Abstract

Bovine lactoferrin (bLF) is widely known as an iron-binding glycoprotein from the transferrin family. The bLF molecule exhibits a broad spectrum of biological activity, including iron delivery, antimicrobial, antiviral, immunomodulatory, antioxidant, antitumor, and prebiotic functions, thereby making it one of the most valuable representatives for biomedical applications. Remarkably, LF functionality might completely differ in dependence on the iron saturation state and glycosylation patterns. Recently, a violently growing demand for bLF production has been observed, mostly for infant formulas, dietary supplements, and functional food formulations. Unfortunately, one of the reasons that inhibit the development of the bLF market and widespread protein implementation is related to its negligible amount in both major sources—colostrum and mature milk. This study provides a comprehensive overview of the significance of bLF research by delineating the key structural characteristics of the protein and elucidating their impact on its physicochemical and biological properties. Progress in the development of optimal isolation techniques for bLF is critically assessed, alongside the challenges that arise during its production. Furthermore, this paper presents a curated list of the most relevant instrumental techniques for the characterization of bLF. Lastly, it discusses the prospective applications and future directions for bLF-based formulations, highlighting their potential in various fields.

Keywords: bovine lactoferrin, bLF, iron-binding affinity, functional food formulations, biomedical applications, biological activity

1. Introduction

Whey proteins (WPs) are recognized as one of the most valuable components in milk whose characteristic feature is a wide spectrum of nutritional and health promoting effects. WPs are represented by a mixture of globular proteins, e.g. β-lactoglobulin (β-LG), α-lactoalbumin (α-LA), serum albumin (SA), immunoglobulins (Ig), lactoperoxidase (LPO), and lactoferrin (LF), dispersed in the continuous phase of the milk colloidal system which accounts for about 20% of the total protein fraction.1 On the other hand, whey poses a serious group of waste products with extremely critical levels of BOD (biological oxygen demand) and COD (chemical oxygen demand).2,3 Direct recovery and further supplementation of WPs could be a prospective approach for improving the functionality range of dairy products as well as for environmental protection.

LF is known as globular iron-binding glycoprotein which belongs to the transferrin protein family.4 Chelated ferric ions inside the LF structure ensure the characteristic salmon-pink color of a protein.5 Bovine lactoferrin (bLF) is predominantly found in the granules of neutrophils and mammary gland secretions, such as colostrum, transitional milk, and mature milk. The lactation stage is considered one of the most reasonable factors which strongly affects the composition of the cow’s milk. Significant changes of LF content are usually observed during the transition of colostrum (1.0–5.0 mg/mL) into mature milk (0.02–0.2 mg/mL).6−8 Remarkably, the amounts of lactoferrin and transferrin are relatively similar (LF, 0.83 mg/mL; TF, 1.07 mg/mL) in the colostral phase; however, their concentrations sharply decrease in the lactation period (LF, 0.09 mg/mL; TF, 0.02 mg/mL).9 Since LF is known as a biomarker of inflammation processes, accurate protein detection is extremely important for the monitoring of cattle’s health issues. For instance, the positive correlation between LF and immunoglobulin concentrations in serum is directly related to mastitis in cows.10

The molecular weight of LF might differ in dependence of its source of origin (Figure 1). It has been identified that LF mass from milk and colostrum was found in the range 83–87 kDa, while in neutrophils it was about 87–91 kDa. However, a single protein band appeared in both protein samples at 77 kDa resulting from the partial digestion of LF by N-glycanase.11 Thus, based on the LF source, it might be present in different molecular forms whose size is highly influenced by the nature (heterogeneity) of glycosylation. The major factors that might induce variations in LF glycosylation are the stage of lactation, age, breed of cow, season, and feeding. For instance, Barboza reported that the degree of glycosylation in human milk decreased after 2 weeks of lactation since colostrum was changed into mature milk.12 In addition, Jia et al. observed the same tendency in the case of LF in bovine milk; thus the amount of N-glycans content decreased in the following order of lactation stages: colostrum > transitional milk > mature milk.13 Despite the monomeric form, bLF, the protein also may occur as high molecular weight complexes (HMW-LF). This phenomenon was especially abundant in nonlactating mammary secretions (Holstein cows).14 It was indicated that LF trimers (Mw ∼ 250 Da) had much higher thermal stability as well as resistance to proteolysis than apo-LF and holo-LF.15 The structural stability of HMW-LF is probably caused by the structural integrity of larger oligomers. Besides, Ebrahim et al. showed that such HMW-LF complexes were sensitive to the addition of highly concentrated electrolyte solution (1 M NaCl) and dissociated into smaller structural units.15 LF is also capable of interacting with other proteins of milk, forming heterogenic protein complexes of LF–Ig, LF–CN, LF–SA, and LF−β-LG.14,16 Such bindings are characterized as noncovalent interactions which have a positive impact on the biological activity of the native LF molecule, enhancing some of its primary functions. Thus, Stephens et al. reported a higher antibacterial activity of LF–Ig complexes against Escherichia coli strains compared to LF alone.17

Figure 1.

Comparison of bLF proteins from different sources of origin. Created with BioRender.com.

Until now, isolation of LF has been successfully performed from different mammals, including human, bovine, buffalo, goat, sheep, pig, horse, mouse, camel, and elephant. As it was reported, LF derived from human milk revealed the lowest similarity in sequence homology (>70%) in comparison to LF isolated from milk of other species.18 The difference in amino acid composition has a significant impact on the conformation stability of the biomolecule and other physicochemical properties (molecular mass, isoelectric point, thermal resistance).19 Currently, lactoferrin is a subject of great interest for researchers due to its high biological potential. LF is increasingly characterized as a multifunctional ingredient; it possesses antimicrobial, antiviral, immunomodulatory, and anticancer and prebiotic activities, which make it one of the most attractive candidates in the biomedicine and biotechnology areas.20 LF as an iron carrier avoids the formation of insoluble aggregates of ferric hydroxide; therefore, it might be safely applied in the treatment of anemia, especially in the case of pregnant woman.21 Previously, it was reported that 1.4 mg of iron might be maximum chelated per 1 g of protein, whereas the absorption of microelements by an organism is influenced by numerous factors, such as the daily diet, protein saturation state, pH conditions, human age, and physiological conditions.22 The additional advantage of LF’s iron-binding capacity relies on its antioxidant effect through the prevention of lipid peroxidation and the potential formation of reactive oxygen species (ROS) as a result of the Fenton reaction.23 The functionality of bLF can be developed as a result of interactions with other molecules (ligands), e.g. metals, vitamins, polyphenols, DNA, and lipopolysaccharides (LPS). Recently, interest in the synthesis of biologically active complexes based on bLF and metal ions has been growing. Such biologically active preparations allow for enhancement of beneficial and food values, especially in dairy products.24 For example, Hinrichs et al. pointed out that cheese enrichment in whey proteins is a novel approach in the development of functional food.25 Nevertheless, it is worth knowing that the lactoferrin incorporation will not only improve the nutritional quality and the functional properties of the final product; it will also require the reconstruction of the entire technological line.

Numerous health benefits and a wide spectrum of potential applications led to the significant growth of the demand for lactoferrin. The global production of bovine lactoferrin is expected to exceed a compound annual growth rate (CAGR) of 7.2% until 2028.26 Currently, to the list of key LF manufacturers joined the following companies: Glanbia Nutritionals (Kilkenny, Ireland), Synlait Milk (Dunsandel, New Zealand), Fonterra (Auckland, New Zealand), Merck (Darmstadt, Germany), Milei GmbH (Leutkirch, Germany), and Tatura Milk Industries Ltd. (Tatura, Australia) as a part of the Bega Group (Bega, Australia). The market statistics accounts the biggest application share of lactoferrin to infant formula, followed by dietary supplements and pharmaceuticals. One of current problems relies on the finding of an efficient and selective isolation method which will enable large-scale production of biologically active lactoferrin. The amount of LF found in bovine milk is relatively low (about 1%) in comparison to other WPs. Hence, LF isolation might be a quite challenging and time-consuming process. The first successful purification of bovine LF was performed in 1960 by Groves using DEAE cellulose chromatography.27 Comprehensive study of the nature of LF interactions has initiated the development of more advanced techniques. Traditional methods of ion-exchange chromatography, affinity chromatography, and membrane filtration have been improved by using more effective sorbents and modified membranes.1,28 In recent years, several complex techniques were investigated, including electrodialysis with a filtration membrane and magnetic affinity separation.29

This review presents recent advances in the structural characteristics of the LF molecule, such as glycosylation and metal-binding properties, describes the novel methods of protein isolation, and clarifies the essential role of biomolecules in disease treatment.

