Abstract

Multi-criteria decision-making (MCDM) methods have been widely used among researchers to provide a trade-off solution between best and worst, considering conflicting criteria and sets of preferences. An efficient and systematic literature review of these methods is needed to maintain their application in distinctive domains. To this end, this paper presents a comprehensive and systematic literature survey on “multi-objective optimization by ratio analysis” (MOORA) method and its fuzzy extensions developed and discussed in recent years. This review includes articles categorized based on the publication name, publishing year, journal name, type of applications, and type of fuzzy extensions. In addition, this review will enhance the understanding of practitioners and decision-makers on the MOORA method, its development, fuzzy hybridization, different application areas, and future work. The study revealed that the MOORA technique was predominantly used with the TOPSIS approach, followed by the AHP and COPRAS methods. Furthermore, 76.28 % use single and hybridization approaches among all MOORA studies, while 23.72 % use MOORA in a fuzzy environment.

Keywords: MOORA, Fuzzy hybridization, Decision making, Multi-objective optimization

1. Introduction

The practice of decision-making is an integral element of nearly all human activities, whether executing daily to daily actions or any professional task. Although comparatively more straightforward decisions have less influence on day-to-day work, some decisions with more complexity can have unpleasant effects. Real-world issues are often non-trivial, requiring the search for the best solution after considering several conflicting criteria. In industries, optimal decisions not only minimize different risks but can also enhance the quality of products. Several practitioners and researchers have studied and worked on different methods to provide optimal predictions and critical decisions in such multi-criteria decision-making (MCDM) problems [1,2]. The MCDM method provides quality decisions based on assessing the situation, evaluating and ranking the available alternatives, and managing the finite performance criteria for a specified application [3,4]. The MCDM methods have been an active area of research for more than two decades, helping decision-makers provide the exact information concerning performance rankings and respective criteria weights [5,6]. The MCDM methods have been widely employed in difficult engineering situations [7,8], healthcare problems [9,10], automotive sector [11,12], business management [13,14], solar thermal collector optimization [15,16], waste management [17,18], etc. Moreover, these techniques are significant in defining the significance level of different domains and realizing the order of their execution accordingly, as performed by several estimation methods with superior prediction ability [19].

Over the years, researchers have used the terms multi-attribute decision-making (MADM) or multi-criteria decision aiding (MCDA) or multi-objective decision-making (MODM) instead of MCDM [20]. In realizing a general overview of individual MCDM methods, a comprehensive review of that technique is required covering its basic, methodology, mathematical background, and application area. In past, researchers have provided a generalized review of MCDM techniques and their fuzzy extensions to solve real-world problems effectively. To begin, Vaidya and Kumar [21] summarized past literature on the application of “analytic hierarchy process” (AHP) technique in decision making. Emrouznejad et al. [22] performed bibliographic analysis on classical “data envelopment analysis” (DEA) technique incorporating theoretical background and application areas in thirty years. Similarly, Hatami-Marbini et al. [23] presented four different classification scheme such as tolerance-based approach, a-level approach, fuzzy ranking approach, and possibility centered approach for conducting effective review on DEA under fuzzy environment considering past two decades of literature. In the same context, Behzad et al. [24] presented detailed comprehensive review on classification, application and methodology of “preference ranking organization method for enrichment evaluations” (PROMETHEE) method. Behzad et al. [25] presented a review on “technique for order preference by similarity to ideal solution” (TOPSIS) methodology and its application. Yin [26] performed a bibliometric study on grey relational analysis (GRA) considering 300 articles from ISI web database for grey based problems. Govindan and Jepsen [27] reviewed “elimination et choix radiant la realité” (ELECTRE) and ELECTRE based methods utilized in different research areas besides its modification and comparative analysis with other methods.

Furthermore, Mardani et al. [28] reviewed two decades of MCDM, fuzzy MCDM, and hybrid methods and classified them based on methodology and application after considering 403 papers from renowned published articles. Celik et al. [29] performed a comprehensive literature review on interval type −2 fuzzy sets and the classification of thirty-five MCDM approaches. The study provided insight into type-2 fuzzy techniques applied effectively for vague and uncertain information. Mardani et al. [30] conducted a systematic review on “stepwise weight assessment ratio analysis” (SWARA) and “weighted aggregated sum product assessment” (WASPAS) methods and fuzzy development of these techniques for decision making in uncertain environments. Si et al. [31] reviewed 346 journal articles on “decision making trial and evaluation laboratory” (DEMATEL) and analyzed the methodology used in different applications after classifying them under five categories. Gul et al. [32] reported review on “vlsekriterijumska optimizacija I kompromisno resenje” (VIKOR) and its fuzzy development in various application areas of decision making. The efficacy of MCDM methods under fuzzy environments has been reviewed, summarized, and classified by Kahraman et al. [33]. In addition to generalized MCDM technique reviews, a finite number of comprehensive review papers have been presented by researchers showing the significance of individual MCDM methods in optimal solving of different domain problems. The summary of already available review papers on MCDM methods in past literature have been presented in Table 1.

Table 1.

Summary of MCDM methods review.

| Authors | Country | MCDM method | Paper considered |

|---|---|---|---|

| Vaidya and Kumar [21] | India | AHP | 150 |

| Emrouznejad et al. [22] | UK, USA | DEA | 1637 |

| Hatami-Marbini et al. [23] | UK | Fuzzy DEA | 160 |

| Behzadian et al. [24] | Iran | PROMETHEE | 217 |

| Behzadian et al. [25] | Iran | TOPSIS | 266 |

| Yin [26] | Taiwan | GRA | 300 |

| Govindan and Jepsen [27] | Denmark | ELECTRE | 686 |

| Mardani et al. [30] | Malaysia | SWARA and WASPAS | 240 |

| Si et al. [31] | China | DEMATEL | 346 |

| Gul et al. [32] | Turkey | VIKOR and fuzzy extensions | 343 |

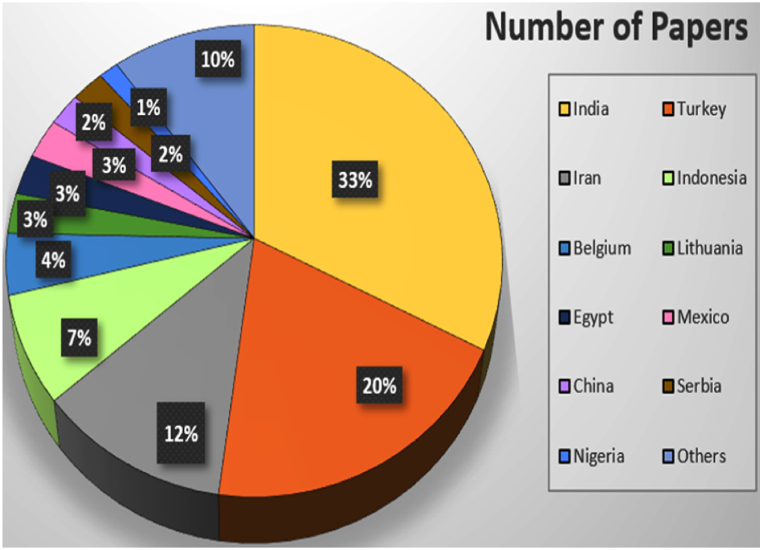

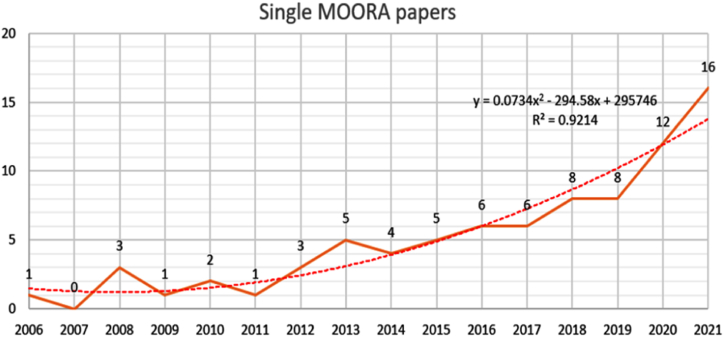

Among various MCDM methods developed and reviewed over the past two decades for solving non-trivial problems, the “multi-objective optimization on the basis of ratio analysis” (MOORA) approach has achieved significant interest in different application domains. The MOORA method utilized dimensionless square root ratios for ranking the alternatives and was initially applied to privatization problems in a transition economy [34]. Subsequently, the MOORA method has been used for many real-world situations. It has expanded significantly among practitioners, decision-makers and researchers, which the authors intend to summarize in this review paper. To date, no literature review is available covering MOORA methodology, its fuzzy interactions, and applications. To this end, this paper presents a comprehensive review and creates a reference repository for MOORA methodology, its hybridization, and applications. In addition, the present study will provide a systematic review of previous studies related to MOORA performance under a fuzzy environment. The current work studied different perceptions in reviewing the articles, such as categorizing the articles according to authors, journal name, publication details, origin country, publication year, methodology, application area, considered method extensions, hybridizations, research objectives and research gaps. Based on the classification strategy, 218 scholarly articles have been considered for this review since its inception. The authors hope to provide a structured review that will provide insightful knowledge of previous articles and give practical directions for future research. The rest of the manuscript is structured as follows: section 2 will be focussing on the implementation methodology of MOORA, section 3 discusses the methodology followed for this review, section 4 provides application areas discussion of MOORA method, section 5 discusses other classification scheme of MOORA method while section 6 provides concluding remarks and future research directions.

