Significance

Transfer printing is of significant technological importance due to its great potential for developing existing or envisioned electronic systems. In this work, we report a laser-driven noncontact bubble transfer printing via a hydrogel composite stamp, which provides a reversible thermal controlled adhesion through the liquid–gas phase transition of water in the hydrogel. The stamp offers benefits of strong adhesion under a small preload and adhesion elimination through the surface bulging due to the strong light-matter interaction at the interface, which cannot be accessible by existing stamps. Demonstrations of deterministic assemblies on various surfaces (e.g., flat, curved, roughed, droplet) illustrate its extraordinary capabilities of damage-free pick-up and receiver-independent printing.

Keywords: transfer printing, laser-driven, hydrogel stamp, adhesion strength

Abstract

Transfer printing that enables heterogeneous integration of materials into spatially organized, functional arrangements is essential for developing unconventional electronic systems. Here, we report a laser-driven noncontact bubble transfer printing via a hydrogel composite stamp, which features a circular reservoir filled with hydrogel inside a stamp body and encapsulated by a laser absorption layer and an adhesion layer. This composite structure of stamp provides a reversible thermal controlled adhesion in a rapid manner through the liquid–gas phase transition of water in the hydrogel. The ultrasoft nature of hydrogel minimizes the influence of preload on the pick-up performance, which offers a strong interfacial adhesion under a small preload for a reliable damage-free pick-up. The strong light-matter interaction at the interface induces a liquid–gas phase transition to form a bulge on the stamp surface, which eliminates the interfacial adhesion for a successful noncontact printing. Demonstrations of noncontact transfer printing of microscale Si platelets onto various challenging nonadhesive surfaces (e.g., glass, key, wrench, steel sphere, dry petal, droplet) in two-dimensional or three-dimensional layouts illustrate the unusual capabilities for deterministic assembly to develop unconventional electronic systems such as flexible inorganic electronics, curved electronics, and micro-LED display.

Transfer printing is a versatile heterogeneous integration technique to deterministically assemble micro/nano-objects (i.e., inks) fabricated on the grown substrates (i.e., donors) into spatially organized, functional arrangements on the target substrates (i.e., receivers) using stamps in a massive or selective manner. Due to its great potential in developing novel electronic systems such as curved electronics (1–3), micro-light-emitting diode display (4–6), and flexible electronics (7–10), transfer printing has attracted great attention from academia and industry with fast developments in recent years. The key for an efficient transfer printing is to modulate the interface adhesion between the stamp and ink to be strong for a reliable pick-up and weak for an easy printing in a reversible and rapid manner. Most of exiting transfer printing techniques utilize an elastomeric polymer or shape memory polymer (SMP) as the stamp material for developing tunable adhesives (11–17). Of particular importance is to achieve suitably strong adhesion by applying a high preload for conformal contact due to the relative large stiffness of stamp during the pick-up step (18–21) and suitably weak adhesion by exploiting the viscoelasticity or shape memory effect during the printing step (22–27). Despite the notable advances in the developments of tunable adhesives for transfer printing (28–32), two challenges still exist. The first is the unfavorable high preload during the pick-up step, which may cause the damage of inks, especially thin inks (33, 34). The second is the limited weak adhesion achieved during the printing step, which leads to a contact printing with performance depending on the geometry and material properties of the receiving surface (35). The above challenges greatly limit the broad utilities of existing transfer printing techniques based on the elastomeric polymer and SMP stamps. Recent efforts demonstrate strategies of liquid droplet stamps (33, 34) to eliminate the undesired effect of preload and dynamic release stamps (36–38) to eliminate the influence of receiving surface, but none of them can meet the stringent requirement on the precise control of adhesion from strong state to weak state in a reversible and rapid manner without the influence of preload.

Here, we report a laser-driven noncontact bubble transfer printing via a hydrogel composite stamp, which provides a reversible thermal controlled adhesion through the liquid–gas phase transition of water in the hydrogel. The stamp features a circular reservoir filled with hydrogel inside the stamp body and encapsulated by a laser absorption layer and an adhesion layer. The ultrasoft nature of hydrogel enables the compliance of stamp, minimizing the influence of preload during the pick-up step without the sacrifice of strong adhesion. The strong light–matter interaction at the interface of hydrogel/laser absorption layer from the infrared laser heats the water in the hydrogel to undergo a liquid–gas phase transition dynamically, which generates a bubble to inflate the stamp surface locally and thus to weaken the interfacial adhesion significantly. The large content of water surrounding the bubble in the hydrogel dissipates the heat rapidly to make the bubble disappear after a gas–liquid phase transition upon removal of the infrared laser, thus enhancing the interfacial adhesion for next transfer printing cycle. Systematically experimental and numerical studies reveal the fundamental aspects of the stamp design and the underlying adhesion modulation mechanism. To illustrate the versatility of the hydrogel composite stamp and the feasibility of using it for noncontact transfer printing to completely eliminate the influence of receiving surface, we demonstrate the printing of microscale Si platelets onto various challenging nonadhesive surfaces (e.g., glass, key, wrench, steel sphere, dry petal, droplet) in two-dimensional or three-dimensional layouts, which cannot be easily accessed by using conventional elastomeric polymer stamps. The results presented here provide an alternate design strategy of tunable and reversible adhesive with significantly enhanced capabilities for deterministic assembly and bring possibilities for developing unconventional functional devices requiring heterogeneous material integrations.

Results and Discussion

Design of the Hydrogel Composite Stamp and Laser-Driven Noncontact Bubble Transfer Printing.

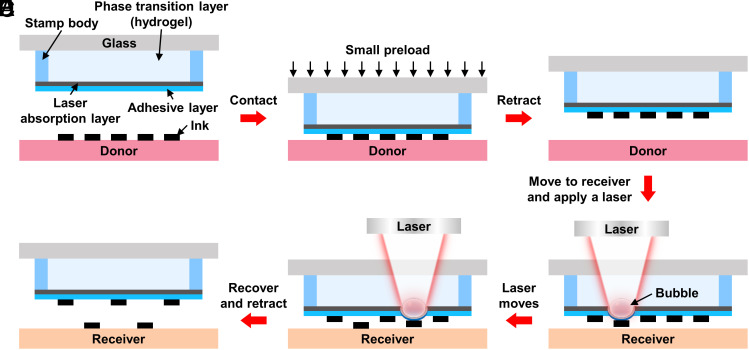

Fig. 1 schematically illustrates the typical process of the laser-driven noncontact bubble transfer printing technique enabled by the hydrogel composite stamp. Here, the stamp features five key components: i) the adhesive layer responsible for providing strong adhesion for reliable pick-up of inks from the donor substrate; ii) the laser absorption layer that can be heated under a laser beam to act as the local heat source; iii) the hydrogel in a reservoir serving as the liquid–gas phase transition layer to form a local bulge under laser heating for easy printing inks onto the receiver substrate; iv) the stamp body used to carry the hydrogel; and v) the glass backing layer used to support the stamp. The stamp body combined with the bottom laser absorption layer and adhesive layer and the glass backing layer seal the hydrogel reservoir and prevent the water loss of hydrogel during the operation of stamp for transfer printing. These five components yield a rapidly reversible and repeatable adhesive, which enables a high-efficient laser-driven noncontact bubble transfer printing technique with capabilities to print inks onto arbitrary receivers.

Fig. 1.

Schematic illustration of the laser-driven noncontact bubble transfer printing process via a hydrogel composite stamp. (A) The stamp moves down close to the donor. (B) The stamp is in contact with inks by a small preload. (C) A rapid separation retrieves the inks onto the stamp. (D) The inked stamp is moved above the receiver, leaving a gap between stamp and receiver, and a laser beam is applied to induce a bulge on the stamp surface, ensuring weak adhesion to facilitate the delamination of ink from stamp. (E) The laser beam is programmably applied to realize selective printing of inks onto the receiver. (F) Without the laser beam, the stamp surface returns to a flat state for another noncontact transfer printing cycle.

