Highlights

-

•

Paddy dried with HA/RF38 and HA can be safely stored for 5 months.

-

•

Whiteness index of white rice increased during 6 months of storage.

-

•

Rice dried with a higher amount of RF energy elongated more during cooking.

-

•

Texture profiles and pasting properties only affected by storage period.

Abstract

The objectives of the study were to observe the milling and cooking qualities of paddy rice dried with hot air (HA) and hot air and radio frequency heating (HA/RF) at 38 °C and 42 °C, and to observe these qualities after 6 months of storage under average temperature and RH of 28.4 °C and 70%, respectively. During storage, the average moisture content of paddy rice decreased from 13.66% to 11.37% in HA, 13.66% to 11.40% in HA/RF38, and 13.58% to 11.63 in HA/RF42. The milling qualities of rice were affected by the RF heating temperature and storage period. Rice dried with HA/RF38 and HA/RF42 could be safely stored for up to 5 months and 4 months, respectively, with satisfactory fissure percentage and head rice yield. The whiteness index significantly increased from 63.37 ± 0.58 to 64.46 ± 0.75 at HA, 62.78 ± 0.97 to 63.75 ± 1.55 at HA/RF38, and 62.77 ± 1.90 to 64.45 ± 0.95 at HA/RF42 during storage. For cooking qualities, elongation ratio (ER) was affected by RF and storage period, while texture profiles and pasting properties were only affected by storage period. The ER increased from month 3, by 10%, 11%, and 11% in HA, HA/RF38, and HA/RF42. The hardness of cooked rice reached its peak value between months 4–5. However, adhesiveness decreased as the storage period increased. The peak viscosity and setback increased with increasing storage period while breakdown conversely decreased. This study showed that hot air drying and RF heating temperatures of 38 °C could replace hot air drying without undesirable changes in milling and cooking properties during storage up to 5 months. Therefore, this is a promising drying technology for the rice milling industry.

Introduction

Freshly harvested paddy rice is dried to a moisture content below 14% (w.b.), and then stored in a warehouse for a certain period of time before being milled. With geopolitical conflicts and climate change around the world, many countries that consume rice are concerned about food security. For this reason, paddy rice is usually stored for long periods of time to ensure adequate supplies for the population. Ambient temperature storage of paddy (rice with husk) is the most popular practice among commercial rice millers in Thailand, as milling and cooking qualities are better preserved than storage in the form of milled rice.

The drying and storage processes are the main postharvest processes that affect the physicochemical characteristics and qualities of rice. The main advantages of hot air drying are its high capacity and short time required, however, there are some disadvantages associated with this method, such as the energy cost to heat the air and the potential damage it can caused to the paddy kernels due to the temperature increase (Mussi et al., 2015). In studies conducted by Fan et al. (1999) and Wiset et al. (2005), it was observed that the temperature of hot air used for drying had an impact on the gelatinization characteristics. Paddy rice could be safely dried using hot air temperature up to 50 °C (Akowuah et al., 2012), but using hot air temperature of 55 °C or higher could negatively impact on the milling quality (Scariot et al., 2020). During storage, other properties of rice, such as color, thermal properties, pasting properties (Tananuwong & Lertsiri, 2010), starch microstructure (Chrastil & Zarins, 1992), and cooking qualities (Kaminski et al., 2013) could also change. Wongdechsarekul & Kongkiattikajorn (2009) showed that 7-month storage of rice flour (var. KDML 105) might cause the protein matrix to become more tightly bound to the starch granules. This could explain why the soluble and pasting properties of the rice flour changed during storage. Scariot et al. (2020) reported that storing white rice for up to 240 days increased the whole grain yield, especially, when the rice was dried at a high temperature of 65 °C. These findings indicate that rice milling requires appropriate drying methods to prevent rice degradation and maintain its quality.

Recently, emerging thermal processing technology using dielectric heating offers a number of advantages over traditional methods for drying paddy rice such as infrared (IR), microwave (MW), and radio frequency (RF). Ding et al. (2016) reported that the physicochemical properties and cooking qualities of rice dried using infrared (IR) were better maintained after 10 months of storage than those of paddy rice dried using hot air or ambient temperature drying. Liu et al. (2011) found that the storage life of white bread stored at room temperature (23 °C) was extended by an average of 28 days when a combined RF and hot air treatment was used. RF heating is described by the penetration of electromagnetic waves into rice grains. These waves cause water molecules inside rice grains to vibrate, which generates heat. It has been used to dry paddy rice and accelerate aging process (Hussain et al., 2021, Sumreerath, 2010, Vearasilp et al., 2011). Nevertheless, there is limited information on the rice quality after storage when dried using hot air and RF heating (HA/RF) compared to hot air (HA) in a large-scale process. This is important for rice millers to decide whether to use this technology in the future. The objectives of the study were (1) to observe milling qualities and (2) to observe cooking qualities during 6 months of storage after treatment.

Material and methods

Paddy rice

A 9-ton newly harvested RD41 paddy was procured in Nakhon Sawan province, Thailand. The initial moisture content of the paddy was 25–26% (w.b.). It was stored in polypropylene (PP) woven bags, with each containing 450 kg of paddy. All replicates were treated within 4 days of harvest and were not used more than once. After treatment, 25-kilogram samples of paddy from each replicate were kept for quality determination.

Hot air dryer and RF heating system

A 15-kW, 27-MHz oscillator type RF heating system (BiO-Q model S-1, Yont Phol Dee, Nakhon Sawan, Thailand) and 450-kg recirculating continuous flow-mixing type hot air dryer (QS-500, Quaser Engineering, Pathum Thani, Thailand) were used to dry the paddy rice as shown in Fig. 1. The configuration of hot air and RF heating was described in detail in Chitsuthipakorn & Thanapornpoonpong (2022). There are two parallel plate electrodes in a heating chamber of RF heating system set in vertical formation. The dimension of the electrodes was 45 cm × 30 cm and the distance between them is 17 cm. The paddy was conveyed to the hot air dryer at the top of the applicator by a bucket elevator. It then flowed by gravity to the RF heating system, where it was discharged back to the bucket elevator to be conveyed to the top repeatedly until the final moisture content of the paddy was measured at below 14% (w.b.).

Fig. 1.

