Abstract

The internet of things and growing demand for smaller and more advanced devices has created the problem of high heat production in electronic equipment, which greatly reduces the work performance and life of the electronic instruments. Thermal interface material (TIM) is placed in between heat generating micro-chip and the heat dissipater to conduct all the produced heat to the heat sink. The development of suitable TIM with excellent thermal conductivity (TC) in both in-plane and through-plane directions is a very important need at present. For efficient thermal management, polymer composites are potential candidates. But in general, their thermal conductivity is low compared to that of metals. The filler integration into the polymer matrix is one of the two approaches used to increase the thermal conductivity of polymer composites and is also easy to scale up for industrial production. Another way to achieve this is to change the structure of polymer chains, which fall out of the scope of this work. In this review, considering the first approach, the authors have summarized recent developments in many types of fillers with different scenarios by providing multiple cases with successful strategies to improve through-plane thermal conductivity (TPTC) (k⊥). For a better understanding of TC, a comprehensive background is presented. Several methods to improve the effective (out-plane) thermal conductivity of polymer composites and different theoretical models for the calculation of TC are also discussed. In the end, it is given a detailed conclusion that provides drawbacks of some fillers, multiple significant routes recommended by other researchers to build thermally conductive polymer composites, future aspects along with direction so that the researchers can get a guideline to design an effective polymer-based thermal interface material.

Keywords: Thermally conducive fillers, Through-plane thermal conductivity (k⊥), Thermally conductive polymer composites (TCPCs), Thermal interface materials (TIMs), Thermal management

Symbols

- k

Thermal conductivity

- R

Thermal resistance

Abbreviations

- AlN

Aluminum nitride

- AO

Aluminum oxides

- ABN

Aligned boron nitride

- ANFs

Aramid nanofibers

- ARs

Aspect ratios

- BC

Bacterial cellulose

- BN

Boron nitride

- BNNS

Boron nitride nanosheets

- BNNTs

Boron nitride nanotubes

- CFs

Carbon fibers

- CA

Cellulose aerogel

- CNFs

Cellulose nanofibers

- CVD

Chemical vapor deposition

- CTE

Coefficient of thermal expansion

- e-BN

Core-shell BN/epoxy

- c-BAs

Cubic boron arsenide

- c-BN

Cubic boron nitride

- CuNWs

Copper nanowires

- GHP

Graphene hybrid paper

- GNPs

Graphene nanoplatelets

- GNWs

Graphene nanowalls

- GT

Graphite

- GP

Graphite paper

- h-BN

Hexagonal boron nitride

- HOGF

Highly oriented graphite framework

- IPTC

In-plane thermal conductivity

- ITR

Interfacial thermal resistance

- LMs

Liquid metals

- MWCNTs

Multi-walled carbon nanotubes

- PCCs

Phase-change composites

- PCMs

Phase-change materials

- PAAS

Polyamic acid salt

- PDMS

Polydimethylsiloxane

- PE

Polyethylene

- PEG

Polyethylene glycol

- PTFE

Polytetrafluoroethylene

- PU

Polyurethane

- PVA

Polyvinyl alcohol

- PVC

Poly vinyl chloride

- PVDF

Polyvinylidene fluoride

- SR

Silicone rubber

- SiC

Silicon carbide

- SiCNWs

Silicon carbide nanowires

- SF

Silk fibroin

- AgNWs

Silver nanowires

- TBR

Thermal boundary resistance

- TC

Thermal conductivity

- TCPCs

Thermally conductive polymer composites

- TIMs

Thermal interface materials

- TPU

Thermoplastic polyurethane

- TPTC

Through-plane thermal conductivity

- VA

Vertically aligned

- VACNTs

Vertically aligned carbon nanotubes

- VAGF

Vertically aligned graphene film

1. Introduction

A polymer composite is a versatile material that combines various fillers with the polymer matrix to produce coordinated properties that are not possible from any one of the components alone [1]. Polymers and polymer composites are extensively used in medical [2], biological [3], energy [4], industry [5], and all fields of daily life, owing to their lightweight, stability, low cost, good processing, and excellent corrosion resistance, etc. [6].

From a technological point of view, polymers can be classified into three types: thermosets, thermoplastics, and elastomers (rubbers). Thermosets are polymers that cannot be re-formed when heated, adopt a fixed or permanent shape, and break down when heated further. Thermosets are generally amorphous types of polymers. Thermoplastics are polymeric materials that can be remolded if heated and solidified again on cooling. Thermoplastics can be amorphous or crystalline. Elastomers are those polymeric materials whose dimensions can be greatly altered by applying moderate force and when the force is released, the elastomers return to their initial dimensions. Soft thermally conductive elastomers are of interest in electronic devices because of their thermally conductive properties [7]. Elastomers illustrate a fresh category of soft and versatile composites when tiny liquid metal (LM) alloy droplets are dispersed in their matrix, these composites have the power to revolutionize wearable electronics, soft robotics, as well as biocompatible machining. However, LM alloys have to stay liquid throughout the complete range of temperatures if they are to be used in the aforementioned applications and preserve acceptable mechanical performance throughout the duty cycle [8].

As time goes by, electronics are getting more powerful and compact and have new functions. This rapid development is facing the problem of unequal temperature distribution and high heat accumulation in the device which leads to short life and unreliability of the electronic equipment. This is the main challenge for the best operation and reliability of electronics [9]. Thermal management failures cause almost 55 % of problems in electronic devices. Thermal management is defined as the heat transfer through the device to heat dissipaters, such as heat sinks and spreaders [10]. The results of earlier experiments showed that a temperature rise of just 2 °C can cause a 10 % reduction in device performance [11]. Therefore, the establishment of an effective and cost-effective procedure is crucial for the automatic cooling of electronic devices. Generally, metals like gold (Au), silver (Ag), copper (Cu), and aluminum (Al) have higher TC than polymers. But metals are heavy and come at a high price [12]. Thermally conductive polymer composites (TCPCs) have become more important due to the growing demand for smaller, lighter, and more powerful electronic devices. They represent an interesting option for efficient heat management [13]. This is undoubtedly owing to the truth that thermally conductive and electrically insulating polymers have developed considerably in the present era, mainly because of remarkable developments in material science and technology. Due to the poor transport capacity of the thermal carriers (phonons), the intrinsic TC of polymers is just 0.1–0.5 Wm−1K−1 [14,15]. Because polymer composites are simple to construct, environmentally acceptable, and have affordable processability, new ways to increase the TC of TCPCs are attracting a great deal of interest [16]. These efforts can be divided into two types, depending on the approach used. The first strategy is to appropriately organize molecules and chains and their orientations in the pure polymer to improve TC, usually by creating a highly organized structure, which encourages the transport of phonons. At the same time, the rearrangement will cause a decrease in the phonon scattering at interface defects and minimize chain entanglement. These two aspects work together to encourage the intrinsic polymer to achieve a high value of TC while keeping up a low value of EC without the addition of electrically conductive materials. The second is the improvement of the TC of the polymer by including thermally conductive fillers, or a structure produced by such fillers, in the polymer matrix. By modifying the content, type, geometry, and distribution of the different fillers, the characteristics of the resulting polymer composite can be enhanced [17]. Of these two approaches, the first is challenging for large-scale production and is therefore limited to nanoscale laboratory research. Therefore, this review focuses mainly on the second approach. The TC of polymers can be effectively improved by introducing different fillers into their matrix [[18], [19], [20]].

This review gives a summary of the achievable ways to optimize the TC of polymers. There are many good reviews on the advancement of polymer TC but less research has been done on the effective TC (through-plane thermal conductivity, TPTC, k⊥) and suitable types of fillers. A broad review is needed for the better development and effective design of polymer-based compounds, which would be helpful for the removal of heat particularly when insulation is required. The outline of this review article is as follows: Initially, a background section is included for a better understanding of polymeric TC and the potential of polymeric materials. Then, in the third section, the methodologies to improve the TPTC of polymer composites are presented. In the next section, the types of fillers and results of using these different types of fillers in terms of through-plane TC (k⊥) of polymers are mentioned. In the last section, the authors have given a short discussion on the theoretical calculation models of effective TC. In the end, a conclusion is provided detailing the drawbacks of some fillers, challenges, multiple significant routes recommended by other authors to construct thermally conductive polymer composites, and future aspects along with some guidelines that may help other researchers in the design of new efficient polymer-based TIMs.

2. Background

Polymers have generated new markets of their own. Since 1930 polymers have made significant improvements in the industries of vulcanized rubber that has been used extensively in most of the industrial components and household goods in the past. Polymers also play a significant role in the leather, glass, wood, and paper markets [21].

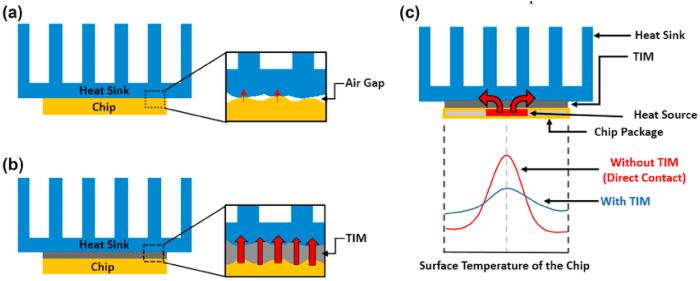

The quick development in the field of artificial intelligence, 5G technology, and the internet of things have created a substantial need for materials that can conduct heat efficiently while providing electrical insulation for microelectronic devices. These devices are facing challenges due to high operating temperatures. The difficulty in transferring the heat generated by the chip to the cooling equipment rapidly is the main reason for this problem during the operation of microelectronic devices [22]. To minimize the heat produced by electronic components, the typical approach is to transfer the heat to materials that dissipate heat, like heat sinks, heat spreaders, or external casings. TIM is installed between the heat removal material and the thermal source which is a semiconductor chip (Fig. 1). The primary purpose of TIM is to create a bridge between the heat radiator fin and the microelectronic device that reduces the interfacial thermal resistance. Although a heat source may seem to be in close interaction with a thermal dissipater there will actually be a small gap of air at the interaction site on a microscopic level. This gap is caused by tiny surface irregularities that prevent the two surfaces from making full contact with each other. Due to the smaller TC of the air gaps, the heat produced by the heating material can only transfer through the points with no air gap between the materials, leading to inefficient heat dissipation (Fig. 2a) [23]. To solve this problem, TIMs can be used to fill the empty space and facilitate efficient heat transfer (Fig. 2b) [23,24]. The effect of TIM on the surface temperature of the heat generating chip can be seen in Fig. 2c [23]. The selection of TIMs should prioritize their thermal properties that have an impact on heat transmission. In choosing TIMs, one should consider the material and shape of both the heat source and dissipater surfaces. Additionally, it is important to consider not only the TC properties but also the flexibility and ease of use of the material [22].

