Graphical abstract

Keywords: Chinese liquor, Alcoholic beverage, Flavor, Aroma-active compounds, Sensory property

Chemical compounds studied in this article: Ethyl hexanoate (PubChem CID31265), 3-Methylindole (PubChem CID6736), 3-(Methylthio)propanal (PubChem CID18635), Ethyl acetate (PubChem CID8857), β-damascenone (PubChem CID5366074), 2-Methyl-3-furanthiol (PubChem CID34286), 2-Furfurylthiol (PubChem CID7363), 3-Mercaptohexanol (PubChem CID521348), 4-Methyl-4-mercapto-2-pentanone (PubChem CID88290), β-phenylethanol (PubChem CID6054)

Highlights

-

•

The key odorants of Baijiu and some world-renowned distilled liquors are summarized.

-

•

A comprehensive review of the flavor and odorants of various distilled liquors.

-

•

This work enhances the comprehension of the flavor in distilled liquors.

Abstract

The flavor characteristics of distilled liquors significantly affect consumer acceptance and adoption. Therefore, odorants that contribute to sensory properties have received more attention. The odorants depend on the operating parameters, such as raw materials and ingredients, manufacturing process and maturing circumstances. This review summarized the odorants in the Baijiu and other world-renowned distilled liquors. Especially, the contribution of the odorants to the dominant aroma attributes is given more attention. The variations in the constituents and contents of odorants among the liquors are discussed comprehensively. In general, further research is still needed on the interaction mechanism between the odorants and sensory properties of distilled liquors.

Nomenclature

- DI

direct injection

- SPE

solid phase extraction

- SPME

solid phase microextraction

- LLE

liquid–liquid extraction

- LLME

liquid–liquid micro extraction

- SBSE

stir bar sorptive extraction

- SDE

simultaneous distillation extraction

- SIDA

stable isotope dilution analysis

- GC–MS

gas chromatography-mass spectrometry

- GC-O

gas chromatography–olfactometry

- GC × GC

two-dimensional gas chromatography

- MDGC-MS

multidimensional gas chromatography-mass spectrometry

- FPD

flame photometric detector

- NPD

nitrogen phosphorus detector

- Osme

odor-specific magnitude estimation

- AEDA

aroma extract dilution analysis

- OAV

odor activity value

- SEBES

new sensomics-based expert system

- FD

flavor dilution

1. Introduction

Alcoholic beverages are a significant part of embedded human civilization. In the 14th century, ethanol, also recognized as “burning water”, was extensively used as a remedy for diseases and epidemics (Tonutti and Liddle, 2010). Over time, distilled liquors emerged as a lifestyle commodity, satisfying the sensory and psychological needs of humanity. They were developed in various parts of the world during the early stages of civilization. The flavor characteristics of distilled liquors have become crucial in determining consumer acceptance and adoption. Ethanol and water are the main components, accounting for 97% to 98% of the total content, while the remaining 2% to 3% consists of trace components (Fan et al., 2012). These trace components, known as odorants or aroma-active compounds, interact with human olfactory receptors. They include alcohols, acids, esters, aldehydes, ketones, acetals, furans, terpenes, sulfur-containing and nitrogen-containing compounds, each contributing to the unique sensory properties and aroma attributes such as fruity and floral notes (J. Wang et al., 2022).

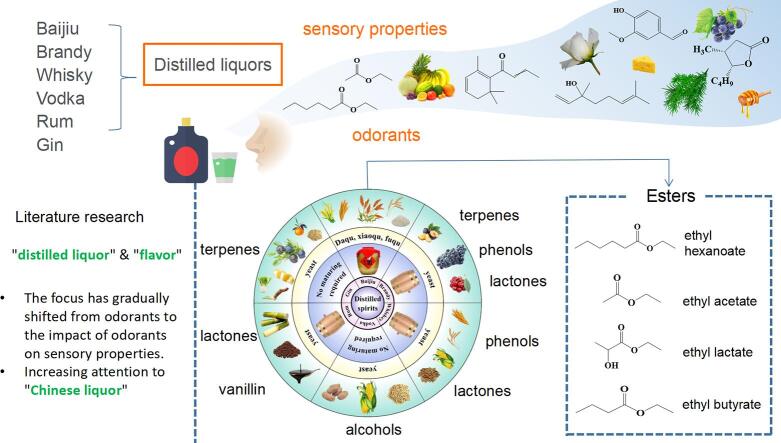

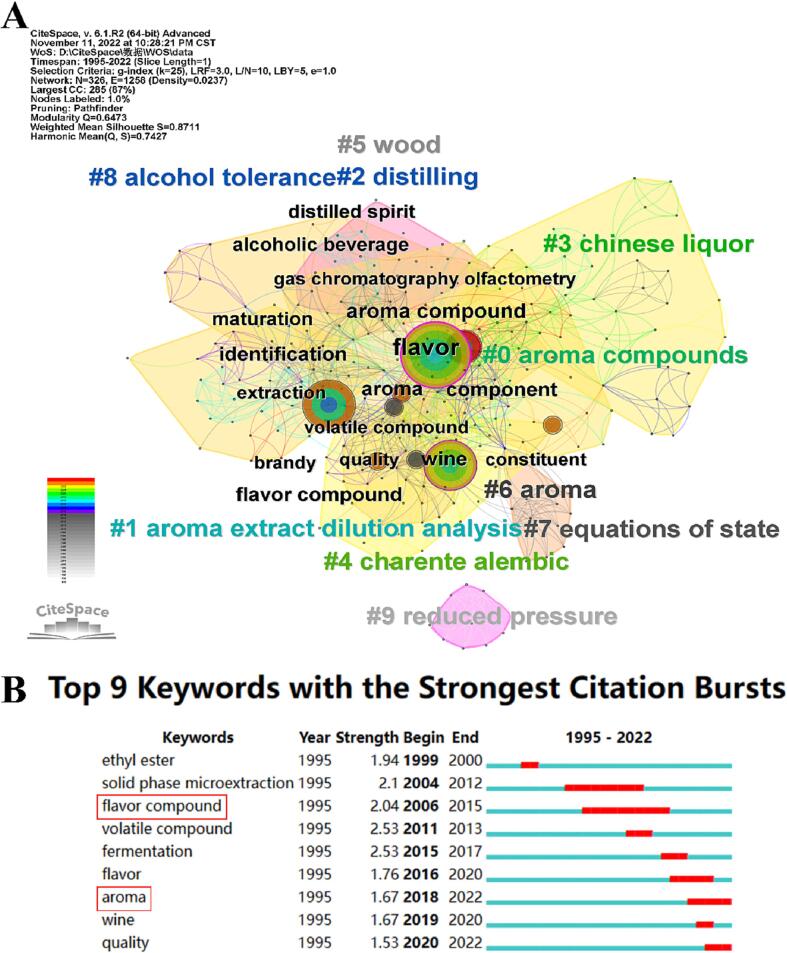

Numerous studies have focused on identifying potent odorants that contribute to the flavor of various distilled liquors. Fig. 1 visualizes research trends and the keywords with the strongest citation bursts. The data, gathered from 1995 to 2022 using Web of Science, focused on the themes of “distilled liquor” and “flavor.” The visualization software used was Citespace, v. 6.1.R2 (64-bit) Advanced. Fig. 1A indicates that the top four clusters are “aroma compounds,” “AEDA,” “distilling,” and “Chinese liquor,” suggesting increased attention on odorants, analytical methods, and Baijiu. Fig. 1B presents the top nine keywords with the strongest citation bursts during the same period. It is evident that research focus has shifted gradually from “flavor compound” to “aroma.” This evolution indicates a growing emphasis on studying the effects of odorants on sensory properties. Consequently, there is a need to summarize the odorants and sensory properties associated with various distilled liquors.

Fig. 1.

Recent trends and research hotspot in flavor of distilled liquors (A: The keyword clustering co-occurrence landscape; B: The top 9 keywords with the strongest citation bursts).

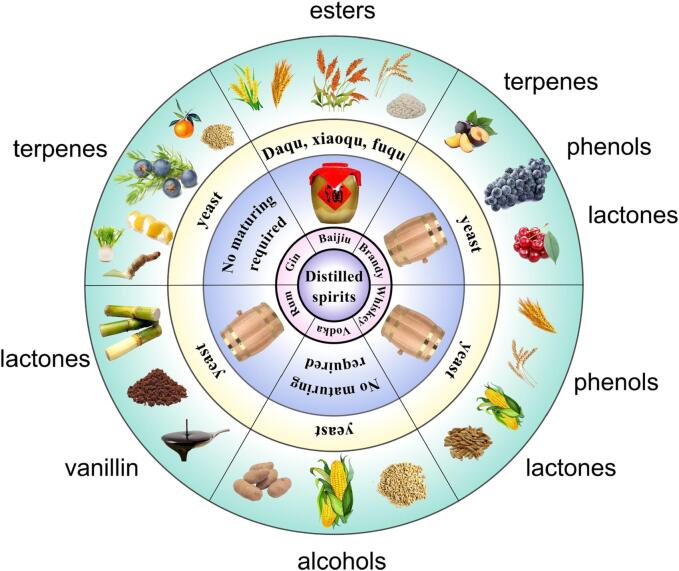

The odorants in distilled liquors depend on several key operating parameters, including raw materials, ingredients, manufacturing processes, such as fermentation and distillation, and maturation circumstances (refer to Fig. 2). Raw materials for brewing are generally crops with high sugar or starch values (M. C. Qian, An, Chen, & Qian, 2019). In the case of gin, it involves the use of botanicals and grain distillates as ingredients (Fig. 2). Distilled liquors produced through grain fermentation exhibit some similarities in terms of alcohol compounds, esters, and carbonyls (Jeleń et al., 2019, Ng et al., 1996, Niu et al., 2017); The manufacturing process of distilled liquors consists of two main sections: fermentation and distillation. Fermentation is a natural process in which microorganisms break down organic substances containing carbohydrates (Liu et al., 2020). Baijiu, for example, utilizes a mixture called “Qu” to catalyze saccharification and fermentation, while other distilled liquors employ yeast. Distillation, on the other hand, involves heating the fermentation mixture in an ethanol atmosphere in the gas phase to enrich substances, which are then returned to the liquid fraction to generate the desired flavor (Rodríguez Madrera, Blanco Gomis, & Mangas Alonso, 2003). Reactions that occur during the manufacturing process include enzymatic and non-enzymatic reactions (Zhang & Cheng W**, Pan T.Q., L. N., 2019). Enzymatic reactions primarily involve biosynthesis processes using precursors like straight-chain, branched-chain, aromatic, sulfur-containing amino acids, as well as linolenic acid, linoleic acid, pigments, and other constituents (Mosedale, 1995). Non-enzymatic reactions encompass the thermal effects of the distillation process, resulting in oxidation, decomposition, degradation, and the production of aroma substances. Additionally, interactions between components or thermal degradation (Maillard reaction) contribute to the formation of odorants (Luo, Fan, & Xu, 2008); Maturation circumstances also play a vital role in the formation of odorants (Alcarde et al., 2014, Mosedale, 1995). Baijiu, for instance, is initially stored in pottery jars for a limited time and then may undergo extended maturation in stainless steel tanks (Z. Wang et al., 2022). Brandy, whiskey, and rum, on the other hand, involve maturation in oak barrels, where the degradation of hemicellulose and lignin supports the formation of volatile phenols and lactones. The duration of maturation and the type of maturation vessel both have an impact on the development of odorants.

