Abstract

The ever-increasing landscape of heterogeneous catalysis, pure and applied, utilizes many different catalysts. Academic insights along with many industrial adaptations paved the way for the growth. In designing a catalyst, it is desirable to have a priori knowledge of what structure needs to be targeted to help in achieving the goal. When focusing on catalysis, one needs to cope with a vast corpus of knowledge and information. The overwhelming desire to exploit catalysis toward commercial ends is irresistible. In today’s world, one of the requirements of developing a new catalyst is to address the environmental concerns. The well-established heterogeneous catalysts have microporous structures (<25 Å), which find use in many industrial processes. The metal–organic framework (MOF) compounds, being pursued vigorously during the last two decades, have similar microporosity with well-defined pores and channels. The MOFs possess large surface area and assemble to delicate structural and compositional variations either during the preparation or through postsynthetic modifications (PSMs). The MOFs, in fact, offer excellent scope as simple Lewis acidic, Brönsted acidic, Lewis basic, and more importantly bifunctional (acidic as well as basic) agents for carrying out catalysis. The many advances that happened over the years in biology helped in the design of many good biocatalysts. The tools and techniques (advanced preparative approaches coupled with computational insights), on the other hand, have helped in generating interesting and good inorganic catalysts. In this review, the recent advances in bifunctional catalysis employing MOFs are presented. In doing so, we have concentrated on the developments that happened during the past decade or so.

Keywords: Metal−organic frameworks, Lewis acid catalysis, Lewis basic catalysis, Bifunctional catalysis, Multifunctional catalysis, Tandem reactions, Deacetalization−Knoevenagel condensation reactions, CO2 fixation reactions, Nanoparticle supported MOFs

1. Introduction

Catalysis has been so widely woven into the fabric of life that the practice and pursuit of the subject transcends across different disciplines of science and engineering. The canvas of catalysis has been large and continuously growing over the years. It may be noted that there has been considerable success in discovering newer catalysts compared to obtaining greater insights over the known ones.1−3

For carrying out efficient catalysis and understanding the catalytic process, two different strategies exist toward the design of solid catalysts. In one approach, the individual steps for the overall reaction are considered and optimized, and the second approach focuses on the location of the active site within the structure. For one of the goals of preparing new compounds that could be potential catalysts, one needs to look for maximum surface area, precise catalytic reaction centers, and good activity, selectivity, and durability. The desiderata of designing a new catalyst need to encompass the following: (i) to be able to operate under mild conditions that are environmentally benign; (ii) reasonable freedom from restrictions imposed by diffusional considerations of molecules (reactants and products); (iii) possession of well-defined and specially separated reaction centers; and (iv) the scope to probe the mechanistic understanding of the catalytic action.

In the area of catalysis, the idea that the catalyst possesses bifunctional or multifunctional character is a desired property. There have been studies toward the multifunctional behavior of catalysts, especially those involving zeolites and mesoporous compounds.4 It is becoming clear that in seeking to create compounds with good surface areas and catalytic activity one needs to have solids that have pore diameters in the microporous region (∼20 Å).

Aluminosilicate zeolites have been the backbone of the study of catalysts and the science of catalysis over many decades. These compounds possess porosity in the microporous range of 4–20 Å. The discovery of metal–organic frameworks (MOFs) in the late 90s and its subsequent developments appear have caught the imagination of the catalyst community.5−10 The attractive features of many MOF compounds toward catalysis are as follows: (i) they permit free flow of reactants and products through the channels (pores) and cages; (ii) they have spatially distributed distinct catalytic sites; and (iii) they create the possibility for performing shape-selective, enantioselective, and regioselective reactions. The MOFs offer ease of synthesis coupled with a diverse range of compositional variations, which would be desirable toward heterogeneous catalysis. The MOFs offer the following advantages: (i) The MOF structures are flexible (breathable) and expand and contract by external stimuli;11−14 (ii) the metal as well as the ligand that forms the structures can be replaced by postsynthetic modifications to render them attractive toward many physical and chemical properties;15−21 (iii) the organic ligands are amenable for manipulations to create specific functionality in the compounds, which would be desirable toward organocatalysis;22−30 and (iv) MOFs can provide hydrophilic and hydrophobic environments which can be exploited toward specific catalysis.31−35

There have been many catalytic studies that were carried out employing MOFs. In most of the studies, the metal sites were always exploited for their Lewis-acidic behavior.24,36−38 Most of the earlier attempts toward catalysis employing MOFs were predominantly Lewis acid catalysis only.39−42 Brönsted acid catalysis was also attempted employing MOFs.43,44 Over the years it has been shown that the organic ligands in MOFs also catalyze many reactions, especially acting as a Lewis base.45−48 As the MOFs possess both the Lewis acidic as well as basic centers, bifunctional catalysis was attempted.49−52

The bifunctional MOFs offer advantages toward studying the cascade reactions. The cascade/domino/tandem reactions53,54 utilize at least two consecutive reactions and involve different chemical functionality available within the compound. The cascade process involves a set of reactions where the product(s) of the reaction(s) is consumed in a subsequent reaction. In these reactions, the isolation of intermediates is not required and the reaction(s) proceeds in a stepwise manner. The cascade reaction requires different catalytically active sites distributed over a large surface area and in a periodic manner. The MOFs with their large surface area with good pore size distribution and availability of functional groups would be ideally suited for such reactions.55−57

In this review, we focus on the recent developments on MOFs that offer multifunctionality toward heterogeneous catalysis. We have specifically given closer attention to the developments toward catalytic reactions that have been performed employing MOFs during the past decade or so. In this task, there may be a few oversights, which are not intentional.

2. Generation of Functionality in MOFs

Most of the MOF compounds possess Lewis acidity due to the metal centers—the strength of the acidity depends on the size of the metal ions, the oxidation state, and its coordination preferences. In addition to this, it may be possible to create acidity in MOFs by suitable postsynthetic modifications. Here, we outline a few such scenarios:

2.1. Lewis Acid Functionality

The acidity can be classified as Brönsted acid or Lewis acid—the former is the stronger acid compared to the latter. The MOFs that were explored toward acid catalysis are tabulated in Table 1. Lewis acidity in MOFs generally refers to an accessible metal site, with a low coordination number, which is also known as a coordinatively unsaturated metal site (CU). The coordinatively unsaturated metal sites can be achieved in situ by the removal of labile ligands bonded to the metal, which usually are the solvent molecules. A Zn MOF, {[Zn(BPBN)Cl]·5H2O}n (BPBN = 3,5-bis(4-oxo-4H-pyridin-1-yl)-benzonitrile) (Figure 1a) has been synthesized and has been utilized for the synthesis of naphthimidazole from 2,3-diaminonaphthalene and DMF at 120 °C with good yield (Figure 1b). The tetrahedrally coordinated Zn center acts as Lewis acid site and facilitates this reaction.58 UiO-66 (UiO = University of Oslo) is one of the MOFs which was studied toward the Lewis acid catalytic reaction. Zr-MOFs provide unsaturated metal sites, which could be exploited as Lewis acid centers in catalytic reactions. The open metal sites generally act as electron pair acceptors and accelerate the reaction process.59 Most of the earlier studies exploiting the Lewis acid functionality concentrated on cyanosilylation of imines.60 These are typically low temperature reactions, and in most cases the yield is >95%. Recently, lanthanide centers were explored as possible Lewis acid catalytic centers in the compound, [La2/3(qptca)1/2] (qptca = 1,1′:4′,1′′:4″,1‴:4′′′,1⁗-quinquephenyl]-2,2′′,2′′′′,5′′-tetracarboxylic acid), toward the Friedel–Crafts reaction. The alkylation of indole and pyrrole with β-nitrostyrene with a wide substrate scope gave the desired product with high yield and recyclability.61

Table 1. MOFs with Different Lewis Acidic Functionalities and Their Utilities toward Catalysisa.

| Sr. No. | MOF Compound | Lewis acidic metal site | Labile solvent | Catalytic reaction | Ref |

|---|---|---|---|---|---|

| 1 | Zr6-fBDC and Zr6-fBPDC | Zr4+ | H2O | Arene C–H Iodination | (258) |

| 2 | Zr6OTf-BTB | Zr4+ | - | Povarov Reactions | (259) |

| 3 | [Zn2(TBIB)2(HTCPB)2]·9DMF·19H2O | Zn2+ | - | Cycloaddition of CO2 | (260) |

| Friedländer Reaction | |||||

| 4 | MOF-525, PCN-222 and PCN-224 | Zr2+, Mn2+, Zn2+ | - | Cycloaddition of CO2 | (261) |

| 5 | M-NU-1008 | M = Zr4+, Hf, Th, Ce3+ | H2O | Cycloaddition of CO2 | (262) |

| 6 | ZIF-8 | Zn2+ | - | Epoxide Hydroxylation | (263) |

| 7 | Tb(BTC)(H2O)3(DMF)1.1 | Tb3+ | H2O, DMF | Synthesis of β-Aminoalcohols | (264) |

| 8 | Er(BTC)(H2O)·(DMF)1.1 | Er3+ | H2O, DMF | Hantzsch Coupling and Tetrahydro-4H-Chromene Synthesis | (265) |

| 9 | [Ba2(BDPO)(H2O)]·DMA | Ba2+ | H2O | Cycloaddition of CO2 | (266) |

| 10 | NH2-MIL-101/PAN | Cr3+ | - | Friedel–Crafts Acylation of Anisole | (267) |

| Esterification reaction | |||||

| 11 | Cu(II)-MOF | Cu2+ | H2O | Cycloaddition of CO2 | (268) |

| 12 | Zr6O4(OH)4(OAc)2.4[M(PNNNP)X]2.4 [M = Pd, Pt] | Zr4+, Pd(I), Pt(I) | - | Hydroamination of o-Alkynyl Aniline | (269) |

| 13 | [Zn2(iso)2(bpy)2] | Zn2+ | DMF | Cycloaddition of CO2 | (270) |

| 14 | [Zn(BPBA)Cl]·5H2O | Zn2+ | H2O | Cyclization of ortho-Substituted Diaminonaphthalene to Naphthimidazole | (58) |

| 15 | Ce-doping MIL-88A(Fe) | Ce3+, Fe3+ | - | Catalytic Ozonation | (271) |

| 16 | Pd(II)/UIO-66 (Zr), Pd(II)/MIL-101 (Cr) and Pd(II)/MOF-5 (Zn) | Pd2+, Cr3+, Zn2+ | H2O | CO Esterification to Dimethyl Carbonate | (272) |

| 17 | UiO-66 | Zr4+ | H2O | Aldose Sugars to Polyhydroxyalkyl and C-Glycosyl Furans | (273) |

| 18 | [Cd3(BDC)3(OPP)(DMF)2]·2DMA | Cd2+ | DMF | Hantzsch Reaction | (274) |

| 19 | Cu-BTC(MOF-199) | Cu2+ | - | Aerobic Oxidative Synthesis of Imines | (275) |

| 20 | MIL-101(Fe,Sc) | Fe3+, Sc3+ | - | Glucose to 5-Hydroxymethyl Furfural | (276) |

| 21 | Al-ITQ-Br, Al-ITQ-NO2, L-MOF-EB L-MOF-AB | Fe3+, Al3+ | - | Oxidation of Thiophenol to Diphenyldisulfide | (277) |

| 22 | [Eu(tctb)(H2O)] | Eu3+ | H2O | Diamines to Benzimidazoles | (278) |

| 23 | [M6(TATAB)4(DABCO)3(H2O)3]·12DMF·9H2O | M = Co2+, Ni2+ | H2O | Chemical Fixation of CO2 | (279) |

