Abstract

Potassium-sulfur batteries attract tremendous attention as high-energy and low-cost energy storage system, but achieving high utilization and long-term cycling of sulfur remains challenging. Here we show a strategy of optimizing potassium polysulfides for building high-performance potassium-sulfur batteries. We design the composite of tungsten single atom and tungsten carbide possessing potassium polysulfide migration/conversion bi-functionality by theoretical screening. We create two ligand environments for tungsten in the metal-organic framework, which respectively transmute into tungsten single atom and tungsten carbide nanocrystals during pyrolysis. Tungsten carbide provide catalytic sites for potassium polysulfides conversion, while tungsten single atoms facilitate sulfides migration thereby significantly alleviating the insulating sulfides accumulation and the associated catalytic poisoning. Resultantly, highly efficient potassium-sulfur electrochemistry is achieved under high-rate and long-cycling conditions. The batteries deliver 89.8% sulfur utilization (1504 mAh g−1), superior rate capability (1059 mAh g−1 at 1675 mA g−1) and long lifespan of 200 cycles at 25 °C. These advances enlighten direction for future KSBs development.

Subject terms: Batteries, Batteries, Batteries, Materials chemistry

Potassium-sulfur battery are promising materials for next-generation high energy, low cost batteries. Here the authors explore a tungsten based catalytic composite for optimizing potassium polysulfides and improve K-S electrochemistry in batteries

Introduction

The development of efficient energy storage systems (ESS) is one key initiative for pursuing carbon neutrality worldwide1. Based on the high capacity of sulfur redox2,3 and the low potential of potassium metal4, potassium sulfur batteries (KSBs) have desirable theoretical energy density of 1023 Wh kg−1 thereby holding great promise for next-generation ESS. KSBs are intrinsically low in cost due to the abundance of sulfur and potassium. Nonetheless, some challenges around sulfur cathode significantly plague the KSB operation, such as the low sulfur utilization, the sluggish kinetics of potassium polysulfides (KPSs) conversion, the severe shuttling, and the difficult decomposition of solid end-products (K2Sx, 1 ≤ x ≤ 3)5. These intractable impediments limit the capacity and lifespan of KSBs. Therefore, it is of vital importance to develop functional hosts accommodating the sulfur for addressing these issues.

Some pioneering efforts innovated functional sulfur hosts for KSBs. Most of the hosts are carbon-based, taking advantage of the good electrical conductivity, diverse surface chemistry, and versatile porosity of carbon6,7. The sulfur confinement is the primary function of the host. Physically confining sulfur in the carbon porosity is a popular strategy8,9. For instance, microporous carbons confining small molecular (S1–3) exhibited promising capacity and cyclability in KSBs. Nonetheless, the limitation of pore volume normally sacrificed the sulfur loading7,10. The carbon hosts employed were normally decorated by nitrogen moieties, which are effective of enhancing the sulfur anchoring via covalent bonding at heterointerfaces11. In addition, the chemical confinement strategy was also widely reported12–14. Sulfurized polyacrylonitrile (SPAN) utilizing the covalent sulfur-carbon bonds greatly inhibited KPSs shuttling14–17. The chemical confinement also includes the chemical adsorption between KPSs and certain polar species of the host, such as heteroatom groups, nanostructured compounds, atomic metal assemblies7,18,19. For instance, single metal atoms18,20,21 and metal carbides22–25 were reported providing adsorption effect towards polysulfides.

The function of catalytic conversion towards KPSs in sulfur host attracted increasing attention in recent years. Some highly enlightening studies introduced catalytic sites in the hosts to improve the KPSs conversion kinetics, especially the solid-state reactions including K2S oxidation26. Metallic single atoms18,26 and metallic atom clusters27 were reported as electrocatalytic species, which suppressed the long-chain KPSs shuttling and reduced the polarization of solid-state sulfide conversion, thereby enhancing the sulfur utilization, rate and cycling capability. The design of catalytic materials for KPSs can be inspired by the prior achievements in Li/Na-sulfur batteries. The metal element in various forms (e.g. single atom, atomic cluster, compounds) that can deliver general catalytic capability towards both lithium and sodium polysulfides deserves particular attention. For example, tungsten is catalytically active in Li-S batteries (tungsten single atom20, tungsten carbide23–25, tungsten sulfide28,29) and Na-S batteries (tungsten nanoparticle30). The successful applications of tungsten-based catalysts in metal sulfur batteries were largely ascribed to the special electronic structure of tungsten atomic assemblies and tungsten compounds31. These insights are highly instructive for KSBs explorations.

The previous researches reveal the importance of introducing catalytically active sites in sulfur hosts for KPSs conversion. Considering the complex potassium-sulfur electrochemistry, more factors should be considered beyond the catalytic conversion. First, sulfur is essentially confined in the carbon porosity, which distributes ubiquitously in the host. On the contrary, the isolate nanostructured catalytic species can only locate disjunctively19,32. Therefore, there is an inherent mismatch in the distribution of sulfur and catalytic sites, which makes the KPSs migration among the catalytic sites highly necessary. More importantly, the reduction products of solid-state KPSs conversion are highly insulating and difficult to decompose33, which can easily accumulate over the catalytic sites and cause catalytic poisoning34,35. Therefore, the migration of K2S/K2S2 away from the catalytic sites is important for preventing the expansion of electronically inactive areas in the cathode, especially under high current density and aggressively repeated charge/discharge conditions. The above considerations suggest that KPSs migration can play an important role in KSBs, which unfortunately has been totally overlooked. This motivated us to develop sulfur host with combined functionalities of accelerating KPSs migration and catalyzing KPSs conversion for pursuing high-performance KSBs.

In this study, to implement the principle of optimizing KPSs behavior, the coupling of tungsten single atom (WSA) and tungsten carbide (W2C) is designed based on density functional theory (DFT) calculation. Creating different coordination environments for tungsten in metal organic framework precursor drives the symbiosis of WSA and W2C on nitrogen-doped carbon (NC) upon pyrolysis. Employing the obtained WSA-W2C@NC as sulfur host enables the KSBs to deliver ultra-high capacity of 1504 mAh g−1, rate performance (1059 mAh g−1 at 1675 mA g−1) and stability (cycling over 200 cycles). Combined spectroscopic characterizations and theoretical computations revealed the critical role of KPSs optimization in avoiding inert sulfides accumulation and catalytic poisoning, as well as enhancing rate and cycling performances of KSBs.

Results

Theoretical guidance and screening for sulfur host design

The interactions between the functional species in sulfur hosts and potassium polysulfides (KPSs) are comprehensively investigated to acquire the principles of the host design21,36. Regarding to the catalytic conversion functionality towards KPSs, the chemical binding of key polysulfide on the sulfur host is the primary factor21,36,37. For saving trial-and-error experiments, density functional theory (DFT) calculation was first conducted to screen the optimal catalytic species. The stoichiometric middle point of the whole KPSs conversion, i.e. K2S4, was employed as the representative for the binding energy calculations. Figure 1a lists the tungsten species including tungsten metal/carbides/nitride/oxide/sulfide/selenide and nitrogen coordinated single atom tungsten (WSA) for the theoretical screening. The specific crystal planes of tungsten species to interact with K2S4 were determined based on the maximum surfaces of the Wulff configurations (Supplementary Fig. 1 and Supplementary Table 1). The optimized binding configurations of K2S4 on tungsten species and corresponding binding energy values were displayed in Fig. 1a. W2C (102) was screened out by the highest binding energy for K2S4 (−3.01 eV).

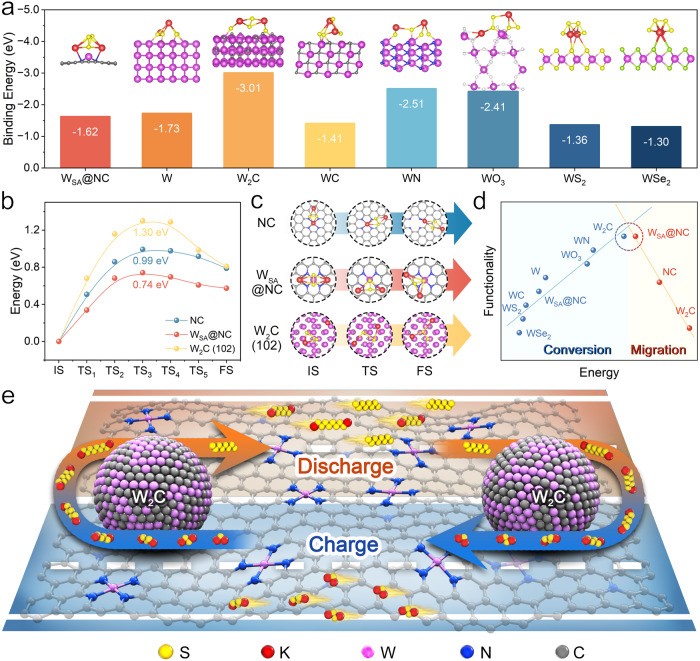

Fig. 1. Theoretical guidance and screening for sulfur host design.

a The binding energies of K2S4 on WSA@NC, W metal (110), W2C (102), WC (101), WN (112), WO3 (100), WS2 (002) and WSe2 (006) and the corresponding configurations (insets). b The energy profiles of K2S2 migration on NC, WSA@NC, and W2C (102). c The calculated initial, transition and final states of K2S2 migration. d Volcano plot of KPS conversion and migration functionalities with respect to specific energy values. e Schematic demonstrating the design principle of the WSA-W2C composite based sulfur host for efficient sulfur redox in KSBs guided by the theoretical calculation. Source data are provided as a Source Data file.

