Highlights

-

•

Physicochemical properties and volatiles in TSRW and semi-dry HRW were compared.

-

•

Trehalose, glucose, sucrose, maltose of semi-dry HRW were lower than those of TSRW.

-

•

Esters, alcohols and ketones of semi-dry HRW were significant different with TSRW.

-

•

No significant differences of organic acids and amino acids were observed.

Keywords: Semi-dry Hakka rice wine, Total sugar, Organic acid, Amino acids, Volatile components

Abstract

This study aimed to explore effects of indica rice addition, rice soaking time and rice soup addition on total sugar and alcohol content of semi-dry Hakka rice wine (HRW) and compare its difference in physicochemical properties and volatiles with traditional sweet rice wine (TSRW) via HPLC, GC–MS and E-tongue. The optimal fermentation conditions of semi-dry HRW were 50 % indica rice addition, 12 h rice soaking time and 85 % rice soup addition. The total sugar (16.13 mg/mL) of semi-dry HRW was significantly lower than that of TSRW (135.79 mg/mL), especially the trehalose, glucose, sucrose and maltose. Its alcohol content was significantly higher than that of TSRW. There were significant differences in volatile components between semi-dry HRW and TSRW, especially esters, alcohols and ketones, but no significant differences in organic acids and amino acids. Results obtained could provide reference data for improving the fermentation process and quality of semi-dry HRW.

1. Introduction

Chinese rice wine, a traditional fermented alcoholic beverage, is commonly made from glutinous rice with the addition of fermentation starters such as wheat Qu (Mài Qŭ) and Hong Qu (Hóng Qŭ). China rice wine can be mainly divided into three types including millet wine in the north of China, wheat Qu rice wine, and Hong Qu glutinous rice wine (Huang et al., 2018, Zhao et al., 2022). Guangdong Hakka rice wine (HRW) is a type of yellow rice wine that is famous for its crystal clear, mellow taste, strong fragrance, sweet, and long aftertaste, which has been widely consumed and appreciated in south China (Bai et al., 2015, Guo et al., 2022, Liu et al., 2020). Over the last few decades, some investigations have confirmed that Guangdong HRW has a wide range of pharmacological efficacy, including reducing blood pressure, regulating lipid metabolism, decreasing body weight, and alleviating aging due to it is rich in amino acids and have an excessive abundance of a unique aroma, vitamins, active peptides (Lu et al., 2015). However, with the implementation of the low sugar concept, semi-sweet or semi-dry Guangdong HRW attracts the attention of young consumers. Although there are several studies on Hakka yellow rice wine, there is no report on the preparation and quality analysis of semi-dry Guangdong glutinous rice wine.

Guangdong HRW is a brewed wine with low ethanol contents made from high-quality glutinous rice, liquor medicine and Hong Qu. HRW has a unique fermentation technology, namely the addition of liquor maintains the balance of saccharification and fermentation in the later stage of fermentation, and then the liquor is sterilized by burning after pressing. Some reports have exhibited that different raw materials and their states have great influences on yellow rice wine fermentation, such as inhibiting microbial metabolism or hindering carbohydrate metabolism (Xiao et al., 2022). Total acid, pH value, amino acid, and reducing sugar of fermentation broths were affected by raw materials and states (Wang, Sun, Jeong, Yeo, Choi, & Choi, 2014). In addition, the rice soaking time has certain effects on the process of rice cooking and ripening, leading to changes in the fermentation process and flavor generation (Yang et al., 2021). Some studies also indicated that fermentation water also changed the quality of yellow rice wine. For example, a certain amount of cold rice soup or cold water was added to rice wine before the 5 days of toasting in ancient times. A previous report has suggested that soybean soup instead of water is beneficial for reducing total sugar content and elevating the nutritional value of yellow rice wine (Zhao, et al., 2022). During yellow rice wine fermentation process, rice soup provided a nutrient substance to microbial growth, which elevated not only the quality but also the flavor of yellow rice wine. However, effect of rice soup on the quality of HRW has been rarely reported.

Therefore, the aim of the present study was to investigate the effects of indica rice addition, rice soaking time, and rice soup addition on the quality of Hakka yellow rice wine by single-factor tests. Moreover, the differences in physicochemical properties and volatiles between semi-dry type HRW and traditional sweet type rice wine (TSRW) were compared by means of high performance liquid chromatography (HPLC), headspace solid-phase micro-extraction coupled with gas chromatography-mass spectrometer (HS-SPME-GC–MS) and gas chromatography olfactometry (GC-O) analysis. This study could provide theoretical support for the quality control of semi-dry type HRW.

