Abstract

Enormous amount of protective masks was consumed in connection with the COVID-19 pandemic and they still burden the environment. Therefore, it is necessary to look for possibilities of their disposal in an ecologically acceptable way. This article focuses on particulate matter produced concerning the energy disposal of pandemic FFP2 masks. These masks were processed into small pieces, added to spruce and beech wood (in the weight proportion 5 % and 10 % of FFP2 masks) and formed into pellets. The concentration of particulate matter formed during their combustion was measured by the gravimetric method. The inorganic elements were detected from filters with captured particulate matter by an energy-dispersive X-ray fluorescence spectrometer and verified by inductively coupled plasma-optical emission spectroscopy. It was found that higher concentrations of particulate matter were recorded predominantly with a higher mass airflow. In both airflows (40 % and 50 %), beech pellets had a higher mass concentration than spruce pellets probably caused by the presence of bark in beech wood. Based on the chemical composition, the following elements in small amounts (0–2 mg on a filter) were identified: K, S, Cl and Fe. High concentrations of harmful elements carried in particulate matter have not been detected. FFP2 masks added in a small percentage (up to 10 %) can be used in wood pellets for combustion purposes without significantly affecting the combustion process.

Keywords: Disposal of masks, Waste utilization, COVID-19, Particulate matter, Emissions, Mass concentration, Inorganic elements

1. Introduction

Pollution is a major environmental problem that affects the health and wellbeing of people all over the world. Air pollution in indoor and outdoor environment is causing damage first to respiratory system and then can cause long term health complications with early deaths [1]. Pollutants such as particulate matter, ozone, and other air pollutants are known to cause a range of adverse health effects, including respiratory and cardiovascular diseases, as well as cancer [2].

Increased air pollution can also have effect on children behaviour, where study made by Hongjun Yu [3] showed decrease of physical activity in observed group of children in China. Road dust, biomass burning or present sea salt was likely to be associated with adverse cardiovascular and respiratory health effects. In cold seasons, coal combustion is the primary source responsible for adverse health effects, while in warm seasons, traffic is the primary source. However, the specific sources which are associated with adverse health effects vary across different studies [4].

In world comparison made by Mukherjee [5], most polluted are areas with heavy industry and locations where coal is the main energy source. In Europe, primary energy resources and pollution sources differ according to region or area. Different pollution was observed in urban roadsides than in rural alpine valleys. As shown in this presented study Kaspar R. Daellenbach [6], one of main sources for heating sector in Europe is primary wood, in form of wood logs, briquettes and pellet. New combustion equipment brought to market made it possible to achieve more comfort with automated devices. Updated design was applied to main parts of such biomass heat source – the combustion chamber with burner, feeding system and also heat exchanger. Measurement systems are also applied to small heat sources to lower the amount of harmful emissions released to the environment, first of all lambda probe and modular controllers for air and fuel control [7].

These systems make it possible to better steer the burning process and achieve desired effectivity of a small heat source. Air flow distribution plays crucial role in achieving low emissions, not only of gases like CO, NOx, but first of all to emissions of particulate matter. Although the division of combustion air into three airflow rates is theoretically satisfactory, even with total amount of air required for complete combustion of fuel present, incomplete burning process products are still released. This can be assigned to required dynamic airflow change [[8], [9], [10]]. New technologies, that emerged in last time period, are using wood fuel in form of pellets. These new energy sources made it possible to better regulate the burning process and in final step helped to achieve lower emissions.

In closer look at particulate matter (PM) from biomass used for heating as such, huge differences occur even with similar fuels used. As shown in study of E.D. Vicente [11], which focused on different combustion appliances with various fuels, quality of fuel used is heavily influencing released PM to environment. This study showed large differences between low quality pellets and pellets made according to environmental specifications. In case of low quality pellets, the total PM varied between 75 and 139 mg. MJ−1. For pellets made from mixture of pine and spruce burned in modern pellet stove, the total PM released to environment was in range of 15–43 mg. MJ−1 [11].

In order to reduce air pollution from burning apparel and reduce the associated health risks, it is important to reduce emissions by promoting the replacement of old burning stoves, but also to use quality fuels. Knowledge about particulate matter emissions is essential to define strategies for environmental protection. Considerable variance is present, especially between older home appliances compared to advanced residential energy conversion systems such as modern wood stove and automatic pellet stove that can achieve not only low emissions, but also higher combustion efficiency, up to 90 % [12].

Next step in lowering the use of fossil fuels are plant based fuels [13]. Agricultural waste products are more often used as alternative fuels to high quality wood based fuels. Many studies were made focused at biomass as energy source. The study of Perea-Moreno et al. [14] shows the feasibility of agricultural products usage as addition and substitution for wood and fossil fuels. Agricultural residues as straw or even hay are presented as more commonly used solid biofuel. Also the lower price for such fuel is one of important parameters [15].

Particulate matter produced by burning of such agriculture biomass based pellets pose also danger for health. PM, especially particles with an aerodynamic diameter <1 μm emitted from agricultural biomass combustion, are generally in higher concentrations than many environmental standards due to its high alkali content in comparison to classical wood pellets. To lower these amounts, additives are used in biomass combustion. Additives can be categorized into Si–Al-based, Ca/Mg-based and P-based sorbents, based on prevalent chemical composition. For example, the addition of kaolin has been widely studied to reduce particulate matter emissions. Latest studies also show, that some kind of chemical pre-treatment for biomass can cause lowering of total PM released after burning process [16].

