Abstract

The pollution of soil and aquatic systems by inorganic and organic chemicals has become a global concern. Economical, eco-friendly, and sustainable solutions are direly required to alleviate the deleterious effects of these chemicals to ensure human well-being and environmental sustainability. In recent decades, biochar has emerged as an efficient material encompassing huge potential to decontaminate a wide range of pollutants from soil and aquatic systems. However, the application of raw biochars for pollutant remediation is confronting a major challenge of not getting the desired decontamination results due to its specific properties. Thus, multiple functionalizing/modification techniques have been introduced to alter the physicochemical and molecular attributes of biochars to increase their efficacy in environmental remediation. This review provides a comprehensive overview of the latest advancements in developing multiple functionalized/modified biochars via biological and other physiochemical techniques. Related mechanisms and further applications of multiple modified biochar in soil and water systems remediation have been discussed and summarized. Furthermore, existing research gaps and challenges are discussed, as well as further study needs are suggested. This work epitomizes the scientific prospects for a complete understanding of employing modified biochar as an efficient candidate for the decontamination of polluted soil and water systems for regenerative development.

Subject terms: Environmental sciences, Environmental biotechnology

Introduction

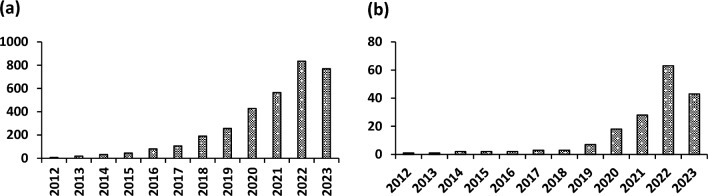

Biochar is a carbon-rich material produced from different organic waste feedstocks, such as municipal sewage sludge and agricultural wastes1. Biochar gained much attention due to its unique characteristics such as large specific surface area, stable structure, high cation exchange capacity, and carbon content1,2. Its significance could be realized by the increasing number of published articles in the last ten years (Fig. 1). Biochar can amend the fertility of the soil and can sequester carbon; hence it can potentially lead to the mitigation of climate change2–5. To enhance soil fertility and carbon sequestration potential, biochar improves physical (moisture level, oxygen content, and capacity of water holding), chemical (sequestration of carbon and immobilization of pollutants), and biological (microbe’s abundance, activity, and diversity) properties of soil. It also helps in the removal of various contaminants from soil and water systems3–6. Various conventional methods are used to remove organic, inorganic, and other emerging pollutants from the water and soil, such as coagulation/flocculation, chemical precipitation, and biochemical degradation3. These methods usually eliminate valuable contaminants from water and soil but have low efficiency with high operational and maintenance costs and massive waste production2–4. In contrast, adsorption using agricultural organic wastes is emerging as a cost-effective, user-friendly, and efficient method for removing various impurities from soil and water systems5. Adsorption is a key mechanism for biochar to eliminate organic and inorganic pollutants. The adsorption capability of biochar is directly linked to its physicochemical attributes such as functional groups, cation exchange capacity, distribution of pore size, and surface area, however, these attributes vary with the production conditions like nature of biomass utilized for biochar production, pyrolysis temperature, etc.2,3 However, pristine biochar due to limited adsorption sites and low surface functionality does not display specific and high nutrient adsorption capability4. To enhance the adsorption capacity, biochars are modified/functionalized using multiple-modification agents including alkali, acids, metal oxides, and oxidizing agents, which manifest improved surface properties and novel structures after treatment1,4,5. Compared to pristine biochar, modified/functionalized biochar with enlarged surface area and abundant functional groups presents a new type of carbon-based material with enhanced adsorption potential for pollutants in water and soil systems3,5. Generally, functionalization techniques for biochar can be considered into three main modification types such as biological, chemical, and physical6. Chemical modification techniques include oxidizing treatment, soaking with acid and base, magnetization, loading of carbon nanomaterials, doping with clay minerals, organic surfactants, non-metallic elements, and layered double hydroxides7,8. These modifications not only improve the biochar's physical attributes but also influence its chemical characteristics such as surface functional groups, elemental distribution, zeta potential, electron transfer capacity, and cation exchange capacity due to their impact on porosity and enrichment of biochar surface with O-containing functional groups, especially carboxyl ones6,7. Physical modification such as activation by CO2/steam and microwave, and ball milling improves the particle size, pore structure, functional groups, and surface area of biochar8,9. It provides advantages over chemical techniques being less polluted in nature and economically more viable for biochar fabrication8. Moreover, chars can be functionalized via biological technique; which carries advantage of various microbes and biological-linked methods, and further assists in the elimination of toxic contaminants9–11. There have been few reviews focusing on diverse applications of biochar such as soil fertility and quality improvement, catalysis, and aqueous pollutant removal10. So far, various studies emphasize more on applying raw and modified biochar to eliminate pollutants from the water system4,5,7,8,12,13. Nonetheless, a comprehensive study including the use of multiple-functionalized biochar-based adsorbents in the removal of pollutants from soil and aquatic systems has scarcely been described. Furthermore, the compiled knowledge of multiple functionalization techniques for char/adsorbents, for example, doping of non-metallic heteroatom is scanty. Aiming to describe a thorough analysis of multiple-functionalized biochars for the remediation of environmental impurities, based on recently published literature, this updated study exhaustively outlined the novel approaches in multiple functionalized techniques for the biochars. Moreover, the reusability of modified/functionalized biochar as well as the economic perspective of the biochar production and application as compared to other expensive sorbents like activated carbon has also been discussed. This review could be helpful in the large-scale preparation and application of modified/functionalized biochars for managing polluted soil and aquatic systems and may ensure the sustainable protection of the environment.

Figure 1.

The number of papers (a) research + review and (b) review articles published in the last 10 years.

Various modification techniques for the preparation of functionalized biochars and effects on the water system

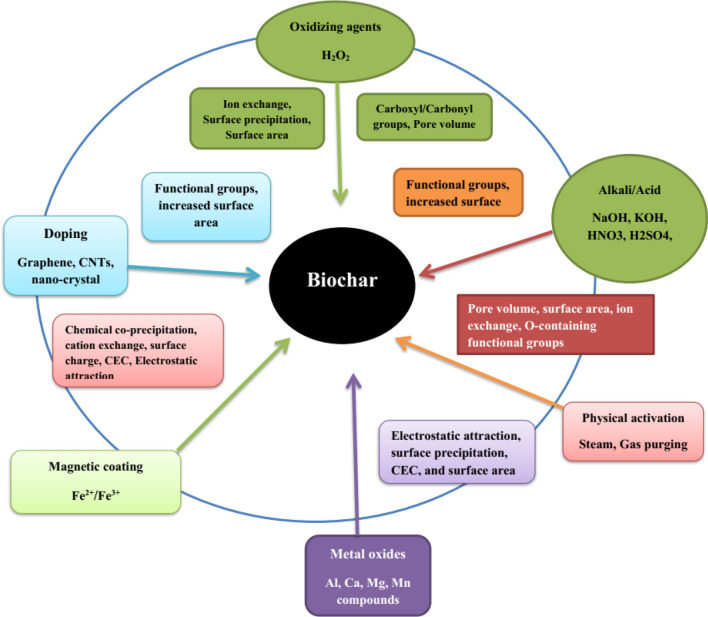

Accessible modification techniques have been scrutinized in the published literature and are summed up in (Table 1) which can be distributed into 4 major classes, including physical and chemical modifications, magnetic modifications, and soaking with minerals (Fig. 2). Changes in biochar physiochemical properties after multiple modifications are detailed in (Table 2).

Table 1.

Various modification approaches of biochars, production temperature, pollutant removals from the water and soil systems, mechanisms, and their applications.

| Biochar Feedstock | Pyrolysis temperature (°C) | Modification method | Target contaminant | Decontamination status | Mechanism involved | References |

|---|---|---|---|---|---|---|

| Chemical modification | ||||||

| Peanut hull | 300 | H2O2 treatment | Cd, Ni, Cu, and Pb | increased Pb sorption from 0.88 to 22.82 mg g−1, which was higher than commercial AC | Increased oxygen-rich functional groups on the biochar surfaces | 11 |

| Bamboo | 550 | Chemical oxidation (NaOH, HNO3) | Furfural | suppressed the sorption of furfural | A substantial amount of acidic functional groups on the adsorbent surface. Contrastingly, heat and NaOH modifications raised the basicity of adsorbent | 12 |

| Municipal waste | 400–600 | KOH modification | Arsenic pentoxide | Increased 1.3 times adsorption rate than un-treated biochar | Enhance SSA and alter the porous structure, particularly functional groups on the surface of the modified adsorbent | 13 |

| Pine-chips | 300 | NaOH treatment | Ibuprofen, Naproxen and Diclofenac | showed greater sorption efficiency | Large amounts of oxygen-enrich functional groups introduced on the surface of treated biochar | 15 |

| Rice husk | 400, 500 | Treated by H2SO4 and KOH | Tetracycline | Shown better adsorption efficiency (58.8 mg g−1) compared to other biochars | owned larger SA than those of acidic-modified and pristine biochars | 16 |

| Sawdust | 500 | Amino-treated | Copper (Cu) | Improved the sorption up to 5-folds and 8-folds for fixed-bed and batch experiments | Amino moiety strongly complexes with heavy metals because of the high stability constants of metal complexes | 17 |

| Rice husk | 400, 500 | Methanol-treated | Tetracycline | Almost 45% heightening of removal capacity in 12 h and 17% at equilibrium | Due to alteration in oxygen-comprising functional groups | 9 |

| Buttonwood waste | 400 | Modified by (Mg(OH)2) | Fe2+ | Greater removal capacities for treated biochar (84–99%) than by un-treated biochar (38–97%) | Mineral constituents e.g., silicate Mg(OH)2 and calcite in the biochars stimulate the oxidation of Fe2+ and form a precipitate of Fe3+ hydroxides | 18 |

| Rice husk | 450 and 500 | Polyethylenimine treatment | Chromium | Highest removal capability of (435 mg g−1), it was better than Un-treated biochar (23.09 mg g−1) | The appearance of the amino- group stimulates the chemical reduction of chromium and enhances the removal capacity | 19 |

| Walnut-chips | 600 | Carbon nanotube-coating | Methylene blue | Maximum removal capacity among all contaminants | Coated biochar has well thermal stability, greater SA, and higher pore volume | 12 |

| Rice husk and fruit branches | 600 | Ferric coated | As (III) and As (V) | Enhancement of removal capacities | Interactions with FeOH2 and FeOH groups | 20 |

