The upswing in EV sales means a flood of used batteries in the coming years. What's the best way to minimize their environmental impact and reuse precious minerals?

Sales of electric vehicles (EVs) continue to grow. According to the Paris-based International Energy Agency, 2.3 million EVs sold worldwide in the first three months of 2023 alone, which was 25% higher than the same stretch in 2022. At this rate, by the end of the decade, more than 60% of new vehicles sold could be EVs, and the world could see more than 250 million on the roads (1).

Discarded LIBs can overheat and catch on fire, while also posing an environmental threat due to toxic metals. So, what to do with them? Researchers generally talk about either recycling or reusing as part of less-demanding applications. But the right path to technical and economic viability is still unclear. Image credit: Shutterstock/Smile Fight.

But there’s a problem in the offing: EV batteries have a limited lifespan, usually 10–20 years, and companies are not ready to handle the coming glut of tens of millions of used batteries. And experts predict that full decarbonization will require more than 100 terawatt-hours of battery storage—which is about 100 times the current global production and sums to billions of tons of new batteries.

EVs use lithium-ion batteries (LIBs), which can’t simply be thrown into landfills—partly because they can overheat and burst into flames. Smaller LIBs have caused hundreds of fires in the United States, sometimes in the back of trash trucks. Discarded EV batteries also pose an environmental threat. Left to break down in a landfill, they could leach toxic metals into the environment (2).

So, what to do with them? Researchers generally talk about two options: reusing in less-demanding applications, such as golf carts or grid storage, and recycling. The latter could, in principle, directly lead to a new source of batteries and a revenue stream for companies, which is why researchers are racing to develop cost-effective and sustainable battery recycling technology. “Every single car company has research and development around recycling,” says chemical engineer Ilias Belharouak, head of the Electrification Section at the Oak Ridge National Laboratory in Tennessee, who has been working on high-density LIBs for more than 20 years.

The basics are in place, he says. Some of the necessary processes are already in use, but not efficient enough to handle the coming flood. “We are trying to look at these existing processes, but we’re also looking at ways that do not exist today in industry,” Belharouak says. Using components from old batteries rather than newly mined materials could offer a win–win: The approach mitigates the environmental threat, provides a steady stream of materials, and is financially appealing.

Lead and Lithium

Developed in the 1970s, LIBs have a high energy density, which correlates to a long runtime between charges. They appeared on the market when Sony began selling the first commercial LIB in 1991. “But nobody actually talked about recycling,” Belharouak says. “They never thought that the market would explode, that it would grow to these levels.” Even when it did, he says, “recycling was mainly left to industry to deal with.”

Scientists and engineers focused on optimal recycling methods might do well to look to the past for lessons on what to pursue—and what to avoid. The lead-acid battery, which is also rechargeable, was developed in the 1850s, and methods for the large-scale recovery of lead were well under way in the 1920s (3). It has remained a workhorse ever since; it’s still used for ignitions and lights in today’s cars. Almost every part of a lead-acid battery can be recycled. The lead and plastic recovered from old batteries can readily be reused in new ones, and most estimates place the recycling rate at higher than 95%. The US Environmental Protection Agency estimates that in 2018, the most recent year studied, 99% of all battery lead in the United States was recycled. But it’s not a resounding victory: Unsafe battery recycling facilities, especially in low- to middle-income countries, have led to widespread lead poisoning and what some experts call a major environmental threat to the health of children (4, 5).

A major challenge for LIBs is to recover the valuable metals, such as lithium and cobalt, without incurring major environmental and health costs. Given the future prospect of billions of tons of batteries, experts also need to think about recycling the less valuable (but still increasingly expensive) components, such as copper and aluminum. Recycling LIBs is more complicated than recycling lead-acid batteries, and it’s a much newer industry. An oft-debated, oft-cited 2013 report estimated that only about 5% of LIBs were recycled (6). The number may have increased since, but global rates are hard to estimate, Belharouak says, because companies have different definitions of EV battery recycling and because most recycling happens in China, where there is little access to such information.