Fig. 1.

In the electronics sector, a very common power device plan, the TIM is installed in between the heat sink and the thermal source which is a semiconductor chip.

Fig. 2.

Heat dissipation (a) without TIM, (b) with TIM, and (c) surface temperature of heat generating chip (Reprinted with permission from Ref. [23] Copyright 2022, Springer Nature).

Traditionally, the thermal problems of encapsulated electronics have been solved by costly integrated heat sinks, prone to thermal cracking and with fewer benefits in thinner packages. In this context, high TC polymeric materials have become cost-effective solutions for heat management [25]. With the application of very thin polymer frameworks, heat sink systems can be efficiently established with better outcomes at cheaper prices and lighter weight as compared to the traditional systems. It has become possible to create affordable thermal sinks that can perform similarly to copper by employing polymer matrix composites (PMCs).

Because of their good thermal stability, excellent adhesiveness, and electrical insulation, polymeric materials just like epoxy resin and silicone rubber are often utilized as TIMs. Unfortunately, their low values of TC (below 0.3 W m−1 K−1) are insufficient to satisfy the requirements of microelectronic devices. The introduction of new types of fillers (with continuous network) into polymer matrix opens up numerous opportunities for polymeric materials to acquire more favorable comprehensive properties. It is important to notice that thermal conduction can occur via through-plane direction (y-axis) or in-plane direction (z-axis or x-axis) [16] as shown in Fig. 3b and a respectively. TIMs with outstanding through-plane TC (k⊥) that can transport heat outside the system after carrying it to the radiator fin, are desperately needed [22].

Fig. 3.

Direction of thermal conduction: (a) in-plane (longitudinal direction) and (b) through-plane or cross-plane (perpendicular direction).

Based on softness or flexibility of the polymer matrix, TIMs can be divided into two types, namely hard and soft. With hard TIMs, a high TC (27–160 W m−1 K−1) has been attained. However, the main issues with their applications in daily life were fragility and non-conformal contact with corresponding rough edges. The utilization of soft polymer composites can lessen the thermal contact resistance along with stress resulting from the coefficient of thermal expansion mismatch [26]. Soft TIMs are being extensively researched to address these obstacles. Despite the high filler loading, the TC of soft isotropic TIMs was very small (≤12 W m−1 K−1).

Based on dimensions, there are three types of filler shapes (Fig. 4):

-

(1)

Zero-dimensional (0D),

-

(2)

One-dimensional (1D),

-

(3)

Two-dimensional (2D).

Fig. 4.

(a) Spherical shape of 0D, (b) fiber, rod, tube, and wire shapes of 1D filler, (c, d) disc and triangular shapes of 2D filler, (e) platelets, sheets, and flakes shapes of 2D fillers, (f, g) agglomeration, (h) piling up of each nanofiller (Reprinted with permission from Ref. [16] Copyright 2021, John Wiley and Sons).

A nanoparticle with a spherical shape is an example of a 0D shape (Fig. 4a), forms of fillers just like tubes, fibers, rods, and wires are examples of a 1D shapes (Fig. 4b), and disc, triangular and platelets shapes are examples of 2D shapes (Fig. 4c, d, and 4e). Fig. 4f and g shows the agglomeration, while Fig. 4h shows the piling up of nano fillers. BN and graphene family are examples of 2D shapes of fillers. When 1D or 2D anisotropic fillers (BNNS, natural graphite, graphite nanosheets, and CF) were arranged, the TC of soft TIMs may be enhanced along the perpendicular axes (5–80 W m−1 K−1). Nevertheless, the random printing method could not be used to coordinate the anisotropic fillers. Also, the TC in the vertical direction (through-plane) was lower [27]. Polymer composites that exhibit high through-plane TC, low modulus, and significantly high flexibility are considered ideal TIMs.

It is important to comprehend TC (k) and thermal resistance. TC refers to the quality of a composite material that determines how easily it can transfer heat. Materials with higher thermal conductivity (TC) facilitate faster heat transfer, resulting in more efficient cooling.

For heat conduction through a material, the relation between the rate of heat transfer and temperature difference can be calculated using Fourier's equation (Equation (1)) [28],

| (1) |

Where Q = Rate of heat flow (W), A = Area through which the heat is conducted (m2), T = Temperature gradient (K), k = Thermal conductivity (W m−1 K−1), and x = Distance between the two temperatures of interest (m). This equation describes how efficiently a compound can exchange heat at various temperature differences, either from a heated to a chilled zone or the opposite. It also explains how TC facilitates heat dissipation within the material [16]. Thermal energy manifests itself in a material through electron transport and the frequency of atomic vibrations (phonons). Only certain discrete vibrational frequencies are permitted in a way similar to light energy. These quanta of thermal energy are known as phonons. Phonons transmit energy by interaction with other phonons as well as with subatomic particles (neutrons, electrons, protons) [28]. Energy is transmitted during these interactions because momentum must be conserved.

These two mechanisms in TC taken together can be expressed by following Equation (2) [16]:

| (2) |

where ke and k1 respectively are the contributions from electrons and phonons to TC. TC behavior varies among solid materials due to the involvement of different heat carriers. In insulating materials such as those based on polymers and ceramics, the dominant influence on TC comes from lattice vibration waves or phonons, whereas in metals, the main carriers are electrons and holes. This means that the TC of insulators is affected by phonons significantly, while in metals, electrons and holes play a more dominant role. However, in comparison to phonons, electrons can transfer heat more effectively because of their reduced scattering effect. Consequently, metal and carbon-based fillers exhibit significantly better TC than ceramic-based fillers [16].

Phonon-mediated heat transport is also efficient. However, phonon transmission is only efficient along crystalline structures, and it is significantly decreased by numerous scattering processes that result in increased thermal resistance. Amorphous solids, for example, have such disordered molecular structures that phonon scattering is even more prominent. This explains why these materials have such low TC. Semi-crystalline polymers include enough amorphous areas and inter-crystalline flaws that considerably limit their TC due to heat resistance. Experiments on highly orientated chain-extended polyethylene have confirmed this [28]. The formula below (Equation (3)) can be used to determine thermal resistance.

| (3) |

where R = Thermal resistance (W K−1), A = Solid body heat transfer Area (m2), L = Length of heat transferring solid structure (m), and k = Thermal conductivity (W m−1 K−1). When the TC remains constant, the thermal resistance is determined by the material thickness and the area of heat transfer at the contact surface between the materials. Between two or more connected fillers the contact thermal resistance can be significant. If there are fine irregularities on the surface of materials or poor interfacial bonding between polymers and fillers, it may cause an air gap or scattering of phonons, resulting in heat flow resistance at the contact interface between the materials. The distribution of fillers in a discontinuous pattern also obstructs the establishment of ongoing thermally conductive channels, which results in the broadening of the area of interface, and therefore, a rise in contact thermal resistance [29].

The overall thermal resistance (thermal impedance) includes both the actual thermal resistance of the materials and the thermal resistance that is produced at the interface where the materials come into contact. Therefore, the thermal impedance θ is calculated by using Equation (4).

| (4) |

A Thermal Interface Material must possess both excellent TC in the inner region (thickness) and adaptability to fill any air gaps to effectively decrease thermal resistance at the bonding interface.

To implement TIMs on a large scale, it is crucial for them to have not only high thermal conductivity but also the capacity to reduce fluctuations during installation and to adapt to unevenness of the mounting surface. Therefore, the ease of use and workability during installation of TIMs is also a significant factor to consider.

In the past, about 40 years ago, the studies were mainly focused on analyzing three crucial factors that influence the TC (k) of polymeric materials, namely, the impact of temperature changes, the influence of crystallinity, and the effect of orientation [30]. These observed characteristics can be explained by the balance between two opposing factors: the naturally greater conductivity in crystalline areas and the decrease in TC caused by an extra mechanism of phonon scattering that becomes significant at lower temperatures. The scattering observed could be attributed to either the relation between spatial variations in the velocity of sound within the polymer or to the acoustic incompatibility that occurs at the interfaces between both the amorphous and crystalline regions [30]. Choy conducted a thorough examination of how TC in polymers is impacted by factors such as orientation, crystallinity, and temperature [30].

Silicon nitride, aluminum alloy, boron fiber epoxy composite, AISI stainless steel, glass fiber epoxy composite, and pyroceram corning were the selected aerospace materials until 1977 [31]. Glass-metal composites were one of the solutions proposed for increasing thermal conduction in glassy solids with high nuclear waste content. Glass-copper composites were chosen and their conductivities were investigated to explore the effect of metal addition on the TC of glasses. Pressure sintering of glass and copper powder mixtures at different temperatures resulted in fully densified composites. Depending on the type of copper powder used, TC is enhanced with increasing copper loading. The TC of composites with the same copper loadings varies significantly. Fine copper powder increased TC effectively [32]. The most commonly used polymers until 1980 were epoxy, polystyrene, silicone rubber, polyester, natural rubber, and ethylene vinyl acetate. Common fillers were copper, silver, gold, stainless steel, aluminum, glass, tin, CaO, MgO, Al2O3, quartz, and diamond.

When high or super-high levels of quartz or Al2O3 are used as fillers to effectively increase the TC in polyethylene and polystyrene composite materials, which were prepared by the standard casting method, the resulting fractional volume of voids is not completely filled by the filler particles. This leads to an incomplete filling of void space. Research was performed to look into the connection between the mixing percentages of filler particles of different sizes and the discrete voidage at various levels of compression force. It was observed that a specific combination of filler particles resulted in the lowest fractional voidage. To create polymers with significantly reduced fractional voidage, this effective mixture of fillers was used during the compression process. The resulting TC of polymers increased monotonically across a variety of filler concentrations, from low to super high [33]. The main purpose of the study was to investigate the influence of conductive particle chains on the electrical conductivity (EC) and TC of polyvinyl chloride (PVC) and polyethylene (PE) composites filled with carbon compounds across a broad range. As the concentration of carbon particles in the composites increases, the number of generated conductive chains also increases exponentially. These conductive chains generally increase the TC of polymeric composites [34]. One of the most commonly used systems consisted of a molded plastic part with a conductive metal surface coating. The coating was created by spreading a conductive paint or depositing a metallic vapor layer on the surface of the object. Such procedures, however, are usually pricey, and results over the long run are not always as satisfactory as anticipated. Due to the shortcomings of these procedures, there has been increased interest in the thermally conductive composite approach, which involves the integration of filler into a nonmetallic matrix [35].