2. Materials and methods

2.1. Chemicals and reagents

Glutinous rice was provided by Yanzhifang Co., Ltd (Hefei, China). Indica rice Hong Qu, wheat Qu, and liquor were purchased from Jinchuliangyou Co., Ltd (Wuhan, China). Rice was purchased from Changwangmiyue Co., Ltd (Changzhou, China). Glutamate and other amino acids were purchased from Sigma–Aldrich (St Louis, MO, USA). Acetic acid and other organic acids were purchased from Yuanye Biotechnology Co., Ltd (Shanghai, China). Glucose (Glc), fructose (Fru), trehalose (Tre), maltose (Mal), sucrose (Suc), fucose (Fuc), rhamnose (Rha), arabinose (Ara), galactose (Gal), sactose (Lac), stachyose (Sta), and raffinose (Raf) were purchased from Sigma–Aldrich (St Louis, MO, USA).

2.2. Preparation and optimization of semi-dry HRW

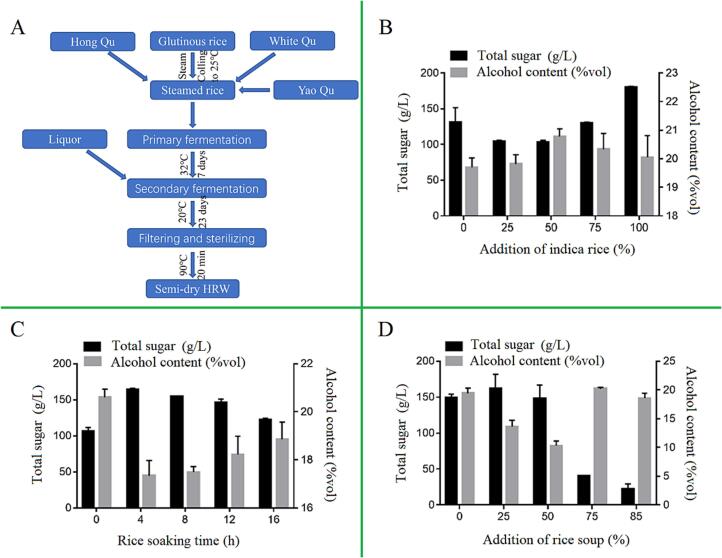

Semi-dry HRW was manufactured by our previous report (Zhao, et al., 2022). Fig. 1A exhibits a flow chart describing the semi-dry HRW fermentation process. The influence of the addition of glutinous rice/indica rice ratio, rice soaking time, and liquor/rice soup ratio on alcohol content and total sugar content in the preparation of semi-dry HRW was explored. Single-factor tests were conducted by varying the addition of indica rice (0 %, 25 %, 50 %, 75 % and 100 %), rice soaking time (0, 4, 6, 8, 12 and 16 h) and addition of rice soup (0 %, 25 %, 50 %, 75 % and 85 %).

Fig. 1.

The fermentation process of semi-dry HRW (A), effects of indica rice addition (B), rice soaking time (C) and rice soup addition (D) on total sugar and alcohol content of semi-dry HRW. Each value is the mean ± SD of triplicate measurements (n = 3).

2.3. Physicochemical analysis

Physicochemical properties including total sugar content, alcohol content, total acid, pH value, main sugars, organic acids and amino acids were determined according to our previous report and literatures (Liu et al., 2020, Qian et al., 2023, Zhao et al., 2022).

2.4. Determination of color

The color of HRW was detected by a chromaticity meter (CR-400, Konica Minolta, Japan), and all samples were repeated three times. L* value, a* value, and b* value represent the sample color of tends to brightness, redness, and yellowness, respectively.

2.5. Analysis of volatile compounds

Volatile compounds of HRW were determined by HS-SPME-GC–MS according to our reports (Bai et al., 2017, Qian et al., 2023).

2.6. Electronic-tongue analysis

Electronic-tongue (E-tongue) analysis was performed on the basis of our previous report (Qian, et al., 2023).

2.7. Statistical analysis

All experiments were performed in triplicate. Results data were expressed as means ± SD and analyzed for ANOVA and Tukey’s test (p < 0.05) by using SPSS Statistics 22.0 (software v.10.0.2, Minnesota, USA). OriginPro 2021(Origin Lab, Northampton, MA) and Prism 8.0 (GraphPad Software, USA) were used for plotting.

3. Results and discussion

3.1. Effects of processing conditions on total sugar and alcohol content of semi-dry HRW

Total sugar and alcohol content were regarded as the most important parameters during the fermentation process that assess yellow rice wine quality (Jin, Cai, Wu, Hu, Xu, Xie, et al., 2021). Therefore, in order to optimize the total sugar content and alcohol content of semi-dry HRW, the relevant variables should be fixed and explored. The influence of the addition of indica rice (0 %, 25 %, 50 %, 75 % and 100 %) on the total sugar content and alcohol content in semi-dry HRW was explored. As shown in Fig. 1B, with the increase of the addition of indica rice, a clear appearance that the total sugar content gradually reduced and alcohol content gradually increased in the range of 0 % to 50 %. However, there was an obvious uptrend in the total sugar content and downtrend in alcohol content with the increase of addition of indica rice ratio (from 50 % to 100 %). Result exhibited that when the proportion of indica rice was 50 %, the total sugar was the lowest. The Previous study showed that the total starch content of glutinous rice was higher than that of indica rice, lead to the reduction of total sugar content in semi-dry HRW with the increase of addition of indica rice (Gong et al., 2020). In addition, the amylose content of indica rice was higher than that of glutinous rice, which promotes the occurrence of retrogradation and then prevents saccharification process and fermentation process (Kuo, Shieh, Huang, David Wang, & Huang, 2019).