| Sawdust and pine tree | 550 | H3PO4 modification | Fluoride | Substantial increase in removal performance modification | Increasing Fluoride sorption resulting from chemistry reaction and increased SSA | 21 |

| Rice husk | 600 | Coated with silica | Pb | Improvement of removal capacities | A larger SSA observed after coating | 7 |

| Wheat straw | 450 | Coated with Fecl3 and treated by HCL | phosphate and nitrate | Substantial increase of removal after HCl treatment and coating with Fecl3 | – | 4 |

| Wheat straw | 300, 700 | Acid activation | Sulfamethazine | Noteworthy increase in SA and enhancement in the removal of sulfamethazine | – | 22 |

| Bagasse | 600 | Modified by carbon nanotube | Sulfapyridine and Pb | Maximum sorption capacity observed | – | 13 |

| Bamboo hardwood | 550 | NaOH modification | Cd | Highest cadmium sorption capacity | NaOH-treated adsorbent has more roughness compared to un-treated biochar | 23 |

| Cow manure and wheat straw | 450 | HNO3 treatment | U(VI) | Showed the highest sorption capacities after modification, it was higher than un-modified biochar, Highest removal capacity by the treated wheat straw adsorbent exhibited an enhancement of 40 times | Due to a large number of surface COO groups, a great negative surface charge | 18 |

| Swine manure and rice straw | 700 | H3PO4 modification | Tetracycline | Increased the TC removal capacity | Enhancement of the SSA, higher micropore, and total pore after treatment | 15 |

| Poplar chips | 550 | AlCl3-modification | PO43−, NO3- | PO43−, NO3− removal significantly enhanced on Al-treated biochar | The surface area markedly improved with the Al content of the adsorbent. The C content of Al-treated biochar greatly decreased than pristine biochar | 3 |

| Dairy manure | 300 | NaOH-modification | Cd, Pb | The highest removal capacities were 68.08 and 175.53 mg g−1 for Cd and Pb respectively. The sorption capacities of dairy manure biochar for Cd and Pb improved after modification | NaOH modification increased the SSA, amount of O-enrich functional group, and ion-exchange capacity of biochar | 8 |

| Coconut shell | 800 | HCl + ultra-sonication | Zn, Ni, and Cd | Modified biochar showed the highest sorption capacities for heavy metals | Modified-biochar improved surface functional groups | 15 |

| Corn straw | 500 | KOH | Atrazine, Hg(II) | The sorption capacity of treated biochar for Hg (II) enhanced by 76.95%, while that for atrazine enhanced by 38.66% | After modification enhanced SA which was 59.23 m2 g−1 | 23 |

| Auricularia auricular dreg | 400 | Cetyl trimethyl ammonium bromide | Cr (IV) | The removal rate increased by 40 times more as compared to un-treated biochar | The number of micropores and mesoporous in the unit area enhanced, After treatment, the SA enhanced by 6.1% and the average pore diameter increased by 16.5% | 24 |

| Seaweed | 200 | KOH | V(V) | 12 mg g−1 sorption capacity noticed | Complexation, electrostatic interaction and pore diffusion | 25 |

| Rice straw | 400 | β-cyclodextrin and HCl | Pb2+ | 130 mg g−1 sorption capacity found was higher than unmodified biochar | Complexation, ion exchange, and physisorption | 29 |

| Horse manure | 500 | Bismuth(III) nitrate | U(VI) | 516 mg g−1 adsorption capacity found was higher than un-modified biochar | Reductive reaction, ion exchange, and precipitation | 11 |

| Physical modification | ||||||

| Bur cucumber | 300, 700 | Steam activation | Sulfamethazine | Around 55% enhancement in removal capacity | – | 10 |

| Whitewood | 550 | Steam activation | Emission of CH4 | Suppress CH4 emission | – | 2 |

| Maize stover | 350 | Steam activation | Emission of N2O | Suppress N2O emission | – | 26 |

| Tea waste, soybean straw, bagasse, and shrub | 300, 700 | Steam activation | Sulfamethazine | Maximum sulfamethazine sorption among all the biochars | Due to its higher SA and pore volume | 27 |

| Guayule, corn stover and cob, switchgrass, alfalfa stems, and chicken manure | 500 | Steam activation | Cu | Highest sorption capacities observed | Largest SSA and porous structure | 28 |

| Cornstalk | 500, 900 | CO2/NH3 Modification | CO2 | – | NH3 reacts with the biochar surface, introducing the nitrogen functional groups; CO2 modification forms more micropore | 30 |

| Black spruce | 454, 900 | Steam activation | Sulfur dioxide | The sorption capacity of sulfur dioxide was found higher (76 mg g−1) | Surface area (590 m2 g−1) and pore volume increased | 31 |

| Canola straw | 700 | Steam modification | Pb (II) | Removal capacity observed (195 mg g−1) | Due to its higher SA and pore volume | 30 |

| Rice straw | 800 | Steam activation | Naphthalene | The sorption rate was noticed at 76% | Higher surface area (106 m2 g−1) and a large amount of surface functional groups | 32 |

| Poplar wood | 300 | Ball milling | Mercury | Sorption capacity was 320 mg g−1 | Surface area and pore structure improved | 33 |

| Soybean straw | 800 | Steam activation | Zn2+, Ni2+, Cd2+, and Cu2+ | Removal capacity 27.8, 30, 21,95.7 mg g-1 for Zn2+, Ni2+, Cd2+, Cu2+ | Higher surface area (793 m2 g−1) and average pore diameter enhanced | 34 |

| Bamboo | 500 | Activation by steam | Tetracycline and Copper (II) | Adsorption capacity 0.22 and 5.03 mmol g−1 tetracycline and Copper (II), respectively | Due to changes in oxygen-enrich functional groups | 27 |

| Mushroom | 800 | Steam activation | Crystal violet | 1057 mg g−1 adsorption capacity found | Higher surface area (332 m2 g−1) | 24 |

| Invasive plants | 700 | Steam modification | Sulfamethazine | 37.7 mg g−1 adsorption capacity observed | Because of higher SA and pore volume | 22 |

| Dendro | 700 | Ball milling | Cadmium and chromium | Sorption capacity for chromium 922 mg g−1 and cadmium 7.46 mg g−1 | Improved pore structure after modification | 30 |

| Tea waste | 700 | Steam activation | Sulfamethazine | 33.81 mg g−1 adsorption capacity noticed | Higher surface area (576.9 m2 g−1) and a large amount of surface functional groups | 35 |

| Hickory chip | 600 | Ball milling | Reactive red | 34.80 mg g−1 adsorption capacity noticed | Enhanced O-moieties and N-enrich functional groups favored the contaminant elimination by electrostatic interaction | 35 |

| Pine sawdust | 550 | Activation by steam | Reduce emission of greenhouse gases | Reduce the CO2 and N2O emission | Decreased enzyme and microbial activities as well as higher surface area (397 m2 g−1) | 35 |

| Poplar wood | 300 | Ball milling | Enrofloxacin | Removal capacity noticed at 80.20% | The increased photocatalytic performance of ball milled-modified-biochar was owing to the generated radicals | 37 |

| Orange peel waste | 950 | Microwave activation | Congo red | 136 mg g−1 sorption capacity noticed | Surface functionality improved | 32 |

| Hickory, bagasse, and bamboo | 600 | Clay-biochar composites | Methylene blue | Enhancement of removal capacities by around 5 times | Electrostatic attraction (with biochar) and Ion exchange (with clay) | 20 |

| Corn straws | 600 | MnOx-doped biochar | Cu | Highest removal capacity; maximal removal capacity as high about 160 mg g−1 | Formation of the inner-sphere complexes with MnOx and oxygen-comprising groups | 9 |

| Mg-accumulated tomato tissues | 600 | Mg-loaded biochar | Phosphate | Around 88% removal of Phosphate from the solution | Nano-scale Mg(OH)2 and MgO particles as core sorption sites for aqueous | 38 |

| Mg-enriched tomato leaves | 600 | Mg-doped biochar | Phosphorus | Highest removal capacity > 100 mg g−1 | Precipitation of Phosphorus by chemical reaction with Mg-particles and surface deposition of Phosphorus on Mg-crystals on biochar surfaces | 38 |

| Peanut hull, hickory chips, sugarcane bagasse, and bamboo | 600 | Chitosan-loaded biochars | Cd, Cu, and Pb | Increased elimination of metals | Electrostatic interaction | 39 |

| Corn | 300,450,600 | Mg-modified biochar | Phosphorus | Highest removal noticed | – | 11 |

| Sugar beet | 300 | Mg-modified biochar | Phosphorus | Highest removal volume > 100 mg g−1 | The appearance of the nano-sized MgO-particles on the biochar surfaces as active sorption sites for aqueous P | 12 |

| Rice straw | 200–500 | Mineral loaded composite by [Ca(H2PO4)2]), CaCO3, and kaolin | Carbon retention | Three minerals, particularly [Ca(H2PO4)2]) were effective in enhancing C retention and strengthening biochar stabilization | Increased C retention and stability of biochar with mineral loading due to increased formation of aromatic Carbon | 18 |

| Pinewood | 600 | MnO-loaded adsorbent | Pb, As(V) | Removal capacities of As(V) enhanced by around 4 and 5 times, while those of Pb enhanced by around 2 and 20 times | The occurrence of birnessite particles exhibited strong interactions with metals | 27 |

| Soybean straw, peanut straw, and rice straw | 750 | Aluminum-treated | As(V) | Al-treated adsorbents sorbed 445–667 mmol kg−1 at 5 pH, in contrast to slight removal on un-treated biochars | Inner sphere complexes with Al(OH)3 on the surfaces of treated adsorbents | 12 |

| Hickory chips | 600 | Fe-doped biochar | Arsenic | Highest removal capacity of About 2 mg g−1 in contrast to negligible removal on raw biochar | Chemisorption mechanism on Fe-loaded biochar | 20 |

| Rice hull | 350 | Composite with nZVI | Trichloroethylene | The degradation efficiency of Trichloroethylene was around 99% due to the nZVI-biochar composite | Higher SSA and O-enrich functional groups of nZVI-treated biochar increased SO4 generation and induced Trichloroethylene degradation | 6 |

| Rice husk | 300 | Fe and Ca-treated biochar | Chromium and As(V) | Observed more than 90% removal | Electrostatic interactions and heavy metal precipitation | 2 |

| Cotton stalk | 350 | Fe2O3-loading | Phosphate | Enhanced phosphate removal capacity from 0 to 0.963 mg g−1 | Desegregation of porous trait of biochar, maximum removal ability of Fe2O3, and exceptional flow features of granular particles | 39 |

