Abstract

In the Indo-Gangetic Plains (IGP), rice–wheat cropping system (RWCS) predominates, producing large quantity of crop residue and its management is major concern. Farmers usually burn the residue to clear the field for succeding crop, and burning damages soil microbes, resulted in loss of soil organic matter. Hence, current study was conducted to assess the impact of different Happy seeder based residue management options on changes in microbial dynamics, enzyme activities and soil organic matter content and also to know that alternative method for attaining sustainable wheat productivity in sandy loam soils of Haryana, India. Results revealed that Zero tillage wheat (ZTW) with partial and full residue retention treatments sown with Happy seeder (after using chopper and spreader), and ZTW with anchored stubbles significantly enhanced soil microbial count by 47.9–60.4%, diazotropic count by 59.0–73.1% and actinomycetes count by 47.3–55.2%, grain yield by 9.8–11.3% and biomass yield by 7.4–9.6% over conventional tilled (CT) residue burning and residue removal plots. ZTW sown with surface retention of rice crop residue increased the organic carbon by 0.36–0.42% and the soil moisture content by 13.4–23.6% over CTW without residue load. Similarly, ZTW sown with Happy seeder with full residue enhanced alkaline phosphatase activity from 95.3 µg TPF g−1 soil 24 h−1 in 2018–2019 to 98.6 µg TPF g−1 soil 24 h−1 in 2019–2020 over control plots. Likely, microbial population and enzymatic activity showed strong positive correlation under variable residue retention practices. However, increased microbial population reduced the soil pH from 7.49 to 7.27 under ZTW with residue retention plots. The wheat yield enhanced by 9.8–11.3% during 2018–2019 and 2019–2020 under ZTW with Happy seeder with full residue load over residue burning and residue removal plots. ZTW sown with Happy seeder under full residue retention, achieved maximum net return 43.16–57.08 × 103 ₹ ha−1) and B-C ratio (1.52 to 1.70) over CTW without residue. Therefore, rice residue needs to be managed by planting wheat using appropriate machinery under ZT for sustaining higher productivity in RWCS and improve soil health and environment under IGP regions.

Subject terms: Microbiology, Plant sciences

Introduction

The primary cropping system in the north-western (N-W) Indo-Gangetic Plains (IGP) of India is the rice–wheat cropping system (RWCS), which covers 4.1 million hectares, primarily in the states of Punjab, Haryana, Uttarakhand, and western Uttar Pradesh and produces 34 million tonnes of rice crop residue1. According to recent estimates, Southeast Asian countries produce 150 MT of rice residues each year2,3. Harvesting and threshing of coarse rice are largely and commonly done by combine harvesters ending into leftover residues behind (in narrow strips or gluts), particularly when these machines are not attached with spreader. The window for disposal or use of rice residues is very constrained between rice harvest and the sowing of rabi (october to november) crops like wheat, potatoes, or vegetables. As a result, 80% of the total rice residue produced annually is burnt fully or partially by the farmers4,5. And burning of rice and wheat residue contributes about 42% of total green house gas emmision (GHGs) of the country6. Not only GHGs, aromatic hydrocarbons, volatile organic compounds, and fine inhalable particles are released during residue burning7, which are the factors contributing to the formation of atmospheric brown cloud (ABC), having an impact on the air quality index and atmospheric visibility in several Asian countries8. However, wheat crop residues are not burnt at scale as these are being used for feeding the livestock. Despite the importance of RWCS, over the past three decades, signs of yield stagnation, groundwater depletion, and declining soil health have made the sustainability of the system as the most pressing concern9. The most obvious concern for the threatening sustainability of RWCS in the IGPs in the context of multicontemporary challenges is the environmental pollution caused by residue burning3. The N-W Indian states burn 23 million tonnes of rice residue each year, and collecting and storing this residue is neither practical nor cost-effective10,11. This results not only into a serious environmental pollution but also into huge loss of nutrients12–15. Burning of rice residues reduces the amount of C added as residue into the soil's organic C pool because it leaves high C footprints3. Crop residues are rich source of plant nutrients which are released in soil on decomposition by beneficial microbes. As a result, returning crop residue to the soil rather than burning it helps to improve several soil quality parameters. In order to sustain the health of the soil in the RWCS in NW India, it is necessary to manage rice residue in a way that is affordable, environmentallybeing, and logistically possible.

In general, crop residues contain about 40 to 45% of carbon, which if returned back to soil, the soil microbes utilized it to increase soil organic matter and thus returning of crop residues reduces organic carbon loss16. Soil organic carbon directly influences biological properties of soil17,18. Microorganisms play a significant role in nutrient availability and the development of a number of soil health indices, knowledge of soil biological characteristics is crucial for sustainability15,19–21. Total microbial count, diazotrophs, actinomycetes and enzymatic activities like dehydrogenase and alkaline phosphatase are some of the major soil quality indicators22. By converting organic matter's organic form to an easily-accessible inorganic form, soil bacteria aid in the breakdown of organic matter23. Recycling of crop waste is essential to return organic matter into the soil24–27. Actinomycetes help in cellulose and hemicellulose compound degradation in rice residue. Diazotrophs are nitrogen fixers; which utilize the carbon from residue and release nitrogen for the growing crop. As per Costa et al.28 and Shahrayini et al.29, reduced tillage and stubble retention result in abundance of diazotrophs as decreased levels of soil disturbance promote good soil pore network which helps interaction of stubble decomposing organisms and nitrogen fixers. In order to develop and maintain lower O2 tension, which is necessary for many N fixers using diazotrophs, this increases the number of soil microsites with organic carbon and improves soil macro-agregates30. A sensitive indicator of soil quality, dehydrogenase enzyme is an oxide-reductase enzyme that is found in all living microbial cells and is essential for sustaining soil health and fertility31. According to Rana et al.32 alkaline phosphatase activity is primarily of microbial origin and can be utilised as a short-term indication of changes in microbial activity. The breakdown process and biochemical processes are accelerated by soil enzymes, which also release plant nutrients33–35.

The most effective intervention needed to improve the C sustainability and resilience of RWCS is to switch from burning rice residue in-situ to retaining it and/or incorporating it into the field. Varied levels of residue retention on the surface or incorporation, coupled with residue removal and partial or full residue burning, are the resultant of different tillage and residue management strategies12,36–38. This ultimately has an impact on the processes and activities of soil microorganisms39,40. Crop residue burning raises soil temperature, which in turn leads to a decline in microbial populations. When paddy straw is burnt in the field a major change undergoes in soil microbial population. However, limited information is available on soil microbial dynamics under residue burning in RWCS of north-west IGP of Haryana situations. For in-situ residue management, a recent technological advancement with the development of second generation machinery such as the Happy Seeder is critical, which is a modest and viable rice residue management (RRM) option, capable of directly drilling wheat seed in rice stubbles without tillage. Happy Seeder has enabled direct wheat seeding while cutting heavy loads of loose and anchored rice residue into mulch41. In comparison to CT, residue retention as mulch in wheat establishment using Happy Seeder technology reduces C and energy footprints by 14.1 and 12.9%, respectively42. Therefore, a focused research efforts on these issues are required to generate viable and sustainable options for residue management and improving soil fertility and productivity of the strained rice–wheat system. Thus, the current study was carried out to assess the effect of different Happy seeder based residue management options like residue retention, incorporation, and burning on changes in microbial dynamics, soil organic carbon, enzymatic activities,and productivity of wheat under rice–wheat system.

Material and methods

Study area

The experiment was carried out in sandy loam soils at CCS Haryana Agricultural University's Regional Research Station in Karnal, India [290 43′ 41″ North and 760 58′ 50″ East]. The study soils had 57.5%, 23.4%, and 18.2% sand, silt and clay, respectively. Prior to commencing the study soil was sampled from the entire experimental field at 0 to 15 cm depth, and was analysed subsequently after making a composite sample. The soil's initial pH value was 7.74 (1:2.5 soil–water ratio) with elctrical conductivity (EC) of 0.22 dS m−1, 1.52 g cm−3 bulk density, 0.34% soil organic carbon, 134.2 kg ha−1 KMnO4 oxidizable N, 13.74 kg ha−1 NaHCO3 extractable phosphorus (P) and 280.4 kg ha−1 1.0 N NH4OAc exchangeable potassium (K).

Experimental details and field management

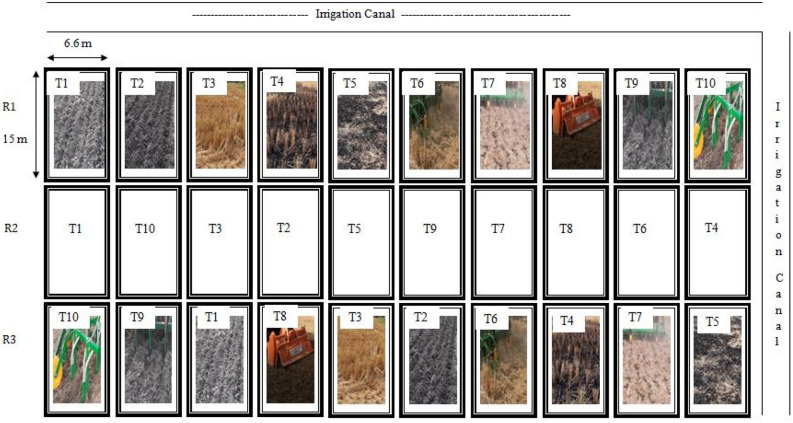

The current study consisted of 10 treatments viz., conventional tillage wheat (CTW), CTW drill sown (without burning), zero tillage wheat (ZTW) with anchored stubbles, ZTW after partial burning, ZTW after full residue burning, ZTW with Happy seeder (HS) in full residue load, ZTW with Happy seeder after using chopper and spreader (full residue load), CTW broadcast sown with rotavator, CTW drill sown after using chopper, spreader & rotavator, and CTW spatial drill sown, were laid out using randomized complete block design (RCBD) with three replications (Fig. 1). Happy seeder is a tractor-mounted machine that cuts and lifts rice straw, sows wheat into the soil, and deposits the straw over the sown area as mulch (https://www.cimmyt.org/news/happy-seeder-can-reduce-air-pollution-and-greenhouse-gas-emissions-while-making-profits-for-farmers/). It consists of a straw management rotor for cutting the previous crop residues and a zero till drill for sowing of next crop. Flail type straight blades are mounted on the straw management rotor which cuts (hits/shears) the standing stubbles/loose straw coming in front of the sowing tyne and clean each tyne twice in one rotation of rotor for proper sowing. The flails push the residues as surface much between the seeded rows.

