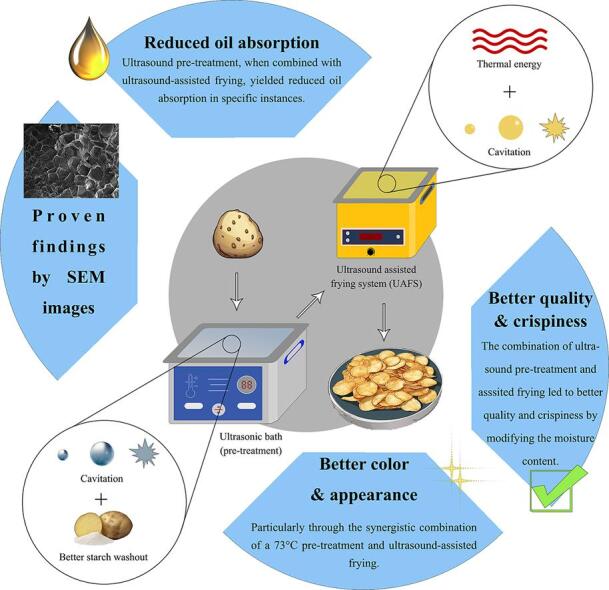

Graphical abstract

Keywords: Ultrasound-assisted frying, Properties, Oil content: Process optimization

Highlights

-

•

Ultrasound-assisted frying system (UAFS) significantly reduces oil absorption in potato chips.

-

•

Dual-stage ultrasound results in minimal oil absorption due to the pores creation.

-

•

Ultrasound (US) pre-treatment reduces enzyme activity and color changes during frying.

-

•

USB73-US produces the optimal potato chips by 32.29 % reduced oil content.

Abstract

Potato chips are popular high-consuming ready-to-eat meals in all of the world which specially attract a lot of attention from youth and children. Reducing oil absorption and improving the quality of chips are major undertakings within the industry. This research aimed to find the best ultrasonic bath-based method by investigating the optimal ultrasonic pre-treatment and developing an ultrasound (US) assisted frying system (UAFS) to reduce the oil absorption of potato chips while maintaining an acceptable quality. Through this technique, the potato chips get sonicated during deep frying in hot oil. US-pretreatment at temperatures of 25 °C and 73 °C, along with US-assisted frying, resulted in the minimal amount of oil which may be due to the US creating potential pores during the pre-treatment phase, which then expand further during the subsequent sonication stage. UAFS in combination with US-pretreatment produced more crispy chips due to the fact that the texture of potato slices becomes more porous. UAFS resulted in a decrease in the moisture content of the fried chips attributed to an increase in the effective diffusion coefficient and mass. Pretreating the chips at 73 °C significantly reduce the color change producing brighter product by inactivation of enzymes such as polyphenol oxidase. Finally, the result of TOPSIS optimization based on potato chips properties confirms that US-pretreatment in 73 °C brine followed by frying using UAFS is the best approach. Scanning electron microscope (SEM) images of potato chips also support this issue.

1. Introduction

Potato, which ranks fourth in terms of global consumption, is a major source of energy, carbs, and dietary fiber [1]. Like other fried foods, potato chips have a high oil content, ranging from 35 % to 45 % [2]. One of the most significant mass transfer phenomena that researchers are working to minimize using a variety of techniques is the amount of oil absorbed by potato chips [3], [4], [5], [6], [7], [8], [9], [10]. The availability of prepared foods and the rise in consumer interest in them have increased the importance of this issue today. French fries and potato chips as high-consuming ready-to-eat meals which have attracted a lot of attention specially from children and adolescents can be one of the factors that increase diseases such as diabetes and obesity, which are rooted in the consumption of oils and fats, because of the fat and oil accumulated in these products [11]. In addition to the necessity of focusing on the issue of food safety, the amount of oil absorption includes financial implications for both individuals and manufacturers. Given the economic and environmental implications of this concern over oil absorption, it is sense to investigate novel solutions in food preparation. Ultrasound (US) is utilized in food processing as a cutting-edge non-thermal technology since it has benefits including being economical, environmentally benign, and highly effective. Other methods of treatment, such as pulsed electric field, microwave vacuum frying, treating with enzymes, and pre-drying, are also effective but may have some drawbacks such as the loss of nutrients, the development of harmful sugar compounds, and an alteration in flavor. US reduces the process time by increasing the effective diffusion coefficient of moisture leading to a dwindling oil absorption while conserving most of the nutrients.

The importance of human health motivated this research to improve one of the most consumed products by attempting to reduce the amount of fat in the diet. Although other studies on the subject have been conducted [7], [10], [12], [13], we endeavored to find the best ultrasonic-based method by investigating the optimal ultrasonic pre-treatment and US assisted frying approach aiming to lowering the oil content of potato chips while maintaining an acceptable texture and crispiness as a substitute for the conventional common product. To put it differently, our objective was to experiment with US assisted frying to discover the most effective ultrasonic treatment for potato chips. In order to achieve this, we combined various pre-treatments with both traditional and US-assisted frying.

2. Materials and methods

2.1. Raw material

Potato tubers (Solanum Tuberosum) from the Jelly variety which is suitable for industrial chips with an initial moisture content of 82 ± 2 %, were collected from local field and stored in nylons at 4 °C to minimize any negative effects on the physicochemical properties of the tubers before the process. Palm free sunflower frying oil was bought and stored at room temperature out of direct sunlight inside darkroom. Hexane solvent (CH3(CH2)4CH3, M = 86.18 g/mol) supplied by Emplura®-Germany was bought from labor chemicals market. Oil absorbent paper, kitchen paper towels and iodized cooking salt were purchased from al local market.

2.2. Sample preparation

Among the tubers, only the ones without eye (axillary bud) and germinating bud (shoot) on their skin were collected for experiment. A large part of the skin (periderm) of the tubers was peeled off during washing due to the thin skin envelopment of the Jelly variety. The remaining part of the skin was then peeled off smoothly. Samples were sliced circular with a thickness of 1.0 ± 0.1 mm slices using an electric slicing machine (IMB, Bora Electric). The slices with a diameter of 60 ± 6 mm were rinsed well using lukewarm deionized water to remove starch from their surface. Both surfaces of the slices were then blotted dry by kitchen paper towel to reduce negative effects of excess moisture and stored at 4 °C (<2h) until the experiment. The samples were then separated in two groups of US and non-ultrasound (NUS) pre-treatments.

2.3. Ultrasound pre-treatment

An ultrasonic bath (Backer vclean 1_L4; Vira Tejarat Bakr Co., Iran) was used to treat samples before frying. The treatment operated under 40 kHz, continuous mode, power of 100 W and sonication time of 15 min. Kim & Moreira (2013) provided that using a solution of 3 % NaCl decreases potato chips oil absorption while enhances texture, color and flavor [14]. During brining, due to the phenomenon of osmotic pressure difference, water and salt shift from the food; so that water transfers from food to brine while NaCl is transferring from brine to the food [15]. Therefore, two different mediums were considered for the US pre-treatment; a) 3 L of distilled water (W) and b) 3 L of brine (B); NaCl dissolved in distilled water, 3 % g/mL. Six potato slices were sonicated at each run. The experiment was carried out under three different controlled temperature levels (4, 25 and 73 ± 3 °C) which are the temperature levels used in potato chips industry for blanching and de-starching [16], [17]. Generally, all pre-treatments are shown in Table.1. After the treatment, samples were carried out of the bath and gently dried by blotting paper towel to get prepared for frying.

Table 1.