Polymer composites have been traditionally utilized in structural applications. Currently, research is being carried out on multifunctional polymer composites that can serve in electronic packaging and heat management applications. The versatile characteristics of polymer composites have been advanced throughout the time, making them even more significant to the electrical sector by expanding their application range. Polymers are most frequently used in electronics for electrical insulation and thermal conduction, preventing the loss of signal currents and confining them in desired paths, as well as eliminating excess heat [21].

3. Methodologies to improve the effective thermal conductivity of polymer composites

The heat flow is in perpendicular direction to the interface in real-life applications of TIMs. For the real-life applications, the arrangement of the fillers should be in the out-plane direction. The distribution of fillers in the polymer matrix is very challenging due to inertness and poor interfacial compliance of majority of the thermally conductive fillers with the polymer. As a result, at low filler content, heat conduction channels cannot be created, while deterioration of the polymer's mechanical and dielectric properties occurs when high filler content is used [36]. There are many strategies that are used to build a thermally conductive network in a through-plane direction with low filler loading. These are listed below.

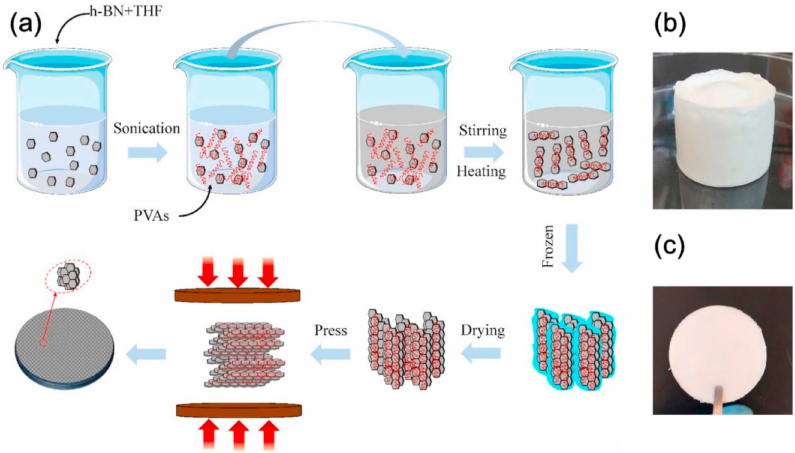

3.1. The template method

Template assembly is the most common method that is used to create a three-dimensional thermally conductive network. Ice, protein, polyurethane foam, nickel foam, and carbon-based nanorods can be used as templates. This technique utilizes the self-assembly induced by template crystal growth. The production method consists of two steps. The first step is the attachment of the TC filler material to the template and the second step is the removal of the template once the filler has set. The resulting 3D TC filler network is incorporated into a resin of excellent fluidity to obtain composites [37]. Boron nitride/polyvinyl alcohol (BN/PVA) composites with proper arrangement were fabricated by Wenjie et al. [38] using an ice-template self-assembly technique (Fig. 5a). They used lyophilization after freezing to create BN/PVA aerogels (Fig. 5b). The BN fragments were compressed by the ice crystals to create a 3D channel at the ice interfaces. Then hot pressing was used to further remove the gaps between the BN fragments (Fig. 5c). A compact BN/PVA composite was achieved possessing IPTC and TPTC of 10.04 and 1.28 Wm−1K−1 respectively [38].

Fig. 5.

Ice-template assembly for the synthesis of BN/PVA composites (Reprinted with permission from Ref. [38] copyright 2021, Elsevier).

3.2. Chemical vapor deposition (CVD)

One microfabrication technique that is frequently employed in the semiconductor industry is chemical vapor deposition. It is a technique widely used to enhance interfacial characteristics. In this technique, the material coating is created on the surface of the substrate as a result of chemical reactions between the vapors of liquid or gaseous reactants [39]. This technique is straightforward, can be easily operated and enables the generation of films with varying thicknesses and shapes with growth in the desired direction. Using the CVD technique, Qingwei et al. created vertically aligned graphene nanowalls (GNWs) that were covalently attached to excellent quality CVD graphene nanosheets. Thanks to this special network, GNWs showed an exceptional TC. With only 4 wt% of filler, its composite film with a polyvinylidene fluoride (PVDF) matrix demonstrated a good TPTC of 12.8 Wm−1K−1 [40]. On the other hand, CVD has certain disadvantages, like difficult reaction conditions and high cost of preparation.

3.3. Electrospinning

Electrospinning is used to prepare electrostatic fibers. Polymer fibers with diameters that range from 2 nm to a few μm are obtained from a polymer solution using an electrical force. This process provides special features for the fabrication of nanofibers with adjustable pore structures, flexibility in spinning a wide range of polymeric fibers, and uniformity in fiber production in the selected range [41]. The diameter of the electro-spun fiber can be altered to adjust the TC of a composite. This approach results in an even dispersion of fillers. In addition to the potential orientation of thermally conductive fillers as well as aligned polymeric nanofibers, electro-spun composites have smaller inter-filler contact distances, which improves the TC of the composites. Zhe et al. [42] constructed a liquid metal/boron nitride nanosheet/silk fibroin (LM/BNNS/SF) composite. They fabricated a BNNS/SF electrospinning film and then infiltrated it with a liquid metal/polyvinyl alcohol (LM/PVA). The LM/BNNS/SF composite film was obtained by compression molding (Fig. 6). The gradient distribution of LMs was caused by gravity-driven settlement and PVA bonding. The thus obtained LM/BNNS/SF composite film exhibited a TPTC and IPTC of 3.24 and 12.53 Wm−1K−1 respectively [42].

Fig. 6.

Fabrication of a LM/BNNS/SF composite film by electrospinning (Reprinted with permission from Ref. [42] copyright 2023, Elsevier).

3.4. 3D printing

Fused deposition modeling (FDM) is among the most trendy 3D printing techniques. It consists of building three-dimensional parts layer by layer by selectively depositing a molten thermoplastic in a predetermined path. When a molten polymer composite undergoes extrusion, thermally conductive fillers organize and connect with adjacent ones creating a network that leads to enhanced TC of the polymer composites in the desired direction [43]. Jia et al. used the FDM technique to fabricate polymer/graphite composites in which graphite particles were oriented in the through-plane direction, resulting in a TPTC of 5.5 Wm−1K−1 [44].

3.5. Electric field-induced orientation

Fillers can be induced to position themselves in a desired direction by an electric field. It includes electrostatic flocking and electrophoresis deposition. Electrostatic flocking consists of placing the fillers on a particular instrument and orienting them in the direction of an electric field by the application of a high electric potential field. Ji et al. [45] used carbon fibers coated with silicon carbide (SiC@CF) as a precursor and a CVD technique was applied to grow vertically arranged carbon nanotubes on CFs (CF-VACNTs). Subsequently the electrostatic flocking technique was applied to vertically arrange the CF-VACNTs and attach them smoothly in a polyimide matrix. Because of the highly oriented CFs and vertically grown CNTs, the composite created a 3D hierarchical network that showed a high TPTC of 7.51 Wm−1K−1 [45].

Electrophoresis deposition is another type of electric field-induced orientation technique. In this process, the material is plated as the electrode and when the electric field is applied, the groups or ions present in the electrolyte proceed towards the oppositely charged electrode [46]. This method has many advantages, including its simplicity, high efficiency, broad specific surface area, uniform distribution, controllability, and the addition of a greater number of surface active groups to enhance the interface efficiency. Barako et al. [47] applied electrophoresis deposition and capillary infiltration techniques to fabricate vertically arranged Copper nanowire/PMDS composites. By using 20–25 % dense Cu nanowires (CuNWs), the thermal and mechanical characteristics of CuNW composites were enhanced. Xiru et al. [46] used the electrophoresis deposition technique to apply the hybrid filler system of hBN and Cu particles (hBN/Cu) on the surface of CF tapes (Fig. 7b). They found an increase in TC with increasing deposition time. CF reinforced polymer composites made up of annealed CF tapes coated with hBN/Cu showed a TPTC and IPTC of 2.16 and 6.14 Wm−1K−1 respectively. The electrophoresis deposition set-up is shown in Fig. 7a [46].

Fig. 7.

Electrophoresis deposition setup and schematic representation of electrophoresis deposition process (Reprinted with permission from Ref. [46] copyright 2019, Elsevier).

3.6. Magnetic field-induced orientation

Fillers can be arranged in the desired direction with the help of a magnetic field, but it requires magnetically responsive fillers in a low-viscosity suspension. Fillers can be arranged in two ways. The first way is the direct arrangement of magnetically responsive fillers in the desired direction. The second is the indirect arrangement of fillers that do not respond magnetically. These fillers are functionalized with magnetic materials such as cobalt tetroxide (Co3O4) and superparamagnetic iron oxide (Fe3O4) before their orientation under the application of a magnetic field [48]. Weak magnetic materials just like graphite can be handled and directed at a distance by a very high magnetic field. In a research, graphite filler particles were vertically oriented in the presence of a very powerful magnetic field of 10T. After magnetic field-induced orientation, the composite enhanced its TPTC by 330 % [49]. Fe3O4–SiC was added into the epoxy resin and then it was sandwiched within two powerful magnets to completely arrange the filler network in the required direction. The TPTC of the organized composite was greater than that of a random composite material, at a filler loading of 20 vol% [50].