Different goals are achieved with additives, that should change primary properties of pellets, such as tear resistance or forming temperature. The main purpose of many additives is to improve properties of pellets made from different biomass sources. Additives are added up to 60 %, but this changes not only the mechanical properties, but also the caloric value [17]. These additives also influence ash forming, where the increased volume of additives can result in higher ash formation, up to 50 % [18]. Latest trends show, that as additives are also considered secondary resources, as for example coffee dregs, coffee husks or hazelnut shells and switch grass. These additives include mostly agricultural residues, energy crops or even solid waste materials [19].

As additive material can be used also material, that is not changing mechanical properties of pellets, but is used to replace part of wood material used for pellets production. This approach is used in many cases, where wooden biomass is not present in adequate amount. With this production of pellets, also different fuels, such as straw or hay, even waste can be used and utilized this way.

FFP2 masks are one such waste material, which has been used to reduce the COVID-19 transfer from one person to another. For this reason, enormous amounts of protective masks were consumed and they burden the environment. This article deals with emissions produced in connection with the energy disposal of pandemic FFP2 masks. These masks were processed by crushing and mixing devices into small pieces suitable for the pelleting process and further blended with spruce and beech sawdust. However, re-use of protective masks in this way can bring the formation of emissions during the combustion of pellets with the presence of FFP2 masks. FFP2 masks were added in small weight percentage (5 % and 10 %), so there is no need to re-adjust the combustion process. The concentration of particulate matter formed during their combustion was measured by the gravimetric method. Particulate matter was captured on filters in the flue pipe of the chimney and further analyzed in ARL™ QUANT'X EDXRF spectrometer by energy-dispersive X-ray fluorescence spectrometry for detection of inorganic elements. The measurements of inorganic elements were verified by inductively coupled plasma-optical emission spectroscopy.

2. Material and methods

2.1. Used fuel

Wood pellets were chosen as a fuel for further measurements and analyses. Wood pellets were made from spruce and beech sawdust. Other tested pellets consisted also from 5 % to 10 % of the weight proportion of processed FFP2 masks prepared by crushing and mixing devices into small pieces useable in the pellet process. The main component was carbon for all samples, for pure spruce pellets (Spruce 100) 47.34 %, for spruce pellets with 5 % of FFP2 masks (Spruce 95) about 2.43 % higher and for spruce samples with 10 % of FFP2 masks (Spruce 90) about 4.03 % higher than pure spruce, further pure for beech pellets (Beech 100) 45.90 %. For beech samples with 5 % of FFP2 masks (Beech 95) about 2.94 % higher and for beech samples with 10 % of FFP2 masks (Beech 90) about 5.07 % higher than pure beech. Hydrogen content was in the range of 6.14–7.04 %, Sulphur content in the range of 0.03–0.05 % and no nitrogen content for all tested samples was detected. These samples had ash content in the range of 0.55–1.6 %. However, higher ash content was measured for beech samples (1.0–1.6 %). The presence of FFP2 masks increased the lower calorific value (LCV) from 17.59 MJ/kg up to 19.95 MJ/kg for spruce samples and from 16.86 MJ/kg up to 19.78 MJ/kg for beech samples. Ultimate and proximate analysis of individual pellet samples are stated in Table 1.

Table 1.

Ultimate and proximate analysis of pellet samples.

| Sample | Carbon [%] | Ash – carbon [%] | Hydrogen [%] | Nitrogen [%] | Sulphur [%] | Moisture [%] | Volatile matter dry [%] | Fixed carbon dry [%] | Ash dry [%] | LCV [MJ/kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| Spruce 100 | 47.34 ±0.59 |

25.84 ±1.36 |

6.30 ±0.09 |

0.00 ±0.00 |

0.04 ±0.04 |

5.66 ±0.12 |

82.02 ±0.09 |

17.43 ±0.12 |

0.55 ±0.02 |

17.59 ±0.08 |

| Spruce 95 | 49.77 ±0.27 |

16.94 ±2.29 |

6.14 ±0.04 |

0.03 ±0.04 |

4.63 ±0.05 |

82.14 ±0.08 |

17.14 ±0.09 |

0.73 ±0.02 |

18.97 ±0.17 |

|

| Spruce 90 | 51.37 ±0.24 |

10.16 ±0.12 |

6.68 ±0.04 |

0.03 ±0.04 |

4.10 ±0.04 |

83.28 ±0.22 |

15.83 ±0.17 |

0.89 ±0.05 |

19.95 ±0.14 |

|

| Beech 100 | 45.90 ±0.25 |

7.07 ±0.25 |

6.93 ±0.02 |

0.05 ±0.00 |

5.25 ±0.05 |

81.77 ±0.14 |

16.64 ±0.14 |

1.60 ±0.01 |

16.86 ±0.18 |

|

| Beech 95 | 48.87 ±0.04 |

6.57 ±0.18 |

6.64 ±0.03 |

0.01 ±0.01 |

4.78 ±0.05 |

83.19 ±0.13 |

15.81 ±0.12 |

1.00 ±0.01 |

18.15 ±0.06 |

|

| Beech 90 | 50.97 ±0.28 |

7.69 ±0.08 |

7.04 ±0.07 |

0.05 ±0.01 |

4.60 ±0.02 |

84.06 ±0.10 |

14.84 ±0.12 |

1.10 ±0.02 |

19.78 ±0.09 |

More detailed analysis of the energy assessment of COVID-19 medical waste as a potential fuel was realized in previous research [20]. All pellet samples were combusted in a small heat source USPOR 18 AUTOMAT with a retort burner.

