Abstract

Objectives

To examine the 16-year developmental history, research hotspots, and emerging trends of zinc-based biodegradable metallic materials from the perspective of structural and temporal dynamics.

Methods

The literature on zinc-based biodegradable metallic materials in WoSCC was searched. Historical characteristics, the evolution of active topics and development trends in the field of zinc-based biodegradable metallic materials were analyzed using the bibliometric tools CiteSpace and HistCite.

Results

Over the past 16 years, the field of zinc-based biodegradable metal materials has remained in a hotspot stage, with extensive scientific collaboration. In addition, there are 45 subject categories and 51 keywords in different research periods, and 80 papers experience citation bursts. Keyword clustering anchored 3 emerging research subfields, namely, #1 plastic deformation #4 additive manufacturing #5 surface modification. The keyword alluvial map shows that the longest-lasting research concepts in the field are mechanical property, microstructure, corrosion behavior, etc., and emerging keywords are additive manufacturing, surface modification, dynamic recrystallization, etc. The most recent research on reference clustering has six subfields. Namely, #0 microstructure, #2 sem, #3 additive manufacturing, #4 laser powder bed fusion, #5 implant, and #7 Zn–1Mg.

Conclusion

The results of the bibliometric study provide the current status and trends of research on zinc-based biodegradable metallic materials, which can help researchers identify hot spots and explore new research directions in the field.

Keywords: Zinc-based biomaterials, Zn alloys, Biodegradable stent, Bone defect repair, Vascular implant, Bibliometric

Highlights

-

•

Research on zinc-based biodegradable materials has surged remarkably.

-

•

The mechanical properties and corrosion behavior are classic topics.

-

•

The strain softening and creep of zinc alloys should also be considered.

-

•

In vivo performance, dynamic recrystallization, etc., have become hotspots.

-

•

Biomimetic bone repair materials and nerve stents are the latest trends.

1. Introduction

Biomedical metallic materials represented by stainless steel, Co–Cr alloys, and Ti alloys have been widely used as implants, such as bone plates, bone screws, fusion devices, dental implants, vascular stents, and pacemakers, due to their superior mechanical properties and resistance to corrosion, wear, and processability [[1], [2], [3], [4], [5], [6]]. However, the benefits of implants typically diminish as the body recovers, and there is even a possibility of harm to the human body after a certain degree of recovery. For example, bone plates and screws can reduce the gaps between fractured bone tissue, promoting effective fusion, but the presence of bone plates and screws may hinder further fusion of bone tissue and even cause inflammation due to defects in the surface oxide film. Once inflammation occurs, a secondary surgery to remove the implant is needed, resulting in secondary damage and additional costs [7,8]. Additionally, metallic stents lose their beneficial effects after being implanted for six months in the treatment of atherosclerosis, thus necessitating long-term use of anticoagulants to alleviate adverse reactions in the late stage after implantation. However, even with such medication, the presence of stents affects the recovery of vascular dilation and contraction function while also increasing the risk of restenosis [9,10].

Biodegradable metals and alloys are known to degrade gradually in vivo once they have completed their intended function, with the degradation products having no significant adverse effects on the surrounding tissues [[11], [12], [13]]. This is beneficial for restoring bodily functions, reducing complications, and eliminating the need for a secondary surgery to remove the implanted materials, which would cause additional pain and economic burden to the patient. Preferentially selecting metal elements with essential physiological functions as candidates ensure both appropriate degradation rates and adjusts their content through human metabolism, thereby avoiding toxicity caused by accumulation in the body. Among biodegradable metals, Mg-based, Fe-based, and Zn-based alloys have been studied extensively (Fig. 1).

Fig. 1.

Major advantages and disadvantages of Mg-, Zn- and Fe-based biodegradable metals [1,14,15].

Magnesium is the earliest developed and most extensively clinically tested among these three biodegradable metals [15,16]. Compared to traditional alloys (such as Ti or Co-based alloys), magnesium has mechanical properties closer to human bone tissue, which can generate a stress shielding effect and reduce the risk of implant deformation or displacement [17]. Additionally, magnesium ions, as the main cations in organisms and cells, are involved in rhythm regulation, blood pressure, neuro-muscular conduction, as well as ATP hydrolysis, DNA replication, and glucose metabolism within cells [18]. However, magnesium has exhibited a rapid degradation rate and quick release of by-products (hydroxide and hydrogen) in numerous in vitro and in vivo experiments [18]. It leads to inadequate mechanical integrity of implants, hindering the completion of tissue repair at the implant site and potentially causing alkalinization and inflammation. To regulate the degradation rate of magnesium and the release of hydrogen, researchers have employed alloying methods. Bogdan et al. successfully reduced the degradation rate and hydrogen release by decreasing the potential difference between phases by adding calcium and zinc elements to magnesium-based materials [19].

Iron has the highest mechanical strength and excellent formability among these three commonly used metal systems (Fig. 1) [15,16]. Consequently, it offers greater potential for shaping and allows for thinner implant thickness. However, the high elastic modulus of iron-based alloys can lead to stress shielding, and they exhibit poor non-austenitic phase nuclear magnetic compatibility. Most of the iron in the body participates in the formation of hemoglobin to maintain oxygen transport, as well as various redox or hydrolysis reactions in the body. Although iron is essential for life, the Fenton reaction mediated by iron (the reaction between Fe2+ and H2O2 leads to the formation of Fe3+, OH−, and highly destructive HO•) can produce and accumulate reactive oxygen species. Animal experiments have found that the degradation rate of iron-based scaffolds is too slow (more than 2–3 years), and the hydroxide layer formed on the scaffold surface can be penetrated by oxygen, causing HO• to continuously form on the material surface during the entire implantation period, leading to dysfunction of surrounding tissues [20]. Moreover, the final degradation products (mainly iron oxide) may accumulate in surrounding tissues and biological matrices, causing complications [15,21].

Zn, with a standard corrosion potential of 0.76 V vs. SHE, exhibits a degradation rate that falls between that of Mg (2.37 V vs. SHE) and Fe (0.44 V vs. SHE) [22]. Zinc does not produce gas during the degradation process, and its degradation products are non-toxic. It has a low melting point, low molten reactivity, and good processability. Additionally, it shows excellent MRI compatibility. And Zn as an essential nutrient in human physiology, playing a crucial role in protein synthesis, signal transduction, and the normal function of various enzymes. Furthermore, zinc, as a reducing agent, exhibits antioxidant and anti-inflammatory properties both in its elemental form and in the form of zinc compounds. It also has demonstrated characteristics such as promoting wound healing and increasing the blood vessel formation rate, making it a hot topic among biodegradable metals [22]. Despite its excellent fracture elongation (60 %–80 %), pure zinc has a relatively low tensile strength of only 120 MPa and is prone to creep and age hardening. However, with the addition of alloying elements and optimization of processing techniques, these issues are gradually being addressed.

As a biomedical researcher, it can be challenging and time-consuming to comprehend the development history of biodegradable Zn alloys and extract research highlights from over 600 relevant articles published in the last dozen years on the Web of Science. Moreover, due to limitations in one's own experience, memory, and the integrity of literature, researchers are often forced to make subjective judgments about the development in the scientific field. Therefore, different from traditional academic reviews based on viewpoints, literaturebased bibliometric reviews can provide a more objective and comprehensive overview of a field's historical features, research hotspots, and development trends [23]. Bioidentification tools such as CiteSpace, CitNetExplorer, and VOSviewer have been applied to scientometric evaluation to assess the overall picture of an academic field [[24], [25], [26], [27]]. CiteSpace's multiple advantages distinguish it from similar software tools (such as VOSViewer, CitNetExplorer, SCI2, Pajek, and Gephi). As shown in Table 1, while CiteSpace may lag slightly behind Pajek in network analysis and network visualization and VOSViewer in heatmap generation, it excels over other software in various aspects such as automatic cluster naming, dual-map overlay, and timeline functionality. Its high efficiency, user-friendliness, customizability, and powerful visualization capabilities contribute to its wide-ranging applicability and value. This study used CiteSpace software (version 6.1 R4), HistCite Pro 2.1, and burst detection to evaluate research on biodegradable Zn alloys. The purpose of this research includes (1) summarizing the historical characteristics of the biodegradable Zn alloys literature, (2) highlighting articles that have made significant contributions to the field, (3) identifying active topics in the research field, and (4) revealing new trends for future research.

Table 1.

Comparative of bibliometric software.

| Tool | Network Analysis | Network Visualization Analysis | Network Analysis | Turning Points | Automatic cluster naming | Macro theory | Dual-map overlay | Concept tree | Timeline |

|---|---|---|---|---|---|---|---|---|---|

| CiteSpace [28] | ++ | ++ | + | + | + | + | + | + | |

| VOSViewer [29] | + | ||||||||

| CitNetExplorer [30] | + | + | |||||||

| SCI2 [31] | + | ++ | |||||||

| Pajek [32] | +++ | + | |||||||

| Gephi [33] | ++ | +++ |

+: Good; ++: Very good; +++: Excellent.