Figure 1.

Layout of the experimental field.

The net plot size of the individual plots was 15 m × 6.6 m = 99 m2. Brief details of treatments with procedure of residue incorporation and burning are given in Table 1. Burning of crop residues was done by putting the loose straw on fire on the field itself after harvesting of the rice crop and before applying the pre-sowing irrigation in the field. For the treatment of residue removal, loose straw was collected from the field manually and taken out. Before planting the next wheat crop, a chopper-cum-spreader machine was used to uniformly spread and chop up loose straw across the field. Pre-sowing irrigation was given before sowing of wheat crop. Different levels of residue burning (no burning, partial burning, or complete burning) were maintained in zero-tillage plots with anchored stubbles according to treatments, and seeding was done by drilling with a zero-till drill (T3, T4, T5). In zero tillage plots with full residue retention (chopped or unchopped), sowing was done using the Happy seeder machine which directly sows the seed in loose stubbles (T6, T7). In conventional tillage plots without crop residues (after residue burning or removal), two harrowing and one-time rotavator followed by planking were used for field preparation (T1, T2). Sowing was done by using the seed-cum-fertilizer drill. In conventional tillage plots with full residue retention (chopped), the residues were mixed in soil by using the rotavator twice. Sowing was done by broadcast of seed and fertilizers and mixing with rotavator (T8), using normal zero-tillage drill (T9) and spatial drill (T10) to avoid heap collection of chopped crop residues in rows, as per different treatments. All the sowing machines were having seed-cum-fertilizer drill application mechanism, hence basal dose of fertilizers was also applied through these machines in all the treatments. Cutting, chopping, spreading and tillage operations were done 1–2 days before sowing.

Table 1.

Details of different treatments imposed.

| S. no | Treatment | Details |

|---|---|---|

| T1 | Conventional tillage wheat (CTW) drill sown after full residue burning | Anchored stubbles (the stubbles remaining intact in the field after mechanical harvest of rice crop) were cut with shrub master machine. Burning of crop residues was done by putting the loose straw on flame fires in the field itself after harvesting of the rice crop and before applying the pre-sowing irrigation in the field. For field preparation, two harrowing and one-time rotavator followed by planking were used. Sowing was done by using the zero-tillage drill |

| T2 | CTW drill sown after removal of residues (without burning) | Anchored stubbles were cut with shrub master machine. Loose straw was collected from the field manually and taken out. Two harrowing and one-time rotavator followed by planking were used for field preparation. Sowing was done by using the zero-tillage drill |

| T3 | Zero tillage wheat (ZTW) with anchored stubbles | Loose straw was removed manually and only anchored stubbles (30% residue) were maintained. Sowing was done by directly drilling with Zero-till drill under no-till situations in anchored stubbles |

| T4 | ZTW after anchored stubbles partial burning | Loose straw was removed manually, and partial burning of anchored stubbles was done by flame fires. In no-till situation, sowing was carried out by directly drilling with a zero-till drill |

| T5 | ZTW after full residue burning | Complete burning of all crop residues including anchored stubbles cut with shrub master was done. Flame fires were used for burning the residues. In no-till situation, sowing was carried out by directly drilling with a zero-till drill |

| T6 | ZTW with Happy seeder (HS) in full residue load | Full residues (6 t ha−1) was maintained on surface under no-till situations. There were anchored stubbles and loose straw uniformly spread in the whole plot. The Happy seeder machine was used for sowing the seed in loose stubbles |

| T7 | ZTW with Happy seeder after using chopper & spreader (full residue load) | Full residues (6 t ha-1) was maintained on surface under no-till situations. These residues were cut into pieces and spread uniformly by use of Chopper and Spreader machine before sowing of the succeeding wheat crop. The Happy seeder machine was used for sowing the seed in loose stubbles |

| T8 | CTW broadcast sown with rotavator after using chopper & spreader (full residue load) | Full residue of 6 t ha−1 was maintained. Residues were cut into pieces and spread uniformly by use of Chopper and Spreader machine. Residues were mixed in soil by using the rotavator twice followed by planking. Sowing was done by broadcast of seed along with fertilizer and mixing with second pass of rotavator |

| T9 | CTW drill sown after using chopper, spreader & rotavator (full residue load) | Full residue of 6 t ha−1 was maintained. Residues were cut into pieces and spread uniformly by use of Chopper and Spreader machine. Residues were mixed in soil by using the rotavator twice followed by planking. Sowing was done by using zero-till drill |

| T10 | CTW spatial drill sown after using chopper & spreader (full residue load) | Full residue of 6 t ha−1 was retained in the field. Residues were cut into pieces and spread uniformly by use of Chopper and Spreader machine. The residues were mixed in soil by using the rotavator twice followed by planking. Sowing was done by using Spatial drill, which avoids collection of residue in heaps over the sowing rows |

Rice variety HKR-47 transplanted in the field on 1st July was harvested on 23rd October and 25th October during kharif seasons of 2018 and 2019, respectively. Cultivation practices were followed as per package and practices of Haryana Agricultural University, Hisar (India). Sowing of wheat was carried out in zero-till plots using a Happy seeder and a ZT seed-cum-fertilizer drill equipped with inverted T-tynes. CT plots with residues were sown with the same ZT seed-cum-fertilizer drill, and residues were manually broadcasted and mixed with a rotavator before sowing. Wheat variety HD-2967 was sown on 4th November and 17th November during 2018 and 2019, respectively, using a seed rate of 100 kg ha−1. Recommended quantities of phosphorus (60 kg P2O5 ha−1) and nitrogen (150 kg N ha−1) were applied during both growing seasons. Phosphorus (100%) and 50% of N were given as the basal dose. After first irrigation, remaining 50% of nitrogen was top dressed as urea in two splits. Urea and DAP were the sources of the nitrogen and phosphorus, respectively. Based on soil indications (gravimetric method) and visual plnat symptoms, total of 7 irrigations in first year and 5 irrigations in second year were given in a season from sowing to the harvest of the crop including one pre-sowing irrigation. Herbicide, mesosulfuron + iodosulfuron 12 + 2.4 g ha−1 was used to control weeds at 35 days after sowing (DAS) as a spray in a water volume of 500 L ha−1 using a knapsack sprayer equipped with a flat fan nozzle. Other management techniques were employed as per recommendations of the State University.

Data curation and analysis

The soil samples were taken from the field before and immediately after the treatments were assigned. At harvest of the termination of the experiment (after two years), soil samples were again taken from each plot (two samples from each plot were combined to make one composite sample) at a depth of 0 to 15 cm. A post-hole auger was used for drawing composite samples and determined soil moisture content gravimetrically (w/w) at 75 days after sowing and at maturity.

Likewise, with a post-hole auger, soil samples were taken from each plot at two different stages of wheat growth, i.e., 75 DAS and at crop maturity, for the estimation of the microbial community and enzyme activity. Fresh soil samples were then crushed, sieved through a 2 mm sieve, and allowed to air dry before being utilised for chemical analysis. The methodology used for soil analysis on chemical and biological parameters are provided in Table 2.

Table 2.

Methods used for different soil biochemical analysis.

| Soil biochemical properties | Method used | References |

|---|---|---|

| pH | pH meter | Datta et al. (1997) |

| EC | electronic EC meter | Datta et al. (1997) |

| OC | Wet oxidation method | Walkley and Black (1934) |

| Available N | Kjeldahl method | Subbiah and Asija (1956) |

| Available P | Olsens method | Olsen et al. (1954) |

| Available K | Flame photometer method | Hanway and Heidel (1952) |

| Soil microbial count (107 cfu/g soil) | Standard serial dilution technique on soil extract media | Wright (1933) |

| Diazotrophic count (104 cfu/g soil) | Standard serial dilution technique on nutrient agar media | Wright (1933) |

| Actinomycetes count (105 cfu/g soil) | Standard serial dilution technique on Kenknights media | HiMedia (2009) |

| Dehydrogenase activity | Triphenylformazon through reduction of 2,3,5 triphenyltetrazolium chloride | Casida et al. (1964) |

| Alkaline phosphatase activity | n-nitrophenyl method | Tabatabai and Bremner (1969) |

To determine the impact of various crop establishment and residue management techniques on the chemical and biological activities of the soil, analysis of variance (ANOVA) was carried out for statistical evaluation of different treatments. To determine the significant differences between various treatments, Duncan's multiple range test (DMRT) was used in conjunction with the standard error of mean (SEm ±) and least significant difference (LSD) computations43.

Results

Influence of rice residue management alternatives soil chemical properties

Rice residue management techniques in wheat influended the soil organic carbon during 2019–2020 (Table 3). Both initial and final values of soil pH showed non-significant differences among the various treatments. Surface retention of rice residue resulted in higher organic carbon content than residue incorporation or CTW without residue (burning/removal). ZTW sown with surface retention of rice crop residue increased the organic carbon (0.36–0.42%) than CTW without residue (0.32–0.33%) and CTW with full residue incorporation (0.39–0.40%). In comparison to conventional tillage (T2), full crop residue retention on the soil surface with ZTW planted with HS (T6) resulted in an increase in organic carbon in the upper 0–15 cm soil layer by 23.8%.

Table 3.