2. MOORA methodology

The MOORA method was introduced by Brauers and Zavadskas in Ref. [34] as an MCDM/MODM technique for solving complex multi-objective (may be conflicting) privatization problems in transition economies. The MOORA method ranks the available alternatives based on ratio systems in which each alternative performance concerning a criterion is equated to a denominator representing all alternatives relating to that criterion [34,35]. The MOORA method has the following steps during its implementation for ranking the alternative among available options:

Before defining the original steps of MOORA, certain assumptions are made [34]. The first one being the use of cardinal numbers for defining nominal scales for instance excellent, good, fair, and bad. The next assumption concerns the choices of alternatives to be discrete instead of continuous. Finally, the attributes definition must be interrelated to objective description, and both will go together. Let number of available alternatives be designated as and be the number of criteria (objective) denoted as . Now, is the performance rating of alternative related to objective, where and .

Step 1

The first step is defining a decision matrix with a performance rating of available alternatives considering different objectives. The decision matrix will be defined as shown in Eq. (1):

(1)

Step 2

The next step deals with normalizing the above decision matrix. The normalization transforms performance rating to relative terms that come from 0 to 1. This step employs ratio scheme in which each alternative performance on criterion is equated to denominator representing all alternatives concerning that criterion. For choosing the best denominator here, several ratio systems were tested, such as (a) Voogd ratios (Eq. (2)):

(2)

(3)

(4) where and are the maximum and minimum value of objective/criteria .

- (c)

Van delft and Nijkamp ratios (Eq. (5))

(5) where is either maximum or minimum value of depending on requirement.

- (d)

stop ratios (Eq. (6)) for maximization

(6) stop ratios (Eq. (7)) for minimization

(7) However, the best choice selected for denominator is square root of sum of squares of individual alternative/objective [36] as shown as Eq. (8).

(8) where, is denoted as dimensionless number having interval of [0, 1] showing the normalized performances measures of alternative related to objective.

Step 3

This step involves formulation of optimization problem by adding normalized performance measures for maximization (beneficiary objective - benefits) and subtracted for minimization (non-beneficiary objective - cost). The expression can be written as:

(9) Where, the maximization objective/criteria numbers are denoted as and () denotes the number of objectives to be minimized. The term represents normalized evaluation of alternative with respect to all criteria.

Step 4

The MOORA method also suggests providing more weightage to one objective/ criteria in comparison to other criteria, thus, Brauers and Zavadskas [35,36] multiplied individual objective with significance coefficient (). After consideration of , Eq. (9) changes to Eq. (10):

(10) where, the significance coefficient may be determined typically through entropy or ANP or AHP method. The normalized performance measure can be positive or negative depending on summation of beneficiary and non-beneficiary objective value.

Step 5

Finally, the last step has to sort and rank the results of available alternatives depending on the normalized performance measure () values. The highest preference value alternative will be ranked first, while the lowest preference value alternative is least desired.

3. Review methodology followed

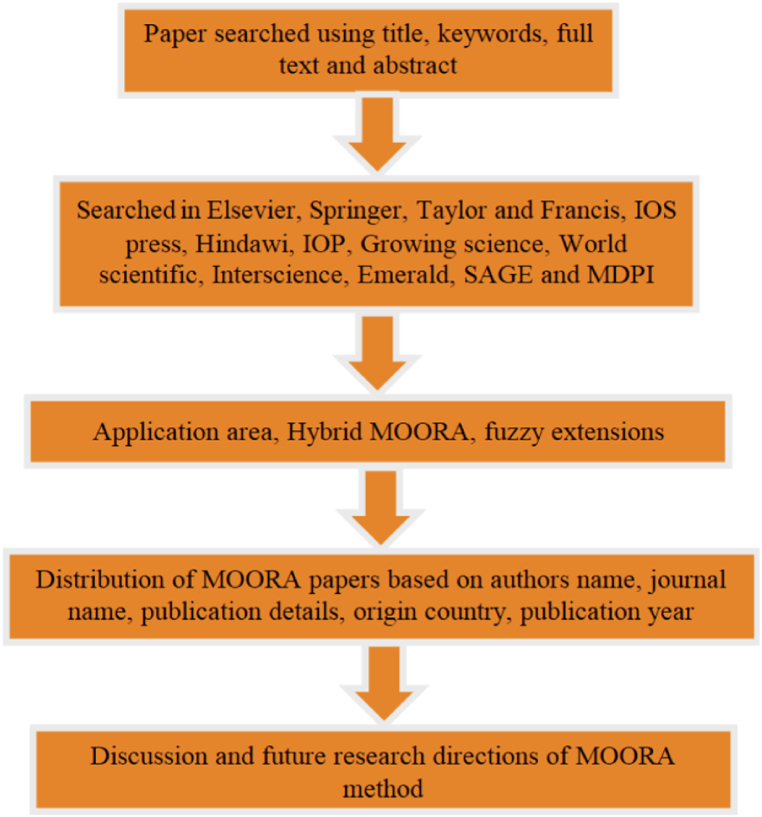

To further educate academics and practitioners working on non-trivial issues utilizing the MOORA approach, the present literature study aimed to investigate papers from reputable journals. Fig. 1 displays the results of the well-thought-out review technique developed with this in mind. Finding publications that use MOORA methodologies and analyzing their titles, abstracts, keywords, and full texts are all part of the review approach. The term "MOORA" was searched in several reputable databases, including those belonging to Elsevier, Springer, Taylor & Francis, IOS press, Hindawi, IOP, Growing Science, World Scientific, Interscience, Emerald, SAGE, MDPI, and many more. This review aimed to improve its quality by excluding publications on MOORA approaches that were already published or could be found in books, theses, or unpublished research. After initial checking and selection through searching the titles, abstract, keywords and full text, 976 papers from 2006 to 2021 were identified as potentially relevant papers on the MOORA method. The first paper on the MOORA method was published in 2006 by Brauers and Zavadskas and that's why 2006 was considered the starting date of the search. Furthermore, a paper is included in this review if it discusses the MOORA methodology, its hybridization, and fuzzy developments or if it is applied to an application or performance comparison with other MCDM methods. Of 976 initial MOORA papers, we excluded 819 papers that fell outside the above-mentioned criteria of selection, thus choosing 157 MOORA papers for this review. These selected articles are further examined, categorized, and recorded in excel under a classification system as author, author country, year of publication, journal name, application area, hybridization or single, fuzzy sets type, general focus of study, etc. While the current MOORA review is not comprehensive, it does encompass the bulk of journal publications on MOORA techniques and their fuzzy advancements, along with numerous applications. This will provide valuable information to practitioners and academics in decision making areas.

Fig. 1.

Methodology adopted for MOORA literature review.

4. Application areas

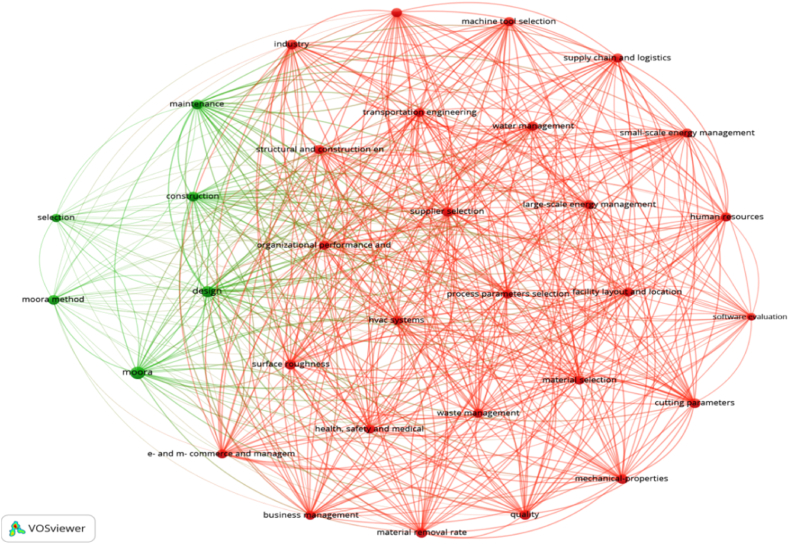

The classification and summarizing of the application areas of selected papers have been challenging, as the MOORA method is utilized in various domains, as shown in Fig. 2. The authors used expert opinion in categorizing applications and sub-domain areas. Therefore, based on experts’ advice, the categorization includes mechanical engineering and manufacturing, structural and construction engineering, supply chain and logistics, business supervision, medical and healthcare systems, environment management, financial management, information technology, and education system.

