Abstract

Retro-reflective (RR) materials, applied to building envelopes, constitute an option to tackle Urban Heat Island phenomenon, thanks to their capability to reflect the sunlight predominantly towards the solar incidence direction. RR coatings are obtained with the deposition of glass beads on traditional diffusive materials. During their lifetime, outdoor aging and soiling affect their optical behavior. In addition, without a proper protection, some glass beads could detach from the paint and disperse in the environment. Hence, a necessity arises for the application of a safeguarding stratum on RR materials to avert the separation of glass beads in RR coatings following the aging process. In this paper, five RR samples were produced, employing a highly reflective paint as foundation, RR glass beads and a protective layer. A diffusive sample, without glass beads, was made for comparison. Samples underwent spectrophotometric and angular distribution analyses. The effect of the protective layer on the optical behavior was assessed comparing the results with those obtained for the same RR materials without the protective layer. RR samples with a protective layer exhibit a higher reflectance with respect to the same RR sample without a protective layer. In the near-infrared (NIR) region, a lower reflectance occurs for all RR samples with a protective layer. A less concentrated angular distribution of the reflected light was observed for all RR samples with the addition of a protective layer.

Keywords: Urban heat island, Retro-reflective materials, Cool materials, Smart optical coatings, Directional materials

1. Introduction

The expansion of urban areas resulted in significant changes in natural landscapes through human activity, leading to a disruption in the thermal and energy balance of cities [1]. This has caused an increase of urban temperatures above those of nearby rural areas, leading to the Urban Heat Island (UHI) effect due to the higher absorption and retention of solar radiation by artificial surfaces [1]. The negative effects of UHI include increased heat and pollution, reduced thermal comfort [2], higher building energy consumption [3], and increased electricity demand during summer [4]. The impact of UHI is further intensified by the occurrence of climate change and heat waves, posing a greater risk to human health. Recent research has focused on developing effective strategies to mitigate the negative impacts of UHI, including increasing the amount of greenery in urban areas [[5], [6], [7], [8], [9]], implementing water bodies [10,11], and employing highly reflective materials for exterior building coatings [12].

There is a wide body of knowledge on the multiple effects of highly reflective “cool” materials, such as the reduction of building energy consumption, the mitigation of UHI phenomenon, and, at global level, also the global warming mitigation [13]. As a matter of fact, with a high amount of reflected radiation, they provide a cooling effect both at building and urban level and, increasing the global terrestrial albedo, they induce a change in the radiative forcing, directly correlated to a CO2 offset potential [14,15]. From an optic-energy point of view, highly reflective materials are characterized by high solar reflectance and high infrared emittance [16].

Highly reflective materials include not only traditional diffusive materials, with the distribution of the reflected light following the Lambert's cosine law, but also the so-called retro-reflective (RR) materials. RR materials have directional optic properties aimed at reflecting most of the incident radiation backwards. Studies show that the RR behaviour could change with specific wavelengths [17].

Experimental and simulation studies are available in literature, showing that a diffusive cool material helps in reducing the air temperature and wall temperatures inside urban canyons with different geometries, with respect to a traditional grey diffusive material, while in same cases the pavement temperature increases because of the higher amount of the energy reflected by the cool facades [18]. In fact, the inter-building effect can not be neglected, as reflection increases the cooling energy required for spatially-proximal buildings [19].

Thanks to their angular distribution, when RR materials are applied to the building skin, they can hinder numerous reflections and inter-building impacts, diminishing the thermal energy circulating within the urban canopy. Consequently, this leads to a cooling influence in the urban canyon [20,21].

The coupling of RR façade and RR pavement brings to an increase of the equivalent albedo on the canyon's ceiling with respect to diffusive surfaces, with a consequent reduction of the thermal energy trapped inside the canyon and a cooling effect [22]. Also in Ref. [23], RR materials bring to a higher improvement in the thermal conditions than diffusive coatings, especially in the higher enclosure degree of buildings.

RR materials for building applications are generally developed starting from a construction material, where the RR optic element is deposited [24]. Tiles, plasters and panels are the most used building supports, while prisms or beads are the most studied RR elements [25].

The application of RR materials is also tested to enhance the performance of bifacial photovoltaic panels, resulting in a 10 % increase of the maximum produced power [26].

The current investigation worldwide is focused on several aspects. One is the industrial development of the RR material, based on the design of layers (type of support, microspheres’ superficial density and diameter) and on the characterization of the samples in terms of optic-energy performance [[27], [28], [29]]. Another paper focused on the effect of the RR materials in function of the geographical locations, showing that RR have an important cooling effect at middle or high latitudes while there are no benefits comparing to diffusive materials at very low latitudes [30]. At the middle latitudes, with hot arid climate, a highly reflective RR coating on the south-facing facade and roof reduces the annual cooling load up to 26 % [31]. Also, there is an effect of RR on regional albedo, wall temperature and air temperature at a middle latitude compared to the diffusive materials: results show that in high-density urban spaces, albedo increases by 5 % and there is a sensible decrease in the wall and air temperature [32]. In addition, RR materials were tested to study their effect on the outdoor thermal comfort with different values of the canyon aspect ratio. Results show that RR walls are more effective than traditional diffusive materials in terms of standard effective temperature (– 0.5°) and operative temperature (-1.2 °C) [33].

Despite the beneficial effects of RR in the built environment, some concerns were raised, mainly related to glare, due to the strong directional behavior, and to the building thermal performance in winter, due to their cooling effect. As regards visual comfort, real-scale measurements show that the Daily Glare Probability for the RR wall is always lower than that for the diffusive wall [34].