| 24 | MixUMCM-1-NH2. | Zn2+ | - | Aldol–Tishchenko Reaction | (280) |

| 25 | [In3(NIPH)3(HNIPH)(OH)2]·4H2O | In3+ | -H2O | Multicomponent Strecker Reactions | (281) |

| 26 | [Mn2(TDP)(H2O)2]·3H2O·3DMF | Mn2+ | -H2O | Chemical Fixation of CO2 | (282) |

| 27 | [Cu6(TADIPA)3(DABCO)(H2O)2(DMF)2]·13H2O [Cu6(TADIPA)3(H2O)6]·16H2O·8DMF | Cu2+ | -H2O, DMF, DMA | Chemical Fixation of CO2 | (283) |

| [H3O][Cu6(TPTA)3(DMA)4(COO)]·12H2O·7DMA | |||||

| [Cu6(C17O9N2H8)3(C6H12N2)(H2O)2(DMF)2]·3DMF·8H2O | |||||

| 28 | UiO-66-TA | Zr4+ | -H2O | Hydrogenation of Cinnamaldehyde | (284) |

| 29 | MIL-101(Cr)-LP | Cr3+ | - | Reduction of Imine | (285) |

| 30 | MIL-101(Cr) MOF | Cr3+ | - | glucose to fructose | (286) |

| 31 | [Zn3(Hbtc)2(atz)2]·CH3CN·2CH3OH [Co3(Hbtc)2(atz)2]·H2O·2DMF | Zn2+ Co2+ | - | Coupling of CO2 and Epoxides | (287) |

| 32 | [Zn(bix)]{V2O6}(V-Zn-MOF | Zn2+ | - | Cyanosilylation Reaction of Aldehydes | (288) |

| 33 | [Dy3(data)3·2DMF]·DMF | Dy3+ | DMF | Chemical Fixation of CO2 | (155) |

| 34 | Cu-MOF | Cu2+ | - | Catalytic CO2 Fixation | (289) |

| 35 | [Cd(bpp)(L)(H2O)]·DMF | Cd2+ | -H2O | Strecker Reaction | (290) |

| 36 | Cr-UiO-66-CAT | Zr4+ | - | Oxidation of Alcohols to Ketones | (85) |

H2fBDC = 2,3,5,6-tetrafluoro-1,4-benzenedicarboxylic acid; H2fBPDC = 2,2′,3,3′,5,5′,6,6′-octafluoro-4,4′-biphenyldicarboxylic acid; TBIB = 1,3,5-tri(1H-benzo[d]imidazol-1-yl)benzene); H3TCPB = 1,3,5-tris(4′-carboxyphenyl-)benzene; BTC = 1,3,5-benzenetricarboxylate; DMF = N,N-dimethylformamide; PAN = polyacrylonitrile; PNNNP = 2,6-(HNPAr2)2C5H3N; Ar = p-C6H4CO2–; X = Cl–, I–; iso = isophthalic acid; bpy = 4,4-dipyridyl; BPBA = 3,5-bis(4-oxo-4H-pyridin-1-yl)-benzoate; OPP = N,N′-(oxybis(4,1-phenylene))bis(1-(pyridin-4-yl)methanimine); H2BDC = terephthalic acid; H3tctb = tris(p-carboxylic acid)tridurylborane; H3TATAB = 4,4′,4″-s-triazine-1,3,5-triyl-tri-p-aminobenzoic acid; DABCO = 1,4-diazabicyclo[2.2.2]octane; BDC = 1,4-benzenedicarboxylate; ABDC = 2-amino-1,4-benzenedicarboxylate, btb = 4,4′,4″,-benzene-1,3,5-triyl-trisbenzoic acid; H2NIPH = 5-nitroisophthalic acid; H4TPTA = 1,1′,3′,1″-terphenyl-3,3′′,5,5′-tetracarboxylic acid; H4CBDA = 5,5′-(carbonylbis(azanediyl)) diisophthalic acid; TA = terephthalic acid; LP = Lewis pair; bix = 1,4-bis(imidazole-1-ylmethyl)benzene; 2,5-data = 2,5-diamino-terephthalate; H2L = 5-(1-oxo-2,3-dihydro-1H-inden-2-yl)isophthalic acid; H2L = 4,4′-(dimethylsilanediyl)bis-benzoic acid; bpp = 1,3-bis(4-pyridyl)propane.

Figure 1.

(a) 3D structure of the [Zn(BPBN)Cl]·5H2O MOF. (b) Synthesis of naphthimidazole in the presence of heterogeneous catalyst. Reproduced with permission from ref (58). Copyright 2020 Elsevier.

As an example of unusual Lewis acidity in MOFs, the example of easily modifiable nature of the ligand was exploited in preparing Pd-mono(thiocatecholato) units inside the MOF UiO-66.85 This modified MOF exhibited excellent regioselectivity toward the sp2 carbon, oxidation of alcohols to ketones, etc.85,86 A more interesting approach is to replace the ligand, which expands the MOF, allowing for enhanced catalytic activity.83 In this work, C2 symmetry ligands were exchanged for C3 symmetric, which causes defects in the overall structure, paving the way for better Lewis acid activity.87

2.2. Brönsted Acid Functionality

In the traditional framework compounds of aluminosilicate zeolites, metal phosphates, etc. Brönsted acidity was generated by manipulating the structure by having elements of different valencies.88−90 The charge compensating protons have been found to have strong Brönsted acid character. In MOFs, such a possibility is difficult to achieve, as the framework contains metal centers with fixed valences and organic ligands. There are examples of MOF compounds where elements of mixed valency exist as part of the structure.91,92 The Brönsted acidity in many MOFs, however, appears to arise out of the nonbonded acidic groups of the ligands (Scheme 1).43,72 The MOFs, thus, provide the versatility of having both the Lewis acidic as well as Brönsted acidic functionality within the same MOF.68,93−95 The many catalytic reactions that have been carried out employing Brönsted acid functionality in MOFs are listed in Table 2. In MIL-(Cr)-101-SO3H, the Cr3+ ions act as a Lewis acidic and the -SO3H groups act as the Brönsted acidic centers for the catalytic conversion of glucose.83

Scheme 1. Schematic Showing How the Additional Functionality Is Used in Generating Brönsted Acidity in MOFs: (a) Direct Synthesis; (b) via Postsynthetic Modification.

Table 2. MOFs with Brönsted Acidity and the Associated Catalysisa.

| Sr. No. | MOF | Brönsted acidic site | Catalytic reaction | Ref |

|---|---|---|---|---|

| 1 | PTA⊂MIL-101(Al)-NH2 | H3[PW12O40]·nH2O | Glucose Dehydration to 5-Hydroxymethylfurfural | (62) |

| 2 | H3PW12O40@Zr-MOF | -SO3H | Levulinic Acid to γ-Valerolactone | (63) |

| 3 | [(CH2COOH)2IM]HSO4@H-UiO-66 | [(CH2COOH)2IM]HSO4 | Biodiesel Synthesis | (64) |

| 4 | PO4/NU(eq) and PO4/NU(half) | -PO4 | Glucose to 5-Hydroxymethylfurfural | (65) |

| 5 | MIL-101(Cr)-SO3H | -SO3H | Cross-Dehydrogenative Coupling of C–H Bonds | (66) |

| 6 | CoFe2O4/MIL-88B(Fe)-NH2/(Py-Ps)PMo | -SO3H | Transesterification | (67) |

| 7 | MIL-101(Cr)-NH-CO-Pr-COOH | -COOH | Synthesis of Quinazolin-(4H)-1-one | (68) |

| 8 | MOF-808-SO4 | -SO4 | Dimerization of Isobutene (2-Methyl-1-propene) | (69) |

| 9 | [Zr6O4(OH)5.6(C9H3O6)2(HCOO)0.18(SO4)2.1](H2O)2 | -OH | Isobutene Dimerization | (70) |

| 10 | Hf-MOF-808 | μ3-OH | Meerwein–Ponndorf–Verley Reduction | (71) |

| Styrene Oxide Ring-Opening | ||||

| α-Pinene Oxide Isomerization | ||||

| 11 | MIL-100(Cr) and MIL-100(Fe) | -H2O-CO | Acetalization of Benzaldehyde with Methanol | (72) |

| 12 | PCN-222(Ni)-SO4 | SO42– | Tandem Semisynthesis of Artemisinin | (73) |

| 13 | Zr-MOF-808-S | OH–/H2O | Glycerol Dehydration | (74) |

| 14 | Al-MIL-53-RSO3HAl-MIL-53-ArSO3H | -SO3H | [4 + 2] Cycloaddition Reaction | (75) |

| 15 | UiO-66 (Zr, Hf), Zr-BTC | μ3-OH | Cycloaddition Reaction | (76) |

| 16 | MIL-100(Fe) (Lys-PM2) | Lys-PM2 | Conversion of Glucose to Levulinic Acid | (77) |

| 17 | [BSO3HMIm][HSO4](IRMOF-3) | [BSO3HMIm][HSO4] | Bligh–Dyer Method for Biodiesel Production | (78) |

| 18 | MIL-101(Cr)-SO3H | -SO3H | Methanolysis of Styrene Oxide | (79) |

| 19 | Cr3(μ3-O)(H2O)3(NDC(SO3H5/6)2)3(BUT-8(Cr)-SO3H | -SO3H | Esterification Reaction | (80) |

| 20 | MIL-IMAc-Br– | Br– | Cycloaddition of CO2 | (81) |

| 21 | (H4SiW12O40) (POM@MOF) | H4SiW12O40 | Glucose into 5-Hydroxymethylfurfural | (82) |

| 22 | MIL-(Cr)-101-SO3H | SO3H | Catalytic Conversion of Glucose | (83) |

| 23 | UiO-66(SO3H)2 | SO3H | Synthesis of Dihydro-2-oxypyrrole Derivatives | (84) |

PTA = phosphotungstic acid; Py-Ps = pyridine with 1,3-propanesultone; H4TADIPA = 5-5′-(1H-1,2,4-triazole-3,5-diyl) diisophthalic acid; Lys = lysine functionalized phosphotungstic acid; [BSO3HMIm][HSO4] = 1-butylsulfonate-3-methylimidazolium bisulfate; NDC(SO3H)22– = 4,8-disulfonaphthalene-2,6-dicarboxylatlate); IMAc = 1H-imidazole-1-acetic acid.

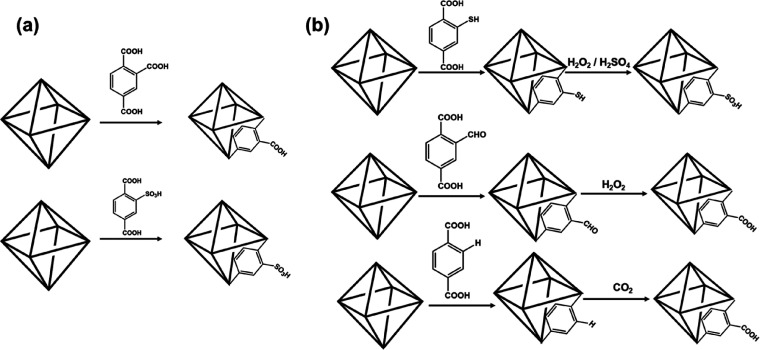

The acidic stability of the MOFs was exploited in generating new Brönsted acidity through postsynthetic modifications in UiO-66(SH)2.96 In this study, UiO-66(SH)2 was modified by treatment with H2O2 and H2SO4 to form UiO-66(SO3H)2, which was later found to be a good catalyst for synthesis of dihydro-2-oxypyrrole derivatives.84

2.3. Basic Functionalities in MOFs

It has been well established that Lewis acidities are much easier to generate in MOFs. In many of the traditional framework compounds, the basic functionality is generated when the extra-framework protons are the Brönsted acid sites and the framework oxygens and their conjugate form the basic sites.97,98 In addition, alkali and alkaline earth exchanged zeolites are also designated as basic.