However, he cautions that the methods used today are expensive, detrimental to the environment, and inefficient. LIBs are much more complex and have more components than conventional lead-acid batteries, making them harder to disassemble. The most common recycling methods focus on cobalt, nickel, and lithium, he explains, but industries haven’t fully reckoned with the other ingredients, such as copper, aluminum, and the electrolyte. “Attempting to scale up these industries while still facing the same issues,” he says, will mean “magnifying the problems that are associated with them.”

Researchers are working on the best ways to recycle EV battery components, including those seen here postshredding: (left to right) black mass (a mix of anode and cathode materials), plastic, and metals. Image credit: Christopher Kramer (Argonne National Laboratory).

Fire and Acid

Recycling begins with separating the materials. Commercial approaches typically use two main methods, sometimes combined (7): pyrometallurgy, using intense heat to remove metal; and hydrometallurgy, in which a soup of liquids—traditionally acids—leaches out the recoverable metals.

For pyrometallurgy, used batteries are dismantled and crushed, then heated, usually above 500 degrees Celsius. This evaporates the liquid part of the electrolyte, leaving the lithium salts behind. They’re heated further. As the temperature soars to above 1,400 degrees Celsius, metals such as cobalt, nickel, copper, and iron melt and can be recovered and purified for reuse. Other metal oxides break down into useful compounds.

Lithium often remains in the slag and is difficult to extract. But in the last few years, researchers have found that by adding certain salts, they can increase the recovery of lithium, along with manganese, which is also usually lost at this stage. Experimental tests have reportedly leached out 90–100% of the lithium, a promising step. However, this method requires chemicals that lead to additional waste streams (8).

Pyrometallurgy can be scaled up and even used for other types of rechargeable batteries, such as nickel–metal hydride batteries. But it’s energy-intensive and produces greenhouse gases and other environmentally dangerous by-products.

The other process, hydrometallurgy, doesn’t have the same energy requirement, as it can be carried out well below 100 degrees Celsius. “It’s basically dissolving these lithium ion cells into acids, mostly sulfuric acid,” Belharouak explains. This turns the batteries into a caustic liquid, from which the metals in the cathode—including the lithium—can be precipitated.

But hydrometallurgy has its own waste problems. “This process needs a lot of solvent, and it produces a lot of pollutants,” says chemical engineer Zaiping Guo at the University of Adelaide, in Australia. There may be ways to reduce the environmental load: Researchers in Sweden (9), for example, recently showed how oxalic acid might be used to recover almost all the lithium from shredded batteries—and with a much smaller environmental risk.

Some recyclers combine the two methods, using hydrometallurgy to extract lithium and other cathode materials in the stuff left over after pyrometallurgy, but that adds expensive steps to the process.

Full Circle

And it’s quite possible that neither conventional hydrometallurgy nor pyrometallurgy will solve the recycling conundrum. “When you look only at those two processes, you only get an incremental improvement—no game-changers,” says chemical engineer Jeffrey Spangenberger at Argonne National Laboratory, in Chicago. What’s needed, says Guo, is an environmentally friendly, closed-loop system—a series of steps that can reuse materials and mine nearly all the metal, of all types, from old batteries without producing new troublesome waste streams. The potential benefits of closed-loop recycling include zero emissions of carbon dioxide and nitrogen oxides, benefiting both the climate and air quality.

Materials scientist Eric Gratz, who helped start Ascend Elements in Westborough, Massachusetts, says his company’s approach achieves those objectives. It’s called direct precursor synthesis, and he describes it as a modified hydrometallurgical process. It begins the same way, shredding the batteries. But whereas conventional hydrometallurgy uses chemicals to remove the metals, Ascend Elements instead uses chemicals to leach out both lithium and impurities, leaving behind nickel, cobalt, and manganese in an aqueous solution. The exact proportions can be adjusted in the solution, Gratz says, by adding small amounts of recycled or virgin materials. With the right proportions, he says, new cathode precursor material can be synthesized from the solution.