In [35], the authors monitored the RR coatings’ effect on building thermal performance not only in summer but also in winter, when their cooling potential is not desired. Results show that while thermal benefits in summer are higher than those of diffusive materials, the penalties in winter are small, at least in the middle latitudes. Such outcomes are encouraging for the utilization of RR materials in the construction and building sector.

There is just another point which needs to be addressed: the aging and soiling. The positive impacts of RR materials can deteriorate due to the effects of aging and soiling, which alter their properties and efficacy. Both weathering (such as exposure to UV rays, temperature fluctuations, and moisture) and soiling (encompassing microbiological growth and deposition of atmospheric aerosols) are the principal factors leading to the deterioration of the material over time. Various natural and synthetic aging techniques have been examined in the literature to assess the long-term effectiveness of RR materials. For instance, in Ref. [36], a natural aging experiment was conducted on roofing membranes in Italy for two years. The outcomes present an average reflectance reduction of 0.18. Other previous studies have tested the aging and soiling of RR samples, both with laboratory accelerated aging tests and natural outdoor aging and soiling tests [37,38]. After the lab accelerated aging tests, based on high levels of temperature and moisture alternating with cycles of UV light, comparable to 20 years of natural outdoor exposure conditions, all the aged RR tiles maintained their global reflectance and has a small loss of directivity. Nevertheless, with this type of study, the effect of atmospheric pollutants, wind and microbiological contamination are not taken into account [37]. The naturally aged RR samples, developed starting from different type of wood and plastic panels, exhibited lower global reflectance values, especially those with a smooth substrate, proving that external atmospheric factors affect the behavior of samples [38].

Furthermore, in the absence of adequate protection, some glass beads could detach from the paint and disperse in the environment. Hence, it is essential to apply a safeguarding coating on RR materials that could hinder the separation of glass beads in RR specimens and so to maintain their cooling effect and optic behavior. The present paper aims at giving an experimental contribution in this sense, with a focus on the effect of an upper protective layer over the RR material.

RR specimens were developed, employing a substrate of highly reflective paint, different glass beads diameter ranges, as well as a protective layer. To facilitate comparison, a diffuse sample was also prepared without glass beads. The samples were characterized by spectrophotometric and angular distribution analyses. The impact of the safeguarding coating on the optical properties of RR materials was evaluated by comparing the outcomes with those obtained from the same RR materials without the protective layer.

2. Materials and METHODS

Here, there is the description of the examined samples, with a particular focus on their optical behavior. Then, the methodology used to investigate the samples’ optical performances is outlined.

2.1. Samples preparation

Six samples were manufactured. Each sample was composed by a mortar square (10 × 10 cm2) plate painted with a high-reflective white paint. A diffusive (DIFF) sample is taken as a reference case. The high-reflective paint provides a diffusive reflection, following Lambert's cosine law. RR materials were obtained by putting glass beads on a white paint. Glass beads were manually added to wet white paint on mortar plates. After one day from the deposition, any surplus glass beads not integrated into the paint were eliminated. The weight of the glass beads incorporated into the mortar plates was determined through the disparity in weight before and after eliminating the surplus glass beads. In Ref. [27], the uniformity of the microspheres distribution on the surface was verified. RR and DIFF samples investigated in this study are shown in Table 1 and Fig. 1(a–f). From a previous study [27], RR samples with a diameter ranging from 200 to 300 μmdemonstrated the highest RR efficacy, both concerning Solar Reflectance (SR) and the analysis of angular distribution around the incident direction, irrespective of the superficial density. Thus, in this study RR samples characterized by the same glass beads superficial density (ρs2) ranging from 0.20 to 0.30 kg/m2 and different glass beads diameter ranges were investigated. The following glass beads diameter classes have been assessed:φ1 = 40 ÷ 70 μm; φ2 = 70 ÷ 110 μm; φ3 = 100 ÷ 200 μm; φ4 = 200 ÷ 300 μm and φ5 = 400 ÷ 800 μm.

Table 1.

Samples with glass beads superficial density ρs2=0.20 ÷ 0.30 kg/m2 and five glass beads diameter range investigated.

| Glass beads diameter, φ [μm] | Glass beads superficial density, ρs2 = 0.20 ÷ 0.30 [kg/m2] |

|---|---|

| φ1 = 40 ÷ 70 | RR φ1, ρs2 = 0.21 |

| φ2 = 70 ÷ 110 | RR φ2, ρs2 = 0.30 |

| φ3 = 100 ÷ 200 | RR φ3, ρs2 = 0.27 |

| φ4 = 200 ÷ 300 | RR φ4, ρs2 = 0.25 |

| φ5 = 400 ÷ 800 | RR φ5, ρs2 = 0.30 |

Fig. 1.

Picture of plaster samples characterized by the identical superficial density of glass beads and varying ranges in glass beads diameter. Samples are respectively: a) DIFF; b) RR φ1, ρs2; c) RR φ2, ρs2; d) RR φ3, ρs2; e) RR φ4, ρs2; f) RR φ5, ρs2.

On both RR and DIFF samples was applied a matt transparent finishing layer to protect the glass beads from atmospheric agents and soiling. In this paper, the effect of the finishing layer is assessed.

2.2. Materials

The mortar is provided by Colacem S.p.A., and Prochima® S.r.l. has supplied the glass beads. The white highly reflective paint is furnished by INDEX Construction Systems and Products S.p.A. and the finishing layer by Giorgio Graesan & friends s.a.s. di Shila Graesan. In Table 2, Table 3, a summary of the materials and the equipment used to characterize them, along with their specifications, is provided, respectively.