2. Methods

2.1. Data collection and statistics

The Web of Science Core Collection (WoSCC) from Thomson Reuters includes over 12,000 influential academic journals that are widely recognized as necessary in the international academic community. In this study, we used WoSCC as the target database and employed the search strategy "(((TS=(Zn or Zn-base or zinc or zinc-base)) AND TS=(alloy or metal)) AND TS=(cytotoxicity or biocompatibility or Biocompatible or Bioabsorbability or biodegradable or biodegradation or bioabsorbable or bioresorbable or Degradability)) NOT TS=(pollution or pollute or contamination or contaminate or contaminated or soil or metal organic framework or mofs or mof or wastewater)" to retrieve relevant literature on zinc-based biodegradable metal materials. The first article on zinc-based biodegradable metal materials was published in 2007, and the research period covered complete years from 2007 to 2022. Therefore, the search spanned from January 1, 2007, to December 31, 2022, yielding 5724 documents. After manually selecting relevant articles, 528 documents were retained, and an additional search was conducted on the top 50 most cited documents among the 528 articles. The collected literature records were downloaded and saved in a plain text file in the format of “complete records and cited references” as a sample for data analysis, named DATAZn, totaling 632 entries. In addition, we collected the original data on publication country/region information, such as institutions, journals, authors, and types of articles, and then used Excel (WPS 221214) to conduct data statistics.

2.2. Bibliometric analysis tools

For the present study, CiteSpace was used for co-occurrence analysis, burst analysis, and cluster analysis. Use the citation score in HistCite to evaluate the importance of the article. We utilize CiteSpace to generate a series of separate networks based on co-occurring keywords. These networks are exported from CiteSpace and loaded into the Alluvial Generator, resulting in an alluvial map, to explain how the theme evolves over time. Further details regarding the bibliometric analysis tools can be found in another article on drug-eluting stents in this research group [34].

2.2.1. CiteSpace

The specific steps are as follows: importing data DATAZn into CiteSpace software (6.1. R6), setting ‘Time Slicing’ as ‘2007–2022′ with each slice representing ‘1′ year, selecting term sources such as ‘Title,’ ‘Abstract,’ ‘AuthorKeywords (DE),' and ‘KeywordsPlus,’ choosing node types as needed, while keeping the other settings at default values, generating a knowledge map of national (or regional) institutions or author collaborations automatically, and finally manually adjusting the map for clarity and aesthetics. Similarly, we created a keyword cluster map, with the only difference being the selection of nodes as 'Keywords' and the time slicing set as ‘2007–2022'. Furthermore, when generating citation timeline graphs using ‘Reference,’ we selected the ‘layout’ tab in the ‘control panel’ and continued to choose the ‘timeline view’ to generate the citation timeline graph. In the ‘control panel,’ under the 'Burstness' tab, we clicked ‘view’ to generate a burstness map for keywords, categories, or references.

2.2.2. Hiscite

We imported 632 research articles from DATAZn into HistCite Pro 2.1, set the ‘Limit’ to 30, kept other settings as default, selected ‘Make graph’, and generated the network of the DES research field to locate important literature quickly.

2.2.3. The alluvial generator

To generate the alluvial diagram, we utilize CiteSpace to generate a series of separate networks based on co-occurring keywords. These networks are exported from CiteSpace and loaded into the Alluvial Generator (http://www.mapequation.org/apps/AlluvialGenerator.html).

3. Results

3.1. Historical characteristics of the literature

3.1.1. Literature distribution characteristics

The changes in the quantity of scientific literature at specific time points can reveal the accumulation of knowledge in a particular research field, providing important parameters for us to grasp the development of the field quantitatively. A total of 632 relevant literature on zinc-based biodegradable metallic materials were retrieved, including 553 research articles, 50 reviews, and 29 other papers. In total, 1797 authors and 554 institutions participated in these publications, published in 187 different journals. These publications covered 33 research directions (Table 2).

Table 2.

Basic information on the distribution of the publications.

| Categories | Publications | Research articles | Review articles | Other papers | Authors | institutions | Journals | Subject Categories |

|---|---|---|---|---|---|---|---|---|

| Amount | 52 | 553 | 50 | 29 | 1797 | 554 | 187 | 33 |

The annual research output is shown in Fig. 2A. Sporadic publications on zinc-based biodegradable metallic materials emerged from 2007 to 2013, while the number of publications has shown a sharp increase every year from 2014 to 2022. Fig. 2B lists the top 20 journals with the highest productivity in zinc-based biodegradable metallic materials, serving as a reference for researchers when considering manuscript submissions. Among these, ACTA BIOMATERIALIA published the most papers (46), followed by MATERIALS SCIENCE AND ENGINEERING C MATERIALS FOR BIOLOGICAL APPLICATIONS (32), MATERIALS (29), and JOURNAL OF ALLOYS AND COMPOUNDS (27).

Fig. 2.

(A) The annual distribution of publications (blue columns). (B) The top 20 most fruitful journals (red columns). Numbers on the bar graphs indicate numbers of articles published.

3.1.2. Citation co-occurrence analysis of zinc-based biodegradable metal materials

The citation co-occurrence network graph displays the literature relationship in the field of zinc-based biodegradable metallic materials in the past dozen years (Fig. 3). A total of 769 nodes and 3989 links were present, indicating extensive connections among the literature in this research domain. In the early literature (2007–2016), nodes resembled the roots of a tree. Despite having a lower node density, clear clusters were formed, which provided the foundation for subsequent stages (2017–2022) of research. These later stages formed the main trunk of the tree, with dense node density and abundant connectivity, suggesting a concentration in the research field. Among them, Mostaed E (2018) [35], Mostaed E (2016) [36], and Yang HT (2017) [37] had cocitation frequencies of 148, 143, and 140, respectively. Liu XW (2015) [38] and Li HF (2015) [39] exhibited higher centrality. Furthermore, we utilized hisitePro 2.1 to generate the citation historiography of the research articles (Supplementary Figure). The milestone articles are highlighted in Table 3, with Bowen PK (2013) [40], Vojtech D (2011) [41], and Zheng YF (2014) [42] ranking as the top three local citation score (LCS) articles. Larger nodes indicate greater importance and more connections, resulting in higher intermediary centrality. By employing these two methods, we not only visualized the citation pulse structure of the literature but also focused on high-contributing articles in this field.

Fig. 3.

The citation co-occurrence network.

Table 3.

Information on the top 30 literature sorted by LCS score.

| NO. | Article information | Journal | LCS | GCS |

|---|---|---|---|---|

| 19 | Zinc Exhibits Ideal Physiological Corrosion Behavior for Bioabsorbable Stents [40] | ADV MATER | 324 | 513 |

| 15 | Mechanical and corrosion properties of newly developed biodegradable Zn-based alloys for bone fixation [41] | ACTA BIOMATER | 274 | 413 |

| 26 | Biodegradable metals [42] | MAT SCI ENG R | 224 | 1338 |

| 63 | Novel Zn-based alloys for biodegradable stent applications: Design, development and in vitro degradation [36] | J MECH BEHAV BIOMED | 184 | 243 |

| 126 | Zinc-based alloys for degradable vascular scent applications [35] | ACTA BIOMATER | 149 | 216 |

| 43 | Design and characterizations of novel biodegradable ternary Zn-based alloys with IIA nutrient alloying elements Mg, Ca and Sr [43] | MATER DESIGN | 147 | 182 |

| 51 | Structure, mechanical characteristics and in vitro degradation, cytotoxicity, genotoxicity and mutagenicity of novel biodegradable Zn–Mg alloys [44] | MAT SCI ENG C-MATER | 143 | 182 |

| 100 | Evolution of the degradation mechanism of pure zinc stent in the one-year study of rabbit abdominal aorta model [37] | BIOMATERIALS | 141 | 198 |

| 178 | The influence of alloying and fabrication techniques on the mechanical properties, biodegradability and biocompatibility of zinc: A comprehensive review [1] | ACTA BIOMATER | 134 | 213 |

| 59 | Biodegradable Metals for Cardiovascular Stents: from Clinical Concerns to Recent Zn-Alloys [45] | ADV HEALTHC MATER | 132 | 253 |

| 92 | Potential biodegradable Zn–Cu binary alloys developed for cardiovascular implant applications [46] | J MECH BEHAV BIOMED | 128 | 160 |

| 76 | Research on a Zn–Cu alloy as a biodegradable material for potential vascular stents application [47] | MAT SCI ENG C-MATER | 115 | 152 |

| 89 | Zn–Li alloy after extrusion and drawing: Structural, mechanical characterization, and biodegradation in abdominal aorta of rat [48] | MAT SCI ENG C-MATER | 113 | 130 |

| 53 | Micro-alloying with Mn in Zn–Mg alloy for future biodegradable metals application [49] | MATER DESIGN | 112 | 168 |

| 45 | In vitro biodegradation behavior, mechanical properties, and cytotoxicity of biodegradable Zn–Mg alloy [50] | J BIOMED MATER RES B | 104 | 136 |

| 84 | Design and characterizations of novel biodegradable Zn–Cu–Mg alloys for potential biodegradable implants [51] | MATER DESIGN | 99 | 122 |

