Abstract

Limestone calcined clay cement (LC3) is a recently developed binder with huge potential to reduce the clinker factor in cement and the environmental impact. This study aimed to evaluate the evolution of the research on LC3 by conducting a bibliometric analysis, evaluating key metrics such as publications, authorships, sources, or countries, to provide greater knowledge and a strategic vision of this technology. This work provides an important perspective of the field and elucidates the research trends and path that the LC3 technology followed from its beginning to date. The analysis reveals a noticeable increase in technology readiness and researchers' interest, as indicated by a significant rise in publications' number over time. Also, the authorship metrics reveal an important cooperation between communities in the development of this technology. The research on LC3 is essential since the technology is a viable and reliable approach to decreasing the cement industry's carbon footprint.

Keywords: Limestone calcined clay cement (LC3), Supplementary cementitious materials, Bibliometric analysis, Sustainable construction, Low-carbon cement

1. Introduction

The growth of population and the development of society are causing a huge yearly demand for construction materials, mainly concrete and Portland cement (PC), which is the most produced material in the world [1]. The environmental impact of concrete is relatively low, but PC production is accountable for around 90–95 % of concrete greenhouse gas emissions [2]. The manufacture of cement is an energy-intensive process since a step of raw materials (clays and limestone) calcination at around 1450 °C is needed to obtain a highly reactive material (clinker) [3]. Around 60 % of CO2 associated with PC production is directly emitted from CaCO3 decomposition to CaO and CO2, while the remaining 40 % is mainly associated with the energy required during the calcination process (fuel burning) [4]. Due to the large amount of cement consumed worldwide, the cement industry emerges as one of the foremost contributors to environmental pollution, being accountable for roughly 5–8 % of anthropogenic global CO2 emissions [5]. Thus, there is an increasing need for research on approaches to reduce the carbon footprint in the construction sector. According to the International Energy Agency (IEA), a 3 % yearly reduction of direct CO2 intensity is needed to get on track with Net Zero Emissions by 2050 Scenario [6].

Despite its large carbon footprint, cement production is already very efficient; therefore, few improvements can currently be achieved in the clinker obtention [7]. The combustion of waste fuels can reduce CO2 emissions, but the emissions from CaCO3 calcination to obtain CaO cannot be mitigated. Therefore, two main research topics rise to reduce the carbon footprint of the sector. The first is to reduce the clinker-to-cement factor through the implementation of alternative cementitious materials (ACMs) and the use of supplementary cementitious materials (SCMs) [8,9]. The second approach involves the implementation of innovative technologies for carbon capture as well as the exploration of novel raw materials for clinker production [6]. ACMs comprise a wide variety of materials such as alkali-activated cement, calcium aluminate cement, calcium sulfoaluminate cement, magnesium-based cement, and belite cement, among others [10,11]. These binders are of particular interest due to their ability to significantly reduce CO2 emissions compared to PC. However, due to PC's exceptional robustness and the lack of regulation to use ACMs, most of these cementitious materials are not suitable for short-term applications. On the other hand, one notable advantage of SCMs is their ability to reduce the clinker factor in cement without completely replacing it, hence presenting immediate applicability. Nowadays, most commercial cement types contain small amounts of SCMs, typically slags, fly ash from power plants, clays, natural pozzolans and limestone [12]. Slags and fly ash are residues and therefore contribute to waste valorisation and circular economy. However, their availability is very local and limited, and their composition is variable depending on external factors [13]. In contrast, limestone and clays are extensively accessible worldwide and can easily meet the current demand of the cement industry [14].

Cement demand is directly related to the growth of the population. Since most of the population increase will be among low-income countries, the cement demand will also be from developing economies [15]. Consequently, the reduction of CO2 must be achieved without increasing the production cost and the preparation of concrete should be easy to low skilled workers. Limestone calcined clay cement (LC3) is a newly developed cement with limestone and calcined clay as SCMs which fulfils all the requirements. LC3 can reduce up to 40 % of PC emissions by substituting 50 wt % of clinker [16]. Moreover, its production does not involve the introduction of new manufacturing technologies, which makes it easy to introduce to the construction and building sector [7]. Furthermore, the combination of limestone and calcined clay (LC2) substituting clinker in the formulation of cement has the potential to meet the large amounts of material that the cement industry demands [14]. Clays with a wide range of kaolinite contents have been tested, demonstrating that even with low kaolinite contents (more than 40 wt %), the properties of LC3 are equivalent to PC or better [17]. LC3 is a reliable cement with great performance even with high substitution of clinker. Therefore, it has become one of the main solutions for mitigating the global warming potential associated with the cement industry.

The interest in LC3 has been reflected not only in the industry but also in the scientific community. The number of studies about LC3 has increased a lot in recent years. Moreover, the potential of substituting high percentages of clinker has been so promising that it has influenced the modification of European standards in 2021. LC3 is now officially included in these standards with its intended use being the preparation of mortar and concrete (cement type II/C-M in the EN 197–5:2021) [18].

This work aims to study the advances and impact of LC3 in the construction field through bibliometric study. Through bibliometric analyses, the efforts of authors, journals, and countries on a specific research topic are highlighted. In addition to monitoring the information and the knowledge on a subject, bibliometric analyses have become a very useful tool to identify the evolution of a field of interest. Bibliometrics can provide a thorough scientific background on the main trends of a specific area [19]. These studies can help to target issues to address in a research field, perform strategic decision-making, and select the relevant directions to follow in future research [20]. Bibliometric analyses have been used in several research areas: econometrics, management, statistics, ecology, waste management, production management, renewable energies, and thermal energy storage technologies, among others [21]. The interest in bibliometric analyses has also reached the construction and building research field. Cañas-Guerrero et al. published in 2014 a generic bibliometric analysis in the international context of Construction and Building Technology [22]. Since then, more studies targeted at specific construction materials have been published: Det Udomsap and Hallinger studied the research of sustainable construction [23], Chang et al. focused on the mapping of asphalt and pavement publications [24], Afgan and Bing performed a scientometric review on the use of PCMs in buildings applications [25], and Yang et al. presented the recent publications of geopolymer composites [26], among some others.

The main goal of this research is to highlight the importance of the new low-carbon cement LC3, by providing an overview of the research and development of this topic. To achieve this objective, a bibliometric analysis considering the existing research on the subject is conducted. Moreover, this work intends to highlight the relevance of the material to the construction industry. By doing so, it aims to contribute to the understanding and targeting of new research lines, while also promoting international collaborations between different research groups in the subject matter.

2. Methodology

The methodology employed in this bibliometric study follows the methodology developed by Calderón et al. [27], which has been widely employed in various bibliometric studies [20,21]. Such methodology consists of several steps, detailed in Fig. 1.

Fig. 1.

Methodology for the development of bibliometric studies, adapted from Ref. [27].

As mentioned before, the chosen research field for this study is LC3 low-carbon cement. For defining the correct terms for searching the publications in this research field, several keyword words and phrases were identified. The main keywords were: “LC3”, “Limestone”, “*Kaolin”, “Calcined Clay”, “LC2”, and “Cement”. Moreover, the “Geopolymer*” keyword was stated as an exclusion keyword in order to refine the database obtained. The asterisk symbol (*) represents any combination of letters attached to the keyword itself. For example, *kaolin keyword will include both kaolin and metakaolin.

Once the keywords were defined, the following step involved selecting the most suitable data source. Web of Science (WoS) from Clarivate Analytics and Scopus from Elsevier were the data sources selected. These data sources were considered due to the reliable and accessible metadata of the publications [28]. Furthermore, only scientific papers and conference proceedings were considered when filtering the results from both data sources.

Four different query strings were stated for each database (Table 1). To select a valid publication, all the keywords under the same row must be found in the document title, author keywords or abstract. In addition, exception keywords were used to avoid selecting publications outside the research field limits. Therefore, if a publication meets all the keywords required but also includes any exception keyword then the record is discarded from the search results.

Table 1.