The transfer printing process can be divided to two steps: the pick-up step (Fig. 1 A–C) and the printing step (Fig. 1 D–F). The pick-up step starts by placing the composite stamp above the donor (Fig. 1A). A small preload applied to the stamp creates an intimate contact of the adhesion layer and the ink (Fig. 1B) due to the intrinsic soft compliance of stamp. The quick retrieval of the stamp completes the pick-up step (Fig. 1C). The small preload avoiding the possible damage of ink from the compression of stamp and the rapid separation of the stamp maximizing the adhesion due to the viscoelastic effect ensures a reliable pick-up of the ink from the donor. The printing step starts by moving the inked stamp above the receiver with a small gap between the stamp and the receiver. This small gap provides the space for the stamp deformation to delaminate the ink from the stamp and allows the printing independent of the receivers. When heated by a laser beam, the laser absorption layer absorbs the laser energy and heats the water in the hydrogel to experience a local liquid–gas phase transition (i.e., water becomes water vapor) at the interface between the hydrogel and the laser absorption layer. The local liquid–gas phase transition induces a bulge on the stamp surface, which eliminates the interfacial adhesion and facilitates the ejection of inks (Fig. 1D). The laser beam can be applied in a programmable (or massive) way such that the inks can be selected (or massively) printed onto the receiver (Fig. 1E). When the laser beam is turned off, the water vapor in the bulge experiences a rapid gas–liquid phase transition (i.e., water vapor becomes water) due to the heat reabsorbing by the surrounding water in the hydrogel. Thus, the bulge disappears and the stamp surface recovers back to the flat state for another noncontact transfer printing cycle (Fig. 1F).

Adhesion Characteristics of the Hydrogel Composite Stamp.

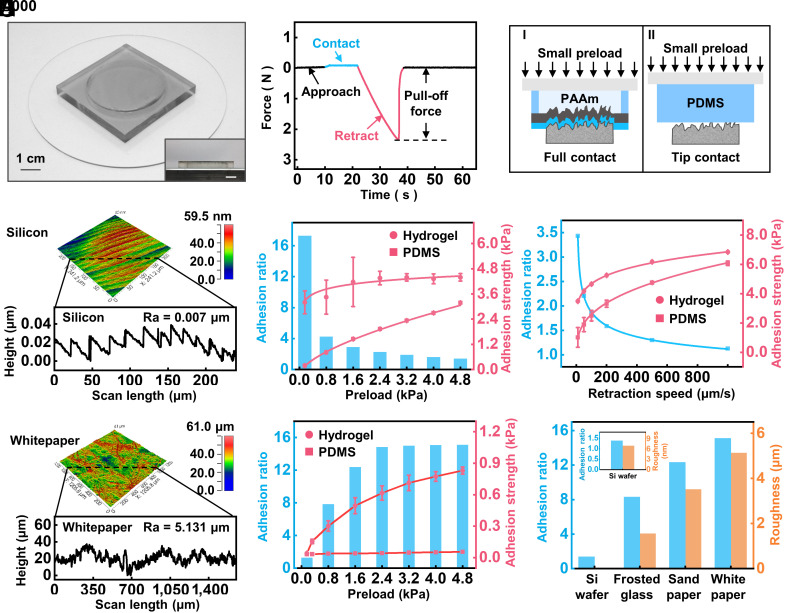

Fig. 2A shows a photograph of the hydrogel composite stamp with the stamp body attached to a glass backing for easy handling. The stamp features a circular reservoir (31 mm in diameter and 6 mm in depth) in a square polydimethylsiloxane (PDMS) stamp body (43.5 mm × 43.5 mm × 7 mm) filled with the PAAm hydrogel as the phase transition layer and encapsulated by a laser absorption layer (thickness: 35 μm) made of a mixture of PDMS and black dye (Nanjing Haozhuo Material Technology Co., Ltd) and an adhesion layer (thickness: 15 μm) made of PDMS. More details about the fabrication of the composite stamp appear in SI Appendix, Fig. S1. To measure the adhesion of the stamp against substrates of different materials, vertical pull tests were carried out under various preloads and retraction speeds. The home-made measurement setup (SI Appendix, Fig. S2) is composed of a material testing system (Model 5944, INSTRON) and a manual tilt stage. Fig. 2B shows a typical force-time curve for the adhesion measurement for the stamp/silicon interface. The silicon substrate approaches (black line) and contacts with the stamp at a small preload of 0.1 N. After keeping the preload constant for 10 s (blue line), the retraction of the silicon substrate (red line) at a retraction speed of 50 μm/s gives the pull-off force. The adhesion strength can then be obtained by dividing the pull-off force by the stamp area.

Fig. 2.

Adhesion characteristics of the hydrogel composite stamp. (A) Photograph of the composite stamp with the Inset showing the side view of stamp. (Scale bar: 1 cm.) (B) A typical force-time curve for the adhesion measurement. (C) Schematic illustrations of the hydrogel composite stamp and PDMS stamp against roughed surface under a small preload. (D) Surface roughness of Si wafer. (E) Surface roughness of white paper. The adhesion strength and the adhesion ratio of stamps against Si wafer as functions of (F) preload under a retraction speed of 50 μm/s and (G) retraction speed under a preload of 3.2 kPa. (H) The adhesion strength and the adhesion ratio of stamps against white paper as functions of preload under a retraction speed of 50 μm/s. (I) The adhesion ratio of stamps against different surfaces under a preload of 4.8 kPa and a retraction speed of 50 μm/s.

The proposed hydrogel composite stamp holds an ultrasoft nature of hydrogel, whose modulus (~kPa) is 3 orders of magnitude lower than that (~MPa) of the conventional polymer stamp (e.g., PDMS). Thus, a small preload could yield a very conformal contact of the hydrogel composite stamp with inks (Fig. 2 C, I) and gives a relative strong interfacial adhesion, which is very helpful to reduce the undesired effect of preload on the pick-up performance since a large preload could cause the damage of inks especially thin inks. However, an unfavorable high preload is required to achieve a strong enough adhesion for pick-up when using a conventional polymer stamp since a small preload cannot ensure an intimate interfacial contact (Fig. 2 C, II), which greatly increases the possibility of failure of inks (33) and poses a great challenge on the control of preload during the pick-up process. To illustrate the advantage of this small preload on the adhesion strength, adhesion tests on surfaces (Si wafer, frosted glass, sandpaper, and white paper) with various surface roughness were carried out by using the hydrogel composite stamp and the PDMS stamp. The Si wafer has the minimum surface roughness (0.007 μm, Fig. 2D) while the white paper has the maximum surface roughness (5.131 μm, Fig. 2E). The surface roughnesses of frosted glass and sandpaper are 1.56 μm and 3.51 μm (SI Appendix, Fig. S3), respectively.

Fig. 2F shows the adhesion strength of stamp against the surface of silicon wafer as the function of preload under the retraction speed of 50 μm/s. The Si wafer is quite flat such that a small preload of 0.16 kPa is large enough to ensure an intimate interfacial contact due to the ultrasoft nature of hydrogel composite stamp, which yields a reliable adhesion of 3.2 kPa. The further increase of the preload only increases the adhesion strength slightly. For example, when the preload increases 30 times from 0.16 to 4.8 kPa, the adhesion strength just increases 37.5% from 3.2 to 4.4 kPa. However, the relative stiff nature of PDMS stamp yields a strong preload-dependent adhesion strength. When the preload is 0.16 kPa, the adhesion strength is only 0.18 kPa. When the preload increases 30 times to 4.8 kPa, the adhesion strength increases 17.8 times to 3.2 kPa. To quantitatively compare the adhesion strengths of two stamps, we defined the adhesion ratio as the adhesion strength of hydrogel composite stamp to that of PDMS stamp. Fig. 2F also shows the adhesion ratio as the function of preload. The adhesion ratio decreases as the preload increases since a large preload enhances the adhesion strength of the hydrogel composite stamp slightly while that of the PDMS stamp dramatically. The maximum adhesion ratio can reach as high as 17.3. The unique feature of small preload-strong adhesion of the hydrogel composite stamp against Si wafer surface is very useful for damage-free and reliable deterministic assembly of semiconductor thin films in electronics industry. Since the adhesive layer of hydrogel composite stamp is made of PDMS, the stamp exhibits rate-dependent adhesion strength, as illustrated in Fig. 2G under a preload of 3.2 kPa. The dependence of adhesion strength on the retraction speed is similar to that on the preload. For example, a small retraction speed can yield a relatively strong adhesion strength of the composite stamp and the adhesion strength increase and adhesion ratio decrease with the retraction speed. Besides the commonly used PDMS stamp, other stamp with bistable, shape memory effect, soft hollow pillar, and microcavity designs (12, 19, 28, 35, 39) were also compared with the hydrogel composite stamp (SI Appendix, Fig. S4), which further illustrates the superior advantage of the proposed stamp on reducing the preload effect on interfacial adhesion.