Table 2.

Materials for experiments.

Table 3.

Instruments for experiments.

| Instrument | Supplier | Specification |

|---|---|---|

| PerkinElmer UV/Vis/NIR Spectrophotometer LAMBDA™ 1050+ | PerkinElmer | Wavelength range: 300–2500 nm Data interval: 5 s Wavelength accuracy: UV/Vis ±0.025 nm; NIR ±0.200 nm |

| Delta Ohm HD2302.0 photo-radiometer with LP 471RAD probe | Delta-OHM | Measurement range: 1,0·10−3 W/m2 ÷ 2000 W/m2 Instrument accuracy: ±0.15 % rdg. ±1 digit with a reference temperature of 25 °C ± 5 °C |

2.3. Spectrophotometric analysis

Spectrophotometric analysis was performed using a PerkinElmer UV/Vis/NIR Spectrophotometer LAMBDA™ 1050+ [43] fitted with a 150 mm InGaAs Integrating Sphere. To calibrate the device, a Spectralon™ certified reflectance standard was utilized, furnished by Labsphere [44]. In order to determine the mean spectral reflectance of each sample, three measurements were assessed. The measurements were conducted within a wavelength range of 300–2500 nm, employing a data interval of 5 nm. Subsequently, the data were gathered using the UV WinLab Software, and the ASTM E 903–20 method was applied for executing the reflectance measurements, in tandem with the use of ASTM G 173–03 to acquire terrestrial solar irradiance values. This protocol enabled the calculation of the SR for each individual sample. In Fig. 2, an overview of the PerkinElmer LAMBDA™ 1050+ Spectrophotometer is shown with details of the integrating sphere and the sample compartments, and the software used for data elaboration.

Fig. 2.

An outside view of the PerkinElmer UV/Vis/NIR Spectrophotometer LAMBDA™ 1050+, with details of the integrating sphere compartment, the sample holder and the software interface.

2.4. Angular reflectivity analysis

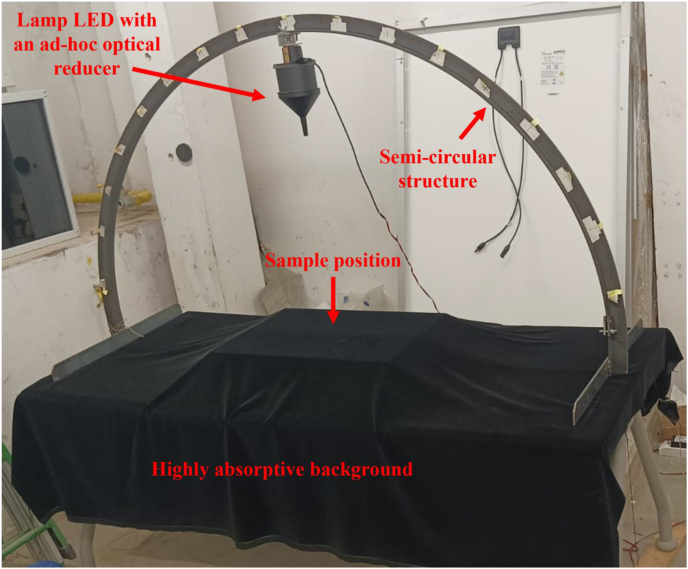

The directional reflectivity analysis was used to characterize the samples’ angular distribution of the reflected radiation for different directions of the incident radiation, a. To perform directional reflectivity measurements, an ad-hoc experimental facility was developed, as described in previous [27]. The ad-hoc experimental facility is formed by: (i) a semi-circular structure, with a radius of 85 cm, at the centre of which the sample is positioned to be tested. The semi-circular arch is graduated every 10°, from −80° (left), to 80° (right); and the 0° indicates the perpendicular direction to the sample); (ii) a LED lamp [45,46], that closely mimics the color and spectrum of sunlight in the Vis range. The Correlated Colour Temperature (CCT) is 5000 K and its Colour Rendering Index (CRI) is equal to 97, ensuring a lighting response which is close to sunlight in the Vis range. The light source can be securely positioned in the desired location along the semi-circular structure, allowing it to be, enabling the simulation of various incident directions towards the sample. To reduce light dispersion to a minimum, a custom optical reducer was constructed and mounted on the lamp. Consequently, the light beam specifically targeted the sample surface, resulting in minimal dispersion of incident light onto other surfaces. To further mitigate unwanted reflections, a black, highly absorbent material in the visible range was applied to cover the measurement surface; (iii) a Photo radiometer Delta OHM HD2302.0 with an LP471RAD probe [47] was used to measure the irradiance [W/m2] on each angular position, by moving the probe along the arch i.e. with an interval of 10°, from −80° to 80°.

In the angular position occupied by the light source, two consecutive irradiance measurements were carried out, one on the right and the other on the left of the light source, then the average value is considered as representative of the reflected radiation in that position.

For each position of the light source on the semi-circular facility, directional reflection distribution was investigated by measuring irradiance [W/m2] in each angular position along the structure, with an interval of 10°. Half of the total light source directions have been investigated, because the optical behavior of the surface is symmetrical to the vertical plane. The analysis has been focused on materials’ directional reflectivity distributions for incident radiation angles from 0° to −70°, as they represent the majority of solar elevation angles at middle latitudes.

Fig. 3 illustrates the developed gonio-reflectometer, where the semi-circular structure, the LED lamp with an ad-hoc optical reducer and the black, highly absorptive material for the measurement surface are indicated.

Fig. 3.

Overview of the developed gonio-reflectometer.

