Graphical abstract

Keywords: Sodium chloride substitutes, Superheated steam, Volatile compound, Beef, Physicochemical properties

Highlights

-

•

Low sodium salt had no effect on physicochemical properties of beef.

-

•

Replacing salt with low sodium had little effect on the flavor of beef.

-

•

The sensory score of beef was better with low sodium instead of salt.

Abstract

In this study, beef was marinated with different low-sodium salt substitutes and heated and aged by employing superheated steam roasting and traditional roasting to investigate the effects of the various substitutes on the physicochemical properties, texture profile, sensory properties, volatile compounds, microstructural characteristics, and safety of cured and aged beef. Twenty kilograms of beef were arbitrarily divided into five treatments and pickled with different low-sodium salt substitutes. The results revealed no significant differences in saltiness, physicochemical characteristics, texture profile, or volatile compounds between the T2 and T3 and T1 (100% NaCl, T1; 75% KCl + 25% NaCl, T2; 50% KCl + 50% NaCl, T3) samples. Furthermore, the T4 and T5 (50% NaCl + 25% KCl + 20% MgCl2 + 5% CaCl2, T4; 100% yeast extract, T5) samples had lower saltiness than the T1 sample. The plasmolysis percentage and osmotic pressure of the T2 and T3 samples were lower than those of the T1 sample. Therefore, reducing sodium by substituting NaCl with 50% KCl or 75% KCl maintained an acceptable sensory and safety profile for beef consumption.

1. Introduction

Sodium chloride (NaCl) is among the most used additives in the meat industry. NaCl can maintain food quality and improve its aroma and plays a crucial role in maintaining human health (Giuseppina et al., 2006). However, excessive sodium intake has been demonstrated to increase the risks of headache, hypertension, and cardiovascular disease (Laranjo et al., 2017). Sodium consumption in China is high, averaging 4.1 g per day, which is twice the amount recommended by the World Health Organization (Du et al., 2020). Excessive sodium intake (>2 g/day) is estimated to account for over 70% of deaths from cardiovascular disease and 30% of fatal injuries in individuals aged < 70 years (Mozaffarian et al., 2014, Zhao et al., 2019, Tahir et al., 2019). High dietary sodium intake can be detrimental to the health of patients with hypertension. Hence, the high sodium content of the brine meat industry is a major limitation to its growth.

Replacing NaCl with other types of chloride salts or ingredients is a key strategy for reducing salt in meat products (Aaslyng et al., 2014, Bhat et al., 2020). Many studies have used calcium chloride (CaCl2) and potassium chloride (KCl) as salt substitutes in food products (Tobin et al., 2013, Laranjo et al., 2017, Yang et al., 2021). Because NaCl and KCl have the same chemical properties, KCl is used as a substitute for NaCl, and KCl can reduce sodium levels and increase potassium absorption (Katsiari et al., 2001, Katsiari et al., 2001, Valerio et al., 2017). However, an increase in the KCl content in foods can result in bitter and metallic tastes (Zanardi et al., 2010, Zhang et al., 2020). Moreover, KCl can exert negative effects in terms of sensory perception. Thus, new strategies must be developed to prevent the adverse effects associated with substitutes on the organoleptic quality of food products. Yeast extract is a widely used natural flavor enhancer and is rich in peptides, nucleotides, vitamin B, amino acids, and other compounds or precursors (Harada-Padermo et al., 2020). Alim et al. (2018) reported that most volatile and nonvolatile compounds as well as active aromatic compounds in yeast extract that enhance flavor develop during the heating process; yeast extract is used in various meat products. Processed meat, including marinated beef, which is a traditional food product widely consumed by humans, is a major source of dietary salt intake, and processed meat containing a high salt content might be appealing to older individuals because of their deteriorating sensory perception.

Given the high sodium content in meat products, reducing sodium levels without substantially affecting the quality of cured meat products is challenging. To date, no studies have used descriptive sensory-driven salt reduction strategies to effectively reduce the salt content in corned beef. This study investigated the effects of KCl, CaCl2, magnesium chloride (MgCl2), and yeast extracts—alternatives to NaCl—on the physical, chemical, and sensory properties of pickled meat products.

2. Material and methods

2.1. Materials

The beef tenderloin sample used in this study was purchased from a local commercial company. The sample was transported to the laboratory on ice. NaCl (food grade), KCl (99%, food grade), CaCl2 (food grade), MgCl2 (food grade), and yeast extract (food grade) were used to prepare marinades.

2.2. Preparation of salted meat products and treatments

We purchased 20 kg of beef tenderloin from a local market and stored it at − 18 °C until the meat was pickled. The frozen meat was cut into approximately 8-cm3 pieces by using a band saw and then treated with five salts containing different sodium contents: 100% NaCl (T1, control), 75% KCl + 25% NaCl (T2), 50% KCl + 50% NaCl (T3), 50% NaCl + 25% KCl + 20% MgCl2 + 5% CaCl2 (T4), and 100% yeast extract (T5). The pieces were marinated as one group per solution. KCl, MgCl2, and CaCl2 were used instead of NaCl. On the basis of the molecular weight of chemical elements, the same molar concentration (molar equivalent) was obtained, and the final brine concentration was set at 8%. Subsequently, the meat was marinated under a 0.09-MPa vacuum for 4 h. Wash the marinated tenderloin with tap water, wherein a part of the tenderloin is roasted at 200 °C for 40 min with superheated steam, and another part of the tenderloin is roasted at 200 °C for 40 min with hot air in a traditional oven. Three samples were processed in each batch for further analysis.

2.3. Centrifugal loss, cooking loss, moisture content, and beef yield

A sample (W1) was weighed and placed in a 50-mL centrifuge tube with a filter paper. The sample was centrifuged (800C, Anting Scientific Instrument Co., Ltd. Shanghai, China) at 2000 rpm for 15 min and weighed (W2). The centrifugal loss was calculated using the following formula:

| (1) |

where w1 is the sample mass before centrifugation and w2 is the sample mass after centrifugation.

The beef tenderloin samples were cleaned and weighed on an analytical balance. After cooking, the remaining weight of the meat was recorded. The cooking loss was calculated using the following formula:

| (2) |

Each value represents the average of 6 measurements (two independent trials × three samples).where Wb is the weight of meat before cooking and Wa is the weight of meat after cooking.