Fig. 2.

Visualizing MOORA decision-making in several contexts.

4.1. Mechanical engineering and manufacturing

For meeting the challenges of changing environments, industries are facing an uphill task in appropriate selection of manufacturing processes, machine tools, process parameters, product designs. To this end, researchers have utilized MOORA method to aid the decision makers and industrialists in the field of mechanical engineering and manufacturing applications involving machine tool selection, material selection and product development as sub-application areas for enhancing their decision-making capabilities and appropriate selection of machine, material, and tools. The different sub-application areas in the mechanical engineering and manufacturing field are categorized as process parameters selection (20 papers), material selection (17 papers), machine tool selection (9 papers), and others in different fields of mechanical engineering (4 papers).

4.1.1. Machine tool selection

Chakraborty [37], in their study, applied the MOORA method to six different examples of real-time manufacturing environments involving robot selection, machine tool selection, non-traditional machine process selection, rapid prototyping process selection, inspection system selection and FMS selection. The results prove that the method is computationally cheap with comparable results and robust in solving complex decision-making problems. Sarkar et al. [38] applied the MOORA and MOOSRA methods for ranking and selecting the best non-traditional machine in the NIT Agartala workshop considering quantitative and qualitative machining parameters. Similarly, Madic et al. [39] applied MOORA to select non-traditional machining among four available processes and provided a perfect correlation in results with the TOPSIS method. Zaied et al. [40] combined the advantage of the neutrosophic set concept with the MOORA method for evaluating and selecting a CNC vertical machining center and considering the incomplete and subjective attributes. Similarly, Attri and Grover [41] applied the MOORA methodology for optimal decision-making at different stages in the production life cycle considering, product design selection, layout selection, FMS selection, welding process selection and supplier selection. Stanujkic et al. [42] proposed a decision model using the MOORA method for optimal grinding circuit design selection for the processing of ore particles in the mining industry. Pérez-Domínguez et al. [43] proposed hybridising the Pythagorean fuzzy set and MOORA method for handling vagueness and incompleteness in real-life decision-making problems. The proposed hybrid MOORA method solved the tool selection problem and provided results comparable to the fuzzy TOPSIS method. Mathew and Sahu [44] performed a comparative study to select adequate material handling systems using CODAS, EDAS, WASPAS, and MOORA methods. The correlation of all the techniques was comparable in selecting the conveyor system. Ertuğrul and Öztaş [45] determined the best sewing machine using the MOORA method, considering essential criteria such as price, energy consumption, speed, etc., to enhance global market competitiveness. The MOORA method was employed to select the best sewing machine, and a comparison was performed with the TOPSIS method to prove its applicability.

4.1.2. Process parameters selection

Gadakh et al. [46] selected the optimal set of welding process parameters for six different welding problems using the MOORA method, considering other performance attributes. The MOORA results are comparable with past literature results, confirming the efficacy and flexibility of the MOORA method in solving different complex natural problems. Singaravel et al. [47] have optimized the machining parameters while turning EN25 steel workpieces by integrating entropy and the MOORA method. The entropy-MOORA method provides optimal machining parameters for maximizing material removal rate (MRR) and minimizing surface roughness, which is finally validated by experimental results. Tansel and Yildrim [48] applied a MOORA-based Taguchi approach for evaluating and selecting the best washing machine system considering finite parameters. The proposed MOORA-Taguchi method provides optimal results compared to TOPSIS, VIKOR and GRA methods with less calculation time. In his study, Jain [49] combined the PSI and MOORA methods for ranking flexible manufacturing systems, considering productivity, quality, and flexibility as three critical parameters to be ranked. From this hybrid method, he found productivity to be the most vital factor in enhancing flexible manufacturing systems. Saha and Mondal [50] combine principal component analysis (PCA) with the MOORA method to select optimal process parameters for the metal arc welding process. Asjad and Talib [51] applied GRA, TOPSIS and MOORA methods with PCA to realize optimal CNC machining parameters.

Majumdar and Maity [52] coupled PCA with the MOORA approach during the EDM of titanium alloys for optimizing the response of average cutting speed, surface roughness, and Kerf width. Paul et al. [53] combined the PCA-MOORA hybrid method for optimizing EDM parameters during the machining of the Inconel 800 workpiece. The results are compared with the primary MOORA method and confirmed that the hybrid PCA-MOORA approach provides more accurate results. Similarly, Majumdar and Saha [54] applied MOORA-PCA to determine optimal turning parameters during machining ASTM A588 mild steel workpieces, and the results of the MOORA-PCA method outperformed the TOPSIS-PCA comprehensively. Similarly, Majumdar and Maity [55] applied fuzzy MOORA to determine optimal WEDM process conditions; Patahapalli et al. [56] utilized the WASPAS and MOORA method for improving machining efficiency by selecting suitable process parameters. Kuriakose et al. [57] used the MOORA method to realize optimal process conditions, i.e., feed rate values, abrasive grit size, and slurry concentration, during ultrasonic machining of metallic glass. Modanloo et al. [58] applied the MOORA and TOPSIS methods to attain optimal sheet hydro-forming process conditions while using AHP and entropy weights to determine criteria weights. Lukic et al. [59] benefitted from applying 14 MCDM techniques in multi-response optimization during high-speed thin-walled aluminium alloy component machining. The results recommended that MOORA is among five MCDM methods providing optimal process conditions among available techniques.

Reddy et al. [60] applied MOORA and WASPAS in multi-response optimization during abrasive water jet machining of an Inconel 625 workpiece. Both techniques provided comparable results and were validated by experiments. Kalirasu et al. [61] employed the MOORA method to study the effect of abrasive water jet machining parameters during the machining of jute/polyester composite samples. The results conclude that the MOORA model is in complete agreement with developed analytical models. Lee et al. [62] determined optimal injection moulding process conditions using the MOORA method among 16 alternatives for producing nanocomposite foams with higher structural and mechanical properties. Shihab and colleagues [63] assessed the gas metal arc welding parameters using the conventional MOORA technique. The researchers discovered that the current and voltage parameters most significantly influence the final quality of welding. Wankhede and Hole [64] used the MOORA and TOPSIS methodologies to ascertain the most favourable input parameters for vapour absorption refrigeration systems. The MCDM techniques confirm the best solution as 40 W input power followed by 60 W and 70 W power systems. Abhang et al. [65] optimized the machining parameters using the MOORA method by minimizing chip-tool interface temperature and tool wear rate. The results are compared with the GRA method, which showed the applicability and flexibility of the MOORA method in optimizing machining parameters effectively.

4.1.3. Material selection

Selection of the best material among a set of available materials has always been critical and challenging. The problem is complex and involves multiple criteria that may be beneficial or non-beneficial, such as cost, availability, strength, and processing [[66], [67], [68]]. In the same context, among available alternatives, Emovon et al. [69] proposed a fuzzy MOORA method for selecting the best shaft material for a hammering machine. The study recommended using alloy steel for the shaft to achieve maximum efficiency. Fuzzy VIKOR, fuzzy TOPSIS, and fuzzy GRA methods also validated the results. Mahale et al. [70] ranked eight friction materials using the MOORA method, considering ratio analysis and using the reference point approach individually. The results are also compared with the extension evaluation method, revealing that the MOORA method has more simplicity and flexibility and takes less time to rank friction materials considering conflicting criteria. Karande and Chakraborty [71] selected four material selection problems to solve using three MOORA method versions. The results are compared with different MCDM techniques, and MOORA results follow other techniques with any number of decision criteria and alternatives. Yazdani et al. [72] disclosed the application of WASPAS and MOORA methods to solve hard magnetic material selection problems and rank the alternate materials. The sensitivity analysis was also employed to neglect the effect of normalization and check the robustness of the methods.

Sen et al. [73] compared some typical MCDM methods, such as COPRAS, MOORA, TOPSIS, VIKOR, and ARAS methods, for solving the material selection problem of connecting rods. Moradian et al. [74] applied MOORA, TOPSIS, and VIKOR methods to select the best brake booster valve body material, considering different criteria. The three MCDM techniques selected 35 wt% glass fiber-filled PET as the optimal material for the braking system with the agreement of the Spearman correlation coefficient. Raju et al. [75] applied AHP-MOORA and AHP-TOPSIS methods for evaluating and ranking the aluminium-coconut shell ash composite samples, considering different physical, mechanical, and tribological properties. Sofuoğlu [76] developed new decision-making models using the ITARA, TOPSIS, VIKOR, and MOORA methods. ITARA will be used to determine the criteria's weights and successfully applied to two material selection problems, showing consistent results with the literature. Hasanzadeh et al. [77] applied an integrated methodology of AHP-TOPSIS and AHP-MOORA for selecting the material of automotive bumper beams where AHP and entropy methods are used for determining weights. Chawla and Singari [78] applied novel integration of the TOPSIS-PROMETHEE-MOORA methodology for material selection among six aluminium alloys, considering seven performance criteria for the case of crankcase cover. In his study, Agarwal [79] applied four MCDM technologies involving SAW, MOORA, TOPSIS, and VIKOR to select the best material for four additive manufacturing technologies. The author also emphasized the rank reversal problem associated with MCDM methods and provided three materials suitable to support cleaner additive manufacturing production.