The recirculating continuous flow-mixing type hot air dryer and RF heating system used in an experiment.

Paddy rice storage

Dried samples obtained from the dryer were stored in a PP woven bag at ambient conditions in Nakhon Sawan, Thailand. To monitor the ambient condition during storage, humidity and temperature data were recorded using a data logger (EL-USB-2-LCD, Lascar Electronics Inc., Pennsylvania, USA). Samples were taken during 0, 1, 2, 3, 4, 5, and 6 months of storage, and the moisture content (MC) of the paddy was measured in triplicate using the hot air oven method and presented as the mean and standard deviation.

Fissure percentage and head rice yield

The samples were processed using a cleaner and a huller to produce brown rice. The fissure percentage was determined for each sample using 100 kernels. The procedure was described in detail in our previous studies (Chitsuthipakorn and Thanapornpoonpong, 2021, Chitsuthipakorn and Thanapornpoonpong, 2022). The fissure percentage determination was proposed by Shen et al. (2019) using Eq. (1).

| (1) |

where Nf refers to the total number of brown rice kernels with a fissure degree of 0, 1, 2, 3, 4, or>5), and Nt refers to the total number of brown rice kernels.

The head rice yield (HRY) was calculated using Equation (2), which is in accordance with the Thai Standards for Rice.

| (2) |

where Wpd refers to the weight of paddy rice and Whr refers to the weight of head rice.

White rice color determination

A chromameter (CR −400, Konica Minolta Sensing, Osaka, Japan) was used to determine the color of white rice in the CIE (L*, a*, b*) color system. The whiteness index (WI) and the total color difference (ΔE*) were used to evaluate the whiteness level of rice and determine whether the color values passed or failed the repeatability testing, respectively.

| (3) |

where L* is a measure of lightness–darkness, with value ranging from 0 (black) to 100 (white). a* is a measure of redness, with positive value indicating redder color and negative value indicating greener color. b* is a measure of yellowness, with positive value indicating yellower color and negative value indicating bluer colors.

| (4) |

where the difference between the L* values of the specimen and the reference is ΔL*. Δa* is the difference between the a* values of the specimen and the reference, and Δb* is the difference between the b* values of the specimen and the reference.

Elongation ratio

The elongation ratio of white rice was determined using a procedure proposed by Juliano & Perez (1984). Fifty kernels of white rice were picked from the samples and then soaked, boiled and measured. The elongation ratio was defined in Eq. (5):

| (5) |

Texture profiles analysis

The texture profiles of cooked milled rice were analyzed using a texture analyzer (TA.XT plus, Stable Micro Systems, Surrey, UK) according to the procedure of Champagne et al. (1998) and the cooking procedure was based on a procedure in our previous study (Chitsuthipakorn & Thanapornpoonpong, 2022) with a rice-to-water weight ratio of 1:1.7.

Pasting properties

The pasting properties of rice were determined using a rapid viscosity analyzer (RVA-4, Newport Scientific, New South Wales, Australia) according to the procedure of AACC Method 61–02. The RVA profiles were analyzed using Thermal Cycle (TCW 2.5) software for Windows (Yan et al., 2005).

Statistical analysis

A factorial experiment was conducted in a randomized complete block design (RCBD) with three replicates to investigate the milling and cooking qualities of treated rice during storage. The factors were the storage period (0, 1, 2, 3, 4, 5, and 6 months) and the drying condition (HA, HA/RF38, and HA/RF42). The measurement was performed three times for each replicate, and the mean and standard deviation were calculated. The means were then compared using an analysis of variance (ANOVA) and Duncan's new multiple range test (DMRT) for mean comparison at a probability level of 5% (p < 0.05) using SPSS software version 25 (IBM, New York, NY, USA).

3. Results and discussion

Ambient conditions and moisture content

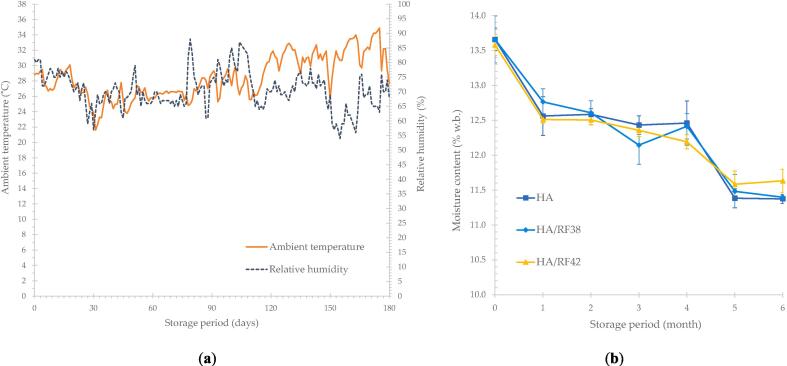

Paddy samples were stored for 6 months (180 days) from November 4, 2021, to May 3, 2022, in PP bags. The average ambient temperature and relative humidity (RH) on each day during the 6-month storage period is shown in Fig. 2a. The temperature and RH ranged from 21.6 °C to 34.9 °C and 54% to 88%, and the average temperature and RH were 28.4 °C and 70%, respectively.

Fig. 2.

Changes in ambient conditions and moisture content during storage: (a) ambient temperature and RH versus storage period; (b) Moisture content of paddy versus storage period.

An average moisture content (MC) of all treatments is shown in Fig. 2b. During storage, the average MC decreased from 13.66% to 11.37% in HA, 13.66% to 11.40% in HA/RF38, 13.58% to 11.63 in HA/RF42. In storage, the final or equilibrium MC of paddy depends on the temperature and RH of the ambient air. The result showed that MC of paddy decreased drastically in month 1 and month 5 when temperature rose and RH dropped. This was due to the hygroscopic property of paddy, which releases moisture to the ambient air to reach the equilibrium MC with the environment.