According to the method of AOAC 934.01, the moisture content was measured by gravity after drying at 105 °C for 24 h (Horwitz, 2010).

Following the method used by Angiolillo et al. (2015), we calculated the yields of the beef tenderloin samples in triplicate by using the following equation:

| (3) |

where Wb is the weight of meat before cooking and Wa is the weight of meat after cooking.

2.4. Determination of color

The color of the beef tenderloin surface was determined following the method described by O’Neill et al. (2018). Using a colorimeter (Konica Minolta, CR-400, Japan), calibrated with a white tile (L = 92.5, a = − 1.20 and b = 1.10) using an illuminant D65, and 10° standard observer, and aperture size of 8 mm diameter. Determination from the cross section of the product. CIELAB values (L*, a*, and b* for luminance, red, and yellow, respectively) were calculated, Determination after superheated steam roasting and traditional roasting respectively. with each value representing the average of 12 measurements.

2.5. Protein content determination

The total protein content of the beef tenderloin samples was determined using the Kjeldahl nitrogen determination method. The sample was titrated with standard hydrochloric acid (0.1 mol/L) until the pH value reached 6.10. The protein was calculated by nitrogen, and the coefficient was 6.25. Each assay was performed in triplicate.

2.6. Texture profile analysis

The texture profiles of the beef tenderloin samples were analyzed using the Express TA-TX2 texture analyzer and computer. A sample was cooled to room temperature and cut into cylinders with a thickness of 2 cm and a diameter of 2 cm. Subsequently, the cut samples were compressed with a 45-mm-diameter probe for two cycles. The speed before and after measurement was 1 and 5 mm/s, respectively, the distance was 10 mm, the time was 5 s, and the trigger force was 5 g.

2.7. Sensory evaluation

Sensory analysis was conducted according to methods described by Smith et al. (2015). The beef tenderloin samples were served to 36 untrained panelists across 2 sessions and 3 nights (6 sessions in total). There were 6 participants in each session. The beef tenderloin samples for each round were selected and allocated to panelists under a restricted randomization, each panelist tested each treatment at least once. Sensory tests were conducted in a separate scaffold under controlled light and temperature conditions at the Sensory Analysis Laboratory of the Department of Food Technology and Science of the Jiangsu University. All reviewers sign free and informed consent and agree to participate in the research. The evaluators were asked to rate sensory characteristics on a 6-point hedonic scale, with 1 and 6 being extreme values for each situation. Attributes included salinity (1 = nonsalinity and 6 = extremely salty), juiciness (1 = extremely dry and 6 = extremely juicy), color (1 = pink white and 6 = deep red), overall hardness (1 = extremely mushy and 6 = extremely hard), other flavors (1 = not found and 6 = extremely strong), overall texture (1 = extremely poor and 6 = excellent), and general acceptability (1 = unacceptable and 6 = highly acceptable). Each sample was marked using a three-digit random number, and each sample was evaluated four times.

2.8. Volatile compound analysis

Following the method reported by Mansur et al. (2019) with some modifications, we extracted and analyzed volatile components in the beef tenderloin samples. Each process was performed in triplicate. Briefly, 5.0 g of ground beef tenderloin was placed into a 20-mL sample bottle. Solid-phase microextraction fibers coated with polydimethylsilane/ divinylbenzene and carboxylic acid were mixed with 100 μL of octylic acid methyl ester, placed in a 20-mL sample bottle, and exposed to the bottle headspace for 45 min at 45 °C. Volatile compounds in the samples were determined through gas chromatography–mass spectrometry (GC-MS). In the experiment, a capillary column (Cap-Wax) was used to separate and identify volatile compounds in the samples. The carrier gas was helium, and the flow rate was 1 mL/min. The temperature in the chromatography furnace was maintained at 40 °C for 4 min; increased from 40 °C to 135 °C at 3 °C/min, from 135 °C to 200 °C at 5 °C/min, and from 200 °C to 230 °C at 15 °C/min; and finally maintained for 5 min. Identical conditions were used for the treatment of C6–C20 n-alkanes in the experiments. Mass spectrometry results were compared to experimental spectra from the NIST17 mass spectral library to identify volatile compounds in the sample. The final content of volatile compounds was calculated by dividing the peak area of the target compound by the peak area of the internal standard (expressed in μg/kg).

2.9. Microstructure analysis

The microstructure of samples T1, T2, T3, and T4 was determined. The samples for observing the microstructure were prepared using the method described by Wattanachant et al. (2005). The meat was cut into 0.5 × 0. 5 × 0. 5-cm3 pieces, frozen in liquid nitrogen, and dried in a freeze dryer (Beijing Yatai Kelong Instrument Technology Co., Ltd, China). A treated sample was cut into 2 × 2 × 2-mm3 pieces. Spray gold samples. The samples were examined under a scanning electron microscope.

