Highlights

-

•

Key fatty acids in Jinmudan fresh tea leaves were selected.

-

•

The dynamic changes of fatty acid-derived volatile compounds (FADVs) were revealed.

-

•

Most of FADVs were accumulated during turning-over and fermentation period.

-

•

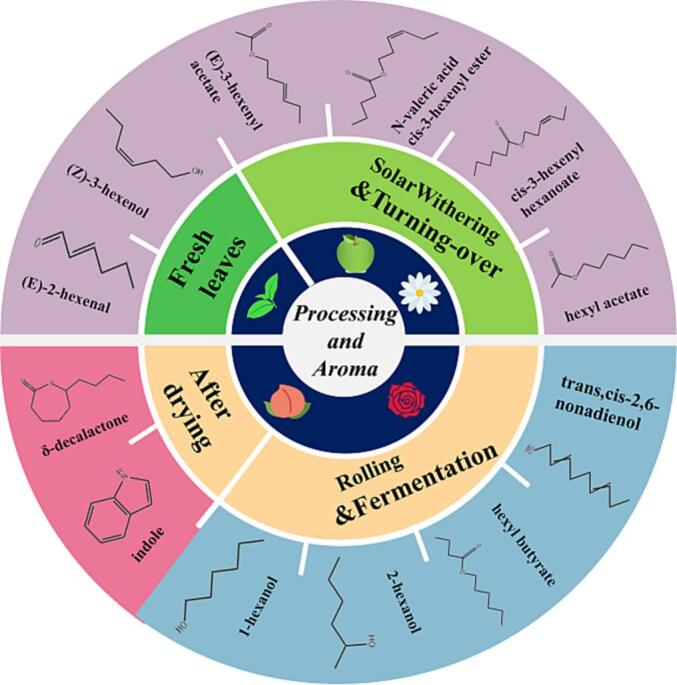

The aroma wheel shows character covered from fresh leaves to processed tea.

Keywords: Jinmudan black tea, Precursors, Fatty acids, Tea processing, Aroma quality

Abstract

Aroma is an important factor affecting the quality of tea. Fatty acids are one of precursors and their derived contributes to tea aroma considerably. In this study, we analyzed the fatty acids of Jinmudan fresh tea leaves in different stalk position. It was found that with shoot maturity increased, the content of PUFAs (Polyunsaturated fatty acids) was increased while the content of SFAs (Saturated fatty acids) and MUFAs (Monounsaturated fatty acids) gradually decreased. During the processing period, totally 704 kinds of compounds were identified, among them, 27 kinds of fatty acid-derived volatile compounds were selected including 6 kinds of aldehydes, 8 kinds of alcohols, 13 kinds of esters and their dynamic change were revealed. Finally, the character of aroma during main processing stages and processed tea was concluded by using a flavor wheel. This study results provide a theoretical basis for the improvement of processing and quality in Jinmudan black tea.

1. Introduction

Acting as the second famous beverage after water, tea is consumed world-widely. When concerning the regulation of tea quality, several factors could be included, such as cultivar (Si, Meihong, Gongyu, Tingting, Jun, Shanshan, Xiaxia, Qianlin, Shixian, & Yang Zhenbiao, 2018), grown environment (Xiaohua, Sun Haiyan, Dong, Wengang, Hai, Chen, Yifan, & Li Chongyong, 2020), plucking seasons (Fei, Xinbo, Bo, & Haiqiang, 2022), maturity of leaves (Chunhui et al., 2021a), and post-harvesting methods (Hengbin, Hui, Jie, He Wei, Chunlai, Renliang, & Qiongqiong, 2023), among others.

Fatty acids are the indispensible precursors of most volatile compounds in tea. Several studies have identified fatty acids both in fresh tea shoots and undergoing-processing tea leaves. In pre-harvest stage, Jiazhi, Zhongwei, Xuzhou, Lin, Yuhua, Wanping, and Xujun (2018) found out that different maturity leaves of purple tea variety, tender leaves has higher content of fatty acids than mature green leaves due to the different rate of chlorophyll biosynthesis that influences the fatty acids degradation between leaf maturity. Li, Zhenghua, Zhi, Yaling, and MingJie (2020) reported that the harvest time of tea leaves would influence the fatty acids content, in details, tea leaves plucked in morning had higher concentration of fatty acids than that in afternoon and evening, which suggested that fatty acids in Tiguanyin leaf were degraded faster during day period especially in sunny afternoon. As for other abiotic factors such as temperature, previous study also found that the tolerance ability to cold stress could regulat the fatty acids content (Ding, 2016). In post-harvest stage, (Ziwei et al., 2019) used processing oolong tea as materials and concluded that the mechanical force (including pressing, shaking, and rubbing) brought by turning-over treatment could facilitate the degradation of fatty acids such as linolenic acid and linoleic acid, while the spreading treatment (stable placing) only regulate the content of linoleic acid. And due to the variance of processing methods between different tea categories, the content of fatty acids also varied (Xuejin, Pengjie, Mingxiu, Lin Xinying, Mengya, Yucheng, Feng, Shan, & Naixing, 2021), which would influence the flavor evaluation.

Fatty acids not only retained their initial form in tea, but also transform into fatty acid-derived volatile compounds (FADVs) under both biotic and abiotic stresses. For example, when facing herbivores attack, the green leaf volatiles, which belong to FADVs, were released acting as responding and signaling compound (Fang et al., 2011, Zhaojun et al., 2019). What’s more, the processing of tea also progressed by reference to gradual emission of green leaf volatiles (Zi, 2021). When concerning the role of FADVs in tea aroma quality, most FADVs tend to possess with floral, fruity, sweet and herbal aroma character. And the formation of these substrates greatly rely on processing treatments because during processing, dual stress occurred in the same time, which could accelerate the accumulation of FADVs to some extent (Lanting et al., 2018). Li et al. (2022) found that during oolong tea processing, the content of FADVs firstly increased then decreased, and the dynamic change of several compounds such as 4-methylpentyl isobutyrate, (Z)-3-hexenyl butyrate, and other FADVs was analyzed. Zhihui, Yifan, Ping, Wang Jieqiong, Yongquan, Xiaoting, Xiaogen, Xiaochun, and Junfeng (2023) had applied two tea categories (Anxi Tieguanyin that belongs to oolong tea; Taiping Houkui that belongs to green tea) as materials, and revealed the change as well as the isomerization of (Z)-methyl epijasmonate, which is a key contributor to orchid-like aroma properties in tea.

Among six traditional tea categories, black tea gains reputation due to its distinguished flavor and aroma. And precious research also found that black tea had higher numbers and concentration of volatile than other tea categories, especially those related to floral and fruity aroma (Biying, Jing, Junyao, Shimao, Zheng-Zhu, Rangjian, & Weiwei, 2021). One of the important reasons would be the variance between the processing of tea categories. Usually, the processing methods of traditional black tea (Congou black tea) consist of four main stages, including withering, rolling, fermentation, and drying. Furthermore, the treatment of turning-over that originated from oolong tea manufacture was applied in black tea producing innovatively, hence the final product was entitled “Innovative congou black tea”, which also made by aroma-enriched tea cultivar. And our group have characterized the key aroma-active compounds of fruity aroma in innovative Jinmudan black tea and also concluded that processing methods lead to the distinguished peach-like aroma (Qingyang, Ziwei, Yining, Huang Huiqing, & Xiaoxi, 2023). However, the dynamic change of aroma volatile compounds during Jinmudan black tea processing, especially the change of FADV is still unclear.