3.7. Mechanical cutting

High voltage is needed for the electric field-induced alignment of fillers. On the other hand, in order to achieve the magnetic field-induced filler alignment, the filler is also required be magnetic. Therefore, there are limitations in the execution of these two orientation strategies. Mechanical cutting has recently been used to establish excellent filler arrangement in the out-plane direction. The method comprises rolling around, in-plane placement, and slicing in a particular manner to accomplish the vertical filler orientation. If the composite possesses an extremely high IPTC, TIMs can achieve an extremely high TPTC by mechanical cutting. As a result, the complete pattern of the filler can build a highly efficient thermal conduction pathway in the polymer matrix. To form a vertically aligned graphene film (VAGF)/PDMS composite, graphene sheets (Fig. 8A) were rolled around (Fig. 8B and C) and then soaked in liquid PDMS (Fig. 8D) [51]. Following solidification, the composite material was sliced into small sections perpendicular to the cylinder direction (Fig. 8E). As a result, the graphene film was aligned vertically within the PDMS-based thin composite (Fig. 8F). The VAGF/PDMS showed an improvement in TPTC up to 614.85 W m−1K−1. This improvement can be attributed to the vertical arrangement of graphene films possessing extremely high IPTC, which created rapid and effective thermal conduction channels [51]. Stacking is also able to yield a highly significant TPTC, just like rolling. By using the stacking approach, Zhang et al. fabricated TIMs with two types of orientations; in-plane and out-plane. In the first step, they stacked the graphene films, then each of these films was infiltrated with epoxy resin while adjusting the filling percentage. At the end, hot pressing and curing were done successively. At a filler loading of 44 vol%, a TPTC of 384.9 Wm−1K−1 was achieved [52]. In the same way, graphite paper (GP) was creased along a single side, piled up, infiltrated with epoxy resin, and cut into small pieces to obtain a polyline-folded GP/epoxy resin (PFGP/EP) composite (Fig. 9A–G). The tightly piled multilayered GP developed efficient TC pathways within the epoxy matrix. It showed an enhanced TPTC of 24.19 Wm−1K−1 [53].

Fig. 8.

Fabrication process of vertically aligned graphene film/PDMS composite (Reprinted with permission from Ref. [51] copyright 2016, Elsevier).

Fig. 9.

Fabrication process of PFGP/EP composite (Reprinted with permission from Ref. [53] copyright 2020, Elsevier).

4. Through-plane thermal conductivity (TPTC) of polymer composites with different fillers

Although there has been significant progress in the development of paper-like sheets that are extremely thermally conductive in the in-plane direction (k∥), still their uses are restricted by the insufficient TPTC (k⊥) (0.05–2 W m−1K−1). In actual practice, paper-like durable composites with a greater value of TPTC are highly preferred over bulk materials for TIMs. To improve the TC of polymer compounds, it is common practice to incorporate thermally conductive fillers that can form new composites with improved thermal and mechanical characteristics. Even so, using a lot of unique fillers in a polymer matrix to develop a thermally conductive polymer composite (TCPC) presents several scientific and technological challenges. Despite theoretical predictions, the measured TC of these composites often falls short. This is because of the presence of thermal resistances, which cannot be avoided [29].

As illustrated in Fig. 10, TC depends on the composition and characteristics of the polymer and fillers, the structure of the polymer composites, and the association of the polymers and fillers. When designing a TCPC, a comprehensive strategy must be adopted to ensure that all application criteria are met. It is not enough to just choose proper polymers and fillers. The structure of polymers and fillers, as well as their interactions, must be thoroughly understood and managed. Additionally, various qualities and processability must be examined and balanced in addition to the TC.

Fig. 10.

Various elements that influence the TC of composites and should be taken into account when developing new composites [54].

The impacts of different types of fillers on the through-plane TC of various polymer matrixes are reviewed in this section. Different types of fillers to be discussed in this section are summarized in Fig. 11. This section also discusses filler selection according to specifications and applications. TC values of some fillers are listed in Table 1.

Fig. 11.

Different types of thermally conductive fillers to make polymer composites.

Table 1.

Recently Reported Thermal Conductivity values with different fillers.

| Matrix | Filler | Loading | Interaction | Technique | Thermal Conductivity (Wm−1K−1) | Year Ref |

|---|---|---|---|---|---|---|

| PI | PDA-BNF@BNNPs | 40 wt% | brick and plank strategy | 6.43 (k∥) 11.85 (k⊥) |

2022 [72] | |

| epoxy | (AlN–H) | 47.26 vol% | freeze-casting method infiltration method |

9.48 (k∥) 4.45 (k⊥) |

2020 [73] | |

| CNF | BNNT | 25 wt % | Hydrophobic- hydrophobic interaction | Vacuum assisted filtration | 21.39 (k∥) | 2017 [74] |

| PDMS | BNNS | 16 w.t % | Guided assembly | 11.05 (k∥) 1.15 (k⊥) |

2019 [75] | |

| Epoxy | 3D-BNNS | 9.6 vol % | Covalent bonding, H-bonding |

Templated assembly | 3.13 | 2017 [76] |

| ANF | BNNS | 10 wt % | H-Bonding, Van der Waals interaction |

Vacuum assisted filtration | 2.4 (k∥) 0.7 (k⊥) |

2019 [14] |

| Epoxy | BNNS | 15 vol % | Freezing assembly (bidirectional | 6.54 (k∥) 0.7 (k⊥) |

2019 [77] | |

| ANF | BNNS (functionalized) | 30 wt % | H-Bonding, Van der Waals interaction |

Vacuum assisted filtration | 46.7 (k∥) | 2020 [78] |

| CNF | BNNS (hydroxylated) | 60 wt % | H-bonding | Vacuum assisted filtration | 24.27 (k∥) | 2018 [79] |

| PS @PDDA | BNNS | 13.4 vol % | Electrostatic interaction | Mold pressing | 8.0 (k∥) | 2017 [80] |

| Epoxy | BNNS-rGO | 13.16 vol % | Van der Waals interaction | Ice-templated assembly | 5.05 (k⊥) | 2018 [81] |

| Epoxy | 3D-BN | 59.43 vol % | Templated assembly | 6.11 (k⊥) | 2020 [82] | |

| olefin block copolymer (OBC) | carbon fiber | 30 vol% | sharing force induce alignment | melting extrusion method | 15.06 (k⊥) | 2023 [83] |

| epoxy | graphene-diamond framework (GRDF) | 43 wt% | simple filtration method | 22.7 (k⊥) 21.8 (k∥) |

2022 [84] | |

| Polylactic acid (PLA) | graphene nanoplatelets (GNP) | 6 wt% | solution blending compression molding process |

0.87 (k∥) 0.58 (k⊥) |

2019 [85] | |

| Cu–B | Diamond Boron |

67 vol% 0.3 wt% |

interfacial bonding due to covalent bond | metal matrix alloying method, gas pressure infiltration |

868 (k∥) | 2019 [86] |

| BaTiO3 | Cu | 22.3 vol% | Epsilon-negative permittivity behavior | 17.7 at 150 °C | 2020 [82] | |

| epoxy | AgNPs, AgNWs, CFs |

3 wt% | 0.76 (k⊥) | 2022 [87] | ||

| PVA | h-BNNS | 0 to 60 wt% | vacuum filtration process self-assembly process |

14.21 (k∥) 7.29 (k⊥) |

2021 [88] | |

| PDMS | AgNWs, Cu, graphite |

2.0 mg/mL 7.5 wt % 20 wt % |

Ball-milling, 3D printing |

5.96 (k⊥) 41.7 (k∥) |

2022 [23] | |

| BN-SiC | (PDMS) | 8.35 vol % | atomic-level coupling | ice-templated assembly and high-temperature sintering | 3.87 (k⊥) | 2022 [89] |

4.1. Thermal conductivity with metallic fillers

Metallic thermally conductive fillers like Al, Au, Cu, and Ag offer significant benefits such as efficient heat conduction and their adjustable morphology [29]. Liquid metal (LM) droplets inserted into silicone elastomer were reported to have an excellent TC of 4.7 W m−1 K−1 and a good capacity for stretching of over 600 percent strain [55].

A new method has been developed by Chuan et al. [56] for creating a film with exceptional mechanical strength, durability as well as high TC. The film is made by the use of vacuum infiltration method by the combination of LM and aramid nanofibers (ANFs). This composite film demonstrated excellent TC in both longitudinal and vertical directions (7.14 W m−1 K−1 and 1.68 W m−1 K−1) due to the development of a densely organized framework, in which LM droplets were arbitrarily dispersed within the organized ANFs to create effective heat transmission channels. Meanwhile, The LM/ANF composite films exhibited a stiffness of 10.3 MJ m−3 along with a remarkable tensile strength of 108.5 MPa.

The ice-templated [[57], [58], [59]] and salt-templated techniques [60] are used to obtain the best arrangement in the required direction. They describe the method of first creating a porous packing structure before submerging it in the polymer. Owing to the fillers' effective interaction, they offer great TC and are a good choice for thermal interface material. But they always require multiple treatment steps. An ice-template assembly technique, for constructing thermally conductive three-dimensional BN nanosheets' networks and silver nanowires (AgNWs) in epoxy composites, has been published by Li et al. [59]. The combined impacts of 2D BNNS and 1D AgNWs make it simple to construct a thermal-conduction pathway. Additionally, the bonding of neighboring AgNWs via low-temperature sintering increases the overall area of connection per unit volume of filler. The generated polymer composite has a TPTC of 1.10 W m−1 K−1 at a filler volume of just 5.0 vol%, which is six times greater than the pure epoxy resin (Fig. 12a and b). This innovation is very promising for today's packaging materials, just like printed circuit boards (PCBs) and substrates. Semiconductors possessing excellent TC and high electron-hole mobility have significant importance for the production of photonic and electronic devices as well as fundamental research. Cubic boron arsenide (c-BAs) is considered to be one of the most effective ultrahigh thermal conductive materials due to its ability to exhibit high electron and hole mobility exceeding 1000 cm2/Vs. This quality makes it a strong contender for the development of next-generation electronics, as the combination of higher ambipolar mobility and ultrahigh TC offers significant advantages [61]. Sheng. et al. [62] reported the preliminary achievement of excellent TC at ambient temperature in cubic boron arsenide (BAs) which is synthesized by using a modified chemical vapor transport process. Only diamond and graphite basal-plane values are better than BAs' TC of 1000 W m−1K−1. Their research demonstrates that BAs belong to a class of materials with extremely high TC, as suggested by a recent theory, according to which it could be a suitable material for heat management in high power-density electrical appliances [62].

Fig. 12.

Diagrammatic representation of the production of the BNNS-AgNWs-300/epoxy composite (reprinted with permission from Ref. [59] copyright 2021, Elsevier).