Fig. 2H shows the adhesion strength of stamp and adhesion ratio against the surface of white paper as the function of preload under the retraction speed of 50 μm/s. The white paper has a relatively large surface roughness such that a small preload is not large enough to ensure an intimate interfacial contact of the hydrogel composite stamp. Therefore, the adhesion strength of the composite stamp against white paper increases significantly with the preload. When the preload is 0.16 kPa, the adhesion strength is only 0.04 kPa. As the preload increases 30 times to 4.8 kPa, the adhesion strength increases 21 times to 0.83 kPa. However, the relative stiff nature of PDMS stamp makes it difficult to have an intimate contact with the roughed surface of white paper. Thus, the adhesion strength of PDMS stamp is much smaller than that of hydrogel composite stamp. The adhesion strength increases very slightly with the preload, and when the preload increases 30 times from 0.16 to 4.8 kPa, the adhesion strength of PDMS stamp only increases 1.7 times from 0.032 to 0.055 kPa. Contrary to the Si wafer surface with a decreasing preload-dependent adhesion ratio, the adhesion ratio on the white paper surface increases with the preload and reaches the maximum steady value of 15 when the preload increases to 2.4 kPa since a large preload enhances the adhesion strength of the hydrogel composite stamp significantly while that of the PDMS stamp slightly. The further increase of preload from 2.4 kPa within the range of 4.8 kPa has a negligible effect on the adhesion ratio.

Fig. 2I shows the adhesion strength ratio against substrates of different materials with surface roughness given in SI Appendix, Fig. S3. The preload is 4.8 kPa and the retraction speed is 50 μm/s. The adhesion ratio increases as the surface roughness. These results show that compared with the PDMS stamp, the hydrogel composite stamp has larger adhesion strengths to various substrates, especially rough substrates at relatively small preloads and low retraction speeds, which allow the hydrogel composite stamp to pick up inks from the donor more easily without damage.

Principle of Laser-Driven Noncontact Bubble Transfer Printing.

A high-efficient adhesion elimination is required for a successful noncontact transfer printing since even a tiny weak adhesion may cause failure of printing at small scales. The chemical evaporation or sublimation of a sacrifice layer has been successfully demonstrated to deposit precise patterns of inks using the most important noncontact printing approach: laser-induced forward transfer technique (40–44). However, the laser-induced forward transfer process is not reversible due to the permanent thermal damage of the sacrifice layer, which greatly limits its broad utility. The proposed hydrogel composite stamp offers a fast and reversible adhesion adjustment through the quick bulging deformation, which is ideal to develop a laser-driven noncontact transfer printing technique for deterministic assembly.

To systematically investigate the local bulging behavior of the hydrogel composite stamp and the noncontact printing of microscale ink when heated by a laser beam, we established a laser-driven transfer printing observation platform (SI Appendix, Fig. S5). A high-speed camera (OSG030-815UM, Shenzhen YVSION Tech. Co., Ltd) and a charge coupled device (CCD) camera were used to record the printing process of a Si platelet (400 μm × 400 μm × 10 μm) from the side view (Movie S1) and from the top view (Movie S2), respectively. A laser beam (wavelength: 808 nm and spot diameter: 400 μm) from a laser-generation system (FC-W-808 nm-10 W, Changchun New Industries Optoelectronics Tech. Co., Ltd) was utilized to heat the system. A laser power measurement platform (SI Appendix, Fig. S6) was established to investigate the relationship between the input power and the absorbed power. The input power depends on the input current of the laser system with their relationship given in SI Appendix, Fig. S7A. It should be noted that the laser input power will be absorbed by both the laser absorption layer and the ink. The absorbed powers linearly depend on the input laser power as shown in SI Appendix, Fig. S6B. The laser absorption layer absorbs 30% more laser power than the ink, which indicates that the laser absorption layer plays an important role for the laser-driven bubble transfer printing.

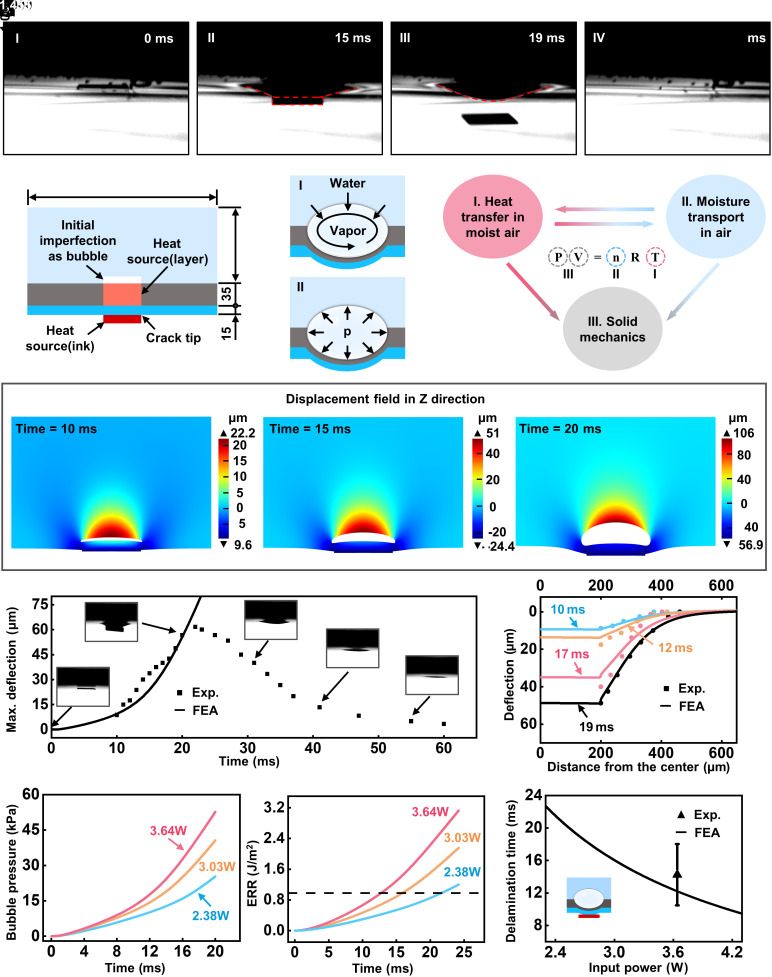

Fig. 3A shows the typical side-view snapshots of printing a Si platelet under an input laser power of 3.64 W with the powers absorbed by the laser absorption layer and the ink as 0.34 W and 0.26 W, respectively. The hydrogel composite stamp remains a conformal contact with the Si platelet before the laser is applied (Fig. 3 A, I). When heated by a laser beam, the stamp absorbs the laser energy and causes a local liquid–gas phase transition at the interface between the hydrogel and the laser absorption layer, inducing a bulge on the stamp surface to delaminate the ink. At the time of 15 ms, the stamp/ink interface starts to delaminate with the bulging profile highlighted by the red dot line, as illustrated in Fig. 3 A, II). At the time of 19 ms, the Si platelet is released completely from the hydrogel composite stamp, from which the generated bubble is very obvious. Thus, the delamination of ink from stamp is very quick and can be completed within 20 ms. The local bulging disappears and the stamp surface recovers back to be flat at 1,454 ms (Fig. 3 A, IV) for another noncontact printing cycle.

Fig. 3.

