Abstract

The use of supplementary cementitious materials has been widely accepted due to increasing global carbon emissions resulting from demand and the consequent production of Portland cement. Moreover, researchers are also working on complementing the strength deficiencies of concrete; fiber reinforcement is one of those techniques. This study aims to assess the influence of recycling wheat straw ash (WSA) as cement replacement material and coir/coconut fibers (CF) as reinforcement ingredients together on the mechanical properties, permeability and embodied carbon of concrete. A total of 255 concrete samples were prepared with 1:1.5:3 mix proportions at 0.52 water-cement ratio and these all-concrete specimens were cured for 28 days. It was revealed that the addition of 10 % WSA and 2 % CF in concrete were recorded the compressive, splitting tensile and flexural strengths by 33 MPa, 3.55 MPa and 5.16 MPa which is greater than control mix concrete at 28 days respectively. Moreover, it was also observed that the permeability of concrete incorporating 4 % of coir fiber and 20 % of WSA was reduced by 63.40 % than that of the control mix after 28 days which can prevent the propagation of major and minor cracks. In addition, the embodied carbon of concrete is getting reduced when the replacement level of cement with WSA along with CF increases in concrete. Furthermore, based on the results obtained, the optimum amount of WSA was suggested to be 10 % and that of coir fiber reinforcement was suggested to be 2 % for improved results.

Keywords: Cementitious material, coir fiber, Embodied carbon, Mechanical characteristics, Wheat straw ash

Abbreviations List

- WSA

Wheat Straw Ash

- CF

Coir fibers

- PC

Portland Cement

- SCM

Supplementary Cementitious Material

- FA

Fine Aggregate

- CA

Coarse Aggregate

- CM

Control Mixture

- MPa

Mega Pascal

- MOE

Modulus of Elasticity

- CO2

Carbon Dioxide

- TCM

Ternary Cementitious Materials

- CBA

Coal Bottom Ash

- SCBA

Sugarcane Bagasse Ash

- MK

Metakaolin

- MHA

Millet Husk Ash

- NDT

Non-destructive Testing

1. Introduction

Concrete is considered one of the most adaptable and commonly utilized building materials on the planet [1,2] as it possesses numerous advantages over stone, bricks, and steel, etc. because of its properties like moldability, durability, and fire resistance, etc. [3]. With such wide acceptance, It is used to build many different kinds of structures, such as homes, highways, tunnels, buildings, and commercial properties [4]. It is composed of Portland Cement (PC), fine and coarse aggregates, water, and additives [5]. With each passing day, the need for cement also increases owing to the extensive utilization of concrete. The present usage of PC is assessed to be over 12 million tonnes annually and is increasing day by day [6,7]. The manufacture of cement is extremely harmful to the environment since it generates heat and emissions of carbon dioxide [[8], [9], [10], [11]].

Moreover, the minerals used to manufacture cement contributes to the loss of environmental assets [12]. In reality, the utilization of natural assets like natural aggregates as well as PC as a binding agent for concrete mixtures has resulted in depletion of a great number of natural resources [13]. Environmentally speaking, concrete manufacturing is the primary emitter of greenhouse gases [14]. Based on current facts, the global annual making of concrete is around 1.6 billion metric tons, resulting in the release of 7 %–10 % of carbon dioxide [15]. Because of these environmental problems, the price of construction materials, scarcity of raw resources, need for energy, and use of solid waste as a replacement have all become global problems [16]. Therefore, many research scholars have taken efforts to minimize the use of cement in concrete and replace cement in concrete mixtures with such appropriate unused constituents, which induce the assets such as the cement in concrete. The emphasis is being placed on the exploitation of commercial and agricultural byproducts, that are a burden on the ecosystem, since their safe disposal demands significant effort but still burdens the ecosystem [17]. It is believed that its usage in concrete is highly advantageous since it is not just economically feasible, but also reduces the need for cement, thereby protecting the environment [17]. Such practices of using industrial and agricultural waste in concrete also help in the safe disposal of said wastes [18,19]. Most research scholars have conducted experimental investigations focusing on the possibility of finding alternatives for cement replacement materials [20]. These alternatives are of low value, including industrial/agricultural waste, and their possible aids can be attained through reprocessing, reuse, and renewal procedures [[21], [22], [23]]. Therefore, scientists are studying the effective and practical utilization of agricultural wastes which are pozzolanic and are best suited to potential cement-replacing materials [24]. The researchers believe that the consumption of additional binders in concrete could help decrease the negative effects on the atmosphere that come with making cement or concrete [21,25]. By consuming such wastes as supplementary cementitious material (SCM) in concrete, it is possible to conserve a significant amount of energy and minimize cement use, which helps to reduce carbon dioxide emissions into the environment [[26], [27], [28]]. In addition, the usage of supplementary binders in concrete can significantly grow strength and durability. Therefore, another few compounds, including millet husk ash [29], rice husk/straw ash [30,31], corn cob ash, peanut husk ash [32], and sugar cane bagasse ash [33,34], fly ash [35] have indeed been thoroughly examined [36] sewage sludge ash, wheat straw ash [[37], [38], [39], [40]] and palm shale oil, etc. [41].

In addition, a significant agricultural output of cereal production is wheat straw waste which contributes to environmental contamination since it is burned in open areas by farms. Meanwhile, wheat is the greatest grain crop and is among a billion people's biggest food sources (FAO, 2020). From 2016 to 2017, global wheat production is estimated at 750 million tons. Pakistan also ranks as one of the greatest suppliers of wheat on the planet. From 2017 to 2018, Pakistan's annual wheat production is estimated at 26.6 million tons [42,43]. Approximately 1.3–1.4 kg of wheat straw are produced per kilogram of wheat grain according to Pan et al. [44]. The vast majority of this wheat straw is utilized to feed animals [45]. In rare instances, however, it has been discovered that burning wheat straw in an open location might result in environmental pollution (smog) and related health issues for residents. In a few cities in Pakistan, for example, it has been said that respiratory illnesses and car accidents are mentioned [46]. Recent studies have studied the purpose of WSA as a possible extra-binding element in concrete [[47], [48], [49]]. The efficiency of WSA as pozzolanic substantial primarily be subject to its source, therefore, due to changes in soil and weather conditions, the composition of WSA will change from one area to another [46,49]. Though the resultant ash has a larger proportion of silica and is finer than cement, hence wheat straw ash (WSA) is regarded as a potential supplemental cementing agent to enhance hardened concrete [48] but the main drawback of concrete is that it is weak under tensile loads [50].

To address such shortcomings, several kinds of fiber are added to concrete mixtures such as polypropylene, steel, plastic, jute, nylon, hemp, human hair, etc. [[51], [52], [53], [54], [55], [56]]. In this study, a volume percentage of coir (or coconut) fiber is included in the concrete. Nonetheless, coir fiber is an agricultural byproduct derived from the production of coconut oil. It may be utilized extensively throughout tropical parts of the globe, particularly in Africa, Asia, and the United States. Coir fiber is seldom utilized in the building sector since it is often dumped as agricultural residue [57]. Though, given the need for low-cost housing for rural and urban residents in developing countries, a number of schemes to reduce the cost of traditional construction materials have been proposed. The search for, development of, and use of alternative, non-traditional local building materials is one of the most creative ideas. For example, some agricultural waste and leftovers could be used as a building construction resource reinforcement [58]. The industrial manufacture of coir fiber, which could be utilized as concrete reinforcement, is one such alternate way. The factory generates a great deal of coir fiber trash. Presently, industrial combustion waste disposal procedures are conducted uncontrollably, considerably adding to environmental pollution. Thus, disposing of such wastes in an ecologically responsible way becomes costly. In this instance, attempts are being undertaken to increase the consumption of these wastes by creating goods with added value. One option for reducing waste is to use coir fiber as reinforcing components in construction products. In addition, the use of fiber in the mixture of concrete to improve the ductility and strength started in the early twentieth century [59,60]. Fibers in concrete can improve tensile and flexural strength [[61], [62], [63], [64], [65]], slow crack propagation, and increase toughness [66]. The fiber can control cracking caused by plastic shrinkage and drying shrinkage [67]. Therefore, a lot of research study has been conducted on coir (or coconut) fiber as reinforcement material and WSA used as cement substitution material in concrete individually. Moreover, no experimental work on the combined use of coir fiber as reinforcement and WSA as cement substitutions in concrete was found in the available extensive literature. Hence, the key purpose of this study is to fill this gap by using WSA as cement substitutions along with coir fiber in concrete for determining the workability, mechanical characteristics, permeability, and embodied carbon of concrete.

2. Experimental Program

2.1. Materials

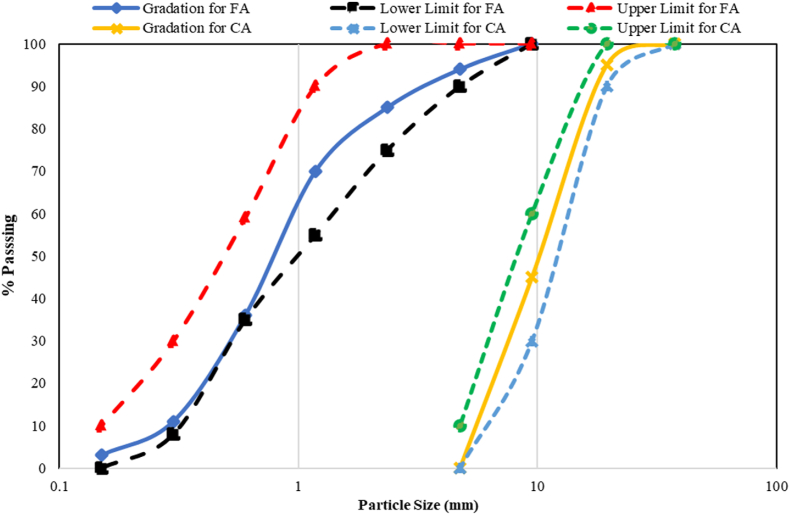

The widely accessible coir fiber was employed as a reinforcing ingredient in concrete. However, coir fiber is obtainable in a variety of lengths between 10 mm and 30 mm with a diameter of 0.2 mm. The properties of coir fiber are indicated in Table 1. In addition, wheat straw was collected and then burned for 5 h at 500 °C–750 °C under a controlled combustion setup to turn it into wheat straw ash (WSA). After achieving the ash, it was put through a 75 μm mesh to get rid of big pieces and then used in place of cement in the mixture. Besides, Portland cement (PC) was utilized as binding material under the brand name Lucky Cement obtained from the local market. The chemical composition of cement is detailed in Table 2. In addition, the crushed stone was obtained and it was utilized as coarse aggregates (CA) having 20 mm in size and hill sand was collected which passed through the 4.75 mm sieve and it was utilized as fine aggregates (FA). The aggregates' physical characteristics are shown in Table 3. Moreover, the sieve analysis of aggregates was conducted in accordance with ASTM C136:2019 as shown in Fig. 1 while the water absorption and specific gravity of sand were accomplished by using ASTM C128:2015. Likewise, the water absorption and specific gravity of CA were done by obeying ASTM C127-93, while the bulk density test for FA and CA was done in accordance with ASTM C29-97. Besides, tap water was used for the manufacturing and curing of experimental materials.