Metals are excellent heat conductors. Metallic fillers with shorter sizes of particles and low filler loading provide greater thermal conductivity. When polymers are loaded with metallic particles, mechanical characteristics like modulus and stress at break generally improve [63]. However, when metallic particles are added to a polymer matrix, they degrade the electrical insulation and dielectric characteristics of the composites, resulting in a huge increase in electrical conduction and a decrease in dielectric strength, restricting their broader applications in the electronic packaging materials industry. Additionally, other problems like increase in density, high manufacturing expenses, and the ease with which they oxidize in humid and hot environments have also limited their properties and uses in polymer composites [29]. It is necessary to use treatments to stop corrosion and surface oxidation. Metals are added as filler in situations where weight reduction and electrical insulation are not significant factors [16].

4.2. Thermal conductivity with ceramic fillers

Ceramic compounds have been investigated broadly as insulators and thermally conductive fillers because of their high TC. Non-oxide fillers such as Si3N4, SiC, AlN, BNNT, h-BN, and BNNS are preferred due to their higher TC and electrical resistivity as compared to the metal oxide fillers. This is attributed to the strong inter-atomic bonds and crystalline structure of ceramic fillers, which effectively reduce phonon scattering [29].

Ceramic fillers can be classified into three types.

-

1.

Oxide fillers

-

2.

Nitride fillers

-

3.

Carbide fillers

4.2.1. Oxide fillers

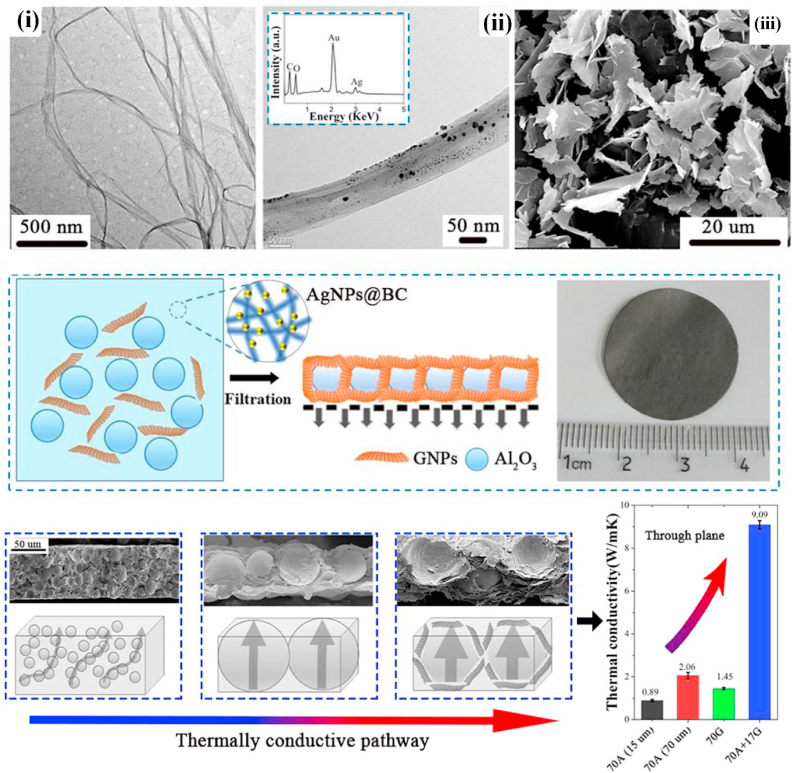

As a common ceramic, Al2O3 is broadly utilized as a thermally conductive filler in commercial applications due to its greater TC, reasonable cost, and significantly high electrical resistivity. It is considered a good quality filler for the production of composites that offer both TC and electrical insulation. Despite not having a very high intrinsic TC, due to its consistent chemical performance, Al2O3 is still receiving significant interest in the field of TCPCs. As a result, Al2O3 is emerging as a promising filler material for future industrial applications [29]. By using a simple vacuum-assisted self-assembly procedure, Chang et al. [64] created flexible paper-like composites that are based on bacterial cellulose (BC) having a perfect structure for heat transfer. In this structure, one layer of Al2O3 particles is attached in perpendicular direction to the films, and the Al2O3 particles are wrapped by high-TC graphene nanoplatelets (GNPs). Among the known paper-like polymer-based composites, these films exhibited excellent TPTC value (9.09 W m−1K−1), exceptional conformability (in over 20,000 bending cycles), as well as durable mechanical characteristics (Fig. 13a and b). The excellent heat-managing capacity of the generated film was illustrated by evidence-based studies and finite volume modeling, clearly indicating their considerable potential for usage as super TIM in modern electronic packaging technologies [64].

Fig. 13.

Diagrammatic illustration of the fabrication procedure and the images of AgNPs@BC/Al2O3/GNPs composites. The TPTC of BC-based composites with various morphologies (Reprinted with permission from Ref. [64] copyright 2020, Elsevier).

Gayoung et al. [65] added spherical aluminum oxide (s-AOs) as a filler at a concentration of 40 wt % into the h-BN composites. This leads to the increase in TPTC of the h-BN/AO composites, which reached a value of 2.47 Wm−1K−1. Additionally, the h-BN/AO hybrid composites had a low viscosity due to the round shape of the s-AOs despite high loading of filler [65].

4.2.2. Nitride fillers

Among nitride fillers, h-BN has gained significant interest as a thermally conductive filler owing to its exceptionally high TC. It is very stable and has exceptional temperature resistance, which, combined with its low density, makes it an excellent choice for today's electronic devices, communications machinery, and lighting equipment. Among the different ceramic fillers, 2D BN has also become a focus of study because of its remarkable IPTC (approximately 400 W m−1 K−1), high electrical insulation, and lower dielectric constant compared to conventional ceramic fillers [29]. Chen et al. [66] discovered that isotopically pure cubic BN (cBN) possesses a TC that is 75 % compared to diamond. The use of boron-11 or boron-10 allows the heat-carrying vibrations of the crystal to effectively pass through the substance. This quality can be used to improve the temperature regulation of high-power electronics. Cubic BN also has a very broad band gap (6.2 eV), which makes it very attractive for ultraviolet optoelectronics. With isotopically enriched cBN crystals, a high TC of over 1600 W m−1 K−1 has been demonstrated. By reducing the prominent isotopic scattering of phonons that occurs in natural cBN, this ultrahigh TC was achieved [66].

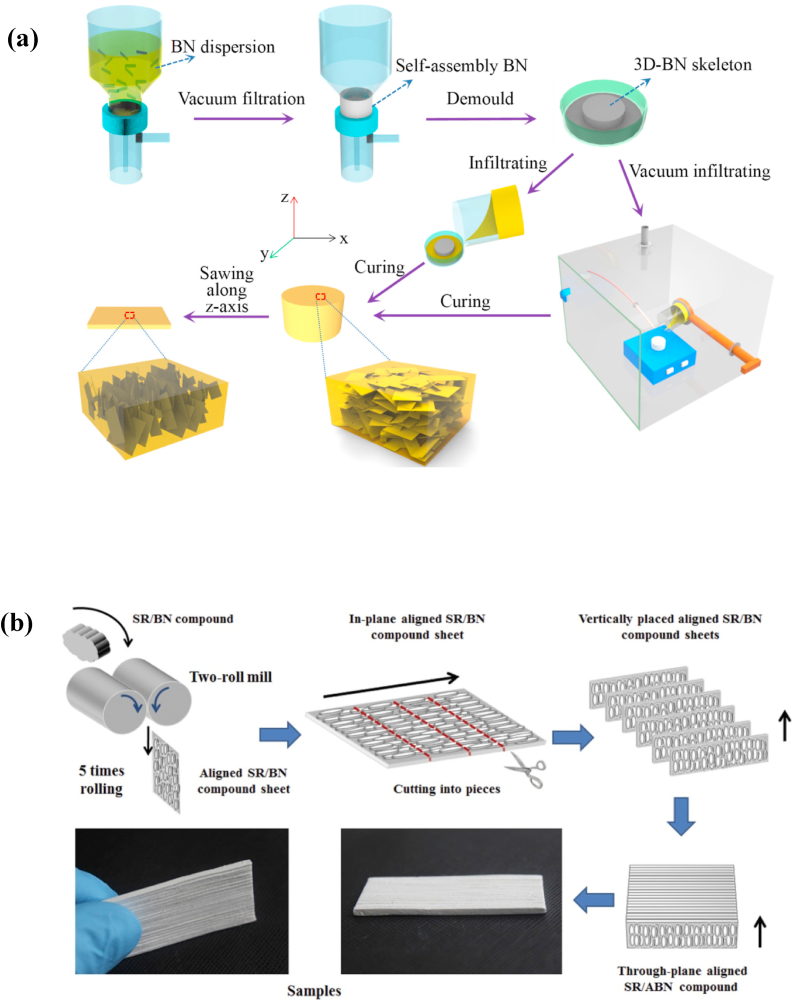

Zhengdong et al. [22] suggested a simple and environmentally friendly strategy to improve the TPTC of epoxy composites, which involved the use of a 3D boron nitride (3D-BN) structure. The results showed that the epoxy composites having a larger lateral size of BN displayed a superior through-plane TC of 2.01 W m−1 K−1 while maintaining a low dielectric constant of 3.7 (Fig. 14a). These characteristics make it an attractive choice for its application in microelectronic devices [22].

Fig. 14.

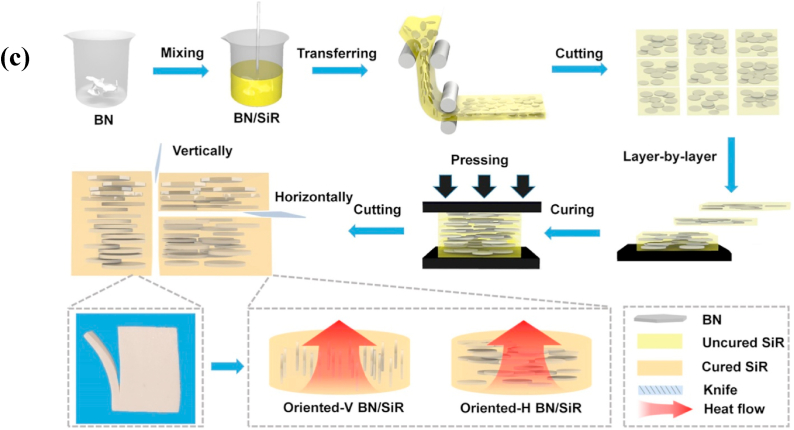

(a) Schematic representation of the fabrication process of 3D-BN/epoxy composite (Reprinted with permission from Ref. [22] copyright 2022, Nanomaterials, MDPI). (b) drawing of production method of SR/ABN composites (Reprinted with permission from Ref. [69] copyright 2019, Elsevier). (c) Graphic representation of the fabrication method of aligned BN/SiR composites (Reprinted with permission from Ref. [26] copyright 2022, Elsevier).