Principle of laser-driven noncontact bubble transfer printing. (A) The side view snapshots of printing a Si ink (400 μm × 400 μm × 10 μm): (I) The ink is initially on the stamp. (II) The delamination of ink from stamp. (III) The ink is completely released from stamp. (IV) The stamp recovers to its initial state. (B) The geometry of finite element model. (C) Mechanism of surface bulging for adhesion elimination: (I) water surrounding the bubble experiences a liquid–gas transition and more vapor is transmitted into the bubble and (II) The pressure inside the bubble increases. (D) Schematic illustration of the multiphysics coupling in FEA. (E) The displacement distributions in the Z direction at 10, 15, and 20 ms. (F) The maximum deflection of the bulge as the function of time. (G) The deflection of the bulge as the function of the distance from the center of the model under various times. (H) The bubble pressure and (I) the interfacial crack tip ERR as functions of laser heating time under various input laser powers. (J) The delamination time as the function of the input laser power.

To reveal the underlying delamination mechanism of ink from the stamp and obtain the critical delamination condition, a finite element model for the inked stamp was established to investigate the stamp surface deformation, the bubble generation, and interfacial crack tip energy release rate (ERR) under various absorbed laser powers. Fig. 3B schematically shows the geometry of the finite element model, which consists of a phase transition layer of hydrogel (2,000 μm in diameter and 1,000 μm in height), a laser absorption layer (2,000 μm in diameter and 35 μm in height), an adhesion layer of PDMS (2,000 μm in diameter and 15 μm in height), an initial imperfection (400 μm in diameter and 4 μm in height) and a Si platelet (400 μm in diameter and 10 μm in thickness) as the ink. Since the laser absorption layer and the ink absorb the input laser energy when heated by a laser beam, both act as heat sources to heat the phase transition layer of hydrogel. As the hydrogel receives heat from below, the water vapor in the defect at the interface between the hydrogel and laser absorption layer experiences a thermal expansion, which yields a tiny bubble. At the same time, the water within the hydrogel surrounding the bubble undergoes a liquid–gas phase transition and more vapor go into the inner circulation of the bubble through the side wall of bubble (Fig. 3 C, I). The combination of thermal expansion and liquid–gas phase transition enhances the pressure in the bubble (Fig. 3 C, II) and increases the bubble volume rapidly, which squeezes the laser absorption layer and the adhesive layer downward to form a bulge on the stamp surface for printing the ink. To validate the above underlying bulging mechanism, the finite element model involves coupled analysis (Fig. 3D) among the heat transfer in moist air, the moisture transport in air and the solid mechanics. Under the laser heating, the water in the hydrogel changes from liquid to gas and continuously transfers to the tiny defects between the laser absorption layer and the hydrogel, resulting in the increase of water vapor in the defects and the increase of air pressure. The increased water vapor in turn affects the temperature distribution of the defect and its surroundings and enlarges defect volume. Because of the increased pressure and thermal expansion, the delamination between the stamp and ink occurs. More details about finite element analysis (FEA) can be found in Materials and Methods.

Fig. 3E shows the displacement distributions in Z direction at 10, 15, and 20 ms under an input power of 3.64 W from FEA. The corresponding absorbed powers by the laser absorption layer and ink are 0.34 W and 0.26 W, respectively. A more detailed stamp deformation process is shown in Movie S3. As expected, the bubble volume increases with the heating time, which yields an increasing bulging deflection and facilitates the delamination of ink from the stamp. Fig. 3F shows the maximum deflection of the bulge as the function of time. The experimental measurements are denoted by a solid square. The laser duration time is 20 ms. The maximum deflection of bulge increases exponentially with the heating time before the ink is released from the stamp. After the bulge of the stamp delaminates most of the ink area at 20 ms, the deflection decreases quickly with time due to the large content of water surrounding the bubble in the hydrogel, which dissipates the heat rapidly to make the bubble disappear through a gas–liquid phase transition (i.e., water vapor to water). Predictions of the maximum deflection from FEA (solid line) are also shown in Fig. 3F for the comparison. Due to the complexity of delamination process, FEA only considers the deformation before the ink is released from the stamp. It should be noted that the modulus of hydrogel experiences a significant change due to the water loss through phase transition under the laser heating. To account for this modulus change, an effective modulus of hydrogel (80 kPa) is introduced by fitting the value of maximum deflection at 19 ms. This simple treatment gives the maximum deflections numerically with a reasonably good agreement with experiments. To further validate FEA, Fig. 3G compares the deflection of the bulge as the function of the distance from the center of model under various times of 10, 12, 17, and 19 ms. When the distance is within 200 μm, the deflection of bulge reaches the maximum and remains flat due to the constraint by Si platelet. With the distance increases above 200 μm, the deflection of bulge decreases gradually to zero when the distance is about 600 μm. The minimum distance without thermal affection is on the order of ink size. The good agreements on deflection profiles from FEA and experiments validate the accuracy of the finite element model, which is to be used to identify the critical delamination condition.

Fig. 3 H and I show the bubble pressure of the stamp and the interfacial crack tip ERR as functions of time under various input powers of 3.64 W, 3.03 W, and 2.38 W. The corresponding absorbed powers by the laser absorption layer and the ink are 0.344 W and 0.260 W, 0.336W and 0.191 W, and 0.261 W and 0.165 W, respectively. Obviously, both the bubble pressure and the interfacial crack tip ERR increase with the time and the input laser power since more heat energy is transferred into the system, which yields a larger deflection to facilitate the interfacial delamination. The Si ink starts to delaminate from the stamp when the crack tip ERR reaches the work of adhesion of the interface (e.g., 0.98 J/m2 for PDMS/Si interface obtained in 90° tape peeling test, SI Appendix, Fig. S8), which yields the delamination time. Fig. 3J shows the dependence of the delamination time on the input power. As the input power increases, the delamination time decreases. Under an input power of 3.64 W, the predicted delamination time is 14.25 ms, which lies within the range of experimental measurements.

Moreover, the maximum deflection of the stamp can have a high repeatability, as shown in SI Appendix, Fig. S9, for a 50-time repeated laser heating test on an uninked stamp with the duration of 200 ms each time. It should be noted that the durability of hydrogel composite stamp may be limited by the relative high air permeability of the PDMS film, which is made as the laser absorption layer and the adhesion layer. The water loss of stamp as the function of the laser irradiation times and the water loss of stamp as the function of time in the ambient environment are shown in SI Appendix, Fig. S10. After 1,000 laser actions, the weight of the hydrogel composite stamp decreased by only 0.32% (SI Appendix, Fig. S10A). SI Appendix, Fig. S10 B and C compares the dehydration rate of the hydrogel composite stamp and pure hydrogel stamp under the room temperature of ~25 °C and the humidity of ~50%, which shows that the hydrogel composite stamp does not exhibit noticeable change in its weight (down only 4.13%) over 72 h, while the pure hydrogel stamp obviously lost water (weight drop 71.07%), demonstrating the effective antidehydration of the hydrogel composite stamp. Although the water loss is not obvious, an alternative material with lower permeability (45) or a hydrogel that retains water content (46) to improve the durability of stamp is highly desired in the future design of the hydrogel composite stamp.

Transfer Printing of Si Platelets of Different Sizes onto Various Challenging Receivers.

