Abstract

Composites made from fiber-reinforced polymers (FRPs) are a crucial and highly adaptable category of materials widely utilized in numerous fields. Their flexibility and the range of criteria for classification enable the creation of tailored solutions to address distinct requirements in sectors such as civil engineering, aerospace, automotive, and marine, among others. The distinguishing characteristics of FRP composites include the type of reinforcing fiber used, the composition of the matrix material, the employed manufacturing process, the orientation of the fibers, and the specific end-use application. These classification variables offer engineers a versatile structure to determine and select the most appropriate materials and production techniques for their specific needs. Furthermore, the present study aims to reunite the criteria of classification for FRPs and specific manufacturing technologies of FRPs, such as conventional ones (matched die molding, contact molding), automated ones (filament winding, tape lay-up, and fiber placement), and advanced ones (electrospinning and additive manufacturing),with the chronological development of FRPs, insights on material characteristics, and comprehensive design guidelines based on their behavior in different environments of use.

Keywords: FRP, mechanical properties, manufacturing technologies, applications, environmental conditions, reinforcement

1. Introduction

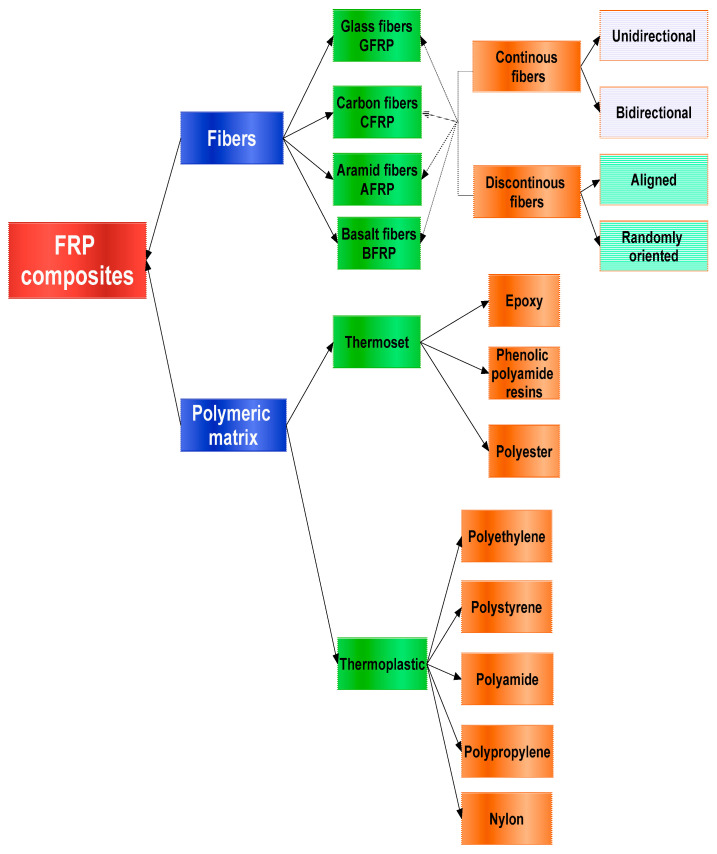

Fiber-reinforced polymer (FRP) refers to a type of composite material wherein a polymer is strengthened through the incorporation of fibers (Figure 1). These composites belong to a broader category known as composite materials. Such materials are created by blending particles of one or more substances within another material, creating a cohesive network that surrounds and reinforces them.

Figure 1.

Types of FRP composites.

The composite materials contain two elements, namely the fibers and matrices.

The matrix material in fiber-reinforced polymer (FRP) composites serves as the foundation for the overall performance and characteristics of the material. In thermoset matrices such as epoxy, polyester, and vinyl ester, the focus is on providing structural rigidity and resilience at elevated temperatures. Epoxy, for instance, is known for its high strength and excellent adhesion to fibers, making it suitable for applications where structural integrity is critical, such as in aerospace components. On the other hand, thermoplastic matrices like polyamide and polyethylene offer malleability and reversibility, allowing for reshaping and repairability. This flexibility in design and the ability to withstand impact make thermoplastics advantageous in applications requiring durability and recyclability. The matrix–fiber interaction is crucial, influencing properties like tensile strength, modulus, and flexural strength. The choice of matrix also dictates manufacturing processes, with thermosets like polyester offering cost-effective and faster curing options, while thermoplastics involve more intricate procedures. The adhesion strength between the matrix and fibers, along with the matrix’s role in controlling fiber orientation, contributes to the anisotropic properties of the composite. In essence, the matrix material composition plays a nuanced role in tailoring FRP composites, allowing engineers to adjust characteristics to meet specific needs in diverse industries.

The composite materials contain two elements, namely the fibers and matrices. For FRP composites, the main components are fibers and matrices, but their composition also includes fillers and additives. The fibers, with their high elastic modulus, significantly contribute to the mechanical properties of FRPs. Concurrently, resins play a crucial role in transferring and distributing stresses among fibers, protecting them from both mechanical and environmental damage. Beyond these primary elements, fillers play a role in minimizing shrinkage and overall cost. Additionally, additives are incorporated to enhance the physical and mechanical properties of the composite, improving both its performance and workability.

In construction, three primary fiber types stand out: carbon, glass, and aramid. The acronym name of the composite often reflects the type of reinforcing fiber used; for example, CFRP denotes carbon-fiber-reinforced polymer. The crucial distinctions between these fiber types lie in their stiffness and tensile strain properties. Figure 1 presents a summarized classification of FRP composites.

1.1. Criteria of Classification for FRPs

-

A.

Based on the type of reinforcing fiber.

Carbon-fiber-reinforced polymer (CFRP): Uses carbon fibers for reinforcement, demonstrating numerous superior performances, including high strength, lightweight, corrosion resistance, and remarkable fatigue resistance [1].

Glass-fiber-reinforced polymer (GFRP): Uses glass fibers, offering good electrical insulation and corrosion resistance, high strength, flexibility, stiffness, and durability. By using proper orientations and compositions of glass fibers, the desired characteristics and functional properties of GFRP composites can be achieved, making them comparable to steel in terms of stiffness while having a lower relative density than steel. Additionally, GFRPs are known for being the most cost-effective [2].

The glass fibers are subdivided into different sub-categories, as presented in Table 1, according to [3].

Table 1.

Types of glass fibers.

| Glass Fiber Type | Characteristics/Advantages |

|---|---|

| E-glass | High strength and electrical resistivity |

| A-glass | High durability, strength, and electrical resistivity |

| S-glass | High tensile strength |

| C-class | High corrosion resistance |

| D-glass | Low dielectric constant |

| R-glass | High strength and acid corrosion resistance |

| AR-glass | High alkali resistance |

Aramid (Kevlar)-fiber-reinforced Polymer (AFRP): Uses aramid fibers, providing a balance of strength, stiffness, and impact resistance. Aramid fibers surpass other synthetic fibers by 5–10% in mechanical properties, making them excellent replacements for metal wires and inorganic fibers. In addition to outperforming steel and glass fibers at equal weights, aramid fibers exhibit remarkable heat and flame resistance even at high temperatures [4]. Despite its positive attributes, aramid fibers have certain disadvantages, such as moisture absorption and relatively low compressive strength, restricting their applications in certain industries [4]. According to [3], there are several types of Kevlar fibers, as seen in Table 2.

Table 2.

Types of Kevlar fibers.

| Kevlar Fibers Type | Characteristics/Advantages |

|---|---|

| K-29 | Regular, light weight, medium thermal and electrical resistance |

| K-49 | High modulus, light weight, good thermal and electrical resistance, traction resistance |

| K-100 | Colored, light weight |

| K-119 | High durability, higher elongation, flexible and more fatigue resistant, light weight, good traction resistance |

| K-129 | High strength, higher tenacity, high thermal and electrical resistance, light weight, good traction resistance |

| K-149 | Ultra-high modulus, highest tenacity, light weight, high thermal and electrical resistance, high traction resistance |

Basalt-fiber-reinforced polymer (BFRP):This type has good corrosion resistance and designability [5]. This alternative material is both cost-effective and has exceptional properties compared to glass fibers. Some of the notable benefits of these composites are their high specific mechano-physico-chemical properties, biodegradability, and non-abrasive characteristics [6].

-

B.

Based on the matrix material.

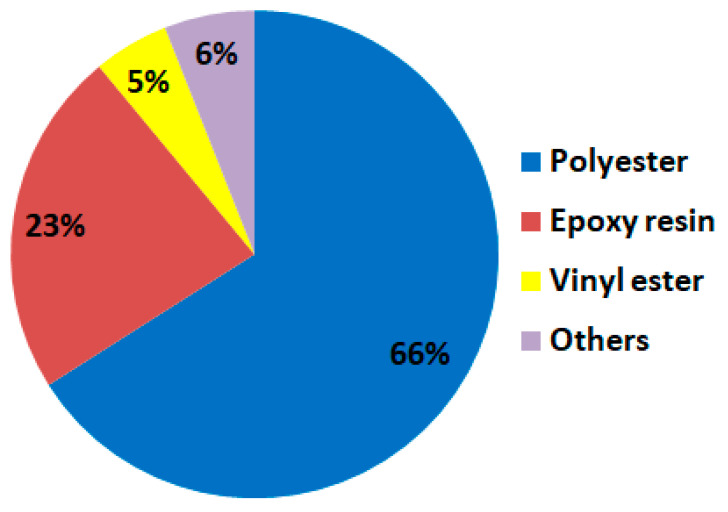

Thermoset FRP: In this type, the polymer matrix is a thermosetting resin, such as epoxy or polyester, which hardens irreversibly when cured. The main advantage of thermosetting polymers lies in their ability to maintain structural rigidity even at elevated temperatures, making them ideal for high-temperature applications. The main disadvantage is that once catalyzed, a thermosetting resin loses its ability to be reversed or re-shaped, rendering the formed thermoset composite unalterable. As a consequence, recycling thermoset composites becomes exceptionally challenging and costly. The thermoset resin itself is not recyclable due to its irreversible chemical properties. Several examples of thermosetting polymer matrices include polyester, vinyl ester, epoxy, phenolic, cyanate ester, polyurethane, polyimide, and bismaleimide. Within the FRP composites sector, the most commonly used thermoset resins are polyester, vinyl ester, and epoxy (as seen in Figure 2, according to [3]). Among them, polyester holds a dominant position, with 66% of the market share. Epoxy, on the other hand, accounts for a moderate 23% share, while vinyl ester has the smallest market presence at 5%.

Figure 2.