Different applied treatments based on various temperature and mediums.

| Temp. | Medium | Name |

|---|---|---|

| 4 °C | Water | NUSW4 |

| US + Water | USW4 | |

| Brine | NUSB4 | |

| US + Brine | USB4 | |

| 25 °C | Water | NUSW25 |

| US + Water | USW25 | |

| Brine | NUSB25 | |

| US + Brine | USB25 | |

| 73 °C | Water | NUSW73 |

| US + Water | USW73 | |

| Brine | NUSB73 | |

| US + Brine | USB73 | |

2.4. Ultrasound-assisted frying system

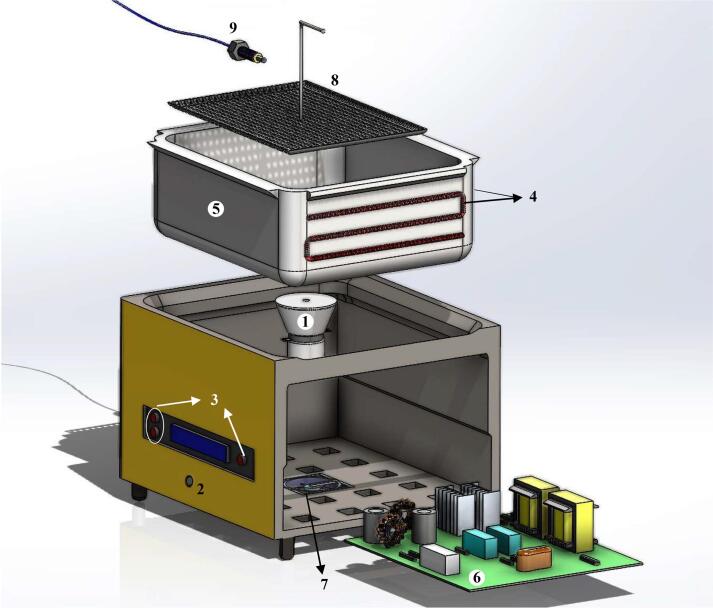

As a novel method in food processing, an ultrasound-assisted frying system (UAFS) was developed, with the aim of simultaneously applying US during and in combination with the deep thermal frying process of potato chips. As outlined in Fig. 1, UAFS consists of a 40 kHz and 50 W ultrasonic transducer beneath the stainless-steel container (interior: 6 × 13.7 × 15.1 cm3, filleted corners). The need for higher voltages than the mains voltage, led us to use a step-up transformer in the input power section. A MOSFET-based switching regulator (13007) and a voltage multiplier circuit made up of capacitors and diodes were embedded to work synchronously and generate a 1200 V potential difference (-600 V, +600 V). Adjusting the frequency between the transformer and the transducer was achieved using a polyester capacitor. A volume controller on the facing side adjusts the heating rate of the electrical elements stretched across the container. Moreover, two keys embedded on the facing side make it possible to adjust the duration of ultrasonication and turn on/off the US transducer. As a design experience, the opposite section of the electrical element was removed to prevent thermal damage to the control panel. In order to have as much thermal insulation as possible, glass wool was wrapped around the transducer, container and between the integration point of the board and the container. A proportional cooling fan was also installed on the board to balance the interior temperature of UAFS. Through this technique, the potato chips get sonicated during deep frying in hot oil which is conceptually shown in Fig. 2.

Fig. 1.

The developed UAFS. 1- US transducer; 2- Volume controller; 3- US control keys; 4- Electrical elements; 5- Container; 6- Main board; 7- Cooling fan; 8- Grid-shaped holder; 9- K-type thermocouple sensor.

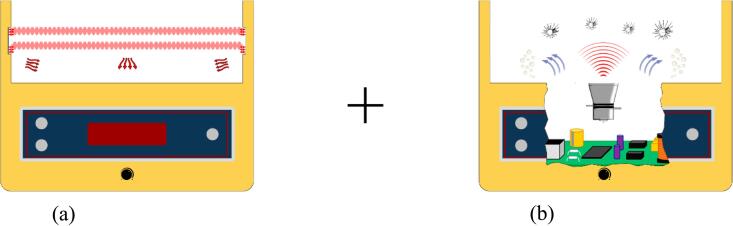

Fig. 2.

Concept of UAFS. (a), heat transfer mechanism; (b), ultrasonication mechanism.

So as to maintain the potato chips floating during sonication, a grid-shaped holder was taken in to the consideration for UAFS. The holder allowed the potato chips to be immersed and prevented them from sticking to the side walls; because the streaming produced by sonication tends to drive the chips toward the walls. Due to small heat transfer coefficient of sunflower oil at 180 °C which is around 170 W/m2 °C [18], the temperature had to be measured from the middle of the frying medium where the samples were frying. This was achieved by attaching a K-type thermocouple in the center of the holder, while controlling the temperature by a PID controller.

2.5. Frying process

As [2] described, low frying temperatures lead to an increase in the oil content of potato chips. So, the frying process performed under two different frying systems; i: traditional deep fat frying (-NUS) and ii: UAFS (-US). All the samples were fried by these two methods. The frying process was carried out at 180 °C for 90 s inside 1 L sunflower oil. Then, the potato chips were immediately removed from the oil and let to sit in a basket for 1 min to make the oil drip from their surface. After that, the samples were gently cleaned of any leftover oil using an oil absorbent paper. The oil was renewed after two runs, meaning that every liter of the oil was used for one pre-treated sample to fry in two different modes: first, for conventional frying method, and secondly, for the same treatment while sonicating was applied. In this method, possible adverse physicochemical effects that can result from the sonication of the oil were avoided by draining it each time before frying the subsequent sample.

2.6. Oil absorption measurement

Soxhlet extraction procedure with hexane as the solvent was carried out at 69 °C for 3 h to measure the amount of oil absorbed by the samples. This oil cannot be removed from the tissue once it has been fried, but it can be lessened by treatment. 100 g of each sample was collected after pulverizing finely in a mortar. Then the weighted crumbs were placed into a filter tube after they were dried in oven for 24 h at 105 °C. The final results were obtained from two replicates and based on %g/g dried sample.

2.7. Crispiness

The crispiness of the potato chips was measured using texture analyzer (STM - Santam, Bongshin DBBP-500 Loadcell 20 kgf, Korea). According to the method used earlier by [5], a spherical steel probe (12.7 mm) was used to break the potato chips, while the sample was fixed on a rigid cylinder with an 18 mm diameter hole in the center. The penetrating speed was set to 6 mm/min for all the tests and the test was stopped after 5 mm penetration. Each test's maximum force (N) was recorded, and after two repetitions, the final reported hardness number was reported.

2.8. Moisture content

When it pertains to oil content and quality, moisture content is one of the most effective criteria. On the other hand, the loss of moisture can create microscopic voids within the texture of the potato slices, which can create a suitable space for oil absorption. Therefore, the content was measured. The remaining moisture content of the chips after frying, was appraised using an oven by drying 2 g of each sample for 24 h at 105 °C according to AOAC [19]. Final data were the result of duplicate repetition.

2.9. Color properties

The color properties of the potato chips were reported as the difference between the fried slices and the raw material. Sample images were captured using a cellphone 12 MP camera (4032 × 3024 pixels) with constant light settings (ISO 100, 76 mm, −0.7 ev, f 2.2, 1/33 s, JPEG) in a housing unit (Fig. 3) (white LED) containing a pitch-black background. The images were then analyzed by the ImageJ software. ΔE was calculated as Eq.1 describes:

| (1) |

where , , and represent the color parameters of the fresh potato.

Fig. 3.

The imaging unit used for colorimetric-based investigations.

2.10. Degree of shrinkage

The degree of shrinkage (DOS) of the potato slices was calculated by Eq. (2) as the difference in the area between raw sample and the fried one. DOS is a reliable indicator to express the uniformity of the final product, which is an effective factor on the quality, consumer acceptance and amount of the final product, and is directly related to the production cost.

The samples were considered to be oval, and each sample's two diameters were precisely measured through the use of a digital caliper (GuangLu China, 0–150 mm, 0.01).

| (2) |

where AR is the area of the raw sample and AF represents the area of the same slice after frying.

2.11. Optimization and optimum clusters

With a view to optimizing the experimental data and finding the optimal method, TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution) was utilized in the study. TOPSIS is one of the Multiple Attribute Decision Making (MADM) techniques. The phrases “Ideal Solution” and “the Most Similarity to the Ideal Solution” act as determinants in this method. The ideal solution is the solution which doesn’t practically exist and we are looking for the closest alternative. In order to assess how similar a design matches with “Ideal Solution” and the “Anti-ideal Solution”, the distance between this design and both the ideal and anti-ideal solutions is measured. Then, different treatments are evaluated and ranked based on the ratio of the distance from the anti-ideal solution to the total distance from the ideal and anti-ideal solutions. The steps to implement TOPSIS are:

-

i)

Formation of the decision matrix: The first step of this method is the formation of the decision matrix in which the criteria are placed in the columns and the options are placed in the rows, and each cell of the matrix is the data of each category according to a specific criterion.

-

ii)

Data normalization: Each level is divided by the square root of the sum of the squares of the levels in that column in this manner. The choice matrix is transformed into a dimensionless matrix at this point.

| (3) |

where xij represents a data from row i and column j.