Query strings used for WoS and Scopus data sources.

| Source | Query |

|---|---|

| WoS | TS=(“limestone” AND “calcined clay” AND “cement”) |

| TS=(“limestone” AND "*kaolin” AND “cement” NOT “geopolymer*”) | |

| TS=(“lc3” AND “cement”) | |

| TS=(“lc2” AND “cement”) | |

| Scopus | TITLE-ABS-KEY (“limestone” AND “calcined” AND “clay” AND “cement”) |

| TITLE-ABS-KEY (“limestone” AND “*kaolin” AND “cement” AND NOT “geopolymer*”) | |

| TITLE-ABS-KEY (“lc3” AND “cement”) | |

| TITLE-ABS-KEY (“lc2” AND “cement”) |

When the bibliometric database was obtained, it was processed using Python coding and MS Excel to process the data of the different metrics, calculate the H-indexes, performance ratios, and prepare the data for visualisation. OriginLab Pro, VOS Viewer, and Complexity Lab Barcelona (CLabB) were used to represent the obtained data to perform the systematic analysis and obtain the metrics. The metrics selected were the number of publications and citations, most cited publications, most relevant sources/journals and their evolution, country and regional influence on the research area, most relevant authors and author communities’ interaction, and author keywords evolution.

Results from both Scopus and WoS sources were compared to merge both datasets into a single database. However, it was found that almost all the publications found in WoS were also included in Scopus results. Therefore, only Scopus results were analysed using the different metrics. Because of this, the number of publication citations and the journal quartiles were determined by Scopus and SCImago Journal Rank (SJR). SJR rank is also provided by Scopus.

A total of 672 publications were obtained in March 2023 from Scopus. These publications were manually cribbed based on a thorough examination of the title, authors’ keywords and abstract. As a result, 284 publications were excluded from the analysis as they did not align with the primary scope of this study. Hence, a total of 388 publications were considered for obtaining the selected metrics. The number of publications examined is adequate to obtain a valid outcome [29].

3. Results and discussion

3.1. Publications and sources evolution

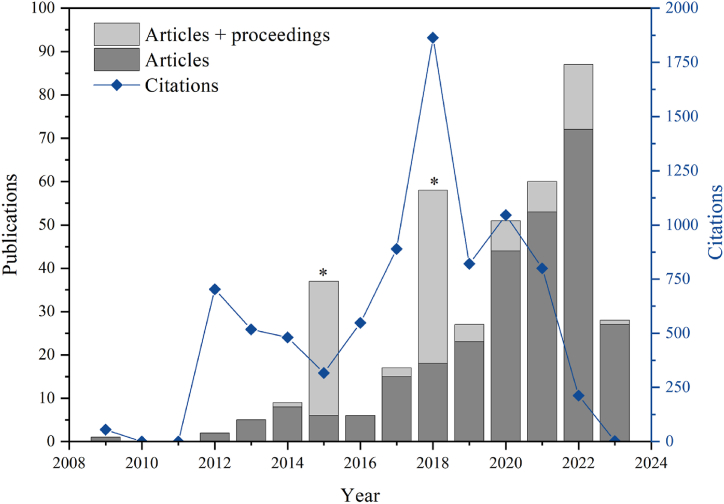

Fig. 2 presents the evolution of publications and citations related to the use of limestone and calcined clay for cement-based materials. The total number of publications comprises research articles and proceedings (or papers derived from conferences) contributions. The number of publications per year presents an increasing trend from 2016, indicating a growing interest over time. The citations also tend to increase with time, reaching two maximums (2012 and 2018) which align with the publication years of the two most cited papers in the field. The number of citations in recent years is lower since they have still not reached their full citation potential. As more time elapses, it is expected that the citation count will continue to increase. The results of the bibliometric analysis confirm that the technology of LC3 is very new. Although the first paper that used a combination of calcined clay and limestone was in 2009 by A. Skaropoulou et al. [30], it is important to note that this paper is not specifically focused on LC3. Instead, it discusses the inclusion of 10 wt % metakaolin, among other SCMs, as an admixture in Portland limestone cement mortars to mitigate thaumasite formation.

Fig. 2.

Publications (articles and proceedings/conference papers) and citations evolution.

The first article where the ternary blend of limestone, calcined clay and PC was proposed was “cement substitution by a combination of metakaolin and limestone” by M. Antoni et al. [31] in 2012. In the publication, which can be considered the scientific origin of LC3, different substitutions of PC by limestone and metakaolin (separated and mixed) were made and compared with the same substitutions with quartz as a reference. In the paper, the researchers from Switzerland (M. Antoni, J. Rossen and K. Scrivener) together with F. Martirena (Cuba) confirmed that the substitution of PC by a mixture of calcined clay and limestone caused a synergic reaction between the two SCMs and with cement phases, resulting in improved performance compared to using PC alone. Given the good results presented in the publication, there was a notable increase in interest regarding the utilization of this blended cement. LC3 demonstrate that high clinker substitutions can be achieved without a decline in cement properties. This achievement aligns with one of the main goals in the construction sector, which is to pursue the Net Zero Scenario by reducing the carbon footprint associated with cement production [6].

It is also interesting to note that there are two years, 2015 and 2018, where the number of publications does not follow the increasing trend (highlighted with a *) because the number of proceedings is much higher. This discrepancy is attributed to the higher number of proceedings published in the International Conferences on Calcined Clays for Sustainable Concrete. This is especially interesting since a whole conference has been created to disseminate results mainly focused on LC3, which highlights the importance that this material has acquired in a short period of time. The proceedings are published in RILEM (International Union of Laboratories and Experts in Construction Materials, Systems and Structures) bookseries and are one of the main ways of diffusion of the research on the topic. The 1st conference proceedings book was published in 2015 and the conference was held in the École Polytechnique Fédérale de Lausanne (EPFL, Switzerland), promoted by Prof. K. Scrivener and her research group. The 2nd edition took place in La Habana (Cuba) and the proceedings book was published in 2018, and the 3rd was held in New Delhi (India) in 2019 and the proceedings book was published in 2020. However, the proceedings for the 3rd edition are still not available in Scopus to date. The 4th edition is scheduled to be held in Nanjing (China) in 2024.

Table 2 presents the 10 most relevant (most cited) publications within the field. Remarkably, eight of the ten publications are published in Cement and Concrete Research, meaning that it is probably the leading journal for LC3-related publications. The most cited publication is not a review, which is noteworthy since review papers are usually the most cited type of publication. This is because, as previously described, the publication of M. Antoni et al. [31] contains the roots of LC3 development and therefore is highly referenced. In contrast, the second most cited article is not an experimental research paper [14]. This paper introduces LC3 as a promising material for mitigating the carbon footprint associated with cement production. The paper provides a comprehensive description of the technological, environmental, and economic aspects of LC3, and highlights future research priorities and suggestions. This paper is a collaboration between the three main developers of LC3: Switzerland, Cuba and India, explaining the most relevant characteristics of LC3 and its production. Until 2021, this was the only review-like paper. The later advances in the topic led to the publication of the paper “Limestone calcined clay cement and concrete: A state-of-the-art review” by M. Sharma et al. which reviews the literature focusing on the new type of LC3 cement [7]. The article of F. Avet et al. is also remarkable since it is the response to the necessity of accurately evaluating the reactivity of calcined clays for LC3 production [32]. A new test method, R3 (rapid, relevant and reliable), was developed to assess the suitability of kaolinitic clays as SCMs. This test is based on the development of pastes with calcined clay and limestone, while adjusting the sulfate and alkali levels, to reproduce the reaction environment of the hydration in LC3 or other blended cements. The reactivity of the pastes is then determined by measuring the heat release of the reaction via isothermal calorimetry or by bound water determination by controlled heating within the range of 110 °C to 400 °C. The next most cited paper entitled “Options for the future of cement” by K. Scrivener (2014) serves as a comprehensive review that provides an analysis of potential options for future cement [33]. It states the concerns of cement production and explores various possibilities to improve the industry. Thereafter, it focuses on the introduction of LC3 as a very promising alternative. This paper is the first to use the nomenclature LC3 to describe blended cements using limestone and calcined clay.

Table 2.

