Abstract

A novel test methodology was developed for quantitative evaluation of critical radiant power characteristics as a function of time for diode pumped solid state (DPSS) laser pointers. It is based on a simultaneous measurement of time-dependent radiant power characteristics of multi-wavelength spectral components emitted by DPSS laser pointers. The authors tested green DPSS laser pointers, which emit three spectral components at the fundamental near-infrared (1064-nm), pumping near-infrared (808-nm), and second-harmonic green (532-nm) wavelengths. The obtained experimental results are employed for performing eye hazard evaluation according to U.S. and International laser safety standards. All tested green laser pointers demonstrated significant variability of radiant power as a function of time and wavelength. Thus, the severity of the potential eye hazard from DPSS laser pointers for a given exposure time depends on when a person was exposed after the pointer was turned on. Most laser pointers emitted radiation in excess of their classification limits, including unwanted infrared radiation that is not necessary for their intended use as laser pointers.

Keywords: lasers, radiation, non-ionizing, risk analysis, safety standards

INTRODUCTION

Recently, high-power handheld laser pointers have become more prevalent and attractive as new laser technologies have provided high-power, multi-wavelength, compact, and low-cost laser pointers. At the same time, due to their higher power and complex multi-wavelength radiation characteristics, measurements for hazard evaluation of laser pointers have become more challenging and require the development of innovative test methodologies.

The operating principle of conventional laser pointers is based on the use of various laser diodes or diode-pumped solid state (DPSS) lasers at different wavelengths. A widely used DPSS laser pointer technology produces green light (532-nm wavelength) (Galang et al. 2010). Usually, the green DPSS laser pointer design involves a 808-nm-central-wavelength high-power laser diode used to pump a Neodymium-doped Yttrium Vanadate (Nd:YVO4) laser crystal. This crystal emits laser radiation at 1,064-nm fundamental wavelength into a second-harmonic generator crystal of potassium titanylphosphate (KTP), which doubles the fundamental frequency and emits a laser beam at a green (532-nm) wavelength. However, in addition to this green laser pointer wavelength, near-infrared laser emissions at 808-nm and 1,064-nm wavelengths may also be present in the output laser beams due to missing or inadequate near-infrared blocking filters. Moreover, the output radiant power of the three spectral components of these laser pointers tends to fluctuate with time due to some commonly observed limiting effects such as inherent thermal drifts, pump source power fluctuations, fluctuations in the second-harmonic conversion efficiency, instability of the laser cavity and changes in output mode structure.

A number of studies have been recently published regarding hazards associated with improperly classified DPSS green laser pointers. Hadler and Dowell (2013) reported that 11 out of 12 pointers acquired in the U.S. in 2013 and labeled as Laser Class 3R laser products actually exceeded Class 3R Accessible Emission Limits (AEL) when evaluated according to standards IEC 60825-1:2007 (IEC 2007) and ANSI Z 136.1 (ANSI 2007). Wheatley (2013) reported testing 15 green laser pointers that were purchased at www.ebay.com.au and shipped to and evaluated in Australia. These laser pointers were advertised as laser products with radiant power of less than 1 mW, but all samples demonstrated higher optical output. Moreover, a significant number of these laser pointers exceeded Class 2 AELs and Class 3R AELs by more than factors of 10 and 2, respectively. Dickman and Nitzshke (2013) indicated that a DPSS green laser pointer labeled as providing a radiant power of 1 mW was acquired and tested in Germany, but the measured power was 17.8 mW. In addition, the authors of these studies acknowledged that it was important to control the emission duration during the laser pointer tests. Some of the measurement conditions, including the variations in emission durations reported in these publications, are summarized in Table 1. These inconsistent testing results, along with the indicated multi-wavelength laser emissions and time-dependent radiant power variations, show the need to develop alternative and more accurate methods for testing laser pointers.

Table 1.