An easier approach toward the generation of Lewis basicity is feasible in MOFs compared to the traditional framework of zeolites and aluminophosphates. In this approach, the functionality of organic ligands plays an important role in creating the basicity to the structure. More importantly the Lewis basic sites are spatially separated and, in a sense, can be considered as a single basic site, similar to the acid site, which many researchers have exploited.99,100

Thus, in MOFs the -NH2 group plays a crucial role as the Lewis basic site. In addition, researchers have also used nonbonded carboxyl (-COO–) and similar units as Lewis bases.101 The Lewis basic sites in MOFs and their utility toward catalysis are listed in Table 3. For example, IRMOF-1 (commonly known as MOF-5) is constructed from the Zn2+ ions and ligand BDC, while replacement of BDC with NH2-BDC yields IRMOF-3, which exhibits Lewis basic behavior toward the Knoevenagel condensation reaction.102,103 A range of metals viz., Zn,47 Zr,104 Al,105 Ti,106 and Cu107 were employed for the preparation of MOFs with NH2–BDC, which were found to be useful in base catalyzed Knoevenagel condensation reactions. ZIFs (zeolite imidazolate frameworks), which were formed by assembling Zn metal and imidazole linker, provide high stability, high surface area as well as sufficient basicity, arising out of the N atoms of the imidazole have been exploited toward base catalysis.108 Such ZIF compounds were also found to be good catalysts toward Knoevenagel condensation reaction at room temperature with ∼99% yield.109

Table 3. MOFs with Different Basic Functionalities and Their Utility toward Catalysisa.

| Sr. No. | MOF Compound | Ligand responsible for basicity | Catalytic reaction | Ref |

|---|---|---|---|---|

| 1 | [Cd(C16H10N2O8S)(H2O)] | -NH | Knoevenagel Condensation | (110) |

| 2 | [(Nd2(TATMA)2·4DMF·4H2O]n | -N | Knoevenagel Condensation | (111) |

| 3 | [H2N(CH3)2]·[Zn4(L)1.5(ad)3(H2O)2)]·4DMF | -NH2 | Knoevenagel Condensation | (112) |

| 4 | {[Zn2(D-CAM)2(L)]·MeOH·2H2O}n | -NH | Ring-Opening of Spiro-Epoxyoxindoles | (113) |

| 5 | Co2(bdda)1.5(OAc)1·5H2O | -NH | Henry Reactions | (114) |

| 6 | [Zn(OBA)(BPDB)0.5]n·2DMF | -N | Knoevenagel Condensation | (115) |

| 7 | [Y3(μ3-O)2(μ3OH)(H2O)2(BTCTBA)2]·2[(CH3)2NH2]·5DMF·C6H5Cl·4H2O | C=O–N–H | Knoevenagel Condensation | (116) |

| 8 | [Zn2(hfipbb)2(4-bpdh)]·0.5DMF and [Zn2(hfipbb)2(4-bpdb)]·2DMF | -N=N- | Knoevenagel Condensation | (117) |

| 9 | UiO-67-BPY@UiO-66 | -Nbpy | Knoevenagel Condensation | (118) |

| 10 | [Zn2(3-tpom)(L)2]·2H2O | -O | Strecker Reaction | (119) |

| 11 | [Cu2(L)(H2O)2]·(3DMF)(4H2O) | -N | Henry Reactions | (120) |

| 12 | [(CH3)2NH2+]2[Zn3((μ3-O))(L)2(H2O)]·4DMF·2H2O | -NH2 | Chemical Fixation of CO2 | (121) |

| Biginelli Reactions | ||||

| 13 | [Cu2(L)(H2O)2]·(5DMF)(4H2O) | -NH2 | Biginelli Reactions | (122) |

| 14 | [CoL(H2O)3]·2NO3 | -N | Knoevenagel Condensation | (123) |

| 15 | UiO-67@Fe | -Nbpy | Morita–Baylis–Hillman Reaction | (124) |

| 16 | ZIF-8, ZIF-67 | -Nim | Knoevenagel Condensation | (125) |

| 17 | MIL-125-NH2 | -NH2 | Plasticizers Syntheses | (126) |

| 18 | SB-Cu1 | -N | N-Arylation | (127) |

| 19 | NH2cCo-PYI1 and NH2cCo-PYI2 | -NH2 | Aldol and Knoevenagel Condensations | (128) |

Nic = nicotinamide; pic = picrate; H3dcp = 3,5-pyrazoledicarboxylic acid; DMA = N,N-dimethylacetamide; ad = adenine; H4L = 5,5′-(1,3,6,8-tetraoxobenzo phenanthroline-2,7-diyl)bis-1,3-benzenedicarboxylic acid; H3TATMA = 4,4,4″-s-triazine-1,3,5-triyltri-m-aminobenzoate; L = N′-(pyridin-4-ylmethylene)isonicotinohydrazide; bdda: 4,4′-[benzene-1,4-diylbis(methylidenenitrilo)] dibenzoic acid); H3BTCTBA = 4,4′,4″-[1,3,5-benzenetriyltris(carbonylimino)]trisbenzoic acid; 4-bpdb = 1,4-bis(4-pyridyl)-2,3-diaza-1,3-butadiene; 4-bpdh = 2,5-bis(4-pyridyl)-3,4-diaza-2,4-hexadiene; H2L = dicarboxylic acid 4,4′-(dimethylsilanediyl)bis-benzoic acid; 3-tpom = tetrakis(3-pyridyloxymethylene)methane; H4L = 5,5′-(piperazine-1,4-diyl)diisophthalic acid; L = 4-(trifluoromethyl)aniline, 1-bromo-3,5-dimethylbenzene; L = tris(4-(4H-1,2,4-triazol-4-yl)phenyl)amine; PYI = pyrrolidine-2-yl-imidazole.

3. Multifunctional Catalytic Centers in MOFs

From the above descriptions, it is clear that forming bifunctional catalytic sites in MOFs is facile. The metal sites can provide the Lewis acidity, and the Lewis basic sites can be generated from the carboxylate units, specific functional groups in the ligand. The acid–base pair can be spatially well separated and in the precise location to facilitate bifunctional catalysis.45,129−131 The bifunctionality available in MOFs can be utilized in multiple ways: (i) in organic reactions involving multiple steps without separation and purification of the intermediates in each step;132 (ii) in catalyzing multiple reactions simultaneously involving more than one reaction pathway; (iii) in promoting tandem catalysis involving reactions that proceed sequentially; and (iv) in catalyzing acid–base reactions. The bifunctionality in MOFs toward catalysis can be achieved by the following: (i) coordinatively unsaturated metal sites for Lewis acid functionality along with a suitable ligand that offers Lewis basic functionality; (ii) use of multifunctional ligands either during the formation of the MOFs or through postsynthetic modifications; and (iii) incorporation of metal nanoparticles within the MOF structure (Scheme S1). These techniques are popular in generating bifunctional MOF compounds, and there are other techniques that may also be utilized to generate bifunctionality in MOFs. The number of MOF compounds with bifunctionality has grown rapidly in recent years. This is not surprising, as the initial efforts during the development of MOFs were toward establishing newer framework compounds and exploring their physical properties.133−136 The emphasis on the utility of MOFs toward catalysis involving both the acidic as well as basic functionalities is summarized in Table 4. In addition to preparing MOFs with bifunctionality by careful choice of the ligands, it is also possible to generate bifunctionality by carrying out postsynthetic modifications. Examples of bi- or multifunctionality through postsynthetic modifications (PSMs) have been known.137,138 The PSM allows better control on the structure and fine-tuning of the functionality toward a particular catalytic activity.

Table 4. MOFs with Bi-/Multifunctionality and Their Use in Catalysisa.

| Sr. No. | MOF Compound | Reactive site | Catalytic reaction | Ref | |

|---|---|---|---|---|---|

| 1 | MIL-101(Cr)-N(CH2PO3H2)2 | Cr(III) Phosphonates, -NH2 | Synthesis of N-Amino-2-Pyridone and Pyrano [2,3-c]Pyrazole Derivatives | (139) | |

| 2 | [Zn2(TCA)(BIB)2.5]·(NO3) | Zn (II), NTCA | Cycloaddition of CO2 | (140) | |

| 3 | [Mn2(DPP)(H2O)3]·6H2O | Mn (II), -Npyridine | Cycloaddition of CO2 | (141) | |

| 4 | [Zn(1,4-NDCA)(3-BPDB)0.5]·(DMF)(MeOH) [Cd4(1,4-NDCA)4(3-BPDB)4]·2(DMF) | Zn(II)Cd(II), -N=N- | Friedländer Reaction | (142) | |

| Michael Addition | |||||

| 5 | [M3(5-CFIA)2(8H2O)]·H2O | Cd(II), Mn(II), -NH | Aldol Condensation | (143) | |

| β-Enamination Reactions | |||||

| 6 | [Zn(HL)2] | Zn (II), -Ntriazole | Knoevenagel Condensation | (50) | |

| 7 | [Zn15(L-NH2)6(HL-NH2)6(LNA)4(HLNA)2(μ3–OH)2] | Zn(II), -NH2 | Knoevenagel Condensation | (144) | |

| 8 | SulP1/SulP2-MOF-808(Hf) | Hf(IV), Phosphonate | Reductive Amination and Hydroaminomthylation Reactions | (145) | |

| 9 | ED/MIL-101(Cr) | Cr (III), -NH2 | Hantzsch Condensation Reaction | (146) | |

| 10 | Zn-Bp-BTC MOF | Zn(II), -Nbipyridine | Knoevenagel Condensation | (147) | |

| Multicomponent Reaction | |||||

| Benzimidazole Synthesis | |||||

| 11 | Lysine - (Zr)MOF-808 | Zr(IV),- NH2 | Henry Condensation and Friedel/Crafts Type Alkylation | (148) | |

| 12 | C32H40Fe2N2S4Zn | Zn(II), -NH2 | One Pot Synthesis of Chromene and Imidazopyrimidine Derivatives | (149) | |

| 13 | Co/Ni2(BTC)(OH)(4-TPT)2(H2O)·(DMA)0.5(H2O)2 | Co(II)Ni(II), Npyridyl | Oxidation–Knoevenagel Cascade Reaction | (150) | |

| 14 | Cu3TATAT | Cu(II), -NH, N | Aerobic Oxidation/Knoevenagel Condensation | (151) | |

| 15 | Hf/Zr MOF-808 | Hf(IV)Zr(IV) Defective -OH | Tandem N-Alkylation of Amines with Benzyl Alcohol | (152) | |

| 16 | PMoV2@DETA-MIL-101 | Cr(III)PMoV2, -NH2 | Aerobic Oxidation-Knoevenagel One-Pot Reaction | (153) | |

| 17 | CuI@UiO-67-IM | CuI | One-Pot Azide–Alkyne Cycloaddition | (154) | |

| 18 | [Dy3(data)3·2DMF]·DMF, NH2-TMU-73 | Dy(III), -NH2 | Solvent-Free Conversion of CO2 to Cyclic Carbonates | (155) | |

| 19 | Co-NDTz and Co-NDPhTz | Co(II), -Ntetrazole | Tandem Oxidation and CO2 Conversion Reactions | (156) | |

| 20 | [Cu2Br2(pypz)]n·nH2O | Cu(II), Br– | Homocoupling of Arylboronic Acids and Epoxidation of Olefins | (157) | |

| 21 | [Cd(PBA)(DMF)]·DMF | Cd(II), -NH | Cyanosilylation and Hydroboration | (158) | |

| 22 | Ni-DDIA | Ni(II)-COOH | Biginelli Reaction | (94) | |

| 23 | MIL-101(Cr)-NH–CO-Pr-COOH | Cr(III)-COOH | Synthesis of Quinazolin-(4H)-1-one Derivatives | (68) | |

| 24 | MIL-101(Cr)-SO3H | Cr(III)-SO3H | Hydrogenation of Imines | (159) | |

| 25 | Arg2PTA/ZIF-8 | Zn2+, -Nimidazole | Production of Biodiesel from Insect Lipid | (160) |