3. RESULTS and discussion

In this paragraph results of the characterization of the samples in terms of their optical performance are presented. The discussion is also based on the comparison of the present analysis with data of the same samples without a protective layer, already published in Authors [27].

3.1. Spectrophotometric characterization

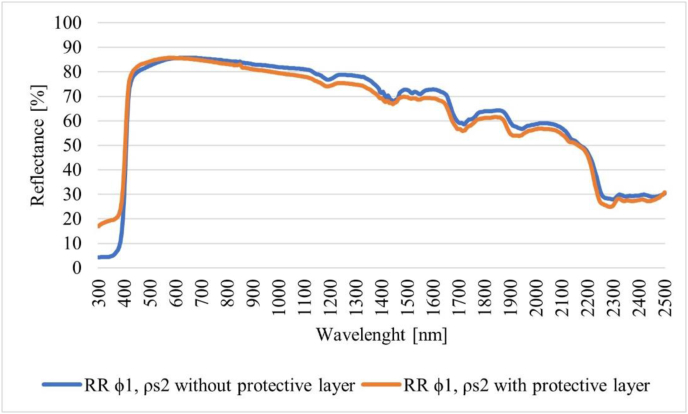

For each sample, the average spectral reflectance was calculated on the basis of three different spectrophotometric measurements. A comparison of the average spectral reflectance of DIFF and RR samples with and without a protective layer is presented in Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9. In Fig. 4, the profile of the average spectral reflectance is presented for the samples with glass beads diameter range φ1 = 40–70 μm; in Fig. 5 the profile of the average spectral reflectance for the samples with glass beads diameter φ2 = 70–110 μm); in Fig. 6 the average spectral reflectance is shown for the diameters in the range φ3 = 100–200 μm; Fig. 7 shows the profile of the average spectral reflectance for the diameter range φ4 = 200–300 μm, wheares in Fig. 8 they are shown for the fifth range of diameter (φ5 = 400–800 μm). Finally, in Fig. 9 the average spectral reflectance is shown for DIFF samples with and without a protective layer.

Fig. 4.

Comparison between RR φ1, ρs2 sample without a protective layer (blue solid line) and RR φ1, ρs2 sample with a protective layer (orange solid line) in terms of average spectral reflectance over three measurements. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 5.

Comparison between RR φ2, ρs2 sample without a protective layer (blue solid line) and RR φ2, ρs2 sample with a protective layer (orange solid line) in terms of average spectral reflectance over three measurements. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 6.

Comparison between RR φ3, ρs2 sample without a protective layer (blue solid line) and RR φ3, ρs2 sample with a protective layer (orange solid line) in terms of average spectral reflectance over three measurements. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 7.

Comparison between RR φ4, ρs2 sample without a protective layer (blue solid line) and RR φ4, ρs2 sample with a protective layer (orange solid line) in terms of average spectral reflectance over three measurements. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 8.

Comparison between RR φ5, ρs2 sample without a protective layer (blue solid line) and RR φ5, ρs2 sample with a protective layer (orange solid line) in terms of average spectral reflectance over three measurements. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 9.

Comparison between DIFF sample without a protective layer (blue solid line) and DIFFsample with a protective layer (orange solid line) in terms of average spectral reflectance over three measurements. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 4 shows that in the VIS range, RR sample with 40 ÷ 70 μm (φ1) glass beads diameter range and a protective layer exhibit a higher reflectance value with respect to the same RR sample without a protective layer. This trend is also confirmed in Fig. 6, Fig. 7, Fig. 8 for RR samples with 100 ÷ 200 μm (φ3), 200 ÷ 300 μm (φ4), and 400 ÷ 800 μm (φ5) diameter ranges and a protective layer. The only exception is represented by RR sample with 70 ÷ 110 μm (φ2) diameter range and a protective layer: it has a lower reflectance in the VIS range, if compared to the same RR sample without a protective layer (Fig. 5).

In the near-infrared (NIR) region, all RR samples with a protective layer have a lower reflectance than the same RR samples without a protective layer, with minor exceptions. In particular, the reflectance of RR sample with 100 ÷ 200 μm (φ3) diameter and a protective layer goes beyond its corresponding RR sample without a protective layer from 700 to 1100 nm; from 1100 to 1500 nm their reflectance correspond almost exactly (Fig. 6). The reflectance of RR sample with 200 ÷ 300 μm (φ4) diameter and a protective layer goes beyond its corresponding RR sample without a protective layer from 700 to 800 nm (Fig. 7). Finally, for RR sample with 400 ÷ 800 μm (φ5) glass beads diameter range and a protective layer, the reflectance goes beyond its corresponding RR sample without a protective layer from 700 to 1000 nm; from 1000 to 1100 nm their reflectance corresponds almost exactly (Fig. 8).

In Fig. 9, there are no particular differences in the VIS range between DIFF samples with and without a protective layer. In the NIR region, DIFF sample with a protective layer hass a reflectance lower than the same DIFF one without a protective layer.

Table 4 summarizes the obtained SR (%),as calculated by the UV WinLab Software. The third column (Δ (%)) in Table 4 reports the differences between the SR values samples with a protective layer and the SR values for the same samples without a protective layer.

Table 4.

Total SR (%)with and without protective layer. The maximum values are in bold.

| Samples | Solar reflectance (%) with a layer | Solar reflectance (%) without layer | Δ (%) |

|---|---|---|---|

| DIFF | 79.5 | 80.8 | −1.3 |

| RR φ1, ρs2 | 76.6 | 76.6 | 0.0 |

| RR φ2, ρs2 | 72.2 | 76 | −3.8 |

| RR φ3, ρs2 | 77.6 | 76 | 1.6 |

| RR φ4, ρs2 | 76.0 | 75.6 | 0.4 |

| RR φ5, ρs2 | 76.8 | 76 | 0.8 |

DIFF sample with a protective layer exhibits a lower SR than the same DIFF sample without a protective layer with a Δ value equal to −1.3 %.