Apart from the KPSs conversion catalysis, the facile KPSs migration over sulfur hosts should be considered with equal importance due to the mismatch between ubiquitously distributed sulfur and disjunctively distributed catalytic sites. Among aforementioned tungsten species, only WSA can achieve the atomically homogeneous dispersion on the host, because the compounds, even being nanostructured, can only exist as spatially discrete islands. Therefore, we calculated the migration kinetics of K2S2 (key intermediate of solid-state KPSs conversion and midpoint of S0/S2- redox) on W2C, WSA modified nitrogen-doped carbon (WSA@NC) and NC. Figure 1b demonstrates the initial, transition and final states of K2S2 migration on NC, WSA@NC, and W2C (102). The corresponding energy barriers for K2S2 migrations are determined to be 0.99, 0.74, and 1.30 eV. Evidently, WSA could effectively lower the energy barrier of K2S2 migration, enabling facile transfer of solid-state KPSs36,38.

The comprehensive consideration of the catalytic KPSs conversion and facilitated KPSs migration results in the volcano-type relationship in Fig. 1d. At the vertex of the volcano, W2C and WSA should be selected as dual functional components in sulfur host. Figure 1e is the scheme demonstrating the design principle of the sulfur host guided by the theoretical calculation. W2C nanocrystals provide isolated catalytic sites for KPSs conversion, while WSA modified carbon substrate act as highways for fast KPSs transportation. During the discharge/charge processes, KPSs could be fed to W2C sites for catalytic conversion, and afterwards the reaction products could also be promptly released away from W2C sites. This mechanism can effectively address the distribution mismatch of sulfur and catalytic sites. Moreover, the facile solid-state KPSs migration surrounding W2C is expected to be highly conducive to the durability of the catalytic sites by avoiding catalytic poisoning.

Fabrication and characterization of sulfur hosts and sulfur cathodes

To experimentally implement the conceived sulfur host based on theoretical guidance, we employed a sophisticated method to construct composite of tungsten single atoms and tungsten carbide nanocrystals on nitrogen-doped porous carbon (termed WSA-W2C@NC). Figure 2a demonstrates the synthesis procedure. ZIF-8 nanoparticles were prepared as nitrogen containing carbon precursor for loading tungsten. WO42- anions as tungsten sources were introduced into ZIF-8 matrix through solvothermal treatment. In the obtained WO42--ZIF product, a portion of WO42- anions incorporate into the organic ligands of zinc atoms in ZIF-8 through an anion exchange process. Meanwhile, another portion of WO42- anions adsorbed on the ZIF-8 surface by the electrostatic effect. Therefore, two different coordination environments were created for tungsten in WO42--ZIF precursor, which induced different tungsten coalescence processes during the subsequent pyrolysis. The WO42- anions coupling with the organic ligands of ZIF-8 underwent a spatial confinement pyrolysis, which transmute into nitrogen coordinated single tungsten atoms (WSA). WO42- anions on ZIF-8 surface agglomerated and formed tungsten carbides in the carbon rich atmosphere. ZIF-8 matrix was carbonized into nitrogen-doped porous carbon, supporting the WSA and W2C species.

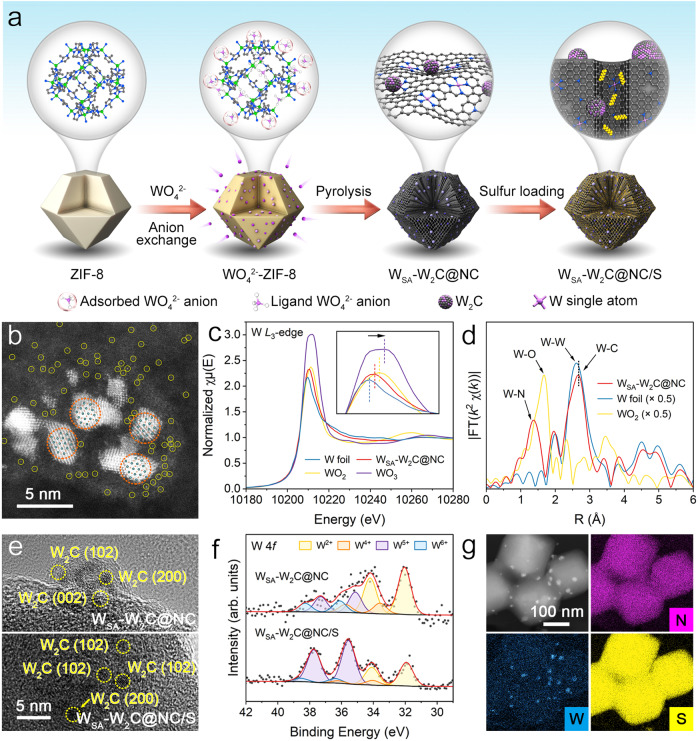

Fig. 2. Synthesis and characterization of WSA-W2C@NC and WSA-W2C@NC/S.

a Schematic synthesis process of WSA-W2C@NC and WSA-W2C@NC/S. b HAADF-STEM image of WSA-W2C@NC. c–d XANES (c) and EXAFS (d) spectra of W L3-edge for WSA-W2C@NC and W foil, WO2, WO3 references. e HRTEM images of WSA-W2C@NC and WSA-W2C@NC/S. f High-resolution W 4 f XPS spectra for WSA-W2C@NC and WSA-W2C@NC/S. g HAADF-STEM image and corresponding EDS mapping of WSA-W2C@NC/S. Source data are provided as a Source Data file.

The obtained WSA-W2C@NC inherited the polyhedron morphology (Supplementary Fig. 2). Aberration-corrected high angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) and high-resolution transmission electron microscopy (HRTEM) images (Fig. 2b, Supplementary Figs. 3 and 4a) demonstrated that tungsten species in WSA-W2C@NC include the W2C nanocrystals (dashed circles) and single tungsten atoms (solid circles). Single tungsten atoms distribute over the whole NC substrate and embrace W2C nanocrystals. Of note, the small-size and relatively low loading W2C nanocrystals cannot be detected by XRD (Supplementary Fig. 5). For determining the optimal content of WSA-W2C in the hosts, specimens with higher WSA-W2C content (WSA-W2C-H@NC) and lower WSA-W2C content (WSA-W2C-L@NC) were also prepared. The WSA and W2C species in these two control specimens could be well identified by SEM, HRTEM and HAADF-STEM images (Supplementary Fig. 6).

W2C@NC was prepared by eliminating the solvothermal anion exchange process during synthesis, in which case only electrostatically adsorbed WO42- existed in the precursor. In HRTEM and HAADF-STEM images (Supplementary Figs. 4b and 7), only tungsten carbide (W2C) nanocrystals were present with scarcely any single tungsten atom observed. Similar to WSA-W2C@NC, the W2C nanocrystals are too small to be detected by XRD (Supplementary Fig. 5). This result verifies the importance of creating different coordination environments of tungsten in the precursor for achieving the symbiosis of WSA and W2C upon pyrolysis. Baseline of nitrogen-doped porous carbon (NC) was prepared by directly carbonizing tungsten-free ZIF-8. HRTEM images and selected area electron diffraction (SAED) patterns confirmed the amorphous tissue of NC (Supplementary Fig. 8).

The electronic structures and atomic configurations of tungsten species in WSA-W2C@NC were verified by X-ray absorption near-edge structure (XANES) and Fourier transform extended X-ray absorption fine structure (EXAFS) spectra. In Fig. 2c, the white line peak in the W L3-edge XANES spectrum of WSA-W2C@NC lies between tungsten metal foil and WO2, indicating an average valence state between 0 and +4. EXAFS spectrum demonstrates the distinct W‒N peak at ~1.35 Å and W‒C peak at ~2.67 Å39–41, which verifies the coexistence of single tungsten atoms and tungsten carbides in WSA-W2C@NC.

Employing the aforesaid hosts, WSA-W2C@NC/S, W2C@NC/S, and NC/S were prepared by melting-impregnation method. The products retained the morphologies of the pristine hosts (Supplementary Fig. 9). No isolated sulfur particle could be observed, suggesting the full infiltration of sulfur in the hosts. According to HRTEM images, the size and crystal structures of the tungsten carbides remain unchanged after sulfur loading for both WSA-W2C@NC/S (Fig. 2e) and W2C@NC/S (Supplementary Fig. 10). Control specimens of WSA-W2C-H@NC/S and WSA-W2C-L@NC/S display the same phenomenon, as revealed in Supplementary Fig. 11. X-ray photoelectron spectroscopy (XPS) demonstrated the interaction between sulfur and the host28,42,43. In the W 4 f spectra (Fig. 2f), the sulfur loading induced an elevated proportion of W5+ and an increase in average valence from +3.43 to +4.07 for WSA-W2C@NC/S. By contrast, the W 4 f in W2C@NC/S hardly changed (Supplementary Fig. 12). This phenomenon indicates that the interaction between sulfur and atomic-level homogeneously dispersed WSA is more pronounced, which also suggests the sulfur distribution all over the entire host.

The HAADF-STEM images and elemental mappings in Fig. 2g and Supplementary Fig. 13 revealed that sulfur uniformly distributed in WSA-W2C@NC, W2C@NC and NC hosts. SAED patterns (Supplementary Fig. 14) display no diffraction spots or rings of crystalline sulfur, suggesting the amorphous texture of sulfur in these specimens. The absence of cyclo-S8 characteristic peaks in the Raman spectra (Supplementary Fig. 15) agreed with the SAED data22. According to the nitrogen adsorption-desorption isotherms analyses (Supplementary Fig. 16), the significantly decreased surface areas of the composites as compared to pristine hosts (e.g. 15.96 m2 g−1 of WSA-W2C@NC/S versus 706.60 m2 g−1 of WSA-W2C@NC) confirmed the effective sulfur infusion. Moreover, the sulfur hosts all provide microporosities for sulfur accommodation, which should be the essential reason for the amorphous structure of the impregnated sulfur44.