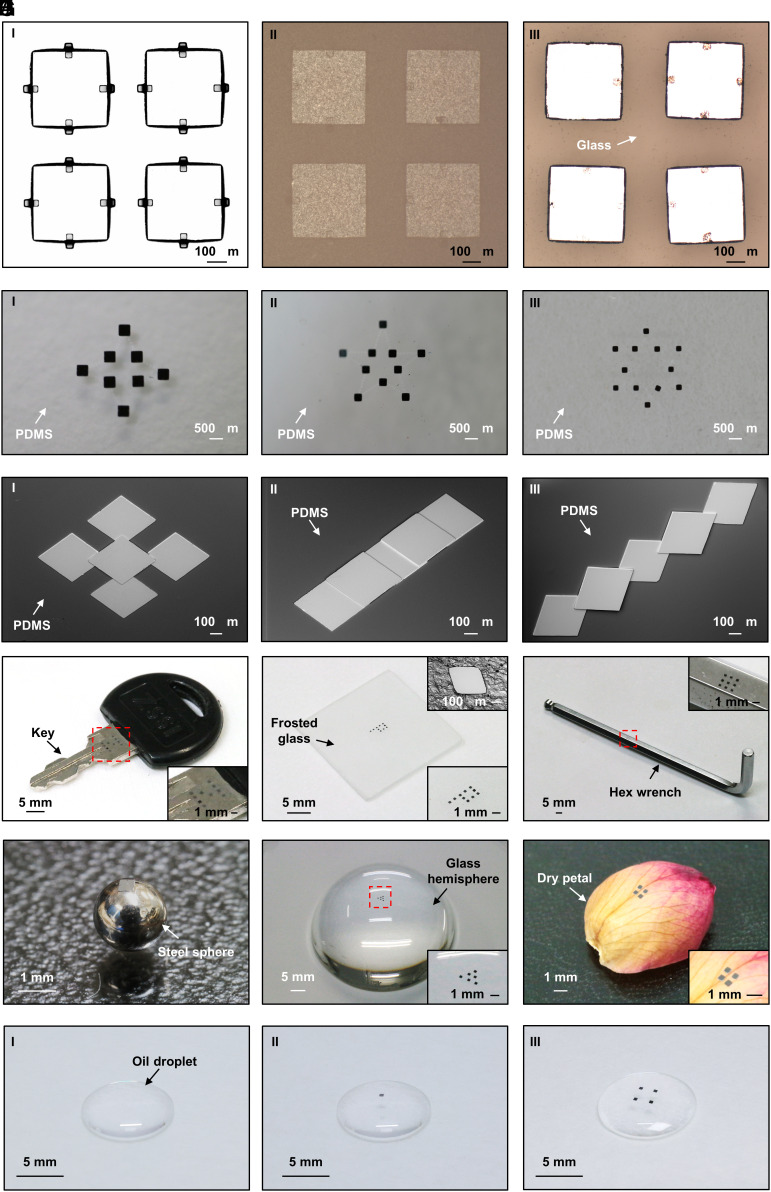

A laser-driven transfer printing platform (SI Appendix, Fig. S11) is established to demonstrate the unusual capability of the hydrogel composite stamp for transfer printing Si platelets onto a variety of unusual surfaces in 2D or 3D layouts, which are not easily accessible through other schemes. Fig. 4A shows the optical images of Si platelets during the typical process of laser-driven bubble transfer printing. First, the Si inks (400 μm × 400 μm × 10 μm) with a large spacing of ~600 μm are fabricated on silicon-on-insulator (SOI) before transfer printing (Fig. 4 A, I; SI Appendix, Fig. S12). The large spacing can avoid the thermal effect of laser printing on neighboring inks. A small preload is applied to the hydrogel composite stamp to facilitate the intimate contact of stamp to inks, yielding a large interfacial adhesion strength due to the van der Waals force for a reliable pick-up. The rapid retraction of the hydrogel composite stamp completes the pick-up process with the inks successfully attached to the stamp (Fig. 4 A, II). The inked stamp is then moved onto the top of a glass receiver. When heated by a laser beam in a programmable way, the laser energy causes local liquid–gas phase transition in the hydrogel layer and induces quick bulges on the stamp surface, which eliminate the interfacial adhesion and facilitate the printing of inks from stamp to the glass receiver in a desired pattern (Fig. 4 A, III). Some misalignments can be observed after transfer printing compared with the designed positions due to the difficulty in precisely controlling the gap and the relative position of the laser spot and the ink and the laser power distribution over the laser spot. It should be noted that the size of bulge due to the local laser heating depends on the size of laser spot and inks. Thus, we can adjust the laser spot size and ink size for programmable printing of inks with various dimensions. Fig. 4B shows the Si inks with three sizes programmably printed onto PDMS receivers in different 2D layouts: four-angle star (ink size: 400 μm × 400 μm × 10 μm, Fig. 4 B, I); five-pointed star (ink size: 300 μm × 300 μm × 10 μm, Fig. 4 B, II); and hexagram star (ink size: 200 μm × 200 μm × 10 μm, Fig. 4 B, III).

Fig. 4.

Demonstrations of transfer printing inks onto different receivers in 2D and 3D layouts. (A) Microscopic images illustrating the laser-driven noncontact transfer printing of Si platelets (400 μm × 400 μm × 10 μm): (I) Si platelets are fabricated on the donor substrate, (II) Si platelets are picked up by the hydrogel composite stamp, and (III) Si platelets printed onto the glass receiver. (B) Selective printing of Si platelets with three sizes onto a PDMS substrate to form (I) a four-angle star (inks size: 400 μm × 400 μm × 10 μm), (II) a five-pointed star (inks size: 300 μm × 300 μm × 10 μm), and (III) a hexagram star (inks size: 200 μm × 200 μm × 10 μm). (C) Scanning electron microscope (SEM) images of printing Si platelets (400 μm × 400 μm × 10 μm) onto the PDMS substrates to form layouts of (I) four silicon platelets capped with one platelet in the center and three silicon platelets capped with two platelets (II) on edges or (III) on corners. (D) A “Z” pattern of Si platelets printed onto a key. (E) A “P” pattern of Si platelets printed onto a frosted glass. (F) A 3 × 3 array of Si platelets printed on a hexagon wrench. (G) A Si platelet printed onto a steel sphere. (H) A triangular layout of Si platelets printed onto a glass hemisphere. (I) A 2×2 array of Si platelets printed onto a piece of dry petal. The size of Si platelet for Fig. 4 D–I is 300 μm × 300 μm × 10 μm. (J) Si platelets (400 μm × 400 μm × 10 μm) printed onto a dimethylsilicone oil droplet surface: (I) an oil droplet on a glass sheet, (II) a Si platelet printed onto the droplet, and (III) a 2×2 array of Si platelets printed onto the droplet.

The noncontact printing capability of the hydrogel composite stamp eliminates the influences of receivers and provides an effective way for 3D assembly. Fig. 4C shows the Si inks (400 μm × 400 μm × 10 μm) assembled in different 3D layouts: four silicon platelets capped with one platelet in the center (Fig. 4 C, I) and three silicon platelets capped with two platelets on edges (Fig. 4 C, II) or on corners (Fig. 4 C, III). These 3D layouts are not possible using contact printing based on conventional polymer stamps. The noncontact printing capability of the hydrogel composite stamp also allows the printing of inks onto arbitrary surfaces since the receiver doesn’t affect the printing performance. We take Si platelet with a size of 300 μm × 300 μm × 10 μm as the ink for demonstrations. Fig. 4 D–F show Si inks printed onto various rough surfaces to form designed patterns: a “Z” pattern printed on a key, a “P” pattern on a frosted glass and a 3 × 3 array on a hexagon wrench. Fig. 4 G and H show Si inks printed onto a curved surface with different arrangements: a Si platelet on a steel sphere and a triangular layout on a glass hemisphere. The inks can even be printed onto a very brittle uneven and curve surface of a dry petal in a designed 2 × 2 pattern (Fig. 4I). Besides the above various challenging solid surfaces, the proposed protocol is also valid for liquid surfaces. Fig. 4J shows a 2 × 2 array of Si inks (400 μm × 400 μm × 10 μm) printed onto a dimethylsilicone oil droplet surface (Macklin, CAS: 63148-62-9, Viscosity: ~60,000 mPa s): a droplet dropped on a glass sheet (Fig. 4 J, I), a Si ink printed onto the droplet (Fig. 4 J, II), and a 2 × 2 array of Si inks printed onto the droplet. The high viscosity of the oil droplet ensures a low flowability, allowing inks to adhere to the droplet surface without causing droplet rupture.