| 56 | Effects of alloying elements (Ca and Sr) on microstructure, mechanical property and in vitro corrosion behavior of biodegradable Zn-1.5 Mg alloy [52] | J ALLOY COMPD | 98 | 123 |

| 123 | Novel high-strength, low-alloys Zn–Mg (<0.1 wt% Mg) and their arterial biodegradation [53] | MAT SCI ENG C-MATER | 96 | 113 |

| 46 | Metallic zinc exhibits optimal biocompatibility for bioabsorbable endovascular stents [54] | MAT SCI ENG C-MATER | 95 | 147 |

| 38 | Cytotoxicity evaluation of biodegradable Zn–3Mg alloy toward normal human osteoblast cells [55] | MAT SCI ENG C-MATER | 89 | 124 |

| 50 | Microstructure, mechanical properties, in vitro degradation behavior and hemocompatibility of novel Zn–Mg–Sr alloys as biodegradable metals [56] | MATERIALS LETTERS | 87 | 115 |

| 54 | In Vitro Cytotoxicity, Adhesion, and Proliferation of Human Vascular Cells Exposed to Zinc [57] | ACS BIOMATER SCI ENG | 87 | 109 |

| 44 | Endothelial Cellular Responses to Biodegradable Metal Zinc [58] | ACS BIOMATER SCI ENG | 85 | 122 |

| 127 | In vitro and in vivo studies on zinc-hydroxyapatite composites as novel biodegradable metal matrix composite for orthopedic applications [59] | ACTA BIOMATER | 84 | 135 |

| 83 | Structural Characteristics and In Vitro Biodegradation of a Novel Zn–Li Alloy Prepared by Induction Melting and Hot Rolling [60] | METALL MATER TRANS A | 81 | 95 |

| 144 | Indirectly extruded biodegradable Zn-0.05 wt%Mg alloy with improved strength and ductility: In vitro and in vivo studies [61] | J MATER SCI TECHNOL | 76 | 96 |

| 49 | Mechanical properties, in vitro degradation behavior, hemocompatibility and cytotoxicity evaluation of Zn-1.2 Mg alloy for biodegradable implants [62] | RSC ADV | 74 | 83 |

| 91 | Long-term surveillance of zinc implant in murine artery: Surprisingly, steady biocorrosion rate [63] | ACTA BIOMATER | 74 | 97 |

| 30 | Progress of biodegradable metals [64] | PROG NAT SCI-MATER | 73 | 234 |

| 215 | Challenges in the use of zinc and its alloys as biodegradable metals: Perspective from biomechanical compatibility [65] | ACTA BIOMATER | 72 | 100 |

LCS: local citation score.

GCS: global citation score.

The above literature consists of milestone articles in the field. Among them, the article by Vojtech D (2011) is the first detailed study on the mechanical properties and corrosion behavior of zinc alloys in simulated biological environments [41]. The results showed that the alloy had a maximum strength of 150 MPa and an elongation of 2 % when the Mg content was approximately 1 wt%. The corrosion rate of Zn–Mg alloy was significantly lower than that of Mg and AZ91HP alloys. Based on the corrosion behavior of zinc alloys, the possible zinc dosage and toxicity were estimated, and it was found that these dosages were negligible compared to the tolerable daily intake of zinc [41]. Bowen PK (2013) implanted pure zinc wires, 15 mm long, into the abdominal aorta of rats for a duration of 6 months. Pure zinc remained intact for up to 4 months or longer and then underwent accelerated corrosion, ensuring timely degradation of the implant. The study demonstrated, for the first time in animals, that compared to magnesium alloys with excessively fast degradation rates and the toxic side effects of iron alloy degradation products, zinc alloys have immense potential as bioabsorbable materials for cardiovascular stents [40]. Zheng YF (2014) provided the first definition and classification of biodegradable metals (BM), summarizing their microstructure, mechanical properties, degradation mechanisms, and in vivo studies. The paper also comprehensively discussed the future development directions and challenges from raw materials to semi-finished products to final medical device [42].

Li HF (2015) utilized important elements of bone matrix such as Mg, Ca, and Sr to ensure the biocompatibility of biomedical zinc alloys. This significantly improved the mechanical properties and corrosion behavior of the alloy. Zn–1Mg, Zn–1Ca, and Zn–1Sr alloys were implanted into the femurs of mice, demonstrating the immense potential of different heat-treated Zn-1X alloys as bioabsorbable implants for orthopedic applications [39]. Liu XW (2015) conducted a systematic study on the mechanical properties, in vitro degradation behavior, and biocompatibility of ultra-pure zinc (10mm10 m m2mm) and its microtubes (outer diameter 2 mm, wall thickness 0.15 mm). Compared to high-purity Mg, ultra-pure Zn exhibited similar mechanical properties and cytotoxicity, while its corrosion rate in Hank's solution (0.011 mm/y) was lower than that of pure Mg. Additionally, the hemolysis rate (1.00 %) was lower than 5 %, indicating no significant damage to red blood cells. Compared to flat samples, tubular samples exhibited higher corrosion rates (Zn 0.028–0.037 mm/y, Mg 0.61–0.73 mm/y) and blood compatibility (Zn 1.19 %, Mg 9.50 %). These findings demonstrated that zinc is a promising candidate material for degradable metal scaffolds. However, alloying and advanced processing techniques are necessary to improve the mechanical properties of UP-Zn [38].

Mostaed E (2016) systematically studied the microstructure, mechanical properties, corrosion behavior, and feasibility of microtube processing for Zn–Mg alloys and low-Al content Zn–Al alloys. Laser cutting was used to investigate the microstructural changes that could potentially affect the mechanical properties of the final product [36]. The results showed that extruded alloys exhibited slightly better corrosion resistance compared to cast alloys, with corrosion rates approximately half of those of standard purity Mg alloys. Hot extrusion transformed the corrosion state of Zn–Mg alloy from localized pitting to more uniform corrosion. Zn-0.5 Mg exhibited good strength, ductility, strain hardening index, and appropriate mechanical integrity loss during degradation, making it the most promising material for scaffolds. It was also possible to fabricate tubes with an outer diameter of 4 mm and inner diameter of 1.5 mm as precursors for biodegradable scaffolds. EBSD analysis near the laser-cut Zn-0.5 Mg tubes showed no grain coarsening or texture change, confirming that the grain size and texture orientation of the final scaffold remained unchanged [36]. Yang HT (2017) implanted pure zinc stents (3.0*10 mm, wall thickness 165 mm) into a rabbit abdominal aortic model, demonstrating their mechanical integrity over a period of 6 months. After 12 months, the volume of the stent decreased by 41.75 ± 29.72 %. The degraded pure zinc stents exhibited good biocompatibility, proving that the inherent characteristics of zinc matched the arterial healing process [37]. Mostaed E (2018) further reviewed the effects of different alloy compositions and processing techniques on the microstructure, mechanical properties, corrosion behavior, and in vivo performance, discussing their suitability for biodegradable vascular scaffolds [35].

An ideal biodegradable metallic material in the field of biomedical research should possess a degradation rate that matches tissue healing, sufficient mechanical properties, and good biocompatibility. The evaluation of whether a biodegradable metallic material can meet clinical needs gradually progresses from in vitro exploration to in vivo research. Throughout this process, continuous optimization of alloy composition and processing technology is carried out, enabling the transformation of raw materials into semi-finished products and ultimately into clinically useable finished medical devices. From these milestone articles, it can be seen that the development of zinc alloy as a biodegradable material for cardiovascular stents can be traced back to different stages. Initially, research focused on studying the mechanical and corrosion properties of the alloy in simulated biological environments in vitro. Subsequently, pure zinc wires were implanted into the abdominal aorta of rats to investigate zinc's corrosion behavior in vivo and explore its biocompatibility. Further studies examined the mechanical properties, in vitro degradation behavior, biocompatibility, and the feasibility of laser cutting for ultra-pure zinc and zinc alloy microtubes. Finally, the safety and effectiveness of zinc stents were validated by implanting them into the abdominal aorta of rabbits. These series of studies gradually demonstrated the appropriate degradation behavior, biocompatibility, and processability of zinc alloys. Through the application of alloying and processing strategies, the mechanical properties of zinc alloys have been improved, making them suitable materials for bioabsorbable heart stents. It is worth noting that the ultimate tensile strength of pure zinc varies from 20 MPa to 120 MPa depending on the processing technique, which is far below the required 300 MPa for vascular stents and orthopedic fixation devices [66,67]. Therefore, alloying and processing strategies are essential. Through these strategies, grain refinement, control of second-phase particle size and distribution, and favorable crystallographic orientation can be achieved, enabling zinc alloys to gradually meet the clinical needs of vascular stents and orthopedics [65]. This ensures good biocompatibility while providing sufficient mechanical properties and controllable degradation rate.

In addition to investigating the mechanical properties, biocompatibility, and degradation rate of alloys, it is important to consider the biological activity of the alloys. For example, the incorporation of Mg, Ca, and Sr can not only improve the mechanical properties of the alloy but also potentially induce bone formation [43]. The introduction of Cu can promote the proliferation of endothelial cells and vascular regeneration [46]. Li can be beneficial for nerve protection [68], while Ag can kill bacteria attached to the surface of implants or prevent their adhesion [69]. Considering the multifunctionality of alloys would be advantageous for local tissue reconstruction.

