distribution (%) | DP ≤ 12 | 26.49a | 26.59a | 26.01b | 30.84a | 29.83b | 28.46c |

| DP13-24 | 50.34a | 47.48b | 48.16b | 46.72a | 45.54b | 45.80b | |

| DP 25–36 | 11.06c | 13.46a | 12.7b | 13.81a | 13.52a | 13.59a | |

| DP ≥ 37 | 12.11b | 12.47b | 13.13a | 8.63c | 11.11b | 12.15a | |

| α-1,6 linkage (%) | 2.55b | 1.23c | 3.79a | 2.37c | 3.14b | 4.11a | |

| α-1,4 linkage (%) | 97.45b | 98.77a | 96.21c | 97.63a | 96.86ab | 95.89b | |

| Degree of branching (%) | 2.55b | 1.23c | 3.79a | 2.37c | 3.14b | 4.11a | |

| Relative of crystallinity (%) | 27.16 | 29.05 | 33.13 | 39.1 | 37.29 | 44.29 | |

| Volume percentage (%) |

d < 10 μm | 69.56b | 71.23b | 73.76a | 88.91b | 88.58b | 89.32a |

| d > 10 μm | 30.44a | 28.77a | 26.24b | 11.09a | 11.12a | 10.68b | |

| Surface area percentage (%) |

d < 10 μm | 91.98a | 92.11a | 90.64b | 93.33a | 93.36a | 91.55b |

| d > 10 μm | 8.02b | 7.89b | 9.36a | 6.67b | 6.64b | 8.55a | |

| Number percentage (%) |

d < 10 μm | 99.77a | 99.79a | 99.76a | 99.68a | 99.02b | 99.76a |

| d > 10 μm | 0.23a | 0.21a | 0.24a | 0.32b | 0.98a | 0.24b | |

| Average diameter (μm) | 4.5a | 4.6a | 4.0b | 4.9a | 4.7a | 4.2b | |

Different lowercase indicates significant differences in different values at p < 0.05 in the same column and the same rice season.

CK, straw removed with chemical fertilizers application; SBR, straw burning returning; SR, straw returning in situ.

DP, Degree of polymerization; d, diameter.

According to Hanashiro et al. (1996), amylopectin can be classified into four types based on chain length: A (DP ≤ 12), B1 (DP 13–24), B2 (DP 25–36), and B3 (DP ≥ 37). Yang et al. (2020) reported that longer chains of amylopectin contribute to its high crystallinity. In the present study, we found that the B3 chains of SR were higher in both early and late rice, resulting in the highest relative crystallinity of SR in two-seasons rice (Table 1). There is a significant and negative correlation between the short chains (chains A and B1) in amylopectin and grain quality (Lin et al. 2022), which showed that a lower ratio of short chains in SR led to better grain quality in both early and late rice. Conversely, in contrast to SR, a higher proportion of short chains in SBR resulted in poorer grain quality in both early and late rice.

Degree of starch branching and starch granule size distribution

Our study found that SR treatment resulted in a higher α-1,6 linkage compared to other treatments, while the α-1,4 linkage content was lower in early and late rice (Table 1). The degree of starch branching of SR also showed a similar response to the α-1,6 linkage (Table 1). Generally speaking, the higher the degree of starch branching indicates a higher proportion of amylopectin long chains, suggesting that it have better solubility and faster breakdown by digestive enzymes (Villas-Boas and Franco. 2016), making the starch under SR treatment easier for the body to absorb and digest. Amylopectin synthesis is closely related to starch branching enzymes. SR treatment was equivalent to the role of organic fertilizers application for an increase of starch branching enzymes, and enhanced the degree of starch branching in the grains during the filling process (Iqbal et al. 2021). Furthermore, the down-regulated starch branching enzymes Ⅱb gene also prevents the transfer of branched starch short chains by regulating the α-1,6 linkage, which ultimately increases the medium-length chains in rice starch (Butardo et al. 2011). Therefore, under the situation of straw return, the factors that induce variations in the degree of starch branching should be investigated further.