To investigate whether there is an underlying correlation between the changes in the rice soaking time and the total sugar and alcohol content of semi-dry HRW (Fig. 1C). Results showed that the rice soaking time of 0 h resulted in the highest alcohol content of semi-dry HRW. When the rice soaking time was altered from 0 h to 16 h, the alcohol content fluctuated within a small range and remained stable, suggesting that the soaking time will affect the fermentation process to some extent. In addition, the total sugar content of semi-dry HRW first elevated with the increase of the rice soaking time from 0 h to 4 h, and then reduced as the rice soaking time further increased. One possible reason was that the polysaccharides in glutinous rice are transferred to water and then removed by filtration, leading to the total sugar content were gradually decreased with the increases of the rice soaking time (Thammapat, Meeso, & Siriamornpun, 2015).

The addition of rice soup is the essential factor in the quality of semi-dry HRW for influencing the total sugar and alcohol content. As expressed in Fig. 1D, increasing the addition of rice soup to 50 % can reduce the alcohol content of semi-dry HRW, whereas the total sugar content remained unchanged with the increase of addition of rice soup ratio from 0 to 50 %. It is possible that high content of liquor prevents the growth of microorganisms and inhibit the enzyme activities (López-Domínguez, Ramírez-Sucre, & Rodríguez-Buenfil, 2019). However, when the addition of rice soup ratio was more than 50 %, the total sugar content was significantly reduced and the alcohol content was significantly increased in semi-dry HRW, which may be associated with an alcohol tolerance of microorganisms during fermentation.

3.2. Comparison of physicochemical parameters of semi-dry HRW and TSRW

Yellow rice wine quality is strongly associated with total sugar content, alcohol content, and total acid content, which also greatly affects the flavor and the taste of yellow rice wine (Chen et al., 2022). As shown in Table 1, the total acid content in semi-dry Hakka rice was significantly higher than that in TSRW, which may be because the sugar was converted into organic acid by microorganisms fermentation (Liu et al., 2022). However, there was no remarkable discrepancy in pH value between the semi-dry Hakka rice and TSRW. In addition, the proper color of the commodity can elevate market competitiveness. Therefore, the color of semi-dry HRW and TSRW were measured. As shown in Table 1, no significant differences were observed in L*, a*, and b* values between semi-dry HRW and TSRW (p > 0.05), suggesting that the color of semi-dry HRW is similar to that of TSRW.

Table 1.

Physicochemical properties of semi-dry HRW and TSRW. Each value is the mean ± SD of triplicate measurements (n = 3).

