Abstract

The COVID-19 pandemic is currently causing a severe disruption and shortage in the global supply chain of necessary personal protective equipment (e.g., N95 respirators). The U.S. CDC has recommended use of household cloth by the general public to make cloth face coverings as a method of source control. We evaluated the filtration properties of natural and synthetic materials using a modified procedure for N95 respirator approval. Common fabrics of cotton, polyester, nylon, and silk had filtration efficiency of 5–25%, polypropylene spunbond had filtration efficiency 6–10%, and paper-based products had filtration efficiency of 10–20%. An advantage of polypropylene spunbond is that it can be simply triboelectrically charged to enhance the filtration efficiency (from 6 to >10%) without any increase in pressure (stable overnight and in humid environments). Using the filtration quality factor, fabric microstructure, and charging ability, we are able to provide an assessment of suggested fabric materials for homemade facial coverings.

Keywords: face masks, facial coverings, COVID-19, aerosols, triboelectricity, cloth filtration efficiency

Graphical Abstract

The coronavirus disease 2019 (COVID-19) pandemic has caused more than six million confirmed infections and major global disruptions to daily life.1 The disease is caused by infection with the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2). The virus appears to be highly infectious and a major mode of transmission is thought to be spread from an infected person releasing virus-filled fluid droplets that may shrink due to evaporation and thereby aerosolize.2-5 Larger particles >5 μm in diameter typically settle due to gravity and usually reach only the upper respiratory tract if inhaled. Meanwhile, fine particles with diameter <5 μm can critically reach the lower respiratory tract.3,4,6 A detailed discussion of the symptoms as well as transmission are discussed in the Supporting Information.

For airborne particulates, including viral aerosols, the U.S. Centers for Disease Control and Prevention (CDC) recommends the use of N95 filtering facepiece respirators (FFR) as respiratory protection.7-9 The N95 FFR designation is determined by the CDC’s National Institute for Occupational Safety and Health (NIOSH) and indicates a minimum filtration efficiency of 95% for particle sizes 0.022–0.259 μm (count median diameter of 0.075 ± 0.02 μm), according to 42 Code of Federal Regulations (CFR) Part 84.10 As the viral aerosols are larger than the ~0.120 μm virus itself,11 N95 respirators are expected to provide suitable protection.12,13 Meanwhile, medical face masks are used by healthcare workers during medical procedures to protect both the patient and the healthcare workers from the transfer of infectious micro-organisms, body fluids, and particulate material. These masks are not recommended by the World Health Organization or the CDC for aerosol generating procedures.9,14 A more detailed discussion of the approval requirements and usage of these two types of masks is given in the Supporting Information.

The widespread and intense response to caring for patients during the pandemic has led to disruptions of the global supply chain and shortage of appropriate personal protective equipment (PPE), especially a shortage of N95 FFRs for healthcare workers.15,16 The WHO has recommended rationing the use of PPE and prioritization of PPE during severe shortages with FFRs reserved for healthcare professionals, leaving the general public without easy access to high-grade personal protective equipment.17 During critical supply shortages, the possibility of disinfection and reuse of disposable FFRs has been proposed.18 The CDC has recommended use of cloth face coverings (the WHO refers to these as “non-medical masks”) by the public to slow the spread of the virus, especially when social distancing measures are difficult to maintain.19 These cloth face coverings can be fashioned from household items at a low cost and used as an additional control option to limit the release of larger infectious droplets from the wearer.20,21 As some local governments are requiring the public to use cloth face coverings, it is reasonable to investigate what readily available and inexpensive materials may provide the public with some degree of protection against airborne viruses. The cloth mask material and construction would not be approved by NIOSH as an N95 FFR unless all applicable requirements of 42 CFR Part 84 were met.

We evaluated the filtration efficiency and pressure drop of common household materials of natural and synthetic origin using a modified version of the NIOSH standard test procedure with 0.075 ± 0.02 μm (count median diameter) NaCl aerosols (fabric samples were not preconditioned in any way and the flow rate was substantially reduced). The testing here did not account for real-world scenarios where the leakage around the edges of the face cover may significantly impact the actual effectiveness of these coverings. Hence, having a tight seal of the cloth around the face is imperative for these results to align with real usage conditions. All tests were conducted on an Automated Filter Tester 8130A (TSI, Inc.) with a flow rate of 32 L/min (unless otherwise specified). While FFR testing uses a flow of 85 L/min to simulate high intensity, a flow rate of 32 L/min was chosen which is similar to that in typical human breathing.22 The filtration efficiency is the percentage of NaCl particles filtered by the material and the pressure drop is the air resistance across the filter material. Lower pressures indicate higher breathability. Additional information may be found in the Methods of the Supporting Information.

A commonly used filtration quality factor () to determine the filter’s performance is defined23

where , is the filtration efficiency (in %), and is the pressure drop across the filter (in kilopascals). A maximum results from a high filtration efficiency (low penetration) with low pressure drop, which is sensible for facial coverings. In addition, is not theoretically altered if multilayers of a singular type of filter material are considered, as penetration is multiplicative and pressure is additive.

Common household materials’ filtration properties are given in Table 1, optical images in Figure S1, and scanning electron microscope (SEM) images are given in Figure 1. The sources of the materials are given in the Methods. For reference as to how common household materials compare to PPE materials, one respirator media (polypropylene 1) and two medical face mask media (polypropylene 2 and 3) were also tested. The quality factor of the respirator grade polypropylene 1 is ~160 kPa−1 and far exceeds any of the other materials. While previous reports show that surgical mask filtration efficiency can vary from 10 to 96% (85 L/min air flow),24 we were only able to obtain two medical face mask brands, both of which had a filtration efficiency of ~20–30% ( kPa−1).