“We recover our water; we recover all the main components in the lithium-ion battery,” Gratz says. “The water is collected and reused. There is no chemical waste.” The company also prioritizes recovering all the metals, not just lithium. “The copper, aluminum, plastics, graphite, cathode material—all of that is recycled,” Gratz says. In findings from lab tests of the approach published in Joule in November 2021 (10), new batteries made with the recycled material often had better cycle life than batteries made with virgin materials extracted from ore. The researchers, led by Ascend Elements co-founder Yan Wang, noted that the recycling process tweaked the crystal structure of the cathode material by introducing larger voids and higher surface area, which likely contributed to the improvement in efficiency.

“Battery technology will keep evolving, and at some point, the majority of materials used in batteries will be recycled, not mined.”

—Eric Gratz

A third method, often called direct recycling, involves rejuvenating spent electrodes by replenishing the lithium ions from used batteries, without resorting to caustic acids at all (11). “At the end of life, they become a little aged,” Belharouak says. Cathode materials can become damaged and lose some of their lithium content, but if they’re not too damaged, an attempt can be made to reverse the process. To restore them, he says, they can be mixed with lithium hydroxide and heated to a high temperature. The process both restores the lithium content and can repair minor damage to the surface. But it’s not easy to standardize, he notes: The amount of lithium required to restore full function to the cathode can vary dramatically from battery to battery. Princeton NuEnergy, in New Jersey, is pursuing a similar form of direct recycling, applying low-temperature plasma to spent cathodes and anodes to remove contaminants and enable the material to be used in new batteries.

But it’s too early to know whether it will catch on, Belharouak says. There are issues to resolve, including guaranteeing the quality of the recovered materials, to convince battery makers to use them. “At the end of the day, it’s all about performance”, he says, "and if a manufacturer finds that my recycled material doesn’t give the same performance, they may not go with it.”

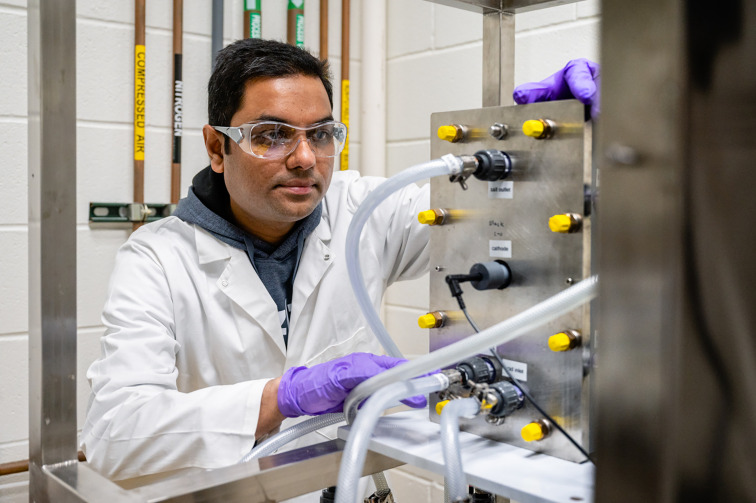

Researchers at Argonne National Laboratory, including environmental engineer Golam Hyder, shown here, are finding ways to reduce the environmental impact of using lithium in new electrode materials. Image credit: Christopher Kramer (Argonne National Laboratory).

Recharging Ahead

To help overcome these challenges, the US Department of Energy launched the ReCell Center, based at Argonne National Laboratory, in February 2019. It focuses on research and development that could lead to the kind of closed-loop system that Spangenberger and others envision. Direct recycling is its main focus. The DOE program is also looking at better ways to recover and use leftover electrode material. To make the electrodes for an LIB, a manufacturer takes rolls of a thin current collector (usually copper or aluminum foil) and applies a coating—graphite on copper for the anode, or cathode material on aluminum for the cathode. They then cut out patterns according to the shape and size of the battery, leaving the rest as scraps.