Emission duration and measurement conditions for testing green laser pointers indicated in other publications.

| Reference | Emission Duration | Measurement Conditions |

|---|---|---|

| Hadler and Dowell (2013) | 20 s | Maximum value during this time interval for an unfiltered total radiant power as well as 808 nm and 1,064 nm components; bandpass filters utilized. |

| Wheatley (2013) | — | Five measurements were taken; an average power variance was calculated; 3% losses in optical filters considered for 1,064 nm and 532 nm; a correction for 808 nm unnecessary due to small emissions. |

| Dickmann and Nitzshke (2013) | 15 s | Inherent thermal drift of the laser power was eliminated by a short operation time; absorbing filters were used for the suppression of 808 nm and 1,064 nm laser lines. |

The present study aims to develop a novel test methodology for quantitative evaluation of radiant power characteristics of DPSS laser pointers by employing a time-dependent measurement approach. The proposed method uses simultaneous measurement of time-dependent radiant powers emitted by green DPSS lasers at 808-nm (pump), 1,064-nm (fundamental), and 532-nm (second harmonic) wavelengths. All tested green laser pointer samples demonstrate significant variability of spectral power as a function of time. The experimental results are used for performing eye hazard evaluation in compliance with currently recognized laser safety standards. The hazard analysis concludes that 9 out of 10 tested laser pointer samples exceeded their labeled Class IIIa designation, along with the emission of unnecessary near-infrared radiation.