Abbreviations: data = 2,5-data = 2,5-diamino-terephthalate; MA = melamine; ED = ethylene diamine; DPP = 2,6-di(2,4-dicarboxyphenyl)-4-(pyridine-4-yl)pyridine; H8L = tetraphenylsilane tetrakis-4-phosphonic acid; H3TCA = tricarboxy triphenyl amine; BIB = 1,3-bis(imidazol-1-ylmethyl)benzene; H4L = 2,6-di(2,4-dicarboxyphenyl)-4-(pyridine-4-yl)pyridine); Bp = 4,4′-bipyridine; BTC = 1,3,5-benzene tricarboxylate; H2LNA = 2,6-naphthalenedicarboxylic acid; H2L-NH2 = 2,2′-diamino[1,1′-biphenyl]-4,4′-dicarboxylic acid; CSMCRI-10 = Central Salt & Marine Chemicals Research Institute; BuPh3P = (4-bromobutyl)triphenylphosphonium bromide; SIPA = 5-sulfoisopthalic acid; ABPY = 4,4′-azopyridine; 5-CFIA = 5-(carboxyformamido)isophthalic acid; BDC = 1,4-benzenedicarboxylate; A = acid; B = base; (BINDIH4) = N,N′-bis(5-isophthalic acid)naphthalenediimide; DATRZ = 3,5-diamino-1,2,4-triazole; pypz = bis[3,5-dimethyl-4-(4′-pyridyl)pyrazol-1-yl] methane; PBA = 5-(4-pyridin-3-yl-benzoylamino)isophthalic acid; H2NDTz = 2,6-naphthaleneditetrazole; H2NDPhTz = 2,6-bis(4-(1H-tetrazol-5-yl)phenyl)naphthalene; Arg = Arginine.

3.1. Examples of Catalysis Involving Acidic and Basic Centers

As listed in Table 4, there have been a number of studies involving bifunctionality in MOFs. In this section, we focus on a few select examples that characterize the bifunctionality in a MOF compound. The examples utilize both the acidic as well as basic functionality toward catalysis, but these reactions are carried out independently and not as tandem catalytic reactions. The tandem catalytic studies are dealt with separately.

The MOF [M3(C10H4O7N1)2(8H2O)]·H2O (M = Cd, Mn), was explored toward the formation of the β-enaminoester (Lewis acid catalyzed), and the -NH moiety present in the ligand was exploited toward the Claisen–Schmidt reactions (Lewis base catalyzed) (Figure 2a).143 The Claisen–Schmidt reaction is a classic base catalyzed aldol condensation reaction involving an aromatic aldehyde and a ketone forming conjugated β-hydroxy carbonyl compounds. The uncoordinated -NH group acts as the basic center and catalyzes the Claisen–Schmidt reaction (Figure 2b). The formation of β-enaminoesters is acid catalyzed, and the Cd2+ center acts as the Lewis acidic center and catalyzes the reaction between ethyl acetoacetate and aniline (Figure 2c).143 A two-dimensional (2D) MOF, [Cd(PBA)(DMF)]·DMF (Cd-PBA), (H2PBA = 5-(4-pyridin-3-yl-benzoylamino)-isophthalic acid), was found to be a catalyst for the base catalyzed (the N from the pyridine acts as the base center) Knoevenagel condensation reaction and the Lewis acid catalyzed (Cd centers) cyanosilylation of various aldehydes with trimethylsilyl cyanide.158

Figure 2.

(a) View of the structure of the MOF [Cd3(C10H4O7N1)2(8H2O)]·H2O with Cd centers (Lewis acidic) and an -NH moiety (Lewis basic). (b) Schematic of the possible reaction pathway for the base catalyzed aldol condensation reaction. (c) Schematic of the acid catalyzed enamine formation involving the Cd center. Reproduced with permission from ref (143). Copyright 2023 American Chemical Society.

There are many reports in the literature where only one of the functional groups (usually the Lewis basic functionality) was investigated toward catalytic studies. As mentioned earlier, in all the MOFs, the metal centers always act as Lewis acid centers. In most of the cases, it appears that the reaction of choice for the Lewis base catalyzed reaction is the Knoevenagel condensation (Table 3).

3.2. Tandem/Cascade Reaction

The chemical industries, generally, look to eliminate the number of steps in a chemical reaction process. Another impediment in many reactions is the need to isolate intermediates for further processing. Tandem/cascade reactions provide a possible alternative to reduce the need to isolate the intermediates and in that way also reduce the number of steps.161,162 To carry out such tandem reactions, it is necessary to have different catalytically active centers, preferably distributed uniformly, across the surface of the compound. It is even more important if the reaction requires both the acidic as well as basic functionalities. There is a need to replace multistep as well as salt forming chemical reactions. The approach that provides some success is the tandem reaction, where multiple reactions are combined in a sequential way to yield a single product. This approach is also known as “one-pot”, “domino”, and cascade reactions.53 There are many advantages in employing “tandem” reactions: (i) good atom economy; (ii) reduction of the formation of chemical wastes; (iii) reduction in the consumption of energy; (iv) no need to isolate any intermediates; etc. The tandem catalyses are known as concurrent tandem catalysis (CTC)53,163 and auto tandem catalysis (ATC).164 One of the important criteria in carrying out the tandem catalytic reactions is the compatibility of the catalyst toward the reactants, intermediates, and solvents. In addition, it is preferable to have the catalytically active centers separated spatially and in a periodic manner. It would be an added advantage if the catalyst can also host both acidic as well as basic catalytic centers. From the arguments as well as the descriptions above, the MOFs have positioned themselves to be an excellent candidate to investigate the multistep tandem/cascade reactions. The many cascade reactions that have been carried out using MOFs are summarized in Table 5. In this section, we provide select examples of such reactions. The reaction that was most studied as tandem reactions in MOFs is the deacetalization (acid catalyzed) followed by Knoevenagel condensation (base catalyzed).

Table 5. Summary of Tandem Deacetalization–Knoevenagel Reaction Employing Bifunctional MOFsa.

| Sr. No. | MOF compound | Reactive site | Reactants | Products | Reaction conditions | Ref |

|---|---|---|---|---|---|---|

| 1 | Yb-BDC-NH2Dy-BDC-NH2Sm-BDC-NH2 | Yb3+Dy3+Sm3+, -NH2 | BDA and MN | 2-benzylidenemalononitrile | DMSO-d6 (2 mL), catalyst (100 mg), 50 °C, 24 h | (291) |

| 2 | 3.1% Ru/UiO-66 | Ru2+, Zn2+ | BA and MN | 2-benzylidenemalononitrile | toluene (1.5 mL), O2 1 atm,100 °C | (292) |

| 3 | HNUST-8 | Cu2+, acylamide | BDA and MN | 2-benzylidenemalononitrile | DMSO, 50 °C, 48 h, 0.5 mol % HNUST-8 | (293) |

| 4 | HNUST-6 | Cu2+, acylamide | BDA and MN | 2-benzylidenemalononitrile | 0.5 mol % catalyst, DMSO, 50 °C, 48 h | (294) |

| 5 | [Zn5(L)4(OH)2(H2O)4]n·8n(DMF)·4n(H2O) | Zn2+, – NH | BDA and MN | 2-benzylidenemalononitrile | 1 mol % of catalyst 1 or 2, DMF (0.5 mL), 80 °C, 3 h | (295) |

| 6 | Cz-MOF-253-800 | Al3+, N | BD and MN | 2-benzylidenemalononitrile | 2 mL of toluene, and 5 mg of Pd/Cz-MOF-253–800, 80 °C, 17 h, 150 psi H2 | (296) |

| 7 | ZIF-8,UiO-66(Zr)-NH2,MIL-101(Cr)-NH2) | Zn2+, O2–, N–, -OH, -NH2 | BDA and MN | 2-benzylidenemalononitrile | 100 °C, 3 h in the Pickering emulsions consisting of water (3 mL)–toluene (2 mL) MOFs (50 mg) | (297) |

| 8 | CSMCRI-15 | Cd2+, -N=N–NH2 | BDA and MN | 2-benzylidenemalononitrile | 2 mol % catalyst, 4 h, 60 °C, solvent free | (298) |

| 9 | H-ZIF-8/Au@mSiO2 | Au, Zn2+, -N- | p-nitro BD and MN | 2-(4-nitrobenzylidene)malononitrile | catalyst (30 mg) and 2.0 mL tetrahydrofuran at 30 °C for 0.5 h | (299) |

| 10 | Hf-UiO-66-N2H3 | Hf, N2H3 | BD, MN | 2-benzylidenemalononitrile | ethanol (0.3 mL), catalyst (20 mg), RT, 4 h | (300) |

| 11 | NUC-29 | Cd2+, Npyridine | BDA, MN | 2-benzylidenemalononitrile | 1.0 mol %, based on the {Cd} center, DMSO 50 mL, 5 h, 70 °C | (301) |

| 12 | NUC – 53 | Zn2+, Npyridine | BDA, MN | 2-benzylidenemalononitrile | 0.3 mol %, DMSO 3 mL, 6h, 70 °C | (302) |

| 13 | UiO-67-(NH2)2 | Zr4+, -NH2 | BDA, MN | 2-benzylidenemalononitrile | ethanol (0.3 mL) and catalyst (15 mg) 10 h, 60 °C | (303) |

| 14 | IRA900(xOH)-MIL-101(Al)-NH2 | Al3+, -NH2 | BDA, MN | 2-benzylidenemalononitrile | solvent free, catalyst 0.3 g, 5 h at 110 °C | (304) |

| 15 | Cu(ABDC)(DMF) | Cu2+, -NH2 | BDA, MN | 2-benzylidenemalononitrile | d3-acetonitrile, 0.1 mol % catalyst, 24 h, 60 °C | (305) |

| 16 | Zr12BDC-NH2 | Zr4+, -NH2 | BDA, MN | 2-benzylidenemalononitrile | CDCl3 (1.5 mL), catalyst, 55 °C, 24 h, 100 mg | (306) |

| 17 | MIL-101(Cr)@PMF | Cr3+, -NH-NH2 | BDA, MN | 2-benzylidenemalononitrile | 30 mg catalyst, 12 h, 4 mL ethanol, 65 °C | (307) |

| 18 | [(CH3)2NH2]2[BaZn(TDP)(H2O)]·DMF·5H2O, (NUC-51) | Zn2+, Ba2+, -COOH, Npyridine | BDA, MN | 2-benzylidenemalononitrile | 1.0 mol % catalyst, 5 mL (DMSO) 4 h 70 °C | (308) |

| 19 | (Me2NH2)[InZn(TDP)(OH2)]·4DMF·4H2O (NUC-42) | Zn2+, In3+, −COOH, Npyridine | BDA, MN | 2-benzylidenemalononitrile | DMSO, 5 mL. 8h, 60 °C, 1 mol % catalyst | (309) |

| 20 | MIL-101(Cr)@MOF-867 | Cr3+, Zn2+, -C=N | BDA, MN | 2-benzylidenemalononitrile | 20 mg, 70 °C, 12 h, DMSO (4 mL) | (310) |

Abbreviations: BA = benzyl alcohol, MN = malononitrile; BDC-NH2 = 2-aminobenzenedicarboxylate; BDA = benzaldehyde dimethyl acetal; PDBAD = 4′,4‴-((pyridine-3,5-dicarbonyl)bis(azanediyl))bis[1,1′-biphenyl]-3,5-dicarboxylic acid; MOPBB = (5-methoxy-isophthaloyl)-bis(azanediyl)]diisophthalic acid; 1,4-BDC = 1,4-benzene dicarboxylate; BD = benzaldehyde; H3TCA = 4,4′,4′-tri- carboxytriphenylamine; DPA = (E)-1,2-di(pyridin-4-yl)diazene; 2-MeIm = 2-methylimidazole; 2- H2BDC-N2H3 = hydrazinyl-1,4-benzenedicarboxylic acid; H6TDP - 2,4,6-tris(2,4-dicarboxyphenyl)pyridine; ABDC = 2,2′-diamino-[1,1′-biphenyl]-4,4′-dicarboxylic acid; PMF = polymelamine formaldehyde.