2. LF Structure

The three-dimensional structure of bLF is generally described as a single polypeptide chain containing 689 amino acid residues folded into two symmetric homogeneous lobes (N-lobe 1–341 and C-lobe Tyr342–Arg689) which are linked by three-turn α-helix (12 residues long from 333 to 344).30 According to crystallographic studies, each lobe is divided into two domains (N1/N2 and C1/C2). Although, the overall bLF structure has been known for a long time, it is worthwhile to mention LF genetic conservation/variation phenomena across different species. The LF gene is expressed in many species, e.g. human, bovine, buffalo, mouse, caprine, deer, equine, murine, and porcine. The protein genes from the transferrin family are typically composed of 17 exons (N-lobe, 2–8; C-lobe, 9–16, hinge region was at exon 9) whose lengths vary in the range 23–35 kb.31 Remarkably, it was found that 15 exons were identical between bovine and human lactoferrins, while the remaining two were responsible for gene differentiations that induced the variations in amino acid sequences.32 Seyfert et al. suggested that exons 4 and 12 play a significant role in the LF iron-binding properties and glycosylation.31 According to Wang et al.’s results, bovine and deer lactoferrins share 92% sequence homology.33 The authors particularly highlighted the difference in the amino acid compositions of two major antibacterial peptides—lactoferricin and lactoferrampin. Numerous molecular studies confirmed that genetic polymorphism is able to affect the protein conformational stability, the tendency to aggregate, and the biological activity.

The metal binding site is localized deeply inside the interdomain clefts of each lobe; thus one LF molecule is able to bind a maximum of two ferric ions. Interestingly, the binding cleft N-lobe reveals a more open conformation in comparison to the C-lobe.34 A slight difference in their flexibility is caused by the presence of a disulfide bridge formed between residues 483 and 677 which restricts additional movements in the C-lobe.34 Based on this, the metal binding capacity will differ between the N-lobe and the C-lobe. According to the iron saturation level, LF can be classified as apo-LF (saturation level <5%) and holo-LF (bound with two ferric ions). Native bLF is an intermediate state between apo-LF and holo-LF and accounts for approximately 15–20% of metal saturation.35 Native bLF is naturally composed of apo-LF, holo-LF, and monoferric LF forms which are present in whole milk in different proportions.36 The level of iron saturation has a great impact on the biological properties of a protein. For example, microbiological studies showed that apo-lactoferrin effectively inhibited the growth of pathogenic bacteria strains (E. coli, Staphylococcus aureus, Pseudomonas aeruginosa, Mannheimia haemolytica A2), whereas the supplementation of holo-lactoferrin did not reveal any antibacterial effect.37 In contrast, the supplementation of holo-LF ensured a more efficient cellular iron uptake, probably due to conformational specificity of the iron-saturated protein.38 Traditional methods of protein detection (ELISA, HPLC) and iron determination (UV–vis, ICP-MS) do not solve the problem of distinction and quantification of each of the present forms.39 Alternatively, Bokkhim et al. applied DSC studies to find the correlations between the iron saturation level and the thermodynamic parameters of protein denaturation.40 However, the suggested approach had a limitation as the iron content exceeded 75% because of the similarity in thermal behaviors of mono- and diferric bLF. The results of cation-exchange chromatographic separation performed by Makino et al. showed the prevalence of apo-LF and monoferric LF fractions in native hLF.36 Additionally, these forms might be distinguished based on their charge surface properties. For example, Kumar et al. observed three individual bands assigned to apo-LF, holo-LF, and monosubstituted LF which were present in buffalo LF samples. Results indicated a faster electrophoretic mobility as the level of iron saturation in protein increased.41

Specific amino acid sequences and their particular arrangement promote an LF high binding affinity toward ferric ions (KA = 1020).42 As a rule, iron complexation is accompanied by coordination of the bicarbonate ion, which plays a fundamental role in holo-LF stabilization. The iron-binding site has an octahedral geometry in which the ferric ion is chelated by the imidazole ring of histidine (His253 in N-lobe, His595 in C-lobe), phenolate oxygens of two tyrosinases (Tyr92 and Tyr192 in N-lobe and Tyr433 and Tyr526 in C-lobe), the carboxylate of aspartate (Asp60 in N-lobe, Asp395 in C-lobe), and two atoms of oxygen from the bicarbonate ion (Figure 2). Remarkably, bicarbonate incorporation is mediated by interactions with the arginine side chain and hydrogen bonding with threonine and the N-terminus of helix 5 in order to maintain a higher protein conformational stability.43−45 In the absence of metal, the conformation of the LF binding site is retained by intramolecular interactions, including the formation of hydrogen bonding between the pair of side tyrosine chains and van der Waals forces between histidine and aspartic acid. Typically, the metal saturation is initiated by insertion of a bicarbonate ion and followed by the attachment of two tyrosine residues. In the final step, iron coordination is completed by chelation with histidine and aspartic acid residues.46 The coordination bonding lengths range from 1.9 to 2.1 Å.47 Nevertheless, the results of LF tryptic digestion performed by Rastogi et al. showed that the binding site located in the C-lobe fragment was slightly deformed from an ideal octahedron at pH below 6.8.48 The geometry of the binding site is mainly influenced by the iron saturation level. The authors have demonstrated that gradually lowering the pH of the solution provides weakening of the bond strength between the ferric ion and the Nε2 imidazole atom of histidine due to enhancing the repulsion forces between these atoms; thus the coordination distance between these atoms tends to be increased. Currently, in the PDB database there are published crystallized structures of apo-LF isolated from human, equine, and camel species, while holo-LF was analyzed from human, bovine, buffalo, and equine organisms. Remarkably, the crystallization of native LF (mixture of apo- and holo-LFs) has not been performed yet. As it was reported, the metal content has a great impact not only on the geometry binding site but also on the protein conformation in general. The iron-free human LF revealed a more open conformation in contrast to the iron-saturated form. What is important is that the N-lobe undergoes loosening in apo-LF, while the C-lobe constantly remains rigid even after the metal release.34 The exact reason for that structural singularity of the C-lobe is still in question. Despite this, it would interesting to compare the behaviors of both lobes in the LF native state. The conformational changes induced by iron binding might vary among LF different species. For example, camel apo-LF possessed both open-structured lobes, thereby showing a higher conformational similarity with apo-ovatransferrin than with other lactoferrins.49 In contrast, the three-dimensional structure of mare apo-LF confirmed the presence of both N- and C-lobes in the closed state.50 The authors explained that the phenomena might be influenced by a difference in the relative orientation between the N- and C-lobes and specific interdomain interactions within the protein structure; nevertheless, this issue requires a more detailed review in the future.

Figure 2.

Three-dimensional structure of diferric bLF (Protein Data Bank code 1BLF).

Although the classical assumption affirms the chelation of only two ferric ions per LF molecule, several studies confirmed that the presence of additional binding sites on the protein surface. As it was shown, the protein modification at appropriate conditions, e.g. the molar ratio of reagents (bLF:FeCl3:NaHCO3), pH, and temperature, enables the formation of a supersaturated Fe–LF complex.51 According to results, a supramolecular structure of the synthesized complex was proposed in which LF molecules (15–16) were electrostatically linked through charged side chains of amino acids and Fe3+–HCO3– ions. Alternatively, Nagasako et al. assumed that LF iron supersaturation might occur by electron donor–acceptor interactions with shares of cysteine, histidine, and tryptophan residues.52 Nonetheless, that question remains open for future research.

Iron exchange by other metals also may induce significant modification in the LF conformation. For example, replacement of ferric ions with copper in the N-lobe led to transformation of the binding site geometry to square pyramidal, resulting in the formation of hydrogen bonding between bicarbonate ion and tyrosine.53 Smith et al.54 studied lactoferrin complexes with different forms of vanadium (V3+, VO2+, VO2+). According to the results, metal chelation was mediated by the same amino acid residues as in holo-LF; however, the structural importance of bicarbonate ion decreased with the increase of the vanadium oxidation state.54 In contrast, the anion substitution of bicarbonate with the much bigger oxalate anion led only to slight changes of its arrangement in the binding site resulting in moving of the side chain of arginine away. Baker et al. also pointed out that the bigger size of substituted metal ions was characterized by lower affinity to LF.55 Thus, a comprehensive study of the bLF structure is crucial for characterization of the protein conformational stability, detection of the potential binding sites, and indication of the type of intra- or intermolecular interactions. Besides, it provides critical insights into the establishment of the relationship between the structure and functionality of biomolecules which is highly important for designing new drug candidates.

3. Factors Affecting LF Stability

It worthwhile to mention that LF conformation is characterized by high sensitivity to various physicochemical factors, such as pH, temperature, and ionic strength.56 Therefore, careful planning of the experiment by the selection of appropriate conditions is a necessary step for the protection of the biomolecule’s native structure and its primary biological function.