Another reason that influences the tea quality is the maturity of tea leaves. For example,

Shanshan et al. (2021) reported that the catechin, epicatechin, and epigallocatechin which relate to green tea taste quality increased with the shoots age while epicatechin gallate, epigallocatechin gallate, and total catechins decreased. Yonglin et al. (2022) had applied “only buds made black tea” as materials and when compared to traditional “one buds and multiple leaves made black tea”, detection results showed that most of the compounds such as heaflavin-gallate, theaflavin-3-gallate, and quinic acid were lower, and the dynamic change of chemical compounds during fermentation were also revealed. Yongquan, Panpan, John, Ying, Shuangqiu, and Junfeng (2018) found that the oxidation degree of oolong teas decreased from the first leaves to the fourth-fifth leaves and correspondingly, some specific volatile compounds like indole and (E)-nerolidol have changed. Accordingly, the plucking tenderness would also be the prerequisite of tea quality (Chenyang, Yue, Haipeng, Zhifang, Jianming, Qunhua, Yin, & Zhi, 2022). Therefore, there still needs to find out how the leaf tenderness influences on aroma precursors, which could sustain the suitable plucking standard for innovative Jinmudan black tea.

In this study, firstly, fresh leaves in different stalk position were applied as materials to search for the relationship between the content of fatty acids and leaves maturity, and the suitable plucking standard was recommended to innovative Jinmudan black tea production. Secondly, the innovative Jinmudan black tea processing was conveyed based on the recommended maturity, and most importantly, the dynamic change of aroma volatile compounds, especially FADV in undergoing-processing tea leaves was revealed. Finally, the sensory results were given briefly, and the total aroma character of innovative Jinmudan black tea during processing was also concluded in a flavor wheel form. In summary, this study aims on the potential effect of both maturity and processing methods on innovative Jinmudan black tea aroma quality, which would provide a reference for oriented manufacturing and quality improvement of tea in both pre-harvest and post-harvest areas.

2. Materials and methods

2.1. Tea materials

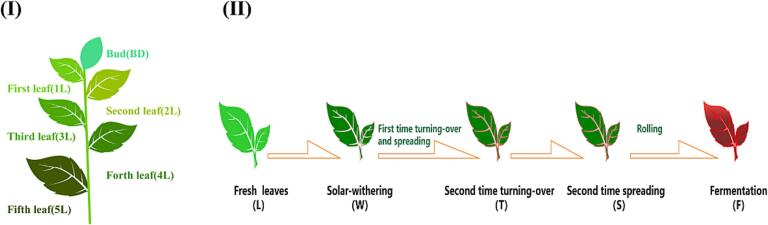

The fresh tea leaves (Camellia sinensis cv. Jinmudan) all were plucked at the educational practicing base of Fujian Agriculture and Forestry University (Fuzhou, China) in April 2023. All leaves were collected from the same branch but in different stalk position (Fig. 1-I), listed as bud (BD), first leave (1L), second leave (2L), third leave (3L), forth leave (4L), fifth leave (5L). After plucking, tea leaves were immediately deep frozen in liquid nitrogen and maintained at −80℃ for the detection of fatty acids content.

Fig. 1.

Materials collected from Jinmudan tea branch in different stalk position (I) and black tea processing (II).

The procedure of innovative Jinmudan black tea processing mainly contained six steps: plucking, withering, turning-over, spreading, rolling, and fermentation. The plucking standard was “one bud and three leaves”, which refers to one bud and three leaves on the same branch. In this study, we selected five moments to collect materials for aroma volatile detection (Fig. 1-II), marked as fresh leaves (L), solar-withering (W), second time turning-over (T), second time spreading (S), fermentation (F). Tea leaves were collected then deep frozen in liquid nitrogen and maintained at −80℃ for further study.

2.3. Detection of fatty acids content

2.3.1. Chemicals and reagents

HPLC-grade methyl tert-butyl ether (MTBE) and methanol (MeOH) and n-hexane were purchased from Merck (Darmstadt, Germany). MilliQ water (Millipore, Bradford, USA) was used in all experiments. Sodium chloride and phosphate were bought from Sigma-Aldrich (St. Louis, MO, USA). Methanol solution of 15 % boron trifluoride were bought from RHAWN (Shanghai, China). All of the standards were purchased from Sigma-Aldrich (St. Louis, MO, USA). The stock solutions of standards were prepared at the concentration of 1 mg/mL in MTBE. All stock solutions were stored at −20 °C and diluted with MTBE to working solutions before analysis.

2.3.2. Sample preparation and extraction

After the sample was thawed, an amount of 0.05 g of the sample was mixed with 150 µL MeOH, 200 μL MTBE,50 μL 36 % phosphoric acid/water (precooled at −20 °C). The sample was vortexed for 3 min under the condition of 2500 r/min, centrifuged at 12,000 r/min for 5 min at 4 °C. Take 200 μL of supernatant into a new centrifuge tube blow dry and add 300 μL methanol solution of 15 % boron trifluoride, vortex for 3 min under the condition of 2500 r/min, kept in the oven at 60 °C for 30 min. Cool to room temperature, then accurately add 500 μL n-hexane and 200 μL saturated sodium chloride solution. After vortexing for 3 min and centrifugation at 4 °C and 12,000 r/min for 5 min, transfer 100 μL n-hexane layer solution for further GC–MS analysis.

2.3.3. GC conditions

The sample derivants were analyzed using an GC-EI-MS system (GC, Agilent 8890ˈ; MS, 5977B System). The analytical conditions were as follows. As for GC column, DB-5MS capillary column (30 m × 0.25 mm × 0.25 μm, Agilent) was applied. High purity helium (purity > 99.999 %) was applied as carrier gas, The heating procedure was started at 40 °C for 2 min, with the speed of 30 °C/min and increased to 200 °C for 1 mintutes, then increased to 240 °C with the speed of 10 °C/minutes for 1 min, finally increased to 285 °C with the speed of 5 °C/minutes for 3 min keeping. The rate of the flow was 1.0 mL/min, the inlet temperature was set as 230 °C and the injection volume was 1.0 μL.

2.3.4. EI-MS (Electron ionization mass spectrometry)

The sample were analyzed using an Agilent 8890-5977B GC–MS System, and the temperature was set at 230 °C, the ionization voltagewas set at 70 eV, the transmission line temperature was set at 240 ℃, the four-stage rod temperature was set at 150 ℃, the solvent delay was set at 4 min, the scanning mode was SIM.

2.4. Detection of aroma volatile compounds

2.4.1. Sample preparation and treatment

Materials were harvested, weighted, immediately frozen in liquid nitrogen, and stored at −80℃ until needed. Samples were ground to a powder in liquid nitrogen. 500 mg of the powder was transferred immediately to a 20 mL head-space vial (Agilent, Palo Alto, CA, USA), containing NaCl saturated solution, to inhibit any enzyme reaction. The vials were sealed using crimp-top caps with TFE-silicone headspace septa (Agilent). At the time of SPME (Solid phase micro extraction), each vial was placed in 60 ℃ for 5 min, then a 120 µm DVB/CWR/PDMS fibre (Divinylbenzene/ carbon wide range/polydimethylsiloxane, Agilent) was exposed to the headspace of the sample for 15 min at 60 ℃.