Most cited publications.

| Title | Authors | Year | Journal | Citations | Reference |

|---|---|---|---|---|---|

| Cement substitution by a combination of metakaolin and limestone | M. Antoni et al. | 2012 | Cement and Concrete Research | 673 | [31] |

| Calcined clay limestone cements (LC3) | K. Scrivener et al. | 2018 | Cement and Concrete Research | 443 | [14] |

| Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays | F. Avet et al. | 2016 | Cement and Concrete Research | 247 | [32] |

| Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3) | F. Avet and K. Scrivener | 2018 | Cement and Concrete Research | 235 | [34] |

| Options for the future of cement | K. Scrivener | 2014 | Indian Concrete Journal | 232 | [33] |

| Hydration and strength development in ternary portland cement blends containing limestone and fly ash or metakaolin | K. Vance et al. | 2013 | Cement and Concrete Composites | 202 | [35] |

| Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3) | Y. Dhandapani et al. | 2018 | Cement and Concrete Research | 201 | [37] |

| Changes in microstructure characteristics of cement paste on carbonation | V. Shah et al. | 2018 | Cement and Concrete Research | 193 | [38] |

| The rheological properties of ternary binders containing Portland cement, limestone, and metakaolin or fly ash | K. Vance et al. | 2013 | Cement and Concrete Research | 172 | [36] |

| Role of calcium on chloride binding in hydrated Portland cement-metakaolin-limestone blends | Z. Shi et al. | 2017 | Cement and Concrete Research | 163 | [39] |

The other most cited papers are aimed at researching the fundamental properties of LC3. F. Avet and K. Scrivener [34] focused their work on the effect of the kaolinite content on the hydration and characteristics of LC3, which is critical since most commonly available clays do not have a high kaolinite content, and those which do, are usually more expensive and often used in other industries such as in the paper treatment industry [14]. The work of K. Vance et al. [35] is also focused on the hydration and strength development of blended cement, in this case of PC-limestone-calcined clay/fly ash blends, using also fly ash as an alumina source. In this case, the substitutions were at lower percentages of SCMs than LC3-50 (50 wt % of clinker replacement), replacing up to 10 % (in volume) of cement with metakaolin or fly ash, while limestone was added to up to 40 % of cement. The researchers also concluded that the ternary blended cement incorporating metakaolin and limestone is promising, exhibiting better properties than the corresponding binary blends. This finding reinforces the notion of a synergy effect between metakaolin and limestone which improves the performance of the cementitious system. On the other hand, the next most cited work by K. Vance et al. in the LC3 research [36], also published in 2013, was centred on the rheological properties of the binary and ternary blended pastes, using the same substitutions of limestone, fly ash and metakaolin as in the previously mentioned study. The paper of Y. Dhandapani et al. [37] discusses the mechanical properties and durability of concretes formulated using LC3. The production of concrete based on LC3 is a step forward for the technology since concrete is the most used material in construction. Therefore, the results are very interesting for LC3 applicability. The work demonstrated the good performance of LC3 compared with other binders to produce durable concrete. Also focusing on LC3 durability, V. Shah et al. [38] studied the carbonation of LC3 compared to PC and PC with fly ash under natural and accelerated conditions, while Z. Shi et al. [39] centred the work on the chloride binding in binders with limestone and metakaolin by exposing the pastes to CaCl2 and NaCl.

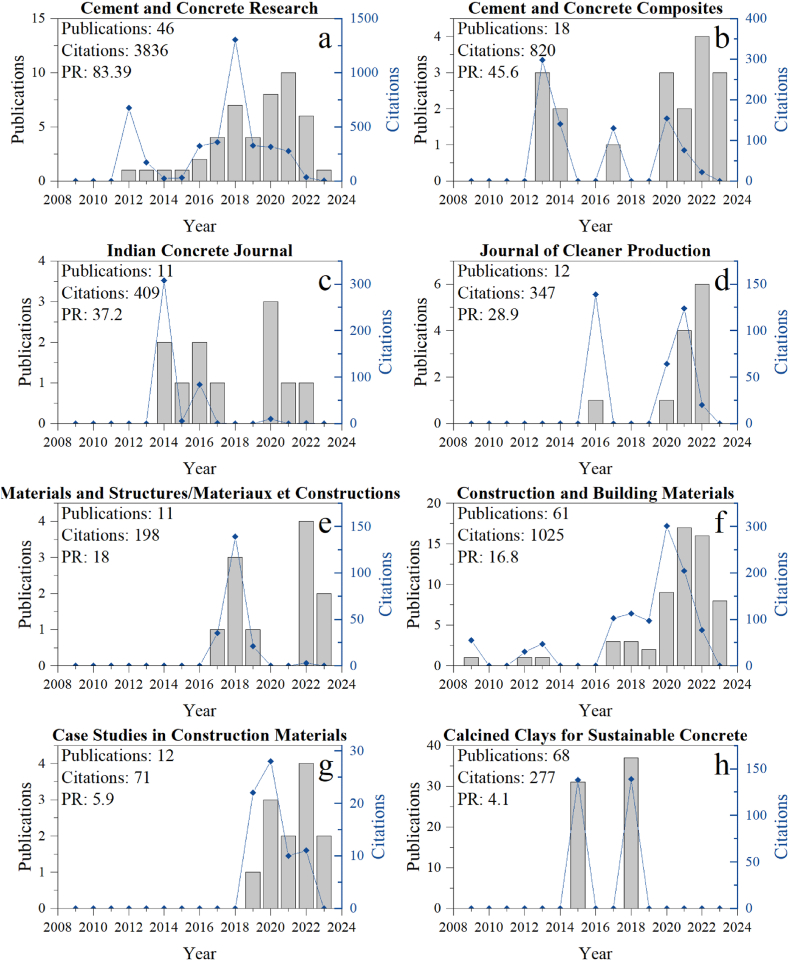

Fig. 3 presents the most relevant sources of limestone calcined clay cement research dissemination. All the journals with more than ten publications on the topic are presented and sorted based on their performance ratio (PR), which is defined as the total number of citations divided by the number of publications. Cement and Concrete Research is the most relevant and influential source. This journal presents the highest PR, the highest total number of citations, and the second highest number of papers, and as previously seen, most of the top publications on the topic are published in this journal. Since the publication of M. Antoni et al., which established the origins of LC3 in 2012, Cement and Concrete Research has consistently been publishing research on the topic every year, demonstrating the trust and recognition of the journal in the increasing interest of the subject. Cement and Concrete Composites journal presents the second-highest PR despite having only 18 publications. This noteworthy achievement highlights the exceptional impact and relevance of the publications featured in this journal. The documents about LC3 were published discontinuously until 2020 when the number of publications increased.

Fig. 3.

Most relevant sources for LC3 publications.

The presence of the Indian Concrete Journal in the third position in terms of PR is very remarkable since it is a Q3 journal. The high PR is mainly due to two key aspects. Firstly, the presence of a highly cited publication by K. Scrivener in 2014 [33] significantly contributes to the journal's PR as well as the inclusion of two publications regarding pilot plants of LC3 production in India, one in 2014 and another in 2016. These publications are very relevant to the research area and demonstrate an interest in increasing the technology readiness level (TRL) of this technology [40,41]. The second noteworthy aspect is the importance that is gaining LC3 production in India, evidenced by the large number of LC3 publications authored by Indian researchers. The emergence of Journal of Cleaner Production among the most publishing journals means that the topic is relevant not only to construction materials journals but also to journals that englobe a wide variety of topics mainly based on environmental sciences and more sustainable technologies. This is mainly due to the huge potential of LC3 to reduce CO2 emissions in the construction industry. As a major global issue, the environmental impact of construction and the need for sustainable alternatives have gained widespread attention [42].

Construction and Building Materials is the most publishing journal and the second with the highest total citations. This means that the journal is very important to the topic's dissemination. The not-so-high PR is due to the large number of publications in recent years (17 in 2021, 16 in 2022, and 8 in early 2023), which have not reached their full potential of citations. The first publication by A. Skaropoulou et al. (2009) [30], where a mixture of limestone and calcined clay was introduced in mortars, was published in this journal. The presence of Case Studies in Construction Materials is particularly intriguing, considering it is a recently indexed open-access journal. This indicates that the journal demonstrates confidence in the potential growth and development of the topic. The last source in Fig. 3 is Calcined Clays for Sustainable Concrete, a proceedings book, which is not a journal, but its impact is also notable. The 68 publications (in this case proceedings) have also increased the knowledge of the research area, and it's a major source for sharing new results and advances in this technology.

3.2. Authors and countries evolution

The ten most publishing authors in terms of their publication output are displayed in Table 3. The H-index is calculated only with the publications and citations related to the topic of study, LC3 in this work. K. Scrivener is by far the most published author. This is due to her implication in the development of LC3 technology. Given the large number of publications and citations, she is widely recognized as the most influential researcher in the field. K. Scrivener is the director of the LC3 project and the laboratory of construction materials at the École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland, and the main developer and promotor of LC3 together with F. Martirena (Cuba). Therefore, she is co-author of the first paper on the research topic of LC3 in 2012 [31]. S. Bishnoi is the second most publishing author. India has made an important effort to contribute to LC3 technology to reduce the CO2 footprint to meet their objectives of climate change mitigation [43]. He is also one of the leading researchers in the LC3 project (team leader in Delhi) and has a valuable experience in the industrial side of LC3 production, regarding the two pilot plants in India [40,41]. F. Martirena is the second most cited author and third most publishing author. He is, together with K. Scrivener, one of the main researchers and developers of LC3, with their first publication in 2012, and the regional leader of the LC3 project in Cuba. He also has collaborated with the industry to develop new clay calcination plants to produce LC3 or blended cement.