2.2. Measurement of particulate matter

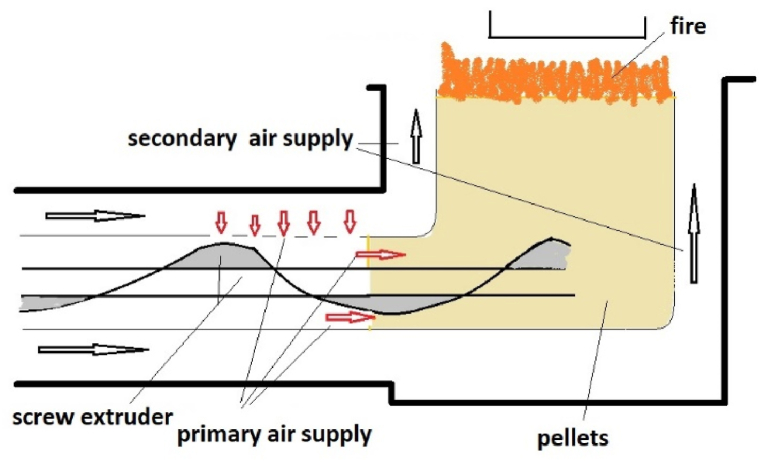

Particulate matter was captured by a gravimetric probe during pellet combustion. This probe was placed in the flue pipe according to STN ISO 9096 and further connected with an evaluation device Tecora ISOSTACK BASIC, Pitot tube, a cooling box, and a silica gel dryer. The layout is shown in Fig. 1.

Fig. 1.

Particulate matter measurement.

The principle of the air and fuel supply is shown in Fig. 2. Air supply was controlled by a fan. It was supplied by two ways: primary with the fuel (pellets) and secondary by the retort burner. The supply of air and fuel was regulated using an electronic control unit. The entire system is hermetically sealed. Automatic operation is protected against backfiring using two protective sensors. The protective sensor on the screw extruder completely turns off the fan when the temperature reaches 92 °C. The additional protective sensor in the hopper will activate the screw rotation and discharge all materials into the boiler when the temperature reaches 92 °C.

Fig. 2.

Air and fuel supply.

Filters with captured particulate matter were weighed before measurement, represented as m1 (mg) and after measurement as m2 (mg). The calculation of mass concentration is stated in Equation (1) and it consists of mentioned weights (m1, m2) and sample volume Vgn (m3). Isokinetic conditions were fulfilled during the measurements with isokinetic deviation in the range from −4.5 % to +3.8 %.

| (1) |

The calculation of mass concentration under reference conditions Cr is stated in Equation (2) with the following quantities: O2ref (%) is the reference content of oxygen and O2oper (%) is oxygen content for operating conditions.

| (2) |

A flue fan kept the chimney draft at a constant 12 ± 2 Pa, while a frequency regulator managed the velocity. A differential pressure sensor with an accuracy of 0.5 % and a range of up to 100 Pa was used to measure this draft. The surrounding pressure was 996.6 hPa ± 0.5 hPa. In these experiments, the fuel supply time was set at a ratio of 18/25 s (supply/standstill). The air supply was implemented in two settings: with a mass airflow of 40 %, which presents 108 kg/h and with a mass airflow of 50 %, which presents 114 kg/h.

Mass airflow Qm was calculated from volume airflow and density. Volume airflow was determined based on the velocity v measured by an anemometer FVAD15HMK20 (accuracy: ±0.5 % of final value sensor and ±1.0 % of measured value) at a sufficient distance placed in a pipe with known diameter. The temperature and air humidity were also measured and their change was within the range of 22 ± 1°C for temperature and 52 ± 1 % for relative air humidity. The mean value of air density ρ = 1.175 kg/m3 was determined from Mollier h-x diagram by using of these data. Equation (3) shows the calculation of mass airflow.

| (3) |

2.3. Analyses of particulate matter

Filters with captured particulate matter were analyzed in ARL™ QUANT'X EDXRF spectrometer by energy-dispersive X-ray fluorescence spectrometry in a vacuum atmosphere. The evaluation of measured spectra was realized in the program UniQuant, which worked on the principle of fundamental parameters. The concentration of elements ranging from sodium (11Na) to uranium (92U) was detected in individual filters by a spectrometer and evaluation software. The conditions during the measurement of inorganic elements in filters are stated in Table S1 in Supplementary materials.

The measurements of inorganic elements on the spectrometer were verified by inductively coupled plasma-optical emission spectroscopy (ICPOES) using an iCAP 7600 DUO (PlasmViewing-axial and radial) instrument (supplier Thermo Fisher Scientific). Instrument parameters of ICP spectrometer are stated in Table S2 in Supplementary materials. The microwave decomposition system was used from CEM company (model MARS6) for the preparation of samples for the ICP spectrometer measurement. This procedure, using a program for the decomposition of cellulose filters, was obtained as complete decomposition of the samples. There were used 26 element standard 100 mg/L (AN9090) samples from ANALYTICA spol. s r.o., Praha (CZ) with the following prepared and used concentrations: 25–50 - 100–250 μg/L. As control standards were used QC-TMFM-B-SPIKED and QC-TMFM-D-SPIKED samples from HPS (High-purity Standards), North Charleston (USA).