2.4.2. GC–MS conditions

After sampling, desorption of the VOCs from the fibre coating was carried out in the injection port of the GC apparatus (Model 8890; Agilent) at 250 °C for 5 min in the splitless mode. The identification and quantification of VOCs was carried out using an Agilent Model 8890 GC and a 7000D mass spectrometer (Agilent), equipped with a 30 m × 0.25 mm × 0.25 μm DB-5MS (5 % phenyl-polymethylsiloxane) capillary column. Helium was used as the carrier gas at a linear velocity of 1.2 mL/min. The injector temperature was kept at 250 °C and the detector at 280 °C. The oven temperature was programmed from 40 °C (3.5 min), increasing at 10 °C/min to 100 °C, at 7 °C/min to 180 °C, at 25 °C/min to 280 °C, hold for 5 min. Mass spectra was recorded in electron impact (EI) ionisation mode at 70 eV. The quadrupole mass detector, ion source and transfer line temperatures were set, respectively, at 150, 230 and 280 °C. The MS was selected ion monitoring (SIM) mode was used for the identification and quantification of analysis.

2.5. Statistical analysis

Statistic analysis and figures drawing were conveyed by WPS 20.0 software. The principal component analysis (PCA) and partial least squares discriminant analysis (PLS-DA) were both performed using SIMCA 14 software. Additionally, in the PLS-DA mode, a VIP value (Variable Importance in Projection) higher than 1 was applied for the measurement.

3. Results

3.1. The profile of fatty acids of Jinmudan fresh tea leaves in different stalk position

Fatty acids are one of the sources of tea aroma, which transformed under specific reactions while some still maintained the original structure and form. For the purpose of identifying the profile of fatty acids in different grown stages and select the suitable maturity for innovative Jinmudan black tea processing, the analysis of the fatty acids of Jinmudan fresh tea leaves in different stalk position was conveyed. Results showed the presence of 32 components in total (Table S1). According to whether there are double bonds of carbon atoms in the carbon chain and the number of double bonds of carbon atoms contained, fatty acids can be divided into saturated fatty acids (SFAs), monounsaturated fatty acid (MUFAs) and polyunsaturated fatty acid (PUFAs).

Therefore, based on qualitative and quantitative analyses, these 32 kinds of fatty acids could be clustered. The majority of fatty acids components belong to the category of SFAs (18 kinds), less components belong to the category of MUFAs (8 kinds). As for the PUFAs, only 6 kinds of components belong to this category.

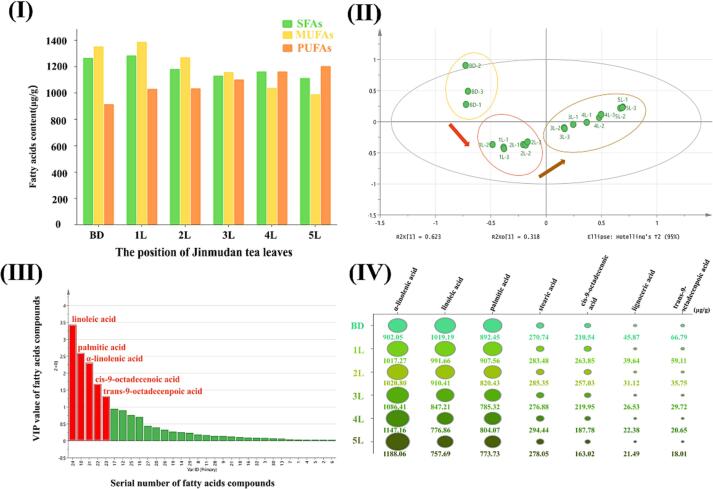

With shoots maturity increased, the content of PUFAs (the orange bar) in Jinmudan tea leaves was increased and achieved the maximum at 5L while the content of SFAs (the green bar) and MUFAs (the yellow bar) gradually decreased(Fig. 2- I). These results consistent with the previous study that found in mature tea leaves, the proportion of long chain PUFAs (represented by α-linolenic acid and linoleic acid) was higher than the proportion of MUFAs (represented by cis-9-octadecenoic acid) and SFAs(represented by palmitic acid) (Zhou ZiWei et al., 2022a). So does the tea plant, along with the grown and maturity period, other plants also thicken leaf wax layer, which mostly consists of lipids that concludes fatty acids, triglyceride, among others (Rita, Isabel, & Helena, 2022).

Fig. 2.

The content of three categories of fatty acids in different position tea leaves (I); the OPLS-DA analysis of fatty acids in Jinmudan fresh tea leaves (II and III); the content proportion of seven kinds of key fatty acids in Jinmudan fresh tea leaves (Ⅳ).

In more details, in bud (BD) and tender leaves(1L and 2L), the content of SFAs and MUFAs accounted for a considerable proportion. Differently, in mature leaves (4L and 5L), the content of PUFAs made up a comparatively major proportion. Interestingly, in 3L, the content of three fatty acids categories shared a similar proportion. When concerning to the whole flavor of tea, we still need to pay attention to the character of taste. And previous study indicated that the difference between leaf position would have a significant effect on tea quality (Xu et al 2018). If the plucking standard is set as “one bud and four/five leaves”, the quality evaluation of final processed black tea would present highly fruity and floral aroma, however, its taste would be thick and pale. Therefore, we supposed “one bud and three leaves” would be more helpful to gain a balance flavor.

3.2. Analysis for key fatty acids of Jinmudan fresh tea leaves in different stalk position

Further investigation of OPLS-DA analysis (Orthogonal partial least squares discrimination analysis) was conveyed to reveal the key fatty acids of Jinmudan fresh tea leaves at different maturity stages, and simultaneously, a VIP (Variable Importance Projection) score higher than 1 was used as a screening criterion. Results showed that the fitting parameters of the established OPLS-DA model were R2X[1] = 0.623 and R2X[2] = 0.318, respectively, suggesting the reliable fitting of this model. Additionally, the distance between the replicates of different samples was close, suggesting reliable repeatability of the samples. Various colors were applied to distinguish and cluster the samples. As Fig. 2- II showed, the yellow circle only covered the BD, which located in the second quadrant; the orange circle covered the tender leaves (1L and 2L), which both located in the third quadrant; the red circle covered the mature leaves (3L, 4L and 5L), which located in both fourth and first quadrant. When VIP more than 1 was applied (Fig. 2-III), totally five kinds of fatty acids were selected, marked as linoleic acid (3.43), palmitic acid (2.59), α-linolenic acid (2.30), cis-9-octadecenoic acid (1.67), trans-9-octadecenpoic acid (1.315). Moreover, lignoceric acid (0.95) and stearic acid (0.90) both had the value close to 1, which would also affect the composition and total content of Jinmudan tea leaves fatty acids to some extent. Therefore, both lignoceric acid and stearic acid were also considered as second-active fatty acids for further analysis.

As Fig. 2-Ⅳ revealed the proportion of five key fatty acids compounds and two second-active fatty acids of Jinmudan fresh tea leaves in different stalk position, α-linolenic acid, linoleic acid and palmitic acid accounted for considerably major proportion, and the rest of components made up the remaining proportion. Comparing the key fatty acids content of Jinmudan fresh tea leaves in different stalk position, the content of linoleic acid (1019.19 μg/g) in BD was higher than the content of α-linolenic acid (902.05 μg/g). However, in tender and mature leaves(except bud), α-linolenic acid had the highest proportion, followed by linoleic acid and palmitic acid. In detail, with the increasing maturity of tea leaves, the content of linoleic acid decreased while α-linolenic acid increased, these two components achieved their minimum and maximum respectively in 5L (757.69 μg/g, 1188.06 μg/g). These two fatty acids are both the reaction substrates for LOX(Lipoxygenase). However, due to the various function and preference of LOX family (Mohd, Maridul, Umar, Priyanka, Abdul, Kajal, Vikash, Sumeet, & Prashant, 2023) as well as the difference between the metabolic pathway branch(Clews Alyssa, Ulch Brandon, Monika, Jun, Mullen Robert, & Yang, 2023), α-linolenic acid and linoleic acid show contrary trend along with the tea leaf maturity. Conceivably, the products that brought by these two substrates totally differ in structure and contribution in tea aroma quality.