3.2.1. Deacetalization–Knoevenagel Tandem Reaction

The functionalization of Cr-MIL-101, with amino and sulfo groups, through postsynthetic modifications, allowed the one-pot deacetalization–Knoevenagel tandem reaction.165 The general mechanistic pathway involves the acidic (Cr or SO3H) center to polarize the oxygen atom of the benzaldehyde dimethyl acetal to form benzaldehyde, which also increases the electrophilicity of the C center. The basic site helps in the nucleophile attack on the -C=O carbon, aiding the formation of the final product. The main outcome of this study appears to be the formation of the ammonium functionality, through proton transfer from the sulfonic acid to the amino group, which acts as the catalytic site. This approach of forming a zwitterionic form in a MOF could be an important development and would pave the way forward to carry out tandem reactions.165 The use of 5-sulfoisopthalic acid as the primary linker and 4,4′-azopyridine (I) and 1,4-bis(4-pyridyl)-2,3-diaza-1,3-butadiene (II) as the secondary linkers along with Cd2+ ions resulted in two different MOFs.166 Both the compounds were explored toward the one-pot tandem deacetalization–Knoevenagel condensation reactions due to the presence of Lewis acidic (Cd metal centers) as well as basic (azine, free pyridine, and uncoordinated sulfo oxygens) sites. This highlight of the study is in identifying the formation of aldehyde (Lewis acidic) as slower compared to the Knoevenagel reaction (Lewis basic). In the tandem reaction, the aldehyde formed by the Lewis acid catalysis was immediately consumed in the subsequent Knoevenagel reaction, which facilitates the forward reaction due to Le Chatelier’s principle.166 A detailed time dependent study clearly outlines the relative merits of the Lewis acidic as well as basic sites in the two-component stepwise cascade reaction (Figure 3).

Figure 3.

Kinetic study for the one-pot tandem deacetalization–-Knoevenagel reaction with I (a) and II (b) as a heterogeneous catalyst (solvent-free condition). Adapted with permission from ref (166). Copyright 2018 American Chemical Society.

The direct synthesis route was adapted in the preparation of PCN-700, where the Brönsted acidity was achieved by introducing H2TPDC-(COOH)2 [(1,1′,4′,1″-terphenyl)-2,2″,4,4″-tetracarboxylic acid] and the basicity by introducing H2BDC-NH2 (2-aminoterephthalic acid) in the framework (Figure 4).167 The modified compound, PCN-700-AB, was found to be a good catalyst toward the one-pot tandem reaction of benzaldehyde dimethyl acetal into benzylidene malononitrile. The spatial distribution of the acidic and basic sites in PCN-700-AB was found to effectively catalyze this cascade reaction. When the acidic sites were blocked by making an ester-CH3 group in the same MOF, PCN-MB (Figure S1), the tandem reaction yields were poorer.167 This clearly establishes the need to have both the acidic as well as the basic functionalities in the same compound for this reaction. A general scheme for this tandem reaction is given in Scheme 2.

Figure 4.

Structures of PCN-700, PCN-700-B, and PCN-700-AB. Hydrogen atoms are omitted for clarity. Reproduced with permission under a Creative Commons CC-BY 3.0 from ref (167). Copyright 2019 CCS Chemistry.

Scheme 2. Mechanism of the Deacetalization–Knoevenagel Condensation Reaction.

LA = Lewis acidic site; LB = Lewis basic site.

3.2.2. Other Tandem Reactions

Though the deacetalization–Knoevenagel reaction was the dominant cascade reaction investigated over many MOFs, there are other tandem reactions that have been explored as well (Table 6). For example, Cr-MOF (MIL-101-Cr) (Cr3(F)(H2O)2O[(O2C)C6H4(CO2)]3) was modified by PSM to generate MIL-101-SO3H-NH2, which was found to be a good catalyst toward the one-pot tandem catalytic reaction.168,169 The modified MOF was prepared through a postsynthetic route by sulfonation of the framework with chlorosulfonic acid in dichloromethane.170 This compound was found to exhibit catalytic activity toward a three-component condensation reaction between aromatic aldehydes, resorcinol, and malononitrile in aqueous medium, forming 2-amino-4H chromene by the Knoevenagel condensation reaction followed by the Michael reaction (Figure S2).170 The unmodified MOF, MIL-101-Cr, was found to give a lower yield of the desired product, and increased acidity by grafting -SO3H to the framework gave improved catalytic activity for the overall reaction (Scheme S2).

Table 6. Summary of Other Cascade Reactions Employing Bifunctional MOFsa.

| Reaction name | Sr. No. | MOF compound | Reactive site | Reactants | Product | Conditions | Ref |

|---|---|---|---|---|---|---|---|

| Multicomponent Hanstch Reaction | 1 | OMS-MIL-101(Cr) | Cr, NH2, | aromatic aldehydes, dimedone, β-ketoesters ammonium acetate | methyl 2,7,7-trimethyl-5-oxo-4-phenyl-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate | 4 mol % of cat., EtOH | (146) |

| 2 | MIL-101(Cr)-N(CH2PO3H2)2 | Cr -NH2, -PO3, -OH, O– | ethyl cyanoacetate or ethyl acetoacetate, hydrazine hydrate, malononitrile, aldehydes | N-amino-2-pyridone and pyrano [2,3-c]pyrazole | 5–10 mol % cat. | (139) | |

| Chromene Synthesis | 3 | Zn-Bp-BTC MOF | N, O–, -OH | benzaldehyde, malononitrile, and active methylene dimedone | 2-amino-4H-chromene | 0.06 mmol cat., ethanol | (147) |

| 4 | zinc(II)-L1/L2/L3/L4 | Zn, -NH2 | aldehyde malononitrile 1,3-diketone | chromene | EtOH (2 mL), RT, 2 h, air | (149) | |

| Henry Condensation–Fridel Craft Alkylation | 5 | (Zr)MOF-808 | Zr, lysine | benzaldehyde, nitromethane, indole | 1-(2-nitro-1-phenylethyl)-1H-indene | 25 mg cat., 30 °C | (148) |

| Oxidation–Knoevenagel Cascade Reaction | 6 | M2(BTC)(OH)(4-TPT)2(H2O)·(DMA)0.5(H2O) | Co, Ni, N | benzyl alcohol malononitrile | benzylidene | 0.25 mmol % cat., air, 400 μL CH3CN, n-dodecane, 12 h, 353 K | (150) |

| Ni3(BTC)2(4-TPT)2(H2O)6·1.5H2O | |||||||

| 7 | Cu3TATAT | Cu, N | benzyl alcohol malononitrile | benzylidene | 8 mol % cat., TEMPO (0.5 equiv), 5 mL CH3CN, 75 °C, 1 atm O2, 12 h | (151) | |

| 8 | H5PMo10V2O40@ MIL-101 | Mo, V, Cr | benzyl alcohol malononitrile | benzylidene | 0.5 mol % cat., toluene (1 mL) O2, sealed, 120 °C, 24 h | (153) | |

| Oxidation–imine Formation | 9 | SulP1MOF-808(Hf)-Ir/Rh | Rh/IrPO3, Hf | ketone, benzyl amine | N-(cyclopentylmethyl)aniline | 1.5 mol % catalyst in 5 mL toluene under 50 bar of H2 at 90 °C for 24 h | (145) |

| 10 | Zr/Hf-MOF-808 | Zr/Hf, defect -OH | aniline, benzyl alcohols | N,1-diphenylmethanimine | T = 120 °C, 0.6 mmol of catalyst and o-xylene as solvent, 2 h | (152) | |

| Knoevenagel Condensation–hydrogenation | 11 | IY-SO3H/Rh@S-ZIF-8 | -SO3H, Zn, N | p-nitrobenzaldehyde, malononitrile | 2-(4-aminobenzylidene) malononitrile | toluene (5 mL), 30 °C, 2 h; 2 MPa H2, 80 °C, 12 h | (221) |

PDEAEMA = poly[(2-diethylamino)ethyl methacrylate; IY = Integrated yolk; H6TATAT = 5,5′,5″-(1,3,5-triazine-2,4,6-triyl)tris(azanediyl)triisophthalate; AP = 2-aminopyridine; BTC = 1,3,5-benzene tricarboxylate; Bp = 4,4′-bipyridine; N-ferrocenylmethyl-N-butyl dithiocarbamate (L1); N-ferrocenylmethyl-N-ethylmorpholine dithiocarbamate (L2); N-ferrocenylmethyl-N-2-(diethylamino)ethylamine dithiocarbamate (L3); N-4-methoxybenzyl-N-3-methylpyridyl dithiocarbamate (L4).

The MOF Hf6(μ3-O)4(μ3-OH)4(HCO2)6((O2C)3C6H3)6/3, [MOF-808(Hf)], (Figure 5a) was modified postsynthetically to give rise to a bifunctional catalyst for the reductive amination of ketones. The compound MOF-808(Hf) was exchanged to incorporate sulfonated phenylphosphines without oxidation to give a ligand attached with the MOF (Figure 5b). This ligand (SulP1/-MOF-808(Hf), Figure 5b) complexes with Ir and Rh to give a bifunctional catalyst (SulP1/-MOF-808(Hf–Ir)), containing both the metal–phosphine complexes and the Lewis acidic framework (Hf metal sites). The metalated MOF is a good example of having possible a homogeneous catalyst anchored over a heterogeneous host, which helps in the tandem reductive amination and hydro aminomethylation reactions. The catalytic tandem reaction of functionalized acetophenones with benzyl amine derivatives under 50 bar of H2 at 90 °C gave the product N-(cyclopentylmethyl)aniline with good yield (>90%). The formation of the product involves Lewis acid catalysis of the aldehyde addition to the amines, forming the corresponding imines, which are reduced further by the Ir/Rh centers (Figure 5c).145 This work is reminiscent of the anchoring of chiral homogeneous noble metal catalysts within mesoporous MCM-41 toward superior performance in allylic amination and other reactions.2

Figure 5.

(a) Structure of MOF-808. (b) Schematic of the postsynthetic exchange of sulfonated phosphines for formate groups on MOF-808(Hf). (c) Scheme for the reductive amination reaction. Reproduced with permission from ref (145). Copyright 2018 John Wiley and Sons.