Compared with CK and SBR, SR significantly decreased the starch volume percentage of large granules (diameter > 10 μm) in early rice and late rice (Table 1). Similarly, the average diameter of SR was also significantly lower among the treatments (Table 1). Previous study reported that the development of starch granules is related to the duration of grain filling stage, implying that longer grain filling durations are more favourable to the formation of tiny starch granules (Liu et al. 2017). According to our findings, the delayed decomposition of rice straw in the field under SR treatment may provide more durable nutrients in the grain filling stage than other treatments, which is favourable for the development of small starch granules. Further, straw return to the field increased soil organic carbon content (Table S1), contributing to the uptake of carbon by the stems, and then the improvement on transfer and accumulation of carbohydrates from stems to grains during filling period (Iqbal et al. 2021).

Starch relative crystallinity

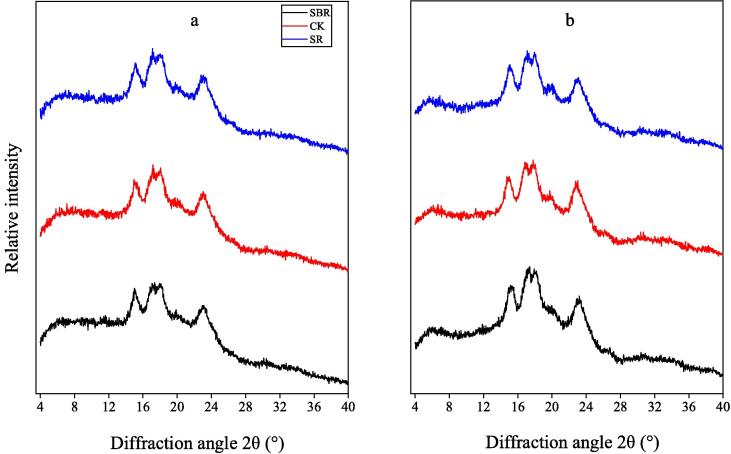

X-ray diffraction of the starch revealed an evident A-type crystalline structure, with prominent peaks at roughly 15° and 23° θ and an unresolved doublet at around 17° and 18° θ (Fig. 1). The relative crystallinity of SR and SBR was higher than that of CK, whereas SR had a higher relative crystallinity compared to SBR in both rice-growing seasons (Table 1). Slow-release fertilizers can assist rice grain to enhance starch crystallinity, because the delay in the supply phase of nitrogen fertilization ensures that sufficient nutrients are available for starch crystal structure development (Yuan et al. 2022). In this study, straw burning to the field during the winter idle period enhanced ammonia volatilization in the rice paddy field following late rice harvest, decreasing nitrogen availability for early rice (Zhang et al. 2016). Nevertheless, the short time interval between early and late rice growth, on the other hand, resulted in partial decomposition of straw from early rice season during late rice growth, making the role of SR treatment similar to slow-release fertilizer effects. The increases of starch relative crystallinity will further positively affect the swelling power of starch.

Fig. 1.

Effects of straw returning on the X-ray diffraction patterns of rice starch. a, Early rice; b, Late rice. CK, straw removed with chemical fertilizers application; SBR, straw burning returning; SR, straw returning in situ.

