Abstract

Mesoporous bioactive glasses (MBGs), which belong to the category of modern porous nanomaterials, have garnered significant attention due to their impressive biological activities, appealing physicochemical properties, and desirable morphological features. They hold immense potential for utilization in diverse fields, including adsorption, separation, catalysis, bioengineering, and medicine. Despite possessing interior porous structures, excellent morphological characteristics, and superior biocompatibility, primitive MBGs face challenges related to weak encapsulation efficiency, drug loading, and mechanical strength when applied in biomedical fields. It is important to note that the advantageous attributes of MBGs can be effectively preserved by incorporating supramolecular assemblies, miscellaneous metal species, and their conjugates into the material surfaces or intrinsic mesoporous networks. The innovative advancements in these modified colloidal inorganic nanocarriers inspire researchers to explore novel applications, such as stimuli-responsive drug delivery, with exceptional in-vivo performances. In view of the above, we outline the fabrication process of calcium-silicon-phosphorus based MBGs, followed by discussions on their significant progress in various engineered strategies involving surface functionalization, nanostructures, and network modification. Furthermore, we emphasize the recent advancements in the textural and physicochemical properties of MBGs, along with their theranostic potentials in multiple cancerous and non-cancerous diseases. Lastly, we recapitulate compelling viewpoints, with specific considerations given from bench to bedside.

Keywords: Mesoporous bioactive glasses, Engineered strategies, Nanoarchitectural morphology, Biofunctionalization, Stimuli-responsive, Disease theranostics

Graphical abstract

Highlights

-

•

MBGs show remarkable biological activities and physicochemical performances.

-

•

Significant progress in MBGs development stems from various engineered strategies.

-

•

MBGs-based stimuli-responsive drug delivery systems hold promise for disease theranostics.

1. Introduction

Ever since Gleiter's groundbreaking work in 1984, which led to the fabrication of nano-metal materials with exceptional performance, a series of cutting-edge disciplines and technologies have emerged successively, including nanomaterials, nanobiology, and nano-micrography [[1], [2], [3]]. Nanotechnology, as an encompassing system of emerging technologies, involves manipulating atoms and molecules at the nanometer scale to process materials, manufacture products with specific functions, and study their compositions or structures [4]. The internationally recognized nanoscale range falls between 0.1 and 100 nm, where physical phenomena occur at the mesoscopic level, serving as a relatively independent intermediate realm between the macroscopic and microscopic scales [5]. Nanomaterials have made unprecedented advancements in numerous fields, such as biomaterials, artificial organs, interventional therapies, diagnostics, drug delivery systems, blood purification, and biological molecular separation, with the potential to drive clinical diagnosis and therapy towards a functional and intelligent direction in the future [[6], [7], [8], [9], [10]].

Recent progress in biomaterials indicates that mesoporous materials, a type of porous nanomaterials, hold promising prospects in biomolecule adsorption and separation, enzyme immobilization, intelligent drug delivery, biosensors, biomarkers, and other applications [[11], [12], [13]]. According to the definition by the International Union of Pure and Applied Chemistry (IUPAC), porous materials with pore sizes ranging from 2 nm to 50 nm are classified as mesoporous materials [14]. Ordered mesoporous materials have garnered significant attention in interdisciplinary research over the past two decades owing to their exceptional performances [[15], [16], [17]]. Among various inorganic nanomaterials, mesoporous bioactive glasses (MBGs) stand out due to the abundant silicon hydroxyl groups on pore surfaces that act as active sites for binding with functional organic molecules, thereby enhancing structure stability and functionality [[18], [19], [20]]. The pioneering work by Zhao and colleagues in 2004 integrated the sol-gel method with surfactant supramolecular chemistry to first prepare MBGs [21]. As anticipated, MBGs have drawn considerable attention from researchers due to their highly desirable bioactivity and superior morphological features, including large specific surface area, ordered mesoporous structures, adjustable pore size and volume, easily controllable surface functionalization, and advantageous physicochemical properties [22]. Nevertheless, the standardized preparation of ordered mesoporous structures in MBGs is often affected by various factors such as components, additives, pH, solvent evaporation temperature, template properties, and concentration, given the complex nature of their multiple structural systems [23]. In recent years, the successful preparation of MBGs with diverse topographic and structural characteristics, such as particles, microspheres, fibers, 3D-printing scaffolds, and hierarchical structures, has been achieved through the utilization of mesoporous templates combined with other preparation techniques [[24], [25], [26], [27], [28]].

Although abundant studies ground on MBGs have been highlighted by researchers, the spectrum of our review covers crucial breakthroughs of MBGs over last twenty years, emphasized MBGs-based intelligent nano system for applications in cancerous/non-cancerous diseases [29,30]. Furthermore, we begin by providing an overview of the general fabrication of MBGs, elucidating the underlying roles of molecular reaction dynamics and the factors that impact their formation. Next, we discuss material modifications made to improve MBGs, focusing on three important areas: surface functionalization, tuning of nanostructures, and network modification. Subsequently, we delve into recent advances in MBGs performances, highlighting the progress made in fabricating these materials with excellent morphological, structural, and physicochemical properties, which have led to their application in disease theranostics. Finally, we conclude the review with critical views, emphasizing the next challenges that need to be addressed for MBGs to transition from the laboratory to the clinic.

2. Development of MBGs

MBGs represent a class of nanostructured bioceramic materials renowned for their exceptional bioactive characteristics. Upon interaction with biological fluids, MBGs exhibit rapid formation of a surface apatite layer within a few hours and have the capacity to uptake and release biomolecules [31]. The synthesis of MBGs was pioneered by Zhao and colleagues in 2004, who developed a multicomponent SiO2–CaO–P2O5 system. This breakthrough enabled the creation of highly ordered mesoporous structures with large surface areas, well-defined surface properties, tunable pore volumes and sizes ranging from 5 to 20 nm [21].

The fabrication process of MBGs shares similarities with that of silica-based ordered mesoporous materials, which were first reported in the early 1990s [32,33]. Typically, MBGs are synthesized using sol–gel processing, and detailed synthetic strategies for MBGs with varying characteristics have been comprehensively summarized and discussed in corresponding literature [34,35]. In essence, integrating supramolecular chemistry into the sol-gel process requires various structure-directing agents to facilitate the effective fabrication of mesoscopic materials. Under suitable conditions, surfactants such as hexadecyltrimethylammonium bromide (CTAB), polyethylene glycol (PEG), and pluronic (P123) self-organize into micelles and self-assemble to form an organized organic-inorganic mesophase [36,37]. Once surfactants are removed by calcination or extraction, the well-ordered mesoporous structure is developed, exhibiting stable texture of hexagonal symmetry, cubic pore morphology, well-ordered mesoscopic scale, high surface area and large pore volume [38]. Furthermore, due to the intricate nature of the sol solution in the preparation process, multiple factors including surfactant properties and concentrations, reactive composition proportions, self-assembly in hydrophilic or hydrophobic microenvironments, and calcination temperature can be manipulated to yield advantageous topographic and structural attributes, alongside excellent physicochemical properties [39]. Owing to these favorable performances, sol-gel derived MBGs are recognized as unique drug delivery nanoplatforms, prospective building blocks of innovative composite materials, versatile inks for 3D bio-printing, novel implant coatings and injectable biomaterials [[40], [41], [42], [43]].

3. Novel engineering strategies of MBGs: surface functionality and nanostructured modification

Advanced MBGs-based materials have been successfully fabricated through emerging nano-engineering technology in the last decade [50]. It is crucial for chemically engineered MBGs to exhibit ideal properties for intelligent drug delivery, characterized by the typical features of easily tailored mesoporous networks [51]. Surface chemistry of MBGs significantly influences the body reaction of drug delivery system. Further, nanostructured features and modified networks of MBGs exhibit improved concentration in the circulating blood and delivery efficiency as well as meliorative immune rejection reaction [35,[52], [53], [54]]. These superior attributes of chemically engineering MBGs make them to be one of remarkable inorganic nanomaterials for theranostic application in various diseases.

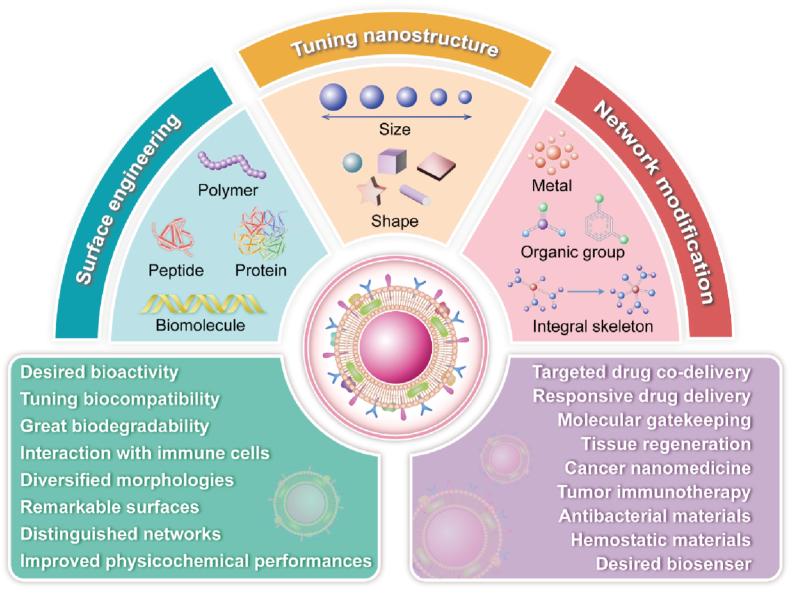

In this section, we mainly concentrate on the discussion based on recent progress in the above three aspects. First, we outline the utilization of miscellaneous components such as polymers, peptides, and molecules to achieve surface modification of MBGs. Further, we discuss the reengineering of nanostructure in MBGs, such as shape modification and particle-size design, as well as tailorable porosity for hetero-structures. In the end, the changes in the siliceous networks of MBGs using various strategies, including insertion of organic groups, doping of metal or metal oxide, and transformation of integral structure, are also elaborately discussed (see Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10, Fig. 11, Fig. 12, Fig. 13, Fig. 14, Fig. 15, Fig. 16, Fig. 17).