The oriented arrangement of fillers makes it easier to build continuous and efficient thermal conduction pathways in the desired direction. For example, the 3D-BN foaming structure method [67], the use of sandwich structure to develop vertical nano-plates of BN [68], the hot-pressing procedure to create a 3D network of BNNSs, and the vacuum filtration technique are techniques based on cutting the slices and then arranging them in the desired direction. Xue et al. [69] fabricated vertically arranged boron nitride silicon rubber composites and then the TC of fabricated composites was thoroughly examined. The vertically arranged BNs established efficient thermal conduction pathways in the out-plane direction in the silicon rubber matrix. This resulted in the higher TPTC (5.4 W m−1 K−1) of SR/ABN composites when compared with those of SR/BN that are not oriented. In addition, surface thermal infrared analysis has shown that the vertically aligned SR/ABN composites have an impressive ability to transfer heat during the heating and cooling process (Fig. 14b). These findings suggest that there is potential to create TIMs with exceptional through-plane TC. Such materials could be used in fields requiring both thermal conduction and electrical insulation [69].

Qinghua et al. [26] reported a soft composite with high TPTC based on SR and created by combination of the layer-by-layer stacking approach and shear orientation. (Fig. 14c). The composite showed an amazing through-plane TC of 7.62 Wm−1K−1 while maintaining the flexibility and high elastic recovery of SR [26]. Electric and magnetic fields can both influence the arrangement of BN in the substrate [70]. The electrostatic flocking technique has recently been used to create TIMs with excellent conduction in the desired direction. The use of a magnetic field makes it possible to adjust the position of the filler particles with magnetic properties within the packed structure. It is clear that the arrangement of the packed structure is influenced by the magnetization's impact. However, one important restriction is that the magnetic filler orientation process must take place in a low viscosity polymer matrix. To boost performance, magnetized fillers are required to be anisotropic, and BN is unquestionably a great option [71].

Where AlN–H = Aluminum nitride honeycomb, BN = Boron Nitride, h-BNNS = Hexagonal boron nitride nanosheets, PDMS = polydimethylsiloxane, BNNT = boron nitride nanotubes, PVA = Polyvinyl alcohol, ANFs = Aramid Nanofibers, CNFs = Cellulose Nanofibers, PI = polyimide, Cu–B = boron-modified Cu, BaTiO3=Barium titanate, AgNPs = Ag nanoparticles, AgNWs = Ag nanowires, CFs = carbon fibers.

The in-plane and through-plane direction of TC is represented by k∥ and k⊥ respectively. The original paper did not indicate the direction of TC which is not labeled.

4.2.3. Carbide fillers

Carbides are the most common carbon precipitate products, either as primary MC-type carbides (with M being a metal component) or as secondary carbides [90].

Carbide epoxy composites were made by Vu. et al. [91]. They used vertically aligned (VA) 3D SiC sheet scaffolds. A unique technique was used to create the desired VA-SiC sheet scaffolds, which starts from a graphene oxide (GO) scaffold. In an argon atmosphere, the VA-GO scaffolds are reduced to VA-graphene scaffolds, which are then converted into VA-SiC sheet scaffolds by a template-assisted chemical vapor deposition method. To construct the mass of the composite, unfilled areas in the 3D scaffold of SiC sheets were filled with epoxy resin (Fig. 15). At a content of 3.71 vol% of SiC sheet, this material has shown anisotropic thermal properties and an extremely high TPTC of 14.32 W m−1 K−1 [91].

Fig. 15.

Diagrammatic illustration of the production procedure of VA-SiC sheet scaffolds (Reprinted with permission from Ref. [91] copyright 2020, American Chemical Society).

Dai et al. [92] created the graphene hybrid paper (GHP) through the intercalation of Si source and the in situ synthesis of SiC nanorods in between the sheets of graphene by using a carbothermal reduction reaction. The GHP has a TPTC of 10.9 W m−1 K−1 and could be up to 17.6 W m−1 K−1 due to the formation of covalent bonds between carbon and silicon at the contact surface of graphene-SiC (Fig. 16a–e) [92]. Song, J. and Y. Zhang [93] prepared vertically oriented SiCNWs/rGO networks by the ice-templated assembly method. Composites made of SiCNWs/rGO/SR were created by introducing SR into the filler matrix. The interface flaws present in the structural framework of filler and SR were reduced and the TC of SiCNWs/rGO/SR composites was boosted by using a novel copolymer named PEG-g-PDMS. With higher SiCNWs and rGO concentrations, the composites' TC was improved. The SiCNWs/rGO/SR composite showed TC of 2.74 W m−1 K−1 at the filler network concentration of 1.84 vol% [93].

Fig. 16.

Surface structures, Diagram of the production method, the image of GHP and in-plane and through-plane thermal diffusivities of GHP and GP (Reprinted with permission from Ref. [92] copyright 2019, American Chemical Society).

Pan. et al. [94] successfully created a vertically arranged SiCNWs/BN network using an ice-template assisted method, which resulted in a cellulose aerogel (CA) with a greatly increased cross-plane TC. The specific network design of SiC NWs coupled with BN provided a good TPTC of 2.21 W m−1 K−1 in the composite at a modest hybrid filler content of 16.69 wt% [94].

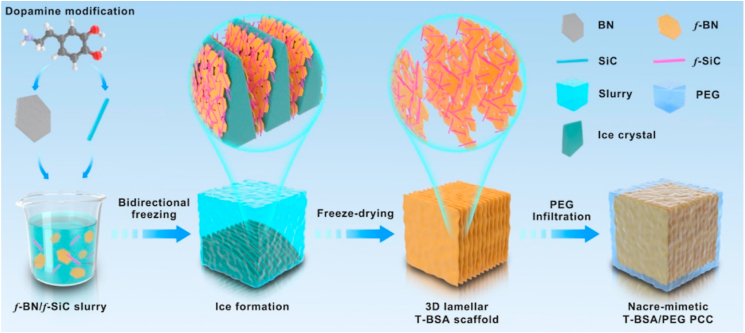

Hu. et al. [95] reported a new type of composite material made of polyethylene glycol (PEG) with a BN/silicon carbide aerogel (T-BSA) scaffold. The scaffold was designed with lamellar alignment and modified with dopamine. The composite material was created using a two-way freezing setup and PEG vacuum-infiltration, which resulted in vertically arranged pathways for the transfer of heat with minimum thermal obstacles at the interface. The resulting T-BSA/PEG composite material showed impressive properties, including a good TPTC of 3.94 W m−1 K−1 (Fig. 17) [95].

Fig. 17.

Diagrammatic illustration for producing nacre-mimetic T-BSA/PEG PCCs. (Reprinted with permission from Ref. [95] copyright 2023, Elsevier).

4.3. Thermal conductivity with carbon fillers

Among the different kinds of fillers, carbon-based fillers have the highest intrinsic TC, followed by metallic and ceramic fillers. Although several intriguing materials have lately been discovered, diamonds always keep the first position with the highest TC [66] (around 2000 Wm−1 K−1) [84,96]. On the other hand, diamonds can be graphitized by processing in vacuum at above 1000 K, leading to even better TC, particularly for diamond at the micrometer level. Additionally, graphite with a size of 8.5 μm exhibits an IPTC of 4300 Wm−1 K−1, which rises with the decrease in size of graphite [97]. Materials that are based on carbon such as CNTs, CFs, graphite, and graphene, possess favorable characteristics such as excellent TC, resistance to corrosion, and a lower coefficient of thermal expansion. These materials are often used in the production of TCPCs that do not require high levels of electrical insulation [29].

4.3.1. Carbon fibers (CFs) and carbon nanotubes (CNTs)

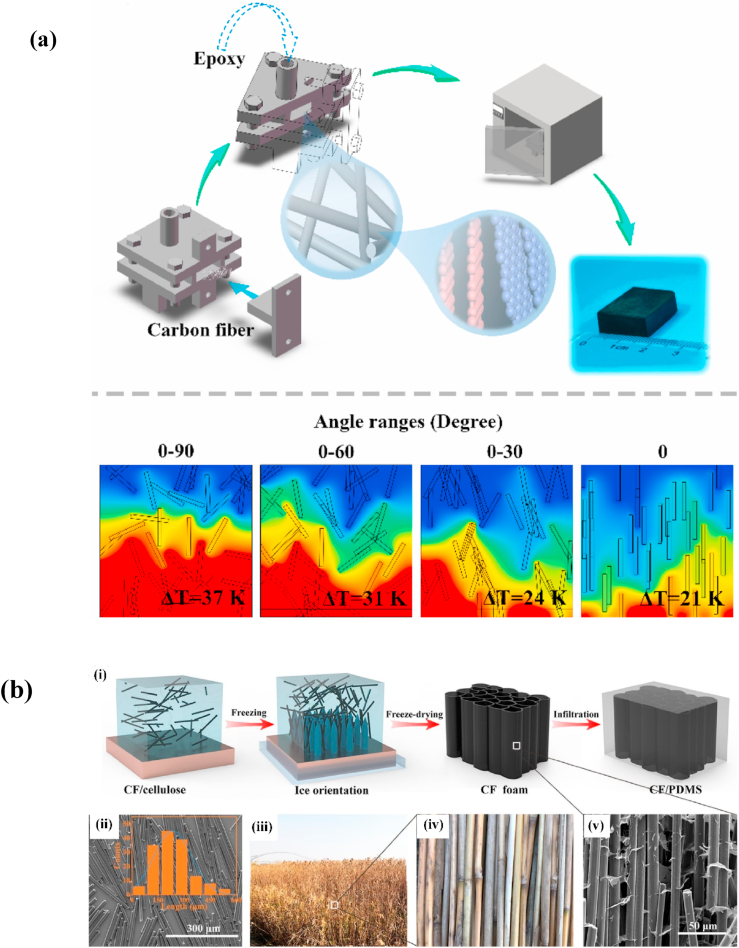

Carbon fibers are a very advantageous choice as fillers due to their exceptional properties, such as excellent TC, impressive strength-to-weight ratio, and desirable fatigue and corrosion resistance [98,99]. However, the incorporation of carbon fibers in TIMs is not commonly practiced because their one-dimensional structure significantly increases the viscosity of the composites when using traditional methods. This results in high processing complexity [100]. A thermally conductive TIM has been developed by Ma. et al. [101] by using a vertically aligned three-dimensional carbon fiber structure. The 3D-CFs structure is created by vertically freezing a CFs solution, followed by freeze-drying to remove the ice, and insertion into an epoxy resin matrix. Even at a lower concentration of CFs (13.0 vol%), the composites show a significantly improved TPTC of 2.84 W m−1 K−1 with respect to a pure epoxy resin, which is 0.19 W m−1 K−1 [101].