TEST METHODOLOGY

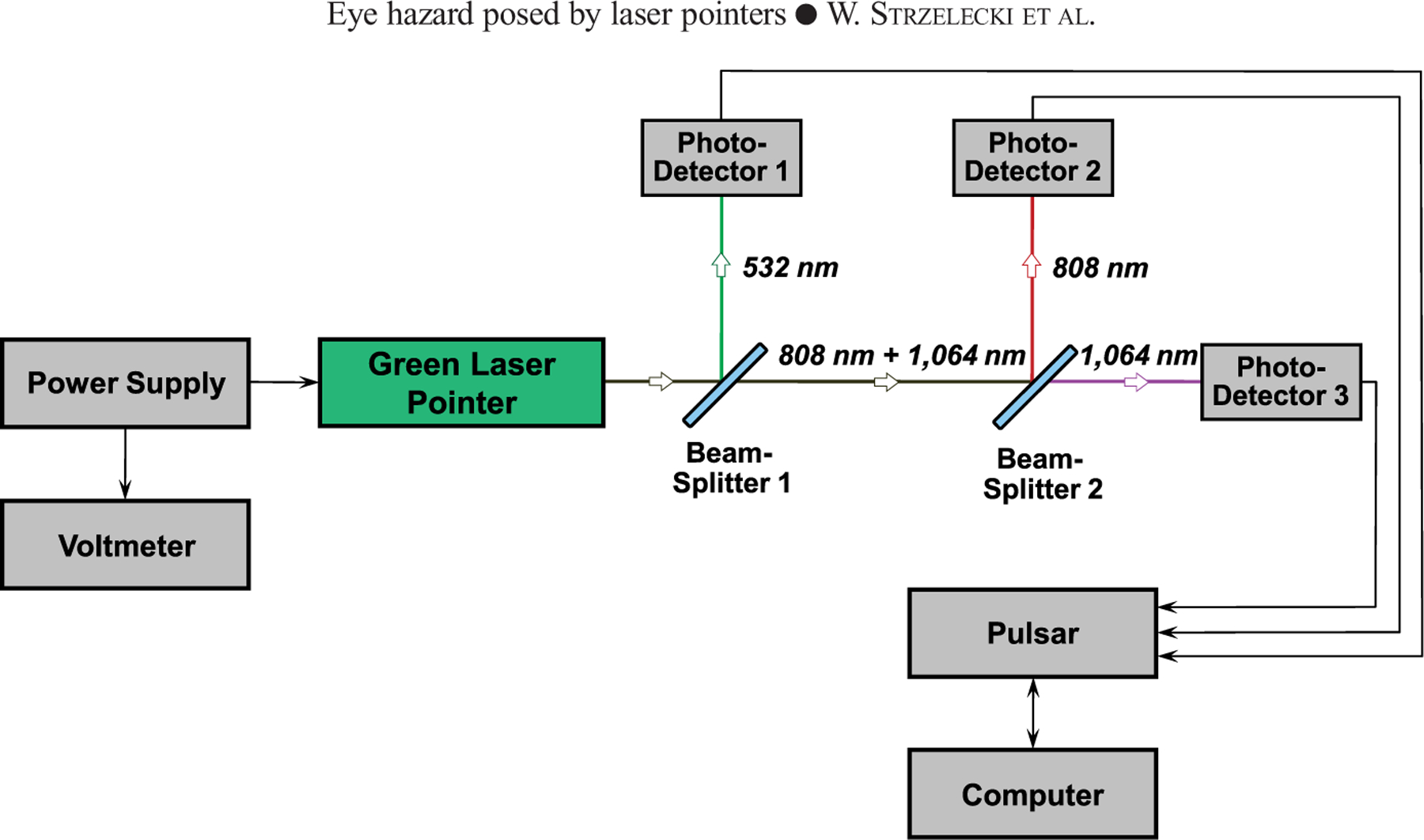

The principle optical setup developed for testing DPSS green laser pointers is illustrated in Fig. 1. It provides for simultaneous measurement of the radiant power as a function of time for each spectral component emitted by the laser pointer. The setup includes three independent detecting channels each equipped with an identical photodiode power sensor (PD300, Ophir Optronics Solution, North Andover, MA, USA) for measurement of the three spectral components emitted at the fundamental near-infrared (1,064-nm), pumping near-infrared (808-nm), and second-harmonic green (532-nm) wavelengths. The photodiode sensors are connected through a multi-channel USB interface power meter (Pulsar-4, Ophir Optronics Solution) to a computer. This three-channel measurement configuration allows for fast simultaneous measurement and recording of the time-dependent distributions of radiant powers for the three spectral components.

Fig. 1.

Three-channel measurement setup developed for simultaneous measurement of the radiant power as a function of time for each spectral component emitted by a DPSS green laser pointer.

These three wavelength components are spectrally separated into the three measurement channels using two beam splitters. Beam splitter 1 (FF665-Di02, Semrock, Rochester, NY, USA) passes both 808-nm and 1,064-nm radiation through (transmission > 93%), while reflecting the 532-nm beam (reflection > 98%). Beam splitter 2 (FF875-Di02, Semrock) passes the 1,064-nm radiation through (transmission > 93%), while reflecting the 808-nm beam (reflection > 98%). The beam splitters are aligned so that the incidence angle of the laser beams is 45°. Radiant power values of each spectral component (532-nm, 808-nm, and 1064-nm) are monitored during the alignment process that aims to maximize these values for each component. Additionally, the spectral distribution of each component is independently verified with a high-resolution calibrated spectrometer (HR4000CG, Ocean Optics, Largo, FL, USA). Measurement data are collected over a 300-s (5-min) time period after the pointer is turned on.

The green laser pointers are connected to a regulated DC power supply set to 3.0 VDC. The supply voltage is monitored throughout the testing with a calibrated voltmeter. In order to allow for temperature stabilization, laser pointers are not operated for a minimum of 30 min before each measurement. Tests indicate that the highest radiant power emissions could occur when the laser pointer is cooled down to room temperature. Data collection is initiated before switching on the power supply.

The 808-nm beam from most laser pointers had a higher divergence than that indicated in the specification for beam splitter 2, so the 808-nm beam measurement was also performed using the setup shown in Fig. 2. The test preparation, voltage setting and the measurement duration in this configuration was the same as described above for the setup in Fig. 1. The single-band bandpass filter (FF02-809/81-25, Semrock) is designed to block 532-nm and 1,064-nm spectral components (OD > 2), while allowing 808-nm to pass (transmission > 93%). In order to properly determine the radiant power values for the 808-nm component, the following calculation and adjusted radiant powers are used:

| (1) |

where, is the adjusted radiant power values of the 808-nm component as a function of time ; is the radiant power measured according to Fig. 1 for the 808-nm component as a function of time ; is the maximum radiant power measured according to Fig. 1 for ; and is the maximum radiant power measured according to Fig. 2 for .

Fig. 2.

Measurement setup for 808-nm laser beam power adjustment evaluation.