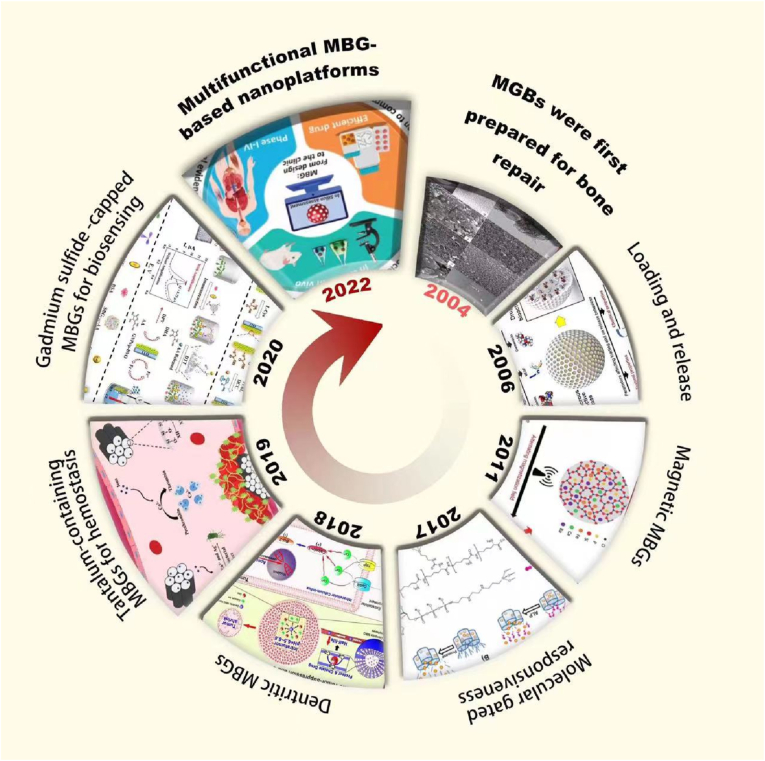

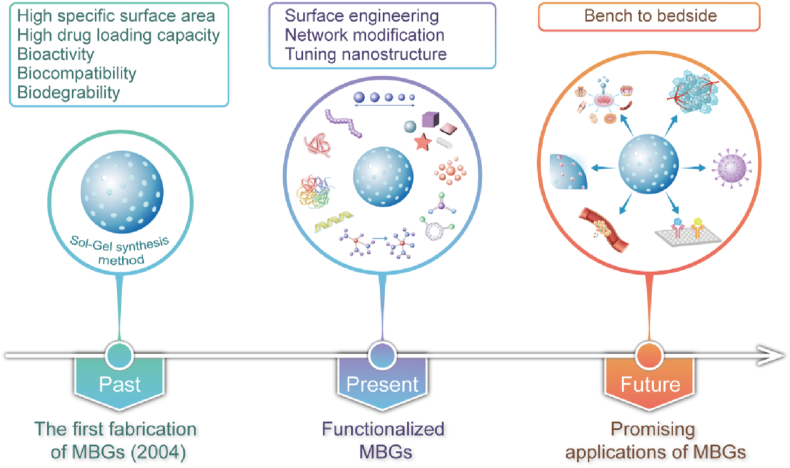

Fig. 1.

Overview of the integral development of MBGs-based nanomaterials: the timeline and representative studies of MBGs. Figures for years 1960–2022, reproduced with permission [21,35,[44], [45], [46], [47], [48], [49]].

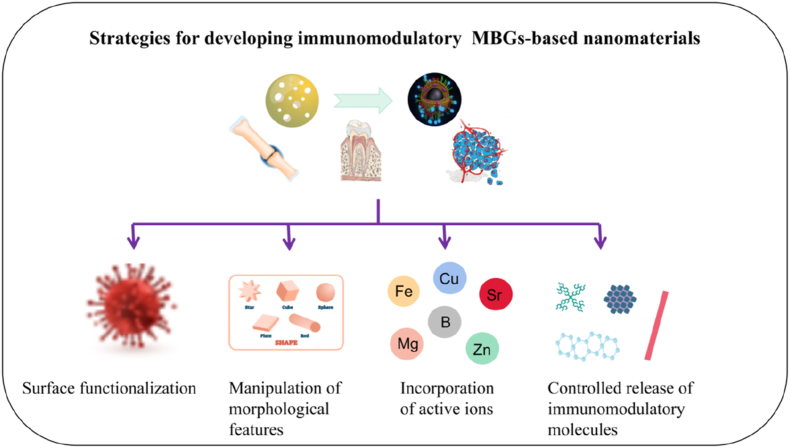

Fig. 2.

The schematic illustration shows systematically engineered strategies of advanced MBGs involved in surface functionalization, nanostructured morphology, and network modification.

Fig. 3.

The schematic illustration shows various type of stimuli-responsive MBGs-based nanoplatforms are fabricated for emerging intelligent drug delivery and theranostic applications.

Fig. 4.

Schematic illustration of molecule gates in MBGs-based nanomaterials are prepared for stimuli-responsive and intelligent drug delivery.

Fig. 5.

Schematic showing the development and tumor suppression of pH-responsive DOX-loaded dendritic MBGs-based nanoplatforms step by step [46]. Copyright 2018, ACS publications.

Fig. 6.

(A) The synthesis of bioinspired trimodal macro/micro/nano-porous MBGs scaffolds. (B) Schematic showing the preparation of trimodal MBGs scaffolds by a modified multi-template method. (C) Micro-CT evaluation of orthotopic bone formation in vivo [116]. Copyright 2016, Elsevier Ltd.

Fig. 7.

Schematic showing smart soft-templating synthesis of hollow MBGs for controlled drug delivery and stimuli-responsive MBGs for disease theranostics in future. Reproduced with permission [119]. Copyright 2015, European Chemical Societies Publishing.

Fig. 8.

(A) The design of poly-l-glutamic acid embedded MBGs-based nanospheres for pH-stimulated chemotherapeutic drug delivery. (B) SEM images representation of (a) spherical MBGs, (b) the corresponding EDX spectrum, and (c, d, and e) elemental mapping of Si, Ca, P as green, red and yellow color, respectively in MBGs [88]. Copyright 2021, Elsevier Ltd.

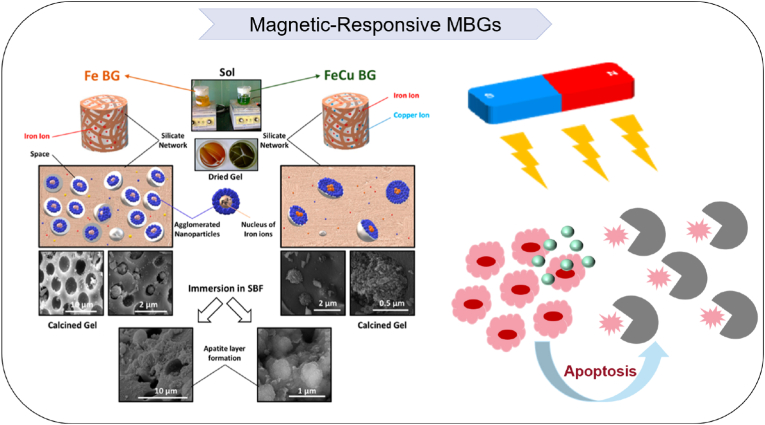

Fig. 9.

Schematic showing the synthesis and characterizations of copper-containing magnetic MBGs-based nanocarriers. Reproduced with permission [173]. Copyright 2018, ACS publications.

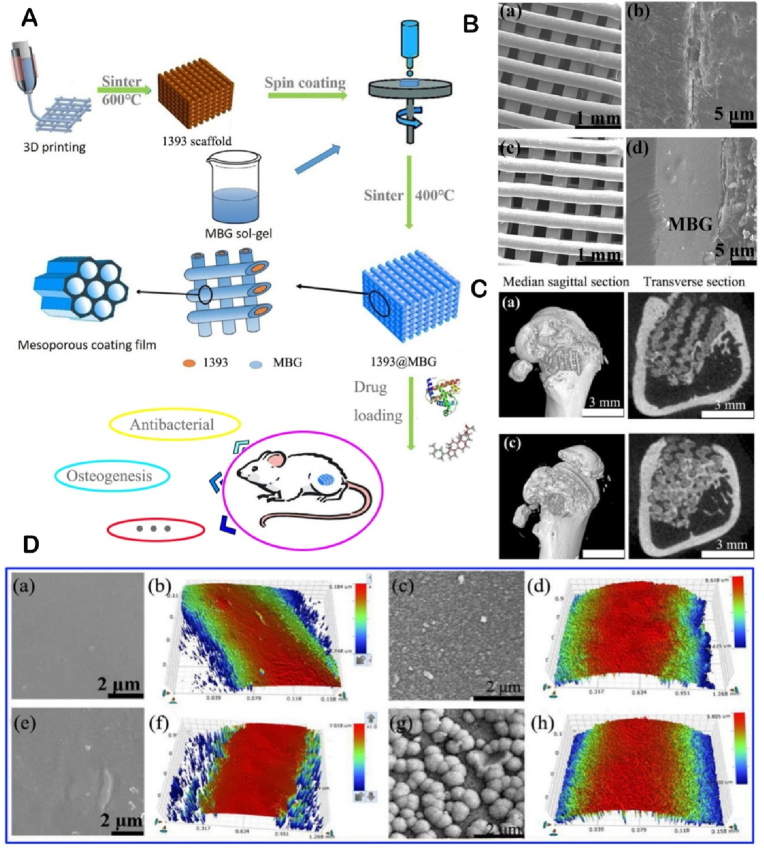

Fig. 10.

(A) The flow chart of preparing a novel vehicle-like drug delivery 3D printing MBGs-based composite scaffold for bone defect repair. (B) FESEM images of (a, c) as fabricated 1393 and 1393@MBGs scaffold; (b, d) the cross section of as fabricated 1393 and 1393@MBGs scaffold. (C) Micro-CT evaluation of bone regeneration in the rat cylindrical defects. (D) (a, b) FESEM images and the surface profile of as fabricated 1393 scaffold; (c, d) after immersed scaffold; (e, f) FESEM image and the surface profile of as fabricated 1393@MBGs scaffold; (g, h) after immersed scaffold [191]. Copyright 2020, International Publisher.