Fig. 2.

Differences between the six distilled liquors (from the inside out, covering: a. types of distilled liquors; b. matured containers; c. fermentation agents; d. raw materials and ingredients; e. key odorants for specific types).

The sensomic methodology is currently extensively used to characterize the flavor of distilled liquors, leading to the identification of numerous odorants. This review will provide an overview of the general steps involved in the sensomic methodology, followed by a focus on the research conducted on odorants in Baijiu. It will further explore the odorants in globally renowned distilled liquors such as brandy, whiskey, vodka, rum, and gin. Additionally, there is still a need for further research to understand the interaction mechanism between odorants and the sensory properties of distilled liquors. The goal of this review is to enhance our understanding of the flavor profiles in distilled liquors.

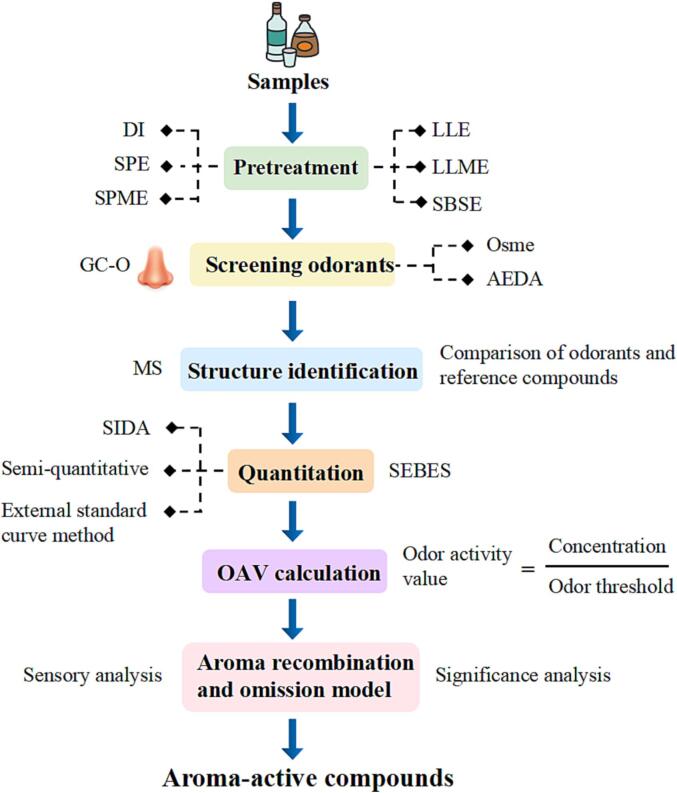

2. Flavor analysis methods

The sensomic methodology is a powerful tool used to unravel the flavor profile of distilled liquors, allowing for the identification and understanding of the chemical composition of specific aroma profiles(Franitza, Granvogl, & Schieberle, 2016b; Granvogl & Schieberle, 2022). It involves aroma analysis based on the sensomics concept, which is commonly employed to evaluate the aroma potential of various components in terms of odor quality and intensity (Granvogl and Schieberle, 2022, Uselmann and Schieberle, 2015). The sensomics concept relies on biological reactions to pinpoint the odorants present in a food matrix that interact with human olfactory receptors(Regalado et al., 2011). By utilizing this approach, researchers are able to decipher the complex aroma profiles of distilled liquors and map out the sensory attributes associated with specific odorants. Fig. 3 presents a comprehensive series of steps for the analysis of liquor samples using the sensomic methodology. The data obtained from these analyses can provide valuable insights into the chemical composition and sensory characteristics of distilled liquors.

Fig. 3.

A complete set of steps for the analysis of liquor samples.

In the analysis of liquors, it is indeed challenging to extract all the flavor substances due to their complex matrix and diverse properties (Sun et al., 2015). Various pretreatment methods are commonly used, including direct injection(DI), solid phase extraction(SPE), solid phase microextraction(SPME), liquid–liquid extraction(LLE), liquid–liquid microextraction(LLME), and stir bar sorptive extraction(SBSE) (Buck et al., 2020, Niu et al., 2017; Y. P. Zhao et al., 2011). These methods help to extract and concentrate the target compounds for further analysis.

To screen odorants, gas chromatography–olfactometry (GC-O) analysis is often employed, which includes odor-specific magnitude estimation (Osme) and aroma extract dilution analysis (AEDA)(Buck et al., 2020; Y. l. Qian, An, Chen, & Qian, 2019; D. Zhao et al., 2018). Osme allows expert panelists to evaluate the quality and intensity of aroma impressions(Dong et al., 2018), while AEDA helps to identify aroma-active compounds and estimate their relative odor potency(Buck et al., 2020).

Identification of odorants can be accomplished by comparing human sensory data with reference compounds or by using techniques such as gas chromatography-mass spectrometry (GC–MS), gas chromatography–olfactometry analysis (GC-O), two-dimensional gas chromatography (GC × GC), or multidimensional gas chromatography-mass spectrometry (MDGC–MS) (Sun et al., 2015) Detectors with high selectivity and sensitivity, such as flame photometric detector (FPD) and nitrogen phosphorus detector (NPD), can also be used for specific compounds(Hong et al., 2020; Niu, Yao, et al., 2017b).

Accurate quantification of odorants is crucial in flavor research, and stable isotope dilution analysis (SIDA) is commonly employed for this purpose(Franitza et al., 2016a). However, SIDA has some limitations, such as being time-consuming and requiring ultra-high resolution mass spectrometry(Poisson and Schieberle, 2008b). Another approach is using a sensomics-based expert system (SEBES), which enables the prediction of key aroma compounds without involving the human olfactory system(Nicolotti et al., 2019).

Key odorants are typically determined based on their concentration in the matrix exceeding the orthonasal recognition threshold, known as the odor activity value (OAV)(J. A. Pino et al., 2012). These compounds significantly contribute to the overall flavor profile. Recombination and omission experiments can further validate the role of key odorants in producing specific aroma profiles(Fan et al., 2015; Q. Fan et al., 2019, Poisson and Schieberle, 2008a).

Chemometric methods, such as the application of artificial neural network techniques, can provide new perspectives for the analysis of alcoholic samples. These techniques can be used to distinguish liquors from different origins(Ledauphin et al., 2010, Sampaio et al., 2008, Song et al., 2020b), investigate sensory properties(Ickes and Cadwallader, 2017, Riu-Aumatell et al., 2008), and identify the origin of specific aroma components (Zhao et al., 2018). Artificial intelligence holds great promise in predicting the impact of food odorants on sensory properties. Its application in flavoromics, such as the diagnosis of rums, has shown potential in providing guidance for flavor analysis in the future (Quesada Granados et al., 2002).

3. Odorants in Baijiu

Baijiu is a precious distilled liquor exclusively found in China, considered as one of the three most ancient liquors in the world, alongside wine and beer(Xu et al., 2022). The Baijiu industry is one of the primary sectors of China’s food industry(J. Wang et al., 2022). According to data from the National Bureau of Statistics, the cumulative annual output of liquor was about 7.1 million kiloliters in 2021. The flavor of Baijiu usually plays an essential role in consumer acceptance. To date, more than 2000 trace components have been detected in Baijiu, including esters, alcohols, aldehydes, ketones, acids, acetals, lactones, terpenes, sulfur-containing and nitrogen-containing groups, which significantly contribute to the sensory properties of Baijiu (Fig. 4) (J. Wang et al., 2022). Baijiu possesses a multitude of sensory properties and a broad range of odorants. The key odorants in the four aroma types of Baijiu, obtained by calculating OAV, are summarized in Table 1. In comparison to other distilled liquors, Baijiu exclusively utilizes “qu” as a saccharifying and fermenting ingredient. “Qu” is a mixture of yeasts, molds, and bacteria cultured on grains, classified into daqu, xiaoqu, and fuqu(Liu et al., 2020). The special advantage of “qu” lies in its natural inoculation with multi-strain organisms during the primarily open process of solid-state fermentation(Z. Zhao et al., 2021). Typically, a diverse and numerous microbiological population evolves in this environment. At the same time, the simultaneous process of saccharification and fermentation facilitates the co-action of microorganisms and enzyme systems, resulting in a richer composition of trace odorants(Liu et al., 2020; Z. Zhao et al., 2021). In contrast, other distilled liquors mainly rely on the fermentation process carried out by a single strain of yeast.

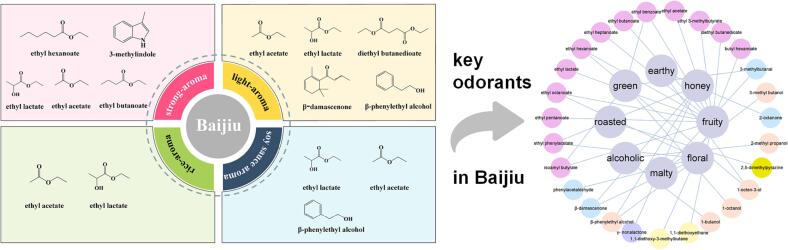

Fig. 4.

Typical flavor properties and key odorants in Baijiu.

Table 1.

