The seas swarm with them, an unimaginable multitude. Algae are the most important carbon sink in the biosphere; the world’s oceans sequester annually 2 gigatons of carbon via carbon dioxide uptake compared with 1.4 gigatons for the total land biosphere. Yet of the 40 000 or so species of algae that exist, but a tiny number—as few as five or six—are exploited by humans. That minuscule fraction, however, amounts to a consumption of 5 billion tons per year, mostly marine multicellular green and green-brown algae, or ‘seaweed’. The Japanese eat it every day as ‘nori’, thin sheets of dried seaweed that wrap sushi rolls and accompany the traditional breakfast; many westerners probably use it daily on their faces in cosmetics and in common household products (Table I).

Table I. Use of algal products.

| Instant puddings |

| Ice cream |

| Sherberts |

| Chocolate |

| Cheese |

| Mayonnaise |

| Lotions |

| Shaving cream |

| Rubbers |

| Latex |

| Fertilisers and soil |

| additives |

These multicellular ‘macroalgae’ provide three principal extracts: alginates, carageenins and agars, which are valued for their physical properties, such as thickening, gel-forming, emulsifying or film-forming. But now the time has come for microalgae, unicellular blue-green and red algae that can be grown in vast photosynthetic bioreactors. They are prized for their micronutritional value, containing substances that those who invest in them believe will boost our immune system, fight cancer, protect us from UV radiation and treat joint ailments, to mention but a few applications. Others have explored their use in bioremediation—the removal of heavy metals from polluted soil and water—and some have even tried to grow microalgae in the CO2-rich flue gas of industrial plants to use the resulting biomass as combustible fuel. But is mass production of microalgae in autotrophic—light-driven—bioreactors economically viable?

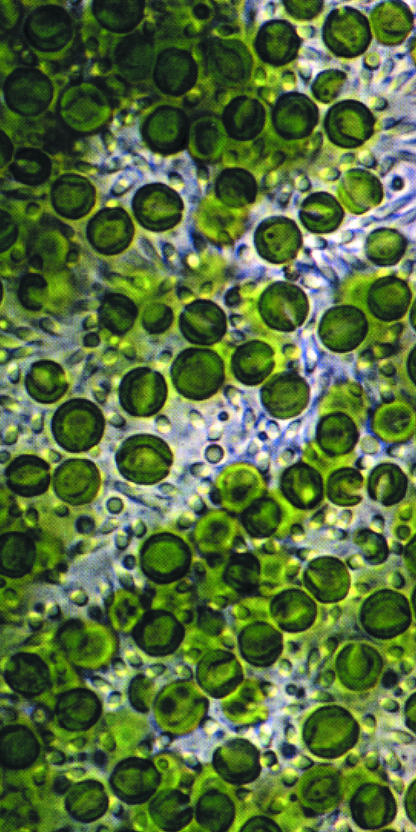

Clearly some believe it is because they have built the world’s largest closed photobioreactor, reliant solely on light as the source of energy, on the outskirts of Klötze in northern Germany. With a capacity of 700 cubic metres, and covering an area of more than one hectare, the German green machine is 10 times larger than its nearest competitor in Hawaii. Its product, Chlorella vulgaris, a single-celled blue-green alga, is destined mainly for food and feed additives, and cosmetics.

But a leading authority on microalgae, Michael Melkonian, professor at the Botanical Institute, University of Cologne, thinks there are still some hurdles to overcome. ‘The biggest problem is how to get the source of energy to the cells. To get light to every cell, you need a thin layer of cells; higher plants solved that problem millions of years ago with the leaf.’ Melkonian believes that although production of microalgae is certainly a worthy pursuit, the present bioreactors need optimising before they can be economically viable.

This is bad news for Gottfried Mende, director of the Klötze plant, though he remains convinced of the success of his venture, and in particular the value of his product. So full of good things are they, that ‘it is possible to exist purely on Chlorella vulgaris’ according to Mende, ‘but it’s not much fun’ he added humorously. His company, Ökologische Produkte Altmark GmbH, has staked its future on the demand for the green gold, which contains more protein per gram of dry mass than soya, and promises to spawn a range of functional or designer foods. Indeed, last year in Germany alone up to 350 tons dry mass of microalgae were used, mainly in human food additives and cosmetics; the Klötze plant produces 150 tons annually in its 500 km of naturally-lit piping, and sells its product for 50 Euros per kg dry mass. However, unlike Soya, it is not for its protein value that Chlorella is eaten by humans and fed to livestock. Though the mechanism is not well understood, a daily dose of 3 g of Chlorella vulgaris can boost the immune system, and make you feel better, says Mende, who takes a dose every day himself.