| Parameters | Semi-dry HRW | TSRW |

|---|---|---|

| Total acid (g/L) | 5.58 ± 0.12a | 4.21 ± 0.16b |

| pH | 4.06 ± 0.01b | 4.10 ± 0.01a |

| L* | 79.31 ± 0.96a | 79.18 ± 0.16a |

| a* | 3.83 ± 0.75a | 4.44 ± 0.37a |

| b* | 18.35 ± 1.12a | 21.88 ± 0.59a |

| Total sugar (mg/mL) | 16.13 ± 0.29b | 135.79 ± 0.79a |

| Alcohol content (%voL) | 19.25 ± 0.11a | 15.08 ± 1.24b |

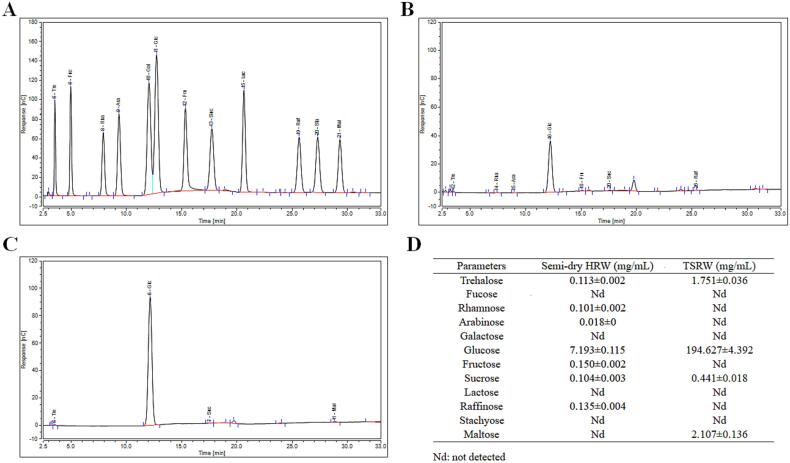

3.3. The changes of main sugars and organic acid contents in semi-dry HRW

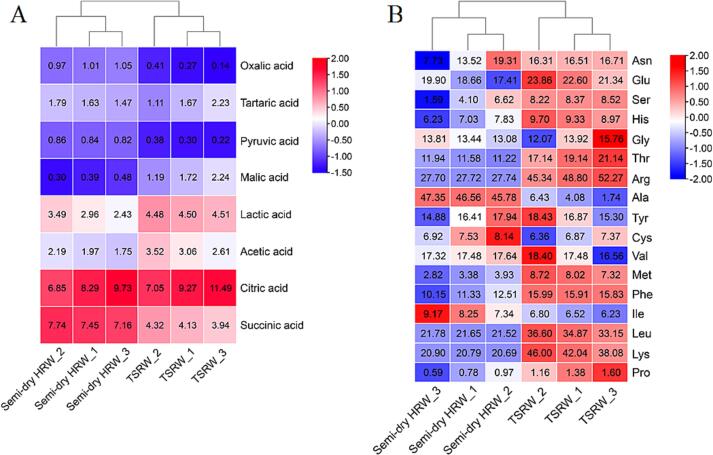

During fermentation of HRW, some low-molecular-weight sugars such as trehalose, fucose, rhamnose, arabinose, galactose, glucose, fructose, sucrose, lactose, raffinose, stachyose, and maltose are mainly consumed by various microorganisms. This is also helpful for elevating the organic acid content. Because of the starch in rice is predominantly degraded from Jiu Qu (Jiŭ Qŭ) by α-amylase and glucosidase, glucose, sucrose and maltose are served as the major fermentable sugars yellow rice wine fermentation (Hong Qu, white Qu, or Jiu Qu) (Kim and Seo, 2021, Yu et al., 2015). The standard chromatogram of twelve main sugars, chromatograms of semi-dry HRW and TSRW are shown in Fig. 2A, Fig. 2B and Fig. 2C, respectively. The contents of glucose, sucrose and maltose in the semi-dry HRW were obviously lower than those of TSRW (Fig. 2D). Especially, the maltose content in the semi-dry HRW was significantly lower than that in TSRW. This result was also in agreement with a previous report (Niu et al., 2008). However, the contents of fructose were obviously increased in semi-dry HRW compared with the TSRW. A previous study also found preferential depletion of glucose rather than fructose during fermentation (Berthels, Cordero Otero, Bauer, Pretorius, & Thevelein, 2008). Moreover, organic acids directly intervene in the stability of flavor, pH value, and quality in fermented foods (Tu et al., 2020). Thus, some organic acids in the semi-dry HRW were measured, as described in Fig. 3A. Compared with the TSRW, the levels of acetic acid, lactic acid, and malic acid in semi-dry HRW were obviously reduced, and the levels of succinic acid, pyruvic acid, and oxalic acid were obviously increased. A previous study exhibited that malic acid is converted to lactic acid via the microbial fermentation process, implying that lactic acid production reflected the degree of malic acid degradation (Pan, Jussier, Terrade, Yada, & Mira de Orduña, 2011). However, lactic acid concentration was decreased despite a significant reduction of malic acid, because of other metabolic pathways using lactic acid as a carbon source in the fermentation of yellow rice wine (Tkacz, Chmielewska, Turkiewicz, Nowicka, & Wojdyło, 2020). Pyruvic acid, with a pungent odor, had the lowest levels in yellow rice wine, which is in agreement with a previous report (Jin, et al., 2021). Interestingly, no remarkable difference in citric acid and tartaric acid levels between the TSRW and semi-dry HRW, and the reason needs further investigation.

Fig. 2.

The standard chromatogram (A) of twelve main sugars, chromatograms of semi-dry HRW (B) and TSRW (C), contents of twelve main sugars in the semi-dry HRW and TSRW (D). Each value is the mean ± SD of triplicate measurements (n = 3).

Fig. 3.

The organic acid levels (A) and amino acid levels (B) in semi-dry HRW and TSRW.

3.4. Amino acids analysis

Yellow rice wine is commonly known as “liquid cake” due to its relatively higher content of amino acids compared to other wines (Wang, Mao, Meng, Li, Liu, & Feng, 2014). In addition, amino acids act as the essential nutritive and flavor precursor ingredients in yellow rice wine, which supplied nitrogen sources to the reproduction of microorganisms during the fermentation, and further improve the wine quality (Liang, Lin, He, Su, Li, & Ren, 2020). Therefore, the amino acid composition of semi-dry HRW was detected, as shown in Fig. 3B. Compared with the TSRW, the contents of Lys, Leu, Phe, Met, Arg, Thr, His, Ser, and Asn in semi-dry HRW were significantly reduced, but the contents of Ile and Ala were significantly increased. However, no significant difference in the contents of Pro, Val, Cys, Tyr, Gly, and Glu between the TSRW and semi-dry HRW was observed. In addition, the levels of bitter amino acids in semi-dry HRW were lower than that in the TSRW, namely 191.82 mg/ mL (accounting for 65.53 % of total amino acids) and 130.67 mg/mL (accounting for 52.22 % of total amino acids). These results are strongly associated with the alteration of glutinous rice/indica rice ratio (Gutiérrez-Gamboa et al., 2017, Yang et al., 2019).