No difference on the total SR occurs by adding a protective layer in RR φ1, ρs2. The addition of a protective layer positively affects RR φ3, ρs2, RR φ4, ρs2, and RR φ5, ρs2 samples which exhibit Δ values equal to 1.6 %, 0.4 %, and 0.8 %, respectively. An exception is represented by RR φ2, ρs2 sample, in which the addition of a protective layer seems to negatively affect the SR, with a Δ value equal to −3.8 %.

3.2. Angular distribution characterization

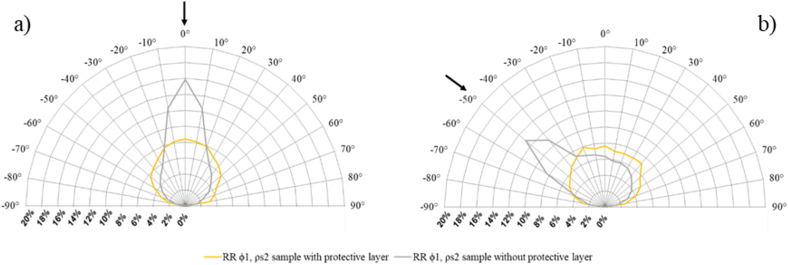

In this section, the angular distribution of the reflected light for all the investigated samples resulted from irradiance measurements is presented. For each position of the light source on the semi-circular facility, measurements of directional reflected radiation by each sample have been done for angles from −80° to 80°, with an angular interval of 10°. Angular distribution of reflection was investigated for half of the total light source positions, i.e. for incident angles from 0° to −80°, because of the symmetry of the optical behavior with respect to the vertical plane. The analysis has been focused on incident radiation angles from 0° to −70°, as they represent the majority of solar elevation angles at middle latitudes. As already described, when a position is occupied by the light source, two irradiance measurements (one on its right and one on its left) were carried out and the average irradiance value was considered for that angular position. By way of example, a comparison of the angular distributions for DIFF and RR samples with and without a protective layer is shown in Fig. 10, Fig. 11, Fig. 12, Fig. 13, Fig. 14, Fig. 15 for two incident radiation angles,0° and −50°. However, all results obtained for all incidence angles are reported in Table 5. The black arrow shos the direction of the incident radiation.

Fig. 10.

Angulardistribution of RR φ1, ρs2 sample with (yellow line) and without a protective layer (grey line)- incident radiation angle equal to 0° (a) and −50° (b). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 11.

Angular distribution of RR φ2, ρs2 sample with (yellow line) and without a protective layer (grey line)- incident radiation angle equal to 0° (a) and −50° (b). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 12.

Angular distribution of RR φ3, ρs2 sample with (yellow line) and without a protective layer (grey line) - incident radiation angle equal to 0° (a) and −50° (b). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 13.

Angular distribution of RR φ4, ρs2 sample with (yellow line) and without a protective layer (grey line) - incident radiation angle equal to 0° (a) and −50° (b). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 14.

Angular distribution of RR φ5, ρs2 sample with (yellow line) and without a protective layer (grey line) - incident radiation angle equal to 0° (a) and −50° (b). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Fig. 15.

Angular distribution of DIFF sample with (yellow line) and without a protective layer (grey line) - incident radiation angle equal to 0° (a) and −50° (b). (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

Table 5.

Relative RR component of each sample, with and without a protective layer.

| Direction of the incident radiation [°] |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0° | −10° | −20° | −30° | −40° | −50° | −60° | −70° | ||

| Relative RR component [%] | DIFF without layer | 8,5 | 8,6 | 8,4 | 7,6 | 6,9 | 6,1 | 5,8 | 5,2 |

| DIFF with layer | 11,5 | 7,8 | 6,7 | 6,4 | 5,8 | 4,8 | 3,9 | 2,9 | |

| RR φ1, ρs2 without layer | 15,9 | 15,5 | 15,1 | 14,4 | 14 | 12,9 | 11,4 | 10,4 | |

| RR φ1, ρs2 with layer | 8,4 | 8 | 7,6 | 7 | 6,4 | 5,7 | 5,2 | 5,9 | |

| RR φ2, ρs2 without layer | 15,5 | 15 | 14,4 | 13,8 | 13,2 | 12,3 | 11,3 | 10,2 | |

| RR φ2, ρs2 with layer | 8,8 | 8,6 | 7,6 | 7,9 | 6,5 | 5,5 | 5,2 | 5,6 | |

| RR φ3, ρs2 without layer | 14,7 | 14,6 | 14,1 | 13,7 | 12,9 | 12,2 | 11 | 10,1 | |

| RR φ3, ρs2 with layer | 9,9 | 10,1 | 9,1 | 9,1 | 8,2 | 9 | 7,2 | 6,8 | |

| RR φ4, ρs2 without layer | 16,8 | 16,5 | 16,1 | 16 | 15,4 | 15 | 13,7 | 12,4 | |

| RR φ4, ρs2 with layer | 11,9 | 11,4 | 11,4 | 11,4 | 10,5 | 10,9 | 10,1 | 9,1 | |

| RR φ5, ρs2 without layer | 15,1 | 15,1 | 15,1 | 14,9 | 14,7 | 13,7 | 12,1 | 10,3 | |

| RR φ5, ρs2 with layer | 10,7 | 10,2 | 9,7 | 9,5 | 8,8 | 8,6 | 7,9 | 7 | |

The profile of the angular distribution, for each angle of the incident radiation, is built evaluating the percentage ratio between the radiation reflected by each sample in one direction, over the sum of the reflected radiation in all directions by the same sample. Therefore, reflection percentages could be compared only for the same sample's angular reflection distribution, but not between different samples.