Electrochemical performances and sulfur redox mechanisms

WSA-W2C@NC/S utilizing the host containing functional species of WSA and W2C is expected to be high-performance cathodes for KSBs. First, WSA-W2C@NC and W2C@NC demonstrated much stronger adsorption capability towards KPSs than that of tungsten-free NC, as proved by the ultraviolet-visible (UV-vis) spectra of K2S6 solutions with different host materials (Supplementary Fig. 17)45,46. This phenomenon agrees well with the calculation demonstrated in Fig. 1. After 12 h, all K2S6 species in the solution were thoroughly adsorbed by WSA-W2C@NC and W2C@NC hosts, as evidenced by the corresponding spectra overlapping with pure DME solvent. To understand the sulfur redox in WSA-W2C@NC/S, W2C@NC/S and NC/S cathodes, cyclic voltammetry (CV) measurements were conducted. As shown in Supplementary Fig. 18, in the first cathodic scan of WSA-W2C@NC/S, there is a strong peak at 0.836 V combining the SEI formation9,19,22,32 and sulfur activation processes8,47–49. The sulfur activation describes the potassiation of pristine sulfur, which probably needs to overcome higher energy barrier than the following potassiation processes22,44,49. Therefore, the cathodic peak of the sulfur potassiation in the 1st cycle CV appeared at lower onset voltage than that in the following cycles9,19,22. Reduction peaks at 1.594 (R1), 1.329 (R2), and 0.761 V (R3) appeared in the 2nd cycle (Fig. 3a). In the anodic scan, oxidation peaks present at 1.844 (O1), 2.159 (O2), and 2.272 V (O3). W2C@NC/S and NC/S exhibit similar CV shapes as WSA-W2C@NC/S, but deliver lower response specific currents and larger polarizations. This phenomenon suggests the faster sulfur redox kinetics for WSA-W2C@NC/S than the other two cathodes.

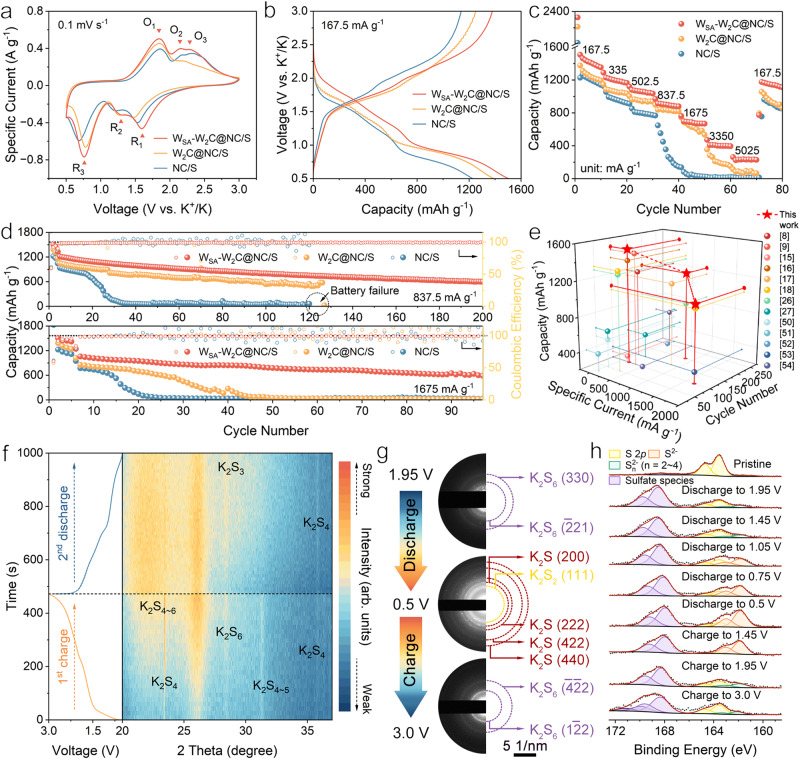

Fig. 3. Electrochemical performances and sulfur redox mechanism.

a CV curves of KSBs employing WSA-W2C@NC/S, W2C@NC/S, and NC/S cathodes. b–d GCD profiles curves at 167.5 mA g−1 (b) rate-performance (c) and cyclability (d) of KSBs employing three cathodes. e Comparison of specific capacity, rate and cycling performance of WSA-W2C@NC/S cathode with the state-of-the-art cathodes for KSBs reported. f In-situ XRD of WSA-W2C@NC/S cathode in the 1st charge and 2nd discharge processes. g Ex-situ SAED patterns of WSA-W2C@NC/S cathode at various discharge/charge states. h Ex-situ S 2p XPS spectra of WSA-W2C@NC/S cathode at selected discharge/charge states. Source data are provided as a Source Data file.

The galvanostatic charge/discharge (GCD) curves of the three cathodes (2nd cycle) were displayed in Fig. 3b. The WSA-W2C@NC/S cathode delivered a high discharge capacity of 1504 mAh g−1 based on the thermogravimetric analysis (TGA) determined sulfur content (40.56%) (Supplementary Fig. 19). This reversible capacity corresponds to 89.8% sulfur utilization, which is the highest value reported by far. The counterpart values for W2C@NC/S and NC/S are 82.8% and 73.3%, respectively, highlighting the advantage of WSA-W2C composite in enhancing the electrochemical activity of sulfur. The discrepancy in sulfur content among three cathodes is below 3.4%, which is at the lowest level in the field (Supplementary Table 2). The cathodes with such sulfur content discrepancy deliver negligible difference in electrochemistry (Supplementary Fig. 20). The absolute sulfur contents above 40% are higher than the reported sulfur-microporous carbon composites and on par with SPANs (Supplementary Table 3). The extremely low capacities of the pure hosts (Supplementary Fig. 21) verified that the capacities of cathodes are provided by the reversible sulfur redox. Of note, the three specimens exhibited highly similar nitrogen moieties in terms of nitrogen types and relative ratios (Supplementary Fig. 22 and Supplementary Table 4). Therefore, the different electrochemical performances of three cathodes should be essentially stemmed from the tungsten species. WSA-W2C@NC/S electrodes with high sulfur loading of 2.86 and 3.61 mg cm–2 delivered slightly lower capacities of 1477.8 and 1221.9 mAh g–1 (Supplementary Fig. 23), which are higher than most previously reported cathodes with low sulfur loading (Supplementary Table 3). Control cathodes of WSA-W2C-H@NC/S and WSA-W2C-L@NC/S delivered capacities of 1274.4 and 1416.1 mAh g−1 (Supplementary Fig. 24), suggesting WSA-W2C@NC/S has the optimal WSA-W2C content.

Regarding to the rate capability (Fig. 3c), WSA-W2C@NC/S cathode exhibited capacities of 914, 697, 408, and 223 mAh g–1 at current densities of 838, 1675, 3350, 5025 mA g–1, respectively. W2C@NC/S cathodes delivered lower capacities than WSA-W2C@NC/S at all rates. It is worth special noting that the capacity fast decayed for W2C@NC/S at 3350–5025 mA g–1, resulting in cell failure at high rate. This issue was more severe for NC/S cathode, as indicated by the rapid cell failure at 837.5 mA g–1. Considering the different constitutions of tungsten species for WSA-W2C@NC and W2C@NC, it is reasonable to speculate that the cooperation between WSA and W2C plays a critical role in maintaining the cell operation because more facile sulfur redox kinetics are required at high specific currents.

The cycling performance were also measured in addition to the rate tests. As shown in Fig. 3d, after 5 activation cycles at 167.5 mA g–1, WSA-W2C@NC/S delivered capacities of 1214 and 1059 mAh g–1 at 837.5 and 1675 mA g–1, respectively. Afterwards, the cathodes kept stable cycling for 200 and 97 cycles, resulting in capacity retention ratio of 49.4 and 56.8%. WSA-W2C-H@NC/S and WSA-W2C-L@NC/S showed inferior cyclability, again proving the optimal content of WSA-W2C in WSA-W2C@NC (Supplementary Fig. 24). For comparison, W2C@NC/S cathode can last for only 127 and 40 cycles at 837.5 and 1675 mA g–1. The cell failure occurred even earlier for NC/S cathode, i.e. at 32nd and 20th cycles. The cell failure can only be postponed by cycling the cathodes at very slow rate (Supplementary Fig. 25). The changes in resistances in the cells provide another aspect reflecting the diversity in cyclability of the cathodes (details in Supplementary Fig. 26 and Table 5). Combining the rate and cycling performance, it could be concluded that certain injurious process continuously deteriorated sulfur redox property and finally damaged the cell, which can be aggravated at higher specific currents. More importantly, the synergy of the functionalities of WSA and W2C can significantly alleviate this negative factor.

It is instructive to compare WSA-W2C@NC/S based KSB with the state-of-the-art KSBs reported. As shown in Fig. 3e and Supplementary Table 3, KSBs employing SPAN cathodes15–17, small-molecular sulfur cathodes8,9,50, polysulfide catholyte51 and cyclo-S8 cathodes18,26,27,52–54 are all included for comprehensive comparison. Remarkably, WSA-W2C@NC/S cathode reaches the highest sulfur utilization and best rate performance. It is worth special noting that the cyclability of WSA-W2C@NC/S cathode is comparable to that of most robust SPAN cathodes, suggesting the advantages of WSA-W2C@NC/S for practical KSBs.

To pursue insights of the K-S redox mechanism, in-situ XRD, ex-situ SAED and XPS were conducted to investigate the WSA-W2C@NC/S cathode during charge and discharge. Per Fig. 3f, as the charging process proceeded, the peaks of K2S6 emerged and gradually strengthened at the expense of K2S4 peak. In the following discharge process, the decrease of K2S4–6 peak intensity and increase of K2S3 peak intensity can be observed, suggesting the reversible conversion between K2S6 and K2S3 in WSA-W2C@NC/S cathode. The diffraction signals of K2S2 and K2S cannot be easily distinguished in the in-situ XRD patterns probably due to the short time for collecting each XRD pattern and the small size of target phases. Thus, SAED was used to further identify the reaction products at various discharge/charge states (Supplementary Fig. 27). Starting from the amorphous halo for pristine cathode (Supplementary Fig. 28), a bright diffraction ring corresponding to K2S6 appeared upon discharge (Fig. 3g). As the discharge continued, K2S6 ring gradually diminished (Dis-1.45 V). Diffraction rings ascribed to K2S phase appeared and became stronger (Dis-1.05/0.75 V). At the lowest discharge voltage of 0.5 V, only strong diffraction rings of K2S and relatively weak diffraction ring of K2S2 existed, suggesting the K2S and minor K2S2 as the discharge end products. During the reversible charge process, diffraction rings ascribed to K2S4 first appeared (Cha-1.45 V). Upon further charging, K2S6 reappeared (Cha-1.95/3.0 V), suggesting the fully reversible conversion from K2S to K2S6 in WSA-W2C@NC/S cathode.