Fissure percentage and head rice yield

The fissure percentage in brown rice was divided into four groups: none, few, moderate, and severe. None refers to rice with no fissures, few refers to rice with 1–2 fissures, moderate refers to rice with 3–4 fissures, and severe refers to rice with 5 or more fissures. This classification was based on the work of Shen et al. (2021). The effects of storage period and drying conditions on the fissure percentage are shown in Table 1. The ANOVA shows a significant difference in the drying conditions and the interaction of drying conditions and storage period for groups of “None”, “Few”, and “Severe”, while a significant difference can be seen for the storage period for groups of “None”, “Few”, “Moderate” and “Severe”. The fissure percentage with “None” decreased significantly from 99.78%±0.39% in HA-month 0 to 80.78% ± 0.39% in HA/RF42-month 2. In order to explain the result from the rice miller's point of view, focusing HRY, the ANOVA in Table 2 shows a significant difference in drying condition with HRY and brokens yield (BY), while a significant difference in storage duration with white rice yield (WRY), HRY and BY is shown. The inverse relationship between the number of fissure kernels and head rice yield (HRY) of milled rice is well-established. As the number of fissure kernels decreases, the HRY increases.

Table 1.

Effects of storage period and different drying conditions on fissure percentage.

| Drying Condition [A] | Storage Period (month) [B] |

None | Few | Moderate | Severe |

|---|---|---|---|---|---|

| (0 Fissure) | (1–2 Fissures) | (3–4 Fissures) | (>5 Fissures) | ||

| HA | 0 | 99.78 ± 0.39 a | 0.22 ± 0.39 h | 0.00b | 0.00 d |

| 1 | 99.45 ± 0.69 a | 0.55 ± 0.69 h | 0.00b | 0.00 d | |

| 2 | 99.11 ± 0.51 a | 0.89 ± 0.51 h | 0.00b | 0.00 d | |

| 3 | 97.89 ± 1.50 ab | 1.45 ± 1.07 gh | 0.11 ± 0.19b | 0.56 ± 0.51 cd | |

| 4 | 99.67 ± 0.58 a | 0.33 ± 0.58 h | 0.00b | 0.00 d | |

| 5 | 98.78 ± 1.54 a | 1.22 ± 1.54 gh | 0.00b | 0.00 d | |

| 6 | 99.56 ± 0.77 a | 0.44 ± 0.77 h | 0.00b | 0.00 d | |

| HA/RF38 | 0 | 98.67 ± 0.00 a | 1.33 ± 0.00 gh | 0.00b | 0.00 d |

| 1 | 87.45 ± 5.42 ef | 12.22 ± 5.74 ab | 0.11 ± 0.19b | 0.22 ± 0.19 d | |

| 2 | 86.23 ± 2.88 efg | 12.44 ± 3.40 ab | 0.44 ± 0.51 a | 0.89 ± 1.26 cd | |

| 3 | 88.89 ± 0.51 de | 9.89 ± 0.70 bcd | 0.00b | 1.22 ± 0.39 cd | |

| 4 | 97.11 ± 1.02 ab | 2.67 ± 1.20 gh | 0.00b | 0.22 ± 0.19 d | |

| 5 | 92.00 ± 2.60 cd | 7.89 ± 2.71 cde | 0.00b | 0.11 ± 0.19 d | |

| 6 | 94.67 ± 2.73 bc | 5.11 ± 3.02 efg | 0.00b | 0.22 ± 0.39 d | |

| HA/RF42 | 0 | 96.33 ± 0.33 ab | 3.67 ± 0.33 fgh | 0.00b | 0.00 d |

| 1 | 83.34 ± 4.63 gh | 15.44 ± 4.72 a | 0.11 ± 0.19b | 1.11 ± 0.19 cd | |

| 2 | 80.78 ± 0.39 h | 15.56 ± 2.50 a | 0.45 ± 0.39 a | 3.22 ± 2.17 a | |

| 3 | 83.00 ± 2.52 fgh | 12.22 ± 1.57 ab | 0.00b | 3.78 ± 1.02 a | |

| 4 | 89.34 ± 3.21 de | 6.89 ± 2.14 def | 0.00b | 3.78 ± 1.07 a | |

| 5 | 86.67 ± 1.86 efg | 11.56 ± 2.22 abc | 0.00b | 1.78 ± 1.95 bc | |

| 6 | 88.34 ± 0.66 de | 8.55 ± 1.38 bcde | 0.11 ± 0.19b | 3.00 ± 0.88 ab | |

| F-test | A | * | * | ns | * |

| B | * | * | * | * | |

| A × B | * | * | ns | * | |

Data is presented as mean of three replicates. If there is no significant difference between the values (p > 0.05), the same letter or no letter will be indicated in a column.

Table 2.

Effects of storage period and different drying conditions on milling yield of white rice.