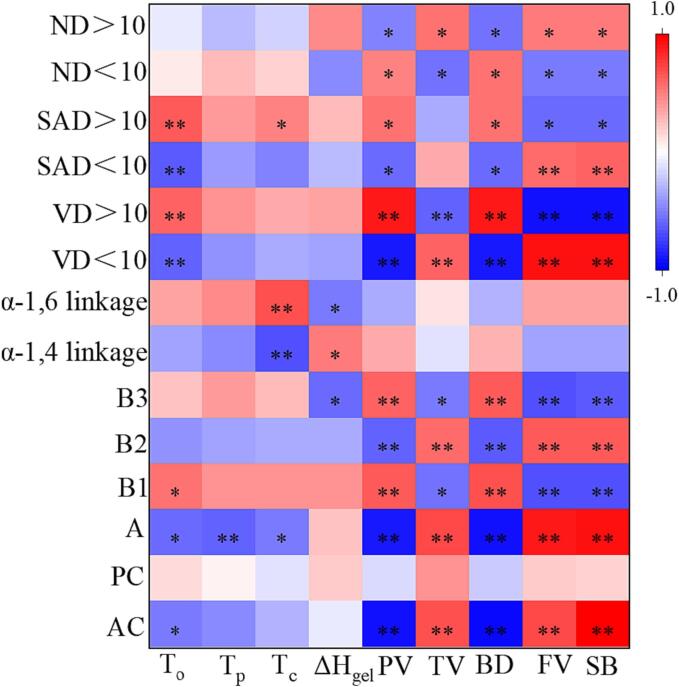

Thermal properties

Starch gelatinization is a process that causes starch granules to inflate and alter in size and shape, accompanied by blocklet-like structures dispersing, crystalline areas broken, and birefringence lost as double helices unwind and starch becoming soluble (Berski et al. 2011). Compared with CK, SBR had lower onset temperature (To) in early rice, but the To and peak gelatinization temperature (Tp) of both SBR and SR was significantly higher in late rice, and SR significantly increased conclusion temperature (Tc) in both early and late rice (Table 2), implying the improvement on gelatinization temperatures under SR, due to the lower amylopectin chain A (Table 1), since they were significantly and negatively associated with amylopectin chain A (Fig. 2). In this study, SBR and SR had higher total organic carbon and the ratios of carbon to nitrogen than CK (Table S1); these differences induced by straw return method could mainly determine the degree of grain filling, accompanied by the arrangement and distribution of starch granule, thereby in turn altering rice starch structure and affecting starch gelatinization (Liu et al. 2017). High gelatinization temperatures are conducive to the stability of starch structure (Kallman et al. 2015), indicating that SR could enhance starch structural stability in early and late rice. SR treatment significantly increased gelatinization enthalpy (ΔHgel) in both early- and late-rice (Table 2). ΔHgel was found to be highly and positively correlated with the relative crystallinity of starch (Zhu et al. 2016), suggesting that more energy is required to break the double helix structure of starch under SR treatment. The gelatinization temperature range (R) indicates the homogeneity of crystallites, which is significantly and positively correlated with amylose content (Hussain et al. 2020). In the present study, it was found that the R-value of SR was higher in early rice compared to other treatments. However, in late rice, the R-value for both SR and SBR decreased (Table 2). This reason could be attributed to the decrease in amylose content of both SR and SBR treatments compared to CK in late rice, although the difference was not statistically significant (Table 1).

Table 2.

Physicochemical properties of rice starch.

| Physicochemical properties | Early rice | Late rice | |||||

|---|---|---|---|---|---|---|---|

| Treatments | CK | SBR | SR | CK | SBR | SR | |

| Thermal properties | To (°C) | 67.1a | 66.2b | 67.5a | 62.6b | 66.2a | 66.6a |

| Tp (°C) | 72.3a | 71.6a | 72.8a | 68.8b | 71.0a | 72.9a | |

| Tc (°C) | 76.6b | 75.5b | 77.6a | 74.0b | 75.9b | 77.2a | |

| ΔHgel (J/g) | 9.8b | 10.3a | 10.5a | 10.4b | 10.7b | 11.1a | |

| R | 9.5b | 9.3b | 10.1a | 11.4a | 9.7c | 10.6b | |

| PHI | 1.9a | 2.0a | 2.0a | 1.7a | 2.2a | 1.8a | |

| Pasting properties | PV(cP) | 4911b | 4939b | 5311a | 3543b | 3432c | 4055a |

| TV(cP) | 2212a | 2034b | 2213a | 2363a | 2352a | 2487a | |

| FV(cP) | 3053b | 3050b | 3260a | 4082a | 4140a | 4208a | |

| BD(cP) | 2699c | 2905b | 3098a | 1181b | 1080b | 1568a | |

| SB(cP) | −1858a | −1889a | −2052b | 539a | 708a | 153b | |

| PaT(°C) | 84.62a | 85.17a | 84.63a | 74.68a | 74.47a | 73.93a | |

| Textural properties | Hardness (g) | 2007.4a | 1950.5b | 1837.7c | 2771.6a | 2731.4a | 2342.2b |

| Stickiness (g) | −399.4b | −427.7b | −354.9a | −257.3a | −363.6b | −260.4a | |

| Springiness | 0.54a | 0.55a | 0.53a | 0.68a | 0.70a | 0.71a | |

| Cohesiveness | 0.24a | 0.24a | 0.20b | 0.37b | 0.41a | 0.31c | |

| Chewiness(g) | 475.6a | 461.5a | 444.2b | 911.2a | 1062.4a | 733.6b | |

Different lowercase indicates significant differences in different values at p < 0.05 in the same column and the same rice season.