Ex-situ XPS characterizations revealing valence change of sulfur were also conducted as supplement analyses on KPSs conversion. In Fig. 3h, a clear increase of Sn2- (163.4 eV, 162.2 eV) and S2- (163.0 eV, 161.8 eV) components at the expense of S0 (164.7 eV, 163.5 eV) can be observed in discharge55,56. S2- started to convert to Sn2- as charge back to 1.95 V. At the cut-off charge voltage of 3.0 V, both Sn2- and S2- completely converted to S0. The XPS observations are highly consistent with the analyses derived from in-situ XRD and ex-situ SAED patterns.

The sulfur redox process can be resolved based on the systematic spectroscopic data. With regard to the CV curve in Fig. 3a, R1/R2 should be ascribed to the successive conversion of long-chain to short-chain KPSs, and R3 is associated with the reduction of short-chain KPSs into K2S. In the anodic scan, O3/O2, and O1 should be ascribed to the long-chain KPSs oxidation and solid-state KPSs oxidation, respectively. Comparing the peak intensities in the CV curves, the prominent long-chain KPSs conversion for NC/S, and facile short-chain KPSs conversion for W2C@NC/S can be well distinguished. Meanwhile, WSA-W2C@NC/S cathode exhibited the most facile kinetics in all the steps of long-/short-chain KPSs conversion.

Sulfur redox kinetics under synergy of KPS conversion and migration

Based on the index of the redox peaks on CV, more in-depth kinetic analysis of the cathodes can be conducted according to multi-rate CV scanning. The different trends of response specific currents and voltage polarizations as a function of scan rate reflect the kinetics of specific sub-steps of sulfur redox (Fig. 4a). First, the comparison of R1/R2 specific currents and polarizations for W2C@NC/S and NC/S demonstrated that W2C catalytic site had no significant promotion on the long-chain KPSs conversion. WSA-W2C@NC/S cathode delivered ca. 25% higher R1 specific current, which may probably be attributed to the facilitated long-chain KPSs migration across the carbon matrix by WSA moieties. The most facile long-chain KPSs reduction kinetics enabled by WSA-W2C can also be demonstrated by the CV profiles of K2S6 based symmetric cell (Supplementary Fig. 29)57–59.

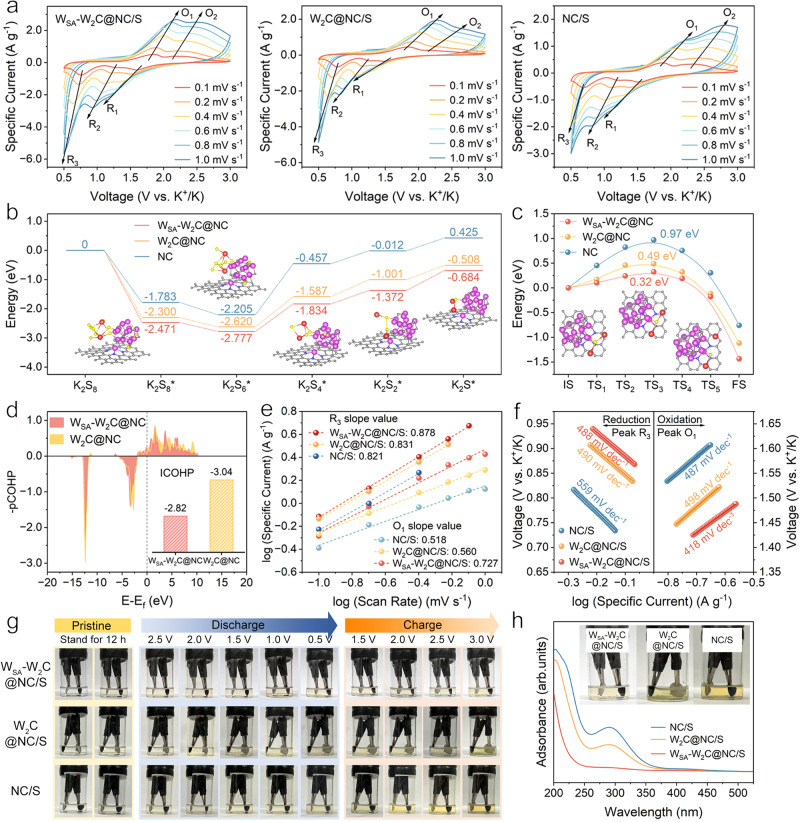

Fig. 4. Sulfur redox kinetics under synergy strategy.

a Multi-rate scan CV curves of KSBs employing WSA-W2C@NC/S, W2C@NC/S, and NC/S cathodes. b Gibbs free energy profiles of sulfur reduction processes on NC, W2C@NC, and WSA-W2C@NC hosts. c Energy profiles for K2S dissociation on WSA-W2C@NC, W2C@NC and NC. d Projected crystal orbital Hamilton population (pCOHP) diagrams of W‒S bonds linking K2S and WSA-W2C@NC, W2C@NC (insert shows ICOHP values). e Linear relationship of log (specific current) vs. log (scan rate) of peaks R3 and O1 for these three cathodes. f Tafel slope of peaks R3 and O1 derived from CV curves at 0.2 mV s−1. g Visual cells under different states employing WSA-W2C@NC/S, W2C@NC/S, NC/S cathodes and potassium foil anodes. h UV-vis spectra and the optical photos (inset) of visual cells employing different cathodes at the end of charge process. Source data are provided as a Source Data file.

Regarding to the R3 peak ascribed to the solid-state KPSs reduction, WSA-W2C@NC/S displayed the lowest polarization and highest response specific current, suggesting the most facile kinetics of solid-state K2S4-K2S conversion. W2C@NC/S displays lower R3 specific current than that of WSA-W2C@NC/S, revealing the synergy of WSA and W2C in enhancing solid-state reaction kinetics. Comparing the characteristics of R3 for W2C@NC/S and NC/S, W2C@NC/S exhibited an accelerated R3 redox, as indicated by the larger response specific currents than that of NC/S. The R3 peak for NC/S is much weaker especially at high scan rate suggesting the difficulty of solid-state KPSs conversion to reach K2S2/K2S without the catalytic effect of W2C nanocrystals.

To reveal the origin of the different sulfur reduction kinetics for the three cathodes, the Gibbs free energy changes along the sulfur reduction pathways were calculated. Figure 4b demonstrates the thermodynamically stable configurations of various KPSs binding with different hosts and the corresponding free energy profiles. It can be distinguished that the reaction sub-steps from K2S8 to K2S6 are exothermic for three cathodes. The successive sub-steps of reduction (from K2S6 to K2S) are all endothermic. The maximum energy barriers occur at the steps of K2S6 to K2S4 for all three cathodes, which are identified as the rate-determining step (RDS) of the whole reduction process. The highest RDS energy barrier (1.748 eV) for NC/S explains the difficulty of the long-chain to short-chain KPSs conversion. With the catalytic effect of W2C nanocrystals, the lower RDS energy barrier (1.033 eV) endows W2C@NC/S with more pronounced solid-state KPSs reduction. As for WSA-W2C@NC/S, the lowest RDS energy barrier (0.943 eV) ensured the advantage in kinetics of both long-chain and short-chain conversion. This optimally balanced multi-step successive reduction process was consistent with the prominent peaks of both R1,2 and R3 displayed in the CV curves.

Regarding to the anodic scan, peaks of O1 and O2 can be distinguished for all three cathodes, which are ascribed to solid-state KPSs oxidation and long-chain KPSs oxidation, respectively. Of note, the O3 peaks distinguishable in the low scan rate (Fig. 3a) integrated into the O2 peak as scan rate increased, thereby being considered as one characteristic O2 peak. The response specific current of O2 peak for NC/S enhanced with increasing scan rate, suggesting the intrinsically facile oxidation of long-chain KPSs. The O1 peak is much lower than O2 peak for NC/S at high scan rate, which is different from that for WSA-W2C@NC/S and W2C@NC/S. This phenomenon indicates the fewer KPSs involving in solid-state conversion during charge for NC/S due to the absence of catalytic species. In the cases of W2C@NC/S, the O1 peak became more pronounced, suggesting the catalytic effect of W2C towards short-chain KPSs oxidation. WSA-W2C@NC/S delivered the highest specific currents for O1,2 peaks, highlighting the most favorable oxidation process from K2S to long-chain KPSs. The K2S6 based symmetric cell tests further proved the most facile long-chain oxidation for WSA-W2C@NC (Supplementary Fig. 29).

The K2S decomposition is the initial step of charging, which is also the most critical obstacle for efficient K-S electrochemistry in KSBs18,26,27. Therefore, the decomposition energy barriers of K2S on WSA-W2C@NC, W2C@NC and NC substrates were calculated to identify the reason for different charging behaviors of the cathodes (Fig. 4c). Based on the configuration determination of initial, transition and final states, the energy barriers for K2S decomposition are respectively 0.32, 0.49 and 0.97 eV for WSA-W2C@NC, W2C@NC and NC, suggesting the highest catalytic activity of WSA-W2C site towards K2S decomposition.

As the transition state provides a snapshot of the real-time K2S dissociation process, the characteristic of transition configuration reveals the origin of catalytic activity (Supplementary Fig. 30). The strength of W‒S bond between W2C and K2S derives from the d-p orbital hybridization37,60, which is an effective descriptor for the catalytic capability18,35. Basically, weaker W‒S bond strength would lead to more facile K2S decomposition and lower overpotential of K2S oxidation18. Projected crystal orbital Hamilton population (pCOHP) analysis were performed to evaluate the W‒S bond strength in the transition states of dynamic interaction between K2S and WSA-W2C, W2C sites (Fig. 4d). According to the integrated-COHP (ICOHP) values, the W‒S bond between K2S and WSA-W2C site is weaker due to the modulation of WSA moieties37,61,62, suggesting the easier K2S dissociation stemming from the catalytic effect of WSA-W2C.