The key odorants in four aroma types of Baijiu obtained by calculating OAV.

| no. | odorants | aroma description | odor threshold (μg/L) | OAV | |||

|---|---|---|---|---|---|---|---|

| strong | light | soy sauce | rice | ||||

| 1 | ethyl hexanoate | fruity | 55.3a | 36848e | 56 g | 319i | 4910 l |

| 2 | ethyl octanoate | fruity | 12.9a | 5303e | 391 g | 215i | 1110 l |

| 3 | ethyl butanoate | pineapple | 81.5a | 2024e | 22 g | 930i | |

| 4 | ethyl pentanoate | apple | 26.8a | 1316e | 10 g | 66i | |

| 5 | hexanoic acid | sweaty, cheesy | 2520a | 316e | 1 g | ||

| 6 | butanoic acid | rancid, cheesy | 964a | 209e | 1 g | ||

| 7 | pentanoic acid | sweaty, cheesy | 389a | 89e | 1 g | ||

| 8 | ethyl 3-phenylpropanoate | honey | 125a | 58e | 1 g | ||

| 9 | ethyl acetate | pineapple | 32600a | 40e | 65 g | 111i | |

| 10 | 1-butanol | alcoholic | 2730a | 40e | 2 g | 3i | |

| 11 | 3-methylbutanoic acid | rancid, acidic | 1050a | 18e | 1 g | 30i | |

| 12 | 2-methylpropanoic acid | acidic, rancid | 1580a | 17e | 5 g | ||

| 13 | 4-methylphenol | animal | 167a | 15e | |||

| 14 | 4-methylpentanoicacid | sweaty | 144a | 12e | |||

| 15 | 4-ethylguaiacol | clove | 123a | 12e | |||

| 16 | 1-hexanol | green | 5370a | 11e | 1 g | ||

| 17 | hexyl hexanoate | fruity | 1890a | 9e | |||

| 18 | octanoic acid | sweaty, cheesy | 2700a | 8e | |||

| 19 | ethyl lactate | green | 128000a | 7e | 38 g | 24i | 27 l |

| 20 | ethyl phenylacetate | rosy | 407a | 6e | 64i | ||

| 21 | isopentyl hexanoate | green | 1400a | 5e | |||

| 22 | 2-methyl-1-propanol | fruity | 28300a | 4e | 7 g | 1i | 4.8 l |

| 23 | ethyl heptanoate | fruity | 13200a | 4e | |||

| 24 | 4-methylguaiacol | smoky | 315a | 3e | 7i | ||

| 25 | acetic acid | vinegar | 160000a | 3e | 2 g | 33i | |

| 26 | propanoic acid | sweaty, acidic | 18100a | 3e | |||

| 27 | γ-nonalactone | sweet | 90.7a | 3e | 3 g | 3i | |

| 28 | nonanal | soapy | 122a | 3e | 1 g | ||

| 29 | ethyl dodecanoate | fruity | 500a | 2e | |||

| 30 | phenylacetaldehyde | floral | 262a | 2e | 7 g | 22i | |

| 31 | 4-ethylphenol | smoky | 123a | 2e | |||

| 32 | 2-heptanol | fruity | 1430a | 2e | |||

| 33 | 3-methyl-1-butanol | fruity | 179000a | 1e | |||

| 34 | heptanoic acid | sweaty | 13800a | 1e | |||

| 35 | 1-octanol | green | 1100a | 1e | |||

| 36 | isobutyl hexanoate | fruity | 5250.31a | 1e | |||

| 37 | dimethyl trisulfide | cabbage, onion | 0.4a | 467f | 621i | 21 l | |

| 38 | butyric acid | cheese, sour | 964a | 307f | 4i | ||

| 39 | ethyl isovalerate | fruit, sour | 7a | 264f | 17 g | 2772i | 16 l |

| 40 | ethyl isobutyrate | fruity, cheesy | 57a | 166f | 11 g | 657i | 91 l |

| 41 | ethyl 4-methylpentanoate | fruity | 6a | 155f | |||

| 42 | 3-(methylthio)propanal | cooked potato, soy | 7.12a | 52f | 34 k | ||

| 43 | ethyl 2-methylbutanoate | green, apple, fruity | 24.7a | 35f | 203i | ||

| 44 | p-cresol | phenolic, animal mimosa | 167a | 20f | |||

| 45 | ethyl 3-phenylpropionate | floral, rose, honey | 125a | 13f | |||

| 46 | 2-methyl propionicacid | butter, cheese, sweat | 1580a | 11f | 3i | ||

| 47 | 4-methyl valericacid | floral | 144a | 9f | |||

| 48 | 3-methylindole | indole-like | 6.09a | 8f | |||

| 49 | phenethyl acetate | floral, rose, honey, fruity | 407a | 5f | 1 h | 2i | 1.3 l |

| 50 | 3-phenylpropionic acid | rose, musk, cinnamon | 420a | 1f | |||

| 51 | propionic acid | cheesy, vinegar | 18100a | 1f | 4i | ||

| 52 | ethyl caprate | waxy, fruity | 1120a | 1f | 6 g | 1j | 14 l |

| 53 | propyl hexanoate | fruity, petrol, pineapple | 12800a | 1f | |||

| 54 | acetaldehyde | pungent, ethereal, aldehydic | 1200d | 492i | |||

| 55 | 2-methylpropanal | fresh, aldehydic, floral | 1300c | 24i | |||

| 56 | 1,1-diethoxyethane | green, fruity | 2090d | 200 g | 5i | ||

| 57 | ethyl propanoate | sweet, fruity, pineapple | 19000d | 5i | |||

| 58 | propyl acetate | celery, fruity, pear | 4700b | 11i | |||

| 59 | 1-propanol | alcoholic, fermented, musty | 223928c | 26i | |||

| 60 | hexanal | green, fatty, aldehydic | 25.5d | 19 g | 29i | ||

| 61 | 3-methylbutyl acetate | sweet, fruity, banana | 93.9d | 63 g | 34i | 33 l | |

| 62 | 3-methylbutanol | fusel oil, alcoholic, fruity | 122000d | 3 g | 4i | ||

| 63 | 3-hydroxy-2-butanone | sweet, buttery, creamy | 259d | 360i | |||

| 64 | 2,6-dimethylpyrazine | cocoa, roasted, nuts | 791d | 2i | |||

| 65 | 2-ethyl-6-methylpyrazine | roasted, potato | 40d | 13i | |||

| 66 | 2,3,5-trimethylpyrazine | nutty, earthy, roasted peanut | 730d | 5i | |||

| 67 | 1-octen-3-ol | mushroom, earthy, green | 21.7c | 8 g | 7i | ||

| 68 | furfural | sweet, woody, almond | 44000d | 13i | |||

| 69 | furfuryl alcohol | alcoholic, chemical, musty | 2000d | 31i | |||

| 70 | guaiacol | phenolic, smoke, woody | 60d | 1i | |||

| 71 | 2-phenylethanol | floral, rose | 1523c | 73i | 8.1 l | ||

| 72 | ethyl myristate | sweet waxy, violet orris | 500d | 1i | 2.3 l | ||

| 73 | ethyl palmitate | mild, waxy, fruity | 1000d | 39i | 1.1 l | ||

| 74 | ethyl 2-phenylacetate | rosy, honey | 407d | 7j | |||

| 75 | methanethiol | rotten cabbage, burnt rubber | 22d | 273 k | |||

| 76 | ethanethiol | onion, rubber | 0.8d | 94 k | |||

| 77 | (S)-methylthioacetate | cheesy, garlic | 21d | 9 k | |||

| 78 | dimethyldisulfide | garlic, sulfurous | 9.1d | 10 k | |||

| 79 | 2-furfurylthiol | roasted sesame seeds | 1d | 390 k | |||

| 80 | β-damascenone | floral, honey | 0.12d | 159 g | |||

| 81 | decanal | oily | 70.8d | 11 g | |||

| 82 | geosmin | earthy | 0.11d | 10 g | |||

| 83 | 2-methylpropyl acetate | fruity | 922d | 2 g | |||

| 84 | ethyl dodeconoate | sweet, foral, fruity, cream | 500d | 1.1 l | |||

| 85 | ethyl linoleate | 450d | 10 l | ||||

| 86 | 2-pentyl furan | green-bean like | 1d | 8 l | |||

| 87 | 2-nonenal | green | 255 l | ||||

Odor thresholds determined in 46% volume hydroalcoholic solution.

Odor threshold determined in 10% ethanol aqueous solution.

Odor threshold determined in 53% ethanol aqueous solution.

Odor thresholds previously reported.

OAV taken from ref. (D. Zhao et al., 2018).

OAV taken from ref. (Dong et al., 2019).

OAV taken from ref. (Gao et al., 2015).

OAV taken from ref. (Niu, Yao, et al., 2017b).

OAV taken from ref. (Niu, Zhang, et al., 2020).

OAV taken from ref. (Niu, Zhu, et al., 2020).

OAV taken from ref. (Chen et al., 2017a).

OAV taken from ref. (Yin et al., 2020).

Baijiu encompasses a wide array of aromas, each with its own unique sensory properties (Hong, Tian, & Zhao, 2020). Within different regions of China, the geology and climate exhibit a complex and diverse nature, and the folk culture varies significantly from place to place (L. Wang et al., 2020). Over thousands of years, people gradually incorporated local starchy raw materials and combined them with the local landscape and culinary preferences to develop a multitude of aromatic Baijiu varieties. This discussion primarily focuses on the strong, light, soy sauce, and rice aroma types of Baijiu, while other aroma types require further research.

3.1. Strong-aroma Baijiu

Strong-aroma Baijiu has garnered high appreciation from consumers due to its sensory properties, often described as a strong “cellar” aroma, and it constitutes approximately 70% of total liquor production in China(He et al., 2020). Most strong-aroma Baijiu varieties are produced using the ‘distilling raw and fermented material together’ brewing process. This method involves proportionally blending matured jiupei from the previous fermentation with crushed new materials, which are then steamed in a conical distiller known as a “zeng” (Sun, 2019)

The primary odorants found in strong-aroma Baijiu are esters, which make up approximately 60% of the total flavor substances(Xu et al., 2022). Traditionally, it was believed that the characteristic flavor of strong-aroma Baijiu is a complex aroma mainly dominated by ethyl hexanoate (which imparts fruity notes, PubChem CID: 31265). In addition, moderate levels of ethyl lactate, ethyl acetate, and ethyl butyrate, in that order of content, contribute to the overall “cellar” aroma (Ding et al., 2016). The sum total of these four esters mentioned above constitutes 90% to 95% of the total ester content in the Baijiu (He et al., 2020). Furthermore, trace amounts of ethyl octanoate can enhance the composite-like aroma of the liquor. Apart from esters, acids and alcohols also play a vital role in the flavor profile of Baijiu. Acids, derived from microorganism metabolism, serve as precursors for the synthesis of other compounds and contribute to taste presentation and the harmonization of taste. The primary acids found in strong-aroma Baijiu include hexanoic acid, lactic acid, acetic acid, and butyric acid, which correspond to the four major esters (Song et al., 2020a). Alcohols, on the other hand, act as the main aroma-enhancing components in liquor, but excessive levels of higher alcohols can result in off-flavors such as bitterness, astringency, and spiciness (Thibaud et al., 2020.