3.1. pH Conditions

LF stability and the level of iron saturation are tightly related to each other and are predominantly affected by the surrounding environment of the medium, especially pH. High iron-binding capacity is one of the fundamental features which contributes conformational stability of the LF structure over a wide range of pH. The nonchelated form of LF is considered more sensitive to unfolding at extremely low values of pH. In contrast, holo-LF was able to maintain ferric ions in the structure even at pH 2.48 LF desaturation is effectively carried out at pHs lower than 3.5, obtaining the protein with <2% metal.57 As expected, that pH lowering provides the opening of the LF conformation. The metal release occurred much slower from C-lobe than N-lobe binding site with pH lowering, which might be related to the higher rigidity of the C-lobe and its greater binding affinity to ferric ion.43 It has been demonstrated that iron dissociation begins at pH 6.7 in the N-lobe of bLF, while desaturation of the C-lobe was initiated at pH 5.6.58 A similar character of desaturation was observed in the case of lactoferrin isolated from human milk and neutrophils.59 Interestingly, in camel LF metal release in the C-lobe begins faster than in the N-lobe at pH 6.5 and 3.5, respectively.49 The stability of LF complexes might vary in dependence of the type of coordinated metal. For example, Jabeen et al. showed that Zn2+ dissociation from the C-lobe starts much lower (pH 4.6), in comparison to Fe3+ (pH 5.7).60 Importantly, that pH-induced LF desaturation is easily reversible and does not lead to the loss of primary protein metal-binding properties.57

3.2. Ionic Strength

Since LF dispersion represents a complex biocolloidal system, its stability is highly affected by ionic strength. The presence of co-ions induces some modification of the thickness of the electric double layer.61 Protein interactions with water molecules are strongly related to the type of present ions, which according to the Hofmeister effect might be classified as kosmotropic (cation, destabilizing; anion, stabilizing) and chaotropic (cation, stabilizing; anion, destabilizing). Sodium chloride is known, as a salt possessing a kosmotropic cation and a chaotropic anion, which tend to interact strongly with protein carboxylic and amino groups, respectively.62 Mela et al. reported that high electrolyte concentration (>30 mM NaCl) disrupts the balance between hydrophobic and electrostatic interactions in LF dispersion, leading to formation of negatively charged aggregates of apo-LF.63 These aggregates are described as micelles with bulk positively charged groups inside aggregates and more exposed to environment negatively charged groups. Conformational rearrangements were corresponding to significant changes of charge density on the protein surface, leading to reduction of the value of the LF isoelectric point from 8.4 to 6 at ionic strengths above 150 mM. Nilsson mentioned that LF conformation undergoes destabilization by aggregation and formation of amyloid fibrils at a relatively high NaCl concentration (150 mM) and heat treatment to 65 °C.64

3.3. Heat Treatment

Investigation of the heat stability of bLF is an essential step in technological processing which allows evaluation of the prospective of a macromolecule as a biologically active additive in new conceptions of food, cosmetic, and drug manufacturing processes. The treatment of extremely high temperatures provides significant conformational changes in the LF structure and subsequent loss of protein biological activity. It was shown that high temperatures are one the driving forces that facilitate the release of bound iron ions by weakening their interactions with LF binding sites.65 A previous study reported that LF thermal stability was positively correlated with the iron saturation level. Unsaturated bLF possess a greater heat sensitivity due to its less closed conformation, which makes its unfolding process more favored than that in holo-bLF. Bokkhim et al. has observed a tendency of apo-LF to denature at 70–71 °C, while the destabilization of holo-bLF occurred at 89–92 °C.40 Besides, the pH of the medium is an important factor that might contribute to LF thermostability. Remarkably, the apo-LF form was resistant to the formation of aggregates during ultra-high-temperature (UHT) processing at low ionic strength and acidic conditions. It was pointed out that pH 4 was the most optimal one allowing LF to maintain its conformation and biological activity under high-temperature processing.66 Heat treatment of bLF could induce a cleavage of disulfide bridges following by aggregation via thiol/disulfide interchange reactions. Many authors revealed that LF two-step aggregation corresponds to different thermal resistances of both LF lobes.67 Large insoluble aggregates of apo-bLF solution start to appear at 60 °C.68 Nevertheless, soluble disulfide-linked aggregates of holo-bLF (pH 6.6) were observed upon heating to 70–75 °C. These bands were more visible by application of SDS-PAGE in nonreducing conditions, because disulfide bridges were not cleaved.16 Difference in aggregate solubility is caused by the presence of ferric ion in the protein structure. Destabilization of iron-free LF occurs too fast compared to iron-saturated LF, favoring the formation of insoluble aggregates. Modification in the tertiary structure of bLF as well as an increase of particle size restricts protein interactions with bacteria membrane, thus its bacteriostatic capacity was reduced.

The highest iron-binding capacity was characterized at lower ionic strength below 0.01 M.69 Heating of LF above 80 °C at an ionic strength above 0.1 M decreased the level of iron saturation, precipitation, and partial unfolding. The authors reported that conformational changes involved breaking only noncovalent interactions (mainly hydrogen and electrostatic) resulting in releasing ferric ion. Heating over 72 °C provides only minor changes in the secondary structure of native LF (pH 7.5).70 Simulation MD studies showed inconsiderable changes in the contents of different types of secondary structure in LF. These minor modifications mainly concerned a partial reduction of the number of hydrogen bonds resulting in partial unfolding of α-helix. The β-sheet structure was less sensitive; thus the content of this structure remained constant during thermal processing. However, the percentages of random coils and turns in the LF structure were slightly increased.42 On the contrary, Iafisco et al. showed that thermal denaturation of LF was accompanied by reduction of α-helix and a significant increase of β-sheet content.71 Goulding et al. showed a similar effect of the irreversible transition of α-helix into β-sheet structure by using a high temperature–short time (HTST) thermal process.72 Thus, the composition of the secondary structure of bLF may vary with regard to the applied method of heat treatment. The temperature of denaturation and enthalpy change of denaturation of holo-LF is much higher than that of apo-LF, which suggests greater thermal resistance of iron-saturated forms of protein.19,73 Application of high hydrostatic pressure as and alternative to heat treatment also confirmed much evident conformation stability of iron-saturated LF at extreme conditions compared to metal unsaturated LF.74

Interestingly, relatively low temperatures are also capable of modifying protein biological functions. It was observed that LF storage of at 20 °C for 6 months significantly influenced the protein immunomodulatory function. The level of secreted tumor necrosis factor-α (TNF-α) decreased after hLF exposure.75 TNF-α plays a crucial role in the regulation of pro-inflammatory cytokine secretion and macrophage differentiation providing more effective protection of the organism against infections.76 Therefore, the consumption of fresh milk is extremely important in the case of infants since it allows preserving the beneficial properties of the product.

4. Isolation of bLF

LF isolation at a high level of purity might be a challenging task since its total amount in milk is negligible compared to other whey proteins.77 Currently, no standard procedure of lactoferrin isolation is established (Table 1). It worth noticing that the selected conditions of LF extraction might affect the yield, purity level, and biological activity of the final product. Main factors that might induce the modifications in each of four levels of the protein structure are included: extremely low pH, high temperature, pressure, and salt concentrations, and addition of chemical denaturants. The mentioned factors could lead to breakdown of intermolecular forces (hydrophobic, ionic, hydrogen, disulfide). For instance, Franco et al. reported that the thermal denaturation of lactoferrin occurs in the range from 60 to 90 °C in dependence on the saturation state.78 Remarkably, thermal processing at high temperatures is frequently accompanied by irreversible denaturation and as a result the complete loss of the functionality of the biomolecule.79 As it was previously reported, high pressure processing (>400 MPa) is capable of modifying the surface charge reducing the electrostatic repulsions between protein particles and facilitates the formation of aggregates.80 A preliminary purification procedure involves a few pretreatment steps, the number of which depends on the type of raw material (whole milk, colostrum, sweet cheese whey, acid whey). Traditionally, whole milk is subjected to centrifugation to receive a skimmed milk. The whey fraction is obtained by removal of casein micelles from skim milk resulting in acidic precipitation at pH 4.6.81 Ion-exchange chromatography is considered one of the most integrated techniques of LF isolation. The major principle of protein fractionation is based on a significant difference of isoelectric points between LF (pI 7.8–8.8) and the rest of the whey proteins, including β-LG (pI 4.9–5.4), α-LA (pI 4.4–5.1), and BSA (pI 4.7–5.2).1,3 The separation process is accompanied by strong interactions of LF with the stationary phase, while other proteins are easily eluted from the column.