Moreover, the proposed hydrogel composite stamp works for curved electronics since it can have a conformal contact with target surfaces and provides a good complementary approach to existing fabrication methods (1), such as 3D inkjet printing (47), kirigami assembly strategy (48, 49), conformal transfer printing (50, 51), liquid tension transfer printing (33, 52), and mechanically guided 3D assembly methods (53, 54). Micro light emitting diodes (Micro-LEDs, 110 μm × 110 μm × 5 μm) were transfer printed onto a hemisphere (diameter: 5 mm) using a hydrogel composite stamp (SI Appendix, Fig. S13A) and PDMS stamp (SI Appendix, Fig. S13B) in the contact way under a relatively high preload to achieve the conformal contact. All micro-LEDs remained completely intact using hydrogel composite stamp, while obvious damages can be observed in a few micro-LEDs transfer printed using PDMS stamp. The transfer printing process of micro-LEDs onto the hemisphere was recorded in SI Appendix, Fig. S14A. The lit LED (200 μm × 200 μm × 5 μm, SI Appendix, Fig. S14 B and C) and the corresponding I-V graph (SI Appendix, Fig. S14D) demonstrate the damage-free contact capability and applicability of the approach to curved electronics with great potential to various material/device systems. It should be noted that although the above demonstrations are limited to inks of hundreds µm, the proposed approach can further scale down for manipulation of objects at smaller length scale of 10 µm by optimizing the stamp with a thinner laser absorption/adhesive composite layer of more elastic material to achieve a smaller local bulge.

Conclusion

Here, we report a laser-driven noncontact bubble transfer printing via a hydrogel composite stamp, which provides a reversible thermal controlled adhesion in a rapid manner (~20 ms) through the liquid–gas phase transition of water in the hydrogel. The stamp features a circular reservoir filled with hydrogel inside the stamp body and encapsulated by a laser absorption layer and an adhesive layer. Systematically experimental and numerical studies were carried out to investigate the fundamental aspects of design and operation of the composite stamp and reveal the underlying adhesion modulation mechanism. It is shown that the hydrogel composite stamp enhances the ability of pick-up using a small preload due to its high compliance and provides a reversible adhesion modulation strategy through the surface bulging due to liquid–gas transition in hydrogel. Demonstrations of noncontact transfer printing of microscale Si platelets onto various challenging nonadhesive surfaces (e.g., glass, key, wrench, steel sphere, dry petal, droplet) in two-dimensional or three-dimensional layouts illustrate the unusual capabilities for deterministic assembly. Despite these successful demonstrations, transfer printing of microscale/nanoscale materials with high precision is still challenging and needs more efforts in the future. The proposed laser-driven noncontact bubble transfer printing technique creates engineering opportunities in wide applications such as flexible inorganic electronics, curved electronics and micro-LED display, where require heterogeneous materials integration.

Materials and Methods

Preparation and Assembly of the Hydrogel Composite Stamp.

The fabrication process is schematically illustrated in SI Appendix, Fig. S1. At first, a liquid PDMS mixture (Sylgard 184, Dow Corning; 10:1 mixture of base to curing agent) was poured against an aluminum mold (SI Appendix, Fig. S1 A, I and II). The PDMS was degassed in a vacuum chamber for 30 min and then cured in an oven at 75 °C for 4 h. The stamp body is then obtained after cooling and demolding from the aluminum mold (SI Appendix, Fig. S1 A, III). Second, a water-soluble sacrificial layer (poly(styrene-4-sulfonic acid), CAS No.: 28210-41-5) was fabricated on a glass substrate at 2,500 rpm for 10 s by spin-coating and then dried in an oven at 100 °C for 5 min (SI Appendix, Fig. S1 B, I). Then, an adhesive PDMS layer was made on the sacrificial layer at 4,000 rpm for 30 s and baked in the oven at 100 °C for 1 h (SI Appendix, Fig. S1 B, II). Then, a mixture of PDMS and black dye (Nanjing Haozhuo Material Technology Co., Ltd) at a mass ratio of 1:0.04 as a laser absorption layer was spin coated on the adhesive layer at 4,000 rpm for 30 s and baked at 100 °C for 2 h to obtain the adhesive/laser absorption composite layer (SI Appendix, Fig. S1 B, III). Third, the bottom surface of PDMS body was bonded to the laser absorption/adhesive composite layer after plasma treatment (SI Appendix, Fig. S1 C, I). The PAAm hydrogel mixture was prepared by stirring solutions acrylamide (2 mol/L AAm; Sigma-Aldrich A8887), N, N-methylenebisacrylamide (0.1 mol/L MBAA; Sigma-Aldrich M7279) and α-ketoglutaric acid (0.1 mol/L Sigma-Aldrich 75890) at a volume ratio of 1,000 μL: 4 μL: 20 μL at 500 rpm for 5 min in a magnetic mixer. Then, the mixture was degassed at 5,000 rpm for 10 min by a centrifuge. Next, the hydrogel mixture was poured into the cavity of stamp body. The top surface of the PDMS body was sealed with a glass sheet and then subjected to a 30 min UV light exposure to cure PAAm hydrogel (SI Appendix, Fig. S1 C, II). Finally, the assembly was immersed in water for 30 min to remove the glass substrate by dissolving the sacrificial layer and extra adhesive/laser absorption composite layer by a cutter (SI Appendix, Fig. S1 C, III) to yield the hydrogel composite stamp for transfer printing (SI Appendix, Fig. S1D).

Adhesion Measurements.

The interfacial adhesion strengths of the hydrogel composite stamp (25 mm × 25 mm × 4.5 mm) against various surfaces were measured by using a materials testing system (Model 5944, INSTRON) and a manual tip/tilt platform (SI Appendix, Fig. S2). The manual tip/tilt platform facilitated alignment between the stamp and the target surface. The target surface was brought into contact with the stamp with a preload and then retracted at a speed. The maximum pull-off force between the stamp and the target surface during retraction defined the adhesion force. The interfacial adhesion strength is then obtained by dividing the adhesion force by the stamp area. The adhesion strengths between the conventional PDMS stamp and various target surfaces were also measured by following the same procedure for comparisons.

Critical ERR Measurement.

The critical ERR can be measured by tape peeling experiments to determine the interfacial separation of ink and stamp (27). To prepare the test sample, PDMS film (thickness: about hundreds of microns) was first cut into desired strip with the size of 1 cm by 10 cm and attached onto a Si chip by a 2-kg roller. Then, one end of the PDMS strip was connected to a materials testing system (Model 5944, INSTRON). The 90° peeling test was performed at a constant peeling speed of 1,000 μm/s to obtain the maximum peeling force (three peeling test curves are shown in SI Appendix, Fig. S8). The ERR was calculated by averaging the maximum peeling force with PDMS strip width from three repetitive trials.

Laser-Driven Transfer Printing Observation Platform.

The observation platform is shown in SI Appendix, Fig. S5. The platform incorporated a laser system (consisted of a laser generator, an optical fiber, a focusing lens, and a dichroic mirror), a displacement control system (consisted of a two-axis tip/tilt stage, a XY-stage and a Z-stage), a transfer printing monitor system for top view (consisted of a coaxial light source, a microscope, an optical CCD camera, and a monitor) and a transfer printing monitor system for side view (consisted of a LED light source, an infrared filter, a microscope, a high speed camera, and a monitor). The stamp was placed on the two-axis tip/tilt stage with two spacers, and the gap between the two-axis tip/tilt stage and stamp enabled the LED light to pass through the lower surface of the stamp into the microscope of the side view system. Due to the translucency of stamp, the coaxial light emitted vertically downward reflected 180° on the Si ink under the stamp and was captured by the microscope of the top view system. The laser beam was focused on the target area by adjusting both the displacement control system and two monitor systems. Then, changes of the stamp and the ink at two views could be observed, as illustrated in Movies S1 and S2.

Laser Power Measurement Platform.

SI Appendix, Fig. S6 schematically shows the laser power measurement setup, which consists of a laser-generated system (FC-W-808 nm-10 W, Changchun New Industries Optoelectronics Tech. Co., Ltd), an optical power meter (Thorlabs S142C and PM100D) and an alignment system. After reflected by the dichroic mirror, the laser beam (wavelength: 808 nm, duration time: 10 ms, spot diameter: 400 μm) passed through the stamp and ink and was completely received by the optical power meter sensor. The reading of the sensor gave the laser power.

Laser-Driven Transfer Printing Platform.

The laser-driven transfer printing platform is shown in SI Appendix, Fig. S11. The platform incorporated a displacement control system (consisted of two displacement consoles), a laser system (consisted of a laser generator, an optical fiber, a focusing lens, and a dichroic mirror), and a transfer printing monitor system (consisted of a light source, a camera, microscope lens, and a transfer printing monitor). The receiver was placed on the lower displacement stage while the stamp was placed on the upper displacement stage. The gap between them can be accurately controlled by the two displacement consoles. Then, the laser beam was focused on the target area by adjusting both the displacement control system and the transfer printing monitor system.