Soil pH and soil organic carbon under rice residue management and crop establishment methods under rice–wheat cropping system (initial and after 2 years cycle).

| Treatment | Soil pH | Soil OC (%) | |||

|---|---|---|---|---|---|

| Initial | Final | Initial | Final | ||

| T1 | CTW drill sown after full residue burning | 7.73 ± 0.07a | 7.74 ± 0.09a | 0.34 ± 0.01a | 0.33 ± 0.02d |

| T2 | CTW drill sown after removal of residues (without burning) | 7.74 ± 0.02a | 7.75 ± 0.16a | 0.34 ± 0.02a | 0.32 ± 0.02d |

| T3 | ZTW with anchored stubbles | 7.76 ± 0.11a | 7.43 ± 0.14a | 0.35 ± 0.02a | 0.38 ± 0.01abc |

| T4 | ZTW after anchored stubbles partial burning | 7.77 ± 0.11a | 7.44 ± 0.11a | 0.34 ± 0.02a | 0.37 ± 0.02bc |

| T5 | ZTW after full residue burning | 7.79 ± 0.17a | 7.49 ± 0.09a | 0.34 ± 0.01a | 0.36 ± 0.02cd |

| T6 | ZTW with Happy seeder in full residue load | 7.78 ± 0.04a | 7.30 ± 0.22a | 0.35 ± 0.02a | 0.42 ± 0.01a |

| T7 | ZTW with Happy seeder after using chopper & spreader (full residue load) | 7.75 ± 0.06a | 7.27 ± 0.30a | 0.34 ± 0.02a | 0.41 ± 0.01a |

| T8 | CTW broadcast sown with rotavator after using chopper & spreader (full residue load) | 7.76 ± 0.07a | 7.50 ± 0.08a | 0.35 ± 0.03a | 0.39 ± 0.02abc |

| T9 | CTW drill sown after using chopper, spreader & rotavator (full residue load) | 7.78 ± 0.05a | 7.51 ± 0.23a | 0.34 ± 0.01a | 0.40 ± 0.01abc |

| T10 | CTW with spatial drill after using chopper & spreader (full residue load) | 7.79 ± 0.06a | 7.50 ± 0.07a | 0.34 ± 0.02a | 0.40 ± 0.01ab |

The values within columns with different letters differed significantly with each other. For all variables n = 3 ± standard error of mean.

Influence of rice residue management alternatives on soil moisture content

In both of the rabi cropping seasons (2018–2019 and 2019–2020), the rice residue management techniques had a substantial impact on soil moisture content (SMC) in wheat (Table 4). All the zero tillage (ZT) treatments retained higher SMC during the entire crop growth period. The SMC was higher at maturity than 75 DAS during both seasons. ZTW sown with Happy seeder (HS) after using chopper and spreader got maximum SMC (17.93 and 20.37% in 2018–2019 and 2019–2020, respectively) which was statistically similar with ZTW sown with HS with full residue load and significantly higher than CTW without residue (burning/removal) and CTW with full residue incorporation. Thus, ZTW sown with Happy seeder (HS) after using chopper and spreader (T7) enhanced soil moisture content by 16.94–23.60% and 13.44–16.20% at 75 DAS and at harvest, respectively over CTW residue removal plots.

Table 4.

Effect of rice residue management and wheat crop establishment methods on soil moisture content (%) in wheat crop under rice–wheat cropping system (2018–2019 and 2019–20).

| Treatment | Soil moisture content (%) at 0-10 cm soil depth | ||||

|---|---|---|---|---|---|

| 75 DAS | Harvest | ||||

| 2018–2019 | 2019–2020 | 2018–2019 | 2019–2020 | ||

| T1 | CTW drill sown after full residue burning | 11.82 ± 0.81b | 11.64 ± 0.59b | 15.63 ± 0.68b | 17.20 ± 1.47b |

| T2 | CTW drill sown after removal of residues (without burning) | 11.62 ± 0.31b | 11.57 ± 0.08b | 15.52 ± 1.04b | 17.07 ± 1.51b |

| T3 | ZTW with anchored stubbles | 12.64 ± 0.49b | 12.62 ± 0.64ab | 17.00 ± 1.00ab | 19.73 ± 0.83a |

| T4 | ZTW after anchored stubbles partial burning | 12.58 ± 0.60b | 12.57 ± 0.30ab | 16.94 ± 1.10ab | 19.72 ± 0.67a |

| T5 | ZTW after full residue burning | 12.21 ± 0.57b | 12.29 ± 0.36b | 16.50 ± 0.50ab | 19.00 ± 1.15ab |

| T6 | ZTW with Happy seeder in full residue load | 15.18 ± 0.38a | 13.86 ± 0.53a | 17.89 ± 0.75a | 20.32 ± 1.44a |

| T7 | ZTW with Happy seeder after using chopper & spreader (full residue load) | 15.21 ± 0.69a | 13.93 ± 0.17a | 17.93 ± 1.07a | 20.37 ± 1.69a |

| T8 | CTW broadcast sown with rotavator after using chopper & spreader (full residue load) | 11.98 ± 1.08b | 12.00 ± 0.51b | 16.23 ± 0.96ab | 18.50 ± 1.32ab |

| T9 | CTW drill sown after using chopper, spreader & rotavator (full residue load) | 12.11 ± 1.51b | 12.18 ± 0.64b | 16.28 ± 0.89ab | 18.63 ± 2.02ab |

| T10 | CTW with spatial drill after using chopper & spreader (full residue load) | 12.15 ± 0.60b | 12.25 ± 0.35b | 16.38 ± 0.69ab | 18.74 ± 1.75ab |

The values within columns with different letters differed significantly with each other. For all variables n = 3 ± standard error of mean.

Influence of rice residue management alternatives on microbial counts

In both of the cropping seasons (2018–2019 and 2019–2020), the effect of rice residue management had a substantial impact on the soil microbial characteristics in wheat (Table 5). Zero tillage treatments performed well in case of soil biological activity. All the microbial populations were more at 75 DAS as compared to at harvest during both seasons. ZTW sown with Happy seeder (HS) after using chopper and spreader got maximum soil microbial count at 75 DAS (94.9 × 107 and 99.8 × 107 cfu/g soil in 2018–2019 and 2019–2020, respectively) followed by ZTW sown with HS with full residue load, which were higher than CTW without residue (burning/removal) and CTW with full residue incorporation. Thus, ZTW sown with Happy seeder after using chopper and spreader enhanced soil microbial count by 23.7–38.3% and 47.9–60.4% at 75 DAS and at harvest, respectively, over residue burning and residue removal plots.

Table 5.

Effect of crop establishment methods and rice residue management on soil microbial count and diazotrophic count under rice–wheat cropping system (2018–2019 and 2019–20).

| Treatment | Soil microbial count (107 cfu/g soil) | Diazotrophic count (104 cfu/g soil) | ||||||

|---|---|---|---|---|---|---|---|---|

| 75 DAS | Harvest | 75 DAS | Harvest | |||||

| 2018–2019 | 2019–20 | 2018–2019 | 2019–20 | 2018–2019 | 2019–20 | 2018–2019 | 2019–20 | |

| T1 | 71.7 ± 0.87e | 82.8 ± 1.44e | 58.7 ± 2.25d | 70.1 ± 1.73d | 49.2 ± 2.31ef | 61.4 ± 3.18d | 41.9 ± 1.53ef | 47.7 ± 2.25d |

| T2 | 68.6 ± 2.02f | 80.7 ± 2.60e | 55.6 ± 2.78d | 60.6 ± 1.73e | 47.8 ± 2.18f | 58.0 ± 1.44e | 36.6 ± 1.15f | 42.0 ± 1.44e |

| T3 | 88.4 ± 2.60b | 96.6 ± 3.01abc | 74.5 ± 2.73b | 80.6 ± 3.06b | 58.0 ± 1.15b | 75.3 ± 1.44b | 50.8 ± 3.51bc | 65.1 ± 2.25b |

| T4 | 82.8 ± 1.44 c | 94.7 ± 1.45bcd | 69.8 ± 1.44c | 77.4 ± 1.73bc | 54.7 ± 1.33c | 66.9 ± 1.44c | 49.9 ± 1.15cd | 56.4 ± 5.41c |

| T5 | 81.2 ± 1.44c | 90.8 ± 1.44d | 68.2 ± 1.44c | 74.4 ± 1.73cd | 53.8 ± 2.89cd | 66.4 ± 1.44c | 45.4 ± 2.31cde | 52.6 ± 2.42cd |

| T6 | 94.1 ± 2.60a | 98.6 ± 4.37ab | 88.0 ± 1.73a | 89.3 ± 3.14a | 61.1 ± 2.31ab | 78.2 ± 1.44ab | 56.0 ± 2.30ab | 71.0 ± 1.53a |

| T7 | 94.9 ± 1.44a | 99.8 ± 1.44a | 89.2 ± 2.12a | 89.6 ± 1.90a | 62.1 ± 1.97a | 79.3 ± 1.44a | 58.2 ± 5.28a | 72.7 ± 0.15a |

| T8 | 80.9 ± 1.44c | 92.8 ± 1.44cd | 67.8 ± 2.77c | 73.3 ± 1.73cd | 51.8 ± 1.15cde | 65.3 ± 3.18c | 44.8 ± 2.00de | 52.8 ± 1.44cd |

| T9 | 80.3 ± 1.49cd | 91.4 ± 1.44d | 67.3 ± 1.49c | 72.5 ± 1.73d | 50.4 ± 1.15def | 64.8 ± 1.44c | 44.5 ± 1.15de | 51.8 ± 1.44cd |

| T10 | 77.7 ± 1.44d | 92.1 ± 1.44cd | 65.8 ± 4.74c | 72.2 ± 1.73d | 50.4 ± 2.31def | 64.1 ± 3.28cd | 42.7 ± 2.00e | 51.4 ± 1.44cd |

The values within columns with different letters differed significantly with each other. For all variables n = 3 ± standard error of mean.