Table 1.

Evaluation of Reference and Common Materials’ Filtration Propertiesa

| material | source | structure | basis weight (g·m−2) |

bulk density (basis weight/thickness) (g·m−2·μm−1) |

initial filtration efficiency (%) |

initial pressure drop (Pa) |

filter quality factor, (kPa−1) |

|---|---|---|---|---|---|---|---|

| Personal Protection Materials | |||||||

| polypropylene 1 | particulate FFR | meltblown (nonwoven) | 25 | 0.17 | 95.94 ± 2.00 | 9.0 ± 2.0 | 162.7 ± 21.3 |

| polypropylene 2 | medical face mask | meltblown (nonwoven) | 26 | 0.21 | 33.06 ± 0.95 | 34.3 ± 0.5 | 5.0 ± 0.1 |

| polypropylene 3 | medical face mask | meltblown (nonwoven) | 20 | 0.20 | 18.81 ± 0.50 | 16.3 ± 0.5 | 5.5 ± 0.1 |

| Household Materials | |||||||

| polypropylene 4 (PP-4) | interfacing material, purchased as-is | spunbond (nonwoven) | 30 | 0.26 | 6.15 ± 2.18 | 1.6 ± 0.5 | 16.9 ± 3.4 |

| cotton 1 b | pillow cover | woven | 116 | 0.57 | 5.04 ± 0.64 | 4.5 ± 2.1 | 5.4 ± 1.9 |

| cotton 2 b | clothing (t-shirt) | knit | 157 | 0.37 | 21.62 ± 1.84 | 14.5 ± 2.1 | 7.4 ± 1.7 |

| cotton 3 b | clothing (sweater) | knit | 360 | 0.45 | 25.88 ± 1.41 | 17.0 ± 0.0 | 7.6 ± 0.4 |

| polyester | clothing (toddler wrap) | knit | 200 | 0.38 | 17.50 ± 5.10 | 12.3 ± 0.5 | 6.8 ± 2.4 |

| silk | napkin | woven | 84 | 0.54 | 4.77 ± 1.47 | 7.3 ± 1.5 | 2.8 ± 0.4 |

| nylon | clothing (exercise pants) | woven | 164 | 0.70 | 23.33 ± 1.18 | 244.0 ± 5.5 | 0.4 ± 0.0 |

| cellulose 1 | paper towel | bonded | 42.9 | 0.33 | 10.41 ± 0.28 | 11.0 ± 0.0 | 4.3 ± 2.8 |

| cellulose 2 | tissue paper | bonded | 32.8 | 0.39 | 20.2 ± 0.32 | 19.0 ± 1.0 | 5.1 ± 3.2 |

| cellulose 3 | copy paper | bonded | 72.8 | 0.76 | 99.85 ± 0.02 | 1883.6 ± 39.3 | 1.5 ± 0.2 |

All materials were tested in samples of three unless denoted. Uncertainties denoted here represent the standard deviation between the samples. Materials in bold were further studied to investigate if the simple triboelectric charging can positively impact the filtration properties. For the particulate FFR sample, the meltblown is independently procured for usage in FFRs as it is difficult to obtain enough sample to test with the filter tester.

Indicates this sample did not have enough material and data is presented in samples of two.

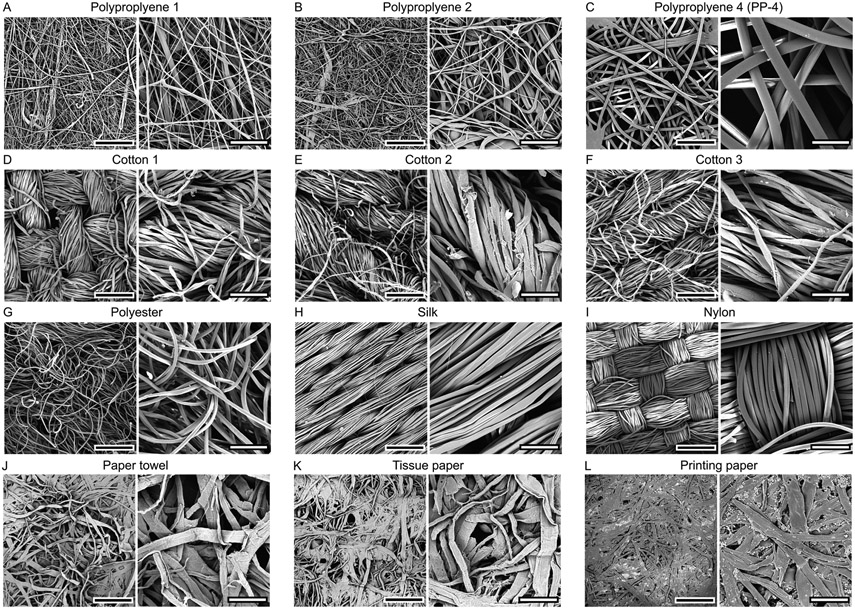

Figure 1.

SEM images of the microscopic structure of various household materials. All images are given in pairs. The first of the pairs has a scale bar (left, black bar in white background) corresponding to 300 μm. The second of the pairs has a scale bar (right, white bar in black background) corresponding to 75 μm. (a–c) Polypropylene samples from PPE (a,b) and common spunbond (c). (d–f) Cotton samples, as given in Table 1. (g–i) Polyester, silk, and nylon samples, respectively. (j–l) Other cellulose-based products, paper towel, tissue paper, and printing paper, as per given in Table 1.