As for other components, the content of palmitic acid fluctuated slightly along with the maturity of tea leaves. The content of cis-9-octadecenoic acid increased firstly and peaked in 1L (263.85 μg/g), then decreased to minimum in 5L (163.02 μg/g) slightly and gradually, and the content of trans-9-octadecenpoic acid showed a continuing downward trend along with the increasing maturity. As for the lignoceric acid and stearic acid, the former component gradually decreased along with the increasing maturity while the latter component fluctuated slightly.

In summary, the content of mostly selected fatty acids compounds decreased or fluctuated along with the increasing leaves maturity, however, only α-linolenic acid increased steadily. Among these selected components, α-linolenic acid and linoleic acid belong to PUFAs, palmitic acid belongs to SFAs, cis-9-octadecenoic acid and trans-9-octadecenpoic acid belong to MUFAs. It is noteworthy that all these components were the main constituent components of fatty acids categories due to their high content and proportion, which would influence the changing trend of overall fatty acids. What’s more, the trend of α-linolenic acid and linoleic acid along with the leaves maturity were coincident with the trend of PUFAs, supporting that these two components play indispensable role in fatty acids of fresh tea leaves.

Although mature leaves tend to contribute to higher aroma (Chenyang et al., 2022), it was reported that along with the tea leaves maturation, the concentration of catechin, epicatechin gallate, and epigallocatechin gallate showed an increasing trend while epicatechin and epigallocatechin showed reverse trend, which would lead to pale and bitter taste (Samanta, Kotamreddy, Ghosh, & Mitra, 2017), which was adverse to the whole flavor and quality of tea. Therefore, based on what we found, the suitable plucking standard of innovative Jinmudan black tea was recommended as “one bud and three leaves”, which contains bud, tender leaves and kind of mature leaves in the same tea shoot.

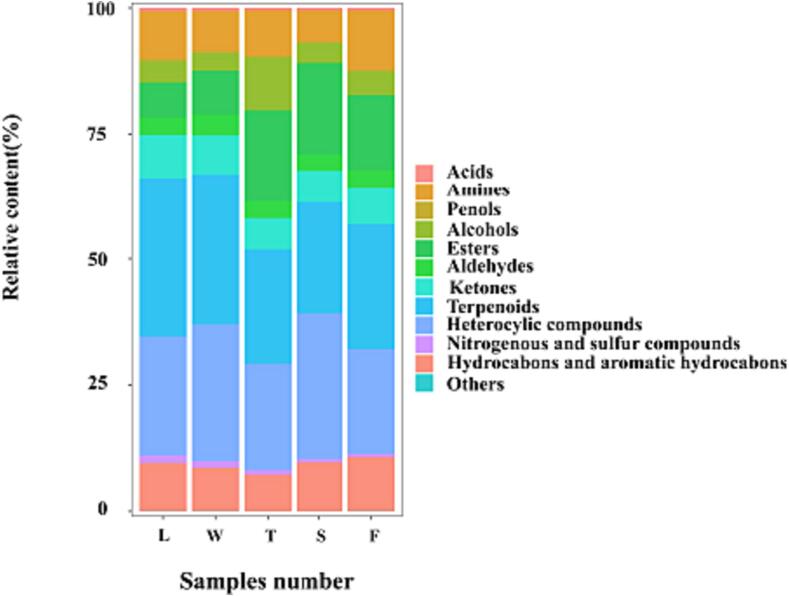

3.3. Aroma profile of Jinmudan black tea during processing

The analysis of aroma compounds in the Jinmudan black tea processing samples showed the presence of 704 compounds in total. Based on the qualitative and quantitative analysis, the compounds were clustered into twelve categories including terpenoids (163 kinds), esters (122 kinds), heterocylic compounds (105 kinds), hydrocarbons and aromatic hydrocarbons (96 kinds), alcohols (52 kinds), aldehydes(50 kinds), ketones (45 kinds), amines (20 kinds), acids (16 kinds), phenols (17 kinds), nitrogenous and sulfur compounds (11 kinds) and the last category termed “others”, in which compounds not pertaining to the previous categories were included (Fig. 3).

Fig. 3.

The aroma profile of processing Jinmudan black tea. The capital letters marked as fresh leaves (L), solar-withering (W), second time turning-over (T), second time spreading (S), and fermentation (F).

The terpenoids (22 % ∼ 31 %) had the highest proportion in all processing treatment, followed by heterocyclic compounds (20 % ∼ 28 %). Moreover, terpenoids decreased after withering treatment (W) while increased slightly after fermentation (F). These may attribute to the mechanical stress that brought by turning-over and rolling (instead of withering), which caused more cellular injury to tea leaves as well as had facilitated the interaction of substrates and enzymes, and many glucoside were hydrolyzed to release free terpenoids (Mingyue, Na, Ting, Jieyang, Tingting, Wang Jingming, Yi, Wilfried, & Chuankui, 2020). And heterocylic compounds fluctuated along with the processing period and peaked at the second time spreading (S). The proportion of amines showed slight fluctuation (6 % ∼ 9 %), and achieved its maximum in fermentation (11 %). As for alcohols, this catergory accounted for only 3 % ∼ 4 % in withering (W), spreading (S) and fermentation (F) treatments without continuously mechanical stimulation, however, it peaked in second time turning-over (T, 11 %), in which mechanical stress facilitated its accumulation. Similar to alcohols, the proportion of esters significantly increased after second time turning-over (T, 18 %) while decreased after fermentation (F, 14 %). Compared to turning-over stages, the oxygen content in fermentation environment was lower while the moisture content was consequently higher, thereby, the climbing content of CO2 and temperature would restrain the accumulation of specific ester compounds.(Ziwei, Wei Yingying, Qingyang, Hongting, Chen Yuanyuan, Linzhen, Liewei, Shizhong, Fang, & Yun, 2022b). Furthermore, the proportion of aldehydes as well as hydrocabons and aromatic hydrocabons fluctuated slightly within the range between 3 % and 4 % and 7 % ∼ 9 %, respectively. Although some kinds of compounds such as acids (0.4 %∼ 0.6 %), phenols (0.3 %∼ 0.5 %), nitrogenous and sulfur compounds (0.7 % ∼ 0.15 %) as well as others (0.003 % ∼ 0.006 %) only made up a very small proportion, they were indispensable to some extent.

In conclusion, during Jinmudan black tea processing, there was little difference between early stages, however, when turning-over method involved, which brought mechanical stress to tea leaves, the content of several compound categories fluctuated and changed consequently. And at the later stages, esters and heterocylic compounds accumulated greatly due to the lasting and static reaction of heat and moisture.