To experimentally evaluate the effect of different tungsten species towards the sulfur redox kinetics, the Tafel slopes and b values were extracted from multi-rate scan CV curves. The b value in i = a vb reflects the reaction kinetics (i and v are the response specific current and scan rate)63,64. As shown in Fig. 4e, the b values of R3 (O1) peaks for WSA-W2C@NC/S, W2C@NC/S and NC/S were 0.878 (0.727), 0.831 (0.560) and 0.821 (0.518), respectively. The highest b values of R3/O1 for WSA-W2C@NC/S cathode indicate the most facile solid-state KPSs conversion, which is the essential reason for the highest sulfur utilization, optimal rate and cycling capability.

The redox kinetics associated with short-chain KPSs conversion can also be interpreted by the Tafel slopes. In Fig. 4f, both WSA-W2C@NC/S and W2C@NC/S exhibited earlier R3 onset potential and distinctly lower Tafel slope than NC/S (488, 490 vs. 559 mV dec–1), which is directly related to the accelerated reduction of solid KPSs by the tungsten species catalysis. In the initial oxidation process, WSA-W2C@NC/S provided a more positive onset potential and exhibited a lower Tafel slope of 418 mV dec–1 for the decomposition of solid short-chain KPSs (K2S2/K2S) compared to W2C@NC/S and NC/S.

The inferior Tafel slope of W2C@NC/S reveals the subtle difference in reaction mechanism caused by the participation of WSA. Due to the lower energy barrier for K2S2 migration on WSA modified NC than that on WSA-free NC, the presence of WSA facilitates the mass transfer around the W2C catalytic center, thereby maximizing the overall efficiency of K2S oxidation. Instead, the sluggish transportation of oxidation product could cause accumulation of insulting solid KPSs (e.g. K2S2) around the catalytic sites diminishing the activity for successive reaction (named catalytic poisoning)65. The WSA-W2C composite synergizing the catalytic conversion and facilitated migration towards KPSs is the key for the highly efficient solid-state KPSs conversion. Of note, W2C@NC/S and NC/S delivered comparable Tafel slopes near the O1 peaks, which is direct evidence of the poisoning effect on W2C catalytic site in W2C@NC/S.

The more facile KPSs conversion kinetics endowed by the synergy of WSA and W2C can also be demonstrated by visual cell measurements. As shown in Fig. 4g, the visual cells employing potassium foils as anodes and WSA-W2C@NC/S, W2C@NC/S, NC/S as cathodes underwent 12 h standing and one entire discharging/charging cycle. The amount of KPSs dissolving in the electrolyte during this process is a reasonable descriptor for the KPSs conversion kinetics, because sluggish KPSs conversion provides more time for KPS dissolving. At the end point of charge-3.0 V, the electrolyte for WSA-W2C@NC/S visual cell remained colorless with negligible KPS signal detected in UV-vis spectrum (Fig. 4h). On the contrary, the electrolytes for W2C@NC/S and NC/S visual cells dissolved much more KPS, suggesting the less facile KPS conversion.

Sulfur redox durability under synergy of KPS conversion and migration

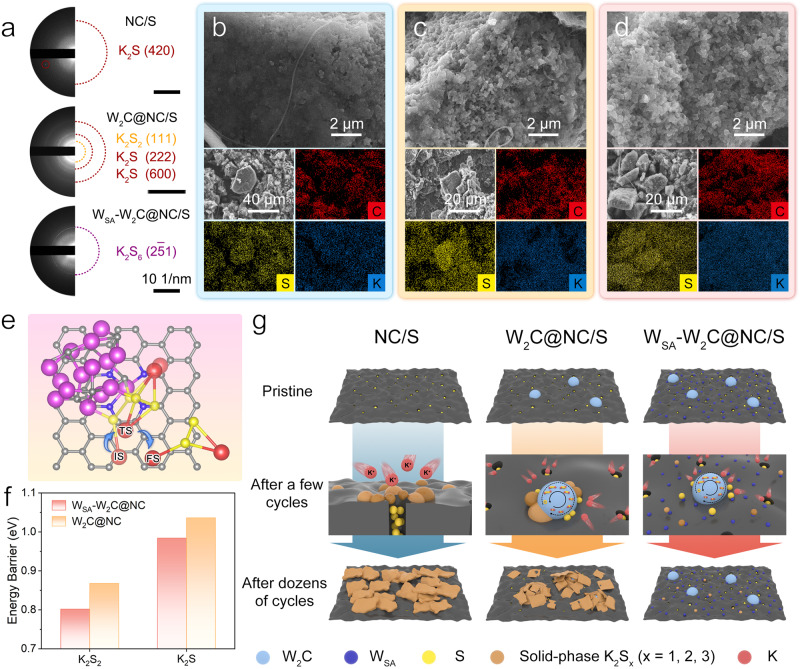

The analyses above revealed the decisive role of WSA-W2C composite in affecting the kinetics of solid-state KPSs conversion. To demonstrate the correlation between the solid-state KPSs conversion and cyclability of KSBs, the post-cycled cathodes (in charged states) were collected and examined. As shown in Fig. 5a and Supplementary Fig. 31, the majority phases of sulfur species are determined to be K2S for NC/S, K2S for W2C@NC/S, and K2S6 for WSA-W2C@NC/S. The result reveals that the sulfur species in NC/S and W2C@NC/S became mainly inert K2S after cycling, which cannot be oxidized back to provide reversible capacity.

Fig. 5. Investigations on sulfur redox durability in KSBs.

a SAED patterns of post-cycled NC/S, W2C@NC/S, or WSA-W2C@NC/S cathodes. b–d SEM images and corresponding EDS mapping of post-cycled NC/S (b), W2C@NC/S (c) and WSA-W2C@NC/S (d) cathodes. e Configuration evolution of K2S2 migration from W2C catalytic site to WSA modified NC substrate. f Energy barriers of K2S2 and K2S migration from W2C catalytic site to WSA modified NC substrate or pure WSA-free NC substrate. g Schematic illustration of the potassium-sulfur electrochemistry in KSBs employing NC/S, W2C@NC/S and WSA-W2C@NC/S cathodes. Source data are provided as a Source Data file.

The morphology and elemental distribution of the post-cycled cathodes were demonstrated in Fig. 5b-d. Severe agglomeration occurred in NC/S cathode, and the original polyhedrons can no longer be discerned, which is due to the extremely thick accumulation of sulfide cementing the polyhedrons66,67. The element mapping of sulfur, potassium and carbon reveals the large size (ca. 30 μm) potassium sulfide particles that detached from the carbon matrix. This phenomenon also appeared for post-cycled W2C@NC/S cathode (Fig. 5c). Although the polyhedron agglomeration is less severe, the non-uniform sulfur and potassium distribution reveal the segregation of potassium-rich sulfides in the cathode. As for post-cycled WSA-W2C@NC/S cathode, the polyhedron morphology almost remained unchanged (Fig. 5d). More importantly, the sulfur mapping overlapped with the shape of micro-size particles, but the potassium distributes uniformly all over the cathode, suggesting the absence of potassium-rich sulfide segregation.

The SEM/EDS results supplement the SAED analyses, further verifying that the accumulation of inert potassium sulfides is the essential reason causing the failure of W2C@NC/S and NC/S based KSBs. We claim that the facilitated migration of the potassium sulfide by WSA plays a key role in significantly alleviating the sulfide accumulation. To prove this point, the migration behaviors of K2S2 and K2S from W2C catalytic site to the carbon substrate were investigated (Fig. 5e and Supplementary Fig. 32). The corresponding energy barriers for the migrations were summarized in Fig. 5f. Apparently, with the participation of WSA, the transfers of K2S2 and K2S from catalytic site can be accelerated due to the distinctly lower migration energy barrier. During the discharge, the fast detachment of K2S reduction product from catalytic site avoids the local accumulation of insulating K2S. In the charge, the oxidation product of K2S2 can efficiently diffuse from catalytic site to the substrate, alleviating the catalytic poisoning and maintaining the consecutive K2S decomposition. These effects become more crucial at high specific current densities and prolonged cycling, which endows WSA-W2C@NC with superior rate capability and long cycling stability.

Discussion

The mechanisms of potassium-sulfur electrochemistry in the cathodes are demonstrated in Fig. 5g. Due to the absence of functional species in NC host, the sulfur redox kinetics is inferior especially for the solid-state KPSs conversion. Consequently, the confined sulfur species rapidly escape from the microporosity and formed a non-uniform deposition of inert K2S on host surface68,69. Upon repeated cycles, the K2S deposition would block the pores and cause thorough passivation. The continuous consumption of electrochemically active sulfur species leads to the fast failure of KSB, which occurs earlier at high rates. Although possessing W2C catalytic sites for W2C@NC host, the sluggish migration of solid KPSs like K2S/K2S2 would inevitably cause the catalytic poisoning due to the inefficiently prompt detachment of solid sulfides from the catalytic sites. In addition, the high energy barrier of KPSs migration on carbon substrate would restrict the contact between sulfur species and catalytic sites. Therefore, the accumulation of inert sulfides would continuously aggravate the cell performance upon prolonged cycling and finally lead to KSB failure12,28. With regard to WSA-W2C@NC/S cathode, the WSA-W2C composite synergizes the facilitated migration and catalytic conversion towards polysulfides. The facile migration of KPSs on WSA modified carbon substrate addresses the mismatch in distribution between ubiquitous sulfur species and isolated catalytic sites. The accelerated transfer of solid K2S/K2S2 around W2C sites prevents the accumulation of inert sulfides and alleviates the catalytic poisoning. Resultantly, high sulfur utilization can be achieved and efficient sulfur redox can be maintained at the conditions of high rates and prolonged cycling, enabling the unprecedented reversible capacity, superior rate performance and long lifespan of KSBs.