From the microscopic images in Figure 1a,b, the PPE meltblown nonwoven has microfibers of various diameters, typically around 1–10 μm with large distances between fibers (tens of microns). The structure is bulky and clearly three-dimensional with multilayers of fibers. In contrast, the polypropylene spunbond (PP-4) sample (Figure 1c), is composed of relatively uniform fibers of size ~20 μm. The nonwoven structure makes for a random network of fibers with select spots that are bonded together (left corners in Figure 1c). The spunbond PP-4 has a large pore size reaching ~100 μm. Both of these nonwoven structures with random fiber networks have a large porosity and lower pressure drops. Though PP-4 has a lower filtration efficiency due to the larger fiber diameter and pores compared to the other polypropylenes, its kPa−1 is among the highest in Table 1. We note a large difference in and filtration efficiency between polypropylenes 2 and 3 (Figure 1b as representative) and polypropylene 1, even though all are produced from the meltblown process. This most likely resulted from the difference in electrostatic charge (discussed later in the text).

Previous reports show that cloth face coverings had 10–60% instantaneous penetration levels when challenged with polydisperse NaCl aerosols.25,26 In this study, the cotton samples taken from common household materials all exhibited similar , though they had various construction and filtration efficiencies. Microscopically, we see that Cotton 1 has a finer fiber diameter (~10 μm) compared to Cottons 2–3 (~20 μm). All the fibers are bundled into yarns of similar size, ~150 μm. However, in Cotton 1 (Figure 1d) clear pores of ~100 μm can be observed, whereas in Cotton 2 and 3 (Figure 1e,f) there are no such clear pores and yarn-to-yarn gaps are not as apparent. The clear pores in Cotton 1 can leak both particles and air through, which explains why it has much lower filtration efficiency of ~5% and lower pressure drop of ~2.5 Pa, compared to Cotton 2 and 3 (20–26% filtration efficiency, 14–17 Pa pressure drop). Based on the data in Table 1, the basis weight and density are not clearly related to the efficiency, as Cotton 3 has nearly double the basis weight of Cotton 2, but the filtration efficiency increase is only moderate. We note that the Cotton 2 and 3 filtration properties were comparable to some grades of medical face masks. As cotton is a very common material for clothing, it would be beneficial to the public to select cotton construction with the highest filtration quality factor. The cotton should be woven/knit at a high density such that there are no visible pores under light. If a lower density cotton is used, it may be best to use multilayers.

Among polyester, silk, and nylon, the most apparent feature is the high thread count in the nylon sample, leading to the high pressure (>200 Pa, whereas most other materials are <20 Pa). The nylon fibers are approximately 10 μm in diameter and in bundles of 200 μm (Figure 1i). It may be possible to procure nylon with a lower thread count, resulting in a lower pressure drop and higher , and it may be more suitable for facial coverings. Comparatively, we can see that the polyester sample (fleece-like fabric source) is composed of more randomly oriented fibers of 10 μm on the surface (Figure 1g). The polyester is comparable to cotton’s and has similar filtration efficiency to some cotton fabrics (dependent on bulk density). Silk is composed of similar fiber sizes and yarns of 100 μm (Figure 1h). From the SEM images, the silk sample has gaps between the yarns of ~50 μm, which led to the leaking of air/particles and thus the lower filtration efficiency and pressure drop.

Finally, among the paper-based products, we see moderate filtration performance with the paper towel or tissue paper, but unsuitable pressure drop in printing paper. In the paper towel and tissue paper, the is comparable to some of the previous fabrics with a slightly higher pressure drop. These products may be suitable to use as a disposable media in some homemade facial coverings, such as between cotton for an increase in filtration efficiency, though their performance in high humidity environments needs to be examined in future work. These products are both similar to thicker, randomly oriented cellulose fibers (Figure 1j,k). The difference between these two and printing paper is how compressed the sample is (Figure 1l). Printing paper is clearly a much more two-dimensional dense-packed structure, leading to its very high pressure drop with little or no pores in the material. All these materials have a low mechanical strength, which would require particular care if integrated into face coverings.

Among these common household materials tested, we see that PP-4 (polypropylene spunbond, 30 g/m2) is a relatively high performing common material with kPa−1, 2–5 times higher than the other materials (arising from the lower pressure drop). While not as common as cotton, polypropylene spunbond is an inexpensive material that can be found in hobby fabric shops, some reusable bags, mattress covers, hygiene products, and disposable work wear. As does not change with multilayers, it suggests that the spunbond material may be suitable as a multilayer structure for facial coverings. In fact, using five layers of the spunbond (30 g/m2) experimentally yields filtration efficiency of ~24% (8 Pa), of ~15 kPa−1 (Table S1). Considering filtration properties alone, multilayer polypropylene material is superior or at least comparable to materials used in some medical face masks (polypropylene 2 and 3).

Both medical face masks and FFRs are typically composed of polypropylene nonwoven fabrics, and in both cases the primary filtration layer is produced via melt-blowing.27,28 The meltblown layer’s polypropylene microfibers have diameters in the range of ~1–10 μm and a fabric thickness of 100–1000 μm. The lofty nature, high porosity, and fine fiber diameter should not be adequate for fine particle filtration used in respirators by itself.29 To improve the filtration efficiency while preserving high air permeability, these fibers are charged through “corona discharge” and/or triboelectric means into electrets with quasi-permanent dipoles.30-32 Once charged, the filter can significantly increase its filtration efficiency without adding any mass or density to the structure. As the basis weights of the meltblown fabrics used in the medical face mask and FFR are similar, this suggests that the meltblown used in the FFR has been charged and the meltblown of both medical face masks may not have undergone any charging process. Qualitatively, the meltblown in the FFR and medical face mask (Figure 1a,b) also has some difference in the density, which contributes to the pressure difference. Thus, achieving a high-performing filter requires both a suitable filter morphology/geometry and a high degree of injected electrical charge.