Table 3.

Most publishing authors.

| Author | Publications | Citations | H-index | Affiliation | Country | First publication |

|---|---|---|---|---|---|---|

| K. Scrivener | 59 | 3401 | 22 | Ecole Polytechnique Fédérale de Lausanne | Switzerland | 2012 |

| S. Bishnoi | 35 | 1220 | 14 | Indian Institute of Technology Delhi | India | 2014 |

| F. Martirena | 30 | 1617 | 9 | Universidad Central “Marta Abreu” de Las Villas | Cuba | 2012 |

| M. Santhanam | 18 | 616 | 9 | Indian Institute of Technology Madras | India | 2015 |

| F. Avet | 17 | 994 | 11 | Ecole Polytechnique Fédérale de Lausanne/VICAT | Switzerland/France | 2015 |

| S. Maity | 17 | 651 | 5 | Technology and Action for Rural Advancement, New Delhi, India | India | 2014 |

| F. Zunino | 16 | 324 | 7 | Ecole Polytechnique Fédérale de Lausanne | Switzerland | 2018 |

| S. Krishnan | 12 | 364 | 7 | Indian Institute of Technology Delhi/Ecole Polytechnique Fédérale de Lausanne | India/Switzerland | 2014 |

| Y. Dhandapani | 12 | 531 | 6 | Indian Institute of Technology Madras/University of Leeds | India/United Kingdom | 2015 |

| O. Çopuroğlu | 11 | 358 | 7 | Delft University of Technology | Netherlands | 2019 |

M. Santhanam and S. Maity are the team leader in Madras (India) and the regional leader in India of the LC3 project, respectively. Their knowledge of the topic has resulted in 18 and 17 publications, respectively, ranking them among the top 5 most published authors. Remarkably, F. Avet presents the third-highest H-index with 17 publications, highlighting the importance of his research on the topic. The presence of F. Zunino and O. Çopuroğlu in the top 10 publishing authors is also noteworthy, given that they published their first work on the topic less than five years ago, in 2018 and 2019, respectively.

Since the main funding source for LC3 research so far has been the LC3 project, a majority of the most publishing authors are affiliated with institutions associated with this project. The LC3-Project-Low Carbon Cement is a coordinated international project, with funding from the Swiss Agency for Development and Cooperation (SDC) through its Global Programme in Climate Change, with research groups in Switzerland, Cuba and India as main partners [44]. The researchers involved in this project are the main ones responsible for the development of LC3 technology as well as its fast progress and spread.

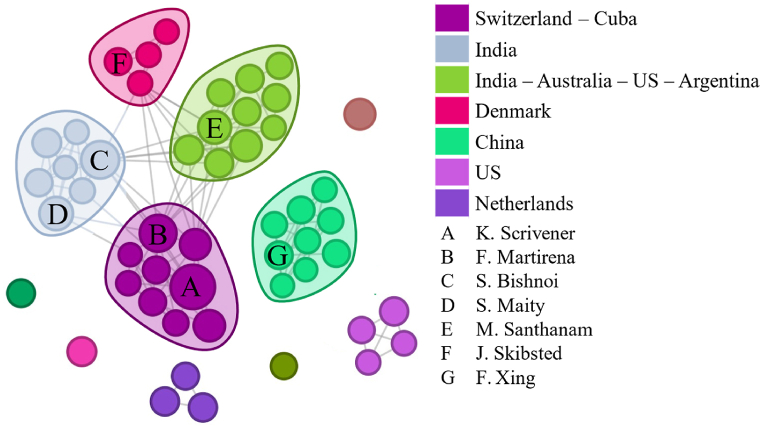

One of the keys to rapidly increasing the knowledge of new technologies to get them to the market is the collaboration between researchers. Fig. 4 depicts the interconnected communities of authors who actively collaborate in the field of LC3 research. The circles represent the authors, and their size, the number of publications. The lines between authors are related to common publications of the linked authors, but not a collaboration strong enough to be considered a community. The communities were obtained with CLabB, and the leaders are assigned based on the number of publications within the clusters. The purple cluster is composed of Swiss and Cuban authors, mostly from the EPFL and the Universidad Central “Marta Abreu” de Las Villas. The community is directed by K. Scrivener and F. Martirena, one from each university, respectively. It is interesting to remark that the affiliation of some authors has changed recently, and five of them are now at ETH Zürich. This shift highlights the growing trust and recognition of ETH Zürich in the potential of LC3 technology. The light blue cluster is composed of Indian researchers, all of them from IIT Delhi and S. Maity from TARA. Here, the leading researchers are S. Bishnoi and S. Maity. The green cluster is composed of authors with various affiliations and countries, although most of them are from IIT Madras, and the community leader is M. Santhanam. These three clusters correspond mainly to the three principal countries involved in the LC3 project, Switzerland, Cuba and India, and the community leaders are also the main researchers of the project (projector director, regional leaders, and team leaders). As could be expected, researchers within the same project exhibit collaboration, which is evidenced by the lines connecting the clusters in the figure. Such collaborations enhance knowledge sharing, promote interdisciplinary approaches, and foster a synergistic environment that accelerates progress in the field.

Fig. 4.

Authors communities (top 50 most published authors).

The authors from the pink community, with J. Skibsted as a leader, are exclusively affiliated with institutions in Denmark. They also present collaborations with the authors from the previous communities, meaning that are probably linked to the LC3 project. Remarkably, two of the authors (D. Herfort and S. Ferreiro) are affiliated with Cementir Holding N.V., a multinational group recognized as a leader in the production of white cement, aggregates, concrete and value-added products. This means that scientific research is also being performed in collaboration with cement companies, revealing the interest in the material.

Finally, some communities do not present strong enough collaborations with the previously mentioned communities. The green-blue cluster is composed of Chinese authors, led by F. Xing, and mainly affiliated with Shenzhen University. The light purple is composed of authors from the United States (US) and the dark purple community is composed of Dutch authors. Furthermore, some authors are not included in communities, probably because their partners have a lower number of publications and therefore are not included in the top 50 of most publishing authors.

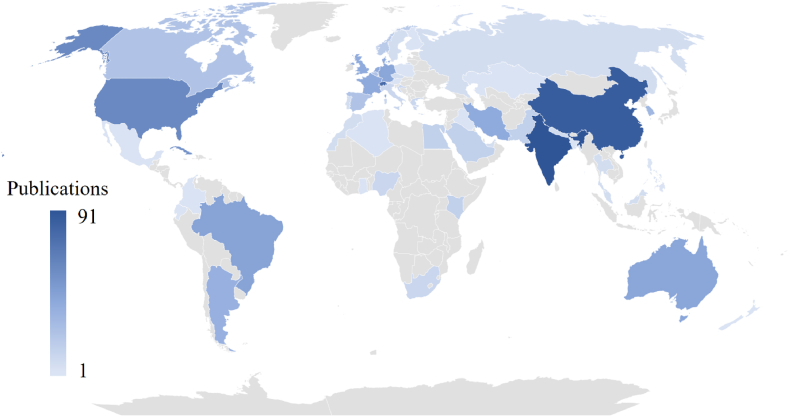

Fig. 5 presents a world map with the publishing countries coloured with increasing intensity with the number of publications. The most publishing countries align mainly with the communities discussed in Fig. 4. The most publishing countries are India and China. The importance of India must be highlighted since it is probably one of the countries more invested in the production of LC3. This is due to the vast expansion of the Indian construction industry, and to less restrictive standards, which makes easier the implementation of new technologies such as LC3. However, although this growth is very important to the development of the Indian economy, researchers have concerns regarding the economic and environmental impact [45]. Therefore, a lot of Indian researchers, have been working on advancing the technological aspects of LC3 for some years at laboratory and industrial scale, obtaining excellent results and performances in the industry. The institutions where the most signs of progress are made in India are the Indian Institute of Technology Delhi (IIT Delhi), the Indian Institute of Technology Madras (IIT Madras), and the Technology and Action for Rural Advancement (TARA). Another country with a high number of publications on the topic is Switzerland. The high number of publications by authors affiliated with Switzerland is particularly noteworthy considering the country's population size. This is mainly due to their important role in the development of the material and later the founding of the LC3 project. Swiss researchers, particularly those associated with the EPFL, have played a pivotal role in the impact and success of LC3. Remarkably, a total of 56 countries have contributed with at least one publication on the topic, especially in Europe, America and Asia.