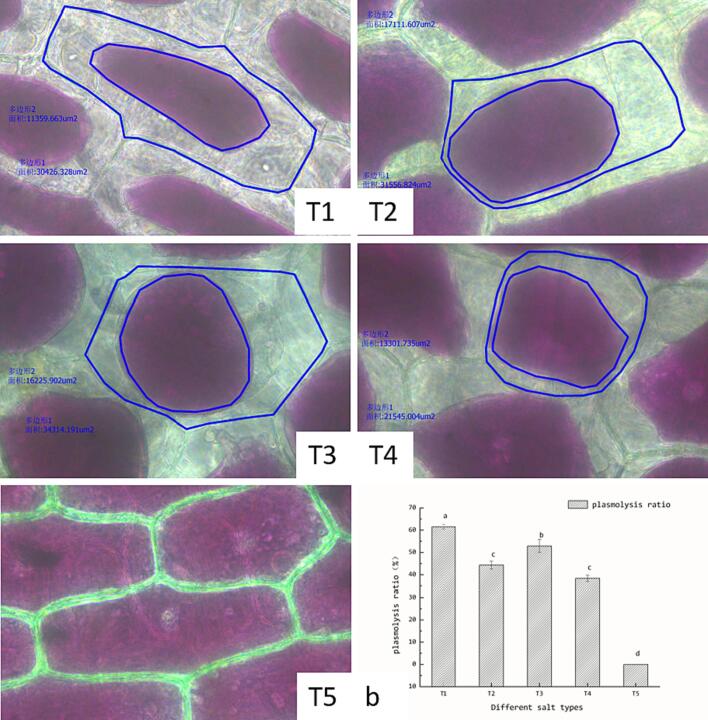

2.10. Observation of plasmolysis

The outer epidermal cells of an onion were removed and placed on slides with different low-sodium replacement salt solutions (T1, T2, T3, and T4). The solution concentration was 0.3 g/mL, and the slide was covered with a cover slip. After 30 min, the degree of plasmolysis of onion cells in different low-sodium replacement salt solutions was observed under a microscope. Sodium will increase the osmotic pressure of cells, and potassium has the effect of lowering blood pressure. Onion cells have cell walls, and we can more clearly see the plasmolysis caused by osmotic pressure. Different salt solutions have different osmotic pressures on cells. By observing the plasmolysis of cells, it can be further explained that low-sodium substitute salts have lower osmotic pressures.

| (4) |

where Ws is the area of cell shrinkage and Wt is the total cell area.

2.11. Statistical analysis

All experiments were repeated three times on different days by using the identical formulas, methods, and techniques. Considering the treatments (marinaded with five salts containing different sodium contents) as a fixed effect and the days as a random effect (Biffin et al., 2020). For the analysis of factors affecting each sensory trait (saltiness, juiciness, color, overall firmness, other flavours, overall texture and overall acceptability) within the beef tenderloin, fixed terms for full models included processing (treated with five salts containing different sodium contents) and cooking (the superheated steam-roasted beef tenderloin and traditionally roasted beef tenderloin) treatments, as well as a cofactor for tasting round. The experimental design factors of panelist, tasting round and session were fitted as random effects. Predicted means, standard errors and least significant difference at 5% critical value for consumer scores of each trait at each treatment level were predicted from each model. At least three parallel samples were analyzed for each process. All experiments were performed in triplicate, and data are expressed as the mean values and standard error. All data were statistically analyzed using SPSS (Version 17.0, Chicago, USA). The significant difference (SD) when the P value was ≤ 0.05 was determined using Duncan’s method. All data were analyzed and plotted using Origin 2019 (Origin Lab Corporation, USA).

3. Results and discussion

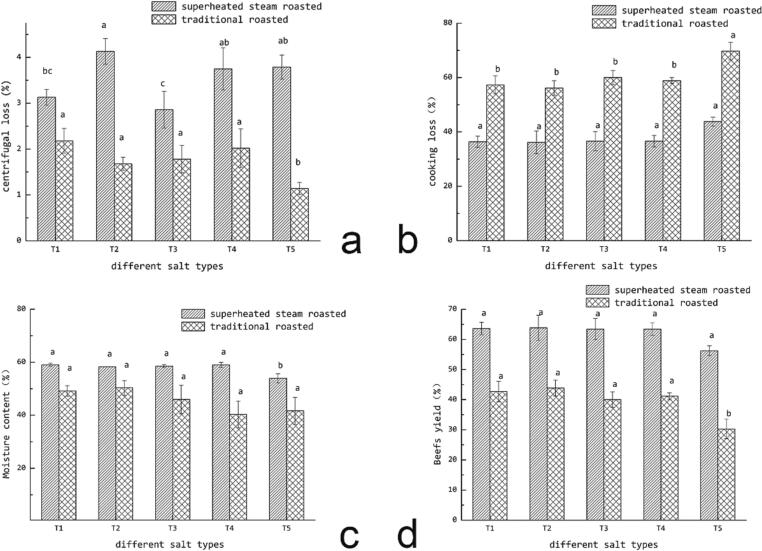

3.1. Centrifugal loss, cooking loss, moisture content, and beef yield

The water-holding capacity (WHC) of meat is typically evaluated by determining cooking loss and centrifugal loss, where centrifugal loss is the water lost from cooked meat samples. The WHC is primarily related to the ability of beef tenderloin to retain its own water. As presented in Fig. 1a, the centrifugal loss of the T1, T2, T3, T4, and T5 superheated steam-roasted beef tenderloin samples was 3.13%, 4.13%, 2.86%, 3.75%, and 3.79% respectively. The centrifugal loss of the T1, T2, T3, T4, and T5 traditionally roasted beef tenderloin samples was 2.18%, 1.68%, 1.78%, 2.02%, and 1.14% respectively. Significant differences in the centrifugal loss were observed among the five superheated steam-roasted beef tenderloin samples (P < 0.05), and the lowest centrifugal loss was noted in the T3 sample. No significant difference in the centrifugal loss was observed among the T1, T2, T3, and T4 traditionally roasted beef tenderloin samples, and the lowest centrifugation loss was noted in the T5 sample. Overall, the centrifugal loss was < 5% in the treated samples.

Fig. 1.

Predicted means ± standard error for centrifugal loss (a), cooking loss (b), moisture content (c), and yield (d) of superheated steam-roasted beef tenderloin and traditionally roasted beef tenderloin treated with different salt types. T1: 100% NaCl, T2: 75% KCl + 25% NaCl, T3: 50% KCl + 50% NaCl, T4: 50% NaCl + 25% KCl + 20% MgCl2 + 5% CaCl2, T5: 100% yeast extract.

The cooking loss values did not significantly differ among the T1, T2, T3, T4, and T5 superheated steam-roasted beef tenderloin samples (Fig. 1b). However, the cooking loss values differed among the T1, T2, T3, T4, and T5 traditionally roasted beef tenderloin samples; the T5 sample exhibited the highest cooking loss value (69.74%). No significant differences were noted between the T1, T2, T3 and T4 traditionally roasted beef tenderloin samples (P > 0.05). These differences may be caused by the amount of KCl addition. The K could react with muscle surface proteins and inhibit the penetration of Na, thereby reducing the loss.

No significant difference (P > 0.05) in the moisture content was observed between the T1 (control) and T2, T3, and T4 superheated steam-roasted beef tenderloin samples (Fig. 1c), and the moisture content of the T5 sample was lower than that of the T1 sample. This difference can be attributed to water migration inside the beef tenderloin and the evaporation of surface moisture during curing (Lorenzo & Franco, 2012). No significant difference (P > 0.05) in the moisture content was observed between the T1 (control) and T2, T3, T4, and T5 traditionally roasted beef tenderloin samples.