Table 1.

| Kind of fiber | Chemical components (%) |

|||||

|---|---|---|---|---|---|---|

| Lignin | Cellulose | Pectin's Related Compound | Hemi-cellulose | Water Soluble | Ash | |

| CF | 45.84 | 43.44 | 3.33 | 0.25 | 5.25 | 2.22 |

Table 2.

Chemical composition of WSA and PC.

| Materials | Oxides (%) |

Physical Property |

||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | SO3 | LOI | Specific Gravity | |

| WSA | 67.34 | 6.44 | 4.36 | 10.60 | 0.47 | 1.85 | ||

| PC | 20.78 | 5.11 | 3.17 | 60.22 | 0.18 | 2.86 | 2.45 | 3.13 |

Table 3.

Physical properties of aggregates.

| Property | FA | CA |

|---|---|---|

| Specific Gravity | 2.61 | 2.65 |

| Fineness Modulus | 2.15 | 6.75 |

| Bulk density (kg/m3) | 1845 | 1630 |

| Absorption (%) | 1.30 | 0.75 |

Fig. 1.

Sieve analysis curve of FA and CA

2.2. Mix proportions

This study was performed on the seventeen mixes introduction of 0%–20 % WSA as a substitution for PC and 1%–4% of coir fiber as reinforcement material together in concrete to investigate the fresh (slump) and hardened properties (compressive, split tensile and flexural strength and permeability) of concrete. However, concrete specimens were made of seventeen concrete mixtures at a 1:1.5:3 mix proportion with a 0.52 water-cement ratio, in which one mixture was done with PC only, and the remaining all mixture of concrete was made with an addition of 5 %–20 % WSA by the mass of PC along with 1 %–4 % of coconut fiber as reinforcement material as indicates in Table 4.

Table 4.

Mix the proportion of high strength concrete.

| Mix ID | Binding and CF Materials (%) |

Mass of constituents needed to Produce 1 m3 Concrete (kg) |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| PC | WSA | CF | PC | WSA | CF | FA | CA | Water | |

| C | 100 | 0 | 0 | 373 | 0 | 0 | 560 | 1120 | 180 |

| WSA5CF1 | 95 | 5 | 1 | 354.35 | 18.65 | 20.53 | 560 | 1120 | 180 |

| WSA5CF2 | 95 | 5 | 2 | 354.35 | 18.65 | 41.06 | 560 | 1120 | 180 |

| WSA5CF3 | 95 | 5 | 3 | 354.35 | 18.65 | 61.59 | 560 | 1120 | 180 |

| WSA5CF4 | 95 | 5 | 4 | 354.35 | 18.65 | 82.12 | 560 | 1120 | 180 |

| WSA10CF1 | 90 | 10 | 1 | 335.70 | 37.30 | 20.53 | 560 | 1120 | 180 |

| WSA10CF2 | 90 | 10 | 2 | 335.70 | 37.30 | 41.06 | 560 | 1120 | 180 |

| WSA10CF3 | 90 | 10 | 3 | 335.70 | 37.30 | 61.59 | 560 | 1120 | 180 |

| WSA10CF4 | 90 | 10 | 4 | 335.70 | 37.30 | 82.12 | 560 | 1120 | 180 |

| WSA15CF1 | 85 | 15 | 1 | 317.05 | 55.95 | 20.53 | 560 | 1120 | 180 |

| WSA15CF2 | 85 | 15 | 2 | 317.05 | 55.95 | 41.06 | 560 | 1120 | 180 |

| WSA15CF3 | 85 | 15 | 3 | 317.05 | 55.95 | 61.59 | 560 | 1120 | 180 |

| WSA15CF4 | 85 | 15 | 4 | 317.05 | 55.95 | 82.12 | 560 | 1120 | 180 |

| WSA20CF1 | 80 | 20 | 1 | 298.40 | 74.60 | 20.53 | 560 | 1120 | 180 |

| WSA20CF2 | 80 | 20 | 2 | 298.40 | 74.60 | 41.06 | 560 | 1120 | 180 |

| WSA20CF3 | 80 | 20 | 3 | 298.40 | 74.60 | 61.59 | 560 | 1120 | 180 |

| WSA20CF4 | 80 | 20 | 4 | 298.40 | 74.60 | 82.12 | 560 | 1120 | 180 |

2.3. Testing methods

2.3.1. Fresh state test

The slump test was conducted on the seventeen mixes of concrete including numerous proportions of WSA as cement replacement material and several percentages of coir fiber by the volume fraction combination by ensuing the standard designated in ASTM C143-90 [70].

2.3.2. Mechanical properties

The mechanical qualities of concrete were attained in terms of compressive strength, splitting tensile strength, flexural strength, modulus of elasticity, and permeability. Nonetheless, compressive strength testing was conducted on 100 mm × 100 mm x 100 mm cubes of the mixture containing varying percentages of WSA as cement substitute material and several percentages of coir fiber by the volume fraction combination under the ASTM C39/C39 M [71] while the indirect tensile strength was performed on cylindrical specimens (200 mm × 100 mm) of concrete including numerous proportions of WSA as cement replacement material and several percentages of coir fiber by the volume fraction in combination by following the ASTM C 496-90 [72]. In the same way, the flexural strength was established over beam (500 mm × 100 mm x 100 mm) of concrete including various percentages of WSA as cement replacement material and several percentages of coconut fiber by the volume fraction in combination by observing the ASTM C293/293 M [73] standard. In addition, the permeability and modulus of elasticity were checked via concrete specimens including various percentages of WSA as cement replacement material and several percentages of coconut fiber by the volume fraction in combination by using the BS EN 12390-8 [74] and ASTM C 469 [75] consistently. All the mentioned mechanical properties of concrete were tested after 28 days in the age of curing. Moreover, the statistical analysis of all properties of concrete were checked for knowing the standard deviation, mean, coefficient of variance, R-square and other parameters by using ANOVA technique.

3. Results and discussions

3.1. Slump test

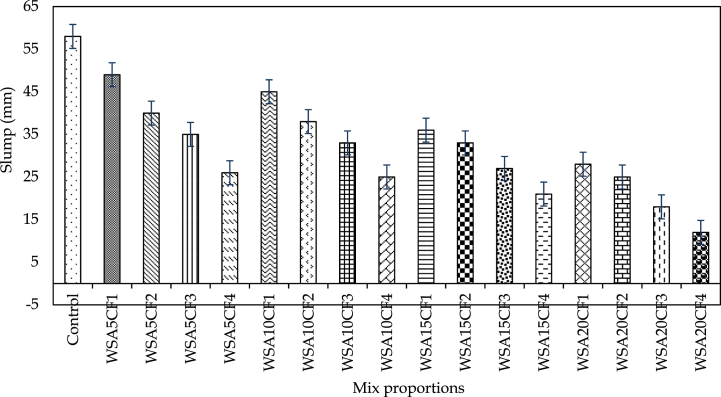

The workability of WSA concrete reinforced with several contents of coir fiber was evaluated in terms of slump value obtained for fresh-state concrete mix and results are presented in Fig. 2. The optimum workability is measured by 58 mm at CM while the lowest workability is recorded by 12 mm at WSA20CF4. It was detected that, with the increase in contents of WSA and coir fiber, the slump value decreased which implies a reduction in flowability and/or workability of concrete. The drop in workability of concrete can be ascribed to an increase in the stiffness of concrete due to a larger specific area of WSA and an increase in the water demand of concrete owing to higher water absorption of coir fibers. The results are in line with the results of Katman et al. [69]. This finding is consistent with that of [48], whereby a WSA was utilized as a sand substitute. However, the existing research indicates that the addition of supplementary cementitious materials tends to diminish the flowability properties of fresh mixture owing to the subsequent matrix stiffness [[76], [77], [78]]. As a suitable approach, admixtures may be added to concrete to compensate for the slump loss. According to the existing research, fibres reduce the amount of water needed for concrete to be useable and flowable while increasing the amount of water that is absorbed [50,51,56,79]. Shar et al. [80] stated that the slump flow is getting declined as the extent of WSA rises in the concrete. Similar kind of observation was done by researchers [15,81,82].

Fig. 2.

Workability of coir fiber reinforced wheat straw ash concrete.

3.2. Compressive strength

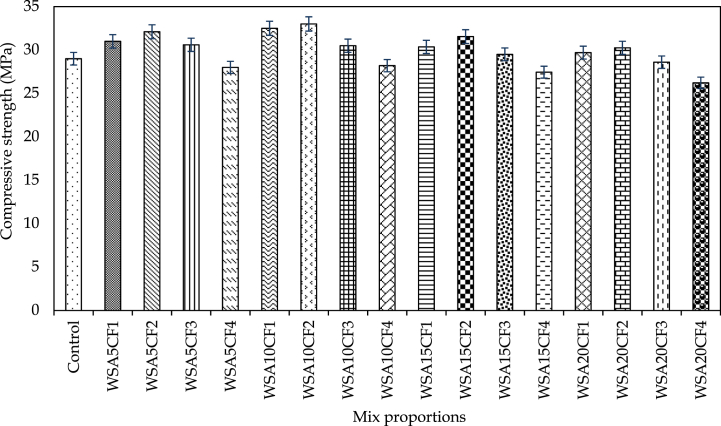

Fig. 3 demonstrates the influence of the combined inclusion of WSA as supplementary cementitious material and coir fiber as reinforcement at 28 days.

Fig. 3.

Compressive strength of coir fiber reinforced wheat straw ash concrete.

It was observed that with the accumulation of coir fiber and WSA content in concrete, the strength of concrete was initially increased while declining beyond a certain limit. The optimum dosage of WSA and coir fiber used in combination was found to be WSA10CF2 where the compressive strength of coir fiber reinforced wheat straw ash concrete was found to be 33 MPa after 28 days. The increase in the strength of concrete is due to the fact that supplementary cementitious materials make the concrete stiffer to sustain loads, while the fibers also add to the strength due to their intrinsic reinforcement characteristics [5,76]. However, the decline in strength can be attributed to the creation of voids in concrete due to the addition of fibers [15,82] and the reduction of the specific surface area of binder due to the addition of cementing material in concrete [5,82]. In addition, several published research on the usage of extra cementitious materials proposes a 10 % substitution as optimal strength [15,78]. The filling impact and pozzolanic characteristics of WSA boosted the compressive strength of mixture when the substituted level of WSA up to 10 %. Nevertheless, when WSA concentration and cement amount increased, the calcium hydroxide needed to react with silica decreased, resulting in a drop in strength. This may be ascribed to the fact that the presence of fibers encourages the aggregates to enter the pores to guarantee appropriate connection, but a rise in fiber extent causes bulkiness, distorting the connection and resulting in a reduction in strength. Furthermore, the entire concrete sample is prone to weakness due to the development of a poor transition zone surrounding the fibres. Also, contaminants on the surface of the fibers and the thickness of the fibers could make it harder to improve the bonding between concrete parts. Thus, it is evident that, while fibres make concrete stronger, there is usually an ideal degree of fibre incorporation [83]. Hwang et al. [84] reported that the incorporation of coir fibre in cement-based components with a large amount of fibre had a detrimental effect on the compressive strength. The researchers proposed that the decrease in strength might be attributed to the clumping of fibres inside the cement paste. The phenomenon of increased volume expansion in the material was found, indicating the presence of a microstructure with higher porosity. Similar trend was observed by researchers [69,82,83].