In summary, we adopted the strategy of synergizing the facilitated KPSs migration and catalytic KPSs conversion for KSBs. Based on the theoretical screening and sophisticated synthesis procedure, NC equipped with WSA-W2C composite was fabricated as sulfur hosts. Comprehensive experimental analyses and theoretical calculations revealed that WSA species optimize the catalytic capability of W2C species for solid-state KPSs conversion (more facile K2S dissociation) and accelerate the KPSs migration near catalytic sites (lower energy barrier for K2S/K2S2 diffusion). As a result, the insulating sulfides accumulation and catalytic poisoning were effectively alleviated in WSA-W2C@NC/S cathode than the WSA free W2C@NC/S and tungsten free NC/S counterparts, which contributes to the ultra-high sulfur utilization, efficient sulfur redox at high rate and long cycling stability. The validated strategy of KPSs migration acceleration and conversion catalysis bi-functional sulfur host brings more possibility for developing high performance KSBs.

Methods

Chemicals

Sodium tungstate dihydrate (Na2WO4·2H2O, 99%) and 2-Methylimidazole (2-MIM, 98%), zinc acetate (Zn(CH3COO)2·2H2O, 99.98%) were purchased from HEOWNS. Methanol (99.9%) was purchased from Shanghai Macklin Biochemical Co., Ltd. N, N-Dimethylformamide (DMF, 99.5%) was purchased from Tianjin Kemiou Chemical Reagent Co., Ltd. Hydrochloric acid (HCl, 36.0-38.0 wt.%) was purchased from Rionion Development Co., Ltd. Sulfur was purchased from Sigma-Aldrich. 0.8 M KPF6 in EC/DEC was purchased from Suzhou DoDoChem Co., Ltd. N-methyl−2-pyrrolidone (NMP) and poly(vinylidene fluoride) (PVDF) were purchased from Guangdong Canrd New Energy Technology Co., Ltd. Multiwalled carbon nanotubes (MWCNTs) was purchased from Nanjing XFNANO Materials Tech Co., Ltd. Potassium metal was purchased from Alfa Aesar (China) Chemicals Co., Ltd.

Synthesis of ZIF-8 and WO42- modified ZIF-8 (WO42--ZIF-8)

In a typical procedure, 8.95 g (0.109 mol) 2 MIM and 2.39 g (10.9 mmol) Zn(CH3COO)2·2H2O were dissolved in 40 ml of deionized water under continuous magnetic stirring and labeled as solution A and solution B, respectively. Subsequently, solution B was rapidly poured into solution A and aged at room temperature for 48 h. The white ZIF-8 powder was collected by centrifugation, washed three times with methanol, and then dried overnight in a vacuum oven at 60 °C. 0.40 g dried ZIF-8 powder was dispersed in 60 ml DMF solution, and 0.20 g (0.606 mmol) Na2WO4·2H2O was added afterwards. The solution was kept stirring until became homogeneous. The mixed solution was then transferred to a 100 ml Teflon-lined stainless-steel autoclave and underwent a solvothermal process at 150 °C for 12 h. After cooling to room temperature, the light yellow WO42--ZIF-8 powder was obtained by centrifugation, washing with deionized water and methanol alternately three times, and drying at 60 °C.

Synthesis of WSA-W2C@NC

The WO42--ZIF-8 powder was heated to 400 °C and kept for 2 h under N2 atmosphere with a slow heating rate of 2 °C min−1 to prevent the formation of large compound particles during the annealing process. Subsequently, the temperature was increased to 800 °C at a rate of 2 °C min−1 and kept for another 2 h. The obtained powders were dispersed in 50 ml 6 M HCl and held at 60 °C for 4 h to etch off the Zn species and to generate microporous. Afterward, the powder was washed with plenty of deionized water and dried in a vacuum oven at 60 °C overnight to obtain the product labeled as WSA-W2C@NC.

Synthesis of W2C@NC

0.20 g (0.606 mmol) Na2WO4·2H2O and 0.40 g ZIF-8 powder was mixed and grounded in the mortar for 30 min. Afterward, the homogeneous mixture was heated up to 400 °C and kept for 2 h under N2 atmosphere with a slow heating rate of 2 °C min–1. Then, the nitrogen-filled tube furnace was ramped up to 800 °C at the same heating rate and kept for another 2 h. Afterwards, the residual Zn species in the as-prepared powder was further etched by 6 M HCl and held at 60 °C for 4 h. After collected by infiltration, the powder was washed with plenty of deionized water and dried in a vacuum oven at 60 °C overnight. The obtained product was labeled as W2C@NC.

Synthesis of NC

The ZIF-8 powder was directly carbonized according to the same two-step heating procedure. In a typical process, ZIF-8 powders were filled in a porcelain boat and heated up to 400 °C for 2 h in a nitrogen-filled tube furnace with a heating rate of 2 °C min−1, and then to 800 °C for another 2 h. Then, the as-prepared powder was treated with 6 M hydrochloric acid solution kept at 60 °C for 4 h, followed by washing with a large amount of deionized water and then placed in a vacuum oven at 60 °C overnight. The obtained product was labeled as NC.

Synthesis of WSA-W2C-H@NC and WSA-W2C-L@NC

The synthesis of WSA-W2C-H@NC and WSA-W2C-L@NC followed the same procedure of WSA-W2C@NC except different amount of Na2WO4·2H2O (0.60 g (1.819 mmol) for WSA-W2C-H@NC and 0.10 g (0.303 mmol) for WSA-W2C-L@NC) were added for preparing WO42--ZIF-8 precursors.

Synthesis of WSA-W2C@NC/S, W2C@NC/S and NC/S composites

The as-prepared WSA-W2C@NC, W2C@NC and NC hosts were uniformly mixed with sulfur powder with a mass ratio of 1:1 and sealed in a glass tube under vacuum. The glass tube was heated to 155 °C at a rate of 5 °C min−1 and kept for 24 h, followed by heating to 300 °C and holding for 2 h. Then, the obtained powders were heated at 200 °C for 1 h under flowing Ar in a tube furnace. The products are termed as WSA-W2C@NC/S (or NC/S, W2C@NC/S) composite.

Adsorption measurements

The K2S6 solution for adsorption measurements was prepared by mixing potassium sulfide (K2S) and sulfur with a molar ratio of 1:5 in dimethyl ether (DME). 5 mg WSA-W2C@NC, W2C@NC, and NC were added into the 2 ml 0.02 M K2S6 solution, respectively, with the blank K2S6 solution as a reference.

Materials characterization

The scanning electron microscopy (SEM) images were obtained by JEOL JSM-7800F with an energy dispersive spectrometer (EDS). The transmission electron microscopy (TEM) images and selected area electron diffraction (SAED) patterns were recorded by JEOL JEM-F200. The aberration-corrected high angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images were collected by JEOL JEM-ARM200F. The X-ray photoelectron spectroscopy (XPS) analysis was performed on Kratos Axis Ultra DLD spectrometer. Raman spectra were recorded with Horiba LabRam HR Evolution spectrometer. Nitrogen adsorption-desorption isotherm measurement was conducted using Micromeritics ASAP 2460 system. The thermogravimetric analysis (TGA) was investigated by using NETZSCH STA 449 C instrument. The ultraviolet-visible (UV-vis) spectra were performed by Shimadzu UV-2700 spectrophotometer. The in-situ X-ray diffraction (XRD) patterns were performed using Bruker D8 Advance with Cu Kα radiation (λ = 0.15406 nm) at 40 kV and 40 mA. The X-ray absorption structure (XAS) spectra (W L-edge) were measured in Shanghai Synchrotron Radiation Facility (SSRF).

Electrochemical measurements

Electrochemical tests were performed by assembling CR2032-type coin cells in an Argon-filled glove box. 60 wt.% cathode materials (WSA-W2C@NC/S (40.56 wt.% sulfur), W2C@NC/S (37.91 wt.% sulfur) or NC/S (43.93 wt.% sulfur)), 30 wt.% MWCNTs, and 10 wt.% PVDF were mixed with an appropriate amount of NMP for the preparation of a uniform slurry. The obtained slurry was cast on carbon-coated aluminum foil with the thickness of 250 μm and dried overnight in a vacuum oven at 60 °C. The electrodes were punched into 12 mm diameter disks for battery assembly. Glass fiber (GF/C, Whatman) with the diameter of 19 mm was chosen as the separator. Potassium metal foils produced from surface oxide layer-free potassium blocks were directly applied as anode. The electrolyte is 0.8 M KPF6 in EC/DEC with a volume ratio of 1:1. The typical sulfur loading of the electrode is ca. 1 mg cm–2. Electrodes with high sulfur loading of ca. 2.8 and ca. 3.6 mg cm–2 were also prepared for electrochemical tests. For the full wetting of the glass fiber separator, the normal electrolyte dosage in one coin cell is 100 μL. Electrochemical measurements were performed on a NEWARE battery testing system and Solartron multi-channel electrochemical workstation with the voltage range of 0.5-3.0 V (vs. K+/K) in a thermostat at room temperature (25 °C). Cycling performance was conducted at specific currents of 167.5, 837.5, and 1675 mA g−1, and rate performance was conducted at a series of specific currents in the order of 167.5, 335, 502.5, 837.5, 1675, 3350, 5025, and 167.5 mA g−1, respectively.

Symmetric cell measurements

The K2S6 electrolyte was fabricated by adding K2S and sulfur (molar ratio corresponds to the nominal stoichiometry of K2S6) into the tetra ethylene glycol dimethyl ether (TEGDME) with 3 M potassiumbis(trifluor-omethylsulfonyl)imide (KTFSI), and then stirring at 60 °C for 24 h. 100 μL obtained K2S6-contained electrolyte (0.052 M) with the identical anodes and cathodes of WSA-W2C@NC, W2C@NC, and NC were assembled into the symmetric cells for the polysulfides conversion mechanism study.

Visual cell measurements

The cathode materials (WSA-W2C@NC/S, W2C@NC/S, or NC/S), MWCNTs, PVDF with a mass ratio of 6:3:1 was dispersed in NMP, and coated on carbon paper, followed by drying at 60 °C for overnight. The potassium foil that was stamped onto the stainless-steel collector was used as anode. Both anode and cathode were clamped by alligator clips, and the electrolyte is 4 M KTFSI in DME. Finally, the reaction vessels were sealed for galvanostatic charge-discharge measurements at 167.5 mA g–1 on Solartron multi-channel electrochemical workstation.