| Drying Condition [A] | Storage Period (month) [B] |

White Rice | Head Rice | Brokens |

|---|---|---|---|---|

| HA | 0 | 65.07 ± 0.70 cdefg | 38.40 ± 2.54 d | 26.67 ± 1.85 a |

| 1 | 66.67 ± 1.41 abcd | 45.69 ± 3.77 bcd | 20.98 ± 2.39 bcde | |

| 2 | 66.49 ± 1.20 abcde | 48.00 ± 2.82 abc | 18.49 ± 1.77 defg | |

| 3 | 67.56 ± 0.93 a | 49.24 ± 2.48 ab | 18.31 ± 1.71 efg | |

| 4 | 65.78 ± 2.27 abcdefg | 49.51 ± 4.64 a | 16.80 ± 3.47 g | |

| 5 | 66.84 ± 0.93 abcd | 47.47 ± 4.41 abc | 19.38 ± 3.54 bcdefg | |

| 6 | 64.98 ± 1.78 defg | 45.51 ± 4.10 cd | 19.47 ± 2.37 bcdefg | |

| HA/RF38 | 0 | 63.82 ± 0.56 g | 37.51 ± 2.48 d | 26.31 ± 1.93 a |

| 1 | 67.02 ± 1.63 abc | 45.07 ± 5.11 cd | 21.96 ± 3.88b | |

| 2 | 65.51 ± 2.24 bcdefg | 46.49 ± 5.88 abcd | 19.02 ± 3.64 cdefg | |

| 3 | 67.29 ± 1.34 ab | 49.25 ± 1.56 ab | 18.04 ± 0.41 fg | |

| 4 | 65.33 ± 2.44 bcdefg | 46.75 ± 5.42 abcd | 18.58 ± 3.70 defg | |

| 5 | 65.07 ± 0.80 cdefg | 46.05 ± 1.87 abcd | 19.02 ± 1.56 cdefg | |

| 6 | 64.62 ± 2.59 efg | 44.35 ± 4.14 cd | 20.27 ± 2.18 bcdef | |

| HA/RF42 | 0 | 64.44 ± 1.01 fg | 38.22 ± 0.16 d | 26.22 ± 1.08 a |

| 1 | 66.76 ± 2.27 abcd | 45.16 ± 5.45 cd | 21.60 ± 3.49 bc | |

| 2 | 66.04 ± 1.61 abcdef | 45.87 ± 4.85 bcd | 20.18 ± 3.70 bcdef | |

| 3 | 66.76 ± 1.20 abcd | 46.58 ± 4.32 abcd | 20.18 ± 3.44 bcdef | |

| 4 | 66.40 ± 2.93 abcdef | 46.75 ± 6.26 abcd | 19.64 ± 3.54 bcdef | |

| 5 | 65.78 ± 2.00 abcdefg | 44.62 ± 2.42 cd | 21.15 ± 0.56 bcd | |

| 6 | 65.33 ± 2.32 bcdefg | 43.56 ± 2.48 d | 21.78 ± 0.94 bc | |

| F-test | A | ns | * | * |

| B | * | * | * | |

| A × B | ns | ns | ns | |

Data is presented as mean of three replicates. If there is no significant difference between the values (p > 0.05), the same letter or no letter will be indicated in a column.

For all drying conditions, HRY generally increased after a storage period of 1 month and reached the highest values at HA with a storage period of 2–5 months, HA/RF38 with a storage period of 2–5 months, and HA/RF42 with a storage period of 3–4 months. This could be due to the fact that starch in rice exhibited reversible glass transition during storage. Srikaeo et al. (2016) found that storage of paddy rice at temperatures above the glass transition temperature, which ranged from 29.53 °C–32.89 °C for non-waxy rice at a moisture content of 11.2% (w.b.), could improve HRY and Yang et al. (2005) found that if rice was not tempered after drying, the internal stresses created during drying would remain in the kernel indefinitely. These stresses could cause internal fissures to form or propagate as the kernel underwent a transition from the rubbery to glassy state. These earlier studies help explain why less fissures could be seen until sometime after drying. Despite the fact that HA, HA/RF38, and HA/RF42 significantly produced more brokens and resulted in less head rice during 6 months of storage, the DMRT mean comparison revealed that head rice in HA and HA/RF38 significantly decreased in month 6, while head rice in HA/RF42 significantly decreased in month 5. This result suggests that paddy dried with HA/RF38 and HA can be safely stored for 5 months.

Determination of white rice color

The determination of the white rice color after drying at different conditions and storage period is shown in Table 3. The ANOVA shows a significant difference in drying conditions and storage period for L*, a*, b* and WI, and a significant difference in the interaction of drying conditions and storage period for ΔE*. It was found that the values of L*, a*, b*, and WI of white rice dried with HA/RF38, HA/RF42 were not significantly different from HA in month 0. Although the values of L*, a*, b* varied during the storage period, WI significantly increased from 63.37 ± 0.58 to 64.46 ± 0.75 at HA, 62.78 ± 0.97 to 63.75 ± 1.55 at HA/RF38 and 62.77 ± 1.90 to 64.45 ± 0.95 at HA/RF42 during the 6-month storage. Additionally, ΔE* was used to compare the distance of color difference between different drying conditions during storage. A lower ΔE* indicates greater closeness, while a higher ΔE* indicates significant variation. The ΔE* values in this test ranged from 0.86 ± 0.67 to 2.27 ± 1.94. Since WI is a useful value for rice trade negotiations, the observation that WI increases with a slight ΔE* during 6 months of storage under ambient conditions would be beneficial to rice millers. This could be because during drying and storage under ambient conditions, the starch granules in rice are altered. This causes them to form a transparent layer, which makes the rice grains shinier and reduces the enzymatic activity that causes browning reaction (Ding et al., 2016, Parnsahkorn and Langkapin, 2013).

Table 3.

Effects of storage period and different drying conditions on color of white rice.

| Drying Condition [A] | Storage Period (month) [B] |

L* | a* | b* | WI | ΔE* |

|---|---|---|---|---|---|---|

| HA | 0 | 64.51 ± 0.66 cdefgh | −0.54 ± 0.15f | 9.02 ± 0.39 gh | 63.37 ± 0.58 abcde | 0.00 |

| 1 | 63.53 ± 0.50 h | −0.44 ± 0.24 cdef | 9.58 ± 1.02 fgh | 62.28 ± 0.74 e | 0.00 | |

| 2 | 64.85 ± 0.52 abcdefgh | −0.27 ± 0.21 bcde | 9.49 ± 0.86 fgh | 63.59 ± 0.72 abcde | 0.00 | |

| 3 | 65.40 ± 0.06 abcde | −0.39 ± 0.14 cdef | 8.63 ± 1.12 h | 64.32 ± 0.28 a | 0.00 | |

| 4 | 65.45 ± 0.83 abcd | −0.52 ± 0.25f | 9.55 ± 1.27 fgh | 64.14 ± 1.03 ab | 0.00 | |

| 5 | 65.66 ± 0.56 abc | −0.40 ± 0.30 cdef | 10.46 ± 1.15 bcdef | 64.08 ± 0.62 abc | 0.00 | |

| 6 | 65.89 ± 0.40 ab | −0.47 ± 0.33 def | 9.88 ± 1.45 defg | 64.46 ± 0.75 a | 0.00 | |

| HA/RF38 | 0 | 64.15 ± 0.73 defgh | −0.41 ± 0.29 cdef | 9.95 ± 1.10 defg | 62.78 ± 0.97 bcde | 1.12 ± 0.90 |

| 1 | 63.86 ± 1.44 fgh | −0.01 ± 0.33 a | 10.91 ± 1.42 abcd | 62.24 ± 1.78 e | 1.64 ± 0.30 | |

| 2 | 64.00 ± 1.86 fgh | −0.11 ± 0.37 ab | 10.13 ± 2.03 cdefg | 62.57 ± 2.35 cde | 1.53 ± 1.30 | |

| 3 | 64.90 ± 0.86 abcdefg | −0.26 ± 0.30 bcde | 9.14 ± 1.82 gh | 63.70 ± 1.31 abcde | 0.87 ± 0.96 | |