Fig. 5.

World map with coloured publishing countries.

Table 4 provides a comprehensive breakdown of the top 10 publishing countries in LC3 research. As previously mentioned, India emerges as the leading publishing country, with especially a large number of proceedings. Despite China being the second most publishing country, it exhibits a low PR. This could be because their publications have been mainly in the last three years, where the citations are still low; 18, 30 and 11 publications from 2021, 2022 and 2023 (until March), respectively. This means that their interest in LC3 is more recent and could justify why their main community (Fig. 4) does not have many interactions with other communities. On the other hand, Switzerland is the most cited country, with a high PR (48.9) and 70 publications (third most publishing country). Cuba has the highest PR, meaning that their publications are very relevant to the field.

Table 4.

Ten most publishing countries.

| Country | Publications | Citations | PR | First publication |

|---|---|---|---|---|

| India | 91 | 2006 | 22.0 | 2014 |

| China | 83 | 797 | 9.6 | 2014 |

| Switzerland | 70 | 3488 | 49.8 | 2012 |

| United States | 41 | 1052 | 25.7 | 2013 |

| Cuba | 32 | 1868 | 58.4 | 2012 |

| Brazil | 17 | 88 | 5.2 | 2017 |

| Germany | 14 | 429 | 30.6 | 2015 |

| Australia | 14 | 185 | 13.2 | 2017 |

| Denmark | 11 | 451 | 41.0 | 2015 |

| France | 11 | 244 | 22.2 | 2013 |

Likewise, Cuba is the third most cited country despite having a relatively smaller number of publications (32) compared to the top two most cited countries with 70 and 91 publications, respectively. This indicates that the work of Cuban researchers exhibits a high level of quality and impact. Cuba must increase its cement production to achieve technological and economic development while reducing the carbon footprint of cement [46]. Since Cuba is an island, the use of locally available materials is critical to mitigate CO2 emissions. Geological surveys conducted in Cuba demonstrated that the Cuban clay deposits had the potential to be used for LC3 production. Therefore, the first industrial trial for calcined clay production was held in Cuba [47,48]. The use of LC3 in Cuba would be cost efficient and the greenhouse gas emissions would be significantly reduced [46,49]. The research in Cuba is mainly conducted at CIDEM (Centro de Investigación y Desarrollo de Estructuras y Materiales), which is a research centre affiliated with the University Universidad Central “Marta Abreu” de Las Villas. The early work of Switzerland and Cuba to introduce LC3 is also significant, being the two promotors of LC3, as observed in the year of the first publication (2012). Denmark's notable PR (41.0), despite having only 11 publications in the LC3 research area, highlights the exceptional impact and influence of their research contributions.

As developing countries need more construction materials, their interest in LC3 is notable. The distribution of resources, such as calcined clay and limestone, significantly influences LC3 applications in construction. The use of calcined clay would be a solution as it is a widely abundant resource and, in countries such as Cuba and India, which have shown much interest in LC3, clay minerals are widely available [50]. Furthermore, calcite is also an easily available resource in most developing countries [51]. India has abundant resources and rapid urbanization, furthermore, the Indian government's emphasis on sustainable building materials aligns with LC3 implementation. Similarly, China is one of the world's largest consumers of construction materials, therefore the use of widely abundant raw materials could make an impact on the country's construction industry.

It is important to remark that the production of LC3 has already been implemented in some countries such as Cuba and India due to more flexible standards, with pilot plants of calcined clay and LC3 production [40,41,52]. Furthermore, the first worldwide production of LC3 was developed by the Indian cement company JK Lakshmi Cement Ltd., where LC3 and LC2 are expected to be viably commercialized [53]. This accomplishment was made possible through the implementation of new standards covering LC3. This influences the research in these countries and thus can be observed in the number of publications and their impact. Nonetheless, the recent modification of the European standard EN 197–5:2021 also contemplates the use of blended cements in Europe, namely CEM VI and CEM II/C-M, which allow for the incorporation of blended cements with high clinker replacement [18]. LC3, with its ability to replace a significant portion of clinker, falls within this latest category. Although this standard modification does not mean that LC3 can be used for concrete production, which is the main construction material, this is an important step forward in terms of incentivisation of the LC3 technology and its implementation in the global market.

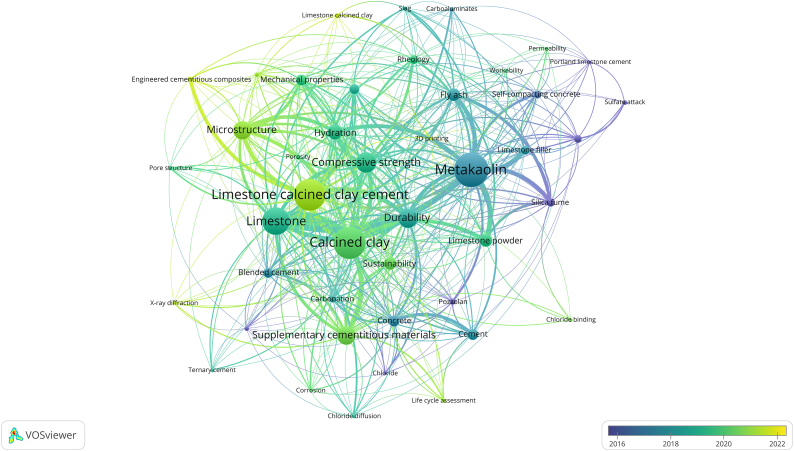

3.3. Keywords

Fig. 6 presents a map of keywords co-occurrences defined by the authors in the publications. The size of the circle indicates the number of articles where the keyword has been used, and the lines connecting the circles indicate that the connected keywords have been used together. The thickness of the line is proportional to the number of documents that have used both keywords. For better clarity, keywords abbreviations have been merged with their full forms. The four most used keywords are LC3 raw materials metakaolin, calcined clay and limestone, and the material (limestone calcined clay cement), which is common in publications about the investigation of SCMs or admixtures in construction materials. The fifth, sixth, seventh, and ninth most used keywords are compressive strength, durability, microstructure, and hydration, respectively, which are common properties studied in construction materials. Supplementary cementitious materials (eighth) and fly ash (tenth) complete the top 10 of most used keywords. The most used pair of keywords is calcined clay and limestone, which could be expected since the study is based on publications that evaluate the combination of metakaolin and limestone to substitute cement.

Fig. 6.

Keywords co-occurrence map.

The prominence of durability-related keywords among the most frequently used keywords indicates the importance of this property on construction materials. One of the main concerns when new materials are proposed is the loss of long-term properties, which can lead to structure damage or collapse. Some keywords detected were durability, carbonation, sulfate attack, chloride, chloride binding, chloride diffusion, corrosion, and permeability. The inclusion of these keywords highlights the recognition and emphasis placed on ensuring long-lasting, resilient, and sustainable materials in the field of LC3 research.

The keywords are also coloured based on the year when they have been more used. As previously mentioned, some of the oldest publications using limestone and calcined clay in construction materials production (including the oldest in 2012) were based on the improvement of some properties of concrete, mainly self-compacting concrete. This can also be corroborated by studying the oldest keywords (coloured in purple or blue), such as mineral admixtures, Portland cement, Portland limestone cement, limestone filler, silica fume and self-compacting concrete. Most of them are not linked to LC3-related keywords. In contrast, since the interest in LC3 is very recent, the keywords limestone calcined clay and limestone calcined clay cement present a yellowish-green colour. Here, the recent trend to use the keyword calcined clay (green) instead of metakaolin (blue) can be observed. This is mainly due to the possibility of using calcined clays with poor kaolinite content and even non-kaolinitic clays.

The presence of other SCMs in the map (fly ash and slag) is explained by two reasons. Firstly, the comparison of LC3 with cements containing other SCMs is very common in scientific publications. This comparative analysis helps evaluate the performance, properties, and environmental benefits of LC3 compared to cement with other SCMs. Secondly, the study of quaternary cements using other SCMs has also gained interest. Keywords in yellow such as 3D printing and engineered cementitious composites indicate that LC3 research is in a more mature state since they are very specific applications of cement.