The boost that Chlorella gives to the immune system is likely to be due to branched chain polysaccharides, which are known to be antigenic; the cardiovascular benefits derive mainly from antioxidants and omega-unsaturated fatty acids. These are the very same that are found in some fish—which acquire them by eating algae. Algal antioxidants such as carotenoids and complex polyphenols, soak up toxic radicals, and can protect against cancer, UV damage and atherosclerosis. The public can now buy Mende’s brown-green Chlorella vulgaris tablets in the local pharmacy, and add them to their morning selection of health and vitality-promoting vitamin and mineral supplements.

What is good for man also turns out to be good for beast. Trials have shown that adding 0.2% Chlorella vulgaris to chicken feed increases the animals’ weight at slaughter by 10%. The chickens are generally healthier, and benefit from a 16% reduction in cholesterol. Here the market for microalgae has recently been boosted by the EC’s new regulations limiting the use of feed antibiotics. Moreover, it would appear that there are no risks to humans or the environment from microalgae, since they have inhabited the earth for billions of years, and have been in the human food chain since the dawn of mankind.

Our historical familiarity with algae has made us unaware of their ubiquity thinks Otto Pulz from the Institut für Getreideverarbeitung GmbH near Potsdam, Germany: ‘I think that algae are already more public than the public realises,’ remarked Pulz, who works on photobioreactor development, and use of microalgal extracts in cosmetics. The consumer acceptance of algal products has increased dramatically in the last 5 years according to Pulz, who is a key figure in the development of the plant in Klötze. And because of the enormous biodiversity in the oceans, bioengineers need only look to nature to find new promising compounds or biochemical pathways. ‘Genetic engineering in microalgae is not a real aim for the biotechnologist,’ as Pulz put it. The potential applications of natural microalgal extracts are growing almost daily (Table II).

Table II. Claimed beneficial effects and applications of microalgal extracts.

| Medicinal and general health: |

| Stimulation of a vigorous immune system |

| Treatment of carpal tunnel syndrome |

| Treatment of joint pain and inflammation |

| Fluorescent pigments for medical diagnosis |

| Improved muscle recovery after exercise |

| Treatment of cold sores |

| Treatment of allergies |

| Cancer treatment |

| Increased general health in humans and farm animals |

| Prophylactic: |

| Cardiovascular disease prevention |

| Cancer prevention |

| Hypertension |

| UV protection |

Entrepreneurs across the Atlantic also believe in the economic viability of large-scale microalgae production. If microalgae are being touted as the next functional food additive in Germany, this can be nothing compared with the hype that surrounds their health-promoting qualities in the USA. Idyllically situated, the waterfront complex in Kailua-Kona, Hawaii, is the largest open culture facility in the world. Glistening emerald green in the pacific sun are 36 hectares of interlinked channels containing Spirulina pacifica, a spiral microalga that thrives at pH 10–11. The company is Cyanotech, and its CEO, Gerry Cysewski certainly believes he is onto a winner. Spirulina Pacifica®—now a registered trademark—is presented as ‘a nutrient-rich dietary supplement… [a] highly absorbable source of natural beta-carotene, mixed carotenoids and other phytonutrients, B vitamins, gamma linolenic acid (GLA), protein and essential amino acids.’ Amazingly this is also true, but it may come as a surprise to western cultures raised on synthetic food that anything so natural could possibly be good for you. Indeed, according to Cyanogen, it ‘has been used as a significant food source for centuries.’

Ironically we have rediscovered via science the accepted wisdom that plants contain a great deal of good things. Nevertheless, brownish tablets will hardly inspire the consumer, so Cyanotech markets it in attractive colourful bottles. Apparently six Spirulina tablets (0.5 g each) provide the essential nutrients of 5–7 servings of fruit and vegetables recommended by the US cancer and heart societies. To add weight to its claimed health benefits, Spirulina has been shown recently to increase the tumor killing ability of Natural Killer cells and interferon gamma, according to a clinical trial on volunteers at the Osaka Institute of Public Health in Japan.