In China, there are three typical regions for strong-aroma Baijiu, including Sichuan, Jianghuai, and the North (Hong et al., 2021). Song et al. (2020b) used GC × GC-TOFMS and metabolomics strategies to model the volatile components of Baijiu samples from the Sichuan and Jianghuai regions, screening 29 characteristic odorants as markers to effectively distinguish the two regions. The content of most markers was higher in the Jianghuai region than in Sichuan.

The flavor signatures of strong-aroma Baijiu from the Sichuan region, with representative brands such as Luzhou Laojiao, Wuliangye, and Jiannanchun, are marked by a thick aging flavor and a mild saucy aroma. The key odorants of Luzhou Laojiao Baijiu were previously reported as ethyl acetate, ethyl isobutyrate, ethyl butyrate, ethyl 3-methylbutyrate, ethyl valerate, ethyl isohexanoate, ethyl caproate, isoamyl butyrate, ethyl heptanoate, ethyl octanoate, ethyl phenylpropanoate, butyric acid, valeric acid, capric acid, 1-butanol, 3-methylbutyraldehyde, 2-octanone, and dimethyl trisulfide (Shi et al., 2019). Fan and Qian (2006) employed GC-O and AEDA to identify the most important odorants in “Wuliangye” and “Jiannanchun” liquors. Based on the FD factors, the most important odorants in Wuliangye and Jiannanchun were ethyl butyrate, ethyl valerate, ethyl hexanoate, ethyl octanoate, butyl hexanoate, ethyl 3-methylbutanoate, hexanoic acid, and 1,1-diethoxy-3-methylbutane(Fan and Qian, 2006a). Apart from hexanoic acid, which imparts sweaty odors, other odorants generate fruity (apple and pineapple) and floral aromas. Most pyrazine compounds have a higher odor potency in Wuliangye than in Jiannanchun, and therefore exhibit stronger nutty and roasted aromas in Wuliangye.

The sensory properties of liquor from the Jianghuai region, represented by brands such as Yanghe Daqu and Gujinggong, are characterized by their “cellar” aroma, “qu” aroma, and grain-like aroma, which are not as strong as those of Sichuan Baijiu. However, the oil aging (a fermented pea-like flavor) is more obvious. Fan W.l. et al. used SPME and GC-O to identify the important odorants of Yanghe Daqu, which were ethyl hexanoate, ethyl butyrate, ethyl octanoate, and ethyl valerate with very high FD factors (FD greater than 8192) (Fan and Qian, 2005, Fan and Qian, 2006b). Additionally, methyl hexanoate, ethyl heptanoate, ethyl benzoate, butyl hexanoate, acetal, and 1,1-diethoxy-3-methylbutane were also found. Several odorants with fruit and floral aromas exhibited high intensity (FD ≥ 256) in Yanghe Daqu Baijiu (Fan and Qian, 2005, Fan and Qian, 2006b). By analyzing the volatile aroma components in Gujinggong jiupei (Baijiu brewed but unfiltered) samples, ethyl hexanoate, ethyl octanoate, ethyl butyrate, and 3-methylbutyl acetate were considered the four major odorants with the highest aroma contribution (Sun et al. 2016). The contents of these four esters, ethyl hexanoate, ethyl lactate, ethyl butyrate, and ethyl acetate, accounted for 81.522% of the total ester content in the Baijiu samples, indicating the prominent strong aroma style of Gujinggongjiu(Sun et al. 2016). D. Zhao et al. (2018) identified ethyl hexanoate, ethyl octanoate, ethyl butanoate, ethyl valerate, hexanoic acid, butanoic acid, γ-nonalacone, 4-methylphenol, and ethyl 3-phenylpropanoate as the key odorants in commercial Gujinggong Baijiu.

Generally, the high intensity of cellar, roasted, and cereal notes in Sichuan samples may be affiliated with higher pyrazine, furan, and carbonyl content, while the high content of esters and alcohol tends to enhance the fruity and floral aromas in Jianghuai samples (He et al., 2020).

The representative brands from the northern region include Hetaowang Baijiu, Mongolian King Baijiu, and others. The cellar aroma of distilled liquors in the northern region is stronger than that in the Jianghuai region and weaker than that in the Sichuan region(Zhang J, Cheng W, Pan T.Q. 2019). A comparison of the major chromatographic backbone components of the three regions revealed that the average total acid content of Hetaowang Baijiu falls between that of Jianghuai samples and Sichuan samples. It is lower than that of the Jianghuai region and higher than that of the Sichuan region (Wang X, 2008).

The strong-aroma Baijiu has sensory properties of a strong “cellar” aroma, softness, sweetness, and a lasting, pure aftertaste (Wang et al., 2022). Dong et al. (2018) identified 3-methylindole (PubChem CID: 6736) as the key compound responsible for the “mud odor” in strong-aroma Baijiu by inspecting liquor samples with a significant “cellar mud flavor”. The study further verified that hexanoic acid, butyric acid, p-cresol, 3-methylindole (PubChem CID: 6736), and 3-(methylthio)propanal (PubChem CID: 18635) were the key odorants contributing to the notes of “cellar mud” and “roasted” through recombination and omission experiments (Dong et al., 2019). Interactions between different odorants can influence the overall flavor profile, as the odors are primarily influenced by the compound’s additive or masking effects.

3.2. Light-aroma Baijiu

Light-aroma Baijiu is very popular among consumers due to its distinct floral and fruity aroma, representing brands such as Fenjiu from Shanxi Province, Baofeng from Henan Province, Niulanshan, and Qingke Baijiu. The qu for light-aroma Baijiu can be medium or low-temperature daqu, xiaoqu, and fuqu (Gao et al., 2015). The brewing process involves steaming the raw materials and auxiliary ingredients individually, then mixing them in the appropriate proportions. The jiuqu is stirred into the mixture twice, followed by refermentation and steaming of the liquor without any new inputs (Z. Wang et al., 2022). This process has the advantage of maintaining the freshness of the Baijiu, with a short fermentation cycle and a high grain release rate (Li et al., 2020). Xiaoqu is commonly used in southern China for producing light-aroma Baijiu, whereas daqu and fuqu are predominantly used in the northern regions (Z. Wang et al., 2022).

The sensory properties of light-aroma Baijiu were described as fruity, floral, alcoholic, grassy, acidic, sweet, fermentation, earthy, mushroom, coconut(Fan et al., 2015; Niu, Yao, et al., 2017a). Ethyl acetate (PubChem CID: 8857) and β-damascenone (PubChem CID: 5366074) were identified as the key aroma contributors to light-flavor Baijiu (Gao et al., 2015). The typical light aroma of Baijiu was simulated by both (Gao et al., 2015) and Niu et al. (2017) teams using 27 odorants, of which 15 were common, including ethyl octanoate, β-damascenone, ethyl acetate, isoamyl acetate, ethyl hexanoate, ethyl lactate, ethyl butyrate, ethyl isobutyrate, ethyl valerate, 1-octen-3-ol, isobutanol, phenylacetaldehyde, ethyl caprate, isobutyric acid, and ethyl 3-phenylpropionate. Among these odorants, ethyl octanoate showed a high Osme value and higher Odor Activity Value (OAV) compared to ethyl acetate and ethyl lactate in typical light-aroma Baijiu samples (Yong et al., 2011). However, omission experiments demonstrated that ethyl acetate and ethyl lactate together, rather than ethyl octanoate, contribute to the typical fruity flavor of light-aroma Baijiu (Gao et al., 2015).

Fenjiu from Shanxi Province, known as a pioneer in light-aroma Baijiu, has characteristic odorants, including ethyl octanoate, ethyl acetate, phenylacetaldehyde, 4-ethylguaiacol, 3-methyl-1-butanol, 2-methylpropanol, 1-octanol, ethyl phenylacetate, phenethyl acetate and β-phenylethanol (Y.L., 2008). These odorants significantly contribute to the fruity, floral, sweet, and alcoholic aromas, which are the core sensory properties of Fenjiu (Li et al., 2020).

Qingke Baijiu, one of China’s protected geographical indication products, is made using shell-less Qingke and peas as the main raw materials, supplemented with Qingke bran. The pure and natural flavor of Qingke Baijiu is guaranteed by using glacier melt well water at an altitude of over 3,000 m and an original “granite cellar.” Important odorants (OAV ≥ 10) in Qingke Baijiu include ethyl acetate, ethyl 2-methyl propanoate, ethyl butanoate, ethyl 3-methyl butanoate, ethyl valerate, ethyl hexanoate, ethyl octanoate, 3-methylbutanal, 3-methyl-1-butanol, 1-octen-3-ol, β-damascenone, 2,3-butanedione (diacetyl), acetoin, and 2-methoxyphenol (Y. l. Qian, An, Chen, & Qian, 2019).

Niulanshan Baijiu, another representative brand of light-aroma Baijiu, is characterized by over 101 aroma-active compounds (Yong et al., 2008). Initially, 25 odorants that significantly contribute to the sensory properties of Niulanshan Baijiu were identified(Yong et al., 2011), including total esters, total alcohols, ethyl acetate, ethyl acrylate, ethyl 2-methylbutyrate, γ-nonalactone, ethyl isovalerate, ethyl butyrate, isoamyl acetate, ethyl octanoate, ethyl valerate, 3-methylbutanal, β-damascenone, and geosmin as potentially contributing to the overall aroma profile of Niulanshan Baijiu (Z. Wang et al., 2022).

Xiaoqu Baijiu brewed with xiaoqu is common in Chongqing, Yunnan, and Hubei. The important aroma contributors to aged Xiaoqu Baijiu’s overall aroma characteristics are 3-hydroxy-4,5-dimethyl-2(5H)-furanone (sotolon), vanillin, and 3-(methylthio)propionaldehyde (methional) (X. Sun et al., 2022).

Caoyuanwang Baijiu, another light-aroma Baijiu brewed with fuqu, is produced in Inner Mongolia, and Hongxing Erguotou is from Beijing. Wang et al. (2021) identified 14 key aroma-active compounds of Caoyuanwang Baijiu. Dimethyl trisulfide was found to be a crucial contributor to the aging aroma, and 9 key odorants were identified as quality markers for different levels of branched light-aroma Baijiu (J. Wang et al., 2021).

Light-aroma Baijiu, being the most historical and diverse type of Baijiu in China, encompasses various manufacturing regions and styles. Despite its rich heritage, the market share of light-aroma Baijiu currently accounts for only about 10%, as reported by the China Alcoholic Drinks Association. This statistic indicates that light-aroma Baijiu possesses significant market space and potential for future development.