A chromium MOF, OMS-MIL-101(Cr) (OMS = open metal site), was reacted with ethylene diamine, which creates basic centers in addition to the Cr acidic centers (Figure 6a).146 This catalyst was useful toward multicomponent Hantzsch reactions. The condensation between aromatic aldehydes, dimedone, β-ketoesters, and ammonium acetate gave the product polyhydroquinoline with good yield (>98%) (Figure 6b).146 The mechanism proceeds via the activation of the aryl halides over the acidic Cr3+ sites, and the -NH2 group helps in activating the β-ketoesters.146 The grafting of lysine (2,6-diamino-hexanoic acid) to (Zr)MOF-808 allowed exploration of the multifunctionality by carrying out two sequential reactions: (i) Henry condensation (base catalyzed) and (ii) Friedel/Crafts type alkylation (acid catalyzed) in one-pot solvent-free conditions.148 In this cascade reaction, both grafted basic sites (aliphatic amino groups) and framework acid sites (coordinatively unsaturated Zr sites) were employed.

Figure 6.

(a) Schematic illustration for the preparation of ED/MIL-101(Cr). (b) Plausible mechanism for MIL-101(Cr)-NH2 catalysis of the Hantzsch reaction. Reproduced with permission from ref (146). Copyright 2018 John Wiley and Sons.

A detailed kinetic study indicated that the former step is slower than the later (Figure S3). The combination of naphthalene dicarboxylic acid as the primary ligand and 1,4-bis(3-pyridyl)-2,3-diaza-1,3-butadiene (3-BPDB) as the secondary ligand gave three-dimensional structures of Zn and Cd. The Lewis acid character (Zn/Cd center) was employed toward the condensation of amino benzaldehyde and ketones (Friedländer reaction). The Lewis basic character (-N=N-) was used for the three-component condensation that involves Knoevenagel and Michael reactions.142 In this study, a cascade reaction of two distinct base catalyzed mechanisms has been investigated. Anchoring CuI over modified UiO-67 was found to be a good catalyst for the azide–alkyne cycloaddition reaction.154 The mechanism involves mediated alkyne interactions followed by the azide reaction forming the triazole derivatives. It is a different approach, as metal salts have been anchored over the MOFs instead of simple metal nanoparticles.

In a recent work, for the first time, a 4-step cascade reaction was carried out using the same strategy of spatially separated Lewis acid and base functionality in [Zn2(SDBA)(3-ATZ)] (SDBA = 4,4′-sulfonyldibenzoic acid; 3-ATZ = 3-amino 1,2,4-triazole) (Figure 7a).171 The different steps that were studied involve deacetalization (Lewis acid catalyzed), Henry, and Michael reactions (Lewis base catalyzed) (Scheme 3). This reaction was possible due to the presence of additional basic sites in the MOFs (primary amine, -NH2, and sulfonyl oxygen atoms). The four-step reaction consists of the following: the first reaction is the formation of an aldehyde (B) from the benzaldehyde dimethyl acetal (A) (Lewis acid catalyzed); the second reaction is between the nitroalkane and the aldehyde, forming (Henry reaction) 2-nitro-1-phenyl ethanol (C) (Lewis base catalyzed); the third reaction is the dehydration of (C) to give trans β-nitrostyrene (D) (Lewis base catalyzed); and finally reaction between nitromethane and (D) gives (1,3-dinitropropan-2-yl)benzene (E) (Scheme 3). The time dependent study clearly indicates that the dehydration of 2-nitro-1-phenyl ethanol to trans-β-nitrostyrene was the rate limiting step and that the Le Chatlier’s principle was in action for the reaction to proceed in the forward reaction. It is clearly a good example where the bifunctionality of the MOF was exploited toward a cascade reaction that involved multiple steps. The number of steps (3) in the base catalyzed reactions is more compared to that of the acid catalyzed one in this cascade reaction. The presence of the primary -NH2 group, which is a strong base, helped in this reaction171 (Figure 7b).

Figure 7.

(a, b) Connectivity between the Zn-ATZ layers through the acid ligand (SDBA) in I and II. (c, d) Time dependent study of the one-pot tandem four-step deacetalization–Henry–Michael reactions for I and II. Reprinted with permission from ref (171). Copyright 2023 American Chemical Society.

Scheme 3. Summary of the Four-Step Cascade Reaction Involving the Deacetalization–Henry–Michael Reaction.

Reproduced with permission from ref (171). Copyright 2023 American Chemical Society.

3.2.3. Oxidation–Knoevenagel/Amination Cascade Reaction

The compounds M(BTC)(OH)(4-TPT)2(H2O)·(DMA)0.5(H2O)2 (H3BTC = 1,3,5-tribenzoic acid; 4-TPT = 2,4,6-tris(4-pyridyl)-1,3,5-triazine; M = Co, Ni) and Ni3(BTC)2(4-TPT)2(H2O)6·1.5H2O have terminal H2O molecules coordinated to the metal centers (Co/Ni) which can be removed by heating (Figure 8a).150 This creates an open coordination site at the metal center, which can act as Lewis acidic center. The secondary ligand 4-TPT can be the Lewis basic center. The compounds were found to be good catalysts for the oxidation of benzyl alcohol to benzaldehyde (acid catalyzed) followed by reaction with malononitrile to give benzilidine malononitrile (base catalyzed) (Figure 8b).150 A similar reaction was also carried out over the Cu3TATAT MOF (H6TATAT = 5,5′,5″-(1,3,5-triazine-2,4,6-triyl) tris(azanediyl)triisophthalate) compound.151

Figure 8.

(a) Structure of MOF highlighting the acidic and basic centers. (b) Schematic of the oxidation–Knoevenagel condensation reaction. Reproduced with permission from ref (150). Copyright 2021 Royal Society of Chemistry.

The use of Zr/Hf-MOF-808 toward the synthesis of secondary amines was established by reacting anilines and benzyl alcohols. This reaction does not require any additional base and/or external H2.152 The reaction proceeds through the deprotonation of the alcohol by the metal center followed by the dehydrogenation to form benzaldehyde, which reacts with the amino group of the aniline, forming the final benzylaniline product (Scheme 4). There are some important observations in this reaction. The presence of a defective -OH group in the Hf-cluster metal center enhances the acidity and helps in the formation of benzaldehyde in the first step. The captured proton at the defective -OH group site also aids in the formation of the final product by reacting with the imine nitrogen formed through the condensation of the aldehyde and amine (Scheme 4). This is an interesting strategy where the proton is captured initially and later released during the final step to give the desired product.

Scheme 4. Possible Mechanism for the N-Alkylation Reaction of Aniline with Benzyl Alcohol to Form the N-Benzylaniline Product.

Adapted with permission under a Creative Commons (CC BY 4.0) from ref (152). Copyright 2021 American Chemical Society.

The encapsulation of polyoxometalate H5PMo10V2O40 (PMoV2) into the cages of an alkylamine-modified MIL-101 was employed for the aerobic oxidation–Knoevenagel one-pot tandem reaction (Scheme S3). The main observation in this reaction is that it does not use any noble metals for the aerobic oxidation of the alcohols.153

3.3. Anchoring Metal Nanoparticles toward Catalysis

The development of metal nanoparticles during the 90s and the associated advancements in nanoscience provide an important opportunity to explore multifunctionality in MOFs.172−174 It may be noted that the use of well distributed supported metal catalysis (e.g., Pd or Pt in Al2O3, SiO2, zeolites, and mesoporous silica) is one of the earlier examples of bifunctional catalysts.175−177 Many of the supported catalysts are useful toward the “spillover” reactions involving hydrogen.178 The noble metal and the support influence the electronic state of the metal along with its precise morphology. Today, it has been possible to prepare noble metal nanoparticles with controlled sizes and shapes,179−182 which may be of importance in heterogeneous catalysis. The noble metal nanoparticles can be stabilized by anchoring the particles through suitable functional groups—most notably the thiol (-SH) functionality. The usefulness of noble metal centers for diverse catalytic reactions has been known over many decades.183−187 Many of these earlier reactions are homogeneous catalytic reactions, where the recyclability of the catalyst would be difficult. In recent years, it has been possible to prepare atom precise metal nanoclusters and assemble them into extended structures.188−192 In addition, the ease of functionalizing the ligands that can be used in the preparation of MOFs opens up an interesting possibility toward anchoring metal nanoparticles at precise locations within the MOFs. The MOFs provide reasonable thermal and chemical stability and pore and channel sizes which can be gainfully employed to explore the usefulness of metal nanoparticles toward catalytic reactions. This approach would be similar to carrying out the homogeneous reactions within heterogeneous surroundings. Catalytic reactions of this nature were attempted by anchoring organometallic complexes directly into the mesoporous compounds, notably on MCM-41 and related ones.193−195

Most of the MOFs possess Lewis acidity, and the functional ligand provides the necessary additional reactive center (either Bronsted acidic or basic). These MOFs are already bifunctional and the anchoring of metal nanoparticles adds to the existing functionality. The main advantages of anchoring the metal nanoparticles are their small (nano) size and the availability of periodically placed metals over the surface of the MOFs, which would be useful toward many heterogeneous catalytic reactions. Much of the earlier work on such type of nanoparticle anchored MOFs was termed “ship in a bottle” catalysts.196,197 The usefulness of this approach was shown by anchoring Au nanoparticles in a MOF, Au@Cu(II)-MOF, toward a tandem oxidation–Knoevenagel condensation reaction that involves the conversion of benzyl alcohol to benzylidene malononitrile with good yield, conversion, and selectivity.198 Similarly, Pd@Ni-MOF was shown to be a good catalyst toward Suzuki coupling of aryl chlorides.199 It is notable that many reactions involving Suzuki coupling are carried out by employing aryl bromides and iodides and that the presence of Pd nanoparticles uniformly distributed in a heterogeneous environment (Pd@Ni-MOF) converts the aryl chlorides with good yield as well as recyclability.199 Many studies of this nature have been known in the literature.200−205 The important nanoparticle loaded MOFs and their utility in heterogeneous catalytic studies are listed in Table 7.