Computational methods

Details of the computational methods is provided within the Supplementary Information.

Supplementary information

Source data

Acknowledgements

We acknowledge financial supports from the National Natural Science Foundation of China (No. 52072257 (J. D.)), the National Key Research and Development Program of China (No. 2019YFE0118800 (Y. X.)), and the National Natural Science Foundation of China (No. 52372218 (J. D.), No. U22A20119 (W. H.)).

Author contributions

W.H. and J.D. conceived the project and designed the experiments. W.S., X.Y., Z.H., and T.Z. carried out the synthesis and characterization of materials and the electrochemical measurements. W.S., Y.X. and J.S. performed the in-situ XRD measurements. W.S., H.W. and J.D. performed the DFT calculation. W.S., J.D., and W.H. wrote the paper. All authors discussed the results and commented on the paper.

Peer review

Peer review information

Nature Communications thanks Chandra Sharma and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Data availability

The data generated in this study are provided in the Supplementary Information and are available from the authors upon request. Source data are provided with this paper.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Haozhi Wang, Email: hzwang001@tju.edu.cn.

Jia Ding, Email: jiading@tju.edu.cn.

Wenbin Hu, Email: wbhu@tju.edu.cn.

Supplementary information

The online version contains supplementary material available at 10.1038/s41467-024-45405-w.

References

- 1.Heede UK, Fedorov AV. Eastern equatorial pacific warming delayed by aerosols and thermostat response to CO2 increase. Nat. Clim. Chang. 2021;11:696. doi: 10.1038/s41558-021-01101-x. [DOI] [Google Scholar]

- 2.Bruce PG, Freunberger SA, Hardwick LJ, Tarascon J-M. Li–O2 and Li–S batteries with high energy storage. Nat. Mater. 2012;11:19. doi: 10.1038/nmat3191. [DOI] [PubMed] [Google Scholar]

- 3.Vijaya Kumar Saroja AP, Xu Y. Carbon materials for Na-S and K-S batteries. Matter. 2022;5:808. doi: 10.1016/j.matt.2021.12.023. [DOI] [Google Scholar]

- 4.Hong X, et al. Nonlithium metal–sulfur batteries: steps toward a leap. Adv. Mater. 2019;31:1802822. doi: 10.1002/adma.201802822. [DOI] [PubMed] [Google Scholar]

- 5.Manthiram A, Fu Y, Chung S-H, Zu C, Su Y-S. Rechargeable lithium–sulfur batteries. Chem. Rev. 2014;114:11751. doi: 10.1021/cr500062v. [DOI] [PubMed] [Google Scholar]

- 6.Wang Y-X, et al. Achieving high-performance room-temperature sodium–sulfur batteries with S@interconnected mesoporous carbon hollow nanospheres. J. Am. Chem. Soc. 2016;138:16576. doi: 10.1021/jacs.6b08685. [DOI] [PubMed] [Google Scholar]

- 7.Mou J, et al. Hierarchical porous carbon sheets for high-performance room temperature sodium–sulfur batteries: Integration of nitrogen-self-doping and space confinement. J. Mater. Chem. A. 2020;8:24590. doi: 10.1039/D0TA08876E. [DOI] [Google Scholar]

- 8.Xiong P, et al. Room-temperature potassium–sulfur batteries enabled by microporous carbon stabilized small-molecule sulfur cathodes. ACS Nano. 2019;13:2536. doi: 10.1021/acsnano.8b09503. [DOI] [PubMed] [Google Scholar]

- 9.Liang J, Song W, Wang H, Ding J, Hu W. Porosity engineering towards nitrogen-rich carbon host enables ultrahigh capacity sulfur cathode for room temperature potassium-sulfur batteries. Nanomaterials. 2022;12:3968. doi: 10.3390/nano12223968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Guo Q, et al. Ultrastable sodium–sulfur batteries without polysulfides formation using slit ultramicropore carbon carrier. Adv. Sci. 2020;7:1903246. doi: 10.1002/advs.201903246. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Xiao F, et al. Covalent encapsulation of sulfur in a MOF-derived S, N-doped porous carbon host realized via the vapor-infiltration method results in enhanced sodium–sulfur battery performance. Adv. Energy Mater. 2020;10:2000931. doi: 10.1002/aenm.202000931. [DOI] [Google Scholar]

- 12.Huang XL, Wang Y-X, Chou S-L, Dou SX, Wang ZM. Materials engineering for adsorption and catalysis in room-temperature Na–S batteries. Energy Environ. Sci. 2021;14:3757. doi: 10.1039/D1EE01349A. [DOI] [Google Scholar]

- 13.Wang Y-X, Lai W-H, Chou S-L, Liu H-K, Dou S-X. Remedies for polysulfide dissolution in room-temperature sodium–sulfur batteries. Adv. Mater. 2020;32:1903952. doi: 10.1002/adma.201903952. [DOI] [PubMed] [Google Scholar]

- 14.Ding J, et al. Review of emerging potassium–sulfur batteries. Adv. Mater. 2020;32:1908007. doi: 10.1002/adma.201908007. [DOI] [PubMed] [Google Scholar]

- 15.Liu Y, et al. Sulfur nanocomposite as a positive electrode material for rechargeable potassium–sulfur batteries. Chem. Commun. 2018;54:2288. doi: 10.1039/C7CC09913D. [DOI] [PubMed] [Google Scholar]

- 16.Ma S, et al. Iodine-doped sulfurized polyacrylonitrile with enhanced electrochemical performance for room-temperature sodium/potassium sulfur batteries. Chem. Commun. 2019;55:5267. doi: 10.1039/C9CC01612K. [DOI] [PubMed] [Google Scholar]

- 17.Lee S, et al. High-energy and long-lifespan potassium–sulfur batteries enabled by concentrated electrolyte. Adv. Funct. Mater. 2022;32:2209145. doi: 10.1002/adfm.202209145. [DOI] [Google Scholar]

- 18.Ye C, et al. Reducing overpotential of solid-state sulfide conversion in potassium-sulfur batteries. Angew. Chem. Int. Ed. 2023;62:e202301681. doi: 10.1002/anie.202301681. [DOI] [PubMed] [Google Scholar]

- 19.Qi Y, et al. A Fe3N/carbon composite electrocatalyst for effective polysulfides regulation in room-temperature Na-S batteries. Nat. Commun. 2021;12:6347. doi: 10.1038/s41467-021-26631-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Wang P, et al. Atomic tungsten on graphene with unique coordination enabling kinetically boosted lithium–sulfur batteries. Angew. Chem. Int. Ed. 2021;60:15563. doi: 10.1002/anie.202104053. [DOI] [PubMed] [Google Scholar]

- 21.Jiang Y, et al. Single-atom vanadium catalyst boosting reaction kinetics of polysulfides in Na-S batteries. Adv. Mater. 2022;35:2208873. doi: 10.1002/adma.202208873. [DOI] [PubMed] [Google Scholar]

- 22.Hao H, et al. Molybdenum carbide electrocatalyst in situ embedded in porous nitrogen-rich carbon nanotubes promotes rapid kinetics in sodium-metal-sulfur batteries. Adv. Mater. 2022;34:e2106572. doi: 10.1002/adma.202106572. [DOI] [PubMed] [Google Scholar]

- 23.Wu Y, et al. Ultradispersed WxC nanoparticles enable fast polysulfide interconversion for high-performance Li-S batteries. Nano Energy. 2019;59:636. doi: 10.1016/j.nanoen.2019.03.015. [DOI] [Google Scholar]

- 24.Wei B, Shang C, Akinoglu EM, Wang X, Zhou G. A full Li–S battery with ultralow excessive Li enabled via lithiophilic and sulfilic W2C modulation. Chem. Eur. J. 2020;26:16057. doi: 10.1002/chem.202002822. [DOI] [PubMed] [Google Scholar]

- 25.Shi N, et al. Strongly coupled W2C atomic nanoclusters on N/P-codoped graphene for kinetically enhanced sulfur host. Adv. Mater. Interfaces. 2019;6:1802088. doi: 10.1002/admi.201802088. [DOI] [Google Scholar]

- 26.Ye C, et al. Catalytic oxidation of K2S via atomic Co and pyridinic N synergy in potassium–sulfur batteries. J. Am. Chem. Soc. 2021;143:16902. doi: 10.1021/jacs.1c06255. [DOI] [PubMed] [Google Scholar]

- 27.Ge X, et al. Metal–organic framework-derived nitrogen-doped cobalt nanocluster inlaid porous carbon as high-efficiency catalyst for advanced potassium–sulfur batteries. ACS Nano. 2020;14:16022. doi: 10.1021/acsnano.0c07658. [DOI] [PubMed] [Google Scholar]

- 28.Zhang B, et al. Optimized catalytic WS2–WO3 heterostructure design for accelerated polysulfide conversion in lithium–sulfur batteries. Adv. Energy Mater. 2020;10:2000091. doi: 10.1002/aenm.202000091. [DOI] [Google Scholar]

- 29.Lei T, et al. Multi-functional layered WS2 nanosheets for enhancing the performance of lithium–sulfur batteries. Adv. Energy Mater. 2017;7:1601843. doi: 10.1002/aenm.201601843. [DOI] [Google Scholar]

- 30.Liu Y, et al. Tungsten nanoparticles accelerate polysulfides conversion: a viable route toward stable room-temperature sodium–sulfur batteries. Adv. Sci. 2022;9:2105544. doi: 10.1002/advs.202105544. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Levy RB, Boudart M. Platinum-like behavior of tungsten carbide in surface catalysis. Science. 1973;181:547. doi: 10.1126/science.181.4099.547. [DOI] [PubMed] [Google Scholar]

- 32.Wang L, et al. Manipulating the electronic structure of nickel via alloying with iron: toward high-kinetics sulfur cathode for Na–S batteries. ACS Nano. 2021;15:15218. doi: 10.1021/acsnano.1c05778. [DOI] [PubMed] [Google Scholar]