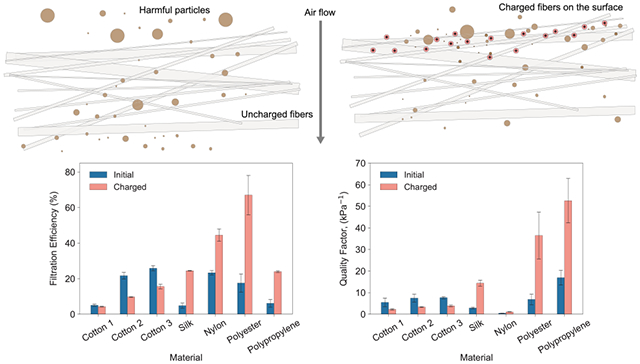

It is worth exploring whether simple triboelectric charging can positively impact the filtration properties of the materials highlighted in blue in Table 1. While it is difficult to charge the samples in the same way as electrets are made in nonwoven meltblown media in a nonindustrial setting, the act of triboelectrically creating some surface charge to mimic an electret filter may be a way to increase the filtration efficiency for a time duration enough for the public’s temporary usage (Figure 2a).

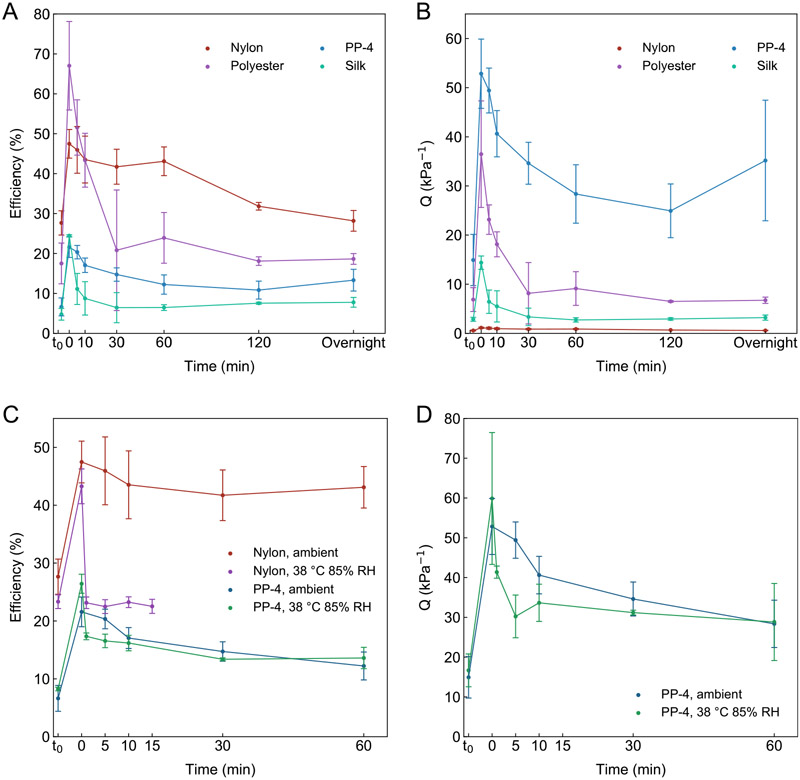

Figure 2.

Filtration properties of common materials before and after charging. Each uncertainty represents the standard deviation of three samples (excluding cotton which are from two samples). (a) Schematic of effect of charging fibers using triboelectricity. Particle filtration efficiency can be enhanced using charges generated from the triboelectric effect. (b) Filtration efficiency of materials before and after charging. Silk, nylon, polyester, and PP-4 all have increases in filtration efficiency after rubbing with latex. Cotton’s efficiency after charging was unchanged or decreased in efficiency, possibly due to abrasion and/or pore size expansion. (c) Quality factor, , of household materials before and after charging. Results are roughly in agreement with data presented in (b), except nylon which had lower performance due to pressure drop and PP-4 is much better performing due to low pressure drop. (d,e) Filtration efficiency (d) and (e) of various polypropylene spunbond fabrics with different basis weights.

The triboelectric effect is a well-known method, commonly used to demonstrate static electricity.33 However, the microscopic mechanism of triboelectricity is still not completely clear. Between solids, it has recently been found that the contact electrification is most likely due to an electron transfer between the two materials.34 In general, when two different materials come into contact with one another, their electron clouds overlap (forming a transient chemical bond). As two different materials approach equilibrium chemical potential, a decrease in the interatomic distance may allow for electron transfer between the two atoms. The transferred electron is only slightly bound to the surface atoms after the two materials have separated from each other.

For the purposes of charging an arbitrary material, two materials with different charge affinities should be able to triboelectrically create surface charges on each other. This has led to well-known triboelectric series,35 which has also recently been quantified.36 We selected latex to initially charge the samples, being a commonly found rubber product. We rubbed the sample for 30 s using a pair of latex gloves and recorded the filtration performance before and immediately after treatment (Figure 2b,c and Supporting Movie M1).