Table 7. Nanoparticle Loaded MOFs and Their Utility in Catalysisa.

| Sr. No. | MOF compound | Reactive site | Nanoparticle | Catalytic reaction | Ref |

|---|---|---|---|---|---|

| 1 | Au@ZIF-8 | Zn2+/-Nim | Au | hydrogenation of n-hexene | (311) |

| 2 | nFe3O4@Pd/ZIF-8@ZIF-8 | Zn2+/-Nim | Fe3O4/Pd | hydrogenation of styrene | (312) |

| 3 | UiO-66-biguanidine/Pd | Zr4+/-NH2 | Pd | Suzuki–Miyaura coupling | (313) |

| 4 | Ag@UiO-66-SH | Zr4+/-NH2 | Ag | three-component A3 coupling | (314) |

| 5 | AgPd@MIL-125-NH2-PDA | Cr3+/-NH2 | Ag-Pd | Suzuki coupling reaction | (315) |

| hydrogenation of aldehyde | |||||

| 6 | MOF-Pd NPs | Cu2+/-NH2 | Pd | aerobic oxidation of benzyl alcohol | (316) |

| 7 | Pt@UiO-66-NH2 | Zr4+/-NH2 | Pt | synthesis of nitrones | (173) |

| 8 | Au-NP/Ni-Cu MOF | Ni2+/Cu2+ | Au | chemical degradation of Rhodamine B | (317) |

| 9 | Au@Cu(II)-MOF | Cu2+/-N | Au | oxidation–condensation reactions | (198) |

| 10 | Co–MOF-74@Cu–MOF-74 | Co2+/Cu2+ | CoCu | 1, 4-diphenyl-1,3-butadiene from phenylacetylene | (209) |

| 11 | Pd(0)@UiO-68-AP | Zr4+/-N | Pd | oxidation–Knoevenagel condensation | (215) |

| 12 | Au/NH2–UiO-66 | Zr4+/-NH2 | Au | tandem reaction | (216) |

| 13 | Pd-Au@Mn(II)-MOF | Mn(II)/N | Pd-Au | alcohol to imines | (217) |

| 14 | Al-ITQ-SO3H/Pd | Al(III), SO3H | Pd | oxidation–acetalization | (219) |

| 15 | IY-SO3H/Rh@S-ZIF-8 | Zn(II)SO3H | Rh | Knoevenagel condensation–hydrogenation reaction | (221) |

| 16 | Pd@UiO-66(Hf) | Hf(IV) | Pd | Hantzsch reaction | (318) |

| 17 | Pd@NH2-UiO-66 | Zr(IV)/-NH2 | Pd | Suzuki coupling/asymmetric aldol condensation | (224) |

| 18 | Ni@ZrOF | Zr(IV)/ -NH2 | Ni | chemical fixation of CO2 | (319) |

| 19 | Au@[Zn14(L)6(O)2(H2O)3] | Zn(II) | Au | chemical fixation of CO2 | (249) |

| 20 | Ag(I)@MOF-NHC | Zn(II)/-N | Ag | chemical fixation of CO2 | (250) |

| 21 | Pt@MOF-5, Pt@UiO-66, Pt@UiO-66-NH2 | Zr(IV)/-NH2 | Pt | biomass valorization | (320) |

| 22 | [Zn(4-bpdh)]3DMF | -N | Pd | Sonogashira coupling reaction | (321) |

| 23 | Ag/UiO-66 | Zr4+ | Ag | 3,4-dihydropirimidin-2(1H)-one synthesis | (322) |

| 24 | Au/MOF-199 | Cu2+ | Au | A3-coupling reaction | (323) |

| 25 | metal/UiO-66 | Zr4+ | Pt, Pd, Ru | oxidation of volatile organic compound | (324) |

| 26 | Pd(0)@UiO-68-AP | Zr, -NH | Pd | oxidation–Knoevenagel cascade reaction | (215) |

| 27 | Au@NH2-UiO-66 | Zr, -NH2 | Au | oxidation–Knoevenagel cascade reaction | (216) |

| 28 | Pd-Au@Mn(II)-MOF | Mn, Npyr | Pd, Au | oxidation–imine/acetal formation cascade reaction | (217) |

| 29 | Pd@MIL-101 | Cr, N | Pd | oxidation–imine/acetal formation cascade reaction | (218) |

| 30 | Pd@Al-MOF | Al, −SO3H | Pd | oxidation–imine/acetal formation cascade reaction | (219) |

| 31 | Pd@PDEAEMA-g-UiO-66 | Zr, -NH2 | Pd | Knoevenagel condensation–hydrogenation | (220) |

| 32 | Pd/MIL-101-SO3H | -SO3H | Pd | hydrogenation esterification cascade reaction | (222) |

| 33 | Pd@UiO-66(Hf) | Zr | Pd | hydrogenation esterification cascade reaction | (223) |

OPNs = organic polymer networks; PDA = polydopamine; AP = aminopyridine; NHC = N-heterocyclic carbene; 4-bpdh = 2,5-bis(4-pyridyl)-3,4-diaza-2,4-hexadiene.

As discussed above, anchoring of noble metal particles supported over the MOFs was found to be dominant in many catalytic reactions. There have been attempts at synthesizing 3d metal nanoparticles, at the expense of the MOF framework, by anchoring them over carbonized MOFs.206−208 It has been shown that MOFs when heated in an inert atmosphere (Ar atmosphere) or under vacuum at elevated temperatures form carbon with the metals distributed over the carbon. This carbonization process, in general, results in the formation of different forms of carbon such as amorphous carbon, graphitized carbon, or a mixture of both. Depending on the composition of the MOFs, the resulting metal nanoparticles can be either single nanoparticles or bimetallic nanoparticles supported over the amorphous carbon. It has been known that amorphous carbon can act as a good support toward many catalytic reactions.209−214 The bimetals supported over the carbonized MOFs can be exploited toward catalytic reactions where the differences in the catalytic activity of the different metals would be important.

This strategy was employed toward the preparation of Co-Cu bimetallic nanoparticles supported on carbon (Co-C@Cu-C) by pyrolyzing Co/Cu-MOF-74.209 This bimetallic catalyst was found to be a good catalyst for the conversion of phenylacetylene to 1,4-diphenyl-1,3-butadiene. This reaction involves C–C coupling as well as hydrogenation reactions, and the reaction proceeds over the Co centers. The possible mechanism for this cascade reaction is given in Scheme 5. Phenylacetylene is initially activated by metallic Cu NPs, forming Cu+-phenylacetylide complex on the surface of Cu NPs. The metallic Co NPs in Co-C@Cu-C help in the dissociation of NaBH4 to form Co-BH3 and CoH, which act as the active species for the hydrogenation of the phenylacetylene. The proposed mechanism also involves the migration the hydrides on Co nanoparticles to diffuse to interact with the adsorbed Cu+-phenylacetylide complex. The remaining hydrides in BH3(i-PrO)− dissociate over the metallic Co NPs, which helps in the spillover of hydrogen to react with the adsorbed Cu+-phenylacetylide complex. The in situ formed complex between CuI-phenylacetylide dimerizes to form 1, 4-diphenyl-1,3-butadiene.

Scheme 5. Co-MOF-74@Cu-MOF-74 Derived Bifunctional Co-C@Cu-C for One-Pot Production of 1,4-Diphenyl-1,3-butadiene from Phenylacetylene.

Reprinted with permission from ref (209). Copyright 2020 John Wiley and Sons.

The pyrolysis of a cobalt MOF, [Co(C14H8O6)(C10H8N2)2H2O)]·(C3H7NO), results in Co supported on amorphous/graphitized carbon. The Co nanoparticles were shown to be a good green catalyst for the selective reduction of nitroarenes to amines in the presence of the hydrazine as a hydrogen source.199 The Co metal particles supported on the carbon matrix help in the decomposition of hydrazine to produce the hydrogen in situ. The hydrogen spillover helps in the reduction of nitroaromatics to the aniline derivatives. The examples clearly support the spillover effect in employing metal nanoparticles toward hydrogenation reactions. A mixed precursor containing Cu, Co, and Ni introduced into MIL-101 was reduced in situ with NH3BH3 to give Cu@Co@Ni NPs inside MIL-101 pores. The compound Cu@Co@Ni/MOF catalyzes nitroarene hydrogenation in the presence of NH3BH3, which supplies the necessary hydrogen for the reaction.204

3.3.1. Cascade Reactions Involving Anchored Nanoparticles

A bifunctional Pd(0)@UiO-68-AP catalyst, prepared using the postsynthetic approach, catalyzes aerobic oxidation of benzyl alcohol by the Pd NPs followed by reaction with malononitrile via the Knoevenagel condensation, forming benzilidine malononitrile.215 The oxidation of the benzyl alcohol is promoted by the Pd catalyst whereas the Knoevenagel condensation is facilitated by the basic nitrogen center.215 A similar reaction was also carried out employing Au nanoparticles anchored over NH2-UiO-66,216 for the selective oxidation of primary alcohols in tandem with Knoevenagel condensation reactions. A Mn(II) MOF, (MnL2)·2CH3OH (L = 4,4,4-trifluoro-1-(4-(pyridin-4-yl)phenyl)butane-1,3-dione), with Pd-Au bimetallic alloy nanoparticles (Pd-Au@Mn(II)-MOF) was employed as a bifunctional heterogeneous catalyst for the one-pot tandem synthesis of imines from benzyl alcohols and aniline (Figure S4). The oxidation reaction was catalyzed by nanoparticles, and the imine formation was due to the N-containing ligand.217 Similar reactions have also been carried out with Pd nanoparticles (NPs) encapsulated in MIL-101.218 An aluminum MOF, Al-ITQ-SH, having thiol units was used to anchor Pd nanoparticles, and the thiol moieties were converted into sulfonic groups (Bro̷nsted acid).219 This compound catalyzes a one-pot, two-step oxidation–acetalization reaction where the oxidation of benzyl alcohol into benzaldehyde under an O2 atmosphere was catalyzed by Pd nanoparticles, followed by the acetalization of aldehydes employing the Brönsted acid functionality. A Pd NP loaded and pH-switchable polymer-grafted UiO-66-MOF, Pd@PDEAEMA-g-UiO-66, (PDEAEMA = poly[(2-diethylamino)ethyl methacrylate]), was employed toward a biphasic Knoevenagel condensation–hydrogenation cascade reaction using different atmospheres (Figure 9a). The Knoevenagel condensation step was carried out under air atmosphere, whereas the hydrogenation reaction was carried out in hydrogen atmosphere (Figure 9b).220

Figure 9.

(a) Schematic of synthesis of Pd@PDEAEMA-g-UiO-66 through PSM. Yellow balls: Pd nanoparticles. (b) Knoevenagel condensation followed by hydrogenation cascade reactions over the Pd@PDEAEMA-g-UiO-66 catalyst. Reproduced with permission from ref (220). Copyright 2017 American Chemical Society.

A bifunctional composite compound with a macro-/microporous ZIF-8 shell and rhodium nanoparticles anchored over sulfonated cross-linked polystyrene was prepared to carry out the Knoevenagel–hydrogenation reaction.221 The reactants containing the aldehyde and malononitrile in toluene solvent under a pressure of hydrogen (2 MPa) gave the benzilidene malononitrile product in near ∼100% yield. The composite catalyst was found to be robust with negligible leaching of the anchored Rh nanoparticles.221 Another reaction that utilizes nanoparticle supported over MOFs is the hydrogenation–esterification reaction. The hydrogenation is catalyzed by the noble metal nanoparticles, and the esterification reaction is catalyzed by the acidic sites. The compound MIL-101-SO3H was appended with Pd nanoparticles to give Pd/MIL-101-SO3H.222 This compound was active to convert furoic acid (FA) (biomass derived) into value chemicals such as ethyl tetrahydro-2-furoate (ETF). The FA was esterified with ethanol, forming ethyl furoate (EF), which was hydrogenated to give ETF (yield = 100%, selectivity >99%) (Scheme 6). A similar reaction has also been attempted over Pd@UiO-66(Hf).223

Scheme 6. Scheme of the Cascade Reaction Process from FA to ETF.

Reproduced with permission from ref (222). Copyright 2019 Royal Society of Chemistry.

The use of bifunctionality was shown elegantly by adding an l-proline functionality to -NH2-UiO-66, which also had Pd nanoparticles through PSM. This modified MOF was shown to be a chiral catalyst toward Suzuki coupling (Pd centered) followed by asymmetric aldol condensation (N centered). The reaction between 1,4-bromobenzaldehyde and phenylboronic acid in EtOH–H2O was catalyzed by Pd@NH2-UiO-66(pro) and K2CO3 at 80 °C.224

As described above, the overall activity of the MOFs has been enhanced by having the nanoparticles. Though most of the studies concentrated on noble metals, there have been efforts toward other transition metals as well. As can be noted, in most of the cases one finds a good synergistic and cooperative effect between the metal nanoparticles and the overall functionality of the MOFs. The reactions, in a way, replicate many of the well-established and known organometallic catalyses in these compounds. This effort paves the way for carrying out homogeneous catalysis under a heterogeneous environment. It is likely that many other reactions would also be attempted in the future to reap the benefits of having well dispersed nanomaterials in bifunctional MOFs. This approach really makes the MOF compounds truly multifunctional.