| 4 | 64.63 ± 1.47 bcdefgh | −0.40 ± 0.37 cdef | 10.14 ± 2.31 cdefg | 63.17 ± 2.08 abcde | 1.42 ± 1.13 | |

| 5 | 64.17 ± 1.32 defgh | −0.22 ± 0.48 abcd | 11.74 ± 1.90 a | 62.27 ± 1.86 e | 2.27 ± 1.94 | |

| 6 | 65.68 ± 0.83 abc | −0.21 ± 0.30 abc | 11.46 ± 2.36 ab | 63.75 ± 1.55 abcde | 1.73 ± 1.06 | |

| HA/RF42 | 0 | 64.08 ± 1.67 efgh | −0.41 ± 0.27 cdef | 9.75 ± 1.15 efgh | 62.77 ± 1.90 bcde | 1.44 ± 1.11 |

| 1 | 64.19 ± 1.44 defgh | −0.11 ± 0.40 ab | 11.04 ± 1.51 abcd | 62.51 ± 1.82 de | 1.84 ± 0.28 | |

| 2 | 63.69 ± 0.95 gh | −0.08 ± 0.34 ab | 9.72 ± 1.76 fgh | 62.39 ± 1.38 e | 1.36 ± 0.65 | |

| 3 | 65.19 ± 0.85 abcdef | −0.26 ± 0.26 bcde | 9.20 ± 1.58 gh | 63.98 ± 1.24 abcd | 0.86 ± 0.67 | |

| 4 | 64.88 ± 1.97 abcdefgh | −0.37 ± 0.38 cdef | 9.86 ± 2.04 defg | 63.49 ± 2.46 abcde | 1.52 ± 0.99 | |

| 5 | 64.85 ± 0.96 abcdefgh | −0.22 ± 0.41 abcd | 11.24 ± 2.06 abc | 63.06 ± 1.57 abcde | 1.45 ± 1.61 | |

| 6 | 65.98 ± 0.57 a | −0.49 ± 0.19 ef | 10.14 ± 1.67 cdefg | 64.45 ± 0.95 a | 0.75 ± 0.17 | |

| F-test | A | * | * | * | * | ns |

| B | * | * | * | * | ns | |

| A × B | ns | ns | ns | ns | ns | |

Data is presented as mean of three replicates. If there is no significant difference between the values (p > 0.05), the same letter or no letter will be indicated in a column.

Elongation ratio

The elongation ratio of cooked rice (ER) under all drying conditions during 6 months of storage is shown in Fig. 3. The results showed that the ER values were significantly different from the effects of drying conditions, storage period, and the interaction of drying conditions and storage period (p < 0.05). The ER of rice dried with HA, HA/RF38 and HA/RF42 stored up to 6 months increased from 1.43 ± 0.01 to 1.58 ± 0.01, 1.43 ± 0.01 to 1.59 ± 0.00, and 1.44 ± 0.00 to 1.60 ± 0.01, respectively. During storage under ambient conditions, it was found that ER increased dramatically from month 3, by 10%, 11%, and 11% in HA, HA/RF38, and HA/RF42, respectively. Rice dried with HA/RF42 had a significantly higher ER value at month 0 than other drying conditions. This suggested that rice dried with a higher amount of RF energy had more voids in the endosperm, which allowed water to be absorbed more conveniently and elongate the rice grains more during cooking (Chitsuthipakorn and Thanapornpoonpong, 2022, Zhang, Wang et al., 2022, Zhang, Zhang et al., 2022). In addition, aged rice had a longer ER values than non-aged rice (Bruce et al., 2022). This might be due to the fact that the cell walls of aged rice were closed tightly, which prevented the high pressure inside the cells during cooking (Le et al., 2014).

Fig. 3.

Elongation ratio of rice dried with different conditions and changes during storage under ambient conditions. * indicates a significant difference between the mean values of treatment in each month (p > 0.05), † indicates a significant difference between the mean values of month in each treatment (p > 0.05).

Texture profiles analysis of cooked rice

As reported in previous study (Zhou et al., 2007), there were three parameters that significantly affects the texture of cooked rice: hardness, adhesiveness, and cohesiveness. The results in Table 4 showed that hardness, adhesiveness, and cohesiveness were significantly different from the effect of storage period. The hardness of rice dried with HA, HA/RF38 and HA/RF42 stored up to 6 months reached its peak value between month 4–5. The adhesiveness decreased with increasing storage period in all drying conditions. This means that less force was required in the opposite direction of plunger movement to remove the rice samples from the plunger surface. The cohesiveness of the rice was significantly different only in the HA treatment. The texture of cooked rice after storage for a long period of time became harder and less sticky (Jungtheerapanich et al., 2017, Saikrishna et al., 2018, Zhou et al., 2002). This could be due to the increase in the resistance of starch granules and increase in the insoluble content (Park et al., 2012). The enzymatic and non-enzymatic reactions that occurred during storage weakened the cell wall structure, allowing protein-rich regions to form more easily. These protein-rich regions had a higher resistance to water absorption that made the aged rice cooked with less water and became harder in texture. The structure of protein-rich and starch-rich regions might also limit the leaching of soluble starch, further contributing to the reduced adhesiveness of the cooked rice (Ding et al., 2016, Ding et al., 2018).

Table 4.