Hafezalkotob and Hafezalkotob [80] applied the hybrid fuzzy entropy-based multiplicative MOORA method to solve the material selection problem in the automotive industry. Compared with past literature, the proposed hybrid method provided comparable results supported by sensitivity analysis. Ranjith and Kumar [81] reached the MOORA and ELECTRE method results on two material selection problems, one for EDM tool material and the second best composited with enhanced tribological properties. The results are comparable, and the techniques suit design and product optimization. Zindani et al. [82] selected the optimal material for leaf spring in automotive applications considering different physicomechanical properties using multiplicative aggregation rule combining VIKOR, TODIM, PROMETHEE, and MOORA methods. The hybrid method was found to be rational and provides accurate results. Soni et al. [83] utilized the AHP-MOORA method to select the best composition of floor tiles made of waste plastic and sand, considering optimal physicomechanical and tribological properties. The AHP-MOORA method provides 50 % of high-density polyethylene and 50 % of sand as optimal composition with maximum strength and less water absorption capacity. By considering tribological properties, Singh [84] used the MOORA approach to choose the best brake friction material, which consisted of waste cement dust. Prabhakar et al. [85] used an integrated approach of MOORA-ELECTRE for selecting the best tool material during the machining of titanium alloy orthopaedic implants.

4.1.4. Other mechanical, manufacturing applications

This section's prime focus is papers related to robot selection and failure analysis that should be included in the above three sections. Ghoushchi et al. [86] introduced hybrid MCDM methods, such as the Z-number theory-based SWARA and MOORA methods, for solving complex failure mode and effect analysis problems. The uncertainty in failure analysis was dealt with through hybridizing these methods, where Z-SWARA takes care of weight assessment. At the same time, the Z-MOORA method performed the ranking, thus helping the decision-makers prioritize the failure and evaluate its significance accordingly. Sindhwani and Malhotra [87] provided a decision strategy integrating entropy, MOORA, and VIKOR methods for agile manufacturing system criteria weightage and their ranking facilitators for practical implementation in the industries. Rashahmadi et al. [88] enhance the properties of poly methyl methacrylate reinforcing TiO2, SiO2, and Al2O3 for dental applications by applying different MCDM techniques such as MOORA, VIKOR, and entropy. The study concluded that all MCDM methods provided TiO2 reinforcement as the best PMMA material for enhancing mechanical properties. Karande et al. [89] performed a selection of industrial robots in two problems using the six most popular MCDM techniques, of which the MOORA method is the most robust among all MCDM techniques.

4.2. Structural, construction and transportation engineering

This domain area is further classified as structural and construction engineering and transportation engineering, covering the important papers considering MOORA methodology, its fuzzy extensions.

4.2.1. Structural and construction engineering

In this sub-application construction domain, contractor selection has been an imperative task from the client's perspective and essential for the maintenance and facility management of any building. To this end, Brauers et al. [90] utilized the MOORA method for evaluating and ranking the contractor based on their objective and subjective criteria. Özşahin et al. [91] presented a hybrid approach of AHP-MOORA for selecting softwood timber for structural and non-structural applications. Brauers and Zavadskas [92] used two versions of MOORA methods to evaluate fifteen contractors' work, considering nine performance attributes in the facility sector. The results prove the robustness of the applied methods. Erkayman and Özkal [93] applied hybrid fuzzy AHP- fuzzy MOORA to assign relative significance to criteria weights and evaluate different framed building type's construction techniques. Kalibatas and Turskis [94] employed the MOORA technique for assessing the building's inner climate, considering humidity, air temperature, dew point, air flow rate, etc., as essential criteria. The best internal environment shall be insightful in determining the market value of individual flats or apartments. Zavadskas et al. [95] performed a comparative analysis of four different MCDM methods, i.e., WSM, WPM, WASPAS, and MOORA, for selecting the best facade alternative for public or commercial buildings.

Latif et al. [96] used the MOORA method to choose the best soil reinforcement to enhance the soil foundation for building construction, considering both qualitative and quantitative criteria. Kracka and Zavadskas [97] adopted MOORA and MULTIMOORA methods in the evaluation and improved the selection of building elements for renovation and energy saving. Serugga et al. [98] evaluated the front design of social housing buildings, integrating utility theory and QFD with MOORA and COPRAS methodology. The integrated decision framework effectively solves the social housing design problem, considering interdependencies between design and user performance criteria. Lazauskas et al. [99] determined the best city for construction business considering finite descriptive criteria using MOORA and MULTIMOORA methods. Kracka et al. [100] applied the MCDM methodology, considering the MOORA method for effectively selecting windows and external walls among six alternatives for the best building design. Lazauskas et al. [101] presented a computing model for evaluating essential criteria for completing unfinished construction projects. In this context, the AHP method was utilized to weigh different criteria, and ARAS, MOORA, and MULTIMORA were employed to assess and rank various alternatives. Ilce and Ozkaya [102] applied AHP and fuzzy MOORA to select the best-raised floor panels to be used in the construction industry after evaluating significant criteria. Bozanic et al. [103] applied five different MCDM techniques and a neuro-fuzzy system for assessing and selecting a construction machine (loader), considering construction characteristics as the basis of the loader selection.

4.2.2. Transportation engineering

Bhandari and Nalmpantis [104] compared three MCDM techniques, i.e., MOORA, TOPSIS, and PROMETHEE, to select and evaluate the best rural road projects in Nepal, considering the weight determined using the AHP method. Brauers et al. [105] presented research based on the MOORA method for evaluating different road design alternatives for highway construction and ranking them, considering longer-run construction price, environment protection, and economic validity as performance attributes. Moslem and Çelikbilek [106], in their study, applied the grey AHP-MOORA method for evaluating and providing the best guidance for improving the public transport system. The transport specialist's recommendation was considered while allocating relative weights to specific criteria. Dinçer et al. [107] presented a practical approach integrating fuzzy DEMATEL, fuzzy ANP, and MOORA methods for evaluating the performance of European airlines. Chawla et al. [108] considered the problem of bike selection in the Indian automobile industry by combining TOPSIS and MOORA methods considering ten different attributes. Stoilova [109] compared six MCDM techniques for evaluating and selecting optimal railway passenger trains in Bulgarian railway systems considering additional essential characteristics. Hamurcu and Tamer [110] applied a hybrid MCDM methodology utilizing AHP to determine criteria weights. To analyze and choose sustainable traffic monitoring systems for efficient road traffic management, VIKOR, TOPSIS, and MOORA approaches were also used. In their study, Patil and Majumdar [111] applied multiple MCDM methods involving TOPSIS, MOORA, WASPAS, and RIM to determine essential performance attributes for two-wheeler usage in the Indian road industry. The MCDM methodology results provide recommendations for the electric two-wheeler industry to improve the sustainability of two-wheelers. The MCDM methodology results provide recommendations for the electric two-wheeler industry for improving the sustainability of two-wheelers. Mete [112], in his study, proposed a hybrid FMEA-AHP MOORA methodology for evaluating the concrete coating process in a gas pipeline construction project under a Pythagorean fuzzy environment. Table 2 shows the summary of research papers applying MOORA and other MCDM techniques in the application area of structural, construction, and transportation engineering. Fig. 3 shows the use of the MOORA basic version, its extension, standard hybridization and fuzzy hybridization in solving problems related to structural, construction, and transportation engineering.

Table 2.