The beef yield did not significantly differ between the T1 (control) and T2, T3, T4, and T5 superheated steam-roasted beef tenderloin samples (Fig. 1d). However, the beef yield differed between the T1 (control) and T2, T3, T4, and T5 traditionally roasted beef tenderloin samples, and the T5 sample exhibited the lowest beef yield (30.26%). No significant differences in the beef yield were observed among the T1, T2, T3, and T4 (P > 0.05) traditionally roasted beef tenderloin samples. Aaslyng et al. (2014) indicated that a small decrease in the NaCl content in sausage (2.2%–1.7%) and ham (2.3%–1.8%) would not lead to a change in yield.

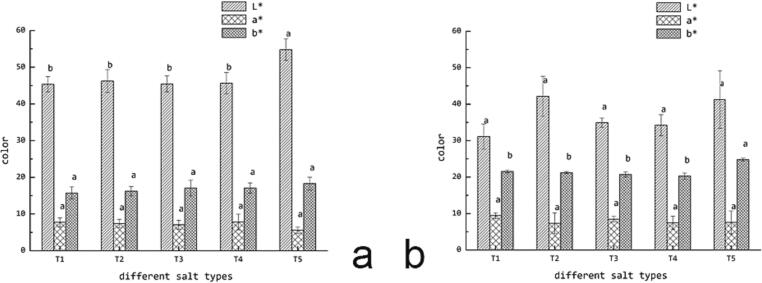

3.2. Determination of color

Salt is an oxidant and can increase the oxidation potential of myoglobin, reduce the surface tension and capacity of meat, and promote the release of iron by cells (Kanner et al., 1991). Fig. 2a presents the color of the superheated steam-roasted beef tenderloin samples. No significant difference in the color parameters a* (red green) and b* (yellow blue) was noted in the different treated samples (P > 0.05). No significant difference in L* (luminosity) was observed between the T1 (control) sample and the T2, T3, and T4 (treated) samples. The T5 sample exhibited a lower L* (luminosity) value than did the T1 sample. Fig. 2b presents the color of traditionally roasted beef tenderloin. The addition of different salts did not affect the chromaticity parameters L* (photometric determination), a* (red-green determination), or b* (yellow-blue determination; P > 0.05).

Fig. 2.

Predicted means ± standard error for color of superheated steam-roasted beef tenderloin cured with different alternative salts (a); Predicted means ± standard error for color of traditionally roasted beef tenderloin cured with different alternative salts (b). L*: Values of lightness, a*: redness/greenness, b*: yellowness/blueness. T1: 100% NaCl, T2: 75% KCl + 25% NaCl, T3: 50% KCl + 50% NaCl, T4: 50% NaCl + 25% KCl + 20% MgCl2 + 5% CaCl2, T5: 100% yeast extract.

3.3. Protein content determination

As presented in Fig. S1, the protein content of the superheated steam-roasted beef tenderloin samples cured with different alternative salts (T2, T3, T4, and T5) was higher than that of the T1 sample. No significant difference in the protein content was noted between the T1 (control) and T2 and T3 (treated) traditionally roasted beef tenderloin samples (P > 0.05). The protein content of the traditionally roasted beef tenderloin samples cured with different alternative salts (T4 and T5) was higher than that of the T1 sample.

3.4. Texture profile analysis

No significant difference in elasticity was noted between the superheated steam-roasted beef tenderloin and traditionally roasted beef tenderloin (P > 0.05; Table S1, Table S2). These improvements in elasticity are consistent with those reported by dos Santos Alves et al. (2017) who indicated that replacing 50% NaCl with KCl did not affect the elasticity of beef tenderloin. Similarly, Horita et al. (2011) reported that replacing 50% NaCl with KCl did not affect the elasticity of beef tenderloin.

The chewiness values were higher for the superheated steam-roasted beef tenderloin samples cured with different alternative salts (T4 and T5) than for the T1 (control) sample (Table S1). Furthermore, the chewiness values were higher for the traditionally roasted beef tenderloin samples cured with different alternative salts (T2, T3, T4, and T5) than for the T1 (control) sample (Table S2). No significant difference in cohesiveness was noted between the superheated steam-roasted beef tenderloin and traditionally roasted beef tenderloin samples (P > 0.05; Tables S1 and S2). A study reported that substituting NaCl in pork sausages with CaCl2, MgCl2, and KCl did not affect their texture profile (da Silva Araujo et al., 2021). However, Horita et al. (2014) indicated that the use of bivalent salts, such as CaCl2 and MgCl2, as substitutes for NaCl in sausages at a ratio of 25%–50% exerted a negative effect on the texture profile. However, in this study, MgCl2 and CaCl2 at 20% and 5%, respectively, did not adversely affect the texture profile of the T4 sample.

3.5. Sensory analysis

Table S3 lists the average sensory scores of the superheated steam-roasted beef tenderloin samples cured by different alternative salts in the categories of saltiness, juiciness, color, overall firmness, other flavors, overall texture, and overall acceptability. No significant differences in color, total hardness, other flavors, and overall texture were noted among the T1, T2, T3, T4, and T5 samples. Compared with the T1 sample, the T2 and T3 samples demonstrated slightly decreased salinity, and the T4 and T5 samples exhibited significantly decreased salinity. Table S4 presents the average sensory test scores of the traditionally roasted beef tenderloin samples pickled with different alternative salts. No significant differences in juiciness, color, total hardness, other flavors, and overall texture were noted among the T1, T2, T3, T4, and T5 samples. Furthermore, no significant difference in salinity was observed among the T1, T2, and T3 samples (P > 0.05); however, the salinity of the T4 and T5 samples was significantly lower than that of the T1 sample. No significant difference in total acceptability was noted among the T1, T2, T3, and T4 samples (P > 0.05). The saltiness and overall acceptability of the T2 and T3 samples were similar to those of the T1 sample. A study reported that replacing 50% NaCl with KCl did not affect the sensory properties of products (Monica et al., 2009).