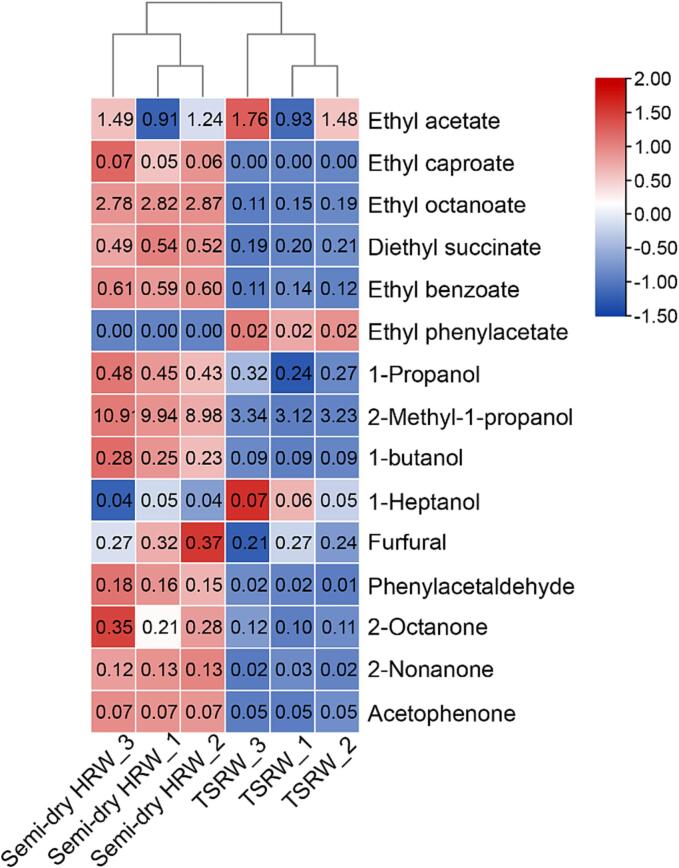

3.5. Comparison of volatile compounds of semi-dry HRW and TSRW

Volatile compounds are an essential parameter to assess the quality of yellow rice wine and a critical factor to determine the acceptance of consumers. Therefore, the volatile compounds of semi-dry HRW were detected by HS-SPME-GC–MS. A total of 85 kinds of volatile compounds were detected and identified in semi-dry HRW and TSRW. However, 15 kinds of volatile compounds in semi-dry HRW were significantly altered, including esters, alcohols, and aldehydes (Fig. 4). Esters play an essential role in the formation of fruity and floral odors in yellow rice wine, and the major esters contained ethyl acetate and ethyl butyrate (Liu, Wang, Lv, Zhu, Chen, & Ni, 2018). A previous report exhibited that the formation of esters in yellow rice wine is mainly attributed to various metabolites stemming from saccharifying and liquefaction agents (Liu et al., 2019). The main esters in semi-dry HRW were ethyl caproate, ethyl octanoate, diethyl succinate, and ethyl benzoate. In addition, moderate levels of higher alcohols help to increase the aromatic complexity of yellow rice wine (Tian et al., 2016). 1-propanol stemmed from Saccharomyces cerevisiae, is help to improve the taste and flavor of Chinese rice wine (Wang, Sun, Wei, Guo, & Xiao, 2021). The content of 1-propanol was significantly increased in semi-dry HRW (0.45 ± 0.3 mg/mL) compared with that in the TSRW (0.33 ± 0.4 mg/mL), indicating that semi-dry HRW has aromatic complexity. In addition, there was a significantly differ in the aldehyde contents between the TSRW and semi-dry HRW. It has been accepted that aldehydes were the major substances that help to improve the flavor of yellow rice wine. Aldehydes were mainly produced during ethanol fermentation, which is thought to be the most powerful aroma-impact compound to contribute to the typical aroma of yellow rice wine (Cai et al., 2020).

Fig. 4.

The relative contents of key volatile compounds in semi-dry HRW and TSRW.