T1, CTW drill sown after full residue burning; T2, CTW drill sown after removal of residues (without burning); T3, ZTW with anchored stubbles; T4, ZTW after anchored stubbles partial burning; T5, ZTW after full residue burning; T6, ZTW with Happy seeder in full residue load; T7, ZTW with Happy seeder after using chopper & spreader (full residue load); T8, CTW broadcast sown with rotavator after using chopper & spreader (full residue load); T9, CTW drill sown after using chopper, spreader & rotavator (full residue load); T10, CTW with spatial drill after using chopper & spreader (full residue load).

Similarly, diazotrophic count at 75 DAS was higher in ZTW sown with HS after using chopper and spreader (62.1 × 104 and 79.3 × 104 cfu/g soil in 2018–2019 and 2019–2020, respectively). It was statistically similar with ZTW sown with HS in uniformly spread full residue load and higher as compared to CTW with full residue incorporation and CTW without residue (Table 5). The similar trend was followed at harvest. Burning of crop residue further reduced the diazotrophic count and attained lowest numbers. Therefore, ZTW sown with Happy seeder after using chopper and spreader enhanced diazotrophic count by 29.9–36.7% and 59.0–73.1% at 75 DAS and at harvest, respectively, over residue burning and residue removal plots.

Actinomycetes count at 75 DAS was also higher in ZTW sown with happy seeder after using chopper and spreader (68.9 × 105 and 64.1 × 105 cfu/g soil in 2018–2019 and 2019–2020, respectively). It was statistically at par with ZTW sown with Happy Seeder in full residue load (Table 6). CTW without residue (burning/removal) got lowest actinomycetes count in ZTW and CTW with or without residue. However, ZTW sown with Happy seeder after using chopper and spreader enhanced diazotrophic count by 37.0–39.2% and 47.3–54.2% at 75 DAS and at harvest, respectively, over residue burning and residue removal plots.

Table 6.

Effect of rice residue management and wheat crop establishment methods on actinomycetes count of wheat under rice–wheat cropping system (2018–2019 and 2019–20).

| S. N | Treatment | Actinomycetes count (105 cfu/g soil) | |||

|---|---|---|---|---|---|

| 75 DAS | At harvest | ||||

| 2018–2019 | 2019–2020 | 2018–2019 | 2019–2020 | ||

| T1 | CTW drill sown after full residue burning | 49.5 ± 1.36e | 51.8 ± 1.44d | 32.8 ± 1.42d | 34.3 ± 0.88c |

| T2 | CTW drill sown after removal of residues (without burning) | 49.7 ± 3.73f | 46.8 ± 1.44e | 33.8 ± 2.04cd | 36.7 ± 1.45c |

| T3 | ZTW with anchored stubbles | 57.8 ± 2.90b | 58.0 ± 3.64b | 39.8 ± 1.41b | 45.9 ± 1.53b |

| T4 | ZTW after anchored stubbles partial burning | 56.1 ± 2.18e | 55.4 ± 1.44bc | 38.2 ± 1.16cd | 44.4 ± 1.15b |

| T5 | ZTW after full residue burning | 55.2 ± 1.76f | 51.0 ± 1.44d | 34.0 ± 1.11cd | 43.5 ± 2.89b |

| T6 | ZTW with Happy seeder in full residue load | 67.6 ± 1.75a | 63.8 ± 2.33a | 47.4 ± 1.68a | 52.0 ± 1.73a |

| T7 | ZTW with Happy seeder after using chopper & spreader (full residue load) | 68.9 ± 0.88a | 64.1 ± 2.34a | 48.3 ± 2.27a | 52.9 ± 1.74a |

| T8 | CTW broadcast sown with rotavator after using chopper & spreader (full residue load) | 53.3 ± 1.76c | 53.9 ± 2.61cd | 34.5 ± 1.02cd | 43.0 ± 1.15b |

| T9 | CTW drill sown after using chopper, spreader & rotavator (full residue load) | 52.7 ± 1.45cd | 57.1 ± 2.80bc | 32.8 ± 2.16d | 42.4 ± 1.15b |

| T10 | CTW with spatial drill after using chopper & spreader (full residue load) | 52.5 ± 2.99d | 56.0 ± 2.67bc | 33.0 ± 2.31d | 42.2 ± 1.15b |

The values within columns with different letters differed significantly with each other. For all variables n = 3 ± standard error of mean.

Influence of rice residue management alternatives on wheat productivity

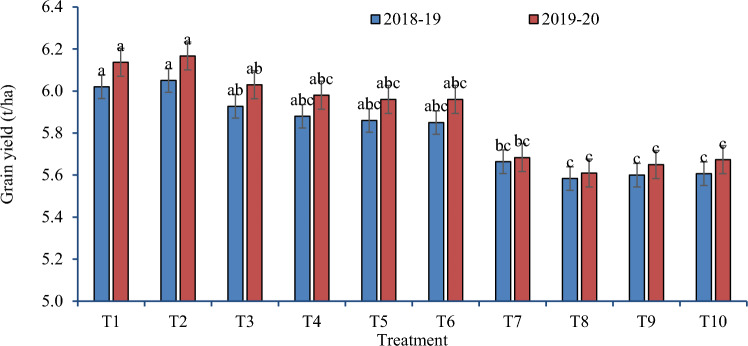

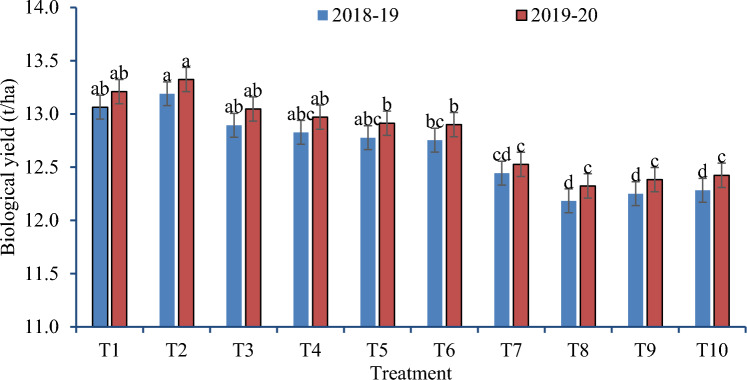

The rice residue management options differed significantly with wheat grain and biomass yields during both cropping seasons (Figs. 2, 3). ZTW without full residue retention (after full residue burning, in anchored stubbles without or with partial burning) and ZTW with happy seeder in uniformly spread full residues produced grain (Fig. 2) and biomass yields (Fig. 3) similar to traditional establishment methods of CTW without residue retention (burning or removal) and higher than CTW with full residue incorporation after chopper and spreader (sown with seed drill, spatial drill or broadcast). However, ZTW sown with Happy seeder with or without using chopper and spreader enhanced wheat grain yield and biomass yields by 9.8–11.3% and 7.4–9.6% during 2018–2019 and 2019–2020, respectively, over residue burning and residue removal plots. ZTW with Happy seeder after chopper & spreader produced lower grain and biomass yield than other methods of ZTW with few exceptions. Performance of Happy seeder sown ZTW after chopper and spreader was similar to Happy seeder sowing in evenly spread residues during 2018–2019. All the methods of crop establishment under ZT/CT after use of chopper and spreader produced lower grain and biomass yields than CTW after residue removal/ burning and ZTW with or without residue retention.

Figure 2.

Effect of rice residue management and wheat crop establishment methods on grain yield of wheat under rice–wheat cropping system (2018–2019 and 2019–2020).

Figure 3.

Effect of rice residue management and wheat crop establishment methods on biomass yield of wheat under rice–wheat cropping system (2018–2019 and 2019–2020).

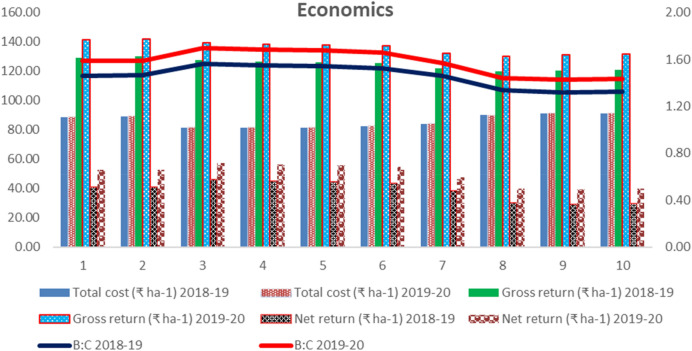

Influence of rice residue management alternatives on economics of the various treatments

The cost of cultivation, gross and net returns and benefit–cost ratio (B:C) of wheat worked out under rice residue management in no-till wheat under rice–wheat cropping system during two cropping seasons of 2018–2019 and 2019–2020 have been given in the Fig. 4. ZTW without full residue retention (after full residue burning, in anchored stubbles without or with partial burning) incurred the lowest cost of cultivation (81.49–81.93 × 103 ₹ ha−1) followed by ZTW sown with Happy seed under full residue retention (Fig. 4) which were lower than CTW without residue (removal or burning) and crop establishment methods after using chopper and spreader (drill sown, broadcast, spatial drill) (Fig. 4) during both the crop seasons. Similarly, ZTW with partial residue (after full residue burning, in anchored stubbles without or with partial burning) and ZTW sown with Happy seeder under full residue retention, achieved maximum net return (43.16–57.08 × 103 ₹ ha−1) and B-C ratio (1.52 to 1.70) over CTW without residue and crop establishment methods after using chopper and spreader (drill sown, broadcast, spatial drill) during both the crop seasons of 2018–2019 and 2019–2020, respectively.

Figure 4.

Effect of rice residue management and wheat crop establishment methods on economics.