3. Results and discussion

3.1. Mass concentration of particulate matter

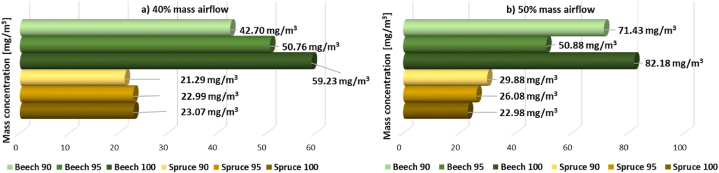

The graphical evaluation of the mass concentration of particulate matter is shown in Fig. 3 for 40 % mass airflow and 50 % mass airflow. In both airflows, beech pellets had a higher PM mass concentration than spruce pellets. It was also found that higher concentrations of particulate matter were recorded predominantly with a higher mass airflow. The lowest PM concentration was detected for spruce pellets with 10 % FFP2 masks and the highest PM concentration for pure beech pellets with adjusted 40 % mass airflow. The lowest PM concentration was detected for pure spruce pellets and the highest PM concentration for pure beech pellets with adjusted 50 % mass airflow. However, the results can be influenced by the presence of bark in the samples, because sawdust was obtained from wood manufacturer.

Fig. 3.

Mass concentration of PM during (a) 40 % mass airflow and (b) 50 % mass airflow.

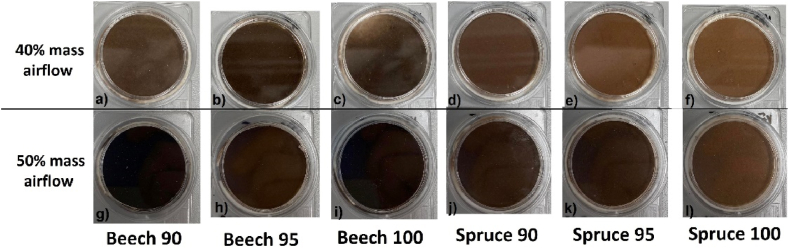

Captured particulate matter on individual filters are shown in Fig. 4. Filters with more particulate matter had darker colors and confirmed the results of assumed mass concentrations.

Fig. 4.

Filters with captured particulate matter during 40 % mass airflow for samples: (a) Beech 90, (b) Beech 95, (c) Beech 100, (d) Spruce 90, (e) Spruce 95, (f) Spruce 100 and during 50 % mass airflow for samples (g) Beech 90, (h) Beech 95, (i) Beech 100, (j) Spruce 90, (k) Spruce 95, (l) Spruce 100.

3.2. Inorganic elemental analysis of particulate matter

Six filters with an air mass flow rate of 40 % during the combustion process and six other filters with an air mass flow rate of 50 % were analyzed for inorganic elements. The following elements were identified in these filters: K, S, Cl and Fe. The weight of these elements in mg/filter is shown in Table 2, Table 3 together with their standard deviation (SD). However, K from all elements had the largest presence. PM from beech pellets had the weight of K on filters higher than 1 mg, while PM from spruce pellets had the weight in the range 0.70–0.82 mg for 40 % mass airflow and in the range 0.64–0.78 mg for 50 % mass airflow. However, PM from beech pellets with 5 % FFP2 had the weight of K approximately 2.01 mg for 50 % mass airflow. This sample had also the highest weight of S with the value of 0.46 mg from all tested samples. However, the weight of Cl was higher for PM from spruce pellets with using 40 % mass airflow during combustion. On the contrary, PM from beech pellets with using 50 % mass airflow had higher weight of Cl than PM from spruce pellets except for pure samples without FFP2. Fe presence was only in very small amounts in the range of 0.001–0.006 mg.

Table 2.

Inorganic elemental analysis of particulate matter during 40 % mass airflow detected by ARL™ QUANT'X EDXRF.

|

Element |

Beech 90 |

Beech 95 |

Beech 100 |

Spruce 90 |

Spruce 95 |

Spruce 100 |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | |

| K | 1.6457 | 0.0044 | 1.8186 | 0.0053 | 1.0747 | 0.0151 | 0.7541 | 0.0040 | 0.7063 | 0.0036 | 0.8122 | 0.0039 |

| S | 0.3185 | 0.0040 | 0.4321 | 0.0046 | 0.2194 | 0.0031 | 0.2988 | 0.0032 | 0.2559 | 0.0030 | 0.2717 | 0.0031 |

| Cl | 0.1389 | 0.0025 | 0.1684 | 0.0032 | 0.1122 | 0.0016 | 0.1778 | 0.0031 | 0.1754 | 0.0031 | 0.2146 | 0.0034 |

| Fe | 0.0036 | 0.0021 | 0.0022 | 0.0021 | 0.0041 | 0.0001 | 0.0064 | 0.0021 | 0.0030 | 0.0021 | 0.0035 | 0.0021 |

Table 3.

Inorganic elemental analysis of particulate matter during 50 % mass airflow detected by ARL™ QUANT'X EDXRF.

|

Element |

Beech 90 |

Beech 95 |

Beech 100 |

Spruce 90 |

Spruce 95 |

Spruce 100 |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | mg/filter | SD [mg] | |

| K | 1.5704 | 0.0039 | 2.0106 | 0.0534 | 1.4993 | 0.0287 | 0.6465 | 0.0038 | 0.6654 | 0.0038 | 0.7790 | 0.0039 |

| S | 0.2433 | 0.0035 | 0.4567 | 0.0121 | 0.2639 | 0.0051 | 0.3195 | 0.0032 | 0.2646 | 0.0030 | 0.2427 | 0.0029 |

| Cl | 0.1452 | 0.0025 | 0.1867 | 0.0050 | 0.1521 | 0.0029 | 0.1032 | 0.0027 | 0.1234 | 0.0028 | 0.2249 | 0.0034 |

| Fe | 0.0024 | 0.0020 | 0.0018 | 0.0000 | 0.0029 | 0.0001 | 0.0058 | 0.0020 | 0.0043 | 0.0020 | 0.0035 | 0.0020 |