Effects of storage period and different drying conditions on texture profiles and pasting properties of cooked rice.

| Drying Condition [A] | Storage Period (month) [B] |

Hardness (g) | Adhesiveness (g.sec) | Cohesiveness (g.sec/g.sec) |

PeakViscosity (cP) |

Breakdown (cP) | Setback (cP) |

|---|---|---|---|---|---|---|---|

| HA | 0 | 10217 ± 258 bcde | −202.49 ± 242.78 d | 0.46 ± 0.01 abcde | 1421 ± 179 ef | 491 ± 23 bcde | 721 ± 37c |

| 1 | 10568 ± 793 abcde | −166.51 ± 184.84 cd | 0.45 ± 0.01 abcde | 1408 ± 145f | 521 ± 192 abcde | 957 ± 59 a | |

| 2 | 9622 ± 669 de | −151.65 ± 111.22 bcd | 0.43 ± 0.01 e | 1735 ± 449 abcd | 602 ± 256 abc | 677 ± 114c | |

| 3 | 10187 ± 636 bcde | −76.35 ± 97.55 abc | 0.44 ± 0.01 de | 1761 ± 282 abc | 617 ± 187 ab | 643 ± 41c | |

| 4 | 10931 ± 470 abcd | −40.19 ± 37.43 ab | 0.48 ± 0.01 ab | 1792 ± 226 ab | 616 ± 124 ab | 681 ± 50c | |

| 5 | 11632 ± 1039 a | –33.23 ± 18.73 ab | 0.48 ± 0.03 a | 1671 ± 149 abcde | 543 ± 135 abcd | 875 ± 181 ab | |

| 6 | 9986 ± 487 bcde | −29.14 ± 29.50 a | 0.47 ± 0.02 abc | 1713 ± 266 abcd | 482 ± 107 bcde | 712 ± 125c | |

| HA/RF38 | 0 | 10187 ± 427 bcde | −121.31 ± 58.70 abcd | 0.46 ± 0.03 abcd | 1596 ± 138 abcdef | 540 ± 43 abcd | 721 ± 54c |

| 1 | 10191 ± 940 bcde | −98.33 ± 101.76 abcd | 0.47 ± 0.01 abcd | 1531 ± 185 abcdef | 568 ± 187 abcd | 926 ± 68 a | |

| 2 | 10028 ± 822 bcde | −102.24 ± 68.06 abcd | 0.45 ± 0.01 bcde | 1654 ± 139 bcdef | 559 ± 105 abcd | 761 ± 12 bc | |

| 3 | 10573 ± 546 abcde | −41.71 ± 34.97 ab | 0.45 ± 0.01 bcde | 1793 ± 188 ab | 625 ± 137 ab | 693 ± 45c | |

| 4 | 10783 ± 1115 abcde | −38.65 ± 27.22 ab | 0.46 ± 0.02 abcd | 1715 ± 122 abcd | 574 ± 54 abcd | 661 ± 87c | |

| 5 | 11168 ± 552 abc | −48.87 ± 12.63 ab | 0.46 ± 0.01 abcd | 1616 ± 148 abcdef | 430 ± 168 cde | 907 ± 100 a | |

| 6 | 9427 ± 525 e | −36.97 ± 42.54 ab | 0.46 ± 0.02 abcde | 1711 ± 84 abcd | 488 ± 67 bcde | 721 ± 80c | |

| HA/RF42 | 0 | 9847 ± 463 cde | −129.6 ± 107.48 abcd | 0.46 ± 0.01 abcd | 1515 ± 57 cdef | 507 ± 66 abcde | 730 ± 123c |

| 1 | 9948 ± 724 bcde | −80.69 ± 63.98 abc | 0.46 ± 0.01 abcde | 1487 ± 170 def | 557 ± 156 abcd | 908 ± 44 a | |

| 2 | 9416 ± 1643 e | −131.76 ± 113.88 abcd | 0.45 ± 0.01 abcde | 1581 ± 230 abcdef | 544 ± 158 abcd | 750 ± 63 bc | |

| 3 | 10198 ± 476 bcde | −65.3 ± 61.28 abc | 0.46 ± 0.01 abcd | 1839 ± 274 a | 679 ± 182 a | 661 ± 50c | |

| 4 | 11311 ± 215 ab | −49.69 ± 29.98 ab | 0.47 ± 0.02 abc | 1814 ± 150 a | 636 ± 120 ab | 684 ± 98c | |

| 5 | 9834 ± 206 cde | −30.64 ± 12.20 a | 0.47 ± 0.03 abcd | 1664 ± 161 abcdef | 365 ± 116 e | 993 ± 200 a | |

| 6 | 9767 ± 603 cde | −40.23 ± 39.39 ab | 0.44 ± 0.01 cde | 1725 ± 98 abcd | 406 ± 72 de | 719 ± 79c | |

| F-test | A | ns | ns | ns | ns | ns | ns |

| B | * | * | * | * | * | * | |

| A × B | ns | ns | ns | ns | ns | ns | |

Data is presented as mean of three replicates. If there is no significant difference between the values (p > 0.05), the same letter or no letter will be indicated in a column.

Pasting properties

The change in pasting properties during storage can be referred to as aging of rice. Previous studies have shown that peak viscosity (PV), breakdown (BD), and setback (SB) are the most sensitive indicators of rice aging (Soponronnarit et al., 2008, Zhou et al., 2015). The results in Table 4 showed that PV, BD and SB were significantly different from the effects of storage period under ambient conditions. The PV and SB increased with increasing storage period while BD conversely decreased during month 2–4. Changes in these parameters during aging could be related to the weakening of the cell wall structure as stated in Section 3.2.4. The increase in PV might be due to the decrease in α-amylase activity in rice (Dhaliwal et al., 1991, Tananuwong and Malila, 2011). The reduction of BD during month 2–4 might be due to the starch granules becoming harder to break when aged (Noomhorm et al., 1997). The BD was a measure of the extent to which the starch granules rupture during cooking, and a lower BD value indicated a harder cooked rice. Zhou et al. (2004) also reported that a reduction in BD was correlated with an increase in hardness and decrease in adhesiveness of cooked rice. At month 5, the decrease in PV and BD could be described as aged rice starch granules were more resistant to swelling than fresh rice starch granules (Katekhong & Charoenrein, 2012), and the ability of starch granules to rupture after cooking was significantly reduced by aging (Zhou et al., 2003). On the other hand, the increase in SB was thought to be due to the formation of starch-lipid complexes in aged rice, which restricted granular swelling, and the retrogradation of starch, the process by which starch molecules recrystallize after cooking. The higher the degree of retrogradation, the firmer the cooked rice would be. The SB was another parameter that was affected by aging, and it was defined as the increase in firmness of cooked rice. Therefore, the SB can be considered as an index of rice aging (Soponronnarit et al., 2008).