Fig. 11.

Schematic illustration showing the development of MBGs and engineered MBGs-based nanoplatforms with superior properties for theranostic applications in multiple diseases in future.

Fig. 12.

Schematic illustration of strategies for developing immunomodulatory MBGs, such as surface functionalization, manipulation of nanoarchitectures, controlled release of immunomodulatory molecules, and incorporation of bioactive ions.

Fig. 13.

Schematic illustration of advanced MBGs-based nanoplatforms for theranostic applications in diversified diseases.

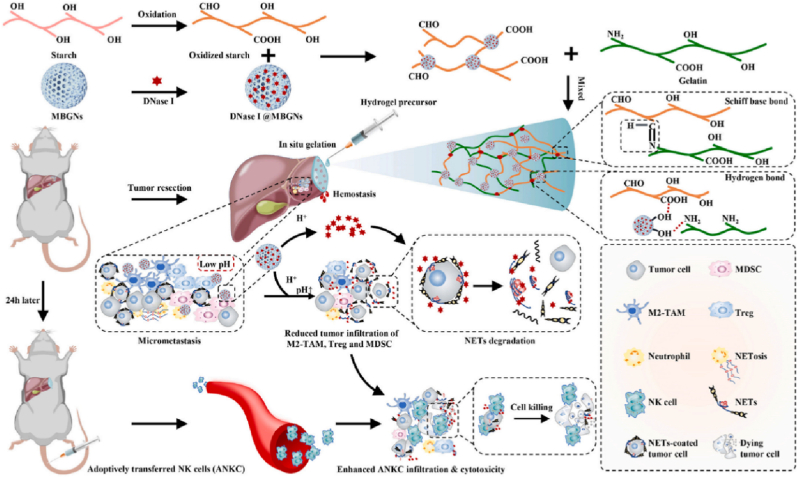

Fig. 14.

Schematic illustration of Gel-OS/DNase I@MBGNs hydrogel was prepared for enhancing adoptive NK cell therapy prevents post-resection recurrence of hepatocellular carcinoma [240]. Copyright 2022, Elsevier Ltd.

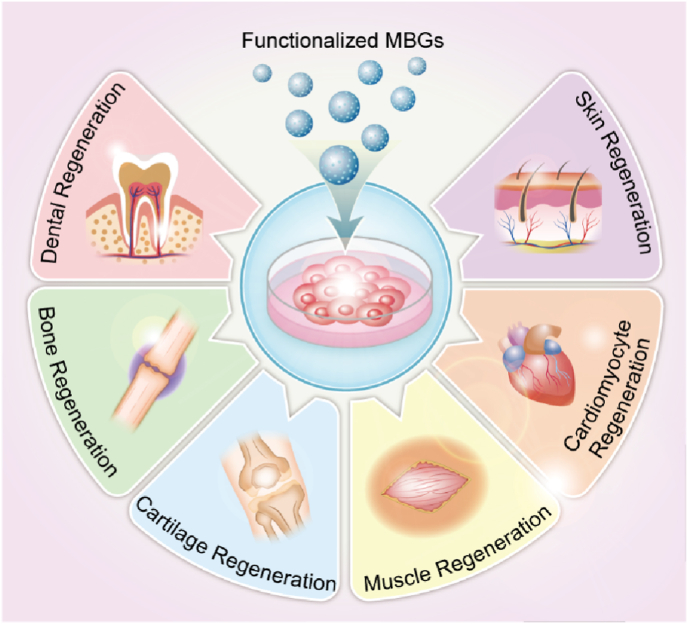

Fig. 15.

Schematic illustration showing the chemical engineering of MBGs for prospective theranostic applications in regenerative medicine.

Fig. 16.

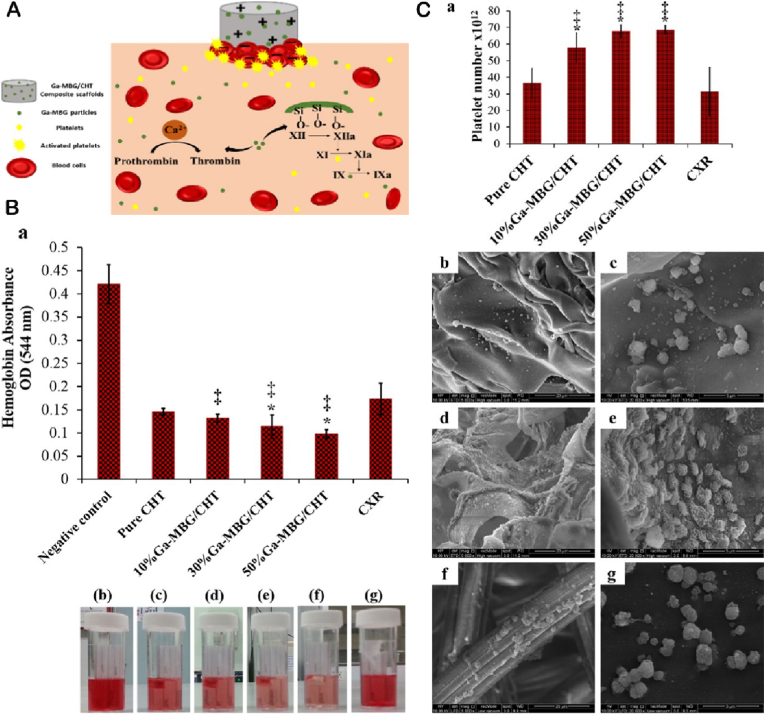

Schematic summary of (A) the hemostatic functions and antibacterial effects of MBGs-based materials with unique structure and desirable bioactivity. (B) Blood clotting rate of scaffolds and CXR (a); Photographs depicting more hemoglobin leaked from pure CHT, 10 % Ga-MBG/CHT, and CXR than that from 30 % Ga-MBG/CHT and 50 % Ga-MBG/CHT (b–g). (C) Effects of materials on platelet adhesion after 30 min of incubation with PRP (a). Low- and high-magnification FESEM images of platelets adhered to the surfaces of (b, c) pure CHT, (d, e) 50 % Ga MBG/CHT, and (f, g) CXR [276]. Copyright 2017, ACS publication.

Fig. 17.

Schematic illustration showing the fabrication of MBGs–based electrochemical biosensors from enzymatic to nonenzymatic. (A) XRD patterns of BOI NSs and p-BVO Nas. SEM images of (B) BOI NSs and (C) p-BVONAs. (D) SEM mapping images depicting the elemental distribution of Bi, V, and O in p-BVO. (E) Assembly process and immunoassay procedure of the FcAI/L-Cys/GNPs/p-BVO/ITO EC sensing interface [48]. Copyright 2021, ACS Publications.

3.1. Surface functionalization

3.1.1. Chemical group modification

It is important to note that a comprehensive understanding of the principles of modifying MBGs is crucial for developing novel surface engineering strategies [55]. In general, chemical modification in MBGs is based on the highly reactive silicon hydroxyl groups. There are three types of silicon hydroxyl groups on the surface of MBGs, namely isolated, twin, and hydrogen bonded hydroxyl groups. The isolated and twin silicon hydroxyl groups exhibit higher reactivity compared to the hydrogen bonded hydroxyl group, which transforms into a free silicon hydroxyl group when heated [56]. Effective surface modification is achieved by interacting chemically active surface silicon hydroxyl groups with various active components, introducing catalytic active sites into the pores or networks [57].

Among the different strategies, organosilane coupling agents play a crucial role in the surface engineering of MBGs. These agents are amphiphilic substances containing both organic functional groups and hydrolyzable groups [58,59]. After hydrolyzing, the alkoxy groups form silanol bonds that react with inorganic surface groups, creating strong chemical bonds and achieving functionalized surfaces with coupling agents [60]. Co-condensation and post grafting are the main methods used. Co-condensation, known as the one-step synthesis method, involves directly adding organosilane coupling agents to the sol during MBGs synthesis. However, the amount of introduced organic functional groups through co-condensation is limited as the silane coupling agent groups cannot cross-link and polymerize with other tetrahedral silicon atoms [61]. Post grafting is a relatively simple method for surface modification. It involves removing physically adsorbed water molecules from the newly synthesized mesoporous materials by heating under vacuum, followed by reacting with organosilane coupling agents in inert organic solvents like benzene, toluene, and cyclohexane to obtain surface-functionalized silicon-based mesoporous materials [62]. Mesoporous materials modified through post grafting possess a relatively high architectural order and protect the primary structures from damage [63].

Taken together, various chemical modifications can be carefully designed on the surface of MBGs with customizable nanoporous structures. These unique advantages provide an excellent opportunity for the efficient preparation of composite MBGs-based materials with uniform nano-sized pores and desirable properties. This makes MBGs an ideal platform for synthesis, self-assembly, and targeted delivery of guest molecules. As a result, the application of advanced MBGs has been expanded, allowing their use in various fields such as catalysis, separation, adsorption, biosensing, and controlled drug delivery.

3.1.2. Polymer coatings

As a novel class of organic/inorganic biomaterials, polymer-based nanocomposites ingeniously combine the advantages of organic polymers and inorganic nanoparticles. These nanoparticles act as drug delivery carriers with superior properties, improving the fate and performance of therapeutic molecules. By tailoring their delivery patterns and offering structural and functional diversities, these composites have demonstrated great potential for a wide range of applications [74,75]. Currently, silica-based mesoporous materials, known as MBGs, have been incorporated into polymers to create multifunctional composite scaffolds with improved attributes compared to matrix materials used alone. Various materials including collagen, chitosan, alginate, gelatin, polyglycerol, aliphatic polyurethane, polycaprolactone, poly lactic-co-glycolic acid, poly glycerol sebacate, poly-l-lactic acid, poly-1,8-octanediol citrate, and poly-3-hydroxybutyrate-co-3-hydroxyhexanoate have been fabricated as polymer coatings for surface functionalization of MBGs [72,[76], [77], [78], [79], [80], [81], [82], [83]].