3.1.3. Scientific cooperation

As shown in Fig. 4, many nodes and abundant connections indicate strong scientific collaborations in terms of country, institution, and author dimensions. The national collaboration network consists of 45 nodes and 116 edges, with China, the United States, Germany, Australia, and the Czech Republic being the largest nodes (Fig. 4A). The institution collaboration network exhibits 271 nodes and 572 edges, with Peking University, Beijing University of Science and Technology, Shanghai Jiao Tong University, Northeastern University, and the Chinese Academy of Sciences as the largest nodes, as shown in Fig. 4B. In Fig. 4C, the author's co-authorship graph displays 396 nodes and 1233 edges. Zheng Yufeng, Goldman Jeremy, Vojtech Dalibor, Drelich Jaroslaw W, and Capek Jaroslav are leading in terms of publication quantity in this field, and their research findings have played a crucial role in advancing the field of biodegradable medical zinc alloys, as mentioned in the previous section.

Fig. 4.

The scientific cooperation network. (A) Country cooperation. (B) Institution cooperation. (C) Author cooperation, i: Author clustering as represented by Zheng Yufeng; ii: Author clustering as represented by Vojtech Dalibor; iii: Author clustering as represented by Goldman Jeremy; iv: Author clustering as represented by Wang Luning. Number: frequency of co-occurrence.

It is worth noting that clustering effects can be observed within author nodes. For instance, a cluster is formed by Zheng Yufeng and Zhu Donghui nodes (Fig. 4C–i); another cluster is formed by Vojtech Dalibor, Capek Jaroslav, Kubasek Jiri, and Pinc Jan nodes (Fig. 4C–ii); Goldman Jeremy and Drelich Jaroslaw W nodes form another cluster (Fig. 4C–iii); and Wang Lu-Ning, Zhang Hai-Ju, and Shi Zhang-Zhi nodes form yet another cluster (Fig. 4C–iv), and authors within each cluster have strong academic communication and collaboration.

3.2. Variation of the most active topics

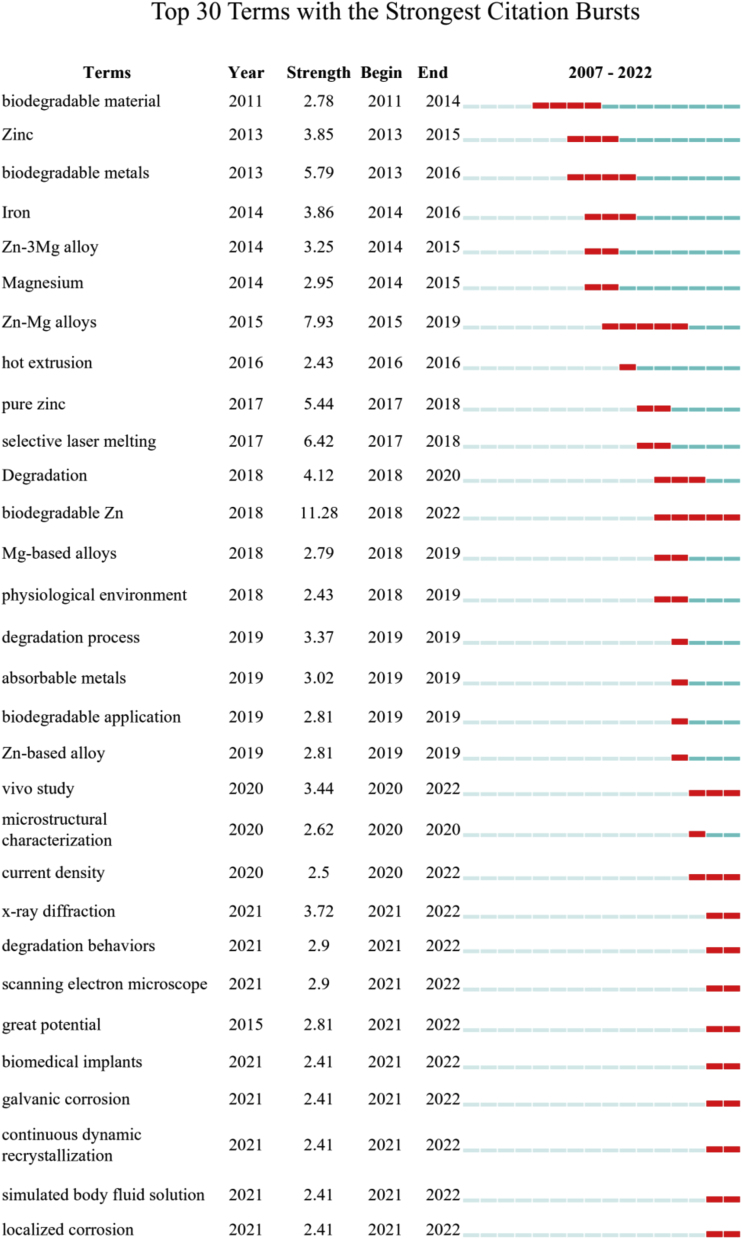

3.2.1. Subject category burst

From 2007 to 2022, 45 of the 520 related subject categories experienced citation bursts. The blue line represents the time interval, and the red line segments indicate the time span of citation bursts, including the starting and ending years. Fig. 5 presents the top 30 terms with the highest burst intensity in different periods. The subject category burst progressed from “biodegradable material” (2011) to “biodegradable metals” (2013), “zinc” (2013), “magnesium” (2014), “iron” (2014), and further to “biodegradable Zn” (2018). This progression indicates that zinc-based biodegradable metallic materials have evolved from the foundations of magnesium and iron. The in vitro mechanical properties, degradation rate, biocompatibility, as well as the biological responses and effectiveness in vivo of zinc alloys can be referenced based on the research foundations of magnesium and iron [70]. For instance, when investigating the implantation of zinc wires into the abdominal aorta of rats, prior experiments had already implanted magnesium and iron into the abdominal aorta of rats and validated the feasibility of these materials as absorbable vascular stents. It is worth noting that in vitro research methods cannot replace relevant in vivo studies currently. For example, there is still no satisfactory medium in vitro to simulate the anti-fatigue performance of zinc alloys in vivo. In vitro studies cannot simulate the complex degradation environment in vivo either. Moreover, due to the characteristics of in vivo research, the quantitative and qualitative analysis of degradation products of zinc alloys in vivo is challenging, thus warranting further investigation into the analysis of zinc alloy degradation products and their metabolism and transportation processes in vivo.

Fig. 5.

The top 30 subject categories with the strongest citation bursts. Year: Year of the first occurrence, Strength: Burst's strength, Begin: Burst's beginning year, nd: Burst's ending year.

Fig. 5 also demonstrates that topic emergence transitioned from “hot extrusion” (2016), “selective laser melting” (2017), “degradation process” (2019), to “in vivo study” (2020), “galvanic corrosion” (2021), and “continuous dynamic recrystallization” (2021). This illustrates the evolution of research on zinc-based biodegradable metallic materials from macroscopic properties to a more in-depth exploration of microscopic level and in vivo experiments. Understanding how the alloy microstructure, such as grain and second phase particle size, quantity, shape, distribution, and crystallographic orientation [66], as well as the density and distribution of alloy dislocations, the solubility of alloying elements with zinc metal atoms, and the influence of microstructure (e.g., dynamic recrystallization) [65] on the mechanical properties, degradation rate, and biocompatibility of the product during deformation, shelf life, and implantation degradation processes, is crucial to determine the usability of the developed products. The validation of product safety, effectiveness, and usability through relevant in vivo studies combining large animals with small animals is necessary to accelerate the industrialization of zinc alloys. Furthermore, the 15 topics from 2022 (Table S2) such as “in vivo study,” “current density,” “biomedical implants,” and “continuous dynamic recrystallization” further substantiate the aforementioned observations.

3.2.2. Keywords burst

At a more granular level, keyword bursts were detected to reveal the research progress of zinc-based biodegradable metallic materials across the entire time span (2007–2022). A total of 76 keywords experienced bursts at different time points, with the top 30 keywords exhibiting the highest burst intensities, as shown in Fig. 6. The keyword ‘biodegradable material’ had its peak burst intensity between 2011 and 2015, reaching a value of 3.07. During this time period, researchers have shown a strong interest and emphasis on biodegradable materials. ‘Magnesium alloy’ experienced the highest burst intensity from 2013 to 2017, with a value of 3.91, indicating that magnesium alloys are being prioritized in the development of biodegradable metal materials at this time. ‘Biodegradable stent’ and ‘bioabsorbable stent’ had the highest burst intensities during 2014–2016 and 2015–2018, reaching values of 2.9 and 4, respectively. ‘Elements Mg’ and ‘alloying elements Mg’ exhibited the highest burst intensities during 2016–2019 and 2018–2019, with values of 5.92 and 3.51, respectively. ‘Cardiovascular stent’ had the highest burst intensity in 2017–2018, with a value of 4.01, while the keywords ‘binary alloy’, ‘texture’, and ‘dynamic recrystallization’ had the highest burst intensities during 2019–2020, 2020–2020, and 2021–2022, respectively. The process and intensity of the emergence of these key terms reveal the development trends and evolutionary path of zinc-based biodegradable metal materials research. Researchers have gradually shifted their focus from magnesium alloys to zinc alloys as candidates for biodegradable metals. Simultaneously, they have expanded the scope of their research applications to a wider range of fields, while optimizing alloy elements and controlling the material's microstructure.