3.3. Soy sauce aroma Baijiu

Soy sauce aroma Baijiu is indeed a well-established and renowned type of Baijiu in China, with iconic brands like Moutai, Langjiu, Xijiu, and Guotai. Moutai, originating from the town of Moutai in Zunyi City on the coast of the Chishui River, serves as a notable example of the sauce flavor style brewed with daqu (Gao et al., 2015). The production process of soy sauce aroma Baijiu is highly intricate and involves steps such as high-temperature jiuqu making, high-temperature stacking, high-temperature fermentation, and high-temperature distillation. Additionally, the aging period for this type of Baijiu is typically three years or more (Duan et al., 2022). The medium–high temperature daqu fermentation, conducted at temperatures ranging from 50 to 60℃, promotes the non-enzymatic browning reaction known as the Maillard reaction. This unique process plays a significant role in the formation of the aroma components found in soy sauce aroma Baijiu.

Numerous works have been undertaken to determine the aroma components of soy sauce aroma Baijiu and approximately thousands of volatile components have been detected(Duan et al., 2022; Niu, Zhang, et al., 2020; Zhu et al., 2020). The odorants such as 3-methylbutanol, 2,3,5,6-tetramethylpyrazine, ethyl 2-phenylacetate, 2-phenylethyl acetate, ethyl 3-phenylpropanoate, 4-methylguaiacol, and γ-decalactone were considered to have high aroma intensity(W. Fan et al., 2012). Sulphur and nitrogen-containing odorants were claimed to have a potential contribution to flavor profiles of Soy sauce aroma Baijiu and have drawn much attention(Chen et al., 2017b; Yan et al., 2020; Zhu et al., 2020). For example, 2-furfurylthiol(roasted sesame seeds-like) (Chen et al., 2017), methanethiol(cooked vegetable-like) (Chen et al., 2017), dimethyl trisulfide(onion-like, sulfurous) (Chen et al., 2017), ethanethiol(onion-like, rubber-like) (Chen et al., 2017), methional(cooked potato-like) (Chen et al., 2017), furfuryl methyl disulfide(roast, smoke) (Yan, Chen, Nie, & Xu, 2020), 2-methyl-3-(methyldisulfanyl)furan(meat-like, roast) (Yan, Chen, Nie, & Xu, 2020), 2-methyl-3-furanthiol(meat-like, sulfur) (Zhu et al., 2020), and 2-isopropyl-3-methoxypyrazine(roast, green, galbanum)(Zhu et al., 2020) had relatively high OAVs. Further to their contribution to the overall aroma, several sulfur-containing odorants have been proposed as markers to distinguish among light, strong and soy saucy aroma Baijiu. These include 2-methyl-3-furanthiol(meat-like, PubChem CID: 34286) (Song et al., 2020), 2-furfurylthiol (toasted sesame-like, PubChem CID: 7363)(Song et al., 2020) , the 3-mercaptohexanol (PubChem CID: 521348) (Song et al., 2021) and 4-methyl-4-mercapto-2-pentanone (tropical fruit-like, PubChem CID: 88290) (Song et al., 2021). Duan et al charted the flavor wheel of soy saucy aroma Baijiu from the classification of fermented aroma, materials aroma, off-odor, and empty cup aroma. The sensory properties of soy sauce aroma Baijiu were described as sauce, ageing, cellar, caramel, floral, fruity and grain (Niu et al., 2017). Notably, the sauce aroma is a crucial characteristic that significantly impacts the overall flavor of soy sauce aroma Baijiu. Niu and colleagues found positive correlations between sauce attributes and ethyl 2-methylbutyrate, benzaldehyde, and 2,3,5-trimethylpyrazine, with correlations of 0.999, 0.998, and 0.997, respectively (Niu et al., 2020). Similarly, the aging attribute showed correlations with butyl butyrate, pentanoic acid, and 3-methylbutyl acetate of 0.979, 0.931, and 0.909, respectively. The caramel attribute exhibited a correlation with ethyl lactate, furfuryl alcohol, and ethyl phenylacetate, with a correlation of 1.000 (Niu et al., 2020). The floral attribute displayed correlations with ethyl hexanoate, ethyl hexadecanoate, and ethyl myristate of 1.000, 0.999, and 0.999, respectively. Lastly, the fruity attribute showed correlations with 3-hydroxy-2-butanone, 1,1-diethoxyethane, and ethyl butyrate of 0.995, 0.982, and 0.957, respectively. In addition, sensory analysis showed a synergistic effect of dimethyl sulfide, dimethyl disulfide, and dimethyl trisulfide on increasing fruit aroma intensity, possibly by lowering the threshold of fruit aroma(Yan, Chen, Nie, & Xu, 2020). Similarly, ethyl hexanoate, 2-methyl-3-furanthiol, 3-mercaporhexyl acetate, and 2-isopropyl-3-methoxypyrazine could significantly decrease the threshold of aromatic reconstitution(Zhu et al., 2020). Niu and colleagues found that different concentrations of ethyl isobutyrate and ethyl isovalerate have additional or synergistic odor effects on the mixture, as determined by the Feller's additive model and OAV analysis(Niu, Zhu, et al., 2020). The burnt note, which resembles an overcooked rice flavor, is indeed a prominent characteristic of soy sauce aroma Baijiu. Researchers have identified 2-hydroxymethyl-3,6-diethyl-5-methylpyrazine and 6-(2-formyl-5-methyl-1H-pyrrol-1-yl) hexanoic acid as the markers for this burnt aroma (T. Zhao et al., 2018, Zhao et al., 2019). However, the key contributors to the unique sauce note in soy sauce aroma Baijiu are still not fully understood. Wang et al conducted reconstitution experiments using 52 aroma compounds but were unable to reproduce the typical sauce aroma(Wang et al., 2012). These experiments confirmed that trimethyl-pyrazine, furfural, 4-ethyl guaiacol, and furaneol were not associated with the characteristic soy sauce aroma. Fan Wenlai and Yan (2012) proposed some conjectures about the nature of the key odorants responsible for the soy sauce aroma. They suggested that these odorants have relatively high boiling points, strong polarity, alcohol-lipid solubility, very low concentrations, even lower thresholds, and a tendency towards acidity or neutrality. These conjectures provide some insights into the potential characteristics of the key odorants that contribute to the soy sauce aroma in Baijiu.

In the brewing process of Baijiu, exceeding the critical concentration of certain flavor compounds can disrupt the overall aroma coordination, resulting in unpleasant flavors. Soy sauce aroma Baijiu is known to have typical defects such as mud-like, pickle-like, rancid, and musty earth odors. The research indicates that geosmin contributes to an earthy note in defective liquors, while 3-octanol and 1-octen-3-ol impart a mushroom/fungal odor to Baijiu (Hai et al., 2010). Sulfur compounds(L. Wang et al., 2020), such as 2-methyl-3-furanthiol, methional, methyl 2-methyl-3-furyl disulfide, dimethyl trisulfide, 2-furfurylthiol, methanethiol, dimethyl disulfide, and higher concentrations of bis (2-methyl-3-furyl) disulfide, play a key role in the pickle-like note of Moutai Baijiu (Chen et al., 2017). Furthermore, 4-methylphenol has been identified as the compound responsible for the animal/fur odor in various types of Baijiu, including soy sauce aroma Baijiu. Understanding the sources of off-odors can help in controlling the quality of Baijiu. For instance, studies have demonstrated that adding high concentrations of 1-propanol or 2-phenylethanol to the Baijiu matrix can mask the sweaty note of 3-methylbutyric acid using σ − τ plot and partition coefficient analysis(Niu, Zhang, et al., 2020).

As detection equipment continues to improve and detection methods are optimized, it is anticipated that the flavor profile of soy sauce aroma Baijiu will eventually be fully understood in the future.

3.4. Rice-aroma Baijiu

Rice-aroma Baijiu is made from rice as the main ingredient and undergoes saccharification and fermentation using xiaoqu. The production process involves solid-state cultivation for microbial saccharification, followed by liquid fermentation and distillation (Luo, Fan, & Xu, 2008). This type of Baijiu is characterized by a distinct rice brewing aroma and a soft, slightly sweet aftertaste. Due to the shorter fermentation period of rice-aroma Baijiu, it contains fewer flavor components compared to other types of Baijiu. As a result, there has been limited research on the odorants specific to rice-aroma Baijiu.

Luo, Fan, and Xu et al. (2008) used HS-SPME combined with GC–MS to identify 97 volatile and semi-volatile compounds in 10 classic rice-aroma Baijiu. The primary odorants identified in rice-aroma Baijiu were ethyl lactate, ethyl acetate (PubChem CID: 8857), and β-phenylethanol (PubChem CID: 6054) (Z. Zhao et al., 2021). These compounds contribute to the characteristic flavors of rice-aroma Baijiu. It is worth noting that the content of ethyl lactate is higher than that of ethyl acetate, especially in high-quality rice-aroma Baijiu, where the level of ethyl lactate can be 3–7 times higher than that of ethyl acetate (Yang, 1981) The presence of ethyl lactate suppresses the fruity aroma of ethyl acetate and contributes to the bitter taste of rice-aroma Baijiu (Yin et al., 2020).

Additionally, the total alcohol content in rice-aroma Baijiu is higher than the total ester content. Due to the shorter fermentation period, a significant amount of alcohol fails to participate in esterification and instead forms hydrogen bonds with water. This gives rice-aroma Baijiu its alcoholic and sweet taste. Some alcohols inherently bring bitterness, such as 2-pentanol and 1-butanol. Moreover, the absolute content of β-phenylethanol, which contributes to a mild honey-sweet aroma along with ethyl acetate, is relatively high, and its threshold value is low. The accumulation of β-phenylethanol primarily occurs during the saccharification stage (Hu et al., 2021). The exact origin of bitterness in Baijiu is still unclear and requires further investigation.

3.5. Other aroma types of Baijiu

Baijiu has indeed diversified beyond the four main aroma types. The sesame-aroma Baijiu was developed by reference to the brewing processes of the light, strong and sauce flavor types(Wu et al., 2021). So far about 460 trace components have been detected in sesame-aroma Baijiu, including 181 esters, 53 pyrazines, 47 sulfur, 45 alcohols, 46 acids, 48 carbonyls, 32 terpenes, and 11 phenols (Hong, Tian, & Zhao, 2020). Current researches have shown that sulfur compounds such as 3-methylthiopropanol, dimethyl trisulfide and thiols are considered as key sulfur compounds for the aroma characteristics of sesame-aroma Baijiu, especially thiols such as 2-furfurylthiol, methylthioaldehyde and benzothiol (Sha et al., 2017, Wu et al., 2021).