MEASUREMENT RESULTS

U.S. Food and Drug Administration (FDA), Center for Devices and Radiological Health (CDRH), developed and implemented a test method employing the experimental setup presented in Fig. 1 for safety evaluation of green DPSS laser pointers. The authors measured simultaneously the time-dependent radiant power characteristics of three laser spectral components emitted at the green (532-nm), and near-infrared (808-nm and 1,064-nm) wavelengths. The measurement results obtained from testing three laser pointer samples (C, L, and M), selected as typical representatives of the time-dependent radiant power variability observed for all laser pointers measured are presented in Figs. 3, 4, and 5. For all test samples, the 808-nm wavelength laser component has the lowest radiant power value. The radiant power plot for sample L (Fig. 4) includes an initial radiant power spike for the 532-nm beam associated with switching on the laser pointers. In sample M (Fig. 5), the power of all laser components, including the 532-nm beam, continued to increase to the point of the test termination. In contrast, for samples C and L (Figs. 3 and 4), an opposite trend of a steady decline of measured radiant power at the end of the test time duration. The authors investigated the time-dependent variations of the radiant power using a test time duration of 300 s. They found that this time, the interval is appropriate for testing laser pointers since during this time the full range of operational capabilities of the tested laser samples was observed, as required in the IEC 60825-1 Ed 2 (2007) and Ed. 3 (2014). Moreover, the evaluated emission durations for the tested samples are significantly shorter than the selected test time duration of 300 s.

Fig. 3.

Radiant power for each wavelength and total radiant power as a function of emission duration for green laser pointer “C”.

Fig. 4.

Radiant power for each wavelength and total radiant power as a function of emission duration for green laser pointer “L”.

Fig. 5.

Radiant power for each wavelength and total radiant power as a function of emission duration for green laser pointer “M”.

COMPLIANCE CRITERIA AND LASER HAZARD EVALUATION

All tested laser pointers were labeled as FDA Class IIIa laser products. The hazard calculations are made using the corresponding sum of the ratios of the measured accessible emissions levels to the corresponding AELs for multi-wavelength laser beams according to 21 CFR 1040.10(d)(2) (21 CFR 1040) for this Laser Class as follows:

| (2) |

where, is the total sum of the ratios of the measured accessible emission levels to the corresponding AELs for each spectral component; , , and are the radiant powers as a function of time for the 532-nm, 808-nm, and 1,064-nm components, respectively.

The AELs for each spectral component are determined as follows:

, which is defined as AELs for Class IIIa in the visible spectral range for laser emission durations greater than 380 μs, according to the Table III-A in 21 CFR 1040.10. The same Table indicates that for wavelengths greater than 710 nm, AELs for Class I apply;

Consequently, or the corresponding average radiant power value of 8.13 mW; and

or the corresponding average radiant power value of 25.1 mW.

In addition, it should be noted that CDRH accepts Class 3R laser pointers classified according to the IEC60825-1 Ed. 2 (IEC 2007) standard as equivalent to Class IIIa and compliant with 21 CFR 1040.11(b). It should be also noted that the same AELs apply to Class 3R DPSS green laser pointers evaluated according to the IEC 60825-1 Ed. 3 (IEC 2014) for the emission duration of 0.25 s. Similar requirements defined in 21 CFR 1040.10(d)(2) are addressed by Paragraph 8.3 (b) of that standard (IEC 2007). Moreover, an equivalent definition of emission duration could be found in Paragraph 3.31 in IEC (2007). Thus, the implementation of the IEC60825-1 Ed. 2 standard requirements for Class 3R to the tested multi-wavelength laser pointers leads to the following sum of the ratios expression:

| (3) |

where,

The duration of 0.25 s is a time base for Class 3R according to the IEC 60825.1 Ed.2 (2007) (IEC 2017) and Ed. 3 (2014) (IEC 2014) standard. It corresponds also to an aversion response to a bright light. For visible laser emission durations not smaller than 0.25 s, AEL for Class 3R has a value of 5 mW. Since the radiant power of the 532-nm spectral component was higher than 1 mW, AEL for 0.25 s is also applied to infrared emissions. While 532-nm AEL for Class 3R has the value of 5 mW for emission durations longer than 0.25 s, the corresponding 532-nm AEL for Class IIIa has the same value of 5 mW for emission durations longer than 380 μs. Therefore, the AELs according to 21 CFR 1040.10 and IEC60825-1, as well as the measured average values of radiant power, are nearly identical to each other; i.e., the difference in AELs for 808 nm and 1,064 nm is less than 2%, which is smaller than the calibration error of the semiconductor detectors used for measurement.