3.4. The dynamics change of volatile fatty acid-derived volatile compounds during black tea processing

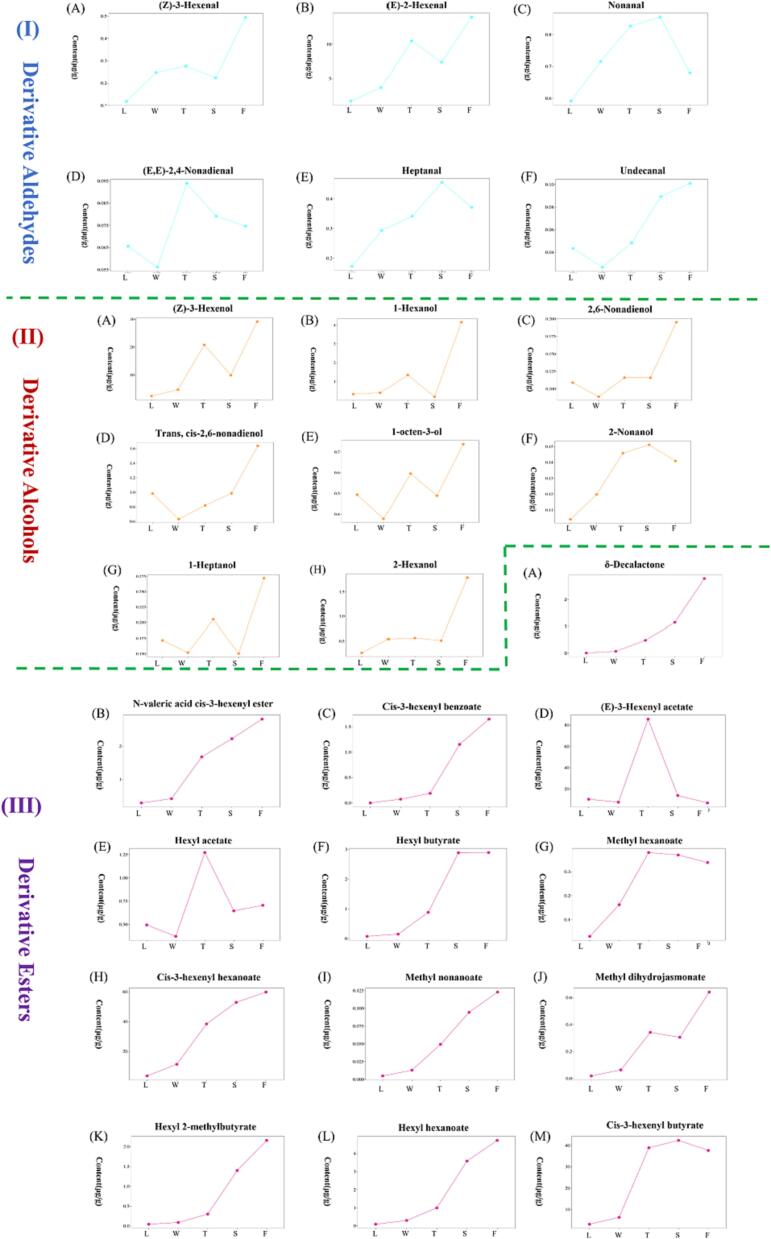

During the processing period, several factors such as mechanical stress and water deficit stress have facilitated the degradation of fatty acids, which leading to the formation and accumulation of fatty acid-derived volatile compounds (FADVs). All these compounds would finally contributed to the tea aroma quality. Hence, based on the GC–MS detection results, totally 27 kinds of FADVs were selected including 6 kinds of aldehydes, 8 kinds of alcohols, 13 kinds of esters, and their content during black tea processing were provided (Table S2) as well as their dynamic changing trend were revealed.

The dynamic trend of six kinds of derived aldehydes listed as (Z)-3-hexenal, (E)-2-hexenal, nonanal, (E,E)-2,4-nonadienal, heptanal and undecanal were showed as Fig. 4- I. In details, (Z)-3-hexenal fluctuated and scored its maximum in fermentation (F, 0.494 μg/g). As for its isomer, (E)-2-hexenal, also shared the similar trend but had higher content. Interestingly, these two compounds both had higher content in second time turning-over (T, 0.276 μg/g and 10.5 μg/g, respectively), illustrating that they may respond to mechanical stress. Both nonanal and heptanal firstly increased and peaked in second time spreading (S, 0.855 μg/g and 0.455 μg/g, respectively), then decreased in fermentation (F), suggesting that the heat and moisture reaction would forbid these two compounds formation and accumulation to some extent. As for the left two compounds, (E,E)-2,4-nonadienal and undecanal firstly decreased during solar-withering (W) then increased sharply, and achieved their maximum in second time turning-over(T, 0.093 μg/g) and fermentation (F, 0.101 μg/g), respectively. In brief, the emission of derived aldehydes continued along with the whole tea post-harvesting period. During the withering and turning-over stages, the emitted aldehydes mostly contributed to the strongly grass-like aroma of undergoing-processing tea leaves. Furthermore, after fermentation and drying, the retained aldehydes were the active compounds of fresh and green aroma character in processed black tea (Jianfeng, Tingyu, & Yang Jiangfan, 2023).

Fig. 4.

The dynamic change of fatty acid derived volatile compounds: the dynamic change of derived aldehyde compounds (I); the dynamic change of derived alcohol compounds (II); the dynamic change of derived ester compounds (III).

The Fig. 4- II showed the dynamic change of eight kinds of fatty acid-derived alcohol compounds including (Z)-3-hexenol, 1-hexanol, 2,6-nonadienol, trans,cis-2,6-nonadienol, 1-octen-3-ol, 2-nonanol, 1-heptanol and 2-hexanol. Among them, five kinds of compounds shared the similar fluctuation trend, they were (Z)-3-hexenol, 1-hexanol, 2,6-nonadienol, 1-octen-3-ol, and 1-heptanol. These compounds firstly peaked higher content during second time turning-over (T) then decreased slightly till fermentation (F) involved, and finally scored the maximum content. Differed to the mentioned above compounds, the left three volatiles had their specific changing trend. As for trans,cis-2,6-nonadienol, this compound firstly decreased during solar-withering (W) then sharply increased to maximum in fermentation (F, 1.637 μg/g). As for 2-nonanol, this compound gradually increased to its peak in second time spreading (S, 0.151 μg/g) then decreased when fermentation involved. The final compound 2-hexanol, showed a more stable trend in the former processing stages while sharply increased to its peak during fermentation (F, 1.794 μg/g).

Derived esters made up the majority proportion, Moreover, these compounds were characterized in fruits and also used as essence in food production due to their lower aroma threshold (Dennis et al., 2012, Nhungoc et al., 2022), which usually endow with tea flavor a pleasant fruity aroma. Totally 13 kinds of compounds were identified, and according to their dynamic trend, these compounds could be divided into three classification roughly (Fig. 4- III and Fig. 4-IV).

Firstly, most derived esters shared the similarly sharp increasing trend, like N-valeric acid cis-3-hexenyl ester, cis-3-hexenyl benzoate, cis-3- hexenyl hexanoate, methyl nonanoate, hexyl 2-methylbutyrate, hexyl hexanoate, and δ-decalactone. These compounds all increased and achieved their maximum during fermentation (F). Secondly, two kinds of compounds includes (E)-3-hexenyl acetate and hexyl acetate may respond to mechanical stress brought by turning-over step. They decreased slightly in solar-withering (W) then peaked during second turning-over (T, 85.634 μg/g and 1.272 μg/g, respectively) while after that, they decreased sharply. Finally, the left three compounds listed as hexyl butyrate, methyl hexanoate and methy dihydrojasmonate fluctuated during the whole processing period, however, these three compounds responded to different processing steps and achieved their maximum in second time spreading (S), second time turning-over (T), and fermentation (F), respectively.