Intriguingly, the polymer surface-coating MBGs have been designed through functional modification as novel drug delivery carriers in response to various external and biological stimuli [[84], [85], [86], [87]]. In a case, pH-responsive nanohybrids were fabricated through aminosilane functionalization of MBGs utilizing 3-aminopropyltrie thoxysilane. With daunomycin (DAN) as a model chemotherapeutic drug, the designed nanospheres enhanced drug loading and delivery rate in a pH-dependent way, where the release rate of DAN was higher at pH 5.5 compared to pH 7.4 [88]. Another example involves an injectable formulation based on polyurethane hydrogel and MBGs that can achieve sustained co-delivery of functional ions and drugs in a temperature-sensitive manner, making drug release timing and dosages controllable. The utilization of poly (ether-urethane) hydrogels with a typical LEGO-like chemical structure evokes polymer attractive properties to be finely tuned by changing their constituting building blocks. Excellent versatility opens the way to preparation of stimuli-responsive and environment-sensitive nanohybrids [89]. Whereas, coating polymeric architectures onto the surface of mesoporous silicon endows various functional attributes such as pH-responsive, molecule-responsive, ultrasound-responsive, and multielement-responsive, in contrast to the utilization observed with MBGs [[90], [91], [92], [93]]. For this reason, further design of multifunctional and stimulus-responsive MBGs/polymer nanohybrids will be the next direction to obtain a novel type of intelligent and environment-sensitive drug delivery system with remarkable bioactivity in the future [94,95].

3.1.3. Peptide modification

Proteins are unique and multifunctional biological macromolecules with abundant sources, excellent biocompatibility, and biodegradability. The fundamental structural unit of proteins is the peptide chain/poly-peptide, which consists of amino acids connected by peptide bonds. Through noncovalent bonding, the peptide chain folds into a flexible three-dimensional protein molecule. Proteins contain numerous functional groups, such as amino, carboxyl, and sulfhydryl groups, along with adjustable electrical properties, which provide binding sites for metal ions and organic compounds. Additionally, proteins possess diverse morphological structures and special biological activities, making them an excellent template for synthesizing composites with various structures [96]. In the biomedical field, protein composites are gradually emerging as promising candidates, particularly in drug targeted delivery systems. One effective strategy involves surface functionalization of nanoparticles using poly-glycerol (PG) grafting through ring-opening polymerization of glycidol, followed by poly-stage organic conversions within the PG layer, and coupling of primary polypeptides using click chemistry [97]. By employing this approach, cationic poly-arginine conjugated MBGs with poly-glycerol coating have been synthesized as potential vectors for gene delivery. The abundant silanol groups on the surface of MBGs serve as starting points for PG functionalization, resulting in a hydrophilic PG layer with versatile architecture for further modification. The cationic poly-arginine moieties play dual roles in efficiently loading plasmid DNA and facilitating cell transfection efficiency [98]. Furthermore, poly-peptide copolymers have been explored as sustained and controlled drug delivery systems due to their non-toxic, non-immunogenic, and minimal accumulation characteristics. A novel dual-drug delivery system was designed by combining MBGs with poly-peptide graft copolymers to create composites for pH-controlled drug release [99]. Among them, water-soluble gentamicin was predominantly released from MBGs in an acid environment, followed by a rapid release of fat-soluble naproxen from poly peptide nano-micelles in an alkaline environment.

In the field of intelligent drug delivery, functional protein composites enhance drug-specific selectivity by regulating their interaction with biological molecules. These composites exhibit excellent biocompatibility and cellular uptake, making them highly promising for biomedical applications. Something needs to be pointed out, although numerous examples have demonstrated the remarkable advantages of protein composites in biomedical and engineering fields, their translation from the laboratory to clinical settings still requires substantial efforts.

3.1.4. Molecule gate valve

It should be noted that surface modification using molecular gate valves is an effective strategy for achieving controlled drug delivery of MBGs in an environment-responsive manner [100]. Researchers have developed a class of artificial solid-state nanochannel materials [101]. Compared to natural ion channels, biomimetic artificial nanochannels offer higher stability, variable shapes, and surface chemical compositions, which make them highly promising for applications in biosensing, analysis, and drug delivery [102]. Currently, by combining with specific gating systems such as inorganic nanoparticles, macrocyclic compounds, biological macromolecules, and polymers, silicon-based nanoparticles have emerged as functional drug delivery systems that respond to stimuli such as pH, temperature, light, redox, magnetic fields, ultrasound, and biological molecules [103]. However, these gated systems have mainly been designed in single pure silica nanoparticles, and their functionality in bioactive glasses remains largely uncertain. Recently, Polo et al. [94] reported advanced enzymatic responsive molecular-gated nanodevices that utilize MBGs as an inorganic support for incorporating adenosine triphosphate (ATP) and polyllysine molecular gates. These stimuli-responsive MBGs-based systems exhibit excellent bioactivity, the ability to form apatite-like phases, and appropriate interactions with fluorescence probes, antibiotics, and anti-tumor drugs. Based on these concepts, tailor-made MBGs-based materials hold great potential for intelligent drug delivery and targeted disease therapy.

In conclusion, nano valves as advanced gating units play a crucial role in stimulative-responsive drug delivery systems by rhythmically blocking pores in inorganic nanoparticles. Mechanistically, molecular gating, such as the rotaxane structure, polymer, plug structure, bridge structure, and liposome, encapsulates drugs in a container and releases them upon specific stimulus response. As biomimetic nanochannels, MBGs have wide-ranging applications in biosensing analysis, gated release, and other areas due to their controllable shapes and ease of chemical modification, attracting significant attention from scientists across various fields.

3.2. Nanostructured morphology

3.2.1. Shape modification

Generally, bioactive glasses have a three-dimensional irregular network structure consisting of interconnected silicon oxygen tetrahedra with bridged oxygen at the top corner [[104], [105], [106]]. Phosphorus oxygen tetrahedra are linked to silicon oxygen tetrahedra through Si–O–P bonds, which play a crucial role in the formation of the glass network structure. Specifically, the presence of a double bond in the phosphorus oxygen tetrahedron creates a network breakpoint due to pentavalent phosphorus [107]. Metal ions existing in the shape of network modifiers destroy the integrity of silicon oxygen network texture and form a non-bridged oxygen bond of -Si-O-M+ [66]. With increasing non-bridged oxygen bonds and network breakpoints, the release rate of Na+ and Ca2+ in bioactive glasses as well as biomineralization rate are quicken. Interestingly, despite with similar network structures, MBGs prepared through different methods have varying nanostructured morphology, which is a significant aspect of material functionalization [108].

Concentrating on this novel modification strategy, variety of advanced MBGs with unique shapes have been prepared for targeted drug delivery, gene transfection, bioengineering and tumor therapy [63]. In one instance, radial mesoporous bioactive glass (rMBGs) nanoparticles were successfully synthesized using a sol gel process combined with microemulsion and gelation-induced phase separation techniques, employing CPB templates. These particles possess a distinctive design characterized by a radial and fibrous texture, customizable pore architecture, excellent dispersion, and superior mineralization ability. Osteoactivin, a model gene, was effectively protected from degradation by Deoxyribonuclease I through adsorption onto aminated rMBGs. Moreover, the aminated rMBGs were taken up by cells in a time- and dose-dependent manner, with primary localization observed in the cytoplasm. Based on these results, rMBGs show great potential as advanced non-viral carriers for targeted DNA gene transfection [109,110]. Optimized MBGs with high specific surface area and variable mesoporous channels were also fabricated by controlling calcium concentration in the silica matrix. Dendritic MBGs nanospheres effectively activated transient receptor potential channels and calcium-sensing receptors on tumor cells through calcium influx, specifically inhibiting tumor growth without affecting normal cells. Furthermore, the dendritic-shaped nanoparticles intelligently synergized with cancer drugs in an acidic microenvironment to enhance anti-tumor efficacy and reduce systemic toxicity [46,111].

Indeed, traditionally synthesized irregularly shaped MBGs often exhibit lower biological and physicochemical performances compared to novel materials that have undergone shape modification, such as regularly spherical particles or radial and dendritic nanoarchitectures. Therefore, there is great potential for bioengineering applications in the development of advanced MBGs-based biomaterials with controllable structures and morphologies through optimized synthesis technologies.

3.2.2. Particle-size design

The size and pore structure of MBGs are widely recognized as critical determinants of their biological and physicochemical properties [112,113]. When reduced to the nanometer level, the particle size of MBGs undergoes significant changes in geometric morphology and electronic structure, resulting in nanoscale characteristics such as the small size effect, surface effect, quantum size effect, and quantum tunneling effect [114]. These characteristics confer advantageous properties to MBGs, including a larger specific surface area, higher proportion of coordination unsaturated atoms and surface atoms, and high catalytic activity due to the increased proportion of surface atoms and insufficient coordination number of surface atoms [113]. Nevertheless, for biomedical applications, larger-sized MBGs are preferred for drug delivery due to their larger pores, which facilitate enhanced mass transfer, penetration, and diffusivity of proteins and genes, leading to improved drug loading rates and enhanced activity and stability of biomolecules. To achieve larger particle sizes, pore-forming templates and pore swelling agents have been developed. The combination of hydrothermal treatment and amphiphilic block copolymers as templates can result in the formation of relatively large pores (15–20 nm), while pore swelling agents such as tetramethylbenzidine (TMB) and ethyl ether have been reported to enlarge the pore size of MBGs up to 40 nm. However, excessive addition of pore swelling agents can potentially disrupt the hexagonal crystal pore structure, resulting in a heterogeneous worm-like pore structure. Therefore, achieving controllable synthesis of particle size and conducting detailed studies on the relationship between size changes and properties are crucial for optimizing the nanostructured morphology of MBGs [67].

In addition, while MBGs demonstrate better performance in gene transfection, drug delivery, and bone regeneration compared to individual silica particles, there is a need for further studies focusing on intracellular localization and long-term biosafety. Recent in vitro studies have indicated that the potential toxicity of nanomaterials is highly dependent on their particle size and shape, with spherical MBGs exhibiting higher bioactivity without obvious cytotoxicity than large-size and irregular bioactive glasses. This encourages researchers to clarify the potential size-dependent mechanisms of intracellular trafficking and cytotoxicity of MBGs. Studies have shown that smaller-size MBGs exhibit weaker cytotoxicity compared to larger particles, indicating a size-dependent mechanism that affects intracellular localization and cytotoxicity [115].