Since one of the main benefits of LC3 in front of conventional Portland cement is the reduction of CO2 emissions in its production, the presence of environmental-related keywords is also significant. This emphasis on environmental considerations reflects the growing global concern for sustainable practices in the construction industry. By incorporating sustainability as a prominent keyword, researchers demonstrate their commitment to developing and promoting environmentally friendly cementitious materials like LC3. It indicates the ongoing efforts to address climate change and reduce the carbon footprint associated with cement production, making LC3 a promising solution towards achieving more sustainable construction practices. Furthermore, the presence of the keyword life cycle assessment in some of the latest publications means that there is an increasing interest in determining the actual environmental impact that could be avoided by using LC3.

The keywords study together with the bibliography studied confirms that, despite its novelty, LC3 technology has already reached an advanced level of technological readiness (TRL). The development of pilot plants, the validation of the material in industrial trials in India and Cuba, and recently the first commercialization of LC3 in Colombia (Cemento Verde from Argos), suggest that the TRL could be in the final stages, around 7–9. In addition to global efforts, companies in Africa, specifically in Ivory Coast and Cameroon, are actively involved in the commercialization of LC3. This development is driven by the significant need for urbanization in several African countries, where the demand for sustainable construction materials is high. In addition, India and Europe are also investing in the use of calcined clay in cement production. This fast evolution of LC3 could not be possible without the efforts of international researchers’ communities to increase the knowledge of the technology. Furthermore, the collaboration of academia with companies, research centres, and institutions to implement the technology and adopt new standards has been essential.

4. Research priorities and trends

The rapid acceptance of LC3 is easily justified due to compelling reasons. The main factor is that LC3 offers comparable or even better properties than PC, while simultaneously reducing CO2 emissions by up to 40 %. This reduction is achieved by significantly decreasing the clinker-to-cement ratio by up to 50 % [54]. Furthermore, as industrial processes transition towards decarbonization, the availability of waste materials such as fly ash from coal power plants or blast furnace slags is expected to decrease due to the replacement of these technologies by green energies and electric arc furnace slag, respectively [6,55,56]. These waste materials, which are commonly used as SCMs in cement production, may become less accessible due to the shift towards cleaner energy sources and processes. While other by-products such as steelmaking slag from electric arc furnace will still be generated since steel is needed in society, their availability will also be limited compared to the needs of the construction industry. Hence, widely available natural resources such as clay and limestone will probably become the main solution to produce blended cements [57]. Another benefit is that calcined clay and limestone do not require high purity to achieve good properties in cement [17,58].

PC technologies have been well-established, robust, and reliable over the years. LC3, with its incorporation of calcined clay and limestone, offers a more sustainable alternative without requiring a drastic modification of existing PC technologies. This continuity and compatibility with PC technologies make LC3 an attractive option for industry adoption, as it can be integrated into existing cement production processes while providing substantial environmental benefits [7]. Moreover, the chemistry of the material is very similar to PC's. The same hydrates and phases are obtained, meaning that little research is needed in this matter. However, there is still the necessity to improve the knowledge through research and testing.

The higher water demand of LC3 caused mainly by the addition of calcined clay should be further researched. Since water is a scant natural resource, the increase in the consumption of mix water should be addressed in order to make the cement more sustainable. Furthermore, since the properties of cement are maximized with a low water/cement ratio, the increase in water demand is an important issue [59]. The use of superplasticizers in blended cements is a viable solution, but optimization and knowledge of their effect on hydration and final properties are still needed [60]. Moreover, LC3 cements usually need an overdose of superplasticizers, which also substantially contribute to the carbon footprint of the cement. Therefore, the need to find specific superplasticizers targeted to improve the workability of LC3 is mandatory.

Durability has been one of the strengths of LC3, being key to its rapid success. However, more studies based on different deterioration mechanisms should be performed, as well as on very extreme conditions (high temperature and fire resistance). This can be studied at a laboratory scale but should also be studied during the service life of concrete produced with LC3. The evaluation of quaternary blends through the addition of locally available wastes and by-products could also be beneficial to increase the sustainability of the material.

Focusing on the implementation of LC3, an important challenge is the need to modify the actual standards to get to use LC3 in concrete. One widely supported solution could be the implementation of performance-based standards [61]. This would allow flexibility in concrete production without reducing its properties, facilitating the implementation of new technologies and materials. The support of regional and international institutions through research funding is needed to move forward a more environmentally friendly construction industry [62]. To meet climate change goals, new low-carbon policies are needed [63]. Furthermore, a socially focused campaign should be done to bring knowledge and technology to companies and researchers, as well as to raise awareness between construction workers and the world population.

5. Conclusions

This work presents a bibliometric analysis of the current evolution of LC3 technology. Using Scopus as the database, 672 articles and proceedings were considered and then refined to 388, which were selected as related to the topic. The metrics number of publications and citations, most cited publications, most relevant sources/journals, country and regional influence on the research area, most relevant authors and author communities' interaction were studied. Moreover, an analysis of the authors’ keywords co-occurrences was also performed.

The results showed that the number of publications has grown especially in the last 5–6 years due to the increasing interest in the subject, demonstrating the importance of LC3 in the field of construction and building materials. This is the response to the need to reduce CO2 emissions in the construction sector to meet climate change objectives. Since LC3 composition is very similar to Portland cement with comparable or even better properties, the confidence in the material is greater than in other ACMs.

Until recently, most of the published work has been developed inside the LC3 project by Swiss, Cuban and Indian researchers. The research groups from these countries are the main promoters of the technology, therefore, the most publishing countries are India, Switzerland, and Cuba. China and the United States have also been publishing on the use of calcined clay and limestone, although until recently, it was less focused on LC3. The more relevant work has been published in Cement and Concrete Research, making the journal a pillar in the LC3 investigation.

Finally, the study of the evolution of the keywords reflects the importance and the recent maturity of the technology as more keywords related to specific applications or studies were detected. The wide range of keywords proves that the study of LC3 is being conducted in different areas; a large variety of properties, characteristics and applications of LC3 are being investigated.

This study demonstrates that international collaboration between research groups and with companies and institutions is mandatory to implement new technologies and get them to the market in order to achieve the objectives of CO2 emissions reduction in the construction industry.

Funding

This work is partially supported by the Spanish Government with the Grants PID2021-125810OB-C21 funded by MCIN/AEI/10.13039/501100011033, by “ERDF A way of making Europe”, and by the “European Union NextGenerationEU/PRTR” and the Catalan Government with the Grant 2021 SGR 00708. Furthermore, the Agència de Gestió d’Ajuts Universitaris i de Recerca (AGAUR) contributed through Mr. Jofre Mañosa's PhD grant (FI 2020).

CRediT authorship contribution statement

Jofre Mañosa: Conceptualization, Formal analysis, Investigation, Resources, Data Curation, Visualization, Writing-Original Draft, Writing-Review & Editing. Alejandro Calderón: Methodology, Software, Data Curation, Writing-Review & Editing. Rebeca Salgado-Pizarro: Methodology, Data Curation, Visualization, Writing-Review & Editing. Alex Maldonado-Alameda: Supervision, Visualization, Writing-Review & Editing. Josep Maria Chimenos: Conceptualization, Supervision, Visualization, Writing-Review & Editing, Funding acquisition.

Data availability

Data will be made available on request.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors would like to thank the Catalan Government for the quality accreditation given to their research group DIOPMA (2021 SGR 00708). DIOPMA is a certified agent TECNIO in the category of technology developers from the Government of Catalonia. Mr. Jofre Mañosa is grateful to the Catalan Government for his research Grant, FI-DGR 2020. The authors also acknowledge the support of CYTED Network ECoEICo—Circular Economy as a Strategy for a More Sustainable Construction Industry and the COST Action CircularB—Implementation of Circular Economy in the Built Environment.