MOORA papers in structural, construction and transportation engineering.

| Ref. | Year | Application/Sub application | Techniques | Type of MCDM |

|---|---|---|---|---|

| [90] | 2008 | Best contractor selection | MOORA | Classical |

| [91] | 2019 | Softwood timber selection | AHP-MOORA | Hybridization |

| [92] | 2009 | Best contractor selection | Two variants of MOORA | Extension |

| [93] | 2016 | Evaluation of framed building types and selection | Fuzzy AHP- Fuzzy MOORA | Fuzzy Hybridization |

| [94] | 2008 | Evaluation of inner climate of building | MOORA | Classical |

| [95] | 2013 | Selection of best facades' alternative | WSM, WPM, WASPAS, MOORA | Classical |

| [96] | 2017 | Selection of best soil reinforcement for enhancing the soil foundation for building construction | Two variants of MOORA | Extension |

| [97] | 2013 | Selection of building elements for renovation and energy saving | MOORA, MULTIMOORA | Classical |

| [98] | 2020 | Evaluated the front design of social housing buildings | Utility theory, QFD with MOORA and COPRAS | Hybridization |

| [99] | 2015 | Determined best city for construction business | MOORA, MULTIMOORA | Classical |

| [100] | 2010 | Selection of windows and external walls for best building design | MOORA | Classical |

| [101] | 2015 | Evaluation of important criteria relevant to complete the unfinished construction projects | AHP-MOORA, ARAS, MULTIMOORA | Hybridization |

| [102] | 2018 | Selecting best raised floor panels for construction industry | AHP-fuzzy MOORA | Fuzzy Hybridization |

| [103] | 2021 | Selecting best construction machine (loader) | LMAW, VIKOR TOPSIS, MOORA, SAW combined with neuro-fuzzy | Hybridization |

| [104] | 2018 | Evaluation of best rural road projects in Nepal | AHP- MOORA, TOPSIS, PROMETHEE | Hybridization |

| [105] | 2008 | Evaluating best road design for highway construction | MOORA | Classical |

| [106] | 2020 | Evaluation on best public transport system | Grey AHP-MOORA | Hybridization |

| [107] | 2017 | Ranking and evaluation of European airlines | fuzzy DEMATEL, fuzzy ANP and MOORA | Fuzzy Hybridization |

| [108] | 2019 | Bike selection in Indian automobile industry | TOPSIS-MOORA | Hybridization |

| [109] | 2021 | Selection of optimal railway passenger trains in Bulgaria | TOPSIS, EDAS, MOORA, COPRAS, PROMETHEE | Classical |

| [110] | 2021 | Selection of sustainable traffic monitoring tools for effective management of road traffic | AHP-VIKOR, TOPSIS, MOORA | Hybridization |

| [111] | 2021 | Determined relevant performance attributes for two-wheeler usage in Indian road industry | TOPSIS, MOORA, WASPAS, RIM | Classical |

| [112] | 2019 | Evaluating coating process in pipeline construction project | Pythagorean fuzzy AHP-MOORA | Fuzzy Hybridization |

Fig. 3.

Percentage of structural, construction and transportation engineering papers utilizing classical MOORA, extension of MOORA and hybridized MOORA.

4.3. Supply chain and logistics

Supply chain management and logistics have been essential areas of research considering the MOORA method. The sub-application fields are divided into three classes: supplier selection (16 papers), facility layout and placement (12 papers), and other supply chain management and logistics applications (8 papers).

4.3.1. Facility layout and location

The sub-application domains of facility layout and location problems were considered by several researchers applying MCDM techniques. Attri and Grover [41] used the MOORA approach. They compared it with other methods in the literature for optimal decision-making in several problems of the product life cycle in which facility layout selection was one of the intricate problems. Gorener et al. [113] considered a problem concerning the location of the bank branch and selected the best location, considering different commercial issues utilizing the hybrid AHP and MOORA approach. Brauers [114] identified and solved a specific project location problem considering criteria concerning various stakeholders. The study involves the use of two different variants of MOORA methodology and integration with input-output tables for determining the best project location. Chakraborty et al. [115] presented an evaluation and selection of facility layout and location problems employing AHP to provide relative importance to criteria. Four different MCDM approaches, i.e., GRA, MOORA, ELECTRE II, and OCRA, were utilized to rank and evaluate optimal facility location while the results were statistically validated. Ray et al. [116] performed a comparative evaluation of various MCDM methods-for solving and choosing the best factory or service facility location. This work employed SAW, TOPSIS, GRA, MOORA, and ELECTRE-I methods for optimal location selection in the manufacturing sector. Hamzaçebi et al. [117] applied a practical MOORA approach for optimal logistics location in the black sea region for improved facilitation of logistic centers. Brauers [118] selected the best seaport-facing location considering different factors and indicators using two variants of the MOORA method.

Kabak et al. [119] proposed a GIS-based methodology for evaluating existing and future site bike-share locations. The AHP-MOORA methodology compared and selected optimal bike share site locations considering user-oriented, urban life, and transport network-based criteria. Choukolaei et al. [120] determined Tehran's best relief center location using fuzzy AHP, MOORA, and PROMETHEE methods. Different criteria were weighted using fuzzy aggregated rule combined with AHP for effective location selection while MOORA and PROMETHEE ranked locations. In their study, Miç and Antmen [121] applied various MCDM methods for selecting the best educational University location to support the youths' socio-economic development. They utilized MOORA, WASPAS, and TOPSIS to evaluate different locations considering several criteria provided by seven experts. Ulutaş et al. [122] compared several MCDM techniques for logistics center location problems, viewing region development, operational efficiency, minimum cost, competitiveness, etc., as the performance attributes. The fuzzy SWARA and CoCoSo methods were compared with VIKOR, ARAS, MOORA, and MABAC techniques, and finally, sensitivity analysis was performed for the robustness of the results. Liu et al. [123] evaluated eleven landfill site locations, and their spatial distribution characteristics and compared five MCDM methods, i.e., DEMATEL, WASPAS, MOORA, COPRAS, and TOPSIS for ranking sites. At the same time, criteria weights were provided by the fuzzy ANP technique.

4.3.2. Supplier selection

Arabsheybani et al. [124] employed the fuzzy MOORA technique for evaluating a supplier's overall performance, considering the risk to the supplier. The proposed method was validated by considering the application of an evaporative cooler in the home appliance industry for enhancing profit and minimizing risk. Karande and Chakraborty [125] applied three different variants of MOORA methodology (classical, reference point approach, and full multiplicative form) for optimal supplier selection from finite available suppliers, considering their strengths and weaknesses for enhancing the productivity and competitiveness of the organization. To enhance the effectiveness of the MOORA method, Pérez-Domínguez et al. [126] proposed an intuitionistic fuzzy MOORA method for selecting the best supplier considering multiple attributes in an uncertain and vague environment. Bera et al. [127] recently developed two new MCDM techniques for supplier selection problems in real-life scenarios. The two MCDM methods involve TOPSIS and MOORA methods in interval type-2 fuzzy environments for handling uncertain objective and subjective factors in efficient supplier selection. Sensitivity analysis was used to verify the robustness of the suggested methodologies, and the findings were confirmed from the literature. Matawale et al. [128] applied two fuzzy MCDM methods (fuzzy TOPSIS and fuzzy MOORA) in a turbulent business environment for supplier selection problems in an agile supply chain. The results are compared and validated with other fuzzy MCDM methods in the literature on supplier selection. Ulutaş et al. [129] proposed a hybrid MCDM method combining MOORA, MOOSRA, and MULTIMOORA techniques to improve selection efficacy in a turbulent environment. The hybrid method was improved by merging weighted sum and product techniques with logarithmic approximation. The suggested improved hybrid approach effectively solved the supplier selection issue.

Dey et al. [130] applied the fuzzy MOORA method to solve three supplier selection problems, and the results proved the effectiveness of this method in the supply chain. Arslankaya and Çelik [131] used the hybrid fuzzy AHP-fuzzy MOORA method to choose the best steel door-producing supplier. The fuzzy AHP provides criteria weights, while the fuzzy MOORA provides the ranking. Yazdani et al. [132] proposed a model combining quality function deployment (QFD) with different MCDM techniques to establish a relationship between selection criteria and customer requirements for solving supplier selection problems. The authors utilized DEMATEL to realize the connection through a cause-and-effect diagram. The COPRAS and MOORA methods were employed to select suppliers to ensure good process and product quality. Similarly, Tavana et al. [133] proposed the ANP-QFD model for acceptance criteria based on sustainable factors and providing appropriate weights to criteria. Further, WASPAS, COPRAS, and MOORA methods are utilized to rank the available suppliers based on different criteria. Silva et al. [134] used dimensional analysis with the Pythagorean fuzzy technique to pick suppliers in an uncertain setting by evaluating criteria and alternatives. Finally, a comparative study of Pythagorean fuzzy MOORA and TOPSIS methods was performed to rank the suppliers’ options. Khoiry et al. [135] proposed a decision-making framework integrating fuzzy-AHP and MOORA methods for good vendor selection. The results were validated by sensitivity analysis and confirmed the robustness of the hybrid approach.

Liou et al. [136] combined the random forest algorithm with DEMATEL and MOORA techniques for selecting and improving green supplier selection. The random forest algorithm establishes an interrelation among various attributes, while DEMATEL and ANP determine the criteria weights, and MOORA was used to evaluate and sort different green suppliers. Sen et al. [137] performed a comparative study among three MCDM techniques, i.e., GRA, TOPSIS, and MOORA, integrating under intuitionistic fuzzy settings for supplier selection considering environmental, economic and sustainability issues. Champatiray et al. [138] applied the weighted MOORA method to solving typical supplier selection problems. Uzan [139] applied ARAS and MOORA methods to solve supplier selection problems for an airline company. The data was analyzed using the “Saaty” scale, and weights for different criteria were evaluated by the DEMATEL method.