All three cotton samples had a decreased or unchanged filtration efficiency, while all other samples had an increase in filtration efficiency. The decrease in the cotton fabrics’ filtration efficiency may be due to the pore size expansion produced by rubbing or even damage to the sample from the abrasion. It suggests that mechanical damage, friction, or stretching the cotton can all cause the filtration efficiency to decrease, and these effects should be considered for cotton face coverings. On the other hand, all other samples reported moderate to high increases in filtration efficiency when tested immediately after charging. Examining shows that PP-4 has the highest performance due to the low pressure drop; polyester is also within a comparable range after charging. The low value of nylon is due to the high pressure drop (because of the very tight weave of this synthetic) with slight increase after charging. After charging, silk has a high initial value (unsurprising as it is also a commonly used material to demonstrate static in the classroom setting), but the higher pressure drop of silk yields a lower , when compared to PP-4 or polyester.

In order to see if this effect can be generalized to other polypropylene fabrics, we tested additional polypropylene spunbond samples of different basis weights (Figure 2d,e, data in Table S2). We see that among three different basis weights of polypropylene spunbond (25, 30, 40 g/m2), the filtration efficiency and are very similar (~5–10% initial efficiency charged to ~20% efficiency with initial kPa−1 charged to ~50 kPa−1). However, for the 60 g/m2 sample, the initial efficiency is much higher than the other samples. At the same time, the pressure is much higher as well (~130 Pa, Table S2), which leads to a lower kPa−1. For the 70 g/m2 sample, it also has a higher filtration efficiency and pressure drop, but the effect of charging was not as significant as the lower basis weight samples. We note that the 70 g/m2 sample was colored pink (Figure S1), whereas the other spunbond samples were white. Addition of additives may affect charging, depending on the additives’ composition. While charging improves the efficiency (and ) of all polypropylene samples, the effect was most prevalent in the lower basis weight samples tested here. Due to sample limitations as well as its behavior, PP-4 was used for all remaining experiments as a representative of polypropylene spunbond.

Static charge will inevitably dissipate due to adsorption of water molecules in the air, or discharge through contact with other surfaces. Therefore, we first evaluated natural, ambient decay (samples were placed on a tabletop without any covering, the temperature and humidity were approximately constant at 22 °C, 40% RH), as plotted in Figure 3a,b. Clearly, all the materials exhibited discharge from their initial charging value (denoted by time “0” here, where t0 denotes the values before charging). From Figure 3a, we see that both polyester and silk decay relatively quickly, reaching a plateau near the initial value at around 30 min. Nylon and PP-4 on the other hand have a much slower decay, with the PP-4 overnight value essentially remaining constant, within error.

Figure 3.

Time evolution of filtration properties of common materials. Each uncertainty represents the standard deviation of three samples. (a) Filtration efficiency decay in ambient conditions (listed in the main text), up to overnight. (b) Evolution of as a function of time, up to overnight. (c) Evolution of filtration efficiency in a humid and warmer environment, up to an hour. (d) Evolution of the PP-4 as a function of the time, up to an hour.

It has been reported that polymers, especially hydrophilic polymers, are able to adsorb layers of water molecules from ambient humidity. Once adsorbed, water molecules in particular can essentially allow for a low concentration of ions (due to dissociation reactions of surface groups) that can discharge the generated triboelectric charge.37 This is a reason why static charge is more apparent in dry environments, as the ambient moisture in the air is not enough to screen the charges generated through triboelectric means. In addition, cotton (and to a lesser extent silk) is hygroscopic, and this explains why cotton is very difficult to charge with latex, even when it is apparent that cotton clothes from a laundry dryer can have static on them.

When considering the surface chemistry of the fibers’ polymer groups, we note that polypropylene, predictably, is the most hydrophobic (it has only hydrocarbon linkages). The remaining nylon (polyamide), polyester, and silk (protein) have components which would make them more hydrophilic or less hydrophobic than polypropylene. This effect is further magnified when conditioning the materials in a humid environment of 38 °C, 85% (Figure 3c,d), which is used to mimic the exhalation temperature and moisture content. A humid environment was tested by charging the fabrics and placing them in an environmental chamber (SH-642) and measuring at the selected times (Methods in Supporting Information). We found that nylon (which was able to retain the charge well in ambient conditions) decayed to the initial value within 1 min in a humid environment and remained constant at this value for the remaining time. These conditions are also similar to the preconditioning used for FFRs in NIOSH STP0059 (85 ± 5% RH, 38 ± 2.5 °C for 25 ± 1 h) prior to measuring filter penetration.38 On the other hand, the hydrophobic PP-4 was able to roughly stay consistent with the results that were conditioned in ambient conditions, and a considerable amount of static was retained on the sample after an hour (efficiency >10% after aging, with an uncharged value of ~6%). The general observations here are consistent with previous studies which found that multilayers of water molecules can adsorb onto the surface polyamide (nylon), but hydrophobic polystyrene has little water adsorption.37

Hydrophobic polymeric materials may be considered for simple triboelectric methods for increasing filtration properties. Though polypropylene is the most common of these, some types of polyester or polyurethane fabrics can potentially be used in the same manner (or as an external/protective layer for polypropylenes like PP-4, if used as the filtration layer). More study is needed on this area to determine other common polymers which can be charged to retain their static, or multilayer polymers which can charge within a homemade face covering through interlayer friction.