Fig. 6.

The top 30 keywords with the strongest citation bursts.

In addition, we specifically focused on 21 key terms that continued to emerge until 2022, as they could represent potential future research hotspots. These key terms include “in vitro corrosion,” “dynamic recrystallization,” “degradation behavior,” “microstructure evolution,” “fracture,” “phase,” “dislocation,” “osteogenic differentiation,” “product,” and “interface” (Table S2). This suggests that alloy processing techniques, compositional elements, changes in the internal microstructure of alloys during use (fracture, phase, dislocation, dynamic recrystallization), studies on alloy degradation behavior, functional activity of alloys, and interface research could now, and perhaps in the forthcoming years, become focal points of research for zinc-based biodegradable metallic materials.

To meet the requirement that absorbable cardiac stents remain mechanically intact within 3–6 months after implantation and are fully absorbed within 12–24 months, research has gradually shifted from early magnesium alloys to zinc alloys with slower degradation rates. The suitable degradation rate of zinc alloys makes them the most promising biodegradable metal materials for absorbable cardiac stents. Meanwhile, to achieve a tensile strength exceeding 300 MPa, alloying becomes an effective approach to enhance the mechanical properties of zinc alloys. How to ensure sufficient elongation at break (at least 20 %) of zinc alloy on the premise of realizing the required strength has become a hot issue of current research. Changes in grain structure, secondary phases, interfaces, and crack filling serve as guidance for the selection of alloying elements and optimization of processing techniques, which are key factors for zinc alloys to meet clinical requirements. Additionally, during the product development process, consideration should be given to strain softening, creep, and room temperature aging caused by dynamic recrystallization.

3.2.3. Reference burst

Through calculation, a total of 80 burst articles were identified. Table 4 presents the top 30 most frequently cited articles from 2007 to 2022. The first article to experience a citation burst was by Vojtech D (2011), which generated significant interest upon its publication with a burst intensity of 28.54. This study continued for 4 years from 2013 to 2016 and provided a comprehensive investigation into the mechanical properties and corrosion behavior of Zn alloys in simulated biological environments [41]. Bowen PK (2013) had a burst intensity of 47.68 from 2014 to 2018, as it examined zinc as a biodegradable material for cardiac stent applications. The authors implanted zinc wires in the abdominal aortas of rats and demonstrated suitable degradation time and good biocompatibility [40]. Zheng YF (2014) experienced its third burst period from 2015 to 2019, with a burst intensity of 37.35. This article introduced the definition and classification of biodegradable metals and summarized the degradation mechanisms and environmental influencing factors, including degradation product metabolism and mechanical integrity degradation. It focused on microstructures, mechanical properties, degradation behavior, in vitro and in vivo performance, as well as preclinical and clinical trials [42]. From 2016 to 2020, Li HF (2015) had its fourth burst period with a burst intensity of 27.59. To enhance their mechanical properties, this study investigated Zn-1X (Mg, Ca, and Sr) alloys under different thermal processing conditions (rolling and extrusion). The microstructure, mechanical properties, corrosion behavior, blood compatibility, in vitro cell compatibility, and in vivo biocompatibility were systematically studied to explore their feasibility as biodegradable implants in orthopedic applications [39]. In 2022, 3 articles emerged, two focused on in vivo studies, and one investigated the influence of alloy immersion media on cellular toxicity. This indicates that biocompatibility research, particularly in vivo studies, has become a hotspot for Zn alloys [[71], [72], [73]]. The endpoint literature obtained from both the reference burst analysis and co-occurrence analysis exhibits a high level of consistency, confirming that these selected articles are key reference sources in the field (see Table 5).

Table 4.

The top 30 references with citation bursts at different period.

| References | Year | Strength | Begin | End | 2007–2022 |

|---|---|---|---|---|---|

| Vojtech D, 2011, ACTA BIOMATER, V7, P3515, DOI 10.1016/j.actbio.2011.05.008, DOI [41] | 2011 | 28.54 | 2013 | 2016 | |

| Pierson D, 2012, J BIOMED MATER RES B, V100B, P58, DOI 10.1002/jbm.b.31922, DOI [74] | 2012 | 10.66 | 2013 | 2017 | |

| Moravej M, 2011, INT J MOL SCI, V12, P4250, DOI 10.3390/ijms12074250, DOI [75] | 2011 | 8.21 | 2013 | 2016 | |

| Bowen PK, 2013, ADV MATER, V25, P2577, DOI 10.1002/adma.201300226, DOI [40] | 2013 | 47.68 | 2014 | 2018 | |

| Cheng J, 2013, J MATER SCI TECHNOL, V29, P619, DOI 10.1016/j.jmst.2013.03.019, DOI [76] | 2013 | 10.07 | 2014 | 2018 | |

| Zheng YF, 2014, MAT SCI ENG R, V77, P1, DOI 10.1016/j.mser.2014.01.001, DOI [42] | 2014 | 37.35 | 2015 | 2019 | |

| Chen YJ, 2014, ACTA BIOMATER, V10, P4561, DOI 10.1016/j.actbio.2014.07.005, DOI [77] | 2014 | 10.12 | 2015 | 2019 | |

| Li HF, 2015, SCI REP-UK, V5, P0, DOI 10.1038/srep10719, DOI [39] | 2015 | 27.59 | 2016 | 2020 | |

| Li HF, 2015, MATER DESIGN, V83, P95, DOI 10.1016/j.matdes.2015.05.089, DOI [66] | 2015 | 22.38 | 2016 | 2020 | |

| Bowen PK, 2015, MAT SCI ENG C-MATER, V56, P467, DOI 10.1016/j.msec.2015.07.022, DOI [49] | 2015 | 15.79 | 2016 | 2020 | |

| Yao CZ, 2014, J ALLOY COMPD, V602, P101, DOI 10.1016/j.jallcom.2014.03.025, DOI [78] | 2014 | 14.44 | 2016 | 2019 | |

| Murni NS, 2015, MAT SCI ENG C-MATER, V49, P560, DOI 10.1016/j.msec.2015.01.056, DOI [50] | 2015 | 13.68 | 2016 | 2020 | |

| Kubasek J, 2016, MAT SCI ENG C-MATER, V58, P24, DOI 10.1016/j.msec.2015.08.015, DOI [67] | 2016 | 13.3 | 2016 | 2019 | |

| Li HF, 2014, PROG NAT SCI-MATER, V24, P414, DOI 10.1016/j.pnsc.2014.08.014, DOI [59] | 2014 | 13.23 | 2016 | 2019 | |

| Ma J, 2015, ACS BIOMATER SCI ENG, V1, P1174, DOI 10.1021/acsbiomaterials.5b00319, DOI [53] | 2015 | 12.28 | 2016 | 2020 | |

| Liu XW, 2015, MATER LETT, V161, P53, DOI 10.1016/j.matlet.2015.06.107, DOI [38] | 2015 | 12.2 | 2016 | 2018 | |

| Liu XW, 2016, MATER LETT, V162, P242, DOI 10.1016/j.matlet.2015.07.151, DOI [51] | 2016 | 10.52 | 2016 | 2019 | |

| Liu XW, 2016, MATER DESIGN, V94, P95, DOI 10.1016/j.matdes.2015.12.128, DOI [69] | 2016 | 9.28 | 2016 | 2019 | |

| Dambatta MS, 2015, MATER DESIGN, V85, P431, DOI 10.1016/j.matdes.2015.06.181, DOI [79] | 2015 | 8.84 | 2016 | 2019 | |

| Seitz JM, 2015, ADV HEALTHC MATER, V4, P1915, DOI 10.1002/adhm.201500189, DOI [80] | 2015 | 6.93 | 2016 | 2020 | |

| Wang JL, 2015, ACTA BIOMATER, V21, P237, DOI 10.1016/j.actbio.2015.04.011, DOI [81] | 2015 | 6.47 | 2016 | 2020 | |

| Mostaed E, 2016, J MECH BEHAV BIOMED, V60, P581, DOI 10.1016/j.jmbbm.2016.03.018, DOI [36] | 2016 | 16.94 | 2017 | 2019 | |

| Bowen PK, 2016, ADV HEALTHC MATER, V5, P1121, DOI 10.1002/adhm.201501019, DOI [65] | 2016 | 15.17 | 2017 | 2019 | |

| Gong HB, 2015, J BIOMED MATER RES B, V103, P1632, DOI 10.1002/jbm.b.33341, DOI [44] | 2015 | 14.74 | 2017 | 2020 | |

| Wang C, 2016, J MATER SCI TECHNOL, V32, P909, DOI 10.1016/j.jmst.2016.06.003, DOI [82] | 2016 | 10.47 | 2017 | 2019 | |

| Chen QZ, 2015, MAT SCI ENG R, V87, P1, DOI 10.1016/j.mser.2014.10.001, DOI [83] | 2015 | 8.43 | 2017 | 2020 | |

| Guillory RJ, 2016, ACS BIOMATER SCI ENG, V2, P2355, DOI 10.1021/acsbiomaterials.6b00591, DOI [84] | 2016 | 7.24 | 2017 | 2019 | |

| Shearier ER, 2016, ACS BIOMATER SCI ENG, V2, P634, DOI 10.1021/acsbiomaterials.6b00035, DOI [52] | 2016 | 7.07 | 2017 | 2020 | |

| Liu XW, 2016, J ALLOY COMPD, V664, P444, DOI 10.1016/j.jallcom.2015.10.116, DOI [47] | 2016 | 6.4 | 2017 | 2018 | |

| Niu JL, 2016, MAT SCI ENG C-MATER, V69, P407, DOI 10.1016/j.msec.2016.06.082, DOI [46] | 2016 | 7.22 | 2018 | 2020 |

Table 5.