3.5. The profile of processing and aroma in innovative Jinmudan black tea

Briefly, the results of processed innovative Jinmudan black tea sensory evaluation were reported that it has typically floral and fruity aroma with mellow and smooth taste. More details had published in our group’s previous study (Wu et al, 2023) as well as key aroma-active such as δ-decalatone and indole were identified. In order to have an obvious version about the dynamic change of aroma character during the main processing procedures of innovative Jinmudan black tea, a flavor wheel was given (Fig. 5) and several representative compounds were selected due to their aroma character or distinguished content at specific processing stages (Table S2). In brief, as shown in Fig. 5, we clustered the procedures of fresh leaves (or plucking), solar-withering and turning-over as former processing stages (purple circle), rolling and fermentation as later processing stages (blue circle), while pink circle represents for processed Jinmudan black tea (after drying). During the former procedures, the overall aroma character have changed from grassy then gradually turned into green-apple like as well as freshly and lightly floral fragrance. The representative compounds, like (E)-2-hexenal, which possess with green and grassy aroma character, had higher content in their related stages. Apart from these, at these steps, the aldehydes gradually transfered to alcohols as well as a little amount esters, like(Z)-3-hexenol, (E)-3-hexenyl acetater and cis-3- hexenyl hexanoate, which also reflecting on the fragrance changing. Moreover, during the later procedures (contains rolling, fermentation), several volatile compounds like hexyl butyrate, δ-decalactone had achieved their maximum during fermentation, which contributed to the mature fruit-like aroma. And alcohol volatiles including trans, cis-2,6-nonadienol and 2-hexanol contributed to strongly floral fragrance. Differed to the mentioned enzymatic reaction, drying stage mainly helps to stabilize and improve tea quality. Several compounds like aldehydes were diffused due to the high baking temperature, while esters still kept. And interestingly, during this period, maillard reaction was involved, which facilitates heterocyclic compounds formation considerably, which may explain why indole was selected as aroma-active compounds in processed innovative Jimudan black tea.

Fig. 5.

The processing and aroma wheel of innovative Jinmudan black tea.

4. Discussion

4.1. Relationship between precursors in tea leaves and tea quality

Tea aroma precursors could metabolize and change into aroma compounds based on four ways including the glycoside hydrolysis, fatty acid degradation, carotenoid degradation, and maillard reaction. On one hand, during the tea processing period, the majority of fatty acids would transform into FADVs, which contribute to floral and fruity fragrance in tea. On the other hand, some specific fatty acids such as α-linolenic acid, hexadecanoic acidhexadecanoic acid (palmitic acid) still keep their initially chemical structure and property without any changing and equally make up for tea aroma quality too (Wenjun et al., 2015, Quanfei et al., 2022). However, during the tea storage period, fatty acids undergo spontaneous and slow oxidation and generate hydroperoxides, regardless of whether they are exposed to light or protected from light, stored under low temperature or high temperature (Chunhui et al., 2021b). These hydroperoxides have little influence on tea quality and nutrition because they are colorless and odorless, however, they are very unstable and could be easily decomposed into aldehydes, ketones, acids, among others. These small molecular compounds mixed and produced unpleasantly rotten or pungent odor, commonly refers to “oily smell” that represents the sourness and deterioration of tea, which adverse to tea sensory quality.

As for other precursors like glycosides, take geraniol as example, this kind of compound not only contributes to the rose-like fragrance in tea, but also acts as aroma precursor in fresh tea leaves.What’s more, geraniol mainly stored in cells, in the form of primeveroside and a portion in glucoside form, and several factors like maturity and processing, among others, would influence the synthesis of geraniol (Qianqian et al., 2024, Sarah et al., 2023).

In summary, it is worth to study about the character of precursors’ accumulation and reveal its synthesis mechanism, because the fresh tea leaves is the initial factor of final quality.

4.2. Relationship between processing methods and the formation of tea aroma quality

The construction of tea quality is an overall procedure, which contains enzymatic reaction and non-enzymatic reaction. In this study, we only aimed at the enzymatic stage that relates to the formation of tea aroma during processing, especially the dynamic change of fatty acid volatile compounds. And we could found that the processing methods had brought stress and injury to tea leaves, which helped specific compounds to form and accumulate. For example, the water deficit and light stress caused by solar-withering have facilitated the the emission of (E)-2-hexenal and (Z)-3-hexenol. Several volatile like (E)-3-hexenyl acetate and cis-3-hexenyl hexanoate changed and fluctuated due to the mechanical damage caused by turning-over. Notably, a large amount of esters have achieved their maximum under the heat and moisture reaction caused by fermentation. During the processing period, static setting were needed when intensive stress had finished, like hours spreading after seconds or minutes turning-over and also hours fermentation after minutes rolling, which could offer enough time for transformation and accumulation of aroma compounds in tea leaves. And during this “waiting” time, enzymatic reaction involved. For example, in LOX-HPL pathway, α-linolenic acid could be transformed into 9/13-HPOT (9/13-hydroperoxy octadeca trienoic acid) firstly (Qian et al., 2017), then regulated by several enzymes such as HPL (Hydroperoxide lyase) (Chang, Hunter, Alborn, Christensen, & Block Anna, 2022), ADH (Alcohol dehydrogenase) (Cirilli, Bellincontro, De, Botondi, Colao, Muleo, & Mencarelli, 2012), AAT (Alcohol acyltransferase) (Shalit et al., 2001) and changed into derived C6/C9 aldehydes, C6/C9 alcohols, and C6 esters correspondingly (Sekiya, Kajiwara, & Hatanaka, 1984). To some extent, due to the regulation of these enzymes stimulated by dual stress during processing, the volatile formed then contributed to tea aroma quality. In the near future, the mechanism between specific fatty acid volatile and its relative enzyme would also be further investigated.

As for non-enzymatic reaction, briefly, the function of this procedure is mainly on the stabilization and improvement of tea quality. For instance, during the baking, maillard reaction was involved and products synthesized, such as furan and pyridine (Qing et al., 2023), which contributed to the caramel-like and nutty fragrance in tea aroma. As for the drying procedure of black tea, this later step was able to compensate for the insufficiency of fermentation caused by the unsuitable temperature and humidity to some extent. Furthermore, the storage stage is another factor that influences the tea quality, which also gained visible attention (Jingming, Ding, & Yasai, 2016).

5. Conclusion

In this study, we have identified the classification and concentration of fatty acids in fresh Jinmudan tea leaves, and also compare the variance between different leaf maturity. Out of the whole flavor concern, the suitable plucking standard for Jinmudan black tea production was set as “one bud and three leaves”. After harvesting and processing, the fatty acids degraded then transformated into derived volatile, totally 704 kinds of volatile compounds were identified and among them, 27 kinds of FADVs were selected and their dynamic change were revealed. Finally, the whole aroma character covered from fresh tea leaves to processed Jinmudan black tea was displayed in an aroma wheel form.

CRediT authorship contribution statement

Wu Qingyang: Writing – original draft, Writing – review & editing, Formal analysis, Data curation. Zhou Ziwei: Writing – original draft, Writing – review & editing. He Jihang: Validation. Zhao Suhui: Software. Ruan Shuling: Software. Liu Xiaochun: Supervision, Project administration. Yu Shuirong: Conceptualization, Funding acquisition. Sun Yun: Conceptualization, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by Fujian Agriculture and Forestry University Construction Projection for Technological Innovation and Service System of Tea Industry Chain (K1520005A06), Youth Research Project of Ningde Normal University (2022ZQ110), the Natural Science Foundation of Fujian, China (2021J05271), and Special Fund for Science and Technology Innovation of Fujian Zhang Tianfu Tea Development Foundation (FJZTF01).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.fochx.2024.101155.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

Data availability

Data will be made available on request.

References

- Zhu, B., Zhang, J., Li, J., Fang, S., Zhang, Z.-Z., Wang, R., Deng, W. (2021). Aroma profile of Jinmudan tea produced using Camellia sinensis, cultivar Jinmudan using solid-phase microextraction, gas chromatography-mass spectrometry, and chemometrics. European Food Research and Technologyl, 247, 1061–1082. https://doi.org/ 10.1007/S00217-021-03687-0.