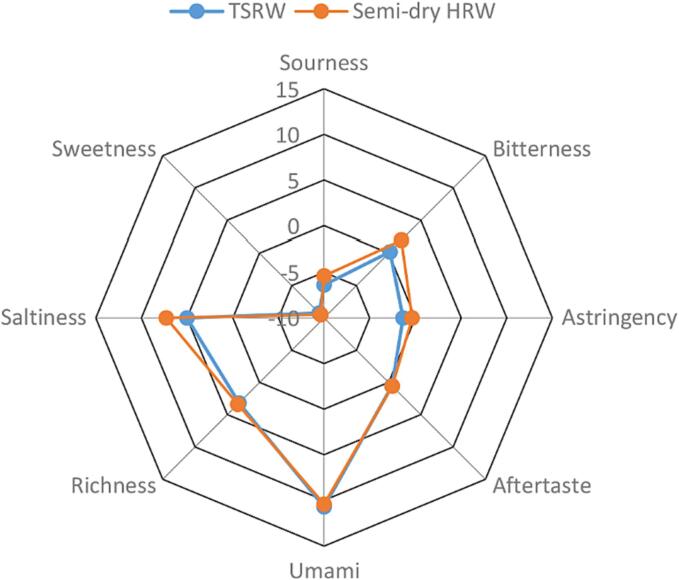

3.6. E-tongue analysis

E-tongue can detect taste characteristics through electronic sensors to simulate people’s taste perception. The result of the rose diagram exhibits the results of E-tongue response values for semi-dry HRW and TSRW (Fig. 5). It is worth noting that the taste of semi-dry HRW and TSRW is not remarkably classifiable, because apart from saltiness, bitterness, and astringency, most plots of other taste parameters in the rose diagram overlap with TSRW. It is also noteworthy that the response values of saltiness, sourness, bitterness, and astringency in semi-dry HRW were higher than those in TSRW, but the difference was no reached the statistical differences (p > 0.05). Therefore, there were no remarkable differences in taste between the semi-dry HRW and TSRW.

Fig. 5.

Average radar map of semi-dry HRW and TSRW based on the E-tongue response data.

4. Conclusion

In the present study, the fermentation process of semi-dry Hakka rice wine (HRW) was optimized and characterized. Under the optimal fermentation conditions (addition of indica rice, 50 %; rice soaking time, 12 h; addition of rice soup, 85 %), the total sugar and alcohol content of semi-dry HRW were 16.13 ± 0.29 g/L and 19.25 ± 0.11 %vol, respectively. Semi-dry HRW exhibited a higher content of total acids, lower pH value and total sugar compared with that in TSRW, which is beneficial for inhibiting the growth of harmful bacteria. Importantly, semi-dry HRW has more volatile substances than TSRW, but no significant differences in total amino acids and organic acids. These results offered reference data for improving the quality of semi-dry HRW.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was financially supported by the Characteristic Innovation Project of Guangdong Universities (2022KTSCX058), Guangdong Provincial Key Laboratory of Lingnan Specialty Food Science and Technology (2021B1212040013) and Guangdong Science and Technology Project (KTP20210224). Authors declare no competing financial interests.

Contributor Information

Min Qian, Email: qianmin@zhku.edu.cn.

Hao Dong, Email: donghao@zhku.edu.cn.

Data availability

Data will be made available on request.

References

- Bai W., Fang X., Zhao W., Huang S., Zhang H., Qian M. Determination of oligosaccharides and monosaccharides in Hakka rice wine by precolumn derivation high-performance liquid chromatography. Journal of Food and Drug Analysis. 2015;23(4):645–651. doi: 10.1016/j.jfda.2015.04.011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bai W., Sun S., Zhao W., Qian M., Liu X., Chen W. Determination of Ethyl Carbamate (EC) by GC-MS and Characterization of Aroma Compounds by HS-SPME-GC-MS During Wine Frying Status in Hakka Yellow Rice Wine. Food Analytical Methods. 2017;10(6):2068–2077. [Google Scholar]

- Berthels N.J., Cordero Otero R.R., Bauer F.F., Pretorius I.S., Thevelein J.M. Correlation between glucose/fructose discrepancy and hexokinase kinetic properties in different Saccharomyces cerevisiae wine yeast strains. Applied Microbiology and Biotechnology. 2008;77(5):1083–1091. doi: 10.1007/s00253-007-1231-2. [DOI] [PubMed] [Google Scholar]

- Cai W., Tang F., Guo Z., Guo X., Zhang Q., Zhao X.…Shan C. Effects of pretreatment methods and leaching methods on jujube wine quality detected by electronic senses and HS-SPME–GC–MS. Food Chemistry. 2020;330 doi: 10.1016/j.foodchem.2020.127330. [DOI] [PubMed] [Google Scholar]

- Chen G.-M., Li W.-L., Tong S.-G., Qiu Y.-T., Han J.-Z., Lv X.-C.…Ni L. Effects of the microbial community on the formation of volatile compounds and biogenic amines during the traditional brewing of Hongqu rice wine. Current Research in Food Science. 2022;5:1433–1444. doi: 10.1016/j.crfs.2022.08.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gong M., Zhou Z., Jin J., Yu Y., Liu S., Han X.…Mao J. Effects of soaking on physicochemical properties of four kinds of rice used in Huangjiu brewing. Journal of Cereal Science. 2020;91 [Google Scholar]