Table 1. Isolation Approaches of LF from Different Sources.

| method of LF isolation | LF source | process | ref |

|---|---|---|---|

| cation-exchange chromatography by CM resin | bovine colostrum | First, milk must be defatted by centrifugation. Second, the casein fraction is removed from skimmed milk by acidic precipitation. Subsequently, the solution is neutralized by addition of NaOH. Some additional proteins were precipitated (salted out) by application of ammonium sulfate. Lactoferrin purification was carried out by the use of carboxymethyl Sephadex-C50 column and 0.2 M phosphate buffer (pH 7.7) as mobile phase. | (102) |

| combination of ultrafiltration with strong cation-exchange chromatography | bovine colostrum | A two-step ultrafiltration process was performed on a tangential flow filtration (TFF) model system with PLC membranes (nominal molecular weight cutoffs for each step were 100 and 10 kDa, respectively). The obtained retentate was adsorbed on a strong ion-exchange SP-Sepharose fast flow column and eluted with buffer solution composed of 0.05 M sodium phosphate with 0.1–1.0 M NaCl (pH 7.7). | (100) |

| ion-exchange chromatography on monolithic columns | acid whey | Preliminary microfiltration of whey was performed with ceramic alumina/zirconia asymmetric membranes (pore diameter < 0.8 μm). The obtained permeate was loaded on a CIM monolithic ion-exchange column. Selective LF isolation was related to its higher pI value in comparison to other whey proteins. Absorbed LF was eluted with a relevant buffer solution. A TFF system was applied in order to desalt and concentrate the obtained LF fraction. Lastly, the protein was freeze-dried. | (73) |

| cross-flow microfiltration coupled with isolation on strong cation-exchanger membranes | sweet cheese whey | Whey cheese was subjected to cross-flow microfiltration with use of a Microdyn tubular system (spun with polypropylene filter cartridge) in order to eliminate insoluble particles (lipids, casein). Subsequently, LF isolation from permeate was performed by application of the strong cationic membrane adsorber Sartobind S. The elution process was carried out in a three-step operating sodium chloride salt gradient. Finally, the obtained eluates were desalted using Sartocon II with cellulose acetate membrane (area of 0.7 m2 and a cutoff of 30 kDa) and lyophilized. | (103) |

| electrodialysis with filtration membrane | whey protein isolate | LF undergoes aggregation in a salty SMUF buffer, such as that available naturally in whey. The solution containing the micelles of lactoferrin and other dairy proteins can then be separated by electrodialysis with a filtration membrane (PVA glutaraldehyde as a cross-linking agent, catalyzed by sulfuric acid), where proteins with smaller size will pass through, while the larger aggregates of will be retained. | (104) |

| separation on magnetic affinity adsorbents | acid whey | Preliminary, skimmed milk obtained by centrifugation was acidified in order to eliminate casein. Remained whey proteins were incubated together with PGMA–NH2–heparin magnetic particles at 10 °C in an ice bath for 2 h. Subsequently, particles were removed from the reaction mixture by use of PBS buffer solution (pH 6) as eluent. The release of LF from magnetic affinity adsorbents was conducted by elution with 0.5 M NaCl. | (29) |

| affinity chromatography equipped with immobilized Cibacron Blue F3GA dye column | bovine colostrum | Colostral milk was subjected to the traditional procedure of sample pretreatment, including defatting and casein removal. Subsequently, whey was slightly alkalized to pH 6 by the addition of sodium hydroxide. The LF fraction was separated on a Cibacron Blue F3GA column using 0.1 M NaOH as eluent. The efficiency of the proposed methodology was related to strong electrostatic interactions between the anionic stationary phase and positively charged LF molecules. | (105) |

In neutral pH positively charged LF has a much higher affinity to a cation-exchange resin. Anionic sorbents containing strong sulfopropyl (SP) and weak carboxymethyl (CM) functional groups belong to the most commonly used resins in cation-exchange chromatography.82 The adsorption behavior and the strength of the interaction of the target protein with the stationary phase could be modified, controlling the surface charge of the biomolecule. Remarkably, Voswinkel et al. paid attention to that the binding affinity of LF to adsorbent is highly dependent on the protein saturation state.83 According to results, apo-LF was more sensitive to applied separation conditions and was characterized by a lower adsorption capacity compared to holo-LF, especially at the low pH range. It might be related to the structural singularities of both LF forms and the difference in distribution of the surface charge. As previously mentioned, apo-LF is characterized by a more “open” conformation; therefore, it is possible to suggest that it has more accessible ionizable groups in contrast to holo-LF. The presence of minor amounts of lactoperoxidase (LPO) molecules (pI 9.3–9.6) and immunoglobulins (5.5–8.3) might become a serious hardship in the production of highly purified biologically active LF by ion-exchange chromatography.84 LPO is known as a minor whey enzyme mainly involved in the immune defense function and whose content in bovine milk varies from 15 to 50 mg/L.3 The problem of LPO elimination could be solved by selection of the appropriate isolation conditions, e.g. flow rate of the mobile phase, buffer pH, and ionic strength.85 Uchida pointed out that the efficiency of separation of LF from LPO might be improved by use of a buffer solution with pH >5 and ionic strength higher than 0.5.86 For instance, Ng et al. applied two-step isocratic elution with 0.4 and 0.6 M sodium chloride buffer (pH 7) for fractionation of an LF–LPO mixture.87 The detection of LPO is frequently performed with UV–vis analysis by measuring the maximum absorbance in the Soret region at λex 412 nm.82 Negligible amounts of lysozyme (0.15–2.7 μg/mL) also might constitute an interfering factor (pI 11) during LF isolation.88,89 In this case, the protein separation was performed by use of UF zirconia membranes, modified with charged cationic (ethylenediamine, EDA) groups.89 Interestingly, Lech et al. has detected the presence of serum albumin after goat whey treatment on a CM-Sepharose column.90 Thus, effective separation of both proteins was achieved by anion-exchange chromatography with a DEAE-Sepharose resin.

Affinity chromatography is another separation technique frequently used for the purification of whey proteins. The stationary phase is composed of immobilized antibodies (ligands) that selectively interact with the target molecule, while other components are easily eluted from the column. Sepharose modified with heparin, metal ions, oligonucleotides, monoclonal antibodies, organic dyes, and even other whey proteins was mentioned as an effective adsorbent for LF molecules.12 Lampreave et al. showed that LF is favored to form noncovalent associations with whey proteins, in particular with β-LG.91 Therefore, the immobilization of insoluble β-LG particles might be a potential approach for the successful isolation of LF.92 Unfortunately, this method is insufficient for bovine milk matrix since it contains great amounts of β-LG which will also compete with LF for binding sites.

In recent years, membrane technology has been becoming more attractive and rapidly developed in food production, especially in the dairy sector. Membranes with specific pore sizes are widely used during diverse technological processes, e.g. microbial decontamination, defatting (microfiltration, MF), concentration and fractionation of whey proteins (ultrafiltration, UF), removal of low-molecular compounds, mainly salts, lactose, and peptides (nanofiltration, NF; reverse osmosis, RO).93 LF purification by the membrane separation approach is not implemented to such an extent as chromatographic technologies, but it also has a great perspective of application in large-scale production. To the major advantages of membrane processing should be included less impact of adsorption and diffusion effects during mass transfer in comparison to chromatographic methods.94 In addition, it enables high separation effectiveness and minimizes the risk of destruction, since samples are subjected to low-temperature conditions.95 Unfortunately, membrane separation becomes challenging in the case of macromolecules with similar molecular weights (such as BSA, 65–69 kDa; LPO, 77–90 kDa; and LF, 78–84 kDa).96 The selectivity of membrane adsorption technologies might be improved as a result of chemical modification of the membrane surface and attachment of specific functional groups. One such approach introduced the separation of milk proteins according to their electric properties with the use of charged membranes.97 Basic principles assume that proteins with the same net charge as the filtration membrane are retained due to electrostatic repulsions, while components having neutral or opposite-charged surfaces easily pass through the membrane barrier.98

Valiño et al.97 showed that pH manipulation allowed for the effective separation of individual proteins in BSA and LF mixtures. In the experiment, the diafiltration was performed by using charge-modified membranes made of regenerated cellulose (100 kDa cutoff). The authors reported that the most optimal fractionation of BSA was performed at pH 5 with the use of a positively charged membrane; however, LF was successfully isolated by application of a negatively charged membrane at pH 9.97 On the other hand, the separation at such conditions might be inefficient because it is known that the pI of LF varies in a wide range from 4 to 10 in dependence of the source of origin, level of glycosylation, the iron saturation state, or instrumental approach.99 Internalization of ion-exchange groups to the membrane surface, similar to ion-exchange columns, provides improved separation of LF from other milk proteins. Such an approach allows operation at high flow rates and minimal diffusion effects. For example, Plate et al. have demonstrated the separation of the LF–LPO mixture from sweet cheese whey by a membrane adsorber modified with sulfonic groups (Sartobind S).1 It was revealed that LPO was gradually eluted by increasing the ionic strength from 0.1 to 0.2 M NaCl, while the LF fractionation required 1 M NaCl eluent. The obtained product was characterized by 95% purity. In contrast, Teepakorn et al. performed the purification of LF from BSA by use of monolithic columns equipped with cation-exchange membranes, the same as previously described.95 In order to improve the LF recovery, the number of membranes equipped into the column was increased to 33. Elution with phosphate buffered saline (pH 6) provided a sufficient adsorption of positively charged LF on the stationary phase with the complete removal of negatively charged BSA molecules. On the other hand, the application of columns with monolithic material might be problematic due to poor reproducibility as a result of pore size heterogeneity. The combination of membrane and chromatographic techniques represents another progressive trend in the isolation of milk proteins. Lu et al. proposed an efficient two-step methodology aimed at large-scale LF isolation from bovine colostrum.100 Primarily, colostral whey was subjected to two-step UF on regenerated cellulose membranes with cutoffs of 100 and 10 kDa, respectively. In the second step, LF was eluted from the obtained filtrate using a cation-exchange SP-Sepharose column and phosphate buffer (pH 7.7). Remarkably, the combination of microfiltration with affinity chromatography enabled obtaining LF product with a final purity of 95%.101 A stable complex formed between LF and heparin Sepharose resin was subjected to microfiltration to remove the unbound protein fraction and other impurities. Finally, the target protein release was conducted by changing the buffer ionic strength. Thus, it is worthwhile to highlight that one of the most substantial advantages of combined isolation techniques relies on the possibility to obtain the product with higher recovery and at a higher purity grade.