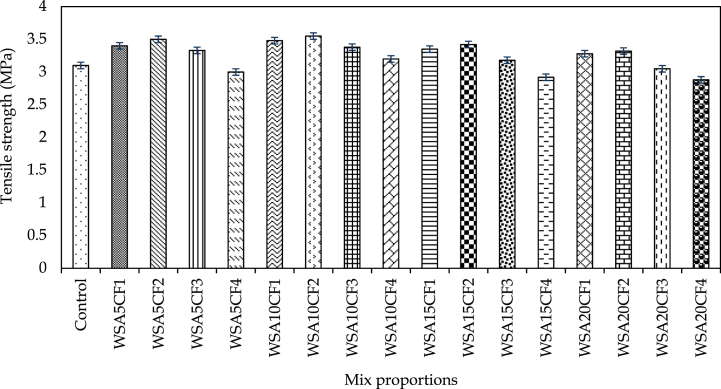

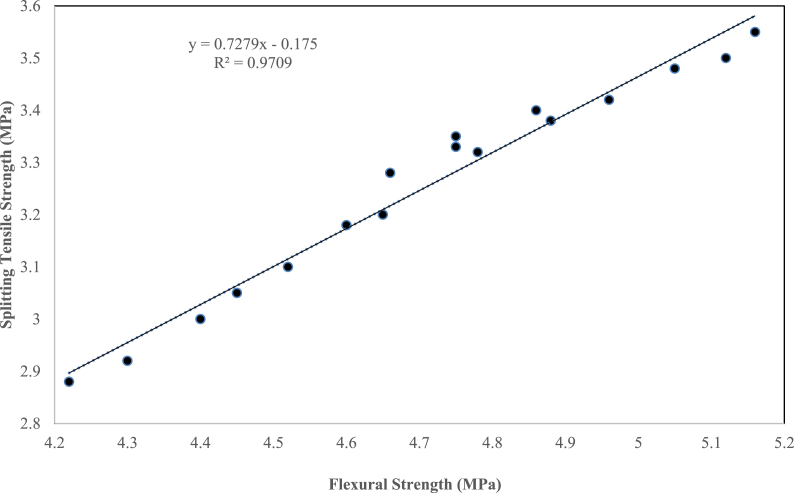

3.3. Splitting tensile strength

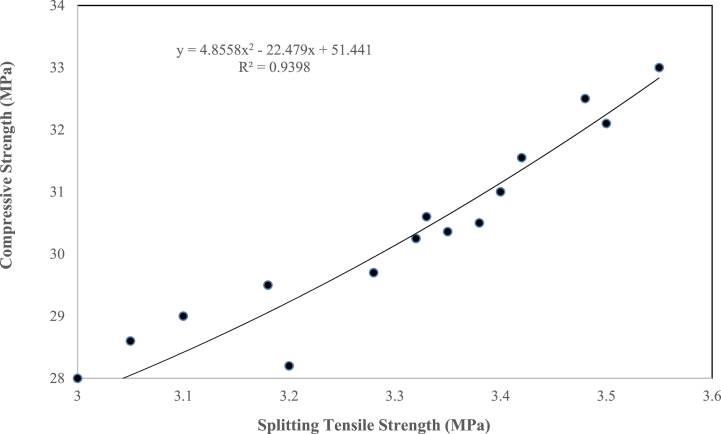

The splitting tensile strength test results of coir fiber reinforced wheat straw ash concrete are depicted in Fig. 4 at 28 days. A finding was made that with the addition of WSA as a supplementary substitution material and coir fiber as a reinforcement ingredient, the tensile strength of concrete was enhanced. The tensile strength values were recorded to be greater than that of control concrete for coir fiber reinforced wheat straw ash concrete at mixes i.e. WSA5CF1, WSA5CF2, WSA5CF3, WSA10CF1, WSA10CF2, WSA10CF3, WSA10CF4, WSA15CF1, WSA15CF2, WSA15CF3, WSA20CF1 and WSA20CF2. However, the maximum tensile strength was recorded for concrete specimens containing 2 % coir fibers and 10 % WSA as cement replacement. From the results, it can be deduced that the concrete strength was initially increased with the incorporation of WSA and coir fibers as cement replacement and reinforcement material respectively. However, it declined after yielding the WSA10CF2 mix as optimum for enhanced strength. The increase in strength can be associated with the observation that fibers prevent crack propagation [56] while the decline in strength can be attributed to the creation of voids in concrete due to the addition of fibers [56]. The cement replacement material i.e. WSA also played role in the observed phenomenon as initially, the concrete became stiffer and strength was increased while in later stages, the strength declined due to the fact that WSA has a higher specific area than that of other concrete ingredients say as aggregates and cement [5,56]. The study conducted by Filho et al. [85] focused on examining the effects of coir fibres on the free, limited, and drying shrinkage of cement mortar. As per the author's assertion, the incorporation of fibre derived from vegetables had a decelerating effect on the initial crack formation and subsequent propagation of fractures induced by tensile strain [85]. The primary influence is mostly associated with the fibre-bridging approach around the crack. According to Hwang et al. [84] and Sathiparan et al. [86], the inclusion of coir fibre in a material is effective in preventing the opening and propagation of cracks, owing to the fiber's stress-dispersing properties. Similar trend was performed by Katman et al. [69]. Moreover, Several investigations in the existing literature suggest that the optimal level for substituting cement with waste or supplemental cement-based substances is 10 % [39,40,82]. Furthermore, the good relationship between the compressive and splitting tensile strength of concrete combined with WSA as SCM along with coir fiber is revealed in Fig. 5. If one property of either the compressive strength or splitting tensile strength of concrete is known, the equation in Fig. 5 can be used to calculate it.

Fig. 4.

Tensile strength of coir fiber reinforced wheat straw ash concrete.

Fig. 5.

Relationship between splitting Tensile Strength and Compressive Strength.

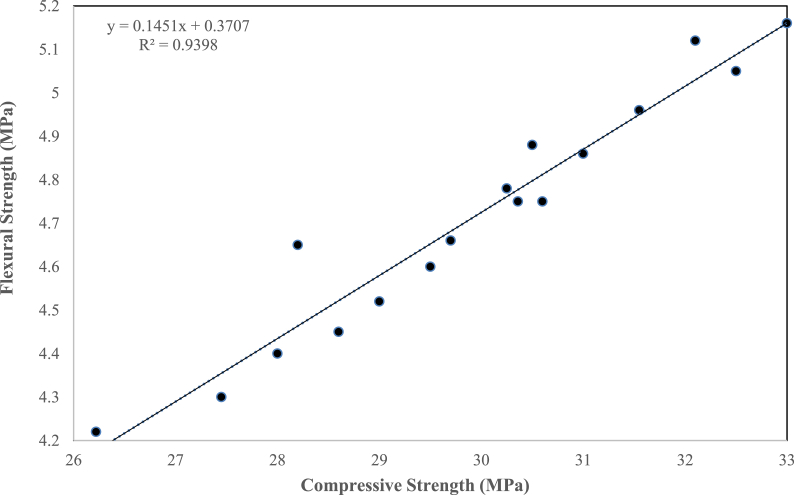

3.4. Flexural strength

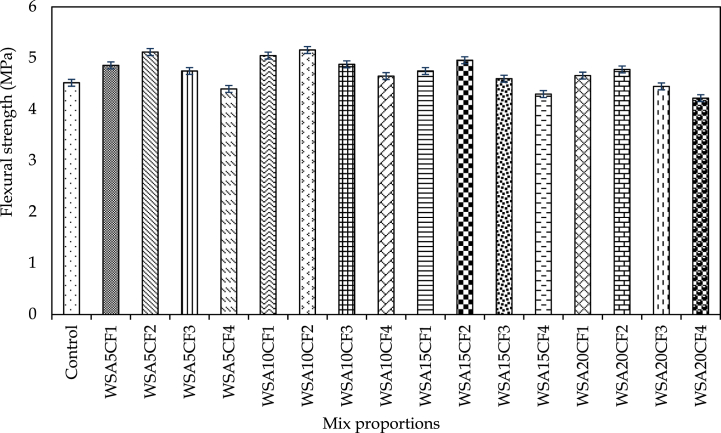

Fig. 6 shows the flexural strength of coir fiber-reinforced concrete along with wheat straw ash at 28 days. As identical to the trend observed in the tensile strength test, with the accumulation of WSA as an SCM and coir fiber as a reinforcement ingredient, the flexural strength of concrete was enhanced up to 5.16 MPa at 2 % coir fiber reinforcement and 10 % WSA incorporation as a cementitious resource after 28 days.

Fig. 6.

Flexural strength of coir fiber reinforced wheat straw ash concrete.

Moreover, the flexural strength was recorded to be greater than that of control concrete for coir fiber reinforced wheat straw ash concrete at mixes i.e. WSA5CF1, WSA5CF2, WSA5CF3, WSA10CF1, WSA10CF2, WSA10CF3, WSA10CF4, WSA15CF1, WSA15CF2, WSA15CF3, WSA20CF1 and WSA20CF2. However, the maximum flexural strength of concrete was recorded for concrete specimens containing 2 % coir fibers and 10 % WSA as cement replacement. It is hence, very evident that the flexural strength of coir fiber reinforced wheat straw ash concrete was initially increased but declined later on the increase in WSA and coir fiber quantities. However, the concrete mix i.e. WSA10CF2 was deemed optimum as it yielded increased strength. Such growth in strength can be accredited to the filler effect of cementing material [87,88] and the reinforcement characteristics of fibers [56,67] while the decline in the strength of concrete can be due to creation of voids due to addition of fibers in concrete [56,89] and the increase in specific surface area of WSA [5,15]. The results of this study are the same as those found by Qudoos et al. [90], who said that a 10 % replacement level is the best because the flexural strength of concrete went up when WSA was added. Similar trend was performed by researchers [39,40,69]. Moreover, Katman et al. [69] reported that the flexural strength was recorded optimum at 2 % of coir fiber in concrete at 28 days. Similar observation was noted in prior literature [84,86]. Furthermore, there is a strong relationship between the splitting tensile strength and flexural strength and compressive strength of concrete blended with coir fiber as reinforcement material along with WSA as SCM as shown in appendix.