References with citation bursts from beginning to 2022.

| References | Year | Strength | Begin | End |

|---|---|---|---|---|

| Li P, 2019, ACTA BIOMATER, V98, P235, DOI 10.1016/j.actbio.2019.03.013, DOI[71] | 2019 | 4.68 | 2020 | 2022 |

| Zhang Y, 2019, MAT SCI ENG C-MATER, V99, P1021, DOI 10.1016/j.msec.2019.01.120, DOI [72] | 2019 | 3.91 | 2020 | 2022 |

| Kafri A, 2018, J MATER SCI-MATER M, V29, P0, DOI 10.1007/s10856-018-6096-7, DOI[73] | 2018 | 2.85 | 2020 | 2022 |

In order to meet the clinical requirements for vascular stents and orthopedic applications, the optimization and characterization of zinc alloys are constantly evolving. From the burst of three articles in 2022, researchers have become aware that the biological environment of zinc alloys varies depending on the implanted part, such as vascular stents coming into contact with serum, hemoglobin, blood cells, etc., which may have an impact on the release of zinc ions and thus lead to differences in cytotoxicity results compared to simple PBS solutions [71]. Although corrosion rate measurements are mainly carried out in Hank's solution at present, referencing ASTM standard G3172 from 2004, it cannot simulate the complex corrosion environment within the human body, and the referenceability of the obtained corrosion rate is limited. It is foreseeable that zinc alloy leachate and degradation media will be continuously optimized for different implant sites. In addition, researchers have also realized that adjusting the types and amounts of alloying elements to form a microcell structure inside the alloy may expand the application of zinc alloys in scenarios where slightly faster degradation rates are required. After more than a decade of research, with the continuous optimization of processing technology and the in-depth study of ternary alloys, more and more zinc alloys that meet clinical requirements have been prepared, such as Zn-0.8%Li-0.2%Mg, Zn-0.8%Li-0.2%Ag, and Zn-0.8Li-0.8Mn, whose ultimate tensile strengths (UTS) are 341.3 MPa, 254.7 MPa, and 515.0 MPa, respectively; yield strengths (YS) are 253.7, 196.2, and 365.0, respectively; and elongations are 30.6 %, 97.9 %, and 103.3 %, respectively [72,85]. The increase in the ultimate tensile strength of these ternary zinc alloys is mainly attributed to nanoprecipitates and grain refinement, while the increase in elongation primarily attributes to grain boundary sliding, dynamic recrystallization, and the grain boundary effect. Among these, the grain boundary effect mainly contributes to enhancing elongation by carrying stress concentration and facilitating crack propagation. In addition, when optimizing the mechanical properties of zinc alloys, the proportion and distribution of brittle phases after the addition of alloying elements should also be considered. As more and more zinc alloy materials that meet clinical requirements are gradually developed, more and more zinc alloy orthopedic and vascular stent products will enter into large animal studies and clinical validations, providing a basis for product launch.

3.3. Emerging trends and new developments

3.3.1. Keyword clustering analysis

There are strong intrinsic correlations among the keywords, and certain keywords can form different clusters based on their affinity. Identifying these clusters provides a more intuitive delineation of the various sub-fields within the research on zinc-based biodegradable metallic materials. The keyword clustering is shown in Fig. 7A. The keyword clustering can be divided into five categories, including traditional alloy composition and microstructure (#2 iron, #8 microstructure), degradation characteristics (#3 biodegradable metal, #6 corrosion resistance), alloy mechanical properties and antibacterial properties (#0 mechanical properties, #1 plastic deformation, #9 antibacterial activity), additive manufacturing processes for alloys (#4 additive manufacturing) and surface modification (#5 surface modification) and activation (#7 activation) related to alloy applications. As shown in Fig. 7B, #0 mechanical performance and #9 antibacterial activity are fundamental requirements for biodegradable materials, and therefore run through the entire development process. Due to its difficulty in degradation, #2 iron has not been overcome, leading to a decrease in research enthusiasm. After experiencing materials such as biodegradable polymers, iron, and magnesium, the selection of #3 biodegradable materials gradually focused on zinc alloys, thus temporarily passing the explosive period. The corrosion resistance of #6 and the microstructure of #8 are in a sustained but not hottest research stage because zinc alloys have been in the selection and development of alloying elements for a long time. Currently, the more ideal alloys selected are being attempted for #1 plastic deformation, #5 surface modification, and #4 additive manufacturing to improve biocompatibility (#7 activation).

Fig. 7.

Keyword cluster snapshots. (A) Clustering form. (B) Timeline form. The Y-axis represents the frequency of occurrence.

Additive manufacturing facilitates the construction of three-dimensional porous structures resembling human bones, which meet the requirements for internal transport of nutrients, tissue fusion, and regeneration in orthopedic implants. The rapid high-temperature heating and cooling process ensures finer grain size and guarantees the mechanical properties of the material. With the optimization of powder, laser, and laser melting space environment, the density of orthopedic implants made from zinc alloys through additive manufacturing has been addressed. Research on the preparation of orthopedic implants using zinc alloys through additive manufacturing will continue to increase. However, further investigation is needed to determine whether their degradation rate and biocompatibility can meet clinical demands. Whether it is for orthopedic materials or vascular stents, achieving tissue fusion and repair while ensuring product biocompatibility is a crucial indicator. Surface modification can functionalize zinc alloy materials, making them “third-generation biodegradable materials.” For example, during the early stages of implantation, surface-modified coatings on zinc alloys control the release rate of zinc ions, increase the biocompatibility of the product, induce bone tissue climbing and endothelialization processes, prevent inflammatory reactions in orthopedic implants, and reduce the probability of clotting in vascular stents. Once they have served their purpose, these coatings can also promote the rapid degradation of the alloy to prevent excessive proliferation of bone tissue or smooth muscle cells and reduce the occurrence of complications.

3.3.2. Keyword alluvial analysis

As shown in Fig. 8, the linked keywords can be combined to form specific research modules. As keywords are recombined, the research modules diverge or converge over time, resulting in new modules. Some influential keywords have a strong lifespan throughout the 12-year period, while others become new research trends, and some fade out from the long history of the research field. Table S4 (Supplementary Material) lists the top five modules with the highest traffic each year. Clearly, in 2022, the keywords contained in Module 4 diverge or converge within our research domain, forming the largest research branch (highlighted in purple). This indicates that Module 4 is the most persistent research module. Additionally, we plotted all the keywords for the top six modules ranked in 2022 (Fig. 9). Fig. 9 shows that Module 4 pertains to the “mechanical property,” signifying a sustained focus on the study of the mechanical properties of zinc-based biodegradable materials. This is related to the fact that the mechanical properties of zinc alloy materials are continuously being optimized to meet clinical demands. It wasn't until recent years that zinc alloys with mechanical properties that truly meet clinical requirements were gradually developed.

Fig. 8.

The keyword alluvial map 2010–2022. X-axis: Time slice. Y-axis: Counting of modules. Number: Order of modules on each time slice sorted by the number of nodes.

Fig. 9.

The keywords of the top 6 modules in 2021. (A) Module 1. (B) Module 2. (C) Module 3. (D) Module 4. (E) Module 5. (F) Module 6.

Module 1 is named ‘laser’ and consists of 11 keywords, including laser, laser powder bed fusion, and steel (Fig. 9A). Module 2 is named ‘strain softening’ and comprises 22 keywords, such as strain softening, plastic deformation, and cytotoxicity (Fig. 9B). Module 3 is named ‘zn implant’ and includes 21 keywords, such as zn implant, composite, and steel (Fig. 9C). Module 4 is named ‘mechanical property’ and consists of 14 keywords, including mechanical property, Mg, and cytotoxicity (Fig. 9D). Module 5 is called ‘in situ reaction’ and comprises nine keywords, such as in situ reaction, selective laser melting, and particle (Fig. 9E). Module 6 is named ‘absorbable metal scaffold’ and includes 12 keywords, such as absorbable metal scaffold, cell viability, and blood compatibility (Fig. 9F). These modules are likely to represent emerging trends in the field of Zn alloys for the next five years or even longer. Based on the above findings, additive manufacturing, strain softening, mechanical property research, implantable materials, and absorbable scaffolds are likely to be emerging trends in the zinc alloy field for the next 5 years or even longer.