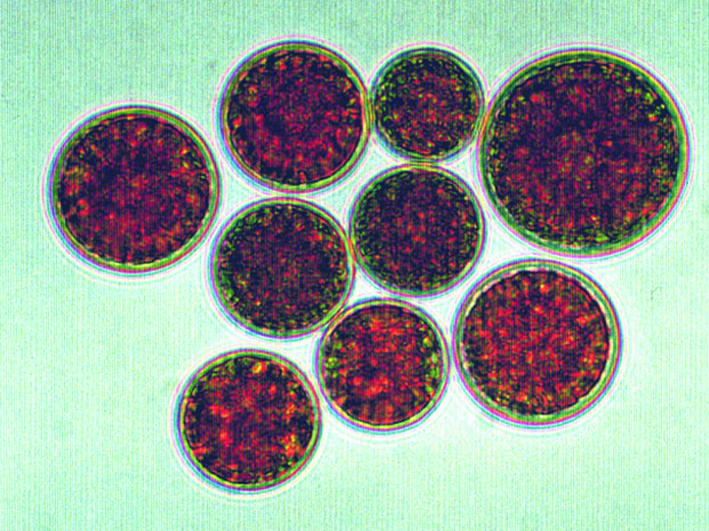

And this may not be the only clinical application of microalgae. Another extract may soon be prescribed for carpal tunnel syndrome and joint inflammation. As the Cyanotech CEO explained, natural astaxanthin—trademark BioAstin‘—a pigment and antioxidant produced by the alga Haematococcus, is the most promising treatment for carpal tunnel syndrome short of surgery. In the USA alone the market for carpal tunnel syndrome and joint ailments is US$ 1.5 billion annually. Produced in a 45 cubic metre closed photobioreactor at Cyanotech, astaxanthin also claims to be beneficial against muscle soreness and reduced immunity resulting from free radical release during strenuous exercise. But the success of natural remedies also depends on the science behind the claims. As Cysewski pointed out, ‘Many products in the US health industry have a lot of questionable science behind them’; this is why Cyanotech is keen to ‘use sound science to support health claims’. The plant also employs environmental practise, recycles all its water and avoids the use of pesticides or herbicides.

After all, microalgae, and plants in general, are well known to be among the world’s greatest environmental cleaning devices. In fact, the prospect that microalgae could be used in environmental bioremediation has been considered for decades. Pilot studies have been conducted in Germany and the USA on the feasibility of using microalgae to remove carbon dioxide from the flue gases of industrial plants, and to use the resulting biomass as combustible fuel. They might also find applications in the removal of heavy metal contamination from water and soil; dentists in Germany already give patients Chlorella tablets to absorb the mercury released during the replacement of mercury amalgam fillings.

But tempting though it is to believe that microalgae could be the solution to global CO2 overproduction, Michael Melkonian can speak of frustrating experiences to the contrary. As a consultant to several industrial projects, he should not be ignored. Working on a 1970s project to reduce CO2 emissions from a Westfalian brown coal plant have taught him that algae are not an economically feasible solution. Though the algae will grow like wildfire in 10% CO2 they must be produced at a cost of no more than 40 Euros per ton to be economically viable as a combustible fuel source. Unfortunately that was not possible. The Japanese have also discovered this to their sorrow, after having spent US$ 100 million on a 10-year project.

So, do microalgae have a future? Microalgae for food and feed additives have to be produced at a cost of no more than 10 Euros per kg dry mass to be commercially competitive thinks Melkonian, who wonders how the Klötze plant can compete with Japanese facilities that grow the algae faster, heterotrophically—not just using light—and can sell the product for 30 Euros per kg. As he concluded, ‘I doubt they can produce it for this price in Klötze.’ It is a fact that the largest production of unsaturated fatty acids for use as human food additives is accomplished in bacterial fermenters, and heterotrophic algal bioreactors, which are much cheaper than the Klötze method.

Despite the caution of people like Melkonian, there appears to be plenty of venture capital waiting to flow into the green tubes, especially in Germany, and larger companies are also investing in microalgal technology. Microalgae may not be a solution to global pollution after all, they may not even cure disease, but if they help us live longer, healthier and with smoother skin, people will buy them, no matter what the price. As Mende concluded, ‘it’s no wonderdrug, but you sure wonder what it can do next.’

Fig. 1. Light microscopy photograph of the alga chlorella vulgaris.

Fig. 2. Aerial photograph of the premises of cyanotech in Hawaii.

Fig. 3. Light microscopy photograph of the alga Haematococcus.

Fig. 4. Light microscopy photograph of the alga Spirulina pacifica.