3.5. Modulus of elasticity

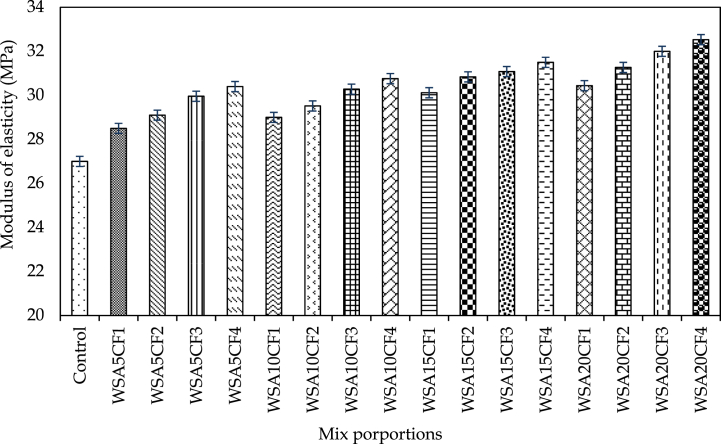

Fig. 7 shows the results of MOE of coir fiber reinforced wheat straw ash concrete on 28 days. It is evident from available results that, with the addition of coir fibers as reinforcement ingredient and WSA as cement replacing material, the stiffness of concrete increased and resulted in enhanced MOE of coir fiber reinforced wheat straw ash concrete after 28 days.

Fig. 7.

Modulus of elasticity of coir fiber reinforced wheat straw ash concrete.

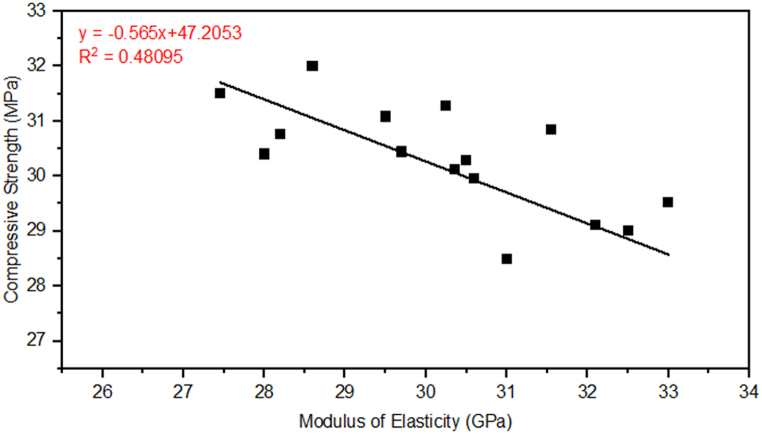

It was also noticed that every concrete mix modified with coir fiber reinforcement and cement blending with WSA, showed MOE greater than the control mix. Nevertheless, the MOE of concrete was enhanced by 20.5 % for the greatest dosage of coir fiber and wheat straw ash combination i.e. WSA20CF4. This phenomenon can be due to the fact that supplementary cementitious materials increase the stiffness of concrete and fibers add to the strength of concrete mixes [5,56,91]. It can, thus, be concluded that the use of coir fibers and wheat straw ash can be a viable option for enhancing the mechanical behavior of concrete. Several researchers have also conducted analyses on the modulus of elasticity (MOE) of cement-based materials, including vegetable fibre, and have confirmed the presence of a consistent pattern in the observed outcomes [92,93]. In a separate study conducted by Pereira et al., it was shown that larger sisal fibres exhibit higher crack resistance compared to smaller fibres [69,93]. Moreover, Katman et al. [82] found that the MOE of concrete is better when they are made with WSA, which has better pozzolanic properties and a higher silica content of 67 % after conditioning at 500 °C–700 °C. Ataie and Riding [94], who studied this, found that the mechanical strength of concrete went up when the silica concentration of WSA reached 86.5 %. This was done by treating the wheat straw's surface before it was burned. Furthermore, the good relationship between the compressive and modulus of elasticity of concrete accumulation with WSA as SCM along with coir fiber is revealed in Fig. 8. If one property of either the compressive strength or modulus of elasticity of concrete is provided, the equation in Fig. 8 can be used to calculate it.

Fig. 8.

Correlation between compressive strength and modulus of elasticity.

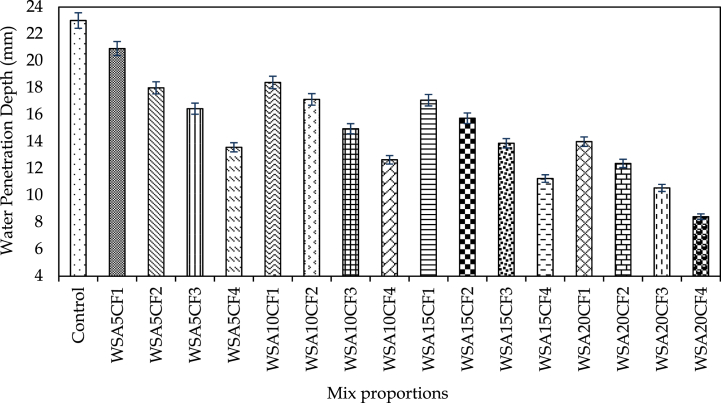

3.6. Permeability of concrete

The permeability of coir fiber-reinforced wheat straw ash concrete was evaluated by recording the results of water penetration depth after splitting the concrete specimens after 28 days. It can be deduced from the results available in Fig. 9, that the increase in contents of WSA and coir fibers reduces the permeability of concrete. It was observed that concrete containing no coir fibers and WSA, had the greatest value for water penetration depth.

Fig. 9.

Permeability of WSA concrete blended with coir fiber.

However, the permeability of concrete was reduced by 63 % for the greatest dosage of coir fiber and wheat straw ash combination i.e. WSA20CF4. These findings can be associated with the filler effect of secondary cementitious material i.e. WSA which tends to make the concrete matrix stiffer [78,82]. In addition, the literature has reported that fibers add to the strength of concrete which prevents crack propagation when concrete specimens are subjected to crushing loads [67,69]. These findings are consistent with those reported by Biricik et al. [15] in which metakaolin was utilized as a cementitious material to lower permeability by 29 % and WSA was employed as cement substitute ingredient in concrete. Moreover, the reduction in permeability of concrete due to fiber reinforcement is also reported in the literature by Bheel et al., in Ref. [56]. Furthermore, several researchers have also argued that the inclusion of coir fibre does not enhance the flowability of materials made from cement. Consequently, it becomes necessary to raise the water content of cement-based materials that include coir fibre as compared to those without it. The observed phenomenon is associated with the need for a significant level of water absorption and the inherent absorptive properties of the coir fibre [95]. Furthermore, it was observed that cement-based materials with a higher volume percentage of fibre exhibited an increased level of porosity. The findings of this study are consistent with previous research conducted in the field [93]. In conclusion, the incorporation of coir fibre into concrete results in a reduction in its permeability. There exists a correlation between the permeability of concrete and its modulus of elasticity and mechanical strengths, wherein concrete with lower permeability tends to exhibit higher values of these properties [69]. Similar type of trend was conducted by researchers in literature [39,69,82,94].

3.7. Statistical analysis of all properties of concrete

Incorporating statistical elements and factors into the technique of an experiment is imperative in order to uphold the dependability, replicability, and soundness of one's study outcomes. It is important to use strict statistical elements and parameters when doing a thorough study of the properties of concrete, especially when looking at properties like workability, compressive strength, splitting tensile strength, flexural strength, modulus of elasticity, and permeability as shown in Table 5. By integrating these statistical elements and variables into the methodology of the investigation on the characteristics of concrete, a transparent and robust framework is established. This framework facilitates the execution of the research, the analysis of the data, and the derivation of significant conclusions regarding the properties and performance of concrete under diverse circumstances. This technique not only boosts the trustworthiness of study results but also adds to a deeper scientific knowledge of concrete behavior and its practical implications. Furthermore, the p-value is significant for all properties of concrete because it is less than 0.05.

Table 5.

Statistical data of the properties of concrete.

| Model Validation Constraints | Slump | Compressive Strength | Tensile Strength | Flexural Strength | Modulus of Elasticity | Permeability |

|---|---|---|---|---|---|---|

| Number of Values | 17 | 17 | 17 | 17 | 17 | 17 |

| Minimum | 12 | 26.22 | 2.88 | 4.22 | 27 | 8.42 |

| Maximum | 58 | 33 | 3.55 | 5.16 | 32.53 | 23 |

| Range | 46 | 6.78 | 0.68 | 0.94 | 5.53 | 14.58 |

| Standard Deviation | 0.85 | 0.56 | 0.046 | 0.085 | 0.043 | 0.040 |

| Mean | 31.00 | 30.00 | 3.29 | 4.75 | 30.48 | 14.72 |

| Coefficient of Variance (%) | 2.76 | 1.87 | 1.39 | 1.80 | 0.14 | 0.27 |

| p-value | 0.001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.001 |

| Standard Error | 0.43 | 0.28 | 0.023 | 0.043 | 0.033 | 0.030 |

| R-Squared | 0.9951 | 0.9438 | 0.9651 | 0.9314 | 0.9994 | 0.9999 |

| Adj R-Squared | 0.9927 | 0.9158 | 0.9476 | 0.8971 | 0.9984 | 0.9999 |

| Pred R-Squared | 0.9871 | 0.8351 | 0.8951 | 0.8409 | 0.9464 | 0.9952 |

| Adeq Precision | 69.119 | 17.038 | 22.049 | 15.579 | 116.844 | 390.595 |

4. Sustainability assessment

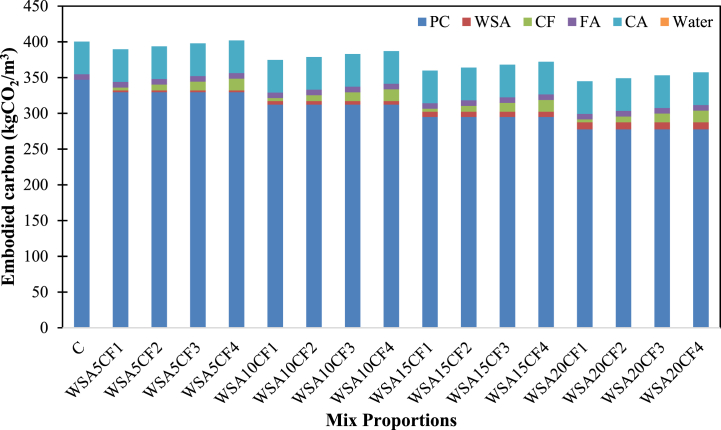

4.1. Embodied carbon

One of the main areas of research on which specialists are currently analyzing and looking for prospective replacements is the impact cement manufacturing has on the ecosystem. Using this technique, cement has been used in place of waste resources, and fiber is used as coir fiber by the volume fraction of concrete. Each waste item utilized as a possible concrete replacement is transported, processed, and sorted, creating embedded carbon in this procedure. But compared to cement, garbage has a substantially reduced embodied carbon concentration. The embodied carbon needs to be taken into account through the integration of WSA and CF in order to acquire industry acceptance as a sustainable concrete. Table 6 available information was used to determine comparable CO2 levels for each component. The manufacturing process, preparation, transportation, and mixing aspects are represented by these numbers. Additionally, the total CO2 emissions from each concrete mixture were calculated using Equation (1) [96], which included calculating the CO2 emissions from each raw material per 1 m3 of concrete and adding them.

| (1) |

where, is total embodied of 1 m3 concrete, in kg /m3

n is total raw materials in mix,

is total amount in kilogram of material

i to produces 1 m3 concretes

is equivalent value of material i in kg /kg

Table 6.