The extracted LF fraction is typically subjected to dialysis (cutoff 12–14 kDa) for several days to remove salts and other contaminants. Alternatively, it might be concentrated by using the cross-flow filtration system Sartocon.1 Drying is a key step in the final preparation of lactoferrin which relies on receiving the powdered product ready for packaging. Among the most popular drying methods widely utilized in lactoferrin preparation, freeze drying (lyophilization) and spray drying might be distinguished. Although previously it was mentioned that drying plays a negligible role in the structural stability and functionality of lactoferrin, the recent studies showed by Morel et al. proved the opposite effect.106 The authors noticed that the spray-drying approach was more destructive in the case of bLF samples inducing the denaturation of 14–17% of the structure, while freeze drying caused only 7% of damage. Such a difference might be related to the extremely high temperature applied during spray drying (>140 °C) in contrast to freeze drying (≤40 °C). What is important is that the selected method had no visible impact on the protein bacteriostatic activity. According to results obtained by Wang et al., the freeze-drying technique was much more effective in water removal; thus the determined moisture content was only 2.7% (w/w) while it was about 5–9% (w/w) in the protein after spray drying.107 Remarkably, the degradation effects in the lactoferrin structure were not much evident as in the previously mentioned study, and they varied in the range 0.9–2.0%.

5. Recovery of Waste Products

As previously mentioned, the total amount of LF in cow milk is trace and varies at about 0.01–0.05% (w/w).108 Waste products derived as a result of LF production constitute the additional milestone in the industrial sector. The main goal of this issue involves the maximum engagement of byproducts obtained at every single stage in order to reduce the effects of environmental pollution and prevent economic losses. Generally, dairy waste might be divided into two categories: effluent and sludge.109 Milk fat, separated during milk microfiltration, might be utilized as a crucial element in the formulation of various dairy products, e.g. cream, cheese, cream cheese, butter, and anhydrous milk fat (AMF).110 Interestingly, the milk fat content plays a significant role in the creation of unique organoleptic features (taste, texture, color) in the final product.111 The recovered casein is characterized by a high nutritional value, which enhances its attractiveness in food manufacturing. Casein produced by acid precipitation is insoluble in water; thus it is preferably dissolved by the addition of a strong alkali, forming caseinates.112 Due to its unique structure, casein is widely utilized for the delivery of numerous bioactive compounds, stimulating the development of novel dietary supplements or pharmaceuticals.113 The whey fraction remaining after LF isolation represents a rich source of high-value proteins, e.g. α-LA, β-LG, SA, and Ig. Whey proteins are characterized by rich contents of essential amino acids which are easily absorbed by organisms and stimulate muscle protein synthesis.114 Recently, the production of functional beverages fortified with whey proteins for athletes is gaining in popularity.115 The major challenge in the spreading of these beverages is focused on the selection of the appropriate packaging and storage conditions to ensure the maximum stability of whey proteins and to prevent their denaturation and the loss of biological activity.

6. The Role of LF–Metal Interactions

Shortly after the isolation, the native protein is subjected to some chemical modifications in order to obtain an LF form with a desired level of iron saturation. LF desaturation is traditionally performed by dialysis against citrate buffer at pH <3.5 and then against deionized water. The described process is known as reversible; thus the protein resaturation might be carried out by mixing of apo-LF with ferric nitriloacetate (Fe-NTA) and then against deionized water in order to remove unbounded ions.35 As it was shown in previous studies, LF is characterized by the greatest thermal and conformational stabilities among the rest of the proteins from the transferrin family.116 Besides, the native structure of bLF exhibits a relatively high resistance in the presence of proteolytic enzymes.117 Many authors directly associated that phenomenon with the conformational specificity of binding sites between LF and TF. The release of iron ions occurs 100 times slower in LF compared to TF. Binding clefts of apo-TF, as a rule, possess a more wide-open conformation being exposed to the aqueous environment. On the contrary, the binding site located in the C-lobe of LF favors maintaining the closed conformation even during desaturation; therefore, the protein contact with the polar medium is always partly restricted.34 LF saturation accompanies the closure of binding clefts which occurs in both lobes.118 The greater percentage of bounded metal provides the growth of surface tension of LF; thus the holo form of the protein achieves a more compact structure.119 In contrast, Bluard-Deconinck et al. did not notice the obvious difference in iron-binding capacity between released N- and C-fragments of LF.120 Indeed, Lin et al. have related the changes in metal complexation between C- and N-sites of apo-hTF with different rates of bicarbonate insertion to each lobe.121 Ferric ions exhibited a more visible binding preference to the C-lobe compared with the N-lobe as the concentration of bicarbonate in the solution decreased. Baker as also pointed out the importance of hydrogen interactions in the dilysine pair (Lys206–Lys296) in the TF structure and its susceptibility to iron release.122 Remarkably, based on previous studies, the presence of a more compact conformation of the N-lobe in rTF and hTF than in bLF was reported.47 In this case, the conformational variations between LFs from other species were related to the specificity of amino acid composition and lobe orientation, but not to iron-binding affinity.47 In addition to this, SDS-PAGE analysis confirmed a higher susceptibility of the bLF structure to trypsin digestion than bTF, showing a greater degradation effect after enzyme treatment.123 Comparing both iron-saturated proteins, 41% of TF remained undigested after 24 h, while in the case of LF it was only 6%. Regarding this, TF could be a more compatible candidate for cellular iron uptake in contrast to LF.

The metal incorporation mostly affects the LF tertiary structure; however, a slight alteration in the secondary structure is also present.124 Based on CD studies, the determined ratios of α/β structures at pH 7 were equal to 20.0/59.0 and 11.5/70.0 for apo-LF and holo-LF, respectively.56 Indeed, Xia et al. reported that the percentage contents of the individual secondary structures in apo-LF and holo-LF were relatively similar and ranged about 18–20% of α-helix and 53–55% of β-structure.125

A characteristic feature of LF among other whey proteins is a comparatively high isoelectric point. Based on the UniProt database, the percentage content of basic amino acids (14.66%) in the bLF polypeptide chain is higher than that of acidic amino acids (11.03%). The protein surface contains regions with high concentrations of positive charge, such as the N-terminal region where the majority of basic amino acids are located.126 Although the protein isoelectric point is directly related to the amino acid composition, the level of iron saturation also has a great impact on the physicochemical nature of the protein surface and the charge distribution.127 As a result, the isoelectric points of apo-LF and holo-LF can vary due to differing availability of charged amino acids.30 For example, Lys637 located in the C1 domain and the Arg463 and Lys544 residues of the C2 domain are deeply buried in holo-LF, although they became more exposed in the cleft of the apo form.46 Isoelectric points of native LF and holo-LF determined by potentiometric titration were found in the range 8.0–9.0 and dropped to 5.7, in the case of apo-LF.119 The major reason for such a broad pI range for LF proteinmight also be related to the type of applied instrumental method, e.g. isoelectric focusing (IEF), two-dimensional gel electrophoresis (2D-PAGE), capillary isoelectric focusing (cIEF), and potentiometric titration. For example, IEF performed by Voswinkel et al. showed a negligible difference between the pI values of apo-bLF and holo-bLF, which were in the ranges 9.3–9.4 and 9.4–9.5, respectively.83 However, the study of Yoshida et al. carried out with the same technique reported the cationic character of bLF, whose pI ranged from 4.8 to 5.3.128 Potentiometric titration is another popular technique widely used for characterization of electrochemical properties of biomolecules which is based on the measurements of zeta potential in the wide pH range by gradual addition of strong acid/basis. Many aspects might be important during the analysis, predominantly the type of dispersion medium, ionic strength and the protein concentration.129 For, example Pryshchepa et al. determined that the pI of bLF dispersed in 0.09% (w/w) sodium chloride solution at the concentration of 1 mg/mL was at about 7.4.130 However, Valiño reported that the pI of bLF suspension (1 mg/mL) in 0.01 M NaCl medium (which is equal to 0.06% (w/w)) rose to 9.2.129

Despite iron, several studies have confirmed the ability of LF to interact with other metal ions, including Cu(II), Zn(II), Mn(III), Co(III), Ti(IV), and Ag(I).131,132 It has been reported that iron substitution with other metals induced exclusively minor changes in the hLF structure; thus their binding mechanisms are considered to be similar. Nevertheless, among all of them, iron was characterized with the highest binding affinity, indicating that the formation of LF–Fe complex is the most favorable.132 Indeed, even inconsiderable conformational modifications of LF in protein structure might cause fundamental changes of its biological activity. The previously mentioned metals belong to d-block elements (transition metals) which are frequently described as essential mediators of various biological processes in the human organism. Iron, copper, manganese, zinc, and copper act as protein inorganic cofactors required for activation of enzymatic reactions and for maintaining the structural stabilities of biomolecules.133 Besides, many metal–protein complexes mediate in the regulation of cellular metabolism, oxygen transport, and prevention of DNA damage.134 Importantly, metals are also capable of promoting the process of protein glycosylation.135 For example, Prabhu et al.135 pointed out that manganese and iron ions might be involved in the regulation of glycosylation pathways since they induce the activation of glycosylation enzymes.134 However, the direct impact of these metals on the glycosylation profile of LF has not been discovered until now.