The distribution of thermoset resins in the FRP composites sector (Adapted form [3]).

Polyester resins are preferred due to their economic advantage, ease of use, and quick curing time. However, their mechanical properties require improvement when compared to vinyl esters and epoxies, which offer better performance in certain applications.

Thermoplastic FRP: In this type, the matrix material is a thermoplastic resin, capable of being melted and reformed multiple times. The most commonly used thermoplastic polymer matrices are polyamide, polyethylene, polypropylene, PEEK, thermoplastic polyimide, thermoplastic polyurethane, polycarbonate, PLA, polysulfide, and polyphenylene sulfide [7]. Thermoplastic composites offer two significant benefits in certain manufacturing applications. Firstly, compared to thermosets, many thermoplastic composites show significantly increased impact resistance. In some cases, this difference can be as remarkable as 10 times the impact resistance [8]. Secondly, another major advantage of thermoplastic composites is their inherent ability to become malleable. While raw thermoplastic resins are solid at room temperature, the application of heat and pressure during the impregnation of reinforcing fibers leads to a physical change (though not a chemical reaction resulting in a permanent, nonreversible alteration). This unique characteristic allows thermoplastic composites to be re-formed and re-shaped as needed.

The process of making thermoplastic composites malleable through heat application poses challenges due to the resin’s natural solid state. Impregnating it with reinforcing fibers requires heating the resin to its melting point and applying pressure to integrate the fibers. Subsequently, the composite needs to be cooled while still under pressure.This complex procedure necessitates the use of special tooling, techniques, and equipment, many of which are expensive. Consequently, the manufacturing process of thermoplastic composites is notably more intricate and costly compared to traditional thermoset composite manufacturing [8].

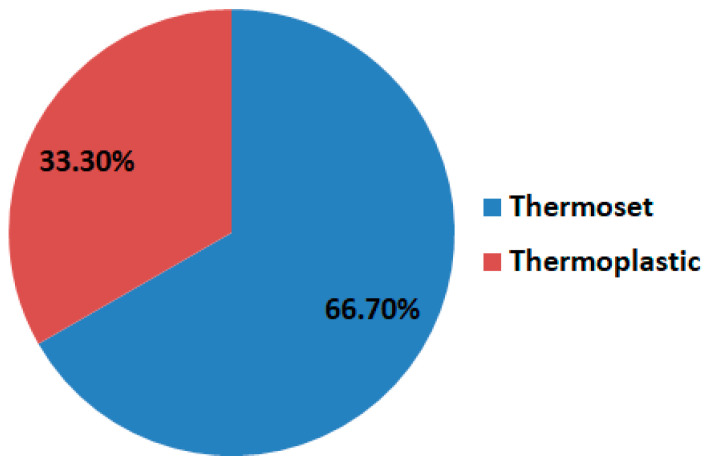

According to [3], compared with thermoplastics, thermoset materials represent approximately two-thirds of the FRP market share, as illustrated in Figure 3.

Figure 3.

The distribution of FRP matrix (Adapted form [3]).

-

C.

Based on the manufacturing process:

Pultruded FRP:Produced through a continuous pultrusion process where fibers and resin are pulled through a die and cured to form the composite.Pultruded FRP composites have a relatively higher fiber volume ratio, typically ranging from 60% to 75%. On the other hand, wet-laid laminates consist of several layers of fibers in multiple directions and generally have a lower fiber volume ratio [9].

Lay-up FRP: Manufactured by layering individual sheets of fiber and impregnating them with resin, followed by curing to create the composite.

Filament-wound FRP: Made by winding continuous fibers under tension around a rotating mandrel and impregnating them with resin.

-

D.

Based on the orientation of fibers:

Unidirectional FRP: The fibers are aligned predominantly in one direction, providing high strength along that axis. They offer remarkable stiffness in the direction of the fibers, making them suitable for load-bearing applications. On the other hand, they may have lower strength and stiffness in other directions.

Bidirectional (or woven) FRP: The fibers are arranged in both longitudinal and transverse directions, offering balanced properties. Unlike unidirectional FRP, bidirectional composites exhibit similar mechanical properties in both warp and transverse directions, making them easier to analyze and design.The interlocking pattern of fibers in woven composites enhances their impact resistance compared to unidirectional materials. Regarding the disadvantages, it should be mentioned that bidirectional composites may have lower tensile strength and stiffness along specific directions compared to unidirectional composites. Also, the weaving process may result in some additional weight due to the overlapping fibers, making them slightly heavier than unidirectional materials.

Random (or chopped) FRP: Short fibers are randomly distributed in the matrix, which is suitable for improving impact resistance. Their production process is relatively simple, involving the mixing of chopped fibers with a resin matrix and molding into the desired shape. This simplicity reduces manufacturing costs, making them suitable for a range of applications where cost-effectiveness is critical. Furthermore, the random distribution of fibers in chopped FRP composites enhances their impact resistance. The entangled and interlocked fibers create a more robust structure, making these composites suitable for applications where high-impact loads are anticipated, such as automotive components, sporting goods, and protective equipment. Moreover, chopped FRP composites provide ease of application. Due to their random orientation, they can be molded into complex shapes without the need for precise fiber alignment. Despite their advantages, chopped FRP composites have certain limitations. One of the main drawbacks is their anisotropic behavior. The mechanical properties of the material vary significantly depending on the random fiber distribution, leading to unpredictable performance in different directions.Another disadvantage is that chopped FRP composites generally have lower tensile strength and stiffness compared to continuous fiber composites like unidirectional or woven FRP. This limits their use in load-bearing structures where high strength and rigidity are essential. Additionally, the random orientation of fibers may result in a rougher surface finish compared to continuous fiber composites.

-

E.

Based on application.

FRP for construction: Used in structural components like beams and columns and in the reinforcement of buildings.

FRP for aerospace: Employed in aircraft components due to their high strength-to-weight ratio.

FRP for automotive: Utilized in vehicle parts to reduce weight and improve fuel efficiency.

FRP composites exhibit remarkable flexibility and adaptability, primarily driven by the choice of reinforcing fibers. The carbon-fiber-reinforced polymer (CFRP) stands out for its high strength, lightweight nature, corrosion resistance, and fatigue resilience, making it a preferred material for aerospace and high-performance applications. The glass-fiber-reinforced polymer (GFRP), utilizing glass fibers, offers good electrical insulation, corrosion resistance, and a cost-effective solution for various industries, including construction and automotive. The aramid-fiber-reinforced polymer (AFRP), featuring aramid fibers like Kevlar, strikes a balance between strength, stiffness, and impact resistance, finding applications in aerospace, military, and sports equipment. The basalt-fiber-reinforced polymer (BFRP) emerges as a cost-effective alternative with good corrosion resistance, biodegradability, and application versatility, particularly in construction and infrastructure. The classification based on matrix materials further enhances adaptability. Thermoset FRP, employing matrices like epoxy, polyester, and vinyl ester, maintains structural rigidity at high temperatures but faces challenges in recycling due to irreversible curing. In contrast, a thermoplastic FRP, with matrices such as polyamide and polyethylene, offers malleability and increased impact resistance, albeit with a more intricate and costly manufacturing process. The selection of manufacturing processes, fiber orientations, and application-driven choices collectively contributes to the extensive range of uses for FRP composites, spanning industries from aerospace and automotive to construction and infrastructure repair.

1.2. Applications of FRPs

FRPs have a wide range of applications due to their high strength-to-weight ratio, corrosion resistance, and durability. Some of the common applications of FRPs include:

-

1.

Civil engineering and infrastructure (because they provide increased strength, load-carrying capacity, and corrosion resistance):

Strengthening and retrofitting bridges and columns with FRP wraps to increase load-carrying capacity and seismic resistance.

Repairing and reinforcing aging concrete structures, such as parking garages, using FRP composites.

Constructing lightweight pedestrian bridges and footpaths using FRP materials.

-

2.

Aerospace and aviation (to reduce weight while maintaining structural integrity):

Manufacturing aircraft components like wings, empennages, and fuselage sections using FRP composites to reduce weight and enhance fuel efficiency.

Designing satellite components and spacecraft structures using FRP materials for their lightweight properties.

-

3.

Automotiveindustry (to reduce vehicle weight, leading to improved fuel efficiency and performance):

Producing carbon fiber composite body panels and chassis components for high-performance sports cars and electric vehicles.

Developing lightweight FRP materials for use in automotive interiors, such as dashboards and door panels.

-

4.

Marine and boat building (due to its resistance to corrosion from saltwater and its lightweight properties):

Fabricating boat hulls and decks using FRP materials to provide corrosion resistance and reduce overall weight.

Constructing marine wind turbine platforms using FRP composites for offshore wind farms.

-

5.

Sports and recreation (due to their ability to enhance performance through improved strength and flexibility):

Manufacturing tennis rackets and golf club shafts using carbon-fiber-reinforced composites for increased strength and better performance.

Designing carbon fiber bicycle frames to create lightweight and rigid bicycles for competitive cycling.

-

6.

Oil and gas industry equipment (for different equipment that require resistance to corrosion and harsh environments):

Installing FRP pipes and fittings for transporting corrosive fluids and gases in chemical processing plants and offshore installations.

Constructing FRP storage tanks to store aggressive chemicals and corrosive materials.

-

7.

Chemical Processing (they offer excellent resistance to chemical corrosion):

Building FRP chimneys and scrubbers for chemical plants, which are resistant to acidic and corrosive fumes.

Fabricating FRP pipe systems for transporting aggressive chemicals in chemical processing facilities.

-

8.

Electrical and electronics (due to their excellent insulating properties):

Manufacturing FRP composite insulators for electrical transmission lines to improve electrical insulation properties.

Developing FRP enclosures for electronic equipment to protect against environmental hazards and electromagnetic interference.

-

9.

Infrastructurerepair and rehabilitation:

Strengthening damaged concrete beams and columns in bridges using FRP wraps to restore structural integrity.

Rehabilitating historical buildings with FRP composites to preserve their structural integrity and aesthetics.

-

10.

Wind energy (due to their lightweight and high strength properties, they enable larger and more efficient blades for capturing wind energy):

Constructing wind turbine blades using advanced FRP materials to improve efficiency and increase energy capture from wind.