Embodied carbon of concrete constituents.

The embodied carbon of concrete is shown in Fig. 10, which incorporates CF and WSA as cementitious materials. Table 6 shows that Portland cement discharges the most carbon, along with certain coarse particles. Fig. 10 shows that WSA's impact on the embodied carbon of concrete is less than that of SCM and CF. Fig. 10 shows that using WSA in place of 5 %, 10 %, 15 %, and 20 % of the cement, together with 1 %, 2 %, 3 %, and 4 % of CF, results in concrete containing less embodied carbon than using CM. Increases in cement replacement percentage have been demonstrated to reduce embodied carbon. Additionally, the total embodied carbon emissions of 4 % of CF and 20 % of WSA were smaller than those of CM. By increasing the amounts of binding ingredients as substitute components in concrete mixes, a trend towards reducing the carbon emissions of concrete has been identified in previous research [[100], [101], [102]].

Fig. 10.

Embodied carbon of concrete containing WSA and CF.

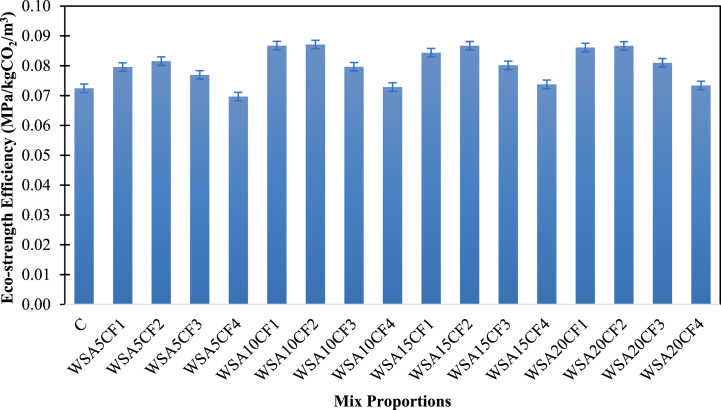

4.2. Eco-strength efficiency

Equation (2) [103] was used to measure the eco-strength of concrete made with coir fiber (CF) and wheat straw ash (WSA) as supplementary cementitious materials (SCM). The lowest recorded value was 0.072 MPa/kg /m3 for conventional concrete (CM), as depicted in Fig. 11. The best eco-strength efficiencies were found at 0.082 MPa/kg /m3, 0.087 MPa/kg /m3, 0.086 MPa/kg /m3, and 0.086 MPa/kg /m3, when 5 %, 10 %, 15 %, and 20 % of Portland cement (PC) was replaced with WSA and 2 % CF, respectively. The eco-strength efficiency of concrete exhibited a similar trend to its compressive strength. Initially, it increased with PC replacements up to 10 % while requiring only binder content and 2 % CF content. However, as these percentages increased further, the eco-strength efficiency decreased. Research suggests that the addition of SCM reduces the eco-strength of concrete, except when replacing up to 10 % of PC with WSA. This is due to WSA's lower embodied carbon content and higher compressive strength compared to other mixtures. According to Bheel et al. [103,104], the eco-strength efficiency improves when PC in concrete is accompanied by coal bottom ash (CBA), SCBA, metakaolin (MK), and MHA up to a 10 % replacement. However, the efficiency decreases further when incorporating SCM alone or with ternary cementitious materials (TCM).

| (2) |

Fig. 11.

Eco-strength efficiency of concrete containing WSA and CFs.

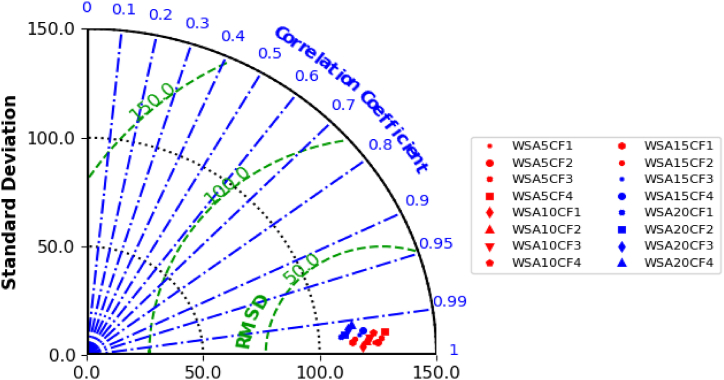

5. Box plot and Taylor Diagram

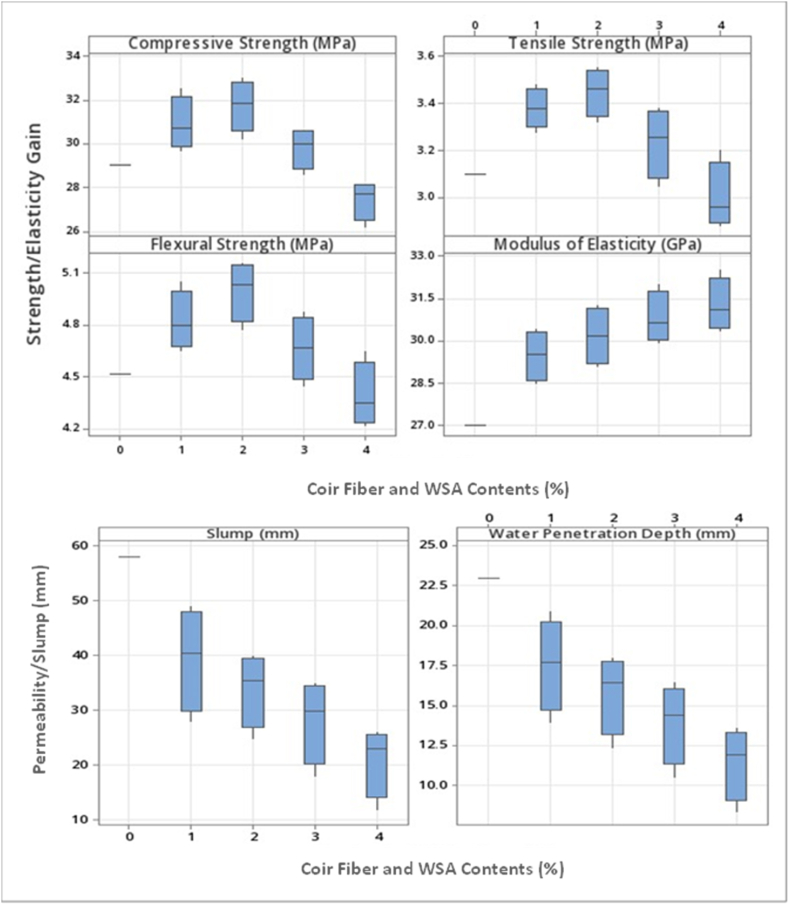

The use of a box plot diagram in the context of concrete reinforced with wheat straw ash and coir fiber serves as a graphical representation that concisely presents the distribution of data pertaining to several parameters, including workability, compressive strength, splitting tensile strength, flexural strength, modulus of elasticity, and permeability as shown in Fig. 12. The data visualization provides information on the median, quartiles, and potential outliers, facilitating the evaluation of central tendency, spread, and changes in these characteristics. This enables a comparative analysis of the performance of the changed concrete in relation to these parameters. The use of box plots for each parameter facilitates the comparison of the distribution of attributes, such as workability, strength (including compressive, splitting tensile, and flexural), modulus of elasticity, and permeability, in concrete samples with and without the inclusion of wheat straw ash and coir fiber. This aids in the visualization of the variations in these aspects and the determination of whether the adjustment has noticeable effects on the performance of the concrete.

Fig. 12.

Box Plot of all properties of concrete.

Moreover, the Taylor diagram serves as a visual tool for the comparative analysis of several performance metrics between concrete reinforced with wheat straw ash and coir fiber, in relation to a reference concrete as show in Fig. 13. Each parameter, namely workability, compressive strength, splitting tensile strength, flexural strength, modulus of elasticity, permeability, embodied carbon and eco-strength efficiency of concrete is subjected to normalization and thereafter shown as a data point on a circle diagram. The presence of longer lines relating the reference and modified points is indicative of enhanced performance in the respective metrics, facilitating a comprehensive evaluation of the overall influence of reinforcing on the characteristics of concrete. The use of these materials in concrete buildings might be advantageous in assessing the comprehensive performance and trade-offs involved.

Fig. 13.

Taylor Diagram of all properties of concrete reinforced with WSA and CF.

6. Conclusions

This investigational study investigated the possibility of consuming WSA as SCM and coir fibers (obtained from the outer shell of coconut) as reinforcement in concrete, separately and in combination. The results revealed that the coir fibers as reinforcement and WSA as SCM were used simultaneously in concrete and fresh-state and hardened properties of concrete were assessed. The key points are summarized below.

-

•

The workability of concrete was decreased in all cases i.e. inclusion of coir fibers and WSA at all modifications of the control mix. Nevertheless, the reduced workability can be compensated by the utilization of superplasticizers and/or admixtures in concrete.

-

•

The outcomes also suggested that coir fiber-reinforced wheat straw ash concrete compressive strength, splitting tensile strength, and flexural strength recorded by 33 MPa, 3.35 MPa, and 5.16 MPa at WSA10CF2 after 28 days respectively. It was concluded that the coir fiber reinforced wheat straw ash concrete demonstrated improved strength than that of the control mix.

-

•

Moreover, the permeability of concrete is getting reduced as the concentration of WSA and CF increases in mixture. In addition, the inclusion of coir fibers as reinforcement and WSA as SCM improved the stiffness of concrete and enhanced the elastic modulus of concrete to prevent the brittle failure of concrete subjected to crushing loads.

-

•

The embodied carbon of concrete is reducing when the content of WSA increases along with CF while the eco-strength efficiency of concrete is enhanced when the replacement level of PC with WSA up to 10 % along with 2 % of CF in concrete.

-

•

From the experimental outcomes, it is recommended that the use of 2 % CF along with 10 % of WSA as SCM in concrete is providing optimum outcomes for construction industry. Hence, a detailed study on the corrosion of concrete with the incorporation of WSA and coir fibers is recommended for future research. Moreover, the future scope of research also includes the simulation of this study on high-strength concrete and the concretes subjected to seismic loads so that the earthquake response of coir fiber reinforced wheat straw ash concrete may be assessed.

Advantages of the research

The study suggests using concrete with varying coir fibre and wheat straw ash concentrations as a cement substitute material, offering significant benefits in building materials and sustainable development, including potential advantages.

-

•

Improved Mechanical Properties: Through the incorporation of coir fibre and wheat straw ash, the mechanical properties of concrete mixtures could be improved. These enhancements in compressive strength, tensile strength, flexural strength, and modulus of elasticity can lead to structures that are more durable and resilient.

-

•

Enhanced Sustainability: The study advocates for environmentally friendly building techniques by utilizing coir fibre and wheat straw ash as cement substitutes, reducing the need for cement and reducing the environmental impact of concrete production.