7. LF Glycosylation

Protein glycosylation is a post-translation modification which has a fundamental influence on the biological activity of a macromolecule in different aspects, including structural stabilization, folding process, proteolytic resistance, immune response, signal recognition, bacterial adhesion, and antiviral activity.81 Glycans are considered the markers of evolution, and their structures and diversity at each position are specific to each species and are influenced by different factors. Milk contains such glycosylated components as LF, κ-CN, immunoglobulins (IgG, IgA, IgM), α-LA, and LPO.136,137 Glycosylation plays a crucial role in the physicochemical characteristics of bLF, particularly the molecular weight and ionic charge. The molecular mass of bLF is variable throughout seasonality, the lactation period, and the cow’s feeding. All of the mentioned factors contribute to the difference in carbohydrate composition and glycosylation level of a biomolecule. For instance, the overall number of N-glycans has decreased from 41 to 22 after the transition of the colostrum into mature milk.13 Besides, the structural diversity of the detected glycans might be affected by the type of applied mass spectrometry technique (MALDI-TOF/MS, ESI-MS).

Glycans in proteins are composed of N-acetylglucosamine (GlcNAc), N-acetylgalactosamine (GalNAc), sialic acid (NeuAc), mannose (Man), galactose (Gal), and fucose (Fuc) monosaccharide residues. Monosaccharide units linked in a particular order represent a glycan chain. Generally, the N-type of glycosylation is only present in the case of the LF molecule, which implies that glycan chains are covalently attached to the nitrogen atom of the asparagine side chain via GlcNAc.136 The glycan core consists of two GlcNAc and three Man residues. Three types of N-glycosylation are distinguished, e.g. complex, hybrid, and high mannose. This classification is based on the carbohydrate moieties associated with the glycan core. The heterogeneity of glycan chains is predominantly affected by enzyme expressions in the bovine mammary gland (mainly, glycosyltransferases and glycosidases), lactation period, and availability of protein substrate.12,138,139 Complex and high mannose are the dominating types of glycosylation in the cow’s mature milk.140

Glycan content in the C-lobe was higher than that in the N-lobe, including three glycan chains.47 Asn368 is linked with one unit of GlcNAc and Asn476 is bounded to one unit of α-1,4-Man and two units of GlcNAc; however, the most glycosylated residue was Asn545, which is connected to four units of α-1,4-mannose and two units of of GlcNAc.58 Based on the number of glycosylation sites, LF can be classified into LF-a and LF-b. Four completely glycosylated distinct N-linked glycosites (Asn233 is located in the N-terminal while Asn368, Asn476, and Asn545 are found in the C-terminal) are present in LF-b.141 Despite all mentioned, LF-a has a fifth potential glycosite which is found at the Asn281 position. The LF-a form is more abundant in bovine colostrum than in mature milk (glycosylation levels are 30 and 15%, respectively).142 Both molecular forms might be separated by use of cation-exchange chromatography with carboxymethyl resin. SDS-PAGE electrophoresis verified a greater size of LF-a (84 kDa) in comparison to LF-b (80 kDa) as a result of additional glycan units at the Asn281 residue.143 The structure of the glycan chain linked to Asn281 was found to be heterogeneous involving GlcNAc, GalNAc, Man, Gal, and Fuc moieties.142 bLF-b was about 10 times less resistant toward trypsin digestion than bLF-a. Thus, the glycan chain at the Asn281 position may actively participate in the stabilization of the protein structure by limiting the availability of basic amino acid residues to enzymatic action.

Despite N-glycan attached at the Asn281 position, other chains also may contribute to the stability of the protein’s three-dimensional structure. Indeed, the glycan chain at Asn545 is arranged between two domains; thus it can easily participate in interactions with protein amino acids.60 It has been observed that this type of “protein–glycan” interactions prevents the release of metal ion at lower values of pH and protect bLF against proteolysis, enhancing the rigidity of the C-lobe conformation. On the other hand, Van Berkel et al. showed no difference in iron-binding capacity between glycosylated and nonglycosylated forms of hLF.144

The origin of LF is a crucial factor which affects the composition and heterogeneity of glycan chains. It was reported that bLF contained a high amount of sialylated N-glycans, while fucose residues occurred predominantly in hLF.145 The content of sialylated N-glycans was higher in bovine milk compared to human and goat milk.93 Sialic acid in the glycan chain might be responsible for the maintenance of metal in the protein structure. Desialation of human LF by neuraminidase treatment induced the alteration in the iron-binding capacity of bLF; thus the LF saturation level was 3-fold reduced.146 Interestingly, that resialation provided partial restoring of the initial amount of bounded metal. Besides, sialic acid is known as the only charged saccharide present in LF, which is traditionally linked in the terminal position of complex or hybrid N-glycans. Consequently, it can be assumed that these carbohydrate residues are capable of modifying the surface charge in glycosylated proteins. For example, Shimazaki et al. related the difference in pI values of bLF isolated from mature milk (pI 8.94) and colostrum (pI 8.3–8.52 and pI 8.18–8.32) with different contents of sialic acid in the protein.99 The phenomenon of charge heterogeneity observed in the pI of colostral LF also could be associated with some variations in the glycosylation profile. Importantly, the distribution of negative charge in bLF molecules was increased after the sugar release (deglycosylation). Analogically, Barrabés et al. noticed that a higher content of sialic acid has a tendency to shift the protein isoelectric point to lower values.147

The role of glycosylation in the protein structure is not completely understood until now. The monosaccharide diversity of LFs from different species may contribute to protein biological activity. In particular, this feature can influence the antibacterial potential of bLF. For example, Karav reported that the complete deglycosylation of LF significantly reduced its antimicrobial action against E. coli DH5a strains.148 It was shown that apo-LF-a had higher antibacterial activity compared to apo-LF-b, indicating the importance of additional glycan at Asn281.143 Various studies have noticed that sialic acid is capable of indirectly interacting with the outer membrane of Gram-negative bacteria. The highly acidic character of sialic acid ensures an effective chelating of calcium ions from lipopolysaccharides leading to destabilization of the bacterial membrane.149 On the other hand, it was shown that in the presence of diasialated hLF the adhesion of Salmonella enterica significantly increased.12 Deasialated bLF exhibits higher antiviral activity against rotavirus infection than native bLF. Treatment by deglycosylated and desialated bLF showed a more effective inhibition of influenza virus infection, especially at the initial step of viral invasion.150 It was suggested that deasilation facilitates the interaction between anionic cellular membrane and bLF; thus the protein becomes more competitive for host cells binding. Furthermore, sialic acid removal enhances the bLF–virus interactions which is leading to prevention of the binding of viral particle to cellular receptor.151 It was reported that the highly fucosylated N-glycan core in human milk positively influences the gut microbiota of infants, reduces the number of pathogen infections, and promotes the growth of beneficial Bifidobacterium and Lactobacillus strains.152