References

- 1.Zunino F., Dhandapani Y., Ben Haha M., Skibsted J., Joseph S., Krishnan S., Parashar A., Juenger M.C.G., Hanein T., Bernal S.A., Scrivener K.L., Avet F. vol. 55. 2022. (Hydration and mixture design of calcined clay blended cements: review by the RILEM TC 282-CCL, Materials and Structures/Materiaux et Constructions). [DOI] [Google Scholar]

- 2.Miller S.A., Horvath A., Monteiro P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20 % Environ. Res. Lett. 2016;11 doi: 10.1088/1748-9326/11/7/074029. [DOI] [Google Scholar]

- 3.Del Serrone G., Moretti L. A stepwise regression to identify relevant variables affecting the environmental impacts of clinker production. J. Clean. Prod. 2023;398 doi: 10.1016/j.jclepro.2023.136564. [DOI] [Google Scholar]

- 4.Skibsted J., Snellings R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cement Concr. Res. 2019;124 doi: 10.1016/j.cemconres.2019.105799. [DOI] [Google Scholar]

- 5.Pillai R.G., Gettu R., Santhanam M., Rengaraju S., Dhandapani Y., Rathnarajan S., Basavaraj A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3) Cement Concr. Res. 2019;118:111–119. doi: 10.1016/j.cemconres.2018.11.019. [DOI] [Google Scholar]

- 6.IEA . 2022. Cement, Paris. [Google Scholar]

- 7.Sharma M., Bishnoi S., Martirena F., Scrivener K. Limestone calcined clay cement and concrete: a state-of-the-art review. Cement Concr. Res. 2021;149 doi: 10.1016/j.cemconres.2021.106564. [DOI] [Google Scholar]

- 8.Shi C., Qu B., Provis J.L. Recent progress in low-carbon binders. Cement Concr. Res. 2019;122:227–250. doi: 10.1016/j.cemconres.2019.05.009. [DOI] [Google Scholar]

- 9.Juenger M.C.G., Snellings R., Bernal S.A. Supplementary cementitious materials: new sources, characterization, and performance insights. Cement Concr. Res. 2019;122:257–273. doi: 10.1016/j.cemconres.2019.05.008. [DOI] [Google Scholar]

- 10.Juenger M.C.G., Winnefeld F., Provis J.L., Ideker J.H. Advances in alternative cementitious binders. Cement Concr. Res. 2011;41:1232–1243. doi: 10.1016/j.cemconres.2010.11.012. [DOI] [Google Scholar]

- 11.Mañosa J., Gómez-Carrera A.M., Svobodova-Sedlackova A., Maldonado-Alameda A., Fernández-Jiménez A., Chimenos J.M. Potential reactivity assessment of mechanically activated kaolin as alternative cement precursor. Appl. Clay Sci. 2022;228 doi: 10.1016/j.clay.2022.106648. [DOI] [Google Scholar]

- 12.Lothenbach B., Scrivener K., Hooton R.D. Supplementary cementitious materials. Cement Concr. Res. 2011;41:1244–1256. doi: 10.1016/j.cemconres.2010.12.001. [DOI] [Google Scholar]

- 13.Provis J.L. Alkali-activated materials. Cement Concr. Res. 2018;114:40–48. doi: 10.1016/j.cemconres.2017.02.009. [DOI] [Google Scholar]

- 14.Scrivener K., Martirena F., Bishnoi S., Maity S. Calcined clay limestone cements (LC3) Cement Concr. Res. 2018;114:49–56. doi: 10.1016/j.cemconres.2017.08.017. [DOI] [Google Scholar]

- 15.Hafez H., Teirelbar A., Tošić N., Ikumi T., de la Fuente A. Data-driven optimization tool for the functional, economic, and environmental properties of blended cement concrete using supplementary cementitious materials. J. Build. Eng. 2023;67 doi: 10.1016/j.jobe.2023.106022. [DOI] [Google Scholar]

- 16.Zunino F., Scrivener K. Microstructural developments of limestone calcined clay cement (LC3) pastes after long-term (3 years) hydration. Cement Concr. Res. 2022;153 doi: 10.1016/j.cemconres.2021.106693. [DOI] [Google Scholar]

- 17.Maraghechi H., Avet F., Wong H., Kamyab H., Scrivener K. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Materials and Structures/Materiaux et Constructions. 2018;51:1–17. doi: 10.1617/s11527-018-1255-3. [DOI] [Google Scholar]

- 18.European Committee for Standardization . 2021. EN 197-5: Cement - Part 5: Portland-composite Cement CEM II/C-M and Composite Cement CEM VI. [Google Scholar]

- 19.Ranjbari M., Saidani M., Shams Esfandabadi Z., Peng W., Lam S.S., Aghbashlo M., Quatraro F., Tabatabaei M. Two decades of research on waste management in the circular economy: insights from bibliometric, text mining, and content analyses. J. Clean. Prod. 2021;314 doi: 10.1016/j.jclepro.2021.128009. [DOI] [Google Scholar]

- 20.Salgado-Pizarro R., Calderón A., Svobodova-Sedlackova A., Fernández A.I., Barreneche C. The relevance of thermochemical energy storage in the last two decades: the analysis of research evolution. J. Energy Storage. 2022;51 doi: 10.1016/j.est.2022.104377. [DOI] [Google Scholar]

- 21.Svobodova-Sedlackova A., Calderón A., Barreneche C., Salgado-Pizarro R., Gamallo P., Fernández A.I. A bibliometric analysis of research and development of nanofluids. Journal of Nanofluids. 2022;12:157–172. doi: 10.1166/jon.2023.1924. [DOI] [Google Scholar]

- 22.Cañas-Guerrero I., Mazarrón F.R., Calleja-Perucho C., Pou-Merina A. Bibliometric analysis in the international context of the “construction & Building Technology” category from the Web of Science database. Construct. Build. Mater. 2014;53:13–25. doi: 10.1016/j.conbuildmat.2013.10.098. [DOI] [Google Scholar]

- 23.Det Udomsap A., Hallinger P. A bibliometric review of research on sustainable construction, 1994–2018. J. Clean. Prod. 2020;254 doi: 10.1016/j.jclepro.2020.120073. [DOI] [Google Scholar]

- 24.Chang X., Zhang R., Xiao Y., Chen X., Zhang X., Liu G. Mapping of publications on asphalt pavement and bitumen materials: a bibliometric review. Construct. Build. Mater. 2020;234 doi: 10.1016/j.conbuildmat.2019.117370. [DOI] [Google Scholar]

- 25.Afgan S., Bing C. Scientometric review of international research trends on thermal energy storage cement based composites via integration of phase change materials from 1993 to 2020. Construct. Build. Mater. 2021;278 doi: 10.1016/j.conbuildmat.2021.122344. [DOI] [Google Scholar]

- 26.Yang H., Liu L., Yang W., Liu H., Ahmad W., Ahmad A., Aslam F., Joyklad P. A comprehensive overview of geopolymer composites: a bibliometric analysis and literature review. Case Stud. Constr. Mater. 2022;16 doi: 10.1016/j.cscm.2021.e00830. [DOI] [Google Scholar]

- 27.Calderón A. Universitat de Barcelona; 2019. Study of Solid Particle Materials as High Temperature Thermal Energy Storage and Heat Transfer Fluid for Concentrating Solar Power. [Google Scholar]

- 28.Martín-Martín A., Orduna-Malea E., Thelwall M., Delgado López-Cózar E. Google Scholar, Web of Science, and Scopus: a systematic comparison of citations in 252 subject categories. J Informetr. 2018;12:1160–1177. doi: 10.1016/j.joi.2018.09.002. [DOI] [Google Scholar]

- 29.Rogers G., Szomszor M., Adams J. Sample size in bibliometric analysis. Scientometrics. 2020;125:777–794. doi: 10.1007/s11192-020-03647-7. [DOI] [Google Scholar]

- 30.Skaropoulou A., Tsivilis S., Kakali G., Sharp J.H., Swamy R.N. Thaumasite form of sulfate attack in limestone cement mortars: a study on long term efficiency of mineral admixtures. Construct. Build. Mater. 2009;23:2338–2345. doi: 10.1016/j.conbuildmat.2008.11.004. [DOI] [Google Scholar]

- 31.Antoni M., Rossen J., Martirena F., Scrivener K. Cement substitution by a combination of metakaolin and limestone. Cement Concr. Res. 2012;42:1579–1589. doi: 10.1016/j.cemconres.2012.09.006. [DOI] [Google Scholar]

- 32.Avet F., Snellings R., Alujas Diaz A., Ben Haha M., Scrivener K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cement Concr. Res. 2016;85:1–11. doi: 10.1016/j.cemconres.2016.02.015. [DOI] [Google Scholar]

- 33.Scrivener K.L. Options for the future of cement. Indian Concr. J. 2014;88:11–21. [Google Scholar]