All RR samples without a protective layer exhibit a good RR capability [27]. In particular, the highest RR capability comes from the RR φ4, ρs2 sample, resulting in the most concentrated profile around the incident radiation direction both for 0° and −50°. The RR component resulted equal to 16.8 % and 15.0 % for RR φ4, ρs2 for 0° and −50° of incident radiation angles, respectively. DIFF sample without a protective layer exhibit an angular distribution following the cosine's Lambert law both for 0° and −50° directions of the incident radiation.

A less flattened profile was observed for all RR samples with the addition of a protective layer. In particular, a predominantly diffusive component appears for the two smaller diameter ranges (i.e. φ1 and φ2). Among the RR samples with a protective layer, RR φ4, ρs2 provides the highest RR capability with a RR percentage of 11.9 % at 0° and 10.9 % at −50°. A RR behavior and a specular reflection appear in DIFF sample with a protective layer: in particular a stronger RR capability was observed at 0° with a RR percentage of 11.5 %, with respect to the DIFF one without a protective layer.

Table 5 shows the relative RR component for all samples investigated with and without a protective layer, calculated as the percentage of the reflected radiation in the incident direction over the sum of the reflected radiations in all the incident angles. Data for sample without layers come from Ref. [27].The RR φ4, ρs2 sample with and without a protective layer has the best RR capability for all directions of incident radiation.

The difference (Δ) between the relative RR components along the incident direction of the sample without a protective layer and the same RR sample with the addition of a protective layer, are shown in Fig. 16. The following considerations can be drawn.

-

•

The addition of a protective layer causes a decrease in the RR behaviour for all the investigated RR samples. In fact, the addition of the protective layer results in a flattening of the elliptic profile in all RR samples for all angles of incidence. This brings to positive Δ values;

-

•

The Δ values vary with the microspheres' diameter. A clear correlation emerges for all angles of incidence and two groups can be identified: the first group consisting of RR φ1, ρs2 and RR φ2, ρs2 samples, and the second group consisting of RR φ3, ρs2, RR φ4, ρs2, and RR φ5, ρs2 samples. The Δ values are greater for smaller diameter ranges of glass microspheres (i.e., RR φ1, ρs2 and RR φ2, ρs2). Within the second group (RR φ3, ρs2, RR φ4, ρs2, and RR φ5, ρs2), there is no clear trend in the dependence of Δ values on diameter.

-

•

Regarding the angle of incidence, the overall trend of Δ values decreases from 0° to −70°. This means that the layer's effect is more significant in case of incident radiation close to the normal.

-

•

The effect of the layer on the DIFF sample is different from RR samples. The Δ value is negative in the direction of normal incidence; this fact indicates that the layer results in a compression of the typically diffusive profile. The Δ values remain positive for the other directions of incidence: this is not due to an increase in the RR component, but to the presence of a specular component as clearly seen in Fig. 15.

Fig. 16.

Difference (Δ) values between the relative RR components with and without the protective layer for different angles of incidence.

4. Conclusions and further developments

This study investigates how the addition of a protective layer affect the optical behaviour of RR materials. Five RR samples were developed, starting from a highly reflective paint as substrate, with the deposition of glass beads and a protective layer. RR samples have similar superficial densities of glass beads, in the range 0.20–0.30 kg/m2, yet they differ in their glass bead diameter ranges: φ1 (40 ÷ 70 μm), φ2 (70 ÷ 110 μm), φ3 (100 ÷ 200 μm), φ4 (200 ÷ 300 μm), and φ5 (400 ÷ 800 μm). A diffusive sample, formed only by the same highly reflective paint without glass beads, was developed for sake of comparison. The study is based on spectrophotometric and angular distribution analyses. The main findings of the investigation are.

-

•

RR φ1, ρs2, RR φ3, ρs2, RR φ4, ρs2, and RR φ5, ρs2 samples with a protective layer exhibit higher reflectance than the same RR samples without a protective layer. The only exception is represented by RR φ2, ρs2 sample with a protective layer which has a lower reflectance than the same RR sample without a protective layer in the VIS range,. In the near-infrared (NIR) area, a lower reflectance values occur for all RR samples with a protective layer with minor exceptions;

-

•

Concerning the angular reflectivity analysis, the introduction of the protective layer yields a noticeable change in the angular reflection distribution, making it less concentrated for all RR samples. This behaviour is particularly pronounced in RR samples φ1 and φ2, where a predominantly diffusive component assumes a prominent role. Among the RR samples with a protective layer, RR φ4, ρs2 provides the highest RR capability with a RR percentage of 11.9 % at 0° and 10.9 % at −50°. A RR behaviour and a specular reflection appear in DIFF sample with a protective layer for all the investigated directions.

-

•

The difference (Δ) values between the relative RR components along the incident direction of the sample without a protective layer and the same RR sample with the addition of a protective layer vary with the diameters of glass microspheres, resulting greater for smaller diameters (i.e., RR φ1, ρs2 and RR φ2, ρs2). Regarding the angle of incidence, the overall trend of Δ values decreases from 0° to −70°. This means that the layer's effect is more significant in the case of incident radiation close to the normal.