-

iii)

Definition of weight matrix: The weight matrix actually represents the weight and importance of each criterion. There are different methods to determine weight, in this research, Stepwise Weight Assessment Ratio Analysis (SWARA) weighing method was used. In this method, the most important criterion (oil content) has the highest weight and the least important criterion (DOS) has the lowest weight. Then the remaining weights of the criteria are distributed between the lowest and the highest weight. After calculating the weights, each column of the normal matrix r is multiplied by the weight corresponding to the same criterion to form the weighted normal matrix.

-

iv)

Finding the ideal and anti-ideal solutions: In this step, the positive or negative influence of the criterion is determined; In fact, we determine whether a criterion with the highest value is in the ideal state or the lowest one. In other words, we must determine whether the increase of a criterion leads to the improvement of the final result or leads to the deterioration of the results.

-

v)

Calculation of the distance from the ideal and anti-ideal solution: based on Eq. (4) and Eq. (5), the distance of each treatment from the ideal and anti-ideal solution is determined:

| (4) |

| (5) |

where and represent the distance from the ideal and anti-ideal solutions, vij is a domain of the weighted normal matrix, and are the largest domain of the criterion with positive charge (the largest ideal domain) and the smallest domain of the criterion with negative charge (the smallest anti-ideal domain), respectively.

-

vi)

Calculating the percentage of similarity: In the final stage of the TOPSIS method, each treatment's degree of similarity to the ideal solution is quantified as a percentage using Eq. (6):

| (6) |

2.12. Statistical analyses

Statistical analyses were performed using SPSS 26.0.0.1 for windows. One-way ANOVA was used to examine the significance of the difference between the various treatment groups, with a 95 % level of significance (p < 0.05). Optimization calculations were performed by Python 3.10. Tables and charts were created using SPSS 26.0.0.1 and OriginLab 2022.

2.13. Flavor, aroma and sensory properties

Five experts received samples that were deemed to be optimal. Panelists were requested to evaluate appearance (color and outward), taste, texture, aroma and overall acceptability from 0 (least) to 10 (most). The result was analyzed and reported.

2.14. Scanning electron microscopes (SEM)

In order to observe the tissue morphology difference between optimal samples, the fried potato chips were completely defatted using hexane solvent and dried in oven for 24 h at 105 °C. Samples were then mounted on a surface and fixed using two-sided adhesive tape to get coated with 14 nm gold coat. The microstructural analysis was then performed by a scanning electron microscope (Zeiss Evo MA 15, Germany) with an accelerating voltage of 16 kV.

3. Results and discussion

3.1. Oil content

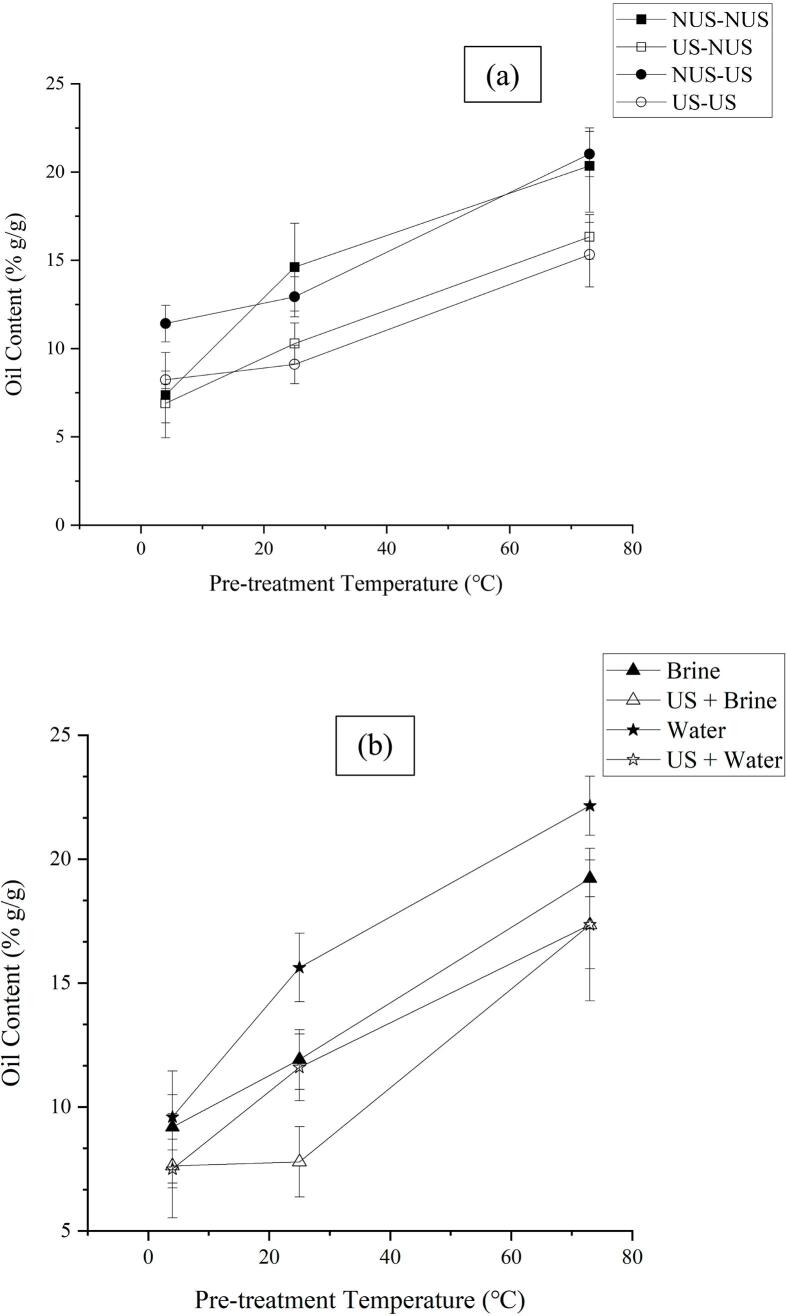

In order to determine the impact of US in both pre-treatment and frying processes, the results are shown in Fig. 4. As shown in Fig. 4a the difference between US and NUS pre-treated samples increased with increasing pre-treatment temperature; while the density change of water in liquid phase is negligible, this can be due to higher viscosity of water in lower temperatures [20] and higher speed of US in higher water temperatures [21], [22]. Furthermore, the direct relation between the medium temperature and vapor pressure of dissolved gases leads to the formation of smaller gas bubbles which are known as cavitation bubbles. Comparing the clusters NUS-NUS with NUS-US and US-NUS with US-US indicates the fact that at the temperature of 4 °C, UAFS broke down the compressed tissue made by low temperature and increased the oil absorption significantly (p < 0.05). The utilization of US-pretreatment at temperatures of 25 °C and 73 °C, along with US-assisted frying, resulted in the minimal amount of oil. This could be attributed to US creating potential pores during the pre-treatment phase, which then expand further during the subsequent sonication stage; this process facilitates the easier flow of the penetrated oil and its absorption into the oil absorbent paper. As a result, the overall oil content within the pores decreases.

Fig. 4.

Relationship between pre-treatment temperature and oil content with different (a), US mode; (b), pre-treatment medium. Vertical I bars represent the standard deviation of each treatment.

Fig. 4b shows the impact of different mediums on the oil content. Based on the findings, it can be inferred that the potato samples treated with brine exhibited reduced oil absorption in both US and NUS pre-treatments. This outcome can be attributed to the presence of NaCl in slices, which restricts the available space for oil absorption. Additionally, the brine-treated samples already possessed lower moisture content, resulting in less moisture loss during frying. Consequently, the osmotic pressure effect, which typically leads to the absorption of oil instead of moisture within the potato tissue, is diminished, resulting in lower oil absorption. On the other hand, when the potato slices are treated in brine, the polar nature of the solution tends to exclude the non-polar oil from directly interacting with the potato surface. This exclusion effect further hampers the adhesion of oil to the potato slices, as the polar brine solution acts like a barrier between the potato and the oil. Regardless to the pre-treatment medium and frying method, higher pre-treatment temperatures resulted in higher oil absorption which confirms the results obtained by [23] indicating that lower blanching temperatures lead to more rigid structure and less oil content in potato chips.

Applying US to 25 °C medium showed significant reduction in both water and brine, 25.75 % and 34.63 % respectively. The sample with the least oil absorption among all clusters was associated with USB4-NUS, with an amount of 4.96 %g/g. On the other hand, the highest oil content was observed in the NUSW73-NUS sample, which was measured equal to 22.4 %g/g.