Overall, size-designed nanoparticles play a significant role in catalysis and drug delivery, with smaller-size MBGs generally demonstrating higher catalytic activity and lower cytotoxicity. Further, it is also essential to prepare nanoscale MBGs with larger pores through the selection of appropriate templates to achieve biomolecule loading and delivery, thereby expanding the range of size control under the micro level and widening the applications of MBGs with improved performances.

3.2.3. Tailorable mesoporosity

Currently, the structural functionalization of MBGs using advanced technology to adjust mesoporous pore size is a promising research focus [115]. The highly ordered MBGs display excellent biological activity, rapid hydroxyapatite-induced formation rates, and higher drug loading efficiency compared to traditional pure silicon-based mesoporous materials [117]. While small molecule drugs can be effectively loaded into MBGs with small mesoporous pore sizes, the loading of macromolecular drugs and proteins into mesoporous channels poses significant challenges, limiting their applications in drug delivery. To address this issue, long-chain surfactants are currently used as templates to prepare macro-porous biological glasses. Furthermore, 1,3,5-trimethylbenzene and N, N-dimethyl decamine are favorable pore-enlarging agents that effectively increase the mesoporous pore size of MBGs. In terms of unique structural characteristics, hollow MBG (HMBG) spheres consist of a large hollow interior with vertical mesochannels in the shell, enabling the uptake and sustained release of drugs on a larger scale [118]. Recently, Li et al. [119] reported the direct synthesis of a novel type of HMBG spheres using a dual-template system, including diblock copolymer and cationic surfactants. The study concluded that the primary contributing factors to the adsorption of large amounts of payloads were the large specific surface area and vertical mesochannels on the shells. The presence of calcium (Ca) ions also facilitated the efficiency of drug loading, as Ca ions and organic drug molecules synergistically formed chelate complexes. Structurally, the HMBG spheres exhibited two types of pores with different sizes: a hollow center with a diameter of approximately 150 nm and a mesoporous shell with a uniform thickness of 50–60 nm. These pores provide effective space for multiple therapeutic agents with different release profiles. Overall, the potential to load two drugs with different release profiles within a single particle has the capacity to overcome some clinical drug antagonism [120].

Indeed, structural optimization of MBGs-based materials are promising strategies to modulate healthy or diseased tissue microenvironments for regeneration or cancer therapy. Considering advantageous features of tailorable nanochannels, there has been significantly interested in altering microscopic nanoarchitecture such as mesopores to generate desirable properties of MBGs for their applications in multiple diseases. In this case, synthetic scaffolds with MBGs as matrix, a trimodal macro/micro/nano architecture with enhanced compressive strength was successfully designed through a multi-template method. Trimodal porous architecture and loading bone morphogenetic protein-2 (BMP2) molecules endowed advanced MBGs-based scaffolds the osteoconductive and osteoinductive activity, which may represent a novel direction for the development of orthopedic materials in future [116].

3.3. Network modification

Researchers are actively exploring novel functional strategies to enhance the mechanical and physicochemical properties of MBGs. Among these, network modification through insertion of organic groups, doping of metals and metal oxides, and transformation of integral skeleton have garnered significant attention. We will introduce above strategies in following chapters [[121], [122], [123]].

3.3.1. Insertion of organic groups

Due to the abundant presence of silicon hydroxyl groups on the surface of MBGs, which can serve as bioactive sites, MBGs-based nanohybrids with unique networks can be developed by doping organic components into these active sites using advanced methods such as co-polycondensation or grafting [40,124]. Among these methods, the co-polycondensation process aims to load organic groups onto MBGs by polymerizing organosilane and orthosilicate. For example, the organic polymer polylactic acid (PLA) was hybridized with MBGs through co-polycondensation, resulting in functional nanohybrids with superior biological induction activity, physical and mechanical properties [125]. For another, the grafting method involves combining organic functional groups with existing MBGs to enhance thermal stability and hydrolysis. Recently, a novel hybrid biomimetic formulation was developed by combining nano-sized MBGs enriched with strontium (Sr) and type I collagen. This bioactive ink was designed for 3D printing bone-like scaffolds and showed well-distributed Sr-MBGs along collagen fibrils, mimicking the organization of hydroxyapatite crystals in the bone extracellular matrix (ECM) [126]. Additionally, various active components such as biopolymers and organic acids have been incorporated into MBGs for structure modification. For instance, polycaprolactone was grafted onto the structure of MBGs using electrospinning technology, resulting in a three-dimensional skeleton with improved mechanical and physicochemical attributes, as well as excellent biodegradability [127]. Moreover, the supercritical carbon dioxide foaming technique was utilized to graft the bioactive lipid FTY720 into MBGs-PLGA composites, creating a favorable microenvironment for cellular adhesion and proliferation [128]. In summary, incorporating active compositions or organic groups into the network of MBGs enables the fabrication of advanced drug delivery carriers with enhanced structural and functional diversity, as well as stimulus responsiveness.

3.3.2. Incorporation of metal or metal oxide

In addition to microstructure tailoring, recent efforts have focused on modifying the networks of MBGs by incorporating metal species (Cu, Zn, Sr, Co, Fe, Zn, Tb, or Eu, etc.) into the siliceous matrix. These metal dopants provide additional attributes such as osteogenesis, angiogenesis, antibacterial, and anti-tumor activities (Table 1) [[129], [130], [131], [132], [133], [134], [135], [136]]. For instance, a three-dimensional magnetic Fe3O4 nanoparticle composite containing MBGs/PCL has been successfully synthesized using rapid prototyping techniques. This composite exhibits a high porosity of 60 %, uniform macropores of 400 nm, and a notable compressive strength of 13–16 MPa. It also allows sustained drug loading and release. Importantly, the incorporation of Fe3O4 imparts superior magnetothermal effects for cancer therapy and significantly improves biological activity without affecting apatite mineralization. Another effective strategy for tissue regeneration involves pre-impregnating therapeutic cations into nanoparticles to modulate the microenvironment [137]. Zhang et al. [138] fabricated a 3D-printed nano-sized MBGs/collagen scaffold enriched with Sr ions, which effectively avoided premature release of Sr and significantly enhanced mechanical and thermal stability while maintaining high biocompatibility. Notably, when nanoscale bioactive structures mimic the natural features of bone tissue, they can reproduce the physiological environment and influence cell behavior during the regeneration process. In another case, an ordered MBGs network was modified with Ce, Ga, and Zn. The Ce and Zn played important roles in the physiological functions related to the bone metabolism environment, while Ga improved the mechanical properties of newly formed bone. However, the biocompatibility evaluation of these pore-blocking caps must be addressed, as some metal and metal oxide nanoparticles are toxic and may cause severe adverse effects and inflammatory reactions when administered [139] (see Table 2).

Table 1.

The advantages and disadvantages of surface functionalized MBGs for disease therapy.

| Representations | Ref. | |

|---|---|---|

| Advantages | Desirable biocompatibility; | [23] |

| Acceptable biodegradability; | [64] | |

| Feasible immunomodulation; | [65] | |

| Tunable particle size; | [66] | |

| Controllable pore size and distribution; | [67] | |

| High specific surface area and pore volume; | [68] | |

| Diversified surface modifications; | [69] | |

| Flexible morphologies and forms. | [70] | |

| Disadvantages | Potential toxicity; | [35] |

| Poor mechanical property; | [71] | |

| High synthesis cost; | [72] | |

| Sophisticated modification process. | [73] |

Table 2.

Incorporation of versatile metal or metal oxide into MBGs for biomedical applications.

| Metal | Function | Biomedical Applications | References |

|---|---|---|---|

| Ag | Antibacterial activity Biocompatibility with soft tissue cells |

Soft tissue regeneration Infectious diseases Dentin hypersensitivity |

[140,141] |

| B | Osteogenesis | Bone regeneration Osteoporosis |

[142,143] |

| Ce | Osteogenesis Antibacterial Antioxidant |

Bone regeneration Infectious diseases |

[144,145] |

| Co | Osteogenesis Angiogenesis |

Hypoxic diseases Tissue regeneration |

[146] |

| Cu | Osteogenesis Angiogenesis Odontogenesis Antibacterial Immune modulation Hyperthermia for tumor cells |

Bone regeneration Dental tissue regeneration Tumor photothermal therapy |

[147,148] |

| Eu | Osteogenesis Anticancer |

Bone regeneration Bone cancer therapy |

[149] |

| Ga | Antibacterial Hemostatic |

Soft tissue regeneration Wound healing |

[150,151] |

| Fe Fe3O4 |

Osteogenesis Hyperthermia for tumor cells |

Bone regeneration Cancer magnetic-heat therapy |

[152] |

| K | Osteogenesis | Bone regeneration | [153] |

| Li | Osteogenesis Cementogenesis |

Bone regeneration Periodontal tissue regeneration |

[154] |

| Mg | Osteogenesis | Bone regeneration | [155] |

| Mn | Antibacterial Osteogenesis |

Infectious diseases Bone regeneration |

[156] |

| Na | Osteogenesis | Bone regeneration | [157] |

| Rb | Osteogenesis Angiogenesis Antibacterial |

Bone regeneration | [158] |

| Se | Osteogenesis Anticancer |

Bone regeneration Bone tumor therapy |

[136] |

| Sm | Anticancer | Bone tumor therapy | [78] |

| Sr | Osteogenesis Cementogenesis |

Bone regeneration Periodontal tissue regeneration |

[[159], [160], [161]] |

| Ta | Hemostasis | Hemorrhagic disease | [162] |

| Tb | Osteogenesis | Bone regeneration | [51] |

| Te | Antibacterial Anticancer |

Bone tumor therapy | [163] |

| Zn | Osteogenesis Anti-inflammatory |

Bone regeneration Soft tissue regeneration |

[139,[164], [165], [166]] |

| Zr | Osteogenesis Radio-opacity at the implant site |

Bone regeneration Nanomolecular imaging |

[167,168] |

Furthermore, recent advances have focused on enhancing the adsorption and acid-base strength of mesoporous surfaces by doping metals or metal oxides to replace specific silicon atoms in MBGs. This takes advantage of the exchangeability of metal elements and ultimately improves the catalytic performance of MBGs [[169], [170], [171]]. Various transition metal elements with different valence states have been doped into MBGs to create redox properties. Typically, the metal or metal oxide is added during the material preparation process to ensure even dispersion within the network structure [172].