To, onset temperature; Tp, the peak of gelatinization temperature; Tc, conclusion temperature; ΔHgel, gelatinization enthalpy.

PV, peak viscosity; TV, trough viscosity; BD, breakdown; FV, final viscosity; SB, setback; PaT, pasting temperature.

CK, straw removed with chemical fertilizers application; SBR, straw burning returning; SR, straw returning in situ.

Fig. 2.

Correlation coefficient between starch structures and physicochemical properties. Each correlation coefficient shows the average value of three replicates per correlation factor. * Correlation is significant at the 0.05 level, while ** correlation is significant at the 0.01 level. AC, amylose content; PC, protein content; A, amylopectin chains with DP 6–12; B1, amylopectin chains with DP 13–24; B2, amylopectin chains with DP 25–36; B3, amylopectin chains with DP > 36; α-1,4, α-1,4 linkage (%); α-1,6, α-1,6 linkage (%); VD, Volume percentage (%) diameter; SAD, Surface area (%) diameter; ND, Number percentage (%) diameter. To, onset temperature; Tp, peak temperature; Tc, conclusion temperature; ΔHgel, gelatinization enthalpy; PV, peak viscosity; TV, trough viscosity; FV, final viscosity; BD, breakdown viscosity; SB, setback viscosity.

Pasting properties

Starch content is closely related to its multilevel structure, especially starch granule size and amylopectin chain length distribution (Fig. 2). SR significantly increased peak viscosity in both early and late rice (Table 2), suggesting that SR treatment boosted starch swelling characteristics due to higher relative crystallinity (Zhu et al. 2016). Final viscosity (FV) reveals the retrogradation characteristics of gelatinized starch. In contrast to CK and SBR, SR significantly increased FV only in early rice, and this improvement was attributed to the higher amylose content (Table 1). Greater breakdown of SR in both early and late rice represents better stability of the hot paste (Huo et al. 2018), whereas lower setback of SR in both early and late rice indicates that straw return reduces starch gel hardness during cooling (Xie et al. 2007). High breakdown and low setback values promote the taste value of rice RVA flour (Chen et al. 2015). Straw return increased peak viscosity and breakdown of RVA (Zhang et al. 2015). Branched starch with more B3 chains and fewer A chains had a higher double helix (Roman et al. 2020), and a greater molecular double helix shape in starch improved starch pasting viscosities (Zhang et al. 2021). Similar results were observed in our study that SR had a higher breakdown and lower setback in both early and late rice (Table 2). Breakdown was negatively associated to chain A and positively correlated with chain B3 (Fig. 3), which also verified our previous finding that SR improved cooking and eating quality in both early and late rice (Zeng et al. 2013). However, the precise mechanism of how straw return affects rice pasting viscosity is unclear. Straw return being similar to the effect of organic fertilizers potentially improves the functional stage of plant leaves such as photosynthetic capacity, and contributes to promoting grain filling and activating enzymes or genes involved in B3 chain synthesis. Further, the improvement on rice starch quality was highly related to soil health derived from organic fertilizers application (Iqbal et al. 2021). In this study, straw return increased soil organic carbon and effectively prolonged nitrogen supply to paddy soils (Table S1; Chen et al., 2022), then facilitated starch granule formation during grain filling, ultimately improved starch pasting viscosities.