Upon further evaluation, the authors considered the equivalent compliance conditions to eqn (3) for Maximum Permissible Exposures (MPE) according to IEC60825-1 and for the injury threshold. Class 3R AELs for 0.25 s are equal to five times Class 1 AEL values for 0.25 s. The Class 1 AEL is equivalent to MPE times the area of a 7-mm limiting aperture for the wavelength range of 400–1,400 nm (Schulmeister 2010); therefore, the MPE condition can be expressed as:

| (4a) |

| (4b) |

where is the area of a 7-mm limiting aperture; or

| (5a) |

| (5a) |

Thus,

| (6) |

is depicted in Figs. 6, 7, and 8 as “MPE condition” on the vertical axis.

Fig. 6.

Compliance criteria for “C” green laser pointer.

Fig. 7.

Compliance criteria for “L” green laser pointer.

Fig. 8.

Compliance criteria for “M” green laser pointer. It should be noted the particular importance of IR filters for the relatively significant contribution of IR emission to the total emissions.

Furthermore, since the reduction factor is 10 times the MPE value for small spot exposures, as noted in Schulmeister (2011) and Schulmeister and Jean (2010), the corresponding equivalent condition for injury threshold is defined as:

| (7) |

The corresponding limit value is depicted in Figs. 6, 7, and 8 as an “injury threshold condition” on the vertical axis. The injury threshold was taken into account in this study because, as indicated in Schulmeister and Jean (2010), compliant Class 3R laser pointers are not likely to cause an eye injury. However, since the tested laser pointers C, L, and M exceed the injury threshold within 5-min emission duration, it was added in Fig. 6, 7, and 8 in order to demonstrate a clear eye injury hazard posed by these products.

Using eqns (2) and (3), the authors plotted the IEC sum of ratios and IEC P/AEL ratios as a function of the emission duration for each laser pointer sample. These graphs are illustrated in Figs. 6, 7, and 8, for the samples C, L, and M, respectively.

The time-dependent sum of ratios function is used in the inequality of eqn (3) to determine the corresponding class level for a laser pointer. It should be noted, however, that this function has additional meaning for DPSS type laser pointers. According to IEC60825-1 Ed. 2 (IEC 2007), the values of the parameter C4 in IEC AELs increase as a function of wavelength in the wavelength range 700 nm to 1,050 nm and correspond to the laser beam absorption in retinal pigment epithelia (RPE) as a function of wavelength. A temperature increase above injury threshold in this absorbing layer of the retina can lead to thermal damage of the photoreceptor cell (Henderson and Schulmeister 2004). In this context, the authors believe that a single particular value of at different time intervals for an individual laser pointer translates to the same retinal thermal hazard for 0.25-s exposure for different spectral compositions of laser emissions.

CONCLUSION

The experimental results obtained from testing three representative DPSS green laser pointers and the performed eye hazard evaluation show that the AELs for Class 3R were exceeded at 1.0 s, 0.2 s, and 8.0 s emission times for the laser pointer samples C, L, and M, respectively (see Figs. 6–8). These variations of the evaluated emission times are associated with the significant time-dependent variations observed in the radiant power measurements (Figs. 3, 4, and 5). The sum of ratios reached a maximum within 5 min for samples C and M but not for the sample L. In Figs. 6–8, the value of “1” on the vertical axis corresponds to the time elapsed from switching “on” the laser pointer, when emission levels are at the AELs for Class 3R. Therefore, for increased “on” time, the laser pointer is emitting at Class 3B levels, indicated by values above the “Class 3R AEL condition” horizontal line. Conversely, for emission durations below that time threshold, the laser emissions are below Class 3R AELs. Therefore, in order to determine a laser class and/or the most hazardous exposure condition from a laser pointer, it is very difficult to specify fixed emission duration for the measurements.