The changes in oil content due to different US stages divided by the medium is illustrated in Table 2. As a novel method, [7] combined pulsed electric field with US assisted frying and reported that the hybrid method had the lowest oil content. Dual-stage US made a reduction in oil content of almost all the clusters. Except for the cases of 73 °C water and 4 °C brine, dual-stage US demonstrated a greater reduction in oil content when compared to the US pre-treatment. As mentioned, this reduction may be due to increase in the pore diameter which is in opposition of findings by [2]. Researchers [6] investigated US pretreatment's effect on oil absorption in sweet potato during frying. Sweet potatoes were treated with US in water, osmotic dehydration with and without US. Samples were then fried in sunflower oil at different temperatures and durations. US pretreatment in water reduced oil absorption in potato chips by 71.47 %. In another study, [9] conducted a study to examine the impact of US treatment on potato chips. They employed two power settings (360 W and 600 W) at a frequency of 20 kHz for a duration of 60 min. The use of lower power resulted in a 27.31 % reduction in surface oil absorption and a 22.25 % decrease in texture oil absorption. Conversely, higher US powers increased surface oil while only reducing tissue oil absorption by 38.05 %. Indeed, in this study US pre-treatment demonstrated a beneficial impact on oil absorption reduction among all treatments.

Table 2.

Fluctuations in oil content caused by the application of US (%).

| Pre-treatment | Assisted frying | Dual-stage | Pre-treatment vs. dual-stage | ||

|---|---|---|---|---|---|

| Brine | 4 °C | −3.89 | +155.92 | +99.18 | +107.25 |

| 25 °C | −39.68 | −20.13 | −42.75 | −5.09 | |

| 73 °C | −11.51 | +10.04 | –32.29 | –23.48 | |

| Water | 4 °C | −7.78 | +0.52 | −35.47 | −30.02 |

| 25 °C | −21.25 | −4.39 | –33.51 | −15.56 | |

| 73 °C | −26.52 | −2.21 | −18.52 | +10.89 |

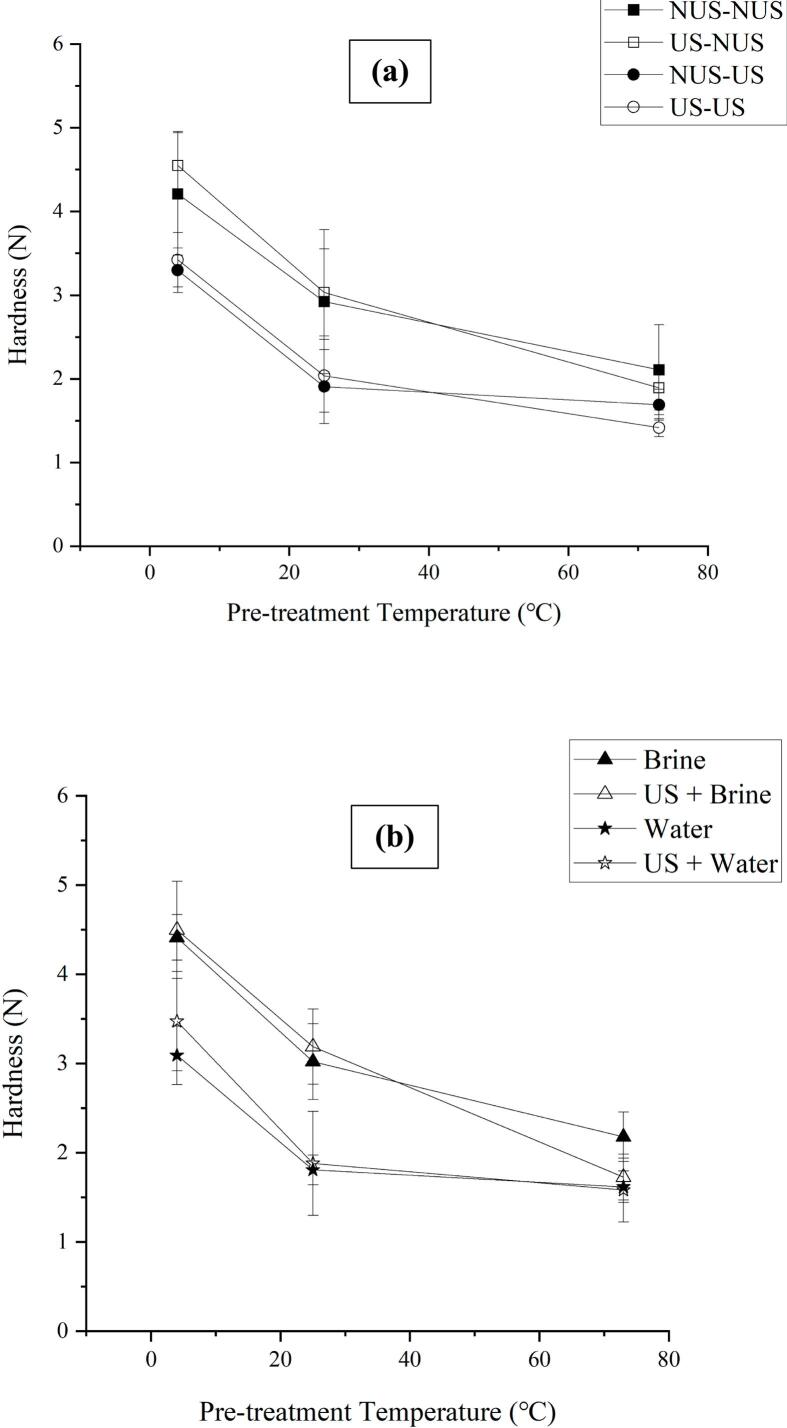

3.2. Hardness

Hardness and crispness have an inverse relationship since the hardness of potato chips was tested for the crispness index. As can be seen in (Fig. 5a) UAFS made a reduction in hardness observed across all treatments, while these differences were not statistically significant (p > 0.05). The impact of the US pre-treatment did not have a significant effect on hardness, whereas the most significant effect was observed in US-assisted frying.

Fig. 5.

Relationship between pre-treatment temperature and hardness with different (a), US mode; and (b), pre-treatment medium. Vertical I bars represent the standard deviation of each treatment.

Elevating the pre-treatment temperature in both water and brine mediums resulted in the production of more crispy chips samples (Fig. 5b). This is because the increase in temperature caused a decrease in micro density and an increase in porosity, which contributed to the crispiness of the chips. Pre-treating the potato slices with a brine medium resulted in less crispy chips at all temperatures. However, adding US to the pre-treatment with brine at 73 °C eliminated this difference and made the chips as crispy as those treated with water. The sample with the highest crispiness was USB73-US, which had a hardness of 1.413 N. In contrast, the firmest sample was USB4-NUS, with a hardness of 5.203 N. This is due to the combined effect of NaCl and cold water and absence of US during frying, which make the structure of the chips tenderer and more compact.