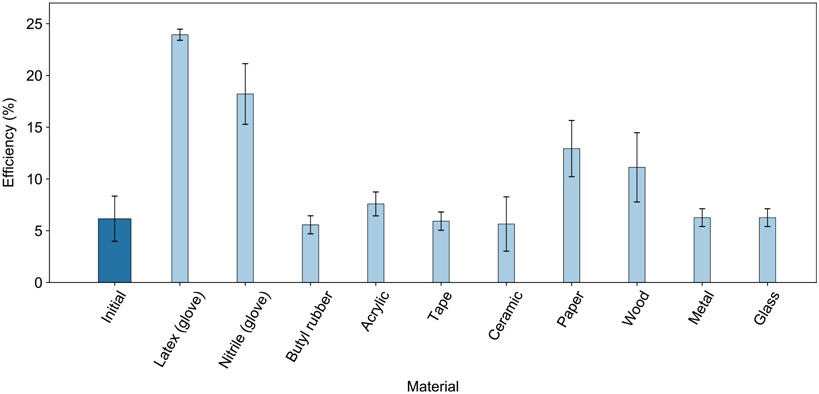

In order to offer options for community use, we tested charging the PP-4 using various other common “charging” materials (Figure 4). We found that latex and nitrile rubbers were the most promising in increasing the filtration efficiency, and various other materials only had moderate (paper and wood) or negligible effect on charging the PP-4. Fortunately, latex and nitrile are commonly used glove materials, which would make the frequent charging of the material relatively easy from a user-application standpoint (i.e., rubbing the mask with gloved hands before putting on).

Figure 4.

Efficiency after charging PP-4 with different materials. Each uncertainty represents the standard deviation of three samples.

We note that recent work has also shown that face coverings of similar fabric materials to have reported filtration efficiencies of ~10–90%.26 The difference between these results and our findings may arise from differences in instrumentation, testing method, and source of material. Our study chose following a modified version of the test procedure that NIOSH uses for the approval of N95 filtering facepiece respirators.

A summary of the results described in this manuscript is presented in Table 2, ranked by filtration quality factor, . Cotton, polyester, and polypropylene multilayered structures can meet or even exceed the efficiency of materials used in some medical face masks. However, the exact number of layers, basis weight, and thread-count of material will need to be considered in addition to the fluid resistance and performance under breathing. In our work (Table S1), we found that a five-layer structure of PP-4 after charging can achieve filtration efficiency ~50%. Although the medical face masks tested here (~19–33% filtration efficiency) have a pressure drop of roughly 16–34 Pa, the five-layer structure can achieve a higher filtration efficiency and pressure drop <10 Pa. This is particularly relevant, as there is a concern in the sealing of both disposable medical masks and cloth face coverings. We reiterate that these filtration efficiencies are only applicable if there is no leakage in the seals of the masks, as loose-fitting devices such as these coverings and medical masks do not have any gasket or tight-fitting mechanism to ensure a proper seal. The leakage of air around the seal areas is significant and can contribute to real-world exposure to aerosols.24,26 Previous reports suggest that 60% of users fail the fitting of surgical masks on first attempt.24 This risk is also carried over in cloth face coverings that do not have any special form of sealing. When designing new facial coverings for community use, it is advisible to make users aware of this risk and to design cloth face coverings with pressure drop across the covering is as low as possible (with filtration efficiency as high as possible), otherwise air contaminants (particulates, viruses, infectious droplets, etc.) will preferentially flow through gaps and leaks at the skin and cloth contact points limiting any effectiveness of filtration in a de facto form of respiratory protection. The general public should be aware of the risks of self-contamination during removal and reuse of cloth face coverings. Finally, an important distinction to make is that surgical masks are designed and intended as a form of barrier protection and provide fluid resistance for use in hospitals. The materials evaluated in this study for cloth face coverings are not intended to be used by healthcare workers or any other workers as a form of respiratory protection. Further, we did not investigate the effects of cleaning or disinfecting of the materials studied. These effects could be evaluated in future work.

Table 2.

Summary and Ranking of Materials Tested Here Based on Filtration Quality Factor, , with Relevant Comments for Each Material

| ~ (kPa−1) |

~filtration efficiency (%) |

material | comments |

|---|---|---|---|

| >100 | >95 | polypropylene meltblown (charged) | material found in FFRs (used for reference) |

| 30 | 10–20 | charged polypropylene (PP-4) | charged value after overnight, polypropylene spunbonds can vary (different basis weight has different efficiency), charging increased the in all cases |

| 15 | 5–10 | uncharged polypropylene (PP-4) | initial polypropylene spunbond fabrics can vary in efficiency, but most tested had low pressure drops |

| 5–10 | 5–20 | cotton | cotton fabrics can vary in initial pressure drop, select cotton fabrics without any visible pores under light illumination or use multilayer configurations |

| 5–10 | 20 | polyester | similar properties and comments as cotton |

| 5 | 30 | polypropylene meltblown (uncharged) | material found in medical face masks (used for reference) |

| 5 | 10–20 | tissue paper, paper towel | low mechanical strength, but may be possible to integrate into some masks with other cloths as a composite material |

| <5 | 5 | silk | silk can be considered for use if cotton and/or polyester are unavailable |

| <1 | 20 | nylon (woven) | the nylon tested in this study had very high pressure drop. If using nylon for masks the fabric needs to have a lower pressure drop to be effective |

Personal protective equipment, such as surgical masks cleared for sale by the FDA and respiratory protection approved by NIOSH, comprise only one aspect of a hierarchy of infection prevention and control measures. The WHO and CDC recommend that other measures also be used with masks or respirators.14,39 These additional measures as well as the efficacy of cloth coverings are covered in the Supporting Information.

Supplementary Material

Footnotes

Supporting Information

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acs.nanolett.0c02211.