Fabrication of Silicon Inks.

The fabrication process of silicon inks (thickness: 10 μm) is schematically illustrated in SI Appendix, Fig. S12. First, the SOI was cleaned with acetone, isopropyl alcohol, and deionized water in an ultrasonic cleaner for 5 min, respectively, and spin coated with AZ 4620 photoresist at 1,200 rpm for 30 s followed by baking it on a thermal stage at 110 °C for 8 min (SI Appendix, Fig. S12A). Second, the SOI was radiated continuously for 57 s by ultraviolet photolithography with a dose of 200 mJ cm−2 (SI Appendix, Fig. S12B), and then the shape of the photoresist was defined by a developer (1:2 AZ400K: deionized water) in SI Appendix, Fig. S12C. After inductive coupled plasma etching for 400 s, the exposed top silicon of the SOI wafer was removed (SI Appendix, Fig. S12D). Then, the remaining photoresist and exposed SiO2 were removed by acetone and hydrofluoric acid, respectively (SI Appendix, Fig. S12 E and F). Through the same process (SI Appendix, Fig. S12 G–I) and different parameters (AZ 5214 photoresist; Spin coating speed at 1,500 rpm for 30 s and bake for 1 min; UV radiation for 27 s and ZX238 developer), the resulting Si inks were fixed using photoresist anchors with side view shown in SI Appendix, Fig. S12J, Top view shown in SI Appendix, Fig. S12K, and the photograph shown in SI Appendix, Fig. S12L.

FEA of Printing Process.

An axisymmetric finite element model was established by using COMSOL Multiphysics to investigate the deformation of stamp and calculate the interfacial crack tip ERR under the absorbed laser power. The finite element model (Fig. 3D) includes the heat transfer in moist air (i.e., module I), the moisture transport in air (i.e., module II), and the solid mechanics (i.e., module III). In the heat transfer module, the ambient temperature is set as 20 °C and the thermal boundary condition is natural convection. The measured powers are applied via a heat rate to the laser absorption layer and the Si ink, respectively. In the moisture transport, the wet surface is applied for the interface of defect and hydrogel, and the evaporation rate factor is 5e-3 m/s. The total amount of water vapor in the defect can be obtained by integrating the water vapor flux over the wet surface in space and time. Then, the temperature obtained from module I, the total water vapor obtained from module II, and the cavity volume influenced by module III are substituted into the ideal gas equation, the pressure of water vapor inside the defect can be obtained as the load boundary condition on the inner surface of the defect in module III. Under the influence of thermal mismatch and water vapor pressure in the defect, the delamination between the stamp and ink occurs. The schematic geometry, as illustrated in Fig. 3B, consists of a block of hydrogel (2,000 μm in diameter, 1,000 μm in height) as the phase transition layer, an initial geometric imperfection (400 μm in diameter, 4 μm in height), a laser absorption layer (2,000 μm in diameter, 35 μm in height), an adhesive PDMS layer (2,000 μm in diameter, 15 μm in height) and a Si platelet (400 in μm width, 10 μm in thickness) as the ink. The Young’s modulus, Poisson’s ratio, density, specific heat, thermal conductivity and thermal expansion coefficient are 179.4 GPa, 0.28, 2329 kg/m3, 703 J/(kg K), 163 W/(m K) and 2.6e-6/°C for Si (20), 1.5 MPa, 0.48, 970 kg/m3, 1,460 J/(kg K), 0.15 W/(m K) and 310e-6/°C for PDMS (55), 1.5 MPa, 0.48, 970 kg/m3, 1,901 J/(kg K), 1.73 W/(m K) and 310e-6/°C for the laser absorption layer. The Young’s modulus, Poisson’s ratio, and thermal conductivity are 80 kPa, 0.48 (56), and 0.96 W/(m K) (57) for hydrogel, and other hydrogel parameters are the same as built-in COMSOL parameters for water. All polymers adopt a hyperelastic constitution (Mooney-Rivlin form). The moving mesh is applied to the defect, and the free quadrilateral element is used to discretize the system.

Supplementary Material

Appendix 01 (PDF)

A high-speed video of the printing process of a Si platelet (400 μm× 400 μm× 10 μm) from the side view.

The printing process of a Si platelet (400 μm× 400 μm× 10 μm) from the top view.

A stamp deformation process simulated by FEA.

Acknowledgments

We acknowledge the supports of the National Natural Science Foundation of China (Grant Nos. U21A20502, 12225209, U20A6001, and 12321002) and National Key Research and Development Program of China (2022YFC2401901).

Author contributions

C.L., H.L., and J.S. designed research; C.L. performed research; H.L. and X.L. contributed new reagents/analytic tools; C.L., H.L., X.L., and J.S. analyzed data; and C.L., H.L., S.Z., and J.S. wrote the paper.

Competing interests

The authors declare no competing interest.

Footnotes

This article is a PNAS Direct Submission.

Data, Materials, and Software Availability

All study data are included in the article and/or supporting information.

Supporting Information

References

- 1.Zhang W., Zhang L., Liao Y., Cheng H., Conformal manufacturing of soft deformable sensors on the curved surface. Int. J. Extrem. Manuf. 3, 042001 (2021). [Google Scholar]

- 2.Rich S. I., Jiang Z., Fukuda K., Someya T., Well-rounded devices: The fabrication of electronics on curved surfaces–A review. Mater. Horiz. 8, 1926–1958 (2021). [DOI] [PubMed] [Google Scholar]

- 3.Wu H., et al. , Fabrication techniques for curved electronics on arbitrary surfaces. Adv. Mater. Technol. 5, 2000093 (2020). [Google Scholar]

- 4.Chen Z., Yan S. K., Danesh C., Microled technologies and applications: Characteristics, fabrication, progress, and challenges. J. Phys. D: Appl. Phys. 54, 34 (2021). [Google Scholar]

- 5.Huang Y., Hsiang E. L., Deng M. Y., Wu S. T., Mini-LED, micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 9, 105 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Ho S. J., Hsu H. C., Yeh C. W., Chen H. S., Inkjet-printed salt-encapsulated quantum dot film for uv-based rgb color-converted micro-light emitting diode displays. ACS Appl. Mater. Interfaces 12, 33346–33351 (2020). [DOI] [PubMed] [Google Scholar]

- 7.Xiao X., et al. , Flexible battery-free wireless electronic system for food monitoring. J. Sci.: Adv. Mater. Dev. 7, 100430 (2022). [Google Scholar]

- 8.Hassan M., et al. , Significance of flexible substrates for wearable and implantable devices: Recent advances and perspectives. Adv. Mater. Technol. 7, 2100773 (2021). [Google Scholar]

- 9.Cai M., et al. , A multifunctional electronic skin based on patterned metal films for tactile sensing with a broad linear response range. Sci. Adv. 7, eabl8313 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Ma Y. J., et al. , Flexible hybrid electronics for digital healthcare. Adv. Mater. 32, 1902062 (2020). [DOI] [PubMed] [Google Scholar]

- 11.Zhao J., et al. , Smart adhesives via magnetic actuation. Adv. Mater. 34, e2107748 (2022). [DOI] [PubMed] [Google Scholar]

- 12.Li C., Luo H., Song J., Magnetically driven non-contact transfer printing based on a bi-stable elastomeric stamp. Adv. Mater. Technol. 6, 2100335 (2021). [Google Scholar]

- 13.Huang Y. G., Highly switchable and reversible dry adhesion for transfer printing. Natl. Sci. Rev. 7, 558–559 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Eisenhaure J., Kim S., Laser-driven shape memory effect for transfer printing combining parallelism with individual object control. Adv. Mater. Technol. 1, 1600098 (2016). [Google Scholar]

- 15.Chen H., Feng X., Chen Y., Directionally controlled transfer printing using micropatterned stamps. Appl. Phys. Lett. 103, 151607 (2013). [Google Scholar]