The spectrum displayed by the ARL™ QUANT'X EDXRF is shown in Fig. 5. These spectra confirm the presence of the inorganic elements listed in Table 2 and Table 3 and they are divided between PM from spruce pellets and PM from beech pellets graphically. Fig. 5 consists also of a pure filter, which was deducted from the results. No peak was recorded in Group 2. The following elements were identified in total: Ba, As, Br, Rb, Sr, Y, Zr, Zn, Fe, S, Cl, K, Ca, Na, Al, Si. However, pure filter consisted of more weight of these elements than individual samples: Ba, As, Br, Rb, Sr, Y, Zr, Zn, Ca, Na, Al, Si. Only elements Fe, S, Cl and K were a part of PM samples, which can be seen in their higher peaks than pure filter. Individual samples are presented in Fig. 5 for example as: B90-40 % (sample Beech 90 with 40 % air supply) or S90-40 % (sample Spruce 90 with 40 % air supply), etc.

Fig. 5.

Spectrum of elements of particulate matter on filters: Group 1 (a) for beech samples and (b) for spruce samples, Group 3 (c) for beech samples and (d) for spruce samples, Group 4 (e) for beech samples and (f) for spruce samples, Group 5 (g) for beech samples and (h) for spruce samples, Group 6 (i) for beech samples and (j) for spruce samples, Group 7 (k) for beech samples and (l) for spruce samples, Group 8 (m) for beech samples and (n) for spruce samples.

The results from element measurements in ICPOES are stated in Table 4. The realized comparison measurements for verification of results showed a correlation coefficient (r) between the following elements: K with average r = 0.68 and S with average r = 2.06. Fe is not listed in Table 4 due to its very small amount at the limit of measurability. Cl cannot be measured by ICPOES, because the iCAP7600 spectrometer measures the emission spectrum from 166 nm and the spectral emission line of Cl is 134.7 nm.

Table 4.

Inorganic elemental analysis of particulate matter detected by ICPOES.

|

Element |

Beech 90 |

Beech 95 |

Beech 100 |

Spruce 90 |

Spruce 95 |

Spruce 100 |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 % mg/filter | 50 % mg/filter | 40 % mg/filter | 50 % mg/filter | 40 % mg/filter | 50 % mg/filter | 40 % mg/filter | 50 % mg/filter | 40 % mg/filter | 50 % mg/filter | 40 % mg/filter | 50 % mg/filter | |

| K | 2.0624 | 1.9309 | 2.0793 | 2.0998 | 1.7608 | 1.7703 | 1.2446 | 1.2847 | 1.2758 | 1.3750 | 1.3236 | 1.4848 |

| S | 0.2541 | 0.2207 | 0.3702 | 0.2856 | 0.0828 | 0.07139 | 0.1303 | 0.1448 | 0.1842 | 0.0683 | 0.2084 | 0.1100 |

The procedure of sample preparation and measurement using the ICPOES spectrometer was verified using CRM standards high-purity standards (hps). The results of the measurements are shown in Table 5 and Table 6. The average stated in Table 5 and Table 6 is calculated from two measurements.

Table 5.

Results of analysis of CRM standards for standard QC-TMFM-B-SPIKED.

| Label | Unit | Al | As | Ba | Cd | Co | Cr | Cu |

|---|---|---|---|---|---|---|---|---|

| Certificate value | μg/filter | 50.0 | 10.0 | 10.0 | 10.0 | 10.0 | 25.0 | |

| RSD-certificate value | μg/filter | 5.0 | 0.1 | 0.1 | 0.1 | 0.4 | 0.3 | |

| Average - QC-TMFM-B-SPIKED | μg/filter | 46.1 | 9.1 | 9.3 | 9.6 | 10.0 | 22.7 | |

| Difference | % | 8.4 | 9.9 | 7.8 | 3.7 | 0.4 | 10.2 | |

| Label | Unit | Fe | Mn | Ni | Pb | Tl | V | Zn |

| Certificate value | μg/filter | 25.0 | 10.0 | 10.0 | 25.0 | 10.0 | 10.0 | 50.0 |

| RSD-certificate value | μg/filter | 0.3 | 0.1 | 0.1 | 0.5 | 0.2 | 0.1 | 1.0 |

| Average - QC-TMFM-B-SPIKED | μg/filter | 24.2 | 9.3 | 9.5 | 21.9 | 8.2 | 9.7 | 45.8 |

| Difference | % | 3.3 | 7.0 | 5.4 | 14.3 | 22.7 | 2.8 | 9.1 |

Table 6.