Discussion on COVID-19 symptoms and transmission, details of the testing procedures used for NIOSH and FDA approval for masks, public health measures suggested by the CDC and WHO, experimental methods, optical images, and additional tables (PDF)

Video demonstrating the simple charging of fabric that clearly has static charge after charging is complete due to the attractive nature of the fabric (MP4)

The authors declare the following competing financial interest(s): Professors Steven Chu and Yi Cui are founders and shareholders of the company 4C Air, Inc. They are inventors on patent PCT /US2015/065608. Authors Mervin Zhao, Lei Liao, Wang Xiao, Xuanze Yu, Haotian Wang, and Qiqi Wang are employed by 4C Air, Inc.

Contributor Information

Mervin Zhao, 4C Air, Inc., Sunnyvale, California 94089, United States.

Lei Liao, 4C Air, Inc., Sunnyvale, California 94089, United States.

Wang Xiao, 4C Air, Inc., Sunnyvale, California 94089, United States.

Xuanze Yu, 4C Air, Inc., Sunnyvale, California 94089, United States.

Haotian Wang, 4C Air, Inc., Sunnyvale, California 94089, United States.

Qiqi Wang, 4C Air, Inc., Sunnyvale, California 94089, United States.

Ying Ling Lin, World Health Organization, Geneva, CH 1211, Switzerland.

F. Selcen Kilinc-Balci, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, Washington, DC 20201, United States.

Amy Price, Stanford Anesthesia Informatics and Media (AIM) Lab, Department of Anesthesiology, Perioperative, and Pain Medicine, Stanford University School of Medicine, Stanford, California 94305, United States.

Larry Chu, Stanford Anesthesia Informatics and Media (AIM) Lab, Department of Anesthesiology, Perioperative, and Pain Medicine, Stanford University School of Medicine, Stanford, California 94305, United States.

May C. Chu, Colorado School of Public Health, Aurora, Colorado 80045, United States

Steven Chu, Department of Physics and Department of Molecular and Cellular Physiology, Stanford University, Stanford, California 94305, United States.

Yi Cui, Department of Materials Science and Engineering, Stanford University, Stanford, California 94305, United States; Stanford Institute for Materials and Energy Sciences, SLAC National Accelerator Laboratory, Menlo Park, California 94025, United States.

REFERENCES

- (1).Dong E; Du H; Gardner L An Interactive Web-Based Dashboard to Track COVID-19 in Real Time. Lancet Infect. Dis 2020, 20, 533–534. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (2).Christian MD; Loutfy M; McDonald LC; Martinez KF; Ofner M; Wong T; Wallington T; Gold WL; Mederski B; Green K; Low DE Possible SARS Coronavirus Transmission during Cardiopulmonary Resuscitation. Emerging Infect. Dis 2004, 10, 287–293. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (3).Yan J; Grantham M; Pantelic J; De Mesquita PJB; Albert B; Liu F; Ehrman S; Milton DK Infectious Virus in Exhaled Breath of Symptomatic Seasonal Influenza Cases from a College Community. Proc. Natl. Acad. Sci. U. S. A 2018, 115, 1081–1086. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (4).Tellier R. Review of Aerosol Transmission of Influenza A Virus. Emerging Infect. Dis 2006, 12, 1657–1662. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (5).Huang H; Fan C; Li M; Nie HL; Wang FB; Wang H; Wang R; Xia J; Zheng X; Zuo X; Huang J COVID-19: A Call for Physical Scientists and Engineers. ACS Nano 2020, 14, 3747–3754. [DOI] [PubMed] [Google Scholar]

- (6).Lindsley WG; Blachere FM; Thewlis RE; Vishnu A; Davis KA; Cao G; Palmer JE; Clark KE; Fisher MA; Khakoo R; Beezhold DH Measurements of Airborne Influenza Virus in Aerosol Particles from Human Coughs. PLoS One 2010, 5, e15100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (7).NIOSH. Interim Guidance on Infection Control Measures for 2009 H1N1 Influenza in Healthcare Settings, Including Protection of Healthcare Personnel. Miss. RN 2009, 71, 13–18. [PubMed] [Google Scholar]

- (8).CDC. Using Personal Protective Equipment (PPE). https://www.cdc.gov/coronavirus/2019-ncov/hcp/using-ppe.html (accessed May 24, 2020).

- (9).CDC. Healthcare Infection Prevention and Control FAQs for COVID-19. https://www.cdc.gov/coronavirus/2019-ncov/hcp/infection-control-faq.html (accessed May 24, 2020).

- (10).Rosenstock L. 42 CFR Part 84: Respiratory Protective Devices Implications for Tuberculosis Protection. Infect. Control Hosp. Epidemiol 1995, 16, 529–531. [DOI] [PubMed] [Google Scholar]

- (11).Matsuyama S; Nao N; Shirato K; Kawase M; Saito S; Takayama I; Nagata N; Sekizuka T; Katoh H; Kato F; Sakata M; Tahara M; Kutsuna S; Ohmagari N; Kuroda M; Suzuki T; Kageyama T; Takeda M Enhanced Isolation of SARS-CoV-2 by TMPRSS2-Expressing Cells. Proc. Natl. Acad. Sci. U. S. A 2020, 117, 7001–7003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (12).Loeb M; Dafoe N; Mahony J; John M; Sarabia A; Glavin V; Webby R; Smieja M; Earn DJD; Chong S; Webb A; Walter SD Surgical Mask vs N95 Respirator for Preventing Influenza among Health Care Workers: A Randomized Trial. JAMA - J. Am. Med. Assoc 2009, 302, 1865–1871. [DOI] [PubMed] [Google Scholar]