Further investigations will focus on the aging of RR samples with an applied protective layer (with outdoor weathering and soiling exposure), to better understand the optic performance over time of the proposed multi-layer materials. Also a study on the superficial morphology of the samples is required before and after the aging process, to establish a correlation between their structural characteristics and optical properties.

Data availability statement

Data will be made available on request.

Additional information

No additional information is available for this paper.

CRediT authorship contribution statement

Beatrice Castellani: Writing – review & editing, Validation, Supervision, Methodology, Investigation, Formal analysis, Conceptualization. Alessia Di Giuseppe: Writing – original draft, Software, Methodology, Investigation, Formal analysis, Data curation. Aron Pazzaglia: Writing – original draft, Software, Investigation, Formal analysis, Data curation. Andrea Nicolini: Writing – review & editing, Validation, Supervision, Resources, Formal analysis. Federico Rossi: Writing – review & editing, Supervision, Project administration.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors would like to acknowledge the Italian Ministry of University and Scientific Research (MUR) for funding the research under the PON Project entitled “BEST4U—Bifacial Efficient Solar Cell Technology with 4-Terminal Architecture for Utility Scale”.

References

- 1.Santamouris M., editor. Energy and Climate in the Urban Built Environment. James and James Science Publishers; London: 2001. [DOI] [Google Scholar]

- 2.Rossi F., Anderini E., Castellani B., Nicolini A., Morini E. Integrated improvement of occupants' comfort in urban areas during outdoor events. Build. Environ. 2015;93:285–292. [Google Scholar]

- 3.Li Y., Zhao X. An empirical study of the impact of human activity on long-term temperature change in China: a perspective from energy consumption. J. Geophys. Res. 2012;117(D17) [Google Scholar]

- 4.Santamouris M., Cartalis C., Synnefa A., Kolokotsa D. On the impact of urban heat island and global warming on the power demand and electricity consumption of buildings −A review. Energy Build. 2015;98:119–124. [Google Scholar]

- 5.Gao Z., Zaitchik B.F., Hou Y., Chen W. Toward park design optimization to mitigate the urban heat Island: assessment of the cooling effect in five U.S. cities. Sustain. Cities Soc. 2022;81 [Google Scholar]

- 6.Jacobs S.J., Gallant A.J.E., Tapper N.J., Li D. Use of cool roofs and Vegetation to mitigate urban heat and improve human thermal stress in Melbourne, Australia. J. Appl. Meteorol. Climatol. 2018;57(8):1747–1764. [Google Scholar]

- 7.Koch K., Ysebaert T., Denys S., Samson R. Urban heat stress mitigation potential of green walls: a review. Urban For. Urban Green. 2020;55 [Google Scholar]

- 8.Price A., Jones E.C., Jefferson F. Vertical greenery systems as a strategy in urban heat island mitigation. Water Air Soil Pollut. 2015;226:247. [Google Scholar]

- 9.Wang X., Li H., Sodoudi S. The effectiveness of cool and green roofs in mitigating urban heat island and improving human thermal comfort. Build. Environ. 2022;217 [Google Scholar]

- 10.Manteghi G., Limit H.B., Remaz D. Water bodies an urban microclimate: a review. Mod. Appl. Sci. 2015;9:6. [Google Scholar]

- 11.Peng J., Liu Q., Xu Z., Lyu D., Du Y., Qiao R., Wu J. How to effectively mitigate urban heat island effect? A perspective of waterbody patch size threshold. Landsc. Urban Plann. 2020;202 [Google Scholar]

- 12.Wang C., Wang Z., Kalous K.E., Shacat J. Cool pavements for urban heat island mitigation: a synthetic review. Renew. Sust. Energ. Rev. 2021;146 [Google Scholar]

- 13.Dongdong T., Zhang J., Gao Z. The advancement of research in cool roof: super cool roof, temperature-adaptive roof and crucial issues of application in cities. Energy Build. 2023;291 [Google Scholar]

- 14.Rossi F., Filipponi M., Castellani B., Bonafoni S., Ghenai C. A novel measurement-based method for assessing global warming mitigation via high-albedo solutions. Energies. 2022;15:5695. [Google Scholar]

- 15.Rossi F., Castellani B., Pazzaglia A., Di Giuseppe A., Bonafoni S., Filipponi M., Presciutti A., Cotana F. Application of the novel satellite calibrated method “Radiative Forcing Meter” on a high albedo test facility for CO2 compensation. Sol. Energy. 2023;263 [Google Scholar]

- 16.Santamouris M., Synnefa A., Karlessi T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy. 2011;85:3085–3102. [Google Scholar]

- 17.Liu S., Wang J., Meng X. Spectral properties of retro-reflective materials from experimental measurements. Case Stud. Therm. Eng. 2022;39 [Google Scholar]

- 18.Morini E., Castellani B., De Ciantis S., Anderini E., Rossi F. Planning for cooler urban canyons: comparative analysis of the influence of façades reflective properties on urban canyon thermal behavior. Sol. Energy. 2018;162:14–27. [Google Scholar]

- 19.Han Y., Taylor J.E., Pisello A.L. Exploring mutual shading and mutual reflection inter-building effects on building energy performance. Appl. Energy. 2017;185:1556–1564. [Google Scholar]

- 20.Rossi F., Castellani B., Presciutti A., Morini E., Filipponi M., Nicolini A., Santamouris M. Retroreflective façades for urban heat island mitigation: experimental investigation and energy evaluations. Appl. Energy. 2015;145:8–20. [Google Scholar]