| Orange peel | 250–700 | Fe2+/Fe3+ prepared magnetic biochar | p-nitrotoluene and Naphthalene | The removal rate was higher than un-treated biochar | – | 40 |

| Pinewood | 600 | Magnetic biochar | As (V) | Higher sorption of As(V) from aqueous | γ-Fe2O3 particles on the treated adsorbent surface functioned as sorption sites by electrostatic interactions | 8 |

| Rice hull | 400 | Zinc sulfide loading | Pb | Notably increased removal capacity | – | 20 |

| Oak Bar, Oakwood | 400, 450 | Magnetic composite | Pb and Cd | Removal capacities were higher than fresh and other un-treated adsorbents | Electrostatic interactions | 30 |

| Cottonwood | 600 | Fe2O3-modified | Arsenic | The highest removal capacity of the 3147 mg kg−1 was noticed | Nano-colloidal structures of strong dispersed γ-Fe2O3 particles on both surface and interior of the treated adsorbent matrix | 6 |

| Corn straw | 500 | Na2S-modifed | Atrazine, Hg(II) | After modification, the sorption capacities for Atrazine, Hg(II) comprehensively increased | The sulfur content was markedly enhanced by 101.29% under Na2S treatment | 13 |

| Thalia dealbata | 500 | MgCl2-loaded | Cd and sulfamethoxazole | The addition of treated biochar enhanced the removal of sulfamethoxazole (by 50–58%) and Cadmium (by 24–25%) as compared with pristine biochar | SA of MgCl2 loaded biochar (110.6 m2 g−1) was greater than un-modified biochar (7.1 m2 g−1) | 1 |

| Bamboo | 700 | FeSO4, Chitosan and Fe2(SO4)3 | Cr (VI) | 127 mg g−1 sorption capacity was observed by modified biochar | Electrostatic attraction, reduction, chelation, and complexation | 19 |

| Maize straw | 600 | N-loading | Cd2+ | 197 mg g−1 adsorption capacity observed was higher than untreated biochar | Hydroxyl groups, complexation with graphitic N | 41 |

| Ficus microcarpa | 500 | Chitosan | Sb3+ | 167 mg g−1 adsorption capacity observed | H–bonding, π–π interaction, surface complexation, chelation, and electrostatic interaction | 42 |

| Rapeseed straw | 600 | MnSO4 | Sb(V) | 0.70 mg g−1 adsorption capacity noticed was greater than untreated biochar | Electrostatic interaction, hydroxyl/carboxyl Sb inner-sphere complexation, Sb-O-Mn complex, and physical adsorption | 43 |

| Populus | 600 | FeCl3 | As(V) | 99% adsorption efficacy was found higher than unmodified biochar | Electrostatic interaction and Fe-As precipitation | 44 |

| Glucose | 800 | N-loading | Cr(VI) | 400 mg g−1 adsorption capacity noticed | Reduction, complexation, and physisorption | 24 |

| Corn straw | 800 | S-loading | Fe2+ | 50 mg g−1 | Co-precipitation, ion exchange, and chemical complexation | 37 |

| Biological modifications | ||||||

| Peanut shell | 500 | hibiscicola strain L1 | Cu2+ | 45.8% removal capacity | Reduction and precipitation | 29 |

| Peanut shell | 500 | Pseudomonas | Cr(VI) | 38.2% removal capacity, which was higher than un-treated biochar | Ion-exchange and complexation | 21 |

| Peanut shell | 500 | Pseudomonas | Ni2+ | 81% removal capacity was noticed, which was higher than un-treated biochar | Reduction and precipitation | 9 |

| Corn straw | 300 | Vibrio | Diesel oil | 94% | Physical adsorption and biodegradation | 24 |

| Erding | 500 | Bacillus cereus LZ01 | Chlortetracycline | 82% | Biochar adsorption and biodegradation via LZ01 | 45 |

Figure 2.

Schematic illustrations of biochar modifications.

Table 2.

Properties of modified biochars obtained from various treatments.

| Modification | Biochar | Pyrolysis temperature (°C) | Experimental condition | pH | C % | H % | O% | N % | Ash % | Pore volume (cm3 g−1) | SSA m2 g−1 | References |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steam activation | Tea waste | 300 | Un-modified | 7.90 | 70.10 | 5.20 | 19.60 | 5 | 5.70 | 0.006 | 2.30 | 10 |

| Modified | 8.60 | 71.50 | 4.80 | 18.20 | 5.50 | 6.40 | 0.004 | 1.50 | ||||

| Steam activated | Invasive plant | 300 | Un-modified | 10.90 | 66 | 5.60 | 23.10 | 5.10 | 25.40 | 0.004 | 0.90 | 11 |

| Modified | 11.10 | 68.10 | 5.10 | 21.40 | 5.10 | 28.70 | 0.003 | 1.20 | ||||

| Steam activation | Tea waste | 700 | Un-modified | 11 | 85.10 | 2 | 8.90 | 3.9 | 10.90 | 0.022 | 342.2 | 12 |

| Modified | 10.50 | 82.40 | 2.1 | 11.60 | 3.9 | 16.70 | 0.109 | 576.1 | ||||

| Steam activation | Invasive plant | 700 | Un-modified | 12.30 | 69.40 | 1.30 | 24.40 | 4.60 | 43.70 | 0.008 | 2.30 | 13 |

| Modified | 11.70 | 50.60 | 1.70 | 44.90 | 2.50 | 70.70 | 0.038 | 7.10 | ||||

| Zn-loading | Pine cone | 500 | Un-modified | – | 67.90 | 3.90 | 22.10 | 0.5 | 2.1 | 0.016 | 6.60 | 15 |

| Modified | – | 71.20 | 3 | 20.40 | 0.5 | 2.1 | 0.028 | 11.50 | ||||

| FeCl3-modified | Wheat straw | 450 | Un-modified | 7 | 47.20 | 2.40 | 18.40 | 1.10 | – | 0.012 | 9.50 | 16 |

| Modified | 8.30 | 25.90 | 1.70 | 21.60 | 0.60 | – | 0.038 | 50 | ||||

| Amino-modified | Sawdust | 500 | Un-modified | 4 | 68.70 | 3.80 | – | 0.30 | – | 0.005 | 2.60 | 17 |

| Modified | 6 | 62.10 | 4.20 | – | 4.60 | – | 0.005 | 2.50 | ||||

| Methanol-treatment | Rice husk | 450 | Un-modified | – | 70.60 | 3.50 | 24.10 | 0.80 | 1 | 51.90 | 18 | |

| Modified | – | 71.10 | 3.60 | 23.40 | 0.80 | 0.90 | 66 | |||||

| KOH modification | Rice husk | 450–500 | Un-modified | 7 | 42.10 | 2.20 | 0.50 | 12.10 | 42.20 | 0.028 | 34.40 | 19 |

| Modified | 7 | 76.40 | 3.30 | 0.90 | 16.90 | 3.50 | 0.073 | 117.80 | ||||

| H2O2 oxidation | Peanut hull | 300 | Un-modified | 6.2 | 56.30 | 5.60 | 36.60 | 0.90 | – | – | 1.30 | 13 |

| Modified | 4.4 | 48.30 | 5.80 | 43.80 | 0.80 | – | – | 96.90 | ||||

| Clay-loaded composite (montmorillonite) | Hickory chips | 600 | Un-modified | – | 81.80 | 2.20 | 14 | 0.70 | – | – | 401 | 20 |

| Modified | – | 80.90 | 2.20 | 15.10 | 0.30 | – | – | 376.10 | ||||

| Clay-loaded composite (montmorillonite) | Bagasse | 600 | Un-modified | – | 76.40 | 2.90 | 18.30 | 0.80 | – | – | 388.30 | 21 |

| Modified | – | 75.30 | 2.20 | 18.90 | 0.70 | – | – | 407 | ||||

| Clay-loaded composite (Kaolinite) | Bamboo | 600 | Un-modified | – | 80.90 | 2.30 | 14.90 | 0.10 | – | – | 375.50 | 22 |

| Modified | – | 83.30 | 2.40 | 12.40 | 0.20 | – | – | 408.10 | ||||

| CO2-ammonia treatment | Cotton stalk | 600 | Un-modified | – | – | – | – | 1.10 | – | 0.070 | 224 | 23 |

| Modified | – | – | – | – | 1 | – | 0.130 | 351 | ||||

| MnOx-loading | Corn straw | 600 | Un-modified | – | 85.30 | 1.70 | 5.20 | 0.80 | 5 | 0.036 | 61 | 24 |

| Modified | – | 73 | 0.30 | 10.90 | 0.70 | 13.10 | 0.006 | 3.20 | ||||

| Metal coating | Pulverized sub-bituminous | 600–1000 | Un-modified | 6.4 | 81.60 | – | 17.90 | – | – | 0.079 | 190 | 25 |

| Modified | – | 65.50 | – | 13.20 | – | – | 0.126 | 245 | ||||

| MnO2-loading | Pinewood | 700 | Un-modified | 4.5 | – | – | – | – | – | 0.200 | 369 | 29 |

| Modified | – | – | – | – | – | – | 0.194 | 361 | ||||

| MnO2-loading | Pinewood | 600 | Un-modified | – | 85.70 | 2.10 | 11.20 | 0.30 | 4.0 | 0.003 | 209.60 | 26 |

| Modified | – | 61.50 | 1.90 | 27.60 | 0.20 | 33.40 | 0.066 | 67.40 | ||||

| CO2/NH2-modified | Cotton stalks | 600 | Un-modified | – | – | – | – | 1.10 | – | 0.070 | 224.10 | 27 |

| Modified | – | – | – | – | 3.50 | – | 0.130 | 351.50 | ||||

| Magnetic biochar (Zero-valent iron) | Paper waste | 700 | Un-modified | – | – | – | – | – | – | 0.083 | 67 | 28 |

| Modified | – | – | – | – | – | – | 0.079 | 102.20 | ||||

| Magnetic biochar (Fe2+/Fe3+) | Orange peel | 700 | Un-modified | – | 67 | 1.50 | – | 2 | 14.90 | 0.390 | 501 | 30 |

| Modified | – | 0.40 | 0.20 | – | 0.20 | 95.70 | 0.033 | 19.40 | ||||

| Magnetic biochar (Fe2+/Fe3+) | Orange peel | 400 | Un-modified | – | 65.70 | 3.50 | – | 1.80 | 6.90 | 0.041 | 28.10 | 30 |

| Modified | – | 29.40 | 2.20 | – | 0.50 | 35 | 0.042 | 23.40 | ||||

| Magnetic biochar (Fe2+/Fe3+) | Orange peel | 250 | Un-modified | – | 56.50 | 5.10 | – | 1.70 | 3.10 | 0.059 | 51.60 | 30 |