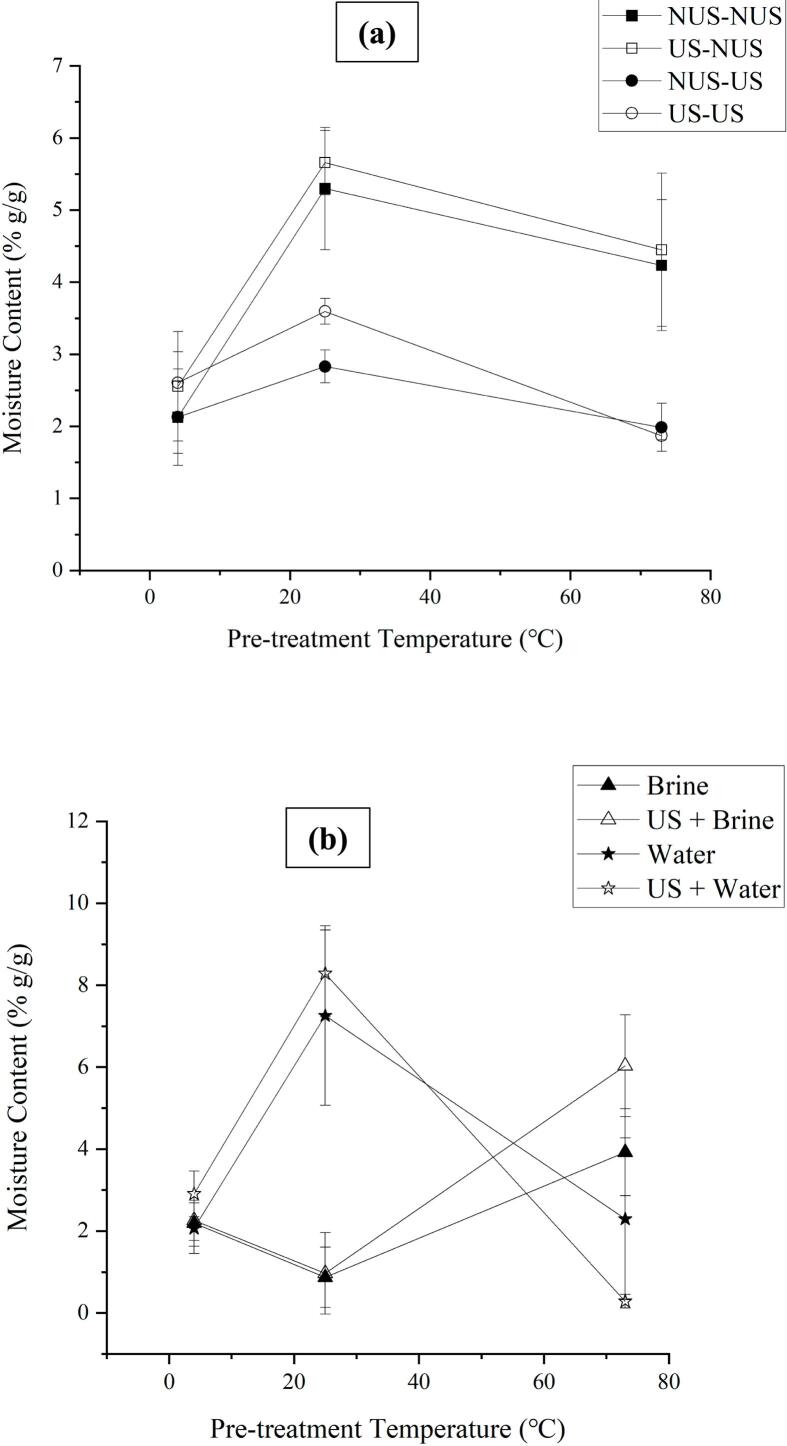

3.3. Moisture content

Moisture is one of the most important and effective factors on the quality of potato chips. Based on observations during sampling, potato chips samples treated in 4 °C became fully fried earlier than other samples. In this research, due to the considering a fixed frying duration, it caused the samples treated in 4 °C to lose a large amount of moisture at the end of the sampling time, and the data of this treatment group could not have a sufficient scientific basis for analysis and review. However, in this pre-treatment, there was no significant difference between water and brine mediums, because the mass transfer did not perform well at low temperature and the salt did not completely penetrate into the potato tissue. The texture of potato slices becomes more porous as the pre-treatment medium is heated up. As a result, potato chips pre-treated at a higher temperature tend to lose moisture more quickly during the frying process. When the treating medium is changed from water to brine, due to the osmotic pressure created in the microchannels of the potato tissue and the outflow of water from them, the moisture content of the treated sample decreases and it starts to be less moist at beginning of the frying process (Fig. 6). Since potato starch starts to gelatinize at temperatures above 60 °C and salt enhances the water-holding capacity of gelatinized starch, the potato samples treated in brine at 73 °C contained more moisture than anticipated (Fig. 7b).

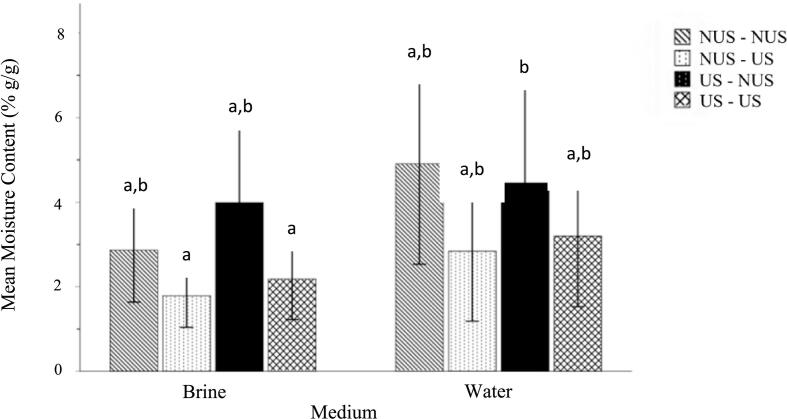

Fig. 6.

Mean moisture content of different US tretments, seperated by the medium. a,b represent no significant difference between the samples (p > 0.05). Vertical I bars represent the standard deviation of each treatment.

Fig. 7.

Relationship between pre-treatment temperature and moisture content with different (a), US mode; and (b), pre-treatment medium. Vertical I bars represent the standard deviation of each treatment.

The use of UAFS resulted in a decrease in the moisture content of the fried samples compared to the conventional frying method, attributed to an increase in the effective diffusion coefficient and mass transfer (Fig. 6 and Fig. 7a). US waves, through various mechanisms such as temperature rise in the boundary layer, cavitation-induced pressure changes, creation of microchannels from cavitation-induced cracking, disturbance in the boundary layer, and structural changes in the environment, may facilitate the outflow of moisture from food [24].

In general, the moisture content of the samples pre-treated in water has a wider range than the brine samples (Fig. 7b) which shows that by using salt in the treatment medium, it is possible to produce a final product with moisture in a certain range.