4.3.3. Other supply chain management and logistics applications papers

Chand et al. [140] identified the best supply chain for improving environmental and economic performance, providing a better product life cycle integrating ANP-MOORA, considering different issues and sub-issues. Mavi et al. [141] proposed a hybrid MCDM model for evaluating and selecting the best third-party reverse logistic provider (3PRLP), considering various risk factors and sustainability issues. The hybrid method combines fuzzy SWARA and fuzzy MOORA methods for criteria weights and ranking the 3PRLP in the plastic industry. Kocaoğlu and Küçük [142] evaluated the reverse logistics performance of six pharmaceutical sectors in Turkey, taking into consideration eight critical criteria. The MOORA and TOPSIS methods were considered adequate MCDM techniques for ranking the drug-producing companies for enhancing customer reach and being economically sustainable. Dey et al. [143] proposed multi-objective performance analysis (MOPA) for solving different supply chain problems and compared the results with SAW, TOPSIS, MOORA, and VIKOR for practical evaluation. Zarbakhshnia et al. [144] proposed a new hybrid MCDM method combining grey MOORA with fuzzy AHP to address concerns with uncertain and qualitative inputs. The proposed hybrid method solved the 3PRLPs problem for the car manufacturing industry and produced viable results in a vague and uncertain environment.

Sahu et al. [145] estimated the performance of the supply chain by combining the grey theory concept with the MOORA method. The grey-MOORA method benchmarked different supply chains considering subjective and metric issues. Chand et al. [146] proposed an MCDM framework for analyzing risk assessment in supply chain problems by combining ANP for assigning criteria weight with the MOORA method for evaluating the risk related to supply chain partners. Haiyun et al. [147] analyzed and assessed various innovative approaches in each stage of QFD, considering an energy company's supply chain management operations. A hybrid model combining interval-valued intuitionistic fuzzy DEMATEL and MOORA methods was used to evaluate the criteria and sort the alternatives concerning maximum profit and sustainability.

4.4. Business management

Business management domains have been one of the popular application areas employing MOORA and their fuzzy extensions. The sub-application areas are categorized as organizational performance and benchmarking (16 papers), human resources (8 papers), and other business management papers (5 papers).

4.4.1. Organizational performance and benchmarking

Majumdar and Adhikari [148] developed an integrated MCDM model to evaluate distinct factors affecting the performance of the tourism industry. Different performance attributes were assigned weights using entropy and CRTIC methods, while the TOPSIS-MOORA methodology was utilized for the performance evaluation of super hosts using data from Airbnb. Özbek [149] evaluated the efficiency of nine foreign banks considering different MCDM methods, i.e., OCRA, SAW, and MOORA, for enhancing operational competitiveness and realizing the objectives of investors and customers. Ic [150] developed a credit evaluation model for analyzing different firms' credit decision-making using hybrid MOORA and goal programming methods. Varmazyar et al. [151] in their study integrated a balanced scorecard tool with various MCDM methods for analyzing and evaluating business performance. The weights for different criteria were determined using ANP and DEMATEL methods, while ARAS, MOORA, COPRAS, and TOPSIS were employed to rank the alternatives. Yüksel et al. [152] evaluated the financial performance of Turkish state, private and foreign banks using the integrated methodology of DEMATEL-GRA and DEMATEL-MOORA. The criteria interrelation was established using a text mining process while integrated methods provided rankings, thus showing better performance of foreign banks than others. Dinçer et al. [153] also compared and analyzed distinct Turkish bank performance using fuzzy ANP and MOORA techniques.

Furthermore, Dinçer et al. [154] proposed a hybrid interval type-2 DEMATEL-ANP and MOORA method for evaluating the performance of financial services in seven developing countries. The work was validated using sensitivity analysis and recommended various actions to be taken by governments to enhance the economic systems. Singh et al. [155] evaluated third-party logistics providers' operational and financial aspects of improving customer service quality. Further, applying COPRAS and MOORA methods in evaluating logistics providers was realized while considering the essential attributes. Küçükbay and Sürücü [156] performed sustainable performance analysis for different corporate firms using the MOORA method, and the results were validated by employing dependency, institutional theory, and stakeholder theory. Gavalas et al. [157] performed a comparative analysis of three MCDM methods under a fuzzy environment, i.e., fuzzy DEMATEL, fuzzy MOORA, and fuzzy ANP, for assessing essential performance indicators in the shipbuilding industry considering economic, growth, and customer aspects. Dinçer et al. [158] applied a hybrid method combining interval type-2 fuzzy set with ANP-DEMATEL and MOORA method for evaluating the performance of emerging industries for enhancing the selection capability of external investors for new industries.

Ozcalici and Bumin [159] performed a performance analysis of publicly traded banks in Turkey for 2018 considering the integration of MCDM methods, i.e., MOORA, OCRA, EDAS, and TOPSIS, with a million-weight combination set. Sama et al. [160] applied ARAS and MOORA methods to evaluate India's private banking sector's performance. Singh [161] solved three particular benchmarking problems in Indian service industries considering the wide range of criteria used in the MOORA method, thus helping the executives quickly realize benchmarking. Sahu et al. [162] applied grey MOORA for performance assessment and benchmarking of supply chain services. Integrating grey theory and the MOORA method proved beneficial in handling vague, incomplete, and subjective attributes, finally aiding in supply chain benchmarking. Singh et al. [163] ranked different benchmarking techniques considering a hybrid ANP-TOPSIS-MOORA methodology for Indian service industries.

4.4.2. Human resources

Cetin and Icigen [164] used an integrated SWARA-MOORA method for the manager selection problem of a 5-star accommodation enterprise, considering objective and subjective criteria and realizing the decision-making process as more rational. Çelikbilek [165] selected human resources personnel in the health industry using the grey-AHP-MOORA method. The grey concept is essential in adequately determining alternatives, considering subjective judgments and bias in personal decisions. Mohamed and Ahmed [166] proposed hybridizing the MOORA method with standard deviation weight to solve the personnel selection problem effectively. Abdel-Basset et al. [167] proposed a novel neutrosophic method integrating MCDM techniques for selecting a chief executive officer. The study compared WSM, WPM, AHP, MOORA, and ANP techniques with the proposed framework for validating results. Sinaga et al. [168] applied the MOORA methodology for selecting the best employee by considering five criteria. Karpen et al. [169] decided on the most competent employee in the hotel industry, considering more than ten criteria (height, discipline, written tests, computer, etc.) using the MOORA method. Bos and Chatterjee [170] selected the service technicians for wind turbines integrating ARAS and MOORA under a fuzzy environment, considering five critical criteria. Cheng et al. [171] proposed a hybrid MCDM methodology combining DEMATEL and MOORA-AS methods to evaluate newly graduated nurses' performance.

4.4.3. Other business management papers

The researchers have employed MOORA for critical decisions concerning investments related to the analysis and evaluation of business organizations. Dong et al. [172] proposed a hybrid hesitant interval-valued intuitionistic fuzzy DEMATEL method for evaluating the factors affecting investment strategies in wind energy. Further, hesitant interval-valued intuitionistic fuzzy MOORA was employed to choose the best investment strategies and compared with TOPSIS method results. Dinçer and Yüksel [173] evaluated and selected the investment strategies using interval type-2 fuzzy DEMATEL to weigh the criteria and interval type-2 fuzzy MOORA to rank and choose the best investment strategy in the European tourism industry. Akhavan et al. [174] evaluated and selected a practical and strategic alliance business partner using SWOT analysis. A fuzzy quantitative planning matrix provided the relative importance of individual criteria. Different business partners were ranked using Fuzzy ARAS, fuzzy COPRAS, fuzzy MOORA, and fuzzy TOPSIS methods. Edoardo and Lucio [175] studied different criteria to preserve financial stability during a liquidity crisis and developed a liquidity cascade model applicable to various credit networks. The best option was selected using the MOORA method for improving regulators' decision-making. Cresensia and Simanjorang [176] developed a product marketing strategy for a company considering objective and subjective criteria employing the MOORA method to sustain itself in a competitive environment over other competitors.

4.5. Natural resources and environmental management

There are 17 papers that address specific applications within the larger scope of environmental and resource management. Five papers deal with trash management, seven deals with water management, and the remaining five papers deal with various aspects of natural resource and environmental management.