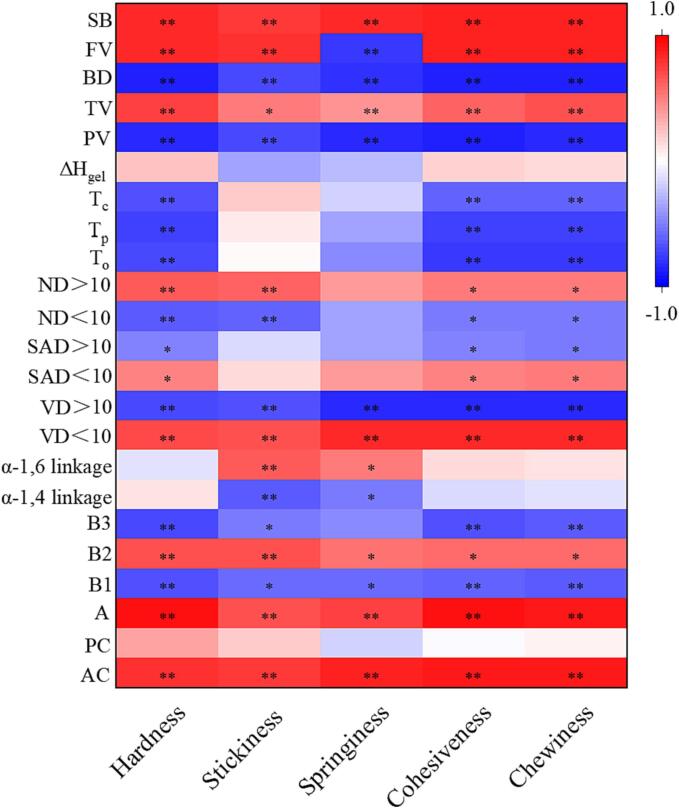

Fig. 3.

Correlation coefficient between cooked rice textural properties and starch components, structures, and physicochemical properties during the maturity stage under different straw management across one year. Each correlation coefficient shows the average value of three replicates per correlation factor. * Correlation is significant at the 0.05 level, while ** correlation is significant at the 0.01 level. AC, amylose content; PC, protein content; A, amylopectin chains with DP 6–12; B1, amylopectin chains with DP 13–24; B2, amylopectin chains with DP 25–36; B3, amylopectin chains with DP > 36; α-1,4, α-1,4 linkage (%); α-1,6, α-1,6 linkage (%); VD, Volume percentage (%) of starch diameter; SAD, Surface area (%) of starch diameter; ND, Number percentage (%) of starch diameter. To, onset temperature; Tp, peak temperature; Tc, conclusion temperature; ΔHgel, gelatinization enthalpy; PV, peak viscosity; TV, trough viscosity; FV, final viscosity; BD, breakdown viscosity; SB, setback viscosity.

Textural properties of cooked rice

Compared to CK and SBR, SR had a lower hardness or higher stickiness in early rice and late rice (Table 2). The harder and less sticky texture of starch is attributed to its higher amount of amylopectin long chains, and longer amylopectin medium to long chains (Li et al. 2022). The decreasing trend of hardness and the formation of stickiness are mainly determined by the molecular mobility of the starch components (Xiong et al. 2022). In the present study, cooked rice with higher amount of amylopectin A chains and shorter amylopectin B1 and B3 chains had harder hardness and higher stickiness (Fig. 3), which might be due to an increase in the proportion of short chains (B1) in the total amylopectin distribution. The higher the proportion of short amylopectin chains, the greater the opportunity for bonding molecular interactions during cooking, resulting in the need for more force to separate the grains, i.e., higher stickiness (Li and Gilbert. 2018). These results indicated that SR treatment increased rice textural qualities, contributing to more flavourful and enjoyable texture of cooked rice to consumer. Furthermore, high pasting temperatures were already showed in research to improve the texture of cooked rice (Umekuni et al. 2003). Because significant and negative correlations were observed between gelatinization temperatures (To, Tp, and Tc) and hardness (Fig. 3). In addition, hardness, cohesiveness and chewiness all showed strong correlations with the amylopectin chain length, starch granules, gelatinization temperatures and pasting viscosities, respectively (Fig. 3). Although protein content was not found to correlate with the texture of cooked rice, higher proteins attached to the surface of starch granules also contrariwise affected rice grain to water absorption during cooking process, resulting in the deterioration of stickiness and hardness of cooked rice (Xiong et al. 2023).

There was a significant relationship between short amylopectin chains and springiness (Fig. 3). However, springiness did not differ in the treatments (Table 2), implying that springiness may be primarily influenced by genetic traits of cultivar itself rather than the fine structure and function of starch (Xiong et al. 2022). In this study, SR treatment significantly decreased the cohesiveness and chewiness of early- and late-season rice (Table 2), which might be attributed to the effect of cooked rice pasting properties (Huang et al. 2022), supported by the significant relationships between breakdown, setback and cohesiveness and chewiness (Fig. 3); and they resulted in the reduction of anti-shear strength of cooked rice and its energy required to chew (Xiong et al. 2022). Meanwhile, the correlations between cohesiveness and chewiness, and starch composition, structural, and physicochemical properties being similar to those of hardness also played an important role in assessing cooked rice quality (Fig. 3).