- (13).Balazy A; Toivola M; Adhikari A; Sivasubramani SK; Reponen T; Grinshpun SA Do N95 Respirators Provide 95% Protection Level against Airborne Viruses, and How Adequate Are Surgical Masks? Am. J. Infect. Control 2006, 34, 51–57. [DOI] [PubMed] [Google Scholar]

- (14).World Health Organization. Advice on the Use of Masks in the Context of COVID-19 (Interim Guidance); 2020. [Google Scholar]

- (15).Artenstein AW In Pursuit of PPE. N. Engl. J. Med 2020, 382, No. e46. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (16).Ranney ML; Griffeth V; Jha AK Critical Supply Shortages — The Need forVentilators and Personal Protective Equipment during the Covid-19 Pandemic. N. Engl. J. Med 2020, 382, No. e41. [DOI] [PubMed] [Google Scholar]

- (17).World Health Organization. Rational Use of Personal Protective Equipment for Coronavirus Disease (COVID-19) and Considerations during Severe Shortages: Interim Guidance, 6 April 2020; World Health Organization, 2020. [Google Scholar]

- (18).Liao L; Xiao W; Zhao M; Yu X; Wang H; Wang Q; Chu S; Cui Y Can N95 Respirators Be Reused after Disinfection? How Many Times? ACS Nano 2020, 14, 6348. [DOI] [PubMed] [Google Scholar]

- (19).CDC. Public Health Recommendations for Community-Related Exposure https://www.cdc.gov/coronavirus/2019-ncov/php/public-health-recommendations.html (accessed May 24, 2020).

- (20).CDC. Recommendation Regarding the Use of Cloth Face Coverings, Especially in Areas of Significant Community-Based Transmission. https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/cloth-face-cover.html (accessed May 24, 2020). [Google Scholar]

- (21).Adams J., Recommendation Regarding the Use of Cloth Face Coverings, CDC; 2020. [Google Scholar]

- (22).Lindsley WG; King WP; Thewlis RE; Reynolds JS; Panday K; Cao G; Szalajda JV Dispersion and Exposure to a Cough-Generated Aerosol in a Simulated Medical Examination Room. J. Occup. Environ. Hyg 2012, 9, 681–690. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (23).Podgorski A; Balazy A; Gradon L Application of Nanofibers to Improve the Filtration Efficiency of the Most Penetrating Aerosol Particles in Fibrous Filters. Chem. Eng. Sci 2006, 61, 6804–6815. [Google Scholar]

- (24).Oberg T; Brosseau LM Surgical Mask Filter and Fit Performance. Am. J. Infect. Control 2008, 36, 276–282. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (25).Rengasamy S; Eimer B; Shaffer RE Simple Respiratory Protection - Evaluation of the Filtration Performance of Cloth Masks and Common Fabric Materials against 20–1000 Nm Size Particles. Ann. Occup. Hyg 2010, 54, 789–798. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (26).Konda A; Prakash A; Moss GA; Schmoldt M; Grant GD; Guha S Aerosol Filtration Efficiency of Common Fabrics Used in Respiratory Cloth Masks. ACS Nano 2020, 14, 6339. [DOI] [PubMed] [Google Scholar]

- (27).Angadjivand SA; Brandner JM; Springett JE Molded Respirator Comprising Meltblown Fiber Web with Staple Fibers. US 7989372 B2, 2011.

- (28).Gaynor M; McManus J Spunbonded/Meltblown/Spunbonded Laminate Face Mask. US 20040000313 A1, 2002.

- (29).Ghosal A; Sinha-Ray S; Yarin AL; Pourdeyhimi B Numerical Prediction of the Effect of Uptake Velocity on Three-Dimensional Structure, Porosity and Permeability of Meltblown Nonwoven Laydown. Polymer 2016, 85, 19–27. [Google Scholar]

- (30).Angadjivand SA; Jones ME; Meyer DE Method of Charging Electret Filter Media. US 6119691 A 1996.

- (31).Angadjivand SA; Jones ME; Meyer DE Electret Filter Media. US 6119691 A, 1994.

- (32).Kubik DA; Davis CI Melt-Blown Fibrous Electrets. US 4215682 A, 1980.

- (33).Henniker J. Triboelectricity in Polymers. Nature 1962, 196, 474–474. [Google Scholar]

- (34).Xu C; Zi Y; Wang AC; Zou H; Dai Y; He X; Wang P; Wang Y-C; Feng P; Li D; Wang ZL On the Electron-transfer Mechanism in the Contact-electrification Effect. Adv. Mater 2018, 30, 1706790. [DOI] [PubMed] [Google Scholar]

- (35).Lee BW; Orr DE The Triboelectric Series. https://www.alphalabinc.com/triboelectric-series/ (accessed May 24, 2020). [Google Scholar]

- (36).Zou H; Zhang Y; Guo L; Wang P; He X; Dai G; Zheng H; Chen C; Wang AC; Xu C; Wang ZL Quantifying the Triboelectric Series. Nat. Commun 2019, 10, 1–9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (37).Németh E; Albrecht V; Schubert G; Simon F PolymerTribo- Electric Charging: Dependence on Thermodynamic Surface Properties and Relative Humidity. J. Electrost 2003, 58, 3–16. [Google Scholar]

- (38).CDC. Standard Respirator Testing Procedures. https://www.cdc.gov/niosh/npptl/stps/apresp.html (accessed May 29, 2020).

- (39).Sanche S; Lin YT; Xu C; Romero-Severson E; Hengartner N; Ke R High Contagiousness and Rapid Spread of Severe Acute Respiratory Syndrome Coronavirus 2. Emerging Infect. Dis 2020,26,26. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.