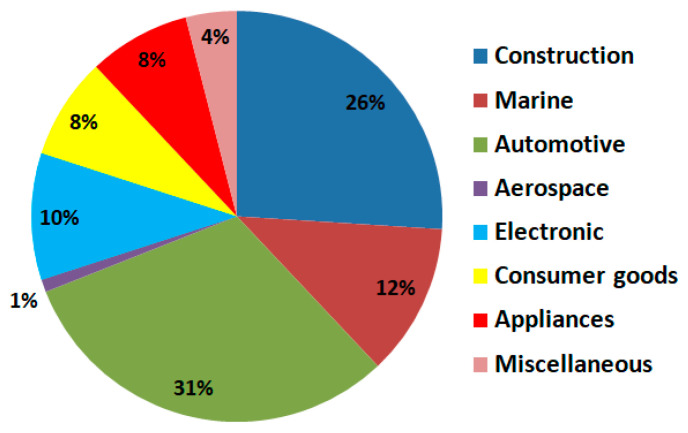

In Figure 4, the market share of FRP applications, according to [10,11], is presented.

Figure 4.

The distribution of fiber-reinforced polymer (FRP) market share across various applications (Adapted form [11]).

Fiber-reinforced polymer (FRP) composites are materials made from a polymer matrix reinforced with engineered, man-made, or natural fibers like carbon, glass, or aramid. Some distinguishing characteristics of FRP composites mentionedin this study include the following:

-

-

High Strength-to-Weight Ratio: FRP composites are known for their high tensile strength while being significantly lighter than metals. This makes them ideal for aerospace, automotive, and sporting goods applications where weight savings are crucial;

-

-

Corrosion Resistance: Unlike metals, FRP composites do not corrode, making them suitable for use in corrosive environments such as chemical processing plants or marine applications;

-

-

Flexibility in Design: FRP composites can be molded into complex shapes, which allows for design flexibility. This is significant in the aerospace and automotive industries, where aerodynamic shapes are required for performance;

-

-

Directional Strength: The strength of FRP composites can be tailored to specific directions through the orientation of fibers. This is important in applications where the load direction is known, and the material can be designed to maximize strength in that direction;

-

-

Good Fatigue Resistance: FRP composites have a high fatigue endurance limit, making them suitable for applications involving cyclic loads, such as bridges or rotating machinery parts;

-

-

Thermal Properties: FRP composites have low thermal conductivity and good thermal insulation properties. This characteristic is crucial in applications where thermal insulation is required or in situations where the material must withstand extreme temperature variations without deforming;

-

-

Electrical Properties: FRPs are generally non-conductive, which makes them useful in electrical insulation applications and for use in electromagnetic-sensitive environments.

The significance of these characteristics in material selection and application is that they allow engineers and designers to tailor materials to the specific needs of their application. For example, in a corrosive environment, the corrosion resistance of FRP might be the deciding factor, while in an aerospace application, the high strength-to-weight ratio would be most critical. Understanding the specific environment and demands of the application is essential to making the best material choice.

2. Historical Background of FRPs

The utilization of composite materials, owing to their intriguing physical and mechanical attributes, has become prevalent across numerous engineering domains. These materials are now integral in advanced applications within civil, mechanical, aerospace, and biomedical fields. Interestingly, the concept of combining two or more elemental materials to create composite solids has been employed since the inception of conscious or subconscious structural design processes [12,13,14].

Historically, ancient Jewish workers, while under Pharaoh rule, blended chopped straws with clay to craft bricks with enhanced mechanical strength. Japanese samurai warriors employed laminated metals, utilizing steel strips for strength and iron strips for flexibility when forging their swords. Around 1200 AD, the Mongols invented the first composite bow by combining wood, bone, and animal glue [15].

In the realm of modern advanced composite materials, particularly during the plastic era, one of the most crucial types, from a structural perspective, is fiber-reinforced composites. In this category, the use of fibers with distinct physical characteristics strategically arranged within a matrix material facilitates the creation of functional materials with desired levels of strength and stiffness. These materials can also exhibit advantageous chemical and physical properties. Typically, the matrix consists of polymeric resins like epoxy, vinylester, or polyester thermosetting plastics. However, metals, such as aluminum, or mortar/concrete, are also employed for specific structural applications [13].

Regarding commonly used fiber-reinforced materials, the primary fiber materials are glass, carbon, and aramid compounds, although other fibers find application in structural contexts [16]. These include vegetable fibers (e.g., cotton, hemp, jute, flax), wood fibers (distinct from vegetable fibers), and mineral fibers (e.g., asbestos). The history of textile fibers spans millennia, with the utilization of wool dating back over 4000 years. In stark contrast, the inception of the synthetic fiber industry can be traced to the initial commercial production of rayon in 1910. The 1950s and 1960s witnessed a significant surge in technological advancements within the synthetic fiber sector.

It is worth noting that fiber-reinforced polymers (FRP) are not a recent innovation. In fact, over a century ago, Leo Baekeland, an American chemist of Belgian origin, pioneered an FRP with his creation known as Bakelite. This material was groundbreaking due to its distinctive properties [6].

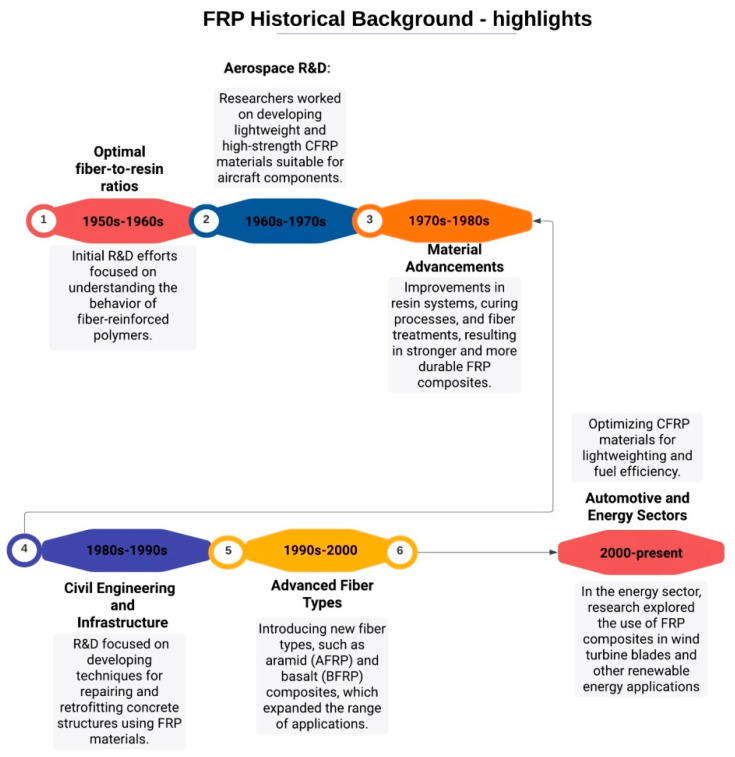

In the year 1935, Owens Corning unveiled the inaugural glass fiber, thereby heralding the inception of the fiber-reinforced polymer (FRP) industry. A year thereafter, in 1936, patents were granted for unsaturated polyester resins. Thanks to their curing capabilities, unsaturated polyester resins remain the predominant choice for manufacturing resins today [4]. Figure 5 presents a historical timeline that encapsulates vital developments regarding fiber-reinforced polymer (FRP) composites. This timeline offers some highlights and an overview of the evolution of FRP compositestudies, from their early experimental stages to their widespread adoption in diverse industries.

Figure 5.

Milestones of the FRP materials evolution across time.

Figure 5 shows the continuous innovation and research efforts that have propelled FRP composites into prominent roles in fields ranging from aerospace to civil engineering.

1940s–1950s:

Early Research: The concept of reinforcing polymers with fibers began to emerge in the mid-20th century. Early experiments involved using materials like fiberglass to reinforce plastic resins.

1950s–1960s:

Development of Fiberglass: The development of fiberglass, which is a glass-fiber-reinforced polymer (GFRP), gained momentum during this period. Companies like Owens Corning and others started producing fiberglass for various applications, including boats and automotive parts.

1960s–1970s:

Aerospace Applications: CFRP (carbon-fiber-reinforced polymer) composites were introduced in the aerospace industry, primarily in the form of carbon-fiber-reinforced epoxy composites. These materials offered significant weight savings for aircraft components.

1970s–1980s:

Growth in the Marine Industry: The GFRP gained popularity in the marine industry due to its corrosion resistance and lightweight properties. It became widely used for boat hulls and structures.

1980s–1990s:

Civil Engineering and Infrastructure: The use of FRP composites in civil engineering and infrastructure projects began to grow. Applications included bridge deck reinforcement and the repair of concrete structures.

1990s–Present:

Advancements in Materials: Ongoing research led to the development of advanced materials like aramid- (AFRP) and basalt- (BFRP) fiber-reinforced polymers, expanding the range of applications for FRP composites.

2000s–Present:

Automotive Industry: CFRP composites found increasing use in high-end and performance vehicles due to their lightweight properties and potential for improved fuel efficiency and performance.

2010s–Present:

Construction and Architecture: FRP materials gained popularity in the construction and architectural sectors. They were used for applications such as building facades, cladding, and reinforcement of concrete structures.

Ongoing Innovations: Research and development in FRP composites continue, with a focus on improving materials, manufacturing processes, and recycling methods. Efforts are also being made to reduce costs and environmental impacts.

Future Prospects: FRP composites are expected to play a significant role in sustainable engineering and construction practices, as they offer the potential for reduced energy consumption and greenhouse gas emissions.

In summary, the history of FRP composites spans several decades and has seen a gradual expansion from early experimentation to widespread use in industries such as aerospace, automotive, marine, construction, and civil engineering. The ongoing development of advanced materials and manufacturing techniques suggests that FRP composites will continue to have a growing impact in various sectors in the future.

3. Manufacturing Technologies of FRPs

The fabrication of FRP composite structures is a complex process, including a variety of methods, depending on the type of reinforcement and the intended application of the product [11,17,18,19]. The production process comprises two essential steps: first, the creation of fiber preforms, followed by the reinforcement of these preforms with the matrix material.