3.4. Fixation of Atmospheric CO2

One of the important issues of concern is the control of CO2 in the atmosphere. CO2 has been designated as an important greenhouse gas, and it is desirable to convert it to other useful chemicals.225−230 There have been attempts to convert the CO2 under atmospheric conditions, both through the catalytic route231−233 as well as electrochemically.234−236 The intense research, over the years, has involved conversion of CO2 into cyclic carbonate, carboxylation, reductive N-functionalization of various amines with CO2 to furnish N-formyl compounds, and carboxylative cyclization of propargyl amines and alcohols.237−241 In many of these attempts, organometallic compounds, nanoparticle grafted compounds, and others have been explored.242 There have been considerable efforts toward fixing CO2 at atmospheric pressures employing MOFs, notably bifunctional ones. Some of the important studies toward the fixation of CO2 employing MOFs are listed in Table 8.

Table 8. Summary of Atmospheric CO2 Fixation over MOFsa.

| Sr. No. | MOF | Reactive site | Reactant | Product | Reaction conditions | Ref |

|---|---|---|---|---|---|---|

| 1 | (I–)Meim-UiO-66 | Zr4+, I– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 0.1 MPa, 120 °C, 24 h | (248) |

| 2 | MIL-IL(A) | Cr3+, Br– | SO | 4-phenyl-1,3-dioxolan-2-one | 2 MPa, 110 °C, 2 h | (325) |

| MIL-IL(B) | ||||||

| 3 | MIL-IMAc-Br– | Cu2+-COOH, Br– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 0.5 MPa, 60 °C, 24 h | (81) |

| 4 | Mg-MOF-74 | Mg2+, Co2+, OH | SO | 4-phenyl-1,3-dioxolan-2-one | 2 MPa, 100 °C, 4 h | (326, 327) |

| Co-MOF-74 | ||||||

| 5 | UiO-66-NH2 | Zr4+, NH2 | SO | 4-phenyl-1,3-dioxolan-2-one | 2.0 MPa, 100 °C, 4 h | (328) |

| 6 | BIT-101 | Zn2+, COO | PO | 4-methyl-1,3-dioxolan-2-one | 3 MPa, 160 °C, 24 h | (329) |

| BIT-102 | ||||||

| BIT-103 | ||||||

| 7 | 1-NH2 | CONH, NH2 | ECH, PO | 4-(chloromethyl)-1,3-dioxolna-2-one-4-methyl-1,3-dioxolan-2-one | 0.1 MPa, 90 °C, 50 h, 3 MPa, 100 °C, 6 h | (330) |

| 8 | UMCM-1-NH2 | Zn4O, NH2 | PO | 4-methyl-1,3-dioxolan-2-one | 1.2 MPa, 120 °C, 24 h | (331) |

| 9 | Zn-TATAB | Zn2+, NH | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 atm, 100 °C, 16 h | (332) |

| 10 | Co/Ni-TATAB | Co2+, Ni2+, NH | ECHECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 bar, 80 °C, 15 h | (279) |

| 11 | Zn-BTC-2MeIm | Zn2+, 2MeIm | ECH, PO | 4-(chloromethyl)-1,3-dioxolan-2-one | 3.0 MPa, 100 °C, 6 h | (333) |

| 12 | Co(tp)(bpy) MOF-508a | Co2+, Zn2+, free pyridine N | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 MPa, 100 °C, 8 h | (334) |

| 13 | (Me2NH2)2·[Zn8(Ad)4(DABA)6O]·7DMF}n | Zn2+, Ad, and NH2 | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 bar, 100 °C, 24 h | (335) |

| 14 | ZIF-8 | Zn2+, Im | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 7 bar, 100 °C, 4 h | (336) |

| 15 | ZIF-90 | Zn2+, CHO | PO | 4-methyl-1,3-dioxolan-2-one | 2 MPa, 120 °C, 8 h | (337) |

| 16 | CZ-ZIF | Zn2+/Co2+, HmIm | ECHPO | 4-(chloromethyl)-1,3-dioxolan-2-one | 7 bar, 100 °C, 4 h | (338) |

| 17 | ZIF-67 | Co2+, HmIm | ECHPO | 4-(chloromethyl)-1,3-dioxolan-2-one | 10 bar, 120 °C, 6 h | (339) |

| 18 | Ti-ZIF | Ti4+, Im | SO | 4-phenyl-1,3-dioxolan-2-one | 1.72 bar, 100 °C, 8 h | (340) |

| 19 | MIL-101-P(n-Bu)3BrMIL-101-N(n Bu)3Br | Cr3+, Br– | POPO | 4-methyl-1,3-dioxolan-2-one | 2.0 MPa, 80 °C, 8 h | (341) |

| 20 | F-ZIF-90 | Zn2+, I– | AGE | 4-((allyloxy)methyl)-1,3-dioxolan-2-one | 1.17 MPa, 120 °C, 6 h | (342) |

| 21 | IL-ZIF-90 | Zn2+, I– | PO | 4-methyl-1,3-dioxolan-2-one | 1.0 MPa, 120 °C, 3 h | (343) |

| 22 | ZnTCPP⊂(Br)Etim-UiO-66 | Zn2+, Br– | AGE | 4-((allyloxy)methyl)-1,3-dioxolan-2-one | 1 bar, 140 °C, 14 h | (344) |

| 23 | Salen-Co(23%)⊂(Br–)Etim-UiO- 66 | Co3+, Br– | SO | 4-phenyl-1,3-dioxolan-2-one | 0.1 MPa, 120 °C,12 h | (345) |

| 24 | UiO-67-IL | Zr4+, Br– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 atm, 90 °C, 12 h | (346) |

| 25 | FJI-C10 | Cr3+, Br– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 bar, 80 °C, 12 h | (347) |

| 26 | IL@MIL101-SO3H(4) | Cr3+, Br– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 atm, 90 °C, 24 h | (348) |

| 27 | MIL-101-IMBr-6 | Cr3+, Br– | PO | 4-methyl-1,3-dioxolan-2-one | 0.8 MPa, 80 °C, 4 h | (349) |

| 28 | IL/MIL-101-NH2 | -COOH, NH2 | PO | 4-methyl-1,3-dioxolan-2-one | 1.3 MPa, 120 °C, 1 h | (350) |

| 29 | polyILs@MIL-101 | Cr3+, Br– | SO | 4-phenyl-1,3-dioxolan-2-one | 1 bar, 70 °C, 48 h | (351) |

| 30 | MIL-101-IP | Cr3+, Br– | PO | 4-methyl-1,3-dioxolan-2-one | 1 atm, 25 °C, 48 h | (352) |

| 31 | IL@ZIF-8(Zn/Co) | Zn2+, Co2+, Br– | SO | 4-phenyl-1,3-dioxolan-2-one | 1 atm, 100 °C, 24 h | (353) |

| 32 | F-IRMOF-3-2d | Zn4O, -NH2, I– | POPOPO | 4-methyl-1,3-dioxolan-2-one | 2 MPa, 140 °C, 1.5 h | (354) |

| F-IRMOF-3-4d | ||||||

| F-IRMOF-3-6d | ||||||

| 33 | F-IRMOF-3(MeI) | Zn-OH, I– | AGE | 4-((allyloxy)methyl)-1,3-dioxolan-2-one | 1.2 MPa, 120 °C, 6 h | (355) |

| F-IRMOF-3(BuI) | ||||||

| 34 | MIL-101-tmzOH-Br | Cr3+, OH–, Br– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 MPa, 80 °C, 2 h | (356) |

| 35 | 2MeIm@Co-BTC-x | Co2+, MeIm | ECHECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 3.0 MPa, 90 °C, 5 h, 3.0 MPa, 90 °C, 7 h | (357) |

| 36 | Cr-MIL-101-[BuPh3P]Br | Cr3+, Br– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 MPa, 80 °C, 2 h | (358) |

| 37 | [TMPyPMn(I)]4+(I–)4@ZIF-8 | Zn2+, Mn2+, I– | ECH | 4-(chloromethyl)-1,3-dioxolan-2-one | 1 bar, 100 °C, 36 h | (359) |

| 38 | [Zn(II)NMeTPyP]4+[I–]4@PCN- 224 | Zn2+, I– | ECHPO | 4-(chloromethyl)-1,3-dioxolan-2-one-4-methyl-1,3-dioxolan-2-one | 0.8 MPa, 90 °C, 24 h | (360) |

Abbreviations: ECH = epichlorohydrin; PO = propylene oxide; SO = styrene oxide; AGE = allyl glycidyl ether; dhtp = 2,5-dihydroxyterephthalate; NH2-BDC = 2-aminoterephthalate; aip = 5-aminoisophthalic acid; NIP = 5-nitroisophthalic acid; L = N4,N4′-di(pyridine-4-yl) biphenyl-4,4′-dicarboxamide; Im = imidazole; BTC = 1,3,5-benzene tricarboxylate; HmIm = 2-methylimidazole; ICA = imidazole 2-carboxaldehyde; TATAB = 4,4′,4″-s-triazine-1,3,5-triyl-tri-p-aminobenzoic acid; DABCO = 1,4-diazabicyclo[2.2.2]-octane; MIL = Materials Institute Lavoisier; UiO = University of Oslo; BIT = Beijing Institute of Technology; Hip = 5-hydroxyisophthalic acid; Bpy = 4,4′-bipyridine; BTB = 1,3,5-tris(4-carboxyphenyl)benzene; DMF = N,N′-dimethylformamide; Ad = adeninate; DABA = 2,2′-dimethyl- 4,4′-azobenzoate; 2-MeIm = 2-methylimidazole; ZIF = zeolitic imidazolate framework; 2-F-BIM = 2-(furan-2-yl)-1H-benzo[d]imidazole; TCPP = 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin; IL = ionic liquid; ICA = imidazole-2-carboxyaldehyde; Etim = ethyl imidazolium; polyILs = poly(ionic liquids); IP = ionic polymer; MeI = methyl iodide; BuI = butyl iodide; IRMOF = isoreticular metal–organic framework; IMAc = 1H-imidazole-1-acetic acid; PCN = Porous coordination network; Zn(II)NMeTPyP = 5,10,15,20-tetrakis(1-methylpyridinium-4-yl) zinc(II) porphyrin; [(Etim-H2BDC)+(Br)] = 2-(3-ethyl-imidazol-1-yl)-terephthalic acid; ImBDC = 2-(imidazole-1-yl)terephthalate; salen-Co(III) - N,N′-bis(3-carboxylsalicylidene)-1,2-cyclohexanediamino cobalt(III) acetate; [BuPh3P]Br = 4-(bromobutyl)triphenylphosphonium bromide; MPImBr = 1-methyl-3-propylimidazolium bromide; HmIm = 2-methylimidazole; 2-Br-BDC = 2-bromoterephthalate; L = (Br) allylium-2-bp functionalized biphenyl dicarboxylic acid.

Tetra(4-pyridyl)porphyrin (H2TPyP) was employed along with 4,4′-oxybis(benzoic acid) (H2OBA) to form a 2D compound, [Zn2(C40H24N8)0.5(C14H8O5)(DMA)](DMA)(H2O)6.243 The Zn2+ ions were ion-exchanged with the Cu2+ in a postsynthetic modification, and the Cu compound was employed for the cyclic carbonate formation reaction with tetra-n-tert-butylammonium bromide (TBAB) as a cocatalyst, which gave cyclic carbonates with high yield.243