| Modified | – | 35.10 | 3.60 | – | 1.10 | 42.40 | 0.052 | 41.20 | ||||

| Zn(NO3)2-modified | Pine cones | 500 | Un-modified | 4.70 | 67.90 | 3.90 | 22.10 | 0.50 | 2.10 | 0.016 | 6.60 | 31 |

| Modified | 4 | 71.20 | 3 | 20.40 | 0.50 | 2.10 | 0.028 | 11.50 | ||||

| Mg-Ca loaded | Corn cob | 300 | Un-modified | – | 35.50 | 6.30 | – | 0.70 | 4 | – | – | 32 |

| Modified | – | 43.30 | 5 | – | 0.60 | 5 | – | 378 | ||||

| H2O2 oxidation | Apple tree branch | 550 | Un-modified | 9.79 | 72.53 | 14.85 | 2.49 | 1.49 | – | – | 6.67 | 33 |

| Modified | 5.93 | 62.69 | 21.58 | 2.86 | 1.42 | – | – | 7.95 | ||||

| HNO3-modified | Tea waste | 300 | Un-modified | 7.16 | 57.80 | 4.42 | 34.12 | 3.66 | 6.15 | – | – | 34 |

| Modified | 2.40 | 57.03 | 4.47 | 32.99 | 5.51 | 2.80 | – | – | ||||

| Chemically modified (H2SO4) | Tea waste | 300 | Un-modified | 7.16 | 57.80 | 4.42 | 34.12 | 3.66 | 6.15 | – | – | 35 |

| Modified | 3.40 | 60.79 | 4.69 | 30.65 | 3.87 | 4 | – | – | ||||

| Chemically modified (HCl) | Tea waste | 300 | Un-modified | 7.16 | 57.80 | 4.42 | 34.12 | 3.66 | 6.15 | – | – | 35 |

| Modified | 2.55 | 63.15 | 4.75 | 28.18 | 3.92 | 3.10 | – | – | ||||

| HNO3-modified | Tea waste | 500 | Un-modified | 7.04 | 69.66 | 2.96 | 24.82 | 2.55 | 11.40 | – | – | 35 |

| Modified | 2.44 | 56.57 | 4.39 | 33.78 | 5.26 | 3.10 | – | – | ||||

| HNO3-modified | Tea waste | 700 | Un-modified | 10.09 | 71.03 | 2.11 | 23.74 | 3.12 | 9.26 | – | – | 35 |

| Modified | 2.57 | 71.30 | 2.21 | 22.69 | 3.80 | 2.50 | – | – | ||||

| Chemically modified (H2SO4) | Tea waste | 500 | Un-modified | 7.04 | 69.66 | 2.96 | 24.82 | 2.55 | 11.40 | – | – | 35 |

| Modified | 2.35 | 61.27 | 4.55 | 30.26 | 3.96 | 3.50 | – | – | ||||

| Chemically modified (H2SO4) | Tea waste | 700 | Un-modified | 10.09 | 71.03 | 2.11 | 23.74 | 3.12 | 9.26 | – | – | 35 |

| Modified | 4.16 | 71.37 | 2.14 | 23.45 | 3.04 | 6.50 | – | – | ||||

| Chemically modified (HCl) | Tea waste | 500 | Un-modified | 7.04 | 69.66 | 2.96 | 24.82 | 2.55 | 11.40 | – | – | 35 |

| Modified | 2.65 | 63.35 | 4.17 | 28.07 | 3.88 | 3.80 | – | – | ||||

| Chemically modified (HCl) | Tea waste | 700 | Un-modified | 10.09 | 71.03 | 2.11 | 23.74 | 3.12 | 9.26 | – | – | 35 |

| Modified | 2.49 | 74.02 | 2.22 | 20.62 | 3.15 | 7.83 | – | – | ||||

| HCl-modified | Peanut shells | 500 | Un-modified | 9.20 | – | – | – | – | 32.54 | – | 36 | |

| Modified | 8.60 | – | – | – | – | 8.52 | – | – | ||||

| H3PO4-modified | Swine manure | 700 | Un-modified | – | 31.96 | 0.66 | 4.77 | 1.60 | 60.73 | 0.07 | 227.56 | 37 |

| Modified | – | 48.35 | 0.66 | 4.41 | 2.23 | 43.98 | 0.09 | 319.04 | ||||

| H3PO4-modified | Rice straw | 700 | Un-modified | – | 31.77 | 0.98 | 7.23 | 0.96 | 58.97 | 0.23 | 369.26 | 39 |

| Modified | – | 37.77 | 0.43 | 5.31 | 1.05 | 55.27 | 0.23 | 372.21 | ||||

| H2O2 oxidation | Eucalyptus saligna | 500 | Un-modified | 5.60 | 82.10 | 0.97 | 9.20 | 0.17 | – | 0.138 | 333.72 | 40 |

| Modified | 6.48 | 78.40 | 1.29 | 12.70 | 0.14 | – | 0.146 | 347.46 | ||||

| HNO3 + H2SO4 | wheat straw | 450 | Un-modified | 8 | 66.15 | 2.09 | 7.21 | 0.87 | – | – | – | 41 |

| Modified | 7.30 | 60.57 | 1.60 | 14.82 | 1.21 | – | – | – | ||||

| H2O2 oxidation | Yak manure | 350 | Un-modified | – | 37.44 | 5.87 | 26.76 | 2.71 | 27.22 | – | 1.03 | 42 |

| Modified | – | 40.04 | 3.99 | 29.17 | 2.90 | 23.91 | – | 6.36 | ||||

| H2O2 oxidation | Eucalyptus wood | 550 | Un-modified | – | 75.5 | 2.90 | 21.50 | 0.1 | – | – | 249 | 43 |

| Modified | – | 64.8 | 2.30 | 32.60 | 0.3 | – | – | 261 | ||||

| H2O2 oxidation | Corn stover | 600 | Un-modified | 8.30 | 41.60 | 1.50 | 8.10 | 0.40 | – | – | 178 | 44 |

| Modified | 7 | 40.60 | 1.30 | 8.30 | 0.40 | – | – | 179 | ||||

| HNO3-modified | Pinewood chips | 300 | Un-modified | 6.20 | 54.80 | 4.10 | 41 | 0.12 | 0.15 | – | – | 45 |

| Modified | 5.80 | 56.50 | 1.20 | 40.30 | 1.99 | 0.11 | – | – | ||||

| H2SO4/HNO3 treatment | Alternanthera philoxeroides | 350 | Un-modified | 9.56 | 47.70 | 4.19 | 25.83 | 2.68 | 19.36 | – | 4.78 | 46 |

| Modified | 2.12 | 60.34 | 1.91 | 28 | 1.85 | 5.46 | – | 7.14 |

Modification/treatment by chemicals

Chemical treatment involves both one-step and two-step modification methods. Activation and carbonization phases are attained simultaneously during one-step chemical modification in the existence of a modifying material. The two-step chemical modification involves raw feedstock’s carbonization tailed through the treatment of pyrolyzed product via mixing with modifying material e.g., various chemicals.

Chemical modification with acids and alkali

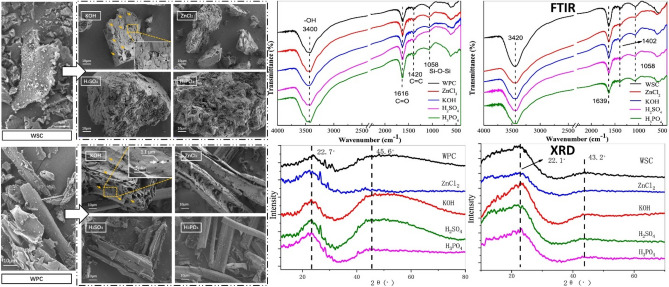

The purposes of acid and alkali modification are to introduce acidic binding sites (carbonylic lactonic, phenolic functional groups) and develop a better porous structure for contaminant removal12. Biochar surface properties have been improved by employing chemical treatment13. Numerous studies have discussed the influence of acid modification on functional groups, pore volumes, and specific surface area (SSA). Soaking with strong acids such as HCl, HNO3, H3PO4, and H2SO4 has been examined for modification, which can increase the adsorbent surface acidities and improve the porous structure of biochar (Fig. 3).

Figure 3.

SEM images, FTIR, and XRD spectra of walnut shell biochar (WSC) and wood powder biochar (WPC) and modified ones with different acids and alkalis (After Liu et al.14).

After treatment with sulfuric acid, hydrochloric acid, citric acid, oxalic acid, or phosphoric acid, the resultant adsorbent generally possessed much higher surface area, pore volume, more hydrophobic and acidic groups for contaminant sorption15–20. The mechanism involves the improvement in the pore structure and specific area of the adsorbent, which has a significant effect on the physical sorption of pollutants21. Functional groups e.g. -COOH formed through acidic treatment also show a significant effect in the contaminant-sorption mechanism, therefore altering the removal ability of treated adsorbent22.

Acid treatment modifies the physicochemical attributes of biochar to increase the adsorption capacities for the elimination of inorganic and organic pollutants from soil and wastewater. The pickling mechanism decreased the sludge-based adsorbent’s micro-pore volume and enhanced the mesoporous volume, thereby improving the sorption capacity of biochar for antibiotics and heavy metals23. Compared to fresh biochar, H3PO4-treated eucalyptus-derived biochar exhibited higher removal efficiency of chromium hexavalent24. Citric acid-modified biochar showed the maximum sorption capacity of 12,109.4 and 2475 mg kg−1 for Pb and Cd in the soil, this capacity was greater than un-treated biochar25. H3PO4 is a frequently used modifying agent for acid treatment and a more eco-friendly material than other hazardous and corrosive reagents e.g., zinc chloride26. H3PO4 can decompose aromatic materials, aliphatic and lignocellulosic while creating polyphosphate and phosphate cross bridges to elude the shrinkage in the porosity enhancement mechanism27. More mineral acids including HCl, H2SO4, and HNO3 have also been extensively used for biochar activation. The modification with nitric acid has been exposed to cause micropore wall degradation owing to its corrosive property, subsequently in a reduction of the surface area28. Comparably, H2SO4 modification caused a reduction in porosity from 12 to 40% and enhanced the distribution size of heterogeneous micropores in biochar. Organic acids e.g., oxalic acid increase the sorption of contaminants through proton-promoted and ligand mechanisms29. However pre-treatment with 10% H2SO4 affected the O and C contents and a mixture application of 30% oxalic acid and H2SO4 showed a 250-fold enhancement of surface area than untreated biochar30. Similarly, the HCl-modified biochar of wheat straw showed more heterogeneous pores compared to un-treated biochar31. Indigenous metal/inorganic contaminants can also be efficiently eliminated by acid application32. Generally, it is documented that modification with acids can establish the various functional groups having acidic contents e.g. amine and carboxyl groups, thus increasing the metals removal capacity and affinity by surface complexation and cation exchange with these more active sites.