- 34.Avet F., Scrivener K. Investigation of the calcined kaolinite content on the hydration of limestone calcined clay cement (LC3) Cement Concr. Res. 2018;107:124–135. doi: 10.1016/j.cemconres.2018.02.016. [DOI] [Google Scholar]

- 35.Vance K., Aguayo M., Oey T., Sant G., Neithalath N. Hydration and strength development in ternary portland cement blends containing limestone and fly ash or metakaolin. Cem. Concr. Compos. 2013;39:93–103. doi: 10.1016/j.cemconcomp.2013.03.028. [DOI] [Google Scholar]

- 36.Vance K., Kumar A., Sant G., Neithalath N. The rheological properties of ternary binders containing Portland cement, limestone, and metakaolin or fly ash. Cement Concr. Res. 2013;52:196–207. doi: 10.1016/j.cemconres.2013.07.007. [DOI] [Google Scholar]

- 37.Dhandapani Y., Sakthivel T., Santhanam M., Gettu R., Pillai R.G. Mechanical properties and durability performance of concretes with limestone calcined clay cement (LC3) Cement Concr. Res. 2018;107:136–151. doi: 10.1016/j.cemconres.2018.02.005. [DOI] [Google Scholar]

- 38.Shah V., Scrivener K., Bhattacharjee B., Bishnoi S. Changes in microstructure characteristics of cement paste on carbonation. Cement Concr. Res. 2018;109:184–197. doi: 10.1016/j.cemconres.2018.04.016. [DOI] [Google Scholar]

- 39.Shi Z., Geiker M.R., De Weerdt K., Østnor T.A., Lothenbach B., Winnefeld F., Skibsted J. Role of calcium on chloride binding in hydrated Portland cement–metakaolin–limestone blends. Cement Concr. Res. 2017;95:205–216. doi: 10.1016/j.cemconres.2017.02.003. [DOI] [Google Scholar]

- 40.Bishnoi S., Maity S., Mallik A., Joseph S., Krishnan S. Pilot scale manufacture of limestone calcined clay cement : the Indian experience. Indian Concr. J. 2014;88:22–28. [Google Scholar]

- 41.Emmanuel A.C., Haldar P., Maity S., Bishnoi S. Second pilot production of limestone calcined clay cement in India: the experience. Indian Concr. J. 2016;90:57–63. [Google Scholar]

- 42.Chen J., Wang Y., Shi Q., Peng X., Zheng J. An international comparison analysis of CO2 emissions in the construction industry. Sustain. Dev. 2021;29:754–767. doi: 10.1002/sd.2172. [DOI] [Google Scholar]

- 43.Planning Commission . Government of India; 2011. Interim Report of the Expert Group on Low Carbon Strategies for Inclusive Growth. [Google Scholar]

- 44.LC3-Project, limestone calcined clay cement, (n.d.). https://lc3.ch/(accessed June 9, 2023).

- 45.Joseph S., Bishnoi S., Maity S. An economic analysis of the production of limestone calcined clay cement in India. Indian Concr. J. 2016;90:22–27. [Google Scholar]

- 46.Sánchez Berriel S., Favier A., Rosa Domínguez E., Sánchez MacHado I.R., Heierli U., Scrivener K., Martirena Hernández F., Habert G. Assessing the environmental and economic potential of limestone calcined clay cement in Cuba. J. Clean. Prod. 2016;124:361–369. doi: 10.1016/j.jclepro.2016.02.125. [DOI] [Google Scholar]

- 47.Vizcaíno-Andrés L.M., Sánchez-Berriel S., Damas-Carrera S., Pérez-Hernández A., Scrivener K.L., Martirena-Hernández J.F. Industrial trial to produce a low clinker, low carbon cement. Mater. Construcción. 2015;65:e045. doi: 10.3989/mc.2015.00614. [DOI] [Google Scholar]

- 48.Almenares Reyes R.S., Díaz A.A., Rodríguez S.B., Rodríguez C.A.L., Hernández J.F.M. Assessment of Cuban kaolinitic clays as source of supplementary cementitious materials to production of cement based on clinker – calcined clay – limestone. RILEM Bookseries. 2018;16:21–28. doi: 10.1007/978-94-024-1207-9_4. [DOI] [Google Scholar]

- 49.Cancio Díaz Y., Sánchez Berriel S., Heierli U., Favier A.R., Sánchez Machado I.R., Scrivener K.L., Martirena Hernández J.F., Habert G. Limestone calcined clay cement as a low-carbon solution to meet expanding cement demand in emerging economies. Dev Eng. 2017;2:82–91. doi: 10.1016/j.deveng.2017.06.001. [DOI] [Google Scholar]

- 50.Ito A., Wagai R. Global distribution of clay-size minerals on land surface for biogeochemical and climatological studies. Sci. Data. 2017;4 doi: 10.1038/sdata.2017.103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Nickovic S., Vukovic A., Vujadinovic M., Djurdjevic V., Pejanovic G. Technical Note: high-resolution mineralogical database of dust-productive soils for atmospheric dust modeling. Atmos. Chem. Phys. 2012;12:845–855. doi: 10.5194/acp-12-845-2012. [DOI] [Google Scholar]

- 52.Sánchez Berriel S., Cancio Díaz Y., Martirena Hernández J.F., Habert G. Assessment of sustainability of low carbon cement in Cuba. Cement Pilot Production and Prospective Case, RILEM Bookseries. 2015:189–194. doi: 10.1007/978-94-017-9939-3_23. [DOI] [Google Scholar]

- 53.Bishnoi S., Maity S., Kumar M., Saxena S.K., Wali S.K. Pilot scale production of limestone calcined clay cement. RILEM Bookseries. 2018;16:69–74. doi: 10.1007/978-94-024-1207-9_12. [DOI] [Google Scholar]

- 54.Redondo-Soto C., Morales-Cantero A., Cuesta A., Santacruz I., Gastaldi D., Canonico F., Aranda M.A.G. Limestone calcined clay binders based on a Belite-rich cement. Cement Concr. Res. 2023;163 doi: 10.1016/j.cemconres.2022.107018. [DOI] [Google Scholar]

- 55.Vogl V., Olsson O., Nykvist B. Phasing out the blast furnace to meet global climate targets. Joule. 2021;5:2646–2662. doi: 10.1016/j.joule.2021.09.007. [DOI] [Google Scholar]

- 56.Zou C., Xiong B., Xue H., Zheng D., Ge Z., Wang Y., Jiang L., Pan S., Wu S. The role of new energy in carbon neutral. Petrol. Explor. Dev. 2021;48:480–491. doi: 10.1016/S1876-3804(21)60039-3. [DOI] [Google Scholar]

- 57.Scrivener K.L., John V.M., Gartner E.M. Eco-efficient cements: potential economically viable solutions for a low-CO2 cement-based materials industry. Cement Concr. Res. 2018;114:2–26. doi: 10.1016/j.cemconres.2018.03.015. [DOI] [Google Scholar]

- 58.Ram K., Flegar M., Serdar M., Scrivener K. Influence of low- to medium-kaolinite clay on the durability of limestone calcined clay cement (LC3) concrete. Materials. 2023;16:1–18. doi: 10.3390/ma16010374. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Lei L., Palacios M., Plank J., Jeknavorian A.A. Interaction between polycarboxylate superplasticizers and non-calcined clays and calcined clays: a review. Cement Concr. Res. 2022;154 doi: 10.1016/j.cemconres.2022.106717. [DOI] [Google Scholar]

- 60.Boscaro F., Palacios M., Flatt R.J. Formulation of low clinker blended cements and concrete with enhanced fresh and hardened properties. Cement Concr. Res. 2021;150 doi: 10.1016/j.cemconres.2021.106605. [DOI] [Google Scholar]

- 61.Ram K., Serdar M., Londono-Zuluaga D., Scrivener K. Does carbon footprint reduction impair mechanical properties and service life of concrete? Materials and Structures/Materiaux et Constructions. 2023;56:1–16. doi: 10.1617/s11527-022-02090-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Scrivener K., Ben Haha M., Juilland P., Levy C. Research needs for cementitious building materials with focus on europe. RILEM Technical Letters. 2022;7:220–252. doi: 10.21809/rilemtechlett.2022.165. [DOI] [Google Scholar]

- 63.Mission Possible Partnership, Low-Carbon Concrete and Construction : a Review of Green Public Procurement Programmes. 2022. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.