- Shao, C., Zhang, Y., Lv, H., Zhang, Z., Zeng, J., Peng, Q., Zhu, Y., Lin, Z., (2022). Aromatic profiles and enantiomeric distributions of chiral odorants in baked green teas with different picking tenderness[J]. Food Chemistry, 388. https://doi.org/ 10.1016/J.FOODCHEM. 2022.132969. [DOI] [PubMed]

- Xu, C., Liang, L., Yang, T., Feng, L., Mao, X., Wang, Y., (2021). In-vitro bioactivity evaluation and non-targeted metabolomic analysis of green tea processed from different tea shoot maturity[J]. LWT,-FOOD SCIENCE AND TECHNOLOGY, 152. https://doi.org/ 10.1016/J.LWT.2021.112234.

- Xu, C., Liang, L., Li, Y., Yang, T., Fan, Y., Mao, X., Wang, Y., (2021). Studies of quality development and major chemical composition of green tea processed from tea with different shoot maturity[J]. LWT-FOOD SCIENCE AND TECHNOLOGY, 142. https://doi.org/ 10.1016/J.LWT.2021.111055.

- Cirilli, M., Bellincontro, A., De, S. D., Botondi, R., Colao, M. C., Muleo, R., Mencarelli, F. (2012). Temperature and water loss affect ADH activity and gene expression in grape berry during postharvest dehydration. Food Chemistry. 132, 447–454. https://doi.org/ 10.1016/j.foodchem.2011.11.020. [DOI] [PubMed]

- Clews, A.C., Ulch, B.A., Jesionowska, M., Hong, J., Mullen, R.T., Xu, Y. (2023).Variety of Plant Oils: Species-Specific Lipid Biosynthesis. [J]. Plant & cell physiology. http://doi.org/ 10.1093/ pcp/ pcad147. [DOI] [PubMed]

- Dennis, E.G., Keyzers, R.A., Kalua, C.M., Maffei, S.M., Nicholson, E.L., Boss, P.K. (2012). Grape contribution to wine aroma: production of hexyl acetate, octyl acetate, and benzyl acetate during yeast fermentation is dependent upon precursors in the must.[J]. Journal of agricultural and food chemistry, 60(10). https://doi.org/ 10.1021/jf2042517. [DOI] [PubMed]

- Ding, Ma, Wang (2016). The differences between two tea varieties in their response to natural cold conditions[J]. The Journal of Horticultural Science and Biotechnology, 91(5). https://doi.org/ 10.1080/ 14620316.2016.1178078.

- Dong, F., Yang, Z., Baldermann, S., Sato, Y., Asai, T., Watanabe, N. (2011). Herbivore-induced volatiles from tea (Camellia sinensis) plants and their involvement in intraplant communication and changes in endogenous nonvolatile metabolites.[J]. Journal of agricultural and food chemistry, 59(24). https://doi.org/ 10.1021/jf203396a. [DOI] [PubMed]

- Ye, F., Guo, X., Li, B., Chen, H., Qiao, X. (2022). Characterization of Effects of Different Tea Harvesting Seasons on Quality Components, Color and Sensory Quality of “Yinghong 9” and “Huangyu” Large-Leaf-Variety Black Tea. Molecules, 27, 8720. https://doi.org/ 10.3390/MOLECULES27248720. [DOI] [PMC free article] [PubMed]

- Guo, L., Du, Z., Wang, Z., Lin, Z., Guo, Y., Chen, M. (2020). Location affects fatty acid composition in Camellia sinensis cv Tieguanyin fresh leaves.[J]. Journal of food science and technology, 57(1). https://doi.org/ 10.1007/s13197-019-04034-8. [DOI] [PMC free article] [PubMed]

- Huang, J., Yan, T., Yang, J., Xu, H. (2023). Aroma components analysis and origin differentiation of black tea based on ATD-GC-MS and E-Nose[J]. Horticulturae, 9(8). https://doi.org/ 10.3390/HORTICULTURAE9080885.

- Shen, J., Zou, Z., Zhang, X., Zhou, L., Wang, Y., Fang, W., et al. (2018). Metabolic analyses reveal different mechanisms of leaf color change in two purple-leaf tea plant (Camellia sinensis L.) cultivars.[J]. Horticulture research, 5(1). https://doi.org/ 10.1038/s41438-017-0010-1. [DOI] [PMC free article] [PubMed]

- Ning, J., Ding, D., Song, Y., Zhang, Z., Luo, X., Wan, X. (2016). Chemical constituents analysis of white tea of different qualities and different storage times[J]. European Food Research and Technology, 242(12). https://doi.org/ 10.1007/s00217-016-2706-0.

- Zeng, L., Zhou, Y., Fu, X., Liao, Y., Yuan, Y., Jia, Y., et al. (2018). Biosynthesis of Jasmine Lactone in Tea (Camellia sinensis) Leaves and Its Formation in Response to Multiple Stresses.[J]. Journal of agricultural and food chemistry, 66(15). https://doi.org/ 10.1021/acs.jafc.8b00515. [DOI] [PubMed]

- Li G., Mingjie C., Yaling G., Zhi L. Variations in fatty acids affected their derivative volatiles during tieguanyin tea processing[J] Foods. 2022;11(11) doi: 10.3390/FOODS11111563. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhao, M., Zhang, N., Gao, T., Jin, J., Jing, T., Wang, et al. (2020). Sesquiterpene glucosylation mediated by glucosyltransferase UGT91Q2 is involved in the modulation of cold stress tolerance in tea plants. [J]. The New phytologist, 226 (2): 362-372. http:// doi.org/ 10.1111/ nph. 16364. [DOI] [PubMed]

- Fayaz, M., Kundan, M., Gani, U., Sharma, P., Wajid, M. A., Katoch, K., et al. (2023).Identification of Lipoxygenase gene repertoire of Cannabis sativa and functional characterization of CsLOX13 gene. [J]. Plant science : an international journal of experimental plant biology, 334 111780-111780. http://doi.org/ 10.1016/J.PLANTSCI.2023.111780. [DOI] [PubMed]

- Dang, N., Pham, H., Kleiner, I., Schwell, M., Grabow, J., Nguyen, H. V. L. (2022). Methyl Internal Rotation in Fruit Esters: Chain-Length Effect Observed in the Microwave Spectrum of Methyl Hexanoate[J]. Molecules, 27(9). https://doi.org/ 10.3390/MOLECULES27092639. [DOI] [PMC free article] [PubMed]

- Qian, X., Sun, L., Xu, X., Zhu, B., Xu, H. (2017). Differential expression of VvLOXA diversifies C6 volatile profiles in some vitis vinifera table grape cultivars. International Journal of Molecular Sciences. 18: 2705. https://doi.org/ 10.3390/ijms181 22705. [DOI] [PMC free article] [PubMed]

- Li, Q., Li, B., Zhang, C., Zhou, X., Liu, W., Mi, Y., et al. (2024). Insights into key aroma of vine tea (Ampelopsis grossedentata) for grade evaluation integrating relative odor activity value, gas chromatography-olfactometry and chemometrics approaches[J]. Food Control, 155. https://doi.org/ 10.1016/J.FOODCONT.2023.110048.