Belharouak says those scraps, often discarded as waste, offer an untapped opportunity if they can be repurposed in new batteries. In April 2021, he and his colleagues reported the successful test of an environmentally friendly, inexpensive, and recyclable solvent that successfully separates the coating from the current-collecting foil (12). The cathode material or graphite can be reused, and the foil can be incorporated into a new roll, ready to be recut into new electrodes.

Researchers point to three things that need to happen to make EV battery recycling efficient and appealing to manufacturers. First, a successful process has to entice EV companies, both by producing batteries that they will actually use and by giving them an incentive to recycle old ones, Spangenberger says. “Working with manufacturers to build batteries that are easier to recycle is a great opportunity to improve recyclability in the future,” he says.

Second, Belharouak says, the technology needs to scale up. In March 2023, Ascend Elements opened a large recycling facility in Covington, Georgia, that, once at full capacity, the company claims will be able to handle batteries from 70,000 EVs every year. But, to meet demand, every state would need its own comparable factory, he says. Four million EVs were sold in 2021 alone.

Finally, experts agree that recycling considerations must drive the design of future batteries. As an example, consider the LIB found in the 2017 Toyota Prius Prime, which has a battery pack consisting of five modules, each with 19 connected cells. The cells are the smallest individual component. Right now, if one cell in a heavy Prius battery pack goes bad, the repair usually involves replacing the whole battery. A more recycling-friendly design would allow the removal of the defective cell, or at least the module, without losing the entire pack.

As warranties expire on EVs, batteries will begin to pile up—slowly at first, then likely in a rush, not unlike the rollout of EVs in the last decade or so. Gratz, at Ascend Elements, thinks that the long lifetimes of today’s EV batteries will give chemists and companies plenty of time—even decades—to come up with ways to scale up the technology. “Battery technology will keep evolving,” he says, “and at some point, the majority of materials used in batteries will be recycled, not mined.” He notes that Ascend Elements is mainly a cathode material supplier, and early on, the company realized that sourcing metals from recycled batteries, rather than new, would lead to lower production costs.

Other recycling companies are similarly expanding their reach and scaling up, though they still won’t be able to meet the full future demand. In August 2023, the Canada-based recycling company Li-Cycle launched a facility in Germany capable of shredding LIBs—of any kind—to produce “black mass” that could later be used to build new cathodes. A pilot recycling plant opened in October 2022, in McKinney, Texas, to test new direct cathode recycling technology developed by researchers at Princeton NuEnergy.

But in the years ahead, the recycling challenge will depend in part on how batteries themselves evolve. Toyota has announced plans, for example, to introduce an EV in the next few years that runs on a solid-state battery, which, as the name suggests, uses a solid, rather than liquid, electrolyte. These batteries promise an energy density more than twice that of today’s LIBs, which means they’ll last longer because they won’t need to go through as many cycles of charging and discharging, which degrade a battery. Researchers have only just begun to investigate ways to recycle them and how to use today’s lithium in tomorrow’s solid-state batteries (13). Regardless, it’s going to be a big challenge, Belharouak says. Conventional LIBs use graphite as the anode. Solid-state batteries instead use lithium metal, which is highly reactive when exposed to air and moisture, he says, “making the recycling process more complex.” Any process, he says, will have to adapt to those challenges.