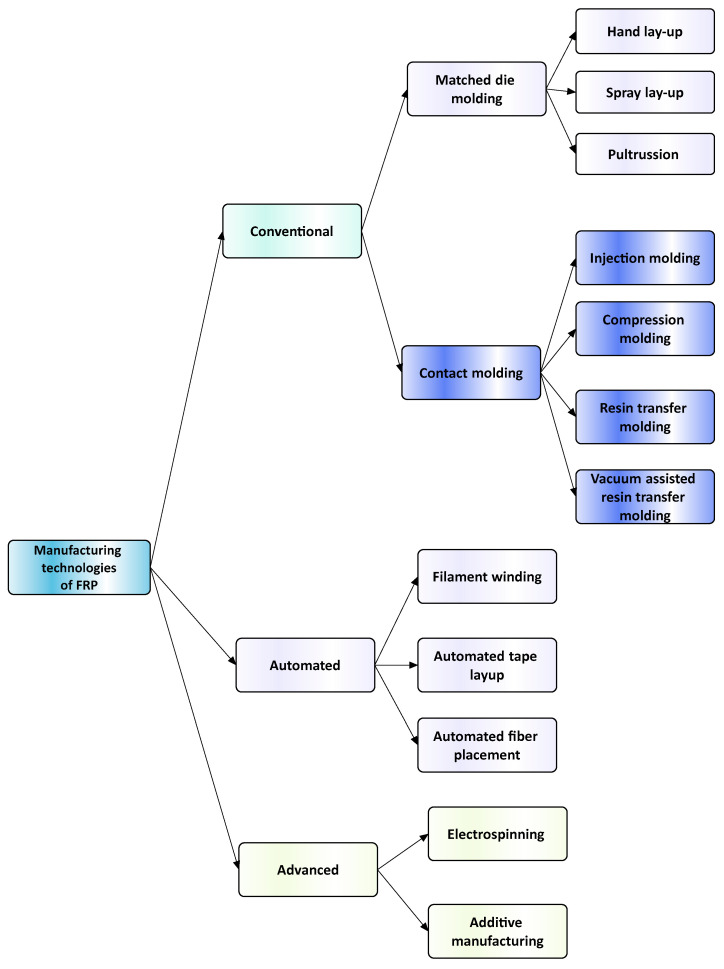

Figure 6 illustrates the classification of the main composite manufacturing process techniques into three groups: conventional, automated, and advanced manufacturing techniques [20,21,22].

Figure 6.

Classification of FRP manufacturing technologies (Adapted form [20]).

Figure 6 illustrates the classification of the main composite manufacturing process techniques into three groups, conventional, automated, and advanced manufacturing techniques, and Table 3 presents a summarized description of each manufacturing technology, including the process schematization, the application field, and the advantages and disadvantages.In this manuscript, we added the key features for each category. Conventional manufacturing methods for FRP are characterized by their inherent flexibility and versatility. Processes like lay-up and filament winding allow for customized designs and intricate lay-up patterns, making them adaptable to diverse project requirements. However, these methods heavily rely on manual labor, which can introduce variability in the final product and may not be as efficient for large-scale production. In contrast, automated manufacturing technologies, exemplified by processes like filament winding, automated fiber placement, and automated tape lay-up, emphasize efficiency and repeatability. Automation reduces dependence on manual labor, leading to consistent and reliable products. These methods improve production rates while maintaining a degree of flexibility, making them suitable for applications where precision and efficiency are essential. Moving further on the technological spectrum, advanced manufacturing technologies like electrospinning and additive manufacturing share a common emphasis on precision and customization in the fabrication of FRP. Electrospinning stands out for its ability to produce ultrafine fibers with remarkable precision, offering control over diameter, alignment, and composition. This characteristic aligns with additive manufacturing, which is defined by its layered construction approach, enabling the additive buildup of intricate designs and complex geometries with precision. Both methods contribute to the development of adapted FRP composites, allowing for the customization of mechanical and functional properties. While electrospinning excels in creating materials with a high surface-to-volume ratio, additive manufacturing’s key feature lies in its versatility across various materials, rapid prototyping capabilities, and the ability to create complex, customized FRP structures, making them valuable advancements in the field of composite material fabrication.

Table 3.

Description of FRP manufacturing technologies.

| Process Name |

Process Description | Application | Advantages | Disadvantages |

|---|---|---|---|---|

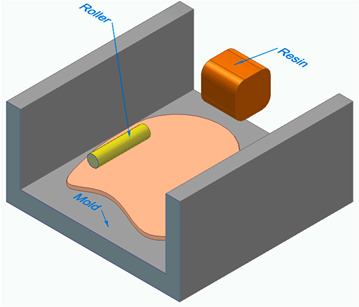

| Hand lay-up |

It is the simplest and most extensively employed open-mold composite manufacturing method. In this process, fiber preforms are initially positioned within a mold, and a thin layer of an antiadhesive coating is applied to facilitate easy removal. Subsequently, resin material is poured or brushed onto the reinforcement material, and a roller is used to effectively drive the resin into the fabric to enhance interaction between successive layers of the reinforcement and the matrix materials [18]. | Manufacturing large structures in low quantities in the marine sector (boat hulls and related components), automotive industry (such as car body panels), energy field (wind turbine blades), transportation (including large containers), and household applications (swimming pools, bathtubs, etc.) [17]. | Low-cost equipment and operation. Suitable for large components. Adaptability to complex shapes. Environmental sustainability (involves lower energy consumption and fewer emissions compared to some automated processes). |

Due to the open-mold, the products have a single well-finished surface, necessitating a secondary trimming operation [17]. Labor-cost heavy and inefficient [23]. |

(Adapted form [20]). (Adapted form [20]). | ||||

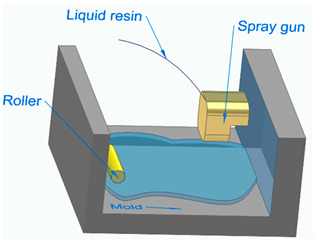

| Spray lay-up |

The spray-up technique shares similarities with hand lay-up, with the main distinction being the utilization of a spray gun that dispenses resin and chopped fibers onto a mold [18]. | The method is suitable for low and moderate production of large FRP composite structures, such as bathroom units and ventilation hoods [17]. | Simplicity. Faster FRP production and greater shape complexity compared to low-cost hand lay-up technique equipment. |

The parts have only one finished part surface. Resin waste. Reduced fiber orientation control. Air entrapment. |

(Adapted form [20]). (Adapted form [20]). | ||||

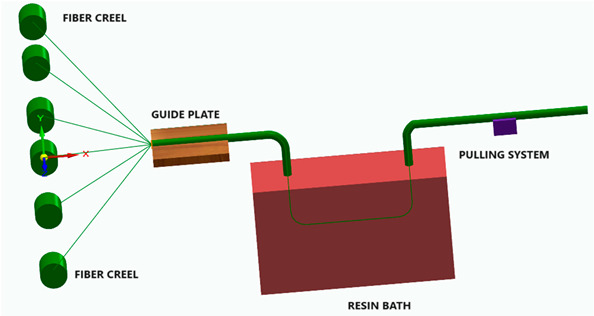

| Pultrusion | This process involves the continuous pulling or reinforcing of fibers through a resin bath, followed by a shaping die or heated die that cures the composite material. | FRP bars, profiles, and strips [11]. |

This method is simple, effective, and adaptable and represents the most economical solution for producing continuous fiber structural composites characterized by a constant cross-sectional profile [19]. It is suitable for mass production. |

It is less suitable for complex or intricate shapes and components that require varying cross-sectional profiles. It is less suitable for complex or intricate shapes and components that require varying cross-sectional profiles. The cost of the required machinery, dies, and tooling can be significant. It is not economical for unit or batch production [22]. Material waste (trimming and cutting are often necessary to achieve the desired component lengths and shapes). Limited thickness control. |

(Adapted form [20]). (Adapted form [20]). | ||||

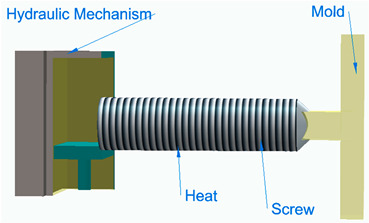

| Injection molding | In a typical injection molding process, composite fibers in granules/pellets/beads/powder form are introduced through a hopper, and they are then transported through a heated barrel with a screw. Once the necessary amount of material is melted within the barrel, the screw propels it through a nozzle into the mold, where it cools and is obtained the desired shape [18]. | Automotive parts (engine covers, door panels, and lightweight structural components); enclosures for electronic devices and components [18]; medical devices (instrument housings, patient-monitoring equipment, and diagnostic devices). |

High precision. Very low cycle times, enabling the rapid production of parts in high volumes, which is especially advantageous for mass production [18]. Reduced material waste. |

High initial investment due to the specialized equipment and tooling. Complex tooling. Design limitations. FRP parts may require additional finishing or coating processes to achieve a smooth surface finish. |

(Adapted form [20]). (Adapted form [20]). | ||||

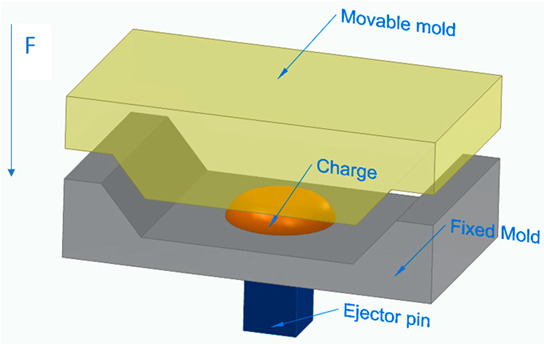

| Compression molding | It utilizes metal molds, which are preheated within a temperature range of 250 °F to 400 °F and then mounted onto substantial hydraulic or mechanical molding presses. The compression molding process involves placing a resin charge into a mold. One of the mold parts remains fixed, while the other movable mold part applies heat and pressure to shape the material into the desired structure [20]. | The production of high-strength FRP components and high-volume, moderately curved parts across a wide size range (automotive components, aerospace parts, decorative panels, cladding, and architectural elements). | It is a quick and precise method. High productivity. Excellent dimensional stability. The resulting FRP parts feature two exceptionally smooth surfaces and consistent part-to-part quality in comparison to other FRP manufacturing methods like injection molding, resin transfer molding, and vacuum-assisted resin transfer molding. It is one of the most cost-effective molding technologies. It minimizes material waste, making it advantageous for working with high-cost compounds, and it requires minimal post-processing and finishing costs [17]. |

Limitations in producing complex geometries. High tooling costs. Variability in part quality. High energy consumption. Limited automation for complex parts.Challenges in maintaining precise part thickness control. |