-

•

Reduced Carbon Footprint: Research suggests wheat straw ash, a byproduct of agricultural waste, could reduce concrete's carbon footprint, potentially aiding climate change mitigation and promoting sustainable building practices.

-

•

Contribution to Scientific Knowledge: The research contributes to the body of scientific knowledge in the field of construction materials. It adds valuable insights into the interactions between coir fiber, wheat straw ash, and cementitious matrices, which can inform future studies and advancements.

In conclusion, the study has the potential to revolutionize building techniques by offering environmentally friendly substitutes and improving concrete's performance. The research promotes a more resilient and environmentally friendly built environment by tackling both technical and environmental aspects of building.

Limitations of the study

While there are various benefits to the proposed research on concrete mixed with wheat straw ash and coir fibre, it is crucial to recognise and deal with any possible restrictions that might affect the study's scope, validity, and applicability.

-

•

Material Variability: Due to variables including source, processing, and climatic conditions, natural materials like coir fibre and wheat straw ash may have a wide range of qualities. When preparing the material, this variability must be carefully considered and controlled since it might introduce uncertainty into the study findings.

-

•

Limited Applicability to Real-World Conditions: Real-world construction activities may not be perfectly replicated in laboratory conditions, and while laboratory research provides valuable insights, implementing these findings may present unexpected challenges.

-

•

Short-Term Testing: The study focuses on short-term testing to assess workability and early-age strength, but further research is needed to understand long-term performance in real-world scenarios.

-

•

Potential Degradation of Fibers: Natural fibres like coir may deteriorate over time as a result of environmental variables including dampness, microbe activity, and UV exposure. An investigation is necessary into the long-term effects of fibre deterioration on the mechanical characteristics of the concrete.

Research gap of the study

The current corpus of scholarly literature demonstrates a substantial body of research that has concentrated on investigating the specific uses of coir (or coconut) fibre as a material for reinforcing as well as wheat straw ash (WSA) as a substitute for cement in concrete. However, it is evident that there is a significant research gap in the field when considering the absence of experimental investigations that explore the synergistic use of coir fibre and WSA in concrete. The combined application of coir fibre as a reinforcing material and wheat straw ash (WSA) as a replacement for cement has received little attention in the existing body of research. No identified studies have particularly investigated this unique combination within the available literature. Moreover, the existence of this study gap highlights the need for a thorough examination of the synergistic utilization of these two substances in the context of concrete. Although the separate impacts of coir fibre and WSA on concrete parameters have been shown to be beneficial, there is a lack of systematic research on their combined impact on workability, mechanical features, permeability, and embodied carbon.

This study aims to fill a research gap by examining the combined effects of coir fibre and WSA in concrete mixes. It evaluates their impact on concrete performance, workability, mechanical characteristics, permeability, and embodied carbon. The findings could help understand the viability, benefits, and potential obstacles of combining coir fibre and WSA in concrete engineering. Moreover, the research gap in sustainable building methodologies should be addressed by examining the combined use of coir fibre and WSA in concrete. This will provide a comprehensive understanding of their relationships within the concrete matrix, potentially leading to the development of environmentally sustainable construction materials with improved mechanical properties and reduced ecological impacts.

Future scope of the research

The research explores the use of coir fiber and wheat straw ash as cement replacement materials in concrete, offering potential for sustainable construction practices. Future research aims to explore further areas and directions to better understand their performance and environmental implications.

-

•

Optimization of Blend Proportions: In the initial phase of research, a range of CF and WSA proportions were examined. Further investigation can involve optimization studies to identify the most effective blend proportions that offer the best combination of mechanical properties, workability, and environmental benefits.

-

•

Long-Term Durability Studies: The long-term performance of sustainable concrete mixes, exposed to environmental conditions like freeze-thaw cycles, chemicals, and moisture, is crucial for determining their practical applications and potential degradation.

-

•

Advanced Testing Methods: Utilize advanced testing methods, such as non-destructive testing (NDT) and microstructural analysis, to gain a deeper understanding of the concrete's behaviour at the micro level. These methods can provide insights into the interfacial interactions between the cementitious matrix, fiber, and WSA.

By expanding the research scope in these directions, the study can contribute to a comprehensive understanding of the potential of coir fiber and wheat straw ash in enhancing the performance and sustainability of concrete. The outcomes of these investigations have the potential to shape future construction practices and pave the way for more eco-friendly and durable building materials.

Funding

Authors are grateful to Deanship of Scientific Research, Taif University for providing the fund to perform this work.

Data availability statement

Data will be made available on request.

CRediT authorship contribution statement

Naraindas Bheel: Writing – review & editing, Writing – original draft, Methodology, Investigation, Data curation, Conceptualization. Sandeep Kumar: Writing – original draft, Methodology, Formal analysis, Data curation. Mehmet Serkan Kirgiz: Visualization, Validation, Software, Formal analysis, Data curation. Mohsin Ali: Writing – review & editing, Visualization, Data curation. Hamad R. Almujibah: Writing – original draft, Visualization, Software, Data curation, Conceptualization. Mahmood Ahmad: Writing – original draft, Methodology, Formal analysis. Roberto Alonso Gonzalez-Lezcano: Visualization, Validation, Methodology, Funding acquisition, Formal analysis, Conceptualization.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The researchers would like to acknowledge Deanship of Scientific Research, Taif University, Saudi Arabia for funding this work.

Contributor Information

Naraindas Bheel, Email: naraindas04@gmail.com.

Sandeep Kumar, Email: nangdevsk@gmail.com.

Mehmet Serkan Kirgiz, Email: nakres42@yahoo.com.

Mohsin Ali, Email: engrmohsin34@gmail.com.

Hamad R. Almujibah, Email: hmujibah@tu.edu.sa.

Mahmood Ahmad, Email: ahmadm@uniten.edu.my.

Roberto Alonso Gonzalez-Lezcano, Email: rgonzalezcano@ceu.es.

Appendix.

Fig. 1.

Relationship between splitting Tensile Strength and Flexural Strength

Fig. 2.

Correlation between Compressive Strength and Flexural Strength

References

- 1.Wang X.Q., Chen P., Chow C.L., Lau D. Artificial-intelligence-led revolution of construction materials: from molecules to Industry 4.0. Matter. 2023;6:1831–1859. doi: 10.1016/j.matt.2023.04.016. [DOI] [Google Scholar]

- 2.Keerio M.A., Abbasi S.A., Kumar A., Bheel N., ur Rehaman K., Tashfeen M. Effect of silica fume as cementitious material and waste glass as fine aggregate replacement constituent on selected properties of concrete. Silicon. 2020 doi: 10.1007/s12633-020-00806-6. [DOI] [Google Scholar]

- 3.Jatoi M.A., Solangi G.S., Shaikh F.A., Khan S., Ahmed S. Effect of lakhra fly ash as partial replacement of cement in traditional concrete. Mehran Univ. Res. J. Eng. Technol. 2019;38:1045–1056. doi: 10.22581/muet1982.1904.16. [DOI] [Google Scholar]

- 4.Jhatial A.A., Goh W.I., Mohamad N., Rind T.A., Sandhu A.R. Development of thermal insulating lightweight foamed concrete reinforced with polypropylene fibres. Arab. J. Sci. Eng. 2020;45:4067–4076. doi: 10.1007/s13369-020-04382-0. [DOI] [Google Scholar]

- 5.Raza M.S., Rai K., Kumar D., Ali M. Experimental study of physical, fresh-state and strength parameters of concrete incorporating wood waste ash as a cementitious material. J. Mater. Eng. Struct. 2020;7:267–276. [Google Scholar]

- 6.Evaluation of Ordinary Concrete Having Ceramic Waste Powder as Partial Replacement of Cement, (n.d.).

- 7.Mangi S.A., Ibrahim M.H.W., Jamaluddin N., Arshad M.F., Memon F.A., Jaya R.P., Shahidan S. A review on potential use of coal bottom ash as a supplementary cementing material in sustainable concrete construction. Int. J. Integr. Eng. 2018;10:127–135. [Google Scholar]

- 8.Memon M.J., Jhatial A.A., Rid Z.A., Rind T.A., Sandhu A.R. Marble powder as fine aggregates in concrete. Eng. Technol. Appl. Sci. Res. 2019;9:4105–4107. doi: 10.5281/zenodo.3249033. [DOI] [Google Scholar]

- 9.Wang S., Hausfather Z., Davis S., Lloyd J., Olson E.B., Liebermann L., Núñez-Mujica G.D., McBride J. Future demand for electricity generation materials under different climate mitigation scenarios. Joule. 2023;7:309–332. doi: 10.1016/j.joule.2023.01.001. [DOI] [Google Scholar]

- 10.Wang T., Yi Z., Song J., Zhao C., Guo R., Gao X. An industrial demonstration study on CO2 mineralization curing for concrete. iScience. 2022;25 doi: 10.1016/j.isci.2022.104261. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Choudhury R., Wild J., Yang Y. Decarbonizing cement production. Joule. 2021;5:1301–1305. [Google Scholar]

- 12.Senthamarai R.M., Devadas Manoharan P. Concrete with ceramic waste aggregate. Cem. Concr. Compos. 2005;27:910–913. doi: 10.1016/j.cemconcomp.2005.04.003. [DOI] [Google Scholar]

- 13.Ghorbani S., Taji I., de Brito J., Negahban M., Ghorbani S., Tavakkolizadeh M., Davoodi A. Mechanical and durability behaviour of concrete with granite waste dust as partial cement replacement under adverse exposure conditions. Construct. Build. Mater. 2019;194:143–152. doi: 10.1016/j.conbuildmat.2018.11.023. [DOI] [Google Scholar]

- 14.Wang S., Scarlata S.F., Rahbar N. A self-healing enzymatic construction material. Matter. 2022;5:957–974. doi: 10.1016/j.matt.2021.12.020. [DOI] [Google Scholar]

- 15.Bheel N., Ibrahim M.H.W., Adesina A., Kennedy C., Shar I.A. Mechanical performance of concrete incorporating wheat straw ash as partial replacement of cement. J. Build. Pathol. Rehabil. 2021;6 doi: 10.1007/s41024-020-00099-7. [DOI] [Google Scholar]

- 16.Assefa S., Dessalegn M. Production of lightweight concrete using corncob ash as replacement of cement in concrete. Am. J. Civ. Eng. 2019;7:17–20. doi: 10.11648/j.ajce.20190701.13. [DOI] [Google Scholar]

- 17.Malek B., Iqbal M., Ibrahim A. Use of selected waste materials in concrete mixes. Waste Manag. 2006;27:1870–1876. doi: 10.1016/j.wasman.2006.07.026. https://www.sciencedirect.com/science/article/pii/S0956053X06002601 [DOI] [PubMed] [Google Scholar]

- 18.Chohan I.M., Ahmad A., Sallih N., Bheel N., Ali M., Deifalla A.F. A review on life cycle assessment of different pipeline materials. Results Eng. 2023;19 doi: 10.1016/j.rineng.2023.101325. [DOI] [Google Scholar]