Conclusion

SBR and SR increased relative crystallinity, amylopectin long chains (B3) in early and late rice, and To and Tp only in late rice, respectively. Compared with SBR, SR decreased protein content, large starch granules, amylopectin short chains, α-1,4 linkage, and △Hgel, whereas increased amylose content, degree of branching and breakdown in early and late rice, suggesting that SR improved starch structure and thermal and pasting properties. In addition, SR increased relative crystallinity and decreased hardness, cohesiveness, and chewiness in both early and late rice, leading to better cooked rice textures. This was mainly attributed to the distribution of amylopectin chain length and starch granule size. The results indicate that SR enhances the structural and physicochemical properties of indica rice starch, contributing to the improvement on cooked rice texture. This study provides important insights for high-quality rice production, as well as rice starch processing and utilization under straw return.

Author contributions

YHZ designed the study and revised the manuscript. SY and LC wrote the first draft of the manuscript. RX, JJ, and YL performed the statistical analysis. XT, TL, YJZ, and XP wrote sections of the manuscript. All authors contributed to writing the manuscript.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (32160503, 32272212), the Key Program of Natural Science Foundation of Jiangxi Province, China (20232ACB205011, 20202ACBL215004), and the Youthful Innovation Research Team of Jiangxi Agricultural University (JXAUCXTD004).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.fochx.2023.100965.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

Data availability

Data will be made available on request.

References

- Berski W., Ptaszek A., Ptaszek P., Ziobro R., Kowalski G., Grzesik M., Achremowicz B. Pasting and rheological properties of oat starch and its derivatives. Carbohydrate Polymers. 2011;83(2):665–671. doi: 10.1016/j.carbpol.2010.08.036. [DOI] [Google Scholar]

- Butardo V.M., Fitzgerald M.A., Bird A.R., Gidley M.J., Flanagan B.M., Larroque O.…Rahman S. Impact of down-regulation of starch branching enzyme Ⅱb in rice by artificial microRNA- and hairpin RNA- mediated RNA silencing. Journal of Experimental Botany. 2011;62:4927–4941. doi: 10.1093/jxb/err188. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen L., Yang S., Gao J., Chen L., Ning H., Hu Z.…Zeng Y. Long-term straw return with reducing chemical fertilizers application improves soil nitrogen mineralization in a double rice-cropping system. Agronomy-Basel. 2022;12(8) doi: 10.3390/agronomy12081767. [DOI] [Google Scholar]

- Chen, S., Z, Liu., K, Zeng. (2016). Effect of straw-decomposing inoculant on decomposition of rice straw. Chinese Journal of Environmental Engineering, 10:839–844. doi: 10.1016/j.scitotenv.2015.02.028.

- Chen, S., Xue, J., Pan, G., Wang, Q. (2015). Relationship between RVA profile characteristics and other quality traits in grain positions of japonica rice. Journal of Nuclear Agricultural Sciences, 29(2), 244-251(In Chinese with English abstract).

- Che W., Piao J., Gao Q., Li X., Li X., Jin F. Response of soil physicochemical properties, soil nutrients, enzyme activity and rice yield to rice straw returning in highly saline-alkali paddy soils. Journal of Soil Science and Plant Nutrition. 2023 doi: 10.1007/s42729-023-01358-5. [DOI] [Google Scholar]

- Guo M., Li J., Li J., Qi J., Zhang X. Changes of soil structure and function after 16-year conservation tillage in black soil. Transactions of the Chinese Society of Agricultural Engineering. 2021;37(22):108–118. In Chinese with English abstract. [Google Scholar]

- Hanashiro I., Abe J., Hizukuri S. A periodic distribution of the chain length of amylopectin as revealed by high-performance anion-exchange chromatography. Carbohydrate Research. 1996;283:151–159. [Google Scholar]

- Hou, P., Ding, Y., wang, G., Li, Q., Wang, S., Tang, S., Liu, Z., Ding, C., Li, G. (2015). Effects of rice or wheat residue retention on the quality of milled japonica rice in a rice-wheat rotation system in China. Crop Journal, 3(1), 67-73. doi: 10.1016/j.cj.2014.08.003.