(Adapted form [20]). (Adapted form [20]). | ||||

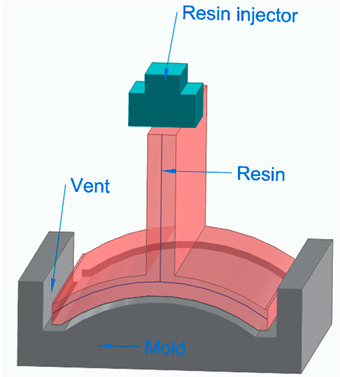

| Resin transfer molding | In this process, the initial step involves placing a dry fiber preform within the mold cavity. Subsequently, the mold is sealed, and resin is injected under pressure, facilitated by either vacuum or an injection device until the entire cavity is thoroughly saturated with resin. Finally, the resin-impregnated preform is subjected to curing, cooling, and subsequent demolding. | Truck panels, boat hulls, and aerospace and wind turbine blade products [17]. | It allows for the production of components with superior strength and a surface finish that closely replicates the mold’s surface [18]. It allows for flexibility in choosing both the material and its orientation, including the use of 3D reinforcements [20]. Minimum percentage of volatile emissions during processing [17]. |

High tooling costs. Achieving a mold shape that facilitates uniform resin distribution to all parts of the component demands rigorous testing and the application of advanced fluid dynamic simulations. The relatively slow curing time for the parts and the potential for displacement of reinforcement fibers during the resin transfer process [17]. |

(Adapted form [20]). (Adapted form [20]). | ||||

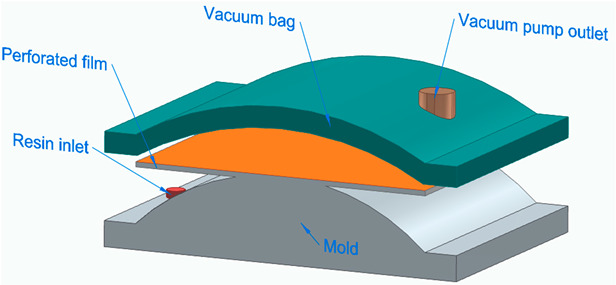

| Vacuum-assisted resin transfer molding | The process begins with arranging cloth fabrics or fibers into a preform according to the desired configuration. Typically, these fabrics are held together by a binder and pre-compressed to match the mold’s shape. A second matching mold tool is then secured over the first and vacuum-sealed, functioning as a flexible vacuum bag. The next step involves injecting pressurized resin into the mold cavity, assisted by a vacuum. Once impregnation is complete, the FRP composite part is left to cure at room temperature, with optional post-curing [17]. | Aircraft fuselage sections, wind turbine blades, aircraft landing gear doors, large composite panels, and components with minimal void content and a high fiber content [17]. | Adaptable tooling design and material options. Ease of mold geometry adjustments. Capacity to create high-quality, load-bearing, and structurally strong complex structures. It achieves remarkable fiber-to-resin ratios, up to 70%, virtually eliminating void. It uses low injection pressures, typically around 1 atm. |

Fiber misalignment. Voids. Complex mold design. Since only one side of the part comes into contact with the tool, it restricts the attainment of a single smooth surface. The challenge of managing variations in part thickness. |

(Adapted form [20]). (Adapted form [20]). | ||||

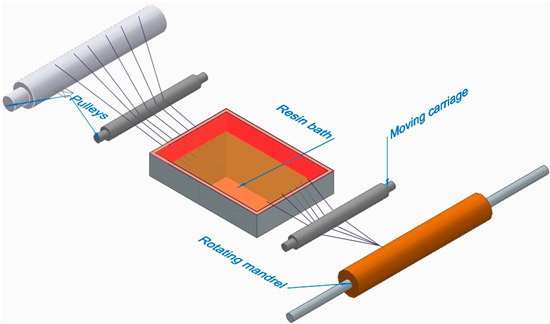

| Filament winding | It uses a rotating mandrel as the mold. Continuous reinforcement fibers are pulled from roving and guided through a heated resin bath. These resin-infused continuous fibers are then wound around the rotating mandrel, which is shaped internally according to the desired product design [20]. | Cylinders, pipes, bicycles, fuel storage and chemical tanks, stacks, rocket motor cases, pressure vessels, drive shafts, aerospace components, military armaments, power and transmission poles [17]. |

High strength and stiffness because it uses continuous fibers.High strength-to-weight ratio and product uniformity [20]. It allows for the orientation of the direction of the fibers to obtain optimized characteristics [17]. Reduced labor content. |

Limitation in structures with convex shapes. The mandrel is enclosed within the winding, making it challenging to precisely align the fiber along the entire length of the composite and the mandrel. The outer surface of the composite remains unmolded, resulting in an unaesthetic appearance [17]. |

(Adapted form [20]). (Adapted form [20]). | ||||

| Automated tape lay-up (ATL) |

Wide unidirectional tapes are applied to a part of a mold using a roller system equipped with different degrees of articulation, which can vary based on the complexity of the part being produced. Automated tape lay-up essentially imitates the manual process of laying down unidirectional tape but does so at increased speeds [24]. | Large, flat, or single-curvature composite structures [18] | Precision. Reduced labor. Improved material efficiency. It is suitable for larger parts. It offers enhanced process control. |

The cost associated with acquiring the necessary specialized equipment makes the technology inaccessible for small-to-medium-sized manufacturers [18]. Limitations in terms of part complexity. It requires additional training and expertise for operators. |

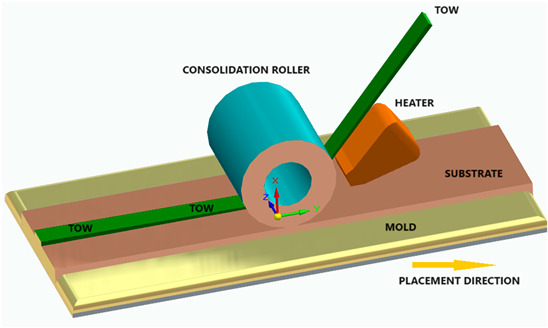

| Automated fiber placement(AFP) | Fiber-reinforced thermoplastic polymer (FRTP) prepreg tapes are applied to a tool, typically using a robotic arm equipped with a fiber placement head. The feeding unit of the fiber placement head directs the prepreg tapes onto the tool. A heat source warms the tape at the nip point, and a compaction roller presses it onto the substrate during the process. The tape is then sliced into strips of predetermined lengths by a cutting unit. The AFP process is managed by a computer program to arrange the FRTP prepreg tapes in the desired lay-up pattern [25]. | |||

(Adapted form [23]). (Adapted form [23]). | ||||

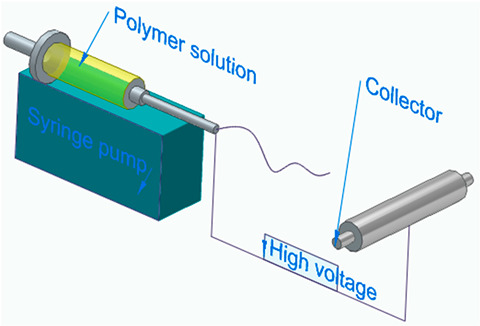

| Electrospinning | It is an electrostatic fiber fabrication method that uses electrical forces to create continuous fibers ranging from two nanometers to several micrometers in diameter. This process involves expelling a polymer solution through a spinneret, resulting in the formation of a continuous fiber [18], and the fibers are then collected at the apparatus. As a result, it has promising applications in various fields. |

Biomedical sector (wound healing, tissue engineering scaffolds, drug delivery, as a membrane in biosensors, immobilization of enzymes, and cosmetics) [18]. | Improved physical and mechanical properties.Flexibility in controlling process parameters. High surface area-to-volume ratio [18] |

Limited production rate. Challenges in achieving precise fiber diameters. The equipment and associated materials can be expensive. The use of high voltages in the electrospinning process can pose safety risks. |

(Adapted form [20]). (Adapted form [20]). | ||||

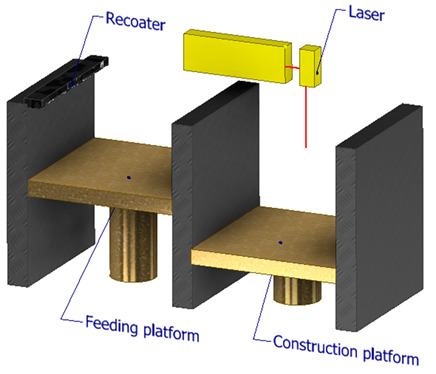

| Additive manufacturing (AM) |

Additive manufacturing techniques for continuous fiber-reinforced composites encompass methods such as fused deposition modeling (FDM), fused filament fabrication (FFF), directed energy deposition (DED), and laminated object manufacturing (LOM). The most used AM technique is FDM due to some advantages such as simple working principle, low production cost, and efficient and rapid production [23]. | It is particularly valuable in industries where lightweight, strong, and complex components are essential. | High level of geometrical complexity. Computer-aided designing eliminates the necessity of molds, decreasing the cost and manufacturing time. Flexibility in choosing both the volume of fibers and their orientation. Reduces material waste material and cycle time [18]. |

The lack of materials with structural capabilities. The materials presently available generally lack the durability required to serve as a finished product or component. The product size is the print area [26]. |

(Adapted form [23]). (Adapted form [23]). | ||||

Table 3 presents a summarized description of each manufacturing technology, including the FRP type used, the application field, and the advantages and disadvantages.

The manufacturing process is a crucial factor in the classification of FRP composites, significantly influencing their final properties and applications. Various processes, such as pultrusion, lay-up, and filament winding, contribute distinct characteristics to the resulting composites. For example, pultruded FRP composites, produced through a continuous process, tend to have a higher fiber volume ratio, offering enhanced strength and stiffness. On the other hand, lay-up processes involve layering individual sheets of fiber and resin, providing flexibility in design and allowing for specific lay-up requirements. Filament winding, where continuous fibers are wound around a mandrel, results in composites with excellent strength and is commonly used for cylindrical structures. The choice of manufacturing process, therefore, allows adapting FRP composites to meet diverse application needs, balancing factors such as strength, flexibility, and cost-effectiveness.

4. Insights into Material Characteristics and Design Guidelines

FRP composites are advanced materials made up of fibers, resins, fillers, and additives. These components work together to give FRP special properties. The fibers provide strength, the resins protect them from damage, and fillers help control costs and shrinkage, so this combination creates FRPs’ unique characteristics [27].