4.5.1. Waste management

Gomes et al. [177] selected the best adjuvant among four waste materials considering technical, environmental, and economic criteria. They used the CRITIC method for the weight determination of individual criteria while utilizing MOORA and TOPSIS methods to choose the best alternative. Eghtesadifard et al. [178] presented a hybrid GIS-MCDM methodology for selecting the best landfills for solid waste disbursement in the Iranian metropolis. They perform a comparative analysis of MOORA, WASPAS, and COPRAS methods for evaluating 13 criteria and selecting of the best waste disposal site. Liu et al. [179] employed a fuzzy MCDM approach for evaluating and selecting municipal solid waste disposal landfill sites in China. The DEMATEL and ANP techniques provided relative importance to 21 criteria. The fuzzy MOORA, WASPAS, TOPSIS, and COPRAS methods were employed to rank available landfill sites, followed by sensitivity analysis. Narayanamoorthy et al. [180] proposed a novel extension of MOORA, i.e., hesitant fuzzy MOOSRA, and subjective and objective weight integrated approach (SOWIA) for biomedical waste management and its disposal. All the available alternatives concerning health and hygiene were evaluated, considering the MCDM method that chooses autoclaving as the best alternative. Pirbasti et al. [181] selected a location for hospital waste disposal using hybrid fuzzy SWARA-GIS-MAIRCA techniques, considering a case study in Tehran. The results of fuzzy MAIRCA were compared with MOORA, TOPSIS, and VIKOR methods to validate ranking disposal locations.

4.5.2. Water management

Adar et al. [182] performed a comparative analysis of CoCoSo, TOPSIS, MOORA, and CODAS methods for prioritizing industrial wastewater management and ranking several processes for managing wastewater disposal. In their study, Ghosh and Mukhopadhyay [183] and Arabameri et al. [184] proposed a hybrid MCDM-ensemble-based approach for sub-watershed prioritization. These studies used ARAS, COPRAS, SAW, MOORA, and TOPSIS methods to rank the watersheds. Spearman rank correlation was used to determine the degree of similarity among different MCDM methods. Narayanamoorthy et al. [185] evaluated and selected the best water distribution system in three districts of Tamil Nadu, combining hesitant fuzzy standard deviation with different MCDM methods. The hybrid MOORA, VIKOR, and TOPSIS were utilized for sorting available water distribution systems that will be relevant and significant for enhancing the water level in drought-prone areas. Furthermore, Narayanamoorthy et al. [186] compared hesitant fuzzy CRITIC, MOORA, and VIKOR methods for the application of reclaimed water use based on five essential criteria. The results found that hesitant fuzzy CRITIC and hesitant fuzzy MOORA approaches provided comparable results for ranking the alternatives. Singh et al. [187] proposed hybrid fuzzy MCDM (SWARAS, WSM, MOORA, TOPSIS) models considering an economic, social, technical, and environmental evaluation for selecting the best hydropower plant. Elshaboury et al. [188] applied a genetic and particle swarm optimization algorithm to evaluate optimal solutions for water distribution network problems. Further, the study employed MOORA and TOPSIS methods for ranking near-optimal solutions.

4.5.3. Other papers on natural resources and environmental management

Bahrami et al. [189] assessed and determined areas with high mineral potential using a combined approach of the SWARA and MOORA methodologies, known as the hybrid MCDM method. The SWARA approach established the prospectivity map and assigned weights to the criteria. MOORA was utilized to rank the various layers based on the created overlay map. Feizi et al. [190] applied two hybrid methods incorporating the full consistency method (FUCOM) with MOORA and MOOSRA techniques for exploring and creating potential mineral mapping. The FUCOM provides criteria weights, and FUCOM-MOOSRA outperformed FUCOM-MOORA in exploring skarn iron deposits in Iran. Tende et al. [191] unravel important attributes aiding gold mineralization by combining distance correlation analysis, prediction area plots, and MCDM methods involving TOPSIS, MOORA, and ARAS in the schist belt of Nigeria. Bakhtavar et al. [192] proposed an integrated methodology integrating a fuzzy cognitive map with fuzzy MOORA for prioritizing the shaft production location in underground mines, considering economic and technical criteria, which is validated by the fuzzy TOPSIS method. Sharif et al. [193] proposed a hybrid fuzzy Delphi ANP technique for weight determination of criteria and a fuzzy MOORA method for evaluating an adequate block size in designing and operating the open-pit copper mine, considering important suggestions from mining experts.

4.6. Energy management

This section discusses papers on MOORA and their extensions under energy management criteria while sub-application areas identified as large-scale energy management (11 papers), HVAC systems and small-scale energy management (7 papers) and other papers on energy management (2 papers).

4.6.1. Large-scale energy management

Erdoğan et al. [194] proposed hybrid MCDM models for optimum fuel selection for CI engines to enhance energy efficiency through effective energy management. The authors combined SWARA-MOORA and ANP-MOORA to evaluate the performance of the CI engine under specified speed and loading conditions. Emovon and Nwaoha [195] used combined AHP-MOORA techniques to identify and sort the problems affecting adequate electricity generation in Nigeria. The results were validated, and it was found that AHP-MOORA proves to be an effective tool for prioritizing the challenges in power generation in Nigeria. Sharma et al. [196] used the TOPSIS-MOORA approach to determine the best input parameters for diesel engines with the best biodiesel blend, providing maximum performance and minimum exhaust emissions. Yazdani-Chamzini et al. [197] proposed an MCDM model for selecting optimal renewable energy options in three case studies among available alternatives combining the AHP-COPRAS method. The output of the proposed model is compared with TOPSIS, SAW, MOORA, VIKOR, and ARAS methods for the validation of results. Rubaiee and Yildirim [198] proposed an MCDM model for solving an energy-efficient scheduling complex objectives problem. The authors utilized WSM-CPLEX and multi-objective ACO algorithms for solving objectives and realizing approximate Pareto front solutions. Finally, the MOORA method was also employed to solve and validate the results of minimized energy costs. Anilkumar et al. [199] selected the best phase change material (PCM) for thermal energy storage integrated with solar cooker using TOPSIS, MOORA, and EDAS methods. The weights were determined using CRITIC, AHP, and entropy methods for different criteria. Firoozi and Eghtesadifard [200] integrated MOORA, COPRAS, and WASPAS to select the best support policies considering various risk factors in developing low- or medium-sized solar PV power plants in Iran. The weights for different risk factors were determined using Delphi and ANP methods, and the MCDM model provides efficient insights to policymakers in renewable energy development. Indrajayanthan and Mohanty [201] defined clean energy transition potential among seven significant power-producing states of India, considering 18 critical criteria using MOORA and TOPSIS with weights evaluated by the fuzzy ANP method. The results recommended Gujarat as the best option, while Uttar Pradesh is the least performing under energy transition states. Bhowmik et al. [202] sorted and ranked the green energy sources to determine the best source, combining the advantages of MOOSRA, TOPSIS, and COPRAS methods considering important functioning features. Salameh et al. [203] compared TOPSIS, MOORA, EDAS, and WASPA methods for evaluating and ranking nine hybrid energy systems for specific loading conditions. Yanar and Demir [204], in their study, determined the best practical strategy for minimizing CO2 emissions from the automotive industry. The authors applied the MOORA method for ranking and the AHP method for evaluating and weighing the criteria.

4.6.2. HVAC systems and small-scale energy management

Moldovan and Slowik [205] used the MOORA method and multi-objective binary grey wolf optimization algorithm to predict energy consumption in household appliances. Finally, the datasets from the machine learning repository were used to validate the results compared with other techniques in the literature. Chauhan et al. [206] proposed novel MCDM methods, i.e., SWARA-MOORA and SWARA-WASPAS hybridization, for evaluating and ranking different drying processes for pineapple for reducing energy consumption with maximum retainment of nutrients. Through CFD simulations, Maji et al. [207] investigated the heat transfer performance of adding different geometrical fins and more perforations in heat sinks. The authors employed the MOORA and entropy minimization methods to select the best-perforated fin with minimum pressure loss. Further, Zeeshan et al. [208–2010] applied the MOORA method for evaluating and enhancing the thermal-hydraulic performance of fin and tube heat exchangers. The optimal layout was identified in Ref. [208] by considering three performance assessment criteria. The optimal location and orientation for pairs of rectangular winglets were defined in Ref. [209]. Simultaneously [210], selects the optimal winglet height based on key performance metrics such as Nusselt number and friction factor. Poongavanam et al. [211] performed a comparative study to select optimal refrigerant among fourteen selected refrigerants in automobile air conditioning systems utilizing TOPSIS, EDAS, and MOORA approaches for effectively obeying the environmental protocols.

4.6.3. Other papers on energy management

Sindhwani et al. [212] identified the best sustainable cooking fuel among seven alternatives considering six critical criteria using a combination of entropy, MOORA, and VIKOR approach. The selection of the best cooking fuel will minimize the effect on human health and emissions concerns. Schaefer et al. [213] analyzed and determined the penetration level of industry 4.0 technologies in energy management organizations considering the MOORA method for data evaluation of neural network software. The ranking provides guides to managers for sustainable strategies using MONNA software.