Fig. 8 demonstrates that, with a satisfactory quality infrared filter, the injury threshold would be exceeded after 59 s of emissions rather than after 15 s. All laser pointers should have superior infrared filters to reduce the emission level for infrared radiation, which is not needed for the function of the product. The importance of these filters is also related to a NOTE in Paragraph 8.3 e) in IEC 60825-1 (IEC 2007), which indicates that AELs for Class 1 for 0.25 s could be applied to Class 3R laser products with emissions in the visible and invisible parts of the spectrum.

Additionally, the substantial time-dependent variability of radiant power levels suggests that the detector used for radiant power measurements should have suitably small rise and fall time values. This experience indicates that thermal detectors are not suitable for laser classification of DPSS green laser pointers.

Furthermore, the inequality in eqn (3) combined with Figs. 6–8 makes it clear that for DPSS green laser pointers, it is necessary to simultaneously measure the radiant power of each spectral component as a function of the emission duration in order to correctly determine the laser class. The presented test methodology accomplishes this task.

For further implementation on the suggested new test methodology described in this paper, due to its advanced potential for quantitative evaluation of time- and spectral-dependent laser radiation safety concerns, this or a modified test methodology is intended to be applied for laser safety evaluation of new emerging DPSS and other collimated multi-wavelength laser sources.

Acknowledgments—

The authors would like to express their gratitude for technical review comments from Emir Galevi and Thomas Gilmore from Winchester Engineering and Analytical Center (WEAC), FDA.

Footnotes

The authors declare no conflicts of interest.

Publisher's Disclaimer: Disclaimer: The mention of commercial products, their sources, or their use in connection with material reported here is not to be construed as either an actual or implied endorsement of such products by the U.S. Food and Drug Administration.

REFERENCES

- American National Standards Institute. American National Standard for safe use of lasers Orlando, FL: ANSI; Z136.1; 2007. [Google Scholar]

- Code of Federal Regulations. Title 21, Part 1040: Performance standards for light-emitting products. Section 1040.10 and 1040.11 Washington, DC, USFDA: 21 CFR 1040; 2017. [Google Scholar]

- Dickman K, Nitzschke N. Laser pointer for pilots and drivers of public transportation. In: Proceedings of an International Laser Safety Conference Orlando, FL: ILSC; 289–298; 2013. [Google Scholar]

- Galang J, Restelli A, Hagley W, Clark C. A green laser pointer hazard. NIST Technical Note 1668; Gaithersburg, NIST. 2010. [Google Scholar]

- Hadler J, Dowell M. Accurate, inexpensive testing laser pointer power for safe operation. Meas Sci Technol 24:045202; 2013. [Google Scholar]

- Henderson R, Schulmeister K. Laser safety New York: Taylor and Francis Group; 2004. [Google Scholar]

- International Electrotechnical Commission. International Standard for safety of laser products: part 1: equipment classification and requirements Geneva, Switzerland: IEC; 60825–1; 2007. [Google Scholar]

- International Electrotechnical Commission. International Standard for safety of laser products: part 1: equipment classification and requirements Geneva; Switzerland: IEC; 60825–1; 2014. [Google Scholar]

- Schulmeister K. Present and alternative dosimetry concept for laser exposure limits. Med Laser Appl 25:111–117; 2010. [Google Scholar]

- Schulmeister K The widely varying risk from Class 3R laser products in light of the revision of IEC 60825-1. In: Proceedings of an International Laser Safety Conference San Jose, CA: ILSC; 72–75; 2011. [Google Scholar]

- Schulmeister K, Jean M. The risk of retinal injury from Class 2 and visible Class 3R lasers including medical laser aiming beams. Med Laser Appl 25:99–100; 2010. [Google Scholar]

- Wheatley T Laser pointer prohibition—improving safety or driving misclassification. In: International Laser Safety Conference, Proceedings of an International Laser Safety Conference Orlando, FL: ILSC; 38–54; 2013. [Google Scholar]