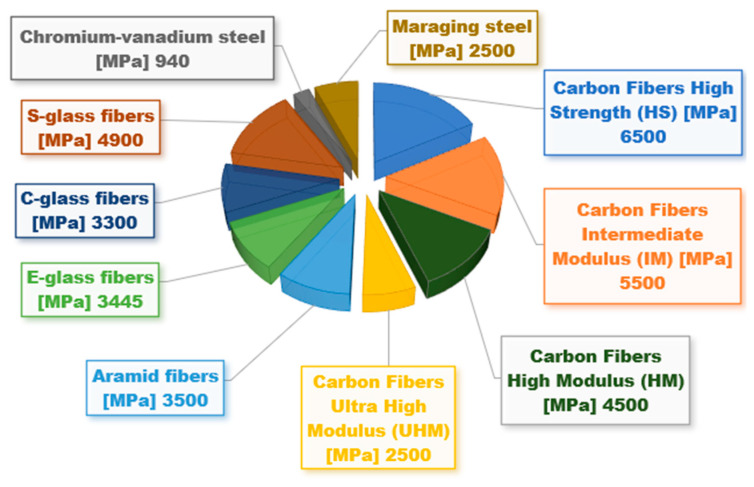

Four primary materials, namely carbon, glass, aramid, and basalt, are commonly employed in engineering to create fibers. These fibers are used to form CFRPs, GFRPs, AFRPs, and BFRPs. Figure 7 illustrates a comparison regarding the tensile strength of different materials used in industry

Figure 7.

Comparison regarding the tensile strength of different materials used in industry.

Reference [28] provides an in-depth examination of four widely used fiber-reinforced polymer composites (AFRPs, BFRPs, CFRPs, GFRPs) by evaluating crucial material properties, as can be seen in Table 4 [28].

Table 4.

Mechanical properties of FRP material types.

| Property | AFRP | BFRP | CFRP | GFRP |

|---|---|---|---|---|

| Density (g/cm3) | 1.25~1.45 | 1.90~2.10 | 1.50~2.10 | 1.25~2.50 |

| Tensile Strength (MPa) | 1720~3620 | 600~1500 | 600~3920 | 483~4580 |

| Elongation (%) | 1.4~4.4 | 1.2~2.6 | 0.5~1.8 | 1.2~5.0 |

| Young’s Modulus (GPa) | 41~175 | 50~65 | 37~784 | 35~86 |

| Coefficient of Linear Expansion (10–6/°C) | –6.0~2.0 | 9.0~12.0 | –9.0~0.0 | 6.0~10.0 |

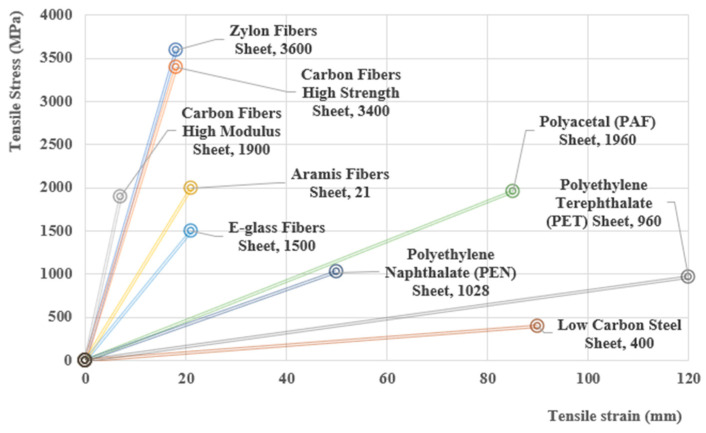

Table 5 presents the key mechanical properties of high-performance sheet materials, including aramid, E-glass, carbon, PBO, Dyneema, PET, PEN, and PAF, providing a comprehensive overview of their mechanical characteristics [28].

Table 5.

Mechanical properties of high-performance sheet materials.

| Type of Sheet | Tensile Strength (MPa) |

Elastic Modulus (GPa) |

Fracturing Strain (%) |

|

|---|---|---|---|---|

| Aramid | 200~2500 | 73~120 | 1.8~3.0 | |

| E-Glass | 1500 | 80 | 1.9 | |

| Carbon | High strength | 3400 | 230 | 1.5 |

| High modulus | 1900 | 540 | 0.35 | |

| PBO * | 3500 | 240 | 1.5 | |

| Dyneema | 1832 | 60 | 3.08 | |

| PET * | 923 | 6.7 | 13.8 | |

| PEN * | 1028 | 22.6 | 4.5 | |

| PAF * | 1730 | 40 | 6 | |

* PBO (Polypara-phenylene-Benzo-bis-Oxazole), PET (Polyethylene Terephthalate/polyester), PEN (Polyethylene Naphthalate), PAF (Polyacetal).

Table 6 provides a comprehensive overview of the typical properties of CFRP (carbon-fiber-reinforced polymer) composites, including variations such as pitch carbon, polyacrylonitrile carbon, common CFRP, high-modulus CFRP, and high-strength CFRP. The properties examined encompass a range of key characteristics crucial for material selection and application.

Table 6.

| Property | Carbon Fiber | |||

|---|---|---|---|---|

| Pitch Carbon | Polyacrylic Nitril Carbon | |||

| Common | High Modulus | High Modulus | High Strength | |

| Density (g/cm3) | 1.6~1.7 | 1.9~2.1 | 1.8~2.0 | 1.7~1.8 |

| Tensile Strength (MPa) | 764~980 | 2940~3430 | 2450~3920 | 3430 |

| Young’s Modulus (Pa) | 37~39 | 392~784 | 343~637 | 196~235 |

| Elongation (%) | 2.1~2.5 | 0.4~1.5 | 0.4~0.8 | 1.3~1.8 |

| Coefficient of Thermal Expansion (10–6/°C) | –0.6 up to –0.2 | –1.2 up to –0.1 | –1.2 up to –0.1 | –0.6 up to –0.2 |

Table 7 showcases the distinctive attributes of various glass fiber reinforcements, including E-glass, S-glass, C-glass, and AR-glass, which have been revealed through a thorough examination of their properties. This comprehensive analysis offers valuable insights into the specialized merits and applications of each type.

Table 7.

| Trade Name | E-Glass | S-Glass | C-Glass | AR-Glass |

|---|---|---|---|---|

| Density (g/cm3) | 2.5 | 2.5 | 2.5 | 2.27 |

| Tensile Strength (MPa) | 3450 | 4580 | 3300 | 1800~3500 |

| Extensionto Break (%) | 2.4 | 3.3 | 2.3 | 2.0~3.0 |

| Modulus of Elasticity (GPa) | 72.4 | 85.5 | 69 | 70~76 |

| Coefficient of Thermal Expansion (10–6/°C) | 5.0 | 2.9 | - | - |

Table 8 outlines the unique properties of diverse aramid fibers, including Twaron, Twaron HM, Technora H, Kevlar 29, Kevlar 49, and Kevlar 149, providing valuable insights into their specific advantages and applications within high-performance materials.

Table 8.

| Property | Aramid Fiber | |||||

|---|---|---|---|---|---|---|

| Twaron | Twaron HM | Technora H | Kevlar 29 | Kevlar 49 | Kevlar 149 | |

| Density (g/cm3) |

1.44 | 1.45 | 1.39 | 1.44 | 1.44 | 1.44 |

| Tensile strength (MPa) |

3000 | 3000 | 3000 | 2760 | 3620 | 3450 |

| Modulus of elasticity (GPa) |

80 | 124 | 70 | 62 | 124 | 175 |

| Extension to break (%) |

3.3 | 2.0 | 4.4 | 4.4 | 2.2 | 1.4 |

Table 9 illustrates the characteristic properties of thermoset resins used as matrices for FRPs, including epoxy, vinylester, and polyesters, as outlined in reference [29]. This comparative analysis offers valuable insights into their suitability and performance in composite materials.

Table 9.

Properties of thermoset resins for FRP matrices [29].

| Property | Resin | ||

|---|---|---|---|

| Epoxy | Vinylester | Polyesters | |

| Density (g/cm3) | 1.2~1.4 | 1.15~1.35 | 1.1~1.4 |

| Tensile Strength (MPa) | 55~130 | 73~81 | 34.5~104 |

| Young’s Modulus (GPa) | 2.75~4.10 | 3.0~3.5 | 2.1~3.45 |

| Poisson’s Ratio | 0.38~0.40 | 0.36~0.39 | 0.35~0.39 |

| Saturation (%) | 0.08~0.15 | 0.14~1.3 | 0.15~0.60 |

| Coefficient of Thermal Expansion (10–6/°C) |

45~65 | 50~75 | 55~100 |

The mechanical attributes of FRP composites are influenced by several factors, including the balance between fibers and matrix materials, the manufacturing process, individual material properties, and the alignment of fibers within the matrix. Fibers can be configured in various ways: ina“Continuous Form” (where fibers are straight, long, and parallel to each other), in a “Woven Form” (forming a cloth-like structure for strength in multiple directions), or in a “Chopped Form” (where fibers are irregularly arranged, discontinuous, and shorter, often referred to as fiberglass) [31].

In relation to tensile strength, as elucidated by the subsequent bibliographic references [32,33,34,35,36,37,38,39,40,41], the ensuing facets have been discerned:

The CFRP offers lower weight and higher tensile stress compared to other FRPs, leading to significant weight reduction and increased span lengths for prestressed components.

The BFRP has exceptional tensile strength and elongation at breaking.The GFRP enhances tensile strength by 36% in hybrid FRPs compared to the BFRP, surpassing PBO by 2.56%.

Tensile strength for the vinyl ester matrix is minimally affected, while for the polyester matrix, it decreases by a significant 80% in GFRPs.

Tensile strengths for GFRPs with epoxy-based and polyester-based matrices decrease by approximately 22.8% and 19.71%, respectively, when filled with rice husk and wheat husk.

Overall, hybrid GFRPs display more variable tensile strength compared to CFRPs or a GFRP alone.

The primary determinants of compressive strength, as outlined by [42,43,44,45,46,47,48], encompass the following:

CFRPs and AFRPs have the highest and lowest compressive strengths among typical FRP composites.

When basalt fibers are used on the surface or in layered formations (creating a sandwich-like structure), they significantly increase strength.

Composites with epoxy-based fibers tend to have higher compressive strength compared to those with polyester-based fibers. This means that composites with epoxy-based materials are generally stronger.

Wrapping hollow columns with CFRP layers (one layer or three layers) improves strength by 66% and 123%, respectively. In comparison, wrapping with a GFRP only improves strength by 36% and 105% for the same layering.

When hollow columns are filled with concrete and wrapped with a CFRP (three layers), the strength increases by 154%. For GFRP wrapping with the same layering, the strength increases by 144%. This shows that filling columns with concrete and adding FRP wrapping greatly enhances their strength.

Using FRPs to strengthen ultra-high-performance concrete (UHPC) increases its compressive strength by at least 115% compared to regular UHPC.