Conclusions

This study verified the rice quality after dried using hot air and RF heating temperatures between 38 °C and 42 °C (HA/RF) during 6 months of storage under ambient conditions, to compare the results of the HA/RF treatment to the HA treatment. Changes in milling qualities, such as fissure percentage, head rice yield, and white rice color, were affected by RF heating temperature and storage period. Rice dried with HA and HA/RF38 could be safely stored under ambient conditions, with satisfactory fissure percentage, head rice yield, and whiteness index for up to 5 months. For the cooking qualities, elongation ratio was affected by RF heating temperature and storage period, while texture profiles and pasting properties were only affected by storage period. This study verified that drying paddy rice with hot air and RF heating temperatures of 38 °C could replace hot air drying without undesirable changes in milling and cooking properties for up to 5 months of storage. Therefore, hot air drying and RF heating is a promising technology for rice millers that can be safely used in the future.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

CRediT authorship contribution statement

Karn Chitsuthipakorn: Conceptualization, Formal analysis, Investigation, Writing – original draft, Funding acquisition, Resources, Validation, Visualization. Sa-nguansak Thanapornpoonpong: Methodology, Data curation, Software, Writing – review & editing, Supervision, Project administration.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This study was supported by Postharvest Technology Innovation Center, Ministry of Higher Education, Science, Research and Innovation, Bangkok, Thailand. The machine and paddy materials were supported by Yont Phol Dee Co., Ltd., Nakhon Sawan, Thailand.

Data availability

The authors do not have permission to share data.

References

- Akowuah J., Addo A., Bart-Plange A. Influence of drying temperature and storage duration on fissuring and milling quality of Jasmine 85 variety rice. Journal of Science and Technology. 2012;32:26–33. doi: 10.4314/just.v32i2.4. [DOI] [Google Scholar]

- Bruce R.M., Atungulu G.G., Sadaka S., Mauromoustakos A. Aging characteristics of rice dried using microwave at 915 MHz frequency. Cereal Chemistry. 2022;99(6):1218–1233. doi: 10.1002/cche.10584. [DOI] [Google Scholar]

- Champagne E.E., Lyon B., Min B., Vinyard B., Bett K., Barton II F.L., Webb B., McClung A., Moldenhauer K., Linscombe S., Mckenzie K., Kohlwey D. Effects of postharvest processing on texture profile analysis of cooked rice. Cereal Chemistry. 1998;75:181–186. doi: 10.1094/CCHEM.1998.75.2.181. [DOI] [Google Scholar]

- Chitsuthipakorn K., Thanapornpoonpong S. Quality of milled rice from large-scale dried paddy rice by hot air combined with radio frequency heating. Processes. 2021;9(12) doi: 10.3390/pr9122277. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chitsuthipakorn K., Thanapornpoonpong S. Effect of large-scale paddy rice drying process using hot air combined with radio frequency heating on milling and cooking qualities of milled rice. Foods. 2022;11(4) doi: 10.3390/foods11040519. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chrastil J., Zarins Z.M. Influence of storage on peptide subunit composition of rice oryzenin. Journal of Agricultural and Food Chemistry. 1992;40(6):927–930. [Google Scholar]

- Dhaliwal Y.S., Sekhon K.S., Nagi H.P.S. Enzymatic activities and rheological properties of stored rice. Cereal Chemistry. 1991;68(1):18–21. [Google Scholar]

- Ding C., Khir R., Pan Z., Wood D.F., Tu K., El-Mashad H., Berrios J. Improvement in storage stability of infrared-dried rough rice. Food and Bioprocess Technology. 2016;9(6):1010–1020. [Google Scholar]

- Ding C., Khir R., Pan Z., Wood D.F., Venkitasamy C., Tu K., El-Mashad H., Berrios J. Influence of infrared drying on storage characteristics of brown rice. Food Chemistry. 2018;264:149–156. doi: 10.1016/j.foodchem.2018.05.042. [DOI] [PubMed] [Google Scholar]

- Fan J., Marks B., Daniels M.J., Siebenmorgen T. Effects of postharvest operations on the gelatinization and retrogradation properties of long-grain rice. Transactions of the ASAE. 1999;42(3):727–731. doi: 10.13031/2013.13233. [DOI] [Google Scholar]

- Hussain S.Z., Iftikhar F., Naseer B., Altaf U., Reshi M., Nidoni U.K. Effect of radiofrequency induced accelerated ageing on physico-chemical, cooking, pasting and textural properties of rice. LWT. 2021;139 doi: 10.1016/j.lwt.2020.110595. [DOI] [Google Scholar]

- Juliano B.O., Perez C.M. Results of a collaborative test on the measurement of grain elongation of milled rice during cooking. Journal of Cereal Science. 1984;2(4):281–292. doi: 10.1016/S0733-5210(84)80016-8. [DOI] [Google Scholar]

- Jungtheerapanich S., Tananuwong K., Anuntagool J. Aging kinetics of low amylose rice during storage at ambient and chilled temperatures. International Journal of Food Properties. 2017;20(8):1904–1912. [Google Scholar]

- Kaminski T.A., Brackmann A., da Silva L.P., Nicoletti A.M., Roberto B.S. Changes in culinary, viscoamylographic and sensory characteristics during rice storage at different temperatures. Journal of Stored Products Research. 2013;53:37–42. [Google Scholar]

- Katekhong W., Charoenrein S. The effect of rice aging on the freeze–thaw stability of rice flour gels. Carbohydrate Polymers. 2012;89(3):777–782. doi: 10.1016/j.carbpol.2012.04.007. [DOI] [PubMed] [Google Scholar]

- Le T., Songsermpong S., Rumpagaporn P., Suwanagul A., Wallapa S. Microwave heating for accelerated aging of paddy and white rice. Australian Journal of Crop Science. 2014;8:1348–1358. [Google Scholar]

- Liu Y., Tang J., Mao Z., Mah J.-H., Jiao S., Wang S. Quality and mold control of enriched white bread by combined radio frequency and hot air treatment. Journal of Food Engineering. 2011;104(4):492–498. doi: 10.1016/j.jfoodeng.2010.11.019. [DOI] [Google Scholar]

- Mussi L.P., Guimarães A.O., Ferreira K.S., Pereira N.R. Spouted bed drying of jambolão (Syzygium cumini) residue: Drying kinetics and effect on the antioxidant activity, anthocyanins and nutrients contents. LWT - Food Science and Technology. 2015;61(1):80–88. doi: 10.1016/j.lwt.2014.11.040. [DOI] [Google Scholar]