Belharouak also points to growing interest in “second-life” applications for EV batteries. In a report published in July 2023, for example, the Natural Resources Defense Council highlights ways that used EV batteries may be repurposed for grid energy storage or for use in lower-demand vehicles like golf carts (14). Doing so shouldn’t be particularly challenging, though it’s not yet profitable or commonplace. Used EV batteries are readily available online, and a handful of startup companies are developing devices that wire together depleted EV batteries to store excess energy, such as from solar panels. The German car company BMW has put used batteries from its vehicles to work in a battery storage farm in Leipzig that stores energy generated by nearby wind turbines and is connected to the grid. In 2018, the car company Nissan developed a power system for a stadium in Amsterdam using 148 new and used batteries from Leaf automobiles; the batteries collected energy from solar panels on the arena’s roof. Reusing batteries, Belharouak notes, won’t obviate the need for EV batteries or better recycling technology, but it does give existing batteries a longer life.

No matter how the field expands, better recycling and battery designs will help EVs grow, Spangenberger says. “Recycling should make it cheaper to make new batteries, and as we drive down the cost of batteries, more people can drive EVs, and that’s good,” he says. “It can help decarbonize the world.”

References

- 1.International Energy Agency, Electric vehicles. https://www.iea.org/energy-system/transport/electric-vehicles. Accessed 25 May 2023.

- 2.Kilgo M. K., Anctil A., Kennedy M. S., Powell B. A., Metal leaching from lithium-ion and nickel-metal hydride batteries and photovoltaic modules in simulated landfill leachates and municipal solid waste materials. Chem. Eng. J. 431, 133825 (2022). [Google Scholar]

- 3.Turner J. M., Following the Pb: An envirotechnical approach to lead-acid batteries in the United States. Env. His. 20, 29–56 (2015). [Google Scholar]

- 4.Pearce F., Getting the lead out: Why battery recycling is a global health hazard. YaleEnvironment360 (2020). https://e360.yale.edu/features/getting-the-lead-out-why-battery-recycling-is-a-global-health-hazard. Accessed 27 October 2023. [Google Scholar]

- 5.Ballantyne A. D., Hallett J. P., D. J., Riley, Shah N., Payne D. J., Lead acid battery recycling for the twenty-first century. R. Soc. Open Sci. 5, 171368 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Friends of the Earth Europe et al. , Less is more: Resource efficiency through waste collection, recycling and reuse of aluminium, cotton and lithium in Europe (2013). https://www.foeeurope.org/sites/default/files/publications/foee_report_-_less_is_more_0.pdf. Accessed 30 November 2023.

- 7.Zhou L.-F., Yang D., Du T., Gong H., Luo W.-B., The current process for the recycling of spent lithium ion batteries. Front. Chem. 8, 578044 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Baum Z. J., Bird R. E., Yu X., Ma J., Lithium-ion battery recycling─Overview of techniques and trends. ACS Energy Lett. 7, 712–719 (2022). [Google Scholar]

- 9.Rouquette L. M. J., Petranikova M., Vieceli N., Complete and selective recovery of lithium from EV lithium-ion batteries: Modeling and optimization using oxalic acid as a leaching agent. Sep. Purif. Technol. 320, 124143 (2023). [Google Scholar]

- 10.Ma X., et al. , Recycled cathode materials enabled superior performance for lithium-ion batteries. Joule 5, 2955–2970 (2021). [Google Scholar]

- 11.Gao H., Tran D., Chen Z., Seeking direct cathode regeneration for more efficient lithium-ion battery recycling. Curr. Opin. Electrochem. 31, 100875 (2022). [Google Scholar]

- 12.Bai Y., Essehli R., Jafta C. J., Livingston K. M., Belharouak I., Recovery of cathode materials and aluminum foil using a green solvent. ACS Sustainable Chem. Eng. 9, 6048–6055 (2021). [Google Scholar]

- 13.Waidha A. I., et al. , Recycling of All-Solid-State Li-ion Batteries: A Case Study of the Separation of Individual Components Within a System Composed of LTO, LLZTO and NMC. ChemSusChem 16, e20220236 (2023). [DOI] [PubMed] [Google Scholar]

- 14.Brinn J., “Building batteries better: Doing the best with less” (Rep. 23-08-9, National Resources Defense Council, 2023).