4.7. Health, safety and medical

This section discusses papers applying the MOORA method concerning safety management and medicine selection in the health sector. Dabbagh and Yousefi [214] proposed a hybrid technique combining a fuzzy cognitive map with the MOORA method for analyzing and controlling occupational health and safety risks. The risk assessment criteria were determined using the FMEA technique, while weights were realized using the fuzzy cognitive map. Abdel-Basset et al. [215] proposed an intelligent medical device selection approach under uncertain environments for diabetic patients using the TOPSIS method. The results were validated by comparison with the hybrid AHP-MOORA method and Spearman correlation. Büyüközkan and Göçer [216] proposed a practical approach for selecting smart wearable monitoring devices under uncertain environments using the intuitionistic fuzzy Choquet integral method for cardiac patients. The outcomes were validated by comparing them with TOPSIS, MOORA, COPRAS, VIKOR, and MLUTIMOORA methods, while the Spearman coefficient was utilized to confirm the robustness of the methodology. Dorosti et al. [217] analyzed the failure mode in reducing patient timing in clinics using the FMEA method. The work also ranked eleven failure modes utilizing the triangular fuzzy integrated MOORA method after providing different criteria weights using the best-worst method. Recently, Özkan et al. [218] applied fuzzy AHP-integrated MOORA methodology for analyzing and prioritizing the criteria based on which the selection of COVID-19 patients in the ICU may be performed. Shi et al. [219] evaluated and ranked seven emerging economies on universal health coverage by analyzing eleven criteria using the fuzzy DEMATEL technique. After considering economic and service-based parameters, countries were ranked using the MOORA approach. Results show that Russia has the highest universal health coverage compared to other countries. Kuriakose et al. [220] analyzed the influence of feedstock extrusion factors on extruding enhanced dimensional accuracy and surface-finished multi-lumen tubes using biocompatible material for biomedical applications. The authors used the MOORA and product fingerprint techniques to identify optimal extrusion conditions to improve minute features and enhance multi-lumen tubes.

4.8. Information technology

The distribution of papers for information technology in sub-application areas of software evaluation (7 papers), E− and M-commerce management (4 papers), and some other articles related to information technology (7 papers).

4.8.1. Software evaluation

Siddiqui and Tyagi [221] proposed the fuzzy MOORA technique for selecting the best component software system in three case studies to enhance the overall system's reliability. Karande and Chakraborty [222] applied the MOORA method under a fuzzy environment in selecting an enterprise resource planning system for improving business productivity and efficacy in terms of improved purchasing, inventory control, product planning, and sales capability. Akmaludin et al. [223] selected and evaluated the best object-oriented software app for enhancing industrial progress in the era of the 4th generation. The authors applied the MOORA approach with the price-quality ratio approach for assessing different software apps considering conflicting criteria. Srivastava et al. [224] combined fuzzy MOORA with the AHP technique for selecting the best agile testing scheme under software development to improve product quality and life cycle. The results were based on evaluating six criteria under an uncertain environment, with AHP providing relative weights. Kurnia et al. [225] integrated AHP with MOORA methodology to develop a web-based decision support system for examining the employee's performance by delivering suitable employee ratings during their appraisal. In their work, Kirmizi and Kocaoglu [226] employed TOPSIS and MOORA methods to develop a new tool for enterprise resource management assessment in the form of an eight-step holistic approach.

4.8.2. E− and M − commerce and management

Contreras-Masse et al. [227] applied the PROMETHEE-II approach to choosing the best platform selection in the industrial Internet of Things, considering a relevant set of criteria. The results were compared with TOPSIS and MOORA methods to validate the outcome with the proposed method. Palas et al. [228] presented an enhanced version of the MOORA method by integrating the classical MOORA technique with the modified entropy method with Q-learning for developing an intelligent mobility management system in minimizing the handovers and improving the quality of service for small mobile users. Brodny and Tutak [229] evaluated the level of digital maturity among different central and eastern European countries integrating MOORA, TOPSIS, and VIKOR techniques with the Shannon entropy method (for weight defining) to understand how these countries have enhanced their economic growth considering digital transformation. Mahendra et al. [230] analyzed and selected the best e-commerce in Indonesia, employing hybrid AHP-WASPAS and AHP-MOORA techniques. WASPAS and MOORA took care of the ranking, while the weight for conflicting criteria was given using the AHP method.

4.8.3. Other papers on information technology

Awathankar et al. [231] evaluated, prioritized, and selected trusted channels under a cognitive radio environment, employing the MOORA method's advantages considering the problem's complexity and criteria. The comparison of channel ranking with other methods proves the efficacy and practicality of the MOORA method. Ngemba et al. [232] established a web-based decision support system using the MOORA method integrated with hypertext Pre-processor software to select the best eligible candidates for the health assistance program. Gupta et al. [233] proposed a framework for examining and determining a data distribution strategy considering different criteria, hybridizing AHP-MOORA methods under a weighted normalized fuzzy environment, and considering five alternatives and six criteria. Valipour et al. [234] combined the fuzzy C-means algorithm with a fuzzy best-worst method for prioritizing the risks. Then hybrid MCDM methods were utilized for ranking different risks for further facilitating preventive actions. The MOORA, VIKOR, and TOPSIS methods were used to solve the problem and prioritize the risks in the automotive application. Shah and Kant [235] proposed fuzzy AHP for relative weights to criteria and fuzzy MOORA for prioritizing and analyzing the manufacturing firms involved in knowledge management on four applications for sustainable performance and improvement. In their study, Ak and Gul [236] extended the AHP-TOPSIS methodology under the Pythagorean fuzzy environment for risk analysis involving information security. Further, the results were validated using fuzzy VIKOR, and Fuzzy MOORA method results on the cardboard sector, analyzing the impact of information security. Ohlan [237] determined the degree of divergence among different intuitionistic fuzzy sets through intuitionistic exponential divergence measure, and results were compared with TOPSIS and MOORA methods on the specific application.

4.9. Policy and education management

The researchers have utilized the MOORA method and its fuzzy version in different problems related to policy development related to social issues, education, e-learning, and policies. Brauers et al. [238] applied the MOORA method for evaluating and improving Lithuania's policy construction to fulfil multiple objectives required in social development. Das et al. [239] analyzed the performance of Indian technical institutions and prioritized them using a hybrid MCDM methodology combining MOORA with a subjective and objective weight-integrated approach (SOWIA) method. For this work, six relevant criteria were identified, and a ranking is provided among seven IITs for performance improvement of the Indian higher education system. Özgür et al. [240] examined and reviewed the healthcare policies of eighteen countries considering different health policy indicators comparing COPRAS, MOORA, and TOPSIS methods. The results suggest the best-performing nations, such as Germany and France, while Turkey is at the bottom, requiring improved health policies related to a rare disease.

Das et al. [241] analyzed and ranked different technical institutions in India, considering critical criteria and fuzzy AHP techniques for providing relative significance to various criteria. Further, the MOORA method was applied to rank them and suggest essential recommendations for improvements to meet the challenges of developing economies. Hanifatulqolbi et al. [242] determined the best teacher prioritization based on criteria using the MOORA method in Islamic board schools, which helps provide incentives semester-wise. Yorulmaz and İç [243] developed a decision support system using the MOORA method for determining the program attainment levels by students after completion of their graduation from any engineering program. Sarkar and Biswas [244] applied Pythagorean fuzzy-based MOORA and MULTI-MOORA methods for strategy formulation of the manufacturing organization. Das et al. [245] evaluated and ranked eight technical colleges and Universities in West Bengal using the MOORA method with simple ratio analysis. In contrast, the AHP method under a fuzzy environment was utilized to determine weights of different criteria. Varmazyar et al. [246] proposed a balanced scorecard-based hybrid MCDM method for prioritizing the best research center and technology organization. The work utilized four methods: COPRAS, ARAS, MOORA, and TOPSIS, while ANP was employed to assign weights to performance criteria.

4.10. Other papers on non-specified applications

Nguyen et al. [247] ranked different stocks of agriculture companies in the Vietnam stock exchange, combining the AHP-GRA-MOORA methodology for compelling investment purposes. Fettahoğlu et al. [248] applied the AHP-MOORA method to provide investment decisions for G7 countries in Balkan countries. Wang et al. [249] considered eight weighting methods and four selection methods involving COPRAS, MOORA, MABAC, and CODAS for analysis and solving thirteen chemical engineering problems. Tamrin and Zahrim [250] applied the MOORA method for optimizing the coagulation-flocculation process of palm oil mill effluent, providing the best settings of input parameters. Rajesh et al. [251] used MOORA to analyze the tribological characteristics of red mud-reinforced aluminium alloy composites. The study concluded an improvement in the wear resistance of prepared composite samples through the MOORA method. Mitra [252] presented a new MCDM technique based on MOORA to select the best cotton fabric that provides optimal thermal comfort among thirteen options. Gurumurthy et al. [253] analyzed different characteristics of bio-based oils and ranked different oil samples using the MOORA methodology. Singh et al. [254] present a comparative analysis of generalized fuzzy knowledge measures integrating the TOPSIS approach with MOORA and VIKOR methods. In addition, one numerical example of pattern recognition was selected to show the efficacy of the proposed methodology. Singh and Ganie [255] presented two parametric variants of knowledge measure under a fuzzy environment and combined them with the MOORA method for solving problems concerning vague and uncertain data.