- Noomhorm A., Kongseree N., Apintanapong M. Effect of aging on the quality of glutinous rice crackers. Cereal Chemistry. 1997;74(1):12–15. [Google Scholar]

- Park C.-E., Kim Y.-S., Park K.-J., Kim B.-K. Changes in physicochemical characteristics of rice during storage at different temperatures. Journal of Stored Products Research. 2012;48:25–29. [Google Scholar]

- Parnsahkorn S., Langkapin J. Changes in physicochemical characteristics of germinated brown rice and brown rice during storage at various temperatures. Agricultural Engineering International: The CIGR Journal. 2013;15:293–303. [Google Scholar]

- Saikrishna A., Dutta S., Subramanian V., Moses J.A., Anandharamakrishnan C. Ageing of rice: A review. Journal of Cereal Science. 2018;81:161–170. doi: 10.1016/j.jcs.2018.04.009. [DOI] [Google Scholar]

- Scariot M.A., Karlinski L., Dionello R.G., Radünz A.L., Radünz L.L. Effect of drying air temperature and storage on industrial and chemical quality of rice grains. Journal of Stored Products Research. 2020;89 [Google Scholar]

- Shen L., Wang L., Zheng C., Liu C., Zhu Y., Liu H.…Xu H. Continuous microwave drying of germinated brown rice: Effects of drying conditions on fissure and color, and modeling of moisture content and stress inside kernel. Drying Technology. 2021;39(5):669–697. doi: 10.1080/07373937.2019.1705331. [DOI] [Google Scholar]

- Shen L., Zhu Y., Wang L., Liu C., Liu C., Zheng X. Improvement of cooking quality of germinated brown rice attributed to the fissures caused by microwave drying. Journal of Food Science and Technology. 2019;56 doi: 10.1007/s13197-019-03765-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soponronnarit S., Chiawwet M., Prachayawarakorn S., Tungtrakul P., Taechapairoj C. Comparative study of physicochemical properties of accelerated and naturally aged rice. Journal of Food Engineering. 2008;85(2):268–276. doi: 10.1016/j.jfoodeng.2007.07.023. [DOI] [Google Scholar]

- Srikaeo K., Boonrod C., Rahman M.S. Effect of storage temperatures on the head rice yield in relation to glass transition temperatures and un-freezable water. Journal of Cereal Science. 2016;70:164–169. doi: 10.1016/j.jcs.2016.06.006. [DOI] [Google Scholar]

- Sumreerath P. Chiang Mai University; 2010. Accelerate aging of paddy rice cv. Pathum Thani 1 by radio frequency. Master’s Thesis. [Google Scholar]

- Tananuwong K., Lertsiri S. Changes in volatile aroma compounds of organic fragrant rice during storage under different conditions. Journal of the Science of Food and Agriculture. 2010;90(10):1590–1596. doi: 10.1002/jsfa.3976. [DOI] [PubMed] [Google Scholar]

- Tananuwong K., Malila Y. Changes in physicochemical properties of organic hulled rice during storage under different conditions. Food Chemistry. 2011;125(1), Article 1 [Google Scholar]

- Vearasilp, S., Chaisathidvanich, K., Thanapornpoonpong, S., von Hörsten, D., & Lücke, W. (2011). Aging milled rice by radio frequency heat treatment. Conference on International Research on Food Security, Natural Resource Management and Rural Development, Stuttgart, Germany. https://www.tropentag.de/2011/abstracts/full/774.pdf.

- Wiset L., Srzednicki G., Wootton M., Driscoll R.H., Blakeney A.B. Effects of high-temperature drying on physicochemical properties of various cultivars of rice. Drying Technology. 2005;23(9–11):2227–2237. doi: 10.1080/07373930500212735. [DOI] [Google Scholar]

- Wongdechsarekul S., Kongkiattikajorn J. Effect of storage time and storage protein on pasting properties of Khao Dawk Mali 105 rice flour. Agriculture and Natural Resources. 2009;43(5):232–237. [Google Scholar]

- Yan C.-J., Li X., Zhang R., Sui J.M., Liang G.H., Shen X.P., Gu S.L., Gu M.H. Performance and inheritance of rice starch RVA profile characteristics. Rice Science. 2005;12:39–47. [Google Scholar]

- Yang W., Zhang Q., Jia C. Understanding rice breakage through internal work, fracture energy, and glass transition of individual kernels. Transactions of the ASAE. 2005;48(3):1157–1164. doi: 10.13031/2013.18489. [DOI] [Google Scholar]

- Zhang Z., Wang Y., Ling J., Yang R., Zhu L., Zhao W. Radio frequency treatment improved the slowly digestive characteristics of rice flour. LWT. 2022;154 doi: 10.1016/j.lwt.2021.112862. [DOI] [Google Scholar]

- Zhang Z., Zhang B., Zhu L., Zhao W. Microstructure, digestibility and physicochemical properties of rice grains after radio frequency treatment. Foods. 2022;11(12) doi: 10.3390/foods11121723. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhou Z., Robards K., Helliwell S., Blanchard C. Ageing of stored rice: changes in chemical and physical attributes. Journal of Cereal Science. 2002;35(1):65–78. doi: 10.1006/jcrs.2001.0418. [DOI] [Google Scholar]

- Zhou Z., Robards K., Helliwell S., Blanchard C. Effect of rice storage on pasting properties of rice flour. Food Research International. 2003;36(6) doi: 10.1016/S0963-9969(03)00013-9. Article 6. [DOI] [Google Scholar]

- Zhou Z., Robards K., Helliwell S., Blanchard C. The distribution of phenolic acids in rice. Food Chemistry. 2004;87(3):401–406. doi: 10.1016/j.foodchem.2003.12.015. [DOI] [Google Scholar]

- Zhou Z., Robards K., Helliwell S., Blanchard C. Effect of storage temperature on cooking behaviour of rice. Food Chemistry. 2007;105(2):491–497. [Google Scholar]

- Zhou Z., Wang X., Si X., Blanchard C., Strappe P. The ageing mechanism of stored rice: a concept model from the past to the present. Journal of Stored Products Research. 2015;64:80–87. doi: 10.1016/j.jspr.2015.09.004. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The authors do not have permission to share data.