8. Multi-instrumental Approach for LF Characterization

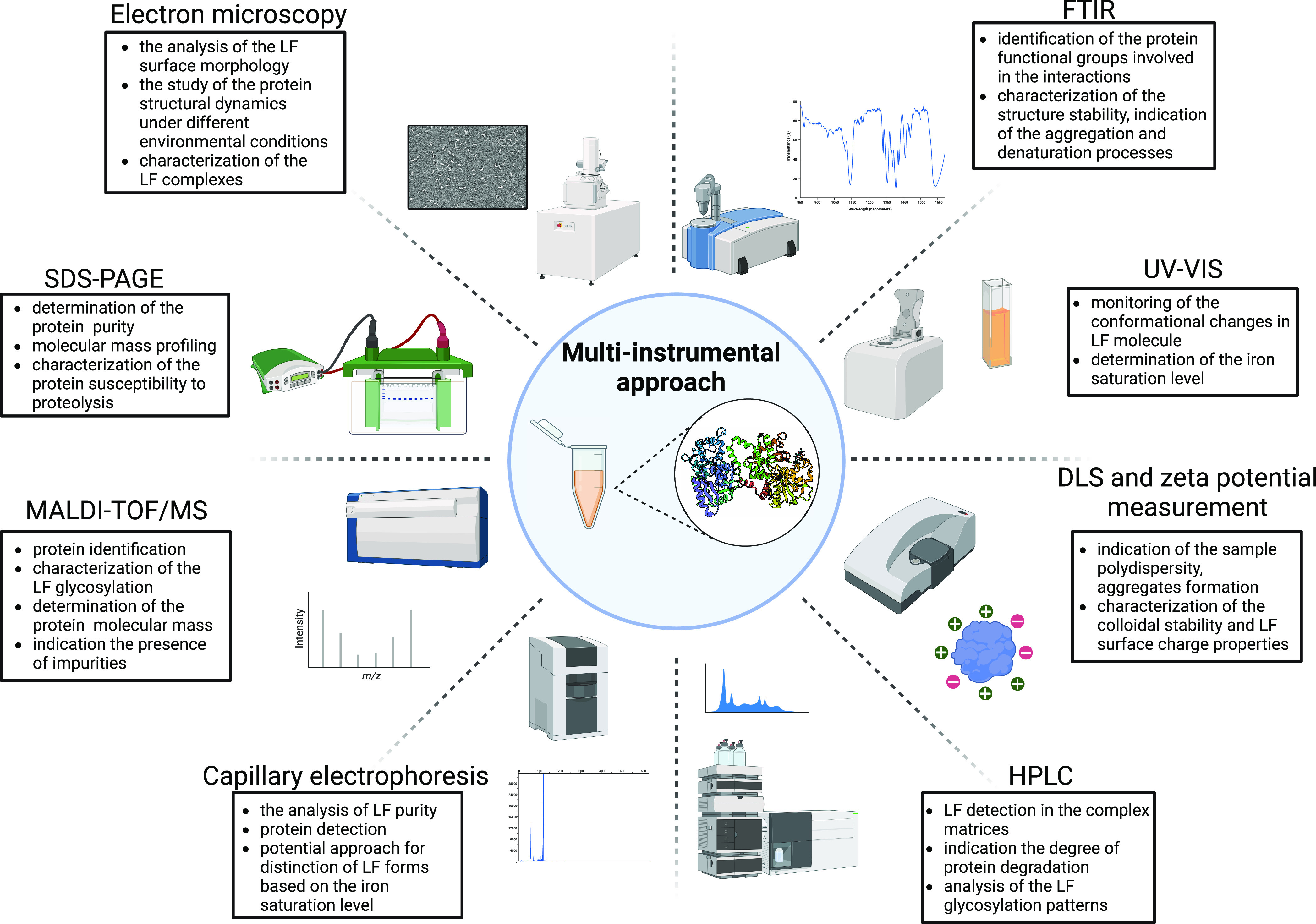

The application of a series of instrumental techniques enables the comprehensive characterization of native LF as well as its complexes, including the molecular mass, isoelectric point, metal saturation level, unfolding degree, secondary structure composition, and conformational stability (Table 2). Besides, the combination of the appropriate analytical techniques will provide the information on the most unknown aspect of LF structure—glycosylation. To the most relevant tools commonly used in the context of LF research are included spectroscopic, electromigration, crystallographic, chromatographic, microscopic, calorimetric, and spectrometric techniques (Figure 3). The advanced instrumental studies on lactoferrin are necessary for the establishment of the relationship between protein structure and its functionality. The present section aims to display the specific details of the methods and the possible issues and challenges during LF detection.

Table 2. Specification of the Relevant Instrumental Techniques for LF Characterization.

| protein characteristic | instrumental technique | classification of the instrumental technique | specific details | applied conditions for LF detection | ref |

|---|---|---|---|---|---|

| molecular mass | SDS-PAGE | electromigration | The key principle of the separation relies on the different mobility of the charged particles under an electric field that appear as a result of the difference in their molecular sizes. The molecular mass of bLF varies in the range 78–91 kDa in dependence of the source of isolation and glycosylation state. | protein separation in 4–12% polyacrylamide gel; reducing agent, 2-mercaptoethanol; running buffer, 1× MES; voltage, 200 V; time of separation, 22 min; gel staining, Coomassie Blue R-350 | (11, 131) |

| MALDI-TOF/MS | spectrometric | MALDI is a soft ionization technique. The appropriate chemical substance is the matrix, which mediates in the energy transfer from laser beam to analyte and then enables its desorption and ionization. LF mass was found at about 82–84 kDa in dependence on the stage of lactation. | MALDI-TOF/TOF mass spectrometer UltrafleXtreme (Bruker Daltonics); laser, Nd:YAG (355 nm); laser frequency, 2 Hz; matrix solution, sinapic acid dissolved in 30:70 (v/v) mixture of acetonitrile and 0.1% trifluoroacetic acid (TFA)—TA30; m/z range, 10–100 kDa | (13, 130) | |

| iron saturation level | UV–vis | spectroscopic | The total LF concentration is recorded at 280 nm. The characteristic band at 465 nm indicates the iron(III) coordination by LF. The calculation of absorbance ratio A465/A280 is relevant for determination of the iron saturation level of LF. | UV300 spectrophotometer (Thermo Scientific, USA); path length of quartz cuvette, 1 cm | (153) |

| ICP-MS | spectrometric | In contrast to UV–vis, ICP-MS analysis is considered more accurate for determination of the negligible amount of bounded iron in LF (<2%). | samples of LF in mineralized HNO3 analyzed by ICP-MS ELAN spectrometer (PerkinElmer, USA); plasma gas, Ar; gas flow, 15 L/min | (57) | |

| particle charge properties | zeta potential measurements | spectroscopic | Electrophoretic mobility was determined based on the Henry equation. The zeta potential was calculated according to the Smoluchowski approximation. The measured zeta potential is highly influenced by the type of electrolyte (NaCl, KCl) used and ionic strength. | Malvern Nano-ZS ZetaSizer (Malvern Instru ments, U.K.); temperature, 25 °C; cuvette, DTS1070; equilibration time, 2 min | (129, 154) |

| IEF | electromigration | Different pI values determined by IEF also might be a matter of the selected separation conditions, e.g. the type of carrier ampholyte (CA), pI marker, buffer composition, and separation time. The possibility of distinction of several LF fractions is based on their pI values. | Multiphor II apparatus (Amersham, Freiburg, Germany); precast gels Servalyt and Blank precotes (Serva, Germany); gel parameters, 126 × 125 × 0.3 mm; temperature, 5–8 °C; voltage, 2000 V; current, 6 mA; power, 12 W | (59, 83) | |

| three-dimensional molecular structure | XRD | crystallographic | XRD provides a detailed insight into the protein’s three-dimensional structure. It indicate the possible metal-binding sites and their geometry, and it is essential for understanding the structural difference between apo- and holo-LF. XRD enables the verification of bLF stability under various environmental conditions. The technique is considered a basis of drug design and development. | synchrotron beamline BM14 at European Synchrotron Radiation Facility (Grenoble, France); space group, P21; cell dimensions, a = 75.8 Å, b = 49.4 Å, c = 97.9 Å; resolution range, 2.42–38.7 Å | (46, 60) |

| secondary structure | CD | spectroscopic | The assignments of individual secondary structures are found in the following ranges: (1) 190–195 nm (max), 208 nm (min), and 220–222 nm (min) for α-helix; 195–200 nm (min) and 215–218 nm (max) for β-sheet. The monitoring of elipticity at 220 nm is frequently to estimate the protein denaturation. | spectropolarimeter J-720 (JASCO, Tokyo, Japan); path length of quartz cell, 10 mm; UV region, 190–260 nm; scan speed, 50 nm/min; temperature, 25 °C | (155) |

| FTIR spectroscopy | spectroscopic | Amide I is considered the most relevant for secondary structure profiling: 1660–1650 cm–1 (α-helix), 1650–1640 cm–1 (random coils), 1680–1670 cm–1 (β-turn), 1690–1680 cm–1 and 1640–1630 cm–1 (β-sheet). Different deconvolution approaches, including Gaussian and Lorentzian fitting, second derivatives with appropriate software program (OMNIC, OriginPro, PeakFit) are frequently used in calculations of the contributions of individual structures in proteins. | FTIR spectrometer (NEXUS, Nicolet, USA) in attenuated total reflectance (ATR) mode; spectral range, 4000–650 cm–1 | (116, 125) | |

| Raman spectroscopy | spectroscopic | The region of 1700–1620 cm–1 was selected for distinction of each type of secondary structure. In contrast to the FTIR technique, Raman spectroscopy is more sensitive to samples containing nonpolar functional groups and is less influenced by interferences caused by hydrogen bonding between analyte and water molecules. | JASCO NRS-2000C; excitation, Ar+ laser (514 nm); detector, charge-coupled device (160 K); spectral resolution, 4 cm–1 | (71) | |

| changes in the tertiary structure | fluorescence spectroscopy | spectroscopic | Aromatic amino acids constitute about 9% of the total sequence in the bLF polypeptide chain. The measurement of the fluorescence intensity ratio F330/F350 is related to protein destabilization, unfolding, and the exposure of aromatic amino acids to a polar microenvironment. | Cary Eclipse spectrofluorimeter (Varian, Middelburg, The Netherlands); emission range, 300–400 nm; path length of quartz cuvette, 1 cm | (73, 156) |