3.6. Volatile compound analysis

Taste is a complex sensation that mainly includes the olfactory and trigeminal nerves. Flavors mainly result from lipid and protein degradation, the Maillard reaction, Strecker degradation, thiamine and carbohydrate degradation, and other reactions. The GC-MS-total ion chromatograms (GC-MS-TIC) of the superheated steam-roasted and traditionally roasted beef tenderloin samples cured with 100% NaCl are presented in Figs. S2 and S3. A total of 80 volatile substances were detected in the superheated steam-roasted beef tenderloin samples cured with different alternative salts, including 10 alcohols, 14 aldehydes, 4 ketones, 5 acids, 8 esters, 31 hydrocarbons, and 8 other compounds (Table S1). Furthermore, 71 types of volatile substances were detected in the traditionally roasted beef tenderloin samples pickled with different alternative salts, including 7 alcohols, 13 aldehydes, 3 ketones, 4 acids, 10 esters, 27 hydrocarbons, and 7 other compounds (Table S2).

No significant difference in the total alcohol content was noted between the T1 and T2 and T3 superheated steam-roasted beef tenderloin samples (P > 0.05; Table S1). The T4 and T5 samples had a lower total alcohol content than did the T1 sample. No significant difference in the total alcohol content was noted between the T1 and T2 and T3 traditionally roasted beef tenderloin samples (P > 0.05; Table S2). The alcohol detected in the traditionally roasted beef tenderloin samples cured with different alternative salts was mainly 1-octen-3-ol.

The odor threshold of aldehydes is low, and aldehydes considerably contribute to the overall flavor of meat products (Ramírez & Cava, 2007). All meat samples contain benzaldehyde and nonanal, which may be due to the oxidation of unsaturated fatty acids such as linoleic acid (Liu et al., 2019). No significant difference in the benzaldehyde content was noted between the T1 and T2 and T3 superheated steam-roasted beef tenderloin samples (P > 0.05). The T4 sample had a lower benzaldehyde content than did the T1 sample. No significant difference in the benzaldehyde content was noted between the T1 and T2 and T3 traditionally roasted beef tenderloin samples (P > 0.05). The benzaldehyde content of the T4 and T5 samples was lower than that of the T1 sample (P < 0.05). The nonanal content was higher in the T1 than in the T5 superheated steam-roasted beef tenderloin sample (P < 0.05). Furthermore, the nonanal content was slightly lower in the T2, T3, and T4 samples than in the T1 sample. The nonanal content was higher in the T1 than in the T4 and T5 traditionally roasted beef tenderloin samples (P < 0.05). The T2 and T3 samples had a slightly lower nonanal content than did the T1 sample. Hexanal has a rancid taste at high concentrations and fruity and bouillon flavors at low concentrations. Some studies have reported that the presence of hexanaldehyde and nonanal in dried sausages, hydrolyzed lard, and fruits.

No significant difference in the total ketone content was noted between the T1 and T2 superheated steam-roasted beef tenderloin samples (P > 0.05). The total ketone content was slightly lower in the T3 than in the T1 superheated steam-roasted beef tenderloin samples. Moreover, the total ketone content was significantly lower in the T4 and T5 than in the T1 superheated steam-roasted beef tenderloin samples. The total ketone content was slightly lower in the T2 and T3 than in the T1 traditionally roasted beef tenderloin samples. Moreover, the total ketone content was significantly lower in the T4 and T5 than in the T1 traditionally roasted beef tenderloin samples.

Most acids, such as caprylic acid, caproic acid, and nonanic acid, result from the autoxidation of lipids and the oxidation of aldehydes (Chen et al., 2021). Five types of acids were identified in the superheated steam-roasted beef tenderloin samples cured with different alternative salts, and the contents of these acids were lower than those of other volatile compounds. No significant difference in the 3-methylbutyric acid content was noted between the T2 and T3 samples and the T1 sample (P > 0.05). The 2-methyl-butanoic acid content in the T2 and T3 samples was higher than that in the T1 sample. Four acids were identified in the traditionally roasted beef tenderloin samples cured with different alternative salts, and their contents were lower than those of other volatile compounds. The 2-methyl-butanoic acid content in the T2 and T3 samples was higher than that in the T1 sample.

Eight esters were identified in the superheated steam-roasted beef tenderloin samples cured with different alternative salts, with 2,2-dimethylpropyl acetate and methyl ether as the main compounds. Ten esters were identified in the traditionally roasted beef tenderloin samples cured with different alternative salts, with 2,2-dimethylpropyl acetate being the major compound. The content of 2,2-dimethylpropyl acetate was higher than those of other methyl esters, and 2,2-dimethylpropyl acetate was identified in all the beef tenderloin samples. Wang et al. (2020) reported that some esters in bacon products may be formed by the nonenzymatic esterification of alcohols and acids.

A total of 31 and 27 hydrocarbons were identified in the superheated steam-roasted and traditionally roasted beef tenderloin samples cured with different alternative salts, respectively. Some flavor compounds, such as toluene, 1,3-dimethyl-benzene, 1,3-di-tert-butylbenzene, o-xylene and 2-pentyl-furan, are difficult to classify. Furan is a typical heterocyclic compound that is formed by the Maillard reaction, Strecker decomposition, and thiamine thermal decomposition (Li et al., 2022).