- 19.Kumar M.H., Mahanta N.R., Samantaray S., Kumar N.M. Combined effect of waste glass powder and recycled steel fibers on mechanical behavior of concrete. SN Appl. Sci. 2021;3 doi: 10.1007/s42452-021-04353-6. [DOI] [Google Scholar]

- 20.Mangi S.A., Wan Ibrahim M.H., Khahro S.H., Jamaluddin N., Shahidan S. Development of supplementary cementitious materials: a systematic review. Int. J. Adv. Sci. Technol. 2020;29:4682–4691. [Google Scholar]

- 21.Thomas J., Thaickavil N.N., Syamala T.N. 2019. Supplementary Cement Replacement Materials for Sustainable Concrete; pp. 387–403. [DOI] [Google Scholar]

- 22.Hakeem I.Y., Amin M., Agwa I.S., Rizk M.S., Abdelmagied M.F. Effect of using sugarcane leaf ash and granite dust as partial replacements for cement on characteristics of ultra-high performance concrete. Case Stud. Constr. Mater. 2023;19 doi: 10.1016/j.cscm.2023.e02266. [DOI] [Google Scholar]

- 23.Hakeem I.Y., Amin M., Agwa I.S., Abd-Elrahman M.H., Abdelmagied M.F. Using a combination of industrial and agricultural wastes to manufacture sustainable ultra-high-performance concrete. Case Stud. Constr. Mater. 2023;19 doi: 10.1016/j.cscm.2023.e02323. [DOI] [Google Scholar]

- 24.Hamada H.M., Yahaya F.M., Muthusamy K., Jokhio G.A., Humada A.M. Fresh and hardened properties of palm oil clinker lightweight aggregate concrete incorporating Nano-palm oil fuel ash. Construct. Build. Mater. 2019;214:344–354. doi: 10.1016/j.conbuildmat.2019.04.101. [DOI] [Google Scholar]

- 25.Ashish D.K. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J. Clean. Prod. 2019;211:716–729. doi: 10.1016/j.jclepro.2018.11.245. [DOI] [Google Scholar]

- 26.Bheel N., keerio M.A., Kumar A., Shahzaib J., Ali Z., Ali M., sohu S. An investigation on fresh and hardened properties of concrete blended with rice husk ash as cementitious ingredient and coal bottom ash as sand replacement material. Silicon. 2022;14:677–688. doi: 10.1007/s12633-020-00906-3. [DOI] [Google Scholar]

- 27.Bheel N., Adesina A. Influence of binary blend of corn cob ash and glass powder as partial replacement of cement in concrete. Silicon. 2021;13:1647–1654. doi: 10.1007/s12633-020-00557-4. [DOI] [Google Scholar]

- 28.Iqbal Khan M., Mourad S.M., Charif A. Utilization of supplementary cementitious materials in HPC: from rheology to pore structure. KSCE J. Civ. Eng. 2017;21:889–899. doi: 10.1007/s12205-016-1781-x. [DOI] [Google Scholar]

- 29.Bheel N., Memon F.A., Meghwar S.L. Study of fresh and hardened properties of concrete using cement with modified blend of millet husk ash as secondary cementitious. Material, Silicon. 2021;13:4641–4652. doi: 10.1007/s12633-020-00794-7. [DOI] [Google Scholar]

- 30.Hakeem I.Y., Amin M., Agwa I.S., Abd-Elrahman M.H., Ibrahim O.M.O., Samy M. Ultra-high-performance concrete properties containing rice straw ash and nano eggshell powder. Case Stud. Constr. Mater. 2023;19 doi: 10.1016/j.cscm.2023.e02291. [DOI] [Google Scholar]

- 31.Alyami M., Hakeem I.Y., Amin M., Zeyad A.M., Tayeh B.A., Agwa I.S. Effect of agricultural olive, rice husk and sugarcane leaf waste ashes on sustainable ultra-high-performance concrete. J. Build. Eng. 2023;72 doi: 10.1016/j.jobe.2023.106689. [DOI] [Google Scholar]

- 32.Abd-Elrahman M.H., Saad Agwa I., Mostafa S.A., Youssf O. Effect of utilizing peanut husk ash on the properties of ultra-high strength concrete. Construct. Build. Mater. 2023;384 doi: 10.1016/j.conbuildmat.2023.131398. [DOI] [Google Scholar]

- 33.Maglad A.M., Amin M., Zeyad A.M., Tayeh B.A., Agwa I.S. Engineering properties of ultra-high strength concrete containing sugarcane bagasse and corn stalk ashes. J. Mater. Res. Technol. 2023;23:3196–3218. doi: 10.1016/j.jmrt.2023.01.197. [DOI] [Google Scholar]

- 34.Cordeiro G.C., Andreão P.V., Tavares L.M. Pozzolanic properties of ultrafine sugar cane bagasse ash produced by controlled burning. Heliyon. 2019;5 doi: 10.1016/j.heliyon.2019.e02566. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Kumar M.H., Mohanta N.R., Patel N., Samantaray S., Reddy S.V.B. Impact of fly ash and metakaoline on the crack resistance and shrinkage of concrete, Iran. J. Sci. Technol. - Trans. Civ. Eng. 2022;46:2011–2026. doi: 10.1007/s40996-021-00748-y. [DOI] [Google Scholar]

- 36.Dayo A.A., Kumar A., Raja A., Bheel N., Shaikh Z.H. Use of sugarcane bagasse ash as a fine aggregate in cement concrete. Eng. Sci. Technol. Int. Res. J. 2019;3:8–11. [Google Scholar]

- 37.Aksogan O., Binici H., Ortlek E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Construct. Build. Mater. 2016;106:253–263. doi: 10.1016/j.conbuildmat.2015.12.102. [DOI] [Google Scholar]

- 38.Jain D., Gupta A., Jain H. Comparative study of concrete when rice husk ash, saw dust ash, wheat straw ash used as partial replacement of cement in concrete. Int. J. Sci. Res. Dev. 2015;3:764–767. [Google Scholar]

- 39.Qudoos A., Kim H.G. Atta-ur-Rehman, J.S. Ryou, Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Construct. Build. Mater. 2018;193:481–490. doi: 10.1016/j.conbuildmat.2018.10.229. [DOI] [Google Scholar]

- 40.Farooqi M.U., Ali M. Effect of pre-treatment and content of wheat straw on energy absorption capability of concrete. Construct. Build. Mater. 2019;224:572–583. doi: 10.1016/j.conbuildmat.2019.07.086. [DOI] [Google Scholar]

- 41.Mohd Sam A.R., Samadi M., Hussin M.W., Lee H.S., Ismail M.A., Lim N.H.A.S., Ariffin N.F., Khalid N.H.A., Abd Majid M.Z., Mirza J. Incorporation of homogenous ceramic tile waste to enhance mechanical properties of mortar. J. Teknol. 2015;77:21–25. [Google Scholar]

- 42.Babar A., Lakho H., Memon M., Gul H., Memon F., Siddiqui F.H. The impact of wheat straw ash as a partial cement replacement material on concrete properties. Resour. Conserv. Recycl. 2022;3:2616–4396. www.uow.edu.pk [Google Scholar]

- 43.Shahbandeh M. Statista; 2020. World Wheat Production by Country 2018/2019. [Google Scholar]

- 44.Pan X., Sano Y. Fractionation of wheat straw by atmospheric acetic acid process. Bioresour. Technol. 2005;96:1256–1263. doi: 10.1016/j.biortech.2004.10.018. [DOI] [PubMed] [Google Scholar]

- 45.Kadam K.L., Forrest L.H., Jacobson W.A. Rice straw as a lignocellulosic resource: collection, processing, transportation, and environmental aspects. Biomass Bioenergy. 2000;18:369–389. doi: 10.1016/S0961-9534(00)00005-2. [DOI] [Google Scholar]

- 46.Memon S.A., Wahid I., Khan M.K., Tanoli M.A., Bimaganbetova M. Environmentally friendly utilization of wheat straw ash in cement-based composites. Sustainability. 2018;10 doi: 10.3390/su10051322. [DOI] [Google Scholar]

- 47.Biricik H., Aköz F., Berktay I., Tulgar A.N. Study of pozzolanic properties of wheat straw ash. Cem. Concr. Res. 1999;29:637–643. doi: 10.1016/S0008-8846(98)00249-X. [DOI] [Google Scholar]

- 48.Al-Akhras N.M., Abu-Alfoul B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002;32:859–863. doi: 10.1016/S0008-8846(02)00716-0. [DOI] [Google Scholar]

- 49.Khushnood R.A., Rizwan S.A., Memon S.A., Tulliani J.M., Ferro G.A. Experimental investigation on use of wheat straw ash and bentonite in self-compacting cementitious system. Adv. Mater. Sci. Eng. 2014;2014:1–11. doi: 10.1155/2014/832508. [DOI] [Google Scholar]

- 50.Okeola A.A., Abuodha S.O., Mwero J. Experimental investigation of the physical and mechanical properties of sisal fiber-reinforced concrete. Fibers. 2018;6 doi: 10.3390/fib6030053. [DOI] [Google Scholar]

- 51.Singh S., Shukla A., Brown R. Pullout behavior of polypropylene fibers from cementitious matrix. Cem. Concr. Res. 2004;34:1919–1925. doi: 10.1016/j.cemconres.2004.02.014. [DOI] [Google Scholar]

- 52.Vadivambal R., Chelladurai V., Jian F., Jayas D.S. Tensile strength and elongation of hemp and sisal ropes at different temperatures. Can. Biosyst. Eng. 2015;57:9–12. doi: 10.7451/CBE.2015.57.3.9. [DOI] [Google Scholar]

- 53.Zhang T., Yin Y., Gong Y., Wang L. Mechanical properties of jute fiber-reinforced high-strength concrete. Struct. Concr. 2020;21:703–712. doi: 10.1002/suco.201900012. [DOI] [Google Scholar]

- 54.Lee S. Effect of nylon fiber addition on the performance of recycled aggregate concrete. Appl. Sci. 2019;9 doi: 10.3390/app9040767. [DOI] [Google Scholar]

- 55.Manaia J.P., Manaia A.T., Rodriges L. Industrial hemp fibers: an overview. Fibers. 2019;7:106. doi: 10.3390/fib7120106. [DOI] [Google Scholar]

- 56.Bheel N., Awoyera P., Aluko O., Mahro S., Viloria A., Sierra C.A.S. Sustainable composite development: novel use of human hair as fiber in concrete. Case Stud. Constr. Mater. 2020;13 doi: 10.1016/j.cscm.2020.e00412. [DOI] [Google Scholar]

- 57.Nor M.J.M., Ayub M., Zulkifli R., Amin N., Fouladi M.H. Effect of different factors on the acoustic absorption of coir fiber. J. Appl. Sci. 2010;10:2887–2892. [Google Scholar]

- 58.Olanipekun E.A., Olusola K.O., Ata O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006;41:297–301. doi: 10.1016/j.buildenv.2005.01.029. [DOI] [Google Scholar]

- 59.Dvorkin L., Dvorkin O., Zhitkovsky V., Ribakov Y. A method for optimal design of steel fiber reinforced concrete composition. Mater. Des. 2011;32:3254–3262. doi: 10.1016/j.matdes.2011.02.036. [DOI] [Google Scholar]