Dai et al.29 applied H2SO4-modified bur cucumber adsorbent for sulfamethazine removal in soil. A high water–solid partition coefficient of 229 L kg−1 was noticed for loamy soil. Both chemisorption onto hemiacetal functional groups and chemical diffusion into pores were supposed to be retention processes. Table 3 sums up the chemical oxidation and acid/alkali modification approaches for biochars described.

Table 3.

Chemical oxidation and base/acid modification process of the biochar.

| Biochar Feedstock | Modification | Ratio of Liquid–solid | Temperature (°C) | Concentration | pH | Time | References |

|---|---|---|---|---|---|---|---|

| Bamboo | NaOH | – | 60 | 10% | – | 6 h | 29 |

| hydrothermal biochar, Alamo switch grass | KOH | 500 mL: 2 g | 25 | 2 M | 5 and 7 | 1 h | 26 |

| Rice hull | KOH | 500 mL: 2 g | 25 | 3 M | – | 1 h | 27 |

| Rice husk | H2SO4 | 200 mL:20 g | 60 | 10% (v/v) | 5 and 9 | 1 h | 28 |

| Burcucumber | C2H2O4 + H2SO4 | 100 mL: 5 g | 25 | 30% | – | 4 h | 30 |

| Jarrah, Sawdust | KOH | 40 mL g−1 | 90 | 0.1 M | – | 1 h | 31 |

| Acacia saligna | H3PO4 | 40 mL g−1 | 90 | 1 M | – | 1 h | 32 |

| Peanut hull | Oxidation (H2O2) | 20 mL:3 g | 25 | 10% | – | 2 h | 33 |

| Bamboo | Oxidation (H2O2) | 1 mL g−1 | 25 | 15–30% | – | 12 h | 34 |

| Apple tree branches | Oxidation (H2O2) | 1:20 (w: v) | 80 | 15% | – | 6 h | 35 |

| Tea waste | H2SO4 | 100 mL:10 g | 60 | 10% | 7 | 1 h | 36 |

| Tea waste | HNO3 | 10 mL: 10 g | 60 | 69% | 7 | 3 h | 37 |

| Tea waste | HCl | 100 mL:10 g | 50 | 5 M | – | 24 h | 38 |

| Poultry manure | H3PO4 | 5.63 mL: 240 g | 25 | 50% | – | 2 h | 39 |

| Bamboo hardwood | NaOH | 100 mL:10 g | 40 | 0.40 M | – | 16 h | 40 |

| Cow manure and wheat straw | HNO3 | 300 mL:10 g | 90 | 25% | 4 h | 41 | |

| Swine manure and rice straw | H3PO4 | 40 mL:20 g | 25 | 14% | – | 24 h | 42 |

| Dairy manure | NaOH | 5:1 | 65 | 2 M | – | 12 h | 43 |

| Coconut shell | HCl | 250 mL:5 g | 20 | 1 M | – | 3 h | 44 |

| Corn straw | Na2S | 500 mL:2 g | 80 | 2 M | – | 4 h | 45 |

| Corn straw | KOH | 500 mL:2 g | 80 | 2 M | – | 4 h | 46 |

| Thalia dealbata | MgCl2 | 100 mL:10 g | 25 | 1 M | 0.5 h | 30 | |

| Auricularia auricular dreg | Cetyl trimethyl ammonium bromide (CTAB) | 250 mL:5 g | 25 | 3.0% | 2 h | 40 |

The main objectives of alkaline modification are to improve the amount of O-comprising functional groups such as ether, carbonyl, carboxyl, and hydroxyl as well as the specific surface area of raw biochar, therefore enhancing the removal of several contaminants11. Alkaline activation is a mechanism including the basic (alkaline-nature) solution applied to change biochar structure at pre -or-post carbonization stages33. The most commonly used alkaline agents are sodium hydroxide (NaOH) and potassium hydroxide (KOH)34,35. Alkali activation of biochar using NaOH and KOH can enhance the surface basicity and O content while dissolving condensed organic matter (such as cellulose, and lignin) and ash to aid subsequent modification36. After alkaline activation, blocked pores are cleansed, causing higher porosity24. Biochars with very large SA have been observed after being functionalized by NaOH and KOH37. Potassium species such as K2CO3 and K2O may be generated during modification due to the intercalation of potassium ions in the crystallite layer that creates condensed carbon structures. K2CO3 and K2O may diffuse into the internal structure of the adsorbent matrix expand available pores and form new different pores of product38.

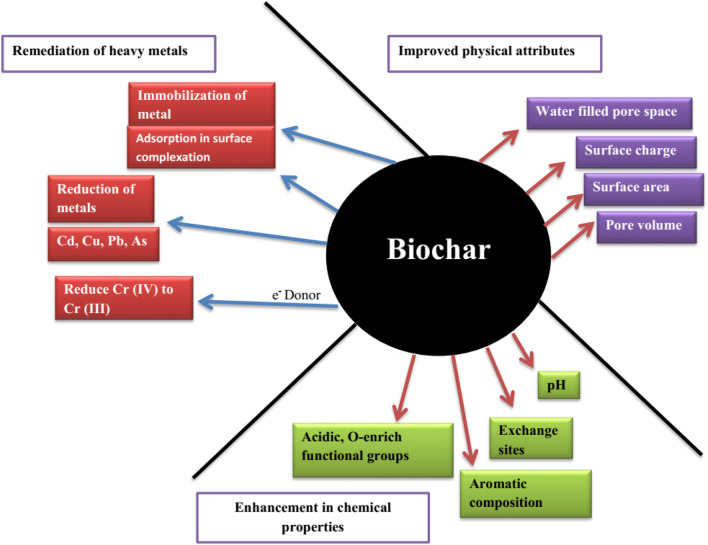

Chemical activation of adsorbent may increase its pollutant sorption capability by forming abundant and additional sorption-sites on improved SA, providing biochar surface more conducive to surface precipitation, surface-complexation, and electrostatic attraction, and providing higher affinity for sorption and strong sorption capacity via sturdy interactions with ether, carbonyl, carboxyl, and hydroxyl functional groups39. Figure 4 and Table 4 encapsulate the mechanism and improved ability of the chemically activated adsorbent for contaminants sorption. However, most surface attributes prevailed unaltered after the KOH-soaking, Cd2+, and Cu2+ sorption was notably increased which may be owing to a large number of oxygen-containing functional groups and higher surface area40. Moreover, amination and carboxyl groups modification of adsorbent also greatly increased Cu2+ adsorption by powerful surface complexation with NH2-functional groups, which were greatly selective and slightly affected via competing cation32. KOH-treated biochar significantly increased its adsorption capacity to As (V) due to the enhancement of pore volume and surface area and the alternation of surface functional groups23.

Figure 4.

Improved performance of multiple-modified biochars.

Table 4.

The mechanisms and enhanced performance of chemically oxidized and base/acid modified biochars.

| Modification | Pollutant | Sorption capacity | Improvement | Functionalities | Mechanism | Reference |

|---|---|---|---|---|---|---|

| NaOH | Chloramphenicol | Around 2100 mg kg−1 | Enhance surface graphitic C and oxygen-enrich groups | Carboxyl and carbonyl groups | Formation of H-bonds among N-comprising groups in adsorbent surface and chloramphenicol, Electron-donor–acceptor π-π interaction | 22 |

| KOH | As (v) | 30.98 mg g−1 | More than about 1.3 times higher removal capacity | Carbonyl group | Ion exchange | 21 |

| KOH | Cd and Cu | 34 and 31 mg g−1 | Approximately 20 times higher removal capacity than other raw biochars | Aromatic carbon | Surface precipitation, ion exchange electrostatic attraction, and surface complexation | 23 |

| H2SO4 | Tetracycline | 23.26 mg g−1 | Larger SSA and porosity, higher oxygen and carbon contents, lower ash content | O-containing functional groups | Π-π electron donor acceptor interaction between the treated adsorbent surface and aromatic ring | 25 |

| H2SO4 + oxalic acids | Sulfamethazine | 183–229 L kg−1 | – | – | Ligand- and proton-enhanced processes; Increase in SA by acid modification | 29 |

| H3PO4 | – | – | Enhance water extractable organic carbon content | – | Hydrolysis of ester groups formed during the pyrolysis | 26 |

| (Oxidation) H2O2 | Pb | 22.82 mg g−1 | Removal for Pb was 20 times greater than un-treated biochar | Carboxyl groups | Enhance carboxyl groups expedite the formation of bound complexes with Pb | 27 |

| (Oxidation) H2O2 | Hg | 1470.5–1347.9 µg g−1 | Substantially higher removal capacity than other un-treated biochars (380–618 ng mg−1) | Ester, Carboxyl, and Carbonyl groups | Higher SSA and total pore volume Surface O-enrich functional groups increase electron transfer, and Hg-oxidation and allow chemisorption centers | 28 |

| Acetic acid + Na2S2O4 + H2SO4 | Cu | 15.97 mg g−1 | Enhancing removal capacity in fixed-bed and batch experiments | Amino groups | Ion exchange | 40 |

| HNO3 + H2SO4 | Cu | 12.47 mg g−1 | Around 4.62% N was present on the treated adsorbent, fivefold enhancement of removal capacity | Amino groups | Foundation of outer-spherecomplexes with amino groups of treated biochar | 41 |

Elimination of organic contaminants could be increased through π-π EDA interaction between aromatic rings of pollutants and biochar13. Another study reported the removal capacity of tetracycline (58 mg g−1) via KOH-treated adsorbent was markedly higher than reported in other studies (5 to 54 mg g−1), while the noticed capacity for the Chloromycetin elimination via NaOH-treated char was remarkably greater than un-activated adsorbent22,24,30,41. Conversely, urea treatment could produce N-enrich functional groups as well as enhance the basic nature of the surface, therefore increasing π-π dispersion forces for carbolic acid sorption27. He et al.42 presented that oxalic and sulfuric acid-modified biochar delivered a better result of 183 to 229 L kg−1 sulphadimethyl pyrimidine removal in various kinds of soil, maybe due to enhancement of surface areas and surface functional groups in activated adsorbent (Table 1).