Another method involves doping metal ion-containing solutions into the prepared MBGs, followed by physical drying and a final firing step. However, metal elements obtained through this method are prone to loss due to weak van der Waals forces. Additionally, the addition of metal ion precursors, usually salts, may destabilize nanoparticles by affecting condensation and altering their surface charge. It is crucial to carefully optimize the metal concentration relative to that of silica when incorporating metals [79]. Proper control of processing parameters, such as the timing of metallic precursor addition and the molar concentration ratio between silica and the metal ion precursor, is necessary along this line.

3.3.3. Transformation of integral architecture

It is particularly significant that the beneficial and desirable properties of MBGs can be harnessed by transforming their integral network into advantageous modalities such as coating materials, composites, core-shell structures, porous spheres, fibrous constructs, and three-dimensional scaffolds [123,[174], [175], [176], [177], [178]]. For instance, MBGs have been incorporated into polymers to create multifunctional composite scaffolds with superior attributes compared to using matrix materials alone. Additionally, innovative MBGs-based nanohybrids with unique core-shell structures have been developed as nanocontainers for sequential multi-drug loading and delivery. Irregularly shaped MBGs synthesized through traditional methods often exhibit lower flow properties compared to regularly spherical particles, limiting their applications in injectable materials and drug delivery systems. Therefore, there has been a significant research interest in fabricating microspheres based on MBGs, as spherical biological glasses demonstrate improved bioactivity, hemostatic activity, excellent apatite mineralization, and high drug-loading capacity, owing to their high surface area and adjustable morphology [179,180]. Ordered microspheres can be synthesized through aerosol-assisted or emulsification-solvent evaporation methods. However, these methods have certain limitations. For instance, spray drying can result in a rapid decrease in surface area and microstructure, while the formation of mesostructure through the self-assembly of silica precursor and surfactant molecules requires a lengthy solvent evaporation process [181]. To address these challenges, Miao et al. developed a novel synthesis method for MBGs-based microspheres by combining sol-gel and water-in-oil micro-emulsion techniques, with or without the presence of ammonia as a catalyst. By adjusting the hydrolysis and polymerization rates of the precursors, they successfully synthesized acid-catalyzed MBGs with dense microsphere structures. Conversely, acid-alkali co-catalyzed MBGs with loose and porous structures were produced by incorporating ammonia during the gelation process. Furthermore, the addition of ammonia increased the mesopore size, pore volume, and surface area of the MBGs [182]. Both types of MBGs exhibited outstanding drug carrier properties with sustained release capabilities and demonstrated high in vitro apatite-forming activity. However, it was observed that acid-alkali co-catalyzed MBGs exhibited a faster rate of apatite deposition compared to acid-catalyzed MBGs [183].

Although MBGs are generally used either in powder or bulk form in most studies, fibrous frames have recently gained more attention [184,185]. For instance, Wang and coworkers reported the preparation of MBGs-based nanofibers by electrospinning β-cyclodextrin-modified MBGs nanoparticles with silk fibroin, resulting in a nanofibrous mesh that acts as a drug delivery system for hydrophobic molecules [186]. Scaffolds should mimic the structure of nanofibrous ECM, which is crucial for achieving biological functions. Pores within the scaffolds provide space for tissue in-growth and efficient mass transport of nutrients, oxygen, growth factors, and waste products. Nanofibers contribute to large surface areas that facilitate cell adhesion. Hsu et al. [123] successfully fabricated and characterized macroporous microbeads containing apatite-modified MBGs nanofibers using poly (methyl methacrylate) as the template combined with electrospray technology. The results showed that MBGs nanofibers provided a favorable environment for cell adhesion.

Developing three-dimensional hierarchical porous scaffolds with optimal features such as pore structure, mechanical strength, degradation rate, controllable drug delivery, and cell response poses a significant challenge in biomedical engineering [[187], [188], [189], [190]]. One study utilized a modified F127/PU co-templating method combined with a simple adsorption and lyophilization process to design and prepare a multiparameter-adjustable MBGs-based composite coating with poly (glycerol sebacate) (PGS) that meets various clinical application requirements. By adjusting the polymer coating amount and pore parameters, the composite scaffolds exhibited a tunable degradation rate for both the MBGs matrix and PGS coating, improved toughness, adjustable mechanical strength over a wide range, multilevel controlled release of proteins while maintaining their activity, and excellent in vitro cytocompatibility [140]. However, traditional fabrication approaches, including sol-gel, gas foaming, and fiber bonding methods, lack accurate control over scaffold architecture, pore shape, porosity, and interconnectivity. They also exhibit very low mechanical strength, making them unsuitable for clinical application. To overcome these disadvantages and challenges, advanced 3D printing technology utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) has been employed to design and fabricate three-dimensional MBGs-based scaffolds, significantly improving mechanical properties and speeding up production processes [[191], [192], [193]]. For instance, Zhang et al. prepared MBGs modified β-tricalcium phosphate (MBGs/β-TCP) scaffolds with hierarchical pore structures and functional surfaces via 3D printing and spin coating, resulting in enhanced apatite mineralization ability and compressive strength compared to pure β-TCP scaffolds [194]. Despite substantial advancements in engineering fabrication technology and the development of multifunctional MBGs-based nanocontainers, various factors ranging from initial processing and manufacturing costs to product implantation and safety must be carefully considered to achieve successful clinical transformation.

4. Superior properties of engineered MBGs

After undergoing versatile modification processes, advanced MBGs exhibit exceptional properties such as desirable bioactivity, biocompatibility, biodegradability, and interaction with immune cells. These attributes position them as potential candidates for disease theranostics. The subsequent subsection focuses on the advantageous properties of engineered MBGs-based nanomaterials and critical considerations for clinical translation.

4.1. Bioactivity

Bioactivity, in the field of biomedical materials, refers to the unique characteristics that can induce specific biological and chemical reactions at the interface between materials and biological tissues. This leads to the formation of chemical bonds between materials and living tissues [195]. MBGs are a type of bioactive material that can repair and regenerate living tissues by forming cooperative bonds between tissues and materials. The degradation products of MBGs facilitate the generation of growth factors, cell proliferation, and gene expression [196]. Engineered MBGs with uniform mesoporous channels and high specific surface area can quickly form hydroxyapatite when immersed in a simulated physiological solution. They also exhibit exceptional biological activity and strong degradability while minimally affecting the pH value of the surrounding microenvironments. Furthermore, they maintain the acid-base stability of local body fluids [197]. This makes MBGs highly valuable for tissue repair and regeneration.

4.2. Biocompatibility

Safety, based on the biocompatibility of carrier-based formulations, is a crucial consideration for biomedical applications, as it significantly influences the translation of such materials from the laboratory to clinical application [198]. MBGs, recognized as third-generation bioactive glasses, possess a nanostructured pore size distribution. These materials are designed to exhibit functional and structural compatibility with living tissues without adverse effects [199]. Furthermore, under biological conditions, MBGs can be distributed throughout the body and primarily eliminated through renal clearance. Therefore, understanding the biodistribution and elimination of MBGs is crucial in assessing long-term biocompatibility and potential toxicity concerns [200]. It is important to consider the potential risks associated with MBGs and ensure that the composition falls below safe biological limits for certain elements. Additionally, sustained release of these elements should not exhibit cytotoxic effects. Histological evaluations of kidney and hepatic structures have indicated non-toxic characteristics of all MBGs when using different surfactants. Numerous studies have demonstrated that the morphology, particle size, surface area, pore volume, pore size, and surface functionality of MBGs can influence their biocompatibility [42,169,201].

Some studies have shown that high concentrations of MBGs can lead to severe acute toxicity, highlighting the need for performance improvements. Mao et al. evaluated the acute toxicity and biodistribution of sub-micrometer MBG spheres (SMBG) when intravenously administered to mice. After 14 days of injection at doses of 20, 100, and 180 mg/kg, SMBG exhibited low in vivo toxicity based on factors such as mortality rates, organ coefficients, hematology data, and blood biochemical indexes. The lethal dose 50 (LD50) was found to be higher than 250 mg/kg. However, these nanocarriers primarily distributed in resident macrophages in the liver and spleen and could be cleared from the body within two weeks. High doses resulted in lymphocytic infiltration and granuloma formation in hepatocytes, as well as megakaryocyte hyperplasia in the spleen [202]. Therefore, when considering the use of MBGs as nanocarriers, it is crucial to consider their beneficial attributes, administration route, and dosage to ensure excellent biocompatibility, low toxicity, controlled biodegradation, and effective clearance. These factors are essential prerequisites for achieving safe and efficient nanocarriers.

4.3. Biodegradability

In addition to improved cytocompatibility and optimal surface architecture, the degradability of MBGs in biological fluids is another crucial attribute directly related to their biosafety. Unlike soft polymeric constructs, inadequate degradation of stable inorganic nanomaterials can result in long-term accumulation in the body, which poses potential risks of toxicity due to the materials' structural integrity and their chemical, thermal, and mechanical stability. It is worth noting that the degradation of MBGs in simulated body fluid occurs in two stages: an initial rapid degradation within the first 72 h, followed by a slower degradation over the subsequent 28 days [203]. Their degradation rates were generally affected by pore size and volume, chemical composition, degree of hydrolysis and condensation, morphology, surface functionality, and type of degradation medium.

Currently, researchers are actively developing bioactive porous scaffolds with time-dependent biodegradation to achieve control over the stability and release profile of guest molecules. These factors are closely associated with considerations of stability, biodistribution, excretion, and toxicity [204]. Ghamor-Amegavi et al. have successfully prepared biphasic yolk-shell granules consisting of a highly bioactive and biodegradable yolk component and a self-curing silicate shell component. They incorporated MBGs into a self-curing β-dicalcium silicate (Ca2SiO4) cement shell to form spherical granules known as MBGs@ Ca2SiO4. The incorporation of MBGs was found to enhance the bioactivity of the composites, control the degradation rate and ion release, and improved the bone repairing ability of the Ca2SiO4 shell-coated granules. Throughout the immersion stage, MBGs@Ca2SiO4 granules exhibited a rapid decrease in mass, with approximately 10 % greater decrease in mass during the first week (65.2 % vs. 75.3 %) and a cumulative decrease of nearly 15 % after 7 weeks (47.3 % vs. 62.6 %). Additionally, the MBGs@Ca2SiO4 granules displayed a slow increase in calcium concentration and a fast release of silicon ions. This confirmed that MBGs@ Ca2SiO4 granules possessed excellent compressive resistance and biodegradability [140,205]. Given these findings, MBGs present themselves as promising candidates for medical applications, as they can effectively regulate the degradation rate to mimic the microenvironments of target tissues.