- Huang M., Hu L., Cao J., Zhang R., Chen J., Cao F.…Zhang M. Texture and digestion properties of hybrid rice: A comparison between two cultivars released 18 years apart. Food Chemistry-X. 2022;13 doi: 10.1016/j.fochx.2022.100215. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huo Y., Zhang B., Niu M., Jia C., Zhao S., Huang Q., Du H. An insight into the multi-scale structures and pasting behaviors of starch following citric acid treatment. International Journal of Biological Macromolecules. 2018;116:793–800. doi: 10.1016/j.ijbiomac.2018.05.114. [DOI] [PubMed] [Google Scholar]

- Hussain S.Z., Beigh M.A., Naseer B., Naik H.R. Visco-thermal and structural characterization of water chestnut flour. Journal of Food Science and Technology-mysore. 2020;57(8):2949–2959. doi: 10.1007/s13197-020-04327-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kallman A., Vamadevan V., Bertoft E., Koch K., Seetharaman K., Aman P., Andersson R. Thermal properties of barley starch and its relation to starch characteristics. International Journal of Biological Macromolecules. 2015;81:692–700. doi: 10.1016/j.ijbiomac.2015.08.068. [DOI] [PubMed] [Google Scholar]

- Li B., Chen X.Y., Yang Y., Wang Q.J., Dong Z.D., Yu X.R.…Xiong F. Returning the rice residue affects accumulation and physicochemical properties of wheat starch. Agronomy Journal. 2019;111(1):39–48. doi: 10.2134/agronj2018.01.0066. [DOI] [Google Scholar]

- Li C., Li E., Gong B. Main starch molecular structures controlling the textural attributes of cooked instant rice. Food Hydrocolloids. 2022;132 [Google Scholar]

- Li H., Gilbert R.G. Starch molecular structure: The basis for an improved understanding of cooked rice texture. Carbohydrate Polymers. 2018;195:9–17. doi: 10.1016/j.carbpol.2018.04.065. [DOI] [PubMed] [Google Scholar]

- Liu J., Zhao Q., Zhou L., Cao Z., Shi C., Cheng F. Influence of environmental temperature during grain filling period on granule size distribution of rice starch and its relation to gelatinization properties. Journal of Cereal Science. 2017;76:42–55. doi: 10.1016/j.jcs.2017.05.004. [DOI] [Google Scholar]

- Iqbal A., Xie H., He L., Ahmad S., Hussain I., Raza H.…Jiang L. Partial substitution of organic nitrogen with synthetic nitrogen enhances rice yield, grain starch metabolism and related genes expression under the dual cropping system. Saudi Journal of Biological Sciences. 2021;28(2):1283–1296. doi: 10.1016/j.sjbs.2020.11.039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Man J., Lin L., Wang Z., Wang Y., Liu Q., Wei C. Different structures of heterogeneous starch granules from high-amylose rice. Journal of Agricultural and Food Chemistry. 2014;62(46):11254–11263. doi: 10.1021/jf503999r. [DOI] [PubMed] [Google Scholar]

- Roman L., Yee J., Hayes A.M.R., Hamaker B.R., Bertoft E., Martinez M.M. On the role of the internal chain length distribution of amylopectins during retrogradation: Double helix lateral aggregation and slow digestibility. Carbohydrate Polymers. 2020;246 doi: 10.1016/j.carbpol.2020.116633. [DOI] [PubMed] [Google Scholar]

- Shi S., Wang E., Li C., Cai M., Cheng B., Cao C., Jiang Y. Use of protein content, amylose content, and RVA parameters to evaluate the taste quality of rice. Frontiers in Nutrition. 2021;8 doi: 10.3389/fnut.2021.758547. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Umekuni T., Kainuma K., Takahashi S. Correlation between taste of cooked rice and properties of gelatinization and retrogradation. Journal of Applied Glycoscience. 2003;50(3):395–403. [Google Scholar]

- Villas-Boas F., Franco C.M.L. Effect of bacterial beta-amylase and fungal alpha-amylase on the digestibility and structural characteristics of potato and arrowroot starches. Food Hydrocolloids. 2016;52:795–803. doi: 10.1016/j.foodhyd.2015.08.024. [DOI] [Google Scholar]

- Wu J., Zeng Y., Pan X., Shi Q., Li T., Wang S. Effects of rice straw returning mode on rice grain yield and soil carbon pool management index in double rice-cropping system. Journal of Applied Ecology. 2013;24(6):1572–1578. In Chinese with English abstract. [PubMed] [Google Scholar]

- Xie, X., Li, X., Xiao, X., Li, Y. (2007). Rice starch: Viscosity property and texture property. Journal of the Chinese Cereals and Oils Association, 22(3), 9-11, 20 (In Chinese with English abstract).