Modification by an oxidant (chemical oxidation)

Oxidant treatment can enhance the content of O-containing functional groups, stimulating the complexation of heavy metals such as Cd, Zn, Cu, Pb, etc.43. H2O2 activation of manure biochar enhanced the carboxyl contents (101%) and oxygen contents (63%) of treated biochar, while the content of ash was reduced by 42% after modification. The oxidant-modified biochar could remove Zn, Cu, Cd, and Pb efficiently, which was due to the shifting of the adsorption process from precipitation to complexation. Nonetheless, H2O2 treatment was inefficient in methylene blue sorption44. After hydrogen peroxide activation of pinewood chip biochar, the sorption capacity of methylene blue decreased as the O-rich groups weakened the forces of delocalized π-interaction which was the core process for methylene blue sorption38. Apart from potassium permanganate which has a direct impact in enhancing cation-π interaction and O-containing functional groups in modified biochar43,44, hydrogen peroxide could also be applied as an activation agent45. The effectiveness of this technique depends mainly on the target pollutant type and pollutant elimination process. It is hypothesized that this technique is appropriate for metal stabilization in the soil as there is an increased surface complexation due to enhancement in O-comprising functional groups.

The hydrophilicity and functional groups of adsorbent can be activated with chemicals to fit the explicit necessities of environmental safety including the elimination of pollutants from soil and water46. In general, biochar derived at low temperatures has more C–H and C=C functional groups27. Chemical treatment using H3PO4, NHO3, H2O2, and KMnO4 and a mixture of H2SO4/HNO3 can generate acidic-content functional groups (e.g., phenolic, lactonic, carbonyl, and carboxyl) on C surface at comparatively low temperatures47. A substantial amount of oxygen-enrich functional groups were formed via chemical activation using nitric acid compared to potassium permanganate, showing a resilient oxidizing ability of nitric acid32. In addition, H2O2 treatment was able to enhance the carboxylic group from 2 to 8% by oxidizing the carbonized structure of the adsorbent22.

N-rich functional groups (such as pyridinic, pyrrolic, lactam, imide, and amide) and oxygen-comprising functionalities play a significant role in the environmental implication for their potent complexation attractions, particularly for the base metal cations e.g. Cd, Zn, Cu48. Formation of the N-bearing functionalities could be achieved through nitration followed by dwindling on the carbon surface20. Nitro-groups are consequently decreased to amino groups on the surface by applying Na2O4S2 (reducing agent). Surface amination leads to the formation of amino-based groups, which stimulate basic attributes and strong attractions to impurities28. Applying chitosan as a modifying agent, established amine functionalities on the surface of biochar to enhance its adsorption capacity and affinity to inorganic pollutants49. Chitosan loading on the surface of biochar can also enhance its effectiveness as a soil rectification, as well as chitosan-loaded adsorbent, may be applied as an efficient, eco-friendly, and low-cost adsorbent to decontaminate the pollutants from the environment50. H2O2-modified biochar derived from peanut hull surface enhanced oxygen-enrich functional groups, particularly the carboxyl group which accelerates the metals removal capacity and affinity of adsorbent9. Another study found that amino-treated char with enhanced functional groups e.g., C–N, N–H, C–O, and CH2 could efficiently eliminate copper from wastewater because copper was intensely complexed with amino-functionalities on the surface of adsorbent18. Besides, char activated through KOH enhanced oxygen-comprising functionalities such as COOH, C=O, C–O, and O–H and consequently increased the tetracycline adsorption capacity40. At pH 7, oxygen-rich functional groups on the alkali-treated biochar accelerated the formation of hydrogen bonding with tetracycline molecules thus increasing its removal capacity41. Modification of biochar with hydrogen peroxide has been depicted to contain a great amount of oxygen-comprising functional groups and efficiently eliminate heavy metals such as Cd, Ni, Cu, and Pb26.

Organic modification/activation by organic solvents

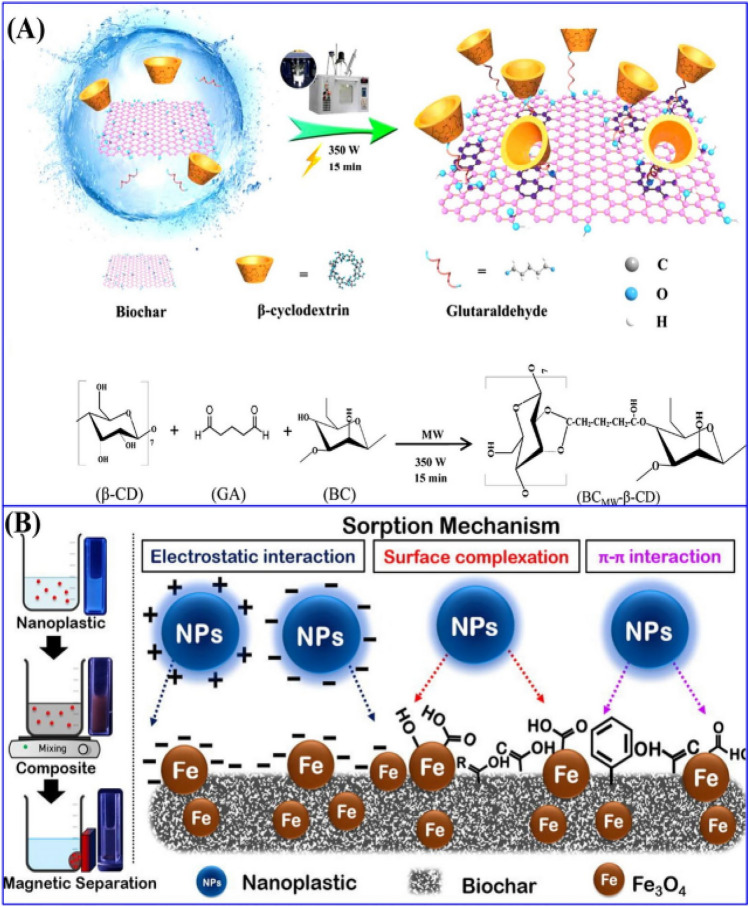

It is conceivable to promote the types and quality of functional groups in biochars by mixing biochars with an organic substance containing a large number of functional groups27. The sorption capability also can be improved by elevating the number of sorption sites51. Out of various substances, chitosan has been applied in many studies. Chitosan is a natural polysaccharide that is produced from the Crustacea shell and is rich in –O,-OH, -NH2 functionalities. The removal capability of contaminants can be raised via doping chitosan onto the char’s surface51. Boraah et al.52 examined how the sole utilization of textile residue biochar coated with chitosan influenced cadmium-contaminated soil on cadmium distribution in horseradish trees. Plant-available cadmium in the soil showed the best efficiency in reducing cadmium concentration in the soil by 58% than the control sample. Braghiroli et al.53 stated that the composite of biochar and chitosan showed a great removal ability of ammonium, with a maximum range of 149.25 mg g−1, comparatively higher than raw biochar. Moreover, reported that the amount of surface functional groups can be improved via activated chars with macromolecules e.g. cyclodextrin, Polyaziridine, lignin, and humic acid, these provide better elimination capacity for impurities52. Figure 5 displays how β-cyclodextrin coated rice biochar was produced appropriately by employing a microwave-based one-pot method. The coated composite was used for concurrently removing Pb (II) and bisphenol-A53. Microwave irradiation could ascertain surface alteration in 15 min and the generated biochar microwave-assisted-β-cyclodextrin composite (BCMW-β-CD) showed higher sorption efficiency with a theoretical monolayer uptake of 240 mg g−1 for lead and a heterogeneous removal volume of 209 mg g−1 for bisphenol A in the monocomponent system. Carboxyl-group activation also can be achieved by applying water-soluble methanediimine and esterification by methanol11. The application of methanol for carboxyl alteration is low-cost. For instance, biochar derived from rice soaked with sodium hydroxide and consequently treated with methanol exhibited an improvement in surface attributes. Chemical mechanisms involved in char activation by methanol are esterification and then direct reaction between biochar carbonylic functional properties with methanol38. Methanol treated-adsorbent was enriched in hydroxyl and ester groups than un-activated char, which contributes to the EDA interaction formation between adsorbent surface and pollutants (pharmaceutic manufacturing wastewater, contaminated water, and soil)54. Jin et al.55 presented that methanol-treated adsorbent was more efficient in TC elimination compared to un-treated char owing to functional group modification as well as enhancement of oxygen-enrich functionalities on the adsorbent. The process proposed by the researchers was the EDA interaction generation between hydroxyl groups or ionized moiety of activated char and electron-depleted sites.

Figure 5.

(A) Schematic sketch and chemical reactions of microwave-assisted one-pot synthesis of β-cyclodextrin composite biochar19. (B) The interaction mechanism between magnetic biochar and nanoplastics15.

Modification with surfactant

Surfactants are categorized into Gemini, non-ionic, anionic, and cationic surfactants rendering to a hydrophilic nature. Generally, surfactants are employed as additives in washing detergents and industrial fabrication in environmental cleaning, as well as recently extensively used as chemical agents to alter the surface attributes of several solid substances e.g. zeolite, bentonite56. Owing to the surface negatively charged of biochar, cationic-surfactant can smoothly capture through biochar via exchange with ample exchangeable cations (K+, Na+, and Mg2+), and electrostatic attraction in the char-matrix, and consequently, a surfactant-char composite/complex is generated57. For instance, the adsorption of cationic surfactant 1-hexadecyl pyridinium chloride on granular charcoal was mostly by ion exchange at a lower level. The partial monomolecular layer may be established with an enhancement of the cetylpyridinium chloride amount in the solution. Further, it enhanced cetylpyridinium chloride level, hydrophobic interaction among hydrophobic chains of cetylpyridinium chloride, and char improved sorption of cetyl pyridinium chloride58. Kumar et al.59 described the influences of cationic surfactants on pentachlorophenol adsorption by biochar and activated carbon. Cationic-surfactant cetrimonium bromide was merely mixed in a solution comprising pentachlorophenol, and the char-activation mechanism through CTAB occurred thru ion exchange concurrently with adsorption of pentachlorophenol on biochar-CTAB composite. Therefore, cationic-surfactants can be applied as an efficient material to alter char to improve the elimination of the anionic contaminants. Non-ionic surfactants also can be removed through charcoal by physisorption mechanism as showed through low free energy alterations in adsorption. Around 300 mg g−1 of Triton X-100 was doped on the charcoal60. Labanya et al.61 also observed a fixed degree of adsorption of non-ionic surfactant Triton X-100 onto the adsorbent. Contrastingly, owing to electrostatic repulsion, both micellar and mono-molecular anionic surfactants are not fluently sorbed on the biochar surface. For instance, the fragile removal of anionic surfactants on charcoal was noticed62. However, substantial removal of anionic surfactant sodium dodecyl sulfate was recorded on modified charcoal48. Labanya et al.61 observed that after CTAB treatment of biochar, pentachlorophenol removal capacity of activated adsorbent reduced with enhancing aqueous CTAB concentrations. This may be because of the hindrance of the hydrophobic sorption site via CTAB sorption. Contrastingly, solubilization and mobilization of pentachlorophenol by CTAB in the solution might contribute to the reduction of pentachlorophenol adsorption onto the adsorbent. The existence of cationic-surfactant CTAB greatly reduced the adsorption capacity of thiodiphenylamine onto modified char. Apart from, the sorption-site-hindrance mechanism; competition of cationic surfactant with cationic thioridazine hydrochloride interdicted the adsorption of thioridazine hydrochloride on char. Nonetheless, the occurrence of anionic surfactant only marginally reduced thioridazine hydrochloride sorption, while non-ionic surfactant Triton X-100 improved thioridazine hydrochloride sorption22.