Vinyl polydimethylsiloxane (PDMS) composites were generated by Huang. et al. [102] by using carbon fibers (CFs) that were precisely oriented and linked by Al2O3 particles through the flow field (Fig. 18a and b). The TPTC (k⊥) of the resulting composites was increased up to 38.0 W m−1 K−1 with filler content of 24 vol% and 47 vol% of CFs and Al2O3 respectively. The effective out-plane thermal conductive network was made up of the arranged CFs connected by Al2O3. This work offers a feasible method to prepare TIMs on an industrial scale [102].

Fig. 18.

(a) Illustrative representation for the fabrication of O-PAC (PDMS/Al2O3/CFs) composites. (b) Softness and processability of O-PAC composites (Reprinted with permission from Ref. [102] Copyright 2022, Elsevier).

Li. et al. [103] proposed a specific approach that is based on orienting carbon fibers (CFs) by using a stress field. Epoxy-based composites consisting of a carbon fiber framework were fabricated by in-situ solidification inside the epoxy matrix. At a CF concentration of 46 wt%, the maximum TPTC of the epoxy composites was 32.6 W m−1 K−1. This is around 171 times that of neat epoxy (Fig. 19a) [103]. Carbon fibers (CFs) display extremely high TC as 1D thermal conductive fillers. However, conventional techniques, do not fully exploit this advantage, especially in the case of short carbon fibers. A micro-phragmites communis framework was produced by Hou. et al. [104] to increase the TC of composites. Then the composites were assembled by vacuum-assisted submersion in polydimethylsiloxane (PDMS). The TPTC of the polymer composites was 6.04 W m−1 K−1 due to the vertical morphology of CFs at their very low concentration. Additionally, the infrared camera was also used to examine the overall temperature shift of composites during the cooling and heating actions, and it shows an outstanding thermal transmission capability. By using this composite in the CPU for the elimination of heat, its practical use was examined. This work suggests acceptable methods for implementing the extraordinary through-plane TC of CFs to create highly thermally conductive composites (Fig. 19b) [104].

Fig. 19.

(a) Diagrammatic representation of orientation process and simulation of CFs (Reprinted with permission from Ref. [103] Copyright 2021, Elsevier). (b) Schematic illustration of the fabrication of CF foam (Reprinted with permission from Ref. [104] Copyright 2019, Elsevier).

4.3.2. Graphene and graphite

Graphene is the earliest two-dimensional compound discovered with a high aspect ratio and a specific surface area made up of carbon atoms. It has been widely used in dual-function composites that function effectively as EMI shielding because of its outstanding TC (>5000 W m−1 K−1), dielectric loss coefficient, and EC (>6000 S cm−1). Graphene/polymer composites are able to achieve a substantial increase in TC with a low percentage of graphene compared to other thermally conductive fillers [105,106].

Gao. et al. [107] proposed a strategy to construct heat conduction pathways within graphene paper along the cross-plane direction to achieve excellent through-plane TC. This was achieved by simultaneously filtering graphene sheets of two dissimilar lateral sizes. Following a typical graphitization post-treatment, the hierarchically organized graphene paper exhibited an improved TPTC of 12.6 W m−1 K−1 due to the thermal conduction pathways that are produced by short graphene sheets in the perpendicular direction (Fig. 20a, b, and 20c) [107].

Fig. 20.

(a) Diagrammatic scheme of the HGP production procedure. (b) Diagrammatic representation of the manner of assembly form in which a mixed distribution composed of two different measurements of graphene sheets in time of a quick filtration technique, resulting in the generation of a hierarchically oriented graphene paper. (c) Hierarchically oriented graphene paper (Reprinted with permission from Ref. [107] Copyright 2021, Elsevier). (d) (i) Schematic representation of preparation of PEG@PU/HOGF composite (ii) digital images of PEG, PEG@PU, and HOGF/PEG@PU heated for 0s, 30s, and 60s at 70 °C (Reprinted with permission from Ref. [108] Copyright 2023, Elsevier).

Phase-change materials (PCMs) have attracted a lot of attention for energy storage and thermal management applications. In research by Zhou et al. [108], an expanded graphite block with highly oriented layer structures was prepared. In the first step, a 3D network of polyurethane (3D PU) was created and then polyethylene glycol (PEG) was interpenetrated into the porous polyurethane network (PEG@PU). In the second step, the PEG@PU was infiltrated into a highly oriented graphite framework (HOGF) using a vacuum infiltration technique (Fig. 20d). The prepared PEG@PU/HOGF composite showed an excellent IPTC and TPTC of 36.52 and 1.53 Wm−1K−1 respectively at a HOGF loading of 40 %. A series of procedures made it possible to fabricate multi-layered structures and reduce the PEG leakage, which enhanced the material's capacity for thermal storage. This work offers a viable and promising method for the production of high-performance phase-change composites (PCCs) for energy storage and battery thermal management applications [108].

The coupling of 3D printing and 2D compounds like graphene, BN, and others opens up an endless number of possibilities for hierarchically ordered structure programming. The creation of an asymmetrically oriented structure of thermoplastic polyurethane (TPU) composites loaded with graphene in the course of the 3D printing technique has been reported by Guo. et al. [109]. With a graphene content of 45 wt%, the vertically oriented printed structure has a TPTC of up to 12 W m−1 K−1, which is almost 8 times higher than the horizontally printed structure and outperforms several standard polymer composites formed by other fillers. The improved TC is mainly due to the anisotropic morphology, which benefits from the optimal degree of graphene alignment, and the dense multiscale structure of a composite created by carefully managing the printing conditions [109].

Liu et al. used a polyamic acid salt/graphene oxide (PAAS/GO) suspension subjected to bidirectional freezing and subsequent lyophilization (freeze-drying) to create PAAS/GO hybrid aerogels with a lamellar structure [110]. Then, polyimide (PI) was formed by polymerization of PAAS, while GO was converted into thermally reduced graphene oxide (RGO) by thermal annealing at 300 °C. At about 2800 °C, PI was converted to graphitized carbon as a result of the latter graphitization by the inductive effect of RGO, while graphene with excellent characteristics was produced by thermal reduction of RGO. As a result, a graphene aerogel with lamellar morphology that possessed excellent TPTC was created for the first time. Its best through-plane TC is attributed to its vertically oriented and densely packed graphene sheets with exceptional quality. After vacuum-assisted interpenetration with the epoxy, with a graphene percentage of 2.30 vol%, the resulting epoxy composite showed exceptional TPTC of up to 20.0 W m−1 K−1, with a TC enhancement of 4310 %. In addition, the graphene aerogel with lamellar morphology provides the epoxy with the ultimate fracture toughness [110].

An. et al. [111] generated an advanced procedure to create strong covalent bonds between the reduced graphene oxide (rGO) and BN by conducting chemical reactions between different functional groups and using a chemical surface modification technology. These integrated materials were then used to create a 3D network in natural rubber (NR) using the ice-templated technique. After vulcanization, the resulting TIM, which is BN-rGO/NR, demonstrated excellent overall performance, including good TPTC of 1.04 W m−1 K−1 and sensitivity to heat flux [111].

Carbon-based fillers improve TC with reduced filler loading; yet, filler dispersion remains a challenge in their research and implementation. Despite carbon materials' high TC and light weight, their poor processing, very high cost, and poor electrical insulation prevent them from finding practical industrial applications in thermal sink equipment [29].

4.4. Thermal conductivity with micro fillers

This section addresses the ability of micro-filled composites containing filler networks oriented in random directions to transfer heat. Graphene has received a lot of interest as a filler to increase the TC of polymers owing to its unique heat-transfer characteristic. However, the TC improvement of graphene-loaded polymers is lower than estimated in reality. One possible option to solve this problem is to incorporate 2D graphene into 3D interconnected graphene, thus taking full advantage of the extraordinary characteristics of graphene. A liquid nitrogen-driven construction method was reported by Chen et al. [18] to produce a 3D, interconnected graphene microsphere structure. Graphene microspheres showed excellent enhancement efficiency (437 %) of TC per 1 wt% content when used as thermally conductive fillers for the epoxy resin matrix, resulting in an exceptional TPTC of 0.96 Wm−1 K−1. This increase in TC is ascribed to graphene microspheres' well-arranged 3D structural framework, which creates efficient thermal conduction channels inside the epoxy resin [18].

There are two major forms of BN, amorphous and crystalline. Both, amorphous (a-BN) and crystalline (hexagonal and cubic) forms are commercially available, but the hexagonal one (h-BN) is the single-layered most durable organized form, with a structure similar to graphite. This form shows a TC of 4.41 W m−1 K−1 with a micro-sized filler volume of 19.6 % [112].

Xie et al. [112] introduced the application of hexagonal boron nitride micro platelets as fillers to enhance the TC of polyvinyl alcohol (PVA). The unique shape of h-BN micro platelets allows them to orient themselves during processing, creating a rough pattern within the polymer matrix that facilitates the establishment of heat conduction channels. Consequently, even very low filler loadings allow for high TCs. For instance, for the h-BN/PVA composite a loading of only 1 wt % (0.6 vol %) resulted in a TC of 1.45 W m−1 K−1, while a 10 wt % (5.9 vol %) led to a TC of 3.92 W m−1 K−1. The study also discovered that the h-BN micro platelets’ shape is crucial, and that the harmony between the organic matrix and inorganic fillers is enhanced by surface treatment on h-BN fillers, improving distribution and degree of alignment, and thus increasing TC [113]. The surface treatment of filler is beneficial in lowering the overall viscosity and thus helps to improve filler distribution. More significantly, it lowers thermal interfacial resistance (TIR), allowing for the achievement of greater TC [54].