Influence of rice residue management alternatives on enzymatic activity

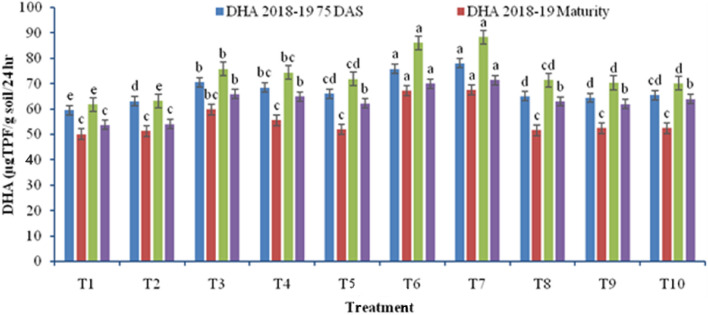

In both of the cropping seasons, the effect of rice residue management had a substantial impact on the enzymatic activity in wheat grown in a rice–wheat system (Fig. 5). Compared to residue retention, residue burning reduced the dehydrogenase activity at both stages of wheat crop. ZTW sown with HS using chopper and spreader in full residue load released highest dehydrogenase activity at 75 DAS (78.0 µgTPF g−1 soil 24 h−1 in 2018–2019; 88.4 µg TPF g−1 soil 24 h−1 in 2019–2020), which was 19.1–23.4% more than CTW drill sown after full residue removal during the study seasons. The treatments T6 and T7 having ZTW sown with HS were statistically similar when wheat was sown after uniformly spread full residues or after chopper & spreader. A similar trend was observed at harvest. ZTW with full or partial residue burning reduced the enzymatic activity as compared to ZTW with full residue retention. CTW with full residue burning further reduced the enzyme activity as compared to CTW without residue.

Figure 5.

Effect of rice residue management and wheat crop establishment methods on dehydrogenase activity (DHA) of wheat under rice–wheat cropping system (2018–2019 and 2019–2020). The values within same colour columns with different letters differed significantly with each other.

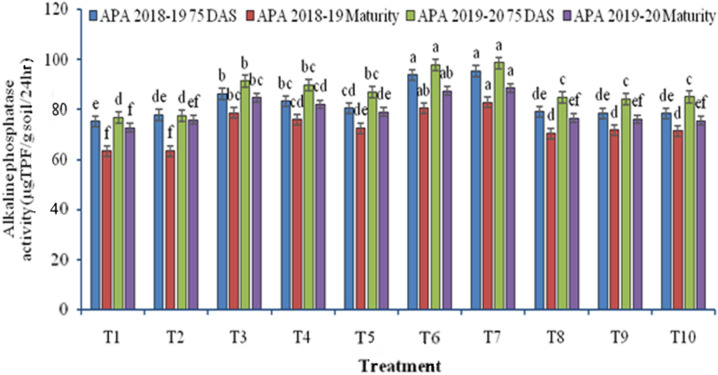

Alkaline phosphatase activity significantly differed with different rice residue management methods during 2018–2019 and 2019–2020 cropping years (Fig. 6). Residue retention on soil surface got higher alkaline phosphatase activity than residue incorporation or removal. ZTW sown with Happy seeder after using chopper and spreader with full residue load got maximum alkaline phosphatase activity at 75 DAS (95.3 µg TPF g−1 soil 24 h−1 in 2018–2019; 98.6 µg TPF g−1 soil 24 h−1 in 2019–2020). It was at par with ZTW sown with HS with full residue load and higher than CTW drill sown with full residue removal. Conventionally tilled plots with full residue burning further reduced the alkaline phosphatase activity at 75 DAS (26.6–28.6%) as compared to ZTW sown with HS after using chopper and spreader with full residue load.

Figure 6.

Effect of rice residue management and wheat crop establishment methods on alkaline phosphatase activity (APA) of wheat under rice–wheat cropping system (2018–2019 and 2019–2020).

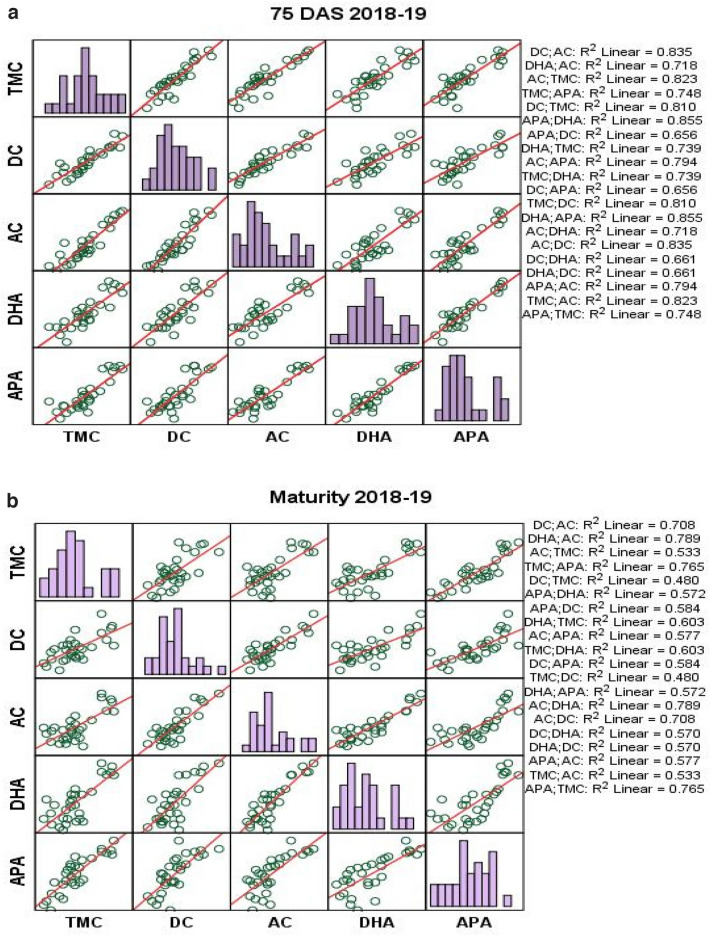

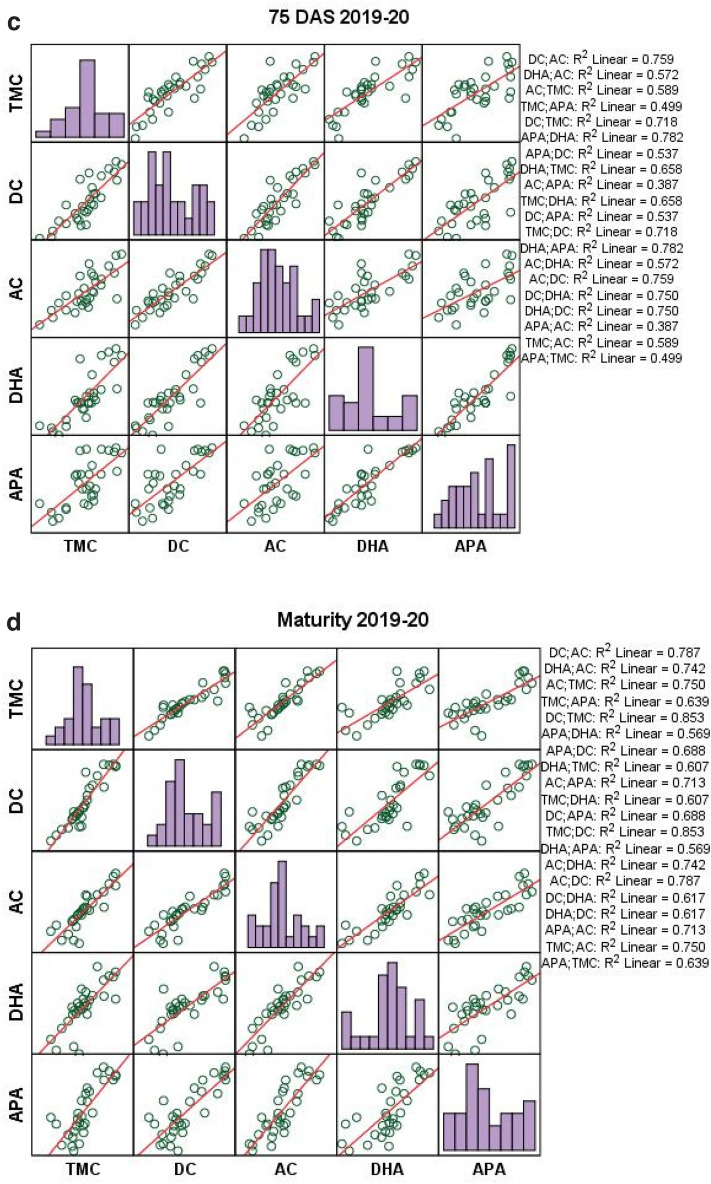

Relationship between microbial populations and enzymatic activity

Rice residue management treatments showed significant correlation (p < 0.01 and p < 0.05) between microbial populations and enzymatic activity in wheat crop under rice–wheat cropping system in both cropping seasons (Fig. 7a–d). Total microbial count had strong positive correlation with dehydrogenase activity at 75 DAS (0.811–0.860) and at maturity (0.776–0.779), and alkaline phospatase activity at 75 DAS (0.706–0.865) and at maturity (0.799–0.875).

Figure 7.

(a−d) Correlation analysis between microbial population and enzymatic activities at 75 DAS and at maturity during 2018–2019 and 2019–2020, respectively.

Diazotrophic count had significantly positive correlation with dehydrogenase activity at 75 DAS (0.813–0.866) and at maturity (0.755–0.785), and with alkaline phospatase activity at 75 DAS (0.733–0.810) and at maturity (0.764–0.830) (Fig. 7a–d). Similarly, actinomycetes activity had significantly positive correlation with dehydrogenase activity at 75 DAS (0.756–0.847) and at maturity (0.861–0.888), and alkaline phospatase activity at 75 DAS (0.622–0.891) and at maturity (0.760–0.845).