Doping of biochars

Recently, doping of biochars by metal-oxides has been applied to enhance the characteristics of biochars and consequently improve their removal performance. Doped biochar can be obtained by biochar mixed with clays, carbonaceous materials (carbon nanotubes, graphene oxide), and metal oxides, to change the surface traits of biochar. Biochar doping is distinguished from chemical modification because it involves the formation of totally new surface functional groups that were not previously present on biochar surfaces.

Doping with metal oxides

The aim of this method to produce doped biochar with metal oxides is to confirm a homogenous spread of metal over the surface of biochar. The biochar is used as a porous carbon support upon which metal oxides precipitate to enhance the surface area of the metal oxide. In general, doping with metal oxides of biochar is performed via soaking biochars in solutions of metal chloride and nitrate. The most used doping agents in literature are MgCl2, Fe (NO3)3, Fe, and FeCl363–65. After mixing biochar with metal oxides or salt solutions, the mixture is heated under oxygenated conditions at temperatures 100–400 °C to allow chlorides or nitrates to be driven off as Cl2 and NO2 gases and alter the metal ions to metal oxides9. Fu et al.66 prepared Fe- and cobalt-soaked bamboo biochar for the elimination of the metal from wastewater. Charcoal of bamboo was mixed in a 100 mL solution comprising iron (III) chloride, cobalt nitrate, and 9 M nitric acid, followed via carbonized by microwave at 640 W for some minutes. Moreover, Mg(OH)2-loaded wheat-straw adsorbent was produced by applying NaOH and MgCl2 solutions63. The iron-impregnated char had markedly enhanced hydroxyl-functional groups than un-coated char due to the creation of Fe oxides on the adsorbent surface64. Chen et al.65 reported that soaking municipal waste and rice husk adsorbents in FeCl3, iron powder, and Cao before pyrolysis generated Fe3+, Fe0, and Ca-coated biochars. These modifications improved the removal capacity of biochar for Cr (IV) and As(V) from wastewater. Most metal oxide loading results in a decrease in the surface area of biochar owing to pores blockage by metal oxide precipitates63. Bamboo biochar-coated with tetrabutylammonium bromide Fe3O4, FeCl3 and used for the removal of polybrominated diphenyl ethers. The findings showed that coated biochar was more efficient for polybrominated diphenyl ether removal compared to other uncoated biochar67. Besides, Fe3+-loaded char was synthesized using ferric chloride salt. Doping adsorbent/char by Fe3+ significantly improved As(III) and As(V) removal capacities68. The removal capacity of Magnesium oxide-loaded biochar for the anionic dye was greatly enhanced compared to untreated biochar by around 5 times. This was due to the surface being positive in the solution after MgO-loading, which increased the removal of anionic dye. Moreover, a large number of functional groups were observed on coated biochar, which aided the elimination of dye66. Thakur et al.51 described a substantial enhancement of Cr(III)-oxyanion sorption via cobalt-loaded bamboo biochar rather than unmodified biochar. The cobalt-loaded showed higher pore volume and surface area compared to uncoated biochar, which led to greater sorption capability. Nonetheless, microwave heating and nitric acid were also involved during the preparation process of cobalt-loaded composite66. Coated biochar was synthesized with the oxides of Mg, Mn, and Al and observed increasing sorption of metal cations (Pb) and oxyanions (P and As) and metal cations (Pb)58. Fu et al.66 prepared a biochar with great removal capacity for P and As from wastewater via modification with aluminum chloride to form an adsorbent-AlCOOH composite. Hemavathy et al.43 modified the biochar with MnCl2 and noticed that the treated biochar showed significantly increased adsorption capacity for Pb and As compared to pristine biochar.

Non-metallic heteroatom doping (emerging technique)

Premarathna et al.69 reported that the non-metallic heteroatom loading is an advanced approach to modifying char by influencing its electronic characteristics, therefore increasing its catalytic sorption ability for pollutant remediation. Previous studies involving non-metallic materials-loaded-biochar and related environmental implications and mechanisms are detailed in Table 5. As reported, the most frequently employed non-metallic elements for modification of biochar include iodine, phosphorus, boron, sulfur, and nitrogen, and can be used to eliminate the aqueous pollutants70. According to Chen et al.71 nitrogen is extensively used heteroatom in char modification. The nitrogen-doping technique can increase the electrochemical functioning of char by creating amine-N, pyridinic-N, and pyrrolic-N, graphitic-N species during the modification mechanism72–75. Cheng et al.72 reported that graphitic-N could stimulate the transfer of electrons within the C skeleton, therefore increasing the catalytic capability of Nitrogen-loaded char for the persulfate-activation. Petrovic et al.73 presented that the pyridinic-N and pyrrolic-N bonds can perform as electron donors and concurrently create N-defects which render more active sites in nitrogen-loaded char. Qiu et al.74 demonstrated that the amine-N could work as a binding site for metals-ions through chelation results. Thus, nitrogen-doped/loaded biochars have been used as efficient catalysts in the elimination of heavy metals, dyes, oxybenzene, and antibiotics in the aquatic system (Table 5). For example, Cheng et al.72 produced nitrogen-doped biochar and it exhibited high sorption capacity for methyl orange (906 mg g−1) and methylene blue (326 mg g−1). Theoretical calculations and spectroscopic studies verified that introduced pyridine-N and pyrrole-N had significant effects on dyes elimination and suggested mechanisms e.g., H-bonding, electrostatic attractions as well as π-π stacking72. In addition, N-doped/loaded biochar exhibited high potential in the catalytic capability for contaminant removal72–75. For instance, Deng et al.75 described that the N-doped biochar exposed high N content (13%) and large surface area (738.50 m2 g−1), and exhibited a strong catalytic capacity for per-oxymoron-sulfate activation to eliminate cotrimoxazole, with an elimination rate of 90% in a half hour. As observed through electron paramagnetic resonance spectra and quenching tests, 1O2 was noticed to be the leading reactive species favoring sulfamethoxazole degradation and non-radical oxidation involving electron transfer and 1O2 was the leading removal mechanism76. Rangabhashiyam et al.77 reported that Sulfur doping provides a modified adsorbent with additional functional groups including C–S–O, C=S, and C–S–C, C–S as well as sulfur rings. In particular, sulfur-containing groups can reinforce the spin density of surrounding C atoms, consequently enhancing the catalytic performance of the char43. Moreover, the C–S–O structure in char can prompt the nucleophilic addition of per-oxymoron-sulfate to create copious 1O278. After S-doping, modified biochar has exposed a great affinity towards inorganic elements. For instance, Rangabhashiyam et al.77 manufactured a hierarchical Fe-maize straw biochar composite, and then Mn2+ and S2− were concurrently introduced, creating a ternary Fe–Mg–sulfur-biochar composite. This composite was examined for Pb2+ removal from an aqueous solution, and they concluded that the Sulfur-doping increased the removal of Pb2+ through PbS precipitation. Dinh et al.79 reported that the Sulfur-loading could introduce Phenoxytamol radicals (C–O·) and vacancy defects on the acacia-derived adsorbent, which expedited peroxymonosulfate activation to degrade 90% of bisphenol A in half an hour. Raman analyses and scavenging experiments confirmed that Sulfur-loaded char prompted the creation of surface-bound ·OH and 1O2 which led to the efficient elimination of BPA Diphenylolpropane79.

Table 5.

Removal of contaminants and associated mechanisms through non-metallic heteroatom-doped biochar.

| Doping agent | Biochar type | Pyrolysis temperature (°C) | Contaminants | Removal capacity | Mechanism involved | References |

|---|---|---|---|---|---|---|

| Nitrogen | Bamboo | 500 | Chlorotetracyclin | 92% |

Non-radical pathways 1O2 Radical pathway: SO4·− |

68 |

| Boron | Wheat straw | 700 | Phenol | 33 mg g−1 |

Non-radical pathways 1O2 Radical pathway: SO4·− |

70 |

| S and N | Peanut shell | 300 | Diethyl phthalate | 14 mg g-1 | Increased removal via pyridinic-N formation and the oxidized sulfur groups on doped-biochar | 71 |

| Nitrogen | Pomelo peel | 800 | Sulfamethoxazole | 95% | Non-radical oxidation involving electron transfer and 1O2 | 72 |

| Sulfur | Tapioca peel | 800 |

Rhodamine B Malachite green |

33 mg g−1 30 mg g-1 |

H- bonding, surface interaction, and electrostatic attraction | 73 |

| Sulfur | Wood pellets | 800 | Bisphenol A | 91% | Driven via hydroxyl radicals and surface-bound singlet O2 | 71 |

| Co-doped (boron and nitrogen) | Wheat straw | 700 | Oxytetracycline | 60% | High defect sites and large SSA | 75 |

| Sulfur | Bamboo | 600 | Oxytetracycline | 89% |

Non-radical pathways 1O2 Radical pathway: SO4·- |

77 |

| Boron | Wheat straw | 900 | Sulfamethoxazole | 90% | Boron-doping restrained the electron transfer | 78 |

| Co-doped (copper and nitrogen) | Glucose | 700 | Tetracycline | 100% | Radical degradation such as electron transfer and ·OH | 84 |

| Nitrogen | Hickory chip | 600 | Reactive red | 37 mg g-1 | zeta potential enhancement and electrostatic interaction | 79 |

| Co-doped (nitrogen and sulfur) | Wood shaving | 800 | Methylene blue | 40% | Activation through the thiophenic S and graphitic-N active sites | 74 |

| Nitrogen | Enteromorpha prolifera | 800 |

Phenanthrene Acenaphthene Naphthalene |

90 mg g−1 51 mg g−1 86 mg g−1 |

Partition effect, π–π stacking, mass transfer, and pore-filling | 81 |

| Nitrogen | Glucose | 700 | Pnitrophenol | 94% | New sorption sites of pyrrolic-N and pyridinic-N | 75 |

| Nitrogen | Maize straw | 600 |

Methyl blue Acid orange 7 |

436 mg g−1 292 mg g−1 |

π–π stacking and pore-filling Lewis acid–base interaction, π–π stacking, and electrostatic attraction |