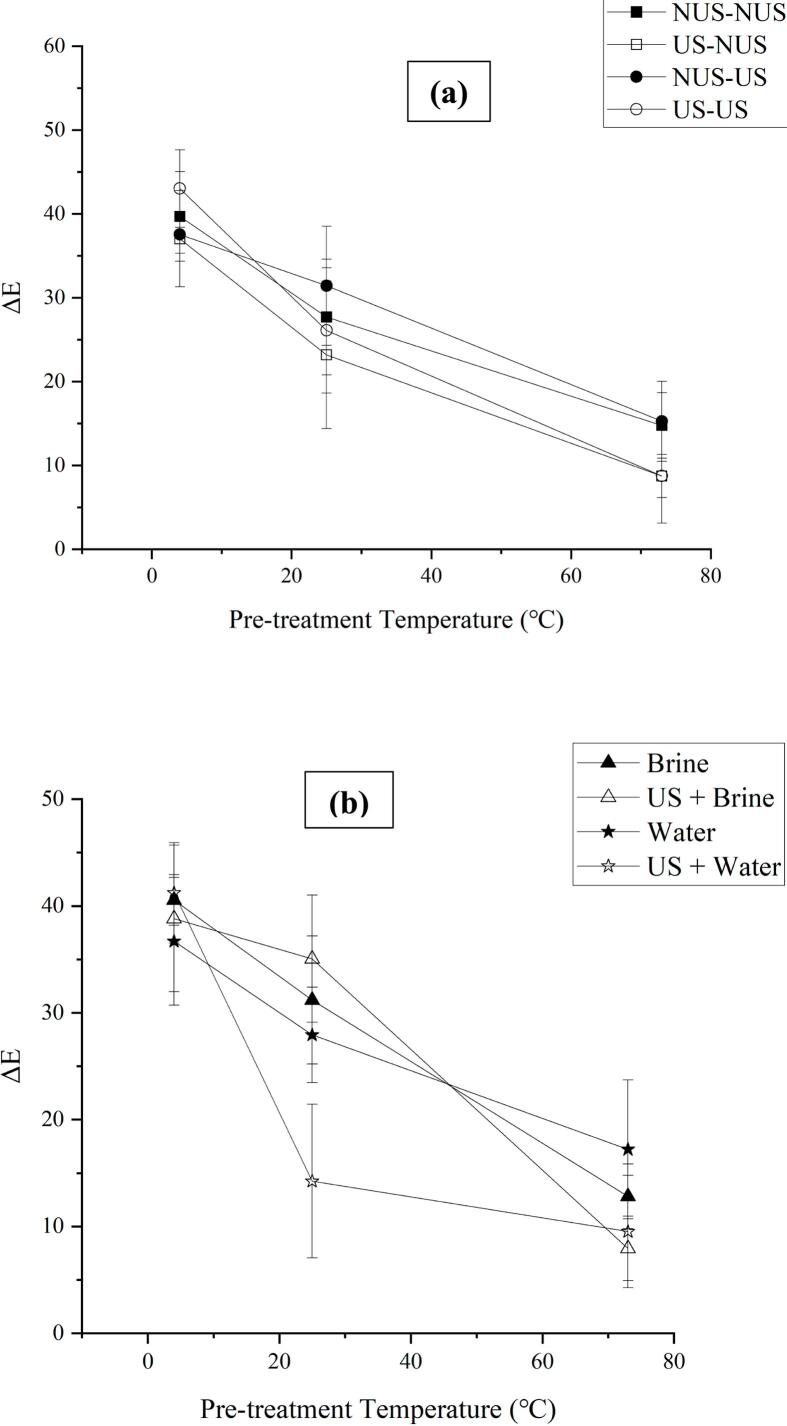

3.4. Color

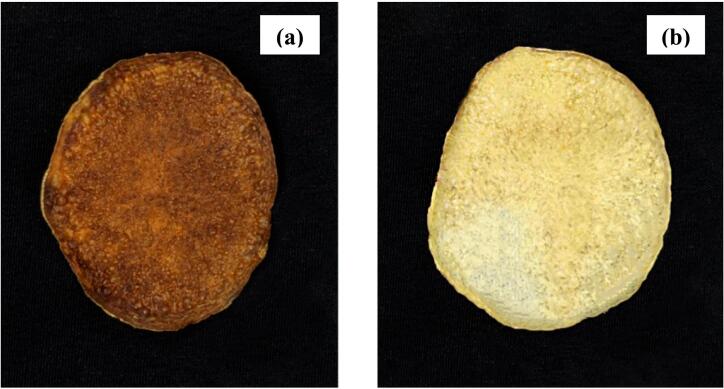

The potato chips color index (ΔE) is one of the crucial aspects of this product, since in addition to having a direct impact on sales, the darker chips denotes the presence of more acrylamide [25] which is one the carcinomic compounds in potato chips. The color of the processed chips was extracted using the specified method, and ΔE was calculated by measuring the difference between the color properties of the final product and the original raw sample. The samples with most and least color changes are shown in Fig. 8. The application of UAFS was not significant on color difference (p > 0.05)(Fig. 9a). In both water and brine mediums, the temperature 4 °C produced browned samples because of the high moisture loss and rapid frying as described earlier. Irrespective of medium and frying technique, 73 °C pre-treatment can significantly reduce the color difference and produce brighter product. As a matter of fact, activity of reducing sugars, amino acids and certain enzymes lead to the browning phenomenon. High temperature treatment helps with producing brighter final product by inactivation of enzymes such as polyphenol oxidase [26] and leeching the reducing sugars. Utilizing US in the pre-treatment stage had the most influence on the color properties (Fig. 9b).

Fig. 8.

Samples with most and least color change, (a) USB4-A; and (b), USB73-T.

Fig. 9.

Relationship between pre-treatment temperature and ΔE with different (a), US mode; and (b), pre-treatment medium. Vertical I bars represent the standard deviation of each treatment.

3.5. DOS

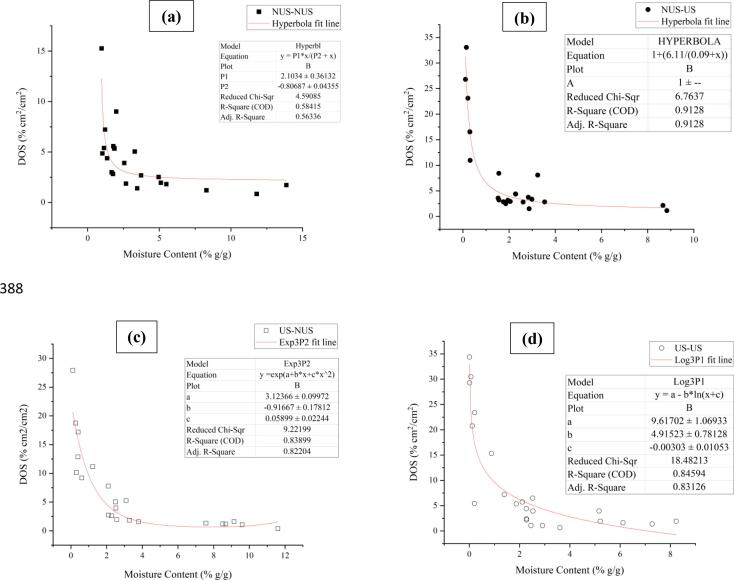

To ascertain whether the loss of moisture has a correlation with DOS, the DOS value of each group was measured and plotted against the moisture content (Fig. 10a:d).

Fig. 10.

Reverse correlation between DOS and moisture content for several US treatments, (a), NUS-NUS; (b), NUS-US; (c), US-NUS; and (d), US-US.

As is apparent, potato chips shrinkage increases with the amount of moisture they lose. The group of potato slices that did not receive any US treatments, referred to as the NUS-NUS group, showed a lower DOS compared to the other groups (Fig. 10a). This is likely due to the fact that this group experienced less moisture loss, since ultrasonication can cause water to be released from the potato cells. Additionally, since this group did not undergo any ultrasonication treatment, they experienced no deformation effects that can be caused by the mechanical forces generated by the sound waves. In the context of optimizing the treatment process, it can be inferred that the optimal treatment would involve using US with a lower DOS. More specifically, the recommended approach would be to apply US in such a way as to ensure uniformity in the shape of the slices, while avoiding any deformation.

3.6. Optimization report

In order to find the most suitable solutions that satisfy all the indicators, a data matrix was constructed and entered into the TOPSIS. The reason for applying optimization is that the individual measurements of each treatment may not be optimal, and thus, a comprehensive approach is needed to identify the optimal solution. For example, the 4 °C treatments had the largest color changes and the least amount of absorbed oil content, according to the explanations in the preceding sections. In contrast, the samples treated at 73 °C had extremely excellent color and hardness, but only some of the treatments in this group are able to effectively reduce oil absorption.

The selection of optimal samples was done considering oil absorption as the most important factor with the highest weight and DOS with the lowest weight. The results of TOPSIS optimization scoring (0 to 1) and the measured characteristics of the optimal potato chips are reported in Table 3. In the pre-treatment stage, ultrasonication was applied to all the samples that met the optimal criteria. Two of the five treatments that were chosen were administered utilizing US-US treatment and were dual-stage ultrasonicated. For the samples treated at 73 °C, two treatments were carried out in brine medium. This resulted from counteracting the opposing effects of NaCl and high temperature on potato tissue micro compaction and porosity, as these two variables cancel each other out in brine samples at 73 °C.

Table 3.

Optimum clusters’ quantities arranged ascending by their rank.

| Moisture Content | Oil Content | Hardness | Color | DOS | TOPSIS Score [0,1] | |

|---|---|---|---|---|---|---|

| Mean | Mean | Mean | Mean | Mean | ||

| S.D. | S.D. | S.D. | S.D. | S.D. | ||

| 1.USB73-US | 3.59 | 12.40c,d | 1.41e | 10.16 h,k | 4.23 m | 0.82 |

| ±1.60 | ±2.89 | ±0.09 | ±2.46 | ±1.49 | ||

| 2.USW25-US | 6.62a | 10.63c | 1.42e | 18.44 k | 3.25 m | 0.80 |

| ±1.27 | ±3.30 | ±0.45 | ±7.87 | ±2.79 | ||

| 3.USW25-NUS | 9.95b | 12.58c,d | 2.34 g | 10.05 h,k | 3.27 m | 0.77 |

| ±1.14 | ±1.52 | ±0.23 | ±2.52 | ±3.89 | ||

| 4.USB73-NUS | 8.48a,b | 16.20d | 2.04f,g | 5.75 | 3.44 m | 0.71 |

| ±0.73 | ±2.75 | ±0.28 | ±1.52 | ±3.91 | ||

| 5.USW73-NUS | 0.42 | 16.46d | 1.74e,f | 11.71 h,k | 14.49 | 0.69 |

| ±0.12 | ±0.31 | ±0.15 | ±6.56 | ±3.75 |

Mean values followed by similar letters are not significantly different (p > 0.05).

3.7. Sensory evaluation

Sensory characteristics of optimal samples were classified and analyzed based on panel scoring.

These attributes are subjective qualities that cannot be quantified by a device or any computer. The only way to assess them is by obtaining ratings based on people's opinions. Table 4 illustrates that the treatment that was most frequently consumed was USW25-NUS, which received an overall score of 8.4 ± 0.8. Conversely, the same treatment but fried using UAFS received the lowest score of 6.6 ± 0.49.

Table 4.