Results of analysis of CRM standards for standard QC-TMFM-D-SPIKED.

| Label | Unit | Al | As | Ba | Cd | Co | Cr | Cu |

|---|---|---|---|---|---|---|---|---|

| Certificate value | μg/filter | 50.0 | 10.0 | 2.5 | 1.0 | 2.5 | 2.5 | 2.5 |

| RSD-certificate value | μg/filter | 0.5 | 1.0 | 0.0 | 0.0 | 0.0 | 0.2 | 0.0 |

| Average - QC-TMFM-D-SPIKED | μg/filter | 50.8 | 8.9 | 2.4 | 0.9 | 2.3 | 2.6 | 2.2 |

| Difference | % | 1.6 | 12.1 | 5.7 | 6.4 | 8.8 | 3.8 | 14.2 |

| Label | Unit | Fe | Mn | Ni | Pb | Tl | V | Zn |

| Certificate value | μg/filter | 2.5 | 1.0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| RSD-certificate value | μg/filter | 0.1 | 0.0 | 0.0 | 0.1 | 0.1 | 0.0 | 0.1 |

| Average - QC-TMFM-D-SPIKED | μg/filter | 2.7 | 0.8 | 2.4 | 2.1 | 2.0 | 2.3 | 2.8 |

| Difference | % | 8.9 | 18.7 | 6.0 | 21.3 | 23.9 | 8.8 | 10.5 |

3.3. Discussion of health risks connected with energy disposal of pandemic waste

Before the treatment of pandemic waste, it is necessary to apply thermal disinfection to sterilize the contaminants. However, the virus such as parvovirus could be stable at a temperature of 80 °C for 30 min [21], so there is need for using other virus reduction methods, for example spraying using alcohol-based materials or ultraviolet radiation [22]. Ultraviolet radiation can inactivate all viruses within 15 min [21]. The technologies to treat and recover pandemic waste consist of incineration (combustion), carbonization (torrefaction), pyrolysis (liquefaction), and gasification. Moreover, not utilized protective masks, which are disposed in landfills or dumpsites, can decompose or degrade into a significantly smaller size of particles, known as micro-plastics [23].

The most commonly adopted technology to effectively treat various medical wastes is high-temperature incineration (combustion) [24]. However, it can lead to high environmental concerns due to high emission of carbon dioxide and high consumption of additional fuel needed to reach the temperature higher than 800 °C [25]. The combustion of pandemic waste should be controlled by proper flue gas treatment [23].

In this article, for safety reasons, FFP2 masks were used in form of uncontaminated waste from their production. Consequently, FFP2 masks were added as an additive in small amounts (5 % and 10 %) to avoid disruption of the pelleting process. These pellets were used as a fuel for heat sources intended for the combustion of wood pellets. More heat should be released with a higher content of FFP2 masks in pellets, and classic heat sources are not constructed for this. Pellets with less mask content do not require adjusting the combustion process with respect to ash and also emission content. In case of the use of higher-content FFP2 masks, these should be treated as alternative pellets requiring special combustion.

The combustion of pellets with the small presence of FFP2 masks caused a slight efficiency improvement due to a slight increase in the calorific value and carbon content. Except it, face masks have a higher content of volatile matter and less ash content than wood sawdust. Therefore, the combustion of samples with the presence of FFP2 masks caused also a slight increase of heat output. However, the presence of small amount of face masks (up to 10 %) did not significantly affect the combustion process. But their presence in wood pellets led to the lower mechanical durability due to lower lignin content, the higher rate of pellet breakage during transport on the conveyor, and the resulting higher rate of flying out of burning fuel particles. However, mechanical durability was acceptable for combusted samples up to 10 % of the weight proportion of face masks. As a result of the use of FFP2 masks in spruce or beech sawdust, the mass concentration of particulate matter has not increased significantly. On the contrary, a slight decrease in mass concentration can be observed. Higher differences were visible during combustion of beech pellets than spruce pellets. It could be caused by higher presence of bark in beech sawdust. Also higher mass concentrations were measured during using larger mass airflow (50 %).

The following elements were identified in filters with captured particulate matter by ARL™ QUANT'X EDXRF spectrometer: K, S, Cl and Fe. This method to identify and quantify many elements was also used in the following studies: for waste polymers [26], for biochar [27] and for example for inorganic elemental analysis of particulate matter in a road tunnel environment [28]. Ueda et al. [29] found an association between mortality and mass of particulate matter PM2.5 (smaller than 2.5 μm) in transitional seasons. Sulfate, nitrate, chloride, ammonium, potassium, EC, and OC were significantly associated with mortality in a single-pollutant model.

Potassium was the most abundant inorganic element in the tested filters in this work. However, its highest measured concentration was 2.01 mg on a filter. Sulphur amount was less than 0.5 mg on a filter in all samples. Chlorine concentration was less than 0.3 mg on a filter in all samples. However, all measured concentrations represent small values.

Analyzing the results, it can be concluded that pellets containing up to 10 % face masks do not impose an environmental burden with inorganic elements in particulate matter. This method of mask disposal seems promising and plays a role in decreasing environmental impact. Moreover, the produced pellets have demonstrated enhanced properties, including a higher calorific value, making them suitable for practical use. From a research standpoint, these pellets emerge as an interesting input material for use in pellet blends. This article contributes to further research into waste disposal, its recovery and the addition of waste to other raw materials to create alternative fuels.

4. Conclusion

This work focuses on particulate matter produced in connection with the energy disposal of pandemic FFP2 masks. A series of experiments were realized aimed at the concentration and chemical composition of particulate matter formed during the combustion of wood (spruce or beech) pellets with FFP2 masks in 5 % and 10 % weight content. Based on the mass concentration of particulate matter produced during combustion process with 40 % and 50 % mass airflow, it was found that higher concentrations of particulate matter were recorded predominantly with a higher mass airflow. In both airflows, beech pellets had a higher mass concentration than spruce pellets. Based on the chemical composition measured on the EDXRF spectrometer, the following elements were identified in filters with captured particulate matter: K, S, Cl and Fe. All measured concentrations represented very small values (the highest measured values: 2.01 mg on a filter for K, 0.46 mg on a filter for S, 0.225 mg on a filter for Cl and 0.006 mg on a filter for Fe).