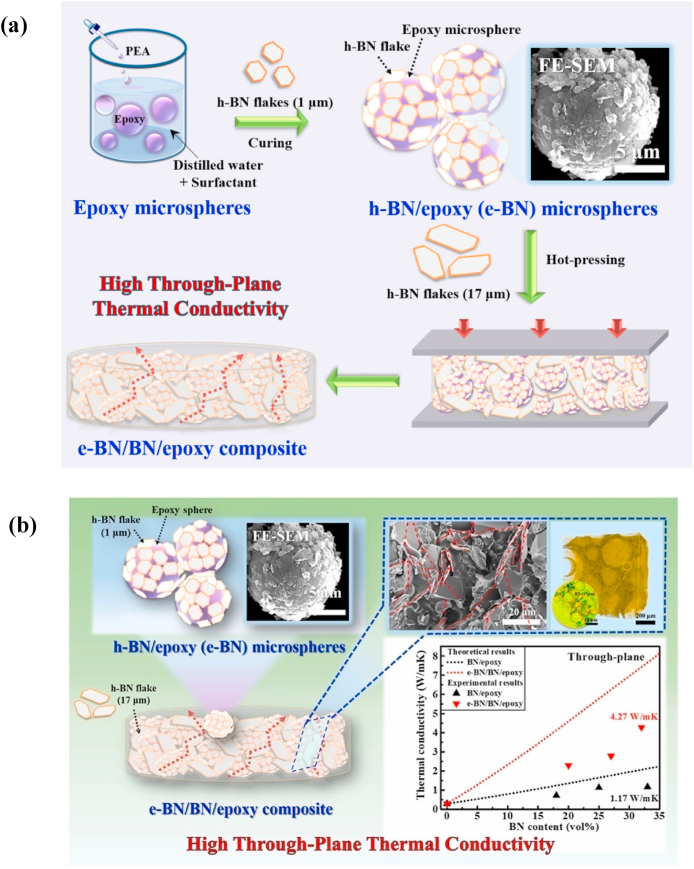

Jang et al. [114] developed high TPTC composites of h-BN and epoxy by the use of core-shell h-BN/epoxy (e-BN) microspheres. These microspheres were fabricated in an environmentally safe aqueous medium via a one-pot emulsion polymerization process. The surface of the epoxy microspheres was surrounded with self-organized h-BN flakes of 1 μm lateral size, resulting in e-BN microspheres, which helped to effectively align and distribute the flakes in the epoxy matrix. By combining the e-BN microspheres with the h-BN flakes (17 μm lateral size), the resulting e-BN/BN/epoxy composites provided outstanding TPTC compared to BN/epoxy composites (which lacked e-BN microspheres) with the same concentration of h-BN flakes. The e-BN/BN/epoxy composite containing 50 wt% (33 vol%) h-BN flakes demonstrated a remarkable TPTC of 4.27 W m−1 K−1, which was around 3.7 times higher than the BN/epoxy composite (1.17 W m−1 K−1). The reason behind this was that the h-BN flakes had a more randomized or isotropic orientation within the e-BN/BN/epoxy composite. The calculated TC values were consistent with those estimated by the use of the customized Mori-Tanaka method for micromechanical analysis. This production process for e-BN microspheres and e-BN/BN/epoxy composites, which is both environmentally friendly and scalable, has the potential to provide a novel technique for the development of electrically insulating polymer composites having exceptional TPTC (Fig. 21a and b) [114].

Fig. 21.

Diagrammatic scheme of the e-BN microsphere and e-BN/BN/epoxy composite fabrication method (Reprinted with permission from Ref. [114] Copyright 2023, Elsevier).

4.5. Thermal conductivity with nano fillers

Since the last decade, researchers have become increasingly interested in nanofillers because of their potential to confer unique properties to microfillers. However, a significant challenge in their use is the prevention of agglomeration of nanoparticles during dispersion. Ceramic fillers at the nanoscale are particularly promising because of their TC, electrical insulation, and lower coefficient of thermal expansion. However, the discontinuous filler contact and mismatch in thermal expansion coefficient limit their ability to enhance TC in randomly dispersed ceramic-polymer composites. Therefore, recent studies have focused on creating highly networked filler contacts to facilitate efficient channels for heat transfer, while minimizing the loading of filler in the composite [115].

Core-shell nanoparticles have emerged as a promising type of nano fillers for TC enhancement in composite materials. In this approach, nanoparticles are first created as cores and then coated with one or multiple layers of high TC materials as shells, before being incorporated into the polymer matrix. By using these core-shell nanoparticles instead of the core-only nanoparticles, the TC of the resulting composite could be enhanced remarkably because of the enhanced TC of the shell layers [116].

A new type of thermally conductive filler network has been fabricated by combining zero-dimensional silver nanoparticles (AgNPs), one-dimensional silver nanowires (AgNWs) as well as carbon fibers (CFs) and incorporating them in an epoxy matrix. The CFs were coated by AgNPs to enhance the heat-conducting paths among them. The incorporation of a very low percentage of AgNWs (only 3 wt %) to CF mats, garnished with AgNPs, resulted in a remarkable increase in TC of epoxy. The epoxy composites containing AgNP@CF/AgNWs networks exhibited a TPTC of 0.76 W m−1 K−1 which is 50 % higher than that of CF-based composites with no silver particles. These findings indicate that the 0D and 1D Ag fillers are highly efficient in improving TC. Furthermore, the epoxy nanocomposites exhibit improved thermal management properties in cross-plane direction compared to CF-based composites, making them promising for efficient cooling applications [87].

TPTC and IPTC of 8.85 Wm−1 K−1 and 32.01 Wm−1 K−1 respectively were shown by the mixture of diamond and graphene when Zhang et al. perfectly homogenized these two compounds in nanofibrillated cellulose and then compressed and annealed them at an elevated temperature of 1500 °C (Fig. 22) [117].

Fig. 22.

Diagrammatic scheme of MDs@GNPs/NFC film generation (Reprinted with permission from Ref. [117] Copyright 2022, Elsevier).

4.6. Thermal conductivity with hybrid fillers

The incorporation of one kind of ceramic material (h-BN) has the obvious benefit of easy and limitation of procedures and artificial factors for its synthesis, as well as improved development of related computational models that have been the subject of extensive research. However, when composites are filled with only one type of filler, improving their TC is challenging because of phonon scattering caused by defects or interfaces. The use of fillers with high TC as reinforcement in the polymer matrix causes a rise in the effective TPTC of the composite as the percentage of filler increases. However, the composites can become hard due to the high amount of filler. The main disadvantages of composites with this high filler content are the significant weight of the polymer, its expensive price, and the loss of the electrical, optical, and mechanical characteristics of the polymer with the hard filler particles (usually ceramic) acting as flaws in the polymer matrix. Furthermore, the viscosity of the composite rises according to the rise in the volume fraction of filler, so the high filler content reduces the material's processability, which is one of the most significant advantages of polymers. Also, high loading of filler results in abrasion of processing equipment [16].

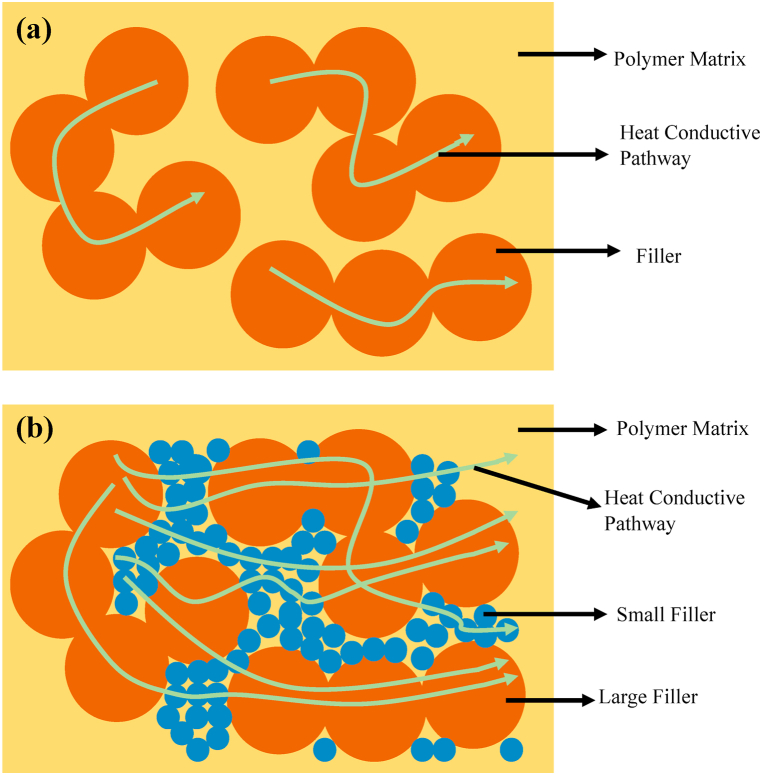

Hybrid fillers can be used to compensate for the inherent shortcomings of single fillers and achieve greater efficiency in TC enhancement. Fillers of various shapes and sizes can be used to facilitate the formation of efficient and continuous thermal conduction passage by filling the spaces or voids between the particles. Researchers have broadly studied the incorporation of multiple thermally conductive fillers with high intrinsic TC into polymers. They have observed that these composites exhibit a clearly larger TC (even at low filler loadings) than composites loaded with only one kind of filler. This increase in TC is due to the synergistic effect between the two or more different fillers. The primary reason for this is because the hybrid fillers cause improved dispersion of fillers inside the polymer matrix and the bridging of particles which facilitate the generation of efficient thermal channels, and in this way reduce the gap in the polymer matrix [111].

To enhance the TC of hybrid fillers, it is crucial to consider multiple interface scattering at the filler contact. There is a critical need to adopt a rational approach to design the filler contact, even though there is currently a lack of established principles in this area. A contact probability model was designed by Qi. et al. [118] to assess the impact of hybrid fillers, including different types of Al2O3 and SiC whiskers, on the TC and chances of contact in silicone rubber composites. Results from both experiments and simulations indicate that the TC of composites is significantly determined by three key factors: filler size, filler shape, and volume fraction. Therefore, these factors should be carefully considered when selecting hybrid fillers for composites.