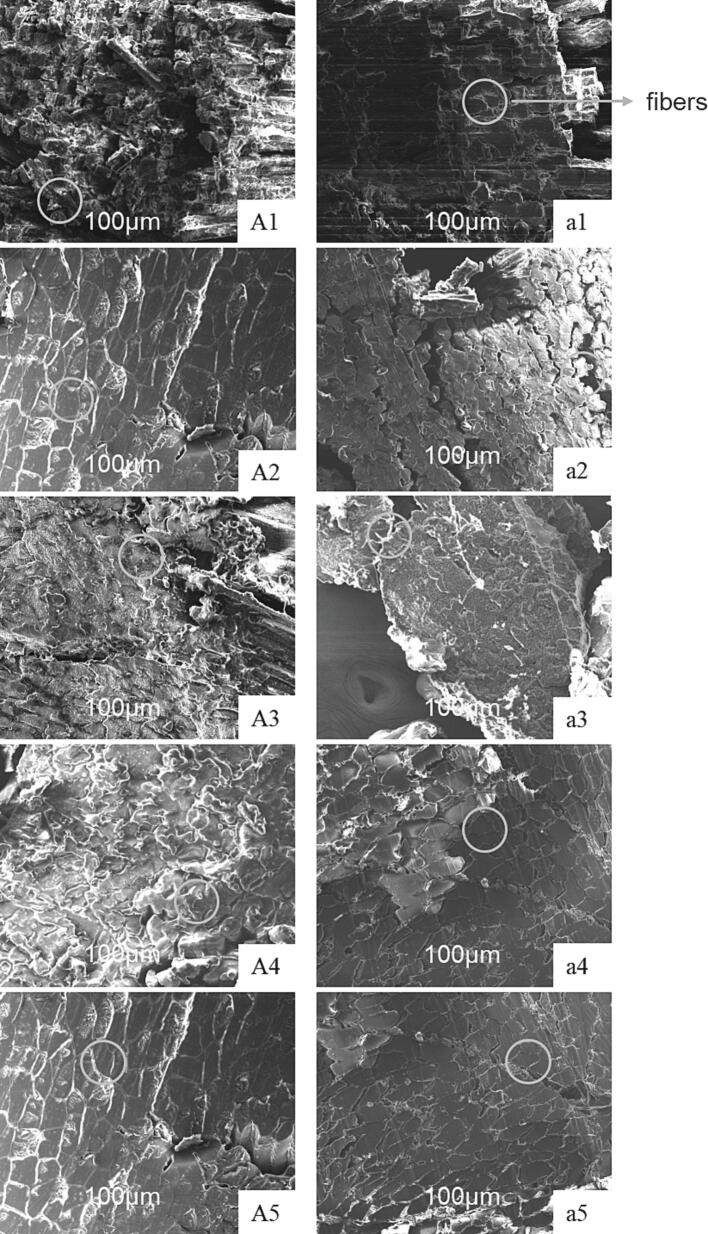

3.7. Effects of different low-sodium substitute salt treatments on the microstructure of beef

The structure and ultrastructure of meat are closely related to the quality of meat products, and changes in the microstructure affect the water retention quality of meat products (Puolanne & Halonen, 2010). A scanning electron microscope was used to observe changes in the microstructure of superheated steam-roasted and traditionally roasted beef tenderloin samples cured with different alternative salts. The results are presented in Fig. 3. In addition to water loss, salt diffusion leads to an increase in the gaps in salt samples. Salt diffusion leads to the overexpansion of fibers and the destruction of muscle structure. Duranton et al. (2012) reported that when salt solution was injected into pigs, the fiber was not obvious but intact.

Fig. 3.

Scanning electron microscopy images of superheated steam-roasted beef tenderloin and traditionally roasted beef tenderloin cured with different salt types at 100 × magnification. A1–A5: T1–T5 (superheated steam roasted); a1–a5: T1–T5 (traditional roasted). T1: 100% NaCl, T2: 75% KCl + 25% NaCl, T3: 50% KCl + 50% NaCl, T4: 50% NaCl + 25% KCl + 20% MgCl2 + 5% CaCl2, T5: 100% yeast extract.

3.8. Comparison of osmotic pressure of different low-sodium substitute salt solutions applied to onion cells

Different low-sodium replacement salt solutions exert different osmotic pressure on cells. The higher the osmotic pressure is, the greater is the degree of separation of the cytoplasmic wall (Segui et al., 2010), and excessively high osmotic pressure is detrimental to human health. The plasmolysis of onion cells under different low-sodium replacement salt solutions was microscopic observed (Fig. 4). Onion cells treated with different low-sodium replacement salt solutions (T1, T2, T3, and T4) exhibited different degrees of plasmolysis. The T5 sample did not exhibit plasmolysis. The plasmolysis percentages of the T1, T2, T3, T4, and T5 samples were 61.56%, 44.29%, 52.9%, 38.34%, and 0%, respectively (Fig. 4b). Compared with the T1 sample, the T2, T3, T4, and T5 samples had lower plasmolysis percentages and lower osmotic pressure, indicating that the salt substitutes are safe for human consumption.

Fig. 4.

Microscopic observation of the plasmolysis of onion cells in different low-sodium replacement salt solutions (T1, T2, T3, T4, and T5) and Predicted means ± standard error for plasmolysis percentage of onion cells under different low-sodium replacement salt solutions (b). T1: 100% NaCl, T2: 75% KCl + 25% NaCl, T3: 50% KCl + 50% NaCl, T4: 50% NaCl + 25% KCl + 20% MgCl2 + 5% CaCl2, T5: 100% yeast extract.

4. Conclusions

The effects of chlorine salts, namely KCl, CaCl2, and MgCl2, and yeast extracts used as substitutes for NaCl on the physicochemical and sensory properties of pickled meat products were investigated. Substituting NaCl with 50% KCl (T3) or 75% KCl (T2) did not reduce the salinity of beef when compared with the T1 (control) sample with 100% NaCl. Substituting NaCl with 50%–75% KCl exerted no adverse effect on the physicochemical and sensory properties of beef (Table S5, S6).

CRediT authorship contribution statement

Li Chuang: Conceptualization, Methodology, Writing – original draft. Shi Jiyong: Supervision, Funding acquisition, Writing – review & editing. Zhou Chenguang: Data curation. Huang Xiaowei: Methodology. Zhai Xiaodong: Resources. Yang Zhikun: Validation, Investigation. Li Zhihua: Validation. Hu Xuetao: Data curation. Li Yanxiao: Resources. Xiao Jianbo: Data curation. Zou Xiaobo: Supervision, Funding acquisition, Writing – review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The Jiangsu Specially-Appointed Professor Project (20TPJS002), Jiangsu Natural Science Foundation for Excellent Young Scholars (BK20200103), Project supported by National Key research and Development Program of China (Grant No. 2018YFD 0400800), Natural Science Foundation of Jiangsu Province (BK20200890), Project of Faculty of Agricultural Equipment of Jiangsu University.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.fochx.2023.100885.

Contributor Information

Shi Jiyong, Email: shi_jiyong@ujs.edu.cn.

Zou Xiaobo, Email: zou_xiaobo@ujs.edu.cn.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

Data availability

The data that has been used is confidential.