However, operation conditions are also a very important parameter during the combustion of solid fuels except for the chemical composition of these fuels. This is confirmed for example by a higher mass concentration of particulate matter at a higher mass airflow (from 40 % to 50 %). Moreover, the fuel is not mixed, only pushed, which may not lead to complete combustion during the combustion using a retort burner. Ash and unburned material can spill over the open side into the ash pan. Further, the fuel subsequently burns poorly in the ash pan.

High concentrations of harmful elements to health carried in particulate matter on filters have not been detected. FFP2 masks added in a small percentage (up to 10 %) can be used in wood pellets for combustion purposes without significant effects on the combustion process. However, a suitable combustion setting (such as 40 % air mass airflow) should be used. The main part of the alternative fuel should be used quality wood without bark and FFP2 masks should be added as an additive (up to 10 %). The higher presence of FFP2 masks in pellets would lead to low mechanical durability, a high rate of pellet breakage during their transport and the resulting high rate of flying out of burning fuel particles. A higher proportion of face masks in the pellets would be undesirable for combustion purposes.

Funding

This publication has been produced with the support of VEGA No. 1/0150/22: Energy utilization of produced waste in connection with the COVID-19 pandemic through pellets as an alternative fuel and APVV-21-0452 Impact of using small electrostatic precipitators to reduce particulate pollutants in domestic fuel combustion.

Data availability statement

Data will be made available on request.

CRediT authorship contribution statement

Nikola Čajová Kantová: Writing – original draft, Funding acquisition, Conceptualization. Robert Cibula: Validation, Methodology, Data curation. Michal Holubčík: Writing – review & editing, Supervision, Funding acquisition. Peter Ďurčanský: Methodology, Investigation, Formal analysis.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2024.e25139.

Appendix A. Supplementary data

The following is the supplementary data to this article:

References

- 1.Shah A.S.V., Langrish J.P., Nair H., McAllister D.A., Hunter A.L., Donaldson K., et al. Global association of air pollution and heart failure: a systematic review and meta-analysis. Lancet. 2013;382:1039–1048. doi: 10.1016/S0140-6736(13)60898-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Kim Ki-Hyun, Kabir Ehsanul, Kabir Shamin. A review on the human health impact of airborne particulate matter. Environ. Int. 2015;74:136–143. doi: 10.1016/j.envint.2014.10.005. [DOI] [PubMed] [Google Scholar]

- 3.Yu Hongjun, Zhang Heran. Impact of ambient air pollution on physical activity and sedentary behavior in children. BMC Publ. Health. 2023;23:357. doi: 10.1186/s12889-023-15269-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Yang Yang, Ruan Zengliang, Wang Xiaojie, Yin Yang, Mason Tonya G., Lin Hualiang, Tian Linwei. Short-term and long-term exposures to fine particulate matter constituents and health: a systematic review and meta-analysis. Environ. Pollut. 2019;247:874–882. doi: 10.1016/j.envpol.2018.12.060. [DOI] [PubMed] [Google Scholar]

- 5.Mukherjee Arideep, Agrawal Madhoolika. World air particulate matter: sources, distribution and health effects. Environ. Chem. Lett. 2017;15:283–309. doi: 10.1007/s10311-017-0611-9. [DOI] [Google Scholar]

- 6.Daellenbach Kaspar R., Uzu Gaëlle, Jiang Jianhui, Cassagnes Laure-Estelle, Leni Zaira, Vlachou Athanasia, Stefenelli Giulia, Canonaco Francesco, Weber Samuël, Segers Arjo, Kuenen Jeroen J.P., Schaap Martijn, Favez Olivier, Albinet Alexandre, Aksoyoglu Sebnem, Dommen Josef, Baltensperger Urs, Geiser Marianne, El Haddad Imad, Jaffrezo Jean-Luc, Prévôt André S.H. Sources of particulate-matter air pollution and its oxidative potential in Europe. Nature. 2020;587 doi: 10.1038/s41586-020-2902-8. [DOI] [PubMed] [Google Scholar]

- 7.Míguez J.L., Morán J.C., Granada E., Porteiro J. Review of technology in small-scale biomass combustion systems in the European market. Renew. Sustain. Energy Rev. 2012;16:3867–3875. [Google Scholar]

- 8.Deng Mengsi, Li Pengchao, Shan Ming, Yang Xudong. Optimizing supply airflow and its distribution between primary and secondary air in a forced-draft biomass pellet stove. Environ. Res. 2020;184(109301) doi: 10.1016/j.envres.2020.109301. [DOI] [PubMed] [Google Scholar]

- 9.Křůmal Kamil, Pavel Mikuška, Horák Jiří, Jaroch Miroslav, Hopan František, Kuboňová Lenka. Gaseous and particulate emissions from the combustion of hard and soft wood for household heating: influence of boiler type and heat output. Atmos. Pollut. Res. 2023;14 doi: 10.1016/j.apr.2023.101801. [DOI] [Google Scholar]

- 10.Rimar Miroslav, Jan Kizek, Kulikov Andrii, Fedak Marcel. Study of selected burner parameters on the gas-air mixture combustion. MM Sci. J. 2022:6251–6256. doi: 10.17973/MMSJ.2022_12_2022158. [DOI] [Google Scholar]

- 11.Vicente E.D., Alves C.A. An overview of particulate emissions from residential biomass combustion. Atmos. Res. 2018;199:159–185. doi: 10.1016/j.scitotenv.2024.171999. [DOI] [PubMed] [Google Scholar]