4.4. Immunomodulation

The size, shape, and deformability of materials significantly influence their uptake by diverse immune cells and subsequent immune responses [206]. Given the vast potential of MBGs in various biomedical fields such as tissue engineering, cancer, and infectious processes, this study aims to explore the in vitro interaction between MBGs and immune cells [118,207]. Montes-Casado et al. [200] demonstrated the beneficial impacts of MBGs on the immune system by assessing different immune cells, including bone marrow-derived dendritic cells, subsets of spleen cells, and cell lines such as dendritic cells and lymphocytes. The findings revealed that MBGs did not disturb the balance of spleen cell subsets, the expression of T cell activation surface markers (CD25 and CD69), or the production of intracellular or secreted inflammatory cytokines. In vitro experiments indicated that T and B lymphocytes, along with dendritic cells, could efficiently and rapidly uptake MBGs by activating phosphoinositide 3-kinase, actin, and clathrin-dependent pathways. Furthermore, the appropriate expression of major histocompatibility complex and co-stimulatory molecules (CD40, CD80, and CD86) suggested that MBGs did not alter the maturation process of dendritic cells. These studies highlight that MBGs with distinct particle sizes, pore structures, and surface functionalities can influence the expression of activation surface markers and pro-inflammatory cytokines in antigen-presenting cells. Through the stimulation of co-stimulatory molecules and cytokines released by antigen-presenting cells, naive T cells can be effectively activated, subsequently influencing Th2 or Th1 cell responses.

With a highly ordered mesoporous structure, large surface area and porosity, MBGs enable high ionic exchange of Ca cation and soluble silica with surrounding media, which may stimulate the expression of several genes of osteoblastic cells and regulate immune reactions by altering the ionic microenvironment between implants and hosts. Gómez-Cerezo et al. evaluated the effects of MBGs-75S scaffold on the osteoimmune microenvironment. MBGs-75S displayed high biocompatibility in contact with Saos-2 osteoblast-like cells and allowed differentiation of macrophages into osteoclast-like cells. In vitro studies focusing on the innate immune response showed that MBGs-75S would facilitate suitable proliferation of macrophages without inducing their polarization towards the M1 pro-inflammatory phenotype. Therefore, MBGs with unique surface topography, precise control of pore size, shape, arrangement, interconnectivity, and hierarchical structure, may serve as potential osteoimmunology biomaterials in tissue engineering [200,208].

In summary, the immune system constitutes a complex network of cells and lymphoid organs that collaborate to defend the host against invading pathogens and tumor growth. Chemically engineered MBGs have the potential to interact with the immune system in various ways. Once inside the human body, MBGs can interact with and be taken up by immune cells. Enhancing our understanding of these interactions and the underlying mechanisms can facilitate the translation of MBGs-based materials from the laboratory to clinical applications.

5. Emerging theranostic applications of multifunctional MBGs

Engineering MBGs-based nanocarriers indicate promising candidates to enhance the bioavailability and safety of active molecules, which will act as a stimuli-responsive intelligent delivery platform for therapeutic applications in multiple diseases, including cancer, tissue regeneration, bacterial infections, hemorrhagic disorders and so forth [[209], [210], [211], [212], [213]].

5.1. Intelligent delivery systems

5.1.1. Drug delivery

In recent years, various organic materials such as organic micelles, liposomes, and biodegradable polymers have been studied as carriers for drug delivery systems. However, these materials often face challenges due to their susceptibility to attacks by immune system and their limited thermal and chemical stability [214]. In contrast, MBGs offer advantages in terms of accurately positioning and sustaining release of assembled drugs. This is made possible by the presence of abundant surface silicon hydroxyl groups that provide active sites and allow for specific surface modifications, enabling the packaging of a variety of drugs within the mesoporous phase (Table 3) [215]. Surface functionalization of the mesoporous channels helps maintain the high structural order of MBGs, strengthens the interaction between drug molecules and the pore surface, and slows down the rate of drug release [41]. For instance, a slower release rate of therapeutic cargo was obtained after NH2 group was modified on the pore surface of MCM-41, taking advantage of the strong ionic bond generated by acid-base reaction. Additionally, by employing self-assembly technology, stimuli-responsive components can be layered outside the hollow mesoporous sphere. These active molecules can respond to specific conditions such as pH value or ionic strength, effectively blocking or opening the mesoporous channels and acting as a switch for controlled drug release. Moreover, mesoporous drug carriers can achieve targeted drug delivery through magnetic control. By integrating iron oxide particles as the core and MBGs as the shell, highly dispersed core-shell magnetic nanocomposites have been developed. Under external magnetic fields, these composite particles can be separated, allowing for targeted transmission of drugs within the human body [216].

Table 3.

Therapeutic guest molecules incorporated into MBGs-based hierarchical scaffolds and systems.

| Cargo | Type | Delivery system | Function | Biomedical applications | Ref. |

|---|---|---|---|---|---|

| Alendronate | Drug | MBGs Aminated MBGs Acid-alkali MBGs |

Osteogenesis | Bone regeneration Osteoporosis |

[224,225] |

| Ampicillin | Drug | MBGs | Antimicrobial | Infectious diseases | [226] |

| Ciprofloxacin | Drug | MBGs | Antimicrobial | Bone or joint infections | |

| Dexamethasone | Drug | MBGs MBGs/Polycaprolactone MBGs/Alginate |

Osteogenesis | Bone regeneration | [191] |

| Dimethyloxallyl glycine | Drug | MBGs | Osteogenesis Angiogenesis |

Bone regeneration | [227] |

| Doxorubicin | Drug | MBGs/Alginate Molecular-gated MBGs Dendritic MBGs |

Anticancer | Cancer therapy | [137] |

| Fingolimod (FTY720) | Drug | MBGs | Osteogenesis Immunomodulation |

Bone regeneration | [228] |

| Gentamicin | Drug | MBGs MBGs/Gelatin |

Antibacterial | Bone regeneration | [79] |

| Ibuprofen | Drug | MBGs MBGs/PLGA/SBA-15 |

Antibacterial Anti-inflammatory |

Bone regeneration | [187,229] |

| Ievofloxacin | Drug | Molecular-gated MBGs | Antimicrobial | Bone regeneration Infectious diseases |

[94] |

| Imatinib | Drug | MBGs MBGs/Polyurethane |

Anticancer | Cancer therapy | [41,230] |

| Isoniazid | Drug | MBGs | Antitubercular | Bone regeneration Osteoarticular Tuberculosis |

[231] |

| Metformin | Drug | MBGs MBGs/PLGA/SBA-15 |

Antidiabetic Osteogenesis |

Diabetes Bone regeneration |

[229] |

| Rifampin | Drug | MBGs MBGs/Gelatin |

Antitubercular | Bone regeneration Osteoarticular Tuberculosis |

[231] |

| Vancomycin | Drug | MBGs/PLGA | Osteogenesis Angiogenesis |

Bone regeneration Infectious diseases |

[232] |

| BDNF | GF | MBGs/Cement | Osteogenesis | Bone regeneration Osteoporosis |

[233] |

| BMP-2 | GF | Trimodal MBGs MBGs/TiO2 nanorod MBGs/Chitosan MBGs/PEG |

Osteogenesis | Bone regeneration | [234,235] |

| bFGF | GF | MBGs | Osteogenesis | Bone regeneration | [220] |

| EGF | GF | MBGs | Osteogenesis Angiogenesis Antibacterial Odontogenesis |

Bone regeneration Dental regeneration |

[221,236] |

| FGF18 | GF | MBGs/Collagen | Osteogenesis | Bone regeneration | [76] |

| IGF-1 | GF | MBGs | Osteogenesis | Bone regeneration | [223] |

| VEGF | GF | MBGs/Cap cement | Angiogenesis | Bone regeneration | [237] |

| IL-8 | Chemokine | MBGs/Chitosan MBGs/PEG |

Immunomodulation Osteogenesis | Bone regeneration | [217,238] |

| Lysozyme | Protein | MBGs/Cap cement | Antimicrobial | Bone regeneration | [237] |

| Bull serum albumin | Protein | MBGs/Sodium alginate | Osteogenesis | Bone regeneration | [187] |

| CGRP | Peptide | MBGs/Gelatin | Osteogenesis | Bone regeneration | [193] |

| Osteostatin | Peptide | MBGs | Osteogenesis | Bone regeneration | [95] |

| BMP2-pDNA | Gene | MBGs | Anti-osteoclastogenesis | Bone regeneration | |

| RANK siRNA | Gene | MBGs | Anti-osteoclastogenesis | Bone regeneration | [239] |

In summary, the preparation of MBGs with superior performances, including uniform pores, large pore volume, and a chemically modifiable pore surface, holds great importance in advancing the field of bioengineering. Such advancements will pave the way for intelligent drug delivery systems.

5.1.2. Gene delivery

There has been a significant focus on utilizing hierarchical MBGs as intelligent platforms for gene delivery. These platforms facilitate specific targeted responses and the dissolution of ionic products, subsequently activating orchestrated cascade signaling in the tissue's physiological environment [40,164,217]. Gene delivery, in general, involves the transportation of nucleic acids with biological functions into target cells, their expression within cells, and the realization of specific functions. This process has been widely utilized in studying genome function and disease therapy. The target gene must overcome various obstacles to successfully enter cells, express in the nucleus, and undergo replication and expression. Each step can significantly impact the efficiency of gene delivery and ultimately determine the success of gene transfection.