- Xiong R., Tan X., Yang T., Pan X., Zeng Y., Huang S.…Zeng Y. Relation of cooked rice texture to starch structure and physicochemical properties under different nitrogen managements. Carbohydrate Polymers. 2022;295 doi: 10.1016/j.carbpol.2022.119882. [DOI] [PubMed] [Google Scholar]

- Xiong R., Tan X., Yang T., Wang H., Pan X., Zeng Y.…Zeng Y. Starch multiscale structure and physicochemical property alterations in high-quality indica rice quality and cooked rice texture under different nitrogen panicle fertilizer applications. International Journal of Biological Macromolecules. 2023;126455 doi: 10.1016/j.ijbiomac.2023.126455. [DOI] [PubMed] [Google Scholar]

- Yang T., Tan X., Huang S., Pan X., Shi Q., Zeng Y.…Zeng Y. Effects of experimental warming on physicochemical properties of indica rice starch in a double rice cropping system. Food Chemistry. 2020;310 doi: 10.1016/j.foodchem.2019.125981. [DOI] [PubMed] [Google Scholar]

- Yu S., Ma Y., Menager L., Sun D. Physicochemical properties of starch and flour from different rice cultivars. Food and Bioprocess Technology. 2012;5(2):626–637. doi: 10.1007/s11947-010-0330-8. [DOI] [Google Scholar]

- Yuan C., Wang S., Lu D. Fertilization time of slow-release fertilizer affects the physicochemical properties of starch from spring-sown waxy maize. Journal of the Science of Food and Agriculture. 2022;102(3):1012–1020. doi: 10.1002/jsfa.11436. [DOI] [PubMed] [Google Scholar]

- Zeng Y., Wu J., Pan X., Shi Q., Zhu D. Study on yield and quality of double cropping rice in different straw return approaches. Plant Nutrition and Fertilizer Science. 2013;19(3):534–542. In Chinese with English abstract. [Google Scholar]

- Zhang G., Wang D., Yu Y., Wang C., Zhuang J. Effects of straw incorporation plus nitrogen fertilizer on rice yield, nitrogen use efficiency and nitrogen loss. Journal of Plant Nutrition and Fertilizer. 2016;22(4):877–885. In Chinese with English abstract. [Google Scholar]

- Zhang Y., Chen C., Wang N., Chen Y., Yu J., Zheng X.…Chen Y. Developing a new modification technology of oat flour based on differential pressure explosion puffing. Lwt-food Science and Technology. 2021;141 doi: 10.1016/j.lwt.2021.110967. [DOI] [Google Scholar]

- Zhang Z., Wang Z., Liu L., Yang J., Li Y. Effect of direct-seeding with non-flooding and wheat residue returning patterns on grain yield and grain quality of rice. Acta Agricultural Boreali-sinica. 2015;30(4):168–173. In Chinese with English abstract. [Google Scholar]

- Zhao C., Yue H., Huang S., Zhou L., Zhao L., Zhang Y.…Wang C. Eating quality and physicochemical properties in Nanjing rice varieties. Scientia Agricultura Sinica. 2019;52(5):909–920. In Chinese with English abstract. [Google Scholar]

- Zhou T., Zhou Q., Li E., Yuan L., Wang W., Zhang H.…Gu J. Effects of nitrogen fertilizer on structure and physicochemical properties of 'super' rice starch. Carbohydrate Polymers. 2020;239 doi: 10.1016/j.carbpol.2020.116237. [DOI] [PubMed] [Google Scholar]

- Zhu D., Zhang H., Guo B., Xu K., Dai Q., Wei C.…Huo Z. Effect of nitrogen management on the structure and physicochemical properties of rice starch. Journal of Agricultural and Food Chemistry. 2016;64(42):8019–8025. doi: 10.1021/acs.jafc.6b03173. [DOI] [PubMed] [Google Scholar]

- Zhu Y., Xu D., Ma Z., Chen X., Zhang M., Zhang C.…Zhang H. Differences in eating quality attributes between japonica rice from the northeast region and semiglutinous japonica rice from the Yangtze River Delta of China. Foods. 2021;10(11) doi: 10.3390/foods1011277. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.