References

- Aaslyng M.D., Vestergaard C., Koch A.G. The effect of salt reduction on sensory quality and microbial growth in hotdog sausages, bacon, ham and salami. Meat Science. 2014;96(1):47–55. doi: 10.1016/j.meatsci.2013.06.004. [DOI] [PubMed] [Google Scholar]

- Alim A., Song H., Liu Y., Zou T., Zhang Y., Zhang S. Flavour-active compounds in thermally treated yeast extracts. Journal of the Science of Food and Agriculture. 2018;98(10):3774–3783. doi: 10.1002/jsfa.8891. [DOI] [PubMed] [Google Scholar]

- Angiolillo L., Nobile M.D., Conte A. The extraction of bioactive compounds from food residues using microwaves. Current Opinion in Food Science. 2015;5:93–98. [Google Scholar]

- Biffin T.E., Smith M.A., Bush R.D., Morris S., Hopkins D.L. The effect of whole carcase medium voltage electrical stimulation, tenderstretching and longissimus infusion with actinidin on alpaca meat quality. Meat Science. 2020;164 doi: 10.1016/j.meatsci.2020.108107. [DOI] [PubMed] [Google Scholar]

- Bhat Z.F., Morton J.D., Mason S.L., Bekhit A.-E.-D.-A. The application of pulsed electric field as a sodium reducing strategy for meat products. Food Chemistry. 2020;306 doi: 10.1016/j.foodchem.2019.125622. [DOI] [PubMed] [Google Scholar]

- Chen Q., Hu Y., Wen R., Wang Y., Kong B. Characterisation of the flavour profile of dry fermented sausages with different NaCl substitutes using HS-SPME-GC-MS combined with electronic nose and electronic tongue. Meat Science. 2021;172(1) doi: 10.1016/j.meatsci.2020.108338. [DOI] [PubMed] [Google Scholar]

- da Silva Araujo D.H., de Souza Rodrigues R.T., da Costa M.M., de Miranda J.O., de Lira-Alencar N.R.C., Queiroz M.A.Á., Bonfá H.C. Reduction of sodium content in frozen goat sausage using different types of salt. LWT. 2021;135 [Google Scholar]

- dos Santos Alves L.A.A., Lorenzo J.M., Gonçalves C.A.A., Dos Santos B.A., Heck R.T., Cichoski A.J., Campagnol P.C.B. Impact of lysine and liquid smoke as flavor enhancers on the quality of low-fat Bologna-type sausages with 50% replacement of NaCl by KCl. Meat Science. 2017;123:50–56. doi: 10.1016/j.meatsci.2016.09.001. [DOI] [PubMed] [Google Scholar]

- Du S., Liu L., Wang H., Zhang B., Popkin B. Arsenic in the Pathway to Cardiovascular Diseases: Arsenic May Mediate Lipid Profile in Adults. Current Developments Nutrition. 2020;4(Supplement_2):1630. [Google Scholar]

- Duranton F., Simonin H., Chéret R., Guillou S., de Lamballerie M. Effect of high pressure and salt on pork meat quality and microstructure. Journal of Food Science. 2012;77(8):E188–E194. doi: 10.1111/j.1750-3841.2012.02816.x. [DOI] [PubMed] [Google Scholar]

- Giuseppina, Imperatore, Yiling, Cheng, Desmond, & Williams, Fulton. (2006). Physical activity, cardiovascular fitness, and insulin sensitivity among U.S. adolescents: the National Health and Nutrition Examination Survey, 1999-2002. Diabetes Care. [DOI] [PubMed]

- Harada-Padermo S., Dias-Faceto L.S., Selani M.M., Alvim I.D., Vieira T. Umami Ingredient: Flavor enhancer from shiitake (Lentinula edodes) byproducts. Food Research International. 2020;137(3) doi: 10.1016/j.foodres.2020.109540. [DOI] [PubMed] [Google Scholar]

- Horita C., Messias V., Morgano M., Hayakawa F., Pollonio M. Textural, microstructural and sensory properties of reduced sodium frankfurter sausages containing mechanically deboned poultry meat and blends of chloride salts. Food Research International. 2014;66:29–35. [Google Scholar]

- Horita C., Morgano M., Celeghini R., Pollonio M. Physico-chemical and sensory properties of reduced-fat mortadella prepared with blends of calcium, magnesium and potassium chloride as partial substitutes for sodium chloride. Meat Science. 2011;89(4):426–433. doi: 10.1016/j.meatsci.2011.05.010. [DOI] [PubMed] [Google Scholar]

- Horwitz, W. (2010). Official methods of analysis of AOAC International. Volume I, agricultural chemicals, contaminants, drugs/edited by William Horwitz: Gaithersburg (Maryland): AOAC International, 1997.

- Kanner J., Harel S., Jaffe R. Lipid peroxidation of muscle food as affected by sodium chloride. Journal of Agricultural and Food Chemistry. 1991;39(6):1017–1021. [Google Scholar]

- Katsiari M.C., Alichanidis E., Voutsinas L.P., Roussis I.G. Proteolysis in reduced sodium Kefalograviera cheese made by partial replacement of NaCl with KCl. Food Chemistry. 2001;73(1):31–43. doi: 10.1016/S0308-8146(00)00275-2. [DOI] [Google Scholar]

- Katsiari M.C., Voutsinas L.P., Alichanidis E., Roussis I.G. Lipolysis in reduced sodium Kefalograviera cheese made by partial replacement of NaCl with KCl. Food Chemistry. 2001;72(2):193–197. doi: 10.1016/S0308-8146(00)00218-1. [DOI] [Google Scholar]

- Laranjo M., Gomes A., Agulheiro-Santos A.C., Potes M.E., Cabrita M.J., Garcia R., Elias M. Impact of salt reduction on biogenic amines, fatty acids, microbiota, texture and sensory profile in traditional blood dry-cured sausages. Food Chemistry. 2017;218:129–136. doi: 10.1016/j.foodchem.2016.09.056. [DOI] [PubMed] [Google Scholar]

- Laranjo M., Gomes A., Agulheiro-Santos A.C., Potes M.E., Elias M. Impact of salt reduction on biogenic amines, fatty acids, microbiota, texture and sensory profile in traditional blood dry-cured sausages. Food Chemistry. 2017;218:129–136. doi: 10.1016/j.foodchem.2016.09.056. [DOI] [PubMed] [Google Scholar]