Discussion

Influence of rice residue management alternatives on soil microbial dynamics

Rice residue management in zero till wheat (ZTW) significantly influenced the total microbial count, diazotrophs, and actinomycetes. during the study seasons of 2018–2019 and 2019–2020. Soil microbial population gradually increased up to 75 DAS (anthesis stage) and decreased during later wheat growth period. In addition to production of noticeably higher SOC-up to 75 DAS, rice straw also had a greater impact on soil microbial composition (Figs. 5, 6). At crop maturity, however, this increase in the mineralization of the already-existing microbial community decreased. These dynamics most likely represent the residue's solubility or relative microbial accessibility in the field44. However, ZTW sown with Happy seeder enhanced soil microbial count by 23.7–38.3% and 47.9–60.4% and diazotropic count by 29.9–36.7% and 59.0–73.1% during 2018–2019 and 2019–2020, respectively, over residue burning and residue removal plots (Table 2). The sufficient amount of residue present in the soil, moderates soil temperature which helped in better multiplication of microbes during wheat anthesis and at maturity. Total microbial and diazotrophic count were higher than actinomycetes count under residue retained plots (ZTW using Happy Seeder, and ZTW without residue). It corroborated the findings of38,45–47. The populations of fungal, bacterial and actinomycetes were higher under ZT with surface residue retention than incorporation or removal in earlier studies as well31,47.

It is probable that these microbes have evolved to grow quickly in response to organic matter that is easily mineralized48. Concurrently CTW without residue (residue removal or burning) showed lower soil microbial count, diazotrophic count, and actinomycetes count compared to ZTW with partial or full residue retention. Immediately after burning of rice straw, top soil layer (0–3 cm) temperature is increased to 50–70 °C which affect drop down of heterotrophic microorganisms population from 77 to 9%49. Conventional tilled rice–wheat cropping without residue had the lowest microbial population38. According to Yadav et al.50, the rise in soil temperature during burning resulted in loss of actinomycetes population.

Despite the fact that our study focused on soil bacterial communities, soil fungi play an important role in SOC cycling51. Furthermore, soil fungi and their oxidative enzymes play a key role in the degradation of organic matter compounds with condensed aromatic ring structures, such as cellulose and lignin52. As a result, fungi are an excellent target for future research into the effects of rice residue on soil microbial communities.

Influence of rice residue management alternatives on wheat productivity

During both study years, ZTW with Happy seeder in uniformly spread full residues produced significantly higher wheat yield (Fig. 2) as compared to CTW without residue (burning or removal) and CTW sown after chopper and spreader (drill sown/broadcast/spatial drill) (Figs. 2, 3). The wheat yield was enhanced by 9.8–11.3% during 2018–2019 and 2019–2020 under ZTW with Happy seeder (T7) over residue burning and residue removal plots. Increased crop residue decomposition likely increased nutrient availability, which in turn increased wheat yield by boosting the soil's microbial population and soil organic matter content15,26,31,37,53,54. Comparatively, higher wheat yield was recorded in ZTW drill sown after full residue removal and lowest was found in CTW broadcast sown with rotavator after using chopper and spreader with full residue load. ZT is the most important tillage method to conserve resources and enhance wheat yield36,55,56. Results from seeding wheat into rice residues using the Happy Seeder showed an increase in grain production by 9–15% over CTW in earlier studies41,57,58. Lowest yields under CTW with incorporation of full residues after chopper & spreader could be due to yellowing of plants during initial days because of N used by microbes for decomposition of incorporated residues.

Influence of rice residue management alternatives on soil moisture content

During both the study years, ZTW sown with Happy seeder with full residue load exhibited higher soil moisture content compared to CTW with full residue incorporation and CTW without residue. ZT plays a significant role in improving soil moisture availability due to less soil compaction and uniform distribution of soil micro and macropores15,26,31. In contrast to tilled soil, un-tilled soil have less evaporative loss because ZTW with residue retention shields the soil surface from direct exposure to solar radiation and functions as a barrier to airflow over the soil surface. Similar results were reported by38, who found that ZT with residue had higher soil water content than ZTW without residue at two distinct depths (0–30 and 30–60 cm). Another study by59 found that no-till had an average soil water content that was between 13 and 14% greater than that of other tillage techniques.

Influence of rice residue management alternatives on soil organic carbon

After a two-year crop cycle, ZTW with a partial or full residue load sown with a drill or Happy seeder significantly increased soil organic carbon in the upper 0–15 cm soil. Furthermore, soil organic carbon increased by 31% compared to CTW without residue or residue burning plots. Because of large-scale disruption of soil macro-aggregates under conventional tillage without residue and direct contact between microorganisms and straw, the retention of straw on the soil surface and subsequent ploughing increased C mineralization. Zero tillage and residue retention on the soil surface prevented direct microbial contact and provided the microbes with very few nutrients. As a result, ZT, in conjunction with residue retention, was found to be an important option for protecting the SOC and limiting C mineralization. Thus resulted in supply of more nutrients to the crop as well as enhanced water holding capacity and provided better aeration18,53,60,61. Due to the availability of a food source, crop residue retention promotes higher microbial population as compared to residue removal under ZT and CT62,63.

Influence of rice residue management alternatives on soil enzymatic activity

Understanding soil microbial growth indices, fundamental biochemical processes, and fertility of any soil is greatly aided by the study of soil enzymatic activities15,40. However, during both study years, ZTW sown with Happy seeder with full residue and ZTW with Happy seeder sown after chopper and spreader with full residue load generated higher dehydrogenase and alkaline phosphatase activity as compared to CTW without residue (burning or removal) and CTW residue incorporation (Figs. 3, 4). Dehydrogenase activity was enhanced by 19.1–23.4% and alkaline phosphatase activity by 26.6–28.6%. Higher enzyme activities found in ZT plots could be due to two reasons.primarily, source of these enzymes are soil microbes, worms and insects, and microbial population is more in residue retained ZT wheat. Secondly, burning of the crop residue, may directly kill the microbes and a hydrolytic enzyme deactivated at high temperature during burning which may reduce the enzyme activity. Likewise, increased soil temperature indirectly altered dehydrogenase activity in soil64. According to Clarholm65, altering soil management procedures alters the microbial activity in the soil. Due to higher microbial activity in undisturbed soil and residue remaining on the soil surface, ZTW had higher dehydrogenase activity than CTW (because of active degradation of paddy straw). Similarly Gupta and Germida66, also observed increased dehydrogenase activity in conservation agriculture. However, in the current study, the lower alkaline phosphatase activity was found at harvest than at 75 DAS. This might be because of fewer substrates available to microbes and thus their population was less67,68. The extracellular production of the phosphatase enzyme is inhibited by an increase in soluble phosphorus69, and fertilisation with phosphatic fertiliser also suppresses phosphatase activity70. Residue retention enhances the nutrient mobilization and inhibits the fixation of available P by the soil. As a result, energy and a favorable environment for the accumulation of soil enzymes are provided. The current results are consistent with66 Gupta and Germida that the macro-aggregates had higher phosphatase activity in crop residues retention and ZT than CT in their respective micro-aggregates.

Soil enzymatic activity showed direct relationship with soil microbial population (Fig. 7a–d). Increased microbial populations like total microbial count, diazotrophic count and actinomycetes count increase the soil enzymatic activities like dehydrogenase and alkaline phosphatise activity. However, only actinomycetes and dehydrogenase activity had positive influence on grain and biomass yields of wheat. Residue management practices revealed a substantial and favourable association between enzyme activity and soil microbial count during the study period. Likewise46 reported that diazotrophic and actinomycetes count were positively correlated with dehydrogenase and alkaline phosphatise activity. These soil moicrobes are greatly enhanced under ZT conditions26,38,71.

Influence of rice residue management alternatives on economics

During both the years, ZTW without full residue retention (after full residue burning, in anchored stubbles without or with partial burning) had the cost of cultivation lower than the ZTW sown with Happy seeder and other crop establishment methods after using chopper and spreader (drill sown, broadcast, spatial drill) and CTW without residue (burning or removal). Similarly, COC in ZTW Happy seeder sown wheat was comparatively higher than ZTW drill sown wheat but, I was lower than conventional tilled crop establishment methods and CTW residue removal. However, ZT drill and Happy seeder sown wheat yields were maximum than CTW residue incorporation and at par with CTW residue removal. Due this, net return and B-C ratio were higher. More number of field operations increased COC. Due to this reason different crop establishment methods under CT reduced B-C ratio. Sidhu et al56 reported that the cost of establishment with the Happy seeder was lesser than the establishment with a conventional method; nearly half of the expenditure of CT. The maximum gross return, net return and B-C ratio were found in wheat sown with zero tillage with residue retention followed by residue burned-zero tillage and residue removed-zero tillage72,73. As per74, Happy seeder zero tillage gave maximum net income (₹ 112,938 ha−1) with a B:C of 1:1.51 compared to conventional method with net income ₹ 102,602 ha−1 B:C of 1:1.33. Zero-till fertilizer-cum-seed-drill system was found as the most economical and gave the highest benefit–cost ratio than conventional wheat crop raising system and other reduced tillage systems75.

Conclusion

The soil microbial characteristics of wheat were strongly impacted by various planting techniques and rice residue management techniques, and these consequently enhanced grain yield, soil organic carbon content and enzymatic activity. In ZTW seeded with Happy seeder under full surface residue retention (after chopper and spreader) enhanced soil microbial count and enzymatic activities by moderating the soil pH in the long run. Lowest soil microbial counts were observed under CTW after residue removal, showing a dynamic role of crop residues in promoting soil biological characteristics. Residue burning decreased the microbial populations, dehydrogenase and alkaline phosphatase activity. In rice–wheat cropping system, rice crop residues are needed to be managed by planting wheat preferably under ZT with residue retention using appropriate machine (like happy seeder) not only to sustain higher productivity and farm income but also to improve soil health and environmental quality.

Rice residue management in rice–wheat cropping system is an interdisciplinary endeavor combining technological innovations and sustainable agriculture practices with economic considerations and policy support. The agricultural sector can optimize residue management practices through these innovations for long-term productivity and environmental stewardship by addressing these aspects collaboratively in South Asia and at global level in the similar crop growing regions.