33 |

| Nitrogen | Phragmites australis | 280 | Phenanthrene | 1.9 mg g−1 | Electrostatic attraction, hydrophobic effect, and π–π interaction | 82 |

| Nitrogen | Alfalfa | 600 |

Methyl orange Methyl blue |

326 mg g−1 906 mg g−1 |

H-bonding, electrostatic interactions, and π–π stacking | 69 |

| Nitrogen | Sawdust | 800 | Bisphenol A | 50 mg g-1 | π-π EDA interactions | 67 |

| Nitrogen | Pomelo peel | 200 | Orange II | 100% | 1O2 and ·OH expedited the degradation | 72 |

| Nitrogen | Peanut shell | 350 | Pb2+ | 130 mg g−1 | ion exchange and surface complexation | 23 |

| Co-doped (phosphorus and nitrogen) | Lotus leaf | 600 | Pb2+ | 321 mg g−1 | Precipitation and surface complexation | 32 |

| Sulfur | Corn straw | 800 | Pb2+ | 181 mg g−1 | Precipitation, reduction, and complexation | 69 |

| Nitrogen | Loofah sponge | 400 | Cr (IV) | 238 mg g−1 | In-situ reduction, complexation, and electrostatic attraction | 44 |

| Nitrogen | Hemicelluloses | 200 | Cr (VI) | 349 mg g−1 | Chelation, redox, and electrostatic attraction | 71 |

| Nitrogen | Maize straw | 600 |

Cd2+ Cu2+ |

197 mg g−1 104 mg g−1 |

Complexation and cation-π bonding with hydroxyl groups and graphitic-N | 74 |

| Boron | Maize straw | 800 | Fe2+ | 50–132 mg g−1 | Co-precipitation, ions exchange, and chemical complexation | 75 |

| Co-doped (nitrogen and oxygen) | Rice husk | 500 |

Zn2+ Ni2+ Cu2+ |

12 mg g−1 8 mg g−1 13 mg g−1 |

Electrostatic attraction and surface complexation | 80 |

Boron (B) is another excellent material heteroatom that can restrain electron dispersion modify the surface characteristics of biochar and offer additional defect sites80. Doping of maize straw-biochar with boron enhanced the O2-enrich functional groups and SSA (890 m2 g−1), which eventually enhanced its capability to adsorb Fe2+81. The contact mechanisms involved between boron-treated biochar and Fe2+ were co-precipitation, ion exchange, and chemical complexation. Respecting the catalytic influence of boron-treated biochar, Murtaza et al.82 applied the boron-doped biochar derived from wheat to activate peroxy-disulfate for sulfamethoxazole elimination and degradation of sulfamethoxazole significantly (up to 90%) was found in 120 min. Theoretical and experimental results explained that the introduced boron species could perform as Lewis acid sites to increase the surface affinity towards peroxydisulfate and that the char-facilitated electron transfer process was mainly accountable for the non-radical route82. In another study, B-doped biochar (B-BC) was prepared using boric acid. The modified biochar had more porosity and SSA up to 897.97 m2 g−1. Among the modified biochars prepared, the maximum adsorption of Fe2+ (132.78 mg g−1) was noted at 55 °C using 800B-BC1:2 due to chemisorption, co-precipitation, and ion exchange18. A spontaneous endothermic physical adsorption process was recorded in the case of neonicotinoid adsorption while using boron-doped porous biochar prepared through hydrothermal carbonization. Electrostatic and hydrophobic interactions were noted between acetamiprid and porous biochar used with a maximum adsorption capacity of 227.8 mg g−1 for acetamiprid83.

Moreover, several studies reported that co-doping of two materials on the char. Copper and nitrogen co-doped char synthesized and was applied for tetracycline degradation, and composite biochar showed better performance compared to raw biochar, Cu-doped, and N-doped biochar72. In another study, Singh et al.49 prepared three kinds of doped biochar (co-doping of S and N, S-doped and N-doped) biochar produced from bamboo. Conversely, they observed that the degradation amount of antibiotics via sulfur and nitrogen-co-doped biochar (70%) was less than sulfur-doped biochar (89%) and nitrogen-doped (90%). The main cause for this mechanism was that nitrogen-doped biochar had the maximum amount of ·OH and SO4· − , higher defects, and higher SSA32. Although substantial advances in non-metal component-loaded biochars have been attained, it is still in infancy with great ability for melioration in environmental decontamination. The non-radical process behind persulfate activation is still unclear, which demands more research. Moreover, complex sample fabrication, poor reusability, and the high cost of this kind of biochar require to be accurately addressed in future exploration.

Modification by carbonaceous nanomaterial

Coating with carbon nanotubes

Biochar in combination with carbon nanotubes, comprising functional groups can generate resilient bonds with contaminants and biochar surface85. Han et al.86 reported that the carbon nanotube shows significant physicochemical characteristics such as greater π-π interactions, large surface area, magnificent thermal conductivity, superior electron mobility, and higher mechanical strength. These properties are helpful for the sorption of several contaminants and work as a perfect catalytic supplement for the removal of impurities. Thus, carbon nanotube shows a substantial potential to be applied in the processes of remediation. Jiang et al.87 produced a composite of carbon nanotube with sludge biochar to remove sulfamethoxazole. Compared with pristine biochar, the composite exhibited a higher surface area (119 m2 g−1), and maximum sorption capacity. The study of physicochemical characteristics, kinetics, thermodynamics, isotherms, and various environmental factors showed that its remarkable removal efficiency was mainly ascribable to pore filling, π-π conjugation as well as the interaction of functional groups87. Chen et al.58 presented the methylene blue adsorption capacities of carbon nanotube doped biochar and untreated bagasse and hickory biochar. The maximal sorption capacities of nano-tube biochar composite and untreated biochar (5.5 and 2.4 and mg g−1 respectively) were about twice the time higher than untreated biochar. Methylene blue took up greater affinity binding sites within the carbon nanotube. Moreover, the char exhibited the capability to eliminate Phenothiazin-5-ium via itself, when sorption-sites of carbon nanotube were fulfilled. The electrostatic interaction was the leading process for Phenothiazin-5-ium sorption and microporous diffusion governed its sorption amount30. Jiang et al.88 observed that the SA of carbon nanotube-doped biochar derived from Giant cane was very low compared to un-doped biochar, but a large amount of acidic-functional groups were noticed on the surface of carbon nanotube-doped adsorbent. These acidic functional groups may smoothly interact with lead and generate a firm type to immobilize it on a coated-biochar surface, which improves the adsorption capacity of lead. Jin et al.55 observed that the cobalt-doped biochar of bamboo showed higher pore volume and surface area than the un-doped adsorbent, which led to greater chromium hexavalent removal capacity. Similarly, a substantial increase in pore volume and surface area was also found with an enhancement of Fe quantity on coated biochar50. Loading of surfactant for carbon nanotube dispersion during the preparation of carbon nanotube doped-biochar resulted in a greatly higher sorption capacity of carbon nanotube-loaded biochar for pollutants (lead and sulfapyridine) than without surfactant owing to the magnificent distribution and dispersion of carbon nanotube on the adsorbent surface11. Captivatingly, no noticeable competition was found between sulfapyridine and lead, signifying the site-specific sorption of both pollutants on carbon nanotube-doped adsorbent surface15. Further, pollutant sorption and hydrogen storage capability were assessed on multi-walled carbon nanotubes that were loaded on bamboo biochar using microwave plasma to improve chemical vapor deposition. Nonetheless, only little enhancement was noticed compared with un-doped biochar because of the lower hydrogen storage ability of multi-walled carbon nanotubes than pristine biochar89. However, carbon nanotubes are very efficient for pollutant elimination due to their nanostructure and large surface area, high cost, and inconvenience for engineering applications limiting their use. Thus, biochar could aid as a mesoporous/microporous carrier of carbon nanotubes to develop new recyclable and effective sorbents for wastewater and polluted soil treatment.

Using graphene for modification

Graphene modification has attracted both engineers and scientists after its discovery for its special two-dimensional structure and novel traits, such as electrical and thermal conductivity, surface area, and mechanical strength90. Compared to carbon nanotubes, difficult recovery and separation for reuse limit the extensive application of graphene in wastewater and polluted soil remediation. To overcome these drawbacks, graphene-based composite covering particles are produced and biochar is one of the promising materials as a carrier of graphene. Production of graphene-doped adsorbent also typically follows the two-step dip-coating process as above, e.g. peanut shell-derived feedstock was soaked in graphene solution to absorb graphene and then pyrolyzed by slow pyrolysis in an N2 environment74. Ghanim et al.91 observed the sorption enhancement of methylene blue and phenol via graphene-doped biochar. Higher pore volume (0.55 cm3 g−1) and surface area (11.30 m2 g−1) after coating graphene on cotton-biochar may be the major reasons for enhanced sorption. Moreover, π-π bonding between methylene blue or phenol graphene sheets contributed to enhancing sorption capacity. Hafeez et al.92 found a substantial enhancement of methylene blue on graphene soaked-biochar (almost 20 times greater), and strong π-π bonding between methylene blue and graphene on biochar surface was believed to be the leading mechanism for the improvement of methylene blue sorption via graphene-doped biochar. Graphene loading on biochar introduces a large amount of oxygen-enrich functional groups such as carboxyl, hydroxyl, and carbonyl creating the binding between biochar surface graphene. For the recover and regeneration of graphene adsorbents, simple desorption processes were sufficient using ethanol and deionized water as eluents. However, the regenerative properties of graphene-based adsorbents have not been rigorously investigated and are required to be explored in future studies for the sustainable circular economy.

Physical modification

Generally, mechanical/physical modification techniques are usually economically feasible and simple but are less efficient compared to chemical modification. The physical modification method uses various oxidizing agents e.g., CO2, air, and stream. Physical modification has been considered an effective method to improve biochar functionality by influencing hydrophobicity, polarity, and surface functional groups of biochar44. Nonetheless, the drawbacks of physical activation techniques include a long time (~ 4 h) for activation and more energy consumption (10.6 to 58.0 kcal)89. For these drawbacks, chemical activation is considered the primary option for biochar engineering. Future studies should focus on filling the research gap to address the drawbacks of physical activation.

Activation by steam