- Li C., Al-Dalali S., Wang Z., Xu B., Zhou H. Investigation of volatile flavor compounds and characterization of aroma-active compounds of water-boiled salted duck using GC–MS–O, GC–IMS, and E-nose. Food Chemistry. 2022;386 doi: 10.1016/j.foodchem.2022.132728. [DOI] [PubMed] [Google Scholar]

- Liu P., Wang S., Zhang H., Wang H., Kong B. Influence of glycated nitrosohaemoglobin prepared from porcine blood cell on physicochemical properties, microbial growth and flavour formation of Harbin dry sausages. Meat Science. 2019;148(FEB.):96–104. doi: 10.1016/j.meatsci.2018.10.008. [DOI] [PubMed] [Google Scholar]

- Lorenzo J.M., Franco D. Fat effect on physico-chemical, microbial and textural changes through the manufactured of dry-cured foal sausage Lipolysis, proteolysis and sensory properties. Meat Science. 2012;92(4):704–714. doi: 10.1016/j.meatsci.2012.06.026. [DOI] [PubMed] [Google Scholar]

- Mansur A.R., Seo D.H., Song E.J., Song N.E., Nam T.G. Identifying potential spoilage markers in beef stored in chilled air or vacuum packaging by HS-SPME-GC-TOF/MS coupled with multivariate analysis. LWT- Food Science and Technology. 2019;112 [Google Scholar]

- Monica A., Maria-Concepcion A., Jose M., Toldra Biochemical and Sensory Properties of Dry-Cured Loins as Affected by Partial Replacement of Sodium by Potassium, Calcium, and Magnesium. Journal of Agricultural and Food Chemistry. 2009;57(20):9699–9705. doi: 10.1021/jf901768z. [DOI] [PubMed] [Google Scholar]

- Mozaffarian D., Fahimi S., Singh G.M., Micha R., Khatibzadeh S., Engell R.E., Powles J. Global Sodium Consumption and Death from Cardiovascular Causes. New England Journal of Medicine. 2014 doi: 10.1056/NEJMoa1304127. [DOI] [PubMed] [Google Scholar]

- O’Neill C.M., Cruz-Romero M.C., Duffy G., Kerry J.P. Shelf life extension of vacuum-packed salt reduced frankfurters and cooked ham through the combined application of high pressure processing and organic acids. Food Packaging and Shelf Life. 2018;17:120–128. [Google Scholar]

- Puolanne E., Halonen M. Theoretical aspects of water-holding in meat. Meat Science. 2010;86(1):151–165. doi: 10.1016/j.meatsci.2010.04.038. [DOI] [PubMed] [Google Scholar]

- Ramírez R., Cava R. Volatile profiles of dry-cured meat products from three different Iberian x Duroc genotypes. Journal of Agricultural and Food Chemistry. 2007;55(5):1923–1931. doi: 10.1021/jf062810l. [DOI] [PubMed] [Google Scholar]

- Segui L., Fito P.J., Fito P. Analysis of structure-property relationships in isolated cells during OD treatments. Effect of initial structure on the cell behaviour. Journal of Food Engineering. 2010;99(4):417–423. [Google Scholar]

- Smith M.A., Bush R.D., Rj V.D.V., Hopkins D.L. Effect of electrical stimulation and ageing period on alpaca (vicugna pacos) meat and eating quality. Meat Science. 2015;111:38. doi: 10.1016/j.meatsci.2015.08.013. [DOI] [PubMed] [Google Scholar]

- Tahir H.E., Arslan M., Mahunu G.K., Shi J., Mariod A.A. Data fusion approach improves the prediction of single phenolic compounds in honey: A study of NIR and Raman spectroscopies. eFood. 2019;1(2) [Google Scholar]

- Tobin B.D., O'Sullivan M.G., Hamill R.M., Kerry J.P. The impact of salt and fat level variation on the physiochemical properties and sensory quality of pork breakfast sausages. Meat Science. 2013;93(2):145–152. doi: 10.1016/j.meatsci.2012.08.008. [DOI] [PubMed] [Google Scholar]

- Valerio F., Conte A., Di Biase M., Lattanzio V.M.T., Lonigro S.L., Padalino L., Lavermicocca P. Formulation of yeast-leavened bread with reduced salt content by using a Lactobacillus plantarum fermentation product. Food Chemistry. 2017;221:582–589. doi: 10.1016/j.foodchem.2016.11.135. [DOI] [PubMed] [Google Scholar]

- Wang Y., Li C., Zhao Y., Li L., Yang X., Wu Y., Yang D. Novel insight into the formation mechanism of volatile flavor in Chinese fish sauce (Yu-lu) based on molecular sensory and metagenomics analyses. Food Chemistry. 2020;323 doi: 10.1016/j.foodchem.2020.126839. [DOI] [PubMed] [Google Scholar]

- Wattanachant S., Benjakul S., Ledward D.A. Effect of heat treatment on changes in texture, structure and properties of Thai indigenous chicken muscle. Food Chemistry. 2005;93(2):337–348. [Google Scholar]

- Yang Y., Niu C., Shan W., Zheng F., Liu C., Wang J., Li Q. Physicochemical, flavor and microbial dynamic changes during low-salt doubanjiang (broad bean paste) fermentation. Food Chemistry. 2021;351 doi: 10.1016/j.foodchem.2020.128454. [DOI] [PubMed] [Google Scholar]

- Zanardi E., Ghidini S., Conter M., Ianieri A. Mineral composition of Italian salami and effect of NaCl partial replacement on compositional, physico-chemical and sensory parameters. Meat Science. 2010;86(3):742–747. doi: 10.1016/j.meatsci.2010.06.015. [DOI] [PubMed] [Google Scholar]

- Zhang D., Li H., Emara A.M., Wang Z., Chen X., He Z. Study on the mechanism of KCl replacement of NaCl on the water retention of salted pork. Food Chemistry. 2020;332 doi: 10.1016/j.foodchem.2020.127414. [DOI] [PubMed] [Google Scholar]

- Zhao C., Lai S., Wu D., Liu D., Xiao J. Mirnas as regulators of antidiabetic effects of fucoidans. eFood. 2019;1(1) [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data that has been used is confidential.