As mentioned earlier, the study of mechanical properties of zinc alloys is a long-standing topic, and additive manufacturing, with its flexible processing characteristics, will also become a useful tool for the development of zinc alloy materials, promoting research progress in orthopedic implants and even absorbable stents. It is worth noting that strain softening will limit the application of zinc alloys, and controlling dislocation motion, interface sliding, and dynamic recrystallization in the alloy is a key to control strain softening. The introduction of high-density twinning and coarse grains can suppress strain softening, but considering the impact of strain softening on the product during the product development process is essential.

Simultaneously, we can observe that the term “cell viability/cytotoxicity” appears frequently in different modules, indicating the importance of evaluating cytotoxicity in the medical device field. However, the numerous published cell compatibility test results of zinc alloys currently available demonstrate that the zinc alloy leachate needs to be diluted 2–4 times to exhibit non-toxicity, which is related to the material's degradability [86]. Establishing a universally applicable cytotoxicity evaluation method for degradable metals is also a key area for future research.

3.3.3. Timeline visualization of references

Based on the timeline visualization of citation span, emerging, classical, and relatively outdated topics were predicted. The timeline graph of research on zinc-based biodegradable metal materials consists of 10 clusters within a given timeframe, arranged from top to bottom according to their sizes (Fig. 10A). Among them, the #1 biodegradable stent and #6 Zn–Mg alloys are classical topics, which may not be the latest ones but have intricate connections with other clusters. #8 biodegradable material and #14 equiaxed and dendritic grains are relatively outdated topics, with limited connections to other clusters and no further development on their timelines. The #0 microstructure, #2 sem, #3 additive manufacturing, #4 laser powder bed fusion, #5 implant, and #7 Zn–1Mg are emerging subjects, as their timelines have remained active since their appearance, indicating that these areas will become future research hotspots. Table S5 provides more detailed descriptions of newly emerged clusters. Additionally, some pivotal papers (large nodes with red rings) played a significant role in advancing this subfield.

Fig. 10.

The reference cluster map. (A) Citation timeline visualization. (B) Citation frequency distribution of the burst citations, X-axis: year, Y-axis: citation frequency.

The article published by Mostaed E in 2018 belongs to cluster #0 and has been cited 148 times. The author focused on the development of Zn alloys from 2015 to 2017, based on a review conducted in 2016. Starting from the effects of elemental composition and processing techniques on microstructural features (grain refinement, control of second phase particle size and distribution, and good crystal structure orientation), the suitability of different alloy compositions and treatment techniques for the application of biodegradable vascular stents was discussed in terms of mechanical properties, corrosion behavior, and in vivo performance. The author concluded that extensive research is needed in the development of bioabsorbable Zn alloys to obtain appropriate compositions that meet strict clinical standards for vascular stent applications, such as good biocompatibility, prolonged mechanical integrity, and controlled corrosion rate [35]. The literature published by Yang HT in 2018 belongs to cluster #2 and has a co-occurrence frequency of 84. The study focused on the preparation of metal matrix composites (MMCs) using pure zinc as the matrix and hydroxyapatite (HA) as the reinforcement through spark plasma sintering (SPS). Adding HA to pure zinc was an effective way to regulate its degradation rate and enhance its in vitro and in vivo biocompatibility. In vivo experiments showed better osteogenic effects with the addition of HA over prolonged implantation time. This study demonstrated that zinc-based MMCs are a promising strategy to improve the application performance of pure zinc in orthopedic implants. It is worth mentioning that the author applied SEM techniques in various aspects of the research, such as immersion tests, hemolysis and platelet adhesion, and cross-sectional analysis [59]. In the same year, the literature published by Hermawan H belongs to cluster #5 with a co-occurrence frequency of 38. The author summarized the advances in absorbable metal research progress from 3 aspects: fundamental research, translational research, and standard development. In discussing the use of porous structures as a method to control the corrosion rate, the author suggested the benefits of additive manufacturing for the development of orthopedic materials [87]. The literature published by Han HS in 2019 belongs to cluster #7 with a co-occurrence frequency of 41. The author provided a comprehensive review of the research progress on biodegradable metals in the medical field, focusing on product translation research and clinical trials. Research on the application of biodegradable metals in the orthopedic and cardiovascular fields has been highlighted [88]. We further analyzed the citation distribution of these four articles in recent years (Fig. 10B) and predicted that they may continue to be referenced in the coming years.

The type and content of alloying elements, processing, and heat treatment processes can change the microstructural characteristics of zinc alloys, thereby affecting the degree of obstruction of dislocation motion and stress concentration, and thus changing the ultimate tensile strength and ductility of zinc alloy materials. Similarly, we can also use the microstructural characteristics of zinc alloys to guide us in selecting alloying elements, processing and heat treatment processes to obtain zinc implant materials that meet clinical needs. In this process, guidelines for standardizing zinc alloys are gradually making progress [45], linking the optimization of material alloying elements, processing and heat treatment processes, in vitro performance research, and in vivo research, thereby solving the remaining challenges in the industrialization process of zinc alloys and benefiting patients. In the standardization process, SEM is an essential means of observing the degradation of zinc alloys, platelet adhesion, endothelialization, inflammation response, and restenosis in in vitro and in vivo environments. Although biodegradable zinc alloys have achieved many milestone results, more basic research is still needed as evidence to prove their clinical applicability.

4. Summary and outlook

4.1. Ongoing challenges and emerging themes coexist in the field of Zn alloys biodegradability

Based on bibliometric analysis, this study reviews the structural and temporal characteristics of publications related to biodegradable Zn alloys from 2007 to 2022. Undoubtedly, the field of biodegradable Zn alloys is still in a prominent phase with a rapid increase in the number of papers, extensive scientific collaboration, and an intensive citation network. While the active topics in this field have evolved over time, the analysis of recent subjects, keywords, keyword clustering, and reference clustering indicates that in vivo-related studies (e.g., vivo study in Terms and #5 implant in reference clustering), degradation performance research (e.g., current density, degradation behaviors in Terms and in vitro corrosion, degradation behavior in keywords), microstructural investigations (e.g., X-ray diffraction, scanning electron microscope, fracture, phase, interface in Terms; #8 microstructure in keyword clustering; #0 microstructure, #2 sem in reference clustering), dynamic recrystallization (e.g., continuous dynamic recrystallization in Terms; dynamic recrystallization in keywords clustering), additive manufacturing (e.g., 4# additive manufacturing in keyword clustering; #3 additive manufacturing, #4 laser powder bed fusion in reference clustering), surface modification and activation (e.g., 5# surface modification, 7# activation in keyword clustering) have the potential to become future research hotspots. Recently, cited literature has also revolved around these hot topics.

4.2. Explore emerging fields

Microstructure Research. Alloying elements are crucial factors influencing the mechanical properties, corrosion rate, and biocompatibility of alloys. Previous studies have demonstrated that the ultimate tensile strength of Zn–Mg and Zn–Li alloys is significantly improved, while the addition of Ag, Cu, Fe, Mn, and Zr can enhance the fracture elongation of the alloys [85,[89], [90], [91]]. Second-phase strengthening, grain refinement strengthening, and heterogeneous deformation-induced strengthening are the major strengthening mechanisms in Zn alloys [90,92,93]. The second phase can strengthen the metal either through load transfer mechanisms or by acting as obstacles to dislocation motion. Grain refinement strengthening arises from the hindrance of dislocation motion at grain boundaries, where an increase in grain boundary volume fraction and a decrease in grain size enhance the impediment of dislocation motion. Heterogeneous deformation induces a simple nonhomogeneous structure in Zn alloys, which improves the strength and ductility of the alloys. The improvement of ductility in Zn alloys is usually associated with refining the microstructure and twinning. The addition of alloying elements leads to a reduction in grain size and an increase in grain boundary volume fraction. When the grain size falls below a critical size, grain boundary sliding is activated, promoting ductility and potentially even enabling room-temperature superplasticity [94]. Due to the low recrystallization temperature of Zn alloys, dynamic recrystallization can occur during tensile testing, releasing accumulated stress and improving ductility. Twinning, on the other hand, can initiate crack formation and accelerate crack propagation by inducing localized stress concentration, thus adversely affecting ductility. The addition of alloying elements can activate the critical stress for twinning, which increases with decreasing grain size. Consequently, when the grain size is less than the critical value, twinning can be completely suppressed, thereby enhancing the ductility of the alloy [95]. The addition of alloying elements promotes the refinement of second-phase grains and enhances the compatibility with the Zn matrix, reducing stress concentration and delaying crack nucleation, thus exhibiting higher plastic deformation ability [90]. In addition to alloying elements, processing and heat treatment techniques, such as casting, equal channel angular pressing (ECAP), hot extrusion, rolling, accelerated cooling, and annealing processes, play a crucial role in the mechanical properties and corrosion rate of alloys. Appropriate processing and heat treatment can optimize the mechanical and corrosion properties of alloys to meet clinical requirements [93,[96], [97], [98], [99], [100], [101]]. Regardless of alloy optimization or processing techniques, they both affect the grain refinement and alloy uniformity, thereby influencing the corrosion rate and uniformity. Currently, it is challenging to achieve both high strength and high elongation in binary Zn alloys, even with various processing methods. Consequently, adopting multiple alloying elements on the basis of binary alloy systems, making the microstructure more complex and increasing the diversity of secondary phases, has been explored. Multicomponent alloying has been shown to be effective in adjusting the mechanical properties of Zn-based biomaterials. Zn–Mg and Zn–Li alloys exhibit tensile strengths over 300 MPa, while Zn–Mn and Zn–Cu alloys exhibit fracture elongations exceeding 25 %. Thus, multicomponent alloys based on Zn–Mg, Zn–Li, Zn–Mn, and Zn–Cu have become research focuses. Mn, Ca, Sr, Ag, Fe, and Zr are added to Zn–Mg alloys; Al, Mg, Sr, Cu, and Ca are added to Zn–Li alloys; Ag, Cu, Ca, Mg, and Fe are added to Zn–Mn alloys; and Ag, Mg, Ca, Fe, and Li are added to Zn–Cu alloys. Combined with different processing techniques, the mechanical properties, corrosion rate, and biocompatibility of the alloys can meet clinical requirements [72,90,[102], [103], [104], [105], [106], [107], [108], [109]]. Research on dynamic recrystallization, strain softening, and creep effects has gradually gained attention in the field of biotechnology. Due to the melting point (Tm) of Zn is 692.65 K, dynamic recrystallization (DRX) in Zn alloys is easily induced during processing, with an initial temperature of approximately 288 K (0.42 Tm). Dynamic recrystallization can be categorized into discontinuous dynamic recrystallization (DDRX), continuous dynamic recrystallization (CDRX), twinning-induced dynamic recrystallization (TDRX), and particle-stimulated nucleation (PSN), and the variation in processing parameters can alter the DRX mechanism. The transition from DDRX to CDRX can be achieved by lowering the deformation temperature and increasing the strain rate, while low temperature and high strain rate can promote the activation of TDRX [110]. In addition to DDRX in the initial deformation stage and TDRX at intermediate and high strain rates, CDRX plays a dominant role in the compression of pure Zn at room temperature [111,112]. Dynamic recrystallization helps reduce local stress concentration, lower deformation resistance, and improve alloy ductility. Additionally, DRX can refine alloy grains and enhance mechanical properties by promoting Hall‒Petch strengthening.