Sensory properties scoring report for potato chips processed by different treatments.

| Sample | Sensory characteristic | Panelist 1 |

Panelist 2 |

Panelist 3 |

Panelist 4 |

Panelist 5 |

Mean ± SD |

|---|---|---|---|---|---|---|---|

| USB73-US | Appearance | 6 | 8 | 7 | 8 | 6 | 7 ± 0.89a |

| Taste | 6 | 7 | 9 | 8 | 8 | 7.6 ± 1.02c | |

| Texture | 10 | 9 | 10 | 8 | 10 | 9.4 ± 0.8f | |

| Aroma | 8 | 10 | 9 | 8 | 8 | 8.6 ± 0.8 g | |

| Overall Acceptance | 7 | 8 | 8 | 8 | 7 | 7.6 ± 0.49 | |

| USW25-US | Appearance | 4 | 5 | 5 | 4 | 6 | 4.8 ± 0.75b |

| Taste | 8 | 9 | 10 | 10 | 8 | 9 ± 0.89c,d | |

| Texture | 10 | 8 | 9 | 9 | 9 | 9 ± 0.63f | |

| Aroma | 7 | 6 | 9 | 8 | 6 | 7.2 ± 1.17 g | |

| Overall Acceptance | 6 | 6 | 7 | 7 | 7 | 6.6 ± 0.49* | |

| USW25-NUS | Appearance | 10 | 10 | 10 | 9 | 9 | 9.6 ± 0.49 |

| Taste | 10 | 8 | 8 | 7 | 6 | 7.8 ± 1.33c,e | |

| Texture | 8 | 8 | 8 | 8 | 9 | 8.2 ± 0.4f | |

| Aroma | 10 | 10 | 10 | 8 | 9 | 9.4 ± 0.8 g | |

| Overall Acceptance | 9 | 9 | 9 | 8 | 7 | 8.4 ± 0.8* | |

| USB73-NUS | Appearance | 8 | 9 | 8 | 7 | 8 | 8 ± 0.63a |

| Taste | 10 | 10 | 10 | 10 | 10 | 10 ± 0.0d,e | |

| Texture | 8 | 8 | 9 | 8 | 9 | 8.4 ± 0.49f | |

| Aroma | 9 | 10 | 8 | 10 | 10 | 9.4 ± 0.8 g | |

| Overall Acceptance | 7 | 8 | 8 | 8 | 9 | 8 ± 0.63 | |

| USW73-NUS | Appearance | 6 | 6 | 5 | 7 | 7 | 6.2 ± 0.75a,b |

| Taste | 8 | 9 | 10 | 10 | 10 | 9.4 ± 0.8c | |

| Texture | 9 | 10 | 9 | 8 | 8 | 8.8 ± 0.75f | |

| Aroma | 9 | 10 | 10 | 9 | 10 | 9.6 ± 0.49 g | |

| Overall Acceptance | 7 | 7 | 6 | 7 | 8 | 7 ± 0.63 | |

a,b,c… Mean values followed by similar letters are not significantly different (p > 0.05).

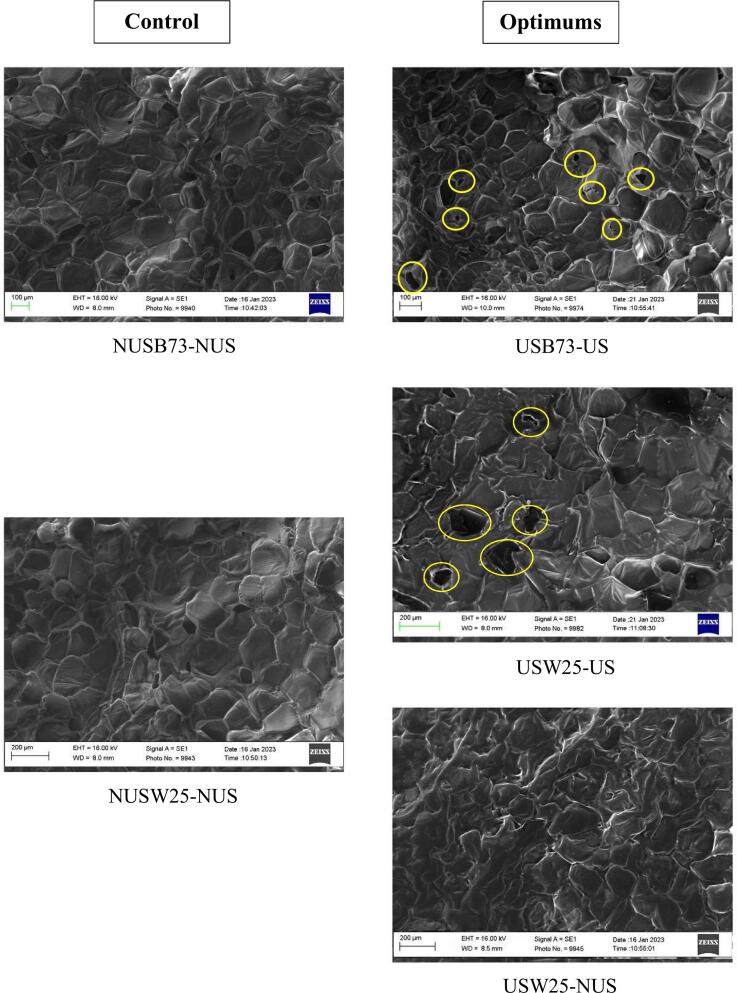

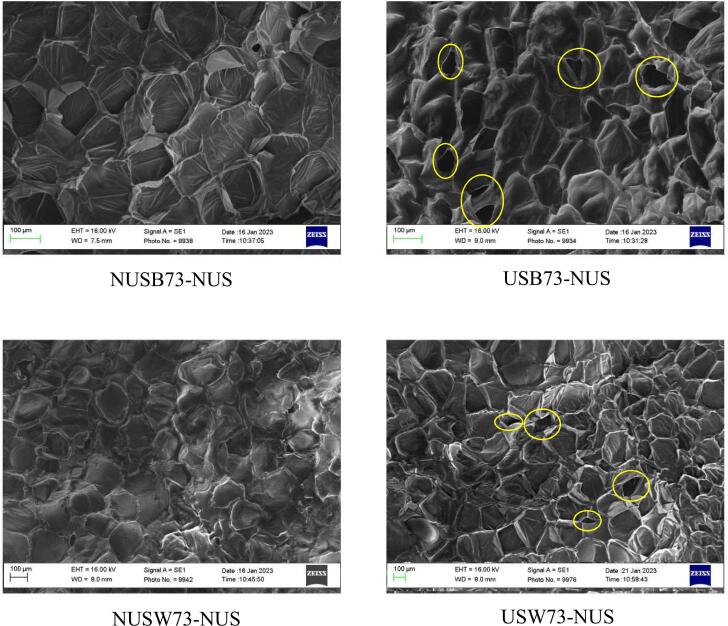

3.8. Texture analysis

Impact of US on microstructural texture of potato chips was studied for the optimum treatments and the control (did not receive US at any stage). Fig. 11 shows the SEM images of these samples arranged according to their optimization rank. All the control samples show a uniform and integral texture without any holes and fractions. While, the utilization of US in both phases (pre-treatment and in-treatment) resulted in the disruption of cell walls and significant damage to the integrity of cells. Specifically, US pretreatment has resulted in the formation of holes in the cellular structure of potato chips. However, the effects of US in the presence of salt are more clearly noticeable and the temperature of 73 °C has intensified these effects, causing an increase in porosity of the chips as well as the pore diameter. However, these effects could also make the water movement in the matrix easier during frying and reduce the final moisture content of the chips. In USW25-US and specifically USB73-US, due to the US applying during frying, the cells were clearly collapsed and even holes and disruptions can be observed. In USB73-US, cell wall fracture is visible, which was not seen in other treatments. The more cell wall fractures and porous microstructure explain the reduced oil contents and crispness of the chips fried by UAFS. When the potato chips were pretreated by US, it was observed that some cells did not have their original shape due to the irregular deformations caused by US, while the control samples kept their original cell structure. This phenomenon may be due to the water evaporation during frying rather than oil absorption [9]. The induced porous microstructure by the US pretreatment helps to the water migration and vapor expansion during the frying process, leading to the irregular deformation of cells. The deformation of cells shape and disruption of cell walls may lead to the change in the oil location of potato chips. Oil seemed to accumulate in the concave shells which are indicated by the circles in Fig. 11, due to the lower resistance of intercellular spaces leading to the changes in oil distribution [9], while applying US in chips frying may reduce the surface adhesion coefficient of the oil and the intercellular spaces of the fried chips which results in reduction of oil absorption (Table 2).

Fig. 11.

SEM images of the optimal samples and their control samples.