Jian-aroma Baijiu combines strong and sauce flavors and has rapidly evolved since its identification as a separate aroma type. Esters, alcohols, and acids, particularly ethyl hexanoate, γ-nonalactone, and dimethyl trisulfide, are considered key aroma substances influencing the flavor of Jian-aroma Baijiu(Du et al., 2021).

Chixiang aroma Baijiu, derived from rice-aroma Baijiu, has a unique fermented soya beans-like aroma resulting from the liquor being soaked with fatty pork during the distillation process. Fan, Fan, and Xu (2015) successfully reconstructed the sensory properties of the Chixiang aroma Baijiu with 34 aroma substances and identified (E)-2-octenal and 2-phenylethanol as its key odorants.

Laobaigan-aroma Baijiu, which has its own brewing process distinct from light-aroma Baijiu, has key aroma-active compounds such as ethyl octanoate, ethyl valerate, ethyl hexanoate, ethyl butanoate, ethyl lactate, ethyl acetate, hexanoic acid, 3-methylbutanal, and 4-ethylguaiacol(Q. Fan et al., 2019).

The aroma compositions of emerging niche types of Baijiu like Texiang aroma, Fuyu aroma, and Yaoxiang aroma are areas that require further in-depth study as the Baijiu industry continues to develop.

4. Odorants in other distilled liquors in the world

Distilled liquors such as brandy, whiskey, rum, vodka, and gin have unique flavors influenced by factors such as raw materials, aging process, and additional botanicals.

Brandy, whiskey, and rum are aged in oak barrels, allowing lignin to degrade and contribute to the generation of specific odorants like phenols and lactones(Qian et al., 2019). Figure S1 shows the volatile phenols and oak lactones produced by lignin degradation and their sensory notes. Oak lactone, also known as whiskey lactone, can exist in four stereoisomeric configurations (Caldeira et al., 2010, Franitza et al., 2016a, Jeleń et al., 2019, Picque et al., 2006, Rodríguez Madrera et al., 2003, Wanikawa et al., 2000). The cis form is generally perceived as more fragrant by sensory evaluation even though the trans form has a higher odor threshold(Franitza et al., 2016b, Jeleń et al., 2019; J. A. Pino et al., 2012; Rodríguez Madrera, Blanco Gomis, & Mangas Alonso, 2003). The sensory properties of the four stereoisomers of oak lactones are described in Table S1.

The constituents of distilled liquors can undergo significant changes during maturation in oak barrels (Caldeira et al., 2010). Differences in phenols and volatile composition have been observed in brandies aged in different oak types (Watts, Butzke, & Boulton, 2003).

Vodka, on the other hand, aims for a neutral and pure perception. It undergoes filtration with activated carbon, resulting in a lesser odorant profile.

Gin is characterized by its aromatic notes, particularly from juniper berries and various botanical preparations. These botanicals contribute to the distinctive flavor of gin.

For more detailed information on the specific odorants detected in various distilled liquors, please refer to Table 2 (excluding vodka) in the original source.

Table 2.

The key odorants in distilled liquors except Baijiu obtained by calculating OAV (excluding vodka because no reference is available).

| no. | odorants | aroma description | odor threshold (μg/L) | OAV | |||

|---|---|---|---|---|---|---|---|

| brandy | whiskey | rum | gin | ||||

| 1 | ethanol | ethanolic | 24900a | 12800d | 12690f | ||

| 2 | (E)-β-damascenone | cooked apple-like | 0.4a | 1800d | 79f | 39 g | |

| 3 | ethyl (S)-2-methylbutanoate | fruity | 0.2a | 1700d | 40 g | ||

| 4 | (S)-2-methylbutanoicacid | sweaty, fruity | 30a | 710d | 0.01 g | ||

| 5 | 3-methylbutanal | malty | 2.9a | 150d | 122f | 12 g | |

| 6 | (E)-2-nonenal | fatty, green | 0.6a | 120d | 16f | ||

| 7 | ethylbutanoate | fruity | 9.5a | 80d | 58f | 8 g | |

| 8 | ethyl (E,Z)-2,4-decadienoate | pear-like, metallic | 1000a | 60d | |||

| 9 | 3-methylbutanoicacid | sweaty, fruity | 80a | 50d | 0.4 g | ||

| 10 | 2,3-butanedione | creamy, caramel | 2.8a | 40d | 12f | 11 g | |

| 11 | (E,E)-2,4-decadienal | fatty, deep-fried | 1.1a | 26d | 35f | 0.1 g | |

| 12 | 2-methylbutanal | malty | 10.6a | 24d | 0.4 g | ||

| 13 | 1,1-diethoxyethane | fruity | 719a | 21d | 21f | 7 g | |

| 14 | ethyl hexanoate | fruity | 30a | 20d | 67f | 2 g | |

| 15 | ethyl (E)-cinnamate | sweet, cinnamon-like | 0.8a | 17d | |||

| 16 | ethyl (E,E)-2,4-decadienoate | pear-like, metallic | 1800a | 9d | |||

| 17 | 3-methylbutanol | malty | 56100a | 7d | |||

| 18 | phenylacetaldehyde | honey-like | 111a | 7d | |||

| 19 | (R/S)-linalool | flowery | 23a | 7d | |||

| 20 | 4-ethyl-2-methoxyphenol | smoky, gammon-like | 6.9a | 7d | 9f | 0.3 g | |

| 21 | (E,E)-2,4-nonadienal | fatty, green | 2.6a | 7d | |||

| 22 | acetaldehyde | pungent, fruity | 19200a | 3d | |||

| 23 | 3-methylbutylacetate | banana-like | 245a | 3d | 11f | 0.3 g | |

| 24 | 4-allyl-2-methoxyphenol | clove-like | 7.1a | 3d | 34f | 3 g | |

| 25 | 1-hexanol | grassy, almond-like | 41000a | 3d | |||

| 26 | 1-octene-3-one | mushroom-like | 2.5a | 3d | |||

| 27 | 4-propyl-2-methoxyphenol | phenolic | 1.9a | 3d | |||

| 28 | ethyl 3-methylbutanoate | fruity | 1.6a | 3d | 4 g | ||

| 29 | 2-methylbutanol | malty | 45000a | 2d | |||

| 30 | 2-phenylethanol | flowery, honey-like | 2600a | 2d | 5f | 0.1 g | |

| 31 | hexylacetate | green, fruity | 1100a | 2d | |||

| 32 | 2-phenylethylacetate | honey-like, flowery | 108a | 2d | 18f | ||

| 33 | γ-decalactone | peach-like, coconut-like | 7.1a | 2d | |||

| 34 | butanoicacid | sweaty | 1200a | 1d | 0.1 g | ||

| 35 | hexanal | green, grassy | 158a | 1d | 0.5 g | ||

| 36 | (Z)-3-hexenal | green, grassy | 45a | 1d | |||

| 37 | methylpropanal | malty | 5.9a | 850e | |||

| 38 | ethylmethylpropanoate | ethereal, fruity | 4.5a | 120e | |||

| 39 | ethyloctanoate | fruity | 147a | 61e | 57f | ||

| 40 | 4-hydroxy-3-methoxybenzaldehyde | vanilla-like | 22a | 24e | 97f | ||

| 41 | 2-methoxyphenol | phenolic | 9.2a | 10e | 6f | 2 g | |

| 42 | 4-vinyl-2-methoxyphenol | clove, phenolic, smoky | 7.1a | 7e | |||

| 43 | methylpropanol | malty | 100691a | 5e | 0.7 g | ||

| 44 | ethyl 2-hydroxy-3-methylbutanoate | fruity | 30.5a | 4e | |||

| 45 | cyclohexanoylacetate | 1.6a | 4e | ||||

| 46 | 3-methyl-1-butylacetate | banana-like, fruity | 245a | 3e | |||

| 47 | phenylaceticacid | honey-like | 9.2a | 3e | |||

| 48 | (3S,4S)-cis-whiskeylactone | coconut-like | 67a | 3e | |||

| 49 | hexanoicacid | sweaty | 7563a | 2e | |||

| 50 | 3-hydroxy-4,5-dimethyl-2(5 h)-furanone | seasoning-like | 24.2a | 2e | |||

| 51 | aceticacid | vinegar | 75521a | 2e | 0.7 g | ||

| 52 | ethylpentanoate | fruity, green, tropical | 3a | 1e | 2 g | ||

| 53 | (Z)-3-hexenol | green, herbal, oily | 1257a | 1e | |||

| 54 | (S)-ethyl2-methylbutanoate | fruity | 0.2a | 138f | |||

| 55 | 2-methylpropanal | aldehydic | 5.9a | 39f | |||

| 56 | (3S,4S)-cis-whiskylactone | light coconut, musty, hay | 67a | 37f | |||

| 57 | ethyl 2-methylpropanoate | fruity | 4.5a | 30f | |||

| 58 | 3-methyl-butanol | alcoholic | 56100a | 19f | |||

| 59 | γ-nonalactone | coconut | 21a | 6f | |||

| 60 | (E,Z)-2,6-nonadienal | cucumber-like | 0.3a | 3f | |||

| 61 | trans-ethylcinnamate | fruity, spicy, berry, plum | 0.7a | 2f | |||

| 62 | myrcene | earthy, metallic, geranium-like | 101b | 8 h | |||

| 63 | limonene | orangepeel-like, lemonpeel-like | 2804b | 1 h | |||

| 64 | 1,8-cineole | eucalyptus-like, menthol-like | 635b | 12 h | |||

| 65 | nonanal | soapy, citrus-like | 254b | 2 h | |||

| 66 | linalool | flowery | 24a | 1189 h | |||

| 67 | estragole | anise-like, fennel-like, licorice-like | 2841b | 1 h | |||

| 68 | trans-anethole | anise-like | 748b | 7 h | |||

| 69 | vanillin | vanilla | 22c | 42 g | |||

| 70 | cis-whiskeylactone | woody, coconut | 67c | 5 g | |||

| 71 | 3-methyl-1-butanol | malty | 56000c | 0.4 g | |||

| 72 | (S)-2-methylbutanol | ethereal | 24000c | 0.2 g | |||

| 73 | 2-methoxy-4-propylphenol | clove, spicy, sweet, phenolic | 1.9c | 0.2 g | |||

| 74 | decanoicacid | fatty | 2800c | 0.1 g | |||

| 75 | trans-whiskylactone | spicy, green walnut | 790c | 0.1 g | |||

| 76 | sotolon | caramellic | 24c | 0.1 g | |||

| 77 | ethylcyclohexanoate | 1.6c | 0.04 g | ||||

| 78 | ethyl 3-phenylpropanoate | floral | 14c | 0.04 g | |||

| 79 | 4-methylphenol | phenolic | 82c | 0.02 g | |||

| 80 | 4-ethylphenol | smoky | 170c | 0.01 g | |||

Odor thresholds in water/ ethanol (6:4, v/v).