- 21.Yuan J., Emura K., Farnham C., Sakai H. Application of glass beads as retro-reflective facades for urban heat island mitigation: experimental investigation and simulation analysis. Build. Environ. 2016;105:140–152. [Google Scholar]

- 22.Castellani B., Nicolini A., Gambelli A.M., Filipponi M., Morini E., Rossi F. Experimental assessment of the combined effect of retroreflective facades and pavement in urban canyons. IOP Conf. Ser. Mater. Sci. Eng. 2019;609 [Google Scholar]

- 23.Wang J., Liu S., Meng X., Gao W. Influence of the building enclosed forms on thermal contribution of retro-reflective and high-reflective coatings. Energy Build. 2022;273 [Google Scholar]

- 24.Morini E., Castellani B., Anderini E., Presciutti A., Nicolini A., Rossi F. Optimized retro-reflective tiles for exterior building element. Sustain. Cities Soc. 2018;37:146–153. [Google Scholar]

- 25.Wang J., Liu S., Meng X., Gao W., Yuan J. Application of retro-reflective materials in urban buildings: a comprehensive review. Energy Build. 2021;247 [Google Scholar]

- 26.Fontani D., Jafrancesco D., Sansoni P., Nicolini A., Di Giuseppe A., Pazzaglia A., Castellani B., Rossi F., Mercatelli L. Field optimization for bifacial modules. Opt. Mater. 2023;138 [Google Scholar]

- 27.Cardinali M., Di Giuseppe A., Castellani B., Filipponi M., Nicolini A., Rossi F. An investigation towards the optimum design of retro-reflective materials as building envelopes for the enhancement of optical performance. Constr. Build. Mater. 2022;358 [Google Scholar]

- 28.Di Giuseppe A., Cardinali M., Castellani B., Filipponi M., Gambelli A.M., Postrioti L., Nicolini A., Rossi F. The effect of the substrate on the optic performance of retro-reflective coatings: an in-lab investigation. Energies. 2021;14:2921. [Google Scholar]

- 29.Yuan J., Masuko S., Shimazaki Y., Chai J. Researching the design of a glass-bead retro-reflective material to reduce downward reflection for urban heat island mitigation. Mater. Today Sustain. 2022;18 [Google Scholar]

- 30.Castellani B. Application of retro-reflective materials in urban canyon at different geographical locations, Build. Environ. Times. 2021;193 [Google Scholar]

- 31.Vakilinezhad R., Khabir S. Evaluation of thermal and energy performance of cool envelopes on low-rise residential buildings in hot climates. J. Build. Eng. 2023;72 [Google Scholar]

- 32.Wang J., Liu S., Liu Z., Meng X., Xu C., Gao W. An experimental comparison on regional thermal environment of the high-density enclosed building groups with retro-reflective and high-reflective coatings. Energy Build. 2022;259 [Google Scholar]

- 33.Yuan J., Shimazaki Y., Zhang R., Masuko S., Cao S. Can retro-reflective materials replace diffuse highly reflective materials for urban buildings' wall to improve outdoor thermal comfort? Heliyon. 2023;9 doi: 10.1016/j.heliyon.2023.e14872. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Castellani B., Gambelli A.M., Nicolini A., Rossi F. Optic-energy and visual comfort analysis of retro-reflective building plasters. Build. Environ. 2020;174 [Google Scholar]

- 35.Wang J., Qi Y., Liu S., Gao Y., Gao W. Influence of retro-reflective and high-reflective coatings on thermal performance of buildings in summer and winter: a contrast experiment. Case Stud. Therm. Eng. 2023;49 [Google Scholar]

- 36.Paolini R., Zinzi M., Poli T., Carnielo E., Mainini A.G. Effect of ageing on solar spectral reflectance of roofing membranes: natural exposure in Roma and Milano and the impact on the energy needs of commercial buildings. Energy Build. 2014;84:333–343. [Google Scholar]

- 37.Morini E., Castellani B., Nicolini A., Rossi F., Berardi U. Effects of aging on retro-reflective materials for building applications. Energy Build. 2018;179:121–132. [Google Scholar]

- 38.Di Giuseppe A., Cardinali M., Castellani B., Filipponi M., Nicolini A., Rossi F. The impact of outdoor aging and soiling on the optic features of glass beads retro-reflective coatings. Sol. Energy. 2023;258:28–36. [Google Scholar]

- 39.Website Colacem S.p.a., “Malta composta”. https://www.colacem.com/it/it/malta_bastarda

- 40.Website Prochima, “microsfere perla”. https://www.prochima.it/perla-microsfere-di-vetro/

- 41.Website INDEX.S.p.a. White reflex. https://www.indexspa.it/indexspacom/tecnoplan/pdf/white_reflex-it.pdf

- 42.Website Giorgio Graesan. https://www.giorgiograesan.it/images/schede-tecniche/TDS1015_Vetro-Opaco.pdf

- 43.Website, PerkinElmer UV/Vis/NIR spectrophotometer LAMBDA™ 1050+ https://www.perkinelmer.com/it/product/lambda-1050-2d-base-inst-no-sw-l6020055

- 44.Website Labsphere. https://www.labsphere.com/

- 45.Website SunLike technology by seoul semiconductor. http://seoul-semicon.co.kr/en/product/SunLike/

- 46.Datasheet SpottOne SunLike by essenzialed. https://www.essenzialed.it/wp-content/uploads/2018/05/Spottone-sunlike_01.pdf

- 47.Datasheet of Delta OHM HD2302.0 photo-radiometer. https://www.deltaohm.com/wp-content/uploads/document/DeltaOHM_HD2302.0_datasheet_ENG.pdf

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.