- Guo J., Lu A., Sun Y., Liu B., Zhang J., Zhang L.…Miao J. Purification and identification of antioxidant and angiotensin converting enzyme-inhibitory peptides from Guangdong glutinous rice wine. LWT-Food Science and Technology. 2022;169 [Google Scholar]

- Gutiérrez-Gamboa G., Garde-Cerdán T., Portu J., Moreno-Simunovic Y., Martínez-Gil A.M. Foliar nitrogen application in Cabernet Sauvignon vines: Effects on wine flavonoid and amino acid content. Food Research International. 2017;96:46–53. doi: 10.1016/j.foodres.2017.03.025. [DOI] [PubMed] [Google Scholar]

- Huang Z.-R., Hong J.-L., Xu J.-X., Li L., Guo W.-L., Pan Y.-Y.…Lv X.-C. Exploring core functional microbiota responsible for the production of volatile flavour during the traditional brewing of Wuyi Hong Qu glutinous rice wine. Food Microbiology. 2018;76:487–496. doi: 10.1016/j.fm.2018.07.014. [DOI] [PubMed] [Google Scholar]

- Jin Z., Cai G., Wu C., Hu Z., Xu X., Xie G.…Lu J. Profiling the key metabolites produced during the modern brewing process of Chinese rice wine. Food Research International. 2021;139 doi: 10.1016/j.foodres.2020.109955. [DOI] [PubMed] [Google Scholar]

- Kim M., Seo J.-A. Fermentation profiling of rice wine produced by Aspergillus oryzae KSS2 and Rhizopus oryzae KJJ39 newly isolated from Korean fermentation starter. Applied Biological Chemistry. 2021;64(1):25. [Google Scholar]

- Kuo C.-H., Shieh C.-J., Huang S.-M., David Wang H.-M., Huang C.-Y. The effect of extrusion puffing on the physicochemical properties of brown rice used for saccharification and Chinese rice wine fermentation. Food Hydrocolloids. 2019;94:363–370. [Google Scholar]

- López-Domínguez C.M., Ramírez-Sucre M.O., Rodríguez-Buenfil I.M. Enzymatic hydrolysis of Opuntia ficus-indica cladode by Acinetobacter pittii and alcohol fermentation by Kluyveromyces marxianus: pH, temperature and microorganism effect. Biotechnology Reports. 2019;24:e00384. doi: 10.1016/j.btre.2019.e00384. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liang Z., Lin X., He Z., Su H., Li W., Ren X. Amino acid and microbial community dynamics during the fermentation of Hong Qu glutinous rice wine. Food Microbiology. 2020;90 doi: 10.1016/j.fm.2020.103467. [DOI] [PubMed] [Google Scholar]

- Liu A., Pan W., Li S., Li J., Li Q., He L.…Liu S. Seasonal dynamics of microbiota and physicochemical indices in the industrial-scale fermentation of Sichuan Baoning vinegar. Food Chemistry: X. 2022;16 doi: 10.1016/j.fochx.2022.100452. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu D., Qi Y., Zhao N., Cao Y., Xu J., Fan M. Multivariate analysis reveals effect of glutathione-enriched inactive dry yeast on amino acids and volatile components of kiwi wine. Food Chemistry. 2020;329 doi: 10.1016/j.foodchem.2020.127086. [DOI] [PubMed] [Google Scholar]

- Liu S., Yang L., Zhou Y., He S., Li J., Sun H.…Xu S. Effect of mixed moulds starters on volatile flavor compounds in rice wine. LWT-Food Science and Technology. 2019;112 [Google Scholar]

- Liu X., Qian M., Dong H., Bai W., Zhao W., Li X., Liu G. Effect of ageing process on carcinogen ethyl carbamate (EC), its main precursors and aroma compound variation in Hakka Huangjiu produced in southern China. International Journal of Food Science & Technology. 2020;55(4):1773–1780. [Google Scholar]

- Liu Z., Wang Z., Lv X., Zhu X., Chen L., Ni L. Comparison study of the volatile profiles and microbial communities of Wuyi Qu and Gutian Qu, two major types of traditional fermentation starters of Hong Qu glutinous rice wine. Food Microbiology. 2018;69:105–115. doi: 10.1016/j.fm.2017.07.019. [DOI] [PubMed] [Google Scholar]

- Lu Q.-Y., Lee R.-P., Huang J., Yang J., Henning S.M., Hong X.…Li Z. Quantification of bioactive constituents and antioxidant activity of Chinese yellow wine. Journal of Food Composition and Analysis. 2015;44:86–92. [Google Scholar]

- Niu X., Shen F., Yu Y., Yan Z., Xu K., Yu H., Ying Y. Analysis of Sugars in Chinese Rice Wine by Fourier Transform Near-Infrared Spectroscopy with Partial Least-Squares Regression. Journal of Agricultural and Food Chemistry. 2008;56(16):7271–7278. doi: 10.1021/jf800993e. [DOI] [PubMed] [Google Scholar]