Supplementary Information

Acknowledgements

The authors thankfully acknowledge the research facilities provided by the Choudhary Charan Singh Haryana Agricultural University, Hisar, Haryana, and Indian Council of Agricultural Research, New Delhi, India, for research activities. Also, the authors would like to thank Researchers Supporting Project number (RSP2024R118), King Saud University, Riyadh, Saudi Arabia.

Author contributions

Conceptualization: S.K., D.B.Y., A.Y., R.G.A. H.O.E., E.A.M; Data curation: S.K., J.P., S.T., H.O.E., E.A.M; Original draft: S.K., A.Y., J.P., S.T.; Manuscript editing and language corrections: R.G.A., D.B.Y., A.Y., H.O.E., E.A.M.; software: S.K., D.B.Y., A.Y., R.G.A.; funding: H.O.E., E.A.M.

Funding

Researchers Supporting Project number (RSP2024R118), King Saud University.

Data availability

All data generated or analysed during this study are included in this published article and figure data are given in Supplementary file.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-024-52319-6.

References

- 1.NAAS . Innovative Viable Solution to Rice Residue Burning in Rice-Wheat Cropping System Through Concurrent Use of Super Straw Management System-Fitted Combines and Turbo Happy Seeder. National Academy of Agricultural Sciences; 2017. [Google Scholar]

- 2.Nguyen VH, et al. Generating a positive energy balance from using rice straw for anaerobic digestion. Energy Rep. 2016;2:117–122. [Google Scholar]

- 3.Singh P, Singh G, Sodhi GPS, Sharma S. Energy optimization in wheat establishment following rice residue management with Happy Seeder technology for reduced carbon footprints in north-western India. Energy. 2021;230:120680. doi: 10.1016/j.energy.2021.120680. [DOI] [Google Scholar]

- 4.Yadvinder-Singh HS, et al. Options for Effective Utilization of Crop Residues. Directorate of Research Punjab Agricultural University; 2010. [Google Scholar]

- 5.DOACFW . Review of the Scheme Promotion of Agricultural Mechanization for In-situ Management of Crop Residue in States of Punjab, Haryana, Uttar Pradesh and NCT of Delhi “Ministry of Agriculture and Farmers Welfare. Deptt. of Agriculture Cooperation & Farmers Welfare; 2019. [Google Scholar]

- 6.Agarwal A, Dintwa E, Joshi P. Analysis of agro residue burning and present scenario in key areas of northern plains in India. Int. J. Adv. Res. 2016;4(3):1499–1509. [Google Scholar]

- 7.Jenkins BM, Mehlschau JJ, Williams RB, Solomon C, Balmes J, Kleinman M, Smith N. Rice straw smoke generation system for controlled human inhalation exposures. Aerosol Sci. Technol. 2003;37(5):437–454. [Google Scholar]

- 8.Tipayarom D, Oanh NK. Effects from open rice straw burning emission on air quality in the Bangkok Metropolitan Region. Sci. Asia. 2007;33(3):339–345. [Google Scholar]

- 9.Bhatt R, Singh P, Hossain A, Timsina J. Rice–wheat system in the northwest Indo-Gangetic plains of South Asia: Issues and technological interventions for increasing productivity and sustainability. Paddy Water Environ. 2021;19(3):345–365. [Google Scholar]

- 10.Lohan SK, et al. Burning issues of paddy residue management in north-west states of India. Renew. Sustain. Energy Rev. 2018;81:693–706. [Google Scholar]

- 11.Korav S, et al. Impacts of mechanized crop residue management on rice-wheat cropping system: A review. Sustainability. 2022;14:15641. doi: 10.3390/su142315641. [DOI] [Google Scholar]

- 12.Jat HS, et al. Assessing soil properties and nutrient availability under conservation agriculture practices in a reclaimed sodic soil in cereal-based systems of North-West India. Arch. Agron. Soil Sci. 2017;64:531–545. doi: 10.1080/03650340.2017.1359415. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Singh P, Benbi DK. Nutrient management impacts on net ecosystem carbon budget and energy flow nexus in intensively cultivated cropland ecosystems of north-western India. Paddy Water Environ. 2020;18(4):697–715. doi: 10.1007/s10333-020-00812-9.(2019). [DOI] [Google Scholar]

- 14.Sharma S, Saikia R, Thind HS, Singh Y, Jat ML. Tillage, green manure and residue management accelerate soil carbon pools and hydrolytic enzymatic activities for conservation agriculture based rice-wheat systems. Commun. Soil Sci. Plant Anal. 2021;52(5):470–486. doi: 10.1080/00103624.2020.1862147. [DOI] [Google Scholar]

- 15.Harish MN, et al. Double zero-tillage and foliar-P nutrition coupled with bio-inoculants enhance physiological photosynthetic characteristics and resilience to nutritional and environmental stresses in maize–wheat rotation. Front. Plant Sci. 2022;13:959541. doi: 10.3389/fpls.2022.959541. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Bin F, Ling C, Hongying H, Ping Q, Zhenggui W. Impacts of crop residues on soil health: A review. Environ. Pollut. Bioavailab. 2021;33(1):164–173. doi: 10.1080/26395940.2021.1948354. [DOI] [Google Scholar]

- 17.Blanco-Canqui H, et al. Soil organic carbon: The value to soil properties. J. Soil Water Conserv. 2013;68(5):129–134. [Google Scholar]

- 18.Varatharajan T, et al. Integrated management enhances crop physiology and final yield in maize intercropped with blackgram in semiarid South Asia. Front. Plant Sci. 2022;13:975569. doi: 10.3389/fpls.2022.975569. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Smith JL, Papendick RI, Bezdicek DF, Lynch JM. Soil organic matter dynamics and crop residue management. In: Blaine Metting BM, editor. Soil Microbial Ecology: Applications in Agricultural and Environmental Management. Environmental Sciences Department; 1993. pp. 65–94. [Google Scholar]

- 20.Singh A, Phogat VK, Dahiya R, Batra SD. Impact of long-term zero till wheat on soil physical properties and wheat productivity under rice–wheat cropping system. Soil Tillage Res. 2014;140:98–105. [Google Scholar]

- 21.Gopinath KA, et al. Influence of crops and different production systems on soil carbon fractions and carbon sequestration in rainfed areas of semi-arid tropics in India. Sustainability. 2022;14:4207. doi: 10.3390/su14074207. [DOI] [Google Scholar]

- 22.Doran JW, Zeiss MR. Soil health and sustainability: Managing the biotic component of soil quality. Appl. Soil Ecol. 2000;15:3–11. [Google Scholar]

- 23.Six J, Ogle S, Breidt F, Conant R, Mosier A, Paustian KT. The potential to mitigate global warming with no-tillage management is only realized when practiced in the long term. Glob. Change Biol. 2004;10:155–160. [Google Scholar]

- 24.Ndubuisi-Nnaji UU, Adegoke AA, Ogbu HI, Ezenobi NO, Okoh I. Effect of long-term organic fertilizer application on soil microbial dynamics. Afr. J. Biotechnol. 2011;10:556–559. [Google Scholar]

- 25.Basavalingaiah K, et al. Energy budgeting, data envelopment analysis and greenhouse gas emission from rice production system: A case study from puddled transplanted rice and direct-seeded rice system of Karnataka, India. Sustainability. 2020;12:6439. doi: 10.3390/su12166439. [DOI] [Google Scholar]

- 26.Rajanna GA, et al. Co-implementation of tillage, irrigation, and fertilizers in soybean: Impact on crop productivity, soil moisture, and soil microbial dynamics. Field Crops Res. 2022;288:108672. doi: 10.1016/j.fcr.2022.108672. [DOI] [Google Scholar]

- 27.Paramesh V, et al. Impact of sustainable land-use management practices on soil carbon storage and soil quality in Goa State, India. Land Degrad. Dev. 2022;33(1):28–40. doi: 10.1002/ldr.4124. [DOI] [Google Scholar]

- 28.Gupta V, Roper M, Thompson J. Harnessing the benefits of soil biology in conservation agriculture. In: Pratley J, Kirkegaard J, editors. Australian Agriculture in 2020: From Conservation to Automation. Agronomy Australia and Charles Sturt University; 2019. pp. 237–253. [Google Scholar]

- 29.Li Y, Li T, Zhao D, Wang Z, Liao Y. Different tillage practices change assembly, composition, and co-occurrence patterns of wheat rhizosphere diazotrophs. Sci. Total Environ. 2021;767:144252. doi: 10.1016/j.scitotenv.2020.144252. [DOI] [PubMed] [Google Scholar]

- 30.Ladha JK, et al. Biological nitrogen fixation and prospects for ecological intensification in cereal-based cropping systems. Field Crops Res. 2022;283:108541. doi: 10.1016/j.fcr.2022.108541. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Jat HS, Kumar P, Sutaliya JM, Kumar S, Choudhary M, Singh Y, Jat ML. Conservation agriculture based sustainable intensification of basmati rice-wheat system in North-West India. Arch. Agron. Soil Sci. 2019;65(10):1370–1386. doi: 10.1080/03650340.2019.1566708. [DOI] [Google Scholar]

- 32.Frankenberger WT, Dick WA. Relationships between enzyme activities and microbial growth and activity indices in soil. Soil Sci. Soc. Am. J. 1983;47(5):945–951. [Google Scholar]

- 33.Costa AL, Paixao SM, Caçador I, Carolino M. CLPP and EEA profiles of microbial communities in salt marsh sediments. J. Soils Sedim. 2007;7:418–425. [Google Scholar]

- 34.Shahrayini E, Fallah M, Shabanpour M, Ebrahimi E, Saadat S. Investigation of soil compaction on yield and agronomic traits of wheat under saline and non-saline soils. Arch. Agron. Soil Sci. 2018;64(10):1329–1340. doi: 10.1080/03650340.2018.1431832. [DOI] [Google Scholar]