Odor threshold in water/ ethanol (5.5:4.5, v/v).

Odor thresholds previously reported.

OAV taken from ref. (Willner et al., 2013).

OAV taken from ref. (Uselmann & Schieberle, 2015).

OAV taken from ref. (Poisson & Schieberle, 2008a).

OAV taken from ref. (Nicolotti, Mall, & Schieberle, 2019).

OAV taken from ref. (Buck et al., 2020).

4.1. Brandy

Originally from Cognac in France, brandy was transported to the coastal countries of the North Sea by Dutch merchants in the 13th century, and then it spread directly throughout Europe and the whole world (Uselmann & Schieberle, 2015). Brandy is a distilled liquor produced from fruit, which undergoes fermentation with yeast, followed by double distillation, aging in oak casks, and blending (Picque et al., 2006). Brandy can be classified into grape brandy and other fruit brandies, depending on the raw material used (Panosyan et al., 2001). In broader terms, brandy usually refers to grape brandy. In France, the term “Eau-de-vie” is used to describe various colorless and transparent fruit-based liquors, such as apples, plums, or pears (Y. P. Zhao et al., 2011).

The main odorants of brandy include higher alcohols, esters, terpenes, norisoprenoids, volatile phenols, heterocyclics, aldehydes, ketones, acids, nitrogenous and sulfur-containing compounds (Ledauphin et al., 2004). It were reported that 150 odorants in freshly distilled brandy were identified, with sensory properties described as butter, hay, grass, pear and banana, rose, the lime tree that were interpreted by diacetyl, nerolidol, (Z)-3-hexen-1-ol, 2- and 3-methylbutyl acetates, 2-phenylethyl acetate and linalool, respectively (Ferrari et al., 2004). Zhao et al. (2009) applied AEDA analysis to four commercial brandies and determined that the most important odorants were 2-methylpropanol, 3-methylbutanol, ethyl hexanoate, ethyl heptanoate, ethyl octanoate, β-damascenone, and trans-oaklactone (FD ≥ 1024). Typically, esters, alcohols, and acids are most abundant in freshly distilled brandy, followed by benzene compounds, terpenoids, C13-norisoprenoids, as well as aldehydes and ketones. Additionally, hexanoic, octanoic and their corresponding ethyl esters are relatively high in concentration, especially ethyl caprate with a grape odor. Elevated levels of isoamyl acetate can negatively affect the flavor of Cognac, which enhances the miscellaneous alcoholic base and spiciness in the taste (Sarvarova, Cherkashina, & Evgen’Ev, M. I., 2011). During the maturation process, the alcohol concentration decreases significantly, while concentration of acetal and ester increasing. Changes that occur during long-term storage of Cognac can be accounted by the non-enzymatic oxidation of alcohols and aldehydes to acids, followed by esterification with ethanol and the formation of ethanolides and acetals from aldehydes (Panosyan et al., 2001). Moreover, based on the investigation, there exists a positive correlation between the concentration of furan compounds and maturing duration. Moreover, ethyl 5-oxotetrahydro-2-furancarboxylate, which imparts a smoky aroma, exhibits a high odor activity value(Yuan et al., 2023). Brandy contains a greater abundance of terpenes and C13-norisoprenoids derivatives compared to other distilled liquors. Terpenoids are present in grapes in either free form or glycosidic-bound form. The free state terpenoids are released in low concentrations during distillation. The glycosidic-bound terpenoids are released during fermentation, and their levels have been reported to correlate with β-glycosidase activity in yeast strains (Jiang et al., 2007, Zhao et al., 2012). Previous research (Thibaud, Courregelongue, & Darriet, 2020) quantified and assayed thresholds for terpenoids in aged cognacs, such as geraniol, α-terpinene, nerol, α-terpineol, 1,8-cineole (eucalyptol), the first detection of piperitone, santalol, and α-campholenal in Cognac, as well as the discovery of β-damascenone and whiskey lactone enhanced the perception of terpenes. (E)-β-damascenone has been shown to be a component of the cognac brandy matrix at levels well above its olfactory detection threshold (Uselmann & Schieberle, 2015). It is presumed that the higher concentration of terpenes in matured cognacs may be due to the fact that when the wine is distilled with the yeast lees, the adsorption of terpenes by the yeast lees may occur (Jiang et al. 2007). With the heat of distillation, the adsorption can be stopped and the terpenes can be released. The exposure of Cognac to oak leads to the saturation of phenols such as vanillin, ethyl vanillin, vanillic acid, syringaldehyde, syringic acid, furfural, 5-hydroxymethylfurfural, gallic acid, ellagic acid, ferulic acid and other polyphenols (Sarvarova et al., 2011). By identifying volatiles in Armagnac, Cognac, Calvados and Mirabelle, it was found that both grape brandies contained significant amounts of 1,1-diethoxy-2-methylpropane, 1,1,6-trimethyl-1,2-dihydronaphthalene, 4-methylpentanol, and (Z)-and (E)-whiskey lactones(Ledauphin et al., 2010). Cognac is more likely to be present than in Armagnac, potentially due to differing distillation protocols(Ledauphin et al., 2010). Armagnac is distilled once using a column still, while Cognac undergoes double distillation using a pot still. The second distillation step may play a role in altering the flavor profile of the brandy(Tian et al., 2022). It is suggested that the two distillations of Cognac contribute to higher levels of furan substances, including furfuryl ethyl ether, furfural, 2-acetylfuran, and 5-methylfurfural(Ledauphin et al., 2010).

The factors influencing the aroma in brandy include the raw material and the processing (Y. P. Zhao et al., 2012). The factors that influence the raw material include the environment in which the grapes are cultivated, the grape variety and the ripeness of the grapes, with the grape variety having a significant impact on the flavor of the brandy (Ebeler, Terrien, & Butzke, 2000). While Cognac is produced from grapes of the legally recognized varieties in specific appellations, Ugni Blanc is the most dominant approved grape variety used to produce Cognac, with 98% planting coverage (Picque et al., 2006). Originally from Italy, Ugni Blanc is naturally immune to gray mold. It has lower tannin and volatile acid content, higher total acidity, resulting in a softer and more harmonious brandy with a distinct fruitiness. In addition to Ugni Blanc, the remaining noted grape varieties are Colombard, Folle Blanche, Sémillon, Montils and Folignan. Grapes suitable for cognac production must have properties of high yields and resistance to disease, low sugar levels and high acidity, grapes with mild or neutral aromas with no prominent or aggressive aromas and strong anti-oxidation properties (Fiches et al., 2016). Colombard brandy is richer in grassy and herbaceous aromas than Ugni blanc (Schreier et al., 1979); For the production process, the fermentation process, the distillation conditions and, most crucially, the maturing conditions all have a impact on the quality of brandy. Esters, alcohols, acids and carbonyl compounds, which are mainly generated during the fermentation and distillation stages and to a lesser extent during the maturing process. Pyrazine (cocoa aroma) and furan compounds (caramel aroma) can be higher in brandy distillates (Rodríguez Madrera et al., 2003). The quality of Cognac is often appreciated only after several years of maturation. The maturing process generates dried fruit, balsamic, woody and spicy aromas (Thibaud et al., 2021). During maturation the solvent and fruity notes of the young brandy are gradually replaced by the plummy notes of the aged brandy and a more harmonious woody, vanilla description (Thibaud et al., 2021). Terpenoids contribute significantly to the sensory perception of aged brandy in synergy with β-damascenone and oak lactones (Thibaud et al., 2020.

4.2. Whiskey

Whiskey is a distilled liquor obtained from grains, such as malted wheat or cereal, which are soaked and germinated in water, then mashed and distilled to obtain wort through saccharification. It is then fermented with yeast, distilled twice, aged, and blended in oak casks(Jeleń et al., 2019). Whiskey produced in Scotland, Ireland, USA, Canada, etc. There are generally three kinds of products including malt whiskey, grain whiskey, and blended whiskey, and malt whiskey is further divided into two categories: blended malt whiskey and single malt whiskey(Poisson & Schieberle, 2008b). Piggott and Jardine (1979) developed 35 descriptive terms to describe the odor, flavor perception, and aftertaste in 1979. Lee et al.developed an updated flavor wheel to support the sensory evaluation of the sensory properties of whiskey (Lee et al., 2001). More than 1000 compounds have been identified in whiskey, including higher alcohols, esters, carbonyl compounds and lactones, as well as sulfur-containing, nitrogen-containing compounds and volatile phenols (Nykänen, 1986). Some Scotches whiskey are characterized by the utilization of burning peat to roast the malt, which fully absorbs the “peaty” smoke and delivers a unique smoky smell to Scotch whiskey. It was demonstrated that peat from different regions offered different flavors to Scotch whiskey by pyrolyzing peat from different regions (Harrison & Priest, 2009). Peat pyrolysates are abundant in phenols compounds, hydrocarbon derivatives, aromatic compounds and nitrogenous compounds (Marčiulionytė et al., 2022). Volatile phenols are the most important aroma-active compounds in peat whiskey, such as guaiacol with aromas attributes described as aromatic, phenols, vanilla, woody, bacony, savory, smoky and medicinal; and lilac alcohol with aromas attributes described as aromatic, phenols, spicy, smoky, bacony, sweet, medicinal, creamy, meaty and herbal (Lehtonen, 1982). These phenols are mainly formed by the degradation of hemicellulose and lignin. The main odors of peat-treated single malt whiskey were identified with 20 compounds revealed, having FD factors ranging from 8 to 2048, eight of which were volatile phenols (Jeleń et al., 2019). Besides, odorants with the highest FD factors were guaiacol, 4-ethylguaiacol, 4-methylphenol, 4-vinylguaiacol and 4-ethyl-2-methylphenol. Lactones are likewise regarded as one of the essential odorants in whiskey, with a pleasant aroma and low threshold values. Commonly, lactones in malt whiskey are oak lactone and γ-nonalactone. All whiskies contain considerable amounts of γ-nonalactone. Certain lactones, such as γ-decalactone and γ-dodecalactone contribute sweet and fatty flavors to malt whiskey (Wanikawa, Hosoi, Takise, & Kato, 2000). Lactones also generally originated from oak casks and accumulate during the maturing process. Pyridines, pyrazines and thiazines are reputed to make a substantial contribution to the sensory properties of whiskey(Jeleń et al., 2019). Generally, pyrazines are associated with pleasant baked food which are usually marked by descriptors such as burnt, roasted and nutty(Nicolotti et al., 2019). Note of nutty, green and roasted have been utilized to describe thiazoles, which themselves are thought to smell like pyridines, and the characteristics of pyridines found in whiskey are described as astringent, green, hazelnut, earthy, buttery, caramel, rubbery, roasted, fatty and bitter(Poisson and Schieberle, 2008a). In sensory evaluation, the odor and taste of whiskey improve with decreasing levels of pyridine (Lee et al., 2001). Several aldehydes and alcohols have been shown to contribute to malt whiskey “green” aroma attributes, such as (E,Z)-2,6-nonenal, (E)-2-nonenal, 1-octen-3-ol, 4-hepten-1-ol and nonan-2-ol (Wanikawa et al., 2002). Certain sulfur-containing compounds can impart undesirable notes to whiskey, but maturation can enhance the flavor profile. Some sulfur-containing substances, including dimethyl sulfide, 3-(methylthio) propyl acetate, dihydro-2-methyl-3(2H)-thiophenone and ethyl 3-(methylthio) propanoate, decreased rapidly during aging period and may disappeared within three years (Masuda and Nishimura, 1982). It is speculated that dimethyl disulphide may be formed during distillation process through the interaction of copper.