Sandwich structures reinforced with CFRPs have approximately 24.68% higher compressive strength compared to non-reinforced structures.

Increasing the thickness of FRP layers effectively boosts the compressive strength of reinforced concrete elements in specific areas.

Regarding shear strength, pivotal factors, as outlined by [49,50,51,52,53,54], involve the following:

Absorbing moisture in epoxy weakens shear strength in RC elements. To counter shear stresses, FRP-reinforced structures require stirrups or ties or rely solely on concrete strength (as in RC tanks).

FRP rebars generally have lower stiffness, necessitating deeper elements or extra reinforcement to reduce deflection and crack widths.

ACI 318 guides the design of shear strength for FRPs, while ACI 440 does not allow dowel action for FRP rebars, in contrast to steel rebars.

Textiles are engineered to optimize shear beam strength in 45-degree directions, yet rosette strain gages reveal these materials surpass shear cracks in strength.

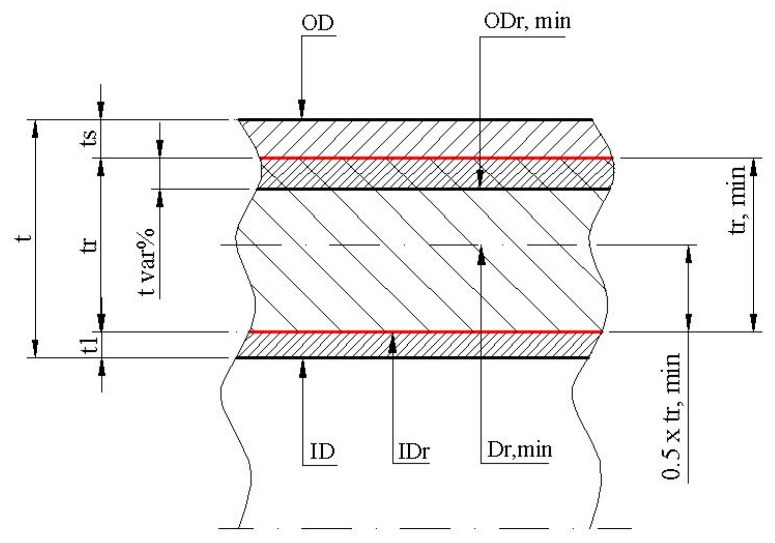

Table 10 delineates the essential characteristics of GRP pipes, with particular emphasis on their hoop and axial properties, as documented in a 2013 research report [55], offering valuable insights into their performance and applicability within composite materials.

Table 10.

Characteristics of GRP pipes.

| Description | RTRP | AWWAM45 | |

|---|---|---|---|

| Diameter (mm) | 2400 | - | |

| Thickness (mm) | 44.5 | - | |

| Hoop | Tensile strength (MPa) | 303.3 | 14~550 |

| Tensile modulus of elasticity (GPa) |

41.6 | 3.5~34.5 | |

| Bending modulus of elasticity (GPa) | 22.3 | - | |

| Axial | Tensile strength (MPa) | 164.0 | 14~550 |

| Tensile modulus of elasticity (GPa) | 12.4 | 3.5~34.5 | |

| Compressive strength (MPa) | 211.0 | 69~275 | |

| Compressive modulus of elasticity (GPa) |

12.2 | - | |

| Bending strength (MPa) | 175.0 | 28~480 | |

| Bending modulus of elasticity (GPa) |

11.0 | 6.9~34.5 | |

| Izod impact strength (J/m) | 256.0 | - | |

| Coefficient of linear expansion (1/°C) | 1.6 × 10−5 | 1.4 × 10−5~5.4 × 10−5 | |

| HDB (forstress) (MPa) | 97.5 | - | |

| HDB (forstrain) (%) | 0.653 | - | |

| Poisson’sratio | 0.159 | - | |

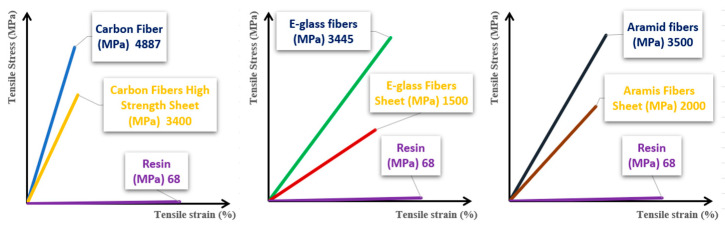

Figure 8 depicts the stress–strain relationships observed in various fiber composites, providing a visual representation of their mechanical behavior and performance under applied loads [56].

Figure 8.

Stress and strain relationships of different fiber composite.

ISO 14692 [57] draws upon ASME B 31.3 guidelines to define system load cases like sustained, expansion, and occasional loads. Additionally, it relies on BS7159 for system design parameters, encompassing flexibility factors, stress intensity factors (SIF), and pressure stress multipliers. These standards collectively inform the approach taken in evaluating the integrity of GRP process piping systems and pipelines, considering factors such as pipework flexibility, layout complexity, pipe supports, pipe diameter, temperature fluctuations, and system criticality and failure risk assessment. Piping stress engineers must conduct a comprehensive analysis to ascertain if flexibility analysis is warranted.

This entails determining various loading conditions—internal or external pressure, thermal, occasional, and support loads—and subsequently assessing the associated stresses and loads, which are then compared with established allowable limits.

Laminated FRP structures exhibit distinct behavior influenced not only by the mechanical attributes of their constituent elements, such as strength, elastic modulus, and stress limits but also by the specific geometry imposed on each ply within the laminate.

In general, the reinforcement fibers tend to possess superior elastic properties in comparison to the polymeric matrix. Consequently, the overall properties of the composite structure predominantly hinge on the characteristics of the reinforcement (see Figure 9).

Figure 9.

Comparative influence of fiber and resin on FRP composite performance.

In order to determine the characteristics of GRP/FRP materials, it can be used the standards [58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91].

The tensile strength of FRP composites is often much higher than that of traditional materials like steel or aluminum when compared on a weight basis. This is largely due to the high tensile strength of the reinforcing fibers, such as carbon or glass fibers.While not as high as tensile strength, the compressive strength of FRP composites is adequate for many structural applications, particularly when designed with appropriate fiber orientations.FRP can be designed to absorb impact energy through damage mechanisms such as fiber breakage and delamination, which can prevent catastrophic failure.The stiffness of an FRP composite, measured by its modulus of elasticity, is determined by the type of fibers used and their volume fraction. High-stiffness fibers like carbon can provide the rigidity necessary for structural applications.In terms of corrosion resistance, an FRP’s polymer matrix is inert to many corrosive substances, which gives FRP composites an advantage in harsh chemical or saline environments, leading to a longer lifespan with less maintenance. On the other hand, UV inhibitors and protective coatings can be added to FRP composites to enhance their resistance to sunlight and weathering, making them suitable for outdoor applications. Furthermore, the lower density of FRP composites compared to metals leads to significant weight savings, which is especially beneficial in the automotive and aerospace industries for fuel efficiency and performance. FRPs have low thermal conductivity, which makes them good insulators. This property is vital in applications where thermal bridging must be minimized, such as in building envelopes, while FRPs typically have a lower coefficient of thermal expansion than metals, which means they have less dimensional change with temperature fluctuations. Also, the dielectric properties of FRP composites make them suitable for electrical insulation applications, as well as for use in structures where electrical conductivity could be hazardous.FRP composites can be molded into complex shapes and sizes, which allows for integrated designs and the reduction of joint and fastener needs.

These material characteristics make FRP composites highly versatile and enable their use in a diverse range of applications, from simple consumer products to advanced aerospace components. The ability to customize the fiber and matrix combinations allows for optimization of performance to meet specific requirements, whether it is maximizing strength for structural components, ensuring durability for outdoor use, or achieving a balance between strength and weight for mobility and transport applications.

5. Comprehensive Design Guidelines for Fiber-Reinforced Polymer (FRP) Structures

Designing structures with fiberglass-reinforced plastic (FRP) materials requires adherence to specific standards and guidelines to ensure safety, reliability, and compliance with industry best practices. The following are some of the key standards and codes that are commonly used for FRP design:

ACI 440.1R-15 (American Concrete Institute) [92].

This document provides comprehensive guidance on using FRP materials as reinforcement in concrete structures. It covers design considerations, material properties, and construction practices.

It addresses various types of FRP reinforcement, such as bars, grids, and sheets.

The standard offers design examples and calculations to assist engineers in designing FRP-reinforced concrete members.

ACI 440.6-08 (American Concrete Institute) [54].

This standard specifies the requirements for carbon and glass fiber-reinforced polymer bars used as reinforcement in concrete structures.

It outlines the materials, fabrication, and testing requirements for FRP bars, ensuring that they meet the necessary strength and durability criteria.

ACI 440.4R-04 (American Concrete Institute) [93].

This guide focuses on the prestressing of concrete structures using FRP tendons.

It covers design considerations, material properties, and construction practices related to prestressed concrete elements reinforced with FRPs.

ASTM D7205 (ASTM International) [94]:

ASTM D7205 provides standardized testing methods for determining the mechanical properties of FRP composites used in civil engineering applications.

It covers tensile, compressive, flexural, and shear testing of FRP materials, ensuring accurate characterization of their performance.

ASCE Manuals and Reports on Engineering Practice No. 124.

This manual is a valuable resource for engineers and designers working with FRP-reinforced concrete structures.

It offers detailed information on the design, analysis, and construction of such structures, including case studies and practical examples.

ISO 10406-1 and ISO 10406-2 (International Organization for Standardization) [95,96].

ISO 10406 standards provide guidelines for the design, manufacturing, and testing of pultruded FRP profiles for structural applications.

Part 1 covers material properties, while Part 2 addresses design considerations and performance requirements.

ACMA FRP Composite Bridge Committee.

This committee within the American Composites Manufacturers Association focuses on developing standards and guidelines specifically tailored to FRP bridges.

Their standards cover topics such as design methodologies, manufacturing processes, quality control, and installation practices for FRP bridge components.

AASHTO LRFD Bridge Design Specifications (American Association of State Highway and Transportation Officials) [97].

These specifications are widely used in the United States for designing bridges, including those constructed with FRP materials.

Engineers should refer to relevant sections within AASHTO LRFD that pertain to FRP design, detailing, and testing requirements for bridge components.

Standards and codes that are commonly used for FRP piping (in petroleum and natural gas industries).