- Pan W., Jussier D., Terrade N., Yada R.Y., Mira de Orduña R. Kinetics of sugars, organic acids and acetaldehyde during simultaneous yeast-bacterial fermentations of white wine at different pH values. Food Research International. 2011;44(3):660–666. [Google Scholar]

- Qian M., Ruan F., Zhao W., Dong H., Bai W., Li X.…Li Y. The dynamics of physicochemical properties, microbial community, and flavor metabolites during the fermentation of semi-dry Hakka rice wine and traditional sweet rice wine. Food Chemistry. 2023;416 doi: 10.1016/j.foodchem.2023.135844. [DOI] [PubMed] [Google Scholar]

- Thammapat P., Meeso N., Siriamornpun S. Effects of NaCl and soaking temperature on the phenolic compounds, α-tocopherol, γ-oryzanol and fatty acids of glutinous rice. Food Chemistry. 2015;175:218–224. doi: 10.1016/j.foodchem.2014.11.146. [DOI] [PubMed] [Google Scholar]

- Tian Y., Huang J., Xie T., Huang L., Zhuang W., Zheng Y., Zheng B. Oenological characteristics, amino acids and volatile profiles of Hongqu rice wines during pottery storage: Effects of high hydrostatic pressure processing. Food Chemistry. 2016;203:456–464. doi: 10.1016/j.foodchem.2016.02.116. [DOI] [PubMed] [Google Scholar]

- Tkacz K., Chmielewska J., Turkiewicz I.P., Nowicka P., Wojdyło A. Dynamics of changes in organic acids, sugars and phenolic compounds and antioxidant activity of sea buckthorn and sea buckthorn-apple juices during malolactic fermentation. Food Chemistry. 2020;332 doi: 10.1016/j.foodchem.2020.127382. [DOI] [PubMed] [Google Scholar]

- Tu C., Hu W., Tang S., Meng L., Huang Z., Xu X.…Dong M. Isolation and identification of Starmerella davenportii strain Do18 and its application in black tea beverage fermentation. Food Science and Human Wellness. 2020;9(4):355–362. [Google Scholar]

- Wang P., Mao J., Meng X., Li X., Liu Y., Feng H. Changes in flavour characteristics and bacterial diversity during the traditional fermentation of Chinese rice wines from Shaoxing region. Food Control. 2014;44:58–63. [Google Scholar]

- Wang Q.J., Sun D.-W., Jeong S.-T., Yeo S.-H., Choi J.-H., Choi H.-S. Screening of rice cultivars for brewing high quality turbid rice wine. LWT-Food Science and Technology. 2014;56(1):145–152. [Google Scholar]

- Wang Y.-P., Sun Z.-G., Wei X.-Q., Guo X.-W., Xiao D.-G. Identification of Core Regulatory Genes and Metabolic Pathways for the n-Propanol Synthesis in Saccharomyces cerevisiae. Journal of Agricultural and Food Chemistry. 2021;69(5):1637–1646. doi: 10.1021/acs.jafc.0c06810. [DOI] [PubMed] [Google Scholar]

- Xiao R., Chen S., Wang X., Chen K., Hu J., Wei K.…Lu F. Microbial community starters affect the profiles of volatile compounds in traditional Chinese Xiaoqu rice wine: Assement via high-throughput sequencing and gas chromatography-ion mobility spectrometry. LWT-Food. Science and Technology. 2022;114000 [Google Scholar]

- Yang Y., Xia Y., Hu W., Tao L., Liu H., Xie C.…Ai L. Soaking induced discrepancies in oenological properties, flavor profiles, microbial community and sensory characteristic of Huangjiu (Chinese rice wine) LWT-Food Science and Technology. 2021;139 [Google Scholar]

- Yang Y., Xia Y., Wang G., Tao L., Yu J., Ai L. Effects of boiling, ultra-high temperature and high hydrostatic pressure on free amino acids, flavor characteristics and sensory profiles in Chinese rice wine. Food Chemistry. 2019;275:407–416. doi: 10.1016/j.foodchem.2018.09.128. [DOI] [PubMed] [Google Scholar]

- Yu H., Zhao J., Li F., Tian H., Ma X. Characterization of Chinese rice wine taste attributes using liquid chromatographic analysis, sensory evaluation, and an electronic tongue. Journal of Chromatography B. 2015;997:129–135. doi: 10.1016/j.jchromb.2015.05.037. [DOI] [PubMed] [Google Scholar]

- Zhao W., Qian M., Dong H., Liu X., Bai W., Liu G., Lv X.-C. Effect of Hong Qu on the flavor and quality of Hakka yellow rice wine (Huangjiu) produced in Southern China. LWT-Food Science and Technology. 2022;160 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.