4.3. Vodka

Vodka is a distilled liquor produced by fermenting raw materials, distilling to produce alcohol, degrading it with water, and purifying it by slow filtration through birch charcoal, without maturing(Sowiński et al., 2005). There are no special requirements for the brewing materials, which can be cereals, potatoes, molasses or other starchy, sugary crops (Ng et al., 1996). Activated carbon-based adsorption can effectively eliminate some harmful compositions in the liquor and cause impurities such as formaldehyde and methanol, enabling vodka to formulate colorless, neutral, pure, gentle and sweet sensory properties(Jeleń, Ziółkowska, & Kaczmarek, 2010). The optimal alcohol concentration in vodka is at 40% v/v, as this was the best ratio of hydrogen bonding between ethanol and water molecules. This recommendation later became the basis for the formulation of the national brand of Russian vodka “Moscow Special” (Jeleń, Ziółkowska, & Kaczmarek, 2010).

According to their origins, it is generally classified into Russian vodka, Polish vodka, Canadian and American vodkas. Researchers (Ng et al., 1996) have proposed that ethyl esters and characteristic substances 5-hydroxymethylfurfural (5-HMF), triethyl citrate (TEC) can be used as markers to distinguish Canadian vodka from American. In the manufacturing process of vodka, the quality of water is quite crucial. The hardness, alkalinity, and pH of the softened water used need to meet certain standards, otherwise the increased content of calcium, magnesium, or other compounds over time can lead to instability or precipitation (Lachenmeier, Attig, Frank, & Athanasakis, 2003). The taste of vodka has the purest of the six distilled liquors, with virtually no other impurities than alcoholic aromas. The liquid–liquid extraction method that commonly used to extract aromas in liquors had been reported to be inefficient in extracting trace components in vodka, what’s more, multiple extractions of a large batch of samples were carried out to increase the enrichment factor, and it was showed that SPME, known for its simplicity and high enrichment capacity, was an ideal technique for trace analysis of vodka (L. a Y. Ng, 1999, Ng et al., 1996). Jeleń et al. (2010) applied SPME-GC–MS to analyze the highest concentrations of compounds in vodka as heteroalcohols, mainly isoamyl alcohol (both 2-methyl-1-butanol and 3-methyl-1-butanol) and propanol. Carbonyl compounds negatively affect the sensory properties of vodka. In particular, certain aldehydes such as propinalp, pentanal, isoamyl aldehyde, hexanal and 2-butenal, which could have a negative impact on the flavor of vodka even at low concentrations. In addition, carbonyl compounds, due to their electrophilic properties, readily react with biological nucleophilic reagents containing amines and sulfur groups (e.g., proteins, nucleic acids or cell membranes) to produce many substances suspected to be carcinogenic. Especially formaldehyde, acetaldehyde and unsaturated aldehydes (propionaldehyde and 2-butenal), whose low concentrations and complex matrices lead to inaccurate determination of carbonyl compounds in vodka (Sowiński et al., 2005). More research is needed on the flavor of vodka.

4.4. Rum

Rum is a distilled liquor obtained from sugarcane juice or sugarcane molasses, fermented by yeast (or yeast and butyric acid bacteria), retorted, and then matured in oak casks. Rum is indigenous to Cuba and is a traditional Sugarcane liquor in many Caribbean and West Indies countries such as Brazil and Jamaica (H. F. Yang et al., 2014). Several styles of rum have been exploited globally, including white, dark, amber, over-proof and spiced rums, depending on the ageing time and process (Mangwanda et al., 2021). White rums, also termed as “sliver”, “light” or “clear” rum, are matured for 1–2 years after distillation and filtered through activated charcoal, the manufacturing process resulted in a lighter taste and pale in color, which is generally used in cocktails rather than neat(Franitza et al., 2016a). Dark rums are aged for two years in charred oak barrels, with a certain darker color(Sampaio, Reche, & Franco, 2008). Amber or gold rums are matured in charred oak barrels for 18 months, and are allowed to age with some caramel toner to bring the rum to a standard color(J. A. Pino, Winterhalter, Gök, & González, 2017). Over-proofed rum is the most popular rum in the Caribbean Islands market and is commonly used to formulate rum-based cocktails (Pounder, 2010). Spiced rums are infused with spices during the mixing stage, such as cinnamon, anise, ginger, rosemary, or pepper(Nicolotti, Mall, & Schieberle, 2019). They are usually of dark color and may incorporate with sugar or caramel to enhance sweetness (Mangwanda et al., 2021).

The volatile components of aged rums have been analyzed on several occasions by the team of Jorge A. Pino. As it reported, 184 compounds were identified in rum using SPME combined with GC–MS, which revealed that it was possible to differentiate between 3 and 7 year aged rums using only 15 volatile compounds (J. A. Pino, 2007). Besides, 19 aroma active compounds with OAVs greater than 1 were identified in rum (J. A.Pino, Tolle, Gök, & Winterhalter, 2012). A follow-up study showed that 19 potential aroma active compounds (FD factors ranged from 8 to 1024) were considered as key odorants of commercial rums aged 3, 7, 10 and 15 years, screening raw spirit, wood, vanilla, fruity, dry fruity, caramel to describe the sensory properties of rums (J. A. Pino, Winterhalter, Gök, & González, 2017). The aroma of a 3-year aged rum is considered to be typically primal (raw alcoholic), and the rum will tend to have more woody and dried fruit aromas with increasing duration of aging. Cis-oak lactones and vanillin are probably the key aroma contributors for aged rums. Fatty acid ethyl esters are thought to provide fruity aromas to rums (J. Pino et al., 2002), including ethyl-2-methylpropanoate, ethyl butyrate, ethyl 2-methylbutyrate, 3-methyl-1-butyl acetate, ethyl hexanoate, ethyl octanoate, and ethyl caprate. Besides, β-damascenone (a typical baked apple odor) and 5-methyl furfural (a caramel-like odor) may contribute to the dry fruit and caramel aromas in aged rums, respectively (De Aquino et al., 2006). Franitza, Granvogl, and Schieberle (2016) employed sensory omics analysis to the identification of rums. The results showed that odorants with the highest FD factors included cis-whiskey lactone, vanillin, caprynic acid and 2- and 3-methylbutanol, and vanillin, maltol, δ-nonalactone, 4-vinylphenol and 2,6-dimethoxyphenol were then characterized as key odorants contributed to the “molasses aroma” of rums (Franitza et al., 2016b). Rum has a high level of acetals, which ranking the highest among the brandy, whiskey, vodka and gin. The formation of acetals reduces the amount of free aldehydes generated in the distillate process, which facilitating the elimination the pungent odor and pungency caused by aldehydes (J. A.Pino, Tolle, Gök, & Winterhalter, 2012). Additionally, gallic acid, furfural, 5-hydroxymethylfurfural, vanillic acid, syringic acid, vanillin, syringaldehyde, sinapaldehyde and coniferyl aldehydel have been reported several times as markers of aged rums (Alcarde et al., 2014, Bortoletto and Alcarde, 2013, Quesada Granados et al., 2002), which are transferred from oak barrels to rums during the maturing process and are key factors in the sensory properties of rums. Chemometric methods (PCA, PLS-DA, LDA) were applied to model 44 rum samples from 15 different countries to distinguish between Cuban and non-Cuban rums (Sampaio, Reche, & Franco, 2008). Nicolotti et al. (2019) developed a (HS-SPME-GCMS) based method for targeted and untargeted analysis, with 40 ions as relevant chemical descriptors corresponding to 13 discriminatory compounds, which allowed an efficient classification of 33 different commercial rums. Regalado et al. (2011) applied high speed counter-current chromatography (HSCCC) full liquid chromatography combined with high performance liquid chromatography coupled with diode-array detection and electrospray ionization mass spectrometry (HPLC-DAD-ESI-MSn) to the separation and identification of phenols compounds in aged rums, indicating that aged rums are enriched in phenols. Since rum requires a long period of aging, researchers hope to use some artificial aging techniques to reduce the aging time cost without changing the flavor. Artificial aging techniques, using specially treated oak chips (Monedero et al., 1998), was adapted to rum samples, and then samples with traditional aged rums were compared with those via artificial neural networks (Quesada Granados et al., 2002). The analysis was based on the phenols and furan composition of each sample. Few statistical differences were found between the samples, thus confirming the possibility of application artificial aging techniques to replace traditional methods.

4.5. Gin

Gin originated in the Dutch and flourished in UK. According to the latest EU regulation (REGULATION (EU) 2019/787 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 17 April 2019, 2019), juniper-flavored liquors are classified based on their intensity, composition and production process as “juniper-flavored liquors drinks”, “gin”, “distilled gin” and “London gin”. Among them, London gin is the most well-known and popular, often referred to as London dry gin because of its maximum permissible sugar content (0.1 g/L) (Buck et al., 2020). There are two alternative modes of gin production. One is a gin produced with moderate amounts of alcohol and natural or artificial flavoring permitted by regulations, called compound gin (Hodel et al., 2019). The other is a distilled liquor made by fermenting and distilling grains such as barley or corn to obtain a grain distillate and then redistilling and blending gin and other botanical preparations with the grain distillate (Riu Aumatell, 2012). Botanical preparations usually include juniper berries, coriander seeds, citrus, purging cassia, orris root, cardamom seeds, angelica root, cinnamon bark, etc(Riu-Aumatell et al., 2008). These plants carry essential oils that contribute to the flavor of gin. However, the main flavor of gin is derived from juniper berries(Greer et al., 2008).