- 60.Banthia N., Gupta R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006;36:1263–1267. doi: 10.1016/j.cemconres.2006.01.010. [DOI] [Google Scholar]

- 61.Dvorkin L., Nwaubani S., Dvorkin O. Nova Publishers; 2010. Construction Materials. [Google Scholar]

- 62.Bayramov F., Taşdemir C., Taşdemir M.A. Optimisation of steel fibre reinforced concretes by means of statistical response surface method. Cem. Concr. Compos. 2004;26:665–675. doi: 10.1016/S0958-9465(03)00161-6. [DOI] [Google Scholar]

- 63.Banthia N., Soleimani S.M. Flexural response of hybrid fiber-reinforced cementitious composites. ACI Mater. J. 2005;102:382–389. doi: 10.14359/14800. [DOI] [Google Scholar]

- 64.Nelson P.K., Li V.C., Kamada T. Fracture toughness of micro-fiber reinforced cement composites. J. Mater. Civ. Eng. 2002;14:384–391. doi: 10.1061/(ASCE)0899-1561(2002)14:5(384). [DOI] [Google Scholar]

- 65.Li V.C., Wang S., Wu C. Tensile strain-hardening behavior or polyvinyl alcohol engineered cementitious composite (PVA-ECC) ACI Mater. J. 2001;98:483–492. [Google Scholar]

- 66.Neville A.M., Brooks J.J. 2011. Properties of Concrete. [Google Scholar]

- 67.Meghwar S.L., Khaskheli G.B., Kumar A. Human scalp hair as fiber reinforcement in cement concrete. Mehran Univ. Res. J. Eng. Technol. 2020;39:443–452. doi: 10.22581/muet1982.2002.20. [DOI] [Google Scholar]

- 68.Kaushik D., Singh S.K. Use of coir fiber and analysis of geotechnical properties of soil. Mater. Today Proc. 2021;47:4418–4422. [Google Scholar]

- 69.Katman H.Y.B., Khai W.J., Bheel N., Kırgız M.S., Kumar A., Benjeddou O. Fabrication and characterization of cement-based hybrid concrete containing coir fiber for advancing concrete construction. Buildings. 2022;12 doi: 10.3390/buildings12091450. [DOI] [Google Scholar]

- 70.ASTM C143/C143M - 15a Standard Test Method for Slump of Hydraulic-Cement Concrete, ((n.d.)).

- 71.ASTM C39/C39M - 20 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. 2020. [DOI] [Google Scholar]

- 72.ASTM C496/C496M - 17 Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens, ((n.d.)).

- 73.ASTM C293/C293M - 16 Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading), (n.d.).

- 74.BS EN 12390-8 Testing hardened concrete Part 8: depth of penetration of water under pressure. Br. Stand. 2009 [Google Scholar]

- 75.ASTM C469/C469M - 14 Standard Test Method for Static Modulus of Elasticity and Poisson's Ratio of Concrete in Compression. 2014. [DOI] [Google Scholar]

- 76.Jhatial A.A., Sohu S., Memon M.J., Bhatti N. ul K., Memon D. Eggshell powder as partial cement replacement and its effect on the workability and compressive strength of concrete. Int. J. Adv. Appl. Sci. 2019;6:71–75. doi: 10.21833/ijaas.2019.09.011. [DOI] [Google Scholar]

- 77.Pathan M.A., Lashari R.A., Maira M., Pathan J.A. Experimental study on the engineering properties of marble waste powder from hyderabad marble market sindh Pakistan for making concrete including recycled coarse aggregates. Saudi J. Civ. Eng. 2019;3:51–58. doi: 10.21276/sjce.2019.3.3.1. [DOI] [Google Scholar]

- 78.Majeed M., Khitab A., Anwar W., Khan R.B.N., Jalil A., Tariq Z. Evaluation of concrete with partial replacement of cement by waste marble powder. Civ. Eng. J. 2021;7:59–70. doi: 10.28991/cej-2021-03091637©. [DOI] [Google Scholar]

- 79.Afroughsabet V., Biolzi L., Ozbakkaloglu T. Springer US; 2016. High-performance Fiber-Reinforced Concrete: a Review. [DOI] [Google Scholar]

- 80.Shar I.A., Memon F.A., Bheel N., Benjeddou O., Alwetaishi M. Effect of used engine oil on the mechanical properties and embodied carbon of concrete blended with wheat straw ash as cementitious material. Environ. Sci. Pollut. Res. 2023;30:75879–75893. doi: 10.1007/s11356-023-27803-7. [DOI] [PubMed] [Google Scholar]

- 81.Bheel N., Sohu S., Awoyera P., Kumar A., Abbasi S.A., Olalusi O.B. Effect of wheat straw ash on fresh and hardened concrete reinforced with jute fiber. Adv. Civ. Eng. 2021;2021 doi: 10.1155/2021/6659125. [DOI] [Google Scholar]

- 82.Katman H.Y.B., Khai W.J., Bheel N., Kırgız M.S., Kumar A., Khatib J., Benjeddou O. Workability, strength, modulus of elasticity, and permeability feature of wheat straw ash-incorporated hydraulic cement concrete. Buildings. 2022;12 doi: 10.3390/buildings12091363. [DOI] [Google Scholar]

- 83.Ranjitham M., Mohanraj S., Ajithpandi K., Akileswaran S., Sree S.K.D. AIP Conf. Proc. 2019. Strength properties of coconut fibre reinforced concrete; pp. 1–8. [DOI] [Google Scholar]

- 84.Hwang C.L., Tran V.A., Hong J.W., Hsieh Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Construct. Build. Mater. 2016;127:984–992. doi: 10.1016/j.conbuildmat.2016.09.118. [DOI] [Google Scholar]

- 85.Toledo Filho R.D., Ghavami K., Sanjuán M.A., England G.L. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005;27:537–546. doi: 10.1016/j.cemconcomp.2004.09.005. [DOI] [Google Scholar]

- 86.Sathiparan N., Rupasinghe M.N., Pavithra B.H.M. Performance of coconut coir reinforced hydraulic cement mortar for surface plastering application. Construct. Build. Mater. 2017;142:23–30. doi: 10.1016/j.conbuildmat.2017.03.058. [DOI] [Google Scholar]

- 87.Abed J.M., Khaleel B.A. Effect of wood waste as a partial replacement of cement, fine and coarse aggregate on physical and mechanical properties of concrete blocks units. Int. J. Integr. Eng. 2019;11:229–239. doi: 10.30880/ijie.2019.11.08.023. [DOI] [Google Scholar]

- 88.Keerio M.A., Khoso S., Khan J.S., Ansari A.A., Bhatti N. ul K. The effect of waste glass as partial replacement of cement on properties of concrete. Eng. Sci. Technol. Int. Res. J. 2017;1:59–63. [Google Scholar]

- 89.Tom A., Anusharee, Varghese D.M., Antony J. 2014. Coconut Fiber Reinforced Concrete. [Google Scholar]

- 90.Qudoos A., Ullah Z., Rehman A.U., Baloch Z. Performance evaluation of the fiber-reinforced cement composites blended with wheat straw ash. Adv. Mater. Sci. Eng. 2019;2019 doi: 10.1155/2019/1835764. [DOI] [Google Scholar]

- 91.Bheel N., Ibrahim M.H.W., Adesina A., Kennedy C., Shar I.A. Mechanical performance of concrete incorporating wheat straw ash as partial replacement of cement. J. Build. Pathol. Rehabil. 2021;6 doi: 10.1007/s41024-020-00099-7. [DOI] [Google Scholar]

- 92.Xie X., Zhou Z., Jiang M., Xu X., Wang Z., Hui D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015;78:153–161. doi: 10.1016/j.compositesb.2015.03.086. [DOI] [Google Scholar]

- 93.Pereira M.V., Fujiyama R., Darwish F., Alves G.T. On the strengthening of cement mortar by natural fibers. Mater. Res. 2015;18:177–183. doi: 10.1590/1516-1439.305314. [DOI] [Google Scholar]

- 94.Ataie F.F., Riding K.A. Influence of agricultural residue ash on early cement hydration and chemical admixtures adsorption. Construct. Build. Mater. 2016;106:274–281. doi: 10.1016/j.conbuildmat.2015.12.091. [DOI] [Google Scholar]

- 95.Ali M., Liu A., Sou H., Chouw N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Construct. Build. Mater. 2012;30:814–825. doi: 10.1016/j.conbuildmat.2011.12.068. [DOI] [Google Scholar]

- 96.Yang K.-H., Song J.-K., Song K.-I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 2013;39:265–272. doi: 10.1016/j.jclepro.2012.08.001. [DOI] [Google Scholar]

- 97.Zhu Q. IEA Clean Coal Centre; 2011. CO2 Abatement in the Cement Industry Industry; pp. 121–127.https://www.usea.org/publication/co2-abatement-cement-industry-ccc184 [Google Scholar]

- 98.Turner L.K., Collins F.G. Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete. Construct. Build. Mater. 2013;43:125–130. doi: 10.1016/j.conbuildmat.2013.01.023. [DOI] [Google Scholar]

- 99.Wang B., Yan L., Kasal B. A review of coir fibre and coir fibre reinforced cement-based composite materials (2000–2021) J. Clean. Prod. 2022;338 doi: 10.1016/j.jclepro.2022.130676. [DOI] [Google Scholar]

- 100.Sahoo S., Parhi P.K., Chandra Panda B. Durability properties of concrete with silica fume and rice husk ash. Clean. Eng. Technol. 2021;2 doi: 10.1016/j.clet.2021.100067. [DOI] [Google Scholar]

- 101.Kumar A., Bheel N., Ahmed I., Rizvi S.H., Kumar R., Jhatial A.A. Effect of silica fume and fly ash as cementitious material on hardened properties and embodied carbon of roller compacted concrete. Environ. Sci. Pollut. Res. 2022;29:1210–1222. doi: 10.1007/s11356-021-15734-0. [DOI] [PubMed] [Google Scholar]

- 102.Keerio M.A., Saand A., Chaudhry R., Bheel N., ul Karim Bhatti N., Soohu S. The effect of local metakaolin developed from natural material soorh on selected properties of concrete/mortar. Silicon. 2022;14:1807–1816. doi: 10.1007/s12633-021-00993-w. [DOI] [Google Scholar]

- 103.Bheel N., Khoso S., Baloch M.H., Benjeddou O., Alwetaishi M. Use of waste recycling coal bottom ash and sugarcane bagasse ash as cement and sand replacement material to produce sustainable concrete. Environ. Sci. Pollut. Res. 2022;29:52399–52411. doi: 10.1007/s11356-022-19478-3. [DOI] [PubMed] [Google Scholar]

- 104.Bheel N., Ali M.O.A., Tafsirojjaman, Khahro S.H., Keerio M.A. Experimental study on fresh, mechanical properties and embodied carbon of concrete blended with sugarcane bagasse ash, metakaolin, and millet husk ash as ternary cementitious material. Environ. Sci. Pollut. Res. 2022;29:5224–5239. doi: 10.1007/s11356-021-15954-4. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.