ISO 14692-1:Petroleum and natural gas industries—Glass-reinforced plastics (GRP) piping Part 1: Vocabulary, symbols, applications and materials [98];

ISO 14692-2: Petroleum and natural gas industries—Glass-reinforced plastics (GRP) piping Part 2: Qualification and manufacture [99];

ISO 14692-3: Petroleum and natural gas industries—Glass-reinforced plastics (GRP) piping Part 3: System design [100];

ISO 14692-4: Petroleum and natural gas industries—Glass-reinforced plastics (GRP) piping Part 4: Fabrication, installation and operation [57].

ASME B31.3: The ASME B31.3 code provides guidelines for the design, construction, and inspection of process piping systems used in the chemical, petroleum, and allied industries, including those made of FRP [101].

API 15LR: Published by the American Petroleum Institute (API), this standard addresses the design, fabrication, installation, inspection, and testing of fiberglass-reinforced thermosetting plastic (FRP) piping systems for offshore platforms [102].

ASTM D2996: ASTM D2996 provides standard specifications for filament-wound “fiberglass” (glass-fiber-reinforced thermosetting resin) pipes, which are commonly used in FRP piping systems [88].

ASTM D3262: This ASTM standard covers “fiberglass” (glass-fiber-reinforced thermosetting resin) sewer and industrial pressure pipes, which may also be used in the petroleum and natural gas industries [103].

NACE MR0175/ISO 15156: NACE International’s MR0175/ISO 15156 standard addresses the selection of materials for equipment used in oil and gas production environments, including FRP piping, where sour (containing hydrogen sulfide) conditions may be encountered [104].

AWWA M45: The American Water Works Association (AWWA) publishes standards for various types of pipes. AWWA M45 provides guidelines for the design and installation of fiberglass pipes and fittings, including those used in water and wastewater services for industries like petroleum refining.

ASTM D4024: ASTM D4024 provides guidelines for designing and specifying glass-fiber-reinforced thermosetting resin pipe, which is commonly used in FRP piping systems.

API 15HR: API 15HR is an API standard specifically addressing the design, materials, fabrication, testing, and inspection of FRP piping systems for use in oil and gas production, processing, and transportation.

ASME RTP-1: While primarily focused on equipment such as tanks and vessels, ASME RTP-1 also includes guidelines for the design, fabrication, and inspection of FRP piping systems in various industries, including petroleum and gas.

BS 7159:1989 British Standard Code of Practice for Design and Construction of Glass-reinforced Plastics (GRP) Piping Systems for Individual Plants or Sites.

Methods for Assessing the Flexibility of FRP/GRP/GRE Pipes

The assessment of the performance of fiber-reinforced plastic pipes under combined pressure and temperature loads is of paramount importance to guarantee their structural integrity and operational efficiency. Extensive research has indicated that FRP exhibits exceptional resistance to corrosion and possesses a remarkable ability to withstand mechanical stresses.

However, when subjected to simultaneous pressure and temperature variations, the behavior of FRP pipes can be influenced significantly.

It is crucial to recognize that pressure and temperature fluctuations can have a substantial impact on several key factors associated with FRP pipes. These factors include but are not limited to the following.

Thermal Expansion:The composite nature of FRP pipes means that they may experience significant thermal expansion and contraction in response to temperature changes. This expansion can affect the overall dimensions and shape of the pipe, potentially leading to structural issues if not properly managed.

Material Stiffness: The mechanical properties of FRP, such as its modulus of elasticity, can be temperature-dependent. Elevated temperatures may reduce the stiffness of the material, affecting its ability to withstand external loads and maintain its shape.

Stability: The combination of pressure and temperature can impact the overall stability of FRP pipes, potentially leading to buckling or deformation under certain conditions.

To ensure the safe and efficient utilization of FRP pipes in specific applications, comprehensive evaluations must be conducted. These evaluations should encompass finite element analysis, stress and strain assessments, and computational simulations to predict the behavior of FRP pipes under various operating conditions. Furthermore, the outcomes of these assessments will play a pivotal role in guiding the design and engineering of FRP piping systems, allowing for the optimization of material selection, reinforcement strategies, and thermal insulation. Ultimately, these efforts will ensure the reliable functionality and safety of FRP pipes, particularly in industries where they are commonly employed, such as chemical processing, oil and gas, and water treatment.

ISO 14692 is an international standard widely used in the petrochemical and natural gas industries for fiber-reinforced polymer (FRP) pipelines. This standard provides detailed guidance on the design, manufacturing, installation, and maintenance of FRP pipelines, including stress analyses.In the context of stress analysis, ISO 14692 offers a methodology for assessing the behavior of FRP pipelines under various loads and operating conditions. The standard defines relevant criteria and parameters for determining the stresses and deformations to which an FRP pipeline may be subjected, as well as for evaluating material compatibility. ISO 14692 contains recommendations and specific requirements for stress analysis in FRP pipelines, covering the following aspects:

Internal Pressure: The standard provides guidelines for calculating and evaluating stresses generated by internal pressure acting on the pipelines. It includes methods for determining the required wall thickness of the pipeline and assessing safety based on the maximum working pressure.

Operating Temperature: ISO 14692 contains recommendations for assessing thermal stresses in FRP pipelines based on operating temperatures. It covers aspects such as thermal cohesion, dimensional changes, and material expansion.

External Loads: The standard also addresses the analysis of stresses caused by external loads, such as mechanical loads, vibrations, earthquakes, or wind loads. It provides guidance on determining external loads and evaluating the stresses generated by them in FRP pipelines.

ISO 14692 also includes requirements and recommendations for verifying and validating the results of stress analyses, as well as tests and inspections necessary to ensure the quality and safety of FRP pipelines.By using ISO 14692 in stress analyses of FRP pipelines, it ensures that these pipelines are designed and manufactured to withstand various loads and operating conditions, thus ensuring their safety and reliability in industrial applications.

Materials like FRP (fiber-reinforced polymer) fall under the category of orthotropic materials, and they fundamentally differ from materials made of steel, which are isotropic. As can be observed, for orthotropic materials (such as FRP and GRP), the modulus of elasticity in the axial direction differs from that in the circumferential direction. Similarly, the Poisson’s ratio in the axial direction differs from that in the circumferential direction.

Orthotropic materials exhibit distinct mechanical properties along different axes, which make them anisotropic. This anisotropy arises from the orientation and alignment of the reinforcing fibers within the polymer matrix. In the case of FRP and GRP, these reinforcing fibers, often composed of materials like glass or carbon, provide the materials with their unique properties.

For example, in FRP composites, the modulus of elasticity is typically higher in the direction aligned with the fibers (axial direction) compared to the direction perpendicular to the fibers (circumferential direction). This is due to the enhanced stiffness provided by the aligned fibers. Consequently, FRP materials are excellent candidates for applications where directional stiffness and strength are critical, such as in the construction of composite structures like pipes, pressure vessels, or aerospace components.

Additionally, the Poisson’s ratio, which describes the ratio of lateral strain to axial strain when a material is subjected to uniaxial loading, can vary in different directions for orthotropic materials. In FRP materials, the Poisson’s ratio in the axial direction may differ from that in the circumferential direction, reflecting the different deformation behavior along these axes.

Understanding these orthotropic properties is crucial in the design and analysis of structures and components made from FRP materials. Engineers must consider these directional variations in mechanical properties when predicting the behavior of such materials under different loading conditions, ensuring that the designs are optimized for performance and safety.

The shear modulus (1), also known as the modulus of rigidity or shear modulus of elasticity, is a measure of a material’s resistance to deformation caused by shear forces. It is typically denoted by the symbol “G” and is calculated as the ratio of the applied shear force to the resulting shear angle, divided by the product of the material’s volume and its displacement under shear.The shear modulus is an important characteristic of materials and is used in engineering to assess a material’s behavior in applications involving shear forces, such as in shafts and motion transmission elements.

| (1) |

where

G is the shear modulus of the material;

Mt is the applied torsional moment;

L is the length of the element subjected to torsion;

∆φ represents the torsional angle or torsional deformation;

l is the length of the material undergoing deformation due to torsion.

The shear modulus (G), in the case of FRP pipes, is calculated using the following equation:

| (2) |

where

Ea, is the Young’s modulus in the axial direction;

Eh, is the Young’s modulus in the hoop direction;

νha, is the Poisson’s ratio in the axial–hoop direction.

Formula (2) is used to determine the stiffness or elastic behavior of a material when subjected to forces or deformations in both the axial and transverse directions. It takes into account the material’s Young’s modulus values in both directions as well as the Poisson’s ratio for axial–transverse deformation.

The relationship between Poisson’s ratio and the elastic moduli (axial and hoop) in fiber-reinforced polymer (FRP) materials is expressed by the following equation:

| Eh/Ea = νha/νah | (3) |

This equation describes a fundamental aspect of the mechanical behavior of FRP materials, where Eh represents the elastic modulus in the hoop direction, which measures the material’s resistance to deformation when subjected to forces applied tangentially to its surface, Ea represents the elastic modulus in the axial direction, which measures the material’s resistance to deformation when subjected to forces applied along its length, νha represents the Poisson’s ratio in the axial–hoop direction. Poisson’s ratio is a dimensionless material property that describes how a material responds to deformation. In this case, it specifically addresses how the material’s width changes when it is subjected to axial stretching, νah represents the Poisson’s ratio in the hoop–axial direction. This is essentially the opposite of νha and describes how the material’s length changes when it is subjected to transverse compression.

The equation tells us that the ratio of the hoop elastic modulus to the axial elastic modulus is equal to the ratio of the axial–hoop Poisson’s ratio to the hoop–axial Poisson’s ratio. This relationship is significant because it helps characterize how FRP materials behave when subjected to different types of loading.

The axial (and hoop) specific strain is determined, in the case of FRP pipes, using the following equations:

| (4) |

| (5) |

In practical terms, understanding this relationship is crucial for designing and analyzing structures and components made from FRP materials. Engineers and researchers can use this equation to predict how FRP materials will respond to various mechanical loads, ensuring the safety and efficiency of FRP-based applications in various industries.In many engineering and structural analysis applications involving pipe-like elements, the circumferential specific strain is not explicitly considered for simplicity because it does not significantly affect the overall behavior of the structure in most cases. In the next list, we provide a more detailed explanation of why this is the case:

Assumption of Thin-Walled Structures: In many situations, pipes and cylindrical structures are thin-walled. This means that the wall thickness is much smaller compared to the radius of the structure. When the wall thickness is significantly smaller than the radius, circumferential strains are typically very small, and thus, they are often neglected.