- 12.Ghorashi Seyed Amin, Khandelwal Bhupendra. Toward the ultra-clean and highly efficient biomass-fired heaters. A review. Renew. Energy. 2023;205:631–647. [Google Scholar]

- 13.Greinert Andrzej, Mrówczyńska Maria, Grech Radosław, Szefner Wojciech. The use of plant biomass pellets for energy production by combustion in dedicated furnaces. Energies. 2020;13 doi: 10.3390/en13020463. [DOI] [Google Scholar]

- 14.Perea-Moreno Miguel-Angel, Samerón-Manzano Esther, Perea-Moreno Alberto-Jesus. Biomass as renewable energy: worldwide research trends. Sustainability. 2019;11:863. [Google Scholar]

- 15.Babu Subhash, Singh Rathore Sanjay, Singh Raghavendra, Kumar Sanjeev, Vinod K., Singh, Yadav S.K., Yadav Vivek, Raj Rishi, Yadav Devideen, Shekhawat Kapila, Ali Wani Owais. Exploring agricultural waste biomass for energy, food and feed production and pollution mitigation: a review. Bioresour. Technol. 2022;360 doi: 10.1016/j.biortech.2022.127566. [DOI] [PubMed] [Google Scholar]

- 16.Cheng Wei, Zhu Youjian, Shao Jing’ai, Zhang Wennan, Wu Guihao, Jiang Hao, Hu Junhao, Huang Zhen, Yang Haiping, Chen Hanping. Mitigation of ultrafine particulate matter emission from agricultural biomass pellet combustion by the additive of phosphoric acid modified kaolin. Renew. Energy. 2021;172:177–187. [Google Scholar]

- 17.Rajput Shailendrasingh P., Jadhav Sachin V., Thorat Bhaskar N. Methods to improve properties of fuel pellets obtained from different biomass sources: effect of biomass blends and binders. Fuel Process. Technol. 2020;199 [Google Scholar]

- 18.Luis Míguez Jose, Porteiro Jacobo, Frank Behrendt, Blanco Diana, Patiño David, Alonso Alba Dieguez. Review of the use of additives to mitigate operational problems associated with the combustion of biomass with high content in ash-forming species. Renew. Sustain. Energy Rev. 2021;141 [Google Scholar]

- 19.García R., Gil M.V., Rubiera F., Pevida C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel. 2019;251:739–753. [Google Scholar]

- 20.Čajová Kantová N., Cibula R., Szlek A., Čaja A., Nosek R., Belany P. The energy assessment of COVID-19 medical waste as a potential fuel. Energy Rep. 2023;9(2023):4995–5003. doi: 10.1016/j.egyr.2023.04.018. [DOI] [Google Scholar]

- 21.Saknimit M., Inatsuki I., Sugiyama Y., Yagami K. Virucidal efficacy of physicochemical treatments against coronaviruses and parvoviruses of laboratory animals. Exp. Anim. 1988;37:341–345. doi: 10.1538/expanim1978.37.3_341. [DOI] [PubMed] [Google Scholar]

- 22.Viscusi D.J., Bergman M.S., Eimer B.C., Shaffer R.E. Evaluation of five decontamination methods for filtering facepiece respirators. Ann. Occup. Hyg. 2009;53:815–827. doi: 10.1093/annhyg/mep070. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Purnomo Ch W., Kurniawan W., Aziz M. Technological review on thermochemical conversion of COVID-19-related medical wastes. Resour. Conserv. Recycl. 2021;167 doi: 10.1016/j.resconrec.2021.105429. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Windfeld E.S., Brooks M.S.-L. Medical waste management - a review. J. Environ. Manag. 2015;163:98–108. doi: 10.1016/j.jenvman.2015.08.013. [DOI] [PubMed] [Google Scholar]

- 25.Peng J., Wu X., Wang R., Li C., Zhang Q., Wei D. Medical waste management practice during the 2019-2020 Novel Coronavirus Pandemic: experience in a general hospital. Am. J. Infect. Control. 2020 doi: 10.1016/j.ajic.2020.05.035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Alghamdi M., Abdallah M.A.-E.-, Harrad S. The utility of X-Ray fluorescence spectrometry as a tool for monitoring compliance with limits on concentrations of halogenated flame retardants in waste polymers: a critical review. Emerg. Contam. 2022;8:9–20. doi: 10.1016/j.emcon.2021.12.002. [DOI] [Google Scholar]

- 27.Faria A.J.G.d., Rufini M., Leite A.d.A., Ribeiro B., T, Silva S.H.G., Guilherme L.R.G., Melo L.C.A. Elemental analysis of biochar-based fertilizers via portable X-ray fluorescence spectrometry. Environ. Technol. Innovat. 2021;23 doi: 10.1016/j.eti.2021.101788. [DOI] [Google Scholar]

- 28.Jandacka D., Durcanska D., Cibula R. Concentration and inorganic elemental analysis of particulate matter in a road tunnel environment (Žilina, Slovakia): contribution of nonexhaust sources. Front. Environ. Sci. 2022;10 doi: 10.3389/fenvs.2022.952577. [DOI] [Google Scholar]

- 29.Ueda K., Yamagami M., Ikemori F., Hisatsune K., Nitta H. Associations between fine particulate matter components and daily mortality in nagoya, Japan. J. Epidemiol. 2016;26(5):249–257. doi: 10.2188/jea.JE20150039. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.