- 33.Gu S, et al. Chemical synthesis of K2S2 and K2S3 for probing electrochemical mechanisms in K–S batteries. ACS Energy Lett. 2018;3:2858. doi: 10.1021/acsenergylett.8b01719. [DOI] [Google Scholar]

- 34.Song X, et al. Improving poisoning resistance of electrocatalysts via alloying strategy for high-performance lithium-sulfur batteries. Energy Stor. Mater. 2021;41:248. [Google Scholar]

- 35.Wang L, et al. Design rules of a sulfur redox electrocatalyst for lithium-sulfur batteries. Adv. Mater. 2022;34:e2110279. doi: 10.1002/adma.202110279. [DOI] [PubMed] [Google Scholar]

- 36.Li Z, et al. Room-temperature sodium-sulfur batteries: rules for catalyst selection and electrode design. Adv. Mater. 2022;34:e2204214. doi: 10.1002/adma.202204214. [DOI] [PubMed] [Google Scholar]

- 37.Han Z, et al. Engineering d-p orbital hybridization in single-atom metal-embedded three-dimensional electrodes for Li-S batteries. Adv. Mater. 2021;33:e2105947. doi: 10.1002/adma.202105947. [DOI] [PubMed] [Google Scholar]

- 38.Zhu R, et al. Modulating bond interactions and interface microenvironments between polysulfide and catalysts toward advanced metal–sulfur batteries. Adv. Funct. Mater. 2022;32:2207021. doi: 10.1002/adfm.202207021. [DOI] [Google Scholar]

- 39.Chen Z, et al. Coordination-controlled single-atom tungsten as a non-3d-metal oxygen reduction reaction electrocatalyst with ultrahigh mass activity. Nano Energy. 2019;60:394. doi: 10.1016/j.nanoen.2019.03.045. [DOI] [Google Scholar]

- 40.Wang Y, et al. W single-atom catalyst for CH4 photooxidation in water vapor. Adv. Mater. 2022;34:2204448. doi: 10.1002/adma.202204448. [DOI] [PubMed] [Google Scholar]

- 41.Zhang F, et al. High-efficiency electrosynthesis of hydrogen peroxide from oxygen reduction enabled by a tungsten single atom catalyst with unique terdentate N1O2 coordination. Adv. Funct. Mater. 2022;32:2110224. doi: 10.1002/adfm.202110224. [DOI] [Google Scholar]

- 42.Zhang H, et al. Isolated cobalt centers on W18O49 nanowires perform as a reaction switch for efficient CO2 photoreduction. J. Am. Chem. Soc. 2021;143:2173. doi: 10.1021/jacs.0c08409. [DOI] [PubMed] [Google Scholar]

- 43.Chen Z, et al. Thermal migration towards constructing W-W dual-sites for boosted alkaline hydrogen evolution reaction. Nat. Commun. 2022;13:763. doi: 10.1038/s41467-022-28413-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Wu C, et al. Continuous carbon channels enable full Na-ion accessibility for superior room-temperature Na-S batteries. Adv. Mater. 2022;34:e2108363. doi: 10.1002/adma.202108363. [DOI] [PubMed] [Google Scholar]

- 45.Bharti VK, Sharma CS, Khandelwal M. Carbonized bacterial cellulose as free-standing cathode host and protective interlayer for high-performance potassium-sulfur batteries with enhanced kinetics and stable operation. Carbon. 2023;212:118173. doi: 10.1016/j.carbon.2023.118173. [DOI] [Google Scholar]

- 46.Wang L, Bao J, Liu Q, Sun C-F. Concentrated electrolytes unlock the full energy potential of potassium-sulfur battery chemistry. Energy Stor. Mater. 2019;18:470. [Google Scholar]

- 47.Wu J, et al. Bifunctional catalyst for liquid–solid redox conversion in room‐temperature sodium–sulfur batteries. Small Struct. 2022;3:2200020. doi: 10.1002/sstr.202200020. [DOI] [Google Scholar]

- 48.Li D, et al. An efficient strategy toward multichambered carbon nanoboxes with multiple spatial confinement for advanced sodium-sulfur batteries. ACS Nano. 2021;15:20607. doi: 10.1021/acsnano.1c09402. [DOI] [PubMed] [Google Scholar]

- 49.Zhao D, et al. Lychee seed-derived microporous carbon for high-performance sodium-sulfur batteries. Carbon. 2023;201:864. doi: 10.1016/j.carbon.2022.09.075. [DOI] [Google Scholar]

- 50.Zhao Q, Hu Y, Zhang K, Chen J. Potassium–sulfur batteries: a new member of room-temperature rechargeable metal–sulfur batteries. Inorg. Chem. 2014;53:9000. doi: 10.1021/ic500919e. [DOI] [PubMed] [Google Scholar]

- 51.Hwang J-Y, Kim HM, Yoon CS, Sun Y-K. Toward high-safety potassium–sulfur batteries using a potassium polysulfide catholyte and metal-free anode. ACS Energy Lett. 2018;3:540. doi: 10.1021/acsenergylett.8b00037. [DOI] [Google Scholar]

- 52.Yuan X, et al. Free-standing, flexible and stable potassium–sulfur battery enabled by controllable porous carbon cloth. J. Power Sources. 2020;480:228874. doi: 10.1016/j.jpowsour.2020.228874. [DOI] [Google Scholar]

- 53.Yang K, et al. Achieving fast and reversible sulfur redox by proper interaction of electrolyte in potassium batteries. ACS Energy Lett. 2023;8:2169. doi: 10.1021/acsenergylett.3c00529. [DOI] [Google Scholar]

- 54.Bharti VK, Pathak AD, Anjan A, Sharma CS, Khandelwal M. Covalently confined sulfur composite with carbonized bacterial cellulose as an efficient cathode matrix for high-performance potassium–sulfur batteries. ACS Sustain. Chem. Eng. 2022;10:16634. [Google Scholar]

- 55.Zhang W, et al. Bidirectional atomic iron catalysis of sulfur redox conversion in high-energy flexible Zn-S battery. Adv. Funct. Mater. 2023;33:2210899. doi: 10.1002/adfm.202210899. [DOI] [Google Scholar]

- 56.Lei Y, et al. Streamline sulfur redox reactions to achieve efficient room-temperature sodium–sulfur batteries. Angew. Chem. Int. Ed. 2022;61:e202200384. doi: 10.1002/anie.202200384. [DOI] [PubMed] [Google Scholar]

- 57.Anjan A, Bharti VK, Sharma CS, Khandelwal M. Carbonized bacterial cellulose-derived binder-free, flexible, and free-standing cathode host for high-performance stable potassium–sulfur batteries. ACS Appl. Energy Mater. 2023;6:3042. doi: 10.1021/acsaem.2c04157. [DOI] [Google Scholar]

- 58.Bharti VK, Pathak AD, Sharma CS, Khandelwal M. Ultra-high-rate lithium-sulfur batteries with high sulfur loading enabled by Mn2O3-carbonized bacterial cellulose composite as a cathode host. Electrochim. Acta. 2022;422:140531. doi: 10.1016/j.electacta.2022.140531. [DOI] [Google Scholar]

- 59.Xiao F, et al. Generating short-chain sulfur suitable for efficient sodium–sulfur batteries via atomic copper sites on a N,O-codoped carbon composite. Adv. Energy Mater. 2021;11:2100989. doi: 10.1002/aenm.202100989. [DOI] [Google Scholar]

- 60.Zhou G, et al. Theoretical calculation guided design of single-atom catalysts toward fast kinetic and long-life Li–S batteries. Nano Lett. 2020;20:1252. doi: 10.1021/acs.nanolett.9b04719. [DOI] [PubMed] [Google Scholar]

- 61.Gong N, et al. Transition metals embedded siloxene as single-atom catalyst for advanced sulfur host in lithium–sulfur batteries: A theoretical study. Adv. Energy Mater. 2022;12:2201530. doi: 10.1002/aenm.202201530. [DOI] [Google Scholar]

- 62.Shen Z, et al. Cation-doped ZnS catalysts for polysulfide conversion in lithium–sulfur batteries. Nat. Catal. 2022;5:555. doi: 10.1038/s41929-022-00804-4. [DOI] [Google Scholar]

- 63.Lindström H, et al. Li+ ion insertion in TiO2 (anatase). 2. Voltammetry on nanoporous films. J. Phys. Chem. B. 1997;101:7717. doi: 10.1021/jp970490q. [DOI] [Google Scholar]

- 64.Augustyn V, et al. High-rate electrochemical energy storage through Li+ intercalation pseudocapacitance. Nat. Mater. 2013;12:518. doi: 10.1038/nmat3601. [DOI] [PubMed] [Google Scholar]

- 65.Li Z, et al. A sulfur host based on titanium monoxide@carbon hollow spheres for advanced lithium-sulfur batteries. Nat. Commun. 2016;7:13065. doi: 10.1038/ncomms13065. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 66.Wei S, et al. A stable room-temperature sodium–sulfur battery. Nat. Commun. 2016;7:11722. doi: 10.1038/ncomms11722. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Chen Y-M, et al. A nitrogen doped carbonized metal–organic framework for high stability room temperature sodium–sulfur batteries. J. Mater. Chem. A. 2016;4:12471. doi: 10.1039/C6TA04529D. [DOI] [Google Scholar]

- 68.Pang Q, Kundu D, Cuisinier M, Nazar LF. Surface-enhanced redox chemistry of polysulphides on a metallic and polar host for lithium-sulphur batteries. Nat. Commun. 2014;5:4759. doi: 10.1038/ncomms5759. [DOI] [PubMed] [Google Scholar]

- 69.Wang R, et al. Bidirectional catalysts for liquid-solid redox conversion in lithium-sulfur batteries. Adv. Mater. 2020;32:e2000315. doi: 10.1002/adma.202000315. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data generated in this study are provided in the Supplementary Information and are available from the authors upon request. Source data are provided with this paper.