| aggregation state | DLS | spectroscopic | Destabilization processes such as protein unfolding and formation of larger aggregates accompany a considerable increase of single particle size up to 30 nm. The protein hydrodynamic size was calculated according to the Stokes–Einstein equation. | Malvern Nano-ZS ZetaSizer (Malvern Instru ments, U.K.); temperature, 25 °C; backscatter angle, 173°; cuvette, rectangular polystyrene cell (10 mm path length); equilibration time, 2 min | (72, 157) |

| SEC | chromatographic | SEC is the appropriate technique for the evaluation of sample purity. The appearance of the additional fractions might indicate the tendency of LF to self-associate or the ability to form complexes with other milk proteins. | SEC-HPLC system (Agilent Technologies, USA); detector, diode array detector; column, TSKgel G3000SWXL (7.8 × 300 mm, 5 μm, Tosoh Biosciences LLC, USA); flow rate, 0.5 mL/min; temperature, 22 °C; elution type, isocratic; mobile phase composition, 30% (v/v) acetonitrile and 0.1% (v/v) | (72) | |

| TEM | microscopic | TEM determines the morphologies of protein aggregates (amyloid fibrils, amorphous aggregates). It provides the insight into the mechanism of protein aggregation. | JEOL JEM 1010 electron microscope (Tokyo, Japan); accelerating voltage, 80 keV; sample placement, Formvar carbon-coated nickel grid (200 mesh) | (64) | |

| glycosylation patterns | MALDI-TOF/MS | spectrometric | The protein sequence analysis as well as its structural modifications might be determined based on the characteristic peptide mass fingerprint (PMF) signal list obtained by the appropriate software (Mascot, Sequest). MALDI tends to generate singly charged ions and better tolerates salts and other impurities. The amount of N-glycans was explored by deglycosylation. | MALDI-TOF/TOF MS spectrometer (Bruker Daltoniks GmbH, Germany); laser, nitrogen (337 nm); matrix solution, 2,5-dihydroxybenzoic acid (DHB) (10 mg/mL) in 50:50 (v/v) mixture of acetonitrile and water for glycopeptide analysis; mode, reflector positive ion (neutral N-glycans), linear positive ion (glycopeptyde), linear negative ion (sialated N-glycans) | (158) |

| LC–ESI-MS | chromatography coupled with mass spectrometry | The liquid samples subjected to the ESI process aimed to generate gas phase ions typically undergo ionization under high voltage in the metal capillary which is followed by solvent evaporation. ESI favors the formation of large hydrophobic peptides with charge states ranging from +2 to +4, providing more detailed fragmentation patterns. A salted sample might provide evident signal suppression. ESI-MS characterizes by exceptional sensitivity to slight impurities, for example salts, that is expressed by a higher tendency of formation of charged adducts which might also suppress the signal intensity from analyte. | HPLC system (Datasystem Millennium, HPLC pumps Waters 510, detector Waters 486); column, C18 Vydac (250 × 10 mm, 5 μm); gradient elution, 0.01% TFA (solvent A) and 0.07% TFA in 95% acetonitrile (solvent B); flow rate, 3.5 mL/min; single quadrupole mass spectrometer (Micromass); scanning range (m/z), 300–1600 | (151) | |

| thermal stability | DSC | calorimetric | The significant difference in thermal resistance of LF is in dependence on iron saturation. The different ratio of apo- and holo-LFs is capable of modifying the thermal stability of native protein. | device, differential scanning calorimetry (DSC1 STARe System, METTLER TOLEDO, Schwerzenbach, Switzerland); heating range, 25–100 °C; scanning rate, 10 °C/min (nitrogen flow) | (119) |

| LF–ligand interactions | ITC | calorimetric | ITC is used for the investigation of the mechanism of interactions (affinity, stoichiometry, thermodynamics) between LF and other molecules, especially metals. Based on the determined thermodynamic parameters, the character of LF–ligand interactions (electrostatic, hydrophobic, hydrogen bonding, van der Waals forces) is evaluated. | VPITC microcalorimeter (MicroCal VP-ITC, Malvern Panalytical, Malvern, U.K.); sample cell, LF (1.425 mL); reference cell, MES buffer (pH 5.5); total number of injections, 58 (5 μL each); injection timing, 10 s; interval, 200 s | (157, 159) |

Figure 3.

Multi-instrumental approach for studying lactoferrin protein. Created with BioRender.com.

8.1. Spectroscopic Techniques

8.1.1. Ultraviolet–Visible (UV–vis) Spectroscopy

UV–vis spectroscopy is known as one of the most popular methods for studying the iron-binding properties of lactoferrin. The measurements of the absorbance relationship A465/A280 can be helpful in the distinction of the degree of iron saturation in bLF.153 Generally, the decrease of the absorption intensity ratio indicates the release of ferric ions from the complex. Remarkably, different glycosylation levels of hLF do not contribute significant changes in UV–vis spectra.160 The analogical mechanism of cation−π interactions induced the rise of the absorption peak in the case of lactoferrin complexes with copper(II), manganese(III), and cobalt(III) ions at the following wavelengths: Cu–LF 438 nm (ε = 4800 mol–1 L cm–1), Mn–LF 435 nm (ε = 9620 mol–1 L cm–1), and Co–LF 405 nm (ε = 10 340 mol–1 L cm–1).161,162 Remarkably, that characteristic LMCT band was not present after the addition of Mn(II) and Co(II) ions, which might be related to the coordination of these metals to other binding sites in the LF molecule, not including deprotonated tyrosine residues.160 Lucas studied protein spectral properties in the presence of Li+, Na+, and Cs+ ions. The authors reported that the change of the absorption peak position was mainly influenced by hydrogen interactions and proton transfer between metal cations and the tyrosyl group.163 Indeed, UV–vis spectroscopy is characterized by the much lower sensitivity of iron quantification in comparison to the ICP-OES and ICP-MS techniques. Bokkhim et al. reported that the absorption peak at 465 nm was not visible during the detection of apo-LF.164 Despite this, the application of the UV–vis approach is limited in the case of supersaturated LF complexes. According to a basic assumption, holo-LF is capable of binding a maximum of two ferric ions (qm 1.4 mg/g); however, Pryshchepa et al. found the 54 total iron-binding sites (qm 36.3 mg/g) in one bLF molecule.165

8.1.2. Fluorescence Spectroscopy

Fluorescence spectroscopy allows the determination of the stability of LF conformation and indicates unfolding processes. Destabilization effects related to protein interactions with metals might be confirmed by the red shift of fluorescence emission maxima from 330–340 nm to 350–355 nm.166 The pH-induced exposure of aromatic amino acids is commonly corresponding to the denaturation of the polypeptide chain. For example, the emission maxima of apo- and holo-LFs at pH 2 were detected at 353 and 348 nm, respectively.56 Measurements of the fluorescence intensity ratio F330/F350 allow indication of the degree of protein unfolding upon different physicochemical conditions.73 For instance, the intrinsic fluorescence might be helpful for monitoring the conformational alterations in the protein structure during iron chelation. As it was previously reported, the level of metal saturation is another factor which affects the position of the LF emission peak. Thus, Wang et al. noticed the characteristic band of apo-LF at 336 nm, while in the case of holo-LF it was shifted to 343 nm, indicating the exposure of tryptophan to a more polar environment.156 Similar results were reported previously by Sreedhara et al. that indicated the maximum emissions at 337.07 and 342.96 nm, for apo-LF and holo-LF, respectively.56 Remarkably, Moshtaghie et al. did not observe any difference in the position of the emission band (λem 355 nm) between apo- and holo-LFs; nevertheless, the fluorescence intensity decreased (quenched) to 35% after the addition of metal.167 The presence of metals has a tendency to reduce the fluorescence (quenching) of the LF molecule. Previously, Harrington et al. related the fluorescence quenching induced by Fe(III), Mn(III), and Co(III) ions to intermolecular energy transfer which corresponds with specific interactions of metal ions with tyrosine residues and conformational changes around LF binding sites.132 Ainscough et al. showed that among all of cations, ferric ions were the most effective quenchers, probably because of their the highest binding capacity to LF.168 The analysis of the protein fluorescence quenching is made with the Stern–Volmer relationship, which is expressed by eq 1:

| 1 |

where F0 is the protein fluorescence intensity in the absence of quencher, F is the protein fluorescence after the addition of quencher, Kq is the Stern–Volmer quenching constant [M–1], and [Q] is the molar concentration of the quencher [M].

The mentioned model is capable of delivering the essential information on the binding affinity and stoichiometry of complex formation. The major problem that arises in studying LF conformational changes upon iron saturation is based on the nonlinear behavior of the Stern–Volmer plot.168 This phenomenon might be explained by the accessibility of fluorophores located in two potential binding sites and their different abilities to interact with metal ions.169 Therefore, the results obtained by spectrofluorimetry seem to be complicated for interpretation of the mechanism of Fe–LF complex formation. In this case, experimental conditions, e.g. temperature, solvent type, pH, and concentrations of protein and ligand, should be carefully controlled, since all of these factors might affect the plot linearity.

8.1.3. Fourier-Transform Infrared (FTIR) Spectroscopy