- 35.Meena HN, et al. Polythene mulch and potassium application enhances peanut productivity and biochemical traits under sustained salinity stress condition. Agric. Water Manag. 2022;273:107903. doi: 10.1016/j.agwat.2022.107903. [DOI] [Google Scholar]

- 36.Rajanna GA, Dhindwal AS, Nanwal RK. Effect of irrigation schedules on plant—water relations, root, grain yield and water productivity of wheat (Triticum aestivum) under various crop establishment techniques. Cereal Res. Commun. 2017;45(1):166–177. [Google Scholar]

- 37.Rana DS, Dass A, Rajanna GA, Choudhary AK. Fertilizer phosphorus solubility effects on Indian mustard–maize and wheat–soybean cropping systems productivity. Agron. J. 2018;110(6):2608–2618. doi: 10.2134/agronj2018.04.0256. [DOI] [Google Scholar]

- 38.Choudhary M, et al. Changes in soil biology under, onservation agriculture based sustainable intensification of cereal systems in Indo-Gangetic Plains. Geoderma. 2018;313:193–204. [Google Scholar]

- 39.Govaerts B, Mezzalama M, Sayre KD, Crossa J, Nicol JM, Deckers J. Long-term consequences of tillage, residue management and crop rotation on maize/wheat root rot and nematode populations in subtropical highlands. Appl. Soil Ecol. 2006;32:305–315. [Google Scholar]

- 40.Saharawat YS, et al. Evaluation of alternative tillage and crop establishment methods in a rice–wheat rotation in North Western IGP. Field Crops Res. 2010;116:260–267. [Google Scholar]

- 41.Sidhu HS, et al. Development and evaluation of the Turbo Happy Seeder for sowing wheat into heavy rice residues in NW India. Field Crops Res. 2015;184:201–212. [Google Scholar]

- 42.Singh P, Singh G, Sodhi GPS. Energy and carbon footprints of wheat establishment following different rice residue management strategies vis-à-vis conventional tillage coupled with rice residue burning in north-western India. Energy. 2020;200:117554. [Google Scholar]

- 43.Gomez AK, Gomez AA. Statistical Procedures for Agricultural Research. 2. Wiley; 1984. pp. 84–101. [Google Scholar]

- 44.Lehmann J, Kleber M. The contentious nature of soil organic matter. Nature. 2015;528(7580):60–68. doi: 10.1038/nature16069. [DOI] [PubMed] [Google Scholar]

- 45.Gaind S, Nain L. Soil health in response to Bio-Augmented paddy straw compost. World J. Agric. Sci. 2011;7:480–488. [Google Scholar]

- 46.Bhagat P, Gosal SK. Long term application of rice straw and nitrogen fertilizer affects soil health and microbial communities. Chem. Sci. Rev. Lett. 2018;7(26):586–593. [Google Scholar]

- 47.Stagnari F, et al. Effects of conservation agriculture practices on soil quality indicators: A case-study in a wheat-based cropping systems of Mediterranean areas. Soil Sci. Plant Nutr. 2020;66(4):624–635. doi: 10.1080/00380768.2020.1779571. [DOI] [Google Scholar]

- 48.Whitman T, et al. Dynamics of microbial community composition and soil organic carbon mineralization in soil following addition of pyrogenic and fresh organic matter. ISME J. 2016;10:2918–2930. doi: 10.1038/ismej.2016.68. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Helgason BL, Walley FL, Germida JJ. Fungal and bacterial abundance in long-term no-till and intensive-till soils of the Northern Great Plains. Soil Sci. Soc. Am. J. 2009;73(1):120–127. [Google Scholar]

- 50.Schimel J, Schaeffer SM. Microbial control over carbon cycling in soil. Front. Microbiol. 2012;3:348. doi: 10.3389/fmicb.2012.00348. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Burns RG, et al. Soil enzymes in a changing environment: Current knowledge and future directions. Soil Biol. Biochem. 2013;58:216–234. [Google Scholar]

- 52.Rajanna GA, Dhindwal AS, Rawal S, Pooniya V. Energetics, water and crop productivity of wheat (Triticum aestivum)–cluster bean (Cyamopsis tetragonoloba) sequence under land configuration and irrigation regime in semi-arid agro-ecosystem. Indian J. Agron. 2019;64(4):450–457. [Google Scholar]

- 53.Biswakarma N, et al. Designing resource efficient integrated crop management modules for direct seeded rice-zero till wheat rotation of north western India: Impacts on system productivity, energy-nutrient-carbon dynamics. Arch. Agron. Soil Sci. 2022 doi: 10.1080/03650340.2022.2079635. [DOI] [Google Scholar]

- 54.Yadav DS, Shukla RP. Effect of zero tillage and nitrogen level on wheat (Triticum aestivum) after rice. Indian J. Agron. 2005;50(1):52–53. [Google Scholar]

- 55.Usman K, Khan EA, Khan N, Khan MA, Ghulam S, Khan S, Baloch J. Effect of tillage and nitrogen on wheat production, economics, and soil fertility in rice-wheat cropping system. Am. J. Plant. Sci. 2013;4:17–25. [Google Scholar]

- 56.Sidhu HS, Humphreys E, Dhillon SS, Blackwell J, Bector V. The Happy Seeder enables direct drilling of wheat into rice stubble. Aust. J. Exp. Agric. 2007;47(7):844–854. [Google Scholar]

- 57.Nandan R, et al. Impact of conservation tillage in rice–based cropping systems on soil aggregation, carbon pools and nutrients. Geoderma. 2019;340:104–114. doi: 10.1016/j.geoderma.2019.01.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 58.Alvarez R, Steinbach HS. A review of the effects of tillage systems on some soil physical properties, water content, nitrate availability and crops yield in Argentine Pampas. Soil Tillage Res. 2009;104(1):1–15. [Google Scholar]

- 59.Munoz A, Lopez P, Ramirez M. Soil quality attributes of conservation management regimes in a semi-arid region of south western Spain. Soil Tillage Res. 2007;95(1–2):255–265. [Google Scholar]

- 60.Alam K, Islam M, Salahin MM, Hasanuzzaman NM. Effect of tillage practices on soil properties and crop productivity in wheat-mungbean-rice cropping system under subtropical climatic conditions. Sci. World J. 2014;15:437283. doi: 10.1155/2014/437283. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 61.Nicolardot B, Bouziri L, Bastian F, Ranjard L. A microcosm experiment to evaluate the influence of location and quality of plant residues on residue decomposition and genetic structure of soil microbial communities. Soil Biol. Biochem. 2007;39:1631–1644. [Google Scholar]

- 62.Govaerts B, et al. Long-term consequences of tillage, residue management, and crop rotation on selected soil micro-flora groups in the subtropical highlands. Appl. Soil Ecol. 2008;38(3):197–210. [Google Scholar]

- 63.Datta SP, Subba Rao A, Ganeshamurthy AN. Effect of electrolytes coupled with variable stirring on soil pH. J. Indian Soc. Soil Sci. 1997;45(1):185–187. [Google Scholar]

- 64.Ceccanti B, Pezzarossa B, Gallardo-Lancho FJ, Masciandaro G. Biotests as markers of soil utilization and fertility. Geomicrobiol. J. 1993;11(3–4):309–316. [Google Scholar]

- 65.Madejon E, Moreno F, Murillo JM, Pelegrin F. Soil biochemical response to long-term conservation tillage under semi-arid Mediterranean conditions. Soil Tillage Res. 2007;94(2):346–352. [Google Scholar]

- 66.Tao J, et al. Effects of earthworms on soil enzyme activity in an organic residue amended rice–wheat rotation agro-ecosystem. Appl. Soil Ecol. 2009;42(3):221–226. [Google Scholar]

- 67.Ross DJ, Tatek R, Cairns A, Meyrick KF. Fluctuations in microbial biomass indices at different sampling times in soil from Tussock grasslands. Soil Biol. Biochem. 1981;13:109–114. [Google Scholar]

- 68.Nannipieri P, Pedrazzini F, Arcara PG, Piovanelli C. Changes in amino acids, enzyme activities, and biomasses during soil microbial growth. Soil Sci. 1979;127(1):26–34. [Google Scholar]

- 69.Clarholm M. Microbial biomass P, labile P, and acid phosphatase activity in the humus layer of a spruce forest, after repeated additions of fertilizers. Biol. Fertil. Soils. 1993;16(4):287–292. [Google Scholar]

- 70.Gupta VVSR, Germida JJ. Distribution of microbial biomass and its activity in different soil aggregate size classes as affected by cultivation. Soil Biol. Biochem. 1988;20:777–787. [Google Scholar]

- 71.Okur N, Altindişli A, Cengel M, Gocmez S, Kayikcioglu HH. Microbial biomass and enzyme activity in vineyard soils under organic and conventional farming systems. Turk. J. Agric. For. 2009;33:413–423. [Google Scholar]

- 72.Hobbs PR. Conservation agriculture: What is it and why is it important for future sustainable food production. J Agric. Sci. 2007;145:127–137. [Google Scholar]

- 73.Mitra B, Mookherjee S, Das S. Performances of wheat (Triticum aestivum) under various tillage and nitrogen management in sub-Himalayan plains of West Bengal. J. Wheat Res. 2014;6(2):150–153. [Google Scholar]

- 74.Iqbal MF, et al. Happy seeder zero tillage equipment for sowing of wheat in standing rice stubbles. Int. J. Adv. Res. Biol. Sci. 2017;4(4):101–105. [Google Scholar]

- 75.Singh P, Singh ES, Singh BR, Mishra DK. Performance evaluation of zero-till ferti-seed drill in comparison to conventional and reduced tillage methods of wheat crop on the same day. Int. J. Sci. Res. Publ. 2014;4(8):1–4. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data generated or analysed during this study are included in this published article and figure data are given in Supplementary file.