- Xiao, Q., Huang, Q., Ho, C. (2023). Influence of deamidation on the formation of pyrazines and proline-specific compounds in maillard reaction of asparagine and proline with glucose.[J]. Journal of agricultural and food chemistry. https://doi.org/ 10.1021/ACS.JAFC.3C00887. [DOI] [PubMed]

- Wu, Q., Zhou, Z., Zhang, Y., Huang, H., Ou, X., Sun, Y. (2023). Identification of key components responsible for the aromatic quality of jinmudan black tea by means of molecular sensory science. Foods, 12, 1794. https://doi.org/ 10.3390/FOODS12091794. [DOI] [PMC free article] [PubMed]

- Zhu, Q., Ge, Y., An, N., Li, N., Xiao, Y., Huang, G., et al. (2022). Profiling of branched fatty acid esters of hydroxy fatty acids in teas and their potential sources in fermented tea. [J]. Journal of agricultural and food chemistry, 2022. http:// doi.org/10.1021/ACS.JAFC.2C01210. [DOI] [PubMed]

- Simões, R., Miranda, I., Pereira, H. (2022). Effect of seasonal variation on leaf cuticular waxes’ composition in the mediterranean cork oak (Quercus suber L.) [J]. Forests, 2022, 13 (8): 1236-1236. http://doi.org/ 10.3390/F13081236.

- Samanta T., Kotamreddy J.N.R., Ghosh B.C., Mitra A. Changes in targeted metabolites, enzyme activities and transcripts at different developmental stages of tea leaves: A study for understanding the biochemical basis of tea shoot plucking[J] Acta Physiologiae Plantarum. 2017;39(1) doi: 10.1007/s11738-016-2298-0. [DOI] [Google Scholar]

- Suffys, S., Richard, G., Burgeon, C., Werrie, P., Haubruge, E., Fauconnier, M., Goffin, D. (2023). Characterization of aroma active compound production during kombucha fermentation: towards the control of sensory profiles.[J]. Foods (Basel, Switzerland), 12(8). https://doi.org/ 10.3390/FOODS12081657. [DOI] [PMC free article] [PubMed]

- Sekiya J., Kajiwara T., Hatanaka A. Seasonal changes in activities of enzymes responsible for the formation of C6-aldehydes and C6-alcohols in tea leaves, and the effects of environmental temperatures on the enzyme activities. Plant and Cell Physiology. 1984;25:269–280. [Google Scholar]

- Shalit M., Katzir N., Tadmor Y., Larkov O., Burger Y., Shalekhet F.…Edelstein M. Acetyl-CoA: Alcohol acetyltrans ferase activity and aroma formation in ripening melon fruits. Journal of Agriculture and Food Chemistry. 2001;49(2):794–799. doi: 10.1021/jf001075p. [DOI] [PubMed] [Google Scholar]

- Shanshan X.u., Zeng Xinsheng W.u., Huiting S.S., Xiaogen Y., Weiwei D., Jingming N. Characterizing volatile metabolites in raw Pu’er tea stored in wet-hot or dry-cold environments by performing metabolomic analysis and using the molecular sensory science approach [J] Food Chemistry. 2021;350:129186. doi: 10.1016/J.FOODCHEM.2021.129186. [DOI] [PubMed] [Google Scholar]

- Chen, S., Li, M., Zheng, G., Wang, T., Lin, J., Wang, S., et al. (2018). Metabolite profiling of 14 wuyi rock tea cultivars using UPLC-QTOF MS and UPLC-QqQ MS combined with chemometrics. Molecules , 81, 321. https://doi.org/ 10.3390/ moleceles23020104. [DOI] [PMC free article] [PubMed]

- Wenjun Z., Xiaochun W., Guohu B. Brick dark tea: A review of the manufacture, chemical constituents and bioconversion of the major chemical components during fermentation [J] Phytochemistry Reviews. 2015;14(3):499–523. doi: 10.1007/s11101-015-9402-8. [DOI] [Google Scholar]

- Chen, X., Sun, H., Qu, D., Yan, F., Jin, W., Jiang, H., et al. (2020). Identification and characterization of key aroma compounds in Chinese high altitude and northernmost black tea (Camellia sinensis) using distillation extraction and sensory analysis methods. Flavour Fragrance, 35, 666–673. https://doi.org/ 10.1002/ffj.3605.

- Chen, X., Wang, P., Wei, M., Lin, X., Gu, M., Fang, W., et al. (2021). Lipidomics analysis unravels changes from flavor precursors in different processing treatments of purple-leaf tea.[J]. Journal of the science of food and agriculture, 102(9). https://doi.org/ 10.1002/JSFA.11721. [DOI] [PubMed]

- YactayoChang J.P., Hunter C.T., Alborn H.T., Christensen S.A., Block Anna K. Production of the Green Leaf Volatile (Z)-3-Hexenal by a Zea mays Hydroperoxide Lyase[J] Plants. 2022;11(17) doi: 10.3390/PLANTS11172201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yao, H., Su, H., Ma, J., Zheng, J., He, W., Wu, C., et al. (2023). Widely targeted volatileomics analysis reveals the typical aroma formation of Xinyang black tea during fermentation. Food Research International, 164, 112387. https://doi.org/ 10.1016/J.FOODRES.2022.112387. [DOI] [PubMed]

- Li, Y., Chen, N., Li, W., Lou, H., Li, Y., Xiong, Q., et al. (2022). Chemical profiling of ancient bud black tea with a focus on the effects of shoot maturity and fermentation by UHPLC-HRMS[J]. European Food Research and Technology, 248(5). https://doi.org/ 10.1007/S00217-022-03972-6.

- Xu, Y., Liu, P., Shi, J., Gao, Y., Wang, S., Yin, J. (2018). Quality development and main chemical components of Tieguanyin oolong teas processed from different parts of fresh shoots[J]. Food Chemistry, 249. https://doi.org/ 10.1016/j.foodchem.2018.01.019. [DOI] [PubMed]

- Zhaojun X., Lingang G.e., Shenglong C., Xiaoling S. Enhanced transcriptome responses in herbivore-infested tea plants by the green leaf volatile (Z)-3-hexenol.[J] Journal of plant research. 2019;132(2) doi: 10.1007/s10265-019-01094-x. [DOI] [PubMed] [Google Scholar]

- Feng, Z., Li, Y., Zhang, P., Wang, J., Xu, Y., Feng, Y., et al. (2023). Formation and isomerization of (Z)-methyl epijasmonate, the key contributor of the orchid-like aroma, during tea processing[J]. Food Research International, 172. https://doi.org/ 10.1016/J.FOODRES.2023.113186. [DOI] [PubMed]

- Zhou ZiWei W.u., QingYang Y.Y., Hu QingCai W.u., ZongJie H.H., HongZheng L., ZhongXiong L., Yun S. The dynamic change in fatty acids during the postharvest process of oolong tea production [J] Molecules. 2022;27(13):4298. doi: 10.3390/MOLECULES27134298. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhou, Z. W., Wu, Q. Y., Ni. Z. X., Hu, Q. C., Yang, Y., Zheng, Y. C., et al. (2021). Metabolic Flow of C6 Volatile Compounds From LOX-HPL Pathway Based on Airflow During the Post-harvest Process of Oolong Tea [J]. Frontiers in Plant Science, 12. https://doi.org/ 10.3389/FPLS.2021.738445. [DOI] [PMC free article] [PubMed]

- Zhou, Z., Wei, Y., Wu, Q., Fan, L., Rao, H., Chen, Y., et al. (2022b). Effect of differential green-making by airflow factors on the aroma quality of oolong tea[J].Transactions of the Chinese Society of Agricultural Engineering, 38(21):240-248. http:// 10.11975/ j.issn.1002-6819.2022.21.028.

- ZiWei Z., Fangning Y., Bingbing L., Tingting D., Zhongxiong L., Yun S. Effect of Mechanical Force during turning-over on the formation of aliphatic aroma in oolong tea. Food Science. 2019;40:52–59. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.