4. Conclusion

Based on the oil content, hardness, moisture content, color, DOS, and overall sensory acceptance, it can be concluded that US is an effective technology in producing healthier and higher-quality potato chips by applying at both the pre-treatment and dual-stage modes. The use of US in the pre-treatment phase accelerates the reduction of enzyme activities and decreases the presence of free sugars, resulting in minimal color changes during frying. UAFS yields more crispy chips, serves as a complement to specific pre-treatments, and prevents excessive oil absorption by the potato texture while enhancing the frying process. Optimization results demonstrate the treatments without US failed to meet the desired standards. SEM images reveal that US disrupts cell walls and alters tissue structure, thereby reducing available space for oil absorption. In comparison to immersion pre-treatment, US pre-treatment significantly reduced oil absorption. Additionally, applying US during the frying stage further decreases oil absorption of specific clusters. US pre-treatment in 73 °C brine and then utilizing UAFS (USB73–US) produced the best optimal cluster with 12.39 %g/g final oil content. Sensory evaluation proved that the final products produced using this innovative method are not only healthy but also delicious to consumers. Furthermore, to provide a more scientific and conclusive evaluation of the 4 °C pre-treatment with dual-stage US, further experiments should be conducted, taking into account the frying duration as a variable. The additional experiments would enable a thorough investigation of the performance and effectiveness of the pre-treatment. By analyzing the effects of different frying durations, a more accurate and definitive opinion can be formed regarding the efficacy of this pre-treatment method. In future research and investigation, it is important to explore the heat transfer effects of an UAFS and its impact on frying time at various frying temperatures. Examining the heat transfer characteristics of this fryer system and studying how it influences the duration of the frying process can provide valuable insights. By understanding the interplay between heat transfer and frying time under different temperature conditions, further advancements and optimizations can be made in the development of UAFS. Researching the effects of power and duty cycle adjustments in both US stages is essential for optimizing outcomes and improving efficiency.

CRediT authorship contribution statement

Peyman Alikhani Chamgordani: Data curation, Formal analysis, Investigation, Visualization, Writing – original draft. Mahmoud Soltani Firouz: Project administration, Resources, Validation. Mahmoud Omid: Project administration, Resources, Validation. Nikoo Hadidi: Formal analysis, Software. Pouya Farshbaf Aghajani: Visualization, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Dourado C., Pinto C., Barba F.J., Lorenzo J.M., Delgadillo I., Saraiva J.A. Innovative non-thermal technologies affecting potato tuber and fried potato quality. Trends Food Sci. Technol. 2019;88:274–289. [Google Scholar]

- 2.Liu Y., Tian J., Zhang T., Fan L. Effects of frying temperature and pore profile on the oil absorption behavior of fried potato chips. Food Chem. 2021;345 doi: 10.1016/j.foodchem.2020.128832. [DOI] [PubMed] [Google Scholar]

- 3.Huang X., Zhang Y., Karrar E., Zhang H., Jin Q., Wu G., Wang X. Effect of moderate electric field on the quality, microstructure and oil absorption behavior of potato strips during deep-fat frying. J. Food Eng. 2022;313 [Google Scholar]

- 4.Liu Y., Tian J., Duan Z., Li J., Fan L. Effect of oil surface activity on oil absorption behavior of potato strips during frying process. Food Chem. 2021;365 doi: 10.1016/j.foodchem.2021.130427. [DOI] [PubMed] [Google Scholar]

- 5.Moreira R.G., Da Silva P.F., Zheng T. Calcium chloride impregnation of potato slices using ultrasound to reduce oil absorption during frying. J. Food Process Eng. 2020;44 [Google Scholar]

- 6.Oladejo A.O., Ma H., Qu W., Zhou C., Wu B., Yang X., Onwude D.I. Effects of ultrasound pretreatments on the kinetics of moisture loss and oil uptake during deep fat frying of sweet potato (Ipomea batatas) Innov. Food Sci. Emerg. Technol. 2017;43:7–17. [Google Scholar]

- 7.Ostermeier R., Hill K., Dingis A., Töpfl S., Jäger H. Influence of pulsed electric field (PEF) and ultrasound treatment on the frying behavior and quality of potato chips. Innov. Food Sci. Emerg. Technol. 2021;67 [Google Scholar]

- 8.Su Y., Zhang M., Chitrakar B., Zhang W. Reduction of oil uptake with osmotic dehydration and coating pre-treatment in microwave-assisted vacuum fried potato chips. Food Biosci. 2021;39 [Google Scholar]

- 9.Zhang J., Xie T., Fan L. Improving the quality and reducing oil absorption of fried potato chips by ultrasound pretreatment. Lwt. 2021;148 [Google Scholar]

- 10.Zheng T., Moreira R.G. Magnesium ion impregnation in potato slices to improve cell integrity and reduce oil absorption in potato chips during frying. Heliyon. 2020;6 doi: 10.1016/j.heliyon.2020.e05834. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Honerlaw J.P., Ho Y.-L., Nguyen X.-M.-T., Cho K., Vassy J.L., Gagnon D.R., O'Donnell C.J., Gaziano J.M., Wilson P.W.F., Djousse L. Fried food consumption and risk of coronary artery disease: the million veteran program. Clin. Nutr. 2020;39:1203–1208. doi: 10.1016/j.clnu.2019.05.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Antunes-Rohling A., Ciudad-Hidalgo S., Mir-Bel J., Raso J., Cebrián G., Álvarez I. Ultrasound as a pretreatment to reduce acrylamide formation in fried potatoes. Innov. Food Sci. Emerg. Technol. 2018;49:158–169. [Google Scholar]

- 13.Schouten M.A., Genovese J., Tappi S., Di Francesco A., Baraldi E., Cortese M., Caprioli G., Angeloni S., Vittori S., Rocculi P., Romani S. Effect of innovative pre-treatments on the mitigation of acrylamide formation in potato chips. Innov. Food Sci. Emerg. Technol. 2020;64 [Google Scholar]

- 14.Kim T., Moreira R.G. De-Oiling and Pretreatment for High-Quality Potato Chips. J. Food Process Eng. 2013;36:267–275. [Google Scholar]

- 15.Cárcel J.A., Benedito J., Bon J., Mulet A. High intensity ultrasound effects on meat brining. Meat Sci. 2007;76:611–619. doi: 10.1016/j.meatsci.2007.01.022. [DOI] [PubMed] [Google Scholar]

- 16.P. Fellows, Acknowledgements, in: P.J. Fellows (Ed.) Food Processing Technology (Third Edition), Woodhead Publishing, 2009, pp. xvi.

- 17.Mestdagh F., De Wilde T., Fraselle S., Govaert Y., Ooghe W., Degroodt J.-M., Verhé R., Van Peteghem C., De Meulenaer B. Optimization of the blanching process to reduce acrylamide in fried potatoes. LWT Food Sci. Technol. 2008;41:1648–1654. [Google Scholar]

- 18.Sahin S., Sastry S.K., Bayindirli L. The determination of convective heat transfer coefficient during frying. J. Food Eng. 1999;39:307–311. [Google Scholar]

- 19.AOAC, The Association of Official Analytical Chemists, (2000) 471-471.

- 20.Podolsky R.D. Temperature and water viscosity: physiological versus mechanical effects on suspension feeding. Science. 1994;265:100–103. doi: 10.1126/science.265.5168.100. [DOI] [PubMed] [Google Scholar]

- 21.Del Grosso V., Mader C. Speed of sound in pure water. J. Acoust. Soc. Am. 1972;52:1442–1446. [Google Scholar]

- 22.Zolfagharpour F., Nezhad F.N. The ultraviolet cutoff and water temperature dependence of the sonoluminescence bubble spectrum. Chin. J. Phys. 2014;52:1802–1811. [Google Scholar]

- 23.Mariotti M., Cortés P., Fromberg A., Bysted A., Pedreschi F., Granby K. Heat toxicant contaminant mitigation in potato chips. LWT Food Sci. Technol. 2015;60:860–866. [Google Scholar]

- 24.Dolatowski Z., Stadnik J., Stasiak D. Applications of ultrasound in food technology. Acta Scientiarum Polonorum: Technologia Alimentaria. 2007;6 [Google Scholar]

- 25.Pedreschi F., León J., Mery D., Moyano P. Development of a computer vision system to measure the color of potato chips. Food Res. Int. 2006;39:1092–1098. [Google Scholar]

- 26.Moscetti R., Raponi F., Monarca D., Bedini G., Ferri S., Massantini R. Effects of hot-water and steam blanching of sliced potato on polyphenol oxidase activity. Int. J. Food Sci. Technol. 2019;54:403–411. [Google Scholar]