- 16.Carlson A., et al. , Active, programmable elastomeric surfaces with tunable adhesion for deterministic assembly by transfer printing. Adv. Funct. Mater. 22, 4476–4484 (2012). [Google Scholar]

- 17.Meitl M. A., et al. , Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 5, 33–38 (2006). [Google Scholar]

- 18.Linghu C., et al. , Overcoming the adhesion paradox and switchability conflict on rough surfaces with shape-memory polymers. Proc. Natl. Acad. Sci. U.S.A. 120, e2221049120 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Zhang S., et al. , A thermal actuated switchable dry adhesive with high reversibility for transfer printing. Int. J. Extrem. Manuf. 3, 9 (2021). [Google Scholar]

- 20.Luo H., et al. , Thermal controlled tunable adhesive for deterministic assembly by transfer printing. Adv. Funct. Mater. 31, 2010297 (2021). [Google Scholar]

- 21.Kim S., et al. , Microstructured elastomeric surfaces with reversible adhesion and examples of their use in deterministic assembly by transfer printing. Proc. Natl. Acad. Sci. U.S.A. 107, 17095–17100 (2010). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Zhao W., et al. , Thermomechanical constitutive models of shape memory polymers and their composites. Appl. Mech. Rev. 75, 20 (2023). [Google Scholar]

- 23.Luo H., et al. , Switchable dry adhesive based on shape memory polymer with hemispherical indenters for transfer printing. Theor. App. Mech. Lett. 11, 100308 (2021). [Google Scholar]

- 24.Linghu C., et al. , Universal SMP gripper with massive and selective capabilities for multiscaled, arbitrarily shaped objects. Sci. Adv. 6, eaay5120 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Eisenhaure J. D., Xie T., Varghese S., Kim S., Microstructured shape memory polymer surfaces with reversible dry adhesion. ACS Appl. Mater. Interfaces 5, 7714–7717 (2013). [DOI] [PubMed] [Google Scholar]

- 26.Kim T.-H., et al. , Kinetically controlled, adhesiveless transfer printing using microstructured stamps. Appl. Phys. Lett. 94, 113502 (2009). [Google Scholar]

- 27.Feng X., et al. , Competing fracture in kinetically controlled transfer printing. Langmuir 23, 12555–12560 (2007). [DOI] [PubMed] [Google Scholar]

- 28.Wan G., et al. , Tunable dry adhesion of soft hollow pillars through sidewall buckling under low pressure. Adv. Funct. Mater. 33, 2209905 (2023). [Google Scholar]

- 29.Wang Y., et al. , Programmable micro-transfer-printing for heterogeneous material integration. AIP Adv. 12, 065110 (2022). [Google Scholar]

- 30.Guo C., et al. , Large-scale programmable assembly of functional micro-components for advanced electronics via light-regulated adhesion and polymer growth. npj Flex. Electron. 6, 44 (2022). [Google Scholar]

- 31.Wang S., Luo H., Linghu C., Song J., Elastic energy storage enabled magnetically actuated, octopus-inspired smart adhesive. Adv. Funct. Mater. 31, 2009217 (2021). [Google Scholar]

- 32.Wang C. J., et al. , Programmable and scalable transfer printing with high reliability and efficiency for flexible inorganic electronics. Sci. Adv. 6, eabb2393 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Liu X., et al. , Liquid droplet stamp transfer printing. Adv. Funct. Mater. 31, 2105407 (2021). [Google Scholar]

- 34.Li H. C., et al. , High-efficiency transfer printing using droplet stamps for robust hybrid integration of flexible devices. ACS Appl. Mater. Interfaces 13, 1612–1619 (2021). [DOI] [PubMed] [Google Scholar]

- 35.Luo H., et al. , Laser-driven programmable non-contact transfer printing of objects onto arbitrary receivers via an active elastomeric microstructured stamp. Natl. Sci. Rev. 7, 296–304 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Lee C. K. W., et al. , Laser-induced transfer of functional materials. Top. Curr. Chem. 381, 23 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Chen F., et al. , Laser-driven hierarchical “gas-needles” for programmable and high-precision proximity transfer printing of microchips. Sci. Adv. 9, eadk0244 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Hu J. L., et al. , Laser projection proximity transfer for deterministic assembly of microchip arrays at scale. Sci. China Technol. Sci. 65, 2205–2214 (2022). [Google Scholar]

- 39.Yoo B., Cho S., Seo S., Lee J., Elastomeric angled microflaps with reversible adhesion for transfer-printing semiconductor membranes onto dry surfaces. ACS Appl. Mater. Interfaces 6, 19247–19253 (2014). [DOI] [PubMed] [Google Scholar]

- 40.Ehsani H., Boyd J. D., Wang J. L., Grady M. E., Evolution of the laser-induced spallation technique in film adhesion measurement. Appl. Mech. Rev. 73, 20 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Serra P., Piqué A., Laser-induced forward transfer: Fundamentals and applications. Adv. Mater. Technol. 4, 1800099 (2019). [Google Scholar]

- 42.Feinaeugle M., et al. , Time-resolved imaging of flyer dynamics for femtosecond laser-induced backward transfer of solid polymer thin films. Appl. Surf. Sci. 396, 1231–1238 (2017). [Google Scholar]

- 43.Marinov V. R., Swenson O., Atanasov Y., Schneck N., Laser-assisted ultrathin die packaging: Insights from a process study. Microelectron. Eng. 101, 23–30 (2013). [Google Scholar]

- 44.Stewart J. S., et al. , Red-green-blue polymer light-emitting diode pixels printed by optimized laser-induced forward transfer. Appl. Phys. Lett. 100, 203303 (2012). [Google Scholar]

- 45.Lei Y., et al. , Studies on parylene C-caulked PDMS (pcPDMS) for low permeability required microfluidics applications. Lab Chip 11, 1385–1388 (2011). [DOI] [PubMed] [Google Scholar]

- 46.Sui X., et al. , Ionic conductive hydrogels with long-lasting antifreezing, water retention and self-regeneration abilities. Chem. Eng. J. 419, 129478 (2021). [Google Scholar]

- 47.Kim F., et al. , Direct ink writing of three-dimensional thermoelectric microarchitectures. Nat. Electron. 4, 579–587 (2021). [Google Scholar]

- 48.Yang L., et al. , Self-healing, reconfigurable, thermal-switching, transformative electronics for health monitoring. Adv. Mater. 35, e2207742 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Chen X., et al. , Wrap-like transfer printing for three-dimensional curvy electronics. Sci. Adv. 9, eadi0357 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Zabow G., Reflow transfer for conformal three-dimensional microprinting. Science 378, 894–898 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Rao Z. Y., et al. , Curvy, shape-adaptive imagers based on printed optoelectronic pixels with a kirigami design. Nat. Electron. 4, 513–521 (2021). [Google Scholar]

- 52.Liu S., et al. , Conformability of flexible sheets on spherical surfaces. Sci. Adv. 9, eadf2709 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Bo R. H., Xu S. W., Yang Y. Z., Zhang Y. H., Mechanically-guided 3D assembly for architected flexible electronics. Chem. Rev. 123, 11137–11189 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Zhang S., et al. , Standalone stretchable RF systems based on asymmetric 3D microstrip antennas with on-body wireless communication and energy harvesting. Nano Energy 96, 107069 (2022). [Google Scholar]

- 55.Saeidpourazar R., et al. , Laser-driven micro transfer placement of prefabricated microstructures. J. Microelectromech. Syst. 21, 1049–1058 (2012). [Google Scholar]

- 56.Wu L., et al. , Mechanical characterization and modeling of sponge-reinforced hydrogel composites under compression. Soft Matter 14, 4355–4363 (2018). [DOI] [PubMed] [Google Scholar]

- 57.Xu S., Cai S., Liu Z., Thermal conductivity of polyacrylamide hydrogels at the nanoscale. ACS Appl. Mater. Interfaces 10, 36352–36360 (2018). [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Appendix 01 (PDF)

A high-speed video of the printing process of a Si platelet (400 μm× 400 μm× 10 μm) from the side view.

The printing process of a Si platelet (400 μm× 400 μm× 10 μm) from the top view.

A stamp deformation process simulated by FEA.

Data Availability Statement

All study data are included in the article and/or supporting information.