The mechanical stability of zinc alloy is of vital importance for its practical applications, and there is a growing body of research focused on investigating strain softening, creep, and ambient temperature aging phenomena associated with it [[113], [114], [115]]. Strain softening refers to the phenomenon where the stress needed for further deformation of the material after one or multiple loading and unloading cycles is smaller than before [114]. Creep is the phenomenon of slow plastic deformation that occurs in materials under constant load over time [116,117]. Ambient temperature aging describes the phenomenon where the mechanical properties of a material change at room temperature. Strain softening, creep, and ambient temperature aging all limit the clinical application of Zn alloy materials. Taking intravascular stents as an example, strain softening can cause a decrease in radial supporting force during balloon expansion, affecting the scaffolding capability of the stent. Vascular stents need to withstand radial pressure from the blood vessels for a long time, and inadequate creep resistance may lead to lumen loss and restenosis. Ambient temperature aging can also impact the shelf life of stents. The low melting point characteristic of zinc alloy is the primary reason for its susceptibility to strain softening, creep, and ambient temperature aging phenomena. The low melting point characteristic of Zn alloys is the main reason for strain softening and creep. When strain or load is applied to the alloy, dislocation motion and grain boundary slip occur due to the low melting point of the Zn alloy, leading to strain softening and creep. Additionally, dynamic recrystallization can cause changes in dislocation density, resulting in the occurrence of these two phenomena [89,90]. Forming high-density twin boundaries to suppress dislocation motion, altering the mode of dislocation motion, improving grain boundary stability through segregation, and introducing low-energy grain boundaries are effective methods to overcome strain softening and creep [65,118]. The low melting point of zinc alloy also leads to extensive atomic migration at room temperature under non-strain and load conditions, resulting in phase transformation during storage and consequently changes in the physical properties. The development direction to overcome ambient temperature aging includes the selection of high melting point alloying elements, regulation of the properties of the second phase (such as softness and hardness), and heat treatment [65].

Surface Modification and Activity Research. The surface characteristics of implants play a crucial role in determining the physiological response upon direct contact with tissues. Surface modification is a simple and effective method for constructing alloys with appropriate corrosion rates, good biocompatibility, and physiological functionality. Surface coating techniques for Zn alloys have been explored for many years, and coatings can be classified into three categories: inorganic, polymer, and composite. Inorganic coatings include oxides, hydroxides, phosphates, ceramics, and metal coatings. Controlling the degradation rate of Zn alloys is crucial to enhance their biocompatibility due to the potential cytotoxicity associated with high zinc ion concentrations. Coatings such as zinc oxide (ZnO), zinc hydroxide (Zn(OH)2), and zinc phosphate (Zn3(PO4)2) can enhance the corrosion resistance of Zn alloy substrates, reduce the release rate of zinc ions, improve the hydrophilicity of the alloy surface, facilitate cell adhesion and enhance the biocompatibility of implants. However, research has shown that zinc phosphate exhibits more significant improvement in alloy biocompatibility compared to ZnO or Zn(OH)2 [119]. Furthermore, zinc phosphate promotes the growth of hydroxyapatite and enhances the cell viability, adhesion, and proliferation of preosteoblasts while inhibiting the adhesion of platelets and Escherichia coli [120]. The role of polymer coatings is similar to that of inorganic coatings, primarily controlling the release rate of zinc ions and enhancing the biocompatibility of the alloy. For example, researchers have used amphiphilic polymers as coatings on zinc-magnesium alloys, significantly improving the corrosion resistance of the alloy [121]. Other researchers have utilized poly(p-xylene) as a coating to enhance the corrosion resistance of stents. Compared to uncoated stents, the poly(p-xylene) coating reduced the corrosion rate by 50 % [122]. To combine the advantages of multiple coatings, composite coatings have become a research hotspot. Composite coatings can include inorganic‒inorganic coatings, inorganic-polymer coatings, and polymer-polymer coatings. The effect of inorganic‒inorganic coatings is similar to that of inorganic coatings, but with multiple layers, it offers more flexibility in adjusting the corrosion resistance of Zn alloys. The corrosion rate can be programmatically set based on the specific application scenario. For example, in the initial stage where mechanical support is needed, the corrosion rate can be reduced to improve effectiveness. In the later stage when tissue regeneration has occurred, the total amount of alloy can be reduced to a certain extent without compromising biocompatibility, thereby accelerating corrosion and minimizing foreign body reactions. Inorganic-polymer and organic-polymer coatings not only control the degradation rate of Zn alloys and enhance their biocompatibility but also impart certain functional properties to the alloy, allowing for better performance within the body. For instance, introducing poly(lactic acid) onto a calcium phosphate coating can improve the corrosion resistance of the alloy while upregulating the expression of osteogenic genes such as RUNX2, OCN, and BMP, thereby promoting cell vitality [123]. Combining biomolecules such as cysteine, phenylalanine, and bovine serum albumin with zinc phosphate allows for a reduction in the release rate of zinc ions, promoting the deposition of hydroxyapatite. This, in turn, enhances the proliferation and adhesion of preosteoblast cells (MC3T3-E1) and rat bone marrow mesenchymal stem cells while upregulating the expression of osteogenic genes [124]. A coating consisting of polycarbonate, tannic acid, and copper ions, applied to Zn alloy scaffolds, exhibited excellent corrosion resistance and long-term stability in both in vitro and in vivo degradation tests. Copper ions act as catalysts for nitric oxide generation, promoting the adhesion and proliferation of endothelial cells on the surface of the Zn alloy. Tannic acid and copper ions synergistically exhibit antibacterial effects and reduce the inflammatory response to the zinc substrate [125]. The zinc ion-crosslinked polycarbonate/heparin composite coating enhances the corrosion resistance of the alloy, decreases the release rate of zinc ions, and enhances endothelial cell adhesion and proliferation on the alloy. Endothelialization occurs at a faster rate compared to bare Zn alloy. Additionally, the surface erosion of the composite coating leads to the uniform and long-term release of heparin, significantly inhibiting platelet adhesion and activation [126]. The PLGA/PDA coating improves the material's corrosion resistance, enhances in vitro biocompatibility, and inhibits hemolysis and smooth muscle cell (SMC) proliferation. The enhanced proliferation of endothelial cells (ECs) is expected to promote re-endothelialization within the scaffold, preventing in-stent restenosis and neointimal hyperplasia [127,128]. Various methods have been employed for coating preparation, including the immersion transformation method [129,130], hydrothermal method [131], plasma electrolytic oxidation (PEO) [[132], [133], [134], [135], [136]], phosphate chemical conversion method (PCC) [120,137], anodic oxidation (AD) [138], magnetron sputtering technique [139], electrophoretic deposition (EPD) [125,126], atomic layer deposition [140], ultrasonic spray coating [141], sol-gel method [142], dip coating method [124], etc.