Of note, MBGs exhibit favorable morphological attributes that make them desirable for gene therapy through the hosting and delivery of biological molecules such as plasmid DNA or siRNA [218,219]. For instance, Kim et al. [220] successfully prepared a gene delivery nanocarrier based on MBGs to load BMP2 plasmid DNA, resulting in high cell uptake levels in mesenchymal stem cells and subsequent promotion of the expression of bone-related genes. Additionally, amine-functionalized MBGs were fabricated as siRNA delivery systems to silence genes and suppress the expression of the receptor activator of nuclear factor kappa B (RANK) for repairing damaged bone tissue. This degradable inorganic nanoplatform exhibited strong complexation with siRNA and effectively inhibited osteoclastic activity [121].

In conclusion, engineered MBGs hold promise as gene delivery systems for disease therapy due to their superior attributes, such as biocompatibility, biodegradability, high loading capacity, and intracellular uptake rate.

5.1.3. Growth factor delivery

It is promising to incorporate growth factor into MBGs and to exert collaborative effects with bioactive materials [221,222]. MBGs, with their excellent properties such as a higher specific surface area and pore volume, have been utilized to load various functional growth factors like BMP, vascular endothelial growth factor (VEGF), transforming growth factor beta (TGF-β), aiming to promote bone regeneration. In addition to these typical growth factors, brain-derived neurotrophic factor (BDNF) has emerged as another therapeutic molecule involved in fracture healing [83]. Kauschke et al. designed MBGs/bone cement composite scaffolds with or without BDNF to compare their effects on fracture healing. The results demonstrated that BDNF-functionalized MBGs/cement significantly enhanced bone formation ability, increased ALP activity, while reducing infiltrated leukocyte numbers and concentrations of C-reactive protein (CRP) compared to controls without BDNF. Therefore, the controlled delivery of growth factors or cytokines may prove to be an efficient approach for disease treatment [223].

5.2. Cancer diagnosis and therapy

MBGs hold great promise for cancer therapy due to their unique properties including low toxicity, high biodegradability and biocompatibility, ease of targeted and controllable anti-tumor drug delivery, and being doped with anti-tumor and magnetic ions [[240], [241], [242]]. Recently, advanced fabrication of MBGs-based nanoplatforms with optimal nanostructure and surface functionalization has sparked great interest in cancer nanomedicine (see Table 4). For example, MBGs have been proven to be valuable vehicles for anti-tumor drug delivery, producing multifunctional actions [225]. Modulation of certain parameters such as the degradation rate of MBGs, initial concentration of loaded drugs, and variation in the pH of the microenvironment could be promising strategies to achieve high-efficiency anticancer therapy. Furthermore, targeted therapy is another focus of cancer research with excellent characteristics that reduce side effects of drugs and elicit powerful lethality to tumor cells. MBGs-based targeted drug delivery has recently been proposed for anti-cancer therapy. In one case, Lin et al. fabricated functionalized MBGs with folate groups and then loaded them with camptothecin, which selectively bonded with folic acid receptors, resulting in a higher kill rate of tumor cells [243].

Table 4.

Representatively engineered MBGs-based nanoplatforms and systems for cancer diagnosis and therapy.

| Nanoplatforms | Engineering strategies | Therapeutic advantages | Ref. |

|---|---|---|---|

| Multifunctional Eu-Gd-Si-Ca MBGs | Integration of Eu-Gd-Si-Ca active irons into MBGs for tumor imaging, inhibiting recurrence and promoting impaired tissue regeneration. | Controlled biodegradation; Ultrahigh drug loading; PH responsive release; Tumor cell-targeted surface; Branched mesoporous structure; Special magneto-optical properties. |

[254] |

| Aminated MBGs | Aminated MBGs were applied for alendronate delivery. | Large surface area; Controlled drug delivery; Stimulatory bone regeneration. |

[225] |

| MBGs/polyurethane nanocomposites | Bioactive nanocomposite was fabricated by using MBGs and biodegradable polyurethane. | Controlled delivery; Enhanced mechanical property. |

[41] |

| Dendritic MBGs nanosphere | Dendritic MBGs were fabricated by adjusting calcium content in silica matrix system. | Large specific surface area; Variable mesoporous channels; Controlled anti-cancer drug delivery; Calcium influx-mediated specific tumor suppression. |

[46] |

| Europium-containing MBGs | Doping of Eu ions into MBGs for intelligent delivery of doxorubicin. | Large surface area; High pore volume; Enhanced mechanical property; Controlled drug delivery; Stimulatory bone regeneration. |

[149] |

| Sm/MBGs/Alginate microspheres | Incorporation of Sm into the network of MBGs; Surface functionalization of MBGs with alginate hydrogels. |

Acceptable biocompatibility; Controlled drug delivery; Stimulatory bone regeneration; Microenvironment modulation. |

[78] |

| Multifunctional magnetic MBGs | Incorporating Fe/Fe3O4 into the nanostructure of MBGs for tumor therapy. | Super-paramagnetic features; Improved mechanical property; Controlled drug delivery; Hyperthermia and photothermal properties. |

[[255], [256], [257]] |

| Copper-containing magnetic MBGs | Impregnation of copper ion into the nanostructure of magnetic MBGs for infectious diseases and tumor therapy. | Acceptable bioactivity; Antibacterial activity; Super-paramagnetism features; Controlled drug delivery; Stimulatory bone regeneration. |

[216] |

| Molecular gated MBGs | Surface functionalization of MBGs with adenosine triphosphate (ATP) and e-poly-llysine molecular gates. | Superior biodegradability; High surface area; Dual-drug loading system; Controlled drug delivery. |

[45] |

Immunotherapy is widely recognized as a promising targeted-tumor therapeutic strategy due to its high specificity, efficiency, and adaptability, utilizing the patient's own immune system to recognize and destroy tumor cells instead of relying on exogenous toxic substances [[244], [245], [246]]. Certain tumor immunotherapies, such as immune checkpoint blockade therapy, adoptive cell therapy, and cancer vaccines, have demonstrated significant advantages in clinical trials [[247], [248], [249], [250]]. Thanks to advancements in nanotechnology, multifunctional MBGs materials have been developed with high biocompatibility, porosity, self-adjuvanticity, and ease of surface modification, showing great promise in cancer immunotherapy and modulation of the tumor microenvironment [251,252]. It is important to note that the tumor microenvironment often creates immune-suppressive conditions and weakens immune activity. However, multifunctional MBGs can deliver various drugs specifically to tumors and release them responsively, as well as enhance the efficacy of immunotherapy by modulating the tumor microenvironment where immune cells may encounter antigens, stimulatory signals, cancerous cells, or other immunomodulatory cells [253].

Taken together, multiple unique features involving tailorable nanoscale morphology and modifiable surface chemistry, endow the advanced MBGs with excellent capability of molecule loading/release, which make it become a promising nanoplatform for targeted drug delivery.

5.3. Tissue regeneration

Numerous studies, conducted through in vivo experiments and animal models, have showcased the immense potential of engineered MBGs in the regeneration of both hard and soft tissues [[258], [259], [260]]. MBGs possess inherent properties that promote vascularization, enzyme activity, and mesenchymal stem cell differentiation. They find utility as bone graft materials and play crucial roles in coatings for dental or orthopedic implants [195,[261], [262], [263]]. For instance, Wang et al. utilized 3D-bioprinting technology to create polycaprolactone/MBGs/doxycycline scaffolds, which demonstrated dual functionality by increasing osteogenic activity and broad-spectrum bacterial inhibition. These scaffolds released BMP2 to actively stimulate osteoblast differentiation and induce ectopic bone formation [83]. Similarly, the reconstruction of osteochondral defects necessitates scaffold materials that simultaneously promote cartilage and subchondral bone morphogenesis to restore joint structural integrity and functionality. Lin et al. synthesized hierarchical PEGylated poly (glycerol sebacate) scaffolds through a spontaneous pore-forming and solvent-free urethane cross-linking procedure. By combining MBGs with viscoelastic low-crosslinked PEGS, they constructed a bifunctional MBGs/PEGS bilayer scaffold. This scaffold facilitated chondrogenic differentiation, enhanced cartilage matrix secretion, maintained chondrocyte phenotype, and successfully reconstructed integrated articular hyaline cartilage and its subchondral bone [80]. Recent studies also indicate great interest in using MBGs for dental regeneration [221]. For example, Mocquot et al. fabricated fine and large particles with fixed biological glass composition, which exhibited excellent cytocompatibility and bioactivity on human dental pulp cells [195]. Lee et al. employed 3 % propylamino triethoxysilane to aminate MBGs (MBGs-NH2), effectively reversing their charge from negative to positive. Consequently, MBGs-NH2 induced odontogenic differentiation of dental pulp stem cells [238,264,265]. MBGs-based biomaterials may serve as potential additives for dentin regeneration [266].

Chronic wounds present a significant global health issue and impose a substantial burden on patients and healthcare systems. Recent studies have demonstrated the potential of utilizing biological glass to stimulate angiogenesis and accelerate healing in soft tissue wounds, positioning MBGs as promising materials for chronic wound applications. For instance, Wang et al. developed a composite scaffold by combining copper-containing MBGs (Cu-MBGs) with nanofibrillated cellulose (NFC). Cu-MBGs exhibited high bioactivity when exposed to simulated body fluids and displayed dose-dependent cytotoxicity on fibroblasts due to the presence of copper cations. Furthermore, the incorporation of Cu-MBGs into the NFC matrix enhanced the angiogenic effects on human umbilical vein endothelial cells [267]. These findings suggest that Cu-MBGs could serve as dressing materials for chronic wound healing. In another case, researchers successfully prepared an Ag-doped MBGs/poly (1,8-octanediol citrate) elastomeric composite scaffold using the salt-leaching technique. Among these scaffolds, Ag-MBGs exhibited favorable biocompatibility with human dermal fibroblast cells, highlighting the potential of MBGs-based biomaterials as intriguing candidates for soft tissue healing [261]. In conclusion, MBGs, as captivating materials possessing excellent bioactivity, biocompatibility, and biodegradability, hold promise for a variety of soft tissue repair and organ regeneration applications in the future.

In summary, although MBGs have been applied in the repair and regeneration of hard and soft tissue defects, the next research direction lies in developing multifunctional MBGs through advanced nanoengineering techniques. This will aim to enhance their in vivo biological activity, reduce foreign body reactions, and